Abstract

In numerous industrial procedures, the main concern of design engineers is ensuring adequate heat and mass transfer, such as in the heating and cooling practices of solar water heaters, geothermal systems, extrusion of metal, insulation of buildings, electronics, turbines, aerodynamics, electronics, paper manufacturing, and glass fiber production. The unsteady double-diffusive mixed convection flow of boundary layer nanofluids above a vertical region near stagnation point flow is developed and examined here. The Brownian motion and thermophoresis effects are incorporated by using Buongiorno's model. In the thermal energy equations, diffusion of regular and cross types is also used. By the use of the local similarity method along with suitable similarity transformations, nonlinear unsteady partial differential equations are converted to nonlinear ordinary differential equations and are numerically solved by the Keller–Box method. The investigation expresses that these profiles of solute concentration and nanoparticle concentration, temperature, and velocity in their boundary layers, respectively, depending on several parameters. A graphic analysis of all these parameters' possessions on nature's boundary layers is depicted. The highest rate of heat transfer is obtained with negligible thermophoresis effect. Furthermore, it is perceived that an increase in Nc and Nt results in a reduction in the reduced Sherwood number of nanoparticles, whereas addition results in an increase in the Nb number. There is a reverse effect on the temperature field and layer thickness for heat generation. In the wake of the above-mentioned potential applications, the current study of fluid flow has been found to be very interesting and innovative in the analysis of the influence of Brownian motion and thermophoresis effects near stagnation point flow, which will further make revolutions in industrial fields. Moreover, Buongiorno's model predicts the characteristics of double-diffusive fluids in enhancing heat transfers. This investigation has been established as a result of the numerous industrial applications mentioned above.

Keywords: Nanofluid, double-diffusive mixed convection, thermal radiation, stagnation point flow, numerical simulation

Introduction

Convection is considered a major part of heat transfer in practical situations.1–5 In medical sciences and engineering for enhancing convective heat transfer, the use of nanofluids is increasing rapidly. Choi and Eastman 6 introduced the term “nanofluids,” which are fluids having nano-sized particles arranged in colloidal suspension in any base fluid of various materials. These include metal particles, such as copper, iron, aluminum, gold, and titanium. The flow of nanofluids plays a significant role in many fields of science and engineering because of their high thermal conductivity, increased stability, and excessive heat transfer. The nanofluids are used practically in fuel engines, hybrid-powered engines, refrigeration, and food processing.7–9

Buongiorno 10 discusses the convection transport of nanofluids in detail, predicting a reasonable discussion for anomalous behavior of increasing thermal conduction and viscosity. He also concentrated on improving heat transfer in convective phenomena. 11 Buongiorno noticed that many researchers believed that the increment in convective heat transfer was due to the presence of dispersed nanoparticles, but he claims that the role of dispersed nanoparticles is minor in explaining the enhancement. He also described that turbulence will not be affected due to the presence of nanoparticles, so turbulence is not sufficient to clarify the witnessed enhancement phenomena.

The enhancement in the transfer of heat is caused by particle rotations, but Buongiorno proposed this as a small effect. Along with dispersion, other significant agents for enhancing heat transfers are particle rotation and turbulence. Another new model is given by Buongiorno on the relative velocities of nanoparticles and base fluids. He 10 further concluded that the absolute velocity of nanoparticles is the sum of the relative and the base fluid velocities. He had taken the seven-slip mechanics: Brownian diffusion, inertia, diffusion phoresies, thermophoresis, the Magnus effect, gravity settling, and drainage of fluid. By carefully examining all these in turn, he determined that thermophoresis and Brownian diffusion play an essential role in the nonappearance of turbulence.

