Abstract

3D bioprinting has enabled the creation of biomimetic tissue constructs for regenerative medicine and in vitro model systems. Large-scale production of 3D structures at the micron-scale resolution is achieved through bioprinting using custom bioinks. Stability and 3D construct compliance play an important role in offering cells with biomechanical cues that regulate their behavior and enable in vivo implantation. Various crosslinking strategies are developed to stabilize the 3D printed structures and new methodologies are constantly being evaluated to overcome the limitations of the existing methods. Photo-crosslinking has emerged as a simple and elegant technique that offers precise control over the spatiotemporal gelation of bioinks during bioprinting. This article summarizes the use of photo-crosslinking agents and methodology towards optimizing 3D constructs for specific biomedical applications. The article also takes into account various bioinks and photo-crosslinkers in creating stable 3D printed structures that offer bioactivity with desirable physicochemical properties. The current challenges of 3D bioprinting and new directions that can advance the field in its wide applicability to create 3D tissue models to study diseases and organ transplantation are also summarized.

Keywords: Photo-crosslinking, Hydrogels, Additive manufacturing, 3D bioprinting, Bioinks, Tissue engineering

1. Introduction

Tissue engineering is a multidisciplinary field that aims to fabricate bio-mimetic three-dimensional scaffolds using the combination of cells, biomaterials, and growth factors. Generally, the applications of tissue engineering aim to repair or regenerate damaged tissues or organs such as skin, bones, nerves, to name a few using functional three-dimensional (3D) scaffolds. Various conventional scaffold fabrication techniques such as solvent casting, particle leaching, gas foaming, freeze-drying, thermal-induced phase separation, and electrospinning have been adopted successfully to develop 3D scaffolds [1]. Some of the scaffold fabrication procedures may also involve gene or immunomodulatory techniques to recapitulate the functionalities of native tissues. However, the use of these techniques was restricted due to consequent disadvantages such as inhomogeneity in pore geometry, nutrient and gaseous diffusion limitations in thicker scaffolds, limited blood vessel formation, poor resolution in scaffold architecture, and a time-consuming process. [2]. Therefore, modern scaffold fabrication techniques such as 3D molding, fused deposition modeling (FDM), selective laser sintering (SLS), and 3D printing have been widely used nowadays. These techniques enable the fabrication of constructs with controllable interconnected porous nature, 3D precision, better resolution, faster process with less human errors, and better vasculature, which enhances mass transfer in thicker scaffolds. Furthermore, there are also reports suggesting the implementation of these 3D bioprinted constructs as in vitro models for drug screening and pharmacokinetics applications [3]. Among these modern methods, 3D bioprinting is an additive manufacturing technique utilized to develop suitable biomimetic structures with complex anatomical patterns using a bioink, which comprises cells and polymers [4]. Typically, the required structures are modeled, digitized, and fed into the bioprinter using 3D modeling software such as computer-aided design (CAD), computer-aided manufacturing (CAM). Largely, these input digital files are derived from target tissues or organs of patients using imaging modalities such as nano/micro-computed tomography (CT), magnetic resonance imaging (MRI). 3D bioprinting is a fabrication process that involves the printing of scaffolds in a “layer-by-layer” fashion, such that one layer is printed and gets solidified before the next layer is deposited. This will result in a temporary framework, which acts as an adhesive layer for cells to perform cell modulatory activities and to deliver growth factors to the cells in a regulated manner [5]. Thus, the bioinks should possess remarkable properties such as good cytocompatibility, native biological cues with desired degradation rate, suitable rheological & mechanical properties, instant crosslinking ability, provide shape fidelity and offer ease of processability [6].

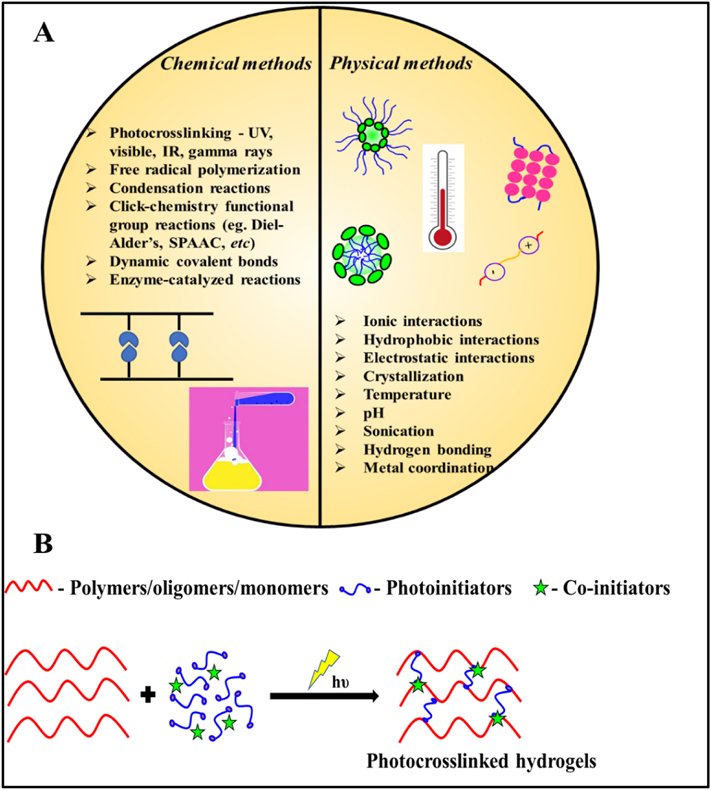

Natural or synthetic polymers such as collagen, gelatin, silk fibroin, alginate, poly(ethylene glycol) (PEG), and poly(caprolactone) (PCL) are widely used as bioink materials. During the bioprinting process, these bioinks form hydrogels via various crosslinking strategies and become stable 3D structures [7]. Crosslinking processes are broadly classified into physical and chemical methods based on the mechanism of action. Among these methods, chemical methods are widely used because of their wide range of tunability and stability under physiological conditions [8]. On the contrary, physical crosslinking occurring via secondary forces such as hydrophobic interactions, hydrogen bonding or van der Waals forces would result in constructs with weak mechanical stability and hence may not be suitable for the long term in vitro culture studies [9]. Importantly, the choice of crosslinking method depends on the biopolymer backbone, functional side groups & their crosslinking mechanism, and other required supplementary chemicals. Considerations of these multiple factors for choosing an efficient crosslinking strategy is very essential as it has a significant impact on the cytocompatibility, mechanical, physiochemical, and cellular behavior of the resultant construct [10].

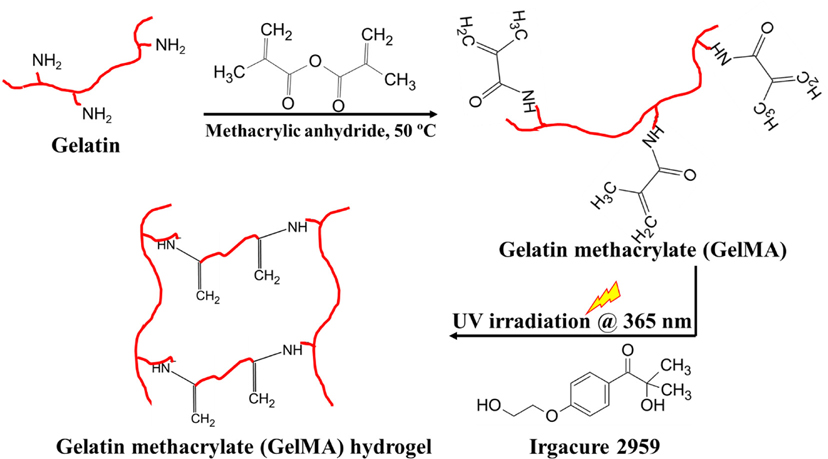

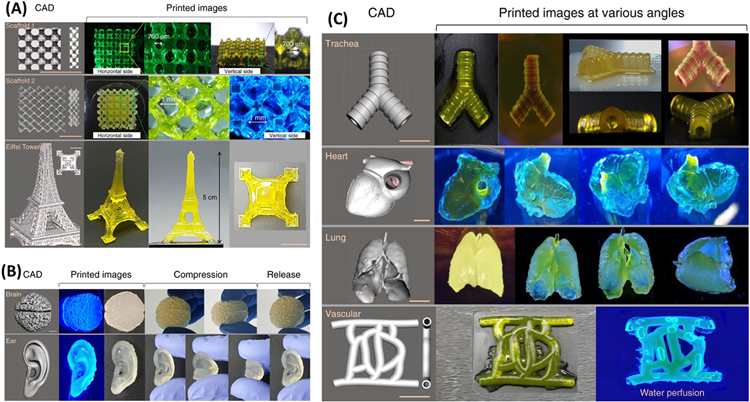

Among different chemical crosslinking methods, photocrosslinking is one of the most commonly employed approaches in 3D bioprinting due to its higher crosslinking efficiency and spatiotemporal controllability in developing sustainable tissue constructs [11]. These superior features of photocrosslinking have directed to wide-ranging applications of tunable hydrogels for various applications. This method utilizes photoinitiators and photo-reactive polymers to enable photoinduced covalent bond formation by simply adjusting certain working parameters such as light source, the intensity of light, exposure time, and area of illumination [11]. For instance, natural biopolymer gelatin is chemically modified into photoreactive gelatin methacrylate (GelMA) using methacrylic anhydride [12]. GelMA undergoes free-radical crosslinking in presence of photoinitiators (Irgacure 2959) under UV light of the wavelength of 360–380 nm and forms chemically stable 3D photocrosslinked gelatin (Fig. 1). This type of photo-induced polymerization allows prepolymer solutions to be tuned into stable hydrogels with a desirable degradation profile and mechanical behavior.

Fig. 1.

General scheme of photocrosslinking of GelMA hydrogels—Gelatin methacrylate (GelMA) is obtained by modifying pristine gelatin via methacrylic anhydride; UV irradiation of GelMA/photoinitiator Irgacure 2959 mixture results in a stable photocrosslinked GelMA hydrogel.

