Abstract

Five pretreatments methods, cold plasma, pressure drop, heating, and bath-type and probe-type sonications were compared to shorten the rehydration process of adzuki bean (Vigna angularis) soaked before the cooking in terms of the hydration and softening efficacies. Moisture content and water activity of the probe-type sonicated beans were most dramatically increased as 11–45% and 0.59–0.97 after soaking for only 2 h, respectively (non-treated: 11–12% and 0.59–0.66). Accordingly, the probe-type sonicated beans were most rapidly softened as 27–5 N in the 2 h-soaking and exhibited the lowest hardness after soaking/cooking as ~ 0.97 N (non-treated: 27–21 N and ~ 5.5 N, respectively). According to scanning electron micrographs, these results can be attributed to formation of prominent fissures or scars in the hilum of the probe-type sonicated beans. Consequently, this study will be provide valuable information for developing a rational process in food industry to shorten the rehydration of the adzuki beans.

Keywords: Adzuki bean, Rehydration, Softening, Pretreatment, Probe-type sonication

Introduction

Adzuki bean (Vigna angularis), also called red mung beans, is an excellent nutritional source, including carbohydrates (57–62%), protein (17–21%), fiber (12–13%), B vitamins, and various minerals such as Fe, Mg, K, and Zn (Tjahjadi et al., 1988; Yadav et al., 2018). Adzuki bean is cultivated in more than thirty countries worldwide and mainly in the temperate regions of East Asia, China, Japan, and Korea (Yin et al., 2019). Adzuki beans are cooked and consumed as a typical ingredient in desserts and snacks in East Asian countries, especially during traditional festivals and celebrations (Honda et al., 2020; Yousif et al., 2002). In Japan, adzuki bean is the most preferred ingredient to make bean paste (so called ‘ann’) and filler in various sweet pastries among various legume seeds because of their desirable color, delicate flavor, and characteristic texture. In Korea, it is widely used for fillings such as red bean porridge, rice cakes, bread, and snacks, as well as for making red bean paste, yokan, and frozen desserts (Woo et al., 2016).

Drying is a common method for preserving and storing various legume seeds including adzuki beans, which is the primary way for maintaining the year-round supply. While increase in the shelf life during the storage in dry conditions, adzuki beans are gradually dried as the time is passed, resulting in the hard-to-cook defects due to several biochemical and biophysical changes in the structure. The biochemical changes include a lignification of cell wall and middle lamella, a formation of insoluble pectinic acids, changes in the structure and functionality of cellular proteins and starches, and a formation of tannin condensates with proteins and starches (Yousif et al., 2007; Zhou et al., 2013). The biophysical change can be a size reduction or a closure of strap hole apertures in the hilum region that is the main area for water entry into the adzuki bean (Yadav et al., 2018; Yousif et al., 2007). In addition, this irreversible hard-to-cook phenomenon can be also happen when storing even at high humidity and high temperature (Reyes‐Moreno et al., 1993; Valencia-Mejía et al., 2019), due to changes in the cotyledon tissue.

Because of those reasons above, adzuki beans stored in dried conditions are typically water-soaked to rehydrate/soften those and shorten/ease subsequent procedures including cooking (Doymaz, 2016; Yadav et al., 2018). However, the longer soaking time, not only the more waste of time but also the more biological contamination risks (Duarte Santos and Badiale Furlong, 2021). To compensate for these disadvantages of water-soaking, some pretreatment methods, including heating (Abdul-Kadir et al., 1990), pulsed electric field treatment (Andreou et al., 2021), ultrasound treatment (Ghafoor et al., 2014), pressure changes (Miano and Augusto, 2018), and cold plasma treatment (Zhou et al., 2020), have been studied for shortening the rehydration procedure of dried legumes and grains. However, all of these pretreatment methods were not applied still for adzuki beans or need to be better studied and compared of each other. Therefore, effects of these pretreatment methods on the rehydration of adzuki beans were investigated in this study, with the comparison based on changes in the water contents, water activity (Aw), hardness, and microstructure of the surface after each pretreatment.

Materials and methods

Materials

Adzuki beans (Vigna angularis) seeds of cultivar Arari grown and harvested in Korea at 2022, were procured from the Department of Southern Area Crop Science, National Institute of Crop Science (Miryang, Korea). Regular-shaped beans without flaw (weight, 0.20 ± 0.02 g/grain; moisture content, 11.02 ± 0.38%) were selected and stored at 4 °C in dried condition before use.

