Abstract

The worldwide economic shock caused by the COVID-19 outbreak has widespread and dramatic effects on the energy sector [1]. The World Health Organization (WHO) declared the COVID-19 outbreak as a pandemic by early March 2020, which resulted in the imposition of partial to complete lockdown in almost all countries and territories worldwide. This unprecedented shock has led oil and gas markets through a strong supply and trade adjustment, resulting in historically low spot prices and a drastic fall in demand [1]. Since the oil and gas supply chain is very dynamic in nature, the disturbances in maintenance operations and routine work in the oil and gas industry may result in heavy disruptions in the oil and gas industry by affecting the various areas like workforce, production, and storage in the supply chain [1,2].

This study is oriented towards the comprehensive study of the upstream oil and gas supply chain, and briefly discusses the complete oil gas supply chain. We have investigated the disruption in the supply chain based on the comparative study of the pre-pandemic and post-pandemic situations. The most affected areas of the supply chain due to the disruptions are termed as 'Hotspots' and these disruptions are imitated by developing a model in Stella software, implementing the system dynamics approach. Further, the model has worked for one fiscal year by providing data input of oil/gas prices, current and forecasted demand and impact of COVID -19 is analysed.

Keywords: Oil and Gas Industry, Resilience, Supply Chain, System Dynamics, COVID-19 Pandemic

1. Introduction

According to the International Energy Agency, global oil and gas demand is expected to decline in 2020 as the impact of the new coronavirus (COVID-19) spreads around the world, constricting travel and broader economic activity [1]. The virus has forced companies to slow or halt physical operations, impacting production in the upstream sector [1,2]. Large scale travel bans and lockdown measures by governments across countries have caused a crisis in the global oil and gas industry [3].

Oil and gas supply chains are critical assets for the global economy. The disruptions caused by drastic reduction in sales causing a sudden plunge in oil and gas prices may have significant economic impacts on companies dealing with the production and distribution of oil and gas. It gets more and more crucial for oil and gas companies to manage and oversee their supply chain activities in the most effective manner to reduce the cost and to enhance and guarantee efficient operations in every stream of oil and gas [2].

1.1. Overview of Upstream Oil and Gas Industry

The Upstream supply chain is responsible for finding crude oil and natural gas deposits, along with producing them [4]. This involves the search for crude oil or natural gas fields and the drilling of exploration wells and established wells to recover oil and gas [5].

The Oil and Gas Exploration process starts with a seismic survey of the area for feasibility. For both onshore and offshore areas, economic feasibility, social acceptance, land acquisition, environmental compliances, and process installations are the major factors affecting the exploration process. Well logging is carried out to visualize the formation and reservoir characteristics, followed by exploratory and workover drilling for final production [6]. In Exploratory drilling, portable drilling rigs drill and establish exploratory wells to locate proven reserves of recoverable gas and oil. Then, factors like reservoir boundaries, production potentials estimate, characteristics of the subsurface geology are decided [7]. Now, the particular reserve is a hydrocarbon proved reserve where oil/gas reserve development, further drilling, and rig deployment operations can be carried out. Exploratory drilling provides the most accurate information during the exploration phase, but it may also be the most expensive method. It is the final phase of exploration [7]. The rigs' deployment follows the exploratory drilling process, and the supply chain from hereon can be considered into two parts: offshore hydrocarbon reserves and onshore hydrocarbon reserves.

Unmanned Process Platform (UPP) is an automated offshore hydrocarbon platform designed for remote operations, without the constant presence of personnel [8]. Such Platforms need infrequent visits for integrity checks. UPP has structures for various operations from oil well drilling to production. SCADA is used to control and collect various data [8].

Offshore production is carried out on various process platforms including UPP. At onshore sites, workforce and machinery are easily accessible. In the onshore production process, the mixture of oil, associated gas, and water comes at Group Gathering Station (GGS). Gas is transferred to Gas Collecting Station (GCS), then it is compressed in Gas Compression Plant (GCP), and then again returns to GCS after compression. However, the crude oil passes through Central Tank Farm (CTF), Desalter- to remove the salt [9]. The crude oil and natural gas are transported to oil and gas terminals, respectively.

The Reserve to Production Ratio (RPR) is used to find out the lifespan of hydrocarbon reserves and to know whether we are exploiting the reserves or not. The RPR for a resource can change as new technologies emerge which can enhance the recovery of oil, extend the life of a reserve and create new reserves [[10], [11]].

As we extract more hydrocarbon, extraction costs for the subsequent unit increase. But if production is not sufficient, then it fails to meet the demand [12]. Use of technology can balance the situation here.

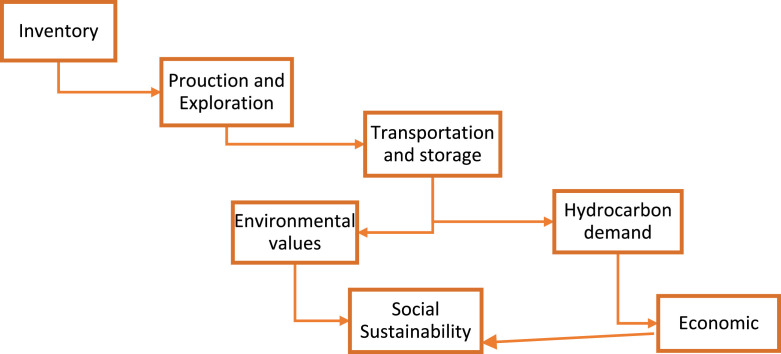

Fig. 1 represents the detailed analysis of Upstream Oil and Gas supply chain and other activities associated with it. Direction of arrow in the supply chain indicates dependency of heading entity on trailing entity. Fig. 1 also depicts the effect these entities on the three pillars of sustainability (Environmental, Economic and Social) enclosed in the octagon.

Fig. 1.

Upstream Oil and Gas Supply Chain and Activities.

Referring to Fig 1.

-

•

Oil and Gas Industry invests a fraction of revenue in exploration for seismic surveys [13], exploratory drilling, and other activities. Higher the investment in exploration implies an increase in exploratory drilling, which subsequently increases the discovery rate of oil and gas reserves. Higher the invested revenue and discovery rate finally enhances the productivity in exploration.

