Abstract

The current study aims to produce coated watermelon rind chips with the approach of reducing oil absorption and optimal use of waste and investigating its physicochemical, textural, and sensory characteristics. The effect of coating with basil seed gum, Tragacanth gum, pectin, and coating formulation with corn flour on oil absorption rate, moisture loss, and color of white skin slices of fried watermelon was studied. The results indicated that due to the controlling role of water in the amount of oil absorption, the amount of oil in all the samples coated with gum and corn flour was decreased compared to the samples coated with gum and the samples without coating. The pretreatment of osmotic dehydration reduces oil absorption in compared to fresh and blanched samples. The color changes in the sample with two pre-treatments of osmosis and blanching were less than other samples, as a result, the brightness of this sample was also higher than others. The lowest amount of oil absorption was observed in samples coated with basil gum and 0.5% and 1% corn flour (0.33 and 0.29, respectively). The highest amount of moisture loss during frying was related to the coated samples was observed with the combination of basil gum and corn flour (0.5%) and pectin and corn flour (2%). The highest level of antioxidant activity of the fried samples was related to the sample coated with 0.5% basil gum. Significant color changes were also observed in the coated samples.

Keywords: Hydrocolloid coating, Deep frying, Oil absorption, Antioxidant activity, Watermelon white skin

1. Introduction

Watermelon (Citrullus lanatus) is a flowering plant species of the Cucurbitaceae family and the name of its edible fruit. Watermelon is a highly cultivated fruit worldwide, with more than 1000 varieties. This fruit is grown in favorable climates from tropical to temperate regions worldwide. It is botanically called a pepo. This fruit can be eaten raw or pickled, and the rind is edible after cooking that rich source of vitamins and phytochemicals [1]. In 2020, the global production of watermelons was 101.6 million tons, with China (mainland) accounting for 60% of the total (60.1 million tons). Secondary producers included Turkey, India, Iran, Algeria, and Brazil – all having annual production of 2–3 million tons in 2020 [2].

The flesh constitutes approximately 68% of the total weight of watermelon, the rind approximately 30%, and the seeds approximately 2% [3]. The watermelon rind, which is the green skin that keeps all that fruit safe, is completely edible. In addition, watermelon skin can be prepared and processed as a practical and valuable material from the waste of watermelon processing units such as paste, marmalade, jam, watermelon juice, and also watermelon nut seeds. Therefore, it is necessary to carry out in-depth studies regarding the identification of different cultivars for different purposes, chemical compositions, nutritional value and processing of their different parts, and the production of emerging products to reduce waste and increase added value.

Frying is a widespread method of cooking that creates a unique taste and texture. Deep-fat frying is a complex process in which foods are completely immersed in hot oil (150–190 °C) to initiate simultaneous heat and mass transfer between the oil, food, and air, resulting in dehydration. Be food meanwhile, the food temperature is heterogeneous and increases slowly with limited oil penetration. As a result, a desirable fried food with attractive flavor, golden color, and beneficial texture (juicy inside and crispy outside/dried surface) is prepared [4]. The amount of absorbed oil is one of the most important quality control factors. However, fried foods usually contain high amounts of oil ranging from 35% to 45% [5]. Exposure of oil to high temperatures and the presence of water and oxygen caused by food provide the conditions for the occurrence of destructive reactions such as oxidation, hydrolysis, and polymerization, which chemical compounds resulting from these reactions affect the cardiovascular system and create undesirable colors.

Edible coatings, a thin layer of edible materials on the surface of the food product to create a semi-permeable barrier to gases, water vapor, and volatile compounds are used. There are two types of food coating: spraying and dipping. The properties of hydrocolloid coatings include low permeability to moisture, reduction of oil absorption, thermal formation of gel or transverse connections, and barrier properties against oxygen, carbon dioxide, and fat [6].

[7] in research about the effect of guar gum with glycerol coating on the properties and oil absorption of fried potato wedges concluded that coating potato wedges with guar gum and glycerol have an effective role in reducing the amount of potato oil absorption. It is fried and in addition, it does not have any negative effect on its breaking force. In addition, the formulation of the coating leads to an increase in the barrier property of the fried slices and prevents the creation of pores and cracks in the fried product [8]. studied the effect of guar gum coated with sorbitol on the oil absorption properties of fried potatoes and concluded that the coating with guar gum and sorbitol plays an effective role in preventing oil penetration into the chips. Potatoes during frying and in addition does not have any negative effect on the texture.

The purpose of this research is to produce coated watermelon rind chips with the approach of reducing oil absorption and optimal use of waste and investigating its physicochemical, textural, and sensory characteristics.

2. Materials and methods

2.1. Osmotic dehydration

The samples are prepared from Jovin Sabzevar watermelon, CRIMSON SWEET variety, from fruit shops in Neyshabur city in Razavi Khorasan provenance of Iran. First, all the red parts of the watermelon were separated and the watermelon rind was cut into pieces, then the thin green part of rind was separated. After that, the white part was cut into pieces with dimensions of 2 × 16 × 34 mm. Then the resulting slices were exposed to boiling water steam for 2 min and immediately transferred to cold water. In addition to deactivating existing enzymes, this step causes the watermelon skin to become softer.

