Abstract

Drying is an energy-intensive process that can be reduced by the application of pretreatment prior to drying to enhance mass transfer and minimize energy consumption. This review summarizes the mechanistic aspects and applications of emerging pretreatment approaches, namely ohmic heating (OH), ultrasound (US), high pressure processing (HPP), and pulsed electric field (PEF), with emphasis on the enhancement of mass transfer and quality attributes of foods. Novel pretreatments significantly improved the drying efficiency by increasing mass transfer, cavitation, and microchannel formation within the cell structure. Various processing parameters have great influence on the drying performance and quality attributes of foods. Several studies have shown that novel pretreatments (individual and combined) can significantly save energy while improving the overall drying performance and retaining the quality attributes. This work would be useful for understanding the mechanisms of novel pretreatment technologies and their applications for future commercial research and development activities.

Keywords: Drying, Drying performance, Novel pretreatment, HPP, PEF, Ultrasound, Ohmic heating

Introduction

Fresh food materials are highly perishable and readily prone to microbial spoilage leading to a decrease in shelf-life and huge amount of postharvest losses if improper preservation methods are followed (Onwude et al., 2017). There are many methods of food preservation such as drying, heating, freezing, cooling, salting, pickling, canning, and smoking. Among these, drying is the most commonly used approach and is generally employed to reduce water activity. Drying is an energy-intensive preservation technique for extending the shelf life and reducing the chances of microbial contamination of the food material (Maisnam et al., 2015). Drying performance is primarily assessed by residual moisture content, drying time, energy consumption, and quality aspects such as mechanical damage, rehydration ability, stress formation, shape, nutritional value, and structural morphology of dried food materials (Llavata et al., 2020). The drying time, temperature, and energy consumptions are the major concerns for evaluating the performance of a drying system. It is always desirable for both the producers and consumers to have cost-effective and energy-efficient drying techniques to meet the demands for high-quality dried food products (Zhang et al., 2015). Despite the intense research and numerous technical literature available on food drying, scientists and engineers are often encountered with significant challenges to improve the existing drying systems and product quality. Most food products have protective layers which obstruct the removal of moisture, leading to longer drying duration, higher energy consumption, and overall deterioration in end-product quality. Therefore, several studies have investigated the different drying pretreatment techniques to address these concerns. The conventional pretreatments (steam blanching, hot water treatment, alkaline solutions, hyperosmotic solution, etc.) may reduce drying time or enhance quality attributes; however, these approaches may lead to chemical absorption, high energy consumption, nutritional values reduction, structural and textural modifications, and poor rehydration capacity (Bassey et al., 2021). Consequently, novel pretreatment methods have been investigated to enhance the overall drying performance. Innovative pretreatment techniques can be applied to enhance the overall drying performance in different drying methods such as (a) convective drying, suitable for solid foods- fruits, vegetables, meats, etc., (b) conductive drying (suitable for drying fruit and vegetable purees and juices, concentrates, and solid foods), (c) spray drying (liquid foods such as milk and juices), (d) sun and solar drying (herbs, spices, leafy vegetables, fruit slices), (e) fluidized bed drying (seeds, granular, and powder), (f) freeze drying (herbs, coffee, flavoring agents, dairy, seafoods, etc.), (g) vacuum drying (thermal and/oxygen sensitive fruits and vegetables), (h) osmotic dehydration (fruits and vegetables), (i) electro-heating technologies such as microwave, ohmic heating, and radio-frequency heating, and (j) non-thermal drying technologies including pulsed electric field, ultrasound, and ultraviolet. Most of these drying methods are well established and widely used at the commercial scale. However, non-thermal drying techniques are under intense research and yet to implement at a large commercial scale. Several studies have indicated the promising application of non-thermal drying technologies in the food drying sector.

The optimum thermal and non-thermal pretreatments for the effective drying of food materials could be achieved by decreasing the drying time and improving the functionality of stable food commodities post drying (Bassey et al., 2021). Research indicated that the drying efficiency could be increased by reducing the energy consumption, improving quality attributes, and reducing drying time by using different pretreatment approaches before drying. The novel pretreatment applied for drying of litchi by ultrasound treatment (Fong-in et al., 2021), ultrasonic and electrical pretreatments of kiwi slices (Bozkır and Ergün, 2021), strawberries slices by the pulsed electric field (PEF) followed by osmo-dehydration (Tylewicz et al., 2017), kiwifruit slices pre-treated by PEF (Traffano-Schiffo et al., 2017), ohmic heating assisted hot air drying of potato slices (Menon et al., 2020) and high pressure processing pretreatment of strawberry (Belmiro et al., 2018; Zhang et al., 2022) were reported to be effective pretreatment methods. However, pretreatment of seedless guava with thermo sonication with amplitude wave (25–75%) at 90 °C prior to osmotic dehydration led to an increase in mass transfer in terms of water loss, while the solid gain remained non-significant (Ganjloo et. al., 2016). To address the drawbacks of the conventional pretreatment approaches, the food industry shows interest in innovative pretreatment techniques which can reduce the drying time, minimize energy consumption, and improve overall drying performance while retaining the quality characteristics of food products. In recent times, cost-effective pretreatment techniques have been implemented by using different innovative non-thermal and thermal pretreatment methods such as microwave, ultrasound, ohmic heating, high pressure processing, pulsed electric field, etc. The present review focuses on the mechanistic understanding of novel pretreatment methods (ohmic heating, ultrasound, HPP, and PEF) and their recent applications in drying of food materials to enhance the drying performance while maintaining the quality attributes.

Ohmic heating technology: mechanistic approach and components

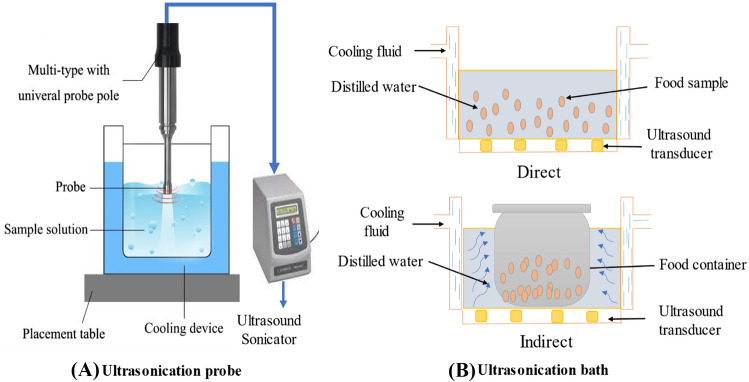

Ohmic heating (OH) is a novel process where internal heat is produced by applying an electric current. Ohmic heating is also called resistance heating or direct resistance heating. The broad-spectrum applications of ohmic heating are used in the food sector to process food products (Cho et al., 2017). OH is a novel pretreatment approach used to process and preserve food materials. It is an innovative technique where the alternating current flows through the food material and generates heat energy internally owing to electrical resistance, and the temperature inside the food rises rapidly (Kaur et al., 2016). The schematic representation of the working principle of ohmic heating is depicted in Fig. 1. A typical OH system consists of two electrodes, treatment chamber, ammeter, voltmeter, variable transformer, thermocouple, and display unit. Many researchers have developed ohmic heating systems by considering the major designs parameters, including power requirement, frequency of AC (50 to 60 Hz), current density, electrode configuration, applied voltage, conductivity, distance between the electrodes, and heating rate (Kong et al., 2008).

Fig. 1.

An illustration of ohmic heating system

The performance of the ohmic heating system can be influenced by numerous aspects such as the electrical conductivity of food materials, heat capacity, frequency and waveform, and material of electrode as well as material viscosity (Indiarto and Rezaharsamto, 2020). When the alternative current (AC) is passed through the material, the electrical conduction indicates that electricity is converted to heat. The food material’s electrical conductivity value is not constant and depends upon various parameters like free moisture content, material’s microstructure, and other parameters (Cho et al., 2017). The selection of electrode material has a great influence on the ohmic heating process and product quality. As the aluminium electrode tends to be electrolyzed, it can contaminate the food materials. Titanium electrode is considered to be the best material, having the potential for electrolysis resistance and offers an optimum heating rate (Cho et al., 2017; Kaur et al., 2016).

However, a higher voltage gradient induces a higher current to pass through the food sample, which results in an accelerated rate of electrical charge transfer within the circuit leading to a decrease in treatment time (Darvishi et al., 2013). The higher the frequency and concentration of ionic constituents, the more will be conductivity of food constituents, causing an intensification in the drying rate (Kaur et al., 2016). The reasons behind the increase in electrical conductivity are high ionic mobility, structural changes, modification of the tissue-like cell wall, breakdown of protopectin matrix, gas bubbles expulsion, and softening of the aqueous phase of the food materials. (Alkanan et al., 2021; Varghese et al., 2012). Several studies of ohmic heating have shown intensification in the discharge of soluble solids owing to the electroporation of cell membranes. The combined consequence of electroporation and softening of the tissue matrix is the possible mechanism behind the ohmic heating approach. Color retention, preservation of nutritional value, and shorter processing time during the treatment make ohmic heating advantageous over the conventional process.

