Summary

The manuscript reviews the research on economic and environmental benefits of second-life electric vehicle batteries (EVBs) use for energy storage in households, utilities, and EV charging stations. Economic benefits depend heavily on electricity costs, battery costs, and battery performance; carbon benefits depend largely on the electricity mix charging the batteries. Environmental performance is greatest when used to store renewable energy such as wind and solar power. Inconsistent system boundaries make it challenging to compare the life cycle carbon footprint across different studies. The future growth of second-life EVB utilization faces several challenges, including the chemical and electrical properties and states of health of retired EVBs, the rapidly decreasing costs of new batteries, and different operational requirements. Measures to mitigate these challenges include the development of efficient diagnostic technologies, comprehensive test standards, and battery designs suitable for remanufacturing. Further research is needed based on real-world operational data and harmonized approaches.

Subject areas: Economics, Electrochemical energy storage, Energy sustainability, Environmental analysis

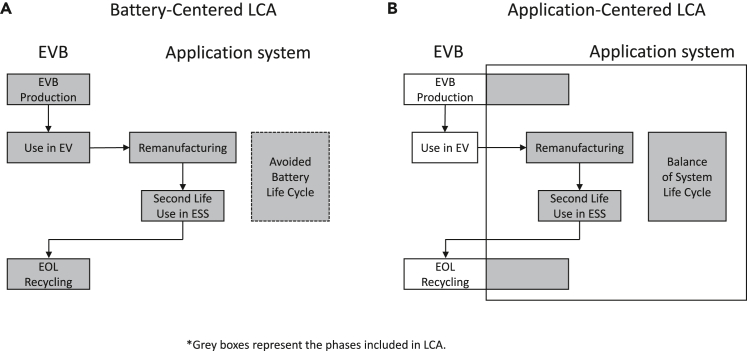

Graphical abstract

Economics; Electrochemical energy storage; Energy sustainability; Environmental analysis

Introduction

Lithium-ion batteries (LIBs) are currently the most suitable energy storage device for powering plug-in hybrid electric vehicles (PHEVs) and battery electric vehicles (BEVs). Hereafter, we refer to PHEVs and BEVs together as EVs. Since retired electric vehicle batteries (EVBs) are expected to retain 70%–80% of their initial energy capacity, they can find second-life use in energy storage applications which require lower performance than EVs.1,2,3,4,5

A growing body of literature has examined the economic and environmental burdens and benefits associated with EVB second-life use. In this study, we review the literature on EVB second-life use to evaluate economic and environmental performance and to highlight key uncertainties to guide future research. This review encompasses 32 studies of application cases, 12 studies of challenges related to second-life EVB applications, 14 studies of economics, and 10 studies of life cycle energy and carbon emissions.

EV and EVB industry

According to the International Energy Agency (IEA),6 about 3 million new EVs were sold globally in 2020 accounting for 4% of total vehicle sales. The primary EV markets were China, the United States, and Europe. The IEA has analyzed the future EV market based on 2 scenarios, Stated Policies Scenario (SPS) and Sustainable Development Scenario (SDS). In the SPS, the global EV stock (excluding two/three-wheelers) expands from about 11 million in 2020 to 145 million in 2030 (7% of the global vehicle stock), and the BEV share of EVs reaches 67% in 2030. In the SDS, the global EV stock increases to 230 million vehicles, EVs account for about 12% of the global vehicle stock, and the BEV share of EVs is 71% in 2030.

The European Union recently announced a ban on the sale of new petrol and diesel cars from 2035.7 In addition, more than 20 governments have committed to phasing out sales of internal combustion engine vehicles within the next 10–30 years.6 Consequently, there will be a substantial surge in demand of EV batteries in the coming decade, projected to reach 1.6 TWh in the SPS and 3.2 TWh in the SDS, as compared to global production of 0.16 TWh in 2020. The global automotive battery market was valued at $43 billion in 2020, and it is expected to reach $59 billion by 2026.8

Battery retirement

The lifetime of LIBs ranges from 5 to 15 years and the cycle life varies from 1000 to 10,000.9 The volume of retired EVBs is expected to increase exponentially driven by increasing deployment of EVs as a green transportation choice.10 Chen and colleagues11 estimate that 1 million EVB packs will be retired in 2030 and 1.9 million in 2040. IEA estimated that 100–120 GWh of EVBs will be retired by 2030,12 a volume roughly equivalent to current annual battery production while McKinsey put the expected global supply of second-life batteries at 15 GWh by 2025 and 112–227 GWh by 2030.13

Various circular economy approaches are being explored for retired EVBs, including recycling and second-life applications. Second life involves repurposing retired EVBs for use in other fields, either at pack or at module level. Recycling involves the separation and purification of battery materials for use in new batteries following their first or second-life usages. The growing production of EVs has resulted in a significant surge in demand for lithium and cobalt, which has led to increased interest in recycling.14,15,16

Several literature studies have discussed the benefits of second-life use of batteries retired from the transportation sector.17,18,19,20 The studies concluded that retired EVBs are suitable for services requiring lower energy storage performance than needed for EVs. Using retired EVBs may reduce the installation cost of energy storage system (ESS). Finally, retired EVBs can be utilized to facilitate increased use of intermittent renewable energy sources.

Battery costs

The costs of new and retired EVBs are expected to decline reflecting market competition and technology progress. Table 1 summarizes literature costs for new and retired EVBs. Care is needed when comparing battery cost values in the literature. Costs can refer to battery cells or battery packs. Battery packs include cells, plus electrical connections between the cells, packaging, and the battery management system. Pack costs are typically approximately 20% more than cell costs.21,22 Battery pack costs can refer to the manufacturing cost or to the retail price equivalent which is the cost to the end user. The increase from manufacturing cost to retail price equivalent reflects costs for research and development, warranty, and sales and marketing. The retail price equivalent is typically assumed to be 50% more than the manufacturing cost.21

Table 1.

LIB cost estimates

| Category | Cost per kWh | Note | Reference |

|---|---|---|---|

| New | baseline: $800–1200 in 2010 projection: $400–600 in 2015 $300–400 in 2025 $250–300 beyond 2025 |

Customer (driver) cost | Gerssen-Gondelach et al.31 |

| >$1000 in 2007 $410 (250–670) in 2014 $300 (140–620) in 2014 for leading BEV manufacturers |

Cost to EV manufacturer | Nykvist et al.23 | |

| $270 Euros in 2015 $90–120 Euros in 2030 |

Battery production cost | Rubel et al.24 | |

| Pack: $732 in 2013 $151 in 2022 <$100 by 2026 Cell: $502 in 2013 $120 in 2022 |

Global volume weighted average LIB prices for various end users including both LFPa and NMCb batteries | Bloomberg New Energy Finance25 | |

| $132 in 2030 $92 in 2040 $71 in 2050 |

Cost to EV manufacturer | Mauler et al.26 | |

| $170 in 2020 $70–100 in 2030 $40–50 in 2050 |

Battery production cost | Islam et al.27 | |

| Retired | $150–250 (new EVBs) $19–131 (retired EVBs) $25–49 (repurposing cost) $44–180 (repurposed battery selling price) |

Repurposing cost includes cost of collection, test, and packaging of retired EVBs. | Neubauer et al.28 |

| $232 (new EVBs) in 2017 $72 (second-life battery) in 2017 |

Battery selling price | Li et al.29 | |

| $23–31 (retired EVBs) in 2020 $62–70 (second-life battery) in 2020 |

Battery selling price | Xu et al.30 |

LFP = LiFePO4.

NMC = LiNixMnyCozO2.

New EVBs

Nykvist and Nilsson23 analyzed 85 cost estimates reported in 2007–2014 and found that LIB pack costs decreased by about 14% per year with an average cost of $410/kWh in 2014. Based on an assumed 6%–8% annual decrease in cost after 2020 by the Boston Consulting Group,24 the battery pack manufacturing cost was estimated to decrease from $270 Euros/kWh in 2015 to $90–120 Euros/kWh in 2030. According to BNEF’s 2022 Battery Price Survey25, LIB pack prices, which were above $732/kWh in 2013, fell 79% in real terms to $151/kWh in 2022, and by 2026, average prices will be below $100/kWh.

Mauler and colleagues26 reviewed 22 studies forecasting battery cost (to EV manufacturer) via technological learning, literature, and expert opinions through 2050. LIB pack costs were estimated to be $132/kWh in 2030, $92/kWh in 2040, and $71/kWh in 2050. Technology-specific and bottom-up modeling indicated that costs for advanced LIB batteries such as NMC811 would be approximately $84/kWh in 2050.

Islam and colleagues27 estimate a LIB pack manufacturing cost of $170/kWh for 2020 model year vehicles and ranges of $70–100/kWh for 2030 and $40–50/kWh for 2050 model year vehicles depending on the level of technology progress. These values were used in modeling by the Argonne National Laboratory to assess the cost of advanced vehicle technologies for the US Department of Energy.21

There is general agreement in the literature that the historical trend of decreasing costs for LIBs will continue in the future. However, the rate of future cost decrease is unknown and hence future battery costs are highly uncertain. For example, estimated costs for 2030–2035 in the literature span a range of approximately a factor of 2 as illustrated in figure 11 in Argonne National Laboratory’s report.21

Retired EVBs

Estimates in the literature are that the cost of second-life EVBs is in the range of 20%–80% of new batteries. However, due to their low depth of discharge (DOD), for example, 50%–60% compared to ∼80% for new batteries, the cost per available capacity (kWh) would be significantly higher. Moreover, the remaining lifetime of repurposed batteries adds more uncertainties to the overall value of second-life EVBs.