Pretreatment methods

Corona discharge plasma jet

For each treatment, adzuki beans (~ 30 g) in a bottle (250 mL) were exposed to corona discharge plasma jet for 20 min, generated from a customized instrument (setting: 20 kV, direct current source at 1.40–1.50 A, and 58 kHz) used in previous studies (Kim et al., 2015; Puligundla et al., 2017). During the treatment, a distance between adzuki beans and a plasma jet electrode was maintained as 15 cm.

Bath-type sonication

For each treatment, adzuki beans (~ 30 g) in a meshed basket (Inlet diameter 9.5 cm, depth 7.5 cm) were sonicated for 20 min using a bath-type sonicator [amplitude, 200 W; NXPC-2010(P); Kodo Technical Research Co., Ltd., Hwaseong, Korea]. During sonication, the basket was not allowed to contact the bottom and walls of the bath, which were equipped with vibrators, to impede uneven sonication. To prevent the temperature elevation from 25 °C during the treatments, all the sonication was performed using the sonicator placed in an ambient condition at ≤ 10 °C without a cover.

Instantaneous pressure drop

For each treatment, a hand-cranked canon corn popper (volume of a chamber, 300 mL; mini popcorn maker; Zhoufeng Machinery & Technology Co., Ltd, Jiaozuo, China) containing adzuki beans (~ 30 g) was heated in a 100 °C water-filled bath (SJP-500WB, Sejong Technology Co., Ltd., Bucheon, Korea). The lid of the popper was opened when reaching gauge pressure of the chamber to 0.1 MPa, the pressure value to avoid the burn of the beans, and the pressure was thereby instantaneously dropped.

Heating

For each treatment, a beaker (100 mL) containing adzuki beans (~ 30 g) and distilled water (50 mL) was incubated for 20 min in the water bath at 53–55 °C.

Probe-type sonication

For each treatment performed with a slight modification from a previously reported study (Choi and Lee, 2017), adzuki beans (~ 30 g) in a 50 mL distilled water-containing beaker (100 mL) were sonicated for 20 min (duty cycle, 1 s) using a prove-type sonicator (amplitude, 750 W; VC750; Sonics & Materials, Inc., Newtown, CT, USA); depth of the probe: 1.5 cm from surface of the water. To prevent gelatinization of starch induced by a heat generation during the sonication, the temperature was maintained at 30 °C using a heating bath circulator (CW3-05P; Jeio Tech. Co., LTD, Daejeon, Korea).

Water-soaking and cooking

For each sample preparation, adzuki beans untreated or pretreated were eliminated from the water after 0, 2, 6, 10, 14, 18, and 22 h of initiation of the soaking in a 150 mL distilled water-containing beaker at 28 °C, carefully wiped off, and used for the following measurements. To cook adzuki beans, 30 g of pretreated or untreated adzuki beans after water-soaking for 6 h and 150 g of rice were mixed with 250 mL of distilled water and cooked in an electric rice cooker (PK-500, ZhanJiang City Standard Electrical Co., Ltd, Zhanjiang, China). Following measurements with the beans were conducted immediately after the water-soaking or cooking as soon as possible without further storage.

Measurement of moisture content and water activity

Moisture content and Aw of the adzuki beans (~ 3 g) pretreated and water-wiped off were measured at the predetermined times after the water-soaking, using a moisture analyzer (MB45; Ohaus Co., Pine Brook, NJ, USA) and a water activity meter (AquaLab 4TE; Meter Group Inc, Pullman, WA, USA) (Nam and Chun, 2021), respectively.

Determination of hardness

Hardness of adzuki beans was determined using a texture analyzer (TA.XT plus; Stable Micro Systems Ltd., Godalming, UK). The measurements were employed in a return-to-start method, measuring the force under compression with a needle probe (P/2N for puncture tests); pre-test speed, 1.0 mm/s; test speed, 1.5 mm/s; post-test speed, 2.0 mm/s. Texture profiles obtained as force–time curves were recorded, and hardness values were determined as the maximum peaks in the profiles. Average of the hardness was determined for the values in at least individual 5 measurements.

Scanning electron microscopy

Microstructure of the surface of adzuki beans was observed and captured using a scanning electron microscope (JSM-7500F; Jeol Ltd., Tokyo, Japan). For a sample preparation, the beans were carefully cut in the half with a razor and dried at 60 °C for 24 h in an oven (OF-11E, Jeio Tech. Co., Ltd, Daejeon, Korea). The surface was metalized through coating platinum plasma for 2 min, using a sputter coater (108 Auto, Ted Pella Inc., California, USA), when the pressure of the coater reached 35 mbar and the coating thickness was ~ 10 nm, and mounted on aluminum stubs for the observation.

