Abstract

Joining dissimilar materials is important in engineering studies to reduce costs, lighten structures, and take advantage of the superior properties of the materials. However, the different chemical compositions, physical, and mechanical properties of dissimilar materials make the joining process difficult. To overcome the limitations of traditional joining techniques, there is an increasing interest towards innovative welding methods such as ultrasonic welding, laser welding, friction stir welding, and so on. In this study, friction stir welding was used to join different types of polymer materials. Polylactic acid (PLA Plus) plates were 3D printed and welded with High Density Polyethylene (HDPE) to create PLA Plus/PLA Plus, HDPE/HDPE, and PLA Plus/HDPE connection pairs. Two different pin profiles (triangle and square), rotational speed (1000 and 1500 rpm) and feed rate (30 and 50 mm/min) were used in the FSW process. Tensile tests were performed to determine the weld strength after FSW. In addition, the hardness changes in the heat-affected zone and in the weld zone were evaluated. Finally, optical inspections were made on the welded samples to identify welding defects. The results showed that the highest weld strength was obtained with the triangular pin profile in PLA Plus/PLA Plus and PLA Plus/HDPE material pairs, and while with the square pin profile in HDPE-HDPE pairs. PLA Plus has been found to be a more suitable material for Friction Stir Welding compared to HDPE. Welding defects caused by changes in welding speed and tool rotation speed were identified in the material pairs.

Keywords: Dissimilar/similar polymer materials, Additive manufacture, Friction stir welding (FSW), Mechanical properties

1. Introduction

Today, although plastic materials cause environmental and health concerns, their use cannot be abandoned because of their advantages such as lightness and low production costs [1]. In recent years, the use of thermoplastic and reinforced polymer materials has been increasing due to their lightness and flexibility, corrosion resistance and low cost [2,3]. In addition, in order to increase fuel efficiency and to use metal resources economically, thermoplastics have begun to replace heavy components in vehicles [4], aerospace [5]. Especially with the additive manufacturing methods, the ability to produce products from plastic-based materials quickly and at desired fill rates has increased the consumption of plastics even more. 3D printers, which are now one of the popular additive manufacturing tools, have made it possible to easily print plastic and plastic-based materials. However, parts produced in 3D printers have dimensional limitations. Therefore, for large-sized parts, the method of assembling small parts together is adopted. Thus, the need to combine with the same or different materials has emerged. Various joining methods such as adhesive bonding, mechanical fastening and welding are used for joining plastic materials. However, there are limitations such as the relatively low strength of adhesives and the loss of their properties in working conditions (depending on the environment, time and temperature), and the increase in the total weight of the structures in mechanical fastening [6]. Cracks and pores occur in the joints made using traditional welding methods. In addition, the difficulties in joining different materials necessitated the need for innovative joining methods [7].

Friction stir welding (FSW) is a solid state welding method that joins similar or different materials using a tool. The tool consists of a shoulder and pin geometry and progress along the weld line by rotational. The shoulder applies pressure against the work piece surface, generating heat by friction [8]. Thus, it converts the mechanical energy at the welding interface into heat. The material that plasticizes around the pin with the effect of heat undergoes dynamic recrystallization and equiaxed grains [[9], [10], [11]] due to large plastic stresses and heat are formed [12]. Since the FSW process allows joining below the melting temperature of the material, defects occurring in fusion welding [13] are prevented. It also requires less energy than fusion welding. And it does not need filler material during welding. In addition, FSW makes it possible to join different materials which has many technical and economic advantages that attract the attention of the industry [14]. Considering these, it is a highly energy efficient and economical method [15,16]. Since it is a new technology, researchers make great efforts to understand its nature and improving welding quality.

The studies have focused on the weldability of the same or different material pairs using FSW and the effects of process parameters on the welding quality. AA6082 [17], AA6063/AA5052 [16], AA5083/Cu [18], Al/mild steel [19], 304 austenitic stainless steel/Q235 low carbon steel [20], AA7075/AZ31B [21], AA3103/AA6063 [22], HDPE-HDPE [23,24], PE-PP [15], PLA [4], polimetil metakrilat (PMMA) [25] are examples of material pairs joined using FSW. However, studies on joining thermoplastics with FSW are scarce in the literature [26]. The studies found in the literature are summarized below.

Senthil et al. [27] prepared PLA sheets using a 3D printer to joined with FSW. Experimental studies were carried out using three different rotational speeds (700, 1400 and 2000 rpm) and three different feed rates (10, 14 and 20 mm/min) and taper cylindrical pin profiled. The best result (weld with high joint efficiency of 40%) was obtained at 1400 rpm and 10 mm/min parameters. In another study, PLA sheets were joined using 600, 1000 and 1400 rpm, 3, 6 and 9 mm/min welding speed and two different pin profiles (cylindrical and frustum). It has been stated that the welding speed is the most important parameter affecting the strength. In addition, the highest strength was obtained at 6 mm/min feed rate, 1400 rpm and cylindrical pin profile [26]. Sharma et al. [4] investigated the effects on weld quality when joining 6 mm thick PLA sheets using different tool speeds (700, 1400 and 2000 rpm), transverse speed (20, 30 and 40 mm/min) and different pin profiles (cylindrical, threaded and conical). The best strength value was obtained in the joints made with cylindrical pins. Regardless of the pin profile, the highest strength value was determined at 1400 rpm at the tool rotation speed. In addition, it has been stated that the temperature formed during welding is in the range of 75–110 °C and plays an important role in high strength.

