Abstract

Following a request from the European Commission, the EFSA Panel on Nutrition, Novel Foods and Food Allergens (NDA) was asked to deliver an opinion on 6′‐sialyllactose (6′‐SL) sodium salt as a novel food (NF) pursuant to Regulation (EU) 2015/2283. The NF is mainly composed of the human‐identical milk oligosaccharide (HiMO) 6′‐SL (sodium salt), but it also contains sialic acid, d‐glucose, d‐lactose, 6′‐sialyllactulose sodium salt, 3′‐sialyllactose (3′‐SL) sodium salt and a small fraction of other related saccharides. The NF is produced by fermentation by a genetically modified strain (Escherichia coli NEO6) of E. coli W (ATCC 9637). The information provided on the identity, manufacturing process, composition and specifications of the NF does not raise safety concerns. The applicant intends to add the NF to a variety of foods, including infant formula and follow‐on formula, food for special medical purposes and food supplements (FS). The target population is the general population. The applicant applies for the same uses and use levels already assessed for 6′‐SL sodium salt produced by fermentation by a genetically modified strain of E. coli K‐12 DH1. Therefore, since the NF would be consumed at the same extent as the already assessed 6′‐SL sodium salt, no new estimates of the intake have been carried out. Similarly, FS are not intended to be used if other foods with added 6′‐SL or human milk are consumed on the same day. The Panel concludes that the NF is safe under the proposed conditions of use.

Keywords: Example: 6′‐sialyllactose, 6′‐SL, sodium salt, human milk oligosaccharide, HMO, HiMO, novel food

1. Introduction

1.1. Background and Terms of Referesnce as provided by the requestor

On 26 March 2021, the company Kyowa Hakko Bio Co., Ltd. submitted a request to the Commission in accordance with Article 10 of Regulation (EU) 2015/2283 1 to place on the EU market 6′‐sialyllactose (6′‐SL) sodium salt as a novel food (NF).

6′‐SL sodium salt is intended to be used in a number of food categories.

The applicant has requested data protection under Article 26 of Regulation (EU) 2015/2283 for data in support of this request.

In accordance with Article 10(3) of Regulation (EU) 2015/2283, the European Commission (EC) asks the European Food Safety Authority (EFSA) to provide a scientific opinion on 6′‐SL sodium salt as a NF.

In this opinion on 6′‐SL sodium salt, EFSA should also document whether and to what extent the requirements of Article 26(2)(c) of Regulation (EU) 2015/2283 are fulfilled regarding the data for which the applicant is requesting data protection.

1.2. Additional information

The sodium salt of 6′‐SL is included in the Union list of authorised NFs (Commission Implementing Regulation (EU) 2017/2470 2 ) when produced by fermentation by a genetically modified strain of Escherichia coli K‐12 DH1 (EFSA NDA Panel, 2020a). Moreover, the safety of the 6′‐SL sodium salt produced by genetically modified strains of E. coli BL21 (DE3) has been assessed by EFSA with a positive outcome (EFSA NDA Panel, 2022a). Two sodium salts of 3′‐sialyllactose (3′‐SL), a constitutional isomer of 6′‐SL, are also included in the Union list of authorised NFs when produced by genetically modified strains of E. coli K‐12 DH1 or E. coli BL21 (DE3) (EFSA NDA Panel, 2020b, 2022b).

Since 2015, several scientific opinions with positive outcomes have been adopted by the EFSA NDA Panel on the safety of human‐identical milk oligosaccharides (HiMOs) as NFs pursuant to Regulation (EC) No 258/97 or Regulation (EU) 2015/2283:

Chemically synthetised 2′‐fucosyllactose (2′‐FL) (EFSA NDA Panel, 2015a) and 2′‐FL produced by a genetically modified strain (APC199) of Corynebacterium glutamicum ATCC 13032 (EFSA NDA Panel, 2022c);

Chemically synthetised lacto‐N‐neotetraose (LNnT) (EFSA NDA Panel, 2015b) and LNnT produced by genetically modified strains of E. coli BL21 (DE3) (EFSA NDA Panel, 2020c);

Extension of use in food supplements (FS) for infants of chemically synthetised 2′‐FL and LNnT (EFSA NDA Panel, 2015c) or 2′‐FL and LNnT produced by genetically modified strains of E. coli K‐12 DH1 (EFSA NDA Panel, 2022d);

Chemically synthetised N‐acetyl‐d‐neuraminic acid (NANA) (EFSA NDA Panel, 2017);

2′‐FL/difucosyllactose (DFL) mixture produced by a genetically modified strain of E. coli K‐12 DH1 (EFSA NDA Panel, 2019a);

Lacto‐N‐tetraose (LNT) produced by genetically modified strains of E. coli K‐12 DH1 (EFSA NDA Panel, 2019b) or E. coli BL21 (DE3) (EFSA NDA Panel, 2022e);

Extension of use in FS for infants of 2′‐FL/DFL mixture and LNT produced by genetically modified strains of E. coli K‐12 DH1 (EFSA NDA Panel, 2022f);

6′‐SL sodium salts produced by genetically modified strains of E. coli K‐12 DH1 (EFSA NDA Panel, 2020a) or E. coli BL21 (DE3) (EFSA NDA Panel, 2022a);

3′‐SL sodium salts produced by genetically modified strains of E. coli K‐12 DH1 (EFSA NDA Panel, 2020b) or E. coli BL21 (DE3) (EFSA NDA Panel, 2022b);

3‐fucosyllactose (3‐FL) produced by genetically modified strains of E. coli K‐12 MG1655 (EFSA NDA Panel, 2021) or E. coli BL21 (DE3) (EFSA NDA Panel, 2022g).

2. Data and Methodologies

2.1. Data

The safety assessment of this NF is based on data supplied in the application, information submitted by the applicant following an EFSA request for supplementary information and additional data identified by the Panel.

Administrative and scientific requirements for NF applications referred to in Article 10 of Regulation (EU) 2015/2283 are listed in Commission Implementing Regulation (EU) 2017/2469 3 .

A common and structured format on the presentation of NF applications is described in the EFSA guidance on the preparation and presentation of an NF application (EFSA NDA Panel, 2016). As indicated in this guidance, it is the duty of the applicant to provide all of the available (proprietary, confidential and published) scientific data (including both data in favour and not in favour) that are pertinent to the safety of the NF.

This NF application includes a request for protection of proprietary data in accordance with Article 26 of Regulation (EU) 2015/2283. The data requested by the applicant to be protected comprise: (i) identity of the NF; (ii) production process; (iii) information on the genetically modified production strain; (iv) composition and stability of the NF; (v) toxicological and allergenicity studies.

2.2. Methodologies

The assessment follows the methodology set out in the EFSA guidance on NF applications (EFSA NDA Panel, 2016) and the principles described in the relevant existing guidance documents from the EFSA Scientific Committee. The legal provisions for the assessment are laid down in Article 11 of Regulation (EU) 2015/2283 and in Article 7 of Commission Implementing Regulation (EU) 2017/2469. The legal provisions for the assessment of food intended for infants and young children, food for special medical purposes (FSMP) and total diet replacement for weight control are laid down in Regulation (EU) No 609/2013 4 and, respectively, in Commission Delegated Regulation 2017/1798 5 (total diet replacement for weight control), in Commission Delegated Regulation (EU) 2016/128 6 (FSMP) and in Commission Delegated Regulation (EU) 2016/127 7 (as regards the specific compositional and information requirements for infant formula (IF) and follow‐on formula (FOF) and as regards requirements on information relating to infant and young child feeding).

This assessment concerns only the risks that might be associated with consumption of the NF under the proposed conditions of use and is not an assessment of the efficacy of the NF with regards to any claimed benefit. This assessment also is not an assessment on whether the NF is suitable as stipulated by Regulation (EU) No 609/2013.

3. Assessment

3.1. Introduction

The NF, which is the subject of the application, contains 6′‐SL sodium salt as primary constituent (≥ 82% w/w dry matter (DM)). 6′‐SL has been identified as a relevant component of the complex fraction of oligosaccharides naturally occurring in human milk, also denominated as human milk oligosaccharides (HMOs). 6′‐SL is a sialylated (acidic) trisaccharide composed of d‐glucose, d‐galactose and NANA (hereinafter also referred to as ‘sialic acid’). 6′‐SL is the predominant acidic HMO and one of the most abundant HMOs along with 2′‐FL, lacto‐N‐fucopentaose I, LNT and LNnT (Thurl et al., 2010, 2017). The Panel notes that although the 6′‐SL sodium salt is the major component of the NF, related substances, namely sialic acid, d‐glucose, d‐lactose, 6′‐sialyllactulose sodium salt, 3′‐SL sodium salt and a small fraction of other related saccharides, are also present. The NF is produced by fermentation by a genetically modified strain (E. coli NEO6) of E. coli W (ATCC 9637), and is isolated as a purified ingredient in the sodium salt form.

The applicant applies for the same uses and use levels (as a food ingredient, including FSMP, IF and FOF and the use in FS) already assessed for the 6′‐SL sodium salt produced by fermentation by a genetically modified strain of E. coli K‐12 DH1 (EFSA NDA Panel, 2020a).

The target population is the general population.