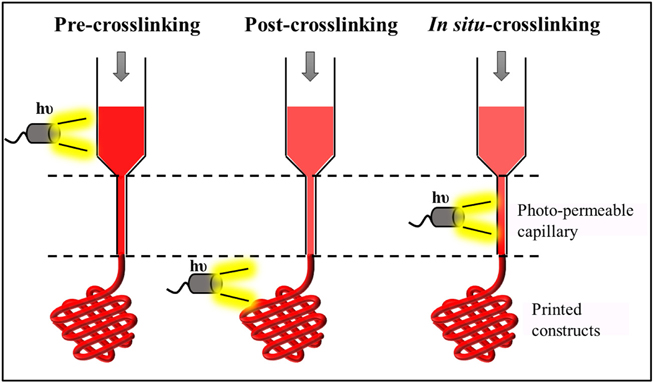

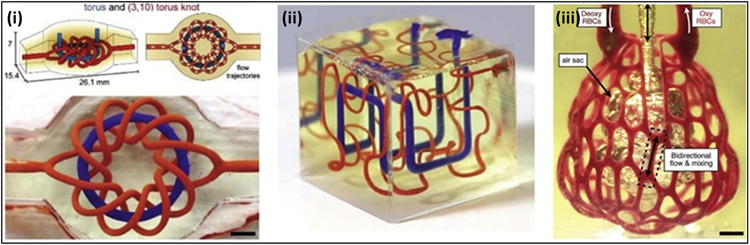

In general, photocrosslinking of biopolymers can be performed at various stages during the bioprinting process such as pre-crosslinking, postcrosslinking, and in-situ crosslinking depending upon the viscosity of the biopolymers (Fig. 2). Low viscous polymers combined with photoinitiators and photochemicals are mostly either pre-crosslinked (pre-crosslinking) or crosslinked during the printing process (in-situ crosslinking) whereas high viscous polymers are preferably crosslinked only after the printed process is over (post-crosslinking). Photocrosslinking methods have been successfully used in the fabrication of 3D constructs as in vitro models that faithfully recapitulate the complexity of both healthy tissues as well as diseased tissues.

Fig. 2.

Various stages involved in photocrosslinking in bioprinting technology.

Pre-crosslinking—Irradiation of light before bioink ejection allowing extrusion of pre-crosslinked bioink; Post-crosslinking—Irradiation of light after the bioink ejection or over the printed constructs; In-situ crosslinking—Irradiation of light in the photo-capillary lumen or during the bioink ejection process.

To date, the demand for photocrosslinking approaches and photocrosslinkable biomaterials for 3D bioprinting is exponentially increasing and thus forms the concrete basis to offer a comprehensive review on the current progress of their applications in 3D constructs development. This review paper provides the basic insights of photocrosslinking mechanisms with a focus on the considerations of various parameters involved in photocrosslinking reactions such as irradiation time, location, light intensity, and irradiation distance. Further, the applications of photocrosslinking in various bioprinting technologies such as stereolithography, digital light processing (DLP), and extrusion bioprinting are discussed. Photocrosslinkable biomaterials explored for 3D bioprinting are described along with the current progress of this approach. Finally, the challenges in developing photocrosslinked 3D constructs and future perspectives on the applications of this strategy in 3D bioprinting are briefly highlighted.

2. Photocrosslinkable biomaterials

Photocurable biopolymers possess light-sensitive functional groups, which can be crosslinked upon the illumination of light at a specific wavelength. These polymers have found substantial and wide applications in numerous fields such as electronics, printing resins, surface coatings, biosensors, surgical applications, drug delivery systems, dental implants, and tissue engineering [13,14]. Further, these biopolymers have also extended their biomedical applications in additive manufacturing techniques, where they crosslink instantaneously to develop a three-dimensional construct during or after the printing process [15]. In addition to the presence of photoreactive side groups, these polymeric bioinks used for successful bioprinting process should possess ideal properties such as (i) mechanical property like toughness, elasticity that matches specific target tissue; (ii) good structural integrity to withstand the desired load and (iii) excellent biocompatibility with negligible inflammatory and immunogenic reactions. These bioink materials are conjugated with photoactive functional groups which are sensitive and selective to a set of photocuring parameters [16]. Table 1 shows a comprehensive list of various conjugated polymeric biomaterials, photoinitiators, crosslinking parameters, and developed 3D constructs using bioprinting methods. It is important to note that unreacted photoactive groups and over-illumination of UV light may lower cell viability, cause inflammatory responses and genetic mutations, which may be considered as drawbacks of this technique. Hence, complete removal of these unreacted groups and shorter UV light illumination time can overcome these limitations to obtain stable and biologically active 3D constructs [17]. These biomaterials can be classified as UV crosslinkable and visible light crosslinkable materials based on the maximum absorption wavelength (λmax) of the photoinitiators.

Table 1.

List of various functionalized polymeric biomaterials, photoinitiators, photocrosslinking parameters for 3D bioprinting of biological constructs.

| Biomaterials | Photoinitiator | Photocuring parameters | Printed construct | Cell types used | Ref. |

|---|---|---|---|---|---|

|

| |||||

| Methacrylated collagen (MeCol), Alginate coated Carbon nanotubes (CNT) | Irgacure 2959 | Light source: UV Wavelength: 365 nm Irradiation time: 45 s Intensity: 6.1 mW/cm2 |

3D bioprinted cardiac patch | Human coronary artery endothelial cells (HCAECs) | [18] |

| PEG norbornene macromers | Lithium phenyl-2,4,6-trimethyl-benzoyl phosphinate (LAP) | Light source: UV Wavelength: 365 nm Irradiation time: 3 min Intensity: 60 mW/cm2 |

Ear shaped construct | Human mesenchymal stem cells (hMSCs) | [19] |

| Methacrylated gelatin (GelMA), poly(γ-glutamic acid) | Irgacure 959 | Light source: UV Irradiation time: 30 s Intensity: 8 mW/cm2 |

Single-layer cylindrical construct and double-layer tubular construct | Human umbilical vascular endothelial cells (HUVECs), smooth muscle cells (HSMCs) | [20] |

| Silk fibroin, Gelatin | Ruthenium (Ru), Sodium per sulfate (SPS) | Light source: Visible light Wavelength: 400–450 nm Irradiation time: 3 min Intensity: 30 mW/cm2 |

Grid pattern (12 × 12 mm), 7 layered constructs | Human articular chondrocytes | [21] |

| GelMA, tyramine | Ruthenium/sodium per sulfate | Light source: Visible light Wavelength: 450 nm |

Grid pattern | Articular chondroprogenitor cells | [22] |

| κ-carrageenan | Eosin Y | Light source: Visible light Intensity: 100 mW/cm2 Irradiation time: 180 s |

Rectangular mold (15 × 5 × 1 mm) | HeLa and fibroblasts | [23] |

| Norbornene-functionalized neutral soluble collagen | LAP | Light source: UV Wavelength:365 nm Intensity: 5 mW/ cm2 Irradiation time: 30 s |

The pyramid side length of 9.2 mm and a height of 5 mm, monolayer tube with a diameter of 8 mm and a height of 10 mm. | Human umbilical vein endothelial cells | [24] |

| Gelatin methacrylate | Irgacure 2959 | Light source: visible light laser Wavelength: 405 nm Intensity: 1–5 mW/mm2 Irradiation time: 10 s |

Microtube pattern | NIH 3T3 fibroblast cells | [25] |

| Gelatin methacryloyl (GelMA) | Eosin Y, triethanol amine, N-vinyl caprolactam | Light source: Visible light Wavelength: 400–750 nm Intensity: 48.6 mW cm−2 Irradiation time: 60 s Irradiation distance: 10 cm |

Honeycomb pattern and miniaturized multi-layered human ear and cross-section of the brain | 3T3 fibroblasts, U118 astrocytes | [26] |

| Methacrylated auricular cartilage-derived decellularized extracellular matrix (cdECMMA), gelatin, glycerol, hyaluronic acid | Irgacure 2959 | Light source: UV light Light intensity: 200 mW/cm2 Irradiation time: 2 min |

Lattice and ear-shaped cell-laden constructs | Rabbit auricular chondrocytes | [27] |

| Oligo (poly(ethylene glycol) fumarate) (OPF), gelatin, polyethylene glycol diacrylate (PEGDA) | Irgacure 2959 | Light source: UV light Irradiation time: 2 min |

Grid pattern with 10 mm × 10 mm width and length with 0.25 mm single layer thickness and 25% infill density | MC3T3 pre-osteoblast cells and PC12 cells | [28] |

| Methacryloyl gelatin, new Coccine | LAP | Light source: visible light Wavelength: 405 nm Light source working parameters: 200 mW & 3.3 V |

Grid structures with different porosities, thin-walled text structure (“EFL”), large inclined structure, thin-plate liver unit structure, and truss liver unit structures | Mouse bone marrow mesenchymal stem cells (mBMSCs) | [29] |

| Methacrylated gelatin, hyaluronic acid glycidyl methacrylate, polyethylene glycol diacrylate | LAP | Light source: UV light Wavelength: 365 nm Intensity: 11 mW/cm2 Irradiation time: 45 s |

Slab, line, grid, dispersion, and random patterns | Neonatal mouse ventricular cardiomyocytes (NMVCMs) | [30] |

| Recombinant methacrylated collagen type I (RCPhC1-MA), Recombinant norbornene collagen type I (RCPhC1-NB), Recombinant thiolated collagen type I (RCPhC1-SH) | Tetrapotassium 4,4′-(1,2-ethenediyl)bis [2-(3-sulfophenyl)diazenesulfonate] (DAS) | Light source: visible light laser Wavelength: 720 nm Laser power: 10–100 mW |

Cube-shaped patterns (200 × 200 × 200 μm) and different logos (TU Wien, B-PHOT, and PBM) | TERT-immortalized human adipose tissue – derived stem cell line (ASC/TERT1) | [31] |

2.1. UV crosslinkable biomaterials

Most natural polymers such as gelatin, collagen, and alginate have cell-binding motifs facilitating cell adhesion, proliferation, and differentiation process. However, these natural polymers possess poor mechanical stability to be suitable for long-term in vitro cultures [32]. For example, gelatin, a denatured form of collagen type I is a fragile, thermosensitive polymer (gel point > 35 °C, although depends on the molecular weight of gelatin) that have a cell-binding motif (RGD) to aid cell adhesion and proliferation for short-term in vitro studies [33]. On the contrary, synthetic polymers such as PEG, poly(vinyl alcohol) (PVA), and poly(acrylic acid) (PAA) were found to be easily tailorable using its functional groups making them have properties such as biodegradability, high mechanical strength, cost-effective and clinically relevant. But they lack biocompatibility by exhibiting immunogenic and inflammatory responses which are undesirable for in vitro culture studies. In addition, the mechanical strength of these polymers needs to be carefully scrutinized to match with the native tissues [34]. Thus, the introduction of photocrosslinkable functional groups such as acrylate, methyl methacrylate, or glycidyl methacrylate via chemical conjugation to natural and synthetic polymers may impart suitable mechanical strength to the final hydrogel 3D constructs without compromising the cell modulatory activities. For instance, gelatin methacrylate (GelMA), methacrylated hyaluronic acid, pectin methacrylate, poly(ethylene glycol diacrylate) (PEGDA) are some of the most commonly used acrylated UV photocrosslinkable biomaterials, which require suitable UV photoinitiators such as Irgacure or LAP for efficient photocrosslinking [35].