Rezgui et al. [24] optimized the process parameters for joining high density polyethylene (HDPE) sheets by FSW using the Taguchi method. The study focused on four process parameters; pin rotation speed (900, 1280 and 1700 rpm), welding speed (16, 29 and 44 mm/min), hold time (9, 15 and 20 s), pin size (M10, M12 and M14). As a result, it has been stated that pin rotation speed and pin size are the parameters that affect the welding quality the most, respectively 21.7% and 15.29%. In another study, it was stated that FSW was successful in joining PE sheets, and it was stated that the rotation speed had a great effect. He explained the reason for this with the increase in temperature in the weld zone with increasing rotational speed [23].

There are few studies in the literature on the welding of HDPE and PLA Plus sheets and the effects of the process parameters used on the weld quality. In this study, the weldability of 3D printed PLA Plus and HDPE material (produced by extrusion method) using FSW method was investigated. PLA Plus/PLA Plus, HDPE/HDPE and PLA Plus/HDPE material pairs were joined by friction stir welding using two different pin profiles, two different rotational speeds and two different feed rates. The effects of process parameters on weld quality were discussed. Tensile strengths were compared to determine the weld quality. In addition, the effect of heat generated during welding on hardness was discussed. Finally, visual and optical inspection was performed and microstructure images were evaluated to identify weld defects.

2. Material and method

2.1. Material

Two different thermoplastic materials were used in the study. The first is PLA Plus, which is taken in the form of eSun PLA Plus filament (Table 1). Creality Ender 3 S1 working with the principles of fused deposition was used to turn the filament into sheet. The specimens produced for the FSW are 72x114 × 5 mm (Fig. 1a). The dimensions of the tensile test samples are given in Fig. 1 b (ASTM D638-10). The recommended automatic temperatures of the printer are preferred for PLA Plus specimens printing. Accordingly, the extruder temperature is 210 °C, the table temperature is 60 °C and the printing speed is 50 mm/s. The part layer thickness is 0.2 mm and the filling density are 100%. Then the specimens were placed in vacuum and airtight storage packages to prevent them from being affected by moisture. The second material used in the experiments is commercial high density polyethylene (HDPE) sheet. The mechanical features of HDPE are seen in Table 2. HDPE was taken in 1 × 2 meter and 5 mm thickness sheets and then cut in the specified dimensions. PLA Plus/PLA Plus, HDPE/HDPE and PLA Plus/HDPE sheets are joined using FSW. The procedure for the FSW process is shown in Fig. 2.

Table 1.

Physical and mechanical properties of PLA plus [28].

| Mechanical Properties | PLA Plus |

|---|---|

| Filament diameter (mm) | 1.75 |

| Color | Black |

| Tensile Strength (MPa) | 63 |

| Elongation (%) | 20 |

| Density (g/cm3) | 1.23 |

| Melting point (°C) | 205–225 |

Fig. 1.

a) Dimension of specimens for FSW and b) tensile test specimens (mm).

Table 2.

| Specific gravity (gr/cm3) | 0.955 |

|---|---|

| Tensile Strength (MPa) | 22 |

| Elongation at yield (%) | 9 |

| Elongation at break (%) | 300 |

| Hardness (Shore D) | 64 |

Fig. 2.

Process steps for FSW of HDPE and PLA Plus (a) 3D printed sheets, (b) HDPE Sheets (c) Schematic view of FSW and Procedure of FSW, (d) Welded sheets by FSW and (e) Tensile specimens for weld strength.

2.2. Determination of process parameters

In FSW, weld quality is directly affected by process parameters such as tool speed, shoulder [31,32], shoulder surface [33], pin geometry [[34], [35], [36]], rotational speed [[37], [38], [39]], plunge rate, tilt angle [40], tool material, and tool design [11,41,42]. Therefore, it is important to determine the process parameters correctly. In addition, the quality of the weld depends on the amount of heat generated in the weld zone, the material flow and the mixing of the material in the weld zone. Tool speed and traverse speed play an important role in the amount of heat generated in the weld zone [8]. If the tool rotation speed is too low, it will cause inadequate heat generation and inadequate plasticization of material. If the tool rotation speed is greater than necessary, excess heat will occur, which causes undesirable grain growth and coarsening of strengthening precipitates. An increase in traverse speed will result in a reduction in heat generated and a greater torque/longitudinal force requirement. This increase in force and torque will negatively affect tool life [11].

In order to determine the tool speed and traverse speed, similar studies were first examined. Some of these studies are given in Table 3. Based on these studies, preliminary experiments were carried out by trial and error method. First, the traverse speed was changed by keeping the tool speed constant. As a result of visual and tensile analysis, the traverse speed was changed at a tool speed. As a result, tool speed was determined as 1000 and 1500 rpm, traverse speed as 30 and 50 mm/min.

Table 3.

Material, welding parameters, pin geometry used in some the literature.

| Traverse Speed (mm/min) | Tool Speed (rpm) | Pin Geometry | Material |

|---|---|---|---|

| 45, 75, 115, | 1500, 2000, 3000 | Cylindrical | HDPE [29] |

| 15 | 1200–2000 | Cylindrical | HDPE [43] |

| 20, 30, 40 | 700, 1400, 2000 | Cylindrical, threaded, and conical pins | PLA [4] |

| 20, 30, 40 | 800,1100, 1400 | PLA semi-consumable pin profile (cylindirical) | PLA/Al [44] |

| 10, 14, 20 | 700, 1400, 2000 | Conical pin | PLA [27] |

| 3, 6, 9 | 600, 1000, 1400 | Frustum and Cylindrical | PLA [26] |

| 16, 29, 44 | 900, 1280, 1700 | Threaded M10, M12, M14 | PE [24] |

| 20, 40, 63 | 500, 710, 1000, 1400, 2000 | Cylindrical | HDPE [23] |

| 8, 10, 12.5 | 900, 1860, 2920 | Threaded cylindrical, Squared, Triangular, Straight cylindrical | PE-PP [45] |

| 8 | 2000 | Square, threaded-tapered, threaded-tapered, four-flute threaded | PP composite [46] |