The sodium salt of 6′‐SL produced by a genetically modified strain of E. coli K‐12 DH1 (EFSA NDA Panel, 2020a) is already authorised as a NF in the European Union (Commission Implementing Regulation (EU) 2017/2470). Moreover, the safety of the 6′‐SL sodium salt produced by genetically modified strains of E. coli BL21 (DE3) has been assessed by EFSA with a positive outcome (EFSA NDA Panel, 2022a). Two sodium salts of 3′‐SL produced by genetically modified strains of E. coli K‐12 DH1 or E. coli BL21 (DE3) (EFSA NDA Panel, 2020b, 2022b) are also included in the Union list of authorised NFs.

According to Article 3(2)(a) of Regulation (EU) 2015/2283, the NF falls under the following categories:

‘food with a new or intentionally modified molecular structure, where that structure was not used as, or in, a food within the Union before 15 May 1997’; and

‘food consisting of, isolated from or produced from microorganisms, fungi or algae’.

3.2. Identity of the NF

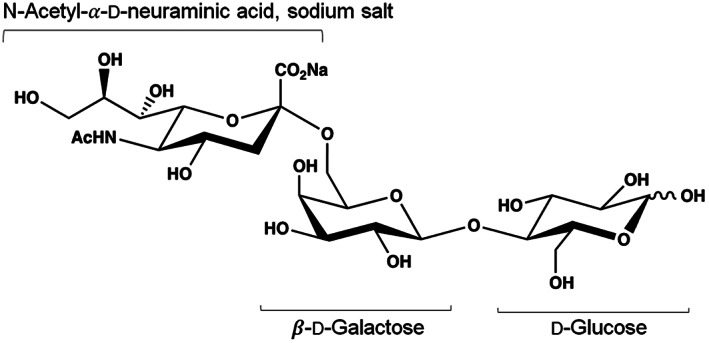

The NF is a powdered mixture mainly composed of 6′‐SL sodium salt (≥ 82.0% w/w DM), but it also contains sialic acid (≤ 6.0% w/w DM), d‐glucose (≤ 3.0% w/w DM), d‐lactose (≤ 3.0% w/w DM), 6′‐sialyllactulose and 3′‐SL sodium salts (≤ 5.0% w/w DM, sum of both) and a small fraction of other related saccharides (sum of other carbohydrates ≤ 13.0% w/w DM). It is produced by fermentation by a genetically modified strain (E. coli NEO6) of E. coli W (ATCC 9637). The main component is the sodium salt of Neu5Ac‐α‐(2–6)‐Gal‐β‐(1–4)‐Glc (6′‐SL), in which sodium N‐acetyl‐d‐neuraminate is linked through an α‐(2–6) bond to d‐galactose, which is linked through a β‐(1–4) bond to d‐glucose, in its α‐ and β‐anomeric forms (Table 1 and Figure 1). 6′‐SL is a regioisomer of 3′‐SL, which contains the same monosaccharide moieties as those present in 6′‐SL but with the linkage between N‐acetyl‐d‐neuraminic acid (Neu5Ac) and d‐galactose being α‐(2–3) instead of α‐(2–6).

Table 1.

Chemical identity of 6′‐SL sodium salt

| Chemical substance | |

| Chemical (IUPAC) name | Sodium; (2R,4S,5R,6R)‐5‐acetamido‐4‐hydroxy‐6‐[(1R,2R)‐1,2,3‐trihydroxypropyl]‐2‐[[(2R,3R,4S,5R,6S)‐3,4,5‐trihydroxy‐6‐[(2R,3R,4R,5R)‐1,2,4,5‐tetrahydroxy‐6‐oxohexan‐3‐yl]oxyoxan‐2‐yl]methoxy]oxane‐2‐carboxylate |

| Common name | 6′‐Sialyllactose, sodium salt |

| Abbreviations | 6′‐SL, sodium salt |

| Alternative chemical names |

|

| CAS Number | 157574‐76‐0 (sodium salt)/35890‐39‐2 (acid) |

| Molecular formula | C23H38NO19Na |

| Molecular mass | 655.53 Da |

CAS: Chemical Abstracts Service; IUPAC: International Union of Pure and Applied Chemistry.

Figure 1.

Chemical structure of 6′‐SL sodium salt (EFSA NDA Panel, 2022a)

Several analyses were performed on the NF in order to confirm the structure of 6′‐SL, the major constituent of the NF.

The structure of 6′‐SL 8 was determined by mono‐dimensional (1D) nuclear magnetic resonance (NMR) spectroscopy, including 1H and 13C spectra, and two‐dimensional (2D) NMR spectroscopy, including COSY (correlation spectroscopy), TOCSY (total correlation spectroscopy), HETCOR (heteronuclear correlation) and HMBC (heteronuclear multiple bond correlation) spectra, by comparison to a commercially available authentic specimen 9 . The relevant coupling constants measured by 1H NMR together with the correlations evidenced on the 2D NMR spectra confirmed: (i) the α‐(2″‐6′) glycosidic linkage between Neu5Ac (C‐2″) and the d‐galactose (Gal‐C‐6′) moiety of d‐lactose; (ii) the β‐(1′‐4) link between the d‐galactose (Gal‐C‐1′) and d‐glucose (Glc‐C‐4) moieties of d‐lactose; and (iii) the β configuration of the Gal unit.

The molecular structure of 6′‐SL 8 was corroborated by liquid chromatography – tandem mass spectrometry (LC–MS/MS) based on its retention factor (Rf) and fragmentation pattern, by comparison to a commercially available high‐purity analytical standard, which allowed to differentiate between 6′‐SL α‐(2″‐6′) and 3′‐SL α‐(2″‐3′).

The identity of 6′‐SL 8 was also corroborated by high‐performance liquid chromatography – charged aerosol detection (HPLC‐CAD) by comparison to a commercially available high‐purity analytical standard.

On the basis of the spectroscopic and chromatographic evidence, the Panel considers that the 6′‐SL present in the NF produced by E. coli NEO6 is identical to the 6′‐SL in human milk, and therefore, it is regarded as being a HiMO.

3.3. Production process

According to the information provided, the NF is produced in line with Good Manufacturing Practice (GMP) and Hazard Analysis Critical Control Points (HACCP) principles, in a facility that is FSSC (Food Safety System Certification) 22000 certified.

The NF is produced by fermentation by a genetically modified strain (E. coli NEO6) of E. coli W (ATCC 9637) using food‐grade raw materials and processing aids. The production microorganism is cultured under sterile conditions in a chemically defined nutrient medium (without soy peptone for commercial production purposes) and uses glucose and lactose to synthesise 6′‐SL, which is excreted into the medium. The production microorganism is removed from the culture medium by microfiltration at the end of the fermentation process. 6′‐SL is isolated as the sodium salt and purified from the fermentation medium using a series of filtration and cationic and anionic exchange steps, followed by concentration and spray‐drying to obtain the final 6′‐SL sodium salt product in powder form.

The production strain E. coli NEO6 is a genetically modified derivative of the parental strain E. coli W (Waksman's strain), which is deposited at the American Type Culture Collection (ATCC) (commercially available under ATCC 9637). The strain E. coli W is well characterised and its genome has been sequenced, annotated and compared to other safe E. coli strains and phylogroup B1 commensal/pathogenic E. coli strains (Archer et al., 2011). Although E. coli W harbours genes that encode pathogenicity determinants, these have been mutationally inactivated or are missing key components required for pathogenicity, similarly to other safe strains (Archer et al., 2011). Genomic analyses also confirmed the lack of genes encoding toxins that can be secreted (Archer et al., 2011). Although the species E. coli is considered not suitable for qualified presumption of safety (QPS) status (EFSA BIOHAZ Panel, 2023), the strain E. coli W does not cause disease in healthy adult humans nor does it colonise the human gut (Bauer et al., 2008; NIH, 2019), and it is considered as a safe and non‐pathogenic or toxigenic microorganism widely used for biotechnological applications.

The production strain has been deposited at the National Biological Resource Center (NBRC) culture collection. A detailed description of the genetic modification steps applied to the parental strain E. coli W to obtain the production strain E. coli NEO6 has been provided by the applicant. No residual DNA from the production strain was detected in the NF by a quantitative polymerase chain reaction (qPCR) assay using primers specific to the production strain. The absence of both DNA and viable cells from the production strain in the NF has been demonstrated in accordance with the EFSA Guidance on the characterisation of microorganisms used as feed additives or as production organisms (EFSA FEEDAP Panel, 2018).

The Panel considers that the production process is sufficiently described and does not raise safety concerns.

3.4. Compositional data

In order to confirm that the manufacturing process is reproducible and adequate to produce on a commercial scale a product with certain characteristics, the applicant provided analytical information for eight batches of the NF produced with (five batches) or without (three batches) soy peptone in the fermentation media, the latter representing the conditions for commercial production of the NF (Table 2). Information was provided on the accreditation of the laboratories that conducted the analyses presented in the application.

Table 2.

