Abstract

Understanding the structural dynamics/evolution of catalysts and the related surface chemistry is essential for establishing structure–catalysis relationships, where spectroscopic and scattering tools play a crucial role. Among many such tools, neutron scattering, though less-known, has a unique power for investigating catalytic phenomena. Since neutrons interact with the nuclei of matter, the neutron–nucleon interaction provides unique information on light elements (mainly hydrogen), neighboring elements, and isotopes, which are complementary to X-ray and photon-based techniques. Neutron vibrational spectroscopy has been the most utilized neutron scattering approach for heterogeneous catalysis research by providing chemical information on surface/bulk species (mostly H-containing) and reaction chemistry. Neutron diffraction and quasielastic neutron scattering can also supply important information on catalyst structures and dynamics of surface species. Other neutron approaches, such as small angle neutron scattering and neutron imaging, have been much less used but still give distinctive catalytic information. This review provides a comprehensive overview of recent advances in neutron scattering investigations of heterogeneous catalysis, focusing on surface adsorbates, reaction mechanisms, and catalyst structural changes revealed by neutron spectroscopy, diffraction, quasielastic neutron scattering, and other neutron techniques. Perspectives are also provided on the challenges and future opportunities in neutron scattering studies of heterogeneous catalysis.

1. Introduction

Achieving the Net Zero carbon goals by 2050 set by many countries requires aggressive decarbonization, which entails both the reduction in, and capture of CO2 emissions from the use of fossil fuels.1 Increasing the use of renewable energy sources such as wind, solar, hydropower, and biomass will help to reduce CO2 emissions but currently makes up only 1/3 of the global power capacity. In the intermediate and foreseeable future, fossil fuels are still the primary energy resources for our society. Reduction of the consumption of fossil fuels can effectively decrease CO2 emissions but requires improving the energy and chemical efficiency of the processes so that the societal demand for energy and fuels can still be met. In both aspects, catalysis can play a significant role in decarbonization by improving the process efficiency in terms of activity and selectivity and transforming renewal resources, including biomass and wastes such as plastics and CO2, into products that are otherwise derived from fossil fuels.2 Realizing the potential of catalysis in decreasing the carbon footprint presents a grand challenge in developing new catalytic materials with unprecedented efficiency. A fundamental understanding of the structure–catalysis relationships in these conventional and new chemical reactions is indispensable for designing such new catalysts and thus addressing the decarbonization challenge.

In the pursuit of understanding the chemical transformations of catalytic reactions and the structural evolution of catalysts at the molecular level, a suite of advanced experimental methods has been developed in the studies of catalysis science, particularly for heterogeneous thermal catalysis.3−6 These include the use of photons (diffraction and spectroscopy using X-ray, infrared (IR), Raman, ultraviolet–visible (UV–vis)),6−12 electrons (microscopy, surface science methods),13−15 and neutrons.16,17 While each method provides valuable information on some aspects of catalysis, multiple approaches, often termed multimodal, are desired to provide a complete picture of the working catalysts under reaction conditions.

Among the many characterization approaches, neutron scattering can provide not only complementary catalytic information to other scattering techniques, typically photons and electrons, but also unique insights into catalyst structures and reaction mechanisms of light elements such as hydrogen, nitrogen, and oxygen, or neighboring elements that are difficult or not possible to interrogate by other methods. Neutrons interact with nuclei rather than electrons. Thus, to a neutron, most matter is empty space allowing penetration deep into a catalyst bed or through the thick reactor walls necessary for reactions in extreme conditions. Due to the weak interaction, neutron irradiation does not alter the catalyst, unlike X-ray techniques, where sample damage can be problematic. Additionally, each isotope has its unique neutron scattering cross section. This unusual isotopic sensitivity allows contrast variation and potential discrimination of elements with similar atomic numbers.18−20

For catalysis research, neutron methods can be classified as elastic (diffraction and imaging) and inelastic (spectroscopic) techniques, as depicted in Figure 1, which are used to investigate where atoms are (structure) and what atoms do (function). Neutron diffraction (ND) has significantly contributed to catalysis as a complement to X-ray-based techniques, especially in revealing the location of light elements in the structure of the catalyst under reaction conditions.20−24 Through investigation of the broadening of the diffraction peak, quasi-elastic neutron scattering (QENS) provides information on molecular motions (diffusion and rotational) on a range of time scales (picosecond to nanosecond) at Ångstrom length scales,25 complementary to the typical dynamic information from nuclear magnetic resonance (NMR) studies.26,27 Upon a change in the energy of the scattered neutrons, inelastic neutron scattering (INS), a neutron analog to optical vibrational spectroscopy, provides access to all types of vibrational and translational modes without any selection rules; thus affording chemical spectroscopy information on the catalyst and surface species.16,28,29 Advantageous over conventional optical spectroscopy techniques, INS can bestow catalytic mechanistic insights into opaque materials and especially spectroscopic modes in the low energy range (typically below 1000 cm–1), which is difficult for infrared (inaccessible) and Raman (dominated by phonon modes) spectroscopies.

Figure 1.

An illustration of typical neutron scattering methods for heterogeneous catalysis investigations. S – intensity, Q – momentum transfer, ω – energy transfer

There have been some excellent reviews17,29−36 and book chapters16,28,37−40 on the application of neutron scattering to heterogeneous catalysis. Most of these have focused on a single technique, especially INS, with limited comprehensive reviews36,37 on various neutron techniques. With the recent advancement of neutron sources, beamlines, and environmental reactor cell setups, neutron studies of catalysis have seen significant progress. Hence, a timely review of neutron scattering studies of heterogeneous catalysis is warranted. This work will overview the applications, especially in the past decade or so, of different neutron scattering techniques in heterogeneous catalysis with a focus on studies of thermal catalysis. After a brief introduction to the fundamentals of neutron scattering, neutron spectroscopy, diffraction, and other techniques will be reviewed regarding the theory, reactor designs, and catalysis studies. Multimodal approaches combining two or more techniques, either all neutron methods or a mixture with other approaches, will also be briefly reviewed in catalysis research. The review will conclude with a summary and perspective on neutron scattering studies of heterogeneous catalysis.

2. A Brief Introduction to Neutron Scattering

Smaller (subatomic) particles are often used as probes to measure the atomic level structure and dynamics. Commonly used techniques include X-ray scattering, Raman/infrared spectroscopy, and transmission electron microscopy. Compared to the above methods using photons or electrons, neutron scattering (i.e., using neutrons as the probe particles) may sound less familiar to many readers. The neutron is an elementary particle with zero electric charge, a rest mass close to that of the proton, and a magnetic moment.41 When a neutron strikes an atom, it interacts with the nucleus and can be either absorbed or scattered. Absorption, which leads to nuclear transformation and is the basis of all neutron detectors, is not of interest in the applications to be discussed here. Instead, we learn the structure and dynamics of the material from the scattered neutrons.42 The scattering can be elastic or inelastic because a neutron has mass; all scattering results in a change of direction, and hence momentum, of the neutron. There is no energy exchange for elastic scattering, and the neutrons change direction upon collision. In the case of inelastic scattering, the neutron exchanges energy and momentum with the scattering nucleus (the scatterer). The scattered neutron may gain or lose energy (Figure 1). The energy transferred from the neutron appears as the scatterer’s rotational, vibrational, or translational energy.28 The scattering can also be coherent or incoherent. Incoherent scattering measures the correlation between the positions of an atom at time zero and at a later time, with each atom contributing independently to the total scattering by simple summation. In contrast, coherent scattering describes interference between waves from the scattering of a single neutron from all nuclei—examples are the Bragg peaks seen in diffraction or the phonon dispersion seen in an inelastic scattering. In 1994, the Nobel Prize in Physics was awarded “for pioneering contributions to the development of neutron scattering techniques for studies of condensed matter” jointly to Bertram N. Brockhouse “for the development of neutron spectroscopy” and to Clifford G. Shull “for the development of the neutron diffraction technique”.43

Neutron scattering shares many similarities with X-ray scattering, but there are also significant differences. Neutrons interact with matter via the relatively weak neutron–nucleon interaction at a very short-range (∼fm). X-rays interact with matter via electromagnetic interaction, which scales with electron density. Because the atomic nucleus is only ∼1/1000th of the diameter of an atom, to a neutron, most matter is empty space. Consequently, a principal advantage of neutrons over X-rays is that neutrons are highly penetrating. This capability of neutrons ensures that the results obtained from neutron scattering are representative of the bulk. For neutron scattering, the scattering cross section is both element- and isotope-dependent, while for X-ray scattering, it is a monotonic function of atomic number.

Moreover, neutron scattering cross sections for light elements are relatively large compared to the much heavier metals. These features are illustrated in Figure 2, which indicates that 1) neutron scattering is ideal for studying catalytic systems involving light elements, mainly hydrogen, which could not be directly detected by X-rays; 2) it is possible for neutron scattering to distinguish adjacent elements in the periodic table since they may have different neutron cross sections; 3) one can use isotope labeling in a neutron scattering experiment to resolve structural or dynamical information that is otherwise inaccessible; 4) more complicated sample environment equipment can be used in a neutron scattering experiment, such as high-pressure and high-temperature sample cells made of metals, without blocking the incident/scattered beam.28,40 There are also disadvantages. Neutron sources have much lower flux than X-rays; thus, much longer data acquisition time and larger sample quantities are required. Neutrons are expensive and difficult to produce. Consequently, while X-ray-based facilities can be easily accessed, there are relatively few neutron facilities worldwide where neutron scattering experiments can be carried out.