Recently, decellularized ECM (dECM), a natural biomaterial obtained from native tissues has received huge attention owing to its thermal behavior (gelation at physiological temperature) and capability of dynamic interaction with cells thereby providing a native ECM-mimetic microenvironment. However, dECM may cause high immunogenic reactions due to its allogenic origin from various organisms. Hence, it requires a complete and strong decellularization process to remove DNA and other contaminants without affecting its native functionalities [36]. Jang et al., have developed photoactive dECM by conjugating riboflavin (Vitamin B2) and illuminated using UV light of wavelength 370 nm and intensity of 30 mW/cm2 for 3 min to initiate photocrosslinking. This step was followed by entropy-driven self-assembly of collagen to produce a grid-patterned, stable, 10 layered 3D construct with high structural integrity when kept in PBS at 37 °C for 30 min. In vitro viability of cardiac progenitor cells remains >95% for 24 h in cell-laden dECM hydrogels prepared using riboflavin concentrations up to 0.1%. Further, the prepared 3D hydrogel constructs had higher stiffness (<1 kPa) similar to that of native cardiac tissue. In addition, the quantitative real-time PCR (qPCR) of the printed constructs showed increased expression of cardiac differentiation factors such as cardiac troponin I, myocyte-specific enhancer factor 2C, GATA4, and Nk2 homeobox after 7 days of culture, which confirms the myogenic differentiation of cardiac cells [37].

2.2. Visible light crosslinkable biomaterials

The visible light crosslinking reactions are devoid of phototoxicity and potential mutations thereby promoting higher cell viability and biocompatibility in the printed structures [16]. On the contrary, the use of UV light in the crosslinking process may affect the cytocompatibility of cell-laden hydrogels and lead to cancer and other related ailments in the neighboring tissues, as observed in the intravital crosslinking process (discussed in Section 4.4). Visible light photoinitiators such as Eosin Y, ruthenium (Ru), camphorquinone, and fluorescein have been widely used in biomedical applications, which act as an additive component in the formation of stable hydrogels. However, conjugating visible light photoactive groups in biopolymers have become a recent trend in developing novel visible light crosslinkable biomaterials [38]. Tyrosine with a phenolic functional group is the most commonly used visible light photoinitiation component conjugated with natural or synthetic biopolymers. Generally, irradiation of visible light in the tyrosine tagged biopolymers causes sequential steps such as (i) hydrogen abstraction in the hydroxyl groups of tyrosine (free radical formation); (ii) radical isomerization causing radical recombination of two different tyrosine molecules, and (iii) enolization forming dityrosine bonds between the tyrosine tagged polymers [39]. This type of reaction can also be performed using additive components such as horseradish peroxide and hydrogen peroxide, iron ions causing Fenton’s reaction, ruthenium/sodium persulfate [40,41]. Sakai et al. developed a bioink made of hyaluronic acid and gelatin tagged with phenolic residues, Ru/SPS crosslinking system, and human-derived adipose stem cells (hADSC). The developed bioink was printed via a micro-extrusion process into two different patterns such as hemisphere and three-layered lattice-shaped 3D structure with 0.6 mm thickness and analyzed for its cytocompatibility. After 24 h, the printed cells were rounded and viable and later the cells showed elongated morphology with high metabolic activity after 5 days. In addition, the cells in the bioprinted constructs exhibited upregulation of pluripotent genes such as Nanog, Oct4, Sox-2 and expression of cell surface marker proteins such as CD34 and CD44 [42]. Another study developed a three-component visible light photoinitiator system using carboxylated camphorquinone (CQCOOH), l-arginine (amine coinitiator), and diphenyl iodonium chloride (DPIC, accelerator) mixed with a water-soluble polymer, 2-hydroxyethyl methacrylate conjugated hydroxyethyl starch (HES-HEMA). Irradiation of visible light from LED lamps for about 1.9 min causes the formation of two initiating radicals by CQCOOH and coinitiator molecule. Additional free radicals were formed using accelerator molecules, which involve in the propagation step during the photocrosslinking process. Mechanical analysis of the photocrosslinked gels showed higher storage modulus (10 kPa) when compared to the non-crosslinked solutions (0.5 kPa). In vitro seeding of human gingival fibroblasts in the developed three-component, visible light photoinitiator system showed good biocompatibility, which was confirmed by MTT and LDH assays [43].

3. Photo-crosslinking strategies

Biomimetic scaffold fabrication techniques such as electrospinning, solvent casting, gas foaming, and additive manufacturing require biomaterials (bioinks / bioresins) to develop films, fiber mats, and hydrogels with desired properties and cell supportive features [44]. Hydrogels are crosslinked polymeric networks that entrap water and become colloidal gel-containing water as the dispersion medium. These hydrogels can be tailored for various tissue engineering applications using crosslinking strategies such as ionic, enzymatic, chemical and photocrosslinking methods [8] (Fig. 3A). Among these crosslinking techniques, photocrosslinking is an emerging technique in bioprinting applications, where absorption of light energy (such as UV, visible, and IR wavelengths) by the prepolymer molecules induce a photo-chemical reaction, which leads to the formation of covalent bonds between the polymeric chains resulting in stiffer and stable hydrogels. Various photo-crosslinking methods such as free radical polymerization, biorthogonal click reaction, redox-based photo-crosslinking, and their combinational methods are commonly adopted for the conversion of precursor polymers into mechanically stable polymeric hydrogels [11]. This is highly useful in conventional scaffold fabrication and 3D bioprinting applications, particularly for the long-term in vivo implantation applications [45,46]. The basic components involved in any photo chemical reactions are precursor polymers, photo initiators, sensitizers, and light energy (Fig. 3B). The basic principles and mechanisms involved in photocrosslinking reactions to fabricate 3D constructs along with their advantages and disadvantages are discussed in subsequent sub-sections.

Fig. 3.

(A) Various crosslinking strategies involved in hydrogel formation – Physical and chemical methods; (B) Basic components involved in the formation of photocrosslinking

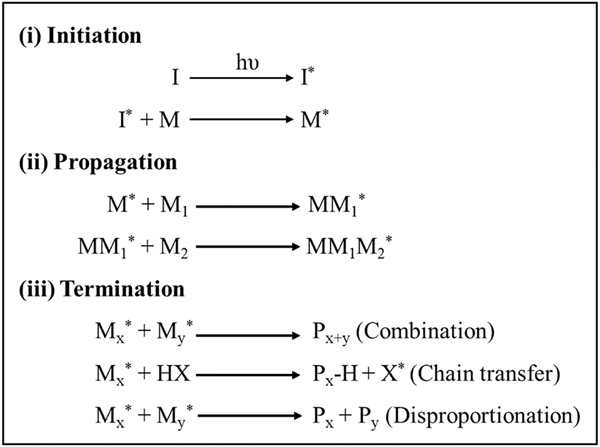

3.1. Free radical polymerization

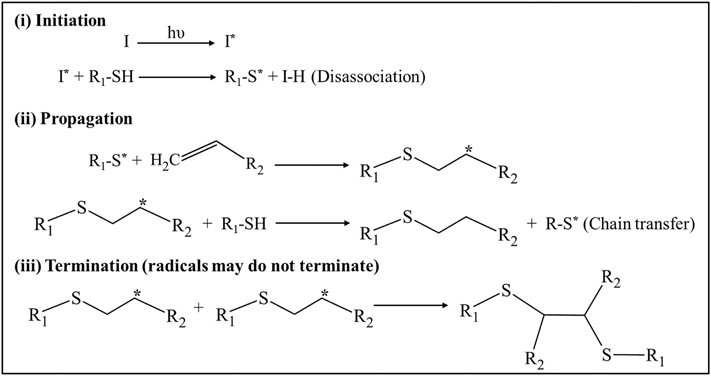

Free-radical or chain-growth polymerization involves the production of free radicals upon exposure to incident light and is one of the most common photo-crosslinking strategies for the preparation of hydrogels. This type of reaction generally undergoes three different stages—initiation, propagation, and termination (Fig. 4). In the initiation step, free radicals (active center) are generated by homolytic photolysis of the initiator molecules, which primarily depends on the light intensity, duration of the incident light, quantum yield, number of free radicals generated per photolytic event, concentration, and efficiency of the photo initiators [47,48]. These generated free radicals in turn react with the non-steric ends of the monomeric units thereby transforming their active centers into pre-polymers (reactive intermediates). In the propagation step, non-reactive monomers react sequentially with these reactive intermediates, thereby leading to the faster growth of polymer chains. In the termination step, these active centers are destructed via several methods – (i) by combining the ends of the radical active centers (radical coupling); (ii) by using a chain transfer agent to transfer the radical species away from the propagating chain and (iii) by disproportionation reaction which lead to the formation of one saturated and another unsaturated terminal group [49].

Fig. 4.

Mechanism of free radical polymerization (i) Initiation: Free radicals (*) are generation via homolytic photolysis of photoinitiator (ii) Propagation: Rapid addition of unreacted monomers/polymers result in polymers with end-group radicals (iii) Termination: Rapid chain-growth reaction was terminated via radical coupling, chain transfer agents or disproportionation reactions.