Batch‐to‐batch analysis of the NF

| Parameters | NF (produced with soy peptone in the fermentation media) | NF (produced without soy peptone in the fermentation media) | Method of analysis | ||||||

|---|---|---|---|---|---|---|---|---|---|

| #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | ||

| Composition | |||||||||

| 6′‐SL sodium salt (% w/w DM) | 87.0 | 92.0 | 90.0 | 92.0 | 92.0 | 91.0 | 93.0 | 95.0 | HPLC‐CAD (validated internal method) |

| Sialic acid (% w/w DM) | 5.1 | 3.5 | 4.9 | 4.3 | 5.4 | 1.8 | 0.1 | 0.2 | HPLC‐CAD (a) (validated internal method) |

| d‐Glucose (% w/w DM) | < 0.02 | < 0.02 | < 0.02 | < 0.02 | < 0.02 | < 0.05 | < 0.05 | < 0.05 | HPLC‐PAD (b) (validated internal method) |

| d‐Lactose (% w/w DM) | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | < 0.05 | < 0.05 | < 0.05 | HPLC‐PAD (b) (validated internal method) |

| Sum of 6′‐sialyllactulose and 3′‐SL sodium salts (% w/w DM) | 0.4 | 0.4 | 0.5 | 0.5 | 0.4 | 1.7 | 0.5 | 0.3 | HPLC‐CAD (a) , (c) (validated internal method) |

| Sum of other carbohydrates (% w/w DM) | 6.6 | 3.3 | 3.8 | 2.5 | 1.4 | 5.0 | 5.8 | 3.8 | Calculation (d) |

| Water (% w/w) | 5.3 | 5.0 | 5.4 | 5.6 | 5.0 | 7.9 | 8.4 | 8.6 | JP 2.48 (e) – Karl Fischer titration (volumetric/coulometric titration) |

| Ash (% w/w DM) | – | – | 11.6 | – | 11.7 | 11.3 | 11.1 | 11.2 |

JP 2.44 (e) (residue on ignition, gravimetry) |

| Protein (% w/w) | – | – | ≤ 0.01 | – | ≤ 0.01 | ≤ 0.01 | ≤ 0.01 | ≤ 0.01 | Bradford assay (f) (spectrophotometry) |

| Sodium (% w/w DM) | 3.8 | 3.8 | 3.8 | 3.7 | 3.8 | 3.5 | 3.5 | 3.6 |

USP 233 (g) (ICP‐MS or ICP‐OES) |

| pH (5% solution, 25°C) | 6.4 | 6.5 | 6.5 | 6.5 | 6.5 | 6.1 | 5.9 | 5.8 | JP 2.54 (e) (potentiometry) |

| Contaminants | |||||||||

| Arsenic (mg/kg) | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | < 0.01 (i) | < 0.01 (i) | < 0.03 (i) |

AOAC (2019) 999.10 and 2011.14 (i) (AAS and ICP‐OES) |

| Cadmium (mg/kg) | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | < 0.01 (j) | < 0.01 (j) | < 0.01 (j) |

AOAC (2019) 999.10 and 2011.14 (j) (AAS and ICP‐OES) |

| Lead (mg/kg) | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | < 0.02 (k) | 0.03 (k) | < 0.02 (k) |

AOAC (2019) 999.10 and 2011.14 (k) (AAS and ICP‐OES) |

| Mercury (mg/kg) | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | < 0.004 (l) | < 0.004 (l) | < 0.004 (l) |

US EPA, February 2007, Method 7473 (l) (AAS) |

| Aflatoxin M1 (μg/kg) | – | < 0.02 | < 0.02 | < 0.02 | < 0.02 | < 0.02 | < 0.02 | < 0.02 |

AOAC 2000.08 (m) (HPLC) |

| Microbial parameters | |||||||||

| Total plate count (CFU/g) | < 10 | < 10 | < 10 | < 10 | < 10 | < 10 | < 10 | < 10 | ISO 4833‐1:2013 (n) (colony count) |

| Yeasts and moulds (CFU/g) | < 100 | < 100 | < 100 | < 100 | < 100 | < 10 (o) | < 10 (o) | < 10 (o) | ISO 21527‐2:2008 (p) (colony count) |

| Enterobacteriaceae (in 10 g) | ND | ND | ND | ND | ND | ND | ND | ND | ISO 21528‐1:2017 (detection or qualitative method) |

| Salmonella spp. (in 25 g) | – | – | ND | – | – | ND | ND | ND | ISO 6579‐1:2017 (detection or qualitative method) |

| Cronobacter spp. (in 10 g) | ND | ND | ND | ND | ND | ND | ND | ND | ISO 22964:2017 (detection or qualitative method) |

| Listeria monocytogenes (in 25 g) | ND | ND | ND | ND | ND | ND | ND | ND | ISO 11290‐1:2017 (detection or qualitative method) |

| Presumptive Bacillus cereus (CFU/g) | < 10 | < 10 | < 10 | < 10 | < 10 | < 10 | < 10 | < 10 |

ISO 7932:2004 (q) (colony count) |

| Endotoxins (EU/mg) | 0.006 | 0.011 | 0.020 | 0.034 | 0.026 | < 0.0002 (r) | < 0.0002 (r) | < 0.0002 (r) | JP 4.01 (e) (kinetic‐turbidimetric method) |

‘–’: Not reported; 6′‐SL: 6′‐Sialyllactose; 3′‐SL: 3′‐Sialyllactose; AAS: Atomic absorption spectroscopy; AOAC: Association of Official Analytical Collaboration; CFU: Colony forming units; DM: Dry matter; EU: Endotoxin units; HPLC‐CAD: High‐performance liquid chromatography – charged aerosol detection; HPLC‐PAD: High‐performance liquid chromatography – pulsed amperometric detection; ICP‐MS: Inductively coupled plasma – mass spectrometry; ICP‐OES: Inductively coupled plasma – optical emission spectroscopy; ISO: International Organisation for Standardisation; JP: Japanese Pharmacopoeia; LOD: Limit of detection; LOQ: Limit of quantification; MW: Molecular weight; ND: Not detected; US EPA: United States Environmental Protection Agency; USP: United States Pharmacopoeia; w/w: Weight per weight.

For batches #1 to #5, the LOD and LOQ for sialic acid, 6′‐sialyllactulose and 3′‐SL sodium salts are, respectively, 0.03% w/w DM and 0.2% w/w DM (as 6′‐SL sodium salt). For batches #6 to #8, the LOD and LOQ for sialic acid are, respectively, 0.15% w/w DM and 0.45% w/w DM (as sialic acid); the LOD and LOQ for 6′‐sialyllactulose + 3′‐SL sodium salts are, respectively, 0.13% w/w DM and 0.18% w/w DM (as 6′‐SL sodium salt).

For batches #1 to #5, the LOD for d‐glucose and d‐lactose is 0.02% w/w DM, and their LOQ is 0.05% w/w DM (as d‐lactose). For batches #6 to #8, the LOD for d‐glucose and d‐lactose is 0.05% w/w DM, and their LOQ is 0.05% w/w DM (as d‐glucose and d‐lactose, respectively).

6′‐sialyllactulose and 3′‐SL sodium salts peaks on the HPLC‐CAD chromatograms overlap.

Sum of other carbohydrates = 100% w/w DM – 6′‐SL (acid) (% w/w DM) – quantified carbohydrates (i.e., sialic acid, d‐glucose, d‐lactose, 6′‐sialyllactulose (acid) and 3′‐SL (acid); % w/w DM) – sodium (% w/w DM). Concentrations in acid form for the respective carbohydrates have been theoretically calculated.

Consistent with the compendial method specified in the 17th edition of the Japanese Pharmacopoeia (2016).

Evaluated using a limit test at 100 ppm.

Method is consistent with the compendial method specified in the United States Pharmacopoeia 35th revision (2011). Batches #1 to #5 were analysed by ICP‐MS (LOQ = 1.25%). Batches #6 to #8 were analysed by ICP‐OES (LOQ = 0.005%).

LOQ for arsenic, cadmium, lead and mercury is 0.05 mg/kg.

Method based on AOAC (2019) 999.10 and 2011.14. LOD = 0.01 mg/kg. LOQ = 0.03 mg/kg.

Method based on AOAC (2019) 999.10 and 2011.14. LOD = 0.01 mg/kg. LOQ = 0.03 mg/kg.

Method based on AOAC (2019) 999.10 and 2011.14. LOD = 0.02 mg/kg. LOQ = 0.03 mg/kg.

Method based on U.S. EPA, February 2007, Method 7473, Mercury Analyser. LOD = 0.004 mg/kg. LOQ = 0.01 mg/kg.

LOQ = 0.02 μg/kg.

LOD = 10 CFU/g.

LOD = 10 CFU/g (in‐depth plating).

LOD = 100 CFU/g (surface plating).

LOD = 10 CFU/g.

LOQ = 0.0002 EU/mg.

Batch‐to‐batch analyses showed that the NF consists of 6′‐SL sodium salt as main component (90.6% w/w DM 10 or 93.0% w/w DM 11 in batches produced with or without soy peptone in the fermentation media, respectively). The remaining constituents include sialic acid (4.6% w/w DM 10 /0.7% w/w DM 11 ), d‐lactose (≤ 0.05% w/w DM 10 , 11 ), d‐glucose (< 0.02% w/w DM 10 /< 0.05% w/w DM 11 ), 6′‐sialyllactulose and 3′‐SL sodium salts (0.4% w/w DM 10 /0.8% w/w DM 11 – sum of both carbohydrates), and a small fraction of other related saccharides (sum of other carbohydrates 12 , 3.5% w/w DM 10 /4.9% w/w DM 11 ).

