Abstract

The color of any food is influenced by several factors, such as food attributes (presence of pigments, maturity, and variety), processing methods, packaging, and storage conditions. Thus, measuring the color profile of food can be used to control the quality of food and examine the changes in chemical composition. With the advent of non-thermal processing techniques and their growing significance in the industry, there is a demand to understand the effects of these technologies on various quality attributes, including color. This paper reviews the effects of novel, non-thermal processing technologies on the color attributes of processed food and the implications on consumer acceptability. The recent developments in this context and a discussion on color systems and various color measurement techniques are also included. The novel non-thermal techniques, including high-pressure processing, pulsed electric field, ultrasonication, and irradiation which employ low processing temperatures for a short period, have been found effective. Since food products are processed at ambient temperature by subjecting them to non-thermal treatment for a very short time, there is no possibility of damage to heat-sensitive nutrient components in the food, any deterioration in the texture of the food, and any toxic compounds in the food due to heat. These techniques not only yield higher nutritional quality but are also observed to maintain better color attributes. However, suppose foods are exposed to prolonged exposure or processed at a higher intensity. In that case, these non-thermal technologies can cause undesirable changes in food, such as oxidation of lipids and loss of color and flavor. Developing equipment for batch food processing using non-thermal technology, understanding the appropriate mechanisms, developing processing standards using non-thermal processes, and clarifying consumer myths and misconceptions about these technologies will help promote non-thermal technologies in the food industry.

Keywords: Non-thermal technologies, Pigments, Food quality, Color measurement

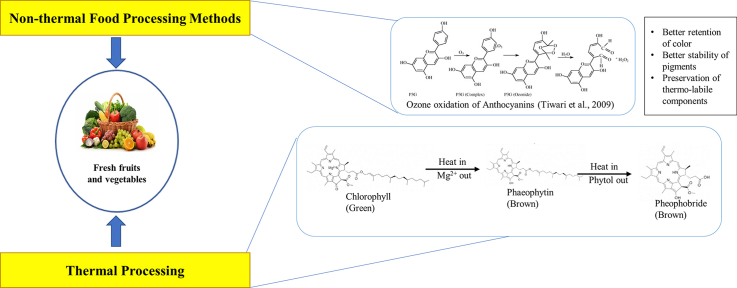

Graphical abstract

Highlights

-

•

Color attributes of food products indicate quality affecting consumer acceptability.

-

•

Naturally occurring food coloring pigments are highly susceptible to thermal degradation.

-

•

Non-thermal techniques are used in preservation of nutritional quality and retention of color.

1. Introduction

Product appearance is a prime feature that establishes a substantial direct and indirect impression on the consumer's quality insight. However, it is an all-encompassing feature considering color, surface shine, size, shape, texture, mass, and others (Nowacka et al., 2019). Among all the individual dimensions of appearance, color is a critical feature that chiefly influences the overall product's acceptability. For instance, if the product's color is improper or undesirable, the other foremost quality features, i.e., texture and flavor, are generally not arbitrated. Several other organoleptic characteristics, for instance, the intensity of sweetness and freshness of the produce, are also directly correlated with the color profile of the food matrix (Dadan and Nowacka, 2021).

The present century consumer demands natural food products that are minimally processed and contain no marginal chemical additives and preservatives. Conventional food processing and preservation approaches, such as blanching, pasteurization, and sterilization, have been used extensively for ages (Jabbari et al., 2018). Thermal processing manifests multifaceted influences on several nutritional and sensorial aspects of foods. For instance, heat-induced enhancements of nutritional quality consider enhanced denaturation and digestibility of proteins, starch gelatinization, and inactivation of antinutritional complexes (Sajdakowska et al., 2018). On the other hand, thermal processing destroys heat-sensitive vitamins, decreased the biological quality of proteins, lipid oxidation, and destruction of natural color pigments and flavor compounds (Dadan and Nowacka, 2021). Heat-related deterioration of natural color pigments results in off-color development and depreciates their biological viabilities. Unfortunately, these color modifications deeply influence the consumer's preferences and thus cause a significant loss of product marketability (Lyerly and Reeve, 2015). Researchers have tried to improve the processing fundamentals to abate their detrimental effects on natural food pigments. However, their complete obliteration is still a massive task for the emerging food processing industries. The trend of the global food market in the last decade affirms the utilization of non-thermal processing techniques amalgamated with surging concerns for natural, green, and minimally processed food preparations (Hemmerling et al., 2016). Presently, some common approaches include cold plasma, ozone, high hydrostatic pressure, irradiation, ultraviolet technology, pulsed electric field, ultrasound, and supercritical technology are extensively explored by the domestic as well as the global food processing industries (Nowacka et al., 2021; Rybak et al., 2021). These processing advancements ensure adequate safety of the products and guarantee proficient conservation of chemical and physical features, bio-viabilities of functional compounds, and maintaining natural food pigments (Singh et al., 2016).

In the present era, where conventional thermal methods for food processing and preservation are transitioned into green and non-thermal innovative approaches, a comprehensive understanding of process-oriented quality is indispensable. Furthermore, an apparent predisposition towards a healthier lifestyle is the dominant driving force for reshaping food trade objectives and their quality standpoint (Petrescu et al., 2013). So, it becomes vital to establish a functional hyphenation between the non-thermal techniques and their respective impacts on the color of the food products. This review aimed to assert the impact of non-thermal food processing techniques on the color profile and natural pigments of various food materials. The general color systems approach for quantifying color characteristics, natural pigments in plant tissues, and the mechanism and changes in the color because of the alteration in natural food pigments after different non-thermal processes are reported.

2. Color systems and measurement

Some of the widely used color coordinates systems or color spaces for defining the color of food materials include RGB (red, green, and blue), Hunter L a b, Commission Internationale de l’Eclairage's (CIE) L*a*b*, CIE XYZ, CIE L*u*v*, CIE Yxy, and CIE LCH (Pathare et al., 2013). The difference among these systems lies in the symmetry of color space and the color coordinates used to define the points. CIE, which stands for the Commission Internationale de l'Eclairage, conveyed that there are three color receptors in the human eye to recognize the three primary colors, i.e., red, green, and blue. Combinations of primary colors can perceive all other colors. The specific amount of these three colors, red, green, and blue, required to develop a specific color are tristimulus values, denoted by X, Y, and Z, respectively. The most widely used color space notation is CIE XYZ, given by the international commission on Illumination. This system follows the trichromatic principle and employs imaginary positive primaries, X, Y, and Z, instead of real red, green, and blue primaries. These are used for the calculation of chromaticity coordinates indicated by lowercase letters x (red), y (green), and z (blue), respectively. The value of x is calculated using Eq. (1)

| Eq. (1) |

Likewise, the value of y and z can be calculated by replacing the value of X with Y and Z in the numerator (Pathare et al., 2013).

3. Color measurement techniques and color quantification

Color measurement is a crucial and widespread practice in food product analysis and quality control measures. There are several methods to determine and identify the color of any object or sample as close to the visual perception of the human eye. These methods include but are not limited to Mores color diagrams, digital colorimeters, spectrophotometers, and computer vision systems.

The Hunter Lab L* a* b* and modified CIE system known as CIELAB color spaces are popularly used in the food industries. The CIELAB explains color coordinates in terms of L*, a*, and b*, where L* defines the measurement of lightness. In contrast, a* and b* represent the redness-greenness and blueness-yellowness, respectively (Wrolstad and Smith, 2017). When a* and b* take up the positive sign (+a*, +b*), they define the red and yellow colors, respectively. On the other hand, parameters with a negative sign (-a* and –b*) represent the green and blue color profile (Jaramillo-Sánchez et al., 2018). The color member of greyscale and between black and white can be defined based on lightness measured by L* color space. In addition, chroma (C*) and hue (h*) are also measured to give the color profile of food materials. They are accounted for as quantitative and qualitative attributes of the colorfulness of material, respectively. The Chroma determines the intensity of a hue variation compared with a grey color with some lightness. Higher values of chroma indicate that humans perceive a higher degree of color. Hue defines the difference between a specific color concerning a grey color with the same lightness and is related to a change in absorbance of color at a different wavelength. A higher hue angle represents a lesser yellow character in the assays. An angle of 0° or 360° represents a red hue, while angles of 90°, 180°, and 270° represent yellow, green, and blue hues, respectively (Pathare et al., 2013).

A computer vision system (CVS) consists of a high-resolution digital camera, a diffused lighting system, and a computer or controller. CVS captures high-resolution images of the object or sample area at regular intervals. These images can be processed or analyzed with a digital controller or computer for various objectives to quantify or estimate different quality parameters (Goñi and Salvadori, 2017). The primary objective of CVS is to determine the color distribution of the sample or sample area in terms of various color parameters (e.g., RGB values) or indices. CIE has established the three ordinate (L*, a*, and b*) color spaces to specify all the colors visually perceptible to the human eye. CVS obtains the Lab or RGB vector matrix for each pixel over the sample area. CVS applications are vast in process, quality control measures, and industrial management perspectives (Ma et al., 2016).

| Eq. (2) |

Different color parameters are considered estimates of the color profile of different samples. The color parameters primarily used in food research and industries are described below. Total color difference or change (ΔE) estimates the color difference between two objects or data points (L*, a*, and b*) values. The ΔE represents the “difference in sensation” for any color measurement system, i.e., CIE or Hunter. It is calculated as the Euclidean distance between the two points in tristimulus color space by following Eq (2)

ΔL, Δa, and Δb differ between the two samples' L*, a*, and b* values. The main drawback of the ΔE values is that it does not consider the directional variation between ordinates, i.e., there can be an infinite number of points (samples) with the same Euclidean distance from the reference points (reference or control sample). That means the ΔE value does not represent the property of a sample but the change in color parameters. For best practices, ΔE should be used when the color variation is antivectorial or presented with other color parameters like chroma and hue angle.