Statistical analyses

All experiments were conducted at least in triplicate. The results are expressed as mean ± standard deviation. Experimental data were analyzed using a software (SPSS Statistics Version 12.0; IBM Co., Armonk, NY, USA). Duncan’s multiple range tests were used to determine significant differences among the data (p < 0.05).

Results and discussion

Changes in the moisture content of adzuki beans

Moisture contents of adzuki beans were monitored over the entire 22 h to compare the efficiencies of pretreatment methods for reducing the time-consumption for the water-soaking. The moisture contents of untreated adzuki beans at 0, 2, 6, 10, 14, 18, and 22 h were 11.02, 12.16, 28.52, 49.43, 57.72, 59.08, and 59.75%, respectively (Fig. 1), and cold plasma-pretreated adzuki beans exhibited the moisture contents of 11.02, 13.14, 27.37, 50.20, 56.91, 59.43, and 59.43% at the same time points. The moisture contents of cold plasma-pretreated adzuki beans were not significantly different (p > 0.05) at all the time points compared to untreated adzuki beans, which indicates inefficiency of the cold plasma treatment in the level used at least in this study. This tendency was also observed in the beans pretreated with either bath-type sonication or pressure dropping, also suggesting the inefficiencies of these pretreatments.

Fig. 1.

Changes in moisture content of water-soaked adzuki beans after either untreatment or pretreatment using cold plasma (plasma), bath-type sonication (bath-type), instant pressure dropping (pressure drop), heating, or probe-type sonication (sonication). Different letters (a–c) on the same soaking time (2, 6, or 10 h) mean significantly difference (p < 0.05)

On the other hand, adzuki beans pretreated with either heating or probe-type sonication exhibited higher moisture contents (p < 0.05) than untreated beans at the time points until 10 h soaking (Fig. 1). Moisture contents of heat-pretreated adzuki beans were 11.02, 16.86, 36.54, 56.23, 58.80, 59.60, and 60.68% at each time scale. Notably, moisture contents of probe-type sonicated adzuki beans were most rapidly elevated to 45.63% within only 2 h soaking and significantly highest until 10 h soaking (p < 0.05). According to Ghafoor et al., nevertheless of a difference in the type of beans, it took ~ 3 h to reach a moisture content of 45.63% when 20 g of navy beans were treated with bath-type sonication of the power of 750 W, the same as the power in this study. This suggests the better efficiencies of heat pretreatment and especially probe-type sonication than those of others for reducing the water-soaking time.

It is generally known that the hydration procedures of unpretreated dried adzuki beans during the water-soaking occur in following three stages: (1) gradual hydration/softening in the initial 1–6 h after the soaking, (2) rapid increase in the hydration/softening during 6–12 h, and (3) almost no increase in the hydration after 12 h (Yousif et al., 2002; 2007). The initial hydration-rate of adzuki beans during the water-soaking is governed by conditions of the coat of adzuki beans (Pervin et al., 2008). Depending on the water-permeability of the coat, the hydration curves of water contents versus soaking-time show two different patterns, sigmoidal shape and downward concave shape (Chiu, 2021; Miano and Augusto, 2015). The effect of the coat then decreases at a particular time point, and particular components in cells of the cotyledon, such as proteins, influence the hydration of the beans (Aravindakshan et al., 2021).

In this study, all of untreated or pretreated adzuki beans exhibited the sigmoidal hydration behavior except for the probe-type sonicated beans. This sigmoidal hydration pattern of water-soaked adzuki beans has been also shown in a previous study (Oh et al., 2021). In detail, a lag phase appeared during the initial stage of the hydration. This could be attributed to not enough glassy-to-rubbery state transition of the coat yet, resulting from unsteady water-transfer into the coat matrix (Aravindakshan et al., 2022; Miano and Augusto, 2015). In this stage, most of water absorbed into the beans only can transfer through the hilum, but the water can enter not only via the hilum but also via the ways of the coat when reaching water contents of the beans above ~ 20% (Miano and Augusto, 2015). The hydration of the adzuki beans rapidly ascended upon increase in moisture contents between ~ 15 and ~ 50%, which might be due to the complete state transition of the coat components. On the other hands, the hydration curve of the probe-type sonicated adzuki beans showed the downward concave pattern. The similar pattern in the water content change was reported in a previous study with bath-type sonicated navy beans (Ghafoor et al., 2014). In the study, there was no delay in the initial hydration. These results might be explained by the formation of highly porous structures on/in the coat by probe-type sonication, which provides an additional pathway for water influx without the state transition of the coat (Miano et al., 2016; Zhao et al., 2021).

