Abstract

Highlights

This article systematically reviews the thermal management wearables with a specific emphasis on materials and strategies to regulate the human body temperature.

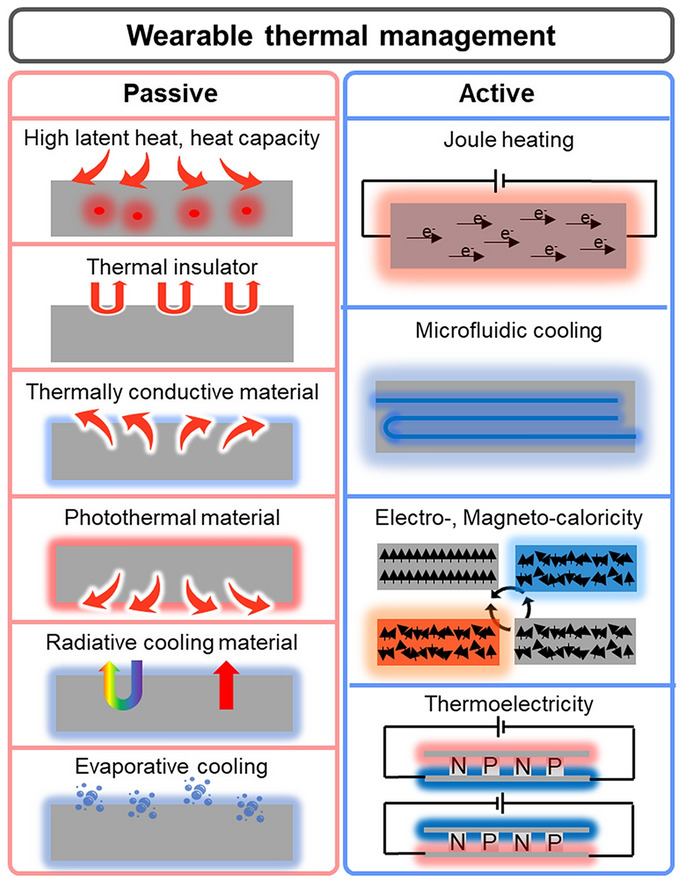

Thermal management wearables are subdivided into the active and passive thermal managing methods.

The strength and weakness of each thermal regulatory wearables are discussed in details from the view point of practical usage in real-life.

Abstract

Thermal management is essential in our body as it affects various bodily functions, ranging from thermal discomfort to serious organ failures, as an example of the worst-case scenario. There have been extensive studies about wearable materials and devices that augment thermoregulatory functionalities in our body, employing diverse materials and systematic approaches to attaining thermal homeostasis. This paper reviews the recent progress of functional materials and devices that contribute to thermoregulatory wearables, particularly emphasizing the strategic methodology to regulate body temperature. There exist several methods to promote personal thermal management in a wearable form. For instance, we can impede heat transfer using a thermally insulating material with extremely low thermal conductivity or directly cool and heat the skin surface. Thus, we classify many studies into two branches, passive and active thermal management modes, which are further subdivided into specific strategies. Apart from discussing the strategies and their mechanisms, we also identify the weaknesses of each strategy and scrutinize its potential direction that studies should follow to make substantial contributions to future thermal regulatory wearable industries.

Keywords: Thermal management, Passive heat transfer, Active heat transfer, Wearable materials, Wearable device

Introduction

The recent advance in nanomaterials and manufacturing processes facilitated the emergence of smart wearables and many wearable applications. Wearable thermal management has received considerable attention in various academic and industry fields because thermal management is deeply associated with homeostasis in our body. Our bodies generate heat, and we rely on our environment to help us dissipate that heat through sweating and radiation to maintain homeostasis. Still, it becomes problematic if the environment temperature deviates largely from our body temperature. For instance, severe dysfunction of thermoregulation in our body harms enzymatic activities and can even lead to multiple organ failures in extreme cases [1, 2]. Besides serious thermoregulatory malfunctioning of the body, thermal discomfort affects our performance and productivity in everyday life. In this regard, air conditioners and heat pumps have been used to regulate the indoor temperature of buildings and vehicles. Still, air conditioners and heat pumps utilize refrigerants such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) that adversely impact the environment [3].

Thus, many alternatives have been developed to promote human thermal management in a wearable form due to the recent advancements in material science and wearable technologies. Instead of regulating the indoor atmosphere temperature, regulating the body temperature directly is rather effective. Therefore, researchers devised various innovative thermal management methods to control body temperature, including nanomaterials to devices with novel functionalities. There are a considerable number of review articles on thermal management wearables. Still, no review paper has systematically categorized thermal management into methodologies. However, several strategies exist to control the body temperature besides simply cooling and heating the human body.

This paper reviews the recent advances in wearable thermal management materials and innovative strategies to help regulate human body temperature. To present them systemically, we categorized thermoregulatory wearables into active and passive thermal management, further subdivided into various strategies of functional materials and devices. The paper discusses the strengths and limitations of each material/device that constitutes each strategy, and then it concludes with the future perspective and challenges of thermal regulatory wearable technologies.

Strategies for Wearable Thermal Management

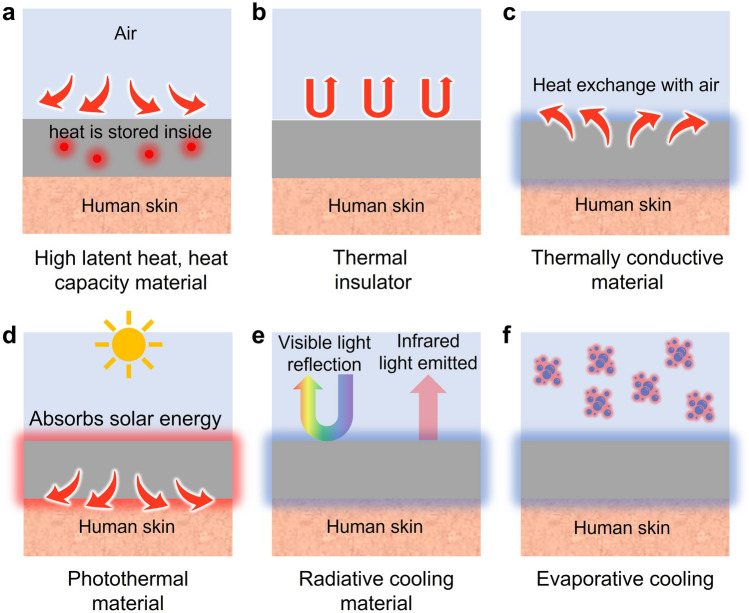

Figure 1 describes various strategies to artificially regulate the human body temperature in passive modes. Figure 1a presents the first strategy of passive thermal management: materials with high latent heat and heat capacity to absorb/release the heat from/to the surroundings such that the external heat is not transferred to the human body. These include a variety of polymers and phase-change materials (PCMs) that absorb/release a substantial amount of heat at a certain temperature. Since PCMs can absorb a vast amount of heat, utilizing PCMs as thermal management materials can be desirable. However, PCMs have a specific phase change temperature, which limits their effectiveness in a wide range of temperature because PCMs would not be able to absorb/release energy if the ambient temperature does not reach the phase change temperature. Another method of passive thermal management is to exchange heat with the surrounding environment by employing materials with high thermal conductivity, including metals and conductive polymer nanomaterials that possess exceptional thermal conductivity (Fig. 1b). Using thermally conductive materials to facilitate heat transfer from/to the surrounding environment can be an effective strategy. Nevertheless, since they follow a passive mechanism, they might transfer heat to/from the human body even when thermal management is not desired. Conversely, inhibiting the heat transfer from the external environment to the human body can be an alternative strategy to achieve thermal management, as in Fig. 1c. It includes a variety of thermal insulators and innovative nanostructures that hinder heat transfer. Although insulating heat transfer can offer a potent solution to attain thermal management, the thermal insulators might cause problematic issues since they can reduce breathability and trap excess heat, which can rather cause discomfort. Furthermore, photothermal materials can heat up by themselves during the daytime in sunlight. These materials collect light energy and convert it into thermal energy, as shown in Fig. 1d, providing thermal management without any electrical power. Nonetheless, the use of the photothermal effect might involve a serious disadvantage since it can elevate the body temperature and even cause a skin burn as the photothermal effect occurs constantly. On the other hand, radiative cooling does the exact opposite of photothermal materials. It can cool down the human body temperature by reflecting visible light while emitting mid-infrared light to space (Fig. 1e). Radiative cooling does not require electricity to generate cooling since it transfers heat to the space by radiation. Yet, just as the photothermal effect, it might cause thermal discomfort because radiative cooling occurs constantly and cannot be controlled. Lastly, evaporative cooling can regulate body temperature as a passive thermal management strategy. These materials artificially facilitate sweat evaporation and decrease the body temperature since sweat evaporation takes energy with it in heat. Specifically, the heat energy from the skin is used to convert the liquid sweat into water vapor. Although evaporative cooling offers an effective tool to regulate body temperature, evaporative cooling suffers from several limitations such as limited effectiveness in high humidity conditions and increased water loss in the human body.

Fig. 1.

Passive thermal management methods: a high latent heat or high heat capacity materials to store heat from the external environment. b Thermal insulator that minimizes heat transfer to the human skin. c Thermally conductive material that exchanges heat with the air. d Photothermal material that absorbs solar energy and heats up the human skin. e Radiative cooling material that refrigerates the human skin by reflecting visible light and emitting infrared light toward space. f Evaporative cooling materials that facilitate liquid-to-vapor transition