Application of ohmic heating in drying of food products

The novel pretreatment technology promotes drying efficiency, reduces drying time, and retains product quality attributes. It has great potential in the food industry for drying processes, for example, pretreatment, pasteurization, dewatering, etc. (Menon et al., 2020). Recent studies on the influence of ohmic treatment on the drying performance of food materials are compiled in Table 1. The study has reported that ohmic pretreatment reduced the drying time by 27.6% during the convective drying of peppers at 60 °C and 70 °C. Moreover, the drying rate and the moisture diffusivity were obtained as 0.080 g water/g DM min and 7.21 × 10–10 m2/s at 60 °C, respectively which are significantly higher as compared to microwave and hot water treated red pepper owing to the breakdown of cell wall which leads to increase intercellular space in the tissue matrix (İncedayi, 2020). Salengke and Sastry (2005) performed experiments for drying grapes pretreated with 14 V/cm field strength and 30 Hz, 60 Hz, and 7.5 kHz frequencies and drying at 60 °C. The results showed that the ohmic pretreated sample shows most pronounced drying rates at low frequencies i.e., 30 Hz and 60 Hz. The grapefruit pulp and orange pulp were dried at 70 or 100 °C at a holding time of 30 min and pretreated with ohmic heating of 30 V/cm. The finding revealed that the energy consumption was reduced due to ohmic heating pretreatment, which is attributed to the disruption of cell structure at the surface and enhanced moisture diffusion (Stojceska et al., 2019). The ohmic heating treatment was applied for tomato paste at 6 V/cm to 16 V/cm and dried at 105ºC and found that with the increase of electric field strength (EFS), the moisture diffusion coefficient, specific energy consumption, and activation energy value were increased, and improved the drying efficiency (Hosainpour et al., 2014). Cokgezme et al. (2017) analyzed the performance of ohmic heating-based vacuum evaporation of pomegranate juice at 7.5 V/cm to 12.5 V/cm. The results exhibited a high energy efficiency value of 42.8% due to the formation of electroporation and increased disruption of the cell during the process. Grapes were treated with 14 V/cm electric field strength at frequencies 30 Hz, 60 Hz, and 7.5 kHz and the results suggested that moisture diffusion rate was improved due to an increase in permeability of the skin layer because of the breaking action of heating (Patidar et al., 2021). The ohmic heating system was developed for fish drying at voltage in the range of 160 to 200 V, with salt concentration range of 0–2% and solar drying temperature in the range of 40–72 °C. The drying rate of fish was enhanced using the developed ohmic heating-assisted solar drying system (Richa et al., 2021).

Table 1.

Recent studies on the influence of ohmic treatment on the drying performance of food materials

| Food commodities | Ohmic treatment (intensities/electric field strength)/time/temperature | Drying methods | Drying conditions | Major findings | References |

|---|---|---|---|---|---|

| Quince slices | 20, 30, and 40 V/cm and 50 Hz for 10, 20, and 30 min | Hot air dryer and microwave | Hot air drying at 40 °C and microwave power (90, 180 and 270 W) |

The optimum conditions were obtained as 40 V/cm and 30 min for retention of quality attributes The effective diffusivities of ohmic heating pretreated quince slices and dried using microwave and hot air were obtained as 6.53 × 10–9 m2/s and 6.11 × 10–10 m2/s, respectively The diffusivity values increased with the increase of electric field strengths and treatment time due to the increase in temperature and consequently water vapor pressure gradient The high rehydration ratio was obtained at low electric field strength |

Kutlu (2022) |

| Pineapple cube | 25, 30, 35 V/cm for 1 to 3 min | Tray dryer | 70 °C and 0.1 m3/s |

The effective moisture diffusivity was significantly increased with ohmic heating and treatment time The drying rate was increased with the increase of electric field strength and significantly reduced the drying time The ohmic treatment substantially impacted the textural attributes and lesser color changes were observed as compared to conventional drying |

Kumar et al. (2021) |

| Fish muscles | 160–200 V for 2.75 to 5 min | Solar dryer | 40–72 °C |

The developed drying system was capable of drying fish muscles from the original MC of 348.5% (db) to 12.66% (db) with an increased drying rate of 2.73 g/min during solar drying The optimized condition was obtained as a voltage of 180 V, salt concentration of 1%, and solar drying temperature of 72ºC The drying rate was improved with the increase of ohmic heating voltage during the drying operation |

Richa et al. (2021) |

| Red pepper |

OH: 16 V/cm for 3.67 min Microwave: 600 W and 2.45 GHz for 3.67 min |

Convective cabinet drier | 60 °C and 70 °C, and 20% RH |

By increasing the temperature from 60 to 70 °C, the reduction in drying time of ohmic heating treated pepper was 27.59% The highest drying rate was observed at 0.080 g water/g DM min as compared to microwave and hot water treated samples Effective moisture diffusivity value was found to be higher in the pretreated sample and observed to be 6.54 × 10–10 m/s, 9.27 × 10–10 m/s, and 9.19 × 10–10 m/s for control, microwave-treated, and ohmic heating treated, respectively dried at 70 °C |

İncedayi (2020) |

| Apple slices | 20, 30, and 40 V/cm at 60 °C for 1 min | Tray dryer | 60 °C and 2 m/s |

The drying time was decreased by 24, 35, and 29% of the sample treated with 20, 30, and 40 V/cm electric field strength, respectively The higher retention of color value and best fitted to the zero-order kinetics model was observed |

Kutlu et al. (2019) |

| Orange and grapefruit | 30 V/cm for 0.43 min | Opus Combi dryer | 70 °C and 100 °C |

3.5 to 5 times less energy consumption was noted in ohmic drying as associated with conventional thermal drying The ohmic heating reduced 10% of the total operational cost in the drying process |

Stojceska et al. (2019) |

| Jerusalem artichoke tuber | 10.5, 15.8 and 21.1 V/cm and 50 Hz, heated upto 100 min | Rotary evaporator | 60 °C |

Water requirement was reduced during the extraction process, which resulted in reduced production time, cost, and energy The extraction yields of ohmic heating were more than that of conventional heating due to its electroporation effect or impact of the EFS that enhanced the permeability of the membrane of the tissue |

Termrittikul et al. (2018) |

| Blueberries | 13 V/cm (100 V) at 30 °C, 40 °C, or 50 °C for 300 min | Hot air dryer | Drying at 50, 60, or 70 °C |

The combined treatment of OH and pulsed vacuum osmotic dehydration enhanced mass transfer and retention of phenolic components The optimum condition was found to be at 40 °C and 240 min at a drying temperature of 60 °C |

Moreno et al. (2016) |

| Pomegranate juice | 7.5, 10, and 12.5 V/cm for 15 to 45 min | Vacuum dryer | 10 °C to 65 °C |

The results indicated that ohmic heating at a voltage greater than 10 V/cm was found to be an effective approach for evaporation The maximum energy consumption of 5844.20 J was observed at 40% at 7.5 V/cm EFS and 40% TSS The exergy efficiency was increased with the increase of EFS |

Cokgezme et al. (2017) |

| Tomato paste | 6, 8, 10, 12, 14, and 16 V/cm for 3.42 to 26 min (moisture reduced from 90 to 70% (wb) during pretreatment) | Hot air oven | 105 °C and 1.0 m/s |

The effective moisture diffusivity and activation energy were observed to be 5.39 × 10–8 m2/s and 2.082 V/g.cm respectively The effective moisture diffusivity values increased greatly with the increase in voltage gradient due to an increase in the vapor pressure gradient within the samples The specific energy consumption and the efficiency of the OH treated sample were determined as 2.29 to 3.72 MJ/kg water and 67.8 to 83.8%, respectively |

Hosainpour et al. (2014) |

| Artichoke | 25, 30 and 40 V/cm and 50 Hz for 5.12 min | Fluidized-bed dryer | 60 °C, 70 °C and 100 °C and 0.8, 1.2, and 1.6 m/s |

Optimum drying conditions were obtained at 40 V/cm voltage gradient, 80 °C, and 0.8 m/s The faster drying was observed in ohmic blanching at 40 V/cm as compared to 25 V/cm and water blanching. This may be due to some electrical effects on cell wall destruction of vegetable products at higher voltage Ohmic heating could be used as low-temperature blanching method ensuing the higher retention of vitamin C and total phenolic content as compared to water blanching process |

Icier (2010) |

The texture and color of the pineapple cubes treated with ohmic heating were changed significantly with EFS and treatment time. The maximum drying rate was found at 35 V/cm, which increases with treatment time (60–180 s) due to the electroporation effect of electric current (Kumar et al., 2021). The ohmic heating at 14 V/cm field strength and various frequencies (7.5 kHz, 60 Hz, and 30 Hz) resulted in the formation of microcracks on the grape skin, probably due to the breaking action of heating. This caused an increase in the permeability of the skin layer and thus increases the moisture diffusion rate of grapes during drying. (Salengke and Sastry, 2005). The drying of the ohmic-treated citrus product was found to be more beneficial in terms of energy, cost, and GHG emissions (3.5–5 times lower) than thermal drying (Stojceska et al., 2019). Athmaselvi et al. (2017) have reported that the OH treatment of papaya pulp, sapota pulp, and guava pulp at 10 V/cm (100 °C for 15 min) electric strength resulted in the decrease of ascorbic acid content by 14.7%, 62.5%, and 21.43%, respectively. Similarly, a study conducted by Chakraborty and Athmaselvi (2014) used ohmic heating of guava juice at various voltage gradients (13.33 V/cm to 23.33 V/cm) to observe the changes in physicochemical properties during treatment. The results showed that the physicochemical properties changed with variation in voltage gradient and treatment time and subsequently the ascorbic acid content was degraded at higher EFS gradients.