Acrylate and methacrylate derivatives of vinyl-based polymers such as PEGDA, poly(ethylene glycol dimethacrylate) (PEGDMA), and gelatin methacrylate (GELMA) are predominantly used for the synthesis of photo-crosslinked hydrogels using free-radical polymerization in the presence of photo-initiators such as 1-benzoylcyclohexanol, LAP, 2,2′-Azobis [2-methyl-N-(2-hydroxyethyl)] propionamide (VA-086) and Irgacure 2959 [50]. Widiyanti et al., have prepared poly(ethylene glycol dimethacrylate)/nano-fibrillated cellulose (PEGDMA/NFC) hydrogels by irradiating UV light at wavelength 366 nm on the precursor solutions containing varying concentrations of PEGDMA and NFC (1:0.25, 1:0.5, 1:0.75) with Irgacure 2959 as photo initiator [51]. Fourier transform infrared spectroscopy (FTIR) analysis of these hydrogels confirmed the presence of CC bonds between the photo-initiator and PEGDMA which confirms the crosslinking reactions. Further, an increase in the concentration of NFC in these hydrogels increases the fibrous morphology with augmented compressive strength (3.42 kPa for 1:0.75 PEGDMA: NFC) and decreased swelling rate (80% for 1:0.75 PEGDMA: NFC) when compared to uncrosslinked PEGDMA hydrogels. In addition, the injectable property of these hydrogels was found to be suitable for the restoration of vertebral disc degenerative disorders. In another study, O’Connell et al. examined the free radical kinetics by illuminating gelatin methacryloyl (GelMA) and Irgacure 2959 as photo-initiator present in DPBS medium using UV light (365 nm). Upon absorption of UV by the photo-initiator, benzyl and ketyl radicals were produced by alpha-cleavage process. These benzyl radicals play a major role in initiation of the polymerization process whereas the ketyl radicals were found to be short lived as they tend to react rapidly with aqueous medium. Moreover, in-situ rheological properties of the GelMA irradiated with varying light intensity (2–150 mW/cm2) showed no significant difference in the storage modulus for each tested concentrations, however the crosslinking kinetics increased dramatically when the light intensity was increased. For example, the onset time of gelation for GelMA samples exposed to 2 mW/cm2 was 290 s while samples exposed to 150 mW was only 4 s. Importantly, decreasing the photo-initiator concentration and light intensity greatly influence the viability and metabolic activity of the human mesenchymal cells embedded in the GelMA hydrogels [52]. Hence, the choice of photo-crosslinking conditions such as light intensity, photo-initiator concentration, and degree of reactive functional groups in polymers have to be carefully considered during the fabrication of 3D hydrogels. Hydrogels produced through ideal conditions possess tunable porosity, degradation rate, and mechanical property, which primarily depend on crosslinking density [53]. For instance, the mechanical property and biocompatibility depend on the degree of methacrylation in GelMA [54]. A decrease in crosslinking density due to low methacrylate groups in GelMA leads to the formation of hydrogel with larger pore size and greater swelling behavior which may favor incorporation of biomolecules but hydrogel processability is greatly compromised. These types of crosslinking reactions yield irreversible bond formation and offer several other advantages such as faster conversion rate, aqueous reaction conditions, and higher reactivity of free radicals. On considering these advantageous attributes, these reactions may be suitable for fabricating 3D constructs using an extrusion-based 3D bioprinting process [35]. However, these reactions may result in heterogeneity in working with high molecular weight and highly branched or cyclic polymer backbones, which are caused due to steric hindrance effect of prepolymers, diffusion kinetics of free radicals, and free radical formation in mid-polymer chain length [55]. These limitations may greatly affect the degradation rate of the fabricated 3D structures.

3.2. Bio-orthogonal click reaction

Bio-orthogonal click chemistry is a light-mediated step-growth reaction characterized by orthogonal reactivity of pre-polymers and uniform formation of polymeric networks with minimal defects [56]. Unlike free-radical polymerization, this type of reaction is insensitive to water and oxygen and possesses advantages such as higher efficiency, faster reaction kinetics even at low concentrations, higher binding selectivity under mild or aqueous conditions, and in vivo high biocompatibility [57]. Aldehyde/ketone condensation, strain-promoted oxidation-controlled cyclooctyne-1,2-quinone cycloaddition (SPOCQ), cyanobenzothiazole condensation; strain-promoted cycloaddition of azides and alkynes (SPAAC), inverse electron-demand Diels–Alder (iEDDA), hetero-Diels–Alder reactions, 1,3-dipolar cycloadditions, and thiol-norbornene photo-click reactions are some of the biorthogonal reactions used for different applications such as drug discovery, polymer synthesis, material science studies, biomolecular modifications, and nanotechnology [58,59]. Among these, thiol-norbornene photo-click reactions have been predominantly used in the preparation of hydrogels [35]. Thiol-norbornene type of reaction also involves three sequential steps (i) Initiation—Irradiation of photoinitiators via light forms radicals, which abstracts protons from thiol group functionalized polymers generating thiyl radicals (ii) Propagation—Thiyl radicals undergo anti-Markovnikov reaction, where they react with electron-rich or strained -enes secondary molecules forming carbon-centered radicals along with intermolecular thioether bonds (Fig. 1) [11]. Rapid addition of polymers results in trimers, oligomers, and eventually longer polymers with a consistent increase in the molecular weight of the formed polymers. Generally, this type of reaction does not terminate and remains active with an active center in the ends or side chains of the polymer [60]. It should also be noted that there is an arguable statement that they can terminate via disulfide formation via thiyl-thiyl radical coupling [61]. Polymers containing or functionalized with -ene groups such as vinyl ethers, methacrylates, and norbornene are commonly used as precursor components in this type of reaction.

Fig. 5.

Steps involved in thiol-ene polymerization reaction (i) Initiation: Generation of thiyl radicals (*) via irradiation of thiol functionalized photoinitiator; (ii) Propagation: Thiyl radicals react with unreacted electron-rich or strained -enes monomers/polymers yielding polymers with end-group radicals along with intermolecular thioether bonds and (iii) Termination: May terminate by disulfide bond formation via thiyl-thiyl radical coupling.

In a study conducted by Pereira et al., a one-pot, photo-crosslinked, and biodegradable pectin-based hydrogels via step-growth polymerization through thiol-ene linkages were synthesized. The precursor solutions containing norbornene functionalized pectin macromolecules, VA086 (0.25%), cell adhesive peptide (RGD), and Type I collagen mimicking crosslinker peptide (CGPQG↓IWGQC (4–6 mM, down arrow, denotes cleavage site for matrix metalloproteinases) were irradiated using UV light (365 nm, 7 mW/cm2) for a shorter duration of 20 s to develop photo-crosslinked hydrogels. There was negligible bubble formation due to nitrogen production by VA086 concentration present in the prepolymer solution. The final hydrogel constructs exhibited decreased swelling ratio and increased elastic modulus (446.75 ± 35.66 Pa). Further, crosslinking density was found to be increased in a higher concentration of crosslinker peptide (6 mM) when compared to lower concentrations (4 mM). In addition, matrix metalloproteinases (MMPs) induced degradation assays showed rapid degradation even for highly crosslinked hydrogels yet these gels were found to be structurally stable and intact for the tested period. Hydrogels embedded with human neonatal dermal fibroblasts (hNDFs) showed uniform and elongated morphology of cells in RGD conjugated pectin-based hydrogels irrespective of their crosslinking densities during the 7 days of in vitro culture. This was attributed to the space availability in loosely crosslinked hydrogels and MMPs mediated degradation for highly crosslinked hydrogels. To mimic the dermal and epidermal regions of native skin, keratinocytes were seeded on fibroblasts-laden hydrogels after 7 days and co-cultured for one week. This in vitro study report confirmed elongated fibroblasts and dense, flattened keratinocytes with proliferative potential and secretion of ECM markers such as Collagen I, Fibronectin, Ki67, and vimentin [62].

Copper-catalyzed SPAAC reactions were one of the oldest click chemistry-based techniques for developing biomaterials, yet had very limited usage in biomedical applications due to the toxicity induced by copper [63]. Hence, copper-free SPAAC reactions were considered to have many advantages such as less cytotoxicity, high specificity, and reactivity, thus best suited for various biomedical applications such as protein labeling, injectable filling materials, and cell-laden hydrogels. Brown et al., developed a three-dimensional muscular scaffold by crosslinking azadibenzocyclooctyne (DBCO) and azide-functionalized poly (ethylene glycol) macromers, which initially yielded a soft hydrogel (SPAAC crosslinking). Subsequently, the addition of LAP as photo-initiator and irradiation of UV light (365 nm, 10 mW/cm2) for 2 min yielded a stiffer hydrogel due to photo-initiated crosslinking of pendant DBCO groups. In vitro studies performed on soft (SPAAC alone without photocrosslinking) C2C12 cell-laden hydrogels showed 87% cell viability with native extended morphology after 24 h. On the contrary, photocrosslinked (SPAAC + photocrosslinking on day 1) C2C12 cell-laden hydrogels showed decreased (80%) cell viability, rounded cell morphology, and decreased expression of Yes-associated protein (YAP) after 24 h. Irradiation of UV light on 7-day cultured soft gels resulted in stiffer hydrogels with increased nuclear localization, better expression of YAP, and also displayed extended morphology within the gels that mimic the native muscular environment with tunable mechanical properties [64]. However, biorthogonal click chemistry-based reactions possess few constraints such as unstable reactants, cross-reactivity with target molecules, and the limited solubility of reactants. Hence, careful tuning of parameters such as concentration of reactants and catalysts, temperature, and pH have to be carried out to overcome these limitations [65].