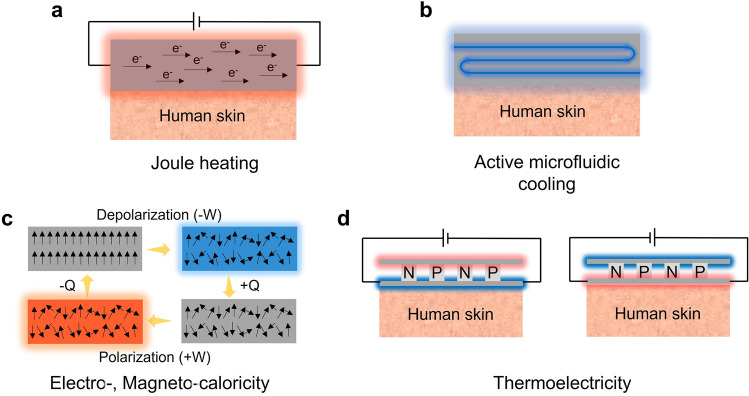

Figure 2 mainly addresses wearable electronics that can cool or heat by actively transferring heat from/to the human body with external input. Figure 2a delineates the mechanism of Joule heating that serves to actively heat in the presence of electrical input. Joule heating is based on the principle that the flow of electrons experiences resistance when they encounter obstacles in the conductor's atomic structure, such as impurities or defects. As the electrons encounter resistance, they lose some of their kinetic energy, which is converted into heat energy. Due to the simple working mechanism, there have been a great number of works on wearable Joule heaters, and Joule heaters can be fabricated in a highly stretchable and thin form such that they can make intimate contact with the skin surface for efficient heat transfer. However, the Joule heater can only provide heating and requires an external power source to supply electrical voltage to the device. Microfluidic cooling exemplifies another example of active wearable thermal management, as shown in Fig. 2b. Microfluidic cooling is a mechanism that involves the use of microscale fluid flow to transfer heat away through convective heat transfer. The development of elastomeric polymer and microfluidic channel manufacturing techniques enables the application of microfluidic cooling for wearable purposes. Depending on the fluid temperature, the microfluidic channels can cool or even heat the human body, but just as Joule heating, they require the external pump to facilitate the fluid circulation, and the incorporation of the pump might aggravate the wearability of the device. Figure 2c illustrates the mechanism of electrocaloric and magnetocaloric devices that induce a reversible temperature change in a material using the electric (electrocaloric) or magnetic (magnetocaloric) fields, respectively. In the process, the entropy of material changes in response to an applied electric/magnetic field, leading to a temperature change, which can be used to cool or heat an arbitrary object, depending on the direction of the applied field. However, one of the most critical limitations of electrocaloric and magnetocaloric devices for wearable applications arises because it requires an additional actuating system to constantly transfer heat in one direction to cool or heat actively. Such a drawback of electrocaloricity and magnetocaloricity limits its widespread use in wearable thermal management applications. We will further discuss its limitations and exemplary studies that overcame such weaknesses in the following section. Lastly, Fig. 2d illustrates the mechanism of thermoelectric devices, which utilizes electrical input to generate active cooling and heating, as electrocaloric and magnetocaloric devices do. However, unlike these devices, thermoelectric devices follow a completely different physical mechanism to induce the temperature difference. In the presence of the electrical voltage, the charged carriers, such as holes and electrons, instantly diffuse to one side of the device, so the device side, which is densely populated with holes and electrons, starts to heat up due to the vibrational energy of the charged carriers, and the other side cools down. Also, unlike many devices and materials that can only cool or heat with a single device structure, the thermoelectrical device can both cool and heat an arbitrary object or space simply by reversing the direction of the electrical current. For this reason, there exists a great number of stretchable and flexible thermoelectric devices that are developed to actively regulate the human body temperature, but just as other active thermal management methods, they require an external power source for electricity input and suffer from low cooling efficiency [4]. Tables 1 and 2 summarize representative works on each mechanism of passive and active thermal management wearables.

Fig. 2.

Active thermal management methods: a Joule heating. b Active microfluidic cooling. c Electro-, magnetocaloric cooling and heating. d Thermoelectric device cooling and heating

Table 1.

Passive thermal management wearables

| References | Active/ passive | Heat transfer mechanism | Capability to cooling and heating | Thermal management performance | Energy consumption | Flexible/ stretchable | Breathability |

|---|---|---|---|---|---|---|---|

| [5] | Passive | Latent heat storage | Heating | High thermal conductivity (5.34 W m−1 K−1), high enthalpy (125.2 J g−1) | No | Flexible | |

| [6] | Passive | Latent heat storage | Heating | N/A | No | Flexible/ stretchable | No |

| [7] | Passive | Latent heat storage | Cooling & heating | Phase change temperature from 5 to 60 °C with varying PEG molecular weights and high latent heat (118.7 J g−1) | No (Yes for electrical heating) | Flexible | No |

| [8] | Passive | Latent heat storage | Cooling & heating | High dimension retention ratio (98.1%) and latent heat value (163.3 J g−1) | No | Flexible/ stretchable | Breathable |

| [9] | Passive | Latent heat storage | Cooling & heating | Latent heat (158.65 J g−1) and economic benefits (4.85 × 10−3 ¥ J−1) | No | Flexible | No |

| [10] | Passive | Heat conduction | N/A | Thermal conductivity of 1.37 W m−1 K−1 | No (Yes for sensing) | Flexible/ stretchable | Breathable |

| [11] | Passive | Heat conduction | N/A | Thermal conductivity (20–30 W m−1 K−1) | No | Flexible | No |

| [12] | Passive | Latent heat storage & heat conduction | Cooling & heating | Enthalpy of 206.0 J g−1 | No | Flexible | No |

| [13] | Passive | Latent heat storage & heat conduction | N/A | Thermal diffusivity of 0.307 mm2 s−1 and latent heat of 94.29 J cm−3 | No | Stretchable | No |

| [14] | Passive | Thermal insulation | N/A | Low thermal conductivity of 0.031 W·m–1 K–1 and high heat resistance (> 500 °C) | No | Stretchable | No |

| [15] | Passive | Thermal insulation | N/A | N/A | No | Flexible | No |

| [16] | Passive | Thermal insulation | N/A | Temperature-invariant compression resilience from − 196 to 1000 °C, and thermal conductivity as low as 0.034 W·m−1 K−1 | No | Stretchable | Breathable |

| [17] | Passive | Thermal insulation | N/A | High-temperature resistance < 1,300 °C and low thermal conductivity of 0.0322 W m−1 K−1 | No | Flexible | No - |

| [18] | Passive | Thermal insulation | N/A | Temperature-invariant superelasticity from − 196 to 1100 °C, low thermal conductivity of 0.0223 W m−1 K−1 | No | Flexible | No - |

| [19] | Passive | Thermal insulation | N/A | Excellent thermal stability at temperatures as high as 1200 °C in butane blow torch or as low as − 196 °C in liquid nitrogen and a thermal conductivity of 28.4 mW m−1 K−1 | No | Stretchable | No - |

| [20] | Passive | Photothermal effect | Heating |

Temperature increase of ∼111 ± 2.6 °C after the application of 600 mW cm–2 light irradiation for 5 min a high optical transmittance of ∼83% |

No | Stretchable | No |

| [21] | Passive | Photothermal effect | Heating | Temperature increases of 60 °C | No | Flexible | No |

| [22] | Passive | Photothermal effect | Heating | 19.7 °C increase with a light intensity of 1,000 W m−2, | No | Stretchable | No |

| [23] | Passive | Photothermal effect | Heating | Light absorbance of > 95% from ultraviolet to far infrared range | No | Flexible | No |

| [24] | Passive | Photothermal effect | Heating | Equilibrium temperature of 65.4 °C under one-sun illumination | No (Yes for electrical heating) | Stretchable | No |

| [25] | Passive | Photothermal effect | Heating | Passive radiative heating (4.9 °C higher than conventional cotton), Solar heating (73.5 °C) | No (Yes for electrical heating) | Flexible | Breathable |

| [26] | Passive | Sweat evaporation & heat conduction | Cooling | 50% higher evaporation rate (1.6 mL h−1) than conventional fabrics | No | Flexible | Breathable |

| [27] | Passive | Sweat evaporation | Cooling |

Sweating rate (520 mL h m2 h−1) ~ 32.3 °C (on the other hand, the temperature of skin covered with normal wicking layer ~ 35.9 °C) |

No | Flexible | Breathable |

| [28] | Passive | Sweat evaporation | Cooling | Forward transportation capability of 1,115%, Backward transportation capability of − 1509% | No | Flexible | Breathable |

| [29] | Passive | Sweat evaporation & heat conduction | Cooling | one-way transport index (1072%), water evaporation rate (0.36 g h−1) | No | Stretchable | Breathable |

| [30] | Passive | Sweat evaporation and heat conduction | Cooling | 3 times higher skin power density (dq/dv) increment than conventional cotton, ~ 3 °C lower than the human body covered with cotton | No | Flexible | Breathable |

| [31] | Passive | Radiative cooling | Cooling | ~ 8, ~ 12.5, ~ 19 °C lower than the same skin covered with natural silk or cotton or left uncovered, respectively | No | Flexible | Breathable |

| [32] | Passive | Radiative cooling | Cooling | ~ 4.8 °C lower than the human body covered with commercial cotton fabric | No | Stretchable | Breathable |

| [33] | Passive | Radiative cooling & photothermal | Cooling & Heating | Cooling: 3.7 °C lower than the skin simulator covered with white cotton, Heating: 6.2 °C higher than the skin simulator covered with black cotton | No | Flexible | Breathable |

| [34] | Passive | Radiative cooling & sweat evaporation | Cooling | ~ 4.2 °C lower than the human body covered with commercial cotton textile | No | Flexible | Breathable |

| [35] | Passive | Radiative cooling & sweat evaporation | Cooling | ~ 16.6 °C lower than the commercial textiles, including a contribution from sweat management (~ 8.2 °C) | No | Flexible | Breathable |

| [36] | Passive | Radiative cooling & sweat evaporation | Cooling |

~ 2.6 °C lower than that of cotton without perspiration ~ 1.0 °C lower than that of cotton only with evaporation cooling |

No | Flexible | Breathable |

| [37] | Passive | Radiative cooling & Sweat evaporation | Cooling | ~ 21.9 °C lower than the traditional cotton-covered skin simulator | No | Flexible | Breathable |

Table 2.

Active thermal management wearables

| References | Active/ passive | Heat transfer mechanism | Capability to cooling and heating | Thermal management performance | Energy consumption | Flexible/ stretchable | Breathability |

|---|---|---|---|---|---|---|---|

| [38] | Active | Heat conduction | Heating | 272 °C at 2.5 V, 89 °C at 1.4 V where environmental temperature was − 30 °C, saturation time of 6 s | 0.85–4.25 W | Stretchable | No |

| [39] | Active | Heat conduction | Heating | Up to 80 °C depending on input voltage | 0.11–4.05 W | Stretchable | Yes |

| [40] | Active | Heat conduction | Heating | Up to 45 °C by safety feedback control@@100 °C at 6 V, saturation time 16 s | 1.0–1.6 W | Flexible | Yes |

| [41] | Active | Heat conduction | Heating | Up to 40 °C by considering conduction, saturation time 1–2 s, 120 °C at 7 V | 1.0–6.0 V | Stretchable | Yes |

| [42] | Active | Heat conduction | Heating | saturation time < 0.6 s by active control, target temperature 25.5 to 36 °C | 1.94 W for blue color | Flexible | No |

| [43] | Active | Heat conduction/ convection | Both | 3–58 °C for robot hand@@27 s to phase transit solid gallium microgranule to liquid@@49 s from liquid to solid | N/A (liquid injection) | Flexible | No |

| [44] | Active | Heat conduction/ convection | Cooling | − 1.4 °C for nerve temp, maximum cooling rate of 3 °C s−1 | N/A (liquid injection) | Flexible | No |

| [45] | Active | Heat conduction/ convection | Cooling | 35.3 to 20.3 °C, saturation time 300 s | N/A (liquid injection) | Flexible | No |

| [46] | Active | Heat conduction/ convection | Both | N/A | 16 μW cm-2 (generation) | Flexible | No |