With regard to physico‐chemical properties, the NF can be described as a white to off‐white powder. The solubility in water was measured in two batches of the NF produced with soy peptone and three batches without soy peptone in the fermentation media, according to the EFSA Guidance on technical requirements for regulated food and feed product applications to establish the presence of small particles including nanoparticles (EFSA Scientific Committee, 2021), resulting in an average value of 451 and 444 g/L, respectively.

The Panel considers that the information provided on the composition is sufficient for characterising the NF.

3.4.1. Stability

3.4.1.1. Stability of the NF

The applicant provided interim results for a 3‐year (real‐time) stability study at 25°C and 60% relative humidity (RH) on one batch of the NF produced with soy peptone in the fermentation media, including 6′‐SL sodium salt, carbohydrate, sodium and water content, and physico‐chemical parameters up to 24 months, and water activity measurements after 6 and 12 months. In addition, a 6‐month accelerated stability study at 40°C and 75% RH was conducted on five batches of the NF produced with soy peptone in the fermentation media, including the above‐mentioned parameters (water activity measured after 6 months of storage). Microbial parameters were also monitored after 24 months under normal storage conditions.

No significant changes in 6′‐SL sodium salt, carbohydrate, sodium and water content, physico‐chemical parameters and water activity were observed over the storage period under normal and accelerated conditions. Microbial parameters were also below the respective limits of detection after 24 months of storage under normal conditions. The applicant proposed a 2‐year shelf‐life under ambient conditions for the NF.

The Panel considers that, since the presence of soy peptone in the fermentation medium does not change the composition substantially, the available data provided sufficient information with respect to the stability of the NF for 24 months.

3.4.1.2. Stability of the NF under the intended conditions of use

No stability data for the 6′‐SL sodium salt in food matrices were provided.

The applicant referred to (i) the stability studies included in the GRAS (Generally Recognised As Safe) notification GRN (GRAS Notice) 766 (US FDA, 2019) on the 3′‐SL sodium salt in powdered IF (at room temperature for 24 months), milk (at 4 and 25°C for 45 days) and yoghurt (at 4°C for 45 days), and (ii) the stability of related HiMOs, e.g., 2′‐FL, 2′‐FL/DFL mixture, LNnT and sialic acid, in IF, FOF, yoghurt, ready‐to‐drink flavoured milk, citrus fruit drinks and cereal bars (EFSA NDA Panel, 2015a,b, 2017, 2019a).

The Panel considers that the available information is sufficient with respect to the stability of the NF in the proposed food matrices.

3.5. Specifications

The specifications of the NF are indicated in Table 3.

Table 3.

Specifications of the NF

| Description: 6′‐sialyllactose sodium salt is a white to off‐white powder produced by microbial fermentation and further isolated, purified and concentrated. | |

| Source: A genetically modified strain (Escherichia coli NEO6) of E. coli W (ATCC 9637). | |

| Parameter | Specification |

| Composition | |

| 6′‐SL sodium salt (% w/w DM) | ≥ 82.0 |

| Sialic acid (% w/w DM) | ≤ 6.0 |

| d‐Lactose (% w/w DM) | ≤ 3.0 |

| d‐Glucose (% w/w DM) | ≤ 3.0 |

| Sum of 6′‐sialyllactulose and 3′‐SL sodium salts (a) (% w/w DM) | ≤ 5.0 |

| Sum of other carbohydrates (b) (% w/w DM) | ≤ 13.0 |

| Water (% w/w) | ≤ 10.5 |

| Protein (% w/w) | ≤ 0.01 |

| pH (5% solution, 25°C) | 4.5–7.5 |

| Sodium (% w/w DM) | ≤ 5.0 |

| Contaminants | |

| Arsenic (mg/kg) | ≤ 0.2 |

| Aflatoxin M1 (μg/kg) | ≤ 0.025 |

| Microbiological parameters | |

| Total plate count (CFU/g) | ≤ 1,000 |

| Yeasts and moulds (CFU/g) | ≤ 100 |

| Enterobacteriaceae (in 10 g) | ND |

| Salmonella (in 25 g) | ND |

| Cronobacter spp. (in 10 g) | ND |

| Listeria monocytogenes (in 25 g) | ND |

| Presumptive Bacillus cereus (CFU/g) | ≤ 50 |

| Endotoxins (EU/mg) | ≤ 10 |

6′‐SL: 6′‐Sialyllactose; 3′‐SL: 3′‐Sialyllactose; CFU: Colony forming units; DM: Dry matter; EU: Endotoxin units; ND: Not detected; w/w: Weight per weight.

6′‐sialyllactulose and 3′‐SL sodium salts peaks on the HPLC‐CAD chromatograms overlap.

Sum of other carbohydrates = 100% w/w DM – 6′‐SL (acid) (% w/w DM) – quantified carbohydrates (i.e., sialic acid, d‐glucose, d‐lactose, 6′‐sialyllactulose (acid) and 3′‐SL (acid); % w/w DM) – sodium (% w/w DM).

The Panel considers that the information provided on the specifications of the NF is sufficient and does not raise safety concerns.

3.6. History of use of the NF and/or of its source

3.6.1. History of use of the NF

There is no history of use of the NF. However, 6′‐SL sodium salt, which is the major constituent of the NF, has been authorised as a NF in the EU (Commission Implementing Regulation (EU) 2021/82 13 ) to be added to IF and FOF, and to a variety of foods including FS. The authorised 6′‐SL sodium salt is produced by fermentation by a genetically modified strain of E. coli K‐12 DH1. Another 6′‐SL sodium salt produced by genetically modified strains of E. coli BL21 (DE3) has been recently assessed with a positive outcome (EFSA NDA Panel, 2022a), but it is not yet included in the Union list of NFs.

6′‐SL has also been detected in domestic farm animal milk, albeit at lower concentrations as compared to human milk. Oligosaccharides in bovine milk are 20 times less concentrated than in human milk. However, sialylated oligosaccharides account for approximately up to 80% of the total oligosaccharide pools. The amount of 6′‐SL in bovine milk is estimated to range from 4 to 10 mg/L and up to 100 mg/L in colostrum (Aldredge et al., 2013; Urashima et al., 2013; Albrecht et al., 2014), which is much lower than human milk concentrations (between 0.40 and 0.74 g/L; Soyyılmaz et al., 2021; EFSA NDA Panel, 2022a).

3.7. Proposed uses and use levels and anticipated intake

The applicant applies for the same uses and use levels already assessed for 6′‐SL sodium salt produced by fermentation by a genetically modified strain of E. coli K‐12 DH1 (EFSA NDA Panel, 2020a). Therefore, since the NF would be consumed at the same extent as the already assessed 6′‐SL sodium salt, no new estimates of the intake have been carried out.

3.7.1. Target population

The target population proposed by the applicant is the general population.

3.7.2. Proposed uses and use levels

The intended uses and use levels for the NF are the ones already assessed for 6′‐SL sodium salt manufactured by fermentation by a genetically modified strain of E. coli K‐12 DH1.

3.7.3. Anticipated intake of the NF

Considering that the same uses and use levels as per the assessed 6′‐SL sodium salt are proposed (EFSA NDA Panel, 2020a), the Panel considers that a new assessment of the intake is not needed.

3.8. Absorption, distribution, metabolism and excretion (ADME)

No ADME data have been provided for the NF.

The applicant made reference to the assessment performed by the NDA Panel on a previously evaluated 6′‐SL sodium salt (EFSA NDA Panel, 2020a) concluding that the NF does not undergo any significant digestion by human enzymes in the upper gastrointestinal tract and that only small amounts are expected to be absorbed. Milk oligosaccharides are then fermented in the colon by intestinal microbiota with a fraction excreted unchanged in the faeces and a small fraction found in the urine (EFSA NDA Panel, 2022a).

In addition, cross reference is made to a study conducted with the labelled isomer of 6′‐SL (13C‐3′‐SL and also its component sialic acid) in the mouse (Galuska et al., 2020). The main goal of the study was to verify the 13C enrichment in different areas of the brain to study the role of SL in brain development and cognitive functions. The study also demonstrated that absorption after oral administration occurs and is followed by rapid urinary excretion.

Finally, there are no indications that the absorption of 6′‐SL, or other structurally related mono‐ and oligosaccharides (e.g., sialic acid) from the NF, differs from that of similar components in human milk.

3.9. Nutritional information

The NF is mainly composed of the non‐digestible oligosaccharide 6′‐SL.

The NF contains other carbohydrates, individually present at low concentrations. Sialic acid is an endogenous human and ubiquitous monosaccharide (EFSA NDA Panel, 2017; Röhrig et al., 2017). d‐Lactose is the most abundant component of human milk (~ 7%) and its monomers, d‐glucose and d‐galactose, are normal constituents of human milk. 3′‐SL is a regioisomer of 6′‐SL and also a normal constituent of human milk (see Section 3.4).

The Panel notes that the NF, being a sodium salt, may contribute to the daily sodium intake. Since the same uses and use levels as per the authorised 6′‐SL sodium salt are proposed and the sodium content is comparable, similar considerations for the sodium intake apply (i.e., intake ranging from 5% to 38% of the safe and adequate intake 14 in different population groups; EFSA NDA Panel, 2020a).

The Panel considers that, taking into account the composition of the NF and the proposed conditions of use, consumption of the NF is not nutritionally disadvantageous.

