Abstract

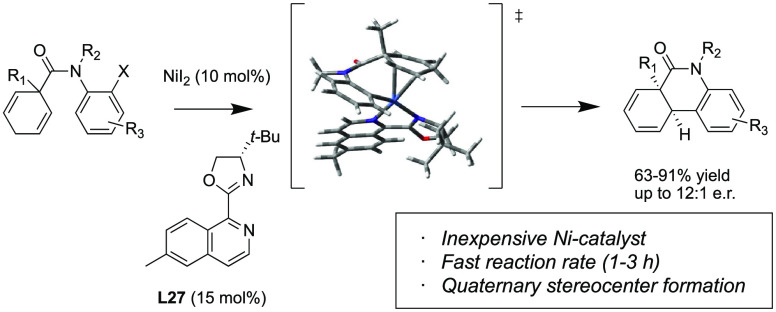

A Ni-catalyzed enantioselective intramolecular Mizoroki–Heck reaction has been developed to transform symmetrical 1,4-cyclohexadienes with attached aryl halides into phenanthridinone analogues containing quaternary stereocenters. Herein, we report important advances in reaction optimization enabling control of unwanted proto-dehalogenation and alkene reduction side products. Moreover, this approach provides direct access to six-membered ring heterocyclic systems bearing all-carbon quaternary stereocenters, which have been much more challenging to form enantioselectively with nickel-catalyzed Heck reactions. A wide range of substrates were demonstrated to work in good to excellent yields. Good enantioselectivity was demonstrated using a new synthesized chiral iQuinox-type bidentate ligand (L27). The sustainability, low price of nickel catalysts, and significantly faster reaction rate (1 h) versus that of a recently reported palladium-catalyzed reaction (20 h) make this process an attractive alternative.

Introduction

Palladium has a privileged status in the world of cross-coupling chemistry, having demonstrated a unique versatility and efficiency in a range of synthetic organometallic transformations.1−4 Nevertheless, palladium’s cheaper, more earth abundant, and environmentally friendly group 10 relative nickel has recently attracted significant attention as a worthy replacement or, more frequently, as a complementary transition metal catalyst with unique reactivity.5−9 Nickel’s reactivity, especially its greater range of oxidation states,9,10 creates significant challenges in developing efficient and useful transformations. Despite this, and following the seminal nickel reports of Watson and Jacobsen11 and Nakao,12 there have been a flood of recent reports5−7 with applications of nickel-catalyzed alkene functionalization and other Heck-type reactions illustrating an impressive array of reactivity. In the specific and most challenging realm of intramolecular enantioselective reactions to form quaternary stereocenters, there has also been a variety of impressive reports.13 However, most of these communications report new alkene reaction manifolds such as dicarbofunctionalization;14−16 therefore, although there was early work demonstrating Ni-catalyzed Heck reactions,17,18 more recently there have been many fewer reports of traditional intramolecular19,20 or intermolecular21−24 Heck reaction transformations likely due to the difficulty in achieving selective reactions with nickel, the difficulty of nickel complexes undergoing β-hydride elimination, and the challenges in regenerating Ni(0) from Ni(II) in the Mizoroki–Heck reaction catalytic cycle.

The more popular Ni-catalyzed Heck-type difunctionalization reactions provide a complementary pathway to traditional palladium-catalyzed Heck reactions and overcome the much slower tendency of nickel complexes to undergo β-hydride elimination. Perhaps predictably then, many fewer examples have offered a direct replacement of nickel for palladium in a traditional enantioselective intramolecular Heck reaction. A second perhaps more surprising deficiency in the recent reports of intramolecular nickel-catalyzed Heck reactions, including alkene difunctionalization, is an example of six-membered ring formation with high levels of enantioselectivity. There is an abundance of reports with excellent enantioselectivity to form five-membered rings,25−51 with indolinone or oxindole structures being the most common product formed by far. In contrast, there is only one recent report with a collection of six-membered substrates with excellent enantioselectivity52 and two additional reports citing just one successful enantioselective six-membered ring example.53,54 Otherwise, communications to date have reported modest enantioselectivities below 50% enantiomeric excess (e.r. = 3:1) or no enantioselectivity achieved for six-membered ring examples.26,29,55,56 Given the importance of six-membered rings in organic chemistry and drug development,57,58 the scarcity of examples of enantioselective six-membered ring formation seems a serious omission. Herein, we demonstrate conditions for a new nickel-catalyzed enantioselective intramolecular Heck reaction that substitutes nickel for palladium in an identical Heck transformation that was recently reported by our group.59 In addition to contrasting the nickel-catalyzed conditions for the identical palladium Heck reaction, it also illustrates a rare example of an enantioselective nickel-catalyzed Heck reaction to form a wide selection of six-membered ring structures. The structures formed are quaternary stereocenter-containing analogues of the highly bioactive phenanthridinone structure and therefore should have interest to the drug development community due to the benefits of three-dimensional structures in successful drug architectures.60−62 As with our first report, the process uses a desymmetrization strategy63,64 to generate a chiral quaternary stereocenter. Importantly, the nickel Heck reaction occurs considerably faster than the palladium-catalyzed reaction, illustrating another important benefit of the nickel process consistent with other recent reports highlighting lower catalyst loadings and lower temperatures in a Suzuki–Miyaura reaction.65

Results and Discussion

The substrates 1 for the Ni-catalyzed Heck reactions were synthesized using the previously reported59 three-step sequence that involves a Birch reduction–alkylation process followed by coupling with a corresponding primary or secondary 2-haloaniline derivative (SI-Table 1). As with the Pd-catalyzed case, tertiary amides must be used and N-methyl and N-methoxymethyl (N-MOM) amides were chosen for this work. The N-MOM amides allow subsequent deprotection to reveal the important H-bond donor in the secondary amide of the parent phenanthridinone (SI-Table 2).

In our previous work with Pd-catalyzed enantioselective desymmetrizing Heck reaction, the more sterically demanding alkyl groups at the quaternary center (e.g., -iPr, -iBu, and -Cy) resulted in lower enantioselectivities. Thus, we initially explored Ni as an alternative catalyst choice to achieve higher levels of enantioselectivity with these more sterically demanding substrates. Our preliminary screening of reaction parameters with tertiary aryl bromide 1d in dimethylformamide (DMF) at 80 °C provided promising results using NiCl2 as the catalyst, bipyridine (bipy) as the ligand, and Zn as the reducing agent (Table 1, entry 1). The reaction was completed in an impressively short time (10 min) versus the palladium-catalyzed reaction (24 h), but with significant formation of two major side products: a protodehalogenated 2-1 species and a cyclized alkene 2-2 species. Both, we suspected, were the result of Ni–H intermediates. Further optimization using aryl bromide 1d as the model substrate was performed to increase product yield and decrease the amount of the major side products.

Table 1. Optimization of the Heck Reactiona.

| entry | R | time | T (°C) | NiX2 (mol %) | M0 (equiv) | additive(s) (equiv) | 2 (%)b | 2-1 (%)b | 2-2 (%)b |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Me | 10 min | 80 | NiCl2 (20) | Zn (3.0) | – | 45 | 49 | 6 |

| 2 | Me | 10 min | 80 | NiCl2 (20) | Zn (3.0) | LiI (1.0) | 56 | 40 | 5 |

| 3 | Me | 10 min | 80 | NiCl2 (20) | Zn (3.0) | KI (1.0) | 67 | 33 | 5 |

| 4 | Me | 1.5 h | 80 | NiCl2 (20) | Zn (3.0) | K3PO4 (1.0) | 59 | 33 | 8 |

| 5 | Me | 1 h | 80 | NiCl2 (20) | Zn (1.5) | KI (1.0) | 63 | 29 | 9 |

| 6 | Me | 10 min | 120 | NiCl2 (20) | Zn (3.0) | KI (1.0) | 62 | 28 | 11 |

| 7 | Me | 2 h | 60 | NiCl2 (20) | Zn (3.0) | KI (1.0) | 57 | 36 | 7 |

| 8 | Me | 20 min | 80 | NiCl2 (20) | Zn (3.0) | KI (1.0), 2-cyclohexenone (2.0) | 85 | 9 | 6 |

| 9 | Me | 18 h | 80 | NiCl2 (20) | TDAE (3.0) | KI (1.0), 2-cyclohexenone (2.0) | 80 | 4 | 10 |

| 10 | MOM | 1.5 h | 80 | NiCl2 (20) | Zn (3.0) | KI (1.0), 2-cyclohexenone (2.0) | 72 | 0.2 | 22 |

| 11 | MOM | 3 h | 80 | NiCl2 (20) | Mn (3.0) | KI (1.0), 2-cyclohexenone (2.0) | 73 | 0.3 | 25 |

| 12 | MOM | 24 h | 80 | Ni(acac)2 (20) | Mn (3.0) | KI (1.0), 2-cyclohexenone (3.0) | 79 | 7 | 14 |

| 13 | MOM | 1 h | 80 | NiBr2 (20) | Mn (3.0) | KI (1.0), 2-cyclohexenone (3.0) | 73 | – | 27 |

| 14 | MOM | 1.5 h | 80 | NiI2 (10) | Mn (3.0) | KI (1.0), 2-cyclohexenone (3.0) | 93 | – | 7 |

Conditions: NiX2 (10–20 mol %), bipy (15–20 mol %), M0 (3 equiv), additives (1–3 equiv), DMF (12 mL/mmol of ArX).

Determined by GC analysis.

We first improved the catalytic system outcome with the addition of 1 equiv of LiI (entry 2). Iodide has been shown to improve the reactivity of Ni-catalyzed transformations, although the exact reason for the benefit is not definitively known. It has been proposed that the iodide either facilitates the transfer of electrons from the reducing agent (Zn) to the Ni catalytic complex,66−68 promotes formation of a beneficial nickelate complex,69,70 or facilitates β-hydride elimination.71,72 Alternatively, a nickel-catalyzed halogen exchange73 of the aryl bromide for iodide with the excess iodide can facilitate substrate reactivity toward oxidative addition of the nickel catalyst. Replacing LiI with KI as an external iodide source resulted in a slight decrease in the amount of unwanted protodebromination product 2-1 (entry 3). To test whether the KI improvement was more the result of the potassium cation than the iodide anion, we used K3PO4 as the additive (entry 4). The absence of iodide significantly prolonged the reaction time and increased the amount of cyclized alkene (2-2) versus the desired cyclized diene. Reducing the amount of Zn led to a decreased catalyst turnover rate (entry 5). Increasing or decreasing the temperature had a minimal impact on product yield (entry 3 vs entries 6 and 7). Because both side products, 2-1 and 2-2, are likely the result of Ni–H intermediates, we explored the use of acceptor olefin additives to consume the hydride species. Prior work by Lv74 elegantly demonstrated that the addition of a sacrificial acceptor olefin facilitated the Ni(0)-catalyzed oxidative Heck arylation via a transfer hydrogenation process. To our delight, the reaction efficiency was significantly improved after the addition of 2 equiv of 2-cyclohexen-1-one as a sacrificial alkene (entry 8). Replacing Zn with tetrakis(dimethylamino)ethylene (TDAE) as an organic reductant resulted in a significantly longer reaction time (entry 9). Unfortunately, after employing our initially optimized conditions to a MOM-protected tertiary amide 1e (entry 10), we observed an increased level of formation of cyclized alkene side product 2-2, so further optimization through additional screening of the Ni source, reductants, and additives was performed (entries 11–14). The reaction efficiency was dramatically improved with NiI2 (10 mol %) as the catalyst and Mn as the reductant (entry 14). Because Mn is a stronger two-electron reductant [E° = −1.18 V vs the standard hydrogen electrode (SHE) in water] than Zn (E° = −0.76 V vs SHE in water), it likely accelerates catalyst turnover by reducing the Ni(II)-H species faster, if the Ni(II)-H is not consumed by the sacrificial alkene.