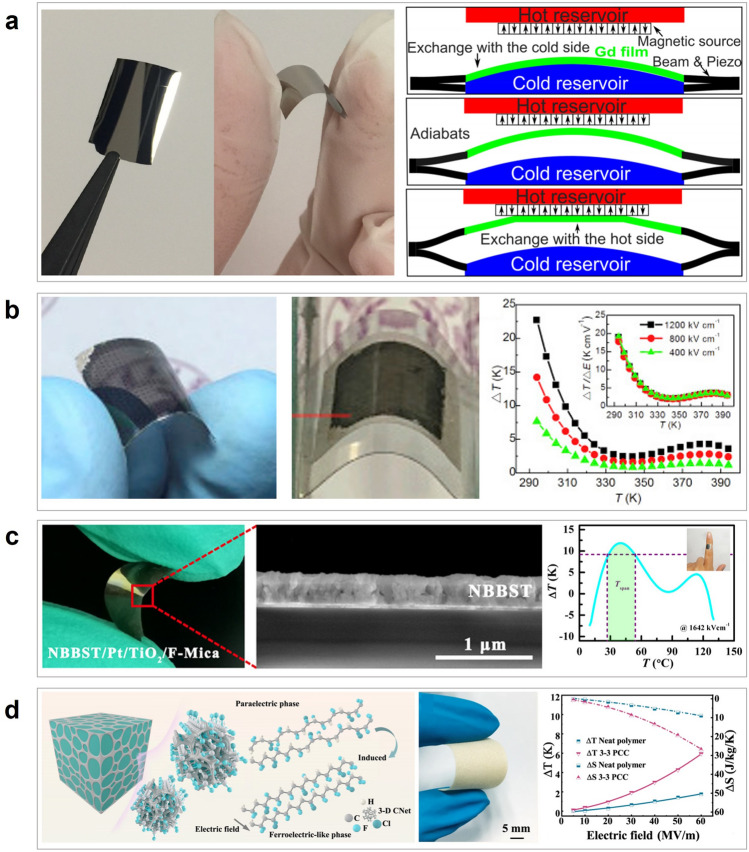

| [47] | Active | Heat conduction | Both | ΔT = 10.1 K, Q = 5.0 kJ kg−1 at room temp (under 60 MV m−1) | N/A | Flexible | No |

| [48] | Active | Heat conduction | Both | ΔT = 22.5 K at room temp (under 1,200 kV cm−1) | N/A | Flexible | No |

| [49] | Active | Heat conduction | Both | ΔT = 12 K at room temp ΔT/ΔE = 0.007 K cm kV-1 | N/A | Flexible | No |

| [50] | Active | Heat conduction | Both | ΔT = 13.99 K at -30 °C (under 1500 kV cm−1), ΔT = 5.08 K at 70 °C (under 1500 kV cm−1), | N/A | Flexible | No |

| [51] | Active | Heat conduction | Both | ΔT = 6 K (under 600 kV cm−1) with high thermal conductivity, saturation time 13.0 to 17.8 s | N/A | Flexible | No |

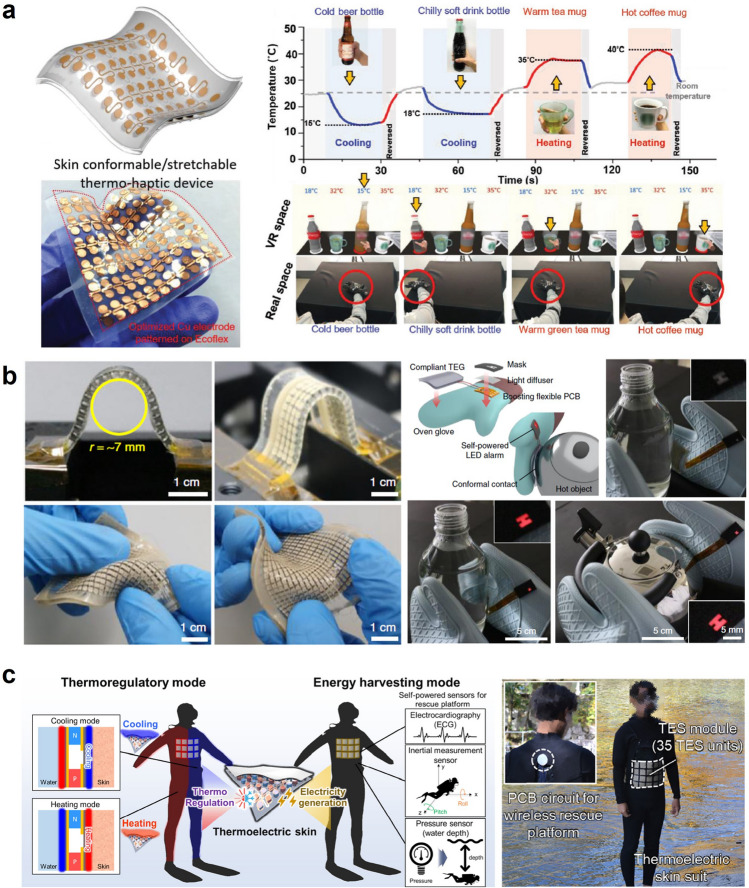

| [52] | Active | Heat conduction | Both | ΔT = 15 K, saturation time 3.52 s for heating, 4.48 s for cooling with active control | 0.2–1.5 A | Stretchable | No |

| [53] | Active | Heat conduction | Both | 10–50 °C for cloaking saturation time 5.1 s for heating, 6.4 s for cooling with active control | 0.6–1.5 A | Flexible | No |

| [54] | Active | Heat conduction | Both | N/A | 7.02 mW (generation) | Stretchable | No |

| [55] | Active | Heat conduction | Both | ≈ 34 °C by PID controlled thermoregulation | 0.7—2 A | Stretchable | No |

Passive Thermal Management

High Latent Heat Storage

Latent heat storage (LHS) stores heat in a storage medium in the form of potential energy between the particles of the substance. Converting heat to potential energy within a substance involves a phase change, resulting in heat storage without significant changes in the storage medium's temperature. The capacity of latent heat storage can be calculated using the following method:

| 1 |

where γ is latent heat in kJ/kg and m is the mass in kg. The thermal storage density of the storage medium can be expressed below:

| 2 |

where and are volume and density in cm3 and kg cm−3, respectively.

PCMs are increasingly used for latent heat storage (LHS) due to their ability to store a large amount of heat during phase transition, providing superior thermal stability and compatibility. LHS is a high-energy density storage technology that can maintain a constant temperature that matches the phase transition temperature of the PCM. This confers a significant advantage over other thermal energy storage technologies, as it can store more heat and better stabilize the temperature [56, 57]. LHS has a wide range of applications in various fields, including heating and cooling systems [58–63], where it can store thermal energy during low-demand hours and release it when needed, thus reducing energy consumption and costs during high-demand hours. Another promising application is in solar thermal energy storage [64–66], where LHS can store solar energy collected during the daytime and release it at night or during cloudy days, providing a reliable energy source for heating and electricity generation.

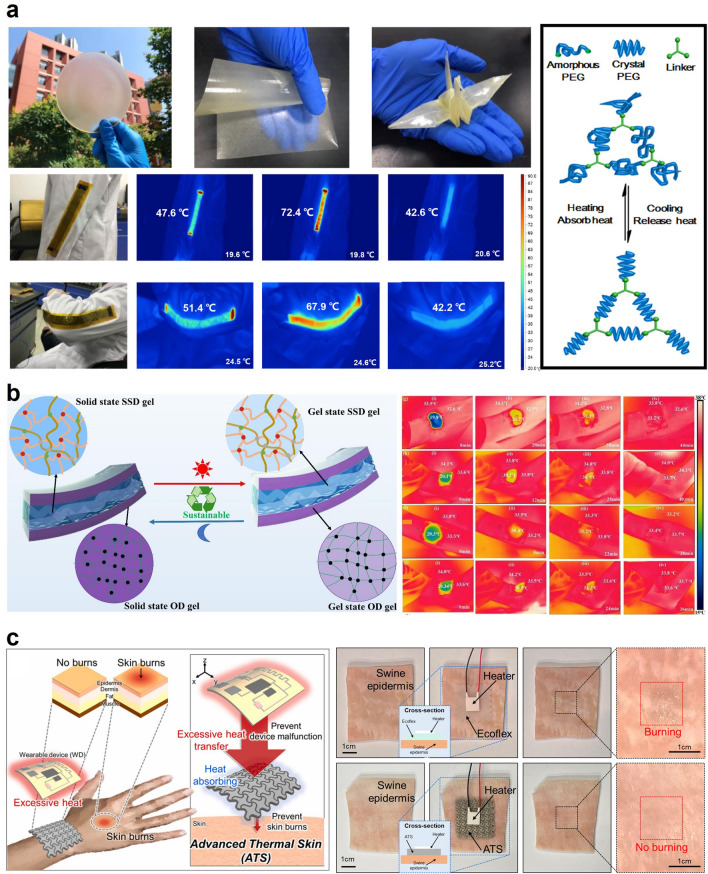

Recently, latent heat storage (LHS) technology has been explored for thermal management in wearable devices [5, 6, 67]. However, the use of phase change materials (PCMs) in this application remains challenging due to their solid rigidity and potential for liquid leakage. To address these issues, Qi et al. developed a new method for thermal management in wearable devices using a flexible PCM film to address the issues of solid rigidity and liquid leakages of conventional PCMs, as in Fig. 3a. This involved synthesizing large-area intrinsic PCM films (MTPEG) with excellent self-support, ultra-flexibility, and shape-conformability through chemical tailoring melamine and toluene-2,4-diisocyanate (TDI) with polyethylene glycol (PEG) materials. The integration of flexible PCM films and a flexible graphene film as a thermal source can result in exceptional temperature control and electro-thermal and photothermal energy conversion performance. For example, the PCM film developed in this work shows the controllable phase change temperature between 5 and 60 °C by adjusting the chemical composition of PEG. Also, the PCM herein exhibited a high latent heat of 118.7 J g−1 and remained intact even after 1,000 heating cycles of the solid–solid transitions. To demonstrate the high energy-storing capability of the proposed PCM, the authors integrated the PCM into the flexible graphene film and applied the electrical current of 1.5 A. The result showed high electro-thermal energy conversion efficiency of 94% and substantiated its potential usage in wearable thermal management applications [7].

Fig. 3.

Heat storage-based personal thermal management: a Phase-change hydrogels with thermal energy storage for personal healthcare. Reproduced with permission [7]. Copyright 2022, Elsevier. b Self-healable thermal energy storage for personal thermal management. Reproduced with permission [9].

Copyright 2023, Elsevier. c High heat storage and thermal diffusivity-based thermoregulation. Reproduced with permission [13]. Copyright 2023, Elsevier

Another work on the flexible PCM by Luo et al. presents the sandwich-structured thermal energy storage composite based on two different PCM gel materials, as shown in Fig. 3b. The authors encapsulated the inorganic PCM (sodium sulfate decahydrate) with the organic PCM (octadecane) to attain high-form stability, cyclic stability, self-repairing, biocompatibility, and latent heat. The encapsulating design that confines sodium sulfate decahydrate endows the material composite with biocompatibility since sodium sulfate is known to be toxic due to high concentrations of salts. As a heat-storing material, the resultant composite exhibits a high latent heat of 158.65 J g−1 without supercooling. Apart from the thermal characteristics of the PCM, the material shows high form-stability without leakage of inorganic PCM that arises from the crosslinking of the inorganic PCM and physical encapsulation of the organic PCM. Also, the material did not show a substantial degradation in thermal performance even after 200 cycles of heating and cooling. Moreover, the material developed in this work exhibits the self-repairing feature based on chemical bonds such as hydrogen, ionic, and Van der Waals bonds that contribute to physical reattachment to the corresponding counterpart. To corroborate its potential applications to thermoregulatory wearables, the authors validated the heat-storing capability of PCM by mounting the PCM composite and examining the body temperature [9].

