Abstract

Embracing innovation and emerging technologies is becoming increasingly important to address the current global challenges facing many food industry sectors, including the dairy industry. Growing literature shows that the adoption of technologies of the fourth industrial revolution (named Industry 4.0) has promising potential to bring about breakthroughs and new insights and unlock advancement opportunities in many areas of the food manufacturing sector. This article discusses the current knowledge and recent trends and progress on the application of Industry 4.0 innovations in the dairy industry. First, the “Dairy 4.0” concept, inspired by Industry 4.0, is introduced and its enabling technologies are determined. Second, relevant examples of the use of Dairy 4.0 technologies in milk and its derived products are presented. Finally, conclusions and future perspectives are given. The results revealed that robotics, 3D printing, Artificial Intelligence, the Internet of Things, Big Data, and blockchain are the main enabling technologies of Dairy 4.0. These advanced technologies are being progressively adopted in the dairy sector, from farm to table, making significant and profound changes in the production of milk, cheese, and other dairy products. It is expected that, in the near future, new digital innovations will emerge, and greater implementations of Dairy 4.0 technologies is likely to be achieved, leading to more automation and optimization of this dynamic food sector.

Keywords: Dairies, Industry 4.0, Automation, Smart factory, Real-time monitoring, Artificial intelligence, Big data, IoT, Robotics, Digital technology, 3D printing, Blockchain, Milk, Cheese

Graphical abstract

Highlights

-

•

Advanced technologies are being progressively adopted in the dairy sector, from farm to table.

-

•

Dairy 4.0 is mainly enabled by robotics, Artificial Intelligence, Internet of Things, Big Data, and Blockchain.

-

•

Advanced technological solutions proposed for a more sustainable milk production.

-

•

Full implementation of Industry 4.0 technologies in the dairy sector will significantly improve its automation.

1. Introduction

Food sustainability is currently facing several unprecedented crises all at once, including climate change, outbreak of pandemics, and political tensions, among others. Building resilient food systems, and encouraging innovation and implementation of technological advances are of utmost importance to meet these challenges (Bisoffi et al., 2021; Hassoun, Siddiqui, et al., 2022a; Galanakis, 2023). One food sector that is highly vulnerable to climate change and other global food challenges, but also is responsible for a significant release of greenhouse gas emissions, is the dairy industry (Ioanna et al., 2022).

Dairy foods are considered an important source of many nutritional and functional compounds. Critical operating conditions for process control of dairy products have been widely studied to ensure high quality and safety of these highly perishable food products (Neokleous et al., 2022; Ribeiro et al., 2022). However, dairy product manufacturers are always searching for sustainable processing techniques and other new technologies in order to offer innovative solutions to this dynamic food sector. The dairy industry actors are among the fast adopters of new technologies and automation spurred by the arrival of the fourth industrial revolution (namely Industry 4.0). The main enablers of Industry 4.0 in the food sector are Artificial Intelligence (AI), robotics, smart sensors, 3D printing, the Internet of Things (IoT), Big Data (BD), the cloud, blockchain, augmented reality, cybersecurity, digital twins, and cyber physical systems (Trivelli et al., 2019; Bai et al., 2020; Hassoun, Aït-kaddour et al., 2022c). Application of these technologies in agriculture is often referred to as smart farming, precision agriculture, or Agriculture 4.0 (Javaid et al., 2022; Sinha and Dhanalakshmi, 2022), while food factories that use these advanced technologies are often called “smart factories” (Echegaray et al., 2022; Mavani et al., 2022).

The dairy supply chain is increasingly adopting automation and digital technologies (Echegaray et al., 2022; Balaska et al., 2023). The application of Industry 4.0 technologies in the dairy sector is termed as “Dairy 4.0”. Although the term Dairy 4.0 was mentioned in two recent publications (Gehlot et al., 2022; Balaska et al., 2023), no references to its definition or enabling technologies were provided. Therefore, this work aims to investigate the potential of Industry 4.0 in the dairy sector, focusing mainly on the latest advances and applications. The organization of the study is as follows: Section 2 describes the methodology used in this study and presents descriptive statistics of the literature review carried out, Section 3 introduces the concept of Dairy 4.0 and determines its enabling technologies, Section 4 discuses some relevant examples of applications of Dairy 4.0 technologies in milk, cheese, and other dairy products, and Section 5 covers the current challenges and future perspectives.

2. Literature review and research methodology

A sample of publications investigating the application of Industry 4.0 technologies in the dairy industry was extracted from Scopus (www.scopus.com) database. Scopus was selected in this study as it is the most comprehensive database of abstracts and citations of peer-reviewed literature, offering wide coverage of scientific production in several scientific disciplines, such as science, technology, medicine, and social sciences, among others (Rejeb et al., 2021). The query used was: (TITLE (dairy AND product) OR TITLE (dairies) OR TITLE (milk) OR TITLE (cheese) OR TITLE (butter) OR TITLE (yogurt) AND TITLE (Industry 4.0) OR TITLE (fourth AND industrial AND revolution) OR TITLE (digitalization) OR TITLE (digital AND transformation) OR TITLE (digital AND technologies) OR TITLE (artificial AND intelligence) OR TITLE (big AND data) OR TITLE (Internet AND of AND Things) OR TITLE (smart AND sensors) OR TITLE (blockchain) OR TITLE (3D AND printing) OR TITLE (cloud AND computing) OR TITLE (cyber AND physical AND systems) OR TITLE (robotics) OR TITLE (augmented AND reality)). The choice of these keywords was based on recent literature on application of Industry 4.0 in agriculture and the food industry sector (Trivelli et al., 2019; Hassoun, Abdullah, et al., 2022b; Hassoun, Aït-kaddour et al., 2022c; Abbate et al., 2023; Bigliardi et al., 2023). By including all types of publications (i.e., articles, reviews, conference papers, and book chapters) without setting a time limitation, the search resulted in 151 documents, while limiting the search to English articles resulted in 147 publications.

Fig. 1 shows the distribution of research attention in this Industry 4.0 and related topics for each publication year. As can be observed, there is a consistent increase in the number of publications and citations over the last few years, especially since 2015, suggesting that the increasing interest in this topic should become even more relevant in the future. When the year range was limited from 2017 to present, 117 publications were identified and investigated for further analysis.

Fig. 1.

Total publication and citations related to Industry 4.0.

Table 1 shows the publications on the topic of Dairy 4.0 that have been cited more than 30 times. The subjects of those publications cover almost all the areas of Industry 4.0 (i.e., BD, 3D printing, blockchain, AI, and digital technology). Three of the highly cited publications are related to BD, in which one publication by Schneider et al. (2016) has the highest citation number (229 citations). The publications related to 3D printing have the second highest number of citations. The list of highly cited publications related to Industry 4.0 also shows two publications focused on blockchain and two publications related to AI. This overview shows that the citation number of these topics is increasing rapidly, highlighting the high interest of the dairy industry and scientists in Industry 4.0 and related technologies.

Table 1.