2.2. Osmotic dehydration

Osmotic dehydration was carried out in a batch system. The hypertonic solution and the watermelon rind cuts were contained in 250 ml Erlenmeyer flasks which are placed inside a temperature and agitation-controlled incubator shaker (Thermoshake-Gerthart). To prevent evaporation from the osmotic solution, Erlenmeyer flasks were covered with plastic wrap during the experiments. Agitation was necessary to improve mass transfer and prevent the formation of a dilute solution film around the samples. Besides, it constitutes a uniform concentration and temperature profile inside the solution. For each experiment, the ratio of solution/sample of 5/1 (w/w) and the agitation speed of 200 rpm was used and maintained constant. At each sampling time (0.5–6.0 h) which is determined according to the experimental design, the watermelon rind cuts were taken out from the osmotic medium, drained, and weighed. After rinsing and drying the surface water with a moisture-absorbent towel, the samples were weighed and prepared for the next step.

In the next step, salt solutions with concentrations of 1, 1.5, 2, 2.5, and 3% (w/v) was prepared at temperatures of 30, 40, 50, 60, and 70 °C. Samples were prepared with ratios of 1–10, 1 to 6, 1 to 5, 1 to 4, and 1 to 3 (watermelon rind to osmotic solution). The prepared samples will be exposed to the specified osmotic treatments for 5 h and sampling will be done every hour. After the desired time in the osmotic solution, the samples are rinsed, and their surface moisture was dried with a moisture-absorbent napkin and weighed.

2.3. Preparation of the solutions

For coating, concentrations of 0.5, 1, and 2% (w/w) of Tragacanth, pectin, and basil seeds are prepared in distilled water. Since the three Tragacanth gums, pectin, and basil seeds are soluble in cold water, water with a normal temperature of 25 °C was used to prepare their solutions. Each solution is stirred on a stirrer at high speed for 1 h until a uniform solution is obtained, and then it is kept at room temperature for 12 h to fully hydrate.

2.4. Formulation and preparation of the coating

First, 5 g of corn flour was mixed with 7.5 ml of distilled water and stirred for 5 min until a uniform solution was obtained on a stirrer at a constant speed. It was mixed with a ratio of 1:4 (concentrations of 0.5 and 1%) and a ratio of 1:6 (concentration of 2%). The final solutions were stored in glass containers at room temperature [9].

2.5. Coating and frying process

The samples that have already been subjected to osmotic pretreatment are immersed in resin solutions for 2 min and then placed inside a metal mesh basket and then immersed in the frying medium.

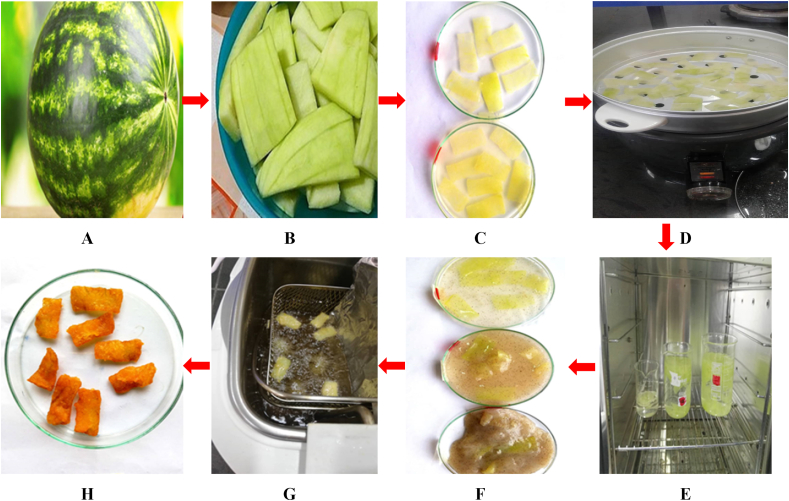

Frying was done in a home fryer (Bosch, Germany) with the ability to adjust the temperature. Canola oil enriched with vitamins D and E was used as frying medium. Before the frying process, 2 L of oil was poured into the fryer and it reached the desired temperature for half an hour. Then, slices of white watermelon skin were fried at 170 °C for 210 s. After that physicochemical tests were performed on slices of fried white watermelon rind. The steps of production of watermelon rind chips is illustrated in Fig. 1.

Fig. 1.

The steps of production of watermelon rind chips. A: Watermelon, B: Watermelon rind, C:Cutting, D:Blanching, E:Osmotic dehydrating, F:Coating, G:Deep frying, H:The product.

2.6. Determining the water loss, solid gain and weight reduction

The soluble solids content of the osmotic solution was measured using a refractometer (Jena Model II) at 20 C. Evaluation of mass exchange between the solution and sample during osmotic dehydration was made by using the parameters such as water loss (WL), solid gain (SG), and weight reduction (WR). To account for initial weight differences between the samples, water loss (WL), solid gain (SG), and weight reduction (WR) were calculated according to the following equations [10,11]:

M0: fresh sample weight; M: weight of osmotic sample; S0: weight of dry matter of fresh sample; S: dry matter of the osmosis sample.