Besides the outstanding works on the heat-storing capabilities of PCMs, our group recently demonstrated the human skin-like material composite that exhibits both high thermal diffusivity and heat storage capability, as shown in Fig. 3c. Despite the favorable thermal properties of phase change materials (PCMs) for wearable thermal management, their low thermal diffusivity is a significant intrinsic limitation. This low thermal diffusivity hinders heat diffusion within the PCM matrices, leading to the concentration of external heat at localized spots without dispersion to the rest of the PCM matrices. To address this issue of the conventional PCMs, the study presented a novel interfacial layer between the skin and wearable device, which consists of a serpentine structure made of silver flake and polydimethylsiloxane (SPS) and a sodium-acetate-based hydrogel matrix (SAHM). The high thermal diffusivity of SPS ensures an even distribution of heat, while the high thermal storage capability of SAHM enables heat absorption without a significant temperature increase. This layer offers both thermal protection to the skin and prevention of device malfunctioning by efficiently absorbing the heat released from the device. Also, owing to the incorporation of hydrogel matrix into the composite, SAHM is found to retain a small modulus change of 4.8 fold while maintaining comparable heat capacity to paraffin (94.29 J cm−3), distinguishing it from typical PCMs and thus addressing the intrinsic limitation of the high modulus change between the liquid and solid phases. The phase-independent softness of the PCM in this work promotes conformal contact with deformable surfaces and enhances the potential for wearable thermal management applications [13]. As discussed, the heat storage materials, especially PCMs, exhibit the desirable features to be applied to the heat regulatory wearables as they can absorb or release heat depending on the temperature gradient. Some recent works, as mentioned above, addressed the intrinsic limitations of conventional PCMs, such as mechanical modulus variation between phases, leakage, and low thermal diffusivity. Nevertheless, further research needs to be done on enhancing the latent heat because the temperature of PCM starts to change after the phase transition. It can cause an undesirable heat transfer between the human body and the external environment.

Thermally Conductive Material

Thermally conductive materials play a crucial role in regulating the temperature of objects by exchanging heat with the surrounding medium, following the equation below:

| 3 |

where , and correspond to local heat flux density, thermal conductivity, and temperature gradient (in this case of thermal management application, the temperature gradient between the body temperature and the surrounding medium), respectively. Recent advancements in nanomaterials and manufacturing technology have led to the development of thermally conductive materials that can elastically deform under stress, making them suitable for wearable applications. By controlling the alignment of the thermally conductive materials, the thermal conductivity of these materials can be tailored to enhance heat transfer in the cross-plane or in-plane directions. Although some studies have not specifically controlled the alignment of the materials [68, 69], aligning them in the cross-plane or in-plane direction is far more effective. For example, materials with high cross-plane thermal conductivity can passively cool the human body temperature by transferring heat from the skin to the external environment [54, 70–84]. On the other hand, materials with high in-plane thermal conductivity can effectively spread heat in the lateral direction, which is particularly useful when the skin temperature of a localized region is too high or low [85–95]. Several fabrication methods are available to control the alignment of thermally conductive materials in both the cross-plane and in-plane directions. One widely used technique to align the thermally conductive materials in the cross-plane direction is to incorporate the magnetic materials into the uncured elastomeric base material and then magnetize the materials while thermal curing such that these materials align in the vertical direction. The filler material for the cross-plane alignment can either have the ferromagnetic characteristic along with high thermal conductivity, as AgNi [54], or the ferromagnetic material can be coated on the surface of the thermally conductive materials [75, 96, 97].

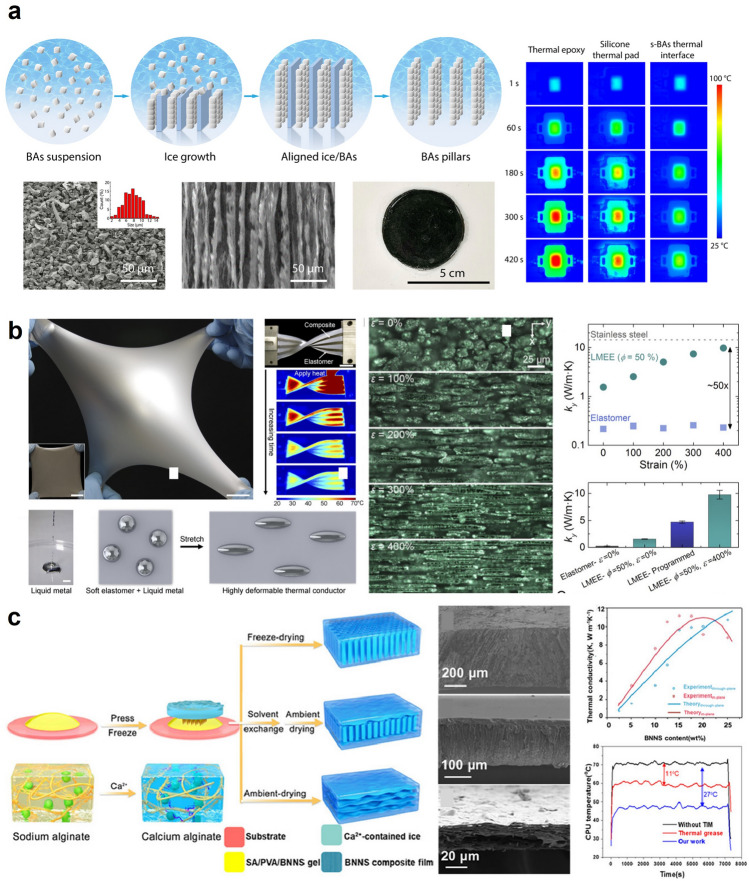

Apart from magnetizing the thermally conductive fillers, an interesting study by Cui et al. demonstrated a flexible thermal interface material for high-performance thermal management applications using self-vertically assembled manufacturing of cubic boron arsenides (BAs), as shown in Fig. 4a. Through the rational design of BAs microcrystals in a polymer composite, BAs exhibited highly desirable properties such as high thermal conductivity up to 21 W m−1 K−1 in the cross-plane direction and excellent elastic compliance similar to soft biological tissues down to 100 kPa. Furthermore, the BAs showed high flexibility and maintained high conductivity over at least 500 bending cycles, opening up new applications for flexible thermal cooling. Furthermore, the group also demonstrated device integration with power LEDs. They measured the superior cooling performance of BAs beyond the current state of the art, with hot spot temperatures reduced by up to 45 °C. This research demonstrates the scalable manufacturing of a new generation of energy-efficient and flexible thermal interfaces, which hold great promise for the advanced thermal management of semiconductors. Although the scope of this research focused on the cooling of electronic devices, the same structure of BA can be directly applied to the human thermal management application since it showed extremely high thermal conductivity in the cross-plane direction with skin-like Young’s modulus [98].

Fig. 4.

High thermal conductivity materials for passive thermal management: a Thermally conductive boron nitride composite that is aligned in the cross-plane direction. Reproduced with permission [98]. Copyright 2021, Springer Nature. b Thermally conductive liquid metal-elastomer composite that has the in-plane oriented alignment. Reproduced with permission [21].

Copyright 2017, PNAS. c Thermally conductive boron nanosheet composite that can be aligned both in the cross-plane and in-plane direction depending on the manufacturing method. Reproduced with permission [71]. Copyright 2022, Elsevier

To fabricate the materials with high in-plane thermal conductivity, the researchers resort to specific manufacturing techniques such as vacuum filtration [90], hot-pressing [88], and spraying [85]. An intriguing study investigated the thermal conductivity of a new type of soft elastomers that contain elongated liquid metal inclusions. Incorporating liquid metal into the elastomeric matrix can improve thermal conductivity to a certain extent. Hence, the research group claimed that they could “program” the thermal conductivity of the liquid metal inclusion elastomer by introducing the biaxial strain of 600%. Application of the biaxial strain results in 210% of the plastic deformation of the base elastomer, and such a mechanical deformation boosts up the in-plane thermal conductivity up to 9.8 W m−1 K−1, which is 50 times greater than the thermal conductivity of the pristine base elastomer. The liquid metal inclusions formed a continuous network throughout the elastomer, allowing for efficient heat transfer by facilitating the movement of heat-carrying phonons. The study suggests that these materials could be useful in a variety of applications where heat dissipation is important, such as in flexible electronics, wearable devices, or soft robotics. The material proposed in this work can also be employed for wearable thermal management applications as it exhibits high thermal conductivity as well as stretchability (Fig. 4b) [21].

A recent study by Huang et al. proposed a manufacturing method that can align the thermally conductive nanomaterials either in both the cross-plane and in-plane directions based on the method called ice-press assembly strategy. The authors created a composite film using boron nitride nanosheets (BNNS) arranged in a ladder-like structure, allowing heat conduction through the BNNSs. To fabricate the film, they used a precursor gel made from an aqueous solution of exfoliated BNNS. It was drop-casted and pressed by frozen ice containing Ca2+ to create a temperature gradient. Due to the weight and smooth surface of the ice, the precursor gel was able to spread out as a flat film. Additionally, the low temperature of the frozen ice caused the water in the precursor to solidify in an oriented manner, causing the suspended BNNS and polymer to align along the vertically arranged ice crystal boundaries and form a frozen monolith consisting of oriented ice crystals surrounded by the polymer. Here, Ca2+ ions and crosslinking of alginate prevent the composite films from dissolving in ethanol, improving the framework's mechanical properties and preventing collapse during drying. The composite film is frozen and then thawed in ethanol before being immersed in acetone and allowed to dry at room temperature to achieve a ladder-structured BNNS in the composite film. However, without freeze dying, BNNS in a precursor gel is deposited on top of one another, facilitating the heat transfer in the in-plane direction. Thus, the work presented a BNNS composite with anisotropic thermal conductivity generated based on the manufacturing methods. Such a flexible composite obtained in this study exhibits 9.6 and 11.2 W m−1 K−1 in the in-plane and cross-plane directions [71]. Recent studies also report manufacturing technologies that create alignment of the thermally conductive fillers in both in-plane and cross-plane [99].

Overall, materials with thermal conductivity regulate the body temperature by facilitating heat exchange between the human skin and the external environment. Thus, if the external temperature is lower than the body temperature, heat transfer will occur from the human body to the surrounding environment without external input, which would cool down the body temperature. However, materials with high thermal conductivities will rather exert a negative effect if the surrounding temperature is higher than the body temperature because, in this case, heat will be transferred to the human body from the external environment, so it is advisable to use the thermally conductive materials for the suitable conditions only.