Considering the battery salvage value of retired EVBs, Neubauer and colleagues28 constructed a framework to estimate the selling price of retired EVBs. They estimated a repurposed battery selling price of $44–180/kWh from a battery health model and a new EV battery price of $150–250/kWh. Based on a purchase price of $19–131/kWh for retired EVBs, the repurposing cost of second-use batteries including labor, equipment, and other recurring costs was estimated to be $25–49/kWh.

According to Liu’s study,29 the price of second-life EVBs for energy storage was $72/kWh, and the price of new EVBs was $232/kWh. Gotion30 estimated that in China, the price of retired EVB was about $23–31/kWh, and the selling price was about $62–70/kWh after testing, screening, and recombination. The McKinsey forecasts the price of second-life batteries at 30%–70% of new batteries in 2025.13

Application of retired EVBs

Fundamentals

Energy storage technologies support transition toward low-carbon and flexible power systems. The China Energy Storage Alliance global storage project database estimates that the global cumulative installed energy storage capacity was 191.1 GW at the end of 2020.32 Pumped hydro accounts for approximately 90% of global energy storage. Electrochemical energy storage is a distant second with a cumulative installed capacity of 14.2 GW in 2020, accounting for 7.5%, up from 5% in 2019.33 LIBs accounted for 92% of electrochemical energy storage technologies in 2020 (see Figure 1).

Figure 1.

Global cumulative installed energy storage capacity in 2020

Battery energy storage systems (BESS) are attractive because of their high efficiency, high energy density, short response time, modularity, installation flexibility, and short construction times. With many EVBs being retired, second-life use is receiving increasing attention. Automotive companies such as Mercedes-Benz,34 Audi,35 BMW,36 Toyota,37 and BAIC Motor38 are exploring second-life use projects using retired EVBs in BESS.

Second-life use types

Second-life use can extend the value of EVBs in the transportation sector into power utility services.5 Second-life batteries can be used in applications requiring lower battery performance such as low-speed EVs (e.g., electric bicycles and tricycles), EV charging stations, communication base stations (CBS), mobile charging devices, and household ESS. Table 2 summarizes typical application scenarios for retired EVBs. In general, second-life use of retired EVBs for energy storage falls into 3 areas of application discussed in the following sections: power generation, grid, and end user.

Table 2.

Application scenarios and cases of second-life EVBs in literature

| Category | Application Scenario | Function | Reference |

|---|---|---|---|

| Power generation side | Centralized renewable energy power station | Renewable energy integration, smoothing control, reducing curtailed electricity | Wind – Hamidi et al.41, Alhadri et al.42, BYD46 PV – Koch-Ciobotaru et al.43, Saez-de-Ibarra et al.44, Leung45, Fitzpatrick71 |

| Grid side | Power transmission and distribution network | Alleviate grid congestion, offer ancillary support to the network, and delay the expansion of power transmission and distribution capacity | Neubauer et al.28, Lacey et al.47, Eyer and Corey48 |

| End-user side | Communication base station | Backup power storage | Li49, Yan50 |

| EV Charging stations | EV Charging | Jiao et al.51, Han et al.52, Kamath et al.53 | |

| Mobile energy storage device | Community EV Charging | Potevio New Energy72 | |

| Power supply for camping trailers | Nissan Energy54 | ||

| Low-speed electric vehicle | EV energy storage | Zhang et al.55, Zhao56 | |

| Street lamp | Energy storage for lamp | Zhu et al.57 | |

| Uninterrupted Power Systems (UPS) | Emergency power | Canals Casals et al.58, Neubauer et al.73 | |

| Residential energy storage | Emergency power, reduce electricity costs | Heymans et al.59, Kamath et al.74, Tang et al.75, Faria et al.76, Saez-de-Ibarra et al.77 |

Power generation applications

Renewable energy technologies including solar photovoltaics (PV) and wind turbines are developing rapidly driven by increasing concerns over climate change. However, renewable energy sources are intermittent and unpredictable. Their connection to the electric grid will make it difficult to manage the power system and maintain its stability.39 Energy storage is used to smooth the intermittent output of renewable power plants, which will improve reliability and thus facilitate deployment of renewable energy.40 Retired EVBs provide an opportunity of developing energy storage for renewable electricity including the off-grid solar and wind power.9

For wind power generation, Hamidi and colleagues41 developed a micro-grid EV charging model using retired LIBs for energy storage to serve as an energy buffer and provide emergency energy upon loss of the grid. Alhadri and colleagues42 developed a sizing model to connect a second-life battery ESS to a wind turbine to manage energy fluctuations.

For PV power generation, Koch-Ciobotaru and colleagues43 proposed a generic model of second-life battery ESS for providing variability smoothing service for a PV power plant and determined the optimal size of the system based on real-world data from a PV plant. Saez-de-Ibarra and colleagues44 used a similar model and approach to size the optimal system and estimated realistic current demand profiles for second-life battery cells, which can be used as a basis for laboratory battery testing. Leung45 developed a PV self-consumption model to assess second-life lithium iron phosphate (LFP) batteries for users to estimate solar energy generation for immediate or deferred consumption.

Regarding real-world implementation, a 1.2 MWh test project took place in Hebei Province, China in 2016, where retired batteries from BYD K9 electric buses were utilized for wind and PV energy storage. This initiative was part of a demonstration project that integrated wind and solar PV energy with energy storage and intelligent power transmission.46 In the US, B2U Storage Solutions operates a 25 MWh hybrid solar and storage facility in Lancaster, California, incorporating 1,300 second-life EV batteries. The company employs a technology that enables the use of existing management systems in EV batteries, resulting in a significant reduction in repurposing costs.

Grid applications

Matching power generation and demand is a crucial subject in the power industry. Lacey and colleagues47 studied the application of ESS in power grids based on a simulation model and concluded that public utilities must design transmission and distribution systems suitable for peak load requirements. Eyer and Corey48 characterized 26 benefits associated with grid energy storage grouped into six categories: electric supply, ancillary services, grid system, end user/utility, customer, renewables integration, and incidental. Neubauer and colleagues28 noted that there are many functions energy storage can provide when connected to the grid, including control of frequency, peak shaving, and relieving transmission congestion.

End-user applications

Potential uses for second-life batteries include CBS, EV charging stations, mobile energy storage, streetlamps, uninterruptible power systems, and residential energy storage.

Li49 studied the feasibility of using second-life batteries in communication base station CBS and concluded they could be used directly and would be profitable in most working conditions. In view of the characteristics of the base station backup power system, Yan and colleagues50 proposed a design scheme for the low-cost transformation of the decommissioned stepped power battery to use in the communication station as a backup power system.

Jiao and colleagues51 studied the use of second-life EVB energy storage in EV charging stations based on a mathematical model. Han and colleagues52 studied the economics of second-life battery in PV combined energy storage charging station using optimized configurations of the PV array and battery system and incorporating actual operation data of the PV combined energy storage. Kamath and colleagues53 analyzed the scenario of second-life LIBs as fast-charging energy storage in terms of economic cost and life cycle carbon emissions. Nissan Energy54 proposed a smart camping recharge system with second-life Nissan EV batteries that can supply the power for one week camping.

Retired EVBs can potentially be used for low-speed electric vehicles such as meal delivery electric bicycles, street sweeping sanitation electric tricycles, and garbage-loading four-wheelers.55,56

Solar streetlamps are suitable for second-life EVBs because of the small energy storage requirement, low charge and discharge rate, and shallow DOD. Zhu and colleagues57 verified the feasibility of second-life EVBs use in solar streetlamps through experiments.

Uninterruptible power systems are designed to supply electrical and electronic equipment with constant power during power outages or state of emergency.9 Casals and colleagues58 estimate that retired EVBs have a useful life of 24 years in uninterruptible power systems based on a battery aging model.

As for residential energy storage, the use of second-life EVBs for energy storage and peak shaving is a strategy that can provide cost savings to residential users. In addition, shifting power from peak demand to off-peak demand times reduces strains on the electric grid.59

Technical challenges in second-life use of retired EVBs

A major challenge with second-life use of retired EVBs is their wide variety of designs differing in their size, electrode chemistry, configuration, and states of health, resulting in complexity in repurposing for second-life usage. Different battery cells have different internal impedances, capacities, and self-discharging rates. In a standard battery structure, there is a possibility of unbalancing between different used battery cells when connected in a string. The traditional equalization methods i.e., capacitor balancing and resistive balancing methods60,61,62,63,64 may not work because they are designed to mitigate small imbalances in battery strings.