The mass transfer of strawberries was increased with the application of ohmic heating coupled with osmotic dehydration due to the enhancement of solvent diffusion through the cellular membranes. This may be credited to the electroporation effect of electric field disrupting pores and improving cell membrane permeability. Ohmic blanching permits the operative mutilation of the cell wall by a combination of electrical and thermal treatment impact (Allali et al., 2010). Castro et al. (2004) used conventional and ohmic heating pretreatment to assess the degradation kinetics of ascorbic acid in strawberries at 60–97 °C and found that an EFS of 20 V/cm does not influence the degradation of ascorbic acid. Cao et al. (2020) have reported that the intermittent ohmic drying of litchi fruit reduced the drying time from 12 to 22%. Sakr and Liu (2014) reviewed and compared ohmic heating with other thermal and non-thermal heating methods namely heat pump heating, microwave heating, and heat-resistant heating, and observed that the ohmic heating method saved 82–97% energy while reducing the heating time by 90–95% as compared to conventional heating. The research findings suggested various reasons for intensification of drying process but the major consequence may be attributed to electroporation of the interstitial spore which leads to an increase in ionic bond length and improved moisture diffusion (Bassey et al., 2021).

Ultrasonication technology: mechanistic approach and components

Ultrasound technology refers to generating sound waves with a valid range frequency exceeding 16 kHz, which is the upper audible of human hearing, and the device is used at frequencies range in between 20 kHz and 10 MHz. The power ultrasound (10–1000 W/cm2) is mainly used for green extraction, filtration, homogenization, and preservation in food processing industries (Zheng and Sun, 2006). Low-intensity ultrasonication (< 1 W/cm2) is usually used as a non-destructive analysis method to ensure quality and control, particularly for physicochemical characteristics like composition, structure, and phase of matter (Tiwari, 2015). The ultrasound effects can be attributed to several physical and chemical occurrences such as agitation, vibration, wave shocks, shear forces, compression, microjets, and cavitation (Agi et al., 2022; Gallo et al., 2018). Ultrasound leads to a change in the temperature and pressure caused by the implosions causing shear disruption, cell membranes thinning, and cell destruction, leading to an increase of solvent infiltrate within the cells matrix and a mass transfer intensification of targeted compounds into the solvent (Chemat et al., 2011). The use of ultrasonication in food processing can result in dramatic agitation and rarefaction, which enhances both heat and mass transfer. Additionally, implosion of cavitation bubbles close to the solid–liquid interface generates micro-jets that further improve mass and heat transfer by breaking down the respective diffusion boundary layer. This creates a rapid series of alternative contractions and expansions, similar to squeezing and releasing a sponge repeatedly, which makes dehydration easier by creating microscopic channels for water movement. Furthermore, high-intensity ultrasound induces the cavitation phenomenon, which aids in the removal of moisture contents that are strongly attached to the products. In addition, high-intensity airborne ultrasound generates micro-streaming at the interfaces, which reduces the diffusion boundary layer and enhances water diffusion (Huang et al., 2020). A study showed that continuous ultrasound-assisted extraction process can improve the extraction of bio compounds from E. caucasicum leaves by potentially opening up the cell matrix through an increase in temperature. During sonication, the cavitation phenomenon generates high energies around the solvent molecules, resulting in the disruption of cell walls, which allows for better penetration of the solvent into the cells (Bimakr et al., 2019).

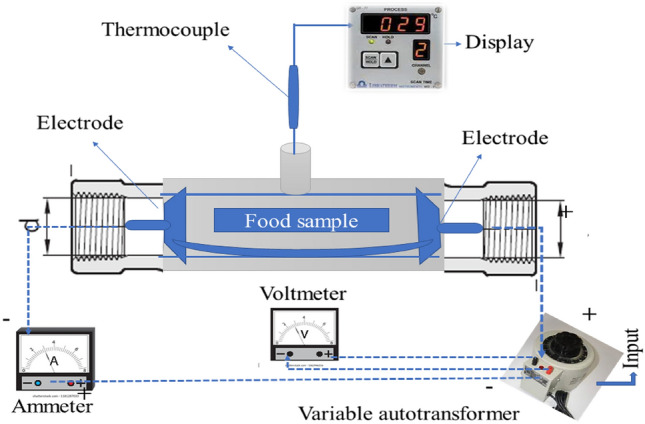

The ultrasonication system is designed for direct and indirect application in solid and liquid food products. There are two types of ultrasonication systems commonly used for food treatment, namely probe type and bath type, as shown in Figs. 2a and b, respectively (Kumar et al., 2022). The bath-type sonication system consists of a chamber containing a liquid medium to transfer ultrasound waves, an ultrasound transducer, and an ultrasound generator. The ultrasonic equipment is designed based on the piezoelectric transducer to treat solid materials in liquid media, such as ultrasonic sonicator with direct application and indirect applications as shown in Fig. 2b. It consists of a transducer, a tank, a heater, and a time and temperature probe. Indirect sonication is most effective for a small amount of sample because foaming and losses of active compounds are eliminated, and the cleaning bath has the advantage of non-invasive exposure to keep the sample intact and to ensure a more uniform distribution of US intensity in the sample. The system is generally used for the indirect application of solid food commodities. On the other hand, the probe type is used for the direct sonication of food products. This system consists of sonication probes of different sizes and specifications, an ultrasonic generator, a temperature control system, etc. In this method, the probe is directly immerged at different amplitudes through the sample for effective process as compared to bath type sonication system. Modern ultrasonic probe devices, made from titanium, are sometimes contaminated by metals like Cr and Al and caused contamination problems in the solution (Yuan et al., 2021).

Fig. 2.

Ultrasonication pretreatment system A probe type B bath type (direct and indirect)

Application of ultrasonication in food drying

Ultrasound (US) is a promising non-thermal pretreatment practice applied in the food processing industry. Ultrasonication-assisted drying was employed to improve the drying performance by increasing the moisture diffusivity and mass transfer in food commodities (Zhang et al., 2015). Recent studies on the influence of ultrasound pretreatment on the drying performance of food materials are compiled in Table 2. Ultrasounds are the longitudinal waves that generate rarefaction and compression due to cavitation which results in the formation of negative pressure in the medium. The high-intensity waves generate rapid vibration that develops microbubbles in the medium, then the coalescence process of microbubbles starts in the acoustic field. During rarefaction, a strong negative pressure causes the product molecules to release water from the capillaries and form numerous tiny cavities/bubbles. The cyclic propagation and collapse of bubbles produce cavitation effects and distort the process ensuing the enhancement of mass transfer and intensification process (Chemat et al., 2011). Moreover, the ultrasonication approach intensifies the heat and mass transfer due to the “heating effect” that increases the temperature and mass diffusivity and shortens the drying time as well as allowing drying to be carried out at lower temperatures (Awad et al., 2012). The enhancement of drying performance is due to the “sponge effect” that causes the water to release from the capillaries to the surface, thereby creating channels simultaneously for matter transport. Several studies have investigated on the application of the ultrasonication prior to drying or during drying operation and studied its impact on the drying quality attributes of the dried food commodities.

Table 2.