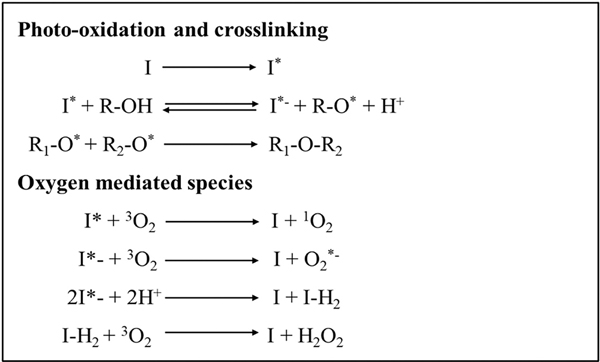

3.3. Redox crosslinking

In this type of photo-crosslinking method, photosensitizers act as light (visible or infrared spectrum) absorbing molecules where they excite and transfer the incident light energy to the neighboring molecules. Upon irradiation of light, these molecules absorb light and excite into a triplet state. Two main reactions might occur during the return of excited photosensitizer to its ground state and production of radicals. (i) Type I reaction—The excited photosensitizer reacts with deoxygenated molecules to form a product and photosensitizer again. (ii) Type II reaction—The excited photosensitizer reacts with ground state triplet oxygen molecules resulting in the quenching of photosensitizer and formation of a singlet state oxygen (typically referred to as Reactive Oxygen Species (ROS)), where it reacts with the substrate to form a product [66] (Fig. 6).

Fig. 6.

Mechanism involved in redox photocrosslinking polymerization—Excited singlet state photoinitiator yield radicals forming intermolecular bonds between reactive groups. Reaction terminates only when complete consumption of photoinitiator occur.

Hong et al. prepared photo-crosslinked tyramine-modified hyaluronic acid (HA/Tyr) hydrogel using Riboflavin (RF) as visible light (440 nm) photosensitizer irradiated for 30 s. These irradiated solutions were left overnight to undergo complete crosslinking of the hydrogels. During this process, phenolic groups of tyramine modified HA reacts with 3RF* (excited riboflavin formed after irradiation) through radical coupling. These photocrosslinked hydrogels showed good stability for up to 3 months under dark conditions and also displayed increased storage modulus with an increase in HA concentration [67].

3.4. Dual crosslinking

Low viscous bioinks or polymer solutions particularly in bioprinting applications favor cytocompatibility but remain challenging in the fabrication of stable 3D structures. Therefore, an efficient, fast, and dual crosslinking method is imperative to maintain the shape and size fidelity of the printed structures especially for the long term in vivo or in vitro studies in tissue engineering applications [68]. The dual crosslinking method can be performed in two ways—first in adding two different photo-initiators in precursor solutions and second in photocrosslinking along with chemical, physical or enzymatic crosslinking methods. Both these methods aim to produce structurally stable hydrogels with desired mechanical strength, particularly for 3D bioprinting of multilayered structures with excellent shape fidelity and superlative bonding between the different layers of the 3D constructs [10] (Table 2).

Table 2.

Dual crosslinking strategies for 3D bioprinting applications.

| Bioink composition | Crosslinking mechanism & parameters | Significant observations | Ref |

|---|---|---|---|

|

| |||

| Gelatin methacrylol (GelMA), microbial transglutaminase (mTGase), Irgacure 2959 | Step 1: Enzymatic crosslinking via Ca2+ independent mTGase Step 2: UV irradiation (365 nm, 1.5 mW/cm2) for 5 min |

• Reduced gelation time and enhanced viscoelastic property observed for increased mTGase concentration | [69] |

| Tyramine modified alginate (Alg/Tyr), Riboflavin (RF), sodium persulfate (SPS) | Homogenous ionic crosslinking by CaCO3 and photo-crosslinking using visible light (440 nm, 2500 mW/cm2) for 3 min | • Dual crosslinked hydrogels formed in a shorter gelation period had interconnected porous network, increased compressive strength of 74 kPa, and 564% swelling ratio with 36% physiological stability when compared to mono-crosslinked (photo-crosslinked) hydrogels | [70] |

| Tyramine modified methylcellulose (MC-Tyr), Riboflavin (RF), Riboflavin 5′-monophosphate (RFp), NIH3T3 fibroblasts | Step 1: Chemical crosslinking via conjugated carboxyl group of MC and amine groups of Tyramine; thermal crosslinking via methoxy groups of methyl cellulose Step 2: Visible light (440 nm, 2500 mW/cm2) for 120 s |

• Hydrophobic and covalent interactions observed in dual crosslinked hydrogels • Gelation temperature (~40 °C) of MC-Tyr remains close to physiological temperature • Compressive strength and elastic modulus (4.01 kPa) of RFp crosslinked hydrogels were higher when compared to RF crosslinked hydrogels due to the salting-out effect of the RFp photo-initiator • Bioink exhibited good printability and increased structural stability of the 3D printed scaffolds (20 × 20 × 0.2 mm) for up to 60 days in PBS • Increased NIH-3T3 cell viability (~90%) was observed within the printed constructs |

[71] |

| Hydroxy butyl methacrylated chitosan (HBC-MA), Eosin Y, triethanolamine, 1-vinyl-2-pyrrolidinone, NIH3T3 cells | Step 1: Chemical conjugation of acrylate and hydroxy butyl groups to chitosan; Thermal crosslinking at ~37 °C Step 2: Visible light (450–550 nm, 10 mW/cm2) for 30 s |

• Hydrogels showed compact and regular porous morphology, thermo-responsiveness (20 °C), good injectability, swellability, increased storage modulus (G′), increased compressive strength, low-temperature degradability • In vitro studies showed increased fibroblasts viability and proliferation for up to 72 h and dependent on pre-polymer concentrations • Subcutaneous injection of dual crosslinked hydrogels in mice showed degradation at physiological temperature |

[72] |

| Gelatin methacrylol (GelMA), microbial transglutaminase (mTGase), Irgacure 2959, human breast cancer cell line HCC1806 | Step 1: Photo-crosslinking via acrylate groups of GelMA Step 2: Enzymatic crosslinking via lysine and glutamine groups of GelMA |

• Dual crosslinked hydrogels exhibited the tunable rheological and mechanical property • Suitable for disease modeling applications • Good printing fidelity with the visco-elastic nature of the dual crosslinked hydrogels for 3D printing applications • Cytocompatible |

[73] |

| Tyramine modified hyaluronic acid (HA-Tyr), Eosin Y, Horse Radish Peroxidase (HRP), hydrogen peroxide (H2O2), hTERT fibroblasts/human mesenchymal stem cells (hMSCs)/bovine chondrocytes | Step 1: Enzymatic crosslinking by HRP and H2O2 Step 2: Visible light (505 nm) crosslinking mediated by Eosin Y |

• Cell-laden bioinks exhibited shear thinning behavior with good printability • Cylindrical construct with criss-cross inner pattern (diameter—20 mm, height—1.4 mm) was printed with cells • After 24 h, cell viability of extruded hMSCs, chondrocytes, and hTERT—laden bioinks was 78%, 70%, and 75% respectively • Chondrocyte laden printed constructs showed higher swelling when compared to other cell-laden printed constructs |

[74] |

| Methacrylated chitosan, β-glycerophosphate disodium salt hydrate (β-GP), LAP, fibroblasts (NIH/3T3)/osteoblast-like cells (Saos-2)/neuronal-like cells (SH-SY5Y) | Step 1: Thermal crosslinking via β-GP Step 2: UV crosslinking (365 nm, 30 mW/cm2) for 2 min |

• Developed ptCS hydrogels showed increased storage modulus and anti-oxidative property • ptCS cell encapsulated hydrogels showed good compatibility for up to 7 days • Four layered grid-shaped constructs were printed successfully |

[75] |

Han et al. recently developed a photocrosslinkable hydrogel using a dual photo-initiator approach. Here, the pre-gel solution contained PEGDA and photo-initiators such as Irgacure 2959 and VA-086 along with L929 mouse fibroblast cells. This composition was irradiated with UV light (365 nm, ~19 mW/cm2) specific for VA-086 at low illumination time (2 min). The free radicals generated due to activation of VA-086 induced the activation of Irgacure 2959 to generate more free radicals, which ultimately enhanced crosslinking efficiency of the developed PEGDA hydrogel solution. In addition, cells embedded in a dual photoinitiator system exhibited increased cell viability (90%) when compared to a single photo-initiator system containing Irgacure (30% viability) [76]. Several reports suggest the use of dual photo-initiators in developing biocompatible, cell-laden polymeric suspensions, microspheres, and hydrogels since it requires low photo-initiator concentrations and provides superior photo-crosslinking efficiency with high product yield [77,78]. Yet another type of dual crosslinking approach involves photo-crosslinking coupled with other crosslinking methods. This hybrid method is one of the widely used approaches for 3D bioprinting applications [10,72] (Table 2). In a study, Soliman et al., utilized allyl functionalized gelatin (Gel-AGE), thiol functionalized DTT or PEG, and visible light photoinitiator Ru/SPS to develop a dual crosslinkable low-density bioinks for extrusion-based bioprinting method. This precursor solution was initially crosslinked by the redox method, where covalent bonds were formed between thiol functionalized DTT or PEG and Gel-AGE. Successively, this solution was irradiated with visible light for 3 min to induce secondary crosslinking via thiol-ene based click chemistry reaction. By utilizing this dual crosslinking method, four-layered human articular chondrocytes (HACs) laden constructs were printed and found to have ~90% cell viability for up to 7 days in vitro. In addition, rheological analysis of the hydrogels developed with direct (photo-crosslinking alone) and dual crosslinking methods (redox and photo-crosslinking) showed similar compressive strength and also enabled good stability in the printed constructs [79].

4. Design considerations in photo-crosslinking

For a successful photocrosslinking technique to bioprint, viable and functional tissue constructs with better resolution and good stability, certain parameters such as light source, photoinitiators, crosslinking density, crosslinking location and rheological characteristics of the hydrogel needs to be scrutinized [52]. In addition, the interactions between these parameters with the biopolymers and cells and their subsequent influence on construct features need to be understood in great detail. In light of the above, these parameters have been discussed in this section as this technology involves a lot of challenges ranging from optimization of resolution to biocompatibility of the printed structures. Rational choice of these parameters is of paramount importance in the development of stable and effective 3D bioprinted tissue constructs using the photocrosslinking technique.