2.3. Design of the tool

Tool geometry in FSW consists of four features: shoulder diameter, shoulder surface angle, profile on the shoulder surface, and pin geometry. These properties affect the rate of heat generation, torque, traverse force and thermo-mechanical properties [47,48]. In addition, shoulder diameter, pin geometry and size significantly affect material flow [49]. In the study, two different geometries were determined as triangular and square profile. It is manufactured with a shoulder diameter of 20 mm and a pin height of 4.5 mm (Fig. 3 a). Since the sheet thickness is 5 mm, a distance of 0.5 mm is left to prevent the contact of the backing sheet and the pin. As the tool material, ledeburitic 12% chromium cold work tool steel (2379 tool steel) was used. The pin sizes and appearances used are shown in Fig. 3 b.

Fig. 3.

(a) Plunging dimension of shoulder and pin (b) Technical drawing and appearance of triangle pin and square pin profile.

2.4. Testing of welded specimens

FSW of the PLA Plus sheet was performed in a CNC milling machine (model: Spinner U630, Germany), in Fig. 4 (a). Tensile samples were cut from welded plates according to ASTM D638 standards [15] to evaluate weld strength (Fig. 4b). Tensile tests were carried out at room temperature and at a tensile speed of 1 mm/min. In addition, each test was repeated 3 times and the averages were taken. Welding strengths were compared according to the tensile test results. Hardness measurements (Shore D) were taken from the base material and the heat affected zone. Finally, the microstructure of the welding zone was investigated using a dijital microscope.

Fig. 4.

a) Equipments of FSW process and b) tensile specimens/Shore D hardness.

3. Results and discussion

In the study, PLA Plus and HDPE materials were joined using FSW. Triangle and square pin profile, 1000 and 1500 rpm rotation speed, 30 and 50 mm/min feed rate were used in the FSW process. The weldability and mechanical properties of PLA Plus and HDPE sheets were investigated using the determined parameters. Finally, microstructure and visual examinations were made on the welded samples to determine the welding defects.

3.1. Results of weld strength

Tensile test was performed to determine the mechanical properties of PLA Plus and HDPE materials (Fig. 5). The tests were repeated 5 times and the averages were taken. Although the ultimate strengths are close to each other, HDPE is seen to be much more ductile. Ultimate strength was determined as 30.72 ± 2.3 MPa for PLA Plus, 30.5 ± 1.7 MPa for HDPE as a result of the tensile test.

Fig. 5.

Stress and strain curves for PLA Plus and HDPE.

Fig. 6 a and b show the outlet hole, welding zone (shoulder and pin area), heat affected zone, advancing side (AS) and the retreating side (RS) of PLA Plus/PLA Plus and HDPE/HDPE FSW joints. In PLA Plus, it was seen that the tool return lines were more prominent, and the tool outlet hole was smoother along the joint area. In HDPE, it is seen that the particles break off during welding in the upper part of the weld zone, but the particles remain on the weld surface due to unsuitable welding parameters. It can be said that this is due to the fact that HDPE is softer than PLA Plus and is subject to excessive deformation due to heat.

Fig. 6.

Weld zones of PLA Plus and HDPE a) PLA Plus/PLA Plus b) HDPE/HDPE.

Table 4 given the tensile strength of PLA Plus/HDPE specimens welded by using triangle and square pin geometry, 1000–1500 rpm tool speed and 30-50 mm-min traverse speed. PLA Plus/PLA Plus, HDPE/HDPE were successfully welded with the selected parameters. In Fig. 7, the highest weld strength for PLA Plus/PLA Plus was triangle pin geometry, 1500 rpm and 30 mm/min (specimen 3), the lowest weld strength was triangle pin geometry, 1000 rpm and 50 mm/min (specimen 2). In Fig. 8, the highest weld strength for HDPE/HDPE is square pin geometry, 1500 rpm and 30 mm/min (specimen 15), the lowest weld strength is triangle pin geometry, 1500 rpm and 50 mm/min (specimen 12).

Table 4.

FSW parameters of the PLA Plus and HDPE for welded.

| No | Pin Profile | Tool speed (rpm) | Traverse speed (mm/min) | Material | UTS (MPa) | Weld efficieny (%) |

|---|---|---|---|---|---|---|

| Base | – | – | PLA Plus | 30.72 | ||

| Base | – | – | HDPE | 30.5 | ||

| 1 | Triangle | 1000 | 30 | PLA Plus/PLA Plus | 31.93 | 103.94 |

| 2 | Triangle | 1000 | 50 | 14.95 | 48.67 | |

| 3 | Triangle | 1500 | 30 | 42.12 | 136.99 | |

| 4 | Triangle | 1500 | 50 | 39.39 | 128.11 | |

| 5 | Square | 1000 | 30 | 30.19 | 98.27 | |

| 6 | Square | 1000 | 50 | 23.03 | 74.86 | |

| 7 | Square | 1500 | 30 | 28.7 | 93.42 | |

| 8 | Square | 1500 | 50 | 32.09 | 104.46 | |

| 9 | Triangle | 1000 | 30 | HDPE/HDPE | 16.27 | 53.34 |

| 10 | Triangle | 1000 | 50 | 19.69 | 64.56 | |

| 11 | Triangle | 1500 | 30 | 17.75 | 58.2 | |

| 12 | Triangle | 1500 | 50 | 7.63 | 25.02 | |

| 13 | Square | 1000 | 30 | 17.38 | 56.98 | |

| 14 | Square | 1000 | 50 | 11.19 | 36.69 | |

| 15 | Square | 1500 | 30 | 20.34 | 66,69 | |

| 16 | Square | 1500 | 50 | 13.21 | 43.31 | |

| 17 | Triangle | 1000 | 30 | PLA Plus/HDPE | – | – |

| 18 | Triangle | 1000 | 50 | – | – | |

| 19 | Triangle | 1500 | 30 | – | – | |

| 20 | Triangle | 1500 | 50 | – | – | |

| 21 | Square | 1000 | 30 | – | – | |

| 22 | Square | 1000 | 50 | – | – | |

| 23 | Square | 1500 | 30 | – | – | |

| 24 | Square | 1500 | 50 | – | – |

UTS: Ultimate Tensile Strength.