Figure 2.

Neutron scattering cross sections of selected elements (isotopes)44 that are relevant to catalysis research.

Neutrons can be produced by fission or spallation.45 The fission approach requires a nuclear reactor, where controlled chain reactions happen in nuclear fuels (containing 235U) to release neutrons. The neutron beams produced this way are continuous (i.e., steady state) with high average flux. The spallation approach is entirely different. It uses a particle accelerator to generate a high-energy proton beam directed onto a “target” made of heavy metals such as Ta, W, or Hg. The interaction of a high-energy proton with the nucleus results in highly excited nuclear states. One of the decay mechanisms is the “evaporation” of neutrons. A significant distinction of this approach is that the beam can be easily pulsed, meaning that the protons, thus the produced neutrons, can be tuned to come in/out as pulses/packets at specific frequencies.

Most spallation sources are operated in a pulsed mode, which enables the energy or wavelength of the neutrons to be measured by time-of-flight (ToF).45 Specifically, since the emission of the neutrons is pulsed and time-stamped, one can measure the time needed for a neutron to travel from the source to the detector and then convert that to velocity and thus energy or wavelength. Modern spallation sources have high peak flux, brightness, and efficiency. A history and locations of neutron sources are presented in Figure 3,46 which also highlights some of the currently running spallation sources including ISIS47 in the UK, J-PARC48 in Japan, and SNS49 in the US. There are also newer spallation sources shown in Figure 3, including the China Spallation Neutron Source (CSNS)50 that has recently been commissioned, as well as the European Spallation Source (ESS)51 and the Second Target Station (STS)52 of SNS that are presently being built/designed.

Figure 3.

(Top) Evolution of thermal-neutron sources (reactor-based and spallation). Adapted with permission from ref (46). Copyright 2006 AIP Publishing. (Bottom) The location of neutrons sources around the world. Those marked in red are spallation sources, and the rest are reactors. Detailed information about the neutron sources can be found in Table S1 in the Supporting Information.

In a neutron scattering experiment (assuming the incident neutron flux is fixed), the scattering intensity (the number of scattered neutrons) depends on three variables: the cross section of the scattering atom (the scatterer), the number of scattering atoms in the neutron beam, and the atomic positions and displacements due to vibrations. The scattering intensity is expressed by the scattering law and can, in principle, be calculated rigorously, assuming all the above information is known.40,42 Since the atomic structure and dynamics, which are often the goal of a neutron scattering experiment, can be difficult to extract directly from the experimental data, an atomistic model (or a series of models) is often used to simulate the neutron scattering data, compare with experiment, and then help to interpret the data and obtain insight. For example, when analyzing the complicated diffraction pattern measured on a disordered or nanomaterial, the reverse Monte Carlo method53,54 is often used to search for a structural model that can reproduce the total scattering intensities. When assigning the peaks observed in an inelastic neutron scattering experiment, lattice dynamics or molecular dynamics based on density functional theory55−57 is a widely used tool to find the structural or dynamical origin (e.g. physical adsorption, chemical reaction, or phase instability) behind the experimental observations.58−62 In addition to the commonly used software packages for atomic simulations, tools have been developed to bridge neutron scattering experiments and atomistic models.54,58,59,61−64 Nowadays, advanced computing and simulation play an increasingly important role in analyzing and interpreting neutron scattering data.

3. Neutron Spectroscopy of Catalysis

Neutron vibrational spectroscopy (NVS), i.e., INS, has dominated the use of neutron techniques for heterogeneous catalysis research thanks to its distinct sensitivity to hydrogen and its involvement in many catalytic reactions. This section will start with an introduction of neutron spectroscopy fundamentals, followed by an overview of applications of NVS for studying different hydrogen and hydrogen-containing species from adsorption and reactions, and a few case studies of other light elements such as oxygen- and nitrogen-containing species in catalysis. For the convenience of the readers, representative examples of the catalysts, adsorbates, and reaction species studied by INS are briefly summarized in Table S2.

3.1. Introduction to Neutron Spectroscopy

INS can be considered the neutron analog of Raman and infrared spectroscopy. Instead of using photons as the probing beam, a neutron beam is directed onto the sample. When INS occurs, one can determine molecular excitations (corresponding to vibrational modes) from the energy loss/gain spectra. INS and Raman/infrared spectroscopy are highly complementary, as summarized in Table 1 and illustrated in Figure 4.

Table 1. Unique Capabilities of INS That Make It an Ideal Complementary Technique to Conventional Raman and Infrared Spectroscopya.

| NVS (INS) | Raman/Infrared spectroscopy |

|---|---|

| Measures dynamics of nuclei (direct) | Measures response of electrons (indirect) |

| Not restricted by selection rules, can detect Raman/infrared-inactive modes | Selection rules apply |

| Great sensitivity to H | Cannot always detect H |

| High penetration (bulk probe) | Lower penetration degree (surface + bulk) |

| Easy access to low energy range (librational and translational modes) | Low energy cutoff usually applies (especially for infrared spectroscopy) |

| Q trajectories in the (Q, ω)* map; averaging over the Brillouin zone | Γ point (Brillouin zone center) only |

| Intensity weighted by neutron scattering cross section | Intensity weighted by change in polarizability or dipole moment |

| Easy to simulate/calculate spectra | More effort to simulate/calculate spectra |

| Weak interaction, no energy deposition in sample | Potential sample damage via heating, photochemistry etc. under laser irradiation (Raman) |

| Low sensitivity: 10–100 mg of hydrogenous sample, >1 g of non-hydrogenous material, 3–50 g of catalyst | Highly sensitive: 1–10 mg of sample, 10–1000 mg of catalyst |

Q: momentum transfer; ℏω: the energy transfer; ω: angular frequency.

Figure 4.

A comparison of the (a) infrared, (b) Raman, and (c) INS spectra measured on the same material (N-phenylmaleimide, as shown in the inset). (d) INS spectrum of N-(perdeuterophenyl) maleimide. Reproduced with permission from ref (65). Copyright 2006 Elsevier.

3.1.1. Instrumentation

For INS spectroscopy, the quantity of interest is generally the energy transfer, i.e., the difference in energy between the incident and scattered neutron. At a pulsed neutron source, the neutron time-of-flight (ToF) is recorded and then converted to energy. There are two modes of operation of a ToF neutron spectrometer: direct geometry and indirect (or inverted) geometry.45 In a direct geometry spectrometer (DGS), the incident neutron beam is chopped by a Fermi chopper to select the initial speed/energy. The sample then scatters the monochromatic beam in different directions with different energy loss/gain. An array of detectors is then used to capture the scattered neutrons and record their positions (scattering angle) and total ToF from the neutron source. Since the incident energy is fixed and known, the initial ToF from source to sample can be calculated. Thus, the ToF on the secondary path (between sample and detector) can be derived, from which the final energy can be calculated. The neutrons are histogrammed by their energy transfer, adequately normalized, and the INS spectrum is obtained. This mechanism is illustrated in Figure 5. ToF methods can also be used at continuous sources such as reactors or the Swiss Spallation Neutron Source (SINQ).66 The MAPS, MERLIN, and MARI instruments at ISIS, ARCS, and SEQUOIA at SNS are examples of DGSs at pulsed sources. Panther (and its predecessor IN4) at the ILL and DCS at NIST are examples of DGSs at continuous sources.67,68 Both of these instruments require complex chopper systems to convert a steady state beam into a pulsed beam. They are also both on thermal sources, so have a maximum energy transfer of ∼1000 cm–1.

Figure 5.

Working mechanism of a DGS. (a) Distance–time plot of the neutrons. L1 is the length of the primary flight path from the moderator to the sample, and L2 is the length of the secondary flight path from the sample to the detector. (b) the measured INS spectrum derived from (c) after conversion of ToF to energy transfer. (c) the raw ToF spectrum.

An indirect geometry spectrometer (IGS) is the opposite. The incident beam is a white neutron beam consisting of neutrons of a wide range of speed/energy, typically ∼0–1500 meV or higher. A crystal analyzer reflects the scattered neutron beam at a particular reflection angle, by which Bragg’s law selects neutrons with specific wavelengths (thus speed/energy). The reflected beam is then passed through a filter that scatters and absorbs the higher-order reflections, leaving only neutrons with a fixed final energy to reach the detector. This mechanism is illustrated in Figure 6.

Figure 6.

Working mechanism of an IGS. (a) Distance–time plot of the neutrons. L1 is the length of the primary flight path from the moderator to the sample, and L2 is the length of the secondary flight path from the sample to the detector. (b) The measured INS spectrum derived from (c) after conversion of ToF to energy transfer. (c) the raw ToF spectrum.