Designing dependable and secure energy storage systems is a significant obstacle when it comes to using retired electric vehicle batteries for a second life. The impact of battery aging on safety is receiving increased attention. As LIBs age, active materials such as electrolyte and reversible lithium ions are gradually lost, a passivation film is gradually formed, and the reactivity of the battery gradually decreases, so the heat release rate decreases and thermal runaway temperature rises.65,66,67 Zhang and colleagues67 found that the thermal runaway temperature increased from about 180°C to 195°C as the battery capacity decreased from 92.5% to 68%. Feng and colleagues68 found that thermal runaway would not happen when the battery with a state of health of 80% is overcharged at charging rate below 0.5C (charging at rate which will provide full battery charge in 2 h).

There are safety and operational performance test standards for the second-life use of batteries such as UL 1974 and IEC 62933-5-3, which outline testing procedures for cells, modules, and packs. However, the standards lack specific details and the varying quality of retired battery poses challenges in developing comprehensive test standards to ensure battery safety and operational performance.69,70 To effectively evaluate retired EV batteries in terms of remaining life, chemistry, and other performance aspects, there is a pressing need for more robust standards.13,70

On the other hand, Börner and colleagues70 discussed the challenges related to operational requirements in stationary energy storage systems and the supply of retired batteries. While EV batteries prioritize high energy density, home storage systems typically undergo one cycle per day with a significant DOD. On the other hand, peak-shaving industrial storage systems require multiple cycles per day highlighting the importance of cycle lifetime. They concluded that retired EVBs from commercial EVs, such as long-haul trucks, may serve as the optimal sources for stationary energy storage due to their larger battery size and potentially well-managed operation mode. Additionally, designing a multi-life battery system is a promising strategy to optimize cost and resource utilization across multiple usage scenarios.

Economic analysis

In general, economic analysis of investment projects is divided into two types, static and dynamic methods. Static methods do not consider the effect of time, treating values uniformly across years. Calculations involve summing expected costs and benefits or selecting average values from a specified period. The most frequently mentioned static methods for investment evaluation include total cost, annual cost-benefit method, and payback period.

Dynamic methods consider changes in cash flows and their economic benefits throughout the project life cycle accounting for the time value of money. Dynamic methods are mainly used for: (1) final decision on program in a detailed feasibility study and (2) evaluation of projects with long life cycles and large differences in the distribution of phased costs and revenues.78,79 The most frequently mentioned and described dynamic methods for investment evaluation include levelized cost of electricity (LCOE), net present value (NPV), and discounted payback period. Table 3 summarizes economic analyses of second-life EVBs.

Table 3.

Analysis of second-life EVBs by economic methods

| Method | Scenarios | Cost and Technical Parameters | Research conclusions | Reference |

|---|---|---|---|---|

| Payback period (PP) | Residential, industrial, and PV power plant application | Repurposed battery cost; operation & maintenance (O&M) cost; peak hour tariff; government electricity cost; number and lifetime of batteries | For residential application in Ahvaz, Iran, repurposed EVBs are not economical, i.e., PP is > 10 years. Industrial and PV plant applications were economical with PP of 2.7–9.1 and 3.6–4.9 years, respectively. |

Mirzaei Omrani and Jannesari80 |

| Residential energy storage for peak lopping, even discharging, and PV | Capital costs; electricity costs; lopping threshold; even discharge rate; hourly discharge limit; overnight charge level | The most beneficial residential operating scenario of second-life battery use is with PV generation with a PP of 14 years. For peak shaving and even discharging, second-life battery use is not economical with a PP of 30 and 25 years, respectively, longer than the battery lifetime of 16 years. | Gladwin et al.81 | |

| Uninterruptible Power System (UPS) energy storage | Used and new battery price; repurposing cost; capital and recurring cost; end-user revenue, i.e., quality & reliability (Q&R) value, time-of-use (TOU) and demand charge (DC) | Potential economic benefits over lead-acid batteries in the commercial and industrial UPS applications. PP is 6.9–10.3 years considering Q&R value. Adding TOU and DC service extends PP due to additional cost. |

Neubauer et al.73 | |

| Levelized cost of electricity (LCOE) Levelized cost of electricity (LCOE) |

Residential energy storage with PV; Utility peak shaving; Utility PV firming |

Costs of battery, PV, and inverter; Electricity prices; discount rate and inflation; project lifetime; efficiency and lifetime of battery, PV, and inverter; PV derating factor |

When replacing new LIBs, SLBs reduce LCOE by 12%–57%. Compared to no battery baseline, LCOE of SLB with residential PV decreases 15%–25% but that with utility PV firming increases by up to 74%, except for Detroit with 8% reduction. LCOE of SLB utility peak shaving decreases 39% in Michigan but increases 61% in Oregon. | Kamath et al.74 |

| EV fast-charging systems | Costs of battery, PV, and inverter; Electricity prices; discount rate and inflation; project lifetime; efficiency and lifetime of battery, PV, and inverter; battery materials replaced; PV derating factor; maximum grid power |

Replacing new with retired LIBs for energy storage reduces LCOE by 12%–41%. Compared with no battery baseline, adding second life EVBs reduces the LCOE compared to grid only for cities with high demand charges or peak electricity price. | Kamath et al.53 | |

| Second-life battery energy storage system (BESS) | Battery capacity, energy to power ratio; state of health, DOD, replacement interval, charging cost, and roundtrip efficiency; project years; operating days; construction time; discount rate; total capital cost; O&M; new and SLB module market and repurposing cost; capacity degradation | For a 15-year time horizon, levelized cost of storage (LCOS) of second-life BESS is $234–278/MWh while that for new BESS is $211/MWh. Total capital cost for second-life BESS is 64%–79% of new BESS. The results are most sensitive to discount rate, DOD, and repurposing cost. |

Steckel et al.82 | |

| Net Present Value (NPV) Net Present Value (NPV) |

PV combined energy storage charging station | EV charging income; subsidies; discount rate; cost and service life of PV and conventional and second-use battery energy storages; O&M costs; electricity prices; cost of testing & restructuring | The annual cumulative NPV of the PV charging station with second-life LFP battery is higher than that with the conventional energy storage system. | Han et al.52 |

| Distributed solar photovoltaics (DSPV) with reused batteries as energy storage systems (RBESS) | Cost of solar panel and balance of system; electricity tariff; subsidies; labor cost; reused battery cost and residual value after reuse; replacement cost; insolation; PV and battery capacity and losses | NPV of RBESS with DSPV in the residential sector is negative for most regions, while that for the commercial/industrial sector is mostly positive because of favorable load profiles. | Bai et al.83 | |

| Distributed PV system with EVB under sharing business model scenarios | Power load profile; solar irradiation; battery degradation; charging/discharging efficiency; state of charge; cost of repurposed battery, installation, and end-user system; maintenance cost; electricity price and feed-in-tariff; discount rate | Among scenarios of S1 (no storage/no PV), S2 (SLB/no PV), S3 (SLB/shared PV-same users), and S4 (SLB/shared PV-different users), the highest NPV, 2,287–3,205 RBM/kWh, is achieved for S4 between office and residential users. | Tang et al.75 | |

| Home energy storage - Distributed electrical storage appliances | New and repurposed battery cost; power conditioning, controls, interfaces; accessories, facilities, shipping, catch all; O&M; Installation, residential circuitry; benefits of application; discount rate | Net present residual value for energy storage of multiapplication combination with a 10-year service life: $397 (Prius PHV battery); $1,510 (Volt battery); $3,010 (Leaf battery) Reductions in monthly battery lease payment during the 8-year first life in EV: 11% (Prius PHV); 22% (Volt); 24% (Leaf) |

Williams84 | |

| Load-shifting in communication base station (CBS) | Project lifetime; cost of SLB purchasing, remanufacturing, installation, replacement and maintenance; VAT; battery lifetime; peak-off-peak electricity prices; subsidy; battery capacity and electricity losses | Load shifting with SLB (case 2) saves life cycle cost by 17.6% compared to grid-only scenario (case 1). New LIB (case 3) is not profitable with negative NPV throughout the project lifetime. Battery purchasing accounts for 61.9% and 91.1% of the total cost for case 2 and case 3, respectively, while the revenue from load shifting is 83.7% and 84% of the total revenue for each case. |

Yang et al.85 | |

| Dynamic payback period (DPP) | Battery energy storage system | Cost of initial investment, operation, and battery replacement; income from balancing power load, subsidy, and battery residual value; social value of postponing grid upgrade, increased grid reliability, reduced carbon emissions | DPP of old battery energy storage is 15 years, while that of new battery energy storage is 20 years. Key determining factors are battery cost, government subsidies, and electricity prices. |

Zhang et al.86 |

| Residential, industrial, and PV power plant application | Repurposed battery cost; O&M cost; peak hour tariff; government electricity cost; number and lifetime of batteries; discount rate; inflation | For an interest rate of 9%, use of second-life battery packs is more economical in the industrial than the residential sector. For PV power plants, DPP is ∼5 years. |

Mirzaei Omrani and Jannesari80 |

Payback period

Payback period is the time required to recover all investment with the net income of a project. Omrani and Jannesari80 evaluated payback periods for second-life EVB use in residential, industrial, and PV power plant applications in Ahvaz, Iran. Repurposed EVBs were not economical for residential, but were economical for industrial, and PV power plant applications.

