Abstract

All forms of energy follow the law of conservation of energy, by which they can be neither created nor destroyed. Light-to-heat conversion as a traditional yet constantly evolving means of converting light into thermal energy has been of enduring appeal to researchers and the public. With the continuous development of advanced nanotechnologies, a variety of photothermal nanomaterials have been endowed with excellent light harvesting and photothermal conversion capabilities for exploring fascinating and prospective applications. Herein we review the latest progresses on photothermal nanomaterials, with a focus on their underlying mechanisms as powerful light-to-heat converters. We present an extensive catalogue of nanostructured photothermal materials, including metallic/semiconductor structures, carbon materials, organic polymers, and two-dimensional materials. The proper material selection and rational structural design for improving the photothermal performance are then discussed. We also provide a representative overview of the latest techniques for probing photothermally generated heat at the nanoscale. We finally review the recent significant developments of photothermal applications and give a brief outlook on the current challenges and future directions of photothermal nanomaterials.

1. Introduction

The Sun, as the brightest star in the Earth’s sky, supplies almost all energy for life and human activities on the Earth. Even conventional fossil fuels are the long-term storage of solar energy.1−3 The Sun radiates its energy by emitting ultraviolet (UV), visible, and infrared (IR) light that carries photons with different vibrational frequencies. When encountering an object, a portion of photons in the light can be absorbed by the object, thereby heating it up. Sunlight that reaches the Earth can be largely absorbed and thus warm the atmosphere, land, and ocean, where the generated heat is essential for creating a suitable climate and environment for all living things.4 Moreover, energy transfer from light to heat occurs widely in physical, chemical, and biological reactions. It is one of the most fundamental processes in nature. This light-to-heat conversion process, where materials can act as light absorbers and efficiently transfer light energy into heat, is called photothermal conversion.5 The photothermal performance of a photoexcited material is mainly determined by two key intrinsic properties—the light-harvesting ability and the light-to-heat conversion efficiency. The investigation of photothermal materials with broadband absorption is beneficial for the utilization of renewable solar energy, while the engineering of materials with efficient heat generation abilities can be widely useful in various fields, including water evaporation,6,7 photothermal catalysis,8,9 and biomedicine.10,11

With the rapid development in both advanced nanotechnologies and materials science, a library of photothermal materials has been developed into nanoscale ones and designed into functional nanostructures. Similar to the classical bulk case, the photothermal effect can be universally observed in numerous nanomaterials, including metallic nanostructures,12,13 semiconductors,14,15 carbon-based nanomaterials,16−19 organic polymers,20,21 two-dimensional (2D) transition metal carbides/nitrides (MXenes),22−24 and their hybrids. In contrast to bulk structures, however, well-designed nanomaterials can exhibit unique thermal, optical, and electronic properties by tailoring their shapes, sizes, compositions, and surrounding environments, thus providing much more possibilities in tuning their photothermal properties. Based on the diversity in nanomaterials and their rich physiochemical properties, various strategies have been proposed and established for improving photothermal conversion capabilities. For example, metal nanostructures such as Au, Ag, Al, and Cu have attracted enormous attention because of their tunable localized surface plasmon resonances (LSPRs) ranging from the visible to IR region.25,26 The extremely large absorption cross-sections of plasmonic metal nanostructures and their associated plasmonic heating are highly promising for converting light into heat through the LSPR effect.27,28 Nanostructured semiconductors typified by metal oxides and chalcogenides represent a new type of photothermal nanomaterials, whose optical properties strongly rely on their bandgap energies.29−31 Either bandgap engineering or free-carrier-induced LSPRs can govern the light absorption of semiconducting nanomaterials and further improve the light-to-heat conversion efficiency.32−34 Carbon- and polymer-based nanomaterials are two other competitive photothermal material candidates with strong light-to-heat conversion abilities through thermal vibrations within the atomic lattices.20,35−38 The conjugation and hyperconjugation effects can easily facilitate the excitation of less tightly held electrons from the π orbitals to the π* orbitals, enabling broad light absorption over the solar spectrum. Apart from these widely used material options, more newly emerging classes of photothermal materials are continuously being developed, such as MXenes,39−41 metal–organic frameworks (MOFs),42−46 and covalent organic frameworks (COFs).47−50 Nevertheless, the mechanisms of the photothermal conversion processes can be typically attributed to the three categories mentioned above, namely, plasmonic localized heating, nonradiative relaxation of electron–hole pairs, and thermal vibrations of molecules. For enhancing the photothermal performance, photothermal nanomaterials can be designed to consist of a single component or multiple components and can involve more than one mechanism of photothermal conversion. The proper selection of materials and the ingenious design of nanostructures are consequently the most deterministic criteria for photothermal technologies.