3.1. Chroma and hue

Chroma is considered as the purity of color or colorfulness of the sample. Chroma is independent of the lightness of the color and is contributed by the spectral reflectance of the sample. It is determined as the Euclidean distance of the color vector (L, a, b) for a sample from the lightness axis. It can be calculated for a particular sample by following Eq. (3)

| Eq. (3) |

Hue is the angular position of a color vector around a central axis in the color space. The hue angle can be calculated as the arc tangent of the ratio of yellowness to redness, as Eq. (4).

| Eq. (4) |

3.2. Whiteness index

The whiteness index indicates the closeness of surface color properties to the perfect reflecting diffuser or ideal white surface. It can be calculated by following Eq. (5) for CIE color space readings and Eq. (6) for Hunter's L, a, and b values.

| Eq. (5) |

| Eq. (6) |

3.3. Browning index

Browning Index is the color parameter that indicates the brownness of the sample (Rani et al., 2020). It can be calculated by following Eq. (7).

| Eq. (7) |

4. Color pigments

Natural color pigments are gaining extensive admiration in the food processing industry. In the last decade, comprehensive investigations have been carried out to withhold and stabilize these natural color constituents in various foods and extract matrixes (Dadan and Nowacka, 2021). The central idea behind these efforts is to substantiate these natural color constituents as an efficient replacement for synthetic colorants (Rodriguez-Amaya, 2019b). Although several criteria for classifying these natural color pigments are recognized depending on the relative differences in color strength, degree of solubility, susceptibility towards environmental conditions, and permanency in the manifestation of other chemical agents (Ngamwonglumlert et al., 2017). The characteristics and stability of various pigments present in food are summarized in Table 1.

Table 1.

Molecular formulae and characteristic chemical behavior of various pigments towards different conditions.

| Pigments | Solvent System | Hue Spectrum | Impact of environmental & chemical conditions |

|---|---|---|---|

|

Anthocyanin Phenolic compounds Flavylium-C15H11O+ |

Water | Red, purple, to blue hue as influenced by the (-OH) and (-O-CH3) group's substitution, - Increase in the number of (-OH) groups leads the color to a more “Bluish shade.” - Increase in the number of (-OCH3) groups leads the color to a more “Reddish shade.” |

Temperature Acylated, glycosylated, or methylated anthocyanins are more thermostable than hydroxylated anthocyanidins. pH pH ≤ 2 – Red hue because of predominance of the “flavylium cation” form of anthocyanin, highly soluble and stable. pH 3 to 6 – Purple hue because of hydration at second carbon of flavylium cation, comparatively less stable. pH ≥ 7 –Blue hue because of deproteination of flavylium cation and generates blue quinoidal alkali substances. Oxygen Highly susceptible towards reaction with oxygen. |

|

Carotenoid Isoprene compounds (Carotenes; α-carotene, β-carotene, and lycopene) CH2=C(CH3)−CH=CH2 Oxygenated isoprenoids Xanthophyll (lutein and zeaxanthin) C40H56O2 |

Oil | Yellow, orange, to red dependable from distribution and number of double bonds |

Temperature Owing to unsaturation high temperature processinginstigates substantial losses, whereas moderate temperature conditions enhance “bio-availability”. pH Low pH conditions assist in the transition of some trans unsaturated bonds to cis configuration. Oxygen Unsaturation of the isoprenoid units render the pigment highly susceptible to oxidative deterioration which is subsequently enhanced in presence of pro-oxidants (metal ions, moisture, and light). |

|

Chlorophyll Porphyrin compounds Chlorophyll-a C55H72O5N4Mg Chlorophyll-b C55H70O6N4Mg |

Organic solvent and oil | Different intensities of green hue |

Temperature Replacement of Magnesium ion with hydrogen ion is prompted by high temperature conditions. pH Low pH conditions result in the removal of the central Mg+ion thereby forming “Pheophytin” (olive color) followed by removal of phytol ring and forming “Pheophorbide” (brown colour). Oxygen Not susceptible. |

|

Betalain Tyrosine compounds Betanin (C24H26N2O13) Vulgaxanthin-I (C14H17N3O7) |

Water | Betacyanins− Red to violet color. Betaxanthins− Yellow to orange color. |

Temperature High temperature instigates substantial structure deterioration of the structure. pH Behave comparable to anthocyanins, color intensities varies as per pH withprominent stability in the pH range of (3.0–7.0) pH ≤ 3violet in color, pH ≥ 7 blue in color. Oxygen Susceptibility of the pigment decrease with the relative increase in oxygen concentration. |

4.1. Anthocyanin

Anthocyanins are among the most common and widespread water-soluble vacuolar natural pigments accounting for a hue ranging from red-purple, and blue (Table 1) (Rodriguez-Amaya, 2019b). Regarding molecular structure and behavior, anthocyanins are associated with the parent class of molecules called “Flavonoids.” Chemically, anthocyanins are glycosides of polyhydroxy and poly ethoxy derivatives of 2- phenylbenzopyrylium or flavyliumcations (Rodriguez-Amaya, 2016). Variability in hues imparted by anthocyanins is chiefly dependent on a broad spectrum of factors such as (1) the extent of methylation of hydroxyl groups, (2) the sites of glycosylation, (3) the number of aliphatic and aromatic acid residue substitutes on the glucosyl units (Rodriguez-Amaya, 2019a). Additionally, the value of imparted paint depends on the double bonds of oxygen in the heterocyclic ring. The unsaturation of the basic structural unit renders it considerably susceptible to molecular oxygen (Ribeiro and Veloso, 2021). As mentioned earlier, the extent of methylation of hydroxyl groups is the most prominent out of all the factors. As hydroxyl group methyl increases, the hue gradually shifts from a “bluish to reddish tint” (Fernández-López et al., 2020). Owing to all these vital structural aspects, anthocyanins of different food articles manifest different colors and intensities. (Rodriguez-Amaya, 2019a). These pigments' dynamic and versatile behavior under different chemical conditions (such as; temperature, pH, oxygen, and enzymes) render them suitable as biochemical and chemical indicators (Pratap-Singh et al., 2018). Among all the chemical stimulates, variation in pH is the most crucial since it significantly influences the rate of methylation of hydroxyl groups, thereby changing into different hues, all-inclusive from red, purple, blue, violet, and yellow (Marszałek et al., 2017). Various organic and inorganic molecules considerably impact the stability of anthocyanin molecules in food matrices, e.g., vitamin C (Rodriguez-Amaya, 2019a). Recent investigations have shown that substituting basic anthocyanidin units with various groups, for example, methyl, acyl, and glycosyl impart significant thermostability to anthocyanins. Compared to carotenoids, all the substituted and non-substituted structural variants of anthocyanidin molecules are less susceptible to degradation at elevated temperatures (Fernández-López et al., 2020).

4.2. Carotenoids

Carotenoids are usually amassed in the chloroplast-dominant parts of the plant, along with roots, seeds, and fruits (Rodriguez-Concepcion et al., 2018). Carotenoids manifest a backbone of isoprenoid units associated with a long chain. The molecular structure of the chromophore system is based on the framework of 40 interlinked carbon atoms. The fortitude of the chromophore system is based on eight linked isoprenoid units resulting in the formation of “tetraterpenes” (C40H64) (Domonkos et al., 2013). The numbers and the distribution pattern of unsaturation of the molecule are responsible for imparting a spectrum of hues ranging from red, orange, and yellow in different foods (Table 1). Genetic makeup, cultivar influences, the season of cultivation, stage of plant and fruit maturity, harvesting, postharvest handling, and storage practices, as well as processing, are a few of the most common factors impacting the overall content, composition, techno functionalities, and bio-viabilities of carotenoids (Fernández-López et al., 2020). In the context of the food article in which the pigment is present, its stability is dependent mainly on intrinsic factors (oxygenation, configuration, esterification, substitution of the molecule) and extrinsic factors (composition, physical, and chemical properties of the food matrix where the pigment is localized) (Finley et al., 2018). Structural disintegration, for instance, cuts, bruises, injuries, and skin breakage, hasten carotenoid molecules' breakdown because of enzymes' decompartmentalization and exposure to oxygen and light (Rodriguez-Amaya, 2016). Another factor that progressively increases the rate of carotenoid degradation is significantly high-temperature treatments (Pratap Singh et al., 2018).