2.7. Determining the moisture content

The moisture content of fried samples was measured according to Ref. [12]. By placing the samples in an oven (Behdad model) at a temperature of 105 °C and for a period of 3 h until reaching a constant weight. After leaving the oven, the samples were cooled in a desiccator and measured.

2.8. Determining the oil content and reduction of oil absorption

The amount of oil was determined according to the [13,14]. For this purpose, samples were weighed and fat extraction was done using diethyl ether solvent for 5 h. The amount of oil was also calculated based on dry weight.

-

•

The reduction of oil absorption is obtained from the following formula:

2.9. Antioxidant activity

Evaluation of antioxidant activity was done using the DPPH test (promoting hydrogen atom or electron by different compounds and extracts) [15,16]. In this test, it was measured by the amount of purple discoloration of 2,2-diphenyl-1-picrylhydrazyl solution in methanol. In this method, DPPH substance (0.1 mM) was used as a stable radical compound as a reagent. In this way, 100 μL of different concentrations of essential oil and ethanol extract were added to 3 ml of DPPH solution in ethanol. After 1 h in the dark at room temperature, the absorbance of the samples was read at a wavelength of 517 nm by a spectrophotometer (Jenway model) [17]. The inhibition percentage of DPPH free radicals was calculated using the following formula:

2.10. Imaging and analysis of images

In order to investigate the effect of different treatments on the color changes of watermelon skin, it was done as follows: A) Machine vision system: First, the samples taken out of the fryer were cooled to room temperature. A flatbed scanner was used for imaging. b) Pre-processing of images: Intersection of the images (separating the real image of the samples from the background) was done using Photoshop software and the images were saved in PNG format. c) Changing the color space from RBG to L*a*b*: Since the L*a*b* color parameters are not dependent on the measuring instrument and provide uniform color regardless of the output or input, the obtained images are The color space becomes L*a*b*. Image analysis was done using Image J software. In order to measure the color of the slices of the white skin of the fried watermelon, photos were first taken of the samples under standard optical conditions. After preparing the required photos, the photos were transferred to the computer and uploaded to the Image J software to measure color changes, and after transferring to the corresponding software, the values of , , and were changed. In this colorimetric system, parameter measures the brightness in the range of 0 (black) to 100 (white). Also, the two parameters and respectively represent the green to red and blue to yellow samples, which are in the range of – (green) to + (red) and – (blue) to + (yellow) respectively. The overall color changes (ΔE) in slices of white watermelon skin were calculated by the following equation [18]:

In this regard, the values of , and are related to the control sample.

2.11. Texture characteristics

The textural properties of fried samples were evaluated with, the texture measuring device and the Penetration test. The instrument was equipped with a 50 N load cell. Test samples were compressed in a unique cycle compression-decompression test, using a 50 mm diameter flat plate with 30 mm min-I as a rate of deformation. Fried samples were compressed to a depth of 4 mm (from the original 10 mm) using a spherical probe of 5 mm diameter under a constant speed of 50 mm mid. Force-deformation (F/D) curves were obtained and hardness parameter were evaluated as:

Hardness = Maximum force (N)/Maximum deformation (mm).

Experimental conditions were restricted to one loading rate at room temperature to eliminate variations from these sources. Each test was repeated on 10 pieces and their mean values were used as indicators of the textural properties of fried samples [19].

2.12. Sensory evaluation

For the purpose of sensory evaluation, the 9-point hedonic scale method is used. Each panelist is given a sample container along with a scoring form. Each panelist tests all the samples randomly and individually, and the sensory factors of the watermelon rind product, including color, smell, taste, crispiness, oiliness, and overall acceptability, are evaluated Twenty-five student and employees from Neyshabur University of Medical Science were chosen as panelists team. Informed consent was obtained from all participants for our experiments. The panelist's gender ratio was female to male. While the panelist's ages ranged from 21 to 30 years old, 31–40 years old, over 50 years old. The panelists had all received the recipes in advance and were all non-smokers. This project was approved by the Ethics Committee of Neyshabur University of Medical Sciences, Neyshabur, Iran with the Ethics No. IR. NUMS.REC.1399.005.

2.13. Statistical analysis

The data were interpreted by analysis of variance with Duncan's multiple range test using SPSS software (SPSS, 21). All the measurements made in this study were made at least in triplicate. As no specific replication effect was detected for the experimental data (P>0.05), the data from total measurements were averaged.