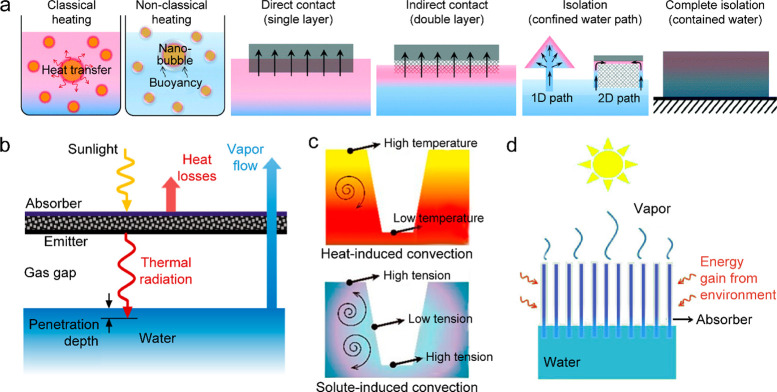

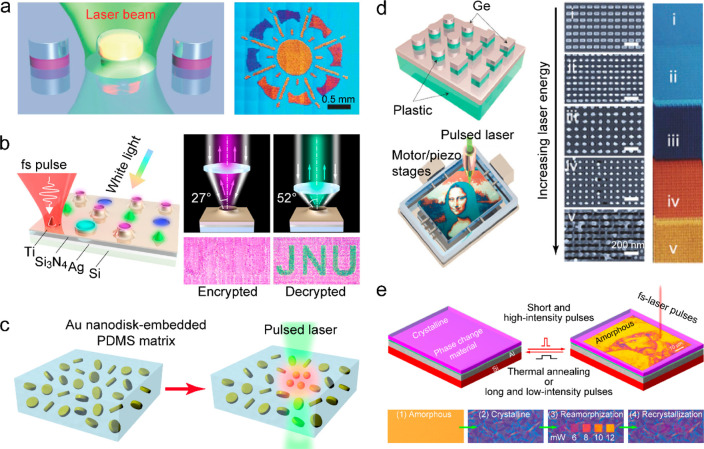

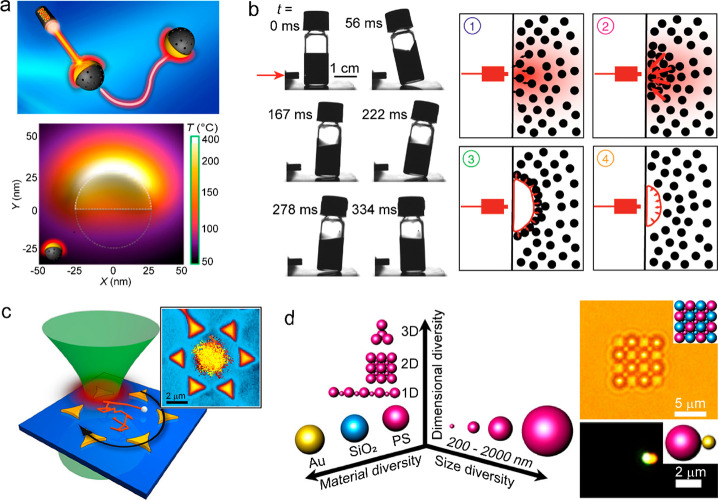

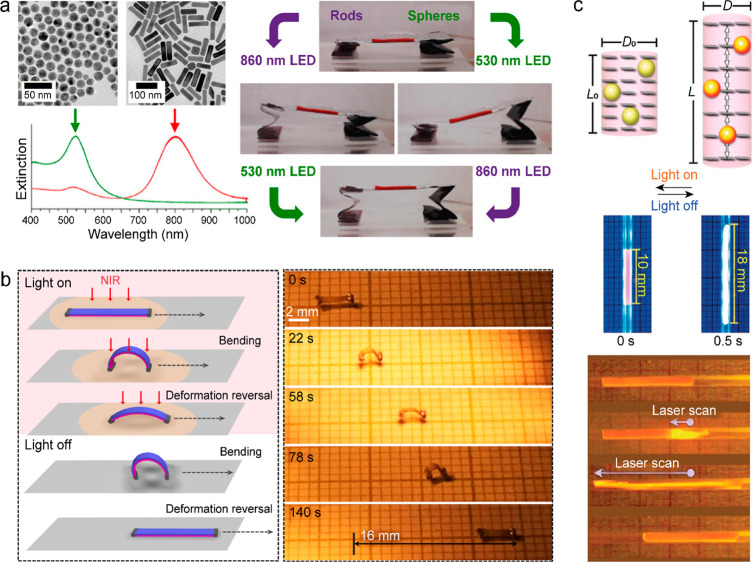

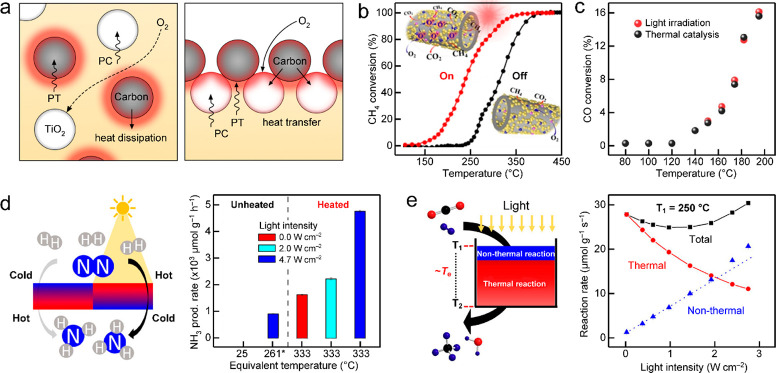

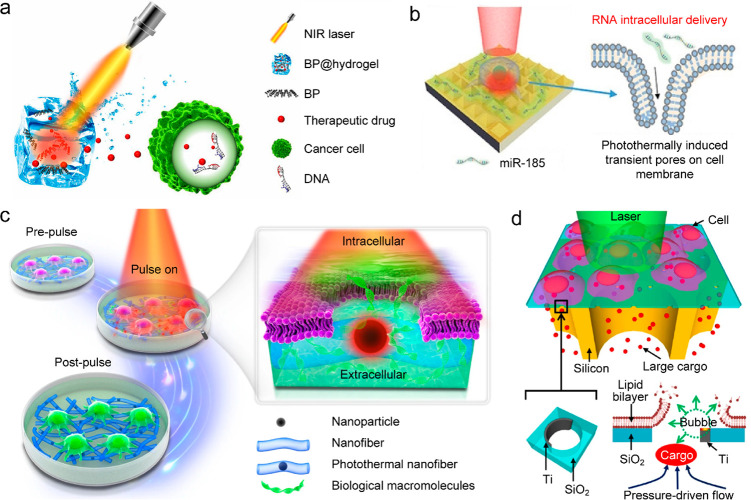

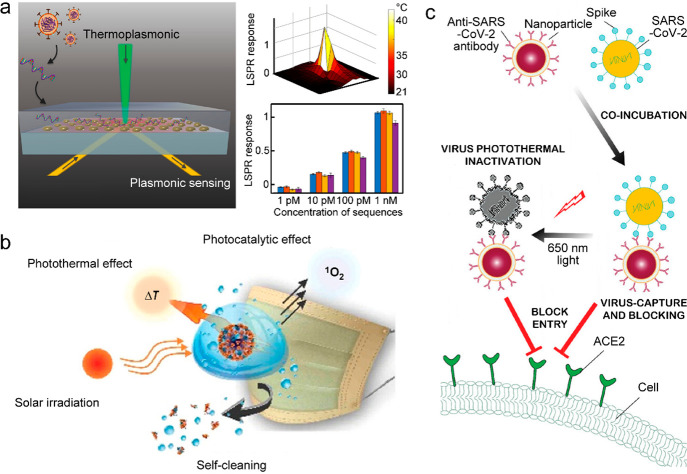

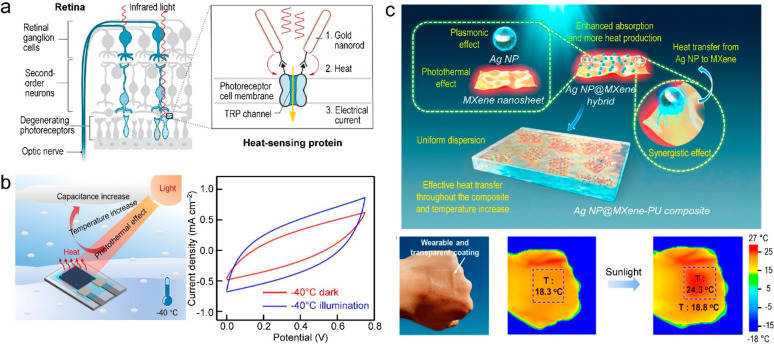

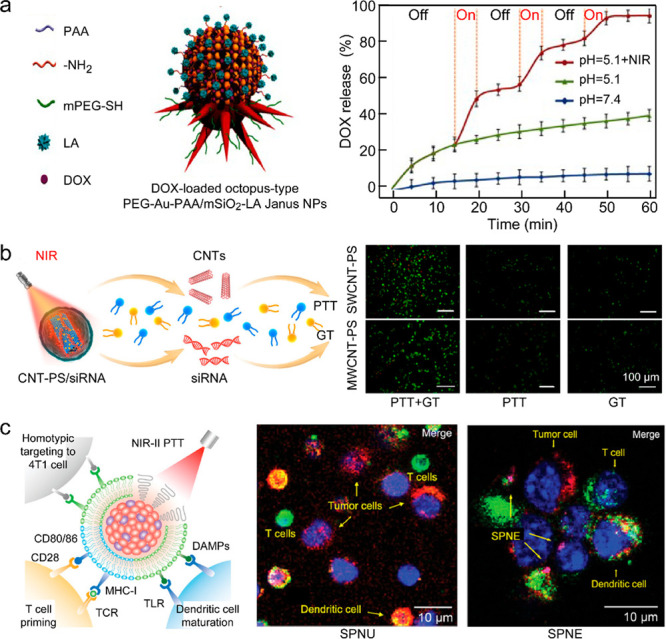

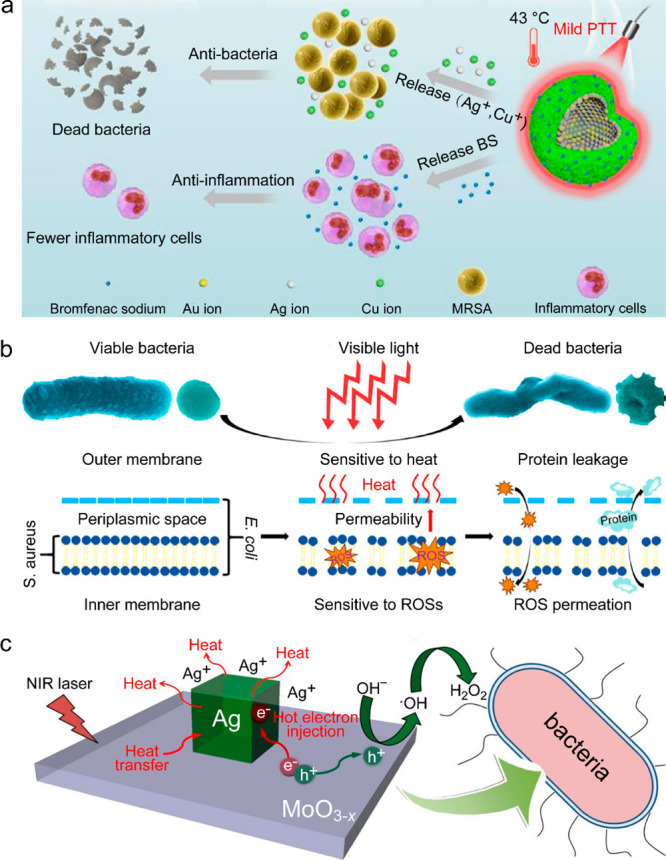

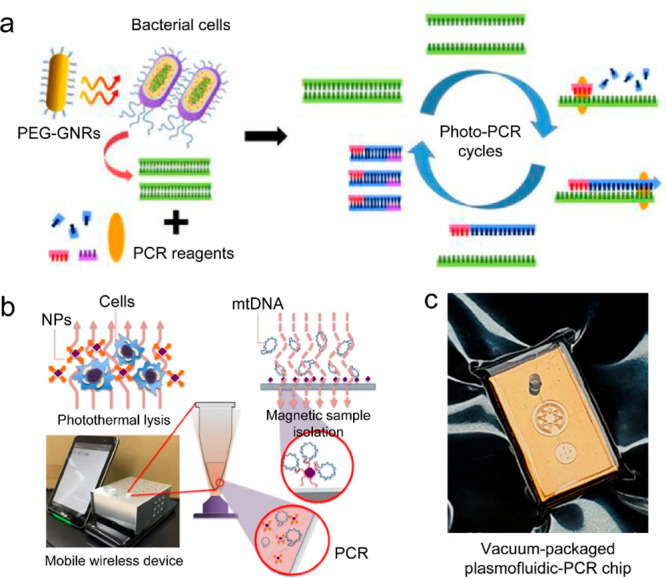

The extensive search for new types of photothermal nanomaterials has emerged as a frontier research area for a wide range of high-potential applications in physics, chemistry, and life sciences.20,45,51 One important implementation of photothermal nanomaterials is the solar evaporation technology that allows steam and clean water to be produced from either seawater or wastewater, while the sustainable solar energy is collected and stored in the form of thermal, electrical, or mechanical energy. To meet the pressing demands of energy and potable water, more and more photothermal nanomaterials with diverse structural designs have been employed for seawater desalination, wastewater purification, and electricity generation.6,7,52−54 Heat-mediated optical manipulation is another emerging technique based on photothermal materials, where the generated optical heating reversely exerts an optothermal force on the heated nanostructures, which are thus endowed with versatile control of movements, including rotating, pulling, oscillating, walking, and swimming.55,56 Based on various optothermo–matter interactions, light-driven photothermal nanomaterials have been demonstrated as optothermal motors, probes, assemblers, and robots for performing complicated motions and realizing functional tasks.57−60 Besides mechanical movements, shape morphing expectedly occurs under excess thermal energy and thus brings new functions of photothermal materials. Localized heating at plasmonic/photonic nanostructures can easily modify their structural morphologies and thereby their LSPRs and dielectric electromagnetic (EM) resonances, leading to promising applications in color printing and display.61−65 The combination of photothermal nanostructures and phase-changing materials has been further developed into soft photothermal actuators with reversible and controllable deformation.66−70 Moreover, the photothermal effect has also been widely used to drive catalytic reactions because of a synergy of thermochemical and photochemical pathways.8,9,45 Thermal energy localized at active sites can effectively reduce the activation energy of photothermal catalysis and promote the transfer of charge carriers, thus greatly enhancing the catalytic process. On the other hand, photothermal nanomaterials have exhibited vast perspectives in biomedical areas because of the remote control of heating with high selectivity and spatial accuracy. Numerous applications and techniques based on the photothermal effect have been developed into photothermal therapy (PTT),20,24,71 drug delivery,13,72,73 the polymerase chain reaction (PCR),74−77 and even the fight against coronavirus disease 2019 (COVID-19).78−82

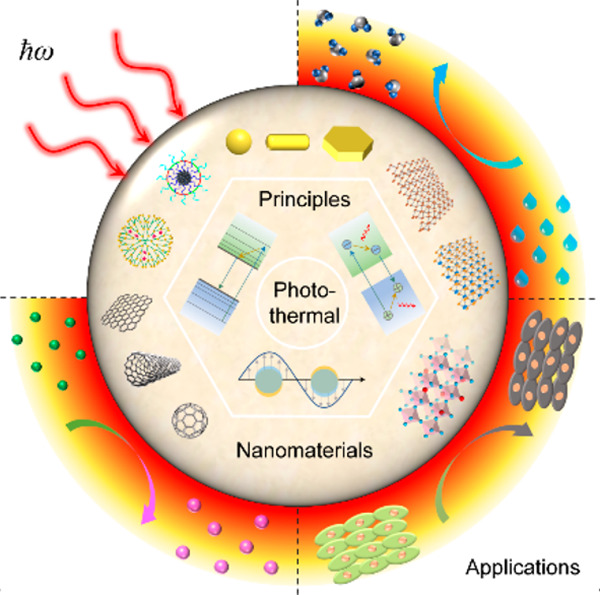

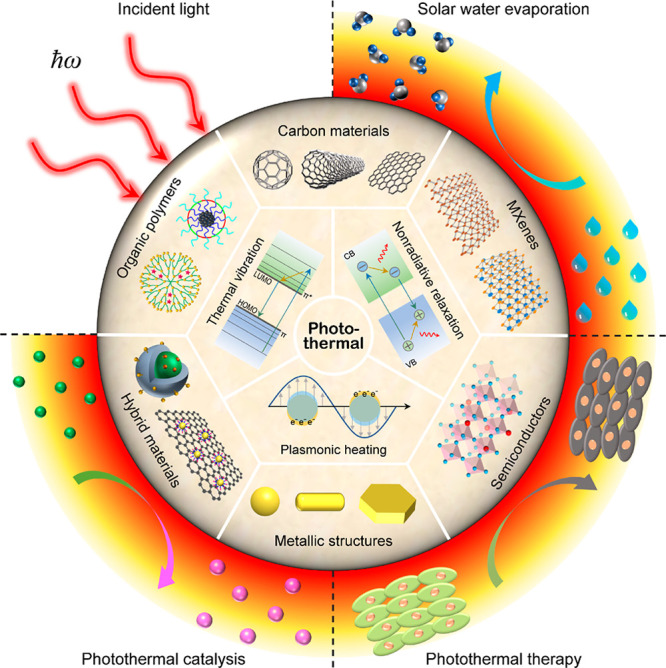

Several comprehensive reviews of photothermal materials have been published in recent years.7,11,12,22 However, most of these only review selected categories of photothermal materials or focus on one or two representatives of their promising technologies. In this review, we endeavor to provide a comprehensive overview of why photothermal nanomaterials can convert light into heat, what the material choices of photothermal converters are, and how the photothermal effect is applied (Figure 1). We will start with the fundamental principles underlying the light-to-heat conversion processes, including the LSPR effect, electron–hole generation and nonradiative relaxation, and molecular vibrations (Section 2). We will summarize the major categories of nanostructured photothermal materials and evaluate their light-to-heat conversion capabilities based on the distinct mechanisms. From this starting point, the proper material choice and rational structural design of photothermal nanomaterials for specified utilizations will become clearer and more achievable (Section 3). We will further review the latest techniques for probing photothermal heat generation at the nanoscale and categorize nanothermometers according to the physical mechanism that is employed to measure the temperature (Section 4). We will also expatiate on the recent significant developments toward the applications of photothermal nanomaterials in solar water evaporation, photothermal manipulation, photothermal catalysis, and PTT (Section 5). In the concluding section, we will provide our perspectives on the current challenges and future directions in the field of photothermal nanomaterials.