The most cited publications focusing on Industry 4.0 in the dairy sector.

| Authors and Publication Year | Title | Industry 4.0 Technology | Journal | Citation on Scopus |

|---|---|---|---|---|

| Schneider et al. (2016) | Big Data from Pharmaceutical Patents: A Computational Analysis of Medicinal Chemists Bread and Butter | Big Data | Journal of Medicinal Chemistry | 229 |

| Le Tohic et al. (2018) | Effect of 3D printing on the structure and textural properties of processed cheese | 3D printing | Journal of Food Engineering | 173 |

| Liu et al. (2019) | Rheological and mechanical behaviour of milk protein composite gel for extrusion-based 3D food printing | 3D printing | LWT | 105 |

| Liu et al. (2018) | 3D printed milk protein food simulant: Improving the printing performance of milk protein concentration by incorporating whey protein isolate | 3D printing | Innovative Food Science and Emerging Technologies | 84 |

| Casino et al. (2021) | Blockchain-based food supply chain traceability: a case study in the dairy sector | Blockchain | International Journal of Production Research | 78 |

| Goli et al. (2019) | Hybrid artificial intelligence and robust optimization for a multi-objective product portfolio problem Case study: The dairy products industry | Artificial Intelligence | Computers and Industrial Engineering | 55 |

| Goli et al. (2021) | An integrated approach based on artificial intelligence and novel meta-heuristic algorithms to predict demand for dairy products: a case study | Artificial Intelligence | Network: Computation in Neural Systems | 42 |

| Mangla et al. (2021) | Using system dynamics to analyze the societal impacts of blockchain technology in milk supply chainsrefer | Blockchain | Transportation Research Part E: Logistics and Transportation Review | 35 |

| (Newton et al., 2020) | Farming smarter with big data: Insights from the case of Australia's national dairy herd milk recording scheme | Big Data | Agricultural Systems | 33 |

| Drewry et al. (2019) | Assessment of digital technology adoption and access barriers among crop, dairy and livestock producers in Wisconsin | Digital technology | Computers and Electronics in Agriculture | 32 |

| Cabrera et al. (2020) | Symposium review: Real-time continuous decision making using big data on dairy farms | Big Data | Journal of Dairy Science | 31 |

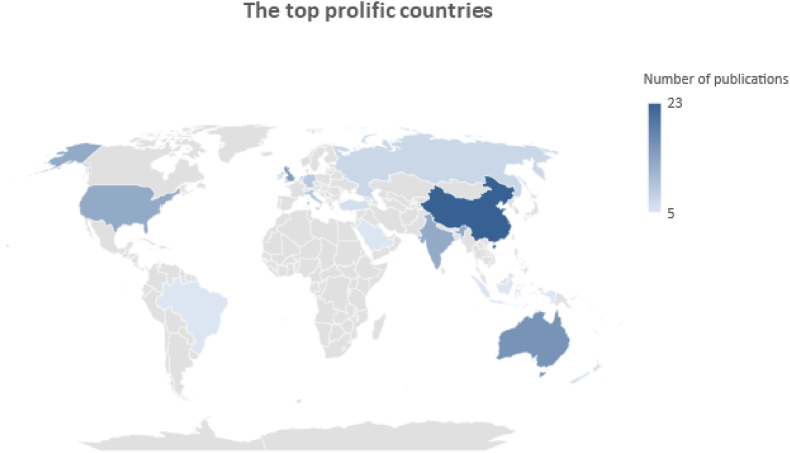

Fig. 2 shows the top contributing countries to publications dealing with the topic of Industry 4.0 and related technologies in the dairy sector. A total of 15 countries participated in publishing of at least 5 or more publications. China was on the top of the rank with 23 publications, followed by Australia (16 publications), UK (15 publications), India (13 publications) and USA (13 publications), highlighting the importance of the dairy sector in these countries.

Fig. 2.

Top contributing countries to publications related to Industry 4.0.

Regarding the document types, 64% of the total number of publications were articles, while conference papers represented 26%. As reported in Fig. 3, only seven journals have published three or more papers. The highest number of publications (five publications) was found in the Journal of Dairy Science and Biosystems Engineering.

Fig. 3.

Most prominent sources by the number of publications in this field of Industry 4.0 in the dairy sector.

Fig. 4 provides the percentage of publications for each subject area of Industry 4.0. The most prominent areas are agricultural and biological sciences, engineering, and computer science that exhibited about two-thirds of the total number of publications, while physics and astronomy and social science areas had the fewest number of publications (only 5% of the total) in relation to Industry 4.0.

Fig. 4.

Publication related to Industry 4.0 in the dairy sector according to their subject areas.

3. Dairy 4.0 enabling technologies

Our literature review revealed that robotics, 3D printing, AI, IoT, BD, and blockchain are the most keywords used in the published research related to Industry 4.0 technologies and their application in the dairy sector (Fig. 5).

Fig. 5.

Most used keywords in published research related to Industry 4.0 in the dairy sector.

Six Industry 4.0 technologies have been identified and considered the main enablers of Dairy 4.0 (Fig. 6). These Dairy 4.0 will be briefly discussed in this section:

Fig. 6.

Dairy 4.0 enabling technologies.

Robotics – Robotics is an interdisciplinary and multidisciplinary field that combines advanced systems related to mechanical, electrical and electronics hardware and software. The use of robotics in the food industry can vary between simple repetitive tasks to complex processes. Robotics technology has been long in use in many manufacturing sectors, e.g., automotive, but potential applications for robotics in dairy industries is being investigated. (Sandey et al., 2017; Gehlot et al., 2022).

3D Printing – Three-dimensional (3D) printing technology (or additive manufacturing) has emerged recently as a promising innovation that use digital data to create various types of solid and semi-solid food products (Zhang et al., 2022). Over the last few years, the application of 3D printing has gained enormous interest in many food sectors (Hu et al., 2022). There has been a rapid increase in scientific work addressing 3D printing of dairy products. Dairy products and ingredients consists of different constituents, functionalities and structures making them a very challenging but at the same time very promising source of raw materials for 3D printing of food (Lee et al., 2020; Le Tohic et al., 2018).

Big Data (BD) - BD refers to extremely large and complex data sets that cannot be analysed or processed using traditional methods (Ayed et al., 2022). Big Data Analytics (BDA) is the process of using advanced analytical tools and techniques to process these massive data sets (Ciccullo et al., 2022). In the dairy industry, BD/BDA can be applied in a number of ways as the dairy industry generates huge amounts of data. Applications relate to milk production, milk quality, farm management, real-time monitoring and decision making, animal health and supply chain sustainability.

The Internet of Things (IoT) – IoT is a system that connects devices through a network allowing the exchange of data. IoT has the potential to create intelligent environments of powerful tools in many agriculture and livestock areas, enabling to create, modify, and share information (da Rosa Righi et al., 2020; Karouani and Elgarej, 2022). IoT is increasingly being used in dairies to collect live, accurate data and share it with the farmer or other stakeholders.

Artificial Intelligence (AI) – AI is a computational technology used to mimic human abilities to perceive their environment, learn, and make decisions (Manning et al., 2022; Ramirez-Asis et al., 2022). In the food sector, AI techniques play a key role in automation in smart farming and food processing industry and could help to accelerate the transition towards sustainable food systems (Kumar et al., 2021; Marvin et al., 2022). Generally, AI-based technologies can be used in real-time monitoring and decision-making process (Nogoy et al., 2021; Sharma et al., 2021).