Thermal Insulation

Thermal insulators are increasingly being considered for various applications, including thermal protection and energy conservation in industries, aerospace, and personal thermal management. Most thermal insulators utilize porous structures to prevent unnecessary heat transfer, because air has lower thermal conductivity than the solid phase, which reduces heat conduction and convection [100]. Aerogel-based materials have been extensively studied for their excellent insulating properties, particularly inorganic aerogels, due to their low thermal conductivity, thermal stability, and high insulating capability. However, challenges remain in using aerogels in a wearable form, mainly their brittleness and fragile properties. Organic aerogels have been studied as a promising alternative due to their outstanding toughness and superior flexibility. Nature-derived materials such as cellulose, chitosan, and polymeric materials have gained significant attention [101]. Nevertheless, the poor stability of organic aerogels at high temperatures limits their potential for widespread applications.

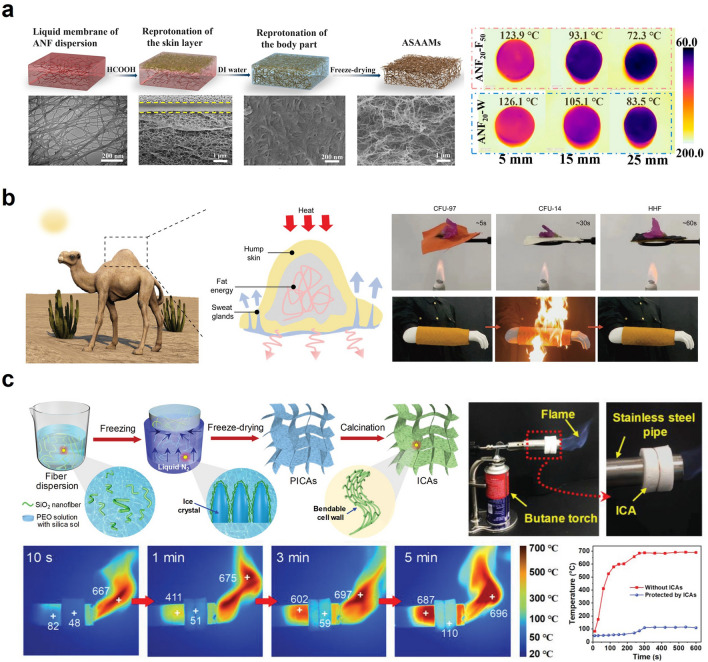

To address the stability issue of organic aerogels at high temperatures, Hu et al. developed aramid nanofiber (ANF) membranes that demonstrate exceptional heat resistance (> 500 °C) [14]. ANFs, typically fabricated from poly(p-phenylene terephthalamide) (PPTA) or Kevlar, have outstanding mechanical properties and excellent thermal stability (Fig. 5a). The researchers created asymmetric porous ANF membranes by subjecting ANFs to protonation processes using formic acid (HCOOH) and DI water as proton donors. The aerogels exhibited an enhanced tensile strength of 11.8 MPa (16.5 times) with an elongation break of 15% and could endure a load of 500 g, which is 3,600 times its weight, owing to their asymmetric structure. In addition, the ANF aerogel demonstrated a low thermal conductivity of 0.0031 W m−1 K−1, which is lower than that of commonly-used flexible insulators such as polystyrene foam, cellulose aerogel, and mineral wool. The aerogels did not shrink or deform after being heated for 10 s on fire, indicating that the carbonization of the dense layer would further block the burning of the inner ANFs. These excellent properties, such as low thermal conductivity and flame-retardancy, make ANF membranes a potential thermal insulator for harsh environments.

Fig. 5.

Thermal insulation for passive thermal management: a Aramid nanofiber aerogel for high-temperature (> 500 °C) thermal insulation. Reproduced with permission [14].

Copyright 2022, ACS Publications. b Hump-inspired fabric for firefighter thermal protection. Reproduced with permission [102]. Copyright 2023, Wiley–VCH. c Ceramic nanofiber aerogel with exceptional bendability and compressibility. Reproduced with permission [18]. Copyright 2020, Wiley–VCH

Likewise, most of the previous research literature has concentrated on wearable thermal insulators, which can further be utilized at elevated temperatures, yet still lack the dynamically controllable thermal insulators that can be adaptable in compliance with environmental changes. For this reason, Choe et al. presented a smart hairy skin for adaptive thermal insulation and camouflage in the infrared (IR) range (Fig. 5b) [102]. Inspired by a hairy structure that serves to block the heat transfer from the epidermis to the surrounding by the air layer between hairs standing upright, the as-presented hierarchically porous shape memory polymers (SMPs) could control the degree of thermal insulation by standing or lying depending on the temperature condition due to its shape memory characteristics. Note that the modulus change of SMPs around glass transition temperature is a key factor in determining shape memory behavior. Moreover, a hierarchically porous structure can also switch between pore-open and pore-closed states by the modulus change. Benefitting from the synergic effect of hair posture (standing and lying states) and pore (open and closed states) modulation, the hairy SMP composites were capable of modulating the thermal insulating performances (dynamic modulation of thermal insulation around 61.4%); at the hair-standing/pore-open states, the SMP composites exhibited high thermal insulation, and on the other hand, the hair-lying/pore-closed states decreased the thermal insulating performance. These smart hairy SMP composites with tunable thermal insulation properties hold promise for future thermoregulation applications such as personal thermal management, industrial energy-saving technologies, and wearable IR camouflages [15].

Similarly, numerous studies have investigated the development of wearable thermal insulators for personal thermal management. However, the need for a high-temperature-resistant thermal insulator that can withstand harsh environments remains a significant challenge. To address this issue, recent research efforts have focused on enhancing the mechanical robustness of inorganic aerogels, known for their high-temperature resistance, while preserving their beneficial properties. One of the major challenges in developing inorganic aerogels as robust wearable thermal insulators is their intrinsic brittleness. Therefore, researchers have explored novel approaches to enhance the mechanical properties of inorganic aerogels to make them suitable for a wide range of high-temperature applications [16, 17, 103–106]. Thus, Dou et al. provided bendable and compressible ceramic nanofibrous aerogels by integrating flexible SiO2 nanofibers with interwoven celluloses (Fig. 5c) [18]. Notably, architectural continuity is a key factor in determining mechanical robustness. The assembly of the silica nanofiber with a high aspect ratio and 3D structured celluloses achieved improved structural continuity, thereby exhibiting superior buckling and compressive recovery (up to 85%). Benefiting from the robust property, the ceramic aerogels presented temperature-invariant superelasticity over a broad temperature range (-193 ~ 1,100 °C). Moreover, the aerogels exposed to the flame of the butane torch showed a slow temperature increase to 110 °C. They maintained an almost constant temperature in the later minutes, implying the potent possibility for high-temperature thermal insulator applications. However, achieving mechanical robustness alone is insufficient for ceramic-based thermal insulators to be practical for wearable thermal management. Further efforts to achieve stretchability are necessary because human skin can stretch up to 25% [19]. Therefore, researchers should focus on developing ceramic-based thermal insulators that not only possess mechanical robustness but also exhibit stretchability, making them suitable for wearable thermal management applications.

Photothermal Effect

Light energy, such as sunlight, is a great source of heat. One absorbs light energy by exposing one’s skin or clothes to light. This absorption endows heating and thereby thermal regulation. However, much of the light energy is reflected or dissipated from one’s body without photothermal effect devices. To be specific, the light energy is divided into three modes when it hits a surface. It is absorbed, reflected, or transmitted. Since there is a limited amount of light energy, it is necessary to absorb as much light energy as possible to fully exploit the photothermal effect and achieve thermal regulation by warming one’s body. Therefore, in order to achieve thermal regulation by the light source, it is essential to come up with an effective photothermal effect device. The photothermal effect refers to the conversion of light energy into heat energy through a process of absorption and conversion. When a material is exposed to light, the photons are absorbed by the material, which then converts the light energy into thermal energy or heat. In recent decades, researchers have explored various materials for photothermal applications, including carbon-based materials, semiconductors, and plasmonic metals. Among them, carbon-based materials exhibit numerous conjugated π bonds, readily excited in the range of solar light, thereby absorbing the solar light in a wide range of wavelengths. In this regard, Peng et al. presented a densely arranged laser-induced graphene (LIG) film to enhance photothermal efficiency [107]. Inspired by the forest structure, hierarchical porous LIG films comprising micro- and nanostructures can trap and absorb the light efficiently, thereby minimizing the light reflection. However, despite the high efficiency of the solar-heating effect, the forest-like LIG film is unsuitable for wearable photothermal applications due to its poor mechanical stability, limited flexibility, and discomfort during wear. Thus, comfortable wearability must be addressed for solar-to-heat conversion technology for wearable applications.

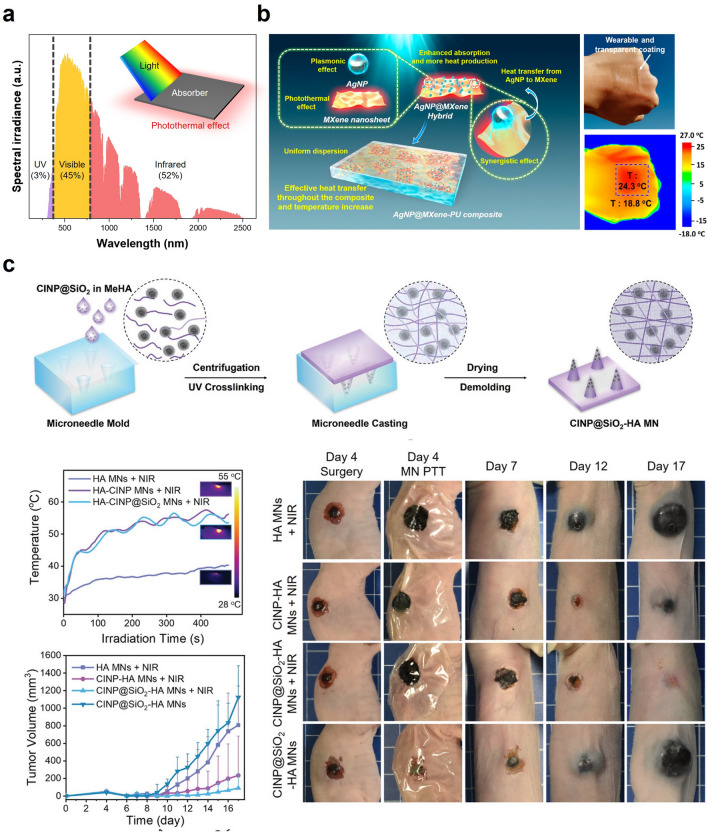

Meanwhile, state-of-the-art wearable devices often malfunction due to the device's vulnerability to external stimuli. In this regard, the healable materials-based wearable device has attracted significant interest in recent decades. The photothermal effect can be a promising trigger for healing procedures due to invasive repairs. Thus, Fan et al. provided a healable and transparent wearable device based on plasmonic silver nanoparticle (AgNP)@MXene nanosheet composites, as shown in Fig. 6a [20]. The wearable composite film showed excellent light-to-heat conversion efficiency due to the synergistic effects of plasmonic AgNPs and thermally conductive MXene. Under light irradiation for 5 min, the temperature of the film rose to approximately 111 ± 2.6 °C, making it a promising material for solar-to-heat conversion applications. Furthermore, the composite exhibited outstanding healing efficiency (> 97%), as the cracked AgNP@MXene-polymer composites could recover their original shape within a few minutes. The wearable healable composite coating can provide a powerful solution to the prolonged-usable wearable electronics due to the light-driven noncontact healing property (Fig. 6b).