4.3. Chlorophylls

The green color of plants is attributed to a specific category of natural food pigment, i.e., “chlorophyll."In terms of molecular structure, a chlorophyll molecule has four integral parts: the pyrrole ring, porphyrin ring, magnesium ion, and phytol chain (Arnold et al., 2014). Chlorophyll pigments naturally manifest in two primary forms (1) Chlorophyll-a, with a color spectrum in the hue range of “blue to green.” The molecular structure is differentiated by the presence of a methyl group (–CH3) at C3 and (2) Chlorophyll-b, which manifests a color spectrum in the hue range of “yellow to green."The molecular structure is differentiated by a formyl group (–CHO) at C3 (Table 1). In the natural distribution system, Chlorophyll-a is three times that of chlorophyll-b, i.e., in a ratio of 3:1 (Espinosa Alvarez et al., 2020). As per the investigation carried out by Sledz et al. (2016), the relative amount of chlorophyll pigment in the plant tissue is chiefly influenced by the genetic makeup of the concerned plant, cultivar influences, conditions of cultivation, particularly with the length of the day (exposure to sunlight). Out of all the factors mentioned earlier, the extent of sunlight exposure is decisive because it provides solar energy, which the plant utilizes to synthesize chlorophyll (Tao et al., 2019). Regarding stability, the chlorophyll molecule is highly versatile in its variable susceptibility toward enzymatic and chemical degradation (Medina-Meza et al., 2015). Apart from the structural distinctions between pigment forms, they also demonstrate variable susceptibilities towards heat treatment. As per the literature, chlorophyll-b is testified to be more stable against high-temperature processing than chlorophyll-a, which can be attributed to the polar nature (the electron-withdrawing tendency) of the formyl group present at C3 (Singh et al., 2015). There are several chemical (acid and enzymes), physical (structural disruptions, cuts, and bruises), and thermal (high temperature) conditions that prompt the breakdown of green-colored chromophores into different compounds (Sledz et al., 2016). Primarily, acidic conditions (pH of 3.5–5.0) complemented with high temperature are responsible for releasing central magnesium ions, thereby breaking down the intense green chromophore into olive green colored pheophytin (Rodriguez- Amaya, 2019a). The sequence of events further progressed toward eliminating the phytol chain, forming pheophorbide, and changing the color from olive brown to dull brown (Ribeiro and Veloso, 2021). Another foremost reason behind chlorophyll breakdown is the enzyme “chlorophyllase,” which catalyzes eliminating the phytol chain. Chlorophyllase is a hydrolytic enzyme that hydrolyses the ester linkage between the central moiety and the phytol chain (Singh et al., 2016). The enzymatic degradation results in comparatively stable chlorophyllides than the parent compounds (Sledz et al., 2016). A few of the technological approaches that are widely employed to mitigate the stability of these pigments are, complexing them with copper and zinc ions, enzyme-assisted formation of chlorophyllide, non-thermal processing, and neutralization of acids (Rodriguez-Amaya, 2019a).

4.4. Betalains

Another class of water-soluble natural plant-based pigments is betalains. The basic building block of betalains' molecular structure is a nitrogen-containing-heterocyclic ring. Although all the betalains are tyrosine-derived pigments following the structural distinctiveness and the hue manifested, they are broadly classified into two categories (1) Betacyanin: This class entails betalain pigments that contribute to a hue from violet to reddish tint. Examples of widespread betacyanin are; neobetanin (pitaya and red beet), isobetanin (cactus pear), pro betanin (amaranth), and betanin (beetroot) (Janiszewska-Turak et al., 2021) (2) Baxanthins: This group of pigments takes into an account of all those betalain pigments which contributes to orange to yellow color (Table 1). Examples of widespread betaxanthins pigments are; portulaxanthin (crayfish), indicaxanthin (red dragon fruit, prickly pear), vulgaxanthin (beetroots, yellow beet), miraxanthin (spinach, broccoli, peas, egg yolks) (Laqui-Vilca et al., 2018). Red beetroot, i.e., Beta vulgaris L., is delegated as the chief natural source of betalains. (Fathordoobady et al., 2016). As mentioned above, apart from beetroots, betalains can also be obtained from several other food sources such as sea foods (salmon, trout, krill, shrimp, crayfish), fruits (cactus, pear, pitaya), vegetables (kale, spinach, broccoli, peas, lettuce) and microbes (algae, fungi, and bacteria) (Nowacka et al., 2019; Ribeiro and Veloso, 2021). Betalains are produced by cyclo-DOPA (cyclo-3,4-dihydroxyphenylalanine), a secondary metabolite acquired from tyrosine. Cyclo-DOPA reacts with betalamic acid, resulting in the chromophore's basic molecular assembly (Fernández-López et al., 2020). Versatile color and their corresponding intensities are remarkably influenced by betacyanin's and betaxanthin's substitutions (Ribeiro and Veloso, 2021). In the case of betacyanin, variable substitutions on R1 and R2 impart colors ranging from purple to red. In contrast, in the case of betaxanthin, variable side chains consisting of different amino acids or amines are responsible for a vast range of orange to yellow (Rodriguez-Amaya, 2019b).

In terms of stability, betalains are not much susceptible to low pH degradation, which substantiates their usage in fruit-based products with a pH range of 3.0–7.0 (Flores-Mancha et al., 2020). Betalains are significantly susceptible to molecular oxygen-induced degradation. According to Chhikara et al. (2019), the speed of betalain degradation increases linearly, corresponding with an increase in oxygen concentration. This class of chromophores is also susceptible to high temperature-induced breakdown (Celli and Brooks, 2017). Usually, the pigment molecules follow the first-order reaction kinetics during their high temperature-induced degradation. The rate of reaction is directly proportional to the reaction temperature. The thermolabile nature of betalains makes their high-temperature-assisted extraction obsolete and dysfunctional for instance, supercritical fluid extraction (SFE) is not suitable for the extraction of betalains. Furthermore, this class of chromophores also manifests photo lability because of which they are preferred to be stored under cold, dry, and dark conditions (Fernández-López et al., 2020).

5. Changes in the color pigments of food during the non-thermal process

The following section discusses the impact of various non-thermal techniques on the color properties and the stability of selected natural pigments.

5.1. Cold plasma technology

The cold plasma processing of food materials is a non-thermal technique for sterilizing food materials. Several gases, such as helium and argon, or their combinations with oxygen, are utilized to produce plasma (Ucar et al., 2021). Several researchers evaluated the effect of cold plasma treatment on the color profile of food materials, and recent studies have been listed in Table 2. The orange juice after cold pre-treatment showed a slight reduction in chroma and hue angle values. The hue angle of 90° represents pure yellow, and orange juice showed a hue angle of 95.47°, very close to pure yellow. Plasma treatment caused a maximum reduction of 2° in the hue angle, considered very low, and orange juice approximates yellow color. Thus, from the analysis, it could be stated that cold plasma did not affect the color profile significantly (Almeida et al., 2015). Atmospheric cold plasma exposure of blueberries resulted in darkening and increased red and blue colors of blueberry surfaces due to declining L* values and an increase of a* and b* (Lacombe et al., 2015). The degradation mechanism for anthocyanin suggests that ozone plays an important role in the oxidative cleavage of chromophores. The cold plasma treatment increased the saffron samples' L*, a*, b*, ΔE, chroma, and hue angle values (Darvish et al., 2022). Similarly, non-thermal plasma treatment significantly changed sesame and sunflower seed oil color parameters (Afshar et al., 2022). Treatment of camu-camu with cold plasma with excitation frequencies of 200, 420, 583, 698, or 960 Hz showed a slight reduction in L* value, but the influence of change in frequency was non-significant (de Castro et al., 2020). The reduced lightness of the sample is related to the degradation of bioactive compounds leading to a darker compound. The increase of excitation frequencies considerably declined a*, indicating the loss of bright red color due to anthocyanin degradation. Besides, an increase in frequency also showed elevation in values of b*, but the difference was significant at the highest frequency, i.e., 960 Hz, indicating a more yellowish color. However, all these color changes led to samples with an overall color difference of less than 1.5, which is very small to be perceived by the human eye. Hence, color change by cold plasma treatment will not interfere with the consumer's decisions. In a study investigating the effects of cold plasma application at different voltages (50, 60, and 70 kV) on fried chicken during the storage period, no significant difference was observed in the L*, a*, and b* values of the chicken between the control and treatment groups during the same storage period (Zhang et al., 2022).

Table 2.