3.10. Toxicological information

The applicant provided four toxicological studies on the NF, which were conducted in compliance with OECD principles of GLP (Organisation for Economic Co‐operation and Development principles of Good Laboratory Practices (OECD, 1998)) and in accordance with the OECD test guidelines TG No 471, 474, 487 and 408. These studies, which were claimed proprietary by the applicant, are listed in Table 4.

Table 4.

List of toxicological studies with the NF

| Reference | Type of study | Test system | Dose |

|---|---|---|---|

| Unpublished Study No. AG200051 | Bacterial reverse mutation test (GLP, OECD TG 471 (1997)) | Salmonella Typhimurium TA98, TA100, TA1535, TA1537 and E. coli WP2 uvrA | Up to 5,000 μg 6′‐SL/plate (absence and presence of S9 mix) |

| Unpublished Study No. 200059 | Micronucleus study in bone marrow cells of mice (GLP, OECD TG 474 (2016)) | Slc:ICR(ICR) mice | 500, 1,000 and 2,000 mg 6′‐SL/kg bw |

| Unpublished Study No. CG220004 | In vitro micronucleus study in cultured mammalian cells (GLP, OECD TG 487 (2016)) | CHL/IU cells | 500, 1,000 and 2,000 μg 6′‐SL/mL (absence and presence of S9 mix) |

| Unpublished Study No. 100603RG | 90‐day repeated dose oral toxicity study in rats (GLP, OECD TG 408 (2018)) | SD rats | 542, 1,084 and 2,168 mg 6′‐SL/kg bw/day |

The Panel also noted that in solution under acidic conditions, the NF will be hydrolysed to d‐lactose and sialic acid (EFSA NDA Panel, 2020a, 2022a). The amount of these by‐products produced during the digestion remains always lower than the intake estimated from human milk. Finally, the possible formation of 6′‐sialyllactulose derived from 6′‐SL by isomerisation of the terminal d‐glucose moiety into d‐fructose mainly under alkaline conditions during the production process (Zeng et al., 2018) is also considered not of concern (EFSA NDA Panel, 2022a).

3.10.1. Genotoxicity

The in vitro assessment of the mutagenic potential of the NF was evaluated in a bacterial reverse mutation test (Unpublished Study Report, 2020a). Two main tests, conducted as pre‐incubation assays, were performed using S. Typhimurium strains TA98, TA100, TA1535 and TA1537 and E. coli strain WP2 uvrA, which were exposed to water or five different concentrations of 6′‐SL sodium salt (313, 625, 1,250, 2,500 or 5,000 μg/plate), either in the presence or absence of liver microsomal fractions (S9 mix). No reproducible or dose‐related increases in revertant colony numbers over control counts were observed with any of the strains following exposure to the NF at any concentration (irrespective of the presence or absence of S9 mix). Neither growth inhibition nor precipitation of the test substance was observed. Based on the results of the study, it was concluded that the NF is non‐mutagenic at concentrations up to 5,000 μg/plate in the absence or presence of metabolic activation.

The potential ability of the NF to induce chromosome aberration in bone marrow of ICR mice was also assessed in an in vivo micronucleus (MN) study (Unpublished Study Report, 2020b). After a dose‐range finding study, the NF was administered twice (with a 24‐h interval) by gavage at doses of 0 (water for injection), 500, 1,000 or 2,000 mg/kg body weight to 5 male ICR mice/group. Animals were euthanised about 24 h after the second administration and femoral bone marrow smears were prepared and analysed. No statistically significant differences were noted in the frequency of micronucleated immature erythrocytes between the NF and negative control groups. No significant difference in the proportion of immature erythrocytes among total erythrocytes among study groups was observed. It was concluded that the NF does not have the potential for induction of chromosomal aberrations under the experimental condition applied. However, the Panel noted that the use of animals for this experiment was unnecessary as no evidence of the exposure of the bone marrow to the test substance was provided. Therefore, the applicant was requested to perform an additional in vitro MN test.

To investigate the MN‐inducing potential of the NF in cultured mammalian cells, a study was conducted in Chinese hamster lung cells (CHL/IU) by a short‐term treatment (6‐h method; with and without metabolic activation (S9 mix)) and long‐term treatment (27‐h method) (Unpublished Study Report, 2022). Concentrations of 500, 1,000 and 2,000 μg 6′‐SL sodium salt/mL in physiological saline in the main test were used. No cytotoxicity (measurement of relative population doubling) was observed in any treatment method. No statistically significant increases in the number of binucleate cells containing micronuclei both after 6‐h treatment in the presence of or absence of S9 mix or following 27‐h treatment were noted and remained within the background range. Therefore, the Panel concludes that the NF did not show any evidence of clastogenicity or aneugenicity in the absence and presence of metabolic activation up to the highest concentration of 2,000 μg/mL.

Taking into account the results provided and considering the nature, source and production process of the NF, the Panel considers that there are no concerns regarding genotoxicity.

3.10.2. Subchronic toxicity

The applicant provided the technical report of a 90‐day study where groups of 10 Crl:CD(SD) rats/sex were given distilled water, 542, 1,084 or 2,168 mg 6′‐SL sodium salt/kg bw per day by oral gavage (Unpublished Study Report, 2021).

There were no deaths in the course of the study and no treatment‐related changes in clinical signs, body weight, body weight gain and food consumption were observed in any rats. Also, functional observations, ophthalmological examination and oestrus cycle examination performed at the end or towards the end of the treatment period did not reveal any test item‐related finding.

Some statistically significant changes (Appendix A) of small magnitude were noted in haematological parameters (change in platelets count in low‐dose males) and in clinical chemistry: increased alanine aminotransferase (ALT) in high‐dose males and increased sodium levels in high‐dose females. At urinalysis, variations in a few electrolytes were recorded: increased sodium concentration at intermediate dose in both sexes and in high‐dose males, decreased chloride concentration in high‐dose males, increased sodium excretion in the intermediate and high‐dosed males, decreased total excretion of potassium and chloride at high dose in both sexes. These observed changes were sporadic, of low magnitude and limited to only one sex and they are overall considered by the Panel as not toxicologically relevant.

No findings in treated rats were noted at gross pathology. Some statistically significant changes were noted in both absolute and relative (to the bw) organ weights: increased thyroid weight (low‐dose males), decreased pituitary weight (low‐ and intermediate‐dose females), decreased thyroid weight (low‐ and intermediate‐dose females), decreased ovaries weight (intermediate dose, limited to absolute weight), which the Panel considers as incidental and not treatment related.

At histopathology, a few changes were observed in rats receiving the high dose. Changes included mononuclear cell infiltration in the ventricular wall of the heart (2M, 1F), focal fibrosis in the pancreas (1M) or atrophy of acinar cells (1M), tubular basophilic change (1M) and unilateral scar in the kidney (1F), lumen dilatation in the glandular stomach (2M, and 1M in controls), focal ectopic tissue in the mucosa of glandular stomach (1M), accessory adrenal gland (1F), unilateral retinal dysplasia (3M and 1M, 1F in controls). These findings occurred in single animals, in controls or historical controls, or were unilateral or mild. Therefore, they were considered as incidental.

The Panel considers that no adverse effects were observed in this study at the highest tested dose of 2,168 mg 6′‐SL sodium salt/kg bw per day.

3.10.3. Human data

No human intervention studies with the NF were provided by the applicant.

The Panel noted that a recent publication (Kim et al., 2022) describes a randomised, controlled clinical trial conducted in 60 healthy adult participants with a 6′‐SL with 98.8% purity produced with enzymes from ‘non‐pathogenic E. coli K‐12’. The oral dose administered was 6 g/day divided in two doses (after the morning and evening meals, approximate interval of 12 h) for 12 consecutive weeks. The placebo group received the same amount of maltodextrin powder according to the same schedule. Only minor adverse reactions (most of the symptoms were gastrointestinal troubles with abdominal discomfort and diarrhoea) were recorded without difference between the treated group and the control group. The Panel notes that the resulting intake is around 90 mg/kg bw per day and that the estimated intake from the proposed uses is ranging from 10 (in elderly) to 192 (in infants) mg/kg bw at the highest 95th percentile (EFSA NDA Panel, 2020a).

The Panel considers this information as supportive for the tolerability of 6′‐SL in adults.

3.11. Allergenicity

The applicant did not identify an allergenic potential of introduced proteins as a result of the genetic modification of the E. coli W (ATCC 9637) parental strain, according to the ‘Scientific opinion on the assessment of allergenicity of GM plants and microorganisms and derived food and feed of the Scientific Panel on Genetically Modified Organisms’ (EFSA GMO Panel, 2010). The criterion used for identifying allergenic proteins was that of considering ‘higher than 35% identity in a sliding window of 80 amino acids’. The applicant also conducted an ELISA test on one batch of the NF for milk proteins, which were below the LOQ (1 μg/g).

The protein content in the NF is low (≤ 0.01% w/w) as indicated in the specifications (Table 3).

The Panel considers that, for these reasons, the likelihood of allergenic reactions to the NF is low.

4. Discussion

The NF is a powdered mixture mainly composed of 6′‐SL sodium salt, but it also contains sialic acid, d‐lactose, d‐glucose, 6′‐sialyllactulose sodium salt, 3′‐SL sodium salt and a small fraction of other related saccharides. The NF is produced by fermentation by a genetically modified strain (E. coli NEO6) of E. coli W (ATCC 9637).