-

•

The remaining recoverable hydrocarbon reserves, and the production rate of hydrocarbon determine the RPR. The discovery of reserves has a positive impact, increasing the RPR [13]. The RPR is directly related to the production rates as the production rates are high, then the RPR will decrease due to the exploitation of reserves [14].

-

•

Hydrocarbon demand greatly influences the hydrocarbon production rate. Industry should produce at required demand level or vary the current production capacity according to demand [13]. Demand, production, and import are interrelated. As demand goes up, the import level rises. However, a higher production rate reduces it [14].

-

•

Oil /gas prices and RPR both affect the introduction of substitutes like Innovative Oil and Gas Energy and Green Energy in the market [13]. Substitute level increases in the market as oil and gas prices go up. The corresponding substitute price also determines the substitute level in the market. High RPR reduces the substitution, as there will be exploitation of reserves. So, due to shortage of reserves, the industry will need to strategically introduce the substitutes.

1.2. Sustainability

Sustainable development deals with economic development, environmental quality, and social equity [15]. It is responsible for the long-term viability of the industry.

1.2.1. Environmental Sustainability

Oil and gas production, transportation, and consumption are associated with large amounts of greenhouse gas emissions. Also, their leakage and spillage highly contaminate useful resources. In some areas where pipelines and other gas transportation infrastructure is not much developed, vast amounts of associated gases are commonly flared as waste or unusable gas [16]. Fracking is responsible for contamination of water reserves.

1.2.2. Social Sustainability

Local community engagement is crucial as it eases operations, especially for the new exploration activities. The industry should provide them employment along with health, safety, and asset security facilities. Corporate Social Responsibility (CSR) activities of an organization for the local community's well-being impacts their quality of life. This factor has positive implications for staff retention, recruitment, and loyalty, leading to more employment and better long-term prospects for communities [17].

1.2.3. Economic Sustainability

It refers to practices that support long-run economic growth without negatively impacting the community's environmental, and social aspects. For economic sustainability, the revenue is strategically utilized in exploration, research, CSR activities, entrepreneur and NGO funding, employee wages, local community's well-being, and other events [17]. The environmental, social, and economic performance builds the reputation of the organization.

The COVID-19 pandemic has forced companies to slow or halt physical operations, impacting production in the upstream sector. The imposition of partial to complete lockdown measures has followed in response to COVID-19. This has led oil and gas markets through a strong supply and trade adjustment, resulting in low prices and a drastic fall in demand. Consequently, the disturbances in maintenance operations and routine work have resulted in disruptions in the supply chain by affecting the various areas like workforce, production, and storage. The most affected areas in the upstream supply chain are termed as ‘hotspots.’

2. Theory

As discussed in previous sections, the overall demand for crude oil/natural gas has seen a drastic decline, so this situation calls for certain amendments by the oil and gas industry. The significant hotspots with their pre- and post-pandemic status are enumerated below:

-

•

Seismic Surveys: COVID-19 pandemic has reduced the research activities of the geologists although it didn't impact the post-pandemic situation much as these are not regular processes.

-

•

Mobilization of machinery: Complexities for the various processes have increased owing to the restrictions in the transportation of machinery and the workforce imposed by the governing bodies.

-

•

Production: In response to the plunge in demand, the production rate has to be reduced but it cannot be minimized beyond a level as it will result in collapsing of well [18]. Continuous production can overflow the storage terminal or inability to confine it may induce some severe accidents (blowouts and leakages). Offshore production platforms flare excessive gas produced, adding up to the greenhouse gas emissions.

-

•

Maintenance operations: The presence of the workforce at sites is reduced to a minimum safe level. Maintenance operations in major routine procedures like drilling rigs/platforms, or processing units have thus, suffered significantly. Thus, the workload on an individual has increased, affecting productivity and increasing the risk of fatalities [19].

-

•

Storage: The demand for oil and natural gas has suffered a drastic decline, which calls for a reduction in production rate [20]. Specified limitation on production discourages reduction beyond specific minimum limits for the well to be productive. The result is excessive oil/gas in terminals, which often forces measures like flaring as a countermeasure. Imports have also increased as a strategic reckoning, the low prices, and future surging demand, which adds to the storage crisis for the industry.

-

•

Transportation in oil and gas supply chain: The low availability of workers and the country-wide lockdown measures have halted several modes of transportation. Transportation through pipeline is the least affected. Extensive use of this mode can be a strategy in dealing with transportation issues [21]. The pigging process has to be carried out for maintaining the required flow rate; lack of maintenance staff results in irregular maintenance, which affects the performance of pipelines [22].

-

•

Workforce as a Hotspot Pandemic: The reduction of working staff to a minimum safe level [3] has reduced safety operations [23] and restricted the routine travel to sites. From a safety perspective, non-critical tasks have to be performed with reduced workforce and safety provisions are mandatory at the sites.

-

•

Greenhouse Gases Emissions: Greenhouse gas emission has surpassed the limits defined for environmentally sustainable conditions. The storage crisis has caused companies to flare the excess natural gas to prevent accumulation in pipes, terminals. However, there is a drastic decline in oil and gas consumption, so significantly reducing emissions.

-

•

Economy: Revenue has been reduced due to a drastic plunge in demand and price. It has impacted industries’ investments (exploration and drilling projects, etc.). Industries are struggling to manage working capital and cash flow due to rise in expenditure, piling of inventories adding to liabilities, under-performing assets, and also reduction in sales. Net profit subsequently has gone down, causing a reduction in CSR expenditures, eventually affecting the industry's social sustainability.

The specific actions and strategies are needed to make the supply chain resilient. Employable resilience strategies are stated below.

2.1. Resilience Strategies

-

•

Collaborations: Collaboration involves the sharing of resources-information, people, and technology-among supply chain members [[24], [25]]. It influences a firm's financial, marketing, operational, or customer service success relative to competition [26] and enables better management of cash flow from producing assets [27]. It can be done by viewing collaboration and knowledge sharing as an opportunity to adapt to rapid change. It also provides new exploration opportunities and access reserves more efficiently. Multi skilled workforce bridges the gap between different business units enabling better information flow. It significantly reduces process costs by avoiding data overlaps, and uncertainty costs.

-

•

Redundant workforce: A redundant workforce can be provided to the sector where the work needs to run continuously. A backup workforce can replace the workers suffering from fatalities and infections.