Fig. 7.

Ultimate tensile strength results for welded PLA Plus.

Fig. 8.

Ultimate tensile strength results for welded HDPE.

The weld efficiency is the ratio of UTS of welded joint to the UTS of PLA Plus and HDPE. The weld efficiency calculation given in Table 5 was calculated with the following formula:

| (1) |

Table 5.

Additional FSW parameters for welding of PLA Plus/HDPE.

| No | Pin Profile | Tool speed (rpm) | Traverse speed (mm/min) | Material | Tool shift distance (mm) | Depth | Fail/Successful | UTS (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | Triangle | 710 | 64 | PLA Plus/HDPE | 1.4 | 4.5 | Fail | Fail |

| 2 | Triangle | 710 | 32 | 1.4 | 4.5 | Successful | Broken | |

| 3 | Square | 570 | 32 | 1.4 | 4.5 | Successful | Broken | |

| 4 | Square | 570 | 19 | 1.4 | 4.5 | Fail | Fail | |

| 5 | Triangle | 570 | 32 | 1.4 | 4 | Successful | 8.64 | |

| 6 | Triangle | 570 | 19 | 1.4 | 4.25 | Fail | Fail | |

| 7 | Square | 570 | 32 | 1.4 | 4.25 | Fail | Fail |

In Fig. 9, specimen numbered PLA Plus 2 (the best) and 3 (the worst), HDPE 12 (the best) and 15 (the worst), PLA Plus/HDPE 21 are given. When the PLA Plus joint was examined, defects were seen in the welding zone in specimen 2. When the microstructure image was examined, unmelted PLA Plus particles were determined in the welding transition zone. This was due to the low rotational speed and the lack of sufficient heat due to the fast feed rate. In addition, it was determined that the welding lines were interrupted/broken during transition from RS to AS. This shows the importance of optimizing the parameters to be able to conduct the heat and mixing process required to obtain a good weld quality in the FSW process. When specimen 3 was examined, it was determined that surface defects did not occur at high rotational speed and low feed rate. In the transition from RS to AS in the welding zone, the welding lines were not interrupted/broken in the direction of rotation, and the base material and welding area were given in the microstructure image after welding. It is seen that the direction of the material passing from the base material to the welding area did not deteriorate and a good joint was obtained. When the specimen 12 was examined, it was seen that in joining FSW and HDPE sheets, a deep slot was formed along the pin profile and the joining process could not be done efficiently. Although rotational speed and feed rate were same in specimens 12 and 15, the difference in welding quality was due to the pin profile. HDPE was found to be relatively ductile, adhered to the triangular pin profile at high rotational speeds and adversely affected the mixing process. A more uniform weld zone was obtained in specimen 15. Compared to PLA Plus joints, it was determined that the weld lines were not clear and there were unmixed HDPE particles on the weld surface. When HDPE/PLA Plus joints (such as specimen 21) were examined, deep cavities were formed along the weld.

Fig. 9.

Microstructure and image of some specimens.

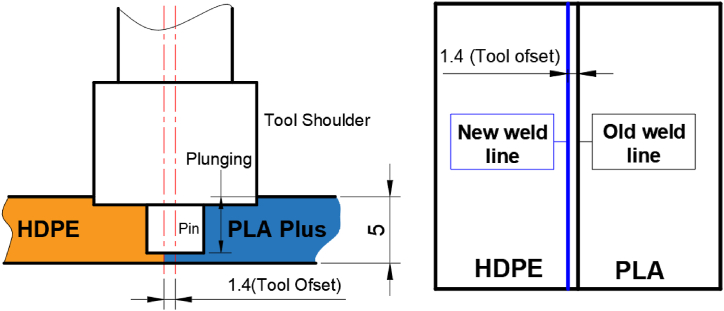

Welding of PLA Plus/HDPE sheets could not be joined with the same parameters used in joining PLA Plus/PLA Plus and HDPE/HDPE. It can be said that the reason for this is difference of the density and the melting temperature between the materials. Therefore, it makes copolymerization difficult during FSW. FSW parameters have been changed for joining PLA Plus/HDPE sheets. The new parameters are given in Table 5. In the FSW parameters for PLA Plus/HDPE welding, the pin geometry was determined as Triangle, tool speed 710 and 570 rpm, traverse speed 19, 32 and 64 mm/min. Also, the tool has been offset towards PLA Plus and the plunging distance has been changed. The tool offset and plunging distance are shown in Fig. 10. Tool offset is a parameter used for joining parts that are difficult in FSW [50]. Joining for PLA Plus/HDPE was successful in specimens 2, 3 and 5. However, in specimen 2 and 3, the tensile sample was broken while removing it. Therefore, only the tensile test was carried out in specimen 5. The tensile test result was determined as UTS 8.64 MPa.

Fig. 10.

Plunging and tool offset parameters in FSW operation.