Recent studies on the influence of ultrasound pretreatment on the drying performance of food materials

| Food commodities | Ultrasound (power/intensities/frequency)/treatment time/temperature | Drying methods | Drying conditions (Temperature/time/air velocity) | Major findings | References |

|---|---|---|---|---|---|

| White mushrooms | 100 and 200 W | Hot air drying | 50 and 70 °C |

The drying rate was increased by 41.73% and 76.77% for 100W and 200W, respectively, at 50 °C and 30.43% and 55.73% for 100 W and 200W, respectively at 70 °C Significant reduction of total drying time and intensification in the specific energy consumption rate were observed during drying More favorable retention of color and polyphenol content |

Szadzińska et al. (2022) |

| Golden berries | Ultrasound: 100 W and 20 kHz with a pulse frequency of 50 Hz for 0.25 to 1 min | Convective hot air and ultrasound-assisted hot air drying | 50 °C and 1 m/s |

The drying time was reduced by 10.80% for ultrasound and 3.60–19.33% for the cold plasma treated sample as compared to the untreated sample The effective moisture diffusivity varied between 6.54 × 10−10 and 11.62 × 10−10 m2/s and increased by 11.30% treated with ultrasound The specific energy consumption was higher in ultrasound treated as compared to cold plasma Faster drying rate exhibited the retention of quality attributes |

Ashtiani et al. (2022) |

| Apple slices | 20 kHz, 5.5 cm probe diameter, 5 mm gap, time: 40 to 80 min | Airborne ultrasound-assisted drying system | 60 °C, 1.7 m/s and 10% humidity |

Pretreatments with sonication were capable to reduce drying time by 1.5–68.9% The drying performance was enhanced by increasing moisture diffusivity and lowering the activation energy The PPO activity showed less affected by sonication, whereas the ultrasound-assisted drying reduced the vitamin B2 content |

Zhu et al. (2022) |

| Pineapple slices | 250 W and 33 kHz for 20 to 40 min at 10 to 30 °C | Convective drying | 60 °C with 1.5 m/s |

The optimum conditions were observed to be at 50°Bx, 26.6 min, and 30 °C for solution concentration, sonication time, and temperature, respectively The solid gain of pretreated samples ranged from 0.02 to 0.119 g solid/g with an increase in mass transfer rate |

Meena et al. (2022) |

| Kiwi slices | 25 kHz and 100 W for 20 min | Convective drying | 104 °C |

The effective moisture diffusivity and solute diffusivity ranged between 5.46 × 10−10 to7.30 × 10−10 m2/s and 2.925 × 10−10 to 3.51 × 10−10 m2/s, respectively The lower value of the shape parameter ranged from 0.570 to 0.616, indicating a faster drying rate |

Prithani and Dash (2020) |

| Persimmon | 35 kHz for 10, 20, and 30 min at 30 °C | Tray dryer | 60 °C and 1.8 m/s |

Drying rates and effective diffusivities increased with the increase in US treatment time by 33% and 46%, respectively Mass transfer and weight loss increased with US treatment time and improved the rehydration capacity |

Bozkir and Ergün (2020) |

| Strawberries | 180, 240, and 300 W for 15 min at 25 ± 5 °C | Pulsed fluidized bed microwave freeze-drying | 60 °C |

The drying time was reduced by 45% as associated with the untreated control sample A better-quality retention rate was observed in the ultrasonication treated sample |

Jiang et al. (2021) |

| Carrot slices |

US: 0 and 80 W, 20 kHz IR: 900, 1200, and 1500 W, gap between tray and IR emitter 25 cm |

Infrared drying | 60 °C and 1 m/s |

The drying time was shortened by 21%, 17%, and 11% for drying at 900, 1200, and 1500 W, respectively The moisture diffusivity was obtained in the range of 8.09 × 10−10 to 26.98 × 10−10 m2/s treated with ultrasound and 6.34 × 10−10 to 22.92 × 10−10 m2/s in the sample of solely IR drying Ultrasound showed a positive effect on the rehydration ratio, whereas vitamin, color, and shrinkage were not significantly affected |

Guo et al. (2020) |

| Okra slices | 80 to 320 W and 5 to 15 min | Convective drying | 70 °C and 2 m/s |

The optimum pretreatment conditions were found to be ultrasound power level of 250W, sample thickness of 0.5 cm, and ultrasonic duration of 15 min The drying time and effective moisture diffusivity were found to be 7.2 h and 5.78 × 10−8 m2/s, respectively, for the untreated sample and 6.3 h and 7.20 × 10−8 m2/s, respectively for the ultrasound treated sample The moisture diffusivity increased with the increase of ultrasound power and subsequently reduced energy consumption by 12.5% |

Wang et al. (2019) |

| Sanhua plum | 40 kHz for 15 min at 30 °C | Heat pump dryer | 60 °C |

Total drying time was decreased by 24% at 90% US power for 15 min ultrasound treated sample as compared to control The moisture diffusion coefficient was observed to be 1.45 × 10−10 to 1.59 × 10−10 m2/s which was increased by 11%, 14%, and 22% with the increase of ultrasound power Quality retention was found to be higher at lower ultrasound intensity |

Li et al. (2021) |

| Kiwi fruit slices | Electrical (ET): 100 V for 0.67 min. Ultrasound: 35 kHz for 30 min | Convective dryer | 50 °C and 1.5 m/s |

Both the pretreatments increased the drying rate by 18.34% for ET and 21.65% for the US The drying process improved with the increase of treatment time in both the ET and US treatment and combined pretreatments (ET and US) and enhanced the drying rate by 35.7% US treated sample increased the rehydration and vitamin C content |

Bozkır and Ergün (2021) |

| Apple slices | 21 and 35 kHz for 30 min | Convective dryer | 70 °C and 2 m/s |

The total drying time was reduced by 13 to 17% for the ultrasound treated sample The moisture diffusivity was increased in the ultrasound treated sample from 1.037 × 109 to 1.059 × 109 m2/s The color changes were retained and showed an increase in the lightness and chroma values |

Fijalkowska et al. (2016) |

| Garlic | 480 W and 35 kHz for 10 to 30 min at 30 °C | Convective drying and microwave drying | 60 °C and 1.0 m/s Microwave: 2450 MHz operated at 540 W |

The drying rate improved in the HAD + US and the MWD + US treatment process by 19.30% and 13.82%, respectively as compared to control sample Effective moisture diffusivity was obtained as 1.42 × 10–10 m2/s, 1.83 × 10–10 m2/s, 1.17 × 10–8 m2/s, and 1.36 × 10–8 m2/s for HAD, US + HAD, MWD, and the US + MWD process, respectively The moisture diffusivity and drying rate were found to be higher in the US-assisted microwave drying as compared to the US-assisted hot air drying |

Bozkir et al. (2018) |

| Shiitake mushrooms | 600 W and 28 kHz for 15 min | Infrared drying (IR) | 60 °C, 2.11 m/s and IR of 1350 W |

Ultrasound pretreatment reduced the drying time by 21.43% as compared to the control samples The texture and color were retained, reduced hardness, and exhibited a higher lightness value of 78.46 |

Zhao et al. (2018) |

| Sweet potato | 300 W and 28 kHz for 20 to 60 min | Vacuum oven method | 70 °C |

The moisture diffusivity of ultrasound assisted osmotic dehydration was higher by 30.82% and 41.62% with solely treated by osmotic dehydration and ultrasound treatment, respectively The maximum color value was retained in ultrasound-assisted osmotic dehydration with enhanced croma value |

Oladejo et al. (2017) |

| Ginger | 600 W and 33 kHz for 30 min at 30 °C | Convective dryer | 30 to 75 °C, 2 m/s, and 1.2 kW |

Ultrasound treatment enhanced the drying rate and reduced drying time by 140 min for Chinese ginger and 170 min for Ghanaian ginger The drying performance was enhanced with the retention of bioactive compounds in ultrasonication treated samples |

Osae et al. (2019) |

| Carrot slices | Power of 30 to 90% and 20 kHz for 0.5 min | Infrared drying | 60 °C and 1.5 m/s |

The total drying time was decreased by 6.3%, 15.6%, and 25% and β-carotene content was improved by 5.46%, 13.07%, and 17.62% at power level 30%, 60%, and 90%, respectively The ultrasound treated samples were observed to enhance flavor, hardness, and color retention |

Wang et al. (2018) |

| Banana, mango, guava | 45 W and 20 kHz for 15 min | Convective drying | 50 °C and 0.2 m/s |

The US treated drying of fruit exhibited a reduction in drying time between 16.23 and 30.19%, 11.34 and 32.73%, and 19.25 and 47.51% for the banana, mango, and guava, respectively The US treatment increased the moisture diffusivity while retaining the polyphenol content and the antioxidant activity |

Méndez et al. (2015) |

The samples pretreated with ultrasound at 21–35 kHz during convective drying at 70 °C increased the moisture diffusivity and decreased the drying time by 13–17% could be due to the degree of tissue disruption and formation of micro-channel within the cell structure (Fijalkowska et al., 2016). Similarly, Nowacka et al. (2012) also investigated the impact of ultrasonication pretreatment prior to drying of apple slices and the results showed that drying time was reduced by 31%, with shrinkage of 9–11% higher than untreated samples. The ultrasound pretreatment improved moisture diffusivity and solid diffusivity in sweet potato samples while retaining the texture and color attributes (Oladejo et al., 2017). The improvement of moisture diffusivity and solid diffusivity probably occurred due to cavity formation and softening of the product tissues. Ricce et al. (2016) performed experiments on the drying of carrot slices pretreated with ultrasonic power of 41W/L and a frequency of 25 kHz. The results indicated that the sample with longer ultrasound treatment showed more formation of microchannels and cell disruption of the tissue, which resulted in higher moisture diffusivity and drying performance. Dias da Silva et al. (2016) examined on the US pretreatment of melon slices and dried the samples at 60 °C and an airflow velocity of 2 m/s in a force convective dryer. It was observed that the drying rate was faster and moisture diffusivity also increased for the melon sample pretreated with ultrasonication and combined pretreatment of ultrasound and vacuum. This could be attributed to the fact that, the interchange of the covalent bonds and release of the natural low molecular weight compounds during the ultrasound treatment process may improve the drying performance. The combined pretreatment of ultrasound-vacuum exhibited higher retention of carotenoid content, texture, and color attributes in the final product.