Changes in the water activity of adzuki beans

The Aw of untreated and pretreated adzuki beans showed a similar pattern with the moisture contents over 22 h water-soaking (Fig. 2). The curves of Aw (0.58 → 0.99) of untreated and cold plasma-pretreated adzuki beans showed the sigmoidal pattern, a lag-phase → rapid increase → saturation. However, the curves of bath type-sonicated, pressure drop-pretreated, heat-pretreated, and probe type-sonicated adzuki beans exhibited the downward concave pattern. Additionally, the Aw values of these adzuki beans were significantly higher at 2 h of the soaking than that of untreated adzuki beans while not significantly different (p < 0.05) after 6 h. Like the water contents, it is shown that the probe type-sonication drove particularly rapid Aw elevation to 0.96 just within 2 h soaking, i.e., the fastest hydration. It is notable in a comparison that the Aw of untreated beans was only 0.65. In particular, probe-type sonication induced a faster Aw increase than heating, which maximizes internal permeation through increased water diffusivity into the hilum region. This suggests that the probe-type sonication treatment affected the expansion of the pathway at the hilum region or the formation of additional pathways that allow water to permeate. This trend in the Aw changes is a good accordance with that of the water content changes, i.e., the probe type-sonication was the most efficient pretreatment method to hydrate adzuki beans at least among methods used in this study.

Fig. 2.

Changes in water activity (Aw) of water-soaked adzuki beans after either untreatment or pretreatment using cold plasma (plasma), bath-type sonication (bath-type), instant pressure dropping (pressure drop), heating, or probe-type sonication (sonication). Different letters (a–d) on the same soaking time (2 or 6 h) mean significantly difference (p < 0.05)

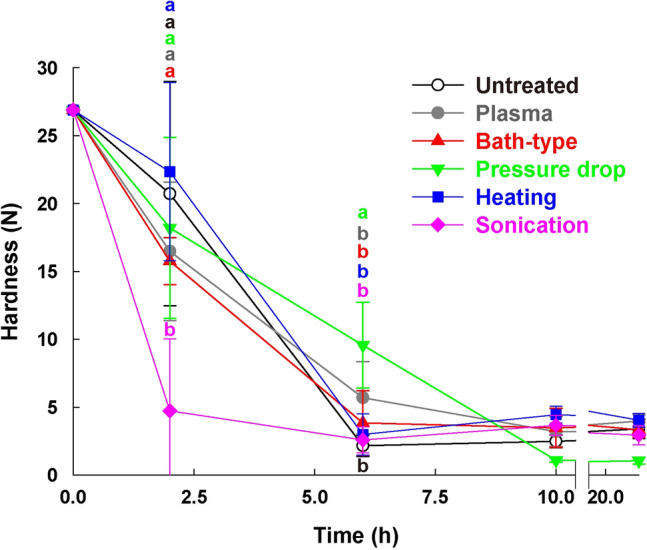

Changes in the hardness of adzuki beans

Changes in the texture of water-soaked adzuki beans can indirectly reflect the degree of the hydration and inner structure change. In this regard, the hardness of untreated and pretreated adzuki beans was monitored during the water soaking (Fig. 3). The hardness of probe type-sonicated adzuki beans was rapidly decreased to ~ 5 N after only 2 h soaking, significantly differed from those of untreated or other pretreated adzuki beans (~ 16 to 21 N; p < 0.05). This means the fastest softening of the probe-type sonicated beans among all the pretreated bean groups. After 6 h soaking, probe-type sonicated beans also had similar hardness level with untreated beans like other pretreated bean groups except for instant pressure drop-pretreated beans. During the soaking in 10–22 h, instant pressure drop-pretreated adzuki beans exhibited notably lower hardness level (~ 1 N) than untreated and other-pretreated groups (~ 3 to 5 N). As shown in Fig. 2, there was no significant acceleration of the rehydration rate by the instant pressure-dropping. This is a clear indirect evidence for structural changes in the internal matrix of the instant pressure drop-pretreated beans rather than the changes in the coat or hilum. The formation of the internal porous structures induced by the pressure drop-pretreatment may have affected the softening of rehydrated adzuki beans (Lyu et al., 2021; Nachaisin et al., 2016).