Fig. 6.

Photothermal effect-based passive thermal management: a AM 1.5 G solar spectrum. The inset shows the schematic illustration of heated material by photothermal effect. b Wearable and transparent MXene & AgNP coating with light-driven healable properties. Reproduced with permission [20].

Copyright 2019, ACS publications. c Microneedle patches using bio-based materials for photothermal therapy. Reproduced with permission [21]. Copyright 2022, Wiley–VCH

Light-to-heat conversion technology has been widely employed as a promising therapeutic strategy for wound healing applications. In this regard, Lei et al. have developed microneedle patches functionalized with melanin nanoparticles for tumor photothermal therapy (PTT) and wound healing (Fig. 6c) [21]. Melanin nanoparticles (MNPs) derived from cuttlefish ink exhibit promising properties for photothermal therapy, including outstanding photothermal and antioxidative functionalities. To improve biocompatibility and promote skin generation, the MNPs were encapsulated in silica, which decomposes to release SiO44−. The resulting MNPs@SiO2 demonstrated excellent photothermal characteristics, with a temperature increase of 60 °C at 100 µg mL−1 under near-infrared (NIR) laser irradiation (808 nm, 1 W cm−2). Benefitting the photothermal conversion property of MNPs@SiO2, the in vivo photothermal therapeutic effects were investigated in nude mice bearing tumor cells. The tumor cells in the mice with the microneedle patches decreased in size. The surgical wound was fully healed on day 17, implying the excellent PTT of the microneedle patches without burn damage on epidermis tissue. Thus, the photothermal effect-based therapeutic strategy will significantly contribute to a potent remedy for wound healing applications. This work broadened the scope of wearable thermal management, showing that thermal managing technologies can be utilized for therapeutic and medical purposes instead of simply maintaining thermal homeostasis.

Besides, tremendous efforts have focused on photothermal technology for wearable thermoelectric generators, thereby enhancing the energy-harvesting efficiency of thermoelectric generators [22]. For instance, Jeong et al. provided a wearable thermoelectric generator that consists of the top side as a transparent PDMS substrate and the bottom side as a solar-absorbing black substrate, improving the power-generating efficiency by the enhanced temperature difference due to the light-to-heat conversion ability of the bottom substrate [23]. Meanwhile, beyond a single heating functionality of the photothermal effect, a myriad of research has been investigated on wearable heaters based on the photothermal effect and joule-heating (detailed information about joule-heating is presented in the later section). For instance, Li et al. reported on developing MXene-based wearable heaters, which both solar and electric power can drive [18]. The hierarchical crest-ridge structure of MXene allows for efficient light absorption (up to 93.2%) and multiple internal reflections, resulting in a temperature increase of up to 65.4 °C in an equilibrium state and excellent photothermal performance. The high electrical conductivity of the MXene coating (2,000 S cm−1) enables it to function as a wearable heater, providing dual heating capabilities with both solar and electric inputs. On the other hand, Shi et al. combined the multifunction of heating such as joule heating, solar heating, and radiative heating for personal thermoregulation [25]. In summary, photothermal conversion technology has gained great interest in wearable thermal management, such as healable devices, healthcare management through PTT, thermoelectric generation, and dual heating sources.

Sweat Evaporative Thermoregulation

The human body regulates its temperature through perspiration as part of homeostasis. However, if sweat is not effectively removed from the skin, it can accumulate and lead to thermal discomfort, compromising an individual's thermoregulation ability. Conventional hydrophilic textiles, such as cotton, can absorb sweat, but the moisture on the fabric can be critical for effective thermoregulation. In this regard, appropriate management of sweat evaporation is important for personal thermoregulation. To address this issue, numerous efforts have concentrated on directional water transport based on the Janus wettability structure comprising one side with hydrophilicity and the other with hydrophobicity. The wettability gradient by Janus architecture facilitates the sweat extraction from the inner hydrophobic to the outer hydrophilic side without sweat accumulation, thereby enabling the human body to maintain homeostasis.

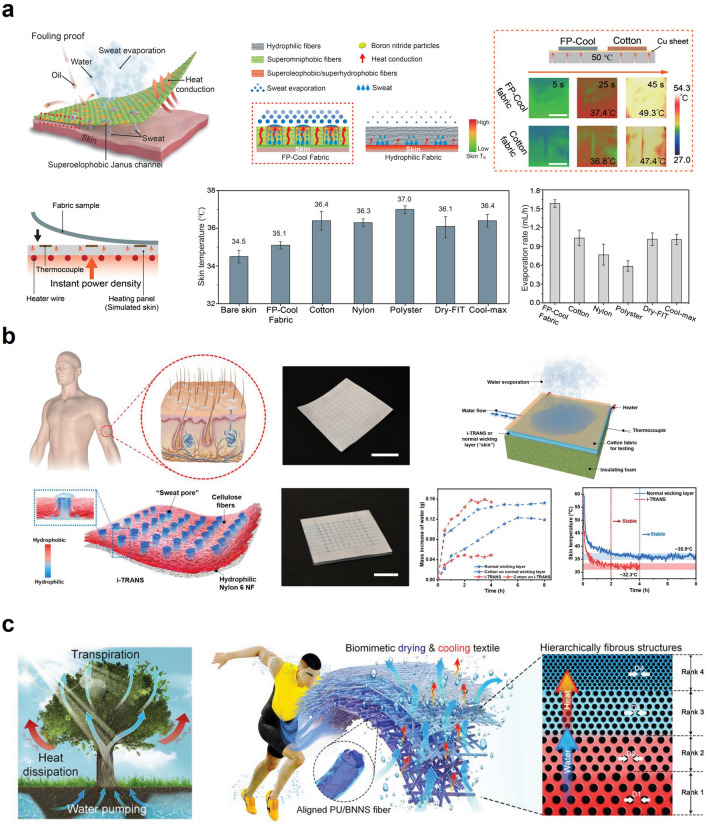

Therefore, researchers have focused on developing textiles that exhibit wettability gradients to enhance both thermal and wet comfort. For instance, He et al. developed a skin-friendly Janus textile based on natural silks, showing two distinct surface properties—one side is hydrophilic, and the other is hydrophobic [108]. In this work, the naturally hydrophilic silk fabric was dip-coated in a hydrophobic solution followed by single-side plasma treatment to realize the Janus structure of hydrophobicity-hydrophilicity. Meanwhile, the duration time of the hydrophilic effect by plasma treatment relies on the type of textiles, exposure time to plasma, textile storage conditions, and type of plasma treatment. The hydrophilicity of the textile endowed by plasma treatment recovers to a lower surface energy state (hydrophobic state) after a few hours at least or weeks at most, depending on the external environment such as the condition of usage and storage [109]. The result demonstrated that the Janus silk fabric temperature on the skin was lower than that of pristine silk (~ 1.5 °C) during exercise. Moreover, Li et al. developed a cooling fabric with spatially-placed Janus channels for personal thermal management (Fig. 7a) [26]. The cotton fabric, which was treated with several chemicals such as poly(diallyldimethylammonium chloride) (PDDA), poly(sodium 4-styrenesulfonate) (PSS), and pentadecafluorooctanoic acid (PFOA), exhibited superomniphobic property. Additionally, to develop island Janus channels on the single-side of the fabric, the UV light was irradiated on the fabric, functionalizing the fabric with oxygen-containing hydrophilic groups. The fouling-proof cooling (FP-Cool) fabric featured the one-way water transport (positive direction), while preventing the negative directional transport. Benefitting the directional sweat flow, the FP-Cool fabric exhibited 50% higher evaporation rate than conventional textiles.

Fig. 7.

Sweat evaporation for passive thermoregulation: a Fouling-proof cooling (FP-Cool) fabric with sweat-wicking functionality for personal cooling. Reproduced with permission [26].

Copyright 2022, Wiley–VCH. b Hydrophobic/hydrophilic designed artificial sweating skin inspired by human body respiration. Reproduced with permission [27]. Copyright 2022, Wiley–VCH. c Biomimetic transpiration textile with one-way water transport. Reproduced with permission [29]. Copyright 2021, Wiley–VCH

In addition to the functionalization of the single textile for Janus wettability, numerous approaches integrated several materials in recent years. Peng et al. developed an integrated hydrophilic/hydrophobic design with selectively distributed sweat pores (Fig. 7b) [27]. Inspired by human body perspiration, the diluted poly(dimethylsiloxane) (PDMS) was spatially coated on the hydrophilic membrane with a gradient in the vertical direction. The as-prepared design, which was optimized by controlling PDMS solution concentration, showed the stable temperature of artificial skin lower than that with a normal wicking layer (~ 3.6 °C).

Also, natural objects have inspired many researchers to develop the engineered design facilitating one-way sweat transportation. For instance, Dai et al. demonstrated cone-shaped micropores-structured Janus textiles inspired by the capillary phenomena of shorebird beaks [110]. The conical pores embedded in Janus textile were prepared by ablation of hydrophobic polyester (PE)/hydrophilic nitrocellulose (NC) membrane. The novel architecture of Janus textiles, in which asymmetric pores were engineered, exhibited an ultrahigh directional water transport capability (1,246%). Based on the biomimetic Janus wettability, the skin temperature covered with the PE/NC membrane showed an average temperature of 24.3 °C in a wet condition, which is higher than that achieved with traditional cotton textiles (21.7 °C). This phenomenon mainly originates from the low thermal conductivity of Janus textile compared to that of conventional cotton in wet conditions, as Janus textile is capable of being dry even in wet conditions due to its spontaneous one-way directional water transport functionality [110]. These results demonstrate the capability of Janus textiles to provide a warmer sensation to individuals and enhance their thermal comfort. Meanwhile, inspired by mussels that exhibit a remarkable capability of sticking to submerged rocks, Wang et al. developed the Janus-structured PET fabric based on cation-π interaction [28]. Several researchers have proven that cation-π interaction enhances the underwater adhesion of mussels [111], thereby extensively developing underwater sticky materials. The cation–π hydrophilic agent (CPHA) was readily stuck on the PET surface due to the active cation-π interaction by the rich aromatic moieties in the PET fibers, which renders the strong adhesion property, thereby converting the single-side of the PET surface from hydrophobic to hydrophilic. The mussel-inspired fabric possessed a remarkable directional water transport ability (1,115%) based on Janus wettability, demonstrating a more excellent cooling effect than conventional cotton and original PET fabrics. In addition, Miao et al. proposed a hierarchical fibrous structured textile for liquid transportation by mimicking vascular plants (Fig. 7c) [29]. The hierarchically structured membrane with capillary pores decreasing in size achieved a large capillary force without resistance to water transport. Moreover, the aligned polyurethane (PU)/boron nitride nanosheet (BNNS) fibers, which contact the human epidermis, served as the thermally conductive path. Benefitting from the favorable properties for drying and cooling, the multilayered textiles exhibited excellent directional water transport capability (1,072%), rapid liquid evaporation rate (0.36 g h−1), and high thermal conductivity (out-of-plane ~ 0.182 W m−1 K−1, in-plane ~ 1.137 W m−1 K−1). Likewise, the technology modulating sweat evaporation combined with enhancement of thermal conductivity is a promising approach for efficient personal thermal management. In this regard, numerous researchers have explored the efficient approach to one-way water transportation based on Janus wettability.