The drying rate was enhanced by approximately five times, and the functional qualities of blackberries were retained by pretreatment with ultrasound for 20 min prior to convective drying at 60 °C (Romero and Yépez, 2015). The intensification of the drying process might be the consequence of the alteration of cells due to acoustic wave energy produced by ultrasound during treatment. Kek et al. (2013) analyzed the ultrasound-induced osmotic dehydration of guava slices and it was observed that the moisture diffusion coefficient was increased by 35%, and the drying time and changes in color value were reduced by 33% and 38%, respectively. The possible explanation for this finding may be due to the formation of longitudinal waves that generate rarefaction and compression of the medium in the transmission path, leading to rapid vibration that develops acoustic cavitation and hydrodynamic forces. Magalhães et al. (2017) explored the combined impact of ultrasonication and convective drying of apple cubes. The results showed that the combined effect led to decreased in drying time by 58% and improved the external mass diffusivity and effective moisture diffusivity by 30% and 93%, respectively during the drying operation. The mass transfer improved with the increase of ultrasound treatment may be because of the formation of large cavitation effects on the porosity within the tissues. The apple cubes treated with ultrasound at 25, 50, and 75 W power considerably improved the drying performance. The drying time was reduced by 80.30% at 75 W power drying at a low temperature of − 10 °C with higher retention of quality attributes in dried apple cubes. These changes can be attributed to the effects of propagation of cavitation and distortion the plant matrix during treatment (Santacatalina et al., 2016).

The effective moisture diffusivity was increased by 33–89% in cherry tomatoes during ultrasound-assisted convective drying at 45 °C at an airflow velocity of 1 m/s with retention of vitamins and carotenoids. The results may be credited to the easy release of membrane-bound vitamins bound through apoenzymes (Fernandes et al., 2016). The pretreatments in hypertonic solutions for osmotic dehydration increase the mass transfer performance, i.e., water loss (WL) and solids gain (SG) in the treated matrix. The combination of ultrasound and osmotic dehydration on kiwifruit was studied at 35 kHz for 10–30 min to investigate the drying performance and quality parameters. It was observed that the mass transfer was improved in the sample treated with ultrasound for 20 min with higher quality retention of food products. The intensification of the performance may be due to higher amplitude ultrasound waves transit through the solvent, forming more cavitation bubbles and creating shock waves that induce cellular uptake into cells, which increases the mass transfer diffusion (Li et al., 2021). The quality of kiwi slices during ultrasound-assisted osmotic dehydration was investigated, and it was observed that kiwifruit drying performance was enhanced and quality characteristics were maintained because of the generation of osmotic pressure and higher solvent penetration into the cellular materials resulting in improving the diffusion rate (Nowacka et al., 2017). Another possible reason behind could be improvement of mechanical vibration of the sonication waves as it increases the contact area between the solid and the solvent, thus increasing moisture diffusion (Magalhães et al., 2017). Santacatalina et al. (2016) performed experiment on the ultrasound-assisted freeze-drying of apple cubes at temperature and air velocity ranging from -10 to 10 °C and 1 to 6 m/s, respectively, with varying ultrasound power ranging from 25 to 75 W. It was reported that the higher temperatures significantly enhanced the effective diffusivity (18.1 × 10−10 to 42.0 × 10−10 m2/s at 10 °C and 17.3 × 10−10 to 26.3 × 10−10 m2/s at -10 °C), however higher air velocities had a negative impact on mass transfer phenomena. The results reported that with increase in temperature and ultrasound treatment, the diffusion coefficient was increased because of the accelerated mass transfer induced by ultrasound shockwave causing a rupture in the plant cell wall (Siucińska and Konopacka, 2014). The ultrasound-assisted drying of eggplant was conducted at temperature − 5 to − 10 °C, and ultrasound power of 0 to 21.9 kHz with an airflow velocity of 2 and 5 m/s. The results revealed that the mass transfer was improved with the increase of ultrasound power and product quality was retained in the dried food products (Colucci et al., 2018).

The drying performance was investigated by considering different conditions of ultrasound frequencies (20–30 kHz) and ultrasound power densities (11.1–18.7 kW/m2) at 30–50 °C temperature during ultrasound-assisted fluidized bed drying of paddy. The observation indicated that the total drying time and specific energy consumption rate was increased by 23% and 22%, respectively (Jafari and Zare, 2017). The ultrasound-assisted hybrid drying technologies such as microwave and infrared could be utilized to improve the drying efficiency and product quality of foods (Hii et al., 2021). The ultrasound-assisted combined convective-microwave drying of raspberries at 55 °C and 0.4 m/s airflow reduced the drying time by 79% at the combined treatment of microwave power of 100 W and ultrasound power (200 W), whereas the drying time was reduced by 54% and 64% for the ultrasound treatment of 100 W and 200 W, respectively. Moreover, the intermittent application of ultrasound (200 W) combined with microwave (100–200 W) treated berry fruits prior to convective drying resulted in reduced energy consumption with retention of better textural characteristics and anthocyanin content due to the short drying time and temperature gradient (Kowalski et al., 2016). This is considered to be a major cause that the heating effect of microwave and vibration effect of ultrasound had a synergistic consequence on the rate of drying during the combined treatment process. The ultrasound pretreated Chinese yam sample dried in a pulsed fluidized bed microwave freeze dryer was reported to have higher mass transfer and better quality retention during the drying process (Li et al., 2020). A similar dryer was used for drying strawberries and was found to decrease the total drying time by 45% and exhibited better retaining of bioactive compounds (Jiang et al., 2021). Jin et al. (2018) have analyzed the ultrasound pretreatment followed by hot air drying (HAD) and radio frequency hot air drying (RFHAD) of bitter melon. The result suggested that the total drying time was decreased by 11.2% and 33.4% in HAD and RFHAD, respectively. Dual-frequency ultrasound pretreatment demonstrated higher mass transfer of apple slices due to the formation of micro-jet and shock-wave generated cavitation during the ultrasound waves (Ma et al., 2021). The ultrasound-assisted infrared drying enhanced the drying performance and quality attributes due to the creation of porous structure and mitigating the formed dense layer on the surface of the product tissue during drying at high infrared power (Guo et al., 2020; Hii et al., 2021). Alizehi et al. (2020) experimented with combined infrared and spouted bed drying of pre-ultrasonicated carrot cubes. The results indicated that the drying time was decreased to 355 min from 470 min with improved quality attributes (shrinkage and color). This may be attributed to tissue fragmentation and pore development, which results in an increase in diffusivity and decrease in drying time.

High pressure processing technology: mechanistic approach and components

High pressure processing (HPP) is a non-thermal technique where the sealed food products are introduced into a closed vessel and exposed to a high level of isostatic pressure of 100–800 or 1000 MPa (43,500–116,000 psi) for a specific period and transmitted by using a suitable fluid (water, glycol, ethanol, sodium benzoate, silicone oil, etc.) (Janowicz and Lenart, 2018; Osae et al., 2020). The representation of HPP system is illustrated in Fig. 3. The HPP system based on the pressure application can be classified as direct treatment and indirect treatment and batch, continuous, and semi-continuous processes based on the processing system. The system comprises a high-pressure vessel, piston, pressure frame, pressure medium tank, intensifier, bottom closure, etc.

Fig. 3.

High hydrostatic pressure processing system (Pou, 2021)

In HPP batch system, treatment is mostly carried out after filling the food product into a flexible packaging material. Batch mode is suitable for processing both solid and liquid food commodities. In a continuous operation, the required processing is achieved by multiple vessels, which are operated automatically ‘out of phase’ with the other leading to the continuous output of treated foods. On the other hand, the semi-continuous process uses two or more pressure vessels, each containing free-floating vessels where the food is pumped into the chamber and transferred to the consecutive pressure vessel. In these systems, the water is pumped into the vessel, creating an immense amount of hydrostatic pressure, which acts with little consequence on covalent bonds, preventing substantial chemical alterations of the food product. The potent mechanisms causing lethal effects on tissues of food products interrupt cell structure, denaturation of proteins and enzymes, disrupt cell membranes, spore formation, and increase the permeability of the cell membranes. Moreover, its impacts on the disturbances of hydrophobic and ionic bonds are deactivated or enthused and depend on the tertiary structure and internal structure changes.