Blockchain – Blockchain can be considered as one of the Industry 4.0 enablers and can address the growing industry need for considerably more reliable and efficient supply chain management infrastructure (Hassoun, Abdullah, et al., 2022b; Al Nuaimi et al., 2023; Hassoun et al., 2023). Blockchain technology can be defined as cryptographically secured distributed ledgers where the ledgers are distributed in a peer-to-peer format among the entities, making it a decentralized system (Gehlot et al., 2022; Yadav et al., 2022). There is a need for decentralized solutions such as blockchain due to the single points of failure, product irregularities, quality compromises, and loss of data present in conventional food supply chains. Adoption of blockchain in the food supply chain, especially when combined with other technologies such as IoT, enables data interoperability, cost reduction, transparency, auditability, integrity and authenticity (Casino et al., 2021; Luo et al., 2022). To protect vulnerable populations, blockchain solutions that go beyond food traceability to maintaining the nutritional values of dairy products, and identification of their adulteration and contamination have been proposed (Khanna et al., 2022).

4. Discussion of applications of dairy 4.0 technologies in milk and dairy products

4.1. Robotics

Robotics has been more recently embraced by the dairy sector, where it has several applications. For instance, automatic milking systems are one of the most successful application of robotics in the dairy industry (Sandey et al., 2017; Perov, 2022). This system allows for a substantial average increase in milking frequency and therefore increased milk production (Hogenboom et al., 2019), while reducing labour costs. Further identified benefits of automatic milking systems are increased overall productivity, profitability, and sustainability (Lyons et al., 2022). Another application of robotics in dairy farms is on floor cleaning, which helps to mitigate risks regarding cow welfare and to avoid ammonia emissions (Gerrits et al., 2023).

In addition, sensors placed in the robotic system allow accurate and live data to be collected. These data can be used to predict the value of important parameters such as daily milk yield, milk composition and milking frequency. For instance, Ji et al. (2022) developed a machine learning framework using data from a robotic dairy farm to predict such parameters.

An important concern for dairy farmers for a more widespread adoption of robotic milking systems is the impact these systems might have on the final product. Johansson et al. (2017) investigated the composition and enzymatic activity in milk from dairy farms with conventional and robotic milking systems, and found some differences, suggesting a significant influence of the management system. For instance, milk from robotic milking systems had a lower protein content, plasmin, plasminogen, total plasmin/plasminogen derived activities, total casein and the β-casein fraction as percentage of total protein, while it had a higher somatic cell count and total proteolysis. Another factor analysed in automatic robotic dairies is heat stress, i.e. the effect of high temperature and humidity on the cow welfare and performance. Bodo et al. (2022) and Osei-Amponsah et al. (2020) found a positive correlation between the heat stress and a reduction in milking time and time spent in the milking box, and in general cows’ welfare. Therefore, the performance of robotic milking systems could easily be improved by simply providing shade and water for cows to cool down during hot months. Finally, robotic milking systems also facilitate the work of farmers, reducing their stress and anxiety and increasing their resilience (King et al., 2021).

Despite their benefits, the development and implementation of such robotic systems is challenging. To facilitate wider adoption of robotic systems on dairy farms, Eastwood et al. (2022) proposed a framework to identify issues that technology developers and policy makers need to consider when considering future innovations for robotics on dairy farms, such as the impact on job design, worker welfare and safety, changes in farming systems, and the influences of market and regulatory constraints.

4.2. 3D printing

Over the last few years 3D printing of milk-based products are gaining popularity among researchers as well as food manufacturers. The 3D printing in dairy is being pursued within 5 thematic areas, i.e., Futuristic, Creative, Healthy, Efficient and Sustainable as shown in Table 2 (Ross et al., 2018).

Table 2.

Themes with their respective 3D printing applications.

| Themes | 3D Application |

|---|---|

| Futuristic | It creates food products with similar consistency and repetition with parameters such as shapes, size and decoration, e.g., celebration cakes artistic decoration. |

| Creative | It creates creative and personalised specially textured food products to suit individual nutritional requirements without discomfort. |

| Healthy | It facilitates the accurate dispensing of ingredients/nutrients during printing of food products. |

| Efficient | It allows layer-by-layer deposition during a process using the most efficient pathway. |

| Sustainable | It results in zero waste or minimal excess material being disposed of in the process and therefore sustainable. |

Liu et al. (2018) showed that the milk powder paste mixture prepared with milk protein concentrate and whey protein isolate (mixed in a certain ratio) was the most desirable material for extrusion-based 3D printing. They researched further to show that the milk protein gel had the best 3D printing performance, which matched the model best and had good fidelity (Liu et al., 2019) and also investigated the effects of hydrocolloids on the microstructures, viscoelastic characteristics and 3D printing performance of milk protein concentrate (Liu et al., 2022).

Some researchers formulated soy protein- and gluten-based gel materials for 3D printing by employing thermosensitive cocoa butter to study its likelihood for preparing meat analogues (Wang and Liu, 2021). (Shahbazi et al., 2021) developed an application of a reduced fat casein-based Pickering emulsions in the 3D printing process to develop functional foods, broadening the micro-biosurfactant utilization in food printing. Similarly (Daffner et al., 2021), presented design and characterisation of casein−whey protein suspensions mixed with dairy fat processed via the pH−temperature-route in preparation for 3D printing. Some researchers showed that the rennet-induced gelation of milk proteins as a potential method for the formation of 3D printed food structures (Uribe-Alvarez et al., 2021), while others investigated 3D printability of the functionalized yogurts on bread, and developed yogurts with bioactive ingredients of high quality and application value (Hu et al., 2022). Li et al. (2022) developed a method for rapid determination of lactose in milk using a bioactive paper-3D printing integration technology.

Lee et al. (2020) developed direct ink writing technique for 3D printing of milk products at room temperature by changing the rheological properties of the printing ink. Le Tohic et al. (2018) used processed cheese as the printing material both at low or high extrusion rates.

4.3. Big Data

An important application of BD/BDA is to improve on-farm decision making, milk yield prediction, milk quality improvement and dairy farm management. In this context, Yan et al. (2015) introduced the Milk Yield Prediction and Analysis Tool (PAT), a cost-effective tool that uses BDA to accurately predict milk yield at both individual cow and group levels. This study highlighted the importance of data-driven decision making for small-scale milk producers. Another study by Zhang et al. (2021) discussed the application of 5G + IoT technology, BD mining and analytics, and AI in smart dairy pasture management, specifically to identify individual cows and accurately feed dairy cows. By using image recognition technology, the study showed that this approach can effectively improve the economic benefits and production efficiency of the cattle farm. Recently, Rodriguez-Venegas et al. (2022) investigated the impact of heat stress on milk production using the Temperature Humidity Index (THI) as a biomarker of heat stress, i.e., a THI-BD approach. The study found that heat stress can lead to a reduction in milk production and highlights the need for mitigation strategies to counteract heat stress. Duruz et al. (2020) investigated the impact of transhumance on cattle productivity. The study used big dairy data to develop a model that considers environmental, physiological and morphological factors on milk production during transhumance. Boiarkina et al. (2018) showed that the application of BD in milk powder processing can improve product quality and reduce in off-specification products. According to Newton et al. (2020), the transition to a new business stage, the importance of the whole farm context, and the use of data beyond short-term decision making are important dimensions influencing farmers' demand for and engagement with BD applications to improve farm decision making.