At a steady state source, an IGS is somewhat different to that at a pulsed facility. In this case, the instruments are simplified versions of the first type of inelastic spectrometer: the triple axis spectrometer (TAS) invented by Bertram Brockhouse in 1952.43,69 A TAS consists of three elements: (i) a monochromator for the incident beam, (ii) the sample, and (iii) a monochromator in the scattered beam. This results in an instrument that, in principle, can access any point in (Q,ω) space. However, because it is a point-by-point method it is very slow and the use of two monochromators means that the detected flux is very low. It was realized very early on that replacing the second (analyzing) monochromator by a beryllium filter would greatly increase the detected flux. This type of instrument was installed at NIST (BT4) and the ILL (IN1-BeF) in the late 1970s and for many years were the workhorses of INS of catalysts (see Section 3.2.6). Both instruments have been upgraded: BT4 to FANS and IN1-BeF to Lagrange.70,71 Lagrange is unusual for a spectrometer at a reactor, in that it views a hot source (a graphite block heated to ∼2000 °C) so one can access the full 0–4000 cm–1 range. Most reactor instruments are limited to ∼1000 cm–1 because they view a thermal (i.e., room temperature) source. Lagrange is also unusual in that it uses a combination of a Be filter and a graphite analyzer to improve the resolution over that obtainable with just a Be filter as the analyzer. Presently, the most frequently used IGSs in catalysis research are TOSCA at ISIS, VISION at SNS, and Lagrange at the ILL.

DGS and IGS both have their advantages and disadvantages. Typically, a DGS offers more flexibility to cover selected regions in the S(Q,E) map, but a wider range coverage sacrifices resolution at low energy transfer. An IGS, however, can cover a wide energy range in a single scan with excellent resolution at low energy transfer. The spectra of the same sample collected at DGS and IGS are compared in Figure 7. With its wide dynamic range and good resolution in the important energy range, IGS is suitable as a generic instrument for chemical spectroscopy. If there is a specific feature of interest, the DGS can focus on that feature. Also, because DGS provides the possibility of accessing the high E and low Q area when a suppressed Debye–Waller factor is needed (such as at elevated temperature or the C–H/N–H/O–H stretch region is of interest), DGS is a better choice and thus might be more suitable for in situ catalysis studies.

Figure 7.

INS spectra of iodomethane recorded at 20 K on (a) TOSCA, (b) TOSCA × 10 ordinate expansion of the 2500–4000 cm–1 region, (c) and (d) MAPS with incident energies of 4840 and 2017 cm–1, respectively. Reproduced from ref (72). Open access.

3.1.2. Sample Environment

Apart from the choice of the spectrometer type, the sample environment (reactor cells) is also a critical factor for heterogeneous catalysis studies where the gas atmosphere, temperature, and pressure need to be controlled. Taking advantage of the high penetration power of neutrons, reactors can be made from various materials ranging from quartz to more durable variants such as steel or copper–beryllium. For example, stainless steel cells are usually used for reactions requiring high temperature and/or high pressure, where there is no need for optically transparent windows (often required in optical spectroscopy and with X-rays). Aluminum produces a lower background and is thus preferred when the reaction conditions are moderate. It is also possible to use quartz cells when it is important to be able to see the sample during the experiment (e.g., to monitor the color change). The reactor can be designed with a separate inlet and outlet for flow-through reactions or a single inlet/outlet for cyclic gas loading. When the sample is highly neutron absorbing or scattering, it is beneficial to use a flat sample holder rather than a cylindrical one. Depending on the maximum reaction temperature, the sample holders can be sealed with indium, lead, or gold wires, as well as aluminum foil or copper gaskets. Some of the reactors used at ISIS and SNS are shown in Figure 8.

Figure 8.

Various reactors used for catalysis neutron scattering experiments. (a, b) Stainless steel Swagelok reactors for flow-through and cyclic gas loading, respectively. (c) A ConflatTM stainless steel can. (d) An aluminum cylindrical can with a diameter of half inch. (e) An aluminum pressure cell that can hold pressure up to 100 bar. (f) is a vanadium cylindrical can, and (g) is an aluminum flat can. Bottom panel (h) shows a sample stick-reactor system developed at SNS for in situ catalytic reactions.

In the case of IGS, the spectral measurements typically require a very low temperature (<50 K) to suppress the Debye–Waller factor. This makes it almost impossible to carry out operando INS study of heterogeneous catalysis, as most reactions typically require above-ambient temperatures. Therefore, most catalysis studies in INS have adopted a “react and quench” approach, where the sample reactor/stick is taken out of the instrument to perform the high-temperature adsorption and reactions and then returned to the spectrometer for spectral acquisition at low temperatures without exposure to ambient atmosphere. This limitation is less of a problem for diffractometers and DGS. One of the few examples of measuring neutron spectra at reaction temperatures (in situ spectroscopy) is the room temperature CO oxidation over a model Pd catalyst investigated on the MAPS spectrometer,73 thanks to the spectrometer’s high sensitivity and ability to access low momentum transfer.

3.1.3. INS Spectral Interpretation Aided with Computational Modeling

In an INS spectrum, several features are of interest to the catalytic systems studied: scattering intensity, energy range, peak positions, peak intensity, and peak shape. The scattering intensity is proportional to the number of scattered neutrons versus the energy transferred from the neutrons to the scatterer. The INS spectrum can provide information in the low-energy region. For IGS, the lower limit is usually 10–20 cm–1; for DGS, it depends on the incident energy, and it can be as low as ∼1 cm–1. Even lower energy can be accessed with quasielastic neutron scattering. However, particularly for IGS, features in INS tend to become weak and poorly resolved above 1600 cm–1 due to multiple factors, including the neutron flux, Debye–Waller factor, and recoil. The peak positions of INS bands are signatures of a molecule’s structure and intramolecular forces that determine the atomic displacements; thus, different transitions show different intensities. In theory, the vibrational modes will be observed at the same energies in the INS, infrared, and Raman spectra (see the example shown in Figure 4). Thus, one could obtain complementary information through different types of vibrational spectroscopy. So, it is the best practice that infrared and Raman studies are carried out to obtain complementary data before the INS experiment. The INS peak intensity, the integrated area under the peak, is proportional to the amplitude of motion during the vibration. Since INS is not limited by selection rules, the shape of the INS peak shows additional structural and dynamic information. The integrated spectral intensity is also directly proportional to the total neutron scattering cross section in the beam (in the case of hydrogenous material, it roughly scales with the amount of hydrogen).28

Theoretically modeling is often required to analyze and understand the obtained INS spectrum. Neutron scattering shows the cumulative effect on the energies and numbers of the scattered neutrons of all collisions with the catalyst and any adsorbed species. The challenge is to separate the spectrum into the different scattering species using modeling. Using computer simulations, phonon information can be obtained from either quantum or classical calculations such as density functional theory (DFT) and molecular dynamics (MD). In these calculations, experimental information such as the instrument geometry, resolution, and the nature of the sample is considered. The OCLIMAX program58 developed at the VISION beamline allows one to calculate the full INS spectrum, including coherent effects and temperature effects for various INS instruments and arbitrary trajectories in the momentum and energy transfer (Q-ω) space. The models used to fit the spectrum can provide information on the vibrational modes and dynamics, and indicators of the structure of the catalysts.

3.2. INS Studies of Hydrogen-Containing Species

3.2.1. INS from Dihydrogen

A free dihydrogen (H2) molecule can be considered as a rigid quantum rotor, with its rotational energy levels expressed as E = BJ(J + 1), where J is the rotational quantum number and B is the rotational constant, which is 7.35 meV (59.3 cm–1, 1 meV = 8.066 cm–1) for H2 with an H–H distance of 0.74 Å. H2 has two spin isomers, para-hydrogen (p-H2, a singlet with spins of the two protons antiparallel to each other) and ortho-hydrogen (o-H2, a triplet with spins of the two protons parallel to each other). Due to symmetry constraints on the total wave function, rotational states with even J (0, 2, 4, ...) can only be occupied by p-H2, and rotational states with odd J values (1, 3, 5, ...) can only be occupied by o-H2. These spin isomers in hydrogen are important for neutron scattering because neutrons have 1/2 spin and scatter differently from p-H2 and o-H2. The complex interaction is best described by Fermi’s golden rule, as detailed by Young and Koppel.74 A main conclusion of this work is that excitations by neutrons from p-H2 to p-H2 (between rotational states with even J values) have very small neutron scattering cross sections compared to excitations from o-H2 to either p-H2 or o-H2. This contrasting scattering behavior is illustrated in the INS spectra of solid p-H2 and solid normal hydrogen n-H2 (a mixture of o-H2 and p-H2 at a 3:1 ratio), as shown in Figure 9. For p-H2, the strongest INS peak appears at ∼118 cm–1 (14.7 meV) corresponding to the J(0 → 1) transition. Since the cross section for the J(0 → 0) transition is negligibly small, there is almost no elastic line or phonon band (expected at ∼50 cm–1) in p-H2. In contrast, the INS spectrum of n-H2 (with 75% o-H2) exhibits a strong phonon band centered at 50 cm–1, as well as an intense elastic line.

Figure 9.

INS spectra of solid p-H2 (black) and n-H2 (red) measured at 5 K on VISION. The small elastic intensity for p-H2 is due to the aluminum sample holder.

