Abstract

We discuss the theoretical solution to the differential equations governing accelerating edge dislocations in anisotropic crystals. This is an important prerequisite to understanding high-speed dislocation motion, including an open question about the existence of transonic dislocation speeds, and subsequently high-rate plastic deformation in metals and other crystals.

Keywords: dislocations in crystals, dislocation mobility, crystal plasticity, transsonic motion

1. Introduction and Background

Dislocations can influence many materials’ properties such as thermal conductivity [1], thermal stability [2], impact sensitivity [3], ferroelectricity [4], and electrical resistance [5]. At extremely high rates, plastic deformation is governed by high-speed dislocations, a regime where dislocation mobility is poorly understood [6,7,8]. High-speed dislocations experience a drag force due to scattering phonons (an effect known as ‘phonon wind’) and this interaction (and thus, dislocation mobility) is sensitive to the stress distribution in the vicinity of the moving dislocation. Dislocation drag is thus key to predicting material strength at extremely high stress and understanding high-rate plastic deformation [9]. The first-principles phonon wind theory was derived in the isotropic and steady-state limit for dislocation glide velocities that are much smaller than the transverse sound speed some time ago; see the excellent review article [10]. More recently, dislocation drag theory was generalized to very high (but still subsonic) dislocation velocities [11] and anisotropic crystals [12], though the effects of acceleration have so far been neglected.

Another key question in this regard is whether dislocations can reach transonic and supersonic speeds under sufficiently high stress. The only indication that such speeds are possible comes from molecular dynamics (MD) simulations [13,14,15,16,17,18,19]. Experiments cannot track dislocations in real time at these high speeds (After the present manuscript was completed, ref. [20] appeared, which for the first time measured transonic dislocations in diamond in real time), but one can hope to indirectly determine the presence of supersonic dislocations and perhaps estimate the fraction and velocity of these dislocations in the near future [21,22]. This in turn requires a thorough understanding of the solutions to the differential equations governing dislocations, i.e., the equations of motion supplemented by the (leading order) stress-strain relations.

Dislocation theory predicts divergences in self energy and stress at certain limiting velocities [23,24,25,26] for steady-state dislocations. In the isotropic limit, it was shown [27,28,29] that an acceleration term together with a regularized dislocation core removes the divergence, thereby opening the possibility of supersonic events. Other authors emphasized the importance of size variations of the dislocation core as a function of dislocation velocity [30,31,32,33]. The steady-state solution for dislocations in arbitrary anisotropic crystals has been known for some time [34,35]. The case of accelerating dislocations in anisotropic crystals has also been studied [36,37,38,39,40,41,42], with pure screw dislocations having been discussed in the most detail [36,42]. The most general solution has been given only in a very formal form [39], apart from an additional asymptotic wave front analysis. In this paper, we consider formal derivation of the accelerating dislocation field of ref. [39] as a starting point to discuss in detail the solution of an accelerating pure edge dislocation in anisotropic crystals.

In particular, we discuss the solution to the following set of differential equations for accelerating dislocations for the special case of pure edge dislocations:

| (1) |

in coordinates aligned with the dislocations, i.e., is aligned with the dislocation line and is parallel to the slip plane normal. The components of the tensor of second-order elastic constants (SOEC) is always measured in Cartesian coordinates that are aligned with the crystal axes, and thus this tensor must be rotated into our present coordinate basis, i.e.:

| (2) |

with rotation matrix U.

In order to study pure edge (or pure screw) dislocations, the rotated tensor of SOEC must fulfill the following symmetry requirements (shown here in Voigt notation which maps index pairs to single digits, ):

| (3) |

i.e., the six components , , , , , and must vanish, see refs. [43,44]. This ensures that implies , and likewise that implies , so that there exists a that solves the differential equations independently from the pair and vice versa. Note that in the present coordinates, can only depend on x, y, and t, but not on z. This latter property implies that non-vanishing components and are allowed since they do not enter the differential equations above for pure screw or pure edge dislocations. On the other hand, the stronger condition implies that the , plane is a reflection plane (and then for pure screw dislocations rather than the weaker ).