The integration of BD/BDA in dairy farming has shown great potential to improve animal health and productivity, and ultimately dairy farm profitability through strategic management. For example, Cabrera et al. (2020) presented a decision-making engine (The Dairy Brain) that integrates precision agriculture, BDA and IoT. The system collects, integrates, manages, and analyses on- and off-farm data in real-time to provide practical applications such as nutrient grouping, early risk detection of clinical mastitis, and prediction of clinical mastitis onset. The results show that the system has the potential to reduce nutritional costs and improve health monitoring. Animal health assessment is an important research area for the use of BD. Assessing the global health of animals is a complex task due to its multifaceted nature, and researchers tend to focus on detecting specific diseases separately. In this context, Franceschini et al. (2022) proposed an approach to assess the global health status of dairy cows using BD from milk records, including milk yield, somatic cell count and Fourier transform mid-infrared (FT-MIR)-based predictors related to milk composition and animal health status. The results suggest that the quantitative traits obtained indirectly reflect some of the major health disorders in dairy farming and could be used to monitor dairy cows on a large scale. In another study, Pralle and White (2020) discussed the challenges faced by dairy farms in detecting hyperketonemia (HYK), a metabolic disorder affecting cows during the transition to lactation. The results suggested that the increasing data streams available to farms, such as milk production and composition, cow management records and genomics, can be used to monitor the onset of postpartum HYK using a BD approach.

BD technologies can also be used to improve supply chain management. However, there are several potential barriers that need to be addressed for their successful implementation. In this context (Kazancoglu et al., 2021), identified economic as the most important barrier to circularity in dairy supply chains, followed by technological and environmental. Optimization is found to be the most important BD solution to overcome these barriers, followed by data mining and machine learning. The main applications of BD/BDA identified are in line with the findings of (Lokhorst et al., 2019). These authors found that the majority of research in precision dairy farming focuses on the animal sublevel, with topics at the dairy farm level dominating. The authors concluded that the full potential of BD in precision dairy farming has not yet been realised and that multiple BD characteristics and sources need to be used to add value to decision making.

4.4. Internet of Things

There are many types of data that IoT can collect and share, such as temperature, heart rate and cow movement, which provide information on the health, position and behaviour of the cows, such as standing, lying down, eating or oestrus events (Pratama et al., 2019; Arago et al., 2022). These data can help farmers to make more informed decisions, for instance regarding the cow health, feeding and milking frequency.

IoT has great potential to collect and share live data from dairies. In fact, recent research has suggested the use of IoT to automate cow feeding, so that nutrition plans can be designed for each cow and a more accurate milk production forecast can be made for each cow (da Rosa Righi et al., 2020). Yavari et al. (2020) also proposed a low-cost IoT solution for milk-quality monitoring. Faruq et al. (2019), on the other hand, used IoT to monitor the temperature and heart rate data of cows, which provides information about the cow's health and enables disease diagnosis and the identification of the most adequate treatment and prevention method.

The potential of IoT extends beyond only the farm to the entire dairy supply chain. There are several examples of using IoT to optimise the logistics of dairy products (e.g., Zou et al., 2020; Kazancoglu et al., 2022; Chakurkar et al., 2018; Karouani and Elgarej, 2022). In the dairy industry, logistics is an important aspect due to the high perishability of dairy products and the need to distribute these products to all population centres.

Finally, IoT can also help to measure the value of different variables that affect the quality of fresh milk, such as pH, temperature, odour, turbidity, colour, fat, taste and the presence of additives (Habsari et al., 2022; Chen et al., 2022). This helps to classify the milk according to its quality and thus determine its optimal price.

4.5. Artificial Intelligence

AI has been mainly employed to assess the health and wellbeing of dairy cows. This is due to a significant need within the dairy industry for robust, automated, and inexpensive technology for the analysis of dairy cow behaviour (Lima et al., 2021). AI can mine data from various currently underused sources to simplify repetitive and difficult decision-making tasks in dairy farming (Nogoy et al., 2021). AI selects the optimal treatment of cows based on the impacts of physiological and environmental factors for superior milk quality and production (Sugiono et al., 2017). Other applications of AI in Dairy 4.0 include consumer demand, food quality, and dairy farming techniques.

The prediction of demand is very important in the dairy industry as most products have a short shelf-life. The implementation of AI has been used to calculate product portfolio risk (Goli et al., 2019) and for demand prediction (Goli et al., 2020, 2021) with application to the dairy industry of Iran.

Food quality is increasingly important to consumers, yet few tools exist outside of advanced laboratories, and current inspection mechanisms are unable to adequately process the various threats to food integrity. Sound vibrations traversing food products used in conjunction with AI have been proposed to detect adulteration and verify quality (Iymen et al., 2020). An optimization process based on AI has been proposed to identify sensory improvements to food products (Bi et al., 2022). Computer vision and machine learning techniques have been used to determine cheese quality during the ripening process (Loddo et al., 2022). The heatwaves resulting from climate change are stressing farm animals. A system based on AI has been proposed to increase or maintain milk quality by reducing heat stress (Fuentes et al., 2020).

There is also pressure to increase herd size while reducing animal husbandry and welfare costs in which AI methods can provide significant support (Hajnal et al., 2022). AI can be used to predict milk production and quality based on computer vision methods that estimate the heart rate and respiration rate of cows (Fuentes et al., 2021). AI has also been applied to aerial imagery to estimate dairy methane emissions and herd size (Jeong et al., 2022).

4.6. Blockchain

Blockchain can be utilized for building intelligent ecosystems for milk supply chains to help meet the demand for food of the growing global population in a sustainable manner (Gehlot et al., 2022). Varavallo et al. (2022) proposed a blockchain-based traceability solution for lowered environmental impact and reduced cost per transaction applied to the Fontina PDO cheese supply chain. Mangla et al. (2021) investigated societal impacts of blockchain technology to build social sustainability in milk supply chains in Turkey and found several benefits in terms of food fraud prevention, rural development, animal health and welfare in addition to promoting healthy food and food security.

Makarov et al. (2019) proposed a blockchain solution for the management of dairy supply chain products to ensure the safety of data, protection of repository documents from hacking, immutability of data on the progress of transportation, and to enable both retailers and consumers to investigate supply chain actors from farm to consumer. Casino et al. (2021) focused their blockchain application on proof of regulatory compliance to both state authorities and demanding customers. Fang and Stone (2021) proposed a dairy logistics supply ecosystem with blockchain technology to provide fresh and safe dairy products at fair prices by employing smart contacts with crowdfunding functionality.

5. Current challenges and future perspectives

There are still several challenges that the industry must overcome to fully exploit the benefits of Industry 4.0 technologies.