The target population proposed by the applicant is the general population. The applicant intends to add the NF to a variety of foods, including IF and FOF, FSMP and FS. The applicant applies for the same uses and use levels already assessed for the 6′‐SL sodium salt produced by fermentation by a genetically modified strain of E. coli K‐12 DH1. Therefore, since the NF produced with the new process has similar composition and would be consumed at the same extent as the already assessed 6′‐SL in IF, FOF and other foods, no new estimates of the intake have been carried out. Similar considerations apply for the sodium intake. The applicant stated that FS containing the NF are not intended to be used if other foods with added NF or human milk are consumed on the same day. Additional sources for the oligosaccharides contained in the NF are cow milk and milk‐derived products. However, the contribution from consumption of cow milk and milk‐derived products is small.

The submitted toxicity studies did not raise safety concerns. No toxicologically relevant effects were observed in the subchronic toxicity study in rats at up to the highest dose tested of 2,168 mg 6′‐SL/kg bw per day.

Taking into account the intrinsic nature of HMOs with their limited absorption, the absence of toxicologically relevant effects in the subchronic study and considering that infants are naturally exposed to these substances, the Panel considers that the consumption of the NF at the proposed uses and use levels does not raise safety concerns.

5. Conclusions

The Panel concludes that the NF, which is composed of 6′‐SL and other structurally related mono‐ and oligosaccharides, is safe under the proposed conditions of use.

5.1. Protection of Proprietary data in accordance with Article 26 of Regulation (EU) 2015/2283

The Panel could not have reached the conclusion on the safety of the NF under the proposed conditions of use without the data claimed as proprietary by the applicant: (i) identity of the NF as confirmed by NMR spectroscopy, LC–MS/MS and HPLC‐CAD; (ii) production process; (iii) information on the genetically modified production strain; (iv) composition and stability of the NF; (v) toxicological (Table 4) and allergenicity studies.

6. Steps taken by EFSA

On 07 December 2021 EFSA received a letter from the European Commission with the request for a scientific opinion on the safety of 6′‐sialyllactose (6′‐SL) sodium salt as a novel food. Ref. Ares(2021)7548385.

On 07 December 2021, a valid application on the safety of 6′‐sialyllactose (6′‐SL) sodium salt as a novel food, which was submitted by Kyowa Hakko Bio Co., Ltd, was made available to EFSA by the European Commission through the Commission e‐submission portal (NF 2021/2458) and the scientific evaluation procedure was initiated.

On 21 July 2022, EFSA requested the applicant to provide additional information to accompany the application and the scientific evaluation was suspended.

On 14 April 2023, additional information was provided by the applicant through the Commission e‐submission portal and the scientific evaluation was restarted.

During its meeting on 27 April 2023, the NDA Panel, having evaluated the data, adopted a scientific opinion on the safety of 6′‐sialyllactose (6′‐SL) sodium salt as a novel food pursuant to Regulation (EU) 2015/2283.

Abbreviations

- 1D

Mono‐dimensional

- 2D

Two‐dimensional

- 2′‐FL

2′‐Fucosyllactose

- 3‐FL

3‐Fucosyllactose

- 3′‐SL

3′‐Sialyllactose

- 6′‐SL

6′‐Sialyllactose

- AAS

Atomic absorption spectroscopy

- ADME

Absorption, Distribution, Metabolism and Excretion

- ALT

Alanine aminotransferase

- AOAC

Association of Official Analytical Collaboration

- ATCC

American Type Culture Collection

- BIOHAZ

EFSA Panel on Biological Hazards

- bw

Body weight

- CAS

Chemical Abstracts Service

- CFU

Colony forming units

- CHL/IU

Chinese hamster lung cells

- COSY

Correlation spectroscopy

- Crl:CD(SD) rats

Charles River Laboratories: Caesarean‐derived (Sprague Dawley) rats

- DFL

Difucosyllactose

- DM

Dry matter

- DNA

Deoxyribonucleic acid

- Escherichia coli W

Waksman's E. coli strain

- EU

Endotoxin units

- FEEDAP

EFSA Panel on Additives and Products or Substances used in Animal Feed

- FOF

Follow‐on formula

- FS

Food supplements

- FSMP

Food for special medical purposes

- FSSC 22000

Food Safety System Certification 22000

- Gal

Galactose

- Glc

Glucose

- GLP

Good Laboratory Practices

- GMO

EFSA Panel on Genetically Modified Organisms

- GMP

Good Manufacturing Practice

- GRAS

Generally Recognised As Safe

- GRN

GRAS Notice

- HACCP

Hazard Analysis Critical Control Points

- HETCOR

Heteronuclear correlation

- HiMO

Human‐identical milk oligosaccharide

- HMBC

Heteronuclear multiple‐bond correlation

- HMO

Human milk oligosaccharide

- HPLC‐CAD

High‐performance liquid chromatography – charged aerosol detection

- HPLC‐PAD

High performance liquid chromatography‐pulsed amperometric detection

- ICP‐MS

Inductively coupled plasma – mass spectrometry

- ICP‐OES

Inductively coupled plasma – optical emission spectroscopy

- ICR

Institute of Cancer Research

- IF

Infant formula

- ISO

International Organisation for Standardisation

- IU

International Units

- IUPAC

International Union of Pure and Applied Chemistry

- JP

Japanese Pharmacopoeia

- LC

Liquid chromatography

- LNnT

Lacto‐N‐neotetraose

- LNT

Lacto‐N‐tetraose

- LOD

Limit of detection

- LOQ

Limit of quantification

- MN

micronucleus

- MS/MS

Tandem mass spectrometry

- MW

Molecular weight

- NANA, Neu5A

N‐acetyl‐d‐neuraminic acid, sialic acid

- NBRC

National Biological Resource Center

- ND

Not detected

- NDA

EFSA Panel on Nutrition, Novel Foods and Food Allergens

- NF

Novel food

- NIH

National Institutes of Health

- NMR

Nuclear magnetic resonance spectroscopy

- OECD

Organisation for Economic Co‐operation and Development

- qPCR

Quantitative polymerase chain reaction

- QPS

Qualified presumption of safety

- Rf

Retention factor

- RH

Relative humidity

- SD rats

Sprague Dawley rats

- TG

Test guidelines

- TOCSY

Total correlation spectroscopy

- US

United States

- US EPA

US Environmental Protection Agency

- US FDA

US Food and Drug Administration

- USP

US Pharmacopoeia

- w/w

weight per weight

Appendix A – Summary of the 90‐day oral toxicity study in rats

1.

| Study title | GLP 90‐day oral toxicity study on 6′‐SL sodium salt in SD rats (Unpublished study report, 2021) | ||||

|---|---|---|---|---|---|

| Key results | |||||

| Parameters | Sex | Dose groups (expressed in mg 6′‐SL sodium salt/kg bw per day) | |||

|

0 (control, G1); mean ± SD |

542 (low dose, G2); mean ± SD |

1084 (intermediate dose, G3); mean ± SD |

2168 (high dose, G4); mean ± SD |

||

| Haematology | |||||

| Platelets (104/μL) | M | 113.1 ± 11.9 | 133.5 ± 12.8** | 117.0 ± 18.7 | 114.6 ± 7.8 |

| F | 116.5 ± 10.5 | 114.5 ± 10.4 | 109.6 ± 14.5 | 122.6 ± 19.3 | |

| Clinical chemistry | |||||

| Alanine aminotransferase (ALT) IU/L | M | 27 ± 4 | 31 ± 4 | 34 ± 9 | 33 ± 4## |

| F | 28 ± 6 | 28 ± 6 | 32 ± 18 | 30 ± 5 | |

| Sodium (mmol/L) | M | 145 ± 2 | 146 ± 1 | 145 ± 1 | 146 ± 1 |

| F | 143 ± 1 | 144 ± 1 | 144 ± 2 | 145 ± 1** | |

| Urinalysis | |||||

| Sodium (mmol/L) | M | 78 ± 21 | 86 ± 22 | 133 ± 37## | 160 ± 80## |

| F | 99 ± 45 | 110 ± 40 | 158 ± 62* | 153 ± 52 | |

| Sodium (mmol/24 h) | M | 1.4 ± 0.9 | 1.5 ± 0.4 | 2.2 ± 0.6* | 2.4 ± 0.8** |

| F | 1.3 ± 0.5 | 1.6 ± 0.4 | 1.5 ± 0.4 | 1.7 ± 0.4 | |

| Potassium (mmol/24 h) | M | 4.3 ± 2.3 | 3.4 ± 0.3 | 3.4 ± 0.5 | 2.6 ± 0.6# |

| F | 3.3 ± 0.7 | 3.3 ± 0.9 | 2.7 ± 0.8 | 2.4 ± 0.7* | |

| Chloride (mmol/L) | M | 88 ± 21 | 64 ± 15 | 70 ± 31 | 52 ± 32* |

| F | 118 ± 46 | 109 ± 46 | 122 ± 54 | 90 ± 34 | |

| Chloride (mmol/24 h) | M | 1.6 ± 0.9 | 1.1 ± 0.2 | 1.2 ± 0.4 | 0.8 ± 0.3# |

| F | 1.5 ± 0.5 | 1.6 ± 0.5 | 1.2 ± 0.4 | 1.0 ± 0.4* | |

| Organ weight values – absolute | |||||

| Pituitary (mg) | M | 17.8 ± 1.8 | 18.8 ± 2.5 | 19.8 ± 2.8 | 16.5 ± 2.0 |

| F | 25.3 ± 4.6 | 18.2 ± 4.7** | 17.6 ± 3.2** | 23.8 ± 3.3 | |

| Thyroid (mg) | M | 44.2 ± 6.8 | 53.6 ± 11.2* | 43.8 ± 6.8 | 37.9 ± 4.5 |

| F | 40.1 ± 4.0 | 25.4 ± 3.1** | 29.26 ± 4.7** | 36.9 ± 3.7 | |

| Ovaries (mg) | M | – | – | – | – |

| F | 112.7 ± 20.0 | 95.3 ± 18.2 | 85.5 ± 17.5* | 94.5 ± 27.2 | |

| Organ weight values – relative to bw | |||||

| Pituitary (mg/g bw) | M | 0.0317 ± 0.0034 | 0.0329 ± 0.0029 | 0.0337 ± 0.0032 | 0.0292 ± 0.0035 |