The elastic line, translational mode, and the J(0 → 1) rotational line are all extremely sensitive to the environment surrounding the hydrogen molecule. For example, the rotational energy levels can change drastically when the hydrogen is no longer a “free” 3D rotor but is subjected to an external potential. Quantitative models have been developed to connect the type/strength of the external potential and the position, splitting, and profile of the peaks.40,75,76 These, combined with the high penetration of the neutron beam (allowing the study of H2–host interactions in bulk materials or opaque sample containers) and the ability to be quantitative (the total INS intensity scales with the amount of H2), make INS a uniquely sensitive and powerful probe to study H2, such as its adsorption and activation in porous materials and on the catalyst surface. In the following, we will show a few applications related to catalysis.

INS has been previously used to study hydrogen on (nanoparticle) metal oxides,77,78 (porous) silica,79 zeolite,80,81 carbon,82,83 and metal–organic frameworks (MOFs).75,84−86 For example, Larese et al.77 studied H2 adsorbed on the MgO(100) surface and recorded a rotational energy J(0 → 1) of 11.25 meV (90.7 cm–1) when there was less than one monolayer of H2, significantly lower than the 14.7 meV (118 cm–1) free rotor. Combined with neutron diffraction and modeling data, they confirmed that this was due to the interaction of H2 with the Mg2+ ion with an effective charge q ∼ 1, which led to a hindered, quasi-2D rotor. As H2 fully covered the surface, additional H2 with no direct interaction with Mg gave rise to a peak at 118 cm–1, consistent with free rotor behavior (Figure 10)

Figure 10.

(a) Adsorption isotherms and (b) INS spectra of p-H2 on MgO(100) surface at different loading/coverage levels. Reproduced with permission from ref (77). Copyright 2008 American Physical Society.

Hydrogen also interacts strongly with the metal sites in MOFs. In a study by Weinrauch et al.,87p-H2 was first dosed into a MOF with Cu(I) sites. Two binding sites were clearly observed, with the stronger site resulting in peaks near 5 meV (40.3 cm–1), and the weaker site having rotational excitations around 14 meV (112.9 cm–1) (Figure 11). Interestingly, when D2 was further added to the system, it preferentially binded to the strong site, displacing the H2 to the weaker site. The origin of this selectivity is associated with nuclear quantum effects and may have potential applications in selective activation or separation of H2/D2. Similar INS features indicating a strong interaction between H2 and open metal sites are also observed in other MOFs.75,85,86 On the contrary, there are also MOFs in which the metal sites are already saturated. Thus, H2 does not have direct access. In these cases, much weaker interactions between H2 and organic linkers or hydroxyl groups are expected, resulting in a rotational peak very close to the free rotor at 14.7 meV (118.6 cm–1).84

Figure 11.

INS spectra of H2/D2 adsorbed on a Cu(I) MOF. Inset highlights the strong (∼5 meV (40.3 cm–1)) and weak (∼14 meV (112.9 cm–1)) adsorption sites, as well as the displacement of H2 from the strong sites to the weak sites upon D2 addition (note that scattering from D2 is an order of magnitude weaker than that from H2). Reproduced with permission from ref (87). Copyright 2017 Nature Publishing Group.

The interaction between H2 and metals can be rather complicated, and the product can be found in a broad spectrum, as illustrated in Figure 12 by Kubas.88 Specifically, between the extremes of an H2 molecule and the metal dihydride, there can be multiple intermediate states depending on the relative strength of the interactions between the two H atoms and the metal site. A key indicator is the H–H distance, which, together with the environment-dependent hindrance experienced by the H2, will exhibit strong signatures in the INS spectra. Assignment of the peaks can lead to important information on H–H distance, nature of the complex, tunneling frequency, energy barrier, etc. In the case of W(CO)3(η2-H2)P2,88,89 the tunneling peaks can be explained by a quantum H2 rotor with an elongated H–H bond (0.82 Å) in a double-well with an energy barrier of 762 cm–1.

Figure 12.

H–H distance under various situations. Reproduced with permission from ref (88). Copyright 2007 American Chemical Society.

Silica, zeolites, and porous carbon are common catalysts or substrate materials for catalysts. Understanding their interaction with H2 is important. A study of p-H2 adsorption on Cu-ZSM-580 found that the rotational excitation J(0 → 1) exhibited a double peak with the first peak around 12 meV (96.8 cm–1) and the second peak around 14 meV (112.9 cm–1). Similar features are also observed in other porous silica or zeolite materials.79 The two peaks usually go side by side, even at very low coverage, indicating that they are not due to two adsorption sites. The integrated intensity of the first peak is about twice that of the second peak. A reasonable explanation is that the first peak is due to excitation from J0M0 to J1M ± 1 (M is the magnetic quantum number and in the free rotor has a degeneracy of (2J + 1)). In contrast, the second peak is due to excitation to J1M0. This suggests that the hydrogen is likely parallel to the surface and has a slightly reduced rotational constant (meaning a slightly compressed H–H distance).

In brief, this section summarizes the basic theory of INS from dihydrogen, as well as the applications of INS to understand the status of H2 adsorbed on different porous materials and surfaces. The strength and advantages of INS are prominent, and it is arguably the most powerful technique available to understand adsorbed dihydrogen.

3.2.2. Metal Hydrides in Ammonia Synthesis and Other Reactions

The cost of CO2 emissions in the Haber–Bosch process for ammonia synthesis has resulted in intensive efforts to find alternative catalysts.90,91 In 2000, it was reported92 that ternary nitrides Fe3Mo3N, Co3Mo3N, and Ni2Mo3N were active catalysts, particularly when doped with Cs. The materials have been studied by in situ neutron powder diffraction.93,94 Computational studies suggest two mechanisms95 are operative: one involves the direct reaction between surface-bound activated N2 and H2; in the second, H2 dissociates on a Co8 cluster and reacts with N atoms on the surface. Presumably, the role of Cs is to promote the dissociation of H2.

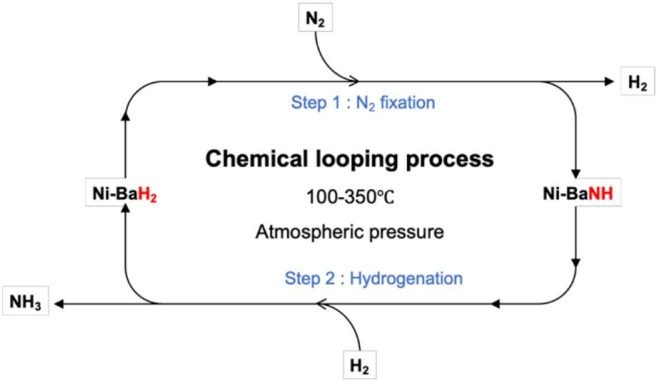

Recent work has shown that alkali metals or alkaline earth hydrides, combined with transition metals, are active ammonia synthesis catalysts.96 The group I and II hydrides have been comprehensively characterized by INS spectroscopy and DFT calculations,97−99 as have many ternary metal hydrides.100 These catalysts are operated in a chemical looping mode involving alternating cycles of nitrogen fixation and hydrogenation, as illustrated schematically in Scheme 1. An INS and in situ neutron powder diffraction study101 of Ni/BaH2 as a model catalyst for ammonia synthesis clearly showed the cycling between BaNH and BaH2. Such systems are ideally suited to neutron scattering, and there are clearly opportunities in this area.

Scheme 1. Proposed Mechanism for the Chemical Looping Process for Ammonia Synthesis over Ni/BaH2.

Reproduced with permission from ref (101). Copyright 2021 Springer.

A novel development in materials chemistry has been the discovery of oxyhydrides.102 The archetype is BaTiO3Hx that contains both O2– and H– ions. Several of the parent compounds have been investigated by INS.103−106 These materials have been proposed as catalysts or catalyst supports for various reactions, including ammonia synthesis,107 selective hydrogenation,108 and steam reforming of ethanol.109 The last of these has been extensively investigated by INS using a CeNixHyOz catalyst.109−112Figure 13 shows a schematic of the reaction and depiction of the active site. The INS spectra are assigned as the hydride (peak at 460 cm–1) and hydrogen chemisorbed on nanoparticulate Ni (peak at 870 cm–1).

Figure 13.

Top: schematic of ethanol reforming using a CeNixHyOz oxyhydride catalyst. Bottom: background subtracted INS spectra of CeNiXHZOY catalysts obtained after treatment in H2 at 250 °C: (a) X = 0.5 and (b) X = 1. Reproduced with permission from ref (110). Copyright 2013 Wiley-VCH.

3.2.3. Hydrogen on/in Metals

While most of the transition metals form binary hydrides of the hydrogen-in-metal type,113 albeit about half of them only do so at high pressure,114 for applications in heterogeneous catalysis, it is the formation of surface hydrides that is generally required.115 Industrially, the most important ones are Ni, Pd, Pt (hydrogenation catalysts), Fe (ammonia synthesis and Fischer–Tropsch synthesis), Co (Fischer–Tropsch synthesis), and Cu (methanol synthesis).