Initially, we explored an enantioselective version of this reaction with a survey of common chiral ligands (L1–18) used in Ni-catalyzed cross-coupling reactions (SI-Table 3). Unfortunately, an array of commercially available bidentate and tridentate N- or P,N-ligands commonly reported with asymmetric Ni-catalyzed reactions75−78 (e.g., pyox, box, pybox, biox, diamine, PHOX, Quinap, and PINAP) did not provide optimal enantioselective results. However, we observed that tBu-pyox- and tBu-iQuinox-type ligands were more enantioselective, and therefore, subsequent studies focused on these ligand types. Thus, we began to synthesize and test novel functionalized tBu-pyox79,80 and tBu-iQuinox (SI-Scheme 1)81,82 chiral ligands (L19–27) (SI-Table 3). To our delight, the enantioselectivity was improved to 9:1 e.r. with (S)-tBu-iQuinox L27, presumably by favorable π-stacking of the substrate aryl group and the isoqunoline ring of the iQuinox ligand.

After establishing the optimal reaction conditions (Table 1, entry 14) and achieving the enantioselectivity with (S)-tBu-iQuinox L27 (SI-Table 3), we proceeded to evaluate the substrate scope of the enantioselective intramolecular Ni-catalyzed Heck reaction with variations at the quaternary center (R1), the amide nitrogen (R2), and the aryl halide (R3) (Table 2). We were pleased to find that a variety of aryl bromides and aryl iodides could undergo this Ni-catalyzed Heck cyclization to furnish the phenanthridinone derivatives in good to excellent yields with good enantioselectivities. Moreover, most reactions were completed within 3 h, which is roughly 7 times faster than with the Pd catalyst.59 Both aryl halides demonstrated compatibility with a simple achiral ligand such as bipy; however, aryl iodides showed better reactivity when employing chiral ligand L27. The higher reactivity of aryl iodides is consistent with the weaker C–I bond being more susceptible to oxidative addition than the C–Br bond of the aryl bromides.83 In addition, we believe it correlates to the complex nature of the iodide effect that seems to increase substrate reactivity.66−68

Table 2. Substrate Scopea.

Unless otherwise noted, the reaction of aryl halide 1 or 1-I (1 equiv) was carried out with NiI2 (10 mol %), bipy or L27 (15 mol %), Mn (3 equiv), KI (1 equiv), 2-cyclohexenone (3 equiv), and DMF (0.08 M) at 80 °C. The yield of 2 is the isolated yield.

At 65 °C.

With L26 (R = F).

A range of alkyl (R1) groups were well-tolerated and showed reactivity comparable to that of the the analogous Pd version,59 including methyl (2a, 2b, 2m, and 2n), ethyl (2c and 2o), and isopropyl (2d, 2e, and 2i–l) groups. A larger scale (1 mmol) enantioselective Heck reaction converting 1c-I to 2c demonstrated a slight reduction in reaction yield and a modest decrease in enantioselectivity. We were particularly delighted to achieve higher enantioselectivity for the isopropyl (2e) derivative (11:1) than with our previous Pd-catalyzed method (7:1). Functional groups such as ether (2f) and ester (2g and 2p) and large benzyl groups (2h) were generally well-tolerated. As with the Pd catalyst report,59 only tertiary amides (R2 = Me or MOM) were successful in this intramolecular Heck reaction. Our previous experimental work with palladium59 suggests the secondary amides experience an ortho effect65,84,85 with a stable six-membered ring chelation event between the amide oxygen and the metal after oxidative addition to the aryl halide. Next, we examined aryl halide substitution (R3) and found a variety of aryl ring substituents were tolerated, including the 2-F, 2-Cl, 2-Me, and 3-Me derivatives (2i–l, respectively). The formation of a protodechlorinated side product was observed with the chloro analogue (2j) in 22% yield for X = Br, which results from oxidative addition of nickel into the C–Cl bond. Formation of this side product was decreased by decreasing the reaction temperature to 65 °C. When X = Br for 2j, a 67% yield was obtained at the lower temperature, and when X = I for 2j, a 91% yield was achieved. The higher yield of the iodo derivative is likely due to the greater difference in reactivity of the Ar–I and Ar–Cl bonds versus the Ar–Br and Ar–Cl bonds. The enantiomeric ratio for 2j was lower, but a similar lower enantiomeric ratio was seen in our studies of the same enantioselective desymmetrizing Heck reaction with palladium.59 Noteworthy was the tolerance of pyridine rings, which afforded 2m–o derivatives in very good yields, albeit with lower er (2o). Interestingly, pyridine bromide 1m delivered exclusively the cyclized alkene product (2m-2). We speculate this may be the result of the initial 1,3-diene product isomerizing to the 1,4-diene product and the resulting conjugation with the pyridine ring promoting reduction with the Ni–H complex before reaction with the cyclohexenone sacrificial alkene. It must be noted that, in our phenanthridinone substrate, the presence of heterocyclic rings was not compatible with the Pd-catalyzed conditions,59 thereby illustrating another benefit of the Ni-catalyzed Heck version. Although enantioselectivity was not studied with bromopyridine derivatives 2m-2 and 2n, iodopyridine 2o did afford enantioselectivity. Lastly, tricyclic 6-5-6 ring system 2p was efficiently formed in good yield.86 Consistent with our previous report,59 removal of the MOM amide protecting group was achieved with TMS-I generated in situ87 for most Heck products, except for pyridine analogues for which BCl3 was used to deprotect the MOM group (SI-Table 4).

Mechanistic Studies

We performed mechanistic studies to shed light on the reaction process (Scheme 1). We first analyzed the role of the reducing metal, Mn primarily, but also the Zn used in the early reaction development. When manganese was removed from the reaction mixture, the reaction was completely hindered, suggesting the catalytic cycle is not initiated by a Ni(II) catalyst (eq 1). Using 10 mol % Ni(COD)2 in the absence of Mn afforded the cyclized diene in low yield (8%) (eq 2), the expected result for one round of catalyst activity. Under identical reaction conditions with the addition of 3 equiv of Mn, 78% of product was formed, which indicates the importance of Mn to turn over the catalytic cycle. In the context of this catalytic process, we speculated that an arylmanganese intermediate (ArMnBr or ArMnI), if formed,88,89 could create an aryl–Ni intermediate via nucleophilic addition instead of direct oxidative addition of Ni into the aryl halide. In addition, insertion of Mn into the Ar–X bond could facilitate the formation of protodehalogenated species. To assess the possibility of ArMnX intermediates, both aryl bromide 1e and aryl iodide 1e-I were used as substrates for stoichiometric reactions with Mn powder (eq 3a). Both reactions were quenched with D2O after 3 h, and the mixtures allowed to stir for an additional 18 h. Deuterated dehalogenated side product D12e-1 was formed in only 13% yield and presumably from an ArMnI intermediate. When stoichiometric reactions were performed with Zn, we observed deuterated side product D12e-I in 82% yield (eq 3b). The additional unknown side product was presumed to be the cyclized alkene, based on the GC retention time and the MS data (Supporting Information). The basis for this cyclization is unclear but may be the result of minor Ni or Pd contamination of the commercial Zn reagent. Overall, these results illustrate protodehalogenation reactions are likely with the aryl iodide substrates, but less relevant to the aryl bromide reactions. Given the short reaction times, it is likely the Mn oxidative addition has a limited impact in hampering the desired Heck product formation. However, insertion of Zn into the Ar–I reaction is likely contributing to some of the protodeiodination side product, 2e-1.90−92 Therefore, the main function of Mn in our reaction is to create a reducing environment for Ni(II) salts to form the necessary zerovalent nickel species, thus making it a better reductant.

Scheme 1. Mechanistic Control Studies.

Reactions were run on a 20–25 mg scale of aryl halide 1 or 1-I and analyzed by GC-MS. s.m. = starting material.

The role of 2-cyclohexenone as a sacrificial alkene was the next reaction component to be analyzed. As noted earlier, it was introduced to remove Ni–H intermediates and reduce the amount of protodehalogenation (2-1) and alkene (2-1) side products. Cyclohexanone was detected and quantified (1.2 equiv) in the gas chromatographic analysis of the reactions, demonstrating that the enone system was reduced. To test for a potential competing reduction of the sacrificial alkene by Mn,93 2-cyclohexenone was stirred and heated at 80 °C with Mn in DMF (eq 4). The formation of cyclohexanone was not observed, which confirms that the Mn is not responsible for the enone reduction. Finally, adding TEMPO (1 equiv) did not impact the reaction, suggesting that the formation of cyclized diene product 2e occurs through a nonradical two-electron pathway (eq 5). Therefore, we propose a traditional two-electron Heck reaction mechanism (Scheme 2). The low-valent Ni(0) species generated under reductive conditions undergoes oxidative addition with aryl halide 1 to afford Ni(II) intermediate A. Ligand association of intermediate A followed by an intramolecular migratory insertion produces alkyl-Ni(II)-Ar species C. A syn-coplanar position of nickel with a β-hydrogen allows for efficient β-hydride elimination to afford product 2 and N(II)–XH species D. The Ni(0) catalyst is regenerated upon Mn reduction. Some of the Ni(II)–H is presumably converted to a Ni–enolate by reaction with 2-cyclohexenone and then subsequently reduced with Mn to Ni(0). Formation of the cyclohexanone, which was detected in our mechanistic studies, could occur by protonation of the Ni–enolate intermediate via a Ni(II)–H complex also present in solution.94

Scheme 2. Proposed Reaction Mechanism.

Computational Study

An understanding of the basis for the enantioselectivity in the catalytic cycle was developed through a computational study of the key 1,2-migratory insertion event taking proposed complex B to C (Scheme 2) for substrate 2a (R1 and R2 = Me; R3 = H). We initially assumed this step would be rate-determining and stereodetermining. The Gibbs free energy of activation for this step with bipyridine ligand was calculated to be quite low at 1.9 kcal/mol, and the reaction is very exothermic (17.5 kcal/mol) and is unlikely to be reversible.

To better understand the asymmetric induction, a study of the transition state of the 1,2-migratory insertion with L27 was conducted considering eight possible geometries: the bidentate chiral ligand in either of two possible binding positions (180° rotated), addition of the aryl group to either alkene of the cyclohexadiene (pro-R or pro-S), and either possible helical twist of the amide in the transition state. These variations were explored for intermediates B and C as well as the transition structure between them. The results are shown in SI-Table 5 and SI-Figure 1.

The lowest-energy structures for intermediate B led to high energy barriers. In fact, of the eight stereoisomeric transition structures, only two had energies of <24 kcal/mol above the global minimum. These two transition structures lay 13.4 and 17.2 kcal/mol above the global minimum for intermediate B, although only 2.2 and 6.0 kcal/mol, respectively, above the corresponding stereoisomers of intermediate B, which were both (coincidentally) 11.2 kcal/mol above the global minimum. These two pathways differed by only a 180° flip of the bidentate chiral ligand and thus corresponded to the same stereochemical outcome of the reaction. The exothermicity (16.3 kcal/mol) closely matched that of the achiral bipyridine case.

Assuming that the barriers for the reaction steps leading up to intermediates B are low, and that the migratory insertion is rate-determining, the pathway having the lowest overall barrier to migratory insertion should dominate. Even if the pathway with the second highest barrier were to contribute, the stereochemical outcome would not be affected. The remaining pathways, leading to different stereochemical outcomes, all involve much higher overall barriers.

The predicted stereochemical outcome from the computational analysis with 2a, R for the quaternary carbon and R for the tertiary bridgehead carbon, with the (S)-L27 ligand (Figure 1) matches in a relative sense the stereochemistry seen from our previous Pd-catalyzed Heck intramolecular desymmetrizing reactions.59 Products generated for both reactions did have the same major enantiomer formed on the basis of chiral HPLC retention times.

Figure 1.

Lowest-energy transition state for 1,2-migratory insertion of B to C.

However, the energy difference between the favored pathway yielding the observed major product and lowest-energy alternate pathway yielding the opposite stereochemistry is notably large (10.9 kcal/mol). If the 1,2-migratory insertion (B to C in Scheme 2) solely controls the stereochemical outcome, as we had supposed, then the selectivity would be far greater than observed. We are thus forced to conclude that this simple explanation of the stereochemical outcome is inadequate, and in fact, there is good reason to suspect as much.