3.2. Results of weld strength with varying traverse speed

Fig. 11, Fig. 12 represent UTS changes according to traverse speed and rotation speed for both pin geometries. In Fig. 11, the UTS decreases if the traverse speed increases while the rotation speed is constant for the triangle pin geometry. For the square pin profile, UTS decreased when the feed rate increased when the rotational speed was 1000 rpm. UTS increased when the feed rate increased when the rotational speed was 1500 rpm. In both pin profiles, UTS increased with increasing rotational speed. However, the increase in UTS with rotational speed is sharper in the triangular pin profile.

Fig. 11.

Response of the ultimate strength for PLA Plus.

Fig. 12.

Response of the ultimate strength for HDPE.

A maximum strength efficiency of 104.46% with the square pin and 136.9% with the triangle pin was obtained compared to the base material. The increase in weld strength can be attributed to the increase in friction with increasing rotational speed and hence the increase in heat generated by friction. The increased heat helps the PLA Plus in the weld zone to plasticize and mix better. It has been seen that using triangular profiled pins for joining PLA Plus plates is more advantageous.

In Fig. 12, it is seen that the UTS decreased with the increase of the traverse speed for the triangle pin profile. In the square pin profile, the UTS increased as the traverse speed increased from 30 mm/min to 50 mm/min at 1000 rpm, while the UTS decreased when the traverse speed increased at 1500 rpm. This shows that the feed rate is an effective factor in joining HDPE sheets. In joining HDPE sheets, compared to base material, weld strength efficiency was achieved as 66.59% with square pin profile and as 64.56% with triangle pin profile. It has been determined that both end profiles can join HDPE sheets.

3.3. Response of weld strength with varying tool speed

Welding strength increases up to a certain point with increasing rotational speed. As the rotation speed continues to increase, the quality of the weld begins to decrease. While this phenomenon is explained by insufficient mixing and repolymerization due to insufficient heat at low rotational speeds, plasticization and deformation rate increases due to high amount of heat at high rotational speeds. These conditions adversely affect the welding quality. It is important to determine the optimum weld quality in FSW [4].

Fig. 13, Fig. 14 give the UTS change depending on the rotational speed for PLA plus and HDPE. UTS increased at both feed rates (30 and 50 mm/min) with increasing rotational speed in square pin profile (Fig. 13). This increase was sharper when the feed rate was 50 mm/min and the rotation speed increased from 1000 rpm to 1500 rpm (23.05 MPa and 32.09 MPa, respectively). While the feed rate in the triangle pin profile was 30 mm/min, the UTS decreased with the increase in the rotation speed, while the UTS increased with the increase in the rotation speed at 50 mm/min feed rate. It is understood that mixing is insufficient when the rotation speed is high, and the feed rate is low in the triangle pin profile.

Fig. 13.

Response of the ultimate strength for PLA Plus.

Fig. 14.

Response of the ultimate strength for HDPE.

For HDPE, as the rotation speed increased in the square pin profile, the UTS increased at both feed rates. In the triangle pin profile, as the rotation speed increased at 30 mm/min, the UTS increased, while at 50 mm/min, the UTS decreased as the rotation speed increased (Fig. 14).