3. Results and discussion

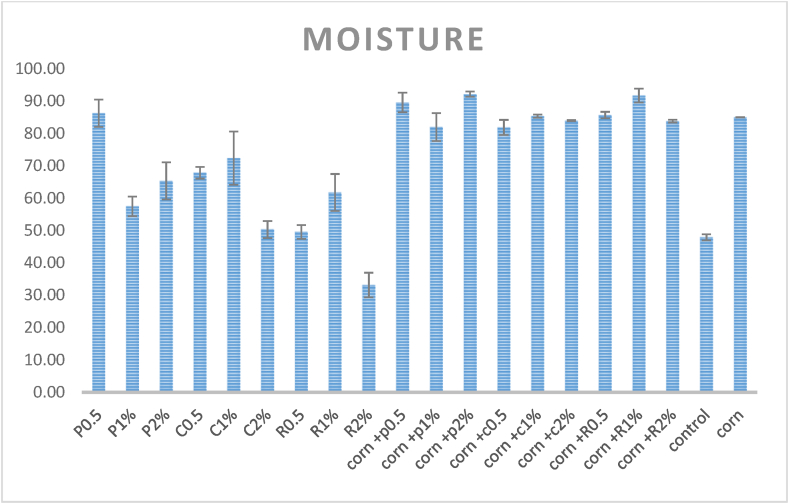

3.1. Moisture content

Moisture is one of the most important quality characteristics of fried products. During the frying process, the moisture is transferred from the inside to the surface of the food and then it is removed and the oil replaces the moisture. As can be seen in Fig. 2, the moisture retention ability of samples with different coatings is different from each other. The highest amount of moisture retention compared to the control sample was related to the formulation of corn flour and pectin gum 2%, corn flour and basil 1%, which was consistent with the results of [7]. The coating leads to an increase in the barrier property and prevents the creation of pores and cracks in the fried product [7]. The use of hydrocolloid coatings leads to moisture retention, and this is related to the ability of hydrocolloids to retain moisture [20]. As can be seen, the efficiency of basil, pectin and Tragacanth gums in concentrations of 0.5%, 1% and 2% as well as the formulation of all gums with corn flour in reducing moisture content was high. This is due to the functional characteristics of the resins, such as better gel formation and less permeability of the formed film to the exit of moisture. These findings are consistent with the chronological results of [21]. The research on potato wedges concluded that coating with hydrocolloid materials due to its blocking property led to a reduction in moisture loss during frying and considering the role of controlling water in the amount of oil absorption, the amount of oil of the coated samples was lower compared to the control sample [22]. The highest amount of moisture loss during frying was observed in samples coated with xanthan gum and pectin.

Fig. 2.

The effect of coating and formulation on the amount of moisture content during the deep-frying process.

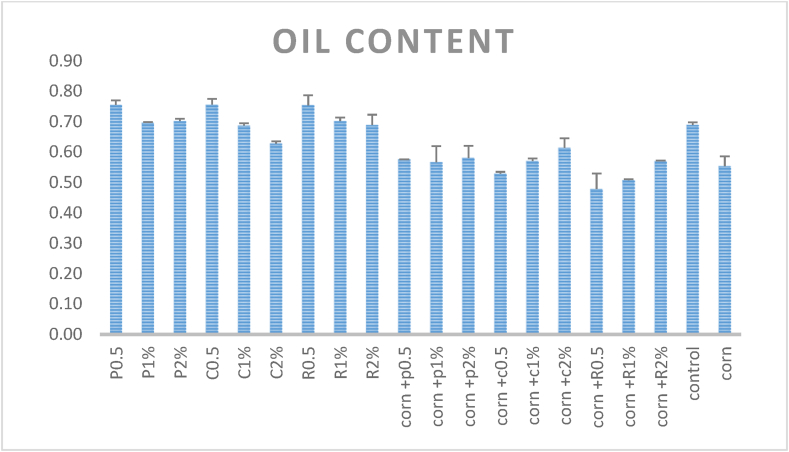

3.2. Oil content

As shown in Fig. 3, the amount of oil absorption of coated slices is different. The results clearly show that corn flour and basil gum formulations at concentrations of 0.5% and 1% had the lowest oil absorption rate of 33.68% and 29.68%, respectively, and this is probably due to the formation of gel and lower permeability. The film formed was oil, which was consistent with the results of [23]. The research they conducted on fried potato wedges, by examining the hydrocolloid coatings, they concluded that gums have the lowest fat absorption rate, due to the ability Gums are in the formation of gels or transverse connections, as well as barrier properties against moisture loss. In addition to improving strength, hydrocolloid coatings reduce the content of acrylamide and the amount of oil during frying, and also lead to an increase in the barrier property of fried slices and prevent the creation of pores and cracks in the fried product [7,9]. Oil content is one of the most important quality parameters of products during the process of deep frying in oil. Blanching pretreatment and osmotic dehydration have an effect on the amount of oil absorption of fried slices. The results clearly show that the process of osmotic dehydration leads to a decrease in oil absorption compared to freshly fried samples, and the reason for this is the simultaneous withdrawal of water from the food and the penetration of salt into the cells and the intercellular space, which is consistent with the results of [24]. By examining the effect of osmotic dehydration pretreatment on the amount of oil and quality of food during the deep-frying process of green bananas [25], concluded that osmotic dehydration pretreatment reduces oil absorption, moisture, total volume, and the frying time. In general, the process of osmotic dehydration leads to the improvement of the color, texture and reduction of the oil absorption of the sample [26]. The results obtained from this research show that the lowest amount of oil absorption related to white watermelon skin chips coated with corn flour and basil gum formulation is 0.5 and 1%, while the highest amount of oil absorption in the samples Covered with pectin, Tragacanth and basil (concentration 0.5%) was observed.