The foregoing analysis presumes that interconversion of the different possible conformations of the initial amide 1 is rapid compared to the rate of reaction (the typical Curtin–Hammett condition). However, this hindered amide is twisted, and axially chiral, although presumably racemic. Furthermore, interconversion of the enantiomers is likely to have a fairly higher barrier, quite likely in the neighborhood of 20 kcal/mol.95 Consequently, the reaction is likely to experience some degree of dynamic kinetic resolution, as detailed below, and has been previously observed for similar Heck reactions.96

The eight aforementioned conformations of intermediate B differ by the orientation of the bidentate ligand, by which alkene the nickel complexes, and by the twist of the amide. If we assume that isomerization of the former two parameters is rapid, but that amide twist interconversion is potentially slow, we arrive at Scheme 3.

Scheme 3. Kinetics of the Reaction in Scheme 2, Assuming That Isomerization of the Amide (k1/k–1 process) Can Be Slow.

Calculated energies are shown in kilocalories per mole (transition state energies for k2B-R, k2BT-S, k2B-S, and k2BT-R, minima for B and BT).

For the sake of simplicity, we do not specify whether the amide twist isomerization occurs in free amide 1, in intermediate A, and/or in intermediate B, because it does not matter for this purpose. The series of structures 1, A, and B have one twist of the amide, and this “B” represents the four isomers of B that were calculated and have this twist (R, RA, RF, and RAF in SI-Table 5 and SI-Figure 1). The series of structures 1T, AT, and BT represent the corresponding structures with the opposite amide twist (including RT, RAT, RFT, and RAFT in SI-Table 5 and SI-Figure 1). The lowest energy of the four “BT” structures is the global minimum, while the lowest energy of the four “B” structures is 1.6 kcal/mol higher.

The BT structures lead via low barriers (13.4 or 17.2 kcal/mol) to the major observed stereochemistry of the product (S,S in this case). Much higher barriers (24.9 or 26.0 kcal/mol) lead to the unobserved product. The B structures, on the contrary, lead preferentially to the minor observed stereochemistry via barriers that are generally fairly high (24.3 or 27.4 kcal/mol above the global minimum), although significantly lower than the barriers leading to the major product stereochemistry (27.4 or 28.4 kcal/mol).

If the interconversion of the different amide twists (k1 and k–1) is rapid compared to k2R, i.e., if the k1 process has a barrier significantly below 24 kcal/mol, then the Curtin–Hammett condition applies, and the reaction would be expected to funnel essentially exclusively through the lowest overall barrier, shown in green, leading exclusively to one stereoisomer product. This is the condition we initially had assumed. On the contrary, if the amide twist interconversion is slow, having a barrier significantly higher than 24 kcal/mol, then one would expect the 50% that had the “desired” twist at the beginning (1T) would proceed to the (S,S) stereochemistry of the product, while the other 50%, having the opposite twist (1), would preferentially yield the (R,R) product. Little if any stereoselectivity would be observed overall. If the rate of the amide twist interconversion is competitive with that of the reaction, i.e., the k1 barrier is in the neighborhood of 24 kcal/mol, then one would expect reduced enantioselectivity, to the extent that 1 cannot isomerize to 1T before reacting through B to yield the (R,R) product. This analysis offers two insights into the reaction process. First, it provides an explanation for why higher enantiomeric ratios are not achieved with the large calculated energy difference (∼11 kcal/mol) between the two diastereomeric transition state complexes in the 1,2-migratory insertion, which might otherwise be expected to afford enantiomeric ratios of >99:1. Second, it leads to the interesting notion that the stereoselectivity of this reaction could be improved by an increase in the barriers for the migratory insertion or, alternatively, a decrease in the barriers for the amide bond rotation. A simultaneous and equivalent change in both the amide rotamer barrier and the migratory insertion barrier would not help, so merely decreasing the temperature is unlikely to improve enantioselectivity. To date, experimental work concurs; attempts to improve the enantioselectivity by decreasing the reaction temperature have failed (data not shown)

Conclusion

In summary, we have developed the first example of an enantioselective intramolecular Ni-catalyzed synthesis of a heterocyclic system with a quaternary stereocenter using the Birch–Heck sequence. This work represents a rare example of a Ni-catalyzed intramolecular Heck reaction to form a six-membered ring with an all-carbon quaternary center and demonstrates the broadest substrate scope to date with good to very good levels of enantioselectivity. In comparison with the Pd-catalyzed version of the reaction, the alternative Ni-catalyzed desymmetrization reaction is much faster (1 h vs 20 h) than the analogous Pd version and can be applied to a wide range of substrates giving good to excellent yields. It affords enantioselectivities comparable to that of the Pd/BINAP Heck reaction59 with the use of a newly synthesized chiral iQuinox-type bidentate ligand L27. Notably, during reaction optimization, we were able to control unwanted Ni–H reductions, including a protodehalogenation side reaction. As such, this work presents a direct and valuable comparison of the performance of nickel and palladium catalysts, which should facilitate the application of Ni catalysis to traditional Heck transformations.

Experimental Section

General Procedures

All reactants and reagents were commercially available and used without further purification unless otherwise indicated. Anhydrous tetrahydrofuran (THF) was obtained by distillation from benzophenone-sodium under argon. All reactions were carried out under an inert atmosphere of argon in flame-dried glassware unless otherwise indicated. Concentrated refers to the removal of solvent with a rotary evaporator at normal water aspirator pressure. Concentrated under high vacuum refers to removal of solvent with a direct-drive rotary vane vacuum pump. Thin layer chromatography (TLC) was performed using silica gel 60 Å precoated aluminum-backed plates (0.25 mm thickness) with a fluorescent indicator. Developed TLC plates were visualized with UV light (254 nm) and KMnO4 spray. Flash column chromatography was conducted with the indicated solvent system using normal phase silica gel (60 Å, 230–400 mesh). Yields refer to chromatographically and spectroscopically pure (>95%) compounds, except as otherwise indicated.

1H and 13C NMR spectra were recorded on a Bruker Avance III 400 instrument at 400 and 100 MHz, respectively. Chemical shifts are reported in δ values (parts per million) relative to an internal reference [0.05% (v/v)] of tetramethylsilane (TMS) for 1H NMR or the solvent signal, chloroform (CDCl3) or DMSO-d6, for 13C NMR. NMR analysis of the tertiary amides was conducted at increased temperatures (77–100 °C) in DMSO-d6 due to the presence of atropisomers. Peak splitting patterns in the 1H NMR spectra are reported as follows: s, singlet; bs, broad singlet; d, doublet; t, triplet; q, quartet; hept, heptet; dd, doublet of doublets; ddd, doublet of doublets of doublets; dt, doublet of triplets; dq, doublet of quartets; m, multiplet. 13C NMR experiments were conducted with the attached proton test (APT) pulse sequence. 13C multiplicities are reported as δu (up) for methyl and methine and δd (down) for methylene and quaternary carbons.

GC-MS analyses were performed with an Agilent 6890 GC instrument and a Hewlett-Packard 5973 EI-MS detector fitted with a 30 m × 0.25 mm column filled with cross-linked 5% PH ME siloxane (0.25 μm film thickness); the gas pressure was 7.63 psi of He. Analysis of samples involved either heating from 70 to 250 °C (10 °C/min) and then being held at 250 °C for 5 min (method A) or heating from 175 to 250 °C (25 °C/min) and then being held at 250 °C for 2 min (method B). Melting points were measured on a Stanford Research Systems MPA160 melting point apparatus and are uncorrected. HPLC analysis was conducted using an Agilent 1100 instrument fitted with a DAD at 254 nm using a CHIRACEL OD-H 4.6 mm × 250 mm, 5 μm column, run under the specified conditions. HRMS were collected at the University of Delaware using a Q-Exactive Orbitrap instrument with an ESI source in positive mode or a Waters GCT Premier instrument equipped with a LIFDI (liquid field desorption ionization). Optical rotations were determined on a PerkinElmer 341 polarimeter at Villanova University at 589 nm and 20.0 °C.

Computational Methods

All calculations were carried out with Gaussian 1697 and using density functional theory (DFT) in the gas phase. We chose the specific configuration applied successfully by Houk, Chen, and co-workers to a related Ni(II) migratory insertion.40 This procedure involves geometry optimization using the B3LYP hybrid functional,98 the def2-SVP basis set,99,100 and the Grimme D3 empirical dispersion correction101 with Becke–Johnson damping,102 followed by a single-point energy correction using the TZVPP basis set. After each optimization [conducted with fopt = (calcfc,tight) or fopt = (calcfc,ts,tight)], a subsequent frequency calculation was performed to confirm the nature of the stationary point as a minimum (NImag = 0) or a transition structure (NImag = 1) and to obtain thermodynamic corrections. Gibbs free energies at 298 K were used for analysis, but essentially the same picture would be obtained using either enthalpies or electronic energies, as the thermodynamic corrections to the energy barriers and differences were small, as would be expected.

The structures computed were those of intermediates B and C in Scheme 2, and the transition structure between them, for the case in which R1 = R2 = CH3, R3 = H, and L–L = (R)-tBu-6-CH3-iQuinox. Eight major stereoisomers were computed, corresponding to the three major factors that could be varied one way or the other: (1) the orientation of the (R)-tBu-6-CH3-iQuinox ligand (a given orientation, or flipped 180° to transpose the positions of the two coordinating nitrogen atoms), (2) which of the two alkenes in the cyclohexadiene unit coordinates to nickel, and (3) whether to twist the amide out of plane in one sense or the other. In a few cases, there were additional orientations of the iQuinox ligand, leading to similar energies. In addition, of course, there would be another eight equivalent structures with the S configuration at the carbon bearing the tert-butyl group, but these would have the same energies and were not computed. The amide functionality was in all cases restricted to the conformation illustrated in Scheme 2. Conformational depictions and calculation details are available in the Supporting Information.

Birch Reduction/Alkylation

General Procedure A

A flame-dried three-necked round-bottom flask with a stir bar, connected to a Dewar condenser, under argon, was charged with benzoic acid (1.0 mmol, 1.0 equiv) that was dissolved in THF (0.4 mL, 2.5 M) and cooled to −78 °C. Ammonia (7 mL, 0.14 M) was distilled into the flask, and lithium (4.0 mmol, 4.0 equiv) was added in small pieces until a dark blue color was maintained for 30 min. Isoprene was added dropwise to quench the excess lithium and produce a bright yellow opaque solution. An alkylating agent (2.0 mmol, 2.0 equiv) was added slowly dropwise. When the addition was complete, the reaction mixture was maintained at −78 °C while the color faded to white/off-white over 1 h. The reaction mixture was then warmed to room temperature, and the ammonia was allowed to evaporate. Once the ammonia had evaporated, the reaction was quenched with water and the mixture washed with diethyl ether. The aqueous layer was acidified with 6 N HCl (until the pH reached ∼1) and then extracted with diethyl ether. The combined organic layers were washed with Na2S2O4 and brine, dried with MgSO4, and concentrated in vacuo.

General Procedure B

A flame-dried flask with a stir bar, connected to a Dewar condenser, under argon, was charged with benzoate ester (1.0 mmol, 1.0 equiv), THF (0.4 mL, 2.5 M), and tBuOH (1.1 mmol, 1.1 equiv) and cooled to −78 °C. Ammonia (7 mL, 0.14 M) was distilled into the flask, and lithium (2.0 mmol, 2.0 equiv) was added in small pieces until a dark blue color was maintained for 30 min. Isoprene was added dropwise to quench the lithium and produce a bright yellow opaque solution. An alkylating agent (1.1 mmol, 1.1 equiv) in THF (0.4 mL, 2.5 M) was added slowly dropwise. When the addition was complete, the reaction mixture was maintained at −78 °C while the color faded to white/off-white over 1 h. The reaction mixture was then warmed to room temperature, and the ammonia was allowed to evaporate under a stream of argon. Once the ammonia had evaporated, the reaction was quenched with water and the mixture extracted with Et2O (5 × 7 mL/mmol). The combined organic layers were washed with brine, dried with MgSO4, concentrated in vacuo, and purified with flash chromatography on silica gel.