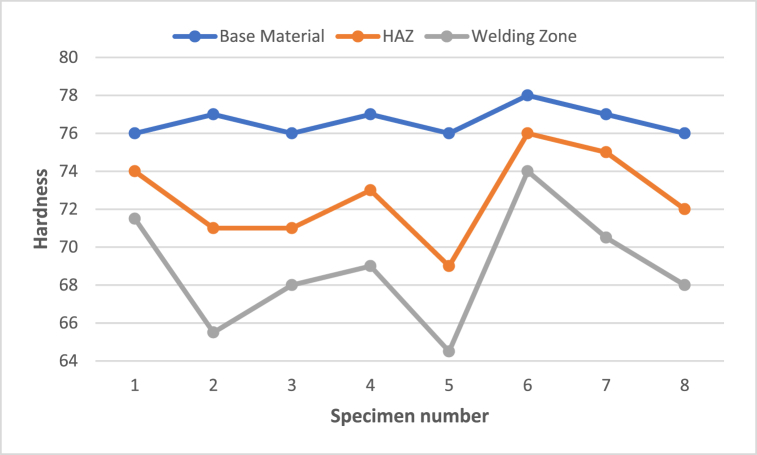

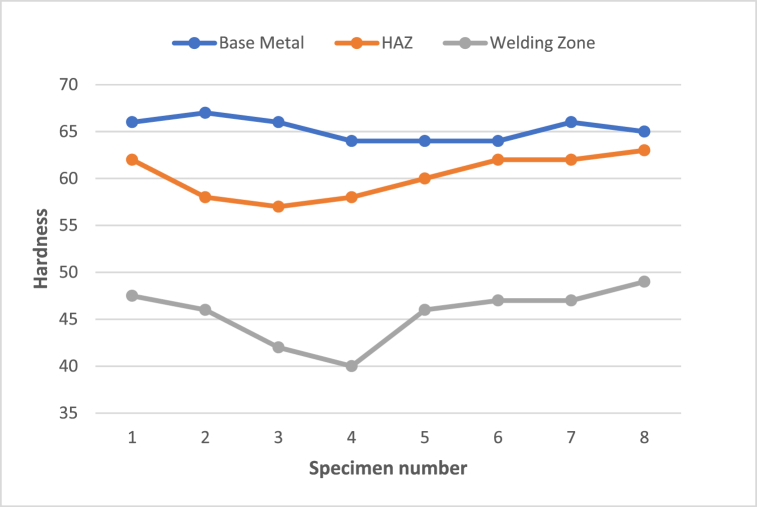

3.4. Evaluation of hardness results

Since different process parameters are used in the FSW of plastic materials, different hardness values were obtained in the heat affected zone (HAZ) and in the weld zone. Hardness (Shore D) distributions of PLA after welding in Fig. 15 and HDPE PLA Plus material in Fig. 16 are given. In both materials, there is a decrease in hardness values in the HAZ and weld zone. The heat generated during the FSW process caused the plastic material to soften. The hardness values in the HAZ region were higher than the hardness values in the weld region. The reason for this is that the mechanical properties of the weld area are greatly affected due to changing of molecular weight or crystallinity during the FSW process [51]. The highest hardness value for PLA Plus in the HAZ region is 76 (specimen 6), the lowest value is 69 (specimen 5), the highest hardness value for the weld zone is 74 (specimen 6), the lowest value is 64.5 (specimen 5). In terms of weld strength, the best UTS 42.12 MPa (specimen 3), the worst UTS 14.95 MPa (specimen 2). This shows that the hardness value is independent of the welding strength. When the hardness values for HDPE are examined, it is seen that the base material hardness measurements are more stable. It can be said that the reason for this is that HDPE is supplied as a sheet and production techniques are affected by fewer parameters. For HDPE, the highest hardness value is 63 (specimen 16) and the lowest hardness value is 57 (specimen 11) in the HAZ region, the highest hardness is 49 (specimen 16) and the lowest hardness is 40 (specimen 12) in the welding zone. Compared to their weld strengths, best and worst welding strength values respectively, they are 66.69 MPa (specimen 15) and 25.02 MPa (specimen 12).

Fig. 15.

Hardness results for PLA plus.

Fig. 16.

Hardness results for HDPE.

4. Conclusions

FSW method can be used to join the same and different plastic material pairs, but it is much more difficult to optimize the process parameters for different plastic material pairs. In this study, the weldability of PLA Plus/PLA Plus, HDPE/HDPE and PLA Plus/HDPE sheets was investigated by using two different pin profiles (triangle and square), rotational speed (1000 and 1500 rpm) and feed rate (30 and 50 mm/min) were used. The effects of FSW process parameters and pin profile on UTS, hardness and microstructure were discussed.

-

•

It was seen that the tool return lines were more prominent, and the tool outlet hole was smoother along the joint area for PLA Plus. On the other hand, it was seen that HDPE remained as particles in the upper part of the weld zone. It can be said that this is due to the fact that HDPE is softer than PLA Plus and is subject to excessive deformation due to heat.

-

•

The highest welding strength (42.12 MPa) in welding PLA Plus material pairs was obtained by using triangle pin profile, 1500 rpm rotational speed and 30 mm/min feed rate with an efficiency of 136.9%. In addition, the highest welding strength (20.34) in HDPE material pair was obtained with 66.69% efficiency when square pin profile, 1500 rpm rotational speed and 30 mm/min feed rate parameters were used. PLA Plus/HDPE material pair could not be joined by using the same process parameters.

-

•

The rotational speed (570 and 710 rpm) and traverse speed (19, 32 and 64 mm/min) were decreased, so that the PLA Plus/HDPE material pair could be joined. The PLA Plus/HDPE material pair was joined using triangle pin profile, 570 rpm and 32 mm/min process parameters, and the welding quality was determined to be 8.64 MPa.

-

•

Welding strength increased with increasing rotational speed in both pin profiles for PLA Plus/PLA Plus. However, the increase in UTS was more evident as a result of FSW made by using the triangle pin profile. It can be said that the increase in heat generated by friction with increasing rotational speed helps PLA Plus in the weld zone to plasticize and mix better.

-

•

According to the UTS results for PLA Plus/PLA Plus, it is understood that mixing was insufficient when the rotation speed was high, and the feed rate was low in the triangle pin profile. The square pin profile for HDPE/HDPE has increased weld quality at both rotational speeds. This shows that the pin profile directly affects the welding quality.

-

•

A decrease in the hardness values was determined in the HAZ and weld zone for both materials. The highest and lowest hardness values in HAZ for PLA Plus were as 76 and 69, the highest and lowest hardness values in the weld zone were as 74 and 64.5. In addition, the highest and lowest hardness values in HAZ for HDPE were as 63 and 57, the highest and the lowest hardness values in the weld zone was determined as 49 and 40.

While it is easier to combine the same material pairs, as seen in this study, it is difficult and costly to optimize the process parameters for joining PLA Plus and HDPE material pairs with FSW. The most important reason for this is the difference in mechanical properties and material density between materials. It is thought that preheating of material pairs in which HDPE is used will facilitate the joining process in subsequent studies.

Author contribution statement

Nergizhan ANAÇ: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Data availability statement

No data was used for the research described in the article.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Da Costa J.P., Rocha-Santos T., Duarte A.C. 2020. The Environmental Impacts of Plastics and Micro-plastics Use, Waste and Pollution: EU and National Measures. [Google Scholar]

- 2.Sharma A.K., Bhandari R., Sharma C., Dhakad S.K., Pinca-Bretotean C. Polymer matrix composites: a state of art review. Mater. Today Proc. 2022;57(5):2330–2333. [Google Scholar]

- 3.Rudrapati R. 2022. Effects of Welding Process Conditions on Friction Stir Welding of Polymer Composites: A Review. Composites Part C: Open Access. [Google Scholar]

- 4.Sharma A.K.R., Roy Choudhury M., Debnath K. Experimental investigation of friction stir welding of PLA. Weld. World. 2020;64(6):1011–1021. [Google Scholar]

- 5.Zeyrek B., Aydogan B., Dilekcan E. Review of thermoplastic composites in aerospace industry. Int J Eng Tech & Inf. 2022;3(1):1–6. [Google Scholar]