Effect of cold plasma treatment conditions on colour profile of different food materials.

| Food product | Treatment conditions | Influence on colour profile | References |

|---|---|---|---|

| Orange juice | Direct plasma exposure (in) Indirect plasma field (out) Time: 15,30,45,60 s |

L* was slightly increased Values of chroma increased. Hue reduced |

Almeida et al. (2015) |

| Meat samples | Direct cold plasma Voltage: 70 kV for 180s |

Cold plasma treatment significantly reduced a* and b* values but there was no effect on L* value | Gao et al. (2019) |

| Blueberries | Frequency: 47 kHz, Power consumption: 549 W Time: 0, 15, 30, 45, 60, 90, and 120 s |

Colour parameters L* and a* were significantly affected by 120 s treatment, while b* values were affected by 45 s. | Lacombe et al. (2015) |

| Green coconut | Atmospheric cold plasma Frequency: 200, 400, 550 and 730 Hz Voltage: 15–20 kV Time: 15 min |

Presented slight colour difference ΔE < 2, which indicated no noticeable colour change. | Porto et al. (2020) |

| Camu-camu juice | Atmospheric cold plasma Frequency: 200, 420, 583, 698 or 960 Hz Voltage: 24 kV |

Cold plasma significantly reduced L* value. Increase of excitation frequency reduced a* and b* | de Castro et al. (2020) |

| Wolfberry | Plasma flow: 3 L/min Frequency: 20 kHz Power consumption: 750 W Time: 15, 30, 45, 60 s |

L*, a*, b* of dried samples pre-treated with cold plasma were higher than those were dried without any pre-treatment. | Zhou et al. (2020) |

| Acai pulp | Excitation frequency: 50, 500, 750 Hz Time: 5, 10, 15 min |

The L* was reduced and b* increased after cold plasma treatment. | Dantas et al. (2021) |

| Sesame and sunflower | Frequency50 Hz Voltage: 25 kV Time: 0–30min |

Cold plasma treatment increased red color intensity, browning index, and general discoloration. Yellow color intensity, whiteness, and the color saturation degree decreased in treated samples. | Afshar et al. (2022) |

| Saffron (Crocus sativusL.) | Frequency: 13.6 MHz Power consumption: 70, 90, and 110 W Time: 5, 10, 15 and 30 min |

The color parameters of samples (L*, a*, b*, ΔE, chroma, and hue angle) increased with cold plasma treatment. | Darvish et al. (2022) |

| Chicken | Direct cold plasma Voltage: 50, 60 and 70 kV Time: 3 min |

No significant difference was observed in L*, a* and b* values of chicken between control and treatment groups at the same storage time. | Zhang et al. (2022) |

Cold plasma was used as pre-treatment before hot air drying of wolfberry and retained higher values of dried samples' L*, a*, and b* values compared to samples not given any pre-treatment before drying. The samples pre-treatment with cold plasma for 30–60 s produced samples with a better color profile compared to a lower treatment time of 15 s, and no significant change in color of samples treated for 30 and 60 s was observed (Zhou et al., 2020). Treatment of Acai pulp with atmospheric cold plasma reduced the brightness of the samples (L*) and increased yellowness (b*). However, it did not significantly influence the a* value (Dantas et al., 2021). The samples treated with 50 Hz for 10 and 15 min and 500 Hz for 5 min showed considerably higher values of b* as compared to the control sample, which is attributed to the hydroxylation of mono phenols to diphenols followed by their oxidation to form quinones which are catalyzed by PPO resulting in the formation of pigments imparting yellow color. The cold plasma treatment of 50 Hz for 15 min caused a maximum total color change in the sample (6.63), while the lowest color change (3.35) was obtained at 50 Hz for 5 min.

5.2. Ozone

Ozone (O3) is a powerful oxidant, disinfectant, and antimicrobial agent in both aqueous and gaseous forms. It has been proven effective in enhancing of shelf life of food materials, destroying and eliminating microbes, and storing pests (Zhu, 2018). The effect of ozonization on the color properties of food materials has been summarized in Table 3 and Fig. 1. In a study by Zalewska et al. (2021), ozone treatment was given to mushrooms at a concentration of 0.5, 1.0, and 2.0 mg/L for 30 and 60 min, followed by storing the samples for 0, 4, 7, 11, and 14 days. The samples treated with ozone gas 1 mg/L for 60 min and 2 mg/L for 30 min showed the highest value of L*. Increasing ozone concentration and storage time considerably increased the b*, leading to more sample yellowness. The Brazil nuts were exposed to the ozonization process with ozone gas concentrations of 2.42, 4.38, 8.88, and 13.24 mg/L with a flow rate of 3.0 L/min at a temperature of 25 °C. An increase in the ozonation period significantly elevated the hue angle and color difference. Besides, the total color difference was also influenced appreciably by gas concentration, and variation is related to the oxidation of pigments of dark brown colored skin surrounding the nuts (de Oliveira et al., 2020). Ozone treatment did not significantly affect the carrot's luminosity, redness, and yellowness (Souza et al., 2018). Similarly, no significant differences in color change were detected between ozone and non-ozone treatments in fresh-cut durian (Sripong et al., 2022). In a study by Chakraborty et al. (2015), longan fruits treated ozone at a concentration of 4,000, 8,500, and 13,000 ppm for 3 and 5 min. The control exhibited lower L* and C*. Treatment of wheat flour with ozone at a dosage of 10 g/kg led to increased whiteness and reduced yellowness. The oxidation of color-imparting compounds, for instance, polyphenols and carotenoids in the presence of ozone, could be a possible reason for the intensification of the whiteness of flour (Zhu, 2018). However, in the case of peach juice, ozone treatment caused a slight decline in lightness, h*, and an increase in the a* value without affecting the b* value. Further, an intensification of orange color and increased browning index were also observed after the ozonization of peach juice, which resulted from the enzymatic and non-enzymatic oxidation of phenolic compounds (Jaramillo-Sánchez et al., 2018).

Table 3.

Effect of ozone treatment conditions on colour profile of different food materials.

| Food product | Treatment conditions | Influence on colour profile | References |

|---|---|---|---|

| Prebiotic orange juice | Ozone concentration: 0.057, 0.128 and 0.230 mg O3/mL | No significant change in L* and chroma of samples Hue angle was significantly reduced |

Almeida et al. (2015) |

| Grass carp surimi | Ozone concentration (in water): 1,3,5,7 and 10 mg/L | Increase of Ozone water concentration increased the L* and whiteness and reduced the a*(greenness) significantly | Liu et al. (2021) |

| Green coconut | Ozone concentration: 0.075–0.37 mg/mL Temperature: 10–30 °C |

No noticeable change in colour was observed as ΔE < 2 | Porto et al. (2020) |

| Carrot | Ozone concentration (as gas): 0–5 mg/L Ozone concentration (in water): 0–10 mg/L |

No influence of ozone treatment on colour profile | Souza et al. (2018) |

| Peach Juice | Ozone concentration (in gas): 18 g/m3 Dose: 0.06 and 2.48 g/L Time: 0.3–12 min |

L* reduced, a* increased, b* was not affected h* mild decrease | Jaramillo- Sánchez et al. (2018) |

| Durian | Ozone concentration (in gas): 500 and 900 mg/L Time: 3 and 5 min |

No significant differences in color change were detected between ozone and non-ozone treatments. | Siripong et al. (2022) |

| Longan Fruit | Ozone concentration (in gas): 4,000, 8,500, and 13,000 ppm Time: 3 and 5 min |

The control exhibited lower L* and C* but was higher in h* than ozonated ones. | Chamnan et al. (2022) |

Fig. 1.

Effect of ozone on anthocyanins and heat induced degradation of chlorophyll in fresh fruits and vegetables.

5.3. High hydrostatic pressure

High hydrostatic pressure processing (HPP) is a promising non-thermal processing technology that has successfully been commercialized for the pasteurization of food products. HPP involves the application of ultra-high pressure in the range of 100–600 MPa using a liquid medium (usually water) to pasteurize food (hermetically sealed). HPP is a mild processing technique that helps retain the flavor and safety of food (Huang et al., 2020). The effect of HPP treatment on the color of different food materials is listed in Table 4. HPP's influence on carambola puree's color was studied by Zhang et al. (2021) by storing the treated samples at 4 °C for 48 h. The fresh samples showed an L* value of 64.82, which was reduced to 60.47 after 48 h storage. The samples treated with 200, 400, 600, and 800 MPa showed the L* value of 57.79, 62.85, 64.52, and 65.03, respectively, indicating a minimum value at lower pressure. An increase in pressure demonstrated an improvement in L* values, and samples with pressure treatment of 800 MPa, witnessed the highest L* value, which was also greater than a fresh sample. The pressure positively affected the b* value of the carabola. The b* values of the fresh sample (8.82) increased to 11.52 after treatment at a maximum pressure of 800 MPa. An increased yellowness index with pressure is ascribed to increased beta carotene in the samples upon pressure treatment. The samples treated at lower pressure of 200 MPa displayed darker color and a higher browning index of 20.63, while samples treated at 600 and 800 MPa showed a color profile closer to the control sample. In a study by Tsai et al. (2022), the influence of HPP on the quality of milkfish fillets was investigated. Samples were treated with HHP at different pressure (300, 400, 500, and 600 MPa). L* increased with pressure up to 600 MPa while a* and b* values decreased. This was related to the degradation of pigments and myoglobin at high pressure. The ΔE value increased significantly with the increase in pressure. Pokhrel et al. (2022) studied the effect of HHP on carrot-orange juice. HPP showed no significant impact on the L*, the Chroma, and the hue angle. Chakraborty et al. (2015) explained the impact of combined high pressure (200, 300, 400, 500, and 600 MPa) and temperature treatment (30, 40, 50, 60, and 70 °C) on the color of pineapple puree with a treatment time of 1 s–20 min. The increase of pressure up to 500 MPa depicted a growing trend of L* value, while a* and b* values were not affected by pressure but were significantly influenced by temperature. The redness of the sample indicated by a* shifted towards the positive scale, and yellowness (b* value) declined significantly with the temperature increase. The minimum color change of 2.80 was achieved at 50 °C and 600 MPa treatment for 15 min, while the maximum color change was shown at 70 °C and 500 MPa treatment for 10 min. The total change of color during HPP treatment at 500 MPa of whole grain, hull, and de-hulled extract of Djulis was revealed to be in the ranges 7.29–41.14, 1.98–6.30, and 23.97–35.17, respectively (Sun et al., 2019). No significant change in the green color of beans was observed during HPP treatment at 600 MPa, indicating the retention of the green color. This can be explained by the permeabilization of plant cells, resulting in chlorophyll leakage into the intercellular space under the pressure of 100–800 MPa. The overall color difference of HPP-treated beans was 4.61, which was found to lie in the range of 3–6, representing a noticeable color difference between before and after HPP treatment (Inanoglu et al., 2021).