Figure 1.

Overview of the mechanisms, categories, and applications of photothermal nanomaterials.

2. Photothermal Conversion Mechanisms

As a representative phenomenon of light–matter interaction, the photothermal effect is generally characterized with the temperature increase in a material through the absorption of light. Various materials possess different light-to-heat conversion abilities that rely on the responses of their electronic or bandgap structures to EM radiation. In this section, we will briefly introduce three major fundamental mechanisms involved in light-to-heat conversion processes.

2.1. Plasmonic Localized Heating

The LSPR effect is the most intriguing phenomenon appearing in metallic structures down to the subwavelength-sized dimensions. Plasmonic nanostructures can break the diffraction limit of conventional optics and further confine incident light into the nanoscale, leading to the enhancement of light–matter interaction.83,84 The unexpected behavior of metallic nanostructures irradiated by an external EM field is associated with their unusual electronic configurations, where electrons are coherently oscillated and redistributed at the surface. LSPRs refer to the collective oscillations of conduction-band electrons restricted inside highly conductive nanostructures. Plasmons are thus termed from the quanta of collective electron oscillations, which is the analogy to photons defined from the quanta of light waves as well as phonons treated from the quanta of sound waves. The excitation of plasmons can not only induce strong electric field enhancement near the surface of the structure but also bring about extremely large absorption and scattering cross-sections at the resonance frequency. These two important effects make metallic nanostructures perfect candidates for harvesting light and concentrating energy, endowing them with an excellent light-to-heat conversion ability.13,85

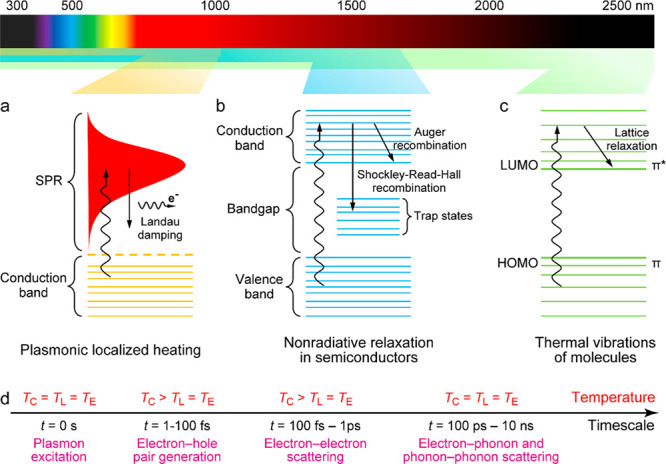

The photothermal conversion process in a metallic nanostructure can be understood from the excitation and damping of the surface plasmons (Figure 2a). Metallic nanostructures as conductive materials are generally featured by a considerable number of free and polarizable electrons. Upon light illumination, a plasmonic nanostructure can absorb energy from incident photons through electron transitions. When the photon energy matches the LSPR band, a strong resonant interaction takes place, giving rise to enhanced light absorption and local field. The free conductive electrons of the metallic nanostructure are displaced from their intrinsic equilibrium state and relocated at the structure surface, together with an in-phase oscillation with the external EM wave. The resultant photoexcitation of the LSPR is a global nonequilibrium, where the dephasing and decay of the plasmons occur at an ultrafast speed (Figure 2d).86 To restore a thermally equilibrated state, the absorbed energy of electrons can therefore be relaxed through either the radiative re-emissions of photons or the nonradiative generation of electron–hole pairs through Landau damping.87,88 During such a pure quantum mechanical process of Landau damping, the energy transfer process from a plasmon quantum to a single electron–hole pair happens in a time interval from 1 to 100 fs.86,89 This process occurs through electron–electron collisions without loss of the absorbed photon energy. The produced energetic electrons from the nonradiative plasmon decay are termed as hot charge carriers, whose distribution is highly nonthermal within the first 100 fs.90 The hot electrons further quickly interact with low-energy electrons on the time scale ranging from 100 fs to 1 ps. This electron–electron collision is an inelastic Coulombic process that converts electron energy into heat. At the same time, low-energy electrons couple with the metallic lattice through electron–phonon scattering processes with a period of several to hundreds of picoseconds. This relaxation step leads to the lattice thermalization of the nanostructure as well as a Fermi–Dirac-like distribution of electrons.91 In the final step, the thermal energy inside the metallic structure is released to the surrounding environment through phonon–phonon collisions in the time scale of 100 ps to 10 ns. With thermal dissipation and lattice cooling, the electrons of the metallic nanostructure in the conduction band eventually return to their ground states before the photoexcitation.

Figure 2.

Three mechanisms of the photothermal effect with the corresponding light absorption range. (a) Plasmonic localized heating. (b) Nonradiative relaxation in semiconductors. (c) Thermal vibrations of molecules. Reprinted with permission from ref (7). Copyright 2019 Royal Society of Chemistry. (d) Physical processes of plasmon excitation and damping at different time scales. TC, TL, and TE represent the temperatures of free charge carriers, the lattice, and the surrounding environment, respectively. Reprinted with permission from ref (28). Copyright 2022 Wiley-VCH.

In summary, the plasmonic effect for localized heating in metallic nanostructures involves the excitation of LSPRs with enhanced absorption, generation, and relaxation of hot electrons, and heat transfer to the surrounding medium. The energy transfer from the absorbed photons to the conduction-band electrons of metallic nanostructures goes through: (1) a resonant excitation of surface plasmons; (2) an athermal process of electron–electron collisions; (3) a fast lattice thermalization through electron–phonon scattering; and (4) a slow thermal dissipation through phonon–phonon collisions.

2.2. Nonradiative Relaxation in Semiconductors

Besides the excitation of the LSPRs in metallic nanostructures, the direct interband/intraband electron transitions of nonplasmonic semiconductors can also display the photothermal effect. When a semiconducting material is excited by photons with sufficient energies, electron–hole pairs are generated with their energies comparable to the bandgap. The energy of the excited electrons can be either released by emitting photons or transferred to the material lattice through nonradiative relaxation.7,92 The release of phonons instead of photons in a semiconductor through the recombination of charge carriers can increase heat loss and therefore lead to a local temperature increase of the lattice. The established thermal distribution is strongly dependent on the characteristics of the light absorption and surface/bulk recombination of the semiconductor. Two types of the nonradiative relaxation processes, including Shockley–Read–Hall and Auger recombination,93,94 are ultimately responsible for heat generation in semiconductors (Figure 2b). Auger recombination, which occurs with three carriers, is an intrinsic process relying on the properties of the involved material. The effect of Auger recombination becomes ascendant with decreasing bandgaps. When an electron–hole pair recombines without the emission of photons, their energy can be transferred to either another electron higher in the conduction band or another hole deeper in the valence band. The third energetic carrier normally thermalizes back to the band edge through lattice vibrations. Shockley–Read–Hall recombination is an alternative nonradiative relaxation that depends on the quality of the material. In the presence of defects/impurities in a semiconductor, midgap energy states are usually created within the bandgap due to the defect modification of the electronic structure.95 These defect states are also known as trap levels that capture charge carriers. The Shockley–Read–Hall recombination process is thus called trap-assisted recombination. It involves a two-step process. Conduction-band electrons first relax to the trap level and then move to the valence band, where a hole is annihilated. These relaxation processes are accompanied with the exchange of thermal energy with the material. For the case of the defect traps located at or near the surface of the semiconductor, the trap-assisted recombination process is termed as surface recombination, which is dependent on the density of surface defects.

2.3. Thermal Vibrations of Molecules

Carbon-based materials and some organic polymers also demonstrate excellent light absorption characteristics and are very competent in the heat generation through lattice vibrations. Although the usual carbon bonds like C-C, C-O, and C-H possess large energy differences between the σ and σ* orbitals that can be hardly excited, loosely held electrons in these materials can be easily excited from the π orbitals to the π* orbitals under low-energy irradiation.23,96,97 When the energy of incident photons satisfies an electronic transition within the material, the π electrons are excited from the ground state (highest-occupied molecular orbital, HOMO) to a higher energy state (lowest-unoccupied molecular orbital, LUMO) (Figure 2c). After the relaxation of the excited electrons to the ground state through vibration–electron coupling, the excess energy is released in the form of heat. Moreover, the conjugation or hyperconjugation of the π orbitals can deeply modify the electron transitions between HOMO and LUMO, whose gap energy decreases with the increase in the number of π bonds.98,99

2.4. Basic Mathematical Descriptions for Photothermal Conversion

To elucidate the light-to-heat conversion process, it is essential to consider the light-harvesting ability and heat generation of a material as well as heat transfer and loss. Owing to the fundamental difference in the physical mechanisms, diversely categorized photothermal materials have various mathematical descriptions for their optical and thermal properties. In this section, basic universal equations are presented for understanding photothermal conversion in terms of three aspects including light harvesting, light-to-heat conversion, and heat transfer.

2.4.1. Light Harvesting

One of the critical factors to evaluate the photothermal performance is the light-harvesting ability that reveals how well a photothermal material absorbs the energy of incident photons. The light absorption is an important process of light-to-heat conversion. Absorptance is defined as the fraction of the energy of incident photons that is absorbed by a material. The absorbed energy for a certain material depends on the range of absorption over the spectrum of the incident light and the intensity of absorbance for each wavelength. By integrating the absorption intensity of the photothermal material over the spectral range, the absorptance can be calculated by the energy ratio of the total absorbed light to the incident radiation. At an incidence angle of θ, the overall absorptance A(θ) of a light absorber can be expressed as51,100

|

2.1 |

where P(λ), λmax and λmin represent the wavelength-dependent radiation power and the maximum and minimum wavelengths of the incident light and R(θ,λ) and T(θ,λ) stand for the total reflectance and transmittance of the absorber at the wavelength λ, respectively. According to this equation, the absorptance can be enhanced by reducing the transmittance and reflectance of the photothermal material. Moreover, broadband light absorption is crucial for light absorbers to harvest enough light for obtaining high light-to-heat conversion efficiencies.

For the case of photothermal materials dispersed in homogeneous semitransparent media, light absorption is a cumulative process with an exponential decay that can be described by Beer–Lambert’s law as I = I0e–κcl, where I and I0 represent the light radiation intensity after and before the absorption, κ stands for the extinction coefficient, c is the particle concentration, and l is the length of the optical path. To further determine how much of the light is absorbed by the material, absorbance a is defined as the attenuation of the incident radiation power. It can be calculated from the transmittance T as

| 2.2 |

The absorbance is therefore proportional to the extinction coefficient of the absorber and the amount of the absorber per unit area. The extinction coefficient is the intrinsic property of the absorber. It depends on the material, size, and shape.

2.4.2. Light-to-Heat Conversion

Besides the light absorption of a photothermal material, the light-to-heat conversion efficiency is another essential factor that directly quantifies the absorbed energy transferred to thermal energy, instead of radiative re-emission of photons. One straightforward method for determining the conversion efficiency is to measure the increase in temperature and calculate the heat generation induced by an incident light. The photothermal conversion efficiency η can be written as101,102

| 2.3 |

where Q is the generated thermal energy by the absorber, E represents the total energy of the incoming light, c and m denote the specific heat and mass of the photothermal material, ΔT is the temperature increase of the material under the light irradiation, p is the power density of the light source, and s and t represent the radiation area and time. By use of this method, all of the incident light including the reflected, scattered, absorbed, and transmitted photons originating from the incident light is taken into account as the input energy. The advantage of this strategy is that only the absorbed photons contribute to the generation of thermal energy in the photothermal material. As the heat generation is dependent on the amount of the used photothermal material, it is difficult for this method to directly compare the efficiency values among different materials. Moreover, the heat transfer from the photothermal material to the surrounding medium is not considered in the calculation.