Hydrogen bound to a surface is difficult to detect by vibrational spectroscopy. Raman spectroscopy is usually hampered by fluorescence; infrared spectroscopy suffers from the bands being intrinsically weak and, for supported catalysts, often from a limited spectral range because of absorption by the support. The metal surface selection rule restricts both forms of spectroscopy: only modes that involve motion perpendicular to the surface are allowed.116 All these factors are irrelevant to INS spectroscopy: metals and supports are essentially transparent to neutrons (so the entire 0–4000 cm–1 range is observable), and there are no selection rules. The disadvantages of INS are that it is insensitive and usually measured at 20 K or less. INS spectroscopy requires 0.1–10 mmol H (depending on the instrument) in the beam. Generally, for metal surfaces, at best, there is a 1:1 ratio of hydrogen to surface atoms; this means that to obtain sufficient hydrogen in the beam, high surface area materials are essential. Thus, the samples are usually either supported metals, where the metal loading is at least 5 wt %, or (relatively) high surface area (10–80 m2 g–1) metals, most commonly Raney-type or metal blacks (skeletal metals). Work before 2005 is reviewed elsewhere,40 so the focus here will primarily be on work since then.

The metals that have been studied by INS are those that form surface hydrides under ambient conditions, and for this reason, almost all of the studies have been of Ni, Pd, and Pt. Hydrogen on these metals has been studied many times40 and, notably, the spectra are consistent between different groups at various institutions across the decades.

3.2.3.1. Nickel

Figure 14a shows the INS spectrum of hydrogen on Raney Ni,117 which is typical of that usually found.118 Shown in Figure 14b is the INS spectrum of hydrogen on a novel type of Ni foam catalyst.119 This evolution of the Raney process results in a highly porous, lightweight material.120 It is clear that the spectra are markedly different. In Figure 14b, there are hints of peaks at 900 and 1030 cm–1, which by comparison to Raney Ni, are assigned to hydrogen on (111) facets. The major difference is the greater intensity in the 400–800 cm–1 region. This is assigned to hydrogen on “non-(111)” facets. The intensity shows a much larger degree of surface heterogeneity in this sample than in Raney Ni. A crude estimation, based on the relative area of hydrogen on the (111) sites to the total area, would indicate that there are approximately equal numbers of (111) and non-(111) sites in the foam catalyst. In contrast, for Raney Ni, the ratio is at least 5:1, (111) to non-(111).

Figure 14.

Difference INS spectra of hydrogen on: (a) Raney Ni (blue) and (b) the Ni foam sample (red). Reproduced with permission from ref (119) under a Creative Commons Attribution 4.0 International License (CC-BY).

3.2.3.2. Palladium

Palladium is exceptional in readily absorbing hydrogen at room temperature to form the archetypal hydrogen-in-metal system.121 The stoichiometry is PdHx where 0 ≤ x ≤ 1. There are two phases, α (x ≤ 0.017) and β (0.60 ≤ x ≤ 1), and the two phases coexist in the intermediate regime. The α-phase is a solid solution of hydrogen in Pd, and the β-phase is an ordered structure.122 Ignoring imperfections, in a face-centered cubic (fcc) metal such as Pd, there are two possible sites for hydrogen to occupy: octahedral (O-site) and tetrahedral (T-site) (see Figure 15, Inset). In bulk PdH, the longer Pd–H distance of the octahedral site means that this is the preferred site for both the α- and β-phases. INS spectroscopy is consistent with this,123 as the 0 → 1 (fundamental) transition in PdH is at ∼500 cm–1, whereas in ZrH2, where the tetrahedral site is occupied,124,125 the fundamental transition is at ∼1050 cm–1 (Figure 15).

Figure 15.

INS spectra of PdH and ZrH2. Inset: the octahedral (O-site) and tetrahedral (T-site) sites available in an fcc solid. The inset is reproduced with permission from ref (125). Copyright 2016 American Chemical Society.

The hydrogenation activity of Pd is dependent on the availability of hydrogen. This is clearly seen in the Lindlar catalyst126 (5%Pd+3.5%Pb/CaCO3). This stereoselectively hydrogenates alkynes to cis-alkenes and is a key reagent in the production of vitamin A.127 INS spectroscopy shows that under 1 bar H2 pressure, the Lindlar catalyst retains 2.2 times less hydrogen than the equivalent Pd-only catalyst (5% Pd/CaCO3).128 The amount of β-PdH formed strongly depends on the catalyst morphology, which is largely determined by the support choice and synthesis conditions. This is apparent in the INS spectra of a series of carbon supported Pd catalysts129 as shown in Figure 16, and the relative areas of the region 350–800 cm–1 are shown in Table 2. The shape and intensity of the 0 → 1 transition of β-PdH at ∼500 cm–1 differ.

Figure 16.

Normalized difference INS spectra of a series of carbon supported Pd catalysts after subtraction of the same sample evacuated at 200 °C overnight. Key: sample 1 (red) Pd(20%)/activated carbon, sample 2 (blue) Pd(20%)/carbon black, sample 3 (olive) sample 2 heated to 300 °C in argon, and sample 4 (violet) sample 2 heated to 400 °C in argon. Reproduced with permission from ref (129) under a Creative Commons Attribution 3.0 Unported License (CC-BY).

Table 2. Integrated Hydrogen Areas from the IINS Spectra in Order of Increasing Average Primary Particle Sizea.

| Catalyst (sample no.) | Morphologyb | DN/nmc | Relative aread |

|---|---|---|---|

| Pd(20%)/carbon black (2) | agg | 2.40 | 1.31 |

| Pd(20%)/activated carbon (1) | prim | 3.58 | 1.00 |

| Pd(20%)/carbon black 300 °C (3) | agg/prim | 6.73 | 1.65 |

| Pd(20%)/carbon black 400 °C (4) | prim | 7.74 | 1.30 |

Reproduced with permission from ref (129) under a Creative Commons Attribution 3.0 Unported License (CC-BY).

Morphological differences according to TEM: agg = mostly aggregates, prim = mostly isolated primary particles.

Average particle size from statistical determination by TEM.

The influence of the support and the effect of alloying were also seen in a series of catalysts tested for hydrogenation of aromatic nitro compounds, a crucial step in the production of isocyanates for polyurethane manufacture.130 In the series Pd(5%)/C, Pd(4.5%)Pt(0.5%)/C, and Pd(4.5%)Pt(0.5%)Fe(5%)/C, the relative amount of hydrogen (normalized to 1 g Pd) is 4.7:3.33:1.00, respectively. This approximately correlated inversely with the activity seen in a model reaction (nitrobenzene hydrogenation): 6.6, 36.9, 23.1 mmol nitrobenzene min–1. A more detailed discussion of the influence of the support and the effect of alloying on morphology and hydrogen capacity is given elsewhere.131

At very low hydrogen concentrations, it is possible to detect surface-bound hydrogen. Figure 17a shows the INS spectrum of a Pd black after dehydrogenation at 100 °C. The key role of modeling in neutron scattering was emphasized earlier in this review. Figure 17b shows the results of a DFT calculation for the model shown in Figure 17c. The model has hydrogen in 3-fold coordination sites at the surface, which results in modes at 815/988 cm–1 (738/966 cm–1) and in subsurface sites that result in the 496 cm–1 (476 cm–1) mode (experimental values in brackets). The width of the calculated peaks is because of strong vibrational dispersion (variation of transition energy with wavevector) in the modes.

Figure 17.

(a) INS spectrum of Pd black after dehydrogenation at 100 °C, (b) calculated INS spectrum based on the model shown in panel (c). Reproduced with permission from ref (129) under a Creative Commons Attribution 3.0 Unported License (CC-BY).

While the state of the hydrogen in β-PdH has been comprehensively studied, the nature of the hydrogen at the surface has been almost completely neglected by NVS: we are unaware of any experimental studies in this area. By using an INS spectrometer that can be optimized31 to look for modes at ∼2000 cm–1, it was possible to detect a weak vibration at 2150 cm–1 that was assigned to hydrogen in the on-top site (i.e., bonded to a single metal atom).129

Differences in the activity and selectivity of α- and β-phase hydride in the selective hydrogenation of ethyne are known,132 and this may be related to the presence or not of the on-top surface site. The on-top site is undoubtedly populated under conditions where H2 gas is present, so it is likely a hitherto unrecognized participant in catalytic hydrogenations by β-PdH.

Earlier, we had stated that hydrogen occupies the O-site in the Pd bulk. Lately, this view has been challenged. Based on neutron diffraction studies of Pd nanoparticles, two groups125,133 have proposed that there is a significant occupation of the tetrahedral sites, particularly near room temperature (Figure 18 upper part). A third group134 claims to have imaged the interstitial hydrogen atoms at the near-surface region of octahedral PdHx nanoparticles by scanning TEM. The absorbed hydrogen occupies the T-site interstices near the surface, while the occupation gradually changes to the O-site in the bulk. DFT calculations show that the absorption energy difference between T-site and O-site hydrogen becomes much smaller at the subsurface than in bulk Pd and can be further reduced at the subsurface of PdH. An INS study135 found excess intensity in the spectra of nanoparticulate PdH0.42 as compared to the bulk (Figure 18 lower part) that was assigned to hydrogen in T-sites. The authors also found additional intensity around 2000 cm–1 that was not accounted for within their model and suggested that this may be surface species. This would be consistent with the earlier study.129 QENS of the same nanoparticles used for Figure 18 (lower part) showed an additional fast process not seen in the bulk, which was interpreted as jumps between T-sites.136 The O- and T-sites are energetically distinct, so they presumably have different reactivity that may influence their properties. This topic merits further investigation.