Gladwin and colleagues81 found that the most beneficial operating scenario for second-life EVB energy storage from the householder point of view is when storage is used in conjunction with PV generation. The payback period using 22.4 kWh of second-life EVBs was 14 years, slightly shorter than the predicted battery lifetime of 16 years. For residential peak shaving and even discharging, the payback time exceeded the lifetime of second-life EVBs.

In an economic analysis by Neubauer and colleagues,73 the potential benefits over lead-acid batteries were realized when using repurposed EVBs in an uninterruptible power system energy storage in commercial and industrial facilities, which have an estimated payback time of 7 years.

LCOE

The LCOE is the average total cost to build and operate a power-generating asset divided by the total energy output of the asset over its lifetime. The LCOE can also be regarded as the minimum cost at which electricity must be sold to breakeven over the lifetime of a project.

Kamath and colleagues53,74 evaluated the costs of using second-life EVBs with PV in residential and in EV fast-charging systems and reported economic benefits (see Table 3) in some applications. The key determining factors of LCOE were electricity cost structure, second-life battery cost and performance, and solar insolation.

Steckel and colleagues82 applied a levelized cost of storage (LCOS) methodology to evaluate the costs of battery ESS using second-life EV batteries. The LCOS using second-life batteries was estimated to be $234–278/MWh while that using new batteries was $211/MWh. Despite substantially lower upfront costs, it was determined that second-life batteries are not economically competitive. The difference in conclusions in the studies reflects different input assumptions. For example, Steckel and colleagues82 assumed a second-life battery cost including repurposing cost of $117/kWh while Kamath’s team74 assumed $65/kWh. For new batteries, Steckel and colleagues82 assumed $151/kWh while Kamath and colleagues74 assumed $209/kWh.

NPV

NPV represents the current value of a future series of payments and revenues and positive NPV signals investment is worthwhile. Han and colleagues52 studied an EV charging station using PV combined energy storage and found that the cumulative NPV using second-life LFP batteries is higher than using a conventional BESS. Bai and colleagues83 studied the potential NPV of distributed solar photovoltaics with retired EVBs for ESS in China. They found that for most regions, the NPV was negative in the residential sector but positive in the commercial/industrial sector because of the different load profiles. Tang and colleagues75 studied the NPV of repurposed EVBs in a distributed PV system under sharing business models, and reported that the maximum NPV can be achieved if the PV ESS is shared between office and residential users.

Williams84 analyzed the cost of battery leasing scenarios for plug-in vehicles in California when the retired battery is repurposed for distributed electrical storage. The NPV of energy storage over a 10-year service life was estimated to be $397, $1510, and $3010 using retired Prius, Volt, and Leaf batteries, respectively, which reduced monthly leasing payments by 11%, 22%, and 24% during the 8-year battery leasing period corresponding to the first life in EVs.

Yang and colleagues85 examined the NPV of load-shifting system in a CBS using second-life EVB over a 10-year project lifetime by evaluating the expenses of battery purchasing, remanufacturing, installation, maintenance, and replacement, as well as the revenues from subsidy and load shifting between peak and off-peak periods. The cash flows of the project indicate that load shifting based on second-life EVB is economically justified, while using new LIB is unprofitable as NPV is negative throughout the project lifetime.

Dynamic payback period

The dynamic payback period is the time when the cumulative present value of net cash flows equals zero. To calculate the dynamic payback period, the net cash flow of each year in the project needs to be discounted into the present value using the benchmark rate of return.

Zhang and colleagues86 assessed the economics of grid energy storage using second-life and new batteries over a 30-year operating period in China. The key cost categories for batteries are the costs of battery purchase, battery cabinet, and distributing electrical equipment. The results show that the payback period of second-life and new battery energy storage is 15 and 20 years, respectively. For the range of input assumptions considered by Zhang et al., the dynamic payback period for new battery storage was always longer than that for second-life battery storage.

Omrani and Jannesari80 studied dynamic and normal payback periods for retired EVBs used in load leveling and peak shaving in residential, industrial, and PV power plant applications in Iran. They found that residential second-life battery ESS is not economical but industrial applications would be economical with relatively short dynamic payback periods.

Yang and colleagues85 examined the dynamic payback time of load-shifting scenarios for CBS based on annual cash flows; the repurposed battery scenario had a payback time of 5.2 years, but the new LIB scenario did not reach payback within the 10-year project lifetime.

Summary

In summary, studies use various economic indicators to measure the cost and benefit of second-life battery applications. Compared with new EVBs and lead-acid batteries, the use of second-life EVBs exhibited favorable economics in terms of payback period, LCOE, and NPV for most application scenarios in the literature. The exception is the study by Steckel and colleagues82 that used conservative technical and cost parameters for utility-scale ESS. Compared with no battery baselines, the economic benefits of second-life batteries range widely depending on data and modeling assumptions. Overall, the key determining factors of the economic benefits include electricity pricing structures such as peak electricity price and demand charge, cost of purchasing and repurposing second-life EVBs, battery performance parameters such as efficiency, DOD, and lifetime, and other factors such as discount rate, utilization rate of battery, and solar insolation.

Life cycle assessments

Literature life cycle assessments (LCAs) evaluated the environmental benefits of second-life EVBs. LCA is a standardized methodology to quantify the environmental impacts of a product or service along its life cycle, considering the use of resources and the emissions to the environment.87,88,89 In this review, we focus on the analyses of greenhouse gas (GHG) emissions and primary energy, which are globally accepted and widely used impact indicators for the automotive LCA.90

According to vehicle LCAs, the GHG emissions over the lifetime of a mid-sized electric passenger car are considerably lower than those of a comparable gasoline car.21 Bieker91 found that the GHG emission savings from electric cars are 19%–34% in India, 37%–45% in China, 60%–68% in the US, and 66%–69% in Europe. Hill and colleagues92 estimated that for the average EU-28 electricity mix, the life cycle global warming potential (GWP) of BEV is 55% lower than that of gasoline ICEV. The second-life use of EVBs could further reduce GHG emissions from the EV life cycle depending on the battery performance and LCA approach.

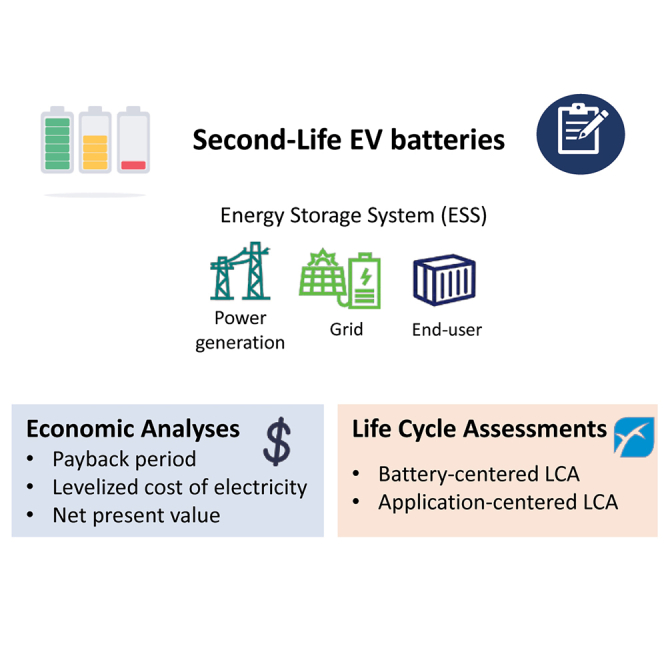

Depending on the research goal and scope, literature LCAs for second-life EVBs can be categorized into battery-centered and application-centered. As shown in Figure 2A, battery-centered LCAs analyze the life cycle of EVBs encompassing the first life in EV and the second life in ESS. In this type, the system boundary typically includes battery production, use in EV, remanufacturing, second-life use, and end of life. The functional unit is an EVB pack or its lifetime energy storage service. The system boundary is often expanded to account for the avoided impacts, such as those from using lead-acid battery. This approach primarily aims to prevent the allocation of battery production impacts between the first and second usages, which is a recommended practice in LCA.88,93 Alternatively, LCAs can compare EVB energy storage with functionally equivalent system, for example, a coal peaking power plant.

Figure 2.

System boundary of (A) battery-centered and (B) application-centered LCA in the literature

Application-centered LCAs focus on evaluating the impact of application systems (e.g., PV with ESS). As shown in Figure 2B, the second life of EVBs (repurposing and second use in ESS) is considered as a subsystem of the application system. The impacts of production and end of life of EVB can be allocated between the first life in EV and second life in ESS depending on LCA approach. The functional unit in this LCA type is typically the application system over a certain period of operation. Literature LCAs often compare the second-life EVB scenario with scenarios of using new, or no, batteries in the application system. Tables 4, 5, and S1 in supplemental information summarize LCAs for second-life EVBs.

Table 4.