Table 4.

Effect of high-pressure processing on colour profile of different food materials.

| Food product | Treatment conditions | Influence on colour profile | References |

|---|---|---|---|

| Carambola puree | Pressure: 200, 400, 600 and 800 MPa Time: 15 min Temperature: 25 °C |

Browning index reduced with pressure, L* and b* increased with pressure | Zhang et al. (2021) |

| Aronia berry juice | Pressure: 200, 400, 600 MPa Time: 2.5, 5 min Ramping rate: 300 MPa/min Temperature: 21–33 °C |

There are no significant change in the colour coordinates L*, a* b*. The ΔE was less than the 1.5, which is threshold for noticeable colour change |

Yuan et al. (2018) |

| Pineapple puree | Pressure: 200–600 MPa Temperature: 30–70 °C Time: 1s-20 min Ramping rate: 300 MPa/min |

L* increased with increase of pressure up to 500 MPa, while a* and b* values were similar at all pressure. Higher temperature significantly increased b* |

Chakraborty et al. (2015) |

| Mango pulp | Pressure: 100–600 MPa Durations 1 s to 20 min Ramping rate: 400 MPa/min |

ΔE values of HPP treated samples was 1.01–2.89. | Kaushik et al. (2014) |

| Hilsa fish fillets | Pressure: 100, 200, and 300 MPa Time: 10 min |

Increase of pressure significantly increased ΔE | Kumar et al. (2019) |

| Dijulis extract | Pressure: 500 MPa Time: 3 min Temperature: 10 °C, 30 °C |

The total colour change observed in the range 1.98–35.17 | Sun et al. (2019) |

| Apple juice | Pressure: 600 MPa Time: 3 min |

Hardly noticeable colour difference between untreated and HPP treated sample | Yi et al. (2017) |

| Hawthorn berry | Pressure: 300, 600 MPa Ramping rate: 300 MPa/min Pressure release time<2 s |

Not noticeable colour changes due to HPP treatment | Lou et al. (2021) |

| Green bean | Pressure: 600 MPa Time: 10 min |

No significant difference in green colour of beans before and after HPP | Inanoglu et al. (2021) |

| Bayberry juice | Pressure: 400, 500, 600 MPa Time: 10 min Ramping rate: 200 MPa/min Decompressurization time: <10 s |

Slight increase in Lightness and reduction in a* and b* value | Yu et al. (2013) |

| Carrot-orange juice | Pressure: 300 MPa Time: 10 min |

HPP showed no significant impact on the L*, the Chroma, and the hue angle. | Pokhrel et al. ,2022 |

| Milkfish fillet | Pressure: 300, 400, 500, and 600 MPa Time: 5 min Ramping rate: 300 MPa/min Temperature: 20 °C |

L* increased with increase of pressure up to 600 MPa while a* and b* values decreased. The ΔE value increased significantly with the increase in pressure. | Tsai et al. (2022) |

5.4. Irradiation

Food irradiation exposes the food materials to certain radiation (ionizing or non-ionizing radiation) to control spoilage and eliminate foodborne pathogens. Radiation can be divided into two broad groups, i.e., ionizing and non-ionizing radiation, based on their interactions with the matter and phenomena of free radical formation. Electromagnetic radiation, which interacts with the food material and triggers free radical formation, is generalized as ionizing electromagnetic radiation (IEMR), otherwise non-ionizing electromagnetic radiation (NIEMR) (Bisht et al., 2021). Three types of IEMR are allowed and used in the application of food preservation, including gamma radiation, X-rays, and high-energy electron beams (e-beam), as per the guidance of Codex Alimentarius Commissions (2003). Gamma rays are the high-energy ionization radiation produced from radioisotopes, viz. Cobalt-60 (60Co) and cesium-137 (137Cs) have energy levels of 1.17 and 1.33 MeV for 60Co and 0.662 MeV for 137Cs. X-rays and e-beams are produced in electron accelerators and possess the maximum quantum energy not exceeding 5 MeV and 10 MeV, respectively. NIEMRs include infrared, visible light, ultraviolet, microwave, and radiofrequency radiation. Most UV radiation does not have an ionizing effect up to the energy level of 3.5–10 eV (wavelength 400-125 nm). However, far UV radiation (wavelength shorter than 125 nm) can have an energy level of 10 eV or higher and induce ionization in the irradiated sample. Hence these UV radiations are considered ionizing radiation. Both IEMR and NIEMR impact the physicochemical properties of food. The impact of irradiation depends upon the nature of the food, type, and radiation dose (Prakash and de Jesús Ornelas-Paz, 2019).

The effect of irradiation on the color profile of various food products is summarized in Table 5. Kanatt et al. (2015) studied the effect of gamma radiation (60Co) on chicken breast meat, lamb meat (biceps femoris region), and buffalo meat irradiated with a dose of up to 10 kGy. Significant changes in the color (ΔE) value in the order of 7.8, 3.4, and 1.7 were reported for the chicken, lamb, and buffalo meat, respectively. Further, a significant increase in redness and a corresponding decrease in brightness of the irradiated meat sample were observed with an increase in radiation dose (Kanatt et al., 2015). Ji et al. (2022) found that the treatment γ -irradiation in combination with microencapsulated essential oils on sausages preserves the product's color during storage. The improvement in redness and color stability during storage can be ascribed to beneficial aspects of the irradiation of meat products. Mandal et al. (2022) explained the effect of pulsed UV light irradiation (1.07–17.2 J/cm2) and pulsed frequency (1–10 Hz) on the color of tea with a treatment time of 5 s–50 s. The redness of samples increased after treatment. No significant differences were observed in yellowness for all the fluence values. Lightness decreased with the fluence delivered. ΔE value increased for the samples with UV-C treatment. Another study showed that treating tomatoes with UV-C radiation of 3.7 kJ/m2 could improve the hue angle and retarded the color degradation during storage for up to 12 days. The effect of UV-C on the coloration of fruit may be due to its interference with carotenoids and pigments. UV-C radiation impacted the gene sequences in tomatoes responsible for several physiological reactions, including ripening, coloration, and toughness (Severo et al., 2015).

Table 5.

Effect of irradiation on colour profile of different food materials.

| Sample | Treatment | Inference | References |

|---|---|---|---|

| Tomato | UV-B radiation Dose: 0.564 and 1.128 kJ/m2 |

Brightness, redness, and hue angle of the tomatoes increased upon UV-B irradiation. | Kasim and Kasim (2015) |

| Tomato | UV-C in combination with 1-methylcycloprpene Dose: 3.7 kJ/m2 |

Increase in hue angle and helped to maintain the hue and green color of tomato fruit during storage up to 12 days. | Severo et al. (2015) |

| Spice paprika | Gamma (γ) irradiation (60Co) Dose: 1, 5 and 10 kGy. | Up to 65% reduction in ASTA color value of paprika extract upon γ-irradiation. | Molnár et al. (2018) |

| Pearl millet | γ -irradiation Dose: 0–8 kGy |

Increase in ΔC and ΔE up to 4 kGy irradiation followed by decrease up to 8 kGy in both the varieties of pearl millet. | Falade and Kolawole (2013) |

| Brown rice based weaning food | γ -irradiation Dose: 2–10 kGy Storage: 12 months at 32 °C. |

Insignificant effect of irradiation on L* and a* values while significant on b* values. | Jan et al. (2020) |

| Brown and milled rice | Electron beam irradiation Dose: 5 kGy |

Very slight change (darkening) in color parameters upon e-beam irradiation of brown and milled rice. Yellowness of rice increased upon irradiation. | Luo et al. (2019) |

| Wheat flour | UV-C irradiation Dose: 56 mJ/cm2 |

There was no significant change in the color of the wheat flour upon UV-C treatment up to 250 s. | Kumar et al. (2020) |

| Black rice flour | γ -irradiation Dose: 0–3 kGy |

Slight changes in the color parameters of black rice flour upon irradiation. | Ito et al. (2019) |

| Black tea | UV-C irradiation Dose: 1.07–17.2 J/cm2 |

Redness of samples increased after treatment. No significant differences were observed in yellowness. The ΔE value increased for the samples with UV-C treatment. | Mandal et al. (2022) |

| Sausages | γ -irradiation in combination with microencapsulated essential oils Dose: 1–5 kGy Storage: 20 weeks at 20–21 °C. |

There was no significant difference inthe L* values between non-irradiated and γ-irradiated groups. L*,a*, and b* values of the samples was not affected significantly by the addition of microencapsulated essential oils, γ-irradiation treatment, and storage time. | Ji et al. (2022) |

5.5. Pulsed electric field

Pulsed Electric Field (PEF) is an innovative technology that involves the application of short high, power electric pulses (respective nanoseconds to milliseconds) on food products curbed between the electrodes, positioned inside a treatment chamber. PEF technique involves treatment at a lower temperature than other thermal technologies and effectively controls microbial populations and sensorial properties (Arshad et al., 2020). This technology revolves around the principle of electroporation and electro-permeabilization PEF induces the electrical breakdown of the cell membranes, which leads to the control of microorganisms. The effectiveness of the whole process depends widely on processing factors like field strength, pulse width and frequency, duration, applied temperature, and product matrix (Salehi, 2020).