Fig. 3.

Changes in hardness of water-soaked adzuki beans after either untreatment or pretreatment using cold plasma (plasma), bath-type sonication (bath-type), instant pressure dropping (pressure drop), heating, or probe-type sonication (sonication). Different letters (a, b) on the same soaking time (2 or 6 h) mean significantly difference (p < 0.05)

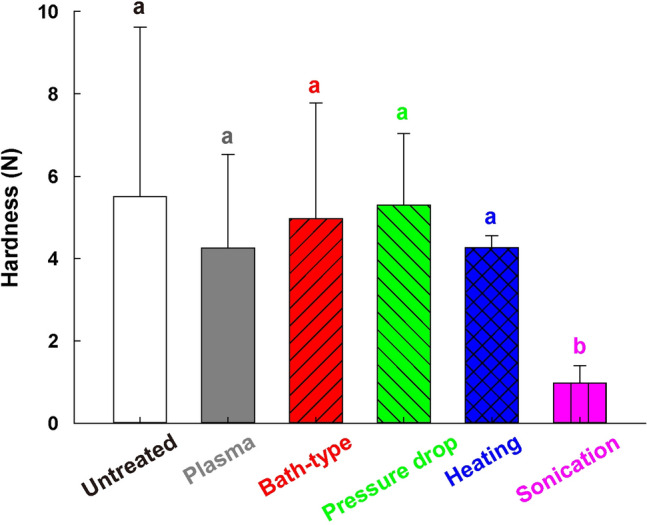

Conventionally in East Asia, especially in Korea, adzuki beans are also taken after cooking whole beans with rice. The texture of whole beans after cooking is one of quality criteria of adzuki beans. With this respect, hardness of adzuki beans cooked after pretreatment and water-soaking procedures was measured to evaluate and compare the quality of the pretreated bean groups (Fig. 4). Except for the probe type-sonicated bean group (0.97 N), all the pretreated groups exhibited similar level hardness values (4.26–5.51 N) with untreated bean group (5.51 N). Significantly lowest hardness level of a probe type-sonicated bean group indicates a great effect on the softening not only after the water-soaking but also after the cooking. This could be attributed to irreversible structural changes on/in the coat, induced by high acoustic cavitation effects during the sonication.

Fig. 4.

Hardness of cooked adzuki beans after either untreatment or pretreatment using cold plasma (plasma), bath-type sonication (bath-type), instant pressure dropping (pressure drop), heating, or probe-type sonication (sonication). Different letters (a, b) mean significantly difference (p < 0.05)

Changes in the microstructures on the surfaces of adzuki beans

Changes in the water contents, Aw, and harness of adzuki beans can be mainly attributed from the changes in the microstructure of the coat and hilum as discussed above. With this respect, scanning electron micrographs for the surface of untreated and pretreated adzuki beans, i.e., the coat or hilum, were obtained to survey the morphological characteristics (Fig. 5). The surface of cold plasma-pretreated, instant pressure drop-pretreated, and heat-pretreated adzuki beans appeared smooth without any cracks under all the magnification (× 43 → × 5000), like the micrographs of the untreated beans. This may contribute the light effects of cold plasma-, instant pressure drop-, and heat-pretreat methods on rehydration of water-soaked adzuki beans as discussed in the sections above. Meanwhile, under the magnification of × 5000, a little bit of the roughness with mild wrinkles was observed on the surface of bath type-sonicated adzuki beans, but this was not possibly enough to increase the rehydration rate. However, under the magnification of × 1600 and × 5000, the surface of probe type-sonicated adzuki beans appeared rough with severe wrinkles. Furthermore, many craters and scars were observed in the micrographs under the magnification of × 100 and × 400. This clearly indicates that probe-type sonication exerted a relatively higher cavitation effect on the surface of adzuki beans than other pretreatments.

Fig. 5.