Summary of battery-centered LCAs

| Scenarios | Functional Unit | Goal/Approach | Key Assumptions/parameters | Results | Reference |

|---|---|---|---|---|---|

| LFP battery with ESS second life | LFP battery delivering 35,040 kWh in EV and 29,004 kWh in ESS | Compare conventional gasoline vehicle + natural gas stationary power scenario versus cascaded EV + ESS by SLB scenario | Analysis based on total kWh delivered by battery in EV and ESS use. Use phases based on grid mix of Ontario, Canada (hydro + nuclear power >80%) | Echelon use EV + ESS scenario has lower GWP than conventional gasoline vehicle + natural gas scenario | Ahmadi et al.1 |

| LFP and NMC battery with ESS second life | 1 kWh battery capacity | Compare life cycle impacts between LFP and NMC including second use in ESS in the system boundary. | Charging-discharging losses and energy use associated with battery mass in EV were included. Use in ESS is the electricity loss from charging-discharging cycle considering the capacity decay of LFP and NMC battery. Average grid mix of China used. |

LFP battery has higher overall impacts than NCM due to its longer lifetime and greater energy losses during secondary use in ESS. | Quan et al.94 |

| EVB with ESS second life | 24 kWh LiMn2O4 EV battery pack | Compare EVB with first use only versus EVB with cascaded first and second use scenario considering avoided lead-acid battery impact. | Charging-discharging losses and energy use associated with battery mass in EV were included. Use in ESS is battery transport to ESS site and charging-discharging loss. 50% of cell repurposed. SLB lifetime is 5 years. |

EVB with secondary use scenario results in 15% reduction of life cycle energy and carbon footprint. | Richa et al.95 |

| LFP battery with ESS second life | 1 kWh battery capacity | Evaluate LFP battery in China including second life in ESS and considering avoided impact of lead-acid battery. | Net impact evaluated based on 1-year and 10-year secondary service lifetime. 50% of the battery is reusable |

Use in ESS is the key determinant of net CO2 emissions. 1-year lifetime scenario increases net emissions by 111–129 kg CO2e. 10-year scenario decreases net emissions by 178–197 kg CO2e. | Wang et al.96 |

Table 5.

Summary of application-centered LCAs

| Scenarios | Functional Unit | Goal/Approach | Key Assumptions/parameters | Results | Reference |

|---|---|---|---|---|---|

| Stationary energy storage | Stationary energy storage delivering 150 kWh per day for 20 years | Compare SLB versus lead-acid battery used in ESS. Production and recycling impact is allocated between first and second life. |

Use phase is battery transport to ESS site and charging-discharging loss. US grid mix assumed. Cutoff allocation used (no EVB production impact) for the baseline case. |

SLB scenario reduces life cycle energy and carbon emissions by 12%–46% and 13%–46%, respectively, compared to lead-acid battery. | Richa et al.95 |

| Residential ESS with PV; Utility PV firming; Utility peak shaving |

Electricity supply for a household; 1 kWh firmed PV electricity delivery; 1 kWh of peak electricity delivery |

Compare GHGs from SLB versus new LIB scenarios in three applications for five locations - Detroit, Los Angeles, New York City, Phoenix, and Portland. | GHGs examined for economically optimized system in each location. Use phase includes electric grid, natural gas peaking, SLB repurposing, and PV and inverter production for 10-year project lifetime. Cutoff allocation used. |

For residential, GHGs with PV + SLB are 22%–51% and 10–44% lower than PV with no and new LIB. For utility-level PV firming, GHGs with SLB are 0.4%–39% lower than new LIBs. For utility peak shaving, GHGs with SLB depend on emission factor of power charging the SLB. |

Kamath et al.74 |

| EV fast-charging system | Electricity delivery for 10,000 EV fast charging for 10 years | Estimate GHGs of four configurations of EV fast-charging station - Grid only, Grid+SLB, Grid+SLB+PV, and SLB+PV in five cities - Detroit, Los Angeles, New York, Phoenix, and Portland. Compare GHGs from SLB versus new LIB scenarios. |

Differences in solar radiation, grid mix, and component design to meet power demand considered for each location. Use phase includes electric grid, SLB repurposing, PV and inverter production for 10-year project lifetime. Cutoff allocation used. |

Compared to grid only, - off-grid SLB+PV saves 42%–75% GHGs. - Grid+SLB increases GHGs in all locations. - Grid+SLB+PV slightly reduces GHGs in some locations. Compared to new LIBs, SLB scenarios save 50%–77% and 7%–15% GHGs in the off- and on-grid cases. |

Kamath et al.53 |

| Repurposed LMO/NMC battery for PV self-consumption in dwellings | Yearly energy balance of system | Compare environmental impacts of SLB scenario with new LIB, no LIB, and diesel generator scenario. | Applied to residential building in Netherlands. Use phase is the difference between electricity input and output of the system. Cutoff allocation used in baseline. |

SLB saves 62% energy and 58% GHGs over new LIB. SLB adds 47% energy and 46% GHGs over no LIB. For off-grid, SLB saves 48% energy and 49% GHGs over diesel generator. |

Bobba et al.97 |

| EV battery second life for energy storage in buildings for peak shaving and load shifting | Daily household energy demand | Assess environmental benefits of using SLB versus grid-only case to meet daily demand in household. | Use phase is daily household electricity consumption Battery capacity degradation and charge-discharge loss considered. Cutoff allocation used. Battery repurposing impact not included. |

Compared to no battery, with French grid, SLB ESS reduces GHGs by 2% and 5% for peak shaving and load shifting, respectively. With Portuguese grid, SLB ESS increases GHGs by 3% and 2% for peak shaving and load shifting, respectively. |

Faria et al.76 |

| SLB as backup energy storage of CBS | 1 kWh electricity delivery to CBS | Compare environmental impacts of SLB with lead-acid battery as backup energy storage of CBS. | Use phase is battery roundtrip and transmission electricity loss. Economic allocation - 33% of battery production and recycling impact allocated to SLB reuse. Chinese grid assumed. |

GHGs are dominated by the battery production and second use stages. SLB use reduces GHGs by 20% compared to lead-acid battery. |

Yang et al.98 |

| SLB in CBS for load shifting | Total electricity delivery to meet CBS demand over 10-year project lifetime | Compare grid only (no load shifting) versus load shifting with SLB and new LIB in China | Economic allocation used. Use phase is charge-discharge electricity loss. Recycling is not included. |

Use phase contributes 79% of GHGs. Compared to no load shifting, load-shifting cases increase GHGs. Load shifting with SLB has higher GHGs than with new LIB due to lower roundtrip efficiency. |

Yang et al.85 |

Battery-centered LCA

Ahmadi and colleagues1 investigated the energy consumption and environmental impacts of LFP EVBs throughout their life cycle cascading into second-life use. The system boundary included the entire manufacturing sequence of LIBs, first use in the EV, repurposing, second use in the ESS for peaking power delivery, and recycling. The life cycle GHG emissions were estimated to be 0.25 kg CO2 e/kWh delivered by the battery pack. The battery pack manufacturing phase generates the most GHG emissions (∼40%), followed by the first and second use phases (31% and 26%), while the remanufacturing phase contributes 3%. Quan and colleagues94 adopted a similar approach in their LCA of LFP and NMC batteries, analyzing the system boundary to include the first use in EV, second-life use in ESS, and recycling. They found that the LFP battery has higher overall life cycle impacts than the NMC battery because the former has a longer lifetime and hence higher energy losses than the latter during secondary use. For example, the LFP battery has a carbon footprint of 441 kg CO2e during the second life in the ESS compared to 181 kg CO2e for the NMC battery. The study by Ahmadi and colleagues1 did not account for the avoided carbon footprint, which would be more significant for the LFP battery than the NMC battery, considering its longer service life in the ESS.

Richa and colleagues95 evaluated the life cycle cumulative energy demand (CED) and GHG emissions of an EVB system with and without stationary second-life use in case 1 of their analysis. The system boundary includes EVB production, first use in EV, stationary second-life use, and EVB recycling. Unlike the previously described studies, Richa and colleagues considered the avoided life cycle impact of incumbent lead-acid battery. The battery use phase in EV is modeled as energy losses in charging and discharging, battery mass-induced energy use, and fuel use of battery transportation from manufacturer to vehicle assembly plant. They found that the avoided impacts of lead-acid battery outweigh the added impacts from remanufacturing and second-life use of EVBs, resulting in a net reduction of 15% in CED and GHG emissions. Similarly, Wang and colleagues96 analyzed the life cycle impacts of LFP batteries for manufacturing, use in EV, repurposing, reuse in ESS, and recycling, compared to the avoided impacts from using lead-acid batteries. The functional unit is 1 kWh battery capacity and 50% of the battery is assumed reusable. Since the electricity loss during ESS operation dominates the second-use impacts in the study, the results are heavily dependent on the lifespan of repurposed battery. For example, the 1-year service life scenario increases the carbon footprint by 111–129 kg CO2e, while the 10-year scenario decreases emissions by 178–197 kg CO2e depending on the subsequent recycling process.

Application-centered LCA

In case 2 of their study, Richa and colleagues95 compared the environmental impacts of a stationary ESS using either a second-life EVB or new lead-acid battery. The functional unit was a stationary ESS delivering 150 kWh per day for 20 years. The system boundary included EVBs repurposing, lead-acid battery production, stationary use (energy losses during charging and discharging), and recycling. Using a cutoff allocation, this study does not include EVB production in the baseline, but a sensitivity analysis explored 50/50 and quality-based approaches to allocate the EVB production impacts between the first and second life. It was found that using second-life EVBs had 12%–46% lower GHG emissions and 13%–46% lower CED depending on the efficiency of lead-acid battery.