Table 6 presents the effect of the pulse electric field on the color attributes of various food products. Color variations allied with produce indicate either enzymatic browning or browning owing to the heat-induced formation of Maillard products. Sánchez-Vega et al. (2020) reported the effectiveness of PEF treatment in controlling broccoli juice's color profile (with higher ΔE values) compared to its thermally treated counterpart, which can be ascribed to activation of enzymes allied with the biosynthesis of chlorophyll upon PEF treatment. Nowacka et al. (2019) inspected the upshot of PEF treatments (electric field strengths at 4.38 and 6.25 kV/cm, 10–30 pulse number) as a pre-treatment in the extraction of betalains from beetroot. A significant increase of a* value (red color) component of the treated pulp samples was reported, which is related to the content of betalains extracted from beets. The color parameters of the beet extracts also rendered a similar trend with a significant increase in red components and a reduction in yellowness (b*) value. PEF at an electric field strength of 4.38 kV/cm for 20 pulses effectively improved extraction efficiency and retainment of color profile than untreated and other treatment parameters.

Table 6.

Effect of pulse electric field on colour profile of different food materials.

| Product | Treatment conditions | Remarks | References |

|---|---|---|---|

| Beetroot | Field strengths: 4.38 and 6.25 kV/cm Pulse number:10–30 |

Increase of a* value- red colour component of the treated pulp samples was reported. PEF at electric field strength of 4.38 kV/cm for 20 pulses was found to be effective | Nowacka et al. (2019) |

| Carrot and apple juice | Field strength: 0.8 kV/cm Pulse: 50 exponential decay pulse Time: 0.5 ms |

Larger ΔE values around 18.49–24.5 for apple and carrot juice samples was observed at treatment-80 °C with PEF. Low ΔE values of 4.36–5.49 was observed for samples at 40 °C and 60 °C with PEF treatment. | Mannozzi et al. (2019) |

| Beef jerky | Field strength of 0.52 kV/cm Pulse width: 20 μs |

Comparable instrumental colour which is consistent with the sensory scores. No effect of PEF was noted | Bhat et al. (2020) |

| Beef | Filed strength: 0.8–1.1 kV/cm Frequency: 50Hz |

No detrimental effect on redness value of beef sample which was between 6.13 and 8.14 for treated ones and 4.5–7.45 for control | Kantono et al. (2019) |

| Turkey meat | Frequency: 10,55 and 110 Hz Pulse number: 100, 200, and 300 (20 μs) Voltage: 7.5, 10, and 12.5 kV (for fresh meat) 14, 20, & 25 kV (for frozen meat) |

Treated fresh and frozen samples showed increase in L* and b* values with a little reduction in a* value. Frozen meat samples report an L value ranging from 76.2 to 79.6 and b value changing from 6.48 to 7.16. | Arroyo et al. (2015) |

| Raw milk | Voltage: 30 kV/cm Time: 22 μs Temperature: 53 or 63 °C |

No significant difference within the PEF treatments at different outlet temperature. Thermal treatments brought in ΔE values of around 0.63 whereas that of PEF samples was around 0.31–0.38 | McAuley et al. (2016) |

| Skim milk | Filed strength: 28 and 40 kV/cm Time: 1122–2805 μs |

ΔE values is distributed between 0.1 and 0.37 which is not noticeably and lesser while compared to other treatments. | Chug et al. (2014) |

| Almond milk | Filed strength: 7, 14, 21, and 28 kV/cm Pulse width: 40 μs Frequency:1 kHz Time: 200 μs |

Electric field intensity positively affected L* value resulting in lowering the browning process. ΔE values of samples were between 3.85 and 7.01 between different field intensities while that of thermally treated ones was 12.31. | Manzoor et al. (2020) |

| Zucchini and Eggplant | Filed strength: 1 kV/cm Pulse width: 40 μs Frequency: 2 kHz |

Untreated samples showed higher lightness and yellowness values than that of PEF treated slices. a* values of PEF treated samples were higher than the untreated samples. | Buzrul et al. (2022) |

| Pomegranate beverage | Filed strength: 11.7 and 18.8 kV/cm Pulse width: 15 and 20 μs Frequency: 200 kHz |

PEF treatment caused an increase in L* values. | Rios-Corripio et al. (2022) |

Faisal et al. (2021) compared the effect of ultrasound (US) and PEF treatment on the color profile of spinach juice. It was conveyed that the color profile of PEF treatments was superior to US-treated spinach juice samples. Wiktor et al. (2021) also reported the superiority of PEF-treated apple samples, with HPP treatment displaying higher browning and total color difference than PEF-treated samples. Different research studies quantified the maintenance and improvement of color parameters of beef (Bhat et al., 2020) and turkey meat (Arroyo et al., 2015) by PEF treatment. The color of beef jerky was not affected by the PEF treatment (electric field strength of 0.52 kV/cm for 20 μs), with superior sensory scores consistent with the instrumental color analysis of the treated samples (Bhat et al., 2020). This was in agreement with the results obtained by Kantono et al. (2019), which covered the effect of PEF on two different cuts of beef. The lightness and yellowness values of treated beef samples displayed small variations with no detrimental effect on redness a* values. The redness value of treated samples remained around 6.13–8.14, whereas the control samples were around 4.5–7.45. Being successful in maintaining the overall color value of turkey meat, Arroyo et al. (2015) report a higher value in lightness and yellowness of the sample with a little reduction in a* value. With slight deviations from the above-stated results, the frozen meat samples which were PEF treated showed a similar trend with L values ranging from 76.2 to 79.6 and b values changing from 6.48 to 7.16. Mcauley et al. (2016) studied the effect of PEF treatment at 30 kV/cm for 22 μs (outlet temperature around 53 or 63 °C) on fresh milk. No significant change was reported between the PEF treatments at different temperatures, with both treatments ensuring the retainment of L*, a*, and b* values of milk samples. Larger ΔE values were observed for thermal treatments compared to the PEF samples having values around 0.31–0.38. Buzrul et al. (2022) investigated the effect of PEF as a pretreatment method before deep-frying zucchini and eggplant slices with two different energy inputs. According to the results, untreated samples showed higher lightness and yellowness values than PEF-treated ones. The decrease in the lightness of PEF-treated samples during frying may be due to more reducing sugars for the Maillard reaction on the surface of vegetables due to increased cell permeability by PEF application. a* values of PEF-treated samples were higher than the untreated samples. This may be due to the accumulation of intracellular materials released from cells perforated by PEF during frying. Rios-Corripio et al. (2022) explained the effect of PEF (11.7 or 18 kV/cm) on the quality characteristics of fermented pomegranate beverages. PEF treatment caused an increase in L* values. No significant changes (P ≥ 0.05) in a* values were observed between the untreated and the samples treated with PEF at 11.7 and 18.8 kV/cm. The yellowness values ranged from 4.01 to 4.99 for control and treated samples. PEF treatment maintained quality attributes in the color characteristic.

5.6. Supercritical technology

Supercritical fluids (SCF) are pure substances at pressure and temperatures above a critical point with liquid-like density properties, gas-like low viscosity, and intermediate diffusivity (Zhou et al., 2021). SCF technique engages compounds like CO2, ethane, propanone, and dimethyl ether for specific applications. Generally recognized as safe, supercritical CO2 (SCCO2) is the most extensively used fluid in the food sector as they are environment-friendly, non-toxic, economical, readily available, and easily removable (Wang et al., 2020). The added advantage of the involvement of low temperatures makes the relevance of SCCO2 in the food sector more appreciative (Silva et al., 2019).