The heat loss to the environment can be estimated by recording the temperature decay process after the incident light is removed. The equation of the photothermal conversion efficiency η can then be expressed as103−105

| 2.4 |

where h is the heat transfer coefficient, s represents the surface area of heat transfer, Tmax is the equilibrium temperature, Tsur represents the temperature of the surrounding environment, Qdis stands for the heat dissipated by the surrounding environment, I is the radiation intensity of the incident light, and aλ represents the absorbance of the photothermal material at the wavelength λ. Although only the absorbed photons are treated as the input energy, this equation quantitatively eliminates the impact of the heat transfer and the concentration of the photothermal material on the light-to-heat conversion efficiency. The photothermal conversion abilities of various materials can therefore be readily compared by this method. But there are a number of parameters that need to be experimentally measured. Some of them are not trivial and can significantly affect the ultimate value of the photothermal conversion efficiency. Some recent works have modified eq 2.4 and provided a more straightforward and reproducible approach for the evaluation of the photothermal conversion efficiency.106,107

2.4.3. Heat Transfer

After the incident light is absorbed by a photothermal material, the photon energy is converted into thermal energy through a light-to-heat conversion process. The generated heat will be further transferred to other lower-temperature materials or released to the surrounding environment. Therefore, heat transfer is the third important process in a photothermal conversion system. The transfer of thermal energy from one material to another is driven by the thermal gradients between the materials, which can be realized in three main means, which are conduction, convection, and radiation.51,104

Thermal conduction usually occurs within a material or contiguous objects, where heat spontaneously flows from the higher-temperature part (the light absorber) to the lower-temperature one (heat transfer object). The conduction energy can be expressed as

| 2.5 |

where k represents the thermal conductivity of the photothermal material, s represents the surface area of heat transfer, L is the conduction length of the light absorber, and Tobj and T are the steady temperatures of the heat transfer object and the light absorber.

Thermal convection refers to the heat energy transfer induced by the movement of fluid. The convection energy from the heating source to the fluid can be written as

| 2.6 |

where h is the heat transfer coefficient. As the reciprocal of thermal insulance, the heat transfer coefficient depends on the physical properties of the fluid and the thermohydraulic conditions.

Thermal radiation takes place in all objects through EM waves without the requirement of any medium. According to the Stefan–Boltzmann law, the emission energy is proportional to the fourth power of the temperature. When an object emits thermal radiation based on its temperature, it also absorbs radiation from the surrounding objects. The thermal radiation energy is the net energy exchange between the hot object and the cold environment, which can be expressed as

| 2.7 |

where ε is the emissivity, σ represents the Stefan–Boltzmann constant, and Tenv stands for the temperature of the environment.

Consequently, the heat transfer not only is dependent on the physical properties of the photothermal material but also is affected by the circumstance of its surrounding environment. The three mathematical expressions provided above offer efficient ways to regulate the heat transfer process. For interfacial solar water evaporation, thermal conduction is the dominant process that requires the minimization of heat loss to the surrounding environment. The generated heat can thus be localized on the surface of the photothermal material for efficient vapor generation. For volumetric water heating, the convection process needs to be first considered, where a promoted heat transfer is demanded for a fast increase in the temperature of the surrounding environment. In short, the proper choice of both photothermal materials and their surrounding media is essential for photothermal applications with desired purposes.

3. Recent Developments of Photothermal Nanomaterials

With the development of advanced nanofabrication methods in the last few decades, nanomaterials, for example, metallic/semiconductor nanostructures, carbon-based nanomaterials, organic polymer nanomaterials, and 2D nanomaterials, have been thoroughly investigated with various beneficial and functional qualities. The light-to-heat conversion mechanisms and intriguing properties of differently categorized nanomaterials are summarized in Table 1. Photothermal conversion as an ancient technology has recently received extensive attention and regained a breakthrough. The capability of photothermal nanomaterials to enhance light absorption, convert heat, and conduct thermal energy is highly dependent on the material choice and structural design. In this section, we will summarize the recent progresses in the development of both new photothermal materials and advanced methods for structural engineering with excellent light-to-heat conversion performances.

Table 1. Proposed Photothermal Conversion Mechanisms and Advantages of Different Types of Nanomaterials for Photothermal Applications.

| references | photothermal materials | working mechanisms | advantages for photothermal applications |

|---|---|---|---|

| (13, 85) | plasmonic metals | LSPR effect | facile synthesis, tunable plasmon resonance, and large absorption cross-sections |

| (32, 33) | slightly doped and intrinsic semiconductors | nonradiative recombination of electron–hole pairs | facile synthesis, low toxicity, and strong extinction coefficients in the NIR region |

| (34) | heavily doped semiconductors | LSPR effect | |

| (326) | carbon-based nanomaterials | nonradiative relaxation of delocalized π electrons | high chemical stability, broadband light absorption, and lightweight |

| (98) | organic polymers | nonradiative relaxation of delocalized π electrons | versatile molecular designs, strong absorption of NIR light, and good biocompatibility |

| (22, 364) | 2D nanomaterials | nonradiative recombination of electron–hole pairs and LSPR effect | layered structures, broad light absorption band, and high photothermal conversion efficiencies |

3.1. Metallic Nanostructures

Noble metal nanostructures show attractive photothermal conversion properties because of the excitation of their strongly confined LSPRs. According to the Drude–Lorentz model, the high density of free electrons and their collective oscillations can give rise to the LSPR effect at the metal–dielectric interface.108,109 Plasmon resonances are excited when the incident photon energy matches the LSPR band of metallic structures. The redistribution of the excited electrons contributes to the generation of plasmonic heating, which can be finely controlled by external irradiation. The LSPR frequency can be further tailored by changing the materials, sizes, and shapes of metallic nanoparticles, as well as their surrounding environments and assembly configurations.110,111

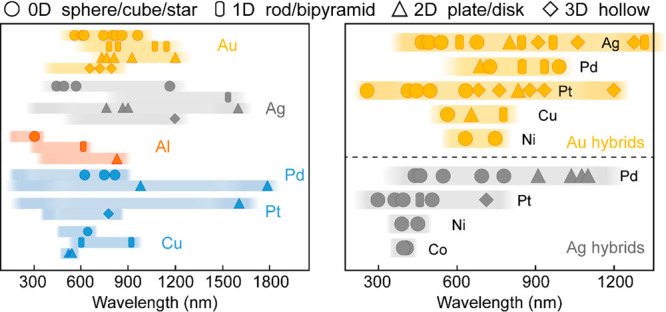

3.1.1. Effect of the Material and Geometry

Because of the LSPR effect, numerous types of metallic nanostructures for light-to-heat conversion have been explored, such as Au,112−119 Ag,120−124 Pd,125−130 Al,131−135 Cu,136,137 Ge,138,139 and other metals. Au and Ag are two of the most commonly employed metals in photothermal conversion because of their high free charge carrier concentrations and relatively low Ohmic losses.140,141 Their plasmon resonances can be finely tuned from the visible to near-infrared (NIR) region through control of the size and morphology (Figure 3, left panel). However, another loss mechanism originating from interband transitions plays an important role for Au and Ag at optical frequencies. For Au structures, the interband losses are dominant at the short wavelengths of the visible region, while the intraband losses are high in the NIR range and limited in the shorter-wavelength region.142 In addition, the plasmonic properties of Ag structures are easily degraded due to rapid oxidation and sulfuration under ambient conditions. The earth-abundant metals such as Al and Cu are newly emerging as intriguing alternatives to Au and Ag in plasmonics. Cu and Al are more cost-effective and possess similar LSPR performances to those of Au and Ag.131,143 Moreover, Al nanostructures can support strong plasmon resonances in the UV range with extremely high photothermal conversion efficiencies.144 Although Al suffers from chemical instability, the formation of a passivation layer of aluminum oxide can effectively protect the structure without degrading its LSPR response. The limitation for Al structures is the broad line widths of their plasmon resonances in the visible range because of interband transitions.145 In addition, a wide variety of metal materials including Ni, Co, Cr, Pt, and Pd have been demonstrated to exhibit LSPRs in the UV region.144 Among them, Pt and Pd are of practical interest in photothermal catalysis owing to their outstanding catalytic properties and high thermal stability.146,147 In general, plasmonic nanoparticles made of these metals can be synthesized by bottom-up methods, where crystal structures are grown by stacking metal atoms. The bottom-up methods are usually based on the chemical reduction of metal salts and the nucleation of tiny particles. One of the famous synthetic approaches is seed-mediated growth with a two-step process.148 The first step is the preparation of small seeds through homogeneous nucleation. The second step is overgrowth on the seeds using shape-directing agents, where nanoparticles are overgrown into the desired geometry and size. A large number of asymmetric metal nanostructures can be facilely synthesized by changing the seeds, metal salt, reductant, and capping agent, as well as the shape-directing agent.149 Asymmetric structures usually have more sharp tips, corners, and edges where plasmonic heating is generated and concentrated because of largely enhanced EM fields. The geometry-dependent photothermal conversion efficiency has been well demonstrated in both numerical simulations and experiments. The effect of the morphology on the heat generation in plasmonic nanoparticles has been numerically investigated using Green’s dyadic method.150 The heat generation can be well quantified by mapping the heating power density within the studied Au nanostructures. This geometry effect has also been experimentally shown in various differently shaped structures, including nanocubes, nanorods, nanoplates, nanocages, and branched nanostructures (Figure 3, left panel).151,152 Nanospheres and nanocubes with high symmetry usually exhibit strong absorption resonance.153,154 On the contrary, low-symmetry polyhedron nanoparticles show broader but weaker absorption resonances with multiple plasmon peaks. The most straightforward way to broaden the absorption spectrum is to mix plasmonic nanoparticles with different sizes and shapes.85 But this method is practically unattractive, as it requires the parallel synthesis of various types of nanoparticles and the careful control of the amount ratio of these different nanoparticles. An alternative strategy is to grow new particles on pre-existing structures to broaden the plasmon resonances. A nearly ideal type of blackbody nanostructure composed of a Au nanorod with an attached Au nanosphere has been reported.155 This material has a nearly perfect absorption of 98–99% over a broad spectral range from 400 to 1400 nm.

Figure 3.

Typical plasmonic spectral bands of material- and shape-dependent metallic nanostructures. Left: homogeneous metals (Au,101,164−182 Ag,183−192 Al,131,145,193−195 Pd,196−199 Pt,186,200 and Cu.136,201−204 Right: metal hybrids (Au hybrids: Au-Ag,156,201−218 Au-Pd,219−224 Au-Pt,225−234 Au-Cu,235−238 and Au-Ni;239,240 Ag hybrids: Ag-Pd,241−248 Ag-Pt,249−251 Ag-Ni,252,253 and Ag-Co254,255) according to their different geometries.

As the LSPR bands of homogeneous metallic structures are intrinsically limited by the materials, metal hybrids, including alloys, can be obtained by reacting two or more metal elements (Figure 3, right panel). Metal alloys containing less conductive metals can effectively lower the free charge concentration and thus reduce the optical losses.108 Their LSPR properties can also be tailored by adjusting the proportion of each plasmonic or functional reactant. For instance, Au-Ag alloyed nanostructures can support plasmon resonances over a much broad range of the UV–visible spectrum and exhibit distinct blueshifts by decreasing the atomic ratio of Au to Ag.156 Because the change in the proportion of an alloy alters the effective dielectric constant of the alloy, the photothermal conversion efficiency can therefore be greatly improved with enhanced light absorption for Au-Ag alloy nanostructures.157−160 Apart from the tunable LSPR frequencies, the formation of alloys offers a new route for improving the sensitivity of plasmonic structures through dispersion engineering.161 The real permittivities of alloyed structures such as Au-Pd162,163 and Ag-Ti161 can be reduced compared to the pure metals, leading to the increase in sensitivity.