Figure 18.

Upper: temperature dependence of the fraction of the D atoms at the T-sites (nT) determined by Rietveld analysis of PdDx.125 Lower: INS spectrum of nano-PdH0.42 at 10 K.135 The difference between H adsorption in the bulk (dashed line) and the nanoparticles (solid line with error bars) is shown at the bottom of the figure as a series of Gaussian bands. These are assigned as hydrogen in T-sites. Upper image reproduced with permission from ref (125). Copyright 2016, American Chemical Society. Lower image reproduced with permission from ref (135). Copyright 2017 American Physical Society.

3.2.3.3. Platinum

In marked contrast to palladium, the hydrogen solubility in platinum is essentially zero, so the hydrogen is entirely at the surface. Hydrogen readily dissociates on platinum at room temperature, but the temperature range over which this occurs was unknown. This can be investigated by QENS. An elastic window scan of a Pt(50 wt %)/C fuel cell catalyst that was loaded with H2 at 20 K137 showed three regions: the decrease in signal in temperature below 60 K corresponded to desorption of physisorbed H2, the increase in signal in the temperature range 60–125 K was because of the dissociation of H2 and consequent binding of hydrogen to the surface. The slow decrease above 150 K was the usual behavior as the Debye–Waller factor increases. The data clearly shows that H2 dissociates on Pt over the range 60–120 K.

INS is a relatively insensitive technique, so to maximize the signal, either Pt black or high metal loading (40–60 wt % Pt) supported catalysts have been used. Improvements in instrumentation mean that 5 wt % Pt catalysts can now be studied.138−140 Remarkably, it is possible to observe both the expected Pt–H modes and molecular hydrogen physisorbed to Pt–hydride species.138

The assignment of the surface sites occupied by hydrogen on platinum has been controversial for decades.40 The INS spectra are remarkable because the overall profile is almost independent of the environment. Hydrogen on Pt black,141,142 on Pt in zeolite Y,142 on Pt on carbon,137 silica,142 or alumina supports138−140 all give essentially the same spectra. DFT calculations of hydrogen on a Pt nanoparticle141 and alumina supported Pt clusters140 have finally resolved the debate. Figure 19 shows a comparison of the INS spectrum of hydrogen on Pt black and that calculated for a Pt44H80 nanoparticle (inset in the figure). Apart from a small shift to higher energy, the calculation is in outstanding agreement with the experimental data. Calculated INS spectra can be readily decomposed into individual contributions, and Figure 19b–d shows the contributions of the on-top site, the 2-fold bridge, and the 3-fold site. No 4-fold coordinated H atoms exist because the Pt–H distance is too long. Instead, hydrogen forms 2-fold bridges around the edges of the 4-fold site, and there is a complete absence of subsurface hydrogen, consistent with the vanishingly small solubility. It had been assumed that the 3-fold site would be dominant because (111) was the lowest energy surface of Pt. This work shows that this is not the case, and the major contributor is the 2-fold site. The work on the supported clusters gave the same results: the best fit to the experimental data was a linear combination of models that mainly had 2-fold sites.140

Figure 19.

Comparison of: (a) the experimental INS spectrum of hydrogen on platinum black (olive) recorded on IN1-Lagrange with that calculated by (b) lattice dynamics (red) for the Pt44H80 nanoparticle shown in the inset. (On-top hydrogen are shown in white, 2-fold hydrogen in red and 3-fold hydrogen in yellow.) Contributions from the different sites to the total spectrum of the Pt44H80 nanoparticle: (a) on-top, (b) 2-fold, and (c) 3-fold. Reproduced with permission from ref (141) under a Creative Commons Attribution 4.0 International License (CC-BY).

One noticeable outcome of the work is that both analyses show the H:Pt ∼ 2. Hydrogen chemisorption measurements to determine the metal dispersion have always assumed H:Pt = 1. This work demonstrates that this is not a reasonable assumption.

3.2.3.4. Cobalt

Cobalt-based catalysts are becoming increasingly important for low temperature Fischer–Tropsch synthesis of long-chain hydrocarbons from syngas (H2 + CO).143−145 A key step in the reaction is the dissociation of H2 on cobalt. Surprisingly, studies by vibrational spectroscopy of hydrogen adsorbed on Co are extremely scarce. There is one comprehensive surface science study of hydrogen on Co(1010)146 and two INS studies that used Raney Co.147,148 Recent work119 has shown that both of these are flawed: bands that were assigned as Co–H modes are, almost certainly, deformation modes of hydroxyls. Distinguishing between hydroxyls and metal–hydrogen modes with the type of spectrometer (“indirect geometry”) commonly used for molecular spectroscopy is difficult. While these give excellent spectra below 2000 cm–1 (most of the INS spectra shown in this review were recorded with this type of spectrometer), their design means that data in the C–H/N–H/O–H stretch region (2500–4000 cm–1) is unreliable (as explained in more detail elsewhere31). The complementary use of a different type of spectrometer (“direct geometry”) that enables the high-energy region to be studied reliably is essential, as the presence or absence of an O–H stretch mode allows an unambiguous distinction between hydroxyls and metal–hydrogen modes.

Figure 20 shows spectra for hydrogen on Raney Co recorded with a direct geometry instrument.119 The difference spectrum (Figure 20c) shows a broad band centered at ∼880 cm–1. Crucially, the difference spectrum shows no change in the O–H stretch region on the addition of hydrogen, so the feature at 880 cm–1 cannot be hydroxyls. Comparison with the transition energies found for the high coverage phase of hydrogen on Co(1013)146 shows that the envelope encompasses the modes and that there are submaxima at, or close to, the Co–H modes found for Co(1010).

Figure 20.

INS spectra of Raney Co, all spectra recorded with a direct geometry spectrometer (MAPS). Top: Ei = 650 meV (5243 cm–1), bottom: Ei = 300 meV (2420 cm–1). (a) Dried, reduced sample, (b) sample plus 1 bar H2, and (c) the difference spectrum (a–b). The vertical bars in the lower part are the transition energies at which the Co–H modes are found for the high coverage phase of hydrogen on Co(1010). Reproduced with permission from ref (119) under a Creative Commons Attribution 4.0 International License (CC-BY).

The work showed that an oxidic and/or hydroxylated Co surface is very resistant to reduction. An extended reduction period at >250 °C is required to remove most hydroxyls. It is also clear that the clean surface is highly reactive: even very small amounts of oxygen (e.g., as found in a typical glovebox) result in the hydroxylation of the surface.

Recently, INS proved that the existence of oxygen vacancies on Co3O4 played an important role in the formation of hydride.149 The activation of H2 over Co3O4 at 250 °C formed Co–H species at 110 meV (887.3 cm–1) and Co–OH moieties evidenced by a broad feature around 80–160 meV (645.3–1290.6 cm–1). However, the activation of H2 over metallic Co did not yield features of Co–H due to the absence of Co–O and oxygen vacancies. DFT calculations indicated that H2 underwent both homolytic and heterolytic dissociation over CoO(100)–OV sites to yield hydride species.

3.2.3.5. Copper

Copper is a key component in the Cu/ZnO/Al2O3 catalyst used for the industrial manufacture of methanol.150 As discussed in more detail in the section on methanol synthesis (Section 3.3.1), copper(I) hydride, CuH, has been proposed as a hydrogen reservoir in the reaction.

CuH was the first binary metal hydride to be discovered (in 1844)151 and has been characterized by neutron diffraction152−155 and INS spectroscopy.154,155 The diffraction studies show that while the stoichiometric material can be made, it is generally nonstoichiometric, CuHx, with x ∼ 0.75. There are aqueous and nonaqueous routes to make CuHx. The resulting materials have different properties, particularly regarding solubility. A combination of total scattering neutron diffraction, INS spectroscopy, and DFT calculations showed that the products from both routes were nanoparticulate with a core of CuHx but with different surface termination: bonded hydroxyls for the aqueous routes and a coordinated donor for the nonaqueous routes.

CuHx provides a particularly clear example of how the nature of an adsorbed layer on a nanoparticle surface determines its properties. Functionalization and optimization of nanoparticles by manipulating the surface layer is a topic of considerable interest,156 as it potentially provides a means to tailor the properties of the system. INS spectroscopy is well-suited to characterize hydrogenous adlayers on nanoparticles,157 as the optical absorption that hampers conventional spectroscopy is irrelevant.