1-Methylcyclohexa-2,5-diene-1-carboxylic acid (S1a). Using Birch reduction/alkylation procedure A with benzoic acid (3.00 g, 24.6 mmol, 1.0 equiv) and iodomethane (3.06 mL, 49.1 mmol, 2.0 equiv) in THF (9.8 mL, 2.5 M) afforded S1a (3.18 g, 23.0 mmol) in 94% yield as a white solid: mp 31.2–33.4 °C. Spectral data were in accordance with the literature.103

1-Ethylcyclohexa-2,5-diene-1-carboxylic acid (S1b). Using Birch reduction/alkylation procedure A with benzoic acid (3.03 g, 24.6 mmol, 1.0 equiv) and bromoethane (3.70 mL, 49.6 mmol, 2.0 equiv) in THF (9.8 mL, 2.5 M) provided S1b (3.74 g, 24.6 mmol) in 100% yield as a clear colorless oil. Spectral data were in accordance with the literature.104

1-Isopropylcyclohexa-2,5-diene-1-carboxylic acid (S1c). Using Birch reduction/alkylation procedure A with benzoic acid (3.01 g, 24.6 mmol, 1.0 equiv) and 2-iodopropane (4.82 mL, 49.2 mmol, 2.0 equiv) in THF (9.8 mL, 2.5 M) afforded isopropyl diene acid S1c (7.07 g, 42.5 mmol) in 96% yield as a white solid: mp 74.0–76.0 °C. Spectral data were in accordance with the literature.59

1-(Methoxymethyl)cyclohexa-2,5-diene-1-carboxylic acid (S1d). Using Birch reduction/alkylation procedure A with benzoic acid (3.02 g, 24.76 mmol, 1.0 equiv) and chloromethyl methyl ether (3.76 mL, 49.5 mmol, 2.0 equiv) in THF (9.9 mL, 2.5 M) afforded S1d (3.74 g, 22.2 mmol) in 90% yield as a white solid: mp 66.9–70.5 °C. Spectral data were in accordance with the literature.59

1-(2-Ethoxy-2-oxoethyl)cyclohexa-2,5-diene-1-carboxylic acid (S1e). Using Birch reduction/alkylation procedure A with benzoic acid (2.00 g, 16.4 mmol, 1.0 equiv) and ethyl 2-chloroacetate (3.51 mL, 32.8 mmol, 2.0 equiv) in THF (6.6 mL, 2.5 M) afforded S1e (3.41 g, 16.2 mmol) in 99% yield as a pale-yellow liquid that solidified to white crystals upon cooling: mp 63.5–66 °C. Spectral data were in accordance with the literature.59

1-Benzylcyclohexa-2,5-diene-1-carboxylic acid (S1f). Using Birch reduction/alkylation procedure A (2.33 g, 19.1 mmol, 1.0 equiv) and benzyl chloride (4.38 mL, 38.1 mmol, 2.0 equiv) in THF (7.6 mL, 2.5 M) afforded S1f (3.83 g, 17.9 mmol) in 94% yield as a white crystalline solid: mp 71.9–75.0 °C. Spectral data were in accordance with the literature.104

Ethyl-1-(2-iodobenzyl)cyclohexa-2,5-diene-1-carboxylate (S1g). Using Birch reduction/alkylation procedure B with ethyl benzoate (5.25 g, 35.0 mmol, 1.0 equiv) and 2-iodobenzyl bromide (11.4 g, 38.5 mmol, 1.1 equiv) in THF (14 mL, 2.5 M) afforded S1g (10.98 g, 29.82 mmol) in 85% yield as a clear colorless oil. Spectral data were in accordance with the literature.86

General Aniline Methylation Procedure A

A flame-dried round-bottom flask with a stir bar, under argon, was charged with aniline (1.0 mmol, 1.0 equiv) dissolved in THF (2 mL, 0.5 M). The solution was cooled to −78 °C, and then nBuLi (2.5 M in hexanes, 0.3 mL, 0.7 mmol, 0.7 equiv) was added slowly dropwise over 15 min. After the reaction mixture was stirred at −78 °C for 30 min, iodomethane (1.1 mmol, 1.1 equiv) was added over 5 min. The solution was stirred at −78 °C for 1 h and then at room temperature overnight. The reaction was quenched with water, and the mixture extracted with Et2O (3 × 5 mL/mmol). The organic layers were combined and washed with brine, dried over MgSO4, and concentrated in vacuo. The crude products were purified by column chromatography.

General Aniline Methylation Procedure B

A flame-dried round-bottom flask with a stir bar, under argon, was charged with aniline (1.0 mmol, 1.0 equiv) dissolved in THF (2 mL, 0.5 M) and cooled to −78 °C. Using an automated syringe pump, MeLi (1.6 M in Et2O, 0.6 mL, 1.0 mmol, 1.0 equiv) was added dropwise over 45 min. After the reaction mixture was stirred at −78 °C for 30 min, iodomethane (1.1 mmol, 1.1 equiv) was dissolved in THF (0.3 mL, 3.3 M) and added dropwise to the flask over 10 min at −78 °C. The solution was stirred at −78 °C for 1 h and then warmed to room temperature overnight. The reaction was quenched with saturated aqueous NH4Cl (1.6 mL/mmol), and the mixture extracted with Et2O (3 × 1.6 mL/mmol). The organic layers were combined and washed with brine, dried over MgSO4, and concentrated in vacuo. The crude products were purified by column chromatography.

2-Bromo-N-methylaniline. Using general aniline methylation procedure A with 2-bromoaniline (3.04 g, 17.7 mmol, 1.0 equiv) in THF (35 mL, 0.5 M) afforded the crude product that was purified by column chromatography (silica, 10:1 hexanes/EtOAc) to afford pure 2-bromo-N-methylaniline (1.98 g, 10.6 mmol) in 60% yield as a clear yellow oil. Spectral data were in accordance with the literature.105

2-Iodo-N-methylaniline. Using general aniline methylation procedure B with 2-iodoaniline (4.0 g, 18.3 mmol, 1.0 equiv) in THF (37 mL, 0.5 M) afforded the crude product that was purified by column chromatography (silica, 60:1 hexanes/EtOAc) to afford pure 2-iodo-N-methylaniline (3.56 g, 15.3 mmol) in 83% yield as a yellow-orange oil. Spectral data were in accordance with the literature.105

General Benzamide Synthesis Procedure

In a round-bottom flask with a stir bar, oxalyl chloride (2.2 mmol, 2.2 equiv) was dissolved in DCM (5.5 mL, 0.4 M) and a catalytic amount of DMF (1.4 μL, 0.02 equiv) was added. The Birch product (1.0 mmol, 1.0 equiv) was dissolved in DCM (2.5 mL, 0.4 M) and added dropwise to the flask. The reaction mixture was refluxed under argon for 1 h until it turned deep yellow. Once the reaction had reached completion, as judged by GC-MS analysis, the mixture was concentrated under vacuum to remove excess oxalyl chloride.

In a round-bottom flask with a stir bar, 2-haloaniline or purified 2-halo-N-methylaniline (1.05–1.3 mmol, 1.05–1.3 equiv) was dissolved in DCM (2.5 mL, 0.4 M) and cooled to 0 °C. Triethylamine (2.5 mmol, 2.5 equiv) was added dropwise followed shortly thereafter by the addition of the acid chloride (1.0 mmol, 1.0 equiv) in DCM (2.5 mL, 0.4 M). The mixture was allowed to warm to room temperature and react overnight. The reaction mixture was diluted with DCM, washed with saturated NaHCO3, 1 N HCl (not used for pyridine- and pyrimidine-containing substrates), and brine, and then dried with MgSO4. The crude product was concentrated under vacuum and purified by column chromatography.

N-(2-Bromophenyl)-N,1-dimethylcyclohexa-2,5-diene-1-carboxamide (1a). Using the general benzamide synthesis procedure, diene acid S1a (1.15g, 7.33 mmol, 1.0 equiv) in DCM (18.3 mL, 0.4 M) reacted with 2-bromo-N-methylaniline (1.77 g, 9.53 mmol, 1.3 equiv) in DCM (23.8 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 4:1 hexanes/EtOAc) to afford pure 1a (2.08 g, 6.79 mmol) in 93% yield as a white solid: mp 42.2–44.4 °C; 1H NMR (400 MHz, CDCl3) δ 7.46 (d, J = 7.5 Hz, 1H), 7.23–7.17 (m, 1H), 7.13–7.02 (m, 2H), 5.59 (d, J = 10.1 Hz, 1H), 5.48–5.38 (m, 2H), 4.94 (d, J = 10.1 Hz, 1H), 3.08 (s, 3H), 2.22 (d, J = 23.1 Hz, 1H), 1.83 (d, J = 23.0 Hz, 1H), 1.26 (s, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 133.1, 131.2, 131.1, 128.9, 128.3, 127.8, 123.5, 121.7, 39.0, 29.3; δd 174.2, 143.3, 124.6, 45.8, 25.9; GC (method B) tR = 2.272 min; EI-MS m/z (%) 305 (M+, 1), 214 (45), 185 (18), 134 (100), 105 (13), 93 (53), 77 (46), 65 (8), 51 (8); HRMS (ESI) calcd for C15H17ONBr [M + H]+ 306.0494, found 306.0493.

N-(2-Iodophenyl)-N,1-dimethylcyclohexa-2,5-diene-1-carboxamide (1a-I). Using the general benzamide synthesis procedure, diene acid S1a (1.16 g, 7.42 mmol, 1.0 equiv) in DCM (18.6 mL, 0.4 M) reacted with 2-iodo-N-methylaniline (2.25 g, 9.65 mmol, 1.3 equiv) in DCM (24.1 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 4:1 hexanes/EtOAc) to afford pure 1a-I (2.07 g, 5.86 mmol) in 79% yield as a white solid: mp 35.8–38.2 °C; 1H NMR (400 MHz, CDCl3) δ 7.80 (d, J = 7.9 Hz, 1H), 7.27–7.18 (m, 2H), 6.96 (t, J = 7.9 Hz, 1H), 5.64 (s, 1H), 5.56 (d, J = 9.9 Hz, 1H), 5.49 (s, 1H), 5.01 (s, 1H), 3.14 (s, 3H), 2.30 (d, J = 23.2 Hz, 1H), 1.94 (d, J = 23.2 Hz, 1H), 1.35 (s, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 139.4, 131.2, 130.2, 128.9, 128.8, 123.6, 121.6, 39.4, 29.4; δd 174.2, 146.6, 101.8, 45.8, 26.0; GC (method B) tR = 2.608 min; EI-MS m/z (%) 353.0 (M+, 1), 260.9 (92), 243.9 (19), 230.9 (20), 202.8 (7), 182.1 (1), 134.0 (100), 105.0 (30), 91.0 (47), 77.0 (47), 64.0 (11), 51.0 (12); HRMS (ESI) calcd for C15H17ONI [M + H]+ 354.0355, found 354.0350.

N-(2-Bromophenyl)-1-methylcyclohexa-2,5-diene-1-carboxamide (S2b). Using the general benzamide synthesis procedure, diene acid S1a (0.505 g, 3.62 mmol, 1.0 equiv) in DCM (9.0 mL, 0.4 M) reacted with 2-bromoaniline (0.44 mL, 3.87 mmol, 1.1 equiv) in DCM (9.7 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 10:1 hexanes/EtOAc) to afford pure S2b (1.01 g, 3.46 mmol) in 95% yield as a clear colorless oil: 1H NMR (400 MHz, CDCl3) δ 8.32 (dd, J = 8.3, 1.6 Hz, 1H), 8.28 (s, 1H), 7.41 (dd, J = 8.1, 1.5 Hz, 1H), 7.25–7.16 (m, 1H), 6.89–6.80 (m, 1H), 5.97–5.87 (m, 2H), 5.76–5.67 (m, 2H), 2.86–2.65 (m, 2H), 1.34 (s, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 132.2, 129.7, 128.4, 126.1, 124.8, 120.9, 24.7; δd 172.8, 136.1, 113.1, 46.4, 26.0; GC (method B) tR = 2.373 min; EI-MS m/z (%) 291.1 (M + 1+, 5), 276.0 (4), 198.9 (9), 171.0 (11), 120.0 (26), 93.1 (100), 77.1(35), 65.1 (10), 51.1 (5); HRMS (ESI) calcd for C14H15ONBr [M + H]+ 292.0337, found 292.0331.