Pressure, time, and temperature are three basic parameters responsible for high pressure processing. Out of these, pressure is the prime parameter responsible for transferring energy (Pou and Raghavan, 2020). Processing time is the second important parameter, followed by temperature. Normally, processing temperature does not go beyond 50 °C and that is one of the major advantages of high pressure processing technology over thermal technology (Janowicz and Lenart, 2018). During high pressure processing, liquid food does not require any kind of packaging, whereas solid foods require packaging before processing (Llavata et al., 2020). High pressure processing technique is mostly applied for enzymatic deactivation, bioactive compound extraction, non-thermal sterilization, etc. (Codina-Torrella et al., 2018; Giannoglou et al., 2018; Irna et al., 2018). This technique not only retains the nutritional quality of the food after processing but also converts the complex food to enhance the processing performance (Osae et al., 2020).

Application of high pressure processing in drying of food products

High pressure processing (HPP) is gaining enormous attention in the food industry due to its efficacy in reducing microorganism activity without compromising the quality of processed and packed food at very low temperatures (Singha et al., 2020). The application of high pressure processing as a pretreatment also boosts the rate of drying and drying efficiency (Belmiro et al., 2018; George et al., 2018; Swami Hulle and Rao, 2016). Recent studies on the influence of HPP on the drying performance of food materials are shown in Table 3. HPP can reduce the processing time, moreover there is no issue regarding heat damage during processing and could retain color, texture, and freshness of the product. High pressure processing minimizes functionality changes, and most importantly, this technique as a pretreatment requires less amount of energy (Al-Khuseibi et al., 2005; Llavata et al., 2020). Moisture diffusion at a faster rate can be achieved by a combined application of HPP pretreatment and drying temperature. However, studies on drying apple, carrot, and green bean along with high pressure pretreatment of 100–300 MPa at 20 and 35 °C for 5–45 min proposed that HPP improves the rate of drying if the samples are dried at low-temperature due to cell permeabilization (Yucel et al., 2010). This improvement can be attributed to the permeabilization of the cell structure or enlargement of micro-pores, thus increasing the diffusivity of water from the inner core to the surface. Therefore, drying temperature is one of the important parameters for attaining better results, along with the rate of pressure, treatment time, and temperature during pretreatment. Structural characteristics of the product also affect the high pressure treatment on drying rate and efficiency. Ueno et al., 2015 conducted a study on adzuki beans, kintoki kidney beans, and soybeans and the results demonstrated that the drying rate was faster for high pressure processed adzuki beans but not kintoki kidney beans and soybeans. It may be concluded that the thick physical structures of kintoki kidney beans and soybeans might be the reason behind the differences.

Table 3.

Recent studies on the influence of high pressure processing on the drying performance of food materials

| Food commodities | HPP conditions (pressure, time, and temperature) | Drying methods | Drying conditions (temperature/time/air velocity/RH) | Major findings | References |

|---|---|---|---|---|---|

| Beans | 50 to 600 MPa for 1 min | Incubator | 40 °C for 24 h |

The effective moisture diffusivity was improved from 1.35 × 10–10 m2/s to 1.72 × 10–10 m2/s with an increase of isostatic pressure from 50 to 600 MPa The water diffusivity was enhanced by around 27% and increased drying rate for sample pretreated at 60 MPa/1 min |

Belmiro et al. (2018) |

| Ginger | 400 MPa for 10 min | Cabinet dryer | 55 °C, 45%, 10 min, and 2 m/s |

The effective moisture diffusivity was observed to be increased from 2.03 × 10–9 m2/s to 6.09 × 10–9 m2/s with an increase of isostatic pressure from 100 to 400 MPa for 10 min The oleoresin yield (28.29%) and 6-gingerol content (34.05%) were found to be higher than the control |

George et al. (2018) |

| Aloe vera | 300–500 MPa for 5–15 min | Dehumidified air drying | 50–70 °C and 1–2 m/s |

The effective moisture diffusivity of high pressure pre-treated samples was increased with the increase of treatment from 300 to 500 MPa The drying rate was improved with the rise of HPP treatment and temperature. The activation energy was found to be varied between 17.65 and 40.67 kJ/mol |

Swami Hulle and Rao (2016) |

| Sweet potato, cocoyam, and Peruvian carrot | 600 MPa for 5 and 30 min | Incubator chamber | 50 °C, 0.127 m/s, and 23 h |

The moisture diffusivity was enhanced by 35% at 600 MPa (5 min), 32% at 600 MPa (5 min), and 44% at 600 MPa (30 min) for sweet potato, cocoyam, and Peruvian carrot, respectively The drying rate was reported to be increased by around 30%, treated with 600 MPa for 10 min The permeability of cell structures was considerably improved due to high pressure processing, thereby enhancing mass transfer rate and subsequently reducing the total drying time |

Oliveira et al. (2015) |

| Carrot and apple | 100, 200, 250, and 300 MPa for 5, 15, 30, and 45 min | Hot-air tunnel dryer | 27 °C, 45 °C, 65 °C, and 85 °C and 0.4 and 0.8 m/s |

The application of high pressure processing above 100 MPa significantly reduced the drying time HPP treatments at 300 MPa and 20 °C or 200 MPa and 35 °C resulted in 10% shorter drying time as compared to the control The highest drying rate was obtained at 200 MPa, 15 min, and 35 °C for green beans and apples and 200 MPa, 15 min, and 20 °C for carrots drying at 65 °C and air velocity of 0.4 m/s |

Yucel et al. (2010) |

| Peach | 50–700 MPa for 5 and 10 min | Cabinet dryer | 70 °C for 5 h |

HPP treated peach slices increased the effective moisture diffusivity from 6.56 × 10−9 m2/s to 7.65 × 10−9 m2/s which improved with the increase of HPP treatment pressure and time High pressure processing improved the permeability, which resulted in drying rate improvement and minimized the drying time HPP treated samples showed less drying time (5 h) than control samples (7 h) Citric acid as a carrier fluid was observed to influence the drying rate |

Kingsly et al. (2009b) |

| Potato | 400 MPa for 15 min | Hot air convection drying | 75 °C for 8–9 h |

A higher drying rate was noted in high pressure pretreated samples during the initial phases of drying process The total color change for HPP pretreated samples was found to be lower as compared to thermally pretreated sample |

Al-Khuseibi et al. (2005) |

Belmiro et al. (2018) have analyzed the effect of HPP treatment on beans at 50 to 600 MPa for 1 min at 25ºC. It was observed that the HPP treated samples enhanced the drying rate and reduced the drying time with the rise in pressure levels. The application of HPP treatment increases the rate of movement of moisture from the inner space to the outer surface by increasing the cell wall permeability and decreasing the turgor pressure (George et al., 2018; Llavata et al., 2020; Oliveira et al., 2015; Swami Hulle and Rao, 2016). This may be the reason behind the decrease in total drying time and increase in moisture diffusivity during the drying operation. Shorter drying time and faster drying rate have been reported by various researchers where high pressure was applied as a pretreatment technique. Belmiro et al. (2018) have reported that HPP treatment enhanced the drying rate of common beans and subsequently increased the effective moisture diffusivity. Similarly, the effective moisture diffusivity in ginger was improved from 2.03 × 10–9 to 6.09 × 10–9 m2/s during the HPP treatment at 100 to 400 MPa and significantly reduced the drying time (George et al., 2018). The intensification of the drying process could be ascribed to the membrane permeation inside the cellular matrix or a change in tissue structure. Swami Hulle and Rao, (2016) have studied the impact of HPP treatment (300–500 MPa, 5–15 min, and 1–2 m/s air velocity) on drying of aloe vera cubes and found that the drying rate was noticeably enriched for higher pressure treated sample; however, the interaction of pressure and airflow velocity was more remarkable than the interaction of pressure and treatment temperature dried at 70 °C. Oliveira et al. (2015) observed a higher moisture reduction rate in high pressure processed cocoyam, sweet potato, and peruvian carrot than the control samples owing to high permeability of the membrane, which enhanced the rate of moisture transport.

A few studies also indicated that using high pressure process as a pretreatment is much more effective on low-moisture food than high moisture food. The main reason of using high pressure prior to drying is to reduce the drying time and to protect the nutritional quality of the dried food. Therefore, a combination of pressure and time during pretreatment must be maintained because high pressure for a longer duration influences the interaction of the covalent and non-covalent bonds, followed by denaturation of protein (Osae et al., 2020). Studies have suggested that drying at a moderate temperature (ranging between 50 and 60 °C) could give better effect of high pressure (Belmiro et al., 2018; Osae et al., 2020). It is recommended to use hybrid concept by intelligently combining two or more pretreatment methods for enhancing the overall drying performance with the potential of synergistic effect. Pérez-Won et al. (2016) analyzed the effect of combined treatment with osmotic dehydration (salt concentration of 10% and 15%) and high pressure (350 and 550 MPa) for 5 to 15 min. The results demonstrated that water and mass transfer during this combined process was satisfactorily enhanced. The diffusivity of all pre-treated samples varied from 4.54 × 10–9 to 9.95 × 10–9 m2/s, indicating an increase in driving force for moisture removal from abalone slices and thereby higher mass transfer and moisture effective diffusivity than the control sample. The results obtained could be attributed to the softening of the tissue and cell structure modification due to higher pressure which resulted in the loss of turgor pressure, thus enhancing moisture diffusivity and reducing drying time. The convective drying of apple slices was performed by pretreatment with a hypertonic solution with high pressure of 650 MPa, which reduced the lightness value by 49.7% and significantly affected the shrinkage as compared to the control sample (Janowicz and Lenart, 2015). The high pressure processing (50 to 700 MPa for 10 min) reduced the hardness and springiness of the pineapple samples, while cohesiveness remained unaffected. Additionally, samples treated at 500 MPa had the most effective reduction in drying time, and effective moisture diffusivity increased with increasing pressure up to 500 MPa (Kingsly et al., 2009a).