Kamath and colleagues74 compared the life cycle GHG emissions associated with using second-life batteries (SLBs) and new LIBs in three applications: residential energy storage with PV, utility PV firming, and utility peak shaving. The functional unit is electricity supply for a household with or without EV, delivery of 1 kWh firmed PV electricity, and electricity delivery to meet 1 kWh of peak demand, respectively, over a project lifetime of 10 years. The system boundary covered battery manufacturing, SLB repurposing, SLB use, PV production, and electricity generation impacts. For residential application, depending on location, the GHG emissions from PV with SLB were 22%–51% and 10%–44% lower than PV with no and new LIB, respectively. For utility-level PV firming, the GHG emissions using SLBs were 0.4%–39% lower than using new LIBs, depending on location. In utility-level peak shaving, the GHG emissions from SLB use depend on the emission factor for the baseload electricity. The SLB peak shaving scenario in Oregon decreased GHG emissions by 27%, whereas in Michigan it increased emissions by 18%, reflecting the fact that the Oregon grid has lower and the Michigan grid has higher carbon intensity than natural gas peaking electricity. However, in both locations, SLBs perform better than new LIBs.

Kamath and colleagues53 evaluated SLB-based energy storage for EV fast-charging systems in terms of CED and GHG. The functional unit is electricity delivery for 10,000 EV fast charging for 10 years. The results show that for off-grid configurations (SLB+PV), the GHG reduction is 42%–75% depending on location compared with the grid-only configuration. However, for on-grid configurations with a charging power of 100 kW, using SLBs (Grid+SLB) increases the GHG emissions in all locations due to the SLB remanufacturing impact and energy losses in SLB, whereas adding PV in the system (Grid+SLB+PV) slightly (1%–5%) reduces the emissions over the grid-only configuration in some locations.

Bobba and colleagues97 analyzed energy flows of a household with PV to estimate the life cycle environmental impacts of installing second-life EVBs and provided somewhat different conclusions. Compared to new LIBs, second-life EVBs have lower impacts across all metrics, e.g., 62% lower CED and 58% lower GWP. However, compared to the no battery baseline, the installation of second-life EVBs increases the impacts, e.g., CED by 47% and GWP by 46% even though it reduces the household’s grid electricity use by 40%. This is inconsistent with the PV with SLB scenarios in Kamath and colleagues74 where 22%–51% GHG savings were reported compared to the no battery scenario. This difference in findings may stem from the differing approach for the use phase including the emission factors of PV and grid electricity.

Faria and colleagues76 studied the environmental benefits of second-life EVBs in household energy storage for peak shaving and load shifting. The system boundary includes electricity use in household and battery secondary use but does not cover the battery remanufacturing impacts. They found that considering the time of charging and the additional losses in the battery and inverter, the battery energy storage could lead to higher GHG emissions than a scenario without a battery. The environmental impacts are directly related to the electricity generation mix. The GHG reduction from use of second-life battery in the French scenario varies between 2% for peak shaving and 5% for load shifting. For the Portuguese mix, using second-life battery for household energy storage increases the emissions by 2% for load shifting and 3% for peak shaving.

Yang and colleagues98 analyzed environmental impacts of repurposed battery as backup energy storage for CBS compared with lead-acid battery. Using economic allocation for battery manufacturing impacts and assuming a battery lifetime of 5 years, they found that repurposed LFP battery reduces GHGs by 20%. Since the life cycle impact is dominated by the battery manufacturing and reuse stages, the results are sensitive to allocation method, lifetime of repurposed LIBs, and electric grid mix to charge the battery. In addition, Yang and colleagues85 explored load-shifting scenarios of repurposed LIB in CBS and found that the importance of the reuse stage is even greater. They found that the CBS load shifting by second-life EVB increases carbon footprint compared to the grid-only scenario due to electricity losses during charging and discharging, although it results in economic benefits as previously discussed. Moreover, the repurposed LIB scenario has a higher carbon footprint than the new LIB scenario due to a lower roundtrip efficiency during load shifting.

Summary

In summary, literature LCAs evaluate environmental benefits of second-life battery use focusing on either extended battery life cycle (battery-centered) or application system using second-life batteries (application-centered). Studies indicate that use of low-carbon electricity is a key strategy to reduce carbon emissions of the second-life EVB scenarios. In general, scenarios where SLBs replace lead-acid and new LIB batteries have lower carbon emissions.74,97,99 However, compared with no energy storage baseline, installation of second-life battery energy storage does not necessarily bring carbon benefits as they largely depend on the carbon intensity of electricity used by the battery.74,99 For residential applications, literature studies yielded similar conclusions.74,76 Therefore, SLB applications to store renewable electricity would be a promising carbon abatement strategy.53,74,99 The key sensitivity parameters associated with the literature LCAs include electricity source, cell conversion rate, battery enclosure materials to replace, repurposed battery lifespan, battery degradation rate, roundtrip efficiency, and DOD. Differences in methodological approach such as how to define the use phase of batteries and how to allocate impacts of battery production and end of life between EV and ESS affect the overall results.

Conclusions

By 2030, the number of EVs on the road reaches 145–230 million in scenarios considered by the IEA.6 The volume of retired LIBs will increase together with promotion of EVs as a green transportation choice. Retired EVBs contain a substantial electrical charge capacity. Second-life application is a promising solution to use the remaining capacity and extract additional value from retired EVBs. Second-life use can alleviate the need for large-scale scrapping of traction batteries and relieve pressure on the upfront costs of electric vehicles.

Studies have used various economic indicators including payback period, LCOE, and NPV to assess the economic benefits of using second-life batteries in a variety of applications. The economics of second-life EVBs are advantageous in most analyses when compared to new batteries, but not necessarily advantageous when compared to no battery baselines. The estimates are sensitive to economic and technical parameters such as electricity pricing scheme, costs of new and retired batteries, and battery performances during operation. The existing literature studies mostly rely on modeling approaches and assumptions for these parameters primarily due to the scarcity of real-world operational data. Future research is needed utilizing long-term operational data and cash flows derived from actual application cases.

For the environmental performance, literature LCAs indicate potential GHG benefits of second-life EVBs in various applications including energy storage for renewable power, EV fast charging, and household and utility applications for peak shaving and load shifting. Depending on the goal and scope, LCAs evaluate extended life cycle of EVB (battery-centered approach) or application system of EVB (application-centered approach). As in the economic analyses, studies show that ESS using second-life batteries generally have lower carbon footprints than those using lead-acid batteries or new EVBs. However, when compared to baseline scenarios without energy storage, the use of second-life batteries does not necessarily lead to a lower carbon footprint. A wide range of carbon benefits in household and utility applications have been reported in the literature largely depending on the source of electricity used to charge the batteries. Furthermore, the lack of consistent LCA approaches presents challenges when comparing various options for retired batteries. To reduce uncertainties in LCAs and provide guidance to decision-makers, it is necessary to establish a harmonized set of LCA rules for second-life EVB applications.

The second-life battery market faces several major challenges. First, retired EVBs have a wide range of chemical and electrical properties and states of health. There are no comprehensive standards to test performances of different cell chemistries, cell formats, and battery pack designs. Planning cost-effective and safe second-life applications for a diverse pool of retired EVBs whose chemical and electrical properties are currently unknown is a major challenge. Future work is needed to develop fast and safe screening and processing methods and standards to handle a diverse variety of retired batteries. Second, the cost of new EVBs has been declining sharply over the past decade. There is general agreement in the literature that this trend will continue, but future battery costs are highly uncertain. Planning a future business where second-life batteries will compete with new batteries is difficult when the cost and performance of new batteries is unclear. In addition, the literature discusses the mismatch between the requirements of EV and stationary applications, as well as potentially limited availability of retired EVBs that meet the requirements of stationary applications.

To address these challenges and improve the cost and resource efficiency of energy storage systems using second-life EVBs, a combination of measures would be needed. These measures would encompass establishing more comprehensive test standards, developing fast diagnostic technologies to assess battery health, and designing batteries for their second life with a focus on enabling disassembly and reconfiguration. An electronic battery passport, with information about the design, performance, and durability of retired batteries, could be a useful tool to promote the use of retired EVBs.100

Limitations of the study

As the EV and second-life EVB markets rapidly expand, a larger volume of operational data for second-life EVBs will become accessible, which is the limitation of this study. This calls for future updates in this field. In addition, a comprehensive and holistic approach is essential for the development of circular economy strategies concerning retired EVBs. This requires consideration of the economic and environmental cost and benefits associated with recycling, remanufacturing, and second-life use. These insights provide a foundation for further research to optimize the sustainable utilization of retired EVBs.

Acknowledgments

The work has been financially supported by Ford Motor Company URP Award: 2nd Life Batteries in China (DEPT2020-J076.2), also with support from major project of “The Beijing Social Science Fund” (17ZDA27).

Author contributions

Q.D.: Conceptualization, Methodology, Formal analysis, Writing – original draft. S.L.: Data collection, Writing – original draft. J.L.: Conceptualization, Supervision. H.C.K.: Methodology, Formal analysis, Original draft improvement. W.S.: Investigation, Original draft improvement. T.W.: Supervision, Original draft improvement, Optimization.