4.1. Light source

The light source is one of the most important considerations in the photocrosslinking process. Photoinitiators or co-initiators get activated by absorbing specific wavelengths of light, thus the light source should primarily be congruent with the maximum absorption wavelength (λmax) of the photoinitiators and possess the following LASER characteristics such as highly monochromatic, polarized, coherent, collimated with high intensity. Light sources having a wide range of wavelengths may be suitable for an extensive variety of photoinitiators (eg. commercially available UV bulbs) but the light cannot be absorbed by the photoinitiators maximally, which may lead to a poor photo-crosslinking process. Commonly used light sources would fall in UV (UV-A (320–400 nm) and UV-B (290–320 nm)) and visible light (400–700 nm) wavelengths during photocrosslinking, of which UV-C (200–290 nm) ranges are avoided as they are mostly used for germicidal and sterility purposes [80]. Further, the chosen wavelengths and their exposure duration have a direct impact on the viability of the cell-laden hydrogel constructs, in which shorter wavelengths (eg. UV-B) and longer exposure duration decrease the cell viability of the constructs causing epigenetic or genotypic damage due to unwanted mutations [81]. In addition, UV light has lesser optical penetration depth, which results in uncrosslinked or poorly crosslinked constructs in interior regions of the hydrogels. In contrast, visible light has deeper optical penetration when compared to UV light sources [42]. It was reported that visible light crosslinked hydrogels showed better cell viability and crosslinking ability with higher tissue penetration depth. Lim et al., investigated the cytotoxicity and metabolic activity of the human articular chondrocytes-laden gelatin hydrogels by photocrosslinking using two different UV and visible light sensitive photoinitiators [82]. Further, in vitro experiments confirmed that visible light crosslinking had greater penetration depth with homogenous crosslinking throughout the construct, 85% cell viability, higher metabolic activity, and extracellular GAG content with chondrogenic differentiation ability even after 35 days when compared to UV crosslinked hydrogels. Another study also reported that GelMA gels photopolymerized with visible light showed higher viability of KUSA-A1 cells over the culture period of 7 days when compared to gels crosslinked with UV light. Visible light crosslinked GelMA hydrogels also showed higher osteogenic differentiation genes such as Runt-Related Transcription Factor 2 (Runx2), Osterix (Osx), bone sialoprotein (Bsp), and osteocalcin (Ocn) [83].

Few other light source parameters such as light intensity (W/cm2) and distance between the light and the biomaterial also play an important role in cell viability, gelation kinetics, and mechanical strength of the crosslinked hydrogels [84]. For instance, irradiating large and thicker 3D constructs at a constant distance, the intensity of the light might decrease in the deeper regions when compared to top/superficial layers of the constructs, hence resulting in differential crosslinking kinetics yielding heterogenous porous network throughout the construct.

4.2. Photo-initiators

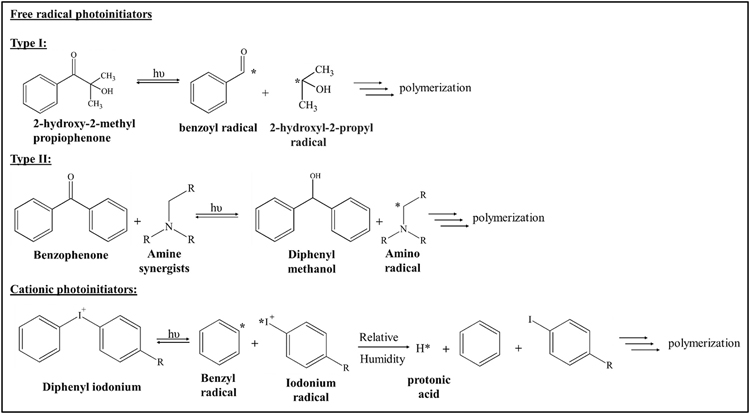

The selection of photo-initiators is another important criterion for efficient photo-polymerization of the developed bioink and allows negligible toxicity during the fabrication of viable 3D cellular constructs [48]. Generally, photo-initiators can be categorized as cationic and free radical systems depending upon the generation of reactant products upon light irradiation (Table 3).

Table 3.

Characteristic features, advantages, and disadvantages of different types of photoinitiators.

| Type of photoinitiator | Free radical photoinitiator |

Cationic photoinitiator | |

|---|---|---|---|

| Type I | Type II | ||

|

| |||

| Mechanism of free radical generation | Unimolecular homolytic cleavage; free radicals generated | Bimolecular cleavage bond; free radicals generated | Homolytic cleavage; radicals generated as the strong acid |

| Used light source & wavelengths | • Mostly UVA & UVB regions • LAP—365 nm • Irgacure 2959–276 nm • Irgacure184–244, 280, 330 nm • Irgacure 651–335 nm • Diphenyl (2,4,6-trimethyl benzoyl) phosphine oxide (TPO)—272 nm |

• Mostly visible light regions (400–700 nm) • Eosin Y—517 nm • Riboflavin—330 to 470 nm • Camphorquinone—468 nm |

• Varied wavelengths—UV/visible light range • Sulfonium salts—343 nm to 372 nm • Diazonium salts—450 nm • Ferrocenium salts—617 nm |

| Advantages | • Very efficient in radical generation • Absorbance in short UV range • Biocompatible only when used at low concentrations • Water-soluble • Better heat and chemical resistance • Photocuring stops after removal of light • Widely used |

• Tissue penetration depth is higher due to long-wave UV absorbance • Better photocuring property • Biocompatible only when used at low concentrations • Water-soluble • Better heat and chemical resistance • Photocuring stops after removal of light • Widely used |

• Not inhibited by oxygen • Good heat and chemical resistance • Water-soluble |

| Disadvantages | • Yellowing of hydrogels • Bad odor • Oxygen inhibition |

• Require co-initiators to initiate photo-polymerization • Aesthetic end product due to yellowing of hydrogels—for Camphorquinone |

• The formation of protonic acids may cause cell damage • Curing continues even after the removal of light • Sensitivity to moisture and water |

| Applications: tissue regeneration (TE) & in vitro 3D Bioprinting (BP) |

In vivo TE: articular cartilage [85], bone [86] In vitro BP: C2C12 cells (red) and fibroblasts, breast cancer cells (MCF7), human umbilical vascular endothelial cells (HUVECs) mesenchymal stem cells (MSCs) & osteoblasts [87], pluripotent stem cell (hiPSC)-derived hepatic progenitor cells & adipose-derived stem cells [88] |

In vivo TE: Cornea [89], cardiac tissues [90] In vitro BP: NIH-3T3 fibroblasts [88,91], adipose stem cells [92] |

Not suitable for biomedical applications due to protonic acid generation |

Typically, these generated products involve the polymerization and crosslinking of the polymeric units. Photoinitiators that generate free radicals upon light absorption are termed free radical photoinitiators, which are mostly of styrene or acrylate conjugated aromatic carbonyl compounds [47]. They are classified as Type I and Type II depending upon their photofragmentation during the free radical generation process Type I molecules cleave with a unimolecular reaction to generate free radicals. Generally, the carbonyl group of the photoinitiator absorbs the light to form excited α-carbons, which will undergo homolytic cleavage to generate two free radical fragments. Type II photoinitiators cleave as a bimolecular reaction, where these photoinitiators require a hydrogen donor (synergists) to generate free radicals [93] (Fig. 7).

Fig. 7.

Photolytic cleavage mechanism involved in photoinitiator types (i) Free radical photoinitiators—Type I: UV Irradiation of 2-hydroxy-2-methylpropiophenone yielded highly reactive benzoyl and 2-hydroxyl-2-propyl radical; Type II: Irradiation of Benzophenone by photons in the presence of amine synergists results in amine-based radicals; (ii) Cationic photoinitiators—Iodonium salt derived molecules irradiation by light energy results in iodonium radicals. The formed radicals involve in the polymerization process.

Cationic photo-initiators include mostly onium salts or organometallic complex salts, which undergo homolytic cleavage similar to Type I photoinitiators but will generate free radicals with strong photoacids such as Lewis or Broensted acids upon absorption of light [94]. These photoacids remain active even after removing light, which may alter the pH thereby affecting the cell viability and considered suitable for cancer-related studies [95] and micro-electronic fabrication [96] but not for tissue regeneration applications. In addition, the light absorption wavelength mostly falls in the deep UV range, which may be cytotoxic to the cells [97]. Some of the commercially available and commonly used photoinitiators and their properties were listed in Table 4.

Table 4.

Commonly used photoinitiators and their properties.

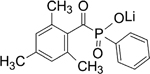

| Photoinitiator | Chemical structure | Property |

|---|---|---|

|

| ||

| Irgacure 2959 |

|

Highly effective, low odor, low volatility and can be used in waterborne photocuring system |

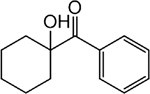

| Eosin Y |

|

Slightly yellowish, soluble in water and sparingly soluble in alcohol, acidic dye, repeated exposure may result in blindness and systemic poisoning |

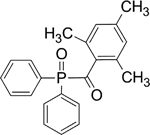

| LAP |

|

Type 1 photoinitiator, water-soluble and showed increased cell viability. Showed increased absorbance at visible light wavelength |

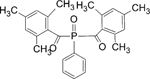

| TPO |

|

Stable, incompatible with strong oxidizing agents, possess high water solubility |

| VA-086 |

|

Crystalline, pale yellow, halogen-free azo-initiator |

| Ruthenium | Ru | The water-soluble photoinitiator changes the color of the hydrogel into yellow/red/orange |

| Bisacylphosphine oxide (BAPO) |

|

Symmetric chemical structure, soluble in water but insoluble in other mono or oligomers |

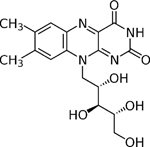

| Riboflavin |

|

Vitamin B2, yellow tricyclic compound, phosphorylated during the biological process |

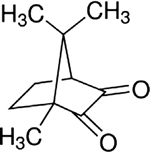

| Camphorquinone |

|

It gives a very faint fluorescence and induces polymerization very slowly |

| Irgacure 184 |

|

White crystalline powder with low odor and water-soluble |

These photoinitiators were chosen based on certain ruling parameters such as maximum absorption wavelength (λmax) of photo-initiators, several quanta of photons absorbed by photoinitiator, quantum yield (φ), photobleaching ability, concentration, solubility and cytotoxicity in physiological conditions, light exposure duration and chosen cell type [48,98]. Many reports are supporting how these parameters have a direct impact on the viability of the bulk or patterned cell-laden constructs [93,99]. Xu et al. compared the cytocompatibility of two different commercially available photoinitiators such as Irgacure 2959 and LAP in Human Umbilical Vein Endothelial Cell (HUVEC) laden 3D printed gelatin methacrylate (GelMA) based constructs. It was suggested that a lower concentration of photoinitiators showed good cellular viability in the printed constructs whereas, at higher concentrations, LAP crosslinked constructs showed good viability than Irgacure 2959 crosslinked constructs during the bioprinting process. In addition, Irgacure 2959 crosslinked GelMA constructs showed poor mechanical property with a faster degradation rate and higher pore size when compared to LAP crosslinked constructs [100].