N-(2-Iodophenyl)-1-methylcyclohexa-2,5-diene-1-carboxamide (S2b-I). Using the general benzamide synthesis procedure, diene acid S1a (0.299 g, 2.16 mmol, 1.0 equiv) in DCM (6.5 mL, 0.4 M) reacted with 2-iodoaniline (0.615 g, 2.81 mmol, 1.3 equiv) in DCM (7 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford pure S2b-I (0.694 g, 2.05 mmol) in 99% yield as an off-white solid: mp 72.7–75.0 °C; 1H NMR (400 MHz, CDCl3) δ 8.33 (dd, J = 8.2, 1.6 Hz, 1H), 8.17 (s, 1H), 7.76 (dd, J = 8.0, 1.5 Hz, 1H), 7.39–7.30 (m, 1H), 6.82 (td, J = 7.6, 1.6 Hz, 1H), 6.09–5.99 (m, 2H), 5.87–5.78 (m, 2H), 3.00–2.76 (m, 2H), 1.44 (s, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 138.8, 129.7, 129.3, 126.1, 125.5, 120.9, 24.8; δd 173.0, 138.6, 89.0, 46.3, 26.2; GC (method B) tR = 2.792 min; EI-MS m/z (%) 339.0 (M+, 13), 324.0 (9), 246.9 (35), 218.9 (20), 202.9 (4), 120.0 (39), 93.0 (100), 77.0 (39), 64.0 (8), 51.0 (5); HRMS (ESI) calcd for C14H15ONI [M + H]+ 340.0198, found 340.0197.

1-Ethyl-N-(2-iodophenyl)cyclohexa-2,5-diene-1-carboxamide (S2c-I). Using the general benzamide synthesis procedure, diene acid S1b (0.501 g, 3.26 mmol, 1.0 equiv) in DCM (8.2 mL, 0.4 M) reacted with 2-iodoaniline (0.935 g, 4.27 mmol, 1.3 equiv) in DCM (10.7 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford pure S2c-I (1.10 g, 3.11 mmol) in 95% yield as a white solid: 1H NMR (400 MHz, CDCl3) δ 8.31 (dd, J = 8.3, 1.6 Hz, 1H), 8.13 (s, 1H), 7.74 (dd, J = 7.9, 1.5 Hz, 1H), 7.32 (ddd, J = 8.5, 7.2, 1.5 Hz, 1H), 6.80 (td, J = 7.6, 1.6 Hz, 1H), 6.16–6.06 (m, 2H), 5.72 (dt, J = 10.4, 2.1 Hz, 2H), 2.96–2.73 (m, 2H), 1.87 (q, J = 7.5 Hz, 2H), 0.86 (t, J = 7.5 Hz, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 138.8, 129.2, 128.1, 127.8, 125.6, 121.1, 8.9; δd 172.8, 138.6, 89.1, 50.8, 29.5, 26.5; GC (method B) tR = 3.101 min; EI-MS m/z (%) 353.1 (M+, 16), 324 (19), 246.9 (50), 218.9 (29), 202.9 (4), 120 (35), 107.0 (64), 91.0 (33), 79.0 (100), 65.0 (8).

N-(2-Bromophenyl)-1-isopropyl-N-methylcyclohexa-2,5-diene-1-carboxamide (1d). Using the general benzamide synthesis procedure, diene acid S1c (0.501 g, 3.00 mmol, 1.0 equiv) in DCM (7.5 mL, 0.4 M) reacted with 2-bromo-N-methylaniline (0.587 g, 3.153 mmol, 1.05 equiv) in DCM (7.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 20:1 hexanes/EtOAc) to afford pure 1d (0.897 g, 2.70 mmol) in 90% yield as a white solid: mp 85.4–86.1 °C; 1H NMR (400 MHz, CDCl3) δ 7.50–7.43 (m, 1H), 7.15–7.01 (m, 3H), 5.54 (d, J = 10.3 Hz, 1H), 5.43 (d, J = 10.4 Hz, 1H), 5.25 (d, J = 10.3 Hz, 1H), 5.02 (d, J = 10.7 Hz, 1H), 3.09 (s, 3H), 2.45 (hept, J = 6.8 Hz, 1H), 2.25 (d, J = 23.2 Hz, 1H), 2.01 (d, J = 20.1 Hz, 1H), 0.80 (d, J = 6.7 Hz, 3H), 0.61 (d, J = 7.0 Hz, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 133.0, 130.4, 130.1, 128.9, 128.9, 127.9, 124.9, 123.9, 38.9, 35.9, 17.8, 17.1; δd 174.7, 143.8, 124.3, 54.0, 26.6; GC (method B) tR = 2.692 min; EI-MS m/z (%) 333.1 (M – 1+, 2), 290.0 (23), 214.0 (55), 185.0 (16), 134.0 (100), 121.1 (9), 105.0 (72), 91.0 (9), 77.1 (78), 51.0 (8); HRMS (ESI) calcd for C17H21ONBr [M + H]+ 334.0807, found 334.0806.

N-(2-Iodophenyl)-1-isopropyl-N-methylcyclohexa-2,5-diene-1-carboxamide (1d-I). Using the general benzamide synthesis procedure, diene acid S1c (0.340 g, 2.05 mmol, 1.0 equiv) in DCM (5.1 mL, 0.4 M) reacted with 2-iodo-N-methylaniline (0.620 g, 2.66 mmol, 1.3 equiv) in DCM (6.7 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford pure 1d-I (0.267 g, 1.64 mmol) in 84% yield as a white solid: mp 89.6–90.8 °C; 1H NMR (400 MHz, CDCl3) δ 7.74 (d, J = 7.9 Hz, 1H), 7.11 (d, J = 3.9 Hz, 2H), 6.93–6.84 (m, 1H), 5.66–5.34 (m, 2H), 5.27 (d, J = 10.4 Hz, 1H), 5.01 (s, 1H), 3.08 (s, 3H), 2.46 (hept, J = 6.9 Hz, 1H), 2.31–1.94 (m, 2H), 0.83 (d, J = 6.8 Hz, 3H), 0.62 (d, J = 6.9 Hz, 2H); 13C{1H} NMR (101 MHz, CDCl3) δu 139.4, 130.3, 129.6, 128.8, 128.8, 125.0, 124.3, 123.8, 39.4, 36.0, 18.1, 17.1; δd 174.8, 147.1, 101.5, 54.0, 26.7; GC (method B) tR = 3.051 min; EI-MS m/z (%) 381.0 (M+, 2), 338.0 (20), 260.9 (75), 244.9 (5), 230.9 (15), 210.1 (14), 134.0 (100), 105.0 (80), 91.0 (9), 77.0 (39), 51.0 (8); HRMS (ESI) calcd for C17H21ONI [M + H]+ 382.0668, found 382.0664.

N-(2-Bromophenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2e). Using the general benzamide synthesis procedure, diene acid S1c (0.800 g, 4.81 mmol, 1.0 equiv) in DCM (12.0 mL, 0.4 M) reacted with 2-bromoaniline (1.08 g, 6.25 mmol, 1.3 equiv) in DCM (15.6 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford pure S2e (1.18 g, 3.68 mmol) in 79% yield as a yellow oil: 1H NMR (400 MHz, CDCl3) δ 8.42 (dd, J = 8.3, 1.6 Hz, 1H), 8.35 (s, 1H), 7.50 (dd, J = 8.0, 1.5 Hz, 1H), 7.29 (ddd, J = 8.6, 7.4, 1.5 Hz, 1H), 6.94 (td, J = 7.7, 1.6 Hz, 1H), 6.17–6.07 (m, 2H), 5.78 (dp, J = 10.6, 2.1 Hz, 2H), 2.81 (qd, J = 3.3, 1.8 Hz, 2H), 2.48 (hept, J = 6.9 Hz, 1H), 0.90 (d, J = 6.9 Hz, 6H); 13C{1H} NMR (101 MHz, CDCl3) δu 132.2, 128.5, 128.4, 126.7, 124.9, 121.3, 33.4, 17.7; δd 172.5, 136.1, 113.4, 54.4, 26.8; GC (method B) tR = 2.897 min; EI-MS m/z (%) 321.1 (M + 1+, 8), 277.9 (14), 198.9 (21), 170.9 (19), 121.0 (55), 105.0 (85), 91.0 (25), 79.0 (100), 65.1 (8), 51.0 (7).

N-(2-Iodophenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2e-I). Using the general benzamide synthesis procedure, diene acid S1c (0.497 g, 2.99 mmol, 1.0 equiv) in DCM (7.5 mL) reacted with 2-iodoaniline (0.863 g, 3.94 mmol, 1.3 equiv) in DCM (9.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 4:1 hexanes/EtOAc) to afford pure S2e-I (0.93 g, 2.53 mmol) in 84% yield as a yellow oil: 1H NMR (400 MHz, DMSO-d6) δ 8.22 (s, 1H), 7.90–7.78 (m, 2H), 7.34 (t, J = 7.5 Hz, 1H), 6.93–6.84 (m, 1H), 6.09 (dt, J = 10.7, 3.4 Hz, 2H), 5.82–5.74 (m, 2H), 2.87–2.67 (m, 2H), 2.33 (m, 1H), 0.91–0.76 (d, 6H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 139.3, 129.3, 128.4, 127.2, 126.7, 124.2, 33.9, 18.0; δd 172.5, 139.3, 93.9, 53.5, 26.9; GC (method B) tR = 3.671 min; EI-MS m/z (%) 367.1 (M+, 14), 324.0 (16), 247.0 (53), 218.9 (32), 197.1 (11), 121.1 (64), 105.1 (65), 91.0 (35), 79.1 (100), 65.1 (11), 51.0 (7).

N-(2-Iodophenyl)-1-(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (S2f-I). Using the general benzamide synthesis procedure, diene acid S1d (0.500 g, 2.97 mmol, 1.0 equiv) in DCM (7.4 mL, 0.4 M) reacted with 2-iodoaniline (0.781 g, 3.57 mmol, 1.2 equiv) in DCM (8.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 7:1 hexanes/EtOAc) to afford pure S2f-I (1.06 g, 2.87 mmol) in 97% yield as a yellow oil: 1H NMR (400 MHz, CDCl3) δ 8.25 (dd, J = 8.2, 1.6 Hz, 1H), 8.21 (s, 1H), 7.67 (dd, J = 8.0, 1.5 Hz, 1H), 7.28–7.20 (m, 1H), 6.73 (td, J = 7.6, 1.6 Hz, 1H), 6.11–6.01 (m, 2H), 5.89–5.79 (m, 2H), 3.62 (s, 2H), 3.33 (s, 3H), 2.92–2.68 (m, 2H); 13C{1H} NMR (101 MHz, CDCl3) δu 138.8, 129.2, 128.4, 125.9, 125.7, 121.3, 59.6; δd 171.1, 138.6, 89.1, 77.0, 51.1, 26.7; GC (method B) tR = 3.353 min; EI-MS m/z (%) 369 (M+, 2), 336.0 (5), 227.9 (4), 262.9 (7), 244.9 (35), 232.0 (26), 218.8 (10), 210.0 (5), 196.0 (8), 150.9 (10), 118.9 (14), 105.0 (26), 92.0 (100), 77.0 (13), 63.0 (6); HRMS (ESI) calcd for C15H17INO2 [M + H]+ 370.0304, found 370.0294.