Lastly, a recent study demonstrated the integrated cooling (i-Cool) textile that combined a thermally conductive path and water transport channels to enhance the evaporation rate and cooling effect [30]. The heat-conducting path efficiently transported thermal energy from the body to the evaporation spots, further accelerating the sweat evaporation into the air due to the synergistic effect of the main functionalities (conductive heat path and water channel). Compared to conventional textiles, i-Cool textiles exhibited lower skin temperature and a more rapid evaporation rate. Hence, many studies concentrated on efficient personal perspiration management based on various approaches, providing significant insights for future perspiration-based thermo-regulative textiles.

Radiative Cooling

Radiative cooling (RC) technology is a promising candidate for passive thermal management due to its passive property that consumes no additional energy input to dissipate the heat [112]. In recent decades, the RC method, which emits heat to the cold outer space through the atmospheric window (λ ~ 8 to 13 μm, where λ is the wavelength), has been extensively developed for passive daytime radiative cooling (PDRC) by simultaneously reflecting solar irradiance. Yet, several PDRC designs based on photonic structures [113], polymers [114], and metamaterials [115] reduce the potent possibility of personal thermal management due to poor comfortable wearability. In this regard, an extensive range of research has been devoted to employing the PDRC techniques to be appropriately applied for personal cooling management by addressing the issue of wearable comfort [116].

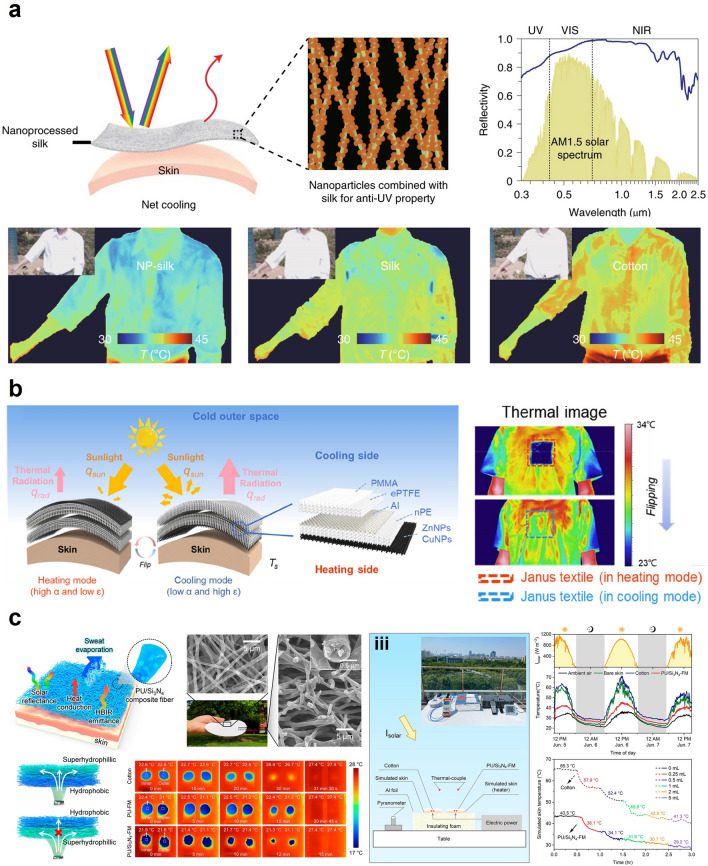

Zhu et al. provided silk-based PDRC textiles with comfortable wearability, as shown in Fig. 8a [31]. The silk, which exhibits a cooling and comfortable sensation on the human epidermis based on a natural-based hierarchical structure, has been regarded as a suitable material for wearable RC application due to the high reflectivity in the visible (VIS) to near-infrared (NIR) range and high emissivity in the mid-infrared (MIR) spectrum and yet, a critical limitation still remains challenging for PDRC application; high absorption in the ultraviolet (UV) region. To address this issue, silk was dip-coated using tetrabutyl titanate (TT) as a coupling reagent and aluminum oxide (Al2O3) that exhibits a minimum absorption in the UV range. As a result, the reflectivity of silk was enhanced from 70 to 85% in the UV range, and that of silk in the VIS–NIR region was also improved from 86 to 95%. Benefitting from the enhanced reflectivity in the UV–VIS-NIR region and high intrinsic emissivity in the MIR range, the nanoprocessed silk exhibited a temperature drop of ~ 3.5 °C in the daytime. Moreover, the simulated skin temperature covered with the nanoprocessed silk textile was ~ 8 and ~ 12.5 °C lower than the skin covered with natural silk and cotton, respectively. Functionalizing the natural material will open a novel energy-saving personal thermal management strategy with comforting wearability.

Fig. 8.

Personal radiative cooling for passive thermal management: a Nanoprocessed silk-based radiative cooling textile. Reproduced under the terms of CC BY [31].

Copyright 2021, Springer Nature. b Janus textile with radiative cooling and solar heating functionalities for all-day outdoor personal thermal management. Reproduced with permission [33]. Copyright 2021, ACS publications. c Hierarchical fibrous membrane that utilizes radiative and evaporative heat dissipation for enhancing the cooling performance. Reproduced with permission [37]. Copyright 2022, ACS publications

Moreover, Zeng et al. presented a large-scale hierarchical structured metafabric for scalable PDRC that cooled a human body ~ 4.8 °C lower than one covered with commercial cotton fabric [32]. Likewise, numerous researchers have employed PDRC technology for wearable personal thermal management. In addition to the personal thermoregulation application, the PDRC technology has been dedicated to enhancing the various electricity-generating modules such as solar-cell [117] and thermoelectric generators [118]. Among them, wearable thermoelectric generators (TEGs) have extensively employed the PDRC structure to maximize the thermal gradient of TEG and enhance the energy-harvesting efficiency, thereby sustainably powering wearable electronics [22, 119, 120]. In this regard, Khan et al. introduced the integration of poly(vinylidene fluoride-co-hexafluoropropylene) (P(VdF-HFP)) radiative-cooled films to a wearable TEG [121]. The porous P(VdF-HFP) films, fabricated via the phase separation method, exhibited excellent solar reflectivity (96.7%) and high emissivity (97.47%) within the IR range. The films effectively reduced the daytime temperature by 6 °C below the ambient temperature. Benefitting the favorable radiative cooling property, the TEG was integrated into the porous film, which served as an efficient heat sink with comfortable wearability due to the micro-thin thickness (~ 800 μm), achieved the enhanced power generation (~ 12.48 μW cm−2) with the daytime temperature difference of 1.37 °C higher than that of TEG with a commercial fin-type heat sink (~ 1.25 °C).

Furthermore, for the PDRC technology to be practically applied, several studies have focused on functionalizing the radiative coolers with solar-heating properties, which can switch between dual modes depending on the environmental condition [122, 123]. For instance, Luo et al. demonstrated a wearable bi-functional Janus textile that is capable of facilitating dynamic passive personal thermoregulation of solar-heating and radiative-cooling (Fig. 8b) [33]. The Janus textile rendered one side with a heating function and the other side with a cooling function; the heating side consists of copper (Cu) and zinc (Zn) nanoparticles (NPs), which exhibits high solar absorption (> 80%) due to the plasmonic resonances and low MIR emittance (~ 16%). The cooling side is comprised of porous polymethylmethacrylate (PMMA) covered expanded polytetrafluoroethylene (ePTFE) on the Al layer, which enhances the solar reflection (~ 91%) and the MIR emissivity (87%). Profiting from the optical properties, the Janus textile in heating mode exhibited a simulated skin temperature of 8.1 °C higher than the skin simulator covered with conventional cotton. In cooling mode, the temperature decreased by 6 °C compared to conventional cotton.

On the other hand, to improve the passive cooling performance beyond a single function of RC, the combined technology of RC with the other passive cooling method has been extensively developed in recent decades. Among them, the synergy of SE and RC has emerged as promising candidates for passive cooling management [34–36]. For instance, Miao et al. demonstrated a hierarchically designed membrane based on polyurethane/silicon nitride (PU/Si3N4) fiber with Janus wettability (Fig. 8c) [37]. The fibrous membrane exhibited high solar reflectance (91%) and IR emittance (93%) due to the high refractive index of Si3N4 and intrinsic bond vibrations of polymer/inorganic membranes, respectively. Moreover, a single side of the membrane achieved hydrophilicity by plasma treatment, enabling directional water transport from the hydrophobic to the hydrophilic side, facilitating sweat evaporation, and improving the evaporative cooling effect. Benefiting from these characteristics, the PU/Si3N4 fiber-based membrane showed a substantial temperature drop of 21.9 °C compared to conventional cotton.

Active Thermal Management

Joule-heating-based Thermal Management

Joule-heating, or resistive heating, elevates a temperature of an electrical conductor by kinetic energy transfer by electrons. When an electron is affected by a certain electric field, it gains kinetic energy. The collision of the electron with particles in the conductor induces a kinetic energy transfer and, eventually, a certain amount of heat energy. Since the total kinetic energy of an electron is proportional to the current and the voltage, the heating power is proportional to the product of the two [124]:

| 4 |

where V, I and R are electrical voltage, current and resistance respectively. Even though bidirectional thermal management, or heating and cooling, by a single joule heating device is not possible, it is still an attractive thermal management unit for many wearable devices due to a simple heating mechanism and a facile application by simply connecting an electrical conductor with the power source. Also, obtaining high temperatures by putting more electrical energy into the heating conductor is not difficult [125–129].