Effects of the application of SCCO2 on the color properties of fruit and vegetable products are widely reported (Table 7). The influence of SCCO2 treatment (10–60 MPa at 45 °C) for 30 min after a storage phase of 10 weeks at 4 °C was studied in apples (Marszałek et al., 2018). The total color difference (ΔE) value of untreated samples was around 40 within 15h of storage, whereas that of treated samples was less than 20 even after 10 weeks of storage. Bertolini et al. (2020) explained the effectiveness of SCCO2 in maintaining the color of pomegranate juice during the optimization of the high-pressure pasteurization process by SCCO2. The color profile was observed to maintain constant values with minor changes in the L value after two weeks of storage time. SCCO2 treatment at 1100 psi for 10 min (31.1 °C) was appropriate in significantly reducing microbes while maintaining the color profile of shrimps (Kustyawati et al., 2021). Analogs to the positive effect on solid food products, Ferrentino et al. (2013a) mark the effectiveness of SCCO2 in application on cubed cooked ham. The total color difference was not significantly affected by treatment, with ΔE values around 1.3, which is much less in consideration. A storage study of these ham samples for 30 days showed a notable increase in redness and a decrease in lightness, making the samples more pinkish. It was reported that the color disparity during the storage cycle of 30 days is within the standard color values stated for commercially cooked ham and could be due to the diminution effect of treatment following an extended storage period. Although the findings of the treatment utility are well mentioned, there is a significantly smaller number of studies involving the effect of different process parameters to ensure viability in terms of nutritional, functional, and sensorial properties. Murtaza et al. (2019) have reported that ΔE has a positive correlation between high pressure and temperature in high-pressure CO2-treated apple juice. Treatment at low pressure and temperature had color change values similar to the control. ΔE values decreased with increased pressure, with ΔE values of 6.7 at 5 MPa and 2.02 at 25 MPa. Further, at constant treatment time, temperature rise also helped maintain the color profile—analogs to ΔE values, browning index, reduced with high pressure and temperature depicting the prior explanations.

Table 7.

Effect of super critical carbon dioxide processing on colour profile of different food materials.

| Product | Treatment conditions | Remarks | References |

|---|---|---|---|

| Coconut | Pressure: 12 MPa Temperature: 40 and 45 °C Time: 15 min and 30 min |

No variation among treatments was observed. 8% decrease in lightness value and zero differences in a* & b* values of coconut was reported with difference acknowledged as ΔE, were 6.92 for sample treated at 12 MPa, 30 min, 40 °C, and 8.15 for that handled at 12 MPa, 15 min, 45 °C. | Ferrentino et al. (2013b) |

| Cubed cooked ham | Pressure: 8, 10 and 12 MPa Temperature: 40, 45 & 50 °C Time: 5, 10, and 15 min |

Total colour difference was not significantly affected by treatment, with ΔE values around 1.3 which is very less in consideration. Storage study of these ham samples for a period of 30 days showed a notably increase in redness and decrease in lightness, making the samples more pinkish | Ferrentino et al. (2013a) |

| Inulin-enriched soursop whey beverage | Pressure: 10 and 20 MPa Temperature: 35 and 55 °C, CO2 volume ratio: 20 and 50%. |

At 10 MPa, ΔE values at 35 °C is between 0.8 and 1.7 and at 55 °C is 0.3–1.7 at two different CO2 volume ratios. At 20 MPa, with increase in temperature the ΔE values seems to be increasing and higher temperature (55 °C) displaying the colour change value of around 3.4–4. | Silva et al. (2019) |

| Banana pulp | Pressure: 20 MPa Temperature: 45–60 °C Time: 30 min |

With increase in temperature, change of colour in banana was lower. Following 6 h storage, juice color from treatment at 45 °C and 50 °C altered to light brown, and that at 55 °C and 60 °C turned dark yellow. | Yu et al. (2013) |

| Chicken meat | Pressure: 80 and 140 bar Temperature: around 40 °C Time: 45 min |

Reported an increase in lightness and a decrease in redness, with higher pressure was showing less colour retention than lower values. | González-Alonso et al. (2020) |

| Apple juice | Pressure: 5, 7.38, 10 & 25 MPa Temperature: 25, 31.1, 40 and 50 °C Time: 20 min |

Treatment at low pressure and temperature had colour change values similar to that of control. ΔE values were decreasing with increase in pressure with ΔE values at 5 MPa around 6.7 and that at 25 MPa was 2.02. | Murtaza et al. (2019) |

| Pork meat | Pressure: 2000 psi Temperature: 35 °C Time: 2 h |

An increase in lightness was observed in treated samples. a* value of the samples decreased with storage time initially and was better than control after 3 days of storage | Huang et al. (2017) |

| Apple | Pressure: 10–60 MPa Temperature: 45 °C Time: 30 min |

Total colour change values were way superior to control, with ΔE values of treated samples was less than 20 after 10 weeks of storage and that of control was 40 after 15 h | Marszałek et al. (2018) |

| Pomegranate juice | Pressure: 12.7 MPa, Temperature: 45 °C Time: 40 min |

Colour profile was observed to be maintaining constant values with less change in L value after two weeks of storage time | Bertolini et al. (2020) |

| Amaranth flour | Pressure: 2900, 3630, and 4350 psi Temperature: 40, 50, and 60 °C Time: 30 min |

An increase in lightness was observed in treated samples. a* and b* values of the samples decreased. | Delgado-García et al. (2022) |

| Hemp seed | Pressure: 10.3 MPa Temperature: 40 °C Time: 15 min |

This additive increased the pork patties yellowness and decreased lightness. | Kerner et al. (2021) |

Information on milk and the processing of their products by SCCO2 technology is still in short supply, and the studies involved are relatively new. Silva et al. (2019) evaluated the effectiveness of SCCO2 technology in processing inulin-enriched soursop (Annonamuricata L.) whey beverage. The dairy beverage formulated with whole pasteurized and homogenized milk, whey powder, frozen soursop pulp, and inulin is treated at temperatures (35 and 55 °C), pressure (10 and 20 MPa), and CO2 volume ratio (of 20 and 50%). At 10 MPa pressure, the temperature increase was effective in controlling the color changes, with ΔE values of 0.8 and 1.7 at 35 °C and 0.3 and 1.7 at 55 °C with a CO2 volume ratio of 20% and 50%, respectively. On the other hand, treatment at 20 MPa exhibited a different result altogether, wherein ΔE values increased with an increase in temperature displaying the color change value of around 3.4–4 (at 20 and 50% CO2 volume ratio) and 55 °C temperature. The deviation in these observed values is due to the collaborative upshot of temperature promoting the Maillard reaction and CO2 volume ratio, which is watchfully linked to particle aggression. Supplementary studies to achieve correlation amongst process parameters like temperature, pressure, processing time, technique optimization, commercial equipment availability, and economic viability studies are obligatory to ensure the efficacy of SCCO2 technology. Delgado-García et al. (2022) determined the effectiveness of SCCO2 at different pressure conditions (2900–4350 psi) and temperatures (40–60 °C) in the production of amaranth flour. An increase in lightness was observed in treated samples. a* and b* values of the samples decreased. Kerner et al. (2021) evaluated the physicochemical properties of pork burger patties produced with the addition of dried raw and defatted by supercritical CO2 extraction hemp seed press-cake. This additive increased the pork patties' yellowness and decreased lightness.

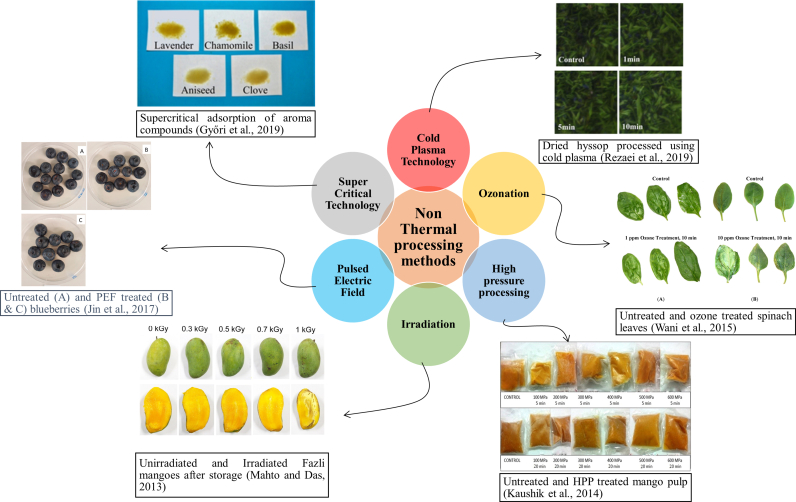

5.7. Combination of non-thermal technologies

Non-thermal techniques that exhibit superior quality and efficacy can be applied in combination with conventional preservation methods, antimicrobial agents, or other non-thermal treatments to improve all aspects of the safety and quality of food. A schematic presentation of the comparative effects of non-thermal food processing methods on product color is provided in Fig. 2. Comparison of individual and combination treatments of sonication and high hydrostatic pressure in microbial and enzyme inactivation of apple juice was studied by Abid et al. (2014). A combination of given technologies exhibited a significant increase in apple juice's lightness, yellowness, chroma, and hue parameters than individual treatments and untreated samples. The controlled enzyme activity of polyphenol oxidase and peroxidase, which are responsible for browning, can be a reason for apple juice's increased color parameters. The efficacy of combining sonication and pulsed light in controlling the microbial populations and quality features of apple juice was studied by Muñoz et al. (2012). The total color difference of the samples was in a noticeable range, with thermal and individual techniques showing higher values, with ΔE values ranging between 1.3 and 2.4. Effect of individual and combination treatments among ultraviolet (UV), pulsed electric field (PEF), manothermosonication (MTS), and high-intensity light pulses (HLP) in apple and cranberry juice blend exhibits color measurements comparable to control samples except that in the case of MTS (Caminiti et al., 2011). Compared to the pasteurization technique, the ΔE values of the combination of UV + PEF and HLP + PEF were around 0.84 and 0.85, while the former was closer to 1. Lightness and a* values of these combinations were also closer to the control sample displaying the effectiveness of the combinations. Despite the efficacy of these combinations, the introduction of MTS as a combination with both PEF and HLP showed poor results, with 34 and 37% decreases in the a* value of samples. Gomes et al. (2017) studied the effectiveness of a combination between high-pressure processing (HPP) and ultrasound (US) on the overall characteristics of prebiotic cranberry juice. The luminosity or lightness value of the product was close for individual, and combination treatments, displaying L* around 49.86 for US + HPP at power density 600 W/L and 47.92 for US + HPP at 1200 W/L, and that of HPP alone was 48.68. Identical inclination was detected for chroma and hue, which specifies the vitality of color characteristics. The amalgamation of these techniques not only aids in overcoming the shortcoming of one process but also unveils a synergistic effect on the food variables. Even though the hurdle concept can be a viable elucidation of the increased efficacy of the combination process, the mechanism of inactivation kinetics is unclear (Zhang et al., 2019).