Scanning electron micrographs for surface of water-soaked adzuki beans after either (A) untreatment or pretreatment using (B) cold plasma, (C) bath-type sonication, (D) instant pressure dropping, (E) heating, or (F) probe-type sonication (magnification: × 43, × 100, × 400, × 1600, and × 5000). C, coat; H, hilum; MWr, mild wrinkle; Er, erosion; Fs, fissure; Cr, crater; Sc, scar; SWr, severe wrinkle

According to a previous study of a research group, the hilum and micropyle of several legume beans can be most important to influence the initial water absorption (Deshpande and Cheryan, 1986). Based on the micrographs with the magnification of × 43, compared to untreated beans, the slight erosion of the matrix in the hilum region of adzuki beans was noted after the instant pressure drop-pretreatments. This possibly affected a slight increase in the rehydration rate during water soaking. However, prominent fissures and scars in the hilum region were observed in probe type-sonicated adzuki beans, which is in a good accordance with previously reported studies (Chiu, 2021; Santacatalina et al., 2016). This clearly indicates that the elevated moisture contents and Aw and lowered hardness of probe type-sonicated adzuki beans could be attributed to the water ingress through the fissures and scars formed in the hilum during the sonication treatment. Consequently, the probe-type sonication brought out the fastest and most efficient rehydration of dry-stored adzuki beans during water-soaking.

In this study, cold plasma, bath-type sonication, instant pressure drop, heating, and probe-type sonication were pretreated to adzuki beans stored in drying conditions to shorten the time for the water soaking. Based on the water contents, Aw, and hardness of water-soaked adzuki beans, the efficiency of the pretreatment methods was estimated and compared with each other. Overall, probe-type sonication was the best pretreatment method to rehydrate and soften adzuki beans well in the shortest time for the water-soaking. Indeed, probe-type sonicated adzuki beans accomplished ~ 46%, 0.96, and ~ 5 N as the water content, Aw, and hardness, respectively, within only 2 h of the water soaking. These values were almost like the respective saturation values (~ 60%, 0.99, and ~ 6 N) that can be accomplished by wasting 22 h for the water soaking without any pretreatment. According to the scanning electron micrographs, the best efficiency of the probe-type sonication might be attributed to the formation of craters and scars on/in the coat and the formation of prominent fissures and scars in the hilum. Consequently, the probe-type sonication could improve the rehydration and softening rate of adzuki beans most effectively among at least the pretreatment methods compared. In conclusion, this study can serve useful information to develop an effective pretreatment method for rehydrating seeds of legumes or cereals.

Acknowledgements

This work was supported by the Gachon University research fund (GCU-2019-0812) and by Korean Rural Development Administration (PJ01515901).

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Changgeun Lee and Eunghee Kim have contributed equally to this study.

Contributor Information

Changgeun Lee, Email: lcg12233@naver.com.

Eunghee Kim, Email: dkrnd2@snu.ac.kr.

Hyungsup Kim, Email: gudtjq2@naver.com.

Wonyoung Heo, Email: hwy981@naver.com.

Sungmo Ahn, Email: dkstjdah58@gmail.com.

Jiyoon Park, Email: yunapark.sd@gmail.com.

Choongjin Ban, Email: pahncj@uos.ac.kr.

Seokwon Lim, Email: slim@gachon.ac.kr.

References

- Abdul-Kadir R, Bargman TJ, Rupnow JH. Effect of infrared heat processing on rehydration rate and cooking of Phaseolus vulgaris (var. Pinto) Journal of Food Science. 1990;55(5):1472–1473. doi: 10.1111/j.1365-2621.1990.tb03964.x. [DOI] [Google Scholar]

- Andreou V, Sigala A, Limnaios A, Dimopoulos G, Taoukis P. Effect of pulsed electric field treatment on the kinetics of rehydration, textural properties, and the extraction of intracellular compounds of dried chickpeas. Journal of Food Science. 2021;86(6):2539–2552. doi: 10.1111/1750-3841.15768. [DOI] [PubMed] [Google Scholar]

- Aravindakshan S, Nguyen THA, Kyomugasho C, Buvé C, Dewettinck K, Van Loey A, Hendrickx ME. The impact of drying and rehydration on the structural properties and quality attributes of pre-cooked dried beans. Foods. 2021;10(7):1665. doi: 10.3390/foods10071665. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aravindakshan S, Nguyen THA, Kyomugasho C, van Loey A, Hendrickx ME. The rehydration attributes and quality characteristics of ‘quick-cooking’ dehydrated beans: implications of glass transition on storage stability. Food Research International. 2022;157:111377. doi: 10.1016/j.foodres.2022.111377. [DOI] [PubMed] [Google Scholar]

- Chiu K-Y. Changes in microstructure, germination, sprout growth, phytochemical and microbial quality of ultrasonication treated adzuki bean seeds. Agronomy. 2021;11(6):1093. doi: 10.3390/agronomy11061093. [DOI] [Google Scholar]