Another crucial parameter that needs to be considered is oxygen inhibition. Oxygen inhibition occurs due to the interactions of the free radicals (generated by photolysis of photoinitiators) with the molecular or atmospheric oxygen (O2) that are present in vitro or in vivo conditions [101, 102]. These oxygen molecules may hinder the kinetics of the photolytic reactions in several ways—(1) Exited photoinitiators formed by absorption of light may get quenched (2) The free radicals generated in the initiation/propagation steps during the polymerization process react with the O2 molecules at a rate constant of 106 times higher than that of the propagation step, which lead to the formation of peroxyl radicals [49] (3) These peroxyl radicals may terminate the polymerization process via radical-radical coupling mechanism or hydrogen abstraction from an adjacent molecule forming a new radical with poor reactivity towards photocrosslinkable functional groups [101,103]. Further, these peroxyl radicals act as a good oxidizing agent causing a reduction in the formation of free radicals and eventually affecting the rate of photopolymerization. In addition, these peroxyl radicals scavenge and hinder the reaction of free radicals with functional groups such as acryloyl and methacrylol groups, which are the most common photocrosslinkable groups present in the biopolymers leading to partial or incomplete crosslinking of the hydrogels [101].

There are several strategies to suppress the effect of oxygen inhibition—(i) By increasing the photoinitiator concentration and light intensity to generate more free radicals than the available oxygen species, (ii) By introducing chemical species or additives such as amines, N-vinyl amines, silanes, thiols, boranes, phosphines and phosphates, ethers and (iii) By removing the oxygen species by degassing or curing in an inert gas (N2, Ar, CO2) atmosphere [104]. Although these approaches may control the oxygen inhibition process, these methods have several limitations and also may alter the basic requirements of in vitro conditions such as pH and other vital parameters. For instance, introducing thiol or amine groups may develop odor and change the color of the photocrosslinked structures. Likewise, the use of high-intensity light for curing may cause damage to the cells and biological moieties present in the photocrosslinking environment [102].

Some photoinitiators like eosin Y may require the addition of amine-based compounds as co-initiators or sensitizer molecules for the abundant production of free radicals. These amine-based co-initiators were found to be toxic, carcinogenic, alter mechanical properties, and turn the color of the hydrogels or printed construct to yellow. However, undesirable features may depend upon the concentration of co-initiators [105,106]. Camp et al., developed an efficient method for preparing a dityrosine based photocrosslinked hydrogel using elastin-like polypeptides (ELP) with tyrosine residues as biopolymer, tris(2,2′-bipyridyl)ruthenium(II) ([Ru(II) bpy3]2+) as photoinitiator and ammonium persulphate (APS) as coinitiator and oxidizing agent. ELP polymer crosslinking occurs as a systematic reaction steps—(i) excitation of [Ru(II)bpy3]2+ by absorption of visible light, followed by reduction of persulphate anions; (ii) Reduced persulphate anions decompose into sulfate radicals and sulfate anions and (iii) Excited [Ru(II)bpy3]2+ reduces the tyrosine phenyl groups present in ELP to form radicals that spontaneously dimerization resulting in stable crosslinked hydrogels. However, the use of APS and [Ru(II)bpy3]2+ in biomedical applications might have an impact on its cytocompatibility with cells. Hence, the authors have examined the cytocompatibility of these compounds at various concentrations. The results showed that use of a low concentration of APS (15 mM) along with [Ru(II)bpy3]2+ (up to 125 μM) in an ELP (Tyr) based construct resulted in less or no cytotoxicity of fibroblast cells when irradiated for 10 min using visible light with wavelength 460 nm when compared to a higher concentration of APS irrespective of Ru concentrations. In addition, elastic moduli of these hydrogels can be modulated according to APS and Ru concentrations and mimic the mechanical strength of native tissues [107].

4.3. Rheological characteristics

Crosslinking the polymers with various concentrations of photoinitiators or co-initiators or the addition of hybrid materials such as nanocomposites would eventually affect the mechanical strength of the final printed or bulk hydrogel in terms of its elasticity, stiffness, compressive strength, and viscosity. These will in turn influence the physical parameters such as porosity, pore size, swelling rate, degradation rate, and stability of the developed hydrogel constructs. Bochove et al., have prepared 1 mm thick, flexible poly(trimethylene carbonate) (PTMC) films using particulate leaching and stereolithography (SLA) method. In the SLA method, PTMC films were photocrosslinked using ethyl(2,4,6-trimethyl benzoyl) phenyl phosphinate (TPO-L), type I photoinitiator, and Orasol orange dye at 365 nm for 30 min. In particulate leached films, porogen (NaCl) and unwanted reactants were removed by immersing in ethanol and water for about 1 week. Results concluded that photocrosslinked PTMC films exhibited higher elastic moduli, tensile strength, and toughness when compared to particulate leached PTMC films. In addition, an increase in crosslinker concentration and a decrease in porogen concentration resulted in porous films with lesser porosity and vice-versa [108]. Generally, a lesser crosslinking density of the polymers results in higher pore size with better cellular migration properties. However, the poor mechanical stability of these crosslinked hydrogels with faster degradation in vivo conditions was obtained [109]. Additionally, increased crosslinking density led to stiffer and decreased pore-sized hydrogels, which will affect the cell migration ability within the gels. Thus, the careful scrutinization of crosslinking density of the polymers has to be performed to obtain an optimized porosity ratio, degradation, and swelling rate required for specific tissue engineering applications. Many reports are suggesting the importance of porosity with crosslinking density with the mechanical strength of the developed hydrogels to maintain a balanced crosslinking density for sustained cell growth and proliferation.

In another study by Shin et al., a bioink was developed using decellularized extracellular matrix derived from porcine cardiac tissues mixed with laponite-XLG nanoclay, and PEGDA. This developed bioink exhibited viscoelastic behavior with high yield stress (σy> critical σy), which indicates good stackability and shape fidelity for the printed constructs. The addition of laponite in the bioink increases the viscosity of the solution and supported solution printability. Further, the prepared bioink was printed as an 18 layered square-shaped (10 × 10 mm) 3D construct using extrusion bioprinting technique and then irradiated at 405 nm for 30 s. Altering the concentrations of PEGDA (photoinitiator) resulted in varied compressive moduli that matched with native tissue ranging from healthy cardiac tissues (5–15 kPa) to fibrotic tissues (30–100 kPa). Further, in vitro studies of the developed bioink with various cells such as human cardiac fibroblasts (HCFs), human induced pluripotent stem cell (hiPSC) derived cardiomyocytes, and human bone marrow-derived stromal cells (HS27A) to fabricate an engineered cardiac tissue (ECTs) resulted in good biocompatibility (>90% viability) within the printed constructs for about 7 days [110]. Xu et al., have developed an ideal tracheal substitute to treat long segmental defects of the trachea using decellularized trachea matrix (DTM) prepared using laser micropore technique (LMT). This resultant matrix LDTM matrix was added with o-nitrobenzyl derivative grafted hyaluronic acid (HA-NB), gelatin, and auricular chondrocytes to fabricate tubular constructs. Then, the prepared bioink was irradiated using UV light (365 nm) for 2 min. Further, rheological analysis of the photocrosslinked hydrogels displayed higher storage modulus (1000 Pa) and compressive modulus (500 kPa), which indicates efficient photocuring property. Moreover, in vitro culture of chondrocytes laden photocrosslinked LDTM bioink showed good viability, proliferative ability, and increased DNA content within the printed constructs for about 7 days. Finally, subcutaneous implantation of these hydrogels in nude mice had demonstrated successful maturation into cartilage tissue similar to native cartilage after 12 weeks of surgery [111].