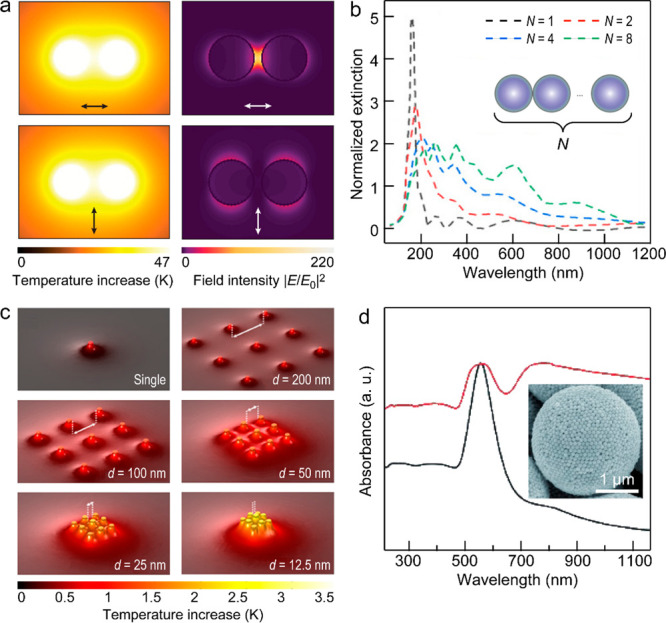

3.1.2. Effect of Plasmon Coupling

The key challenge for improving the photothermal conversion efficiencies of plasmonic nanomaterials is to realize broadband absorption over the solar spectrum. But metal nanostructures often absorb photons at one or a few certain bands, limiting their photothermal performances.144 The most widely used strategy is to assemble two or more metallic nanoparticles into plasmon-coupled structures where the interparticle nanogaps are formed and known as “hotspots”.256 The generation of hotspots can not only achieve strong EM field enhancement but also produce multiple plasmon modes through plasmon coupling. The enhanced local field can give rise to pronounced photothermal conversion in the interparticle nanogaps. The overall photothermal performance of the assembled nanoparticles is based on their collective heating ability and plasmon coupling effect.257 The plasmonic properties of the coupled nanostructures are sensitively dependent on the particle number, gap distance, structural configuration, and polarization state of the incident light.258 When two metallic nanoparticles are placed close to each other, a plasmonic dimer as the simplest coupled structure is formed. According to plasmon hybridization, the interaction between the two nanoparticles produces a lower-energy symmetric (bonding) plasmon resonance mode and a higher-energy antisymmetric (antibonding) resonance mode.259 The total heat generation and temperature distribution in a plasmonic dimer have been numerically calculated.260 The calculated temperature is distributed nonuniformly around the nanoparticles even at the nanoscale. The plasmonic heating has been found to be dependent on the polarization state of the incident light. When the external electric field is polarized along the dimer axis, the heat generation increases as well as the electric field enhancement. Interestingly, an extraordinary photothermal isosbesticity has been discovered in plasmonic nanostructures, where the temperature is invariant with the change of the illumination polarization state at specific wavelengths (Figure 4a).261 The isosbestic wavelength of a given plasmonic nanostructure can be found at the intercrossing of the absorption spectra under two different polarization directions. Since the ability of a single dimer to broaden the LSPR band is limited, more nanoparticles need to be assembled and interact together to increase the light absorption bandwidth.52,262−264 The linear assembly of Al nanoparticles has been shown to broaden the extinction peaks with distinct redshifts toward the visible and NIR regions as the particle number is increased (Figure 4b).133 Randomly distributed Au nanoparticles have been employed as a perfect absorber to fully absorb light. The average absorbance can reach up to 99% in the spectral range from 400 nm to 10 μm because of the suppression of back reflection.265 Analogous to the distance-dependent electric field from a charged particle, the temperature of a heated structure drops slowly as ∼1/d from the particle surface.260Figure 4c shows the simulated temperature profiles for the arrays of nine Ag nanoparticles with varied periodic spacings.266 When a large number of nanoparticles are irradiated at the same time, the overall temperature of the entire particle system can reach large but homogeneous values by adding together all the temperature contributions.267 Three-dimensional (3D) or more disordered nanostructures, such as plasmonic colloidosomes that are generally prepared by assembly approaches, have also been used to produce strong plasmon coupling.123,268−270 For example, Au nanospheres have been assembled into 3D black plasmonic colloidosomes by use of an emulsion-templating method (Figure 4d).271 The fabricated colloidosomes have hexagonal close-packed multilayer shells and exhibit intense broadband light absorption. The assembly process is universal, and this method is suitable for nanoparticles with different sizes and shapes. In general, photothermal heat generation is highly sensitive to the assembly state of metal nanoparticles (particle number, spacing, and configuration) and the polarization state of the incident light. To take advantage of the plasmon coupling effect, the particle arrangement and structural design need to be carefully considered.

Figure 4.

Plasmon-coupling-induced absorption broadening and related heat effects. (a) Temperature distributions (left column) of a Au dimer under the longitudinal (top) and transverse (bottom) polarization excitation and corresponding electric near-field enhancements (right column). Reprinted with permission from ref (261). Copyright 2017 American Chemical Society. (b) Dependence of the calculated normalized extinction spectra of one-dimensional (1D) Al nanoparticle chains on the particle number N. Reprinted with permission from ref (133). Copyright 2016 Springer Nature. (c) Calculated temperature maps of a single array and five arrays of nine Ag nanoparticles in a square lattice with lateral periods from 12.5 to 200 nm. Reprinted with permission from ref (266). Copyright 2020 American Chemical Society. (d) Measured absorption spectra of self-assembled Au colloidosomes (red) and the Au nanoparticles (black) suspended in 1-butanol. The inset shows the corresponding scanning electron microscopy (SEM) image of the Au colloidosomes. Reprinted with permission from ref (271). Copyright 2015 Wiley-VCH.

3.2. Semiconductors

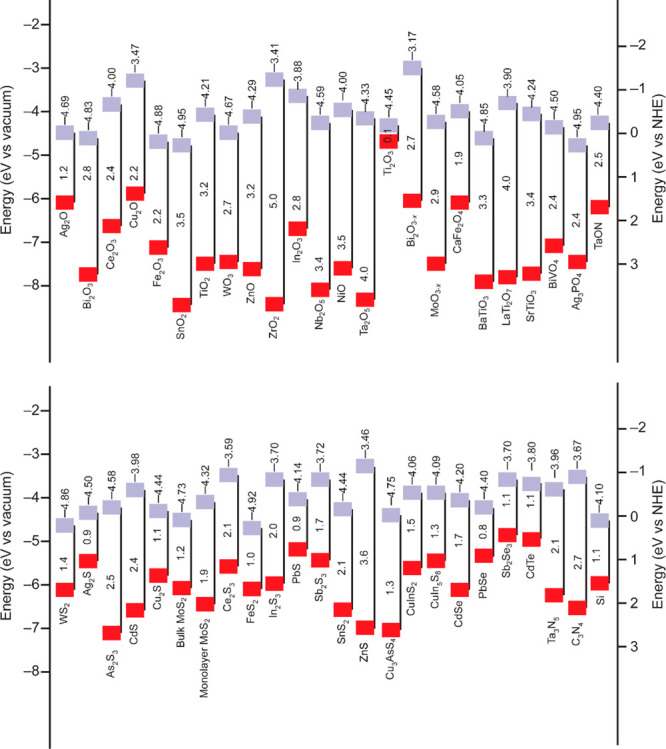

Semiconductor materials, such as metal oxides and chalcogenides, are another type of extraordinary candidate for photothermal conversion because of their low cost, facile synthesis, and low toxicity. Semiconductors are not easily vulnerable to photodegradation or photobleaching compared to organic photothermal materials.14 They also possess tunable absorption wavelengths and exhibit strong extinction coefficients in the NIR region. The bandgaps of semiconductors govern the light absorption based on the free charge carrier generation inside the material. Figure 5 summarizes the bandgaps and band edge positions of some commonly studied semiconductors, including oxides, chalcogenides, nitrides, and silicon.272−274 When the photon energy of incident light matches the bandgap energy, the incoming photons absorbed by a semiconductor can cause the generation of electron–hole pairs (Figure 6a). The heat generation relies on the nonradiative recombination of the electron–hole pairs. Semiconductors usually possess much lower free charge carrier concentrations than metal materials. Semiconductor materials are therefore generally translucent in the IR region but opaque in the visible region.51 To extend the absorption range, doping is one of the classical means to increase the free charge carrier concentrations of semiconductors. While the light absorption of a semiconductor is enhanced by doping, the photothermal conversion efficiency can also be improved owing to the increased probability of nonradiative recombination.

Figure 5.

Band edge positions and bandgaps with respect to the vacuum level and the normal hydrogen electrode (NHE) for selected semiconductors including oxides, chalcogenides, nitrides, and silicon. The top squares indicate the conduction band edges. The bottom squares indicate the valence band edges. The top numbers represent the exact conduction band levels, and the numbers between the squares show the bandgaps. The data are taken from ref (272) with permission from the Royal Society of Chemistry and modified according to the new works.273,274

Figure 6.

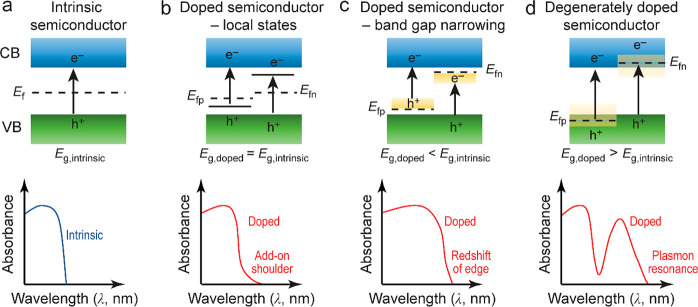

Schematics for engineering the band structures of semiconductors. (a) An intrinsic semiconductor. (b) Doping-induced formation of shallow-level energy states in the bandgap. (c) Doping-induced formation of deep-level energy states in the bandgap. (d) Degenerate-doping-induced LSPR. The electronic band structures are shown on the top, and the corresponding optical absorption curves are displayed on the bottom. Reprinted with permission from ref (7). Copyright 2019 Royal Society of Chemistry.