One of the main challenges is related to the territorial location: the lack of digital infrastructure and connectivity in many rural areas where dairy farms are located impede the full spread of technologies. This can make it difficult for farmers to access and use new technologies for the exploitation of precision farming and automated milking systems (Zambon et al., 2019; Dadi et al., 2021). Another challenge is the high cost of implementing new technologies, particularly for SMEs sized dairy farms typically characterized by limited financial resources (Zambon et al., 2019; Bahn et al., 2021). This will lead to an increase in the digital divide between larger and smaller dairy farms in all the countries, with the former having a competitive advantage due to their greater ability to invest in new technologies.

Another issue emerging from the analysis is the need for skilled employees operating in the industry and implementing these new technologies. The companies that want to implement these technologies must equip themselves with skilled human resources and provide necessary tools and equipment for their training. Even in this case, this aspect can be a challenge for smaller farms that may not find skilled resources to hire or take care of the employees’ training. Data privacy and cybersecurity issues are also important concerns for the dairy industry. With the increasing use of connected devices and data analytics in dairy production, there is a risk of sensitive data being compromised (Bahn et al., 2021; Goller et al., 2021).

Finally, also in the dairy industry a successful implementation of Industry 4.0 technologies requires a greater collaboration and coordination among supply chain stakeholders to ensure that new technologies are effectively integrated into existing systems.

In conclusion, even while technology advancements and digitalization have the potential to be very beneficial for the dairy business, there are still a number of obstacles that must be overcome in order to fully realize these advantages. These include issues related to digital infrastructure and connectivity, the cost of implementing new technologies, the need for skilled labour, and the need for greater collaboration among supply chain actors. In order to take advantage of technological advancements and make sure that the dairy business is competitive and sustainable in the future, it will be essential to address these difficulties.

Credit author statement

Abdo Hassoun: Conceptualization, Methodology / Study design, Resources, Data curation, Writing – original draft, Supervision, Project administration. Guillermo Garcia-Garcia: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing. Hana Trollman: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing. Sandeep Jagtap: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing. Carlos Parra-López: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing. Janna Cropotova: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing, Supervision, Project administration, Funding acquisition. Zuhaib Bhat: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing. Piera Centobelli: Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing. Abderrahmane Aït-Kaddour: Conceptualization, Methodology / Study design, Resources, Data curation, Writing – original draft, Writing – review & editing, Supervision, Project administration.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Handling Editor: Professor A.G. Marangoni

Contributor Information

Abdo Hassoun, Email: abdo.hassoun@eilco.univ-littoral.fr.

Guillermo Garcia-Garcia, Email: guillermo.garcia@juntadeandalucia.es.

Hana Trollman, Email: ht203@leicester.ac.uk.

Sandeep Jagtap, Email: s.z.jagtap@cranfield.ac.uk.

Carlos Parra-López, Email: carlos.parra@juntadeandalucia.es.

Janna Cropotova, Email: janna.cropotova@ntnu.no.

Zuhaib Bhat, Email: zuhaibbhatvet@gmail.com.

Piera Centobelli, Email: piera.centobelli@unina.it.

Abderrahmane Aït-Kaddour, Email: abderrahmane.aitkaddour@vetagro-sup.fr.

Data availability

No data was used for the research described in the article.

References

- Abbate S., Centobelli P., Cerchione R. The digital and sustainable transition of the agri-food sector. Technol. Forecast. Soc. Change. 2023;187 doi: 10.1016/j.techfore.2022.122222. [DOI] [Google Scholar]

- Al Nuaimi M.M.K., et al. Blockchain implementation framework for tracing the dairy supply chain. Lect. Notes Data Eng. Commun. Technol. 2023 doi: 10.1007/978-981-19-3391-2_42. [DOI] [Google Scholar]

- Arago N.M., et al. Smart dairy cattle farming and in-heat detection through the internet of things (IoT) Int. J. Integrated Eng. 2022;14(1):157–172. doi: 10.30880/ijie.2022.14.01.014. [DOI] [Google Scholar]

- Ayed R. Ben, et al. Integration of innovative technologies in the agri-food sector: the fundamentals and practical case of DNA-based traceability of olives from fruit to oil. Plants. 2022;11(9):1230. doi: 10.3390/PLANTS11091230. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bahn R.A., Yehya A.A.K., Zurayk R. Digitalization for sustainable agri-food systems: potential, status, and risks for the Mena region. Sustainability. 2021;13(6):1–25. doi: 10.3390/su13063223. [DOI] [Google Scholar]

- Bai C., et al. Industry 4.0 technologies assessment: a sustainability perspective. Int. J. Prod. Econ. 2020;229 doi: 10.1016/J.IJPE.2020.107776. [DOI] [Google Scholar]

- Balaska V., et al. Automating dairy production lines with the yoghurt cups recognition and detection process in the Industry 4.0 era. Proc. Comput. Sci. 2023;217:918–927. doi: 10.1016/j.procs.2022.12.289. [DOI] [Google Scholar]

- Bi K., et al. ‘Consumer-oriented sensory optimization of yogurt: an artificial intelligence approach’. Food Control. 2022;138 doi: 10.1016/j.foodcont.2022.108995. [DOI] [Google Scholar]

- Bigliardi B., et al. Industry 4.0 in the agrifood supply chain: a review. Proc. Comput. Sci. 2023;217:1755–1764. doi: 10.1016/j.procs.2022.12.375. [DOI] [Google Scholar]

- Bisoffi S., et al. COVID-19 and sustainable food systems: what should we learn before the next emergency. Front. Sustain. Food Syst. 2021;5:53. doi: 10.3389/FSUFS.2021.650987/BIBTEX. [DOI] [Google Scholar]

- Bodo S., et al. Analysis of selected data from robotic milking regarding to heat stress of dairy cows. Acta Technol. Agric. 2022;25(2):92–96. doi: 10.2478/ata-2022-0015. [DOI] [Google Scholar]

- Boiarkina I., et al. Using big data in industrial milk powder process systems. Comput. Aid. Chem. Eng. 2018 doi: 10.1016/B978-0-444-64241-7.50377-3. [DOI] [Google Scholar]

- Cabrera V.E., et al. Symposium review: real-time continuous decision making using big data on dairy farms. J. Dairy Sci. 2020;103(4):3856–3866. doi: 10.3168/jds.2019-17145. [DOI] [PubMed] [Google Scholar]

- Casino F., et al. Blockchain-based food supply chain traceability: a case study in the dairy sector. Int. J. Prod. Res. 2021;59(19):5758–5770. doi: 10.1080/00207543.2020.1789238. [DOI] [Google Scholar]

- Chakurkar P., Shikalgar S., Mukhopadhyay D. International Conference on Advances in Computing, Communication and Control 2017, ICAC3 2017. 2018. An Internet of Things (IOT) based monitoring system for efficient milk distribution; pp. 1–5. [DOI] [Google Scholar]

- Chen Q., Shi H., Chen J. ‘Development management of infant dairy industry integrating internet of things under the background of family planning policy adjustment’. Secur. Commun. Network. 2022;2022 doi: 10.1155/2022/3018374. [DOI] [Google Scholar]