Pulsed electric field technology: mechanistic approach and components

Pulsed electric field (PEF) can be described as a non-thermal treatment that uses low and high voltage pulses of electricity applied through food samples placed between two electrodes. High electric fields were applied at an intensity of 10–80 kV/cm with a very small duration of treatment time of microseconds to milliseconds. The process helps in increasing the permeability of tissues of vegetables and fruits by increasing the heat and mass transfer rate, leading to an increase in the drying performance. This treatment meets customer satisfaction by producing minimal loss to the quality of the products (Osae et al., 2020). Applications of high voltage in pulses lead to swelling, pore formation, enlargement of existing pores, water influx, membrane rapture, and inactivation of cells. These actions led to an increase in the moisture diffusion inside as well as the surface of the food products to enhance the drying performance (Mohamed and Eissa, 2012). The typical PEF system comprises a pulse electric generator, voltage regulator, treatment chamber, control and monitoring system, electrode, baffles, and compression unit. PEF is advantageous when compared to other conventional pretreatment approaches because it can inactivate microorganisms without affecting the total color changes and texture of the food product while improving the drying kinetics and rates (Mohamed and Eissa, 2012).

It is generally used as a pretreatment before drying processes such as osmotic, vacuum, convective, or freeze-drying. The various factors that influence the pulsed electric field are technological factors, biological factors, and medium factors. The technological critical aspects namely field strength, treatment temperature, treatment time, shape of the pulse, pulse width, number of pulses, and pulse frequency were more potent factors that influenced during processing. Moreover, the type and growth of microorganisms, physiological and growth states, and substrate characteristics including intrinsic factors such as conductivity, dielectric properties, resistivity, pH, ionic strength, physical and chemical characteristics of food products have significant impacts during pulsed electric field application. It is a process that involves electroporation and electro-permeability (Saulis, 2010). Electroporation is the development of pores within the cell matrix or an expansion in the existing size of the pores or an interruption of the membrane within the cell (Witrowa-Rajchert et al., 2014). PEF pretreatment depends on treatment intensity (Ostermeier et al., 2018), the number of pulses (Telfser and Galindo, 2018), and the matrix structure (Alam et al., 2018) applied in different food products.

Application of pulsed electrical field in drying of food products

To enhance the drying performance and reduce the drying time, the food products are pretreated with different approaches. Various pretreatments such as high pressure processing ohmic heating, microwave, pulsed electric field, and ultrasound are currently used. Pulsed electric field has emerged to be one of the promising approaches for pretreatment as the non-thermal behavior can prove to be good for the quality of food products (Wiktor et al., 2016). Recent studies on the influence of pulsed electric field on the drying performance of food materials are shown in Table 4. In an apple drying, the pulsed electric field helped stress the cells, which prevented them from thermal denaturation. Pulsed electric field treated samples caused the cellular structure to shrink and stick to the internal tissue structure of the apple, which resulted in better diffusion of small molecules (Donsı` et al., 2010; Llavata et al., 2020). In potatoes, it had contradictory impacts; it enhanced the drying rate and textural attributes and improved mass transfer rates on fluidized bed drying. In the case of carrots, pulsed electric field pretreatment increased cell membrane permeability (Llavata et al., 2020). Yu et al. (2017) reported that pulsed electric field pretreatment before osmotic dehydration accelerated the water loss and solid gain rates in blueberries (2 kV/cm) which may be due to the high pressure inducing solvent permeation inside the cellular matrix. Telfser and Galindo, (2018) have reported that pulsed electric field pretreatment increased the drying velocity and further it was observed that the greatest effect was with moderate temperatures, such as at 60 °C for drying carrots (0.9 kV/cm) (Alam et al., 2018), and at 50 °C for potatoes having 0.6 kV/cm (Liu et al., 2018).

Table 4.

Recent studies on the influence of pulsed electric field on the drying performance of food materials

| Food commodities | Pulsed electric field/ other treatment/ time/temperature | Drying technique and drying condition | Major findings | References |

|---|---|---|---|---|

| Mushroom slices | 1.6 kV/cm, 3 cm electrode gap, 50 pulse/s, US power (405 and 612 W) and sonication times of 10, 20, and 30 min | Hot air dryer at 65 °C, and air velocity of 2 m/s Electrohydrodynamic drying at 17 kV and 65 °C |

The ultrasound and pulsed electric field treated sample reduced the drying time of mushroom slices by 11–39 and 7–25% for the hot air drying and 33–38 and 16–28% for the electrodynamic drying, respectively The specific energy consumption of the ultrasound-treated sample was reduced by 11–40 and 21–35%, respectively, in HA and EHD drying, while the PEF pretreatment was reduced by 4–27 and 16–24%, respectively PEF and US pretreatments significantly increased the effective moisture diffusivity and were found to be 5.85 to 7.97 × 10−10 m2/s and 7.38 and 8.9 × 10−10 m2/s for pulsed electric field and ultrasound treated samples, respectively |

Mirzaei-Baktash et al. (2022) |

| Kiwifruit waste |

PEF: 2 kV/cm and a fixed pulse width of 10 μs OD: 40% (w/w) trehalose for 150 min at 35 °C |

Hot air drying (50, 60, and 70 °C) at 2 m/s |

The drying kinetics were significantly improved by PEF, followed by OD and drying temperature The drying time was reduced in combined pretreatment of PEF and US drying at 70 °C |

Tylewicz et al. (2022) |

| Red bell pepper |

PEF: 1.07 kV/cm US: 21 kHz, 30 min |

− 40 °C vacuum and freeze-drying |

A novel combined treatment method performed better and reduced drying time by 29 to 70% Freeze-dried bell pepper treated with combined pretreatments exhibited higher retention of color value, vitamin C, total phenolic, and antioxidant capacity |

Rybak et al. (2021) |

| Mango | 1 kJ/kg and 3 kJ/kg at a field strength of 1.07 kV/cm | Convective drying at 70 °C and airflow velocity of 2 m/s |

The rehydration ratio decreased with the increase of pulsed electric energy by 16% and 21% in convective and vacuum drying, respectively PEF-treated sample retained 70% of the phenolic compound as compared to 30% in the untreated sample |

Lammerskitten et al. (2020) |

| Carrot |

PEF: 5 kV/cm, 10 pulses and 0.5 Hz US: 21 and 24 Hz for 20 min |

Microwave-assisted hot air drying at 200 W, 40 °C, and 2 m/s air velocity |

Combined pretreatment of PEF and US reduced drying time and enhanced the drying rate by 27–49% and 64–68%, respectively The highest moisture diffusivity of 3.38 × 10–10 m2/s was observed during the treatment of ultrasound, followed by PEF which reduced drying time by 29 min The combined pretreatment enhanced rehydration capacity, retention of color, and carotenoid retention from 2.8 to 5.8 and 93%, respectively |

Wiktor and Witrowa-Rajchert (2019) |

| Blueberries | 2 kV/cm, 2 µs pulse width, 200 pulses per second, and total time 96 ms | Conventional hot air at 45, 60, and 75 °C, and vacuum drying |

The drying time was significantly reduced in the PEF pretreated samples The optimum drying condition based on the drying time and retention of quality attributes was found to be 75 °C for vacuum drying |

Yu and Jin (2017) |

| Onions | Electric field strength between 0.36–1.07 kV/cm, pulse width 40 µs, electrode gap 280 mm, frequency 2 Hz | Convective drying at 45, 60, and 75 °C |

The drying time was reduced by 30.3%, 21.4%, and 6.4% pre-treated with PEF at 45 °C, 60 °C, and 75 °C, respectively The effective moisture diffusivity was enhanced from 3.7 × 10–9 to 1.8 × 10–8 m2/s The internal diffusion was enhanced with the increase in drying temperature and after a certain electric field strength, no further reduction in drying time was observed The drying time was reduced by 21.4% in pre-treated (1.07 kV/cm, 4 kJ/kg) samples dried at 45 °C |

Ostermeier et al. (2018) |

| Carrots, Parsnip |

0.9 kV/cm, pulse width of 20 μs, a frequency of 50 Hz 65.2 kJ/kg for carrots, 65.8 kJ/kg for parsnip |