Through the stratagem of defect or impurity introduction, not only can the band energy be shifted, but also new energy states can be created within the bandgap. There are several doping-induced changes during the bandgap engineering of semiconductors, including (1) the emergence of intraband energy states; (2) the narrowing of the bandgap; and (3) the formation of impurity bands in degenerately doped semiconductors.7 In the first case, doping introduces defect and trap-level states without changing the bandgap (Figure 6b). The defect-level states can work as charge recombination centers for the relaxation of conduction-band electrons, resulting in the extension of the absorption spectrum to longer wavelengths. An add-on shoulder can often be observed in the absorption curve of a defect-level-doped semiconductor. N-doped TiO2 was first prepared in 2001. It possesses a visible-light absorption capability.275 From then on, doping has been extensively employed for TiO2 with either non-metal anions of C, N, S, and P at the O sites or transition metal cations of Fe, Co, Cu, Cr, and Ni at the Ti sites.272,276−279

In the second case of doping, the position of the valence or conduction band is shifted instead of the introduction of any new energy levels (Figure 6c). The bandgap thus becomes narrower compared to that of the pristine semiconductor, resulting in both the broadening and redshift of the absorption edge. Upon light illumination, photons that possess higher energies than the band energy of the narrow bandgap semiconductor can generate above-bandgap electron–hole pairs.33 The subsequent relaxation of the electron–hole pairs to the band edges can effectively convert the extra energy into heat through a thermalization process. On the contrary, most photons absorbed by the broad bandgap semiconductor are radiatively released through light emissions, leading to a lower photothermal conversion efficiency. Various narrow bandgap semiconductors, including black TiO2,32,280,281 Ti2O3,33 MoO3,282 and Fe3O4,283,284 have been developed as light-to-heat converters. Black TiO2 with broadband light absorption has recently received intensive attention as a perfect light absorber.285−288 It can reduce the recombination of electron–hole pairs and further enhance visible light absorption. Since the first discovery in 2011,32 various fabrication strategies have been proposed for the development of black TiO2 with superior photothermal properties. The introduction of surface disorder and the creation of oxygen vacancies are the two main approaches for bandgap engineering. The introduction of surface disorder can destroy the lattice periodicity and modify the edges of the conduction and valence bands, resulting in the narrowing of the bandgap. The created oxygen vacancies can serve as traps for reducing the recombination of photogenerated charge carriers and thus improve the photothermal performance. Remarkably, the bandgap of black TiO2 was reported in 2017 to be further narrowed by adding Ti3+ ions.33 Ti2O3 nanoparticles were synthesized with an excellent absorption capability and a high photothermal conversion efficiency of 92%. Because of the localized hybridization between titanium and oxygen, Ti2O3 tends to generate oxygen vacancies instead of titanium vacancies.289 The presence of vacancies can promote the band overlap near the Fermi level and therefore improve the electronic transport of Ti2O3.290

Degenerately doped semiconductors have recently been discovered with strong LSPRs in the NIR region (Figure 6d). Both n-type and p-type semiconductors can be heavily doped to generate high-enough free charge carrier concentrations, which is necessary for achieving similar absorption characteristics to those of noble metals. The phenomena of free-carrier-induced LSPRs have been widely observed in many metal chalcogenides and oxides, including Cu2-xS, Cu2-xSe, Cu2-xTe, Fe1-xS2, MoO3-x, WO3-x, ZnO, and CdO.34,291−295 In addition to the structural parameters (material, size, shape) that can affect the plasmonic responses, the plasmon resonances of heavily doped semiconductors can also be tuned by controlling their free charge carrier concentrations. The LSPR frequency can be largely spanned from the visible to far-infrared (FIR) region. Increases in the free charge carrier concentration can cause blueshifts of the LSPR peak and increases in the resonance amplitude. The free charge carrier concentrations of the doped semiconductors can be controlled from 1018 cm–3 to 1021 cm–3, which are still smaller than those of the conventional plasmonic metals34 on the order of 1022 cm–3. However, the doping level for many semiconductors is limited owing to the perturbation of high-concentration doping on the band structure. Many factors, including the fraction of the active dopant, the solid solubility limit, and doping compensation effects, need to be considered.296−298

3.3. Carbon-Based Nanomaterials

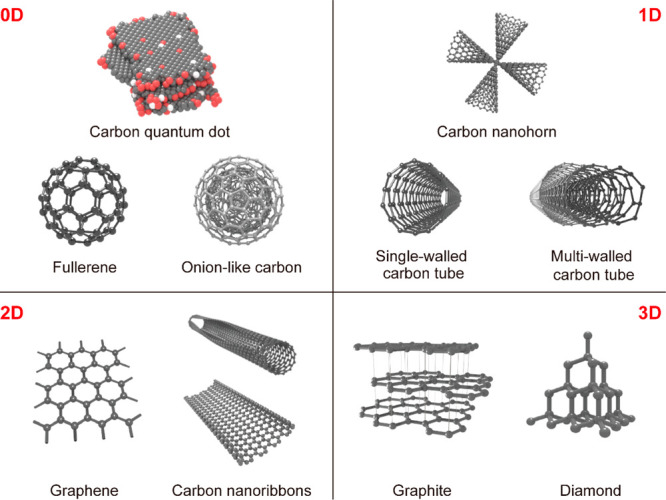

Carbon is one of the most abundant elements in the universe and can be found in all life forms. The atoms of carbon can bond with each other in diverse hybridization states (sp, sp2, sp3), resulting in a variety of carbon allotropes (Figure 7).35 Well-known carbon materials include carbon dots,299−303 nanodiamond,304,305 fullerene,306,307 graphite,308−312 carbon nanotubes (CNTs),313−318 graphene and its derivatives.36,319−325 All these carbon allotropes are excellent candidates as photothermal materials due to their high chemical stability, broadband light absorption, lightweight and low cost.326 Their light-to-heat conversion relies on the excitation of loosely held π electrons and relaxation to their ground states. The light absorption of carbon-based nanomaterials can be extended to a wide range of the solar spectrum. Many efforts have therefore been made to increase the absorption intensity and reduce the surface light reflection rather than broadening the absorption range. The optical properties of carbon-based nanomaterials vary with specific structural parameters, including the size, shape, doping, and number of layers.327 These physicochemical factors are also related to the fabrication methods. The fabrication methods include both top-down and bottom-up approaches. In the top-down approaches, bulk materials are reduced in size, such as mechanical exfoliation. In the bottom-up approaches, the carbon-based nanomaterials are constructed from the atomic level, such as chemical vapor deposition and epitaxial growth.328,329 When carbon-based materials are fabricated into porous nanostructures, the light reflection is significantly reduced through the minimization of the influence of the incidence angle and the reduction of the effective refractive index of the materials.7 For instance, the synthesis of a double-layer structure consisting of an exfoliated graphite layer and a carbon foam layer has been demonstrated.312 The reflectivity of this porous nanostructure reaches down to 3% within the solar spectrum ranging from 250 to 2250 nm. Porous graphene sheets330,331 and CNTs313,314 have also been fabricated to improve light absorption. Optical microcavities can be formed between two sides of a spacer layer. These porous structures can therefore effectively confine light within the structures and significantly enhance the interaction between the materials and light.332 A porous network comprising graphene sheets has been reported to achieve 97% absorption across 200–2500 nm because of the multiscattering effect.331 98% absorption of visible irradiation and almost 100% absorption of NIR light have been realized with vertically aligned graphene sheets.330 In addition, hollow CNTs can be fabricated into a hierarchically nanoporous network structure,314 which exhibits broad absorption of 99% and high photothermal conversion of 86.8%.

Figure 7.

Carbon-based nanomaterials with different dimensionalities. Reprinted with permission from ref (35). Copyright 2015 American Chemical Society.

3.4. Organic Polymer Nanomaterials

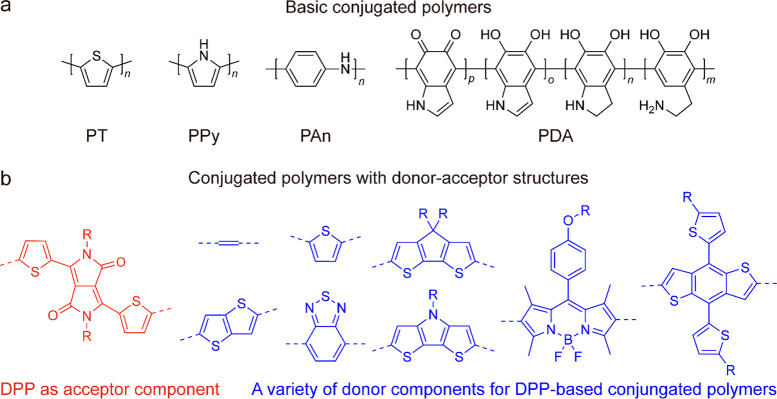

Organic polymers with conjugated structures have emerged as a new category of photothermal nanomaterials because of their versatile molecular designs, strong absorption of NIR light, high light-to-heat conversion efficiencies, and good biocompatibility.98 Similar to the case of carbon-based nanomaterials, the absorption capabilities of conjugated polymers in the visible and NIR regions stem from the nonradiative relaxation of their rich delocalized π electrons. Various polymer photothermal nanomaterials have been strategically designed on the basis of most basic conjugated structures, such as polythiophene (PT), polypyrrole (PPy), polyaniline (PAn), and polydopamine (PDA) (Figure 8a).20,102,333 Through the close stacking of their monomeric units, the intermolecular collisions are strengthened in the formed polymers. The construction of conjugated polymers can partly quench molecular fluorescence and enhance nonradiative relaxation, resulting in efficient photothermal conversion.98 Moreover, donor–acceptor (D-A) strategies have been proposed to develop a new series of conjugated polymers for further extending light absorption and improving light-to-heat conversion efficiencies.334−338Figure 8b presents a typical class of polymer-based photothermal materials with D-A structures consisting of diketopyrrolopyrrole (DPP) as an acceptor and a series of electron-donating polymers as donors.102 While a conjugated polymer serves as a donor for absorbing light, another polymer accepts the excited electrons from the conjugated polymer and further releases them through nonradiative decay. The polymer as an acceptor needs to have a Fermi level that is lower than the excited state of the donor. The bandgap of these D-A structures can be facilely modulated by tuning the ratio and strengths of the donor and acceptor units.339 When the D-A structures are activated under external light irradiation, intramolecular charge transfer is induced along the backbone. The radiative recombination of electrons and holes can be consequently suppressed, which enhances heat generation. This D-A strategy has been employed to prepare conjugated polymer nanoparticles for the harvesting of NIR light.334 The photothermal conversion efficiency as high as 62.3% has been achieved by introducing a porphyrin-pyrene pendant as an extra light-harvesting unit. The same research group has further demonstrated a new type of biodegradable conjugated polymer made of two acceptors and one donor.340 This A-D-A structure not only contributes to nearly complete fluorescence quenching but also brings about a narrow energy gap. The photothermal conversion efficiency has therefore been improved to 82%.

Figure 8.

Summary of polymer-based photothermal materials. (a) Basic conjugated polymers as photothermal materials. Their monomers can be treated as the basic components of the conjugated polymers with D-A structures. (b) Conjugated polymers with donor–acceptor structures as photothermal materials. Reprinted with permission from ref (102). Copyright 2020 American Chemical Society.

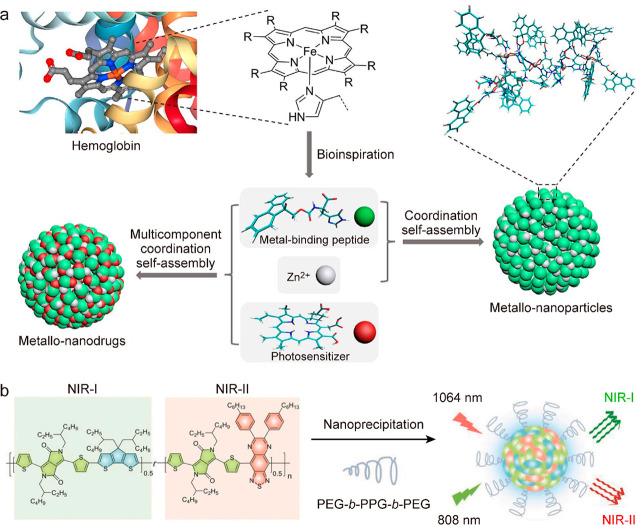

To further improve the photothermal conversion efficiency and enhance the stability of conjugated polymers, supramolecular assemblies have been extensively developed to fabricate new polymer-based photothermal materials.341−346 The assembly is distinguished from traditional molecular structural design and based on flexible noncovalent intermolecular interactions, such as van der Waals interaction, hydrogen bonding, and electrostatic interaction.37 Similar to the aggregation-caused quenching effect, the intrinsic fluorescent emissions of molecules can be largely quenched in the supramolecular system, which results in the enhancement of heat generation.347 In addition, the material stability can be significantly improved through the formation of supramolecular structures. The monomeric molecules are trapped into supramolecular assemblies where only a few peripheral molecules can be affected by the outer environment.21 The isolation of the photothermal molecules can effectively avoid decomposition or oxidation, thereby maintaining their photophysicochemical properties. The photothermal conversion of unstable molecules can be greatly improved. Due to these unique advantages of supramolecular assembly, much effort has been dedicated to the exploration of new assembly methods and the promotion of the light-to-heat conversion performance.348−352 A multicomponent coordination self-assembly approach has recently been developed to synthesize supramolecular nanodrugs (Figure 9a).349 The assembled multicomponent nanoparticles exhibit well-defined spherical structures, uniform sizes, and robust colloidal stability. Moreover, the development of dual-peak absorbing photothermal nanoagents through the supramolecular assembly strategy has been demonstrated (Figure 9b).353 Two types of conjugated polymers with D-A structures are used for light absorption in both NIR-I and NIR-II windows. The photothermal conversion efficiencies of this dual-peak absorbing polymer are 44.9% and 43.4% at 808 and 1064 nm, respectively.