4.4. Photocrosslinking stages

Limitations in incident light penetration into internal regions of thicker hydrogels may lead to incomplete crosslinking or heterogenous crosslinking. To overcome these penetration limits, higher intensity of light or longer exposure time is required for complete crosslinking of the hydrogels [52]. This may severely impact the viability and functionality of the cells. As an alternative, homogenous crosslinking could be achieved by using additive manufacturing technology where hydrogel bioinks are printed and crosslinked in a layer-by-layer manner (post crosslinking). Especially, this strategy would be beneficial for low viscous bioinks to obtain a stable 3D construct with good shape fidelity. This type of crosslinking is widely used in extrusion and ink-jet-based bioprinting methods [56,71,112]. In addition, increasing the concentration of the bioinks by adding viscosity enhancers such as methylcellulose or nanocomposites might result in higher shear stress and also create a clog in the nozzles during the extrusion process, which affects the viability of the extruded cells [185]. Kim et al., synthesized a tyramine modified poly (γ-glutamic acid) (γ-PGA-Tyr) polymer via N-(3-dimethyl aminopropyl)-N′-ethyl carbodiimide hydrochloride-N-hydroxysuccinimide (EDC-NHS) chemistry forming an amide bond between the carboxylic group of γ-PGA and the amino group of Tyramine. Further, γ-PGA-Tyr was photocrosslinked by the addition of a photoinitiator (Ru2+) and co-initiator (sodium persulphate). It was observed that the crosslinked hydrogel showed an increase in compressive modulus and strength with an increase in irradiation time. Moreover, these hydrogels exhibited good cytocompatibility when cultured with NIH3 T3 fibroblasts for up to 5 days. The prepared bioink can also be blended with natural polymers to enhance its printability and cell adhesion properties. For instance, the γ-PGA-Tyr polymer was blended with hyaluronic acid (HA), methylcellulose (MC), alginic acid (Alg), and cellulose nanofibrils (CNF). These blend bioinks were extruded into 3D lattice structures with dimensions 20 × 20 × 2 mm using the pneumatic-based extrusion bioprinting technique. Then, the printed constructs were irradiated using visible light with a wavelength of 454 nm, the distance at 5 cm, and power density at 1.2 W/cm2 for about 1 min to obtain stable photocrosslinked 3D structures [113]. Photocurable chitosan-based hybrid hydrogels were developed using methacrylate conjugated chitosan (CHIMA), acryl amide (AM) & photoinitiator (Irgacure 2959/LAP), which showed highly porous interconnected structures and significant swellability. These hydrogels also exhibited an enhanced compressive strength (345 Pa) when compared to pristine prepolymers such as CHIMA and AM. In addition, the gelation of 100 μm thick hydrogels mixed with 0.2 wt% I2959 and 0.2 wt% LAP occurred in 30 s and 5 s respectively, when irradiated using UV wavelengths (365 nm & 405 nm) making it suitable for DLP technology. Further, this bioink was printed into various 3D models such as external nose, ear auricle with helical fold, and 3D lattice structures with different sized grid patterns. Biocompatibility tests of these hydrogels with human umbilical vein endothelial cells (HUVECs) showed negligible cytotoxicity and promoted cellular adhesion and proliferation for up to 5 days, which was confirmed using Live/Dead staining and MTT assay [114]. Many reports are signifying the importance of post crosslinking of the printed hydrogels in regenerative medicine applications as they possess remarkable advantages such as the use of low viscous bioinks, limited cytotoxicity, and compatibility of crosslinking agents even in vivo conditions [115,116]. Contrarily, the use of pre-photocrosslinked bioinks as adopted for several pre-ionic crosslinked bioinks would be an ineffective method as it results in heterogenous crosslinking of the hydrogels with improper shape and resolution, which causes clogging of the needle during the extrusion-based bioprinting process and creates inconsistent ejection force of droplets during inkjet bioprinting process [38,117].

In-situ crosslinking is another strategy for crosslinking the low viscous bioinks, where light irradiation occurs before the onset of bioink extrusion i.e. within the capillary/needle region [118]. This type of crosslinking produces a stable extrudable hydrogel filament to fabricate 3D constructs of any desired shape and size. Further, this method does not require a postcrosslinking step or the use of any viscosity modifiers, thus offering a single-step crosslinking or printing procedure. Galarraga et al. developed a low viscous bioink composed of pendant norbornene functionalized hyaluronic acid, LAP, and DTT, which was directly photocured in the photo-permeable capillary using visible light (400–500 nm) via thiol-ene linkages. After the photocrosslinking process, the rheology of the synthesized bioink showed an enormous increase in its storage modulus (G′) when compared to the non-crosslinked polymers. In vitro culture of primary juvenile bovine mesenchymal stromal cell-laden NorHA printed hydrogels for up to 7 days displayed good cell viability and uniform distribution of cells within the printed constructs with an average cell density of 750–820 cells/mm2, which was validated by counting the number of cells at randomly chosen regions (top, middle & bottom). In addition, the cell-laden bioink printed in the form of discs were cultured for up to 56 days and demonstrated the presence of chondrogenic expression markers such as type II-collagen (COLII), aggrecan (ACAN), and SOX9. Further, collagen and glycosaminoglycans (GAG) contents were found to be increased which confirmed the formation of neocartilage tissue [118]. Recently, O’Connell et al., developed in-situ crosslinked gelatin-methacryloyl (GelMA) hydrogel using a hand-held co-axial extrusion-based printing system with LED of wavelength 405 nm. Addition of pristine gelatin (3%), photoinitiator—LAP, and viscosity enhancer (1% hyaluronic acid (HA)) to 10% GelMA solution allows the ink to be non-phase separable, crosslinkable, and printable. After photo exposure for 50 s, this GelMA bioink showed increased rheological parameters such as storage and compressive modulus (~40 kPa). In-situ photocrosslinking of these hydrogels via a hand-held device showed minimum onset of gelation time (0.2 s) with a light exposure duration of 1 s. Further, in-situ photocrosslinking of SaOS-2 cell-laden bioink via extrusionbased system had demonstrated good printability with ~80% cell viability in core and shell regions of the printed filaments immediately after the photocrosslinking process [119].

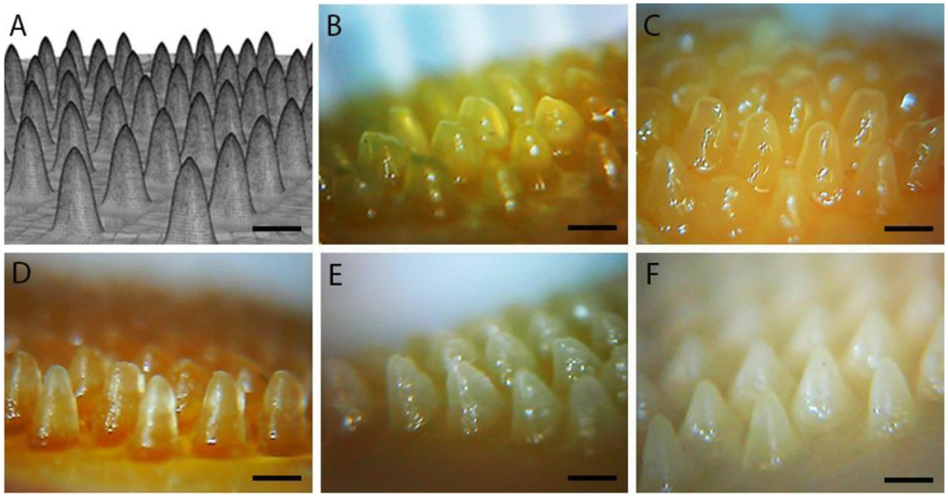

As an alternative to other types of photocrosslinking stages, intravital photocrosslinking is another minimally invasive technique with the advantage of crosslinking the injected photosensitive polymers directly into the target tissues/organs of organisms. In general, photosensitive polymers, photoinitiators, and co-initiators are initially blended with or without cells and then injected into the injured site. Immediately, the injection site is exposed to light illumination at a specific wavelength for complete crosslinking of the polymers [120]. However, illumination of UV light (for hydrogels containing UV-based photoinitiators) might be deleterious both to the injected and neighboring cells at the tissue site [93]. Hence, the use of photoinitiators with absorption wavelengths greater than 385 nm (eg. visible light and infrared wavelengths) might be advantageous due to its higher tissue penetration depth, minimal cell damage, and cytocompatibility [121]. Most SLA-based printers for this type of crosslinking have utilized visible light illuminators for applications in the biomedical field. Considering this fact, novel visible light photoinitiators such as cinnamic-based, coumarin-based, carbohydrate-based, and thiol-ene based derivatives need to be developed to improve this technique for advanced and widespread applications. Recently, Urciuolo et al., developed injectable hydrogel comprising of coumarin-based photoreactive polymers such as 7-hydroxycoumarin-3-carboxylic acid conjugated 4-arm poly(ethylene glycol) (HCC—4-arm PEG), 7-hydroxycoumarin-3-carboxylic acid conjugated 8-arm poly(ethylene glycol) (HCC-8-arm PEG), and 7-hydroxycoumarin-3-carboxylic acid conjugated gelatin (HCC–gelatin). This composition was injected into different sites such as epidermal regions of the abdomen, ear, epimysial muscles of the lateral hind limb, and submeningeal regions of the brain of both inbred (C57BL/6J strain) and transgenic (C57BL/6-(ACTB-EGFP)/J) mice models. This inter-tissue injection was then followed by illumination of near-infrared light (writing duration varies from 1.14 to 5.69 ms/line) with low laser power. After illumination, dimerization of HCC molecules occurs causing coumarin mediated cycloaddition-based crosslinking of hydrogels to stabilize precise and spatially controlled 3D structures within the injected areas. Further, these hydrogels showed excellent biocompatibility with negligible inflammation and cell damage in and around the illuminated regions, which was confirmed using immunofluorescent analysis, histological analysis and absence of cell death markers such as caspases after 4 days. Moreover, injecting mCherry tagged fibroblasts laden HCC-gelatin in epimysial regions of immunocompetent mice showed presence of rounded cell clusters whereas intravital bioprinting of these cell laden HCC-gelatin solutions showed parallelepiped-shaped constructs within 21 days, which confirmed the compatibility of this technique towards localized delivery of cells. In addition, GFP tagged MuSC- and mCherry tagged fibroblast-laden HCC–gelatin solutions were intravitally printed and analyzed for the cellular arrangement and regenerative ability. Interestingly, it was found that mCherry tagged fibroblast cells were surrounded by GFP tagged MuSCs (de novo muscle tissue formation) with striated myotubes and neovascularization similar to native muscle tissue arrangement, which was confirmed by confocal images [120]. Another study by Seo et al. synthesized an injectable hydrogel made of hydroxybutyl methacrylated chitosan (HBC-MA), Eosin Y as photoinitiator, and triethanolamine (TEOA) and 1-vinyl-2-pyrrolidinone (NVP) as co-initiators. This unique composition possessed both thermoresponsive and photopolymerizable properties when subjected to physiological temperature and specific light illumination. Further, in vitro studies using these hydrogels seeded with NIH3T3 fibroblasts displayed good cell viability (>90%) and the proliferative ability for up to 72 h. Subcutaneous injection of HBC-MA solutions induced immediate crosslinking due to its thermoresponsiveness at 37 °C and subsequent illumination of visible light (450–550 nm) over the injected skin area further promoted the crosslinking and increased the mechanical stability of the crosslinked gels in vivo. Thus, this kind of strategy can be applied for a wide variety of in vivo applications such as drug delivery, tissue regeneration, and biosensing applications [72].

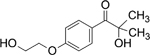

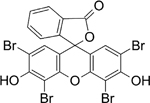

5. Photo-crosslinking in 3D printing and 3D bioprinting technology