-

•

Multi-skilled workforce: Multi-skilled workforce can be employed in the industry to leverage the working in diverse situations. These workers are capable of doing various works with appreciable efficiency and productivity.

-

•

Use of technology: Judicious use of cutting-edge technology in industries may reduce the dependency on the workforce for the operation and maintenance tasks. Technological up-gradation helps in the effective use of time, and enhances the overall efficiency of the supply chain.

-

•

Shift to substitutes: Shift to alternatives is often a strategic move when primary products (oil and gas) suffer plunge in selling prices and demand. It can help generate revenue to recover from disruptions. The corresponding substitute price along with oil/gas price determines the substitute level in the market [13].

-

•

Agility in the supply chain: Agility is the ability of quick responsiveness towards unexpected events employing quick decisiveness, flexibility, and sensitiveness [28]. Agility in collaboration from nearby units may help better manage the inventory and improve information flow between them.

-

•

Supply chain Flexibility: Supply chain flexibility means readiness towards uncertainties and having the ability to use currently available resources/capacity to get better results. It enables firms to develop alternate set of actions to efficiently tackle the adverse market conditions [29]. Technology can be used to search for alternate supply chains with the help of machine learning and automation.

-

•

Supply Chain Visibility: Visibility is the ability to track various units of the supply chain, their position, and performance, and the active conveying of information. It can identify risks in one sector and communicate the decisions in other areas to manage all of them well. It can help in restructuring by keeping proper track of location, stocks, modes, and much more.

-

•

Postponement: Postponement is the intentional delay in the execution of an activity to a later date based on real and reliable information [30]. Extending payables can serve tackle the financial crisis too. It can help better manage working capital and demand variability.

-

•

Adaptive capability: The system can adapt to the changing condition reconfiguring the structure to the new requirements [31]. It involves learning from the various experiences in changing conditions that may or may not arise from any crisis. It is a pre-requisite for developing a risk management culture along with flexibility in the supply chain.

-

•

Information Sharing: It refers to the creation and sharing of the right information at the right place and time, avoiding the creation of any void leading to isolation of the members of the supply chain [32]. It is a prerequisite for collaboration and visibility strategies. It is crucial in policymaking, disaster management, infrastructure development, and research.

-

•

Dynamic Pricing: Dynamic pricing is the assignment of prices to a specific product or set of products for a specified period to maximize the profit and utilize the available resource [33]. Dynamic pricing when combined with other resilient strategies may serve in competitive survival and growth too.

-

•

Warehouse Inventory management: Strategic Warehouse Inventory Management helps in managing the smaller disruptions by reducing and delaying the impact of disruption on other units in supply chain.

-

•

Assortment Planning: Assortment planning makes quantitative decisions for retail to maximize the sales of a specific set of products while fulfilling customer's demand. The assortment decision is based on previous demand data or of a particular strategy of the management to make the most effective use of the market situation.

-

•

Strategic Storage: Strategic petroleum reserves are underground caverns used to store crude oil. These reserves come into play in crisis to catch up with oil demand, subsequently reducing the impact of the supply chain crisis. In the pandemic, countries with a large crude consumption are taking advantage of low prices to fill strategic reserves, countering any storage crisis in the post-pandemic period.

-

•

Supply Chain Restructuring: Often disruptions can be tackled by temporarily or permanently fulfilling the need of a supply chain unit from various other methods. The aim of restructuring is either to recover from the disruption or to take proactive steps to reduce the vulnerability.

-

•

Development of risk management culture: The risk management culture make industry self-reliant in the time of crisis. It is based on the principle of development of business awareness by sensing and interpreting the events that help in understanding and planning against the vulnerabilities [34].

Working capital and Free Cash Flow are critical aspects for companies during disruptions. It can be managed by adopting a cash culture comprising of increased visibility of cash flow, implementing improvements that generates cash flow (i.e., Technology, extending payables- to take longer to pay), analyzing variable costs and revisiting capital investment plans [[24], [35]]. This allows businesses to keep their cash on hand for longer, giving them more liquidity. The cash flow released from working capital can also serve as a source of funding for investments in growth projects and making improvements [36].

Considering the oil and gas supply chain crisis, several resilience strategies have been proposed. Merging two or more strategies can also be an effective solution to many disruptions. In Table 1 , pre and post/during pandemic situation has been summarized along with the suitable strategy to make those hotspots in the supply chain resilient.

Table 1.

The Table describing hotspots with their pre-pandemic and post-pandemic situation along with applicable resilience strategies.

| Sr.No. | Hotspots | Pre-COVID-19 Situation | During-COVID-19 Situation | Resilience Strategies |

|---|---|---|---|---|

| 1 | Seismic Survey | Seismic surveys were carried out as planned to explore oil/gas reserves. | Delay in seismic survey activities due to work restrictions. Not much impacted as this is not a continuous process. | Technology upgrade |

| 2 | Mobilization of machinery to site | Mobilization was done as required during the routine operations. | Mobilization is affected due to reduced working and transportation restrictions. |

|

| 3 | Production | Production was done according to demand and import, as there was no significant variation. |

|

|

| 4 | Storage | Storage management was better. The demand and production both were well aligned. |

|

|

| 5 | Transportation | Transportation was evenly reliant on all modes based on region and requirements. |

|

|

| 6 | Demand | The fluctuations in demand were due to seasonal requirements. | Demand has seen a sharp decline. Due to declined demand, production is piling up the storage. | If demand surges/plunges:

|

| 7 | Imports | Imports were done considering the demand and production of the platforms driven by RPR. | Imports are rising to fulfil the surge in future demand and to take benefit of reduced oil/gas prices, which poses a threat of storage crisis. |

|

| 8 | Workforce |

|

|

|

| 9 | Maintenance Operations | Maintenance and safety operations were carried out periodically. | Reduced workforce and increased workload have made routine inspections less productive. Lack of regular maintenance operations may result in serious accidents (leakages, blasts). |

|

| 10 | Economy | Demand was compatible with production, also the revenue generated was better. | The revenue reduced drastically due to a decrease in sales. The expenditure has increased due to the imposed restrictions in the working pattern. |

|

| 11 | Flaring leading to GHG Emissions | Flaring was under the prescribed limits of the environmental norms. | Flaring has increased to get rid of excess production and to prevent accumulation in pipelines and terminals [37]. | Technology Upgrade for reducing GHG emission |

| 12 | Social Contribution | CSR activities were better as industry consistently achieved significant profits. | Social contributions/investments have reduced as PAT for the oil/gas industries has gone down due to a fall in sales. | Flexibility in Government guidelines |

Companies have used individual or combination of these strategies during pandemic. Assortment planning was being used to respond to the plunge in demand for gasoline. Some companies used existing gasoline assets to increase the LPG sales as it is in high demand. Other than this, OPEC countries collaborated with non-member countries to decide the crude oil price during the pandemic. Substitutes like shale gas, solar energy, wind energy and biofuels energy sectors are utilized to increase the revenue. Some companies decided to delay their payments and force the extension on their suppliers, especially when stuck with inventory. Activities related to reskilling and upskilling in response to the pandemic were implemented.