- Choi E-H, Lee J-K. Effects of sonication on physicochemical properties and pore formation of maize starch. Korean Journal of Food Science and Technology. 2017;49(5):507–512. [Google Scholar]

- Deshpande SS, Cheryan M. Microstructure and water uptake of phaseolus and winged beans. Journal of Food Science. 1986;51(5):1218–1223. doi: 10.1111/j.1365-2621.1986.tb13089.x. [DOI] [Google Scholar]

- Doymaz İ. Hot-air drying and rehydration characteristics of red kidney bean seeds. Chemical Engineering Communications. 2016;203(5):599–608. doi: 10.1080/00986445.2015.1056299. [DOI] [Google Scholar]

- Duarte Santos T, Badiale Furlong E. Biological contamination of the common bean (Phaseolus vulgaris L.) and its impact on food safety. Critical Reviews in Food Science and Nutrition. 2021;62(18):4998–5004. doi: 10.1080/10408398.2021.1881038. [DOI] [PubMed] [Google Scholar]

- Ghafoor M, Misra NN, Mahadevan K, Tiwari BK. Ultrasound assisted hydration of navy beans (Phaseolus vulgaris) Ultrasonics Sonochemistry. 2014;21(1):409–414. doi: 10.1016/j.ultsonch.2013.05.016. [DOI] [PubMed] [Google Scholar]

- Honda Y, Saito Y, Mishima T, Katsumi N, Matsumoto K, Enomoto T, Miwa S. Characterization of physicochemical and digestive properties of starches from various “dainagon” adzuki beans (Vigna angularis) cultivated in Japan. International Journal of Biological Macromolecules. 2020;148:1021–1028. doi: 10.1016/j.ijbiomac.2020.01.145. [DOI] [PubMed] [Google Scholar]

- Kim J-W, Puligundla P, Mok C. Microbial decontamination of dried laver using corona discharge plasma jet (CDPJ) Journal of Food Engineering. 2015;161:24–32. doi: 10.1016/j.jfoodeng.2015.03.034. [DOI] [Google Scholar]

- Lyu J, Bi J, Wang F, Jin X, Wu X, Xie J. Recent developments and trends of instant controlled pressure drop drying—a review. Drying Technology. 2021;39(11):1704–1719. doi: 10.1080/07373937.2021.1916753. [DOI] [Google Scholar]

- Miano AC, Augusto PED. From the sigmoidal to the downward concave shape behavior during the hydration of grains: effect of the initial moisture content on adzuki beans (Vigna angularis) Food and Bioproducts Processing. 2015;96:43–51. doi: 10.1016/j.fbp.2015.06.007. [DOI] [Google Scholar]

- Miano AC, Augusto PED. The hydration of grains: a critical review from description of phenomena to process improvements. Comprehensive Reviews in Food Science and Food Safety. 2018;17(2):352–370. doi: 10.1111/1541-4337.12328. [DOI] [PubMed] [Google Scholar]

- Miano AC, Pereira JDC, Castanha N, Júnior MDDM, Augusto PED. Enhancing mung bean hydration using the ultrasound technology: description of mechanisms and impact on its germination and main components. Scientific Reports. 2016;6(1):1–14. doi: 10.1038/srep38996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nachaisin M, Jamradloedluk J, Niamnuy C. Application of combined far-infrared radiation and air convection for drying of instant germinated brown rice. Journal of Food Process Engineering. 2016;39(3):306–318. doi: 10.1111/jfpe.12226. [DOI] [Google Scholar]

- Nam J-H, Chun J-Y. Effect of browning inhibitors NaCl and CaCl2 on the qualities of Jeju Tamna potatoes during hot-air drying. Journal of the Korean Society of Food Science and Nutrition. 2021;50(2):164–171. doi: 10.3746/jkfn.2021.50.2.164. [DOI] [Google Scholar]

- Oh S-M, Jo Y-J, Chun A, Kwak J, Oh Y-G, Kim M-J, Song S-B, Choi I. Seed and water absorption characteristics of red bean cultivars in Korea. Korean Journal of Food Science and Technology. 2021;53(5):607–612. [Google Scholar]

- Pervin S, Islam MS, Islam MN. Study on rehydration characteristics of dried lablab bean (Lablab purpureus) seeds. Journal of Agriculture & Rural Development. 2008;6(1):157–163. doi: 10.3329/jard.v6i1.1673. [DOI] [Google Scholar]