Declaration of interests

The authors declare that they have no competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Supplemental information can be found online at https://doi.org/10.1016/j.isci.2023.107195.

Supplemental information

References

- 1.Ahmadi L., Young S.B., Fowler M., Fraser R.A., Achachlouei M.A. A cascaded life cycle: reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017;22:111–124. doi: 10.1007/s11367-015-0959-7. [DOI] [Google Scholar]

- 2.Burke A. Institute of Transportation Studies; 2009. Performance, Charging, and Second-Use Considerations for Lithium Batteries for Plug-In Electric Vehicles.https://escholarship.org/uc/item/2xf263qp UCD-ITS-RR-09-17. [Google Scholar]

- 3.Narula C.K., Martinez R., Omar O., Starke M.R., Andrews G. Oak Ridge Natl. Lab. Report ORNL/TM-2011/151; 2011. Economic Analysis of Deploying Used Batteries in Power Systems. [Google Scholar]

- 4.Neubauer J.S., Wood E., Pesaran A. A second-life for electric vehicle batteries: answering questions on battery degradation and value. SAE Int. J. Mater. Manf. 2015;8:544–553. doi: 10.4271/2015-01-1306. [DOI] [Google Scholar]

- 5.Viswanathan V.V., Kintner-Meyer M. Second use of transportation batteries: maximizing the value of batteries for transportation and grid services. IEEE Trans. Veh. Technol. 2011;60:2963–2970. doi: 10.1109/TVT.2011.2160378. [DOI] [Google Scholar]

- 6.International Energy Agency (IEA) Global EV Outlook 2021. 2021. https://www.iea.org/reports/global-ev-outlook-2021

- 7.European Parliament EU Ban on the Sale of New Petrol and Diesel Cars from 2035 Explained. 2022. https://www.europarl.europa.eu/news/en/headlines/economy/20221019STO44572/eu-ban-on-sale-of-new-petrol-and-diesel-cars-from-2035-explained

- 8.Mordor Intelligence Automotive Battery Market - Growth, Trends, Covid-19 Impact, and Forecasts (2021 - 2026) 2021. https://www.mordorintelligence.com/industry-reports/automotive-battery-market

- 9.Šimić Z., Topić D., Knežević G., Pelin D. Battery energy storage technologies overview. Int. J. Electr. Comput. Eng. Syst. 2021;12:53–65. doi: 10.32985/ijeces.12.1.6. [DOI] [Google Scholar]

- 10.Zhang X., Li L., Fan E., Xue Q., Bian Y., Wu F., Chen R. Toward sustainable and systematic recycling of spent rechargeable batteries. Chem. Soc. Rev. 2018;47:7239–7302. doi: 10.1039/c8cs00297e. [DOI] [PubMed] [Google Scholar]

- 11.Chen M., Ma X., Chen B., Arsenault R., Karlson P., Simon N., Wang Y. Recycling end-of-life electric vehicle lithium-ion batteries. Joule. 2019;3:2622–2646. doi: 10.1016/j.joule.2019.09.014. [DOI] [Google Scholar]

- 12.IEA Global EV Outlook 2020. 2020. https://www.iea.org/reports/global-ev-outlook-2020

- 13.Engel H., Hertzke P., Siccardo G. Second-life EV batteries: the newest value pool in energy storage. 2019. https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/second-life-ev-batteries-the-newest-value-pool-in-energy-storage

- 14.Neubauer J., Pesaran A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sources. 2011;196:10351–10358. doi: 10.1016/j.jpowsour.2011.06.053. [DOI] [Google Scholar]

- 15.Vikström H., Davidsson S., Höök M. Lithium availability and future production outlooks. Appl. Energy. 2013;110:252–266. doi: 10.1016/j.apenergy.2013.04.005. [DOI] [Google Scholar]

- 16.Gies E. Recycling: lazarus batteries. Nature. 2015;526:S100–S101. doi: 10.1038/526S100a. [DOI] [PubMed] [Google Scholar]

- 17.Aziz M., Oda T., Morihara A., Murakami T., Momose N. ISGT 2014. 2014. Utilization of EVs and their used batteries in factory load leveling; pp. 1–5. [DOI] [Google Scholar]

- 18.Cready E., Lippert J., Pihl J., Weinstock I., Symons P. DOE Energy Storage Systems Program; 2003. Technical and Economic Feasibility of Applying Used EV Batteries in Stationary Applications. SAND. 2002-4084. [DOI] [Google Scholar]

- 19.Lih W.-C., Yen J.-H., Shieh F.-H., Liao Y.-M. 2012 International Symposium on Computer, Consumer and Control. IEEE; 2012. Second use of retired lithium-ion battery packs from electric vehicles: technological challenges, cost analysis and optimal business model; pp. 381–384. [DOI] [Google Scholar]

- 20.Williams B., Lipman T. University of California, Berkley–Transportation Sustainability Research Center; 2011. Analysis of the Combined Vehicle-And Post-vehicle-use Value of Lithium-Ion Plug-In-Vehicle Propulsion Batteries.https://escholarship.org/uc/item/60m7j3k1 [Google Scholar]

- 21.Kelly J.C., Elgowainy A., Isaac R., Ward J., Islam E., Rousseau A., Sutherland I., Wallington T.J., Alexander M., Muratori M., et al. Argonne National Laboratory Report ANL; 2022. Cradle-to-Grave lifecycle analysis of U.S. Light duty vehicle-fuel pathways: A Greenhouse Gas Emissions and Economic Assessment of Current (2020) and Future (2030–2035) Technologies. [DOI] [Google Scholar]

- 22.California Air Resource Bureau (CARB) Proposed Advanced Clean Cars II (ACC II) Regulations – Appendix G: ACC II ZEV Technology Assessment. 2022. https://ww2.arb.ca.gov/sites/default/files/barcu/regact/2022/accii/appg.pdf

- 23.Nykvist B., Nilsson M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Change. 2015;5:329–332. doi: 10.1038/nclimate2564. [DOI] [Google Scholar]

- 24.Rubel H., Pieper C., Zenneck J., Sunak Y. The Boston Consulting Group; 2017. How Batteries and Solar Power Are Disrupting Electricity Markets; pp. 1–15.https://www.bcg.com/publications/2017/energy-environment-how-batteries-and-solar-power-aredisrupting-electricity-markets.aspx [Google Scholar]

- 25.Bloomberg New Energy Finance Lithium-ion battery pack prices rise for first time to an average of $151/kWh. 2022. https://about.bnef.com/blog/lithium-ion-battery-pack-prices-rise-for-first-time-to-an-average-of-151-kwh/

- 26.Mauler L., Duffner F., Zeier W.G., Leker J. Battery cost forecasting: a review of methods and results with an outlook to 2050. Energy Environ. Sci. 2021;14:4712–4739. doi: 10.1039/D1EE01530C. [DOI] [Google Scholar]

- 27.Islam E., Vijayagopal R., Moawad A., Kim N., Dupont B., Prada D.N., Rousseau A. Argonne National Laboratory; 2021. A Detailed Vehicle Modeling & Simulation Study Quantifying Energy Consumption and Cost Reduction of Advanced Vehicle Technologies through 2050.https://anl.app.box.com/s/xzhqi4x5sw3anw6rbgz7f67l6ti0qikd [Google Scholar]

- 28.Neubauer J., Smith K., Wood E., Pesaran A. 2015. Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries.https://www.nrel.gov/docs/fy15osti/63332.pdf NREL Technical Report Technical Report. [Google Scholar]

- 29.Li Y., Wang X., Butler D., Liu J., Qu J. Second use potential of retired EV batteries in power system and associated cost analysis. Sci. Rep. 2017;7:243–249. [Google Scholar]

- 30.Xu M., Liu D., Wang D. Hefei Gotion High-tech Power Energy Co., Ltd; 2020. Analysis of Retired Lithium Iron Phosphate Power Batteries for Secondary Use.https://mp.weixin.qq.com/s/zAobbGIeFQnwpJD-hWUlpw [Google Scholar]

- 31.Gerssen-Gondelach S.J., Faaij A.P. Performance of batteries for electric vehicles on short and longer term. J. Power Sources. 2012;212:111–129. doi: 10.1016/j.jpowsour.2012.03.085. [DOI] [Google Scholar]

- 32.China Energy Storage Alliance (CNESA) CNESA white paper. 2021. http://en.cnesa.org/our-work

- 33.China Energy Storage Alliance (CNESA) CNESA white paper. 2020. http://en.cnesa.org/our-work

- 34.Auto futures 2019. https://archive.autofutures.tv/2019/08/09/Mercedes-benz-energy-and-beijing-electric-vehicle-start-partnership/

- 35.Audi Media Center Audi and RWE build new type of energy storage system in Herdecke. 2022. https://www.audi-mediacenter.com/en/press-releases/second-life-for-ev-batteries-audi-and-rwe-build-new-type-of-energy-storage-system-in-herdecke-14465

- 36.BMW Group UK second-life battery solution in partnership with off Grid Energy. 2020. https://www.press.bmwgroup.com/united-kingdom/article/detail/T0318650EN_GB/bmw-group-uk-second-life-battery-solution-in-partnership-with-off-grid-energy?language=en_GB