The above-discussed hotspots that have arisen due to the pandemic have significantly affected the routine procedure of the oil and gas industry. The elements of this supply chain have many variations with respect to time. So, to analyse these hotspots, a system dynamics model in Stella software depicting the various processes was developed.

3. Model and Methodology

As the oil and gas supply chain is very dynamic in nature, using a linear approach limits the study to a specific section of the model at a time. However, the use of system dynamics [38] provides tools such as stock-flow diagrams, feedback loops, and time delays.

The model runs in Stella software Version 9. 0. 1. 330 [39] implementing the system dynamics approach. The equations and functions assigned to different converters are shown in Table 2 .

Table 2.

Equations used in the Stella Model.

| Sr | Quantity | Formula |

|---|---|---|

| 1. Production and Exploration | ||

| I | Import of gas | 0.2*forecast gas demand |

| II | Import of oil | 0.15*forecast oil demand |

| III | Production rate of gas(onshore|offshore) | Gas production capacity(onshore|offshore)* installation(onshore|offshore)*productivity((onshore|offshore) |

| IV | Production rate of oil(onshore|offshore) | Oil production capacity(onshore|offshore) *installation(onshore|offshore)*productivity(onshore|offshore) |

| 2. Transportation and Storage | ||

| I | Cost due to leakage (gas) | (0.62/1314) *50[40] *length of pipeline*gas pipeline flow capacity |

| II | Cost due to leakage(oil) | 50[40]*0.62*7.33*10^-3*length of oil pipelines*oil pipeline flow capacity |

| III | Transportation cost(gas) | (5[40]*7.33/1314*10^6*gas pipeline flow capacity) |

| IV | Transportation cost(oil) | 5[40] *7330*oil pipeline flow capacity |

| V | Flaring | Gas pipeline flow capacity*flaring factor 1 + total gas quantity*flaring factor 2 |

| VI | Leakage | 0.015*gas terminal |

| VI | Wastage | 0.015*oil terminal |

| 3. Economy | ||

| I | Extraction cost(offshore) | 45[40] *7330*production rate of oil(offshore) + 6*25.2*production rate of gas(offshore) |

| II | Extraction cost(onshore) | 30[40] *7330*production rate of oil(onshore) + 4.5*25.2*production rate of gas(onshore) |

| III | Total extraction cost | Extraction cost(offshore) + extraction cost(onshore) |

| IV | Total transportation cost | Transportation cost(offshore) + transportation cost(onshore) |

| V | Total cost | Total extraction cost + total transportation cost + storage cost + statuary cost + recouped cost |

| 4. Environmental Values[41] | ||

| I | Total GHG emissions | Flaring + leakage + wastage + venting |

| II | Concentration of heavy metal ions | Spills + wastage |

| III | Impact on environment | (soil pollution + 2*air pollution + water pollution)/4 |

| 5. Social Sustainability | ||

| I | CSR through activists, NGOs, and entrepreneurs | 0.02[17] *PAT |

| II | Human health and employment | 0.25*PAT*impact on environment |

| III | Well-being of community | 0.86*(CSR activities + human health and employment) |

| IV | Social reputation | Well-being of community – (5* 107/1314) * total GHG emissions per month |

Note: All the costs, revenue, and income are in Dollars ($) per month; oil flows are in Thousand Metric Tons (TMT) while the unit for gas flows in Million Metric Standard Cubic Meter (MMSCM). Social reputation and impact on the environment are unit-less. The portion of the equations shown in red is for unit conversion.

The following assumptions are made in order to simplify the model:

-

1.

In the economy section, all the revenue is generated only through crude oil and natural gas sales.

-

2.

The productivity of workers is a periodic (monthly) function where productivity decreases with time.

-

3.

Production of oil and gas is controlled by forecast demand feedback.

-

4.

Only one mode of transportation, i.e., Pipelines, is taken into account.

-

5.

During maintenance of pipelines, the cost incurred due to pigging is negligible compared to total maintenance cost.

-

6.

The working cycle for workers is one month.

-

7.

Import is stored in oil and gas terminals.

The model is based on the Fig. 1. However, the upstream supply chain of ‘Case Industry X’ consists of different processes that cannot be quantified. Some of them have minimal values compared to those taken into account. Therefore, only those processes are considered in the model, which significantly affect the oil and gas supply chain. The oil and gas supply chain model is divided into the following seven sectors - Inventory, Production and Exploration, Transportation and Storage, Hydrocarbon demand, Economy, Environmental Values, and Social sustainability. The ‘Collective Model, which combines all this sectors together is shown in Fig. 2 . The working of these seven sectors is explained below –

Fig. 2.

The Collective Model.

* As per the terms and conditions of the ‘Case Industry X’, we cannot disclose its name.

-

1.

Inventory - Inventory sector is shown in Fig. 2.1 . It consists of two essential components of the supply chain; Machine, and Workforce inventory. Workers at offshore and onshore facilities change according to the working cycle. Similarly, machine deployment takes place at the required facilities. The change in the number of machines and workers, working cycle, and working hours affects the productivity at offshore and onshore facilities, which affects the production quantity.

-

2.

Production and Exploration – The production sector controls the amount of crude oil and natural gas produced. This sector contains two different stocks for the storage of oil and gas, respectively. The inflow to these stocks is the summation of crude oil and natural gas produced at offshore and onshore facilities. The forecast demand and contribution of import controls the amount of crude oil and natural gas produced to fulfill the demand in the future. The forecasted demand works as feedback from the hydrocarbon demand sector to the exploration sector. This sector is shown in Fig. 2.2 .