| F | 0.0840 ± 0.0128 | 0.0611 ± 0.0133** | 0.0584 ± 0.0066** | 0.0790 ± 0.0129 | |

| Thyroid (mg) | M | 0.0782 ± 0.0104 | 0.0937 ± 0.0198* | 0.0750 ± 0.0130 | 0.0674 ± 0.0103 |

| F | 0.1343 ± 0.0171 | 0.0860 ± 0.0132** | 0.0972 ± 0.0113** | 0.1221 ± 0.0138 | |

*p < 0.05; **p < 0.01 significant difference in the parametric procedure; #p < 0.05; ##p < 0.01 significant difference in the non‐parametric procedure.

Suggested citation: EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , Turck D, Bohn T, Castenmiller J, De Henauw S, Hirsch‐Ernst KI, Maciuk A, Mangelsdorf I, McArdle HJ, Naska A, Pelaez C, Pentieva K, Siani A, Thies F, Tsabouri S, Vinceti M, Aguilera‐Gómez M, Cubadda F, Frenzel T, Heinonen M, Prieto Maradona M, Marchelli R, Neuhäuser‐Berthold M, Poulsen M, Schlatter JR, Siskos A, van Loveren H, Colombo P, Noriega Fernández E and Knutsen HK, 2023. Scientific Opinion on the safety of 6′‐sialyllactose (6′‐SL) sodium salt produced by a derivative strain (Escherichia coli NEO6) of E. coli W (ATCC 9637) as a Novel Food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2023;21(6):8025, 23 pp. 10.2903/j.efsa.2023.8025

Requestor European Commission

Question number EFSA‐Q‐2021‐00447

Panel members Dominique Turck, Torsten Bohn, Jacqueline Castenmiller, Stefaan De Henauw, Karen Ildico Hirsch‐Ernst, Helle Katrine Knutsen, Alexandre Maciuk, Inge Mangelsdorf, Harry J McArdle, Androniki Naska, Carmen Pelaez, Kristina Pentieva, Alfonso Siani, Frank Thies, Sophia Tsabouri and Marco Vinceti.

Declarations of interest If you wish to access the declaration of interests of any expert contributing to an EFSA scientific assessment, please contact interestmanagement@efsa.europa.eu.

EFSA may include images or other content for which it does not hold copyright. In such cases, EFSA indicates the copyright holder and users should seek permission to reproduce the content from the original source.

Adopted: 27 April 2023

Notes

Regulation (EU) 2015/2283 of the European Parliament and of the Council on novel foods, amending Regulation (EU) No 1169/2011 of the European Parliament and of the Council and repealing Regulation (EC) N0 258/97 of the European Parliament and of the Council and Commission Regulation (EC) No 1852/2001 (2013/0435 (COD)). OJ L 327, 11.12.2015, pp. 1–22.

Commission Implementing Regulation (EU) 2017/2470 of 20 December 2017 establishing the Union list of novel foods in accordance with Regulation (EU) 2015/2283 of the European Parliament and of the Council on novel foods. OJ L 351, 30.12.2017, pp. 72–201.

Commission Implementing Regulation (EU) 2017/2469 of 20 December 2017 laying down administrative and scientific requirements for applications referred to in Article 10 of Regulation (EU) 2015/2283 of the European Parliament and of the Council on novel foods. OJ L 351, 30.12.2017, pp. 64–71.

Regulation (EU) No 609/2013 of the European Parliament and of the Council of 12 June 2013 on food intended for infants and young children, food for special medical purposes and total diet replacement for weight control and repealing Council Directive92/52/EEC, Commission Directives 96/8/EC, 1999/21/EC, 2006/125/EC and 2006/141/EC, Directive 2009/39/EC of the European Parliament and of the Council and Commission Regulations (EC) No 41/2009 and (EC) No 953/2009. OJ L 181, 29.6.2013, pp. 35–56.

Commission Delegated Regulation (EU) 2017/1798 of 2 June 2017 supplementing Regulation (EU) No 609/2013 of the European Parliament and of the Council as regards the specific compositional and information requirements for total diet replacement for weight control. OJ L 259, 7.10.2017, pp. 2–10.

Commission Delegated Regulation (EU) 2016/128 of 25 September 2015 supplementing Regulation (EU) No 609/2013 of the European Parliament and of the Council as regards the specific compositional and information requirements for food for special medical purposes. OJ L 25, 2.2.2016, pp. 30–43.

Commission Delegated Regulation (EU) 2016/127 of 25 September 2015 supplementing Regulation (EU) No 609/2013 of the European Parliament and of the Council as regards the specific compositional and information requirements for infant formula and follow‐on formula and as regards requirements on information relating to infant and young child feeding. OJ L 25, 2.2.2016, pp. 1–29.

Batches of the NF produced with and without soy peptone in the fermentation media.

6’‐SL isolated from human milk.

Average content in five batches of the NF produced with soy peptone in the fermentation media.

Average content in three batches of the NF produced without soy peptone in the fermentation media.

Sum of other carbohydrates = 100% w/w DM – 6’‐SL (acid) (% w/w DM) – quantified carbohydrates (i.e., sialic acid, d‐glucose, d‐lactose, 6′‐sialyllactulose (acid) and 3′‐sialyllactose (acid); % w/w DM) – sodium (% w/w DM).

Commission Implementing Regulation (EU) 2021/82 of 27 January 2021 authorising the placing on the market of 6′‐sialyllactose sodium salt as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council and amending Commission Implementing Regulation (EU) 2017/2470. OJ L 29, 28.1.2021, pp. 16–22.

An adequate intake (AI) is the value set when there is not enough data to calculate an average requirement for a nutrient. An AI is the average level of intake of a nutrient, based on observations or experiments that is assumed to be adequate.

References

- Albrecht S, Lane JA, Marino K, Al Busadah KA, Carrington SD, Hickey RM and Rudd PM, 2014. A comparative study of free oligosaccharides in the milk of domestic animals. British Journal of Nutrition, 111, 1313–1328. [DOI] [PubMed] [Google Scholar]

- Aldredge DL, Geronimo MR, Hua S, Nwosu CC, Lebrilla CB and Barile D, 2013. Annotation and structural elucidation of bovine milk oligosaccharides and determination of novel fucosylated structures. Glycobiology, 23, 664–676. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Archer CT, Kim JF, Jeong H, Park JH, Vickers CE, Lee SY and Nielsen LK, 2011. The genome sequence of E. coli W (ATCC 9637): comparative genome analysis and an improved genome‐scale reconstruction of E. coli . BMC Genomics, 12, 20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bauer AP, Ludwig W and Schleifer KH, 2008. A novel DNA microarray design for accurate and straightforward identification of Escherichia coli safety and laboratory strains. Systematic and Applied Microbiology, 31, 50–61. [DOI] [PubMed] [Google Scholar]