3.2.4. Hydrogen on/in Oxides

3.2.4.1. Hydride Species: H–

When exposed to H2, surface hydrides could exist on the surface of metal oxides. Generally, H– and H+ species from the heterolytic split of H2 can form a surface hydride (M–H, M is the metal cation) and a hydroxyl (OH), respectively, on nonreducible metal oxide surfaces (e.g., MgO, Al2O3, ZnO). Two hydrogen atoms (H·) from the homolytic split of H2 can reduce a reducible metal oxide surface (e.g., CeO2, TiO2) and generate two hydroxyls. The formation of surface hydrides is not limited to nonreducible metal oxides. For instance, neutron-based experiments find that a hydride could be stabilized on the surface of reducible metal oxides when surface defects are present.158 In addition to surface defects, the electronic properties (e.g., polarization of the metal–O bond, bond strength of metal–H, reducibility, band gap) of metal oxides could also affect the formation mechanism of surface hydrides.159,160 Among all metal oxides that can form hydrides from H2, CeO2 is the most intensively studied.161,162 Over CeO2, it was found that the homolytic splitting of H2 was thermodynamically favored, whereas the heterolytic pathway was kinetically preferred. The results obtained from neutron techniques showed that hydride could exist on the ceria surface, although there were debates on the formation pathway. This section will primarily focus on hydride formation on the ceria’s surface and discuss the results obtained from neutron-based techniques. Reports of hydrogen on other metal oxides (e.g., ZnO) are scarce and will also be summarized.

Using INS, Lamonier et al. observed peaks attributed to hydride species (a peak at 490 cm–1) and surface hydroxyl groups (peaks at 100, 280, and 660 cm–1) on reduced cerium–nickel oxides.163 In addition to the surface hydride and the hydroxyl, several experimental and theoretical studies suggest that −OH and M–H species can be formed in the subsurface and bulk region of ceria due to the migration of surface H adatoms. Via in situ INS spectroscopy, Wu et al. found the existence of bulk Ce–H species in addition to surface hydride after heterolytic dissociation of H2 on ceria.164 However, the −OH groups in the bulk phase of CeO2 were not detected.164 It could be that bulk hydroxyl was unstable and destabilized as the amount of oxygen vacancies increased.165 Specifically, as shown in Figure 21, three groups of peaks were detected in INS spectra. Consistent with results obtained by Lamonier et al., sharp peaks at 400–650 cm–1 (B1) were assigned to the deformation band of surface Ce–H with a possible contribution from bulk CeH3-like species. Broad peaks at 750–1100 cm–1 (B2) were attributed to the deformation band of bulk Ce–H from CeH2 and/or CeH3-like species. The combinations and/or overtones of the B1 and B2 peaks were observed at 1300–1800 cm–1.

Figure 21.

Simulated INS spectra of bulk hydride of CeH2 and CeH3 and surface hydride on reduced (111), (110), and (100) surfaces. The experimental spectra from CeO2 after H2 treatment at 400 °C and bulk CeH3 are also shown for comparison. Reproduced with permission from ref (164). Copyright 2017 American Chemical Society.

Interestingly, products derived from homolytic splitting (surface–OHs) were observed on a close-to-stoichiometric CeO2 surface. In contrast, heterolytic products (Ce–H and −OH) were detected on the CeO2 surface with oxygen vacancies.164 These experimental results suggested that oxygen vacancies participated in the formation of hydride on the surface of ceria via heterolytic splitting of H2 and the proposed pathway was: H2 + O2– + □ → OH– + H– (□ = anionic vacancy). The hydride formed on the surface of ceria via heterolytic split of H2, based on both experimental and theoretical results, could transform into hydroxyl in the presence of O2, under which the oxygen vacancies were filled, leading to the transfer of H to the lattice O, the generation of −OH, and the reduction of two Ce4+ cations.159,161,162,166 The proposed mechanism was: 2H– + O2 → 2OH–.

Apart from neutron scattering studies, recent work proposed new pathways for hydride formation over CeO2,161,167,168 with the results in general agreement with the INS results. In one pathway, the 4f electron from Ce3+ could be transferred to hydrogen on the subsurface of CeO2 with defects to form hydride species and oxidize Ce3+ to Ce4+. The process was depicted as H2 + 2Ce3+Vo → 2Ce4+Vo–H– and could occur because the energy level of the localized 4f electron of Ce3+ was relatively high.167,169 In addition, Wang et al. found that the H– species originated from H2 heterolytic dissociation can exist on various stoichiometric CeO2 surfaces, including the low-index (111) and (100) surfaces and the high-index (221), (223), and (132) ones.169 Depending on the coordination numbers of the surface Ce, the stability of Ce–H was different. Specifically, the stability of the hydride species was higher if the coordination number of the surface Ce was lower. In addition to the correlation between the stability of the hydride with the coordination numbers of the surface Ce, it was also proposed that the pairs of hydride/proton species from heterolytic dissociation of H2 were thermodynamically stable on the CeO2(100) surface.170

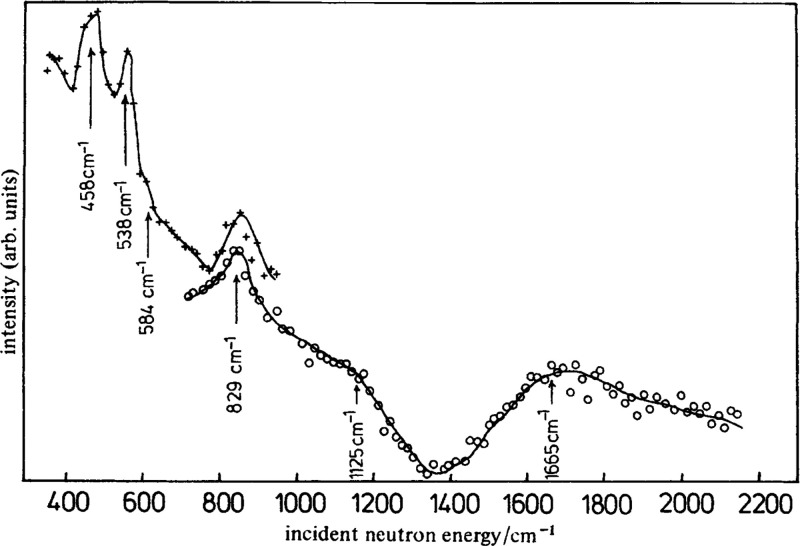

Neutron spectroscopy has also been applied to study hydride formation over ZnO since it was suggested that O vacancies on ZnO could promote the heterolytic dissociation of H2 and the stabilization of hydride species.171 As shown in Figure 22, several bands were observed on the INS spectrum of the H2–ZnO system. The intense band at 829 cm–1 and a strong, broad band at 1665 cm–1 were correspondingly assigned to bending and symmetric stretching modes of Zn–H from reversible dissociative adsorption of H2 on Zn–O dimers.172 The position of the symmetric stretching mode (1665 cm–1) was different from that observed by infrared spectroscopy (1710 cm–1), as the INS band was too broad to locate the center accurately. DFT calculations indicated that the 1665 cm–1 band was contributed by Zn–H species on the nonpolar surfaces and Zn surface.173 The 1125 cm–1 band was ascribed to the bending mode of −OH. According to the DFT results, the shoulder at 584 cm–1 could be attributed to the bending mode of surface bridging Zn–H–Zn species.173 However, the bridging structure (Zn–H–Zn) at 1475 cm–l detected by infrared spectroscopy could not be confirmed by INS.174 When ZnO was reduced under H2 at 20 bar, and at 300 °C, a broadband (∼500 cm–1 to ∼1250 cm–1) was observed in the INS spectrum.175 One might anticipate that hydride species contributed to this band due to the increased amount of oxygen vacancies under a highly reducible environment. However, according to simulated INS spectra, this band was most likely attributed to Zn–OH species (around 750 cm–1) rather than bulk Zn–H species (below 500 cm–1). Meanwhile, the contribution from surface Zn–H species could not be ruled out, as surface hydride species might have a band with a higher frequency than the bulk hydrides.

Figure 22.

Difference spectrum: INS spectrum of ZnO + H2, minus INS spectrum of ZnO. The symbol “+” indicates data collected using the (200) plane, and “o” those collected using the (220) plane of the copper monochromator. Reproduced with permission from ref (172). Copyright 1984 Royal Society of Chemistry.

3.2.4.2. Hydroxide Species: OH

Via different methods (e.g., hydrogen spillover), oxide hydroxides can be formed by hydrogen insertion into several metal oxides (e.g., WO3, ReO3, MO3, UO3, MoxW1–xO3, V9Mo6O40, rutile VO2).176−186 At room temperature, a low amount of H can be inserted into the structure of metal oxide (e.g., H0.34UO3) without changing the framework integrity of parent oxides.187 Higher hydrogen content could result in the formation of amorphous phases (e.g., HxV2O5, x > 3).178,188 By using INS, different types of hydroxide groups (−OH and −OH2) can be observed depending on the polymorphs and the extent of hydrogen insertion.189

In the INS spectrum of cubic H0.4WO3, an intense band at 1145–1170 cm–1 was observed and assigned to a M–O–H deformation vibration.190,191 In addition, the INS spectrum of h-H0.26WO3 showed bands at ∼1613 and ∼484 cm–1 attributed to OH2 groups. For h-H0.26 WO3, it was also proposed that H+ might exist as H3O+ in the hexagonal tunnels rather than −OH. On the other hand, for H0.92Mo0.44W0.56O3 and H1.02Mo0.70W0.30O3, it was proposed that H+ presented exclusively as −OH, as evidenced by the strong deformation band of M–O–H at 1089 cm–1. These outcomes differ from infrared spectroscopy results, which showed the existence of a hydride species (assigned to a trampoline vibration of the hydrogen atom). However, no hydride species at 690 cm–1 was detected by INS.192

For HxVO2, two intense peaks (1083 and 909 cm–1) were observed by INS and ascribed to orthogonal δ-V–OH bending modes according to calculations (Figure 23).182 For V9Mo6O40, which had alternate layers of MoO3-like and ReO3-like units, the inserted H atoms bonded with the O atoms linking edge-shared octahedral chains and constructing the square windows. INS spectra of HxV9Mo6O40 (x = 7.8 and 17.5) exhibited an intense and broad peak at ∼1081 cm–1 assigned to the combination of Mo–OH and V–OH deformation modes.176

Figure 23.