Fig. 3.

The effect of coating and formulation on the reduction of oil absorption during the deep-frying process.

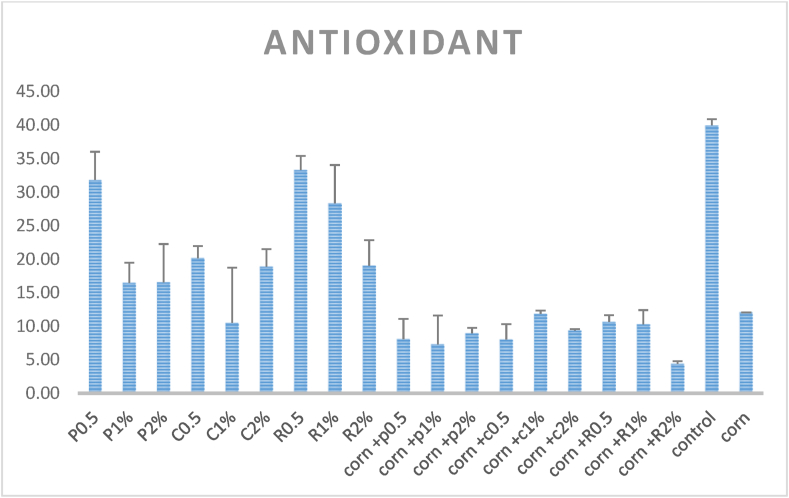

3.3. Antioxidant activity

Fig. 4 shows the effect of coating and formulation on the amount of antioxidant activity. The amount of antioxidant activity in slices of white skin of fried watermelon was reduced compared to the control sample. Among the samples coated with gum and corn flour formulation, the highest antioxidant activity was related to the 0.5% basil sample and the lowest was related to the sample coated with a combination of corn flour and basil 2% [27]. conducted research to investigate the antioxidant activity of fresh and fried samples of native Malaysian fruits and concluded that the antioxidant activity of fresh fruits was higher compared to fried samples [28]. by investigating the effect of the frying process on the antioxidant activity of two types of potatoes showed that the frying conditions are effective on the antioxidant activity and based on the applied conditions, the antioxidant activity of the fried samples in compared with the new sample, there was a significant decrease. The nutritional value and antioxidant activity depend on the cooking method, and the amount of antioxidant activity of fried samples is lower than the control.

Fig. 4.

The effect of coating and formulation on the amount of antioxidant activity and its comparison with the control sample, during the deep-frying process.

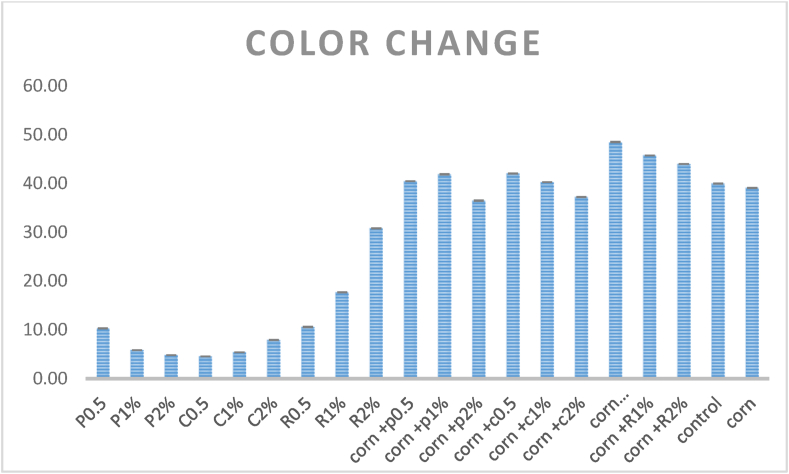

3.4. Imaging and analysis of images

Color is one of the first quality indicators of fried products, which has an effect on the acceptance or rejection of the product. The results obtained from Fig. 5 shows that the color changes (ΔE) among different gums is different from each other and the control sample. The highest amount of color change was related to the sample coated with the combination of corn flour and basil 0.5% and the lowest was related to Tragacanth 0.5%. The L* component shows the lightness of the color of the product, and the biggest change in lightness index compared to other samples was related to 2% pectin. While the lowest amount of light index changes related to the sample coated with the combination of corn flour and basil was 0.5% (the graph is not shown). Component a* show the degree of redness of the sample, the highest amount of component a* was related to the sample coated with the combination of corn flour and pectin in both concentrations of 0.5 and 2%, and the lowest was related to the sample coated with 5% It is 0% (the corresponding diagram is not shown). Component b* is the degree of yellowness of the product, and the consumers of fried products are more inclined to the product with yellow color and golden crust. The highest amount of component b* was related to the sample covered with 1% corn flour and basil, and the lowest was related to the sample covered with corn flour and 0.5% basil (the graph is not shown). The highest ΔE index corresponds to a temperature of 180 °C and time of 4 min with a 4% carboxymethyl cellulose coating. Significant color changes were observed in the samples coated with coating formulations compared to the control sample. So that the amount of components a*, and L* are higher than the control sample and component b* is lower than the control sample.