Figure 9.

Supramolecular assembly of polymer-based photothermal materials. (a) Schematic illustrating the multicomponent coordination assembly of metallo-nanodrugs. Reprinted with permission from ref (349). Copyright 2018 American Chemical Society. (b) Design and synthesis of a dual-NIR-window absorbing photothermal nanoagent. Reprinted with permission from ref (353). Copyright 2018 Wiley-VCH.

3.5. Two-Dimensional Nanomaterials

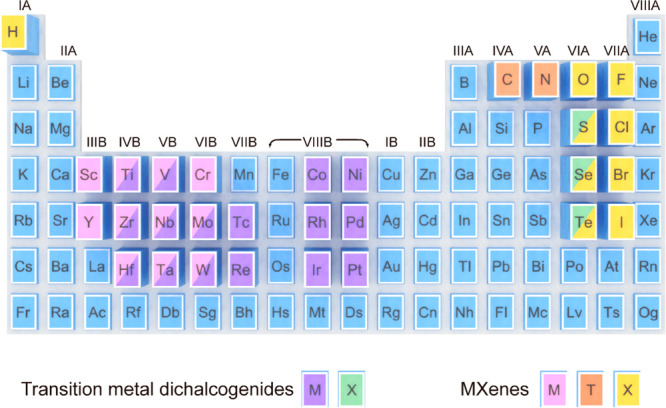

Since the discovery of single-layer graphene in 2004, there has been tremendous growth in the development of 2D nanomaterials with extraordinary physical and chemical properties.354 Various new types of 2D nanomaterials, including MXenes, MOFs, transition metal dichalcogenides (TMDCs), black phosphorus (BP), tellurene, and layered double hydroxides, have been delicately fabricated with appealing photothermal conversion properties.22−24,355−358 Unlike graphene or BP made of a single element, TMDCs and MXenes, as two big fast-growing families of 2D nanomaterials, have been rapidly expanded with a large variety of compositions (Figure 10).359,360 The versatile designability of 2D nanomaterials allows their photothermal performances to be facilely tailored and become competitive with other photothermal materials. 2D nanomaterials possess a typical layered structure. Their bandgaps can be simply tuned by adjusting the number of layers. The thickness-dependent bandgaps endow them with a wide absorption band. For instance, the bandgap of BP can be changed from 0.3 to 2 eV across a broad range from the visible to FIR region by controlling the layer number.361,362 As the thinnest materials ever known, 2D nanomaterials have the highest specific surface areas compared to zero-dimensional (0D), 1D, and bulk materials.363 The ultrathin structure can not only bring rapid response to light but also provide excellent in-plane electron mobilities to achieve high photothermal conversion efficiencies. MXenes, specifically Ti3C2, have been reported to possess a perfect light-to-heat conversion efficiency of 100%, showing the promising future of MXenes for photothermal applications.364

Figure 10.

Periodic table showing the compositions of TMDCs and MXenes.

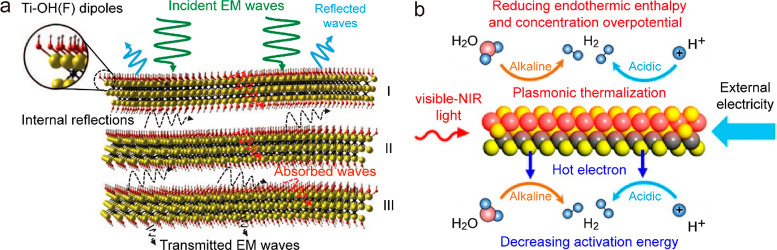

MXenes have become a rapidly rising star among 2D nanomaterials since the first reported synthesis of Ti3C2 in 2011.360,365,366 As carbides and nitrides of transition metals, MXenes have a general chemical formula of Mn+1XnTx, where M represents an early transition metal (Sc, Ti, V, Cr, Y, Zr, Nb, Mo, Hf, Ta, W), X represents carbon or nitrogen, and T denotes the surface termination (OH, O, F, Cl).367 They can be synthesized by selective etching of their precursor ternary MAX phases, where A represents a group IIIA or IVA element.368 While numerous MXene compositions have already been prepared, many more have been predicted by computational methods. Because of the presence of transition metals, the free charge carrier densities of MXenes are on the order of 1022 cm–3 and the reported highest metallic conductivity369,370 reaches up to 20000 S cm–1. Based on their excellent metallic conductivity and layered structure, MXenes exhibit a strong electromagnetic interference (EMI) shielding effect (Figure 11a).371 Except for the immediately reflected waves from the surface, the remaining EM waves suffer from multiple internal reflections within the MXene flakes, leading to more absorption and an overall attenuation of EM waves. In addition to the EMI shielding effect, the abundant free charge carriers of MXenes also bring about LSPRs (Figure 11b).372 The plasmonic properties can be chemically tuned by altering the structure and type of the X and M sites, as well as the stoichiometry of the surface terminations.39 MXenes with various compositions support tunable plasmon resonances in the entire visible and NIR regions.373 The interband transitions of MXenes can also induce strong absorption in the UV region. These unique merits of MXenes are beneficial for efficient light harvesting and thermal energy generation.23

Figure 11.

EMI shielding and LSPR effects in MXenes. (a) Proposed EMI shielding mechanism. Reprinted with permission from ref (371). Copyright 2016 American Association for the Advancement of Science. (b) Schematic illustration of the LSPR-induced photothermal and hot-electron effects. Reprinted with permission from ref (372). Copyright 2021 Wiley-VCH.

3.6. Hybrid Photothermal Nanomaterials

Hybridization is a simple strategy to obtain complementary and synergistic properties from each component. The formation of hybrid nanostructures composed of different photothermal materials has been widely employed to achieve enhanced light absorption and better photothermal capabilities.49,374−380 Metal nanostructures incorporated with plasmonic semiconductors or other metals can create a dual-plasmonic system with multiple plasmon resonance modes for broadening the NIR absorption band.34 The decoration of semiconductors with Pd nanoparticles as metallic active sites is usually used for improving the photothermal catalytic activities.146 The introduction of Ag nanoparticles to other photothermal materials can give rise to a greatly synergistic antibacterial and photothermal performance.381 To overcome the disadvantages of poor photostability and high photoluminescence emission, conjugated polymers are integrated with carbon-based materials or plasmonic metals.99 On the other hand, the modification of these inorganic materials with polymers can also minimize their long-term toxicity. Consequently, the hybrid design provides a promising way to engineer photothermal materials with synergistic optical properties for targeted applications.

4. Probing of Photothermal Heat Generation

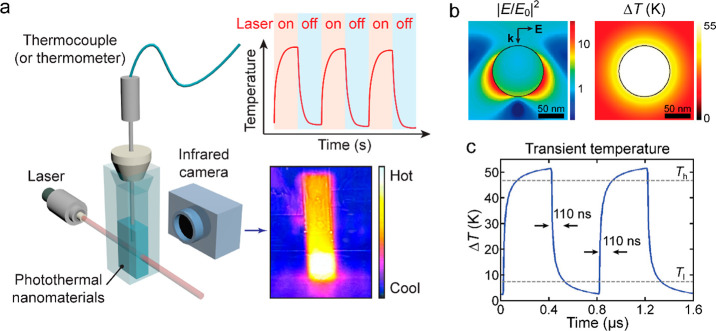

Traditional thermometric techniques, such as mercury thermometers, thermocouples, and IR cameras, can only give macroscopic temperatures as a collective effect of photothermal nanomaterials and are usually limited to the measurements of bulk or surface temperatures with low spatial and temporal resolution (Figure 12a). These conventional thermometers are commonly used for monitoring the heating and cooling processes of photothermal nanomaterials irradiated by a continuous laser on the time scale of a few hundreds of seconds, from which the photothermal conversion efficiency can thereby be derived.12,21,85,363 However, photothermal conversion and the associated effects actually occur on much shorter time scales and in nanoscale dimensions that are beyond the reach of traditional thermometry.

Figure 12.

Macroscopic and microscopic temperature measurements. (a) Schematic diagram of typical photothermal characterization with traditional thermometric techniques. The heating and cooling processes are controlled by switching on and off the laser and monitored with mercury thermometers or thermocouples. The macroscopic temperature distribution can be imaged with an IR camera. (b) Simulation of the photothermal effect of a Au nanosphere (radius, 50 nm) placed in water under an incident light at 530 nm, tuned to the dipole plasmon resonance wavelength. Left: electric field intensity profile normalized to the incident field. Right: equilibrium distribution of the temperature increase. Reprinted with permission from ref (260). Copyright 2010 American Chemical Society. (c) Simulated transient temperature increase of a Au nanosphere (radius, 50 nm) in water excited by on–off modulated light. Th and Tl represent 90% and 10% of the temperature step, respectively, which define the rise and fall time of 110 ns. Reprinted with permission from ref (382). Copyright 2012 American Chemical Society.

Take plasmonic nanoparticles as an example. LSPR and plasmonic heating are intrinsically localized and involve ultrafast excitation. Electromagnetic and thermodynamic simulations show that the photothermal-induced heat is highly concentrated at the surface (<20 nm) of irradiated plasmonic nanoparticles (Figure 12b) and strongly depends on the size and shape of the nanoparticles.260 In addition, the local temperature increase can be extremely rapid (Figure 12c), reaching the nanosecond and even picosecond levels, as revealed in the pioneering works383,384 and a more recent work.382 This recent work shows the reshaping of individual Au nanoparticles triggered by transient photothermal heating with femtosecond and nanosecond laser pulses.