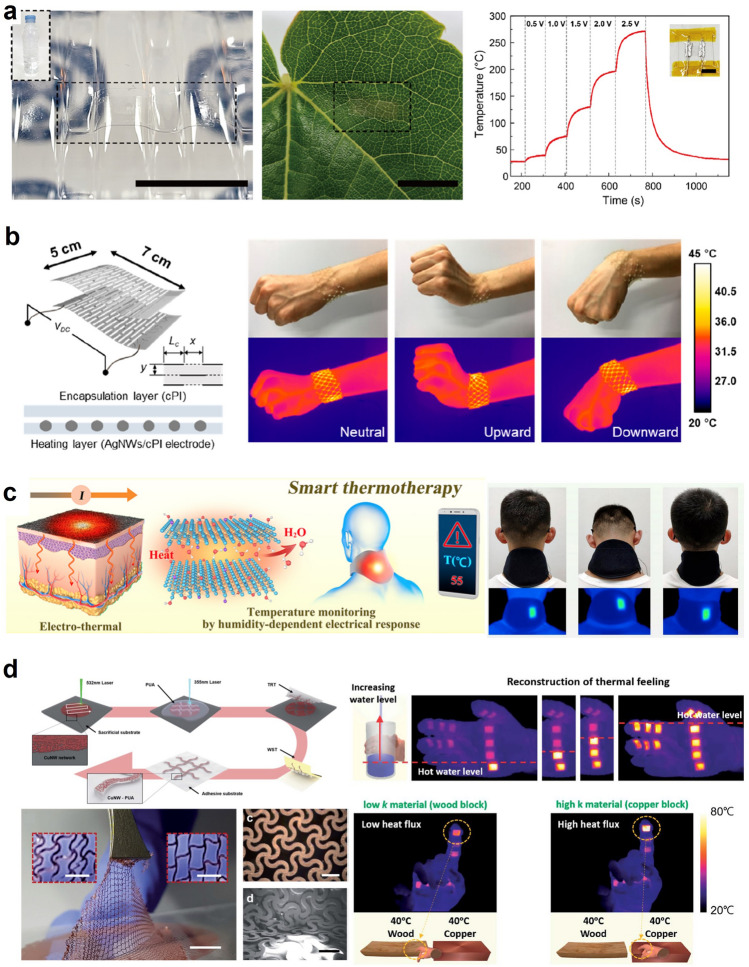

Owing to a simple component of a joule-heating-based device, an electrical conductor, researchers have been fabricating transparent heaters with the mechanism [130–134]. The transparency endows the heater with many abilities, such as watching the affected area while practicing thermotherapy, defrosting for windows, and applying with imperceptibility. Additionally, they have granted the heaters with softness, stretchability, and transparency to realize wearable transparent thermal management units. In doing so, they had to develop methods for minimal temperature change while being applied to a soft surface with mechanical deformation. This could be achieved by minimal resistance change under deformation since the heating power, which is proportional to the temperature of the heater, is directly related to the resistance under the same voltage. For example, Yun et al. presented transferable transparent liquid metal electrodes with grid structure for heaters. Manufacturing an opaque material to have a grid structure with extremely narrow linewidth is one of the typical ways to endow transparency to a device. They used a direct printing method to fabricate the liquid metal grid with a linewidth lower than 5 μm. The transmittance was as high as 90.1% due to the small linewidth. The as-fabricated heater obtained a temperature of 272 °C with an input voltage of 2.5 V due to its low sheet resistance. The heater worked without any failure under a maximum mechanical strain of 100%. It even was able to be operated in an − 30 °C environment, maintaining 89 °C with an input voltage of 1.4 V. The researchers explained that the proposed heater with low sheet resistance and high stretchability is expected to be utilized in thermal management film for windows (Fig. 9a) [38].

Fig. 9.

Joule heating for active thermal management: a Transparent liquid metal electrodes for the heater. Reproduced with permission [38]. Copyright 2022, ELSEVIER. b Stretchable and transparent Kirigami patterned electrodes for the heater. Reproduced with permission [39].

Copyright 2019, ACS publications. c Smart MXene fabric heater for healthcare and medical therapy. Reproduced with permission [40]. Copyright 2020, ACS publications. d Highly stretchable Cu nanowire heater for virtual reality applications. Reproduced with permission [41]. Copyright 2020, Royal Society of Chemistry

Won et al. demonstrated another transparent heater research operated by a joule-heating mechanism. This time, they fabricated the heater with a silver nanowire percolation network since it possesses intrinsic transparency. Moreover, they introduced Kirigami-patterning, which cuts the thin film with the desired pattern to endow extreme stretchability. In this way, they achieved a transparent and stretchable heater. They manufactured a wrist band type heater that can perform stably under various mechanical deformations. Since the Kirigami heater had electromechanical decoupling, it could work stably under 200% strain without any operational degradation. The heater could reach over 80 °C with an input voltage of 9.0 V. The researchers expect this heater to be utilized for wearable thermal haptic, wound healing monitoring, and personal thermal treatment with transparency and stretchability (Fig. 9b) [39].

Zhao et al. demonstrated a smart multifunctional fabric with fast humidity response and joule heating for medical therapy as an example of a personal thermal treatment application. The fabric possessed a smart system that could be utilized as bacterial ablation for healing an infectious wound while having an alarm system for a low-temperature burn. They fabricated the fabric by coating MXene on a nonwoven cellulose fiber. The fabric had breathability with excellent mechanical stability. Firstly, the group devised a fabric-integrated neck-guarding pad. The pad functioned well when positioned on one’s neck. Furthermore, they exploited the humidity-temperature-resistance relation to manufacturing a smart and safe heater system. They developed a built-in alarm to turn on an LED when the heater's temperature exceeds a certain degree. They also verified that the heating induces bacterial ablation and accelerates wound healing performance (Fig. 9c) [40]. This research showed that Joule heating contributes to thermoregulatory wearables. Such a mechanism can be employed to expand the applications of heaters in various fields, including the medical area.

Due to the simple, repetitive, and precisely controllable feature of joule-heating, it can be utilized in fields of virtual reality (VR) as a thermo-haptic device because it can readily control the localized temperature of the user. Hence, it should be considered one of the scopes of thermal management applications. For instance, Kim et al. replicated a feeling of heat in a VR space with a copper nanowire (CuNW)-based heater. To utilize the heater for VR applications, they encapsulated easily oxidized CuNW with polyurethane-acrylate (PUA) to increase the stability and oxidation-resistivity. The as-fabricated heater was patterned into the serpentine structure that granted a high stretchability with small resistance change, which was beneficial for the thermo-haptic device that required precise temperature control. It exhibited a stable repetitive operation with a mean temperature of 120 °C under an input voltage of 7 V. It also demonstrated stability under the stretching condition without apparent temperature variance. They fabricated a thermo-haptic glove by mounting 12 heaters on a nylon glove. They calculated the heat flux that transfers to one’s skin when touching a 40 °C copper and a 40 °C wood. Then, they computed the required temperature for the heater to transfer the same amount of flux to the skin. Finally, they replicated the heat sensing while touching different materials in the VR world, verified by IR image. In addition to that, they also replicated the sense of heat for approaching a fire and holding a cup with increasing water level. The researchers emphasized that the simple mechanism of joule-heating with accurate temperature control with only changing input voltage could realize this highly precise thermo-haptic device for VR space (Fig. 9d) [41]. Although the study mentioned above focused on the VR application, the identical material and manufacturing technologies can be directly applied to make a digitalized heater that provides thermoregulatory functionality.

Kim et al. developed a biomimetic chameleon soft robot realized by a heater and thermochromic liquid crystal as another application for the joule-heating-based heater. The research group developed a vertically-stacked, multi-layered heater component that mimics chameleon skin's crypsis and disruptive coloration. Each heating layer was patterned differently to obtain diverse coloration patterns by controlling each layer. The group used an AgNW percolation network for each layer on a colorless polyimide thin film. Since the film was extremely thin, the heater in each layer had negligible performance differences. With the low sheet resistance of the heater film, the temperature could reach 43 °C with an input voltage of 0.7 V. The heater exhibited improved stability by implementing a proportional-integral-derivative (PID) control-based feedback system to control the input power. It could maintain its target temperature even when the surrounding temperature decreased due to the presence of nearby ice. The group successfully demonstrated the camouflage of a chameleon-inspired soft robot with manufactured skin. Additionally, they installed a color sensor at the bottom of the robot to sense the color of its standing floor and change the skin color accordingly. As a proof of concept, the robot was placed on a floor with red, green, and blue colors and successfully changed color while walking through the different color regions [42]. Even though its main application was devoted to robotics, this work demonstrated that the PID-control integrated heater technology offers insights into thermal managing wearables because the device can transfer a controlled amount of heat to the user regardless of the external temperature.

Micro-fluidic based Thermal Management

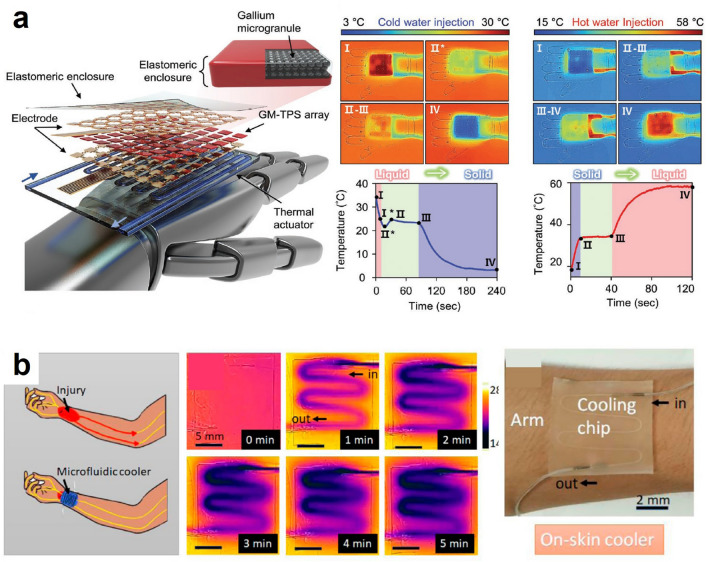

Micro-fluidic thermal management is a method to cool or heat a target surface by exploiting the conduction and convection of fluid in a micro-channel [61, 135–139]. To achieve thermal management, a microfluidic channel must be attached to a target surface. Then, a refrigerant or heating fluid is injected and flows through the channel while heat flux between the target surface and the fluid occurs. Researchers in this field further utilize phase change of the fluid to maximize its cooling or heating performance, similar to a heat pump. Also, they can achieve bi-directional thermal management by simply replacing the fluid with different temperatures. The simple bi-directional thermal managing mechanism and its microscale device with flexibility facilitate wearable applications for one’s nerve or skin. As a representative example, Lee et al. applied micro-fluidic thermal management to control adaptive robotic skin with a sensor. The group fabricated a capacitive sensor that consists of two electrodes and a dielectric layer sandwiched between the two. The dielectric layer was composed of an elastomer with gallium microgranules embedded inside. The gallium microgranule, which had a melting temperature of 29.76 °C, was utilized as a sensing performance shifting agent by phase-change between liquid and solid. When the microgranule was in the solid state, the capacitive sensor could possess a high detecting range of pressure. On the other hand, the sensor could possess high sensitivity when the microgranule was in a liquid state. The group fabricated an array of these sensors to be applied to a robot hand with two distinct sensing abilities. And a thermal actuator, or a thermal management device, employed in hand was a microfluidic channel with water. The facile alteration of target temperature by simply changing the water temperature in the channel was why they chose this management device. Thereby, they could readily manipulate the phase of the gallium microgranule by substituting water with different temperatures. They injected cold water at 1 °C for solidification of the granule and hot water at 65 °C for liquefication of it. It took less than a minute to induce the phase transition achieving an adaptive robotic skin with two distinct capacitive sensing abilities (Fig. 10a) [43].

Fig. 10.

Microfluidic cooling for active thermal management: a An adaptive robotic skin with a microfluidic cooling device. Reproduced with permission [43].

Copyright 2022, Wiley–VCH. b A liquid metal mold-based 3D flexible microfluidics [45]. Copyright 2022, Frontiers Media