Fig. 5.

The effect of coating and formulation on the color changes of the samples during the deep-frying process

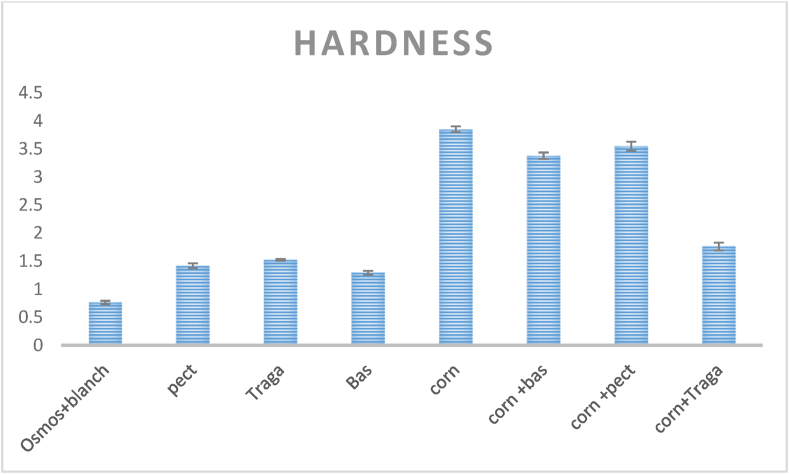

3.5. Texture characteristics

Changes in textural parameters of samples with coating at different formulations as a function of time are shown in Fig. 6. There was a significant increase (p ≤ 0.05) of hardness of the samples coated with corn flour. This increase is due to the formation of a hard shell around the slices of watermelon rind coated with corn flour due to heat. However, texture in terms of the level of hardness and tenderness of materials is related to the amount of water content, whereby the higher water content material will be tenderer than that of a lower water content material [29]. [30] that studied ultrasound-assisted osmotic process on quality of microwave vacuum drying sweet potato, explained that osmotic group pretreatment exhibited a pronounced effect on water loss and solid gain, improved the color, aroma, and taste of dried sweet potato, whereas sucrose impregnation resulted in a hard texture observed with osmotic dehydration sample. Ultrasound-assisted osmotic dehydration samples had a higher expansion ratio, lower hardness and color difference values. The hardness of sample coated with basil gum was less than the other samples coated with gums. These results with the results were inconsistent with [31]. They investigated effect of hydrocolloid coatings (basil seed gum, xanthan, and methyl cellulose) on the mass transfer kinetics and quality of fried potato strips. Hardness of samples coated with xanthan and basil seed gum was more than control and methyl cellulose -treated sample at 190 °C. This result may be related to increase of coating layer thickness on the product surface due to the addition of basil seed gum and xanthan (faster hardening of the crust).

Fig. 6.

The effect of coating and formulation on the amount of hardness and its comparison with the control sample, during the deep-frying process.

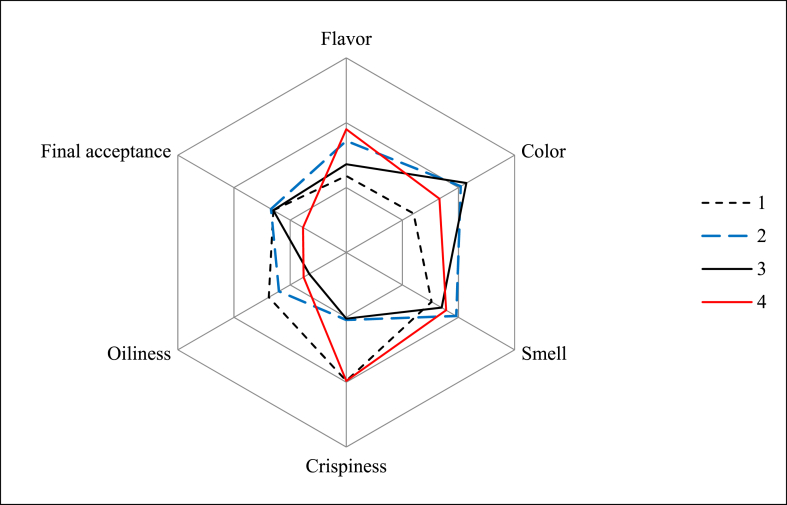

3.6. Sensory evaluation

Sensory evaluation is actually a human experience that results from our interaction with the structure of food and behavior when dealing with it. The panelists evaluated the taste, smell, color, crispiness, oiliness and overall acceptability in the samples and ranked them from 1 to 9. As Fig. 7 shows, the treatment coated with corn flour and 0.5% tragacanth gum had the best smell and the sample coated with corn flour and pectin 5.0% had the best color. The samples coated with corn flour had the highest score in terms of taste, but the overall acceptance rate of the samples coated with corn flour and basil was 0.5% higher than the other samples, and this indicates that the degree of crispiness and oil level are two parameters that have the greatest impact on the overall acceptance of the final product according to sensory evaluators.

Fig. 7.