-

3.

Transportation and Storage –The transportation part of this sector deals with the quantity that advances from the production sector to storage. The length of the pipeline and maximum flow capacity limits the amount of oil and gas transferred. The crude oil and natural gas transported through pipelines are stored in oil and gas terminals, respectively, before their utilization according to their demands in different sectors. Outflows from the terminals vary according to their particular demands. Transportation and storage costs, which are a part of the Economy sector, are calculated here before adding to the total cost, as shown in Fig. 2.3 .

-

4.

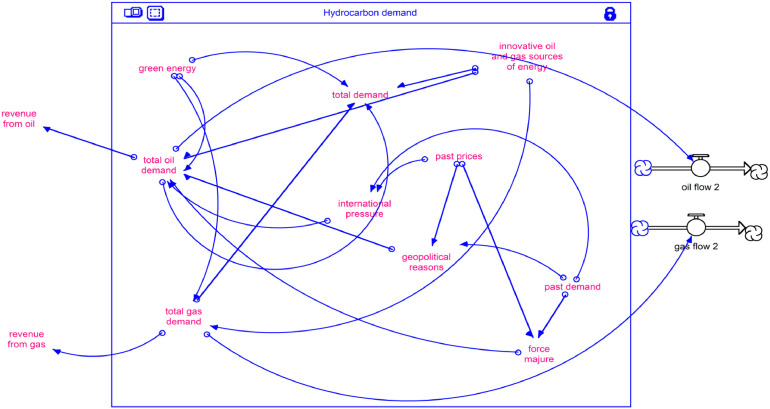

Hydrocarbon Demand – Fig. 2.4 depicts Hydrocarbon Demand sector. It controls the model's behavior by taking the forecast demand as input. The forecast demand is essential as feedback to the Production and Exploration sector as well as Transportation and Storage sector. This sector controls the Economy sector as oil and gas prices, and revenue depends on the demand. Also, this sector takes green energy and alternate sources of energy into account.

-

5.

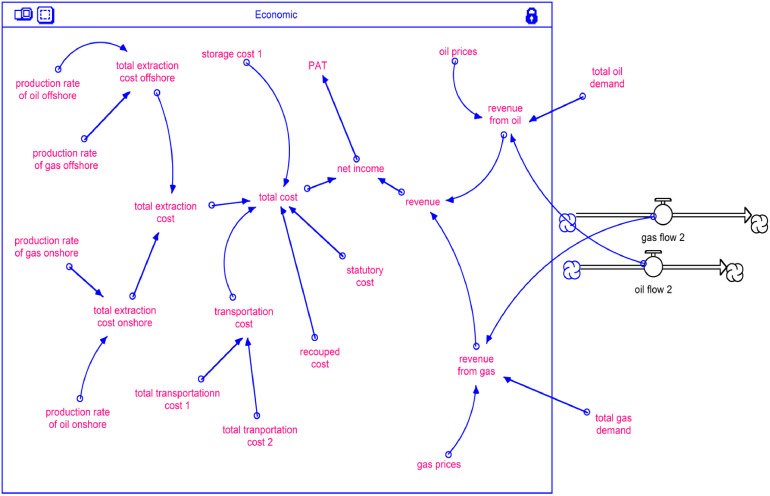

Economy –Economy sector deals with the cost, revenue, income, and PAT (profit after tax) associated with the oil and gas supply chain. This sector is shown in Fig. 2.5 .

-

6.

Environmental values – As depicted in Fig. 2.6 ; Spills, leakages, and wastages contaminate the environment. It can reflect in air, soil, and water pollution.

-

7.

Social Sustainability – This sector shows the contribution of an organization towards society and the impact of different oil and gas activities on society, shown in Fig. 2.7 .

Fig. 2.1.

Inventory sector.

Fig. 2.2.

Production and Exploration sector.

Fig. 2.3.

Transportation and Storage sector.

Fig. 2.4.

Hydrocarbon Demand sector.

Fig. 2.5.

Economy sector.

Fig. 2.6.

Environmental Values Sector.

Fig. 2.7.

Social Sustainability sector.

4. Results and Discussions

The main inputs for the model are oil and gas demand, their respective prices, and demand forecast for one fiscal year. The time step for simulation is one month. Results are expressed in graphical form along with their corresponding deductions. The model input data is obtained from the annual and monthly reports published by the government [[42], [43], [44], [45]].

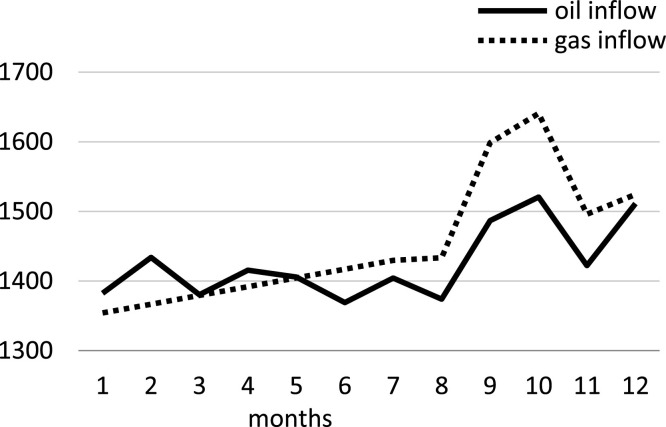

Production of crude oil and gas increases up to January and then decreases at the end of the fiscal year (Graph 1 ). For the Production and Exploration sector, the graph is obtained for variation in the quantity of oil and gas stored in the production facility (Graph 2 ), which shows a sudden decrease in the first month, after that, it has an increasing trend.

Graph 1.

The variation of oil produced (in TMT) and gas produced (in MMSCM) which goes in inflow to storage at production facility.

Graph 2.

Variation of oil quantity (in TMT) and gas quantity (in MMSCM) at the production facility.