- 6.Brockmann W., Geiß P.L., Klingen J., Schröder K.B. John Wiley & Sons; 2008. Adhesive Bonding: Materials, Applications and Technology. [Google Scholar]

- 7.Kah P., Suoranta R., Martikainen J., Magnus C. Techniques for joining dissimilar materials: metals and polymers. Rev. Adv. Mater. Sci. 2014;36(2) [Google Scholar]

- 8.Zhang Y., Cao X., Larose S., Wanjara P. Review of tools for friction stir welding and processing. Can. Metall. Q. 2012;51(3):250–261. [Google Scholar]

- 9.Jata K., Sankaran K., Ruschau J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. 2000;31(9):2181–2192. [Google Scholar]

- 10.Chang W.-S., Rajesh S., Chun C.-K., Kim H.-J. Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy. J. Mater. Sci. Technol. 2011;27(3):199–204. [Google Scholar]

- 11.Bhardwaj N., Narayanan R.G., Dixit U., Hashmi M. Recent developments in friction stir welding and resulting industrial practices. Advances in Materials and Processing Technologies. 2019;5(3):461–496. [Google Scholar]

- 12.Wahab M., Dewan M., Huggett D., Okeil A., Liao T., Nunes A. Challenges in the detection of weld-defects in friction-stir-welding (FSW) Advances in Materials and Processing Technologies. 2019;5(2):258–278. [Google Scholar]

- 13.Sivalingam S., Sureshkannan G., Balaji D., Rajeshkumar L. Influence of filler wire on mechanical and metallurgical behaviour of Inconel 690 alloy welded by pulsed current gas tungsten arc welding. Tierarztilich Praxis. 2020;40(1):69–82. [Google Scholar]

- 14.Akbari D., Farahani M., Soltani N. Effects of the weld groove shape and geometry on residual stresses in dissimilar butt-welded pipes. J. Strain Anal. Eng. Des. 2012;47(2):73–82. doi: 10.1177/0309324711434681. [DOI] [Google Scholar]

- 15.Hajideh M.R., Farahani M., Alavi S.A.D., Ramezani N.M. Investigation on the effects of tool geometry on the microstructure and the mechanical properties of dissimilar friction stir welded polyethylene and polypropylene sheets. J. Manuf. Process. 2017;26:269–279. [Google Scholar]

- 16.Shunmugasundaram M., Kumar A.P., Sankar L.P., Sivasankar S. Optimization of process parameters of friction stir welded dissimilar AA6063 and AA5052 aluminum alloys by Taguchi technique. Mater. Today: Proc. 2020;27:871–876. [Google Scholar]

- 17.Thimmaraju P., Arkanti K., Reddy G.C., Tilak K. Comparison of microstructure and mechanical properties of friction stir welding of Al 6082 aluminum alloy with different tool profiles. Mater. Today: Proc. 2016;3(10):4173–4181. [Google Scholar]

- 18.Tagimalek H., Maraki M.R., Mahmoodi M., Moghaddam H.K., Farzad-Rik S. Prediction of mechanical properties and hardness of friction stir welding of Al 5083/pure Cu using ANN, ICA and PSO model. SN Appl. Sci. 2022;4(4):1–17. [Google Scholar]

- 19.Wang T., Sidhar H., Mishra R.S., Hovanski Y., Upadhyay P., Carlson B. Effect of hook characteristics on the fracture behaviour of dissimilar friction stir welded aluminium alloy and mild steel sheets. Sci. Technol. Weld. Join. 2019;24(2):178–184. [Google Scholar]

- 20.Wang H., Wang K., Wang W., Huang L., Peng P., Yu H. Microstructure and mechanical properties of dissimilar friction stir welded type 304 austenitic stainless steel to Q235 low carbon steel. Mater. Char. 2019;155 [Google Scholar]

- 21.Bilgin M., Ş Karabulut, Özdemir A. Investigation of heat-assisted dissimilar friction stir welding of AA7075-T6 aluminum and AZ31B magnesium alloys. Arabian J. Sci. Eng. 2020;45(2):1081–1095. [Google Scholar]

- 22.Kannan T., Arulmurugan B., Rajeshkumar L. Performance analysis of AA3103 and AA6063 dissimilar weld joints by friction stir welding. Songklanakarin J. Sci. Technol. 2022;44(2) [Google Scholar]

- 23.Raouache E., Boumerzoug Z., Rajakumar S., Khalfallah F. Effect of FSW process parameters on strength and peak temperature for joining high-density polyethylene (HDPE) sheets. Rev. Compos. Matériaux Avancés. 2018;28(2):149. [Google Scholar]

- 24.Rezgui M.-A., Ayadi M., Cherouat A., Hamrouni K., Zghal A., Bejaoui S. Application of Taguchi approach to optimize friction stir welding parameters of polyethylene. EPJ Web Conf.: EDP Sciences. 2010 [Google Scholar]

- 25.Derazkola H.A., Simchi A. Effects of alumina nanoparticles on the microstructure, strength and wear resistance of poly (methyl methacrylate)-based nanocomposites prepared by friction stir processing. J. Mech. Behav. Biomed. Mater. 2018;79:246–253. doi: 10.1016/j.jmbbm.2018.01.007. [DOI] [PubMed] [Google Scholar]

- 26.Vidakis N., Petousis M., Mountakis N., Kechagias J.D. Material extrusion 3D printing and friction stir welding: an insight into the weldability of polylactic acid plates based on a full factorial design. Int. J. Adv. Des. Manuf. Technol. 2022;121(5–6):3817–3839. doi: 10.1007/s00170-022-09595-1. [DOI] [Google Scholar]