Sensory evaluation of watermelon rind chips (1. Basil gum and corn flour, 2. Tragacanth gum and corn flour, 3. Pectin and corn flour and 4. Corn flour).

4. Conclusion

The results of this study showed that the use of hydrocolloid coatings of tragacanth gum, pectin, and basil due to the inhibiting property in reducing moisture and the controlling role in oil absorption, the oil content of the coated samples was lower than the uncoated samples. Among the studied gums, basil gum coating of 0.5% had the highest amount of color changes and reduced oil absorption in fried slices of white watermelon skin compared to uncoated samples. The coating formulation of corn flour and 2% pectin had the highest amount of moisture loss compared to the uncoated sample. In this research, the samples coated with pectin gum with a concentration of 0.5% had the highest antioxidant activity, and the sample coated with corn flour and basil 0.5% had the highest overall acceptance rate compared to other samples. Based on the results of this research, it is possible to consider the pre-treatments of enzyme removal, osmotic dehydration and coating formulation of corn flour and basil, Tragacanth and pectin gums as a suitable and competitive covering material with basil, Tragacanth and pectin gums to reduce the oil content of fried slices of white watermelon skin was taken into account.

Author contribution statement

Alieh Rezagholizade-shirvan: Conceived and designed the experiments; Performed the experiments, Wrote the paper.

Mahboubeh Kalantarmahdavi: Analyzed and interpreted the data; Wrote the paper.

Mohamad Reza Amiryousefi: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Data availability statement

Data will be made available on request.

Additional information

No additional information is available for this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

Hereby, we extend our gratitude to Neyshabur University of Medical Sciences (project number 98-01-133). This study was supported by funding from grant Dr. Kazemi Ashtiani of the Iran's National Elites Foundation. The authors would like to thank all those who helped us during this project especially Ms. Fahimeh Ebrahimi and Ms. Somayeh Nasiri.

References

- 1.Perkins-Veazie P., Collins J. Flesh quality and lycopene stability of fresh-cut watermelon. Postharvest Biol. Technol. 2004;31:159–166. [Google Scholar]

- 2.Urbaneja A., Grout T.G., Gravena S., Wu F., Cen Y., Stansly P.A. The Genus Citrus. Elsevier; 2020. Citrus pests in a global world; pp. 333–348. [Google Scholar]

- 3.Kumar P. Watermelon-utilization of peel waste for pickle processing. Indian Food Pack. 1985;39:49–52. [Google Scholar]

- 4.Chang C., Wu G., Zhang H., Jin Q., Wang X. Deep-fried flavor: characteristics, formation mechanisms, and influencing factors. Crit. Rev. Food Sci. Nutr. 2020;60:1496–1514. doi: 10.1080/10408398.2019.1575792. [DOI] [PubMed] [Google Scholar]

- 5.Liu Y., Tian J., Zhang T., Fan L. Effects of frying temperature and pore profile on the oil absorption behavior of fried potato chips. Food Chem. 2021;345 doi: 10.1016/j.foodchem.2020.128832. [DOI] [PubMed] [Google Scholar]

- 6.Ustunol Z. Edible Films and Coatings for Food Applications. Springer; 2009. Edible films and coatings for meat and poultry; pp. 245–268. [Google Scholar]

- 7.Yu L., Li J., Ding S., Hang F., Fan L. Effect of guar gum with glycerol coating on the properties and oil absorption of fried potato chips. Food Hydrocolloids. 2016;54:211–219. [Google Scholar]

- 8.Jia B., Fan D., Li J., Duan Z., Fan L. Effect of guar gum with sorbitol coating on the properties and oil absorption of French fries. Int. J. Mol. Sci. 2017;18:2700. doi: 10.3390/ijms18122700. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Trujillo‐Agudelo S., Osorio A., Gómez F., Contreras‐Calderón J., Mesías‐Garcia M., Delgado‐Andrade C., Morales F., Vega‐Castro O. Evaluation of the application of an edible coating and different frying temperatures on acrylamide and fat content in potato chips. J. Food Process. Eng. 2020;43 [Google Scholar]

- 10.Taiwo K.A., Eshtiaghi M.N., Ade‐Omowaye B.I., Knorr D. Osmotic dehydration of strawberry halves: influence of osmotic agents and pretreatment methods on mass transfer and product characteristics. Int. J. Food Sci. Technol. 2003;38:693–707. [Google Scholar]

- 11.Amiryousefi M.R., Mohebbi M. Neural network approach for modeling the mass transfer of potato slices during osmotic dehydration using genetic algorithm. Afr. J. Agric. Res. 2010;5:70–77. [Google Scholar]

- 12.Khodaei D., Oltrogge K., Hamidi-Esfahani Z. Preparation and characterization of blended edible films manufactured using gelatin, tragacanth gum and. Persian gum, Lwt. 2020;117 [Google Scholar]

- 13.Lee J., Durst R., Wrolstad R. AOAC official method 2005.02: total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method. Off. Methods Anal. AOAC Int. (OMA) 2005;2 [PubMed] [Google Scholar]