The most general solution for pure screw dislocations was recently derived in ref. [42]. The case of accelerating pure edge dislocations was previously studied by Markenscoff and Ni for the special case of (in addition to (3)) in refs. [37,38], and the general case was presented in ref. [39]. In refs. [37,39], only a formal solution was derived, though not in closed form. Here, we present for the first time, a numerical implementation of the accelerating dislocation field for pure edge dislocations in various anisotropic slip systems and study its properties. Our code is included in version 1.2.7 of PyDislocDyn [45].

2. Most General Differential Equations for Pure Edge Dislocations

Following ref. [39] in this subsection, but setting and plugging the most general rotated tensor of SOEC fulfilling the required properties for studying pure edge dislocations, Equation (3), into the differential Equation (1), we find:

| (4) |

Note that we have dropped the primes on the elastic constants for notational simplicity; nonetheless, all are understood to be in the rotated frame aligned with the edge dislocation. Additionally, we have the boundary conditions

| (5) |

where denotes the Heaviside step function, b is the Burgers vector length, and the slip plane is located at . Clearly, the above differential equations and their boundary conditions simplify significantly when , which is what was studied in ref. [37,38].

In order to solve these more general equations, we apply a Laplace transform in time, i.e.,

| (6) |

as well as a two-sided Laplace transform (which is related to the Fourier transform with ) in x, i.e.,

| (7) |

and thus, . The transformed differential equations read

| (8) |

Likewise, the transformed boundary conditions in the upper half plane () read

| (9) |

| (10) |

where and the integral over time was carried out explicitly as described in ref. [42]. Additionally, we demand . Markenscoff [39] argues that the problem can be reduced to a problem on a half-space, so that we now assume in the following derivation, and we will generalize to negative y only at the very end. Note that the first term in boundary condition (9) is identified as that of the static problem which cannot be treated by a Laplace transform without running into convergence issues [42,46]. Hence, we presently subtract the static contribution and will add it at the end of our derivation; more precisely, we will add the well-known solution to the static problem at the very end so as not to clutter our equations in intermediate steps. Focusing only on the dynamic part of the accelerating dislocation field, we presently replace (9) with

| (11) |

and for notational simplicity, we drop the tilde below (). We furthermore assume that , i.e., we do not include the so-called irregular hyperbolic case [38] in our discussion, as we are unaware of any slip systems that in practice would exhibit this property [23]. The differential Equation (8) can be rewritten in 4 × 4 matrix form as

| (12) |

where we defined the compliances as , i.e.,

| (13) |

Since we focus here on the regular hyperbolic case, we may assume that the eigenvalues of the so-defined 4 × 4 matrix ( with ) are distinct [39]. Given these eigenvalues, we make the ansatz

| (14) |

Plugging this ansatz into the differential Equation (8) yields the determinantal equation

| (15) |

which may be used to calculate the by solving the following fourth-order polynomial:

| (16) |

Note that s is factored out in this equation so that depends on but not on s. Finally, the asymptotic condition tells us that the sum over m in the ansatz (14) above must only include the positive eigenvalues and Markenscoff argued in [39] that because the slowness surface (whose equation coincides with the determinantal Equation (15) above) is symmetric about the origin, there are presently two positive eigenvalues, . The corresponding eigenvectors are where the is determined from

| (17) |

together with the boundary conditions which presently read

| (18) |

Plugging the ansatz into (17), we find for :

| (19) |

where the last equality follows from the fact that solves (15). The boundary conditions (18) finally determine , and written in matrix form we presently have

| (20) |

Thus,

| (21) |

with given in (19). Note that the coefficients do not depend on s; this will be important later when we derive the inverse Laplace transform.

3. Cagniard–De Hoop Method

In order to determine the displacement gradient field in real space and time, we need to apply the inverse Laplace transform and integrate along a line parallel to the imaginary axis. This latter integral will not be carried out explicitly, but rather we want to rewrite it in a way that allows us to interpret this integral as a Laplace transform in time so that a subsequent inversion of the one-sided Laplace transform need not be carried out explicitly.