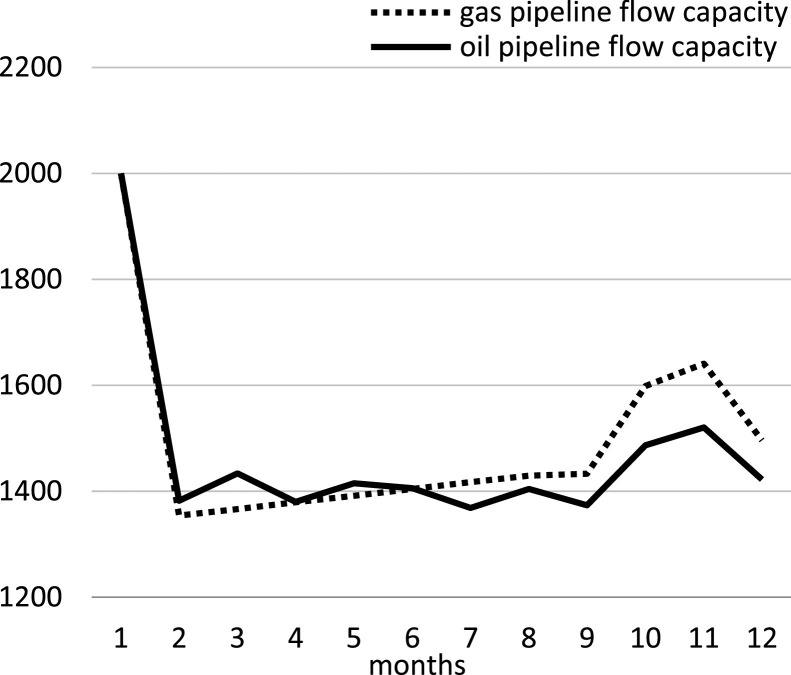

When the number of offshore installations is taken, 4000 and onshore production platforms are taken as 100. Onshore production platforms worked at a maximum production capacity of 73.4% in May 2019, and the minimum production capacity is found to be 37.6% in April 2020. In the case of offshore production, the maximum was 83% in May 2019. However, the minimum production capacity comes out to be 42% for April 2020 (Graph 3 ). The pipeline flow capacity is the amount of oil and gas transported from total storage to terminal. Due to fluctuation in oil and gas production, there is a variation in pipeline flow (Graph 4 ).

Graph 3.

Oil Production capacity (in TMT) and Gas production capacity (in MMSCM) at onshore and offshore.

Graph 4.

Variation of Oil pipeline flow capacity (in TMT) and Gas pipeline flow capacity (in MMSCM).

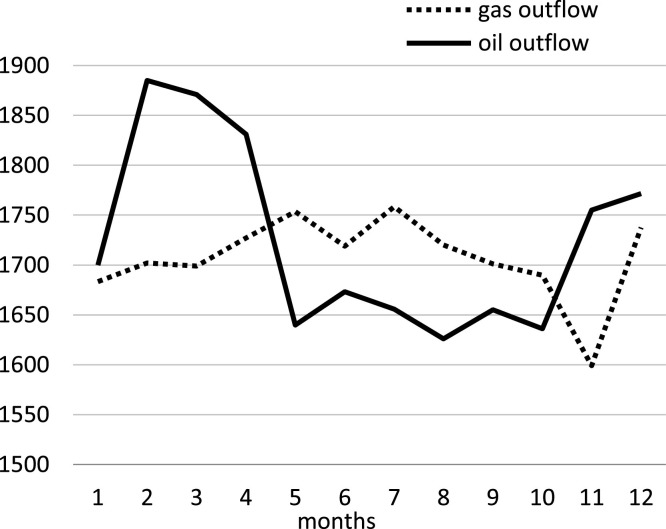

Model output shows that gas storage increases throughout the year, and oil storage terminal quantity decreases at the end of the fiscal year (Graph 5 ). Oil and gas outflow represent the amount of oil and gas taken out of terminals to fulfill the demand. Oil outflow decreases, and gas outflow increases at the end of the fiscal year (Graph 6 ).

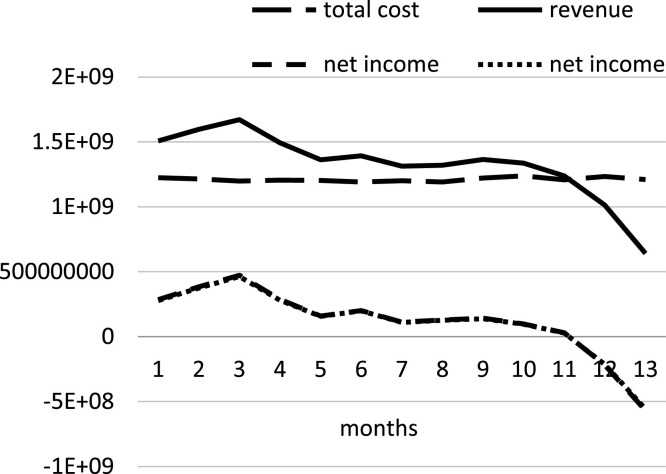

Graph 7.

Variation in economy, all costs in $.

Graph 5.

The amount of oil stored (in TMT) and gas stored (in MMSCM) at oil and gas terminal.

Graph 6.

The outflow from oil terminal (in TMT) and gas terminal (in MMSCM).

Net income depends on revenue earned and the total expenditure throughout the process. There is no significant change in total cost; it is nearly constant throughout the year. Since there is not much change in total cost, the trend followed by Net income is similar to that of revenue.

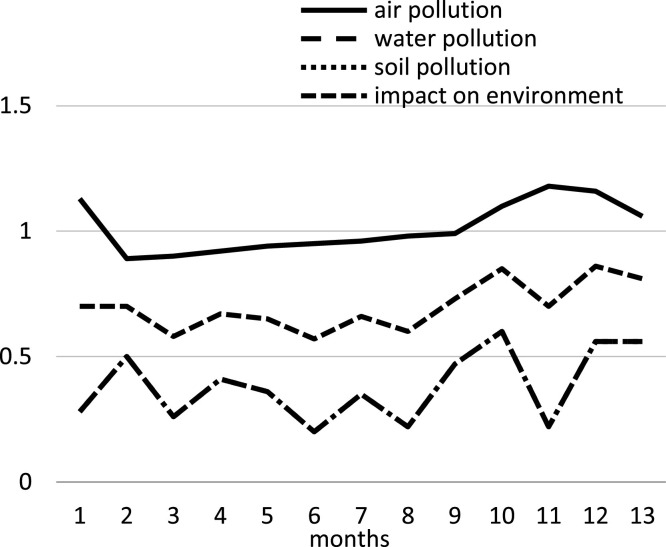

GHG emission is significant throughout the year. Since the flaring and leakage depend on the quantity of gas flowing through the pipeline, the emission value fluctuates accordingly. Initially, the emission is more as the flow of gas is high. At the end of the fiscal year, the emission decreased as the total demand dropped (Graph 8 ). Emissions are the main contributor to air pollution, so air pollution shows similar behavior (Graph 9 ). Results from the Social Sustainability sector show that the CSR funding attains a maximum of $9,270,631 in May and then falls as the PAT decreases (Graph 10 ). Despite a reduction in environmental impacts, the organization's reputation is decreasing during the pandemic period as the declining revenue factor is more dominant among other determining factors.