- 27.Senthil S., Kumar M.B. Effect of tool rotational speed and traverse speed on friction stir welding of 3D-printed polylactic acid material. Applied Science and Engineering Progress. 2022;15(1) [Google Scholar]

- 28.eSUN: PLA+ 2022 https://www.esun3d.com/pla-pro-product/ [Google Scholar]

- 29.Bozkurt Y. The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater. Des. 2012;35:440–445. [Google Scholar]

- 30.Ltd P.G. 2022. Polyethylene PE300 Sheet.https://www.par-group.co.uk/site-content/1/Docs/updates/3-engineering-plastics/3.31.1-polyethylene-pe300-sheet-hdpe-tds.pdf [Google Scholar]

- 31.Devuri V., Mahapatra M., Harsha S., Mandal N. Effect of shoulder surface dimension and geometries on FSW of AA7039. J. Manuf. Sci. Prod. 2014;14(3):183–194. [Google Scholar]

- 32.Sun T., Reynolds A., Roy M., Withers P., Prangnell P. The effect of shoulder coupling on the residual stress and hardness distribution in AA7050 friction stir butt welds. Mater. Sci. Eng., A. 2018;735:218–227. [Google Scholar]

- 33.Hou W., Ding Y., Huang G., Huda N., Shah L.H.A., Piao Z., et al. The role of pin eccentricity in friction stir welding of Al-Mg-Si alloy sheets: microstructural evolution and mechanical properties. Int. J. Adv. Des. Manuf. Technol. 2022;121(11):7661–7675. [Google Scholar]

- 34.Sharma N., Siddiquee A.N., Khan Z.A., Mohammed M.T. Material stirring during FSW of Al–Cu: effect of pin profile. Mater. Manuf. Process. 2018;33(7):786–794. [Google Scholar]

- 35.Kumar P.S., Chander M.S. Effect of tool pin geometry on FSW dissimilar aluminum alloys-(AA5083 & AA6061) Mater. Today: Proc. 2021;39:472–477. [Google Scholar]

- 36.Darmadi D.B., Talice M. Improving the strength of friction stir welded joint by double side friction welding and varying pin geometry. Engineering Science and Technology, an International Journal. 2021;24(3):637–647. [Google Scholar]

- 37.Hynes N.R.J., Velu P.S. Effect of rotational speed on Ti-6Al-4V-AA 6061 friction welded joints. J. Manuf. Process. 2018;32:288–297. [Google Scholar]

- 38.Lombard H., Hattingh D., Steuwer A., James M. Effect of process parameters on the residual stresses in AA5083-H321 friction stir welds. Mater. Sci. Eng., A. 2009;501(1–2):119–124. [Google Scholar]

- 39.Rajakumar S., Muralidharan C., Balasubramanian V. Influence of friction stir welding process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints. Mater. Des. 2011;32(2):535–549. [Google Scholar]

- 40.Arici A., Selale S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 2007;12(6):536–539. [Google Scholar]

- 41.Hovanski Y., Upadhyay P., Carsley J., Luzanski T., Carlson B., Eisenmenger M., et al. High-speed friction-stir welding to enable aluminum tailor-welded blanks. Jom. 2015;67(5):1045–1053. doi: 10.1007/s11837-015-1384-x. [DOI] [Google Scholar]

- 42.Arici A., Selale S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 2013;12(6):536–539. doi: 10.1179/174329307x173706. [DOI] [Google Scholar]

- 43.Saeedy S., Besharati Givi M. Experimental application of friction stir welding (FSW) on thermo plastic medium density polyethylene blanks. Engineering Systems Design and Analysis. 2010:841–844. [Google Scholar]

- 44.Kumar R., Ranjan N., Kumar V., Kumar R., Chohan J.S., Yadav A., et al. Characterization of friction stir-welded polylactic acid/aluminum composite primed through fused filament fabrication. J. Mater. Eng. Perform. 2022;31(3):2391–2409. [Google Scholar]

- 45.Rezaee Hajideh M., Farahani M., Alavi S.A.D., Molla Ramezani N. Investigation on the effects of tool geometry on the microstructure and the mechanical properties of dissimilar friction stir welded polyethylene and polypropylene sheets. J. Manuf. Process. 2017;26:269–279. doi: 10.1016/j.jmapro.2017.02.018. [DOI] [Google Scholar]

- 46.Kordestani F., Ashenai Ghasemi F., Arab N. Effect of pin geometry on the mechanical strength of friction-stir-welded polypropylene composite plates. Mech. Compos. Mater. 2017;53(4):525–532. [Google Scholar]

- 47.Padmanaban G., Balasubramanian V. Selection of FSW tool pin profile, shoulder diameter and material for joining AZ31B magnesium alloy–an experimental approach. Mater. Des. 2009;30(7):2647–2656. [Google Scholar]

- 48.Zhao Y.-H., Lin S.-B., Qu F.-X., Wu L. Influence of pin geometry on material flow in friction stir welding process. Mater. Sci. Technol. 2006;22(1):45–50. [Google Scholar]

- 49.Sharma V., Prakash U., Kumar B.M. Surface composites by friction stir processing: a review. J. Mater. Process. Technol. 2015;224:117–134. [Google Scholar]

- 50.Pankaj P., Tiwari A., Biswas P. Impact of varying tool position on the intermetallic compound formation, metallographic/mechanical characteristics of dissimilar DH36 steel, and aluminum alloy friction stir welds. Weld. World. 2021;66(2):239–271. doi: 10.1007/s40194-021-01203-2. [DOI] [Google Scholar]

- 51.Inaniwa S., Kurabe Y., Miyashita Y., Hori H. Application of friction stir welding for several plastic materials. Proceedings of the 1st International Joint Symposium on Joining and Welding: Elsevier. 2013:137–142. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.