Thus, for each term in we interpret the following combination as a strictly positive time variable in order to apply the Cagniard–De Hoop method [47,48,49]:

| (22) |

The reader is reminded that we presently restrict our calculation to the half plane . In order to be able to integrate over the positive real axis instead of over the imaginary axis, one needs to study an integral over over a closed path in complex space and to account for the residua of all enclosed poles. This step requires knowledge of the locations of all poles in the expressions above, and hence knowledge of the roots . Note, that such poles occur only for transonic and supersonic dislocations, but not in the subsonic regime [39]. Furthermore, in passing from integration variable to integration variable , we need the inverse of function (22), i.e., , as well as the Jacobian . The inverted functions appear in complex conjugate pairs which both need to be taken into account in order to integrate over a closed path [39,42]. Using Cauchy’s theorem, we presently have in the subsonic regime:

| (23) |

where and is given in (21) with (19). In the transonic and supersonic regimes, the expression above needs to be supplemented by appropriate residua for all enclosed poles in the integration path. As discussed in earlier papers [42,46], calculating directly is troublesome due to subtleties with respect to poles, and it is generally better to solve for its gradient. Thus, taking derivatives with respect to x and y prior to passing from to , we find

| (24) |

Another important subtlety concerns the exchange of integrals over and prior to the change of variables, which is only permissible if both integrations converge absolutely; this is not the case in general and a remedy was put forward in the context of pure screw dislocations in refs. [42,46]. In particular, the exchange of integrals leads to poles on the slip plane at which stem from the first two terms of a Taylor expansion of around . On the other hand, if one were to replace with its linear order Taylor expansion terms, the integral over can be carried out analytically before changing integration variables:

| (25) |

In that case, will not depend on (i.e., one defines (22) with ) and only one integral over (resp. ) is left.

To sum up: In order to eliminate divergences on the slip plane in the integration, we must add and subtract the dynamic term with replaced by its linear order Taylor expansion with and , see ref. [42]. Hence,

| (26) |

Considering the properties of the Laplace transform, where multiplication by corresponds to a translation in time and multiplication by s corresponds to a time derivative (modulo boundary terms which are zero here), we can read off the solution:

| (27) |

where depends on the appropriately shifted time , , or , i.e., matching in each term the according part of the argument of the step function.

4. Special Cases: Constant Velocity and Constant Acceleration Rate

The simplest case one can study within the present solution is a dislocation initially at rest which suddenly starts moving at constant velocity v at time . As discussed previously in the context of pure screw dislocations in [42], this “jump” in velocity is nonphysical, but in the large time limit the solution must tend to the well-known steady-state solution, thus providing us with a consistency check. The assumption of constant dislocation velocity at leads to the following simplifications:

| (28) |

Due to the last equality, the second and fourth lines within Equation (27) (i.e., the terms containing the time derivative and the integral over ) vanish identically for a dislocation moving at constant velocity.

The simplest physical case within the present dynamic solution follows from the assumption that the dislocation is at rest at time and starts to accelerate at a constant rate a from time . Then and hence [42]

| (29) |

The velocity at time t is given by and the transition from subsonic to transonic happens when , where is the lowest limiting velocity whose value can easily be computed using the review article [23] and/or the open source code [45].

We have implemented this constant acceleration rate case in Python, using a combination of symbolic (sympy) calculations and numerical methods, and have integrated it into the code PyDislocDyn [45]. The general strategy is as follows: The material’s tensor of elastic constants is rotated into coordinates where the dislocation line is parallel to the z direction, the slip plane normal points in the y direction, and the edge dislocation accelerates from rest in the x direction at rate a. We then calculate the time at which the accelerating dislocation reaches a user-specified target velocity, as well as the position of the dislocation core at that time in order to shift the x coordinate such that the dislocation core resides at the origin at time . We use sympy to calculate the four solutions from Equation (16) after plugging in numerical values for all (rotated) elastic constants and the material density, i.e., is the only unknown. For each of these 4 solutions, we determine and its derivative, and the resulting sympy expressions are subsequently ‘lambdified’, i.e., converted into functions of , x, and y. We then loop over all points we wish to determine the displacement gradient for. At a given point , function depends only on , and since we are interested in one snapshot in time (meaning we know ), we can numerically determine ; note that is a complex number and we use mpmath’s recommended root-finding method (the Muller method). This step constitutes the bottleneck of our implementation, i.e., calculating the dislocation field for accelerating edge dislocations is orders of magnitude slower than for screw dislocations which were discussed in [42]. Once we have , we determine and the Jacobian . At this point, we have four sets of , , but only two satisfy the asymptotic condition . Markenscoff [39] determined that the imaginary parts of and must have opposite signs for positive y, and we drop the other two solutions to . The remaining two sets of are plugged into (19) and (21), and subsequently into the first (i.e., leading) dynamic terms of (27). The static part is computed with the well-known Stroh/integral method [34]. The time-derivative term in (27) can be neglected for constant acceleration rates.