- 14.Amiryousefi M.R., Mohebbi M., Khodaiyan F., Ghazizadeh Ahsaee M. Multi-objective optimization of deep-fat frying of ostrich meat plates using multi-objective particle swarm optimization (MOPSO) J. Food Process. Preserv. 2014;38:1472–1479. [Google Scholar]

- 15.Rezagholizade-shirvan A., Masrournia M., Fathi Najafi M., Behmadi H. Synthesis and characterization of nanoparticles based on chitosan-biopolymers systems as nanocarrier agents for curcumin: study on pharmaceutical and environmental applications. Polym. Bull. 2023;80:1495–1517. [Google Scholar]

- 16.Rezagholizade-shirvan A., Najafi M.F., Behmadi H., Masrournia M. Preparation of nano-composites based on curcumin/chitosan-PVA-alginate to improve stability, antioxidant, antibacterial and anticancer activity of curcumin. Inorg. Chem. Commun. 2022;145 [Google Scholar]

- 17.Shahidi F., Zhong Y. Measurement of antioxidant activity. J. Funct.Foods. 2015;18:757–781. [Google Scholar]

- 18.Amiryousefi M.R., Mohebbi M., Tehranifar A. Pomegranate seed clustering by machine vision. Food Sci. Nutr. 2018;6:18–26. doi: 10.1002/fsn3.475. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Cruz G., Cruz-Tirado J., Delgado K., Guzman Y., Castro F., Rojas M.L., Linares G. Impact of pre-drying and frying time on physical properties and sensorial acceptability of fried potato chips. J. Food Sci. Technol. 2018;55:138–144. doi: 10.1007/s13197-017-2866-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Martínez D.F., Castellanos F.J., Bravo J.E. Application of edible coatings in green plantain slices subjected to deep-fat frying. Ingeniería y competitividad. 2015;17:91–99. [Google Scholar]

- 21.Bouaziz F., Koubaa M., Neifar M., Zouari-Ellouzi S., Besbes S., Chaari F., Kamoun A., Chaabouni M., Chaabouni S.E., Ghorbel R.E. Feasibility of using almond gum as coating agent to improve the quality of fried potato chips: evaluation of sensorial properties. LWT--Food Sci. Technol. 2016;65:800–807. [Google Scholar]

- 22.Kim D.N., Lim J., Bae I.Y., Lee H.G., Lee S. Effect of hydrocolloid coatings on the heat transfer and oil uptake during frying of potato strips. J. Food Eng. 2011;102:317–320. [Google Scholar]

- 23.Mousa R.M.A. Simultaneous inhibition of acrylamide and oil uptake in deep fat fried potato strips using gum Arabic-based coating incorporated with antioxidants extracted from spices. Food Hydrocolloids. 2018;83:265–274. [Google Scholar]

- 24.Udomkun P., Innawong B. Effect of pre‐treatment processes on physicochemical aspects of vacuum‐fried banana chips. J. Food Process. Preserv. 2018;42 [Google Scholar]

- 25.Ikoko J., Kuri V. Osmotic pre-treatment effect on fat intake reduction and eating quality of deep-fried plantain. Food Chem. 2007;102:523–531. [Google Scholar]

- 26.Pandiselvam R., Tak Y., Olum E., Sujayasree O., Tekgül Y., Çalışkan Koç G., Kaur M., Nayi P., Kothakota A., Kumar M. Advanced osmotic dehydration techniques combined with emerging drying methods for sustainable food production: impact on bioactive components, texture, color, and sensory properties of food. J. Texture Stud. 2021;53:737–762. doi: 10.1111/jtxs.12643. [DOI] [PubMed] [Google Scholar]

- 27.Ali-Hassan S.-H., Fry J.R., Abu-Bakar M.-F. Antioxidative phytochemicals and anti-cholinesterase activity of native kembayau (Canarium odontophyllum) fruit of Sabah, Malaysian Borneo. J. Nutr. Food Sci. 2013;4 [Google Scholar]

- 28.Kita A., Bąkowska-Barczak A., Hamouz K., Kułakowska K., Lisińska G. The effect of frying on anthocyanin stability and antioxidant activity of crisps from red-and purple-fleshed potatoes (Solanum tuberosum L.) J. Food Compos. Anal. 2013;32:169–175. [Google Scholar]

- 29.Hani M.N.F., Zahidah W.W.N., Saniah K., Irwani H.M. Effects of drying on the physical characteristics of dehydrated watermelon rind candies. J. Trop. Agric. Food Sci. 2014;42:115–123. [Google Scholar]

- 30.Lagnika C., Huang J., Jiang N., Li D., Liu C., Song J., Wei Q., Zhang M. Ultrasound-assisted osmotic process on quality of microwave vacuum drying sweet potato. Dry. Technol. 2018;36:1367–1379. [Google Scholar]

- 31.Zamani‐Ghalehshahi A., Farzaneh P. Effect of hydrocolloid coatings (Basil seed gum, xanthan, and methyl cellulose) on the mass transfer kinetics and quality of fried potato strips. J. Food Sci. 2021;86:1215–1227. doi: 10.1111/1750-3841.15655. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.