Ethyl 2-{1-[(2-Iodophenyl)(methyl)carbamoyl]cyclohexa-2,5-dien-1-yl}acetate (1g-I). Using the general benzamide synthesis procedure, diene acid S1e (0.502 g, 2.38 mmol, 1.0 equiv) in DCM (6 mL, 0.4 M) reacted with 2-iodo-N-methylaniline (0.721 g, 3.09 mmol, 1.3 equiv) in DCM (7.7 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 4:1 hexanes/EtOAc) to afford pure 1g-I (0.84 g, 1.97 mmol) in 83% yield as a tan solid: mp 63.7–64.8 °C; 1H NMR (400 MHz, CDCl3) δ 7.74 (d, J = 7.8 Hz, 1H), 7.23 (d, J = 7.7 Hz, 1H), 7.14 (d, J = 7.4 Hz, 1H), 6.89 (td, J = 7.6, 1.7 Hz, 1H), 5.78 (d, J = 10.3 Hz, 1H), 5.58 (d, J = 10.2 Hz, 1H), 5.41 (d, J = 10.1 Hz, 1H), 5.10 (d, J = 10.3 Hz, 1H), 4.05 (q, J = 7.1 Hz, 2H), 3.11 (s, 3H), 2.85 (d, J = 16.0 Hz, 1H), 2.52 (d, J = 16.1 Hz, 1H), 2.25 (d, J = 23.3 Hz, 1H), 1.94 (d, J = 22.8 Hz, 1H), 1.17 (t, J = 7.2 Hz, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 139.5, 130.5, 129.0, 129.0, 128.6, 126.9, 124.6, 123.7, 39.5, 14.3; δd 171.1, 146.4, 101.2, 60.2, 47.7, 46.6, 26.1; GC (method B) tR = 4.145 min; EI-MS m/z (%) 380.1 (M+, 8), 260.0 (45), 232.9 (14), 210.1 (9), 165.1 (62), 134.0 (81), 119.0 (24), 105.0 (35), 91.1 (100), 77.0 (14); HRMS (ESI) calcd for C18H21O3NI [M + H]+ 426.0566, found 426.0580.

1-Benzyl-N-(2-bromophenyl)cyclohexa-2,5-diene-1-carboxamide (S2h). Using the general benzamide synthesis procedure, diene acid S1f (1.01 g, 4.71 mmol, 1.0 equiv) in DCM (11.8 mL, 0.4 M) reacted with 2-bromoaniline (1.05 g, 6.12 mmol, 1.3 equiv) in DCM (15.3 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford pure S2h (1.53 g, 4.15 mmol) in 88% yield as a yellow oil that solidified to white-yellow crystals upon cooling: mp 70.2–72.0 °C; 1H NMR (400 MHz, CDCl3) δ 8.43 (dd, J = 8.3, 1.6 Hz, 1H), 8.31 (s, 1H), 7.48 (dd, J = 8.0, 1.5 Hz, 1H), 7.31 (ddd, J = 8.5, 7.5, 1.5 Hz, 1H), 7.27–7.14 (m, 4H), 6.95 (td, J = 7.7, 1.6 Hz, 1H), 5.99 (dt, J = 10.3, 3.3 Hz, 2H), 5.82 (dt, J = 10.4, 2.0 Hz, 2H), 3.21 (s, 2H), 2.73 (dddd, J = 23.4, 5.5, 3.1, 2.3 Hz, 1H), 2.56 (dtt, J = 23.4, 3.6, 1.8 Hz, 1H); 13C{1H} NMR (101 MHz, CDCl3) δu 132.2, 130.7, 128.4, 127.9, 127.8, 127.6, 126.3, 125.0, 121.2; δd 172.0, 137.4, 136.0, 113.3, 51.3, 43.4, 26.2; GC (method A) tR = 19.251 min; EI-MS m/z (%) 367.1 (M+, 7), 276.0 (15), 196.1 (25), 170.1 (12), 152.1 (4), 120.0 (4), 105.0 (29), 91.1 (100), 77.1 (10), 63.1 (10); HRMS (ESI) calcd for C20H19ONBr [M + H]+ 368.0650, found 368.0657.

1-Benzyl-N-(2-iodophenyl)cyclohexa-2,5-diene-1-carboxamide (S2h-I). Using the general benzamide synthesis procedure, diene acid S1f (0.501 g, 2.33 mmol, 1.0 equiv) in DCM (5.8 mL, 0.4 M) reacted with 2-iodoaniline (0.665 g, 3.03 mmol, 1.3 equiv) in DCM (7.6 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 7:1 hexanes/EtOAc) to afford pure S2h-I (0.868 g, 2.09 mmol) in 90% yield as a yellow solid: mp 68.6–70.4 °C; 1H NMR (400 MHz, CDCl3) δ 8.35 (dd, J = 8.2, 1.6 Hz, 1H), 8.11 (s, 1H), 7.75 (dd, J = 8.0, 1.5 Hz, 1H), 7.41–7.32 (m, 1H), 7.27–7.16 (m, 5H), 6.84 (td, J = 7.6, 1.6 Hz, 1H), 6.03 (dt, J = 10.2, 3.4 Hz, 2H), 5.85 (dt, J = 10.4, 2.0 Hz, 2H), 3.23 (s, 2H), 2.85–2.73 (m, 1H), 2.66–2.53 (m, 1H); 13C{1H} NMR (101 MHz, CDCl3) δu 138.8, 130.7, 129.2, 127.9, 127.8, 127.6, 126.3, 125.8, 121.2; δd 172.2, 138.5, 137.4, 89.3, 51.2, 43.4, 26.3; GC (method B) tR = 19.751 min; EI-MS m/z (%) 415.1 (M+, 7), 324.0 (14), 245.9 (10), 218.9 (8), 196.0 (40), 170.0 (14), 119.0 (11), 105.0 (32), 91.0 (100), 77.1 (11), 65.0 (8); HRMS (ESI) calcd for C20H19ONI [M + H]+ 416.0511, found 416.0508.

N-(2-Bromo-4-fluorophenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2i). Using the general benzamide synthesis procedure, diene acid S1c (0.499 g, 3.00 mmol, 1.0 equiv) in DCM (7.5 mL, 0.4 M) reacted with 2-bromo-4-fluoroaniline (0.44 mL, 3.90 mmol, 1.3 equiv) in DCM (9.8 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 20:1 hexanes/EtOAc) to afford pure S2i (0.907 g, 2.68 mmol) in 90% yield as a clear colorless oil: 1H NMR (400 MHz, CDCl3) δ 8.37 (dd, J = 9.2, 5.6 Hz, 1H), 8.23 (s, 1H), 7.26 (dd, J = 7.9, 2.9 Hz, 1H), 7.03 (ddd, J = 9.2, 7.8, 2.9 Hz, 1H), 6.12 (dtd, J = 10.7, 3.4, 1.7 Hz, 2H), 5.77 (dt, J = 10.5, 2.0 Hz, 2H), 2.84–2.76 (m, 2H), 2.47 (hept, J = 6.9 Hz, 1H), 0.90 (d, J = 6.9 Hz, 6H); 13C{1H} NMR (101 MHz, CDCl3) δu 128.5, 126.6, 122.3 (d, 3JC–F = 8.1 Hz), 119.2 (d, 2JC–F = 26.3 Hz), 115.1 (d, 2JC–F = 22.2 Hz), 33.4, 17.7; δd 172.5, 158.3 (d, 1JC–F = 248.5 Hz), 132.6, 54.3, 26.8; 19F NMR (376 MHz, CDCl3) δ −116.66; GC (method B) tR = 2.741 min; EI-MS m/z (%) 337.1 (M – 1+, 7), 294.0 (15), 216.9 (18), 188.9 (17), 138.0 (15), 121.1 (80), 105.0 (58), 79.1 (100), 51.0 (6); HRMS (ESI) calcd for C16H18ONBrF [M + H]+ 338.0556, found 338.0560.

N-(4-Fluoro-2-iodophenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2i-I). Using the general benzamide synthesis procedure, diene acid S1c (0.501 g, 3.01 mmol, 1.0 equiv) in DCM (7.5 mL, 0.4 M) reacted with 4-fluoro-2-iodoaniline (0.37 mL, 3.16 mmol, 1.05 equiv) in DCM (7.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 20:1 hexanes/EtOAc) to afford pure S2i-I (1.06 g, 2.74 mmol) in 91% yield as an orange solid: mp 62.0–62.5 °C; 1H NMR (400 MHz, CDCl3) δ 8.16 (dd, J = 9.1, 5.5 Hz, 1H), 7.95 (s, 1H), 7.40 (dd, J = 7.7, 2.9 Hz, 1H), 7.00 (ddd, J = 9.1, 7.8, 2.9 Hz, 1H), 6.06 (dt, J = 10.3, 3.3 Hz, 2H), 5.72 (dt, J = 10.5, 2.1 Hz, 2H), 2.84–2.65 (m, 2H), 2.40 (hept, J = 6.9 Hz, 1H), 0.83 (d, J = 6.9 Hz, 6H); 13C{1H} NMR (101 MHz, CDCl3) δu 128.6, 126.7, 125.3 (d, 2JC–F = 24.9 Hz), 122.2 (d, 3JC–F = 7.8 Hz), 115.9 (d, 2JC–F = 21.7 Hz), 33.4, 17.7; δd 172.6, 158.4 (d, 1JC–F = 248.6 Hz), 135.1, 88.7, 54.2, 26.9; 19F NMR (376 MHz, CDCl3) δ −116.70; GC (method B) tR = 3.152 min; EI-MS m/z (%) 385.1 (M+, 18), 342.0 (21), 264.9 (54), 236.9 (29), 215.0 (10), 138.0 (26), 121.1 (100), 105.0 (65), 85.1 (17), 79.0 (99) 51.0 (7); HRMS (ESI) calcd for C16H18ONFI [M + H]+ 386.0417, found 386.0408.

N-(2-Bromo-4-chlorophenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2j). Using the general benzamide synthesis procedure, diene acid S1c (0.502 g, 3.02 mmol, 1.0 equiv) in DCM (7.6 mL, 0.4 M) reacted with 2-bromo-4-chloroaniline (0.804 g, 3.90 mmol, 1.3 equiv) in DCM (9.8 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 20:1 hexanes/EtOAc) to afford pure S2j (0.99 g, 2.79 mmol) in 93% yield as a yellow oil: 1H NMR (400 MHz, CDCl3) δ 8.39 (d, J = 8.9 Hz, 1H), 8.32 (s, 1H), 7.50 (d, J = 2.4 Hz, 1H), 7.27 (dd, 1H), 6.15–6.09 (m, 2H), 5.77 (dt, J = 10.5, 2.0 Hz, 2H), 2.82–2.78 (m, 2H), 2.46 (hept, J = 6.9 Hz, 1H), 0.89 (d, J = 6.9 Hz, 6H); 13C{1H} NMR (101 MHz, CDCl3) δu 131.6, 128.6, 128.4, 126.5, 121.8, 116.2, 33.4, 17.7; δd 172.5, 134.9, 129.0, 113.4, 54.4, 26.8; GC (method B) tR = 3.515 min; EI-MS m/z (%) 355.1 (M + 1+, 6), 312.0 (13), 234.9 (16), 206.9 (16), 154.0 (11), 121.1 (90), 105.0 (51), 91.0 (12), 79.1 (100), 51.0 (6).

N-(4-Chloro-2-iodophenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2j-I). Using the general benzamide synthesis procedure, diene acid S1c (0.505 g, 3.04 mmol, 1.0 equiv) in DCM (7.6 mL, 0.4 M) reacted with 4-chloro-2-iodoaniline (0.798 g, 3.15 mmol, 1.04 equiv) in DCM (7.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 20:1 hexanes/EtOAc) to afford pure S2j-I (0.998 g, 2.48 mmol) in 82% yield as a white solid: mp 85.3–86.5 °C; 1H NMR (400 MHz, CDCl3) δ 8.20 (d, J = 8.9 Hz, 1H), 8.04 (s, 1H), 7.66 (d, J = 2.4 Hz, 1H), 7.23 (dd, J = 8.9, 2.4 Hz, 1H), 6.06 (dt, J = 10.3, 3.4 Hz, 2H), 5.71 (dt, J = 10.5, 2.0 Hz, 2H), 2.84–2.65 (m, 2H), 2.39 (hept, J = 6.9 Hz, 1H), 0.83 (d, J = 6.9 Hz, 6H); 13C{1H} NMR (101 MHz, CDCl3) δu 137.8, 129.2, 128.7, 126.6, 121.6, 33.4, 17.7; δd 172.7, 137.5, 129.5, 89.0, 54.4, 26.9; GC (method B) tR = 4.148 min; EI-MS m/z (%) 401.1 (M+, 13), 358.0 (13), 280.9 (40), 252.9 (23), 231.0 (9), 154.0 (20), 121.1 (100), 105.0 (56), 91.0 (15), 79.0 (90), 63.0 (6), 51.0 (5); HRMS (ESI) calcd for C16H18ONClI [M + H]+ 402.0122, found 402.0119.