- 37.Battery international Toyota, JERA launch second-life BESS with hybrid, lithium nickel lead battery mix. 2022. https://www.batteriesinternational.com/2022/10/28/toyota-jera-launch-second-life-bess-with-hybrid-lithium-nickel-lead-battery-mix/

- 38.BAIC News Center BAIC leads the country's first large-scale EV battery echelon use enterprise to lay the foundation stone. 2019. http://www.baicgroup.com.cn/news/1866

- 39.Miguel M., Nogueira T., Martins F. Energy storage for renewable energy integration: the case of Madeira Island, Portugal. Energy Proc. 2017;136:251–257. doi: 10.1016/j.egypro.2017.10.277. [DOI] [Google Scholar]

- 40.Sun Y., Zhao Z., Yang M., Jia D., Pei W., Xu B. Overview of energy storage in renewable energy power fluctuation mitigation. CSEE J. Power Energy Syst. 2019;6:160–173. doi: 10.17775/CSEEJPES.2019.01950. [DOI] [Google Scholar]

- 41.Hamidi A., Weber L., Nasiri A. 2013 International Conference on Renewable Energy Research and Applications (ICRERA) IEEE; 2013. EV charging station integrating renewable energy and second-life battery; pp. 1217–1221. [DOI] [Google Scholar]

- 42.Alhadri M., Zakri W., Esmaeeli R., Mohammed A.H., Hashemi S.R., Barua H., Aliniagerdroudbari H., Farhad S. 2019 IEEE Power and Energy Conference at Illinois (PECI) 2019. Analysis of second-life of a lithium-ion battery in an energy storage system connected to a wind turbine; pp. 1–8. [DOI] [Google Scholar]

- 43.Koch-Ciobotaru C., Saez-de-Ibarra A., Martinez-Laserna E., Stroe D.I., Swierczynski M., Rodriguez P. 2015 IEEE Energy Conversion Congress and Exposition (ECCE) 2015. Second life battery energy storage system for enhancing renewable energy grid integration; pp. 78–84. [DOI] [Google Scholar]

- 44.Saez-de-Ibarra A., Martinez-Laserna E., Stroe D.I., Swierczynski M., Rodriguez P. Sizing study of second life Li-ion batteries for enhancing renewable energy grid integration. IEEE Trans. Ind. Appl. 2016;52:4999–5008. doi: 10.1109/TIA.2016.2593425. [DOI] [Google Scholar]

- 45.Leung C. Murdoch University; 2012. PV Systems with Second Life Li-Ion Battery Technology.https://researchrepository.murdoch.edu.au/id/eprint/11366/1/leung2012.pdf [Google Scholar]

- 46.BYD BYD: your reliable battery partner. 2016. https://www.solarchoice.net.au/wp-content/uploads/BYD_Your-battery-Partner-V1.2.compressed.pdf

- 47.Lacey G., Putrus G., Salim A. The use of second life electric vehicle batteries for grid support. Eurocon. 2013;2013:1255–1261. doi: 10.1109/EUROCON.2013.6625141. [DOI] [Google Scholar]

- 48.Eyer J., Corey G. Sandia National Laboratories; 2010. Energy Storage for the Electricity Grid: Benefits and Market Potential Assessment Guide.https://www.sandia.gov/ess-ssl/publications/SAND2010-0815.pdf SAND2010-0815. [Google Scholar]

- 49.Li L. Harbin Institute of Technology; 2018. Research on Electric Vehicle Lithium Battery Retired Echelon Use in Communication Base Station. [DOI] [Google Scholar]

- 50.Yan Z. Design of base station backup power system constructed with ladder battery. IOP Conf. Ser. Mater. Sci. Eng. 2019;677:032011. doi: 10.1088/1757-899X/677/3/032011. [DOI] [Google Scholar]

- 51.Jiao D., Zhang J., Zhu J., Chi Z., Li X. 2014 China International Conference on Electricity Distribution (CICED) IEEE; 2014. Economic operation analysis of energy storage system based on echelon-use batteries; pp. 499–503. [DOI] [Google Scholar]

- 52.Han X., Liang Y., Ai Y., Li J. Economic evaluation of a PV combined energy storage charging station based on cost estimation of second-use batteries. Energy. 2018;165:326–339. doi: 10.1016/j.energy.2018.09.022. [DOI] [Google Scholar]

- 53.Kamath D., Arsenault R., Kim H.C., Anctil A. Economic and environmental feasibility of second-life lithium-ion batteries as fast-charging energy storage. Environ. Sci. Technol. 2020;54:6878–6887. doi: 10.1021/acs.est.9b05883. [DOI] [PubMed] [Google Scholar]

- 54.Nissan Energy Camping gets a recharge with second-life Nissan EV batteries. 2019. https://thedriven.io/2019/02/19/camping-gets-a-recharge-with-second-life-nissan-ev-batteries/

- 55.Zhang T.P., Yang F., Tang W., Alexander M., Forastiere L., Kumar N., Li K., Zou F., Yang L., Mi G., et al. Analysis of the development of the new energy vehicle power battery echelon use industry. Infect. Dis. Poverty. 2019;8:76–78. doi: 10.3969/j.issn.1008-9500.2019.07.024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Zhao G. 2017. Reuse and Recycling of Lithium-Ion Power Batteries. [DOI] [Google Scholar]

- 57.Zhu M., Wu Z., Huang Y., Zhou S., Jiang Q. Analysis of the application of echelon use batteries in solar streetlights. Sol. Energy. 2020;2:57–60. doi: 10.3969/j.issn.1003-0417.2020.02.009. [DOI] [Google Scholar]

- 58.Canals Casals L., Amante García B., González Benítez M.M. Aging model for re-used electric vehicle batteries in second life stationary applications. Proj. Manag. Eng. Res. 2017:139–151. doi: 10.1007/978-3-319-51859-6_10. [DOI] [Google Scholar]

- 59.Heymans C., Walker S.B., Young S.B., Fowler M. Economic analysis of second use electric vehicle batteries for residential energy storage and load-levelling. Energy Pol. 2014;71:22–30. doi: 10.1016/j.enpol.2014.04.016. [DOI] [Google Scholar]

- 60.Baughman A., Ferdowsi M. 2005 IEEE Vehicle Power and Propulsion Conference. 2005. Double-tiered capacitive shuttling method for balancing series-connected batteries; pp. 109–113. [DOI] [Google Scholar]

- 61.Hung S.T., Hopkins D.C., Mosling C.R. Extension of battery life via charge equalization control. IEEE Trans. Ind. Electron. 1993;40:96–104. doi: 10.1109/41.184826. [DOI] [Google Scholar]

- 62.Lee Y.S., Cheng M.W. Intelligent control battery equalization for series connected lithium-ion battery strings. IEEE Trans. Ind. Electron. 2005;52:1297–1307. doi: 10.1109/TIE.2005.855673. [DOI] [Google Scholar]

- 63.Lindemark B. Thirteenth International Telecommunications Energy Conference-INTELEC 91. IEEE; 1991. Individual cell voltage equalizers (ICE) for reliable battery performance; pp. 196–201. [DOI] [Google Scholar]

- 64.Pascual C., Krein P.T. Proceedings of APEC 97-Applied Power Electronics Conference. Vol. 2. IEEE; 1997. Switched capacitor system for automatic series battery equalization; pp. 848–854. [DOI] [Google Scholar]

- 65.Wang Z., Wang J. An experimental investigation of the degradation and combustion behaviors associated with lithium ion batteries after different aging treatments. J. Clean. Prod. 2020;272:122708. doi: 10.1016/j.jclepro.2020.122708. [DOI] [Google Scholar]

- 66.Xie S., Ren L., Yang X., Wang H., Sun Q., Chen X., He Y. Influence of cycling aging and ambient pressure on the thermal safety features of lithium-ion battery. J. Power Sources. 2020;448:227425. doi: 10.1016/j.jpowsour.2019.227425. [DOI] [Google Scholar]

- 67.Zhang J., Su L., Li Z., Sun Y., Wu N. The evolution of lithium-ion cell thermal safety with aging examined in a battery testing calorimeter. Batteries. 2016;2:12. doi: 10.3390/batteries2020012. [DOI] [Google Scholar]

- 68.Feng L., Jiang L., Liu J., Wang Z., Wei Z., Wang Q. Dynamic overcharge investigations of lithium ion batteries with different state of health. J. Power Sources. 2021;507:230262. doi: 10.1016/j.jpowsour.2021.230262. [DOI] [Google Scholar]

- 69.Zhu J., Mathews I., Ren D., Li W., Cogswell D., Xing B., Sedlatschek T., Kantareddy S.N.R., Yi M., Gao T., et al. End-of-life or second-life options for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2021;2:100537. doi: 10.1016/j.xcrp.2021.100537. [DOI] [Google Scholar]

- 70.Börner M.F., Frieges M.H., Späth B., Spütz K., Heimes H.H., Sauer D.U., Li W. Challenges of second-life concepts for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2022;3:101095. doi: 10.1016/j.xcrp.2022.101095. [DOI] [Google Scholar]