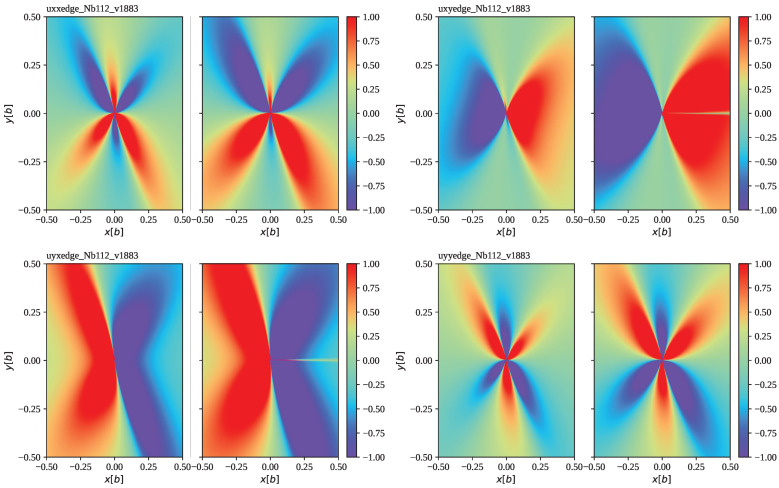

Figure 1 shows the edge dislocation field at the example of hcp Mg for prismatic slip and compares the accelerating field to the steady-state field. Figure 2 shows the edge dislocation field at the example of bcc Nb for the 112 slip planes and compares the accelerating field to the steady-state field. In contrast to the previous example, edge dislocations on 112 slip planes of bcc metals have a non-vanishing (rotated) elastic constant , and thus represent a more general case than the former. Both examples show some enhancement of the dislocation displacement gradient field for moderate acceleration rates of m/s typical for flyer plate impact scenarios [50], albeit maintaining the shape of the steady-state solution for the most part. Only for very extreme acceleration rates do we start to see more significant deviations as illustrated in Figure 3 with the example of Mg. Note that the numerical accuracy of the accelerating edge solution in its current implementation is limited by the accuracy of the (complex) root-finding algorithm.

Figure 1.

We show at dislocation velocity for hcp Mg and prismatic slip ( g/ccm, Å, GPa, GPa, GPa, GPa, and GPa, see [51]). This velocity corresponds to roughly 92% of the critical velocity. All plots are centered at the dislocation core, showing the plane perpendicular to the dislocation line in units of a Burgers vector. On the left of each pair of plots, we show the steady-state solution [34] and on the right we show the full solution for constant acceleration (27) with (29) and m/s at time s needed to reach velocity v. At this point, the dislocation has traveled a distance of microns. We see that the changes in the dislocation displacement gradient due to the inclusion of acceleration lead to a slight enhancement.

Figure 2.

We show at dislocation velocity for an edge dislocation in bcc Nb gliding on a 112 slip plane ( g/ccm, Å, GPa, GPa, and GPa, see [51]). This velocity corresponds to roughly 90% of the critical velocity. All plots are centered at the dislocation core, showing the plane perpendicular to the dislocation line in units of a Burgers vector. We compare the steady-state solution [34] with the full solution for constant acceleration (27) with (29) and m/s at time s needed to reach velocity v. At this point, the dislocation has traveled a distance of ∼0.18 microns. We see that the changes in the dislocation displacement gradient due to the inclusion of acceleration lead to a slight enhancement.

Figure 3.

We compare in Mg (prismatic slip) at dislocation velocity for different acceleration rates.

Furthermore, we confirm (numerically) that the divergence at a ‘critical’ dislocation velocity (which separates the subsonic from the transonic regime) persists for general accelerating edge dislocations with vanishing core size, consistent with previous work on the isotropic limit [27] as well as the accelerating screw dislocation in anisotropic crystals [42].