Accurate temperature measurement of nanomaterials is critical for understanding their photothermal properties, heat generation mechanisms, and roles in physical, chemical, and biological applications. Controlled local heating is essential in biomedical diagnosis and therapeutics, especially for killing cancer cells in tumors with temperature elevation above the physiological level (41–42 °C) and simultaneously preventing excessive injury to the surrounding healthy tissues or post-treatment inflammatory responses.385,386 In photothermal catalysis, the temporal scales of the plasmon-induced hot carrier generation, hot electron transfer, and thermalization processes are on the time scales of fs to sub-ns.9,387 Excessive local heating also poses problems for the stability of the nanomaterials themselves and for the proper functioning of the associated optoelectronic devices. Therefore, monitoring the local temperature distributions and transient temperatures of photothermal nanomaterials, with sufficient sensitivity and accuracy, is of general interest to a wide range of scientific communities, from fundamental materials science to chemical and medical applications. Consequently, nanothermometers and spectroscopic methods have emerged as alternative tools for temperature measurements with improved spatial, temporal and temperature resolutions.388−391

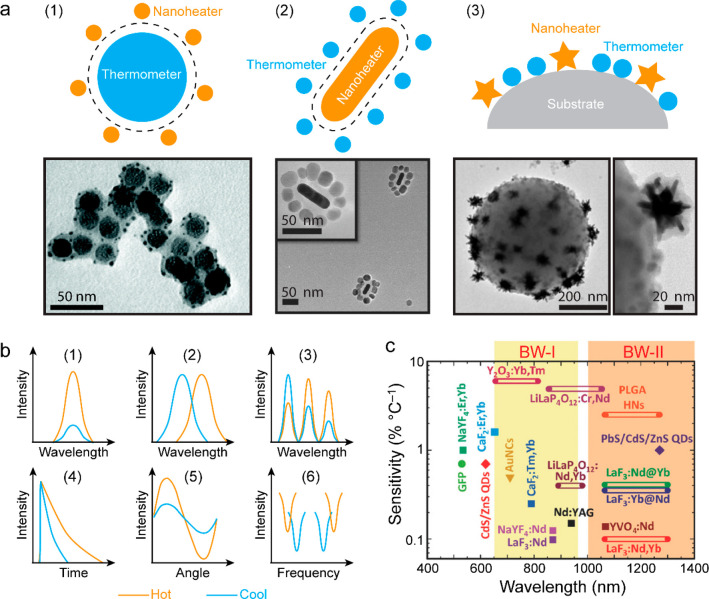

4.1. Heater–Thermometer Nanoplatforms

Heater–thermometer nanoplatforms refer to hybrid nanostructures consisting of photothermal nanomaterials (nanoheaters) and nanothermometers. Such hybrid nanostructures enable simultaneous heating and nanothermometry. A straightforward approach is to simply mix nanoheaters and nanothermometers in a matrix, which has been employed to compare the heating and absorbing efficiency of Au nanoparticles with different geometries,392 as well as to monitor plasmonic heating in a subtissue.393 Nevertheless, direct decoration of nanothermometers on the surface of nanoheaters, or vice versa, is highly desired for local temperature measurements with higher accuracy. Figure 13a illustrates three configurations that have been experimentally proven to work: (1) thermometer–heater core–satellite nanostructures,394−396 (2) heater–thermometer core–satellite nanostructures,397−399 and (3) codeposition of heaters and thermometers on a sub-microscale substrate.400 These heater–thermometer nanoplatforms can be constructed using different photothermal nanomaterials and nanothermometers as building blocks.

Figure 13.

Nanothermometers for local temperature measurements. (a) Schematics (upper row) illustrating three different configurations for combining nanoheaters and nanothermometers and transmission electron microscopy (TEM) images (lower row) of representative hybrid nanostructures: (1) (NaYF4:Yb,Er up-conversion nanoparticle (UCNP))@(mesoporous silica (mSiO2))-(Au nanoparticle) core–satellite nanoassemblies. Reprinted with permission from ref (394). Copyright 2019 Royal Society of Chemistry. (2) (Au nanorod)-(NaGdF4:Yb,Er UCNP) core–satellite nanoassemblies. Reprinted with permission from ref (397). Copyright 2016 Wiley-VCH. (3) Polystyrene beads attached with Au nanostars and CaF2:Nd3+,Y3+ UCNPs. Reprinted from ref (400). Copyright 2019 Ivyspring International Publisher under the CC BY 4.0 license http://creativecommons.org/licenses/by/4.0/. (b) Illustrations showing temperature-sensing strategies relying on (1) emission intensity, (2) peak position, (3) emission intensity ratio, (4) emission lifetime, (5) fluorescence polarization anisotropy, (6) electron spin resonance or ODMR. (c) Thermal sensitivities of different luminescent nanothermometers and their spectral operation ranges. Reprinted with permission from ref (391). Copyright 2017 Wiley-VCH.

The selection of nanothermometers can cover a series

of luminescent

temperature-responsive probes, including fluorescent small molecules,401 fluorescent proteins,402 quantum dots (QDs),403 lanthanide-ion-doped

UCNPs,404 vacancy-containing nanodiamonds,405−407 carbon dots,408,409 and polymeric nanoparticles.409 The operation of these nanothermometers mostly

relies on the temperature-dependent fluorescence properties (Figure 13b), for example,

the emission intensity, emission peak shifting, spectral ratio between

the different fluorescence bands, lifetime, polarization anisotropy,

and electron spin resonance or optically detected magnetic resonance

(ODMR). All of these signals allow for the real-time and noninvasive

monitoring of local temperatures. Briefly, the fluorescence intensity

of small organic molecules generally decreases as the temperature

is increased because of the thermal quenching effect.401 Some specific molecules, such as green fluorescent

proteins and organic dyes, possess temperature-dependent fluorescence

polarization anisotropy; that is, the ratio of the emission intensities

collected under different polarization states can vary with the environmental

temperature.402 Aggregation-induced emission

(AIE) molecules have also been demonstrated to display temperature-responsive

properties in terms of spectral position, fluorescence intensity,

and fluorescence lifetime.410 Most semiconductor

QDs exhibit temperature-dependent spectral shifts and lifetime variations

because of their bandgap changes with temperature.403 UCNPs with specific thermally coupled energy-level pairs,

such as Er3+ (2H11/2 and 4S3/2), Nd3+ (4F5/2 and 4F3/2), and Eu3+ (5D1 and 5D0), are commonly used for temperature

sensing by monitoring the intensity ratio between the two related

fluorescence bands, also known as ratiometric optical nanothermometry.389,404 Fluorescent nanodiamonds for temperature sensing rely on the spin

resonances of the nitrogen-vacancy center and their temperature-dependent

shifts in the ODMR spectrum at microwave frequencies.405−407 An important figure of merit for the comparison of nanothermometers

is the relative thermal sensitivity, which is defined as the rate

of change in the temperature-sensitive parameter with temperature,  , where Q denotes the temperature-sensitive

parameter (intensity, lifetime, ratio) and T denotes

temperature. Sr is comparable between

different systems with the consistent unit of K–1 or % K–1. Figure 13c provides a brief summary of the thermal sensitivities

and spectral operation ranges of different luminescent nanothermometers,

together with the first and second biological windows (BW-I and BW-II)

where the absorption and scattering of biological tissues is minimal.391 Comparison of other factors, such as the thermal

accuracy, sensor size, and thermal and special resolution, and more

detailed discussion about different nanothermometers have been summarized

in a few recent review articles.386,388−391

, where Q denotes the temperature-sensitive

parameter (intensity, lifetime, ratio) and T denotes

temperature. Sr is comparable between

different systems with the consistent unit of K–1 or % K–1. Figure 13c provides a brief summary of the thermal sensitivities

and spectral operation ranges of different luminescent nanothermometers,

together with the first and second biological windows (BW-I and BW-II)

where the absorption and scattering of biological tissues is minimal.391 Comparison of other factors, such as the thermal

accuracy, sensor size, and thermal and special resolution, and more

detailed discussion about different nanothermometers have been summarized

in a few recent review articles.386,388−391

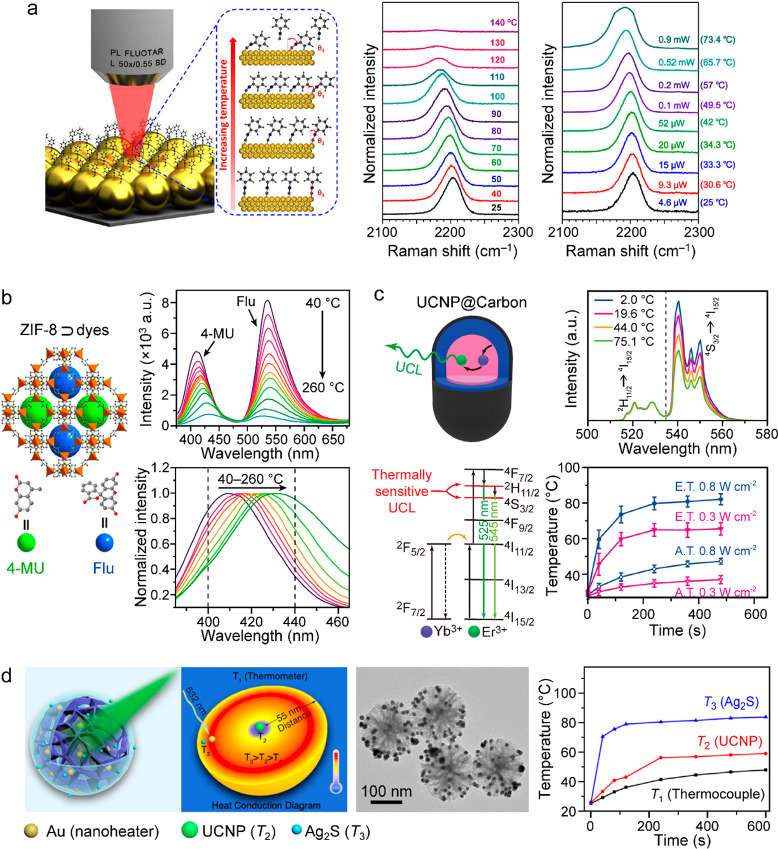

With advances in surface functionalization and assembly techniques, heater–thermometer nanoplatforms with different compositions and various configurations have been experimentally achieved. Plasmonic nanoparticles are the most commonly used nanoheaters because of their high photothermal conversion efficiencies and ease of surface functionalization. For example, local temperature measurements of Au nanoparticles have been demonstrated by monitoring the Raman spectra of phenyl isocyanide molecules functionalized on the top surface of the Au nanoparticles (Figure 14a).411 Since the molecules take a more tilted angle to the Au surface as the temperature is increased, the Raman peak associated with the N≡C stretching vibrations exhibits sensitive shifts with temperature. This phenomenon has further been used to determine CO photothermal desorption from the Au surface at ∼62 °C and to track the local temperature variations of a single living cell. Similarly, Au nanoparticles have been combined with molecular beacons,412 nanodiamonds,413 and UCNPs,400 respectively, for extracellular or intracellular local heating and temperature monitoring. Multimode temperature readout has been realized by encapsulating two types of luminescent dyes (4-Mu and Flu) into the pores of a nanoscale MOF zeolitic imidazolate framework-8 (ZIF-8) and measuring the emission intensity ratio and maximum emission wavelength (Figure 14b).414 The thermal sensitivity can reach Sr = 0.62% K–1 at 240 °C; albeit, the photothermal conversion effect is not significant in this system. UCNP@C core@shell nanoparticles have been successfully prepared for simultaneous photothermal heating and nanothermometry (Figure 14c).396 Accurate PTT has been demonstrated by use of the photothermally active carbon nanoshells as heaters and the UCNPs for the real-time monitoring of microscopic temperatures, so as to reduce injury on the normal tissues during photothermal treatment. The local temperature calculated from the up-conversion luminescence (UCL) spectra is 10–15 °C higher than the macroscopic temperature recorded by a thermal camera, indicating the important role of accurate nanothermometry in biomedical diagnosis and therapeutics. The same group has further developed a complex multilayer structure in the form of NaYbF4:2%Er@NaYF4@mSiO2@Au@SiO2@Ag2S (Figure 14d), where the Au nanoparticles play the role of nanoheaters, whereas both the NaYbF4:2%Er@NaYF4 UCNPs and the Ag2S QDs function as nanothermometers.415 In the photothermal measurements, the Ag2S nanothermometers, which are designed to be closest to the nanoheaters, experience rapid heating and reach an equilibrium temperature rapidly. More interestingly, the measured temperatures follow the order Ag2S > UCNP > thermocouple, which matches well with the order of the distance between the Au nanoparticles (nanoheaters) and the different thermometers. Although there are not many hybrid systems that can perform effective local heating and local temperature detection at the same time, such efforts are beneficial for the development of heater–thermometer nanoplatforms with accuracy, sensitivity, and resolution, as well as for understanding the heating mechanisms of different photothermal nanomaterials. However, it is worth noting that the introduction of a nanothermometer near a nanoheater might affect the optical properties of both sides, including the heating efficiency of the nanoheater and the temperature calibration curve of the nanothermometer. Careful calibration is therefore especially crucial for these new systems.416

Figure 14.