Fig. 2.

Effects of various non-thermal techniques on the color properties of some foods.

6. Future trends and current limitations of non-thermal processed foods

In recent years, with the change in consumer demands, in the processing of foods, non-thermal technologies (high hydrostatic pressure, ultrasound, pulsed electric field, microwave, ohmic heating, irradiation) have emerged as an alternative to thermal processing. According to the research results, it has been determined that non-thermal techniques can be used as a pretreatment in basic food processes at temperatures close to room temperature. Thus quality and nutritional properties of food can be preserved. These techniques can be used for sterilization as they can inactivate some microorganisms found in foods. Non-thermal technologies can be used alone or with other heat treatment methods. In this way, increasing product quality and improving energy efficiency is possible. Since non-thermal techniques are used for very different purposes in the food industry, these techniques can be used in different food processing areas in the future. These techniques are expected to be used not only to increase storage time and quality but also to produce safe foods with high functional properties.

Non-thermal food processing technologies raise many issues, such as consumer acceptance, product quality, and economical ingredients. These issues need to be addressed in improving and developing non-thermal technologies. One of the biggest obstacles to the commercialization of non-thermal technologies is negative reactions from consumers. Irradiation and pulsed electric field technologies need to be better perceived by consumers. Due to a lack of information, consumers associate non-thermal technologies with toxicity, expense, and harmful events. Once these limitations are overcome, non-thermal technologies will have a wider scope of development and commercialization in the food processing industries. They will provide consumers with safe and nutritious food.

7. Conclusions

The color of food is a chief criterion used to judge the quality of food and influences the purchasing behavior of consumers. Physicochemical characteristics, processing methods and conditions, product composition, packaging material, and storage conditions influence food color. Food undergoes several changes (chemical reactions) during various stages in the food chain, which results in the loss of nutrients, polyphenolic compounds, and pigments which affects the color of food. Various pigments in food include chlorophyll, carotenoids, anthocyanins, and betalains. Their stability is susceptible to environmental factors such as temperature, pH, oxygen, enzymes, and the food matrix where pigments are present. Color measurement techniques commonly employed for color profiling food include L*, a*, and b* values, total color difference, chroma, hue index, and browning index. Hunters L*.a* and b* values are most widely used among the various color systems. Food color can be measured using digital colorimeters, spectrophotometers, and computer vision systems. The conventional food processing methods (high temperature for a longer time) adversely affect food's nutritional and sensory properties. Non-thermal food processing techniques were found to be better at maintaining the color profile of food than traditional processing methods and, in some cases, resulting in improved color properties of food. More research on combining mild thermal and non-thermal techniques on food's color profile and pigments can be explored.

Credit author statement

R. Pandiselvam: Conceptualization; Resources; Writing – original draft; Writing – review & editing; Swati Mitharwal: Writing – original draft; Poonam Rani: Writing – original draft; M. Anjaly Shanker: Writing – original draft; Amit Kumar: Writing – original draft; Raouf Aslam: Writing – original draft; Yeliz Tekgül Barut: Writing – original draft; Anjineyulu Kothakota: Writing – original draft; Sarvesh Rustagi: Writing – original draft; Dolly Bhati: Writing – original draft; Shahida Anusha Siddiqui: Writing – original draft; Mohammed Wasim Siddiqui: Writing – original draft; Seema Ramniwas: Writing – original draft; Aynura Aliyeva: Writing – original draft; Amin Mousavi Khaneghah: Writing – original draft; Writing – review & editing.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Handling Editor: Aiqian Ye

Contributor Information

R. Pandiselvam, Email: anbupandi1989@yahoo.co.in, r.pandiselvam@icar.gov.in.

Amin Mousavi Khaneghah, Email: amin.mousavi@ibprs.pl, amin.mousavi@asoiu.edu.az.

Abbreviations

- CIE

Commission Internationale de l’Eclairage's

- CVS

Computer vision system

- SFE

Supercritical fluid extraction

- NIEMR

Non-ionizing electromagnetic radiation

- IEMR

Ionizing electromagnetic radiation

- SCF

Supercritical fluids

- SCCO2

Supercritical CO2

- HLP

High-intensity light pulses

- MTS

Manothermosonication

- PEF

Pulsed electric field

- UV

Ultraviolet (UV)

- US

Ultrasound

- HHP

High-pressure processing

Data availability

No data was used for the research described in the article.

References

- Abid M., Jabbar S., Hu B., Hashim M.M., Wu T., Wu Z., Zeng X. Synergistic impact of sonication and high hydrostatic pressure on microbial and enzymatic inactivation of apple juice. LWT--Food Sci. Technol. 2014;59(1):70–76. doi: 10.1016/j.lwt.2014.04.039. [DOI] [Google Scholar]

- Afshar S., Ramezan Y., Hosseini S. Physical and chemical properties of oil extracted from sesame (Sesamumindicum L.) and sunflower (Helianthus annuus L.) seeds treated with cold plasma. Food Measure. 2022;16:740–752. doi: 10.1007/s11694-021-01205-0. [DOI] [Google Scholar]

- Almeida F.D.L., Cavalcante R.S., Cullen P.J., Frias J.M., Bourke P., Fernandes F.A., Rodrigues S. Effects of atmospheric cold plasma and ozone on prebiotic orange juice. Innovat. Food Sci. Emerg. Technol. 2015;32:127–135. doi: 10.1016/j.ifset.2015.09.001. [DOI] [Google Scholar]

- Arshad R.N., Abdul-Malek Z., Munir A., Buntat Z., Ahmad M.H., Jusoh Y.M., Bekhit A.E., Roobab U., Manzoor M.F., Aadil R.M. Electrical systems for pulsed electric field applications in the food industry: an engineering perspective. Trends Food Sci. Technol. 2020;104:1–13. doi: 10.1016/j.tifs.2020.07.008. [DOI] [Google Scholar]

- Arnold C., Schwarzenbolz U., Böhm V. Carotenoids and chlorophylls in processed xanthophyll-rich food. LWT--Food Sci. Technol. 2014;57(1):442–445. [Google Scholar]

- Arroyo C., Eslami S., Brunton N.P., Arimi J.M., Noci F., Lyng J.G. An assessment of the impact of pulsed electric fields processing factors on oxidation, color, texture, and sensory attributes of Turkey breast meat. Poultry Sci. 2015;94(5):1088–1095. doi: 10.3382/ps/pev097. [DOI] [PubMed] [Google Scholar]

- Bertolini F.M., Morbiato G., Facco P., Marszałek K., Pérez-Esteve É., Benedito J., Spilimbergo S. Optimization of the supercritical CO2 pasteurization process for the preservation of the high nutritional value of pomegranate juice. J. Supercrit. Fluids. 2020;164 doi: 10.1016/j.supflu.2020.104914. [DOI] [Google Scholar]

- Bhat Z.F., Morton J.D., Mason S.L., Bekhit A.E.D.A. The application of pulsed electric field as a sodium-reducing strategy for meat products. Food Chem. 2020;306 doi: 10.1016/j.foodchem.2019.125622. [DOI] [PubMed] [Google Scholar]

- Bisht B., Bhatnagar P., Gururani P., Kumar V., Tomar M.S., Sinhmar R., Rathi N., Kumar S. Food irradiation: effect of ionizing and non-ionizing radiations on preservation of fruits and vegetables–a review. Trends Food Sci. Technol. 2021;114:372–385. doi: 10.1016/j.tifs.2021.06.002. [DOI] [Google Scholar]

- Buzrul S., Öztürk H.İ., Bilge G., et al. Pulsed electric field pre-treatment for frying of zucchini and eggplant: impacts on oil content and color. Food Bioprocess Technol. 2022;15:1188–1194. doi: 10.1007/s11947-022-02814-3. [DOI] [Google Scholar]

- Caminiti I.M., Noci F., Muñoz A., Whyte P., Morgan D.J., Cronin D.A., Lyng J.G. Impact of selected combinations of non-thermal processing technologies on the quality of an apple and cranberry juice blend. Food Chem. 2011;124(4):1387–1392. doi: 10.1016/j.foodchem.2010.07.096. [DOI] [Google Scholar]