N-(2-Bromo-4-methylphenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2k). Using the general benzamide synthesis procedure, diene acid S1c (0.504 g, 3.03 mmol, 1.0 equiv) in DCM (7.6 mL, 0.4 M) reacted with 2-bromo-4-methylaniline (0.48 mL, 3.94 mmol, 1.3 equiv) in DCM (9.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 10:1 hexanes/EtOAc) to afford pure S2k (0.966 g, 2.89 mmol) in 96% yield as a yellow oil: 1H NMR (400 MHz, CDCl3) δ 8.26 (d, J = 8.3 Hz, 1H), 7.32 (dd, J = 2.0, 0.9 Hz, 1H), 7.09 (dd, J = 8.4, 2.0 Hz, 1H), 6.15–6.05 (m, 2H), 5.78 (dt, J = 10.5, 2.0 Hz, 2H), 2.80 (dp, J = 5.4, 1.9 Hz, 2H), 2.46 (h, J = 7.0 Hz, 1H), 2.28 (s, 3H), 0.90 (d, J = 6.9 Hz, 7H); 13C{1H} NMR (101 MHz, CDCl3) δu 132.4, 128.9, 128.3, 126.7, 121.2, 33.4, 20.5, 17.7; δd 172.4, 134.9, 133.5, 113.3, 54.3, 26.8; GC (method B) tR = 3.296 min; EI-MS m/z (%) 333.1 (M – 1+, 13), 290.0 (19), 212.9 (22), 185.9 (24), 134.1 (60), 122.1 (62), 105.0 (65), 91.0 (15), 79.1 (100), 51.0 (8).

N-(2-Iodo-5-methylphenyl)-1-isopropylcyclohexa-2,5-diene-1-carboxamide (S2l-I). Using the general benzamide synthesis procedure, diene acid S1c (0.501 g, 3.00 mmol, 1.0 equiv) in DCM (7.5 mL, 0.4 M) reacted with 2-iodo-5-methylaniline (0.735 g, 3.15 mmol, 1.05 equiv) in DCM (7.9 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 10:1 hexanes/EtOAc) to afford pure S2l-I (1.13 g, 2.96 mmol) in 99% yield as a white solid: mp 78.2–79.1 °C; 1H NMR (400 MHz, CDCl3) δ 8.11 (d, J = 2.1 Hz, 1H), 8.01 (s, 1H), 7.52 (d, J = 8.1 Hz, 1H), 6.57 (dd, J = 8.1, 1.5 Hz, 1H), 6.05 (dt, J = 10.3, 3.3 Hz, 2H), 5.72 (dt, J = 10.5, 2.0 Hz, 2H), 2.85–2.64 (m, 2H), 2.40 (hept, J = 6.9 Hz, 1H), 2.24 (s, 3H), 0.84 (d, J = 6.9 Hz, 6H); 13C{1H} NMR (101 MHz, CDCl3) δu 138.3, 129.50, 128.5, 126.7, 126.7, 122.0, 33.4, 21.3, 17.8; δd 172.8, 139.6, 138.3, 54.3, 26.9; GC (method B) tR = 3.659 min; EI-MS m/z (%) 381.1 (M+, 26), 338.0 (196), 260.9 (60), 232.9 (50), 211.0 (18), 134.0 (99), 121.0 (81), 105.0 (76), 85 (18), 79.0 (100), 65.0 (5), 51.0 (10); HRMS (ESI) calcd for C17H21ONI [M + H]+ 382.0668, found 382.0658.

N-(2-Bromopyridin-3-yl)-1-methylcyclohexa-2,5-diene-1-carboxamide (S2m). Using the general benzamide synthesis procedure, diene acid S1a (0.501 g, 3.62 mmol, 1.0 equiv) in DCM (9.1 mL, 0.4 M) reacted with 2-bromopyridin-3-amine (0.814 g, 4.71 mmol, 1.3 equiv) in DCM (11.8 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 4:1 hexanes/EtOAc) to afford pure S2m (0.899 g, 3.07 mmol) in 85% yield as a white-tan solid: mp 96.0–97.8 °C; 1H NMR (400 MHz, CDCl3) δ 8.69 (dd, J = 8.1, 1.8 Hz, 1H), 8.40 (s, 1H), 8.05 (dd, J = 4.6, 1.8 Hz, 1H), 7.25 (dd, J = 8.2, 4.7 Hz, 1H), 6.05 (dt, J = 10.2, 3.4 Hz, 2H), 5.78 (dt, J = 10.3, 2.1 Hz, 2H), 2.96–2.75 (m, 2H), 1.42 (s, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 144.2, 129.3, 127.8, 126.5, 123.6, 24.5; δd 173.4, 133.9, 132.9, 46.5, 26.0; GC (method B) tR = 2.454 min; EI-MS m/z (%) 292.0 (M – 1+, 1), 199.0 (8), 171.9 (5), 119.0 (6), 93.0 (100), 77.0 (31), 65.0 (8), 51.0 (4).

N-(3-Bromopyridin-2-yl)-1-methylcyclohexa-2,5-diene-1-carboxamide (S2n). Using the general benzamide synthesis procedure, diene acid S1a (0.501 g, 3.62 mmol, 1.0 equiv) in DCM (9.1 mL, 0.4 M) reacted with 2-amino-3-bromopyridine (0.814 g, 4.71 mmol, 1.3 equiv) in DCM (11.8 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 4:1 hexanes/EtOAc) to afford pure S2n (0.858 g, 2.93 mmol) in 81% yield as a white solid: mp 96.0–97.8 °C; 1H NMR (400 MHz, CDCl3) δ 8.47 (s, 1H), 8.43 (dd, J = 4.8, 1.6 Hz, 1H), 7.83 (dd, J = 7.9, 1.6 Hz, 1H), 6.94 (dd, J = 7.9, 4.7 Hz, 1H), 6.06–5.96 (m, 2H), 5.82 (dt, J = 10.4, 2.0 Hz, 2H), 2.94–2.75 (m, 2H), 1.43 (s, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 147.6, 141.1, 129.7, 126.1, 120.8, 24.6; δd 171.7, 148.6, 111.0, 46.6, 26.0; GC (method B) tR = 2.695 min; EI-MS m/z (%) 293.0 (M+, 12), 200.9 (42), 171.9 (83), 157.9 (16), 119.0 (6), 93.1 (100), 77.0 (54), 65.0 (14), 51.0 (7); HRMS (ESI) calcd for C13H14ON2Br [M + H]+ 293.0289, found 293.0287.

N-(3-Bromopyridin-2-yl)-1-ethylcyclohexa-2,5-diene-1-carboxamide (S2o). Using the general benzamide synthesis procedure, diene acid S1b (1.11 g, 6.50 mmol, 1.0 equiv) in DCM (16.3 mL, 0.4 M) reacted with 2-amino-3-bromopyridine (1.71 g, 9.88 mmol, 1.5 equiv) in DCM (24.7 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 3:2 hexanes/EtOAc) to afford pure S2o (1.575 g, 5.13 mmol) in 78% yield as a white solid: mp 81.3–84.5 °C; 1H NMR (400 MHz, CDCl3) δ 8.48 (s, 1H), 8.43 (dd, J = 4.7, 1.6 Hz, 1H), 7.83 (dd, J = 7.9, 1.6 Hz, 1H), 6.94 (dd, J = 7.9, 4.7 Hz, 1H), 6.11 (dt, J = 10.3, 3.4 Hz, 2H), 5.74 (dt, J = 10.4, 2.1 Hz, 2H), 2.87–2.79 (m, 2H), 1.91 (q, J = 7.5 Hz, 2H), 0.86 (t, J = 7.5 Hz, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 147.6, 141.1, 128.0, 127.8, 120.8, 8.8; δd 171.6, 148.6, 111.1, 51.1, 29.3, 26.3; GC (method B) tR = 3.072 min; EI-MS m/z (%) 307.0 (M+, 5), 200.9 (18), 171.9 (49), 157.9 (8), 108.1 (40), 91.1 (30), 79.1 (100), 65.1 (7), 51.1 (5); HRMS (ESI) calcd for C14H16ON2Br [M + H]+ 307.0446, found 307.0447.

N-(3-Iodopyridin-2-yl)-1-ethylcyclohexa-2,5-diene-1-carboxamide (S2o-I). Using the general benzamide synthesis procedure, diene acid S1b (0.561 g, 3.29 mmol, 1.0 equiv) in DCM (8.2 mL, 0.4 M) reacted with 2-amino-3-iodopyridine (0.759 g, 3.45 mmol, 1.05 equiv) in DCM (8.6 mL, 0.4 M) to afford the crude product that was purified by column chromatography (silica, 3:2 hexanes/EtOAc) to afford pure S2o-I (1.04 g, 2.94 mmol) in 89% yield as a white solid: mp 101.3–101.9 °C; 1H NMR (400 MHz, CDCl3) δ 8.38 (dd, J = 4.7, 1.7 Hz, 1H), 8.26 (s, 1H), 7.99 (dd, J = 7.9, 1.6 Hz, 1H), 6.72 (dd, J = 7.9, 4.7 Hz, 1H), 6.09–5.99 (m, 2H), 5.72–5.63 (m, 2H), 2.88–2.67 (m, 2H), 1.84 (q, J = 7.5 Hz, 2H), 0.79 (t, J = 7.5 Hz, 3H); 13C{1H} NMR (101 MHz, CDCl3) δu 148.4, 147.8, 128.1, 127.8, 121.3, 8.8; δd 171.8, 150.9, 86.0, 51.0, 29.3, 26.4; GC (method B) tR = 3.444 min; EI-MS m/z (%) 353.1 (M – 1+, 9), 246.9 (39), 219.9 (100), 203.9 (12), 108.0 (33), 93.0 (21), 79.0 (60), 65.0 (5), 51.0 (4); HRMS (ESI) calcd for C14H16ON2I [M + H]+ 355.0307, found 355.0299.

General Procedure for the Methoxymethyl (MOM) Group Protection of Amide N

A secondary amide (1.0 mmol, 1.0 equiv) was dissolved in THF (7 mL, 0.14 M) and cooled to 0 °C. LiHMDS (1.0 M in hexanes, 1.2 mmol, 1.2 equiv) was added dropwise, and the solution stirred for 10 min. Chloro- or bromomethyl methyl ether (2.0–5.0 mmol, 2.0–5.0 equiv) was added dropwise to the reaction solution, and the mixture was left stirring while slowly warming to rt. Upon completion, the reaction was quenched with saturated NH4Cl, and the mixture diluted with EtOAc. The aqueous layer was extracted twice with EtOAc. The combined organic layers were washed with brine, dried with MgSO4, filtered, and concentrated. The crude product was purified by column chromatography.

N-(2-Bromophenyl)-N-(methoxymethyl)-1-methylcyclohexa-2,5-diene-1-carboxamide (1b). Using the general procedure for MOM group protection, secondary amide S2b (0.444 g, 1.52 mmol, 1.0 equiv) in THF (10.6 mL, 0.14 M) was alkylated with chloromethyl methyl ether (0.248 mL, 3.04 mmol, 2.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1b (0.389 g, 1.16 mmol) in 76% yield as a clear colorless oil: 1H NMR (400 MHz, DMSO-d6) δ 7.62 (d, J = 7.6 Hz, 1H), 7.34–7.21 (m, 3H), 5.58 (s, 2H), 5.46 (s, 1H), 5.25 (s, 1H), 4.25 (s, 1H), 3.25 (s, 3H), 2.45–2.05 (m, 2H), 1.22 (s, 3H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 133.2, 130.5, 130.1, 128.3, 124.4, 122.7, 56.4, 29.4; δd 174.1, 140.6, 121.4, 80.2, 46.0, 25.9; GC (method B) tR = 2.578 min; EI-MS m/z (%) 335.1 (M + 1+, 1), 305.1 (5), 244.0 (4), 224.1 (19), 211.9 (8), 198.9 (8), 184.9 (70), 164.0 (58), 152.0 (5), 134.0 (6), 105.0 (7), 93.0 (100), 77.0 (39), 65.0 (7), 51.0 (5); HRMS (ESI) calcd for C16H19O2NBr [M + H]+ 336.0599, found 336.0590.