Convective drying 50, 60, and 70 °C and 1 m/s air velocity |

The drying time was lessened by 28% at 70 °C and 21% at 60 °C in parsnip and carrot, respectively as compared to the control sample The effective diffusivity of water of the pre-treated sample was obtained in the range of 1.61 × 10−10 and 3.04 × 10−10 m2/s and 1.97 × 10−10 and 3.06 × 10−10 m2/s for carrot and parsnip, respectively, which increased with the increase of drying temperature The pre-treated sample increased moisture diffusivity by 38% with retention of color, nutritional, and sensory properties |

Alam et al. (2018) |

| Mango |

1.85 kV/cm (5.63 J/kg) and 50 pulses, 5 kV/cm (80 kJ/kg) and 10 pulses 5 kV/cm (80 kJ/kg) and 100 pulses |

Convective drying at 70 °C and air velocity of 2 m/s |

The PEF-treated sample reduced the drying time by 6.9–8.2% as compared to the untreated sample The moisture diffusion coefficient of the PEF pre-treated samples was ranged from 0.944 × 10–9 to 1.07 × 10–9 m2/s. It showed an increasing trend with the increase of electric field intensity and PEF pulses The color attributes were retained, and oversaturated electroporation was observed by SEM analysis, causing enhanced drying efficiency |

Wiktor et al. (2016) |

| Goji berry | PEF: 0.9 -2.8 kV/cm, OD: glycerol (60%), maltodextrin (20%), ascorbic acid (2.0%) and sodium chloride (1.0%) | Force convection drying at 60 °C for 400 min |

The mass transfer, i.e., water and solid transfer rate increased significantly with the rise of PEF pulses The water diffusion and solid diffusion were increased by 85.5 and 54.2%, respectively, for the combined approach as compared to individual treatment Better color, phenolic content, and antioxidant activity retention were reported by the application of combined treatment |

Dermesonlouoglou et al. (2018) |

| Potato slices | 4 kV/cm for 1 h | Microwave convective at 50 °C and 1.4 m/s airflow velocity |

The PEF treatment of potato slices showed no significant influence on drying time The moisture diffusivity was obtained as 5.12 × 10−10 and 5.063 × 10−10 m2/s at sole microwave drying and PEF treatment-microwave drying, respectively |

Singh et al. (2015) |

| Kiwi fruit |

PEF: 0.7, 1.1 and 1.8 kV/cm, OD: glycerol, trehalose, maltodextrin, etc., for 240 min |

Convective drying at 45 °C for 240 min |

The effective moisture diffusivity varied from 0.323 × 10−9 to 1.13 × 10−9 m2/s and 0.653 × 10−9 to 1.87 × 10−9 m2/s for the untreated and PEF-treated samples, respectively The diffusion coefficient was enhanced with the increase of electric field strength of PEF during the drying of kiwi fruit slices PEF with OD treated sample presented high-quality color change, increased firmness, and high vitamin C content |

Dermesonlouoglou et al. (2016) |

| Kiwi fruit |

PEF:100, 250, 400 V/cm OD: 61.5°Bx sucrose solution Time: 0–120 min |

Osmotic dehydration at 25 °C |

The combined treatment enhanced the mass transfer rate The PEF treatment accelerated water fluxes and therefore increased the intracellular shrinkage of the sample |

Traffano-Schiffo et al. (2016) |

In potatoes and red bell pepper, it was found that pretreatment using a pulsed electric field system reduced the drying time and increased the drying rate of the product (Donsı` et al., 2010). Dermesonlouoglou et al. (2018) have reported that a pulsed electric field combined with osmotic pretreatment enhanced the drying rate, improved the mass transfer rate, and retained the quality attributes of goji berry during drying. PEF enabled tissue permeabilization at 0.9–2.8 kV/cm up to 7500 pulses and increased the mass transfer during drying. Osmotic dehydration at 55 °C for 60 min combined with PEF at 2.8 kV/cm and 750 p and drying at 60 °C reduced the processing time by 180 min and 33% more in color value retention with high polyphenolic content and antioxidant properties. Pulsed electric field treatment increases the permeability of fruits and vegetables and enables cell breakdown, which in turn leads to increasing the drying rate (Dellarosa et al., 2016). The high pulsed electric field pretreatment before vacuum freeze-drying reduced the practical issues related to drying, such as high consumption of energy, reduced production cost, and increased the permeability of cell membrane, thereby intracellular water could easily diffuse from the system, subsequently enhancing the drying rate and reducing the drying time (Parniakov et al., 2016). PEF has low energy input, which reduces energy consumption and increases productivity (Wu et al., 2011). Pulsed electric field pretreatment exhibited minimal impact on parsnip drying at 50 and 60 °C and did not show any evident change in moisture diffusivity, but it was observed at 70 °C, where the samples experienced 38% more moisture diffusivity than untreated samples. Unlike parsnip, carrot samples showed more reduction in drying time at 50 °C and 60 °C (Alam et al., 2018).

Carrots subjected to convective drying using PEF with or without pretreatment at 0.9 kV/cm with 1000 pulses and 10,000 pulses at 50, 60, and 70 °C, and the drying effect was investigated by checking the whiteness index (WI) and carotenoids, phenols, furosine value, etc. It was found that carrots subjected to PEF pretreatment experienced carotenoids degradation and increased Maillard reaction at 70 °C. The PEF pretreatment induces cells breakdown, which makes them susceptible to enzymatic reactions (Fratianni et al., 2019). Wiktor and Witrowa-Rajchert (2019) also studied the drying kinetics of carrots when subjected to microwave with PEF pretreatment. The PEF treatment at 5 kV/cm followed by ultrasonication reduced the drying time by 27–49%. Carotenoids and rehydration capacity were retained but soluble solids were lost, and numerous porous structures were formed in the sample with no change in the hygroscopic properties. Won et al. (2014) have examined on the pretreatment of red pepper with a pulsed electric field at 2.5 kV/cm and 100 Hz for 4 s. The study revealed that the drying time was substantially reduced, having processing conditions of 34.7%. Pulsed electric field treatment for the considered shortest time (1 s) also showed a 20.4% reduction. Additionally, it was observed that reduced drying time due to the pulsed electric field led to more retention of the carotenoid pigments. The pulsed electric field increased the drying rate without changing the drying mechanism of red pepper because of the falling rate and diffusion-controlled drying characteristics as observed in the control sample. Blueberries were treated with the pulsed electric field at 2 kV/cm and dried at temperatures of 45 to 75 °C using hot air and a vacuum dryer. The drying time and nutritional characteristics were investigated after the pretreatment. It was observed that the drying time was reduced from 6 to 4 h, 10 to 7 h, and 70 to 40 h at 75, 60, and 45 °C, respectively. The pulsed electric field demonstrated the least influence on the nutritional quality of the vacuum dried product at 75 °C (Yu et al., 2017).

Fauster et al. (2018) have studied the influence of PEF pretreatment on French fries production, performance, and product quality. The PEF treatment induced the cell breakdown and the softening of tissue was improved by up to 80% less feathering. This resulted in the reduction of starch loss and less fat uptake from 7.5 to 6.8%. The breaking loss was decreased from 11 to 6% due to the improved elastic properties of the potato sticks. Drying is commonly followed to diminish the deterioration of products and for enhancing the shelf life. PEF pretreatment before drying substantially reduced the drying duration without any effect on ascorbic content or the color index (Lamanauskas, 2015). Singh et al. (2015) have investigated the PEF pretreatment at 4 kV/cm. The results suggested higher moisture diffusivity and drying rate. This characteristic can be attributed to the influence of electric field on the permeabilization of cell membrane and the uniform moisture distribution throughout the sample, which leads to enhanced moisture diffusivity.

The pre-treated potato slices resulted in uniform distribution of moisture, and the samples were less curled while drying in microwave convective and hot air drying. On the contrary, retention of the bioactive compounds did not show a clear trend. Some reports revealed that there was a loss of antioxidant capacity. Several studies have indicated the migration of water and other compounds due to electro-permeabilization (Yu et al., 2017, 2018). Different properties of mango, such as retention capacity of the antioxidant compounds, phenolic compounds, and rehydration capacity were investigated for the PEF pretreated sample and untreated sample, followed by drying. The results demonstrated that the PEF pretreatment showed low rehydration capacity in both the convective and vacuum dried products. The retention of phenolic compounds for pulsed electric field treated sample was 70% higher than the untreated one. The carotenoid retention was found to be higher in the sample treated at 1 kJ/kg, but the antioxidant capacity was reduced at high PEF. This suggests that overtreatment should be avoided in order to minimize the degradation of bioactive compounds (Lammerskitten et al., 2020). Thus, the researchers used PEF along with ultrasound as a pretreatment method to achieve better results. It was also found that this combined method accelerated the drying process. This not only retained the original color but also various bioactive compounds such as flavonoids and polyphenols (Wiktor et al., 2019).