Graph 8.

Variation of GHG Emissions (in MMSCM).

Graph 9.

Impact on environment and pollution.

Graph 10.

Social Sustainability.

5. Conclusions

The upstream sector of oil and gas is vast and responsible for finding crude oil and natural gas deposits, along with producing them. We have described the whole supply chain comprising of exploration, production, along with sustainable development. The whole in-depth study of ‘Case Industry X’ is summarized in Fig. 1. In this research work, we have analysed the performance of the oil and gas supply chain in pre pandemic and during pandemic situation. And also, we have discussed about the resilient strategies that are useful to deal with the disruptions. This study uses the system dynamics approach to study the upstream oil and gas supply chain using Stella software. The model considers the effect of disruptions due to the pandemic on the quantity of oil and gas produced, pipeline flow capacity, storage, demand, and revenue. In addition to that, it also focuses on environmental and social aspects of the supply chain. After simulating the model, we have drawn the following conclusions. The amount of crude oil and natural gas produced, varies according to the forecast values of oil and gas demand. Natural gas stored at the terminal increases near the end of the simulation. We observe that the total cost incurred in supply chain is higher than the revenue obtained during the period. Therefore, the oil and gas production sector is going through heavy reductions in profit as evident from reality. ‘Case Industry X’ has reported a loss of millions of dollar [46,47]. According to the model, GHG emissions increase due to an increase in flaring. The decline in revenue affects the contribution to the local community. Another simulation, varying the number of production facilities, shows that the optimal number of offshore and onshore facilities for the current demand is 4000 and 110, respectively. Onshore production platforms work at a capacity of 37.6% in April 2020. Similarly, offshore production has a minimum of 42% in April this year. The pandemic had severe destabilizing effects on the oil and gas industry which is also reflected in the presented case study [48].

6. Future scope

The results obtained are based on system dynamics modeling using the Stella software. Results and further studies can be improved using different software (like ‘Vensim’ has extensive support for time series data import and export and ‘AnyLogic’ which can be mixed with other modelling paradigm and supports programs in JAVA). This will help to compare the changes in results obtained by the use of other methods. Our study of the upstream oil and gas supply chain highlights the various disruptions in the pandemic situation, which hamper the daily operations and suggests ways of the resilient and robust supply chain. A similar research/ study can be carried out in the midstream, and the downstream sector which has been equally affected and thus a detailed analysis of the supply chain can be achieved. Resilience factors in the supply chain have always been the limelight of the supply chain management system, so better resilience strategies, including the combinations of what is discussed in our study, can be pondered upon, and research can be carried out.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

Dr. Cherian Samuel, Associate Professor, Department of Mechanical Engineering, IIT (BHU), Varanasi.

Dr. Piyush Choudhary, Ph.D., Deputy General Manager (Electrical), Oil and Natural Gas Corporation Ltd (ONGC), Ministry of Petroleum & Natural Gas, Government of India.

Mr. Ajeet Kumar Yadav, Research Scholar, Department of Mechanical Engineering, IIT (BHU), Varanasi.

References

- 1.IEA Global Energy Review . 2020. The impacts of Covid-19 crisis on global energy demand and CO2 emissions.https://www.iea.org/reports/global-energy-review-2020 [Google Scholar]

- 2.Richard G. Blunt, Philip Thomson, Olympe Bory-Baker McKenzie Report: The impact of covid19 on the oil and gas industry bakermckenzie.com/en/insight/publications/2020/04/the-impact-of-covid19-on-the-oil-and-gas-industry.

- 3.Matthew Farmer- Offshore Technology Article: How the Covid-19 coronavirus is affecting the offshore industry: https://www.offshore-technology.com/features/coronavirus-impact-offshore/.

- 4.Refinery Article on Wikipedia: https://en.wikipedia.org/wiki/Refinery.

- 5.University of Calgary-‘Energy education’ Article on Crude oil: https://energyeducation.ca/encyclopedia/Crude_oil.

- 6.‘Case Industry X’ Core Business Expertise Information-Drilling: https://www.ongcindia.com/wps/wcm/connect/en/about-ongc/core-business-expertise/drilling/.

- 7.OpenEI, Department of Energy US, Article on Exploratory Drilling: https://openei.org/wiki/Exploration_Drilling.

- 8.Offshore Technology Article: Inside the first fully automated offshore platform: https://www.offshore-technology.com/features/inside-the-first-fully-automated-offshore-platform/.

- 9.Mithun Chouhan(IIT-Kharagpur)-Summer Internship Presentation: https://www.slideshare.net/chouhanmit/intern-26037531.

- 10.Daniel Liberto-Corporate Finance and accounting, Article on Investopedia: Reserves to Production Ratio https://www.investopedia.com/terms/r/reserves-to-production-ratio.asp.

- 11.Reserves to Production Ratio Article on Wikipedia: https://en.wikipedia.org/wiki/Reserves-to-production_ratio.

- 12.Eiji Sawada Shunsuke Managi-Effects of Technological Change on Non-renewable Resource Extraction and Exploration Journal of Economic Structures: 10.1186/2193-2409-3-1. [DOI]

- 13.Choudhury Sanjib, Sahu K.C. 1992. A System Dynamics Model for the Indian Oil and Gas Exploration/Exploitation Industry - [DOI] [Google Scholar]

- 14.Farzaneh Daneshzand, Mohammad Reza Amin-Naseri, Mehdi Asali, Ali Elkamel, Michael Fowler- A system dynamics model for optimal allocation of natural gas to various demand sectors: 10.1016/j.compchemeng.2019.05.040. [DOI]

- 15.Mitchell Grant-Sustainable Investing, Article on Investopedia: Sustainability: https://www.investopedia.com/terms/s/sustainability.asp.