- Ciccullo F., et al. Exploring the potential of business models for sustainability and big data for food waste reduction. J. Clean. Prod. 2022;340 doi: 10.1016/j.jclepro.2022.130673. [DOI] [Google Scholar]

- da Rosa Righi R., et al. Towards combining data prediction and internet of things to manage milk production on dairy cows. Comput. Electron. Agric. 2020;169 doi: 10.1016/j.compag.2019.105156. [DOI] [Google Scholar]

- Dadi V., et al. Agri-food 4.0 and innovations: revamping the supply chain operations. Prod. Eng. Arch. 2021;27(2):75–89. doi: 10.30657/pea.2021.27.10. [DOI] [Google Scholar]

- Daffner K., et al. ‘Characterising the influence of milk fat towards an application for extrusion-based 3D-printing of casein−whey protein suspensions via the pH−temperature-route’. Food Hydrocolloids. 2021;118 doi: 10.1016/j.foodhyd.2021.106642. [DOI] [Google Scholar]

- Drewry J.L., et al. Assessment of digital technology adoption and access barriers among crop, dairy and livestock producers in Wisconsin. Comput. Electron. Agric. 2019;165 doi: 10.1016/j.compag.2019.104960. [DOI] [Google Scholar]

- Duruz S., et al. Big dairy data to unravel effects of environmental, physiological and morphological factors on milk production of mountain-pastured Braunvieh cows. R. Soc. Open Sci. 2020;7(7) doi: 10.1098/rsos.200638. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Eastwood C.R., et al. Responsible robotics design–A systems approach to developing design guides for robotics in pasture-grazed dairy farming. Front. Robot. AI. 2022;9 doi: 10.3389/frobt.2022.914850. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Echegaray N., et al. Meat 4.0: principles and applications of industry 4.0 technologies in the meat industry. Appl. Sci. 2022;12(14):6986. doi: 10.3390/app12146986. [DOI] [Google Scholar]

- Fang C., Stone W.Z. International Conference on Electrical, Computer, Communications and Mechatronics Engineering, ICECCME 2021. 2021. An ecosystem for the dairy logistics supply chain with blockchain technology. [DOI] [Google Scholar]

- Faruq, et al. IES 2019 - International Electronics Symposium: the Role of Techno-Intelligence in Creating an Open Energy System towards Energy Democracy. Proceedings; 2019. Health monitoring and early diseases detection on dairy cow based on internet of things and intelligent system; pp. 183–188. [DOI] [Google Scholar]

- Franceschini S., et al. Can unsupervised learning methods applied to milk recording big data provide new insights into dairy cow health? J. Dairy Sci. 2022;105(8):6760–6772. doi: 10.3168/jds.2022-21975. [DOI] [PubMed] [Google Scholar]

- Fuentes S., et al. Artificial intelligence applied to a robotic dairy farm to model milk productivity and quality based on cow data and daily environmental parameters. Sensors. 2020;20(10) doi: 10.3390/s20102975. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fuentes S., et al. Biometric physiological responses from dairy cows measured by visible remote sensing are good predictors of milk productivity and quality through artificial intelligence. Sensors. 2021;21(20) doi: 10.3390/s21206844. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Galanakis C.M. The “vertigo” of the food sector within the triangle of climate change, the post-pandemic world, and the Russian-Ukrainian war. Foods. 2023;12:721. doi: 10.3390/foods12040721. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gehlot A., et al. Dairy 4.0: intelligent communication ecosystem for the cattle animal welfare with blockchain and IoT enabled technologies. Appl. Sci. 2022;12(14):7316. doi: 10.3390/APP12147316. [DOI] [Google Scholar]

- Gerrits B., et al. Simulat. Model Cooperat. Robot. Dairy Farms. 2023:831–842. doi: 10.1109/WSC57314.2022.10015409. [DOI] [Google Scholar]

- Goli A., et al. Hybrid artificial intelligence and robust optimization for a multi-objective product portfolio problem Case study: the dairy products industry. Comput. Ind. Eng. 2019;137 doi: 10.1016/j.cie.2019.106090. [DOI] [Google Scholar]

- Goli A., et al. Application of improved artificial intelligence with runner-root meta-heuristic algorithm for dairy products industry: a case study. Int. J. Artif. Intell. Tool. 2020;29(5) doi: 10.1142/S0218213020500086. [DOI] [Google Scholar]

- Goli A., et al. An integrated approach based on artificial intelligence and novel meta-heuristic algorithms to predict demand for dairy products: a case study. Netw. Comput. Neural Syst. 2021;32(1):1–35. doi: 10.1080/0954898X.2020.1849841. [DOI] [PubMed] [Google Scholar]

- Goller M., Caruso C., Harteis C. Digitalisation in agriculture: knowledge and learning requirements of German dairy farmers. Int. J. Res. Vocat. Educ. Train. 2021;8(2):208–223. doi: 10.13152/IJRVET.8.2.4. [DOI] [Google Scholar]

- Habsari W., Udin F., Arkeman Y. IOP Conference Series: Earth and Environmental Science. 2022. An analysis and design of fresh milk smart grading system based on internet of things. [DOI] [Google Scholar]

- Hajnal E., Kovács L., Vakulya G. Dairy cattle rumen bolus developments with special regard to the applicable artificial intelligence (AI) methods. Sensors. 2022;22(18) doi: 10.3390/s22186812. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hassoun A., Siddiqui S.A., et al. Emerging technological advances in improving the safety of muscle foods: framing in the context of the food revolution 4.0. Food Res. Int. 2022:0–42. doi: 10.1080/87559129.2022.2149776. [DOI] [Google Scholar]

- Hassoun A., Abdullah N.A., et al. Food traceability 4.0 as part of the fourth industrial revolution: key enabling technologies. Crit. Rev. Food Sci. Nutr. 2022;0(0):1–17. doi: 10.1080/10408398.2022.2110033. [DOI] [PubMed] [Google Scholar]

- Hassoun A., Aït-kaddour A., et al. ‘The fourth industrial revolution in the food industry — Part I: industry 4.0 technologies’. Crit. Rev. Food Sci. Nutr. 2022:1–17. doi: 10.1080/10408398.2022.2034735. [DOI] [PubMed] [Google Scholar]

- Hassoun A., et al. Implementation of relevant fourth industrial revolution innovations across the supply chain of fruits and vegetables: a short update on Traceability 4.0. Food Chem. 2023;409 doi: 10.1016/j.foodchem.2022.135303. [DOI] [PubMed] [Google Scholar]

- Hogenboom J.A., et al. Invited review: hygienic quality, composition, and technological performance of raw milk obtained by robotic milking of cows. J. Dairy Sci. 2019;102(9):7640–7654. doi: 10.3168/jds.2018-16013. [DOI] [PubMed] [Google Scholar]

- Hu L., et al. ‘Effect of enzymatic-ultrasonic hydrolyzed chitooligosaccharide on rheology of gelatin incorporated yogurt and 3D printing’. Food Hydrocolloids. 2022;132 doi: 10.1016/j.foodhyd.2022.107851. [DOI] [Google Scholar]