N-(2-Iodophenyl)-N-(methoxymethyl)-1-methylcyclohexa-2,5-diene-1-carboxamide (1b-I). Using the general procedure for MOM group protection, secondary amide S2b-I (0.998 g, 2.95 mmol, 1.0 equiv) in THF (20.7 mL, 0.14 M) was alkylated with chloromethyl methyl ether (0.90 mL, 11.8 mmol, 4.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1b-I (0.990 g, 2.58 mmol) in 88% yield as a yellow oil: 1H NMR (400 MHz, DMSO-d6) δ 7.90–7.86 (m, 1H), 7.36 (td, J = 7.6, 1.6 Hz, 1H), 7.28 (dd, J = 7.8, 1.8 Hz, 1H), 7.09 (td, J = 7.5, 1.8 Hz, 1H), 5.72–5.55 (m, 3H), 5.50 (d, J = 9.9 Hz, 1H), 5.27 (s, 1H), 4.22 (d, J = 10.1 Hz, 1H), 3.26 (s, 3H), 2.48–2.14 (m, 2H), 1.26 (s, 3H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 139. 9, 139.5, 132.4, 130.8, 129.9, 129.0, 124.2, 122.5, 56.5, 29.5, 26.8; δd 174.1, 150.7, 144.0, 80.6, 46.1, 25.9; GC (method B) tR = 2.935 min; EI-MS m/z (%) 383.1 (M+, 1), 292.0 (4), 259.9 (6), 244.9 (11), 230.9 (100), 224.1 (18), 202.9 (5), 164.0 (28), 134.0 (4), 93.0 (50), 77.0 (24), 65.0 (5), 51.0 (5); HRMS (ESI) calcd for C16H19O2NI [M + H]+ 384.0461, found 384.0447.

1-Ethyl-N-(2-iodophenyl)-N-(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (1c-I). Using the general procedure for MOM group protection, secondary amide S2c-I (1.10 g, 3.12 mmol, 1.0 equiv) in THF (21.8 mL, 0.14 M) was alkylated with chloromethyl methyl ether (0.47 mL, 6.24 mmol, 2.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1c-I (0.978 g, 2.46 mmol) in 79% yield as an orange solid: mp 64.9–66.0 °C; 1H NMR (400 MHz, DMSO-d6) δ 7.84 (dd, J = 7.8, 2.3 Hz, 1H), 7.30 (t, J = 7.6 Hz, 1H), 7.21 (d, J = 7.7 Hz, 1H), 7.09–7.00 (m, 1H), 5.66 (d, J = 10.0 Hz, 1H), 5.52–5.39 (m, 3H), 5.27 (s, 1H), 4.17 (d, J = 9.8 Hz, 1H), 3.22 (s, 3H), 2.37 (d, J = 23.2 Hz, 1H), 2.18 (d, J = 23.3 Hz, 1H), 1.69 (q, J = 6.9 Hz, 2H), 0.70 (q, J = 0.7 Hz, 3H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 139.5, 132.4, 129.8, 129.2, 128.9, 127.2, 125.6, 123.9, 56.6, 8.7; δd 174.0, 144.1, 117.5, 80.5, 50.4, 33.2, 26.3; GC (method B) tR = 3.233 min; EI-MS m/z (%) 397.1 (M+, 1), 365.0 (5), 292.0 (7), 259.9 (13), 239.0 (16), 230.9 (100), 202.9 (4), 164.0 (25), 134.0 (4), 107.0 (26), 90.0 (17), 79.0 (43); HRMS (ESI) calcd for C17H21O2NI [M + H]+ 398.0617, found 398.0611.

N-(2-Bromophenyl)-1-isopropyl-N-(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (1e). Using the general procedure for MOM group protection, secondary amide S2e (1.10 g, 3.43 mmol, 1.0 equiv) in THF (24 mL, 0.14 M) was alkylated with chloromethyl methyl ether (0.51 mL, 6.86 mmol, 2.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1e (1.01 g, 2.77 mmol) in 81% yield as an orange solid: mp 70.2–71.5 °C; 1H NMR (400 MHz, DMSO-d6) δ 7.61 (dd, J = 7.6, 1.8 Hz, 1H), 7.33–7.19 (m, 3H), 5.62 (s, 1H), 5.46 (s, 1H), 5.40–5.20 (m, 3H), 4.27 (s, 1H), 3.28 (s, 3H), 2.44–2.34 (m, 1H), 2.33–2.12 (m, 2H), 0.75 (s, 6H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 133.2, 133.1, 130.0, 128.3, 124.5, 56.8, 35.09, 17.8; δd 174.4, 141.1, 124.5, 80.6, 54.4, 26.7; GC (method B) tR = 3.046 min; EI-MS m/z (%) 363.1 (M – 1+, 1), 331.1 (7), 252.1 (10), 213.9 (15), 183.0 (68), 164.1 (64), 121.1 (21), 105.1 (100), 91.0 (15), 79.1 (47), 51.1 (6); HRMS (ESI) calcd for C18H23O2NBr [M + H]+ 364.0912, found 364.0907.

N-(2-Iodophenyl)-1-isopropyl-N-(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (1e-I). Using the general procedure for MOM group protection, secondary amide S2e-I (0.359 g, 0.978 mmol, 1.0 equiv) in THF (6.8 mL, 0.14 M) was alkylated with bromomethyl methyl ether (0.16 mL, 1.96 mmol, 2.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1e-I (0.289 g, 0.703 mmol) in 72% yield as a light orange solid: mp 76.9–79.8 °C; 1H NMR (400 MHz, DMSO-d6) δ 7.90 (d, J = 7.9 Hz, 1H), 7.35 (t, J = 7.6 Hz, 1H), 7.24–7.18 (m, 1H), 7.11 (td, J = 7.7, 1.7 Hz, 1H), 5.70 (d, J = 10.2 Hz, 1H), 5.56 (d, J = 9.8 Hz, 1H), 5.41 (m, 2H), 5.27 (d, J = 10.3 Hz, 1H), 4.23 (d, J = 9.9 Hz, 1H), 3.31 (s, 3H), 2.43 (hept, J = 6.7 Hz, 1H), 2.38–2.18 (m, 2H), 0.88 (d, J = 6.6 Hz, 3H), 0.73 (d, J = 6.6 Hz, 3H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 139.5, 132.3, 129.9, 129.6, 129.1, 128.9, 125.9, 124.7, 124.6, 56.8, 35.8, 26.7, 18.3, 17.6; δd 174.3, 144.1, 102.7, 80.6, 54.3, 26.7; GC (method B) tR = 3.451 min; EI-MS m/z (%) 411.1 (M+, 1), 379.1 (4), 292.0 (10), 260.1 (10), 252.1 (12), 230.9 (100), 202.9 (5), 164.0 (34), 121.1 (15), 105.0 (55), 90.0 (10), 79.0 (26), 51.0 (4); HRMS (ESI) calcd for C18H23O2NI [M + H]+ 412.0773, found 412.0767.

N-(2-Iodophenyl)-N,1-bis(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (1f-I). Using the general procedure for MOM group protection, secondary amide S2f-I (0.503 g, 1.36 mmol, 1.0 equiv) in THF (9.5 mL, 0.14 M) was alkylated with chloromethyl methyl ether (0.41 mL, 5.45 mmol, 4.0 equiv). The crude product was purified by column chromatography (silica, 7:1 hexanes/EtOAc) to afford 1f-I (0.506 g, 1.22 mmol) in 90% yield as a dark yellow oil: 1H NMR (400 MHz, DMSO-d6) δ 7.88 (dt, J = 8.2, 2.0 Hz, 1H), 7.37–7.31 (m, 1H), 7.27–7.20 (m, 1H), 7.12–7.05 (m, 1H), 5.66–5.57 (m, 2H), 5.56–5.42 (m, 2H), 5.32 (s, 1H), 4.21 (d, J = 9.9 Hz, 1H), 3.60 (d, J = 8.7 Hz, 1H), 3.35 (d, J = 8.8 Hz, 1H), 3.28 (s, 3H), 3.24 (s, 3H), 2.49–2.19 (m, 2H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 139.5, 132.6, 129.9, 128.9, 126.9, 126.5, 126.3, 124.3, 59.3, 56.6; δd 172.6, 143.6, 102.6, 80.3, 80.0, 51.3, 26.4; GC (method B) tR 3.399 min; EI-MS m/z (%) 413.1 (M+, 1), 337.0 (7), 289.9 (9), 259.9 (6), 245.1 (9), 231.9 (100), 202.9 (4), 180.0 (4), 164.0 (9), 121.0 (6), 105.0 (44), 90.0 (34), 77.0 (16), 65.0 (4), 51.0 (4); HRMS (ESI) calcd for C17H21O3NI [M + H]+ 414.0566, found 414.0557.

1-Benzyl-N-(2-bromophenyl)-N-(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (1h). Using the general procedure for MOM group protection, secondary amide S2h (0.996 g, 2.71 mmol, 1.0 equiv) in THF (19 mL, 0.14 M) was alkylated with bromomethyl methyl ether (0.44 mL, 5.41 mmol, 2.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1h (1.03 g, 2.49 mmol) in 92% yield as a yellow oil: 1H NMR (400 MHz, CDCl3) δ 7.48 (s, 1H), 7.23–7.16 (m, 1H), 7.17–7.11 (m, 3H), 7.11–7.05 (m, 4H), 5.69 (d, J = 10.2 Hz, 1H), 5.63 (s, 1H), 5.52 (s, 1H), 5.41 (s, 1H), 5.01 (s, 1H), 4.28 (d, J = 10.0 Hz, 1H), 3.43 (s, 3H), 3.19 (d, J = 13.1 Hz, 1H), 3.07 (d, J = 13.2 Hz, 1H), 1.93 (s, 2H); 13C{1H} NMR (101 MHz, CDCl3) δu 132.8, 131.4, 129.3, 129.1, 127.3, 126.3, 125.9, 125.5, 123.4, 57.1; δd 174.7, 140.3, 137.4, 124.0, 80.2, 51.4, 46.6, 26.0; GC (method A) tR = 18.724 min; EI-MS m/z (%) 413.2 (M + 1+, 1), 379.1 (4), 288.0 (9), 240.1 (26), 213.9 (8), 184.9 (30), 168.0 (32), 152.0 (6), 105.0 (99), 91.0 (100), 79.0 (16), 65.0 (7); HRMS (ESI) calcd for C22H23O2NBr [M + H]+ 412.0774, found 412.0767.

1-Benzyl-N-(2-iodophenyl)-N-(methoxymethyl)cyclohexa-2,5-diene-1-carboxamide (1h-I). Using the general procedure for MOM group protection, secondary amide S2h-I (0. 501 g, 1.204 mmol, 1.0 equiv) in THF (8.4 mL, 0.14 M) was alkylated with chloromethyl methyl ether (0.37 mL, 4.82 mmol, 4.0 equiv). The crude product was purified by column chromatography (silica, 9:1 hexanes/EtOAc) to afford 1h-I (0.470 g, 1.02 mmol) in 85% yield as a yellow oil: 1H NMR (400 MHz, DMSO-d6) δ 7.80 (d, J = 8.2 Hz, 1H), 7.24 (t, J = 7.6 Hz, 1H), 7.19–6.97 (m, 7H), 5.59–5.40 (m, 4H), 5.13 (s, 1H), 4.19 (d, J = 9.9 Hz, 1H), 3.24 (s, 3H), 3.02–2.90 (m, 2H), 2.10–1.93 (m, 2H); 13C{1H} NMR (101 MHz, DMSO-d6) δu 139.5, 132.4, 131.5, 129.9, 129.2, 128.8, 127.7, 127.6, 126.3, 125.5, 123.8, 56.7; δd 173.8, 143.9, 137.6, 115.1, 80.7, 60.1, 51.3, 46.8, 26.1; GC (method A) tR = 19.957 min; EI-MS m/z (%) 459 (M+, 1), 427.1 (6), 336.0 (15), 300.0 (6), 292.0 (10), 259.9 (10), 259.9 (20), 240.1 (42), 230.9 (70), 213.1 (4), 196.0 (5), 168.0 (31), 150.9 (7), 105.0 (98), 91.0 (100), 79.0 (18), 65.0 (8); HRMS (ESI) calcd for C22H23O2NI [M + H]+ 459.0695, found 459.0696.