5. The Isotropic Limit

The following simplifications apply in the isotropic limit: , , and , as well as and within (13). Hence, Equation (16) simplifies to

| (30) |

where , and solutions are found to be

| (31) |

In both cases, only one of the two signs must be considered, namely, convergence of (14) requires that the real part of has the same sign as y. For positive y, this means that implies and vice versa [39].

Coefficients simplify to

| (32) |

with .

The definition of (with ) then yields

| (33) |

with and the short-hand notation and for the transverse (T) and longitudinal (L) sound speeds. This special case was discussed in ref. [52].

If we assume a constant dislocation velocity from time , i.e., and take the limit of after translating our coordinates to move with the dislocation (i.e., replacing , everywhere prior to taking the limit, see [42]), we recover the well-known steady-state solution for an edge dislocation in an isotropic medium [11,53]:

| (34) |

6. Conclusions

In this paper, we have presented and discussed the full solution to the differential equations for an accelerating edge dislocation in a general anisotropic crystal in the subsonic regime. Taking the formal solution of ref. [39] one step further, we have derived the edge dislocation displacement gradient field using a combination of analytical and numerical methods. Our python implementation is included in version 1.2.7 of the code PyDislocDyn [45]. Two examples were illustrated in Figure 1 and Figure 2 showing that the dislocation strain field is slightly enhanced in the accelerating case, at least for typical dislocation acceleration rates of m/s [50], though still similar enough to the steady-state solution (except for extreme conditions such as very high acceleration rates and velocities near the limiting velocity), so that in most larger simulations it makes more sense to use the (several orders of magnitude) faster-to-compute steady-state solution. The transonic regime of the accelerating edge dislocation as well as accelerating mixed dislocations are left for future work.

Acknowledgments

We thank the anonymous referees for their valuable comments.

Author Contributions

Conceptualization, D.N.B.; Software, D.N.B.; Investigation, D.N.B.; Writing—original draft, D.N.B.; Writing—review & editing, K.D., S.J.F. and D.J.L.; Funding acquisition, D.N.B. and D.J.L. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Funding Statement

Research presented in this article was supported by the Laboratory Directed Research and Development program of Los Alamos National Laboratory under project number 20210826ER. Furthermore, the authors are grateful for the support of the Materials project within the Advanced Simulation and Computing, Physics and Engineering Models Program of the U.S. Department of Energy under contract 89233218CNA000001 in the final stages of this work.

Footnotes

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

- 1.Termentzidis K., Isaiev M., Salnikova A., Belabbas I., Lacroix D., Kioseoglou J. Impact of screw and edge dislocations on the thermal conductivity of individual nanowires and bulk GaN: A molecular dynamics study. Phys. Chem. Chem. Phys. 2018;20:5159–5172. doi: 10.1039/C7CP07821H. [DOI] [PubMed] [Google Scholar]

- 2.Li Y., Krajňák T., Podaný P., Veselý J., Džugan J. Thermal stability of dislocation structure and its effect on creep property in austenitic 316L stainless steel manufactured by directed energy deposition. Mater. Sci. Eng. 2023;A873:144981. doi: 10.1016/j.msea.2023.144981. [DOI] [Google Scholar]

- 3.Quansah J.D., Zhang X., Wasiullah Q., Yan Q. Mechanical and thermophysical properties of energetic crystals: Evaluation methods and recent achievements. FirePhysChem. 2022 doi: 10.1016/j.fpc.2022.10.004. in press . [DOI] [Google Scholar]

- 4.Lubk A., Rossell M.D., Seidel J., Chu Y.H., Ramesh R., Hÿtch M.J., Snoeck E. Electromechanical Coupling among Edge Dislocations, Domain Walls, and Nanodomains in BiFeO3 Revealed by Unit-Cell-Wise Strain and Polarization Maps. Nano Lett. 2013;13:1410–1415. doi: 10.1021/nl304229k. [DOI] [PubMed] [Google Scholar]

- 5.Szot K., Speier W., Bihlmayer G., Waser R. Switching the electrical resistance of individual dislocations in single-crystalline SrTiO3. Nat. Mater. 2006;5:312–320. doi: 10.1038/nmat1614. [DOI] [PubMed] [Google Scholar]