- EFSA BIOHAZ Panel (EFSA Panel on Biological Hazards) , 2023. Scientific Opinion on the update of the list of qualified presumption of safety (QPS) recommended microorganisms intentionally added to food or feed as notified to EFSA. EFSA Journal 2023;21(1):7747, 23 pp. 10.2903/j.efsa.2023.7747 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed) , 2018. Guidance on the characterisation of microorganisms used as feed additives or as production organisms. EFSA Journal 2018;16(3):5206, 24 pp. 10.2903/j.efsa.2018.5206 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA GMO Panel (EFSA Panel on Genetically Modified Organisms) , 2010. Scientific opinion on the assessment of allergenicity of GM plants and microorganisms and derived food and feed. EFSA Journal 2010;8(7):1700, 168 pp. 10.2903/j.efsa.2010.1700 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies) , 2015a. Scientific opinion on the safety of 2′‐O‐fucosyllactose as a novel food ingredient pursuant to Regulation (EC) No 258/97. EFSA Journal 2015;13 (7):4184, 32 pp. 10.2903/j.efsa.2015.4184 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies) , 2015b. Scientific opinion on the safety of lacto‐N‐neotetraose as a novel food ingredient pursuant to Regulation (EC) No 258/97. EFSA Journal 2015;13(7):4183, 32 pp. 10.2903/j.efsa.2015.4183 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies) , 2015c. Statement on the safety of lacto‐N‐neotetraose and 2′‐O‐fucosyllactose as novel food ingredients in food supplements for children. EFSA Journal 2015;13(11):4299, 11 pp. 10.2903/j.efsa.2015.4299 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies) , 2016. Guidance on the preparation and presentation of an application for authorisation of a novel food in the context of Regulation (EU) 2015/2283. EFSA Journal 2016;14(11):4594, 24 pp. 10.2903/j.efsa.2016.4594 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies) , 2017. Scientific opinion on the safety of synthetic N‐acetyl‐D‐neuraminic acid as a novel food pursuant to Regulation (EC) No 258/97. EFSA Journal 2017;15(7):4918, 28 pp. 10.2903/j.efsa.2017.4918 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2019a. Scientific opinion on the safety of 2′‐fucosyllactose/difucosyllactose mixture as a novel food pursuant to Regulation (EU) 2015/2283.EFSA Journal 2019;17(6):5717, 23 pp. 10.2903/j.efsa.2019.5717 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2019b. Scientific opinion on the safety of lacto‐N‐tetraose (LNT) as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2019;17(12):5907, 27 pp. 10.2903/j.efsa.2019.5907 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2020a. Scientific opinion on the safety of 6′‐Sialyllactose (6′‐SL) sodium salt as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2020;18(5):6097, 23 pp. 10.2903/j.efsa.2020.6097 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2020b. Scientific opinion on the safety of 3′‐Sialyllactose (3′‐SL) sodium salt as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2020;18(5):6098, 22 pp. 10.2903/j.efsa.2020.6098 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2020c. Scientific opinion on the safety of lacto‐N‐neotetraose (LNnT) produced by derivative strains of E. coli BL21 as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2020;18(11):6305, 11 pp. 10.2903/j.efsa.2020.6305 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2021. Scientific opinion on the safety of 3‐Fucosyllactose (3‐FL) as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2021;19(6):6662, 25 pp. 10.2903/j.efsa.2021.6662 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022a. Scientific Opinion on the safety of 6′‐sialyllactose (6′‐SL) sodium salt produced by derivative strains of Escherichia coli BL21 (DE3) as a novel food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(12):7645, 29 pp. 10.2903/j.efsa.2022.7645 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022b. Scientific Opinion on the safety of 3′‐sialyllactose (3′‐SL) sodium salt produced by derivative strains of Escherichia coli BL21 (DE3) as a Novel Food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(5):7331, 26 pp. 10.2903/j.efsa.2022.7331 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022c. Scientific Opinion on the safety of 2′‐fucosyllactose (2′‐FL) produced by a derivative strain (APC199) of Corynebacterium glutamicum ATCC 13032 as a Novel Food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(12):7647, 21 pp. 10.2903/j.efsa.2022.7647 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022d. Scientific Opinion on the safety of the extension of use of 2′‐fucosyllactose (2′‐FL) and lacto‐N‐neotetraose (LNnT) as novel foods in food supplements for infants pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(5):7257, 9 pp. 10.2903/j.efsa.2022.7257 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022e. Scientific Opinion on the safety of lacto‐N‐tetraose (LNT) produced by derivative strains of Escherichia coli BL21 (DE3) as a Novel Food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(5):7242, 24 pp. 10.2903/j.efsa.2022.7242 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022f. Scientific opinion on the safety of the extension of use of 2′‐fucosyllactose/difucosyllactose (2′‐FL/DFL) mixture and lacto‐N‐tetraose (LNT) as novel foods in food supplements for infants pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(3):7140, 9 pp. 10.2903/j.efsa.2022.7140 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Nutrition, Novel Foods and Food Allergens) , 2022g. Scientific Opinion on the safety of 3‐fucosyllactose (3‐FL) produced by a derivative strain of Escherichia coli BL21 (DE3) as a Novel Food pursuant to Regulation (EU) 2015/2283. EFSA Journal 2022;20(5):7329, 23 pp. 10.2903/j.efsa.2022.7329 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA Scientific Committee , 2021. Guidance on technical requirements for regulated food and feed product applications to establish the presence of small particles including nanoparticles. EFSA Journal 2021;19(8):6769, 48 pp. 10.2903/j.efsa.2021.6769 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Galuska CE, Rudloff S, Kuntz S, Borsch C, Reutzel M, Eckert G, Galuska SP and Kunz C, 2020. Metabolic fate and organ distribution of (13)C‐3′‐sialyllactose and (13)C‐N‐acetylneuraminic acid in wild‐type mice — No evidence for direct incorporation into the brain. Journal of Functional Foods, 75, 104268. 10.1016/j.jff.2020.104268 [DOI] [Google Scholar]

- Kim JH, Yong S‐Y, Kim SH, Baek A, Go T‐H and Kang D‐R, 2022. Randomized, triple‐blind, placebo‐controlled study to evaluate the safety of 6′‐Sialyllactose in healthy adults. Regulatory Toxicology and Pharmacology, 129, 105–110. 10.1016/j.yrtph.2021.105110 [DOI] [PubMed] [Google Scholar]

- NIH (National Institutes of Health) , 2019. NIH guidelines for research involving recombinant or synthetic nucleic acid molecules. National Institutes of Health (NIH), Office of Science Policy, Bethesda, MD Available online: https://osp.od.nih.gov/biotechnology/nih-guidelines/ (accessed on 15 April 2023)

- OECD (Organisation for Economic Co‐operation and Development) , 1998. OECD Principles on Good Laboratory Practice, OECD Series on Principles of Good Laboratory Practice and Compliance Monitoring, No. 1. OECD Publishing, Paris. 10.1787/9789264078536-en [DOI] [Google Scholar]

- OECD (Organisation for Economic Co‐operation and Development) TG 408 , 2018. Test No. 408: Repeated dose 90‐day oral toxicity study in rodents, OECD Guidelines for the Testing of Chemicals, Section 4. OECD Publishing, Paris. 10.1787/9789264070707-en [DOI] [Google Scholar]

- OECD (Organisation for Economic Co‐operation and Development) TG 471 , 1997. Test No. 471: Bacterial reverse mutation test. In: OECD guidelines for the testing of chemicals, Section 4: Health effects, 11 pp.

- OECD (Organisation for Economic Co‐operation and Development) TG 474 , 2016. Test No. 474: mammalian erythrocyte micronucleus test, OECD Guidelines for the Testing of Chemicals, Section 4. OECD Publishing, Paris. 10.1787/20745788 [DOI] [Google Scholar]

- OECD (Organisation for Economic Co‐operation and Development) TG 487 , 2016. Test No. 487: In vitro mammalian cell micronucleus test, OECD Guidelines for the Testing of Chemicals, Section 4. OECD Publishing, Paris. 10.1787/9789264264861-en [DOI] [Google Scholar]

- Röhrig CH, Choi SSH and Baldwin N, 2017. The nutritional role of free sialic acid, a human milk monosaccharide, and its application as a functional food ingredient. Critical Reviews in Food Science and Nutrition, 57, 1017–1038. [DOI] [PubMed] [Google Scholar]

- Soyyılmaz B, Mik_s MH, R€ohrig CH, Matwiejuk M, Meszaros‐Matwiejuk A and Vigsnæs LK, 2021. The mean of milk: a review of human milk oligosaccharide concentrations throughout lactation. Nutrients, 13, 2737. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Thurl S, Munzert M, Henker J, Boehm G, Muller‐Werner B, Jelinek J and Stahl B, 2010. Variation of human milk oligosaccharides in relation to milk groups and lactational periods. British Journal of Nutrition, 104, 1261–1271. [DOI] [PubMed] [Google Scholar]

- Thurl S, Munzert M, Boehm G, Matthews C and Stahl B, 2017. Systematic review of the concentrations of oligosaccharides in human milk. Nutrition Reviews, 75, 920–933. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Unpublished Study Report , 2020a. Yoshimi Lab – Study No. AG200051. Bacterial reverse mutation test of 6′‐SL sodium salt.

- Unpublished Study Report , 2020b. Yoshimi Lab – Study No. 200059. Micronucleus Study of 6′‐SL sodium salt in bone marrow cells of mice.

- Unpublished Study Report , 2021. Higashimatsuyamai Lab – Study No. 100603RG. 90‐day repeated oral dose toxicity study of 6′‐SL sodium salt in rats.

- Unpublished Study Report , 2022. Yoshimi Lab – Study No. CG220004. Micronucleus Study of 6′‐SL sodium salt in cultured mammalian cells.

- Urashima T, Taufik E, Fukuda K and Asakuma S, 2013. Recent advances in studies on milk oligosaccharides of cows and other domestic farm animals. Bioscience, Biotechnology, and Biochemistry, 77, 455–466. [DOI] [PubMed] [Google Scholar]

- US FDA , 2019. No GRN. 766 [3′‐SL sodium salt; GeneChem Inc., Daejeon, Republic of Korea]. In: GRAS Notices. US Food and Drug Administration (US FDA), Center for Food Safety & Applied Nutrition (CFSAN), Office of Food Additive Safety, Silver Spring (MD). Available online: https://www.cfsanappsexternal.fda.gov/scripts/fdcc/?set=GRASNotices&id=766&sort=GRN_No&order=DESC&startrow=1&type=basic&search=766

- Zeng J, Hu Y, Jia T, Zhang R, Su T, Sun J, Gao J, Li G, Cao M and Song M, 2018. Chemoenzymatic synthesis of sialylated lactuloses and their inhibitory effects on Staphylococcus aureus. PLoS One, 13, e0199334. 10.1371/journal.pone.0199334 [DOI] [PMC free article] [PubMed] [Google Scholar]