- Ioanna M., et al. Energy management for a net zero dairy supply chain under climate change. Trends Food Sci. Technol. 2022;126:153–167. doi: 10.1016/j.tifs.2022.01.015. [DOI] [Google Scholar]

- Iymen G., et al. Artificial intelligence-based identification of butter variations as a model study for detecting food adulteration. Innovative Food Sci. Emerging Technol. 2020;66 doi: 10.1016/j.ifset.2020.102527. [DOI] [Google Scholar]

- Javaid M., et al. Enhancing smart farming through the applications of Agriculture 4.0 technologies. Int. J. Intelli. Netw. 2022;3:150–164. doi: 10.1016/j.ijin.2022.09.004. [DOI] [Google Scholar]

- Jeong S., et al. Artificial intelligence approach for estimating dairy methane emissions. Environ. Sci. Technol. 2022;56(8):4849–4858. doi: 10.1021/acs.est.1c08802. [DOI] [PubMed] [Google Scholar]

- Ji B., et al. A machine learning framework to predict the next month's daily milk yield, milk composition and milking frequency for cows in a robotic dairy farm. Biosyst. Eng. 2022;216:186–197. doi: 10.1016/j.biosystemseng.2022.02.013. [DOI] [Google Scholar]

- Johansson M., et al. Composition and enzymatic activity in bulk milk from dairy farms with conventional or robotic milking systems. J. Dairy Res. 2017;84(2):154–158. doi: 10.1017/S0022029917000140. [DOI] [PubMed] [Google Scholar]

- Karouani Y., Elgarej M. Milk-run collection monitoring system using the internet of things based on swarm intelligence. Int. J. Inf. Syst. Supply Chain Manag. 2022;15(3) doi: 10.4018/IJISSCM.290018. [DOI] [Google Scholar]

- Kazancoglu Y., et al. A fuzzy based hybrid decision framework to circularity in dairy supply chains through big data solutions. Technol. Forecast. Soc. Change. 2021;170 doi: 10.1016/j.techfore.2021.120927. [DOI] [Google Scholar]

- Kazancoglu Y., et al. Circular dairy supply chain management through Internet of Things-enabled technologies. Environ. Sci. Pollut. Control Ser. 2022 doi: 10.1007/s11356-021-17697-8. [DOI] [PubMed] [Google Scholar]

- Khanna A., et al. Blockchain-Enabled supply chain platform for Indian dairy industry: safety and traceability. Foods. 2022;11(17) doi: 10.3390/foods11172716. [DOI] [PMC free article] [PubMed] [Google Scholar]

- King M.T.M., Matson R.D., DeVries T.J. Connecting farmer mental health with cow health and welfare on dairy farms using robotic milking systems. Anim. Welf. 2021;30(1):25–38. doi: 10.7120/09627286.30.1.025. [DOI] [Google Scholar]

- Kumar I., et al. Opportunities of artificial intelligence and machine learning in the food industry. J. Food Qual. 2021;2021 doi: 10.1155/2021/4535567. [DOI] [Google Scholar]

- Le Tohic C., et al. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 2018;220:56–64. doi: 10.1016/j.jfoodeng.2017.02.003. [DOI] [Google Scholar]

- Lee C.P., Karyappa R., Hashimoto M. 3D printing of milk-based product. RSC Adv. 2020;10(50):29821–29828. doi: 10.1039/d0ra05035k. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li Y., et al. Fe-N-C nanozyme mediated bioactive paper-3D printing integration technology enables portable detection of lactose in milk. Sensor. Actuator. B Chem. 2022;368 doi: 10.1016/j.snb.2022.132111. [DOI] [Google Scholar]

- Lima L.M., et al. Proceedings - 2021 International Conference on Computational Science and Computational Intelligence, CSCI 2021. 2021. Artificial intelligence in support of welfare monitoring of dairy cattle: a systematic literature review; pp. 1708–1715. [DOI] [Google Scholar]

- Liu Y., et al. 3D printed milk protein food simulant: improving the printing performance of milk protein concentration by incorporating whey protein isolate. Innovative Food Sci. Emerging Technol. 2018;49:116–126. doi: 10.1016/j.ifset.2018.07.018. [DOI] [Google Scholar]

- Liu Y., et al. Rheological and mechanical behavior of milk protein composite gel for extrusion-based 3D food printing. LWT (Lebensm.-Wiss. & Technol.) 2019;102:338–346. doi: 10.1016/j.lwt.2018.12.053. [DOI] [Google Scholar]

- Liu Y., Wang K., Zhou P. Microscopic structure, viscoelastic behaviour and 3D printing potential of milk protein concentrate-hydrocolloid complex coacervates. Int. J. Food Sci. Technol. 2022;57(7):4422–4431. doi: 10.1111/ijfs.15775. [DOI] [Google Scholar]

- Loddo A., et al. Automatic monitoring cheese ripeness using computer vision and artificial intelligence. IEEE Access. 2022;10:122612–122626. doi: 10.1109/ACCESS.2022.3223710. [DOI] [Google Scholar]

- Lokhorst C., De Mol R.M., Kamphuis C. Invited review: big Data in precision dairy farming. Animal. 2019;13(7):1519–1528. doi: 10.1017/S1751731118003439. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Luo Z., et al. Application of the IoT in the food supply Chain─From the perspective of carbon mitigation. Environ. Sci. Technol. 2022;56(15):10567–10576. doi: 10.1021/acs.est.2c02117. [DOI] [PubMed] [Google Scholar]

- Lyons N.A., et al. third ed. Academic Press; 2022. Technology and Robotic Milking in Dairy Production, Encyclopedia of Dairy Sciences; pp. 823–829. [DOI] [Google Scholar]

- Makarov E.I., et al. Conceptual approaches to the quality system of dairy products based on the blockchain technology. Stud. Comput. Intelli. 2019 doi: 10.1007/978-3-030-13397-9_109. [DOI] [Google Scholar]

- Mangla S.K., et al. Using system dynamics to analyze the societal impacts of blockchain technology in milk supply chainsrefer. Transport. Res. E Logist. Transport. Rev. 2021;149 doi: 10.1016/j.tre.2021.102289. [DOI] [Google Scholar]

- Manning L., et al. Artificial intelligence and ethics within the food sector: developing a common language for technology adoption across the supply chain. Trends Food Sci. Technol. 2022;125:33–42. doi: 10.1016/j.tifs.2022.04.025. [DOI] [Google Scholar]

- Marvin H.J.P., et al. Digitalisation and Artificial Intelligence for sustainable food systems. Trends Food Sci. Technol. 2022;120:344–348. doi: 10.1016/J.TIFS.2022.01.020. [DOI] [Google Scholar]

- Mavani N.R., et al. Application of artificial intelligence in food industry—a guideline. Food Eng. Rev. 2022;14(1):134–175. doi: 10.1007/S12393-021-09290-Z. [DOI] [Google Scholar]

- Neokleous I., Tarapata J., Papademas P. Non-thermal processing technologies for dairy products: their effect on safety and quality characteristics. Front. Sustain. Food Syst. 2022;6 doi: 10.3389/fsufs.2022.856199. [DOI] [Google Scholar]