- 6.Hansen B.L., Beyerlein I.J., Bronkhorst C.A., Cerreta E.K., Dennis-Koller D. A dislocation-based multi-rate single crystal plasticity model. Int. J. Plast. 2013;44:129–146. doi: 10.1016/j.ijplas.2012.12.006. [DOI] [Google Scholar]

- 7.Luscher D.J., Mayeur J.R., Mourad H.M., Hunter A., Kenamond M.A. Coupling continuum dislocation transport with crystal plasticity for application to shock loading conditions. Int. J. Plast. 2016;76:111–129. doi: 10.1016/j.ijplas.2015.07.007. [DOI] [Google Scholar]

- 8.Blaschke D.N., Hunter A., Preston D.L. Analytic model of the remobilization of pinned glide dislocations: Including dislocation drag from phonon wind. Int. J. Plast. 2020;131:102750. doi: 10.1016/j.ijplas.2020.102750. [DOI] [Google Scholar]

- 9.Gurrutxaga-Lerma B., Verschueren J., Sutton A.P., Dini D. The mechanics and physics of high-speed dislocations: A critical review. Int. Mater. Rev. 2021;66:215–255. doi: 10.1080/09506608.2020.1749781. [DOI] [Google Scholar]

- 10.Alshits V.I. The Phonon-Dislocation Interaction and its Role in Dislocation Dragging and Thermal Resistivity. In: Indenbom V.L., Lothe J., editors. Elastic Strain Fields and Dislocation Mobility. Volume 31. Elsevier; Amsterdam, The Netherlands: 1992. pp. 625–697. [DOI] [Google Scholar]

- 11.Blaschke D.N., Mottola E., Preston D.L. Dislocation drag from phonon wind in an isotropic crystal at large velocities. Philos. Mag. 2020;100:571–600. doi: 10.1080/14786435.2019.1696484. [DOI] [Google Scholar]

- 12.Blaschke D.N. Velocity dependent dislocation drag from phonon wind and crystal geometry. J. Phys. Chem. Solids. 2019;124:24–35. doi: 10.1016/j.jpcs.2018.08.032. [DOI] [Google Scholar]

- 13.Olmsted D.L., Hector L.G., Jr., Curtin W.A., Clifton R.J. Atomistic simulations of dislocation mobility in Al, Ni and Al/Mg alloys. Mod. Simul. Mater. Sci. Eng. 2005;13:371. doi: 10.1088/0965-0393/13/3/007. [DOI] [Google Scholar]

- 14.Marian J., Caro A. Moving dislocations in disordered alloys: Connecting continuum and discrete models with atomistic simulations. Phys. Rev. 2006;B74:024113. doi: 10.1103/PhysRevB.74.024113. [DOI] [Google Scholar]

- 15.Tsuzuki H., Branicio P.S., Rino J.P. Accelerating dislocations to transonic and supersonic speeds in anisotropic metals. Appl. Phys. Lett. 2008;92:191909. doi: 10.1063/1.2921786. [DOI] [Google Scholar]

- 16.Oren E., Yahel E., Makov G. Dislocation kinematics: A molecular dynamics study in Cu. Mod. Simul. Mater. Sci. Eng. 2017;25:025002. doi: 10.1088/1361-651X/aa52a7. [DOI] [Google Scholar]

- 17.Peng S., Wei Y., Jin Z., Yang W. Supersonic Screw Dislocations Gliding at the Shear Wave Speed. Phys. Rev. Lett. 2019;122:045501. doi: 10.1103/PhysRevLett.122.045501. [DOI] [PubMed] [Google Scholar]

- 18.Blaschke D.N., Chen J., Fensin S., Szajewski B. Clarifying the definition of ‘transonic’ screw dislocations. Philos. Mag. 2021;101:997–1018. doi: 10.1080/14786435.2021.1876269. [DOI] [Google Scholar]

- 19.Dang K., Blaschke D.N., Fensin S., Luscher D.J. Limiting velocities and transonic dislocations in Mg. Comput. Mater. Sci. 2022;215:111786. doi: 10.1016/j.commatsci.2022.111786. [DOI] [Google Scholar]