- 16.PetroWiki Report-Emission from oil and gas production operations: https://petrowiki.org/Emissions_from_oil_and_gas_production_operations.

- 17.Sustainability Report FY'19 of ‘Case Industry X’.

- 18.How the pandemic wiped out oil demand in the world, in Energy World from The Economic Times: https://energy.economictimes.indiatimes.com/news/oil-and-gas/how-the-pandemic-wiped-out-oil-demand-around-the-world/.

- 19.Press Trust of India-Assam well fire continues, Army joins efforts to douse blaze: https://www.outlookindia.com/newsscroll/assam-well-fire-continues-army-joins-efforts-to-douse-blaze/1867172.

- 20.Christopher M., Peck H. 2004. Building the Resilient Supply Chain. [DOI] [Google Scholar]

- 21.American Petroleum Institute Article-Transporting oil & natural gas: https://www.api.org/oil-and-natural-gas/wells-to-consumer/transporting-oil-natural-gas.

- 22.Aiden Leibel, Callaghan Seagram, Carly McMann, Maia McLellan, Hayden Oliveira, Trusha Savaliya, and Kimmy Bhandal- Project Report on Transportation of Oil and Gas: https://web.uvic.ca/~djberg/Chem300A/GroupLM_OilGasMovement_Proj1.pdf.

- 23.Matthew Farmer- Offshore Technology Article:What does the future hold for the oil and gas workforce: www.offshore-technology.com/features/workforce-offshore-oil-gas-shale-employment-investment/.

- 24.Muqsit Ashraf, Manas Satapathy, Vivek Chidambaram Accenture Report-How oil and gas companies can build resilience in uncertain times: https://www.accenture.com/in-en/insights/energy/coronavirus-oil-gas-companies-build-resilience-uncertain-times.

- 25.Fawcett S.E., Magnan G.M., McCarter M.W. 2008. A Three-Stage Implementation Model for Supply Chain Collaboration. [DOI] [Google Scholar]

- 26.Daugherty P.J. 2011. Review of Logistics and Supply Chain Relationship Literature and Suggested Research Agenda. [DOI] [Google Scholar]

- 27.Rethinking Collaboration in the Oil and Gas Industry https://www.software.slb.com/insights/articles/rethinking-collaboration-in-the-oil-and-gas-industry.

- 28.Banyai T. 2016. Smart Scheduling: An Integrated first Mile and Last Supply Approach - [DOI] [Google Scholar]

- 29.Kumar, P., Shankar, R. and Yadav, S.S. (2008)-Flexibility in the global supply chain: modeling the enablers: 10.1108/17465660810920609. [DOI]

- 30.Biao Yang, Neil D. Burns, C.J. Backhouse- Postponement: A Review and an Integrated Framework: 10.1108/01443570410532542. [DOI]

- 31.Hau L. Lee Harvard Business Review-The Triple-A Supply Chain: https://hbr.org/2004/10/the-triple-a-supply-chain. [PubMed]

- 32.Miguel Baptista Nunes, Fenio Annansingh and Barry Eaglestone- Knowledge management issues in knowledge-intensive SMEs: www.emeraldinsight.com/0022-0418.htm.

- 33.Joseph Blackburn, Gary Scudder-Supply Chain for Perishable Products: The Case of Fresh Produce: 10.1111/j.1937-5956.2009.01016.x. [DOI]

- 34.Maria Jesus Saenz and Elena Revilla-MIT Sloan Management review-Creating more Resilient Supply Chain: https://www.researchgate.net/publication/264037785_Creating_More_Resilient_Supply_Chains/link/0a85e53c925ca08eb9000000.

- 35.COVID-19: Managing cash flow during a period of crisis https://www2.deloitte.com/content/dam/Deloitte/global/Documents/About-Deloitte/gx-COVID-19-managing-cash-flow-in-crisis.pdf.

- 36.Managing Working Capital in the Challenging Oil and Gas Industry https://www.americanexpress.com/en-ca/business/trends-and-insights/articles/managing-working-capital-in-the-challenging-oil-and-gas-industry/.

- 37.Stanley Ngene, Kiran Tota-Maharaj, Paul Eke, Colin Hills-Environmental Implications of Flaring and Venting in Crude Oil and Natural Gas Production: http://article.sciencepublishinggroup.com/html/10.11648.j.ijema.20160406.13.html.

- 38.System Dynamics Article on Wikipedia: https://en.wikipedia.org/wiki/System_dynamics.

- 39.ISEE Systems Information on Stella and iThink: https://www.iseesystems.com/resources/help/v1-2/.

- 40.Karen Clay Akshaya Jha Nicholas Muller Randall Walsh-The External Costs of Transporting Petroleum Products by Pipelines and Rail: 10.5547/01956574.40.1.kcla. [DOI]

- 41.Piyush Choudhary, Rakesh Kumar Srivastava and Somnath De-Integrating Greenhouse gases (GHG) Assessment for Low Carbon Economy Path: Live Case Study of Indian National Oil Company 10.1016/j.jclepro.2018.07.032. [DOI]

- 42.Ministry of Petroleum & Natural Gas, Government of India-Ready Reckoner Snapshot of India's Oil & Gas data: http://petroleum.nic.in/sites/default/files/readyrecknor_Mar14.pdf.

- 43.Ministry of Petroleum & Natural Gas, Government of India-Reports and Studies: https://ppac.gov.in/content/5_1_ReportStudies.aspx.

- 44.Ministry of Petroleum and Natural Gas-Annual Report 2018-2019: http://petroleum.nic.in/sites/default/files/AR_2018-19.pdf.

- 45.Federation of Indian Petroleum Industry-Upstream: https://www.fipi.org.in/index.php/upstream.

- 46.Bloomberg Article India set to take a Rs 40,000 crore blow on account of oil revenue loss https://economictimes.indiatimes.com/news/economy/finance/india-set-to-take-a-rs-40000-crore-blow-on-account-of-oil-revenue-loss/articleshow/75465597.cms?from=mdr.

- 47.Daniel Oberhaus-The world is still producing more oil than it needs, Article in Wired: https://www.wired.com/story/the-world-is-still-producing-more-oil-than-it-needs-why/.

- 48.The Destabilizing effect of Covid-19 https://www.opec.org/opec_web/en/press_room/5874.htm.