Generated atomic displacements of V3OH unit. Reproduced with permission from ref (182). Copyright 1991 Elsevier.

In the case of MoO3, when the H concentration was low (e.g., HxMoO3, x = 0.34), −OH groups existed, whereas, at high hydrogen concentrations (e.g., HxMoO3, x = 0.93, 1.68, 2.0), the hydrogen atoms tended to form −OH2 groups over bridging oxygen atoms of MoO3.191,193−197 Further reduction of MoO3 led to the attachment of H to the terminal O atoms.187 The same trend was also observed over HxUO3.189 Specifically, in the INS spectrum, the −OH deformation vibration band at 968 cm–1 was identified on H0.35MoO3.190 This band shifted to 1267 cm–1 in the INS spectrum of H0.34MoO3.191 A band around 1600 cm–1 was observed in monoclinic phases of HxMoO3 with higher H contents (e.g., x = 0.93, 1.68, 2.0) and was attributed to the H–O–H deformation vibration of the −OH2 group. The band at 1200 cm–1 was very weak in H0.93MoO3, indicating that most H existed as −OH2 rather than as the −OH group.

3.2.5. Hydrogen on/in Other Catalytic Materials

INS measurements have been applied to study the surface of sulfides, carbides, nitrides, and electrides under H2 conditions. Using INS measurements, one could study the H2 activation capability of different metals and H-containing species in the system. For instance, metal sulfides (e.g., MoS2, CoMoS2) are widely applied in the industrial hydrodesulfurization process. In studying MoS2, a band at 660 cm–1 attributed to the Mo–S–H bending mode was observed, suggesting that H2 could be activated and the chemisorbed H species was bounded to the S sites.198 However, no bands assigned to H species on Co9S8 were detected, indicating that Co sites did not function for activating H2. For ruthenium sulfide, H–S bands and two different Ru–H linear species (probably related to different Ru facets) were observed.199 The hydride species was proposed to be active in hydrogenation since it was weakly adsorbed compared with −SH. Depending on the type of metal sulfides, the position of the −SH bending mode was different: 650 cm–1 for MoS2, 694 cm–1 for WS2, 600 and 710 cm–1 for RuS2.200 For a ruthenium sulfide catalyst, it was found that the adsorption of H2 depended on the sulfur-to-metal ratio, and coordinatively unsaturated S–S anion pairs were identified as active sites for H2 adsorption.199

Metal carbides, nitrides, and phosphides are highly active in hydrogenation reactions (e.g., hydrodenitrogenation and hydrodeoxygenation). However, relevant studies about the surface H species over these materials in hydrogenation related reactions are scarce. Based on INS data, it was found that the adsorption site of H depends on the composition of the carbide. For instance, in the H2–NbCx system, peaks at 774 cm–1 for NbC0.76Hx and 524 cm–1 for NbC0.76Dx were assigned to optical vibrations of H or D atoms occupying the centers of carbon vacancies.201 On the NbC0.71H0.28 sample, an additional peak at ∼1049 cm–1 was observed, which might be related to H atoms at sites displaced from the centers of carbon vacancies. Such sites were relatively unstable, as evidenced by the significantly decreased intensity of the 1049 cm–1 peak at elevated temperatures.

INS could help determine the site for H adsorption in systems with multiple surface sites. For instance, when γ-Mo2N was exposed to H2 at elevated temperature, γ-Mo2N–Hx (0.061< x < 0.082) phases were detected.202 According to H2-temperature programmed desorption, there were at least two hydrogen binding sites on the surface of γ-Mo2N–Hx. DFT results suggested that hydrogen heterolytically dissociated on the γ-Mo2N. Surface N (κ1-NHsurf), surface Mo (κ1-MoHsurf), and interstitial Mo (μ6-Mo6Hsub) were the sites for adsorbing H. INS was employed to get detailed information on the H adsorbing sites, and several peaks were detected. Peaks at 800 and 832 cm–1 were assigned to κ1-NHsurf. Peaks at 658, 986, and 1324 cm–1 were attributed to μ6-Mo6Hsub (Figure 24), suggesting that H preferred to adsorb on the interstitial Mo sites over the surface Mo sites. It was also inferred that the subsurface H might migrate to the surface once the reactant (crotonaldehyde) had consumed the surface H species.

Figure 24.

(right axis) Normalized INS spectra for (red) γ-Mo2N and (blue) γ-Mo2N-Hx samples and their difference spectrum (black, γ-Mo2N-Hx – γ-Mo2N). (left axis) Simulated INS spectra (summed over zero to four quantum transitions). Areas in the difference spectrum showing loss upon the addition of hydrogen match the computed κ1-NH surf model (green) well. Areas showing growth upon the addition of hydrogen are consistent with a μ6-Mo6H submodel (pink). Reproduced with permission from ref (202). Copyright 2016 American Chemical Society.

By monitoring the surface species, INS can also examine if the moieties are active or spectator species. For instance, although many electrides were successfully synthesized recently and exhibited interesting catalytic properties in certain reactions (e.g., ammonia synthesis), it needed to be clarified whether the hydride species in the bulk were involved in the reactions. INS spectra and DFT calculations were combined to reveal the role of encaged hydride species on Ru/C12A7:e– under ammonia synthesis conditions.20 According to the INS spectra, the intensity of the hydride band did not change significantly when the catalyst was exposed to N2, suggesting that the hydride species in the cage was chemically stable and might not be the active species in ammonia synthesis. Instead, it was proposed that the surface-adsorbed H species was responsible for the activity of the Ru/C12A7:e– catalysts in NH3 synthesis.

3.2.6. Adsorbed Hydrocarbons on Catalyst Surfaces

This section is focused on how neutron scattering techniques can be used to interrogate catalytic systems involving hydrocarbons. Many catalytic systems connected with contemporary chemical manufacturing techniques involve hydrocarbon transformations. For heterogeneously catalyzed processes, turnover cannot occur without the adsorption step. This section reviews the phenomenon of hydrocarbon adsorption, primarily from the perspective of using INS to access the vibrational spectra of adsorbed moieties. It is informative to consider aspects of the early pioneering work in this area and to follow the topic in time when, via a combination of improved spectrometer specifications and sample environment options, increasingly more complex adsorption systems are being investigated.

INS studies of adsorption (physisorption and chemisorption) in the 1970s and 1980s tended to concentrate on olefin adsorption over various substrates. For example, in 1977, Howard and Waddington used the beryllium filter detector (BFD) spectrometer located at the Atomic Energy Research Establishment (AERE) at Harwell (UK) to examine acetylene adsorption on Ag+ exchanged 13X zeolite.203 The BFD spectrometer provided somewhat limited resolution. The authors deduced from a partial vibrational assignment that acetylene was adsorbed nonlinearly on Ag-13X. Following on from work by Jobic and co-workers on Raney platinum,204 Graham and Howard used a combination of spectrometers located at the AERE and the Institute Laue-Langevin (France) to examine the adsorption of benzene on platinum black.205 A strong coverage dependence of the spectra was reported, and the authors could deduce that the plane of the molecule was parallel to the metal surface.

In 1985 Kelly and co-workers using a triple-axis spectrometer located at the National Bureau of Standards (USA), measured the INS spectra of ethyne and ethene on Raney nickel.206 Decomposition processes were observed on thermal ramping. The vibrational spectra of the molecularly adsorbed species were obtained and compared to vibrational electron energy loss spectra obtained using a nickel single crystal. Contrasts in the spectra enabled the authors to conclude that steps and edge sites on the high surface area material exhibited a reduced activation energy for dissociation.206 In 1992, Jacqueline Nicol reviewed the topic of using INS to investigate chemisorbed hydrogenous molecules, which included an informative section on the important matter of sample environment considerations.207

Improvements in spectrometer design in the 1990s and thereabouts led to improved resolution and sensitivity, enabling a wider range of substrates to be examined. For example, Henson and co-workers used the filter difference spectrometer (FDS) located at the Los Alamos National Laboratory (USA) to investigate the adsorption of ethene on Na zeolite Y.208 McNamara and co-workers used the TOSCA spectrometer located at the ISIS Neutron Facility of the Rutherford Appleton Laboratory (UK) to examine the physisorption of ethene and propene on activated carbon that was representative of that used as a catalyst support material for dispersed metal catalysts.209Figure 25 shows the spectra of solid propene (a) compared to that of the adsorbed variant (b). Normal coordinate analysis revealed the alkene as a physisorbed, disordered layer on the carbon.209

Figure 25.