- 20.Katagiri K., Pikuz T., Fang L., Albertazzi B., Egashira S., Inubushi Y., Kamimura G., Kodama R., Koenig M., Kozioziemski B., et al. Transonic Dislocation Propagation in Diamond. arXiv. 2023 doi: 10.1126/science.adh5563.2303.04370 [DOI] [PubMed] [Google Scholar]

- 21.Wehrenberg C.E., McGonegle D., Bolme C., Higginbotham A., Lazicki A., Lee H.J., Nagler B., Park H.S., Remington B.A., Rudd R.E., et al. In situ X-ray diffraction measurement of shock-wave-driven twinning and lattice dynamics. Nature. 2017;550:496–499. doi: 10.1038/nature24061. [DOI] [PubMed] [Google Scholar]

- 22.Dresselhaus-Marais L.E., Winther G., Howard M., Gonzalez A., Breckling S.R., Yildirim C., Cook P.K., Kutsal M., Simons H., Detlefs C., et al. In situ visualization of long-range defect interactions at the edge of melting. Sci. Adv. 2021;7:eabe8311. doi: 10.1126/sciadv.abe8311. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Blaschke D.N. How to determine limiting velocities of dislocations in anisotropic crystals. J. Phys. Cond. Mat. 2021;33:503005. doi: 10.1088/1361-648X/ac2970. [DOI] [PubMed] [Google Scholar]

- 24.Teutonico L.J. Dynamical Behavior of Dislocations in Anisotropic Media. Phys. Rev. 1961;124:1039–1045. doi: 10.1103/PhysRev.124.1039. [DOI] [Google Scholar]

- 25.Teutonico L.J. Uniformly Moving Dislocations of Arbitrary Orientation in Anisotropic Media. Phys. Rev. 1962;127:413–418. doi: 10.1103/PhysRev.127.413. [DOI] [Google Scholar]

- 26.Barnett D.M., Lothe J., Nishioka K., Asaro R.J. Elastic surface waves in anisotropic crystals: A simplified method for calculating Rayleigh velocities using dislocation theory. J. Phys. F Met. Phys. 1973;3:1083–1096. doi: 10.1088/0305-4608/3/6/001. [DOI] [Google Scholar]

- 27.Markenscoff X., Huang S. Analysis for a screw dislocation accelerating through the shear-wave speed barrier. J. Mech. Phys. Solids. 2008;56:2225–2239. doi: 10.1016/j.jmps.2008.01.005. [DOI] [Google Scholar]

- 28.Markenscoff X., Huang S. The energetics of dislocations accelerating and decelerating through the shear-wave speed barrier. Appl. Phys. Lett. 2009;94:021906. doi: 10.1063/1.3072351. [DOI] [Google Scholar]

- 29.Huang S., Markenscoff X. Is Intersonic Dislocation Motion Possible? Singularity Analysis for an Edge Dislocation Accelerating through the Shear Wave Speed Barrier. Exp. Mech. 2009;49:219–224. doi: 10.1007/s11340-008-9122-8. [DOI] [Google Scholar]

- 30.Pillon L., Denoual C., Pellegrini Y.P. Equation of motion for dislocations with inertial effects. Phys. Rev. B. 2007;76:224105. doi: 10.1103/PhysRevB.76.224105. [DOI] [Google Scholar]

- 31.Pellegrini Y.P. Dynamic Peierls-Nabarro equations for elastically isotropic crystals. Phys. Rev. B. 2010;81:024101. doi: 10.1103/PhysRevB.81.024101. [DOI] [Google Scholar]

- 32.Pellegrini Y.P. Equation of motion and subsonic-transonic transitions of rectilinear edge dislocations: A collective-variable approach. Phys. Rev. B. 2014;90:054120. doi: 10.1103/PhysRevB.90.054120. [DOI] [Google Scholar]

- 33.Pellegrini Y.P. Dynamic Peach-Koehler self-force, inertia, and radiation damping of a regularized dislocation. arXiv. 20202005.12704 [Google Scholar]

- 34.Bacon D.J., Barnett D.M., Scattergood R.O. Anisotropic continuum theory of lattice defects. Prog. Mater. Sci. 1980;23:51–262. doi: 10.1016/0079-6425(80)90007-9. [DOI] [Google Scholar]