- Puligundla P, Kim J-W, Mok C. Effect of corona discharge plasma jet treatment on decontamination and sprouting of rapeseed (Brassica napus L.) seeds. Food Control. 2017;71:376–382. doi: 10.1016/j.foodcont.2016.07.021. [DOI] [Google Scholar]

- Reyes-Moreno C, Paredes-López O, Gonzalez E. Hard-to-cook phenomenon in common beans—a review. Critical Reviews in Food Science and Nutrition. 1993;33(3):227–286. doi: 10.1080/10408399309527621. [DOI] [PubMed] [Google Scholar]

- Santacatalina JV, Contreras M, Simal S, Cárcel JA, Garcia-Perez JV. Impact of applied ultrasonic power on the low temperature drying of apple. Ultrasonics Sonochemistry. 2016;28:100–109. doi: 10.1016/j.ultsonch.2015.06.027. [DOI] [PubMed] [Google Scholar]

- Tjahjadi C, Lin S, Breene WM. Isolation and characterization of adzuki bean (Vigna angularis cv Takara) proteins. Journal of Food Science. 1988;53(5):1438–1443. doi: 10.1111/j.1365-2621.1988.tb09294.x. [DOI] [Google Scholar]

- Valencia-Mejía E, Batista KA, Fernández JJA, Fernandes KF. Antihyperglycemic and hypoglycemic activity of naturally occurring peptides and protein hydrolysates from easy-to-cook and hard-to-cook beans (Phaseolus vulgaris L.) Food Research International. 2019;121:238–246. doi: 10.1016/j.foodres.2019.03.043. [DOI] [PubMed] [Google Scholar]

- Woo KS, Song SB, Ko JY, Kim YB, Kim WH, Jeong HS. Antioxidant properties of adzuki beans, and quality characteristics of sediment according to cultivated methods. The Korean Journal of Food and Nutrition. 2016;29(1):134–143. doi: 10.9799/ksfan.2016.29.1.134. [DOI] [Google Scholar]

- Yadav U, Singh N, Kaur A, Thakur S. Physico-chemical, hydration, cooking, textural and pasting properties of different adzuki bean (Vigna angularis) accessions. Journal of Food Science and Technology. 2018;55(2):802–810. doi: 10.1007/s13197-017-2994-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yin Z-C, Guo W-Y, Liang J, Xiao H-Y, Hao X-Y, Hou A-F, Zong X-X, Leng T-R, Wang Y-J, Wang Q-Y. Effects of multiple N, P, and K fertilizer combinations on adzuki bean (Vigna angularis) yield in a semi-arid region of northeastern China. Scientific Reports. 2019;9(1):1–13. doi: 10.1038/s41598-019-55997-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yousif AM, Deeth HC, Caffin NA, Lisle AT. Effect of storage time and conditions on the hardness and cooking quality of adzuki (Vigna angularis) LWT-Food Science and Technology. 2002;35(4):338–343. doi: 10.1006/fstl.2001.0878. [DOI] [Google Scholar]

- Yousif AM, Kato J, Deeth HC. Effect of storage on the biochemical structure and processing quality of adzuki bean (Vigna angularis) Food Reviews International. 2007;23(1):1–33. doi: 10.1080/87559120600865172. [DOI] [Google Scholar]

- Zhao Y, Zhu H, Xu J, Zhuang W, Zheng B, Lo YM, Huang Z, Tian Y. Microwave vacuum drying of lotus (Nelumbo nucifera Gaertn.) seeds: effects of ultrasonic pretreatment on color, antioxidant activity, and rehydration capacity. LWT-Food Science and Technology. 2021;149:111603. doi: 10.1016/j.lwt.2021.111603. [DOI] [Google Scholar]

- Zhou X-R, Yang X-S, Me Y, Zhu Z-H, Cheng X-Z, Wang L-X, Wang S-H, Ren G-X. Analysis of adzuki bean resistant starch content and cooking hardness. Journal of Plant Genetic Resources. 2013;14(4):740–743. [Google Scholar]

- Zhou Y-H, Vidyarthi SK, Zhong C-S, Zheng Z-A, An Y, Wang J, Wei Q, Xiao H-W. Cold plasma enhances drying and color, rehydration ratio and polyphenols of wolfberry via microstructure and ultrastructure alteration. LWT-Food Science and Technology. 2020;134:110173. doi: 10.1016/j.lwt.2020.110173. [DOI] [Google Scholar]