- Newton J.E., Nettle R., Pryce J.E. vol. 181. 2020. Farming smarter with big data: insights from the case of Australia's national dairy herd milk recording scheme. (Agricultural Systems). [DOI] [Google Scholar]

- Nogoy K.M.C., et al. Precision detection of real-time conditions of dairy cows using an advanced artificial intelligence hub. Appl. Sci. 2021;11(24) doi: 10.3390/APP112412043. [DOI] [Google Scholar]

- Osei-Amponsah R., et al. Heat stress impacts on lactating cows grazing australian summer pastures on an automatic robotic dairy. Animals. 2020;10(5) doi: 10.3390/ani10050869. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Perov I. Robotic dairy systems—change in management paradigm. Smart Innov. Syst. Technol. 2022 doi: 10.1007/978-981-16-3349-2_2. [DOI] [Google Scholar]

- Pralle R.S., White H.M. Symposium review: big data, big predictions: utilizing milk Fourier-transform infrared and genomics to improve hyperketonemia management. J. Dairy Sci. 2020;103(4):3867–3873. doi: 10.3168/jds.2019-17379. [DOI] [PubMed] [Google Scholar]

- Pratama Y.P., et al. IES 2019 - International Electronics Symposium: the Role of Techno-Intelligence in Creating an Open Energy System towards Energy Democracy. Proceedings; 2019. Designing of a smart collar for dairy cow behavior monitoring with application monitoring in microservices and internet of things-based systems; pp. 527–533. [DOI] [Google Scholar]

- Ramirez-Asis E., et al. A review on role of artificial intelligence in food processing and manufacturing industry. Mater. Today: Proc. 2022;51:2462–2465. doi: 10.1016/J.MATPR.2021.11.616. [DOI] [Google Scholar]

- Rejeb A., Rejeb K., Zailani S. Big data for sustainable agri‐food supply chains: a review and future research perspectives. J. Digit. Inf. Manag. 2021 doi: 10.1007/s42488-021-00045-3. [DOI] [Google Scholar]

- Ribeiro N.G., et al. Dairy foods and novel thermal and non-thermal processing: a bibliometric analysis. Innovative Food Sci. Emerging Technol. 2022;76 doi: 10.1016/j.ifset.2022.102934. [DOI] [Google Scholar]

- Rodriguez-Venegas R., et al. Heat stress characterization in a dairy cattle intensive production cluster under arid land conditions: an annual, seasonal, daily, and minute-to-minute, big data approach. Agriculture (Switzerland) 2022;12(6) doi: 10.3390/agriculture12060760. [DOI] [Google Scholar]

- Ross M.M., Kelly A.L., Crowley S.V. Potential applications of dairy products, ingredients and formulations in 3D printing. Fundam. 3D Food Print. Appl. 2018 doi: 10.1016/B978-0-12-814564-7.00007-9. [DOI] [Google Scholar]

- Sandey K.K., et al. Robotics – an emerging technology in dairy industry. Int. J. Eng. Trends Technol. 2017;6(1):58–62. http://www.ijettjournal.org [Google Scholar]

- Schneider N., et al. Big data from pharmaceutical patents: a computational analysis of medicinal chemists bread and butter. J. Med. Chem. 2016;59(9):4385–4402. doi: 10.1021/acs.jmedchem.6b00153. [DOI] [PubMed] [Google Scholar]

- Shahbazi M., Jäger H., Ettelaie R. Application of Pickering emulsions in 3D printing of personalized nutrition. Part II: functional properties of reduced-fat 3D printed cheese analogues. Colloids Surf. A Physicochem. Eng. Asp. 2021;624 doi: 10.1016/j.colsurfa.2021.126760. [DOI] [Google Scholar]

- Sharma S., et al. Sustainable innovations in the food industry through artificial intelligence and big data analytics. Logistics. 2021;5(4):66. doi: 10.3390/LOGISTICS5040066. [DOI] [Google Scholar]

- Sinha B.B., Dhanalakshmi R. Recent advancements and challenges of Internet of Things in smart agriculture: a survey. Future Generat. Comput. Syst. 2022;126:169–184. doi: 10.1016/J.FUTURE.2021.08.006. [DOI] [Google Scholar]

- Sugiono S., Soenoko R., Riawati L. Investigating the impact of physiological aspect on cow milk production using artificial intelligence. Int. Rev. Mech. Eng. 2017;11(1):30–36. doi: 10.15866/ireme.v11i1.9873. [DOI] [Google Scholar]

- Trivelli L., et al. From precision agriculture to Industry 4.0: unveiling technological connections in the agrifood sector. Br. Food J. 2019;121(8):1730–1743. doi: 10.1108/BFJ-11-2018-0747. [DOI] [Google Scholar]

- Uribe-Alvarez R., et al. ‘Evaluation of rennet-induced gelation under different conditions as a potential method for 3D food printing of dairy-based high-protein formulations’. Food Hydrocolloids. 2021;114 doi: 10.1016/j.foodhyd.2020.106542. [DOI] [Google Scholar]

- Varavallo G., et al. Traceability platform based on green blockchain: an application case study in dairy supply chain. Sustainability. 2022;14(6) doi: 10.3390/su14063321. [DOI] [Google Scholar]

- Wang S., Liu S. 3D printing of soy protein- and gluten-based gels facilitated by thermosensitive cocoa butter in a model study. ACS Food Sci. Technol. 2021;1(10):1990–1996. doi: 10.1021/acsfoodscitech.1c00311. [DOI] [Google Scholar]

- Yadav V.S., et al. Exploring the application of Industry 4.0 technologies in the agricultural food supply chain: a systematic literature review. Comput. Ind. Eng. 2022;169 doi: 10.1016/j.cie.2022.108304. [DOI] [Google Scholar]

- Yan W.J., et al. Proceedings - 2015 IEEE International Conference on Big Data. IEEE Big Data 2015; 2015. Big data analytics for empowering milk yield prediction in dairy supply chains; pp. 2132–2137. [DOI] [Google Scholar]

- Yavari A., et al. International Conference on Information Networking. 2020. Internet of things milk spectrum profiling for industry 4.0 dairy and milk manufacturing; pp. 342–347. [DOI] [Google Scholar]

- Zambon I., et al. Revolution 4.0: industry vs. agriculture in a future development for SMEs. Processes. 2019;7(1):1–16. doi: 10.3390/pr7010036. [DOI] [Google Scholar]

- Zhang J., et al. 2021 International Wireless Communications and Mobile Computing, IWCMC 2021. 2021. ‘Research on application technology of 5G internet of things and big data in dairy farm’; pp. 138–140. [DOI] [Google Scholar]

- Zhang J.Y., et al. Advancements in 3D food printing: a comprehensive overview of properties and opportunities. Crit. Rev. Food Sci. Nutr. 2022;62(17):4752–4768. doi: 10.1080/10408398.2021.1878103. [DOI] [PubMed] [Google Scholar]

- Zou B., et al. Information milk powder traceability and rationalization sales system based on internet of things. Lect. Notes Electr. Eng. 2020 doi: 10.1007/978-981-15-5959-4_229. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.