- 35.Pellegrini Y.P. Causal Stroh formalism for uniformly-moving dislocations in anisotropic media: Somigliana dislocations and Mach cones. Wave Motion. 2017;68:128–148. doi: 10.1016/j.wavemoti.2016.09.006. [DOI] [Google Scholar]

- 36.Markenscoff X., Ni L. The transient motion of a screw dislocation in an anisotropic medium. J. Elast. 1984;14:93–95. doi: 10.1007/BF00041084. [DOI] [Google Scholar]

- 37.Markenscoff X., Ni L.Q. Nonuniform motion of an edge dislocation in an anisotropic solid. I. Quart. Appl. Math. 1984;41:475–494. doi: 10.1090/qam/724058. [DOI] [Google Scholar]

- 38.Markenscoff X., Ni L. Nonuniform motion of an edge dislocation in an anisotropic solid. II. Quart. Appl. Math. 1985;42:425–432. doi: 10.1090/qam/766879. [DOI] [Google Scholar]

- 39.Markenscoff X., Ni L. The transient motion of a dislocation in a solid of general anisotropy. Wave Motion. 1987;9:191–199. doi: 10.1016/0165-2125(87)90009-6. [DOI] [Google Scholar]

- 40.Payton R.G. Transient stresses in a transversely isotropic elastic solid caused by a moving dislocation. Z. Angew. Math. Phys. 1985;36:191–203. doi: 10.1007/BF00945456. [DOI] [Google Scholar]

- 41.Payton R.G. Steady state stresses induced in a transversely isotropic elastic solid by a moving dislocation. Z. Angew. Math. Phys. 1995;46:282–288. doi: 10.1007/BF00944758. [DOI] [Google Scholar]

- 42.Blaschke D.N. A general solution for accelerating screw dislocations in arbitrary slip systems with reflection symmetry. J. Mech. Phys. Solids. 2021;152:104448. doi: 10.1016/j.jmps.2021.104448. [DOI] [Google Scholar]

- 43.Foreman A.J.E. Dislocation energies in anisotropic crystals. Acta Met. 1955;3:322–330. doi: 10.1016/0001-6160(55)90036-5. [DOI] [Google Scholar]

- 44.Hirth J.P., Lothe J. Theory of Dislocations. 2nd ed. Wiley; New York, NY, USA: 1982. [Google Scholar]

- 45.Blaschke D.N. PyDislocDyn, version 1.2.7, 2018–2023. [(accessed on 22 May 2023)]. Available online: https://github.com/dblaschke-LANL/PyDislocDyn.

- 46.Markenscoff X. The transient motion of a nonuniformly moving dislocation. J. Elast. 1980;10:193–201. doi: 10.1007/BF00044503. [DOI] [Google Scholar]

- 47.Cagniard L. Ph.D. Thesis. Université de Paris; Sorbonne, France: 1939. Réflexion et Réfraction Des Ondes Séismiques Progressives. [Google Scholar]

- 48.De Hoop A.T. A modification of Cagniard’s method for solving seismic pulse problems. Appl. Sci. Res. 1960;8:349–356. doi: 10.1007/BF02920068. [DOI] [Google Scholar]

- 49.Freund L.B. The Response of an Elastic Solid to Nonuniformly Moving Surface Loads. J. Appl. Mech. 1973;40:699–704. doi: 10.1115/1.3423076. [DOI] [Google Scholar]

- 50.Blaschke D.N., Luscher D.J. Dislocation drag and its influence on elastic precursor decay. Int. J. Plast. 2021;144:103030. doi: 10.1016/j.ijplas.2021.103030. [DOI] [Google Scholar]

- 51.Rumble J.R., editor. CRC Handbook of Chemistry and Physics. 102nd ed. CRC Press; Boca Raton, FL, USA: 2021. [Google Scholar]

- 52.Markenscoff X., Clifton R.J. The nonuniformly moving edge dislocation. J. Mech. Phys. Solids. 1981;29:253–262. doi: 10.1016/0022-5096(81)90029-6. [DOI] [Google Scholar]

- 53.Eshelby J.D. Uniformly Moving Dislocations. Proc. Phys. Soc. A. 1949;62:307. doi: 10.1088/0370-1298/62/5/307. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.