Buongiorno was then successful in proposing conservation equations based on two distinct sound effects, Brownian diffusion, and thermophoresis. The point worth mentioning is that the model of nanoparticles of Buongiorno 10 was recently taken into account by Bachok et al., 12 Neild and Kuznetsov, 13 Khan and Pop, 14 Kuznetsov and Neild, 15 and many others in their research.15–19 Free convection occurs due to differences in temperature at different locations of the fluids, and forced convection occurs because of externally applied forces. Free and forced convection are collectively termed “mixed convection.” Due to the extensive range of applications in numerous industrial appliances like solar collectors, heat exchangers, and electronic equipment, the study of mixed convection flows over stagnation points has gained the interest of various investigators in the recent past. Ramachandran et al. 20 investigated the steady two-dimensional laminar flow in mixed convection stagnation points vertically by varying the surface heat flux and arbitrary wall temperature. Devi et al. 21 expounded on this concept for unsteady flow. Lok et al. 22 used a micropolar fluid with a vertical surface immersed in it. For stagnation point flow in mixed convection, Ishak et al. 23 used a vertically continuous stretching sheet. Ishak et al.24,25 investigated vertical surface mixed convection magnetohydrodynamic (MHD) flow, and Dinarvand et al. 26 used a vertical circular cylinder to control the boundary layer of mixed convection flows of nanofluids. In addition, Makinde et al. 27 considered a similar model for convective heating shrinking or stretching sheets with a magnetic field effect. Combined properties of Brownian motion and thermophoresis are used in these models. Tamim et al. 28 studied the MHD mixed convectional stagnation point flow of nanofluids on a vertically permeable surface.

The effect of mass diffusion has not been considered in the works by former investigators, but the transfer of heat and diffusion occurs in combination in real-life flows. The role of buoyancy forces in concentration differences and temperatures is critical in thermal mixed convection and double diffusion when flow velocities are low, and concentration or temperature differences are large. Due to the occurrence of a gradient of both temperature and concentration, a double-diffusive phenomenon forms in the fluid, which has different mass diffusivities and thermal diffusivities. So, it is concluded that heat transfer happens simultaneously with mass transfer. Practically, triple diffusive convection has a wide range of applications in many scientific fields like oceanology, geology, biology, astrophysics, and crystal growth systems.29–33

Hence, for making developments and advancements in literature, authors are encouraged to examine the changing effect of heat transfer and mass diffusion simultaneously on mixed convection nanofluids flowing on vertical surfaces. The basic goal of the current study is the examination of the double-diffusive mixed convection nanofluid flows by taking into account Buongiorno's model, which is an advancement in the study of free convection phenomena by Neild and Kuznetsov. 34 Tizakast et al. 35 have worked on double-diffusive mixed convection flow in rectangular cavities, and two different geometries are taken into account in double-diffusive mixed convection by some more researchers.36,37 In this case, a parallel solution is obtained, as well as the dependence of 15 dimensionless independent parameters. Our focus is on the investigation of boundary layer behavior in the model. Also, a numerical discussion is made of these 15 parameters in accordance with heat and mass transfer. The current study of fluid flow has been found to be very interesting and innovative in the analysis of the influence of Brownian motion and thermophoresis effects near the stagnation point. A wide variety of industrial processes, such as engine cooling systems, necessitate the transfer of heat; heat should be added, removed, or moved from one process to another throughout the process's operation. It became a major necessity for this industrial process to provide different sources of energy recovery and the cooling and heating of fluid. The enhancement of the processes of heating and cooling has different implications, like saving energy, saving processing time, increasing thermal rating and performance, and increasing the working life of equipment. Moreover, Buongiorno's model predicts the characteristics of double-diffusive fluids in enhancing heat transfers. Due to its numerous industrial applications, the established investigation is of great significance.

Description of the problem

We are considering the unsteady two-dimensional mixed convection boundary layer flow of a binary fluid with dissolved solute and suspended nanoparticles. The chosen coordinate frame has the x-axis expanding along the surface and the y-axis considered normal along the plate's surface, pointing positively from the surface to fluid (Figure 1). Within the current description of a double-diffusive mixed convection system, we are taking the following boundary layers into consideration: thermal, hydrodynamic, nanoparticle concentration, and solute concentration.

Figure 1.

Schematic diagram of the physical model and coordinate system.

We are taking as the velocity of external flow where showing the stagnation point flow. At wall the temperature, the solutal and nanoparticle concentrations are proportionate to the distance from the stagnation point given by , , , and with is characteristic of the temperature difference, is characteristic of the solutal concentration, and is the characteristic concentration of nanoparticle. Being at an enormous distance from the plate temperature, concentration difference, the solute concentration, and the nanoparticle concentration difference are denoted by , , and in turn. The equations by means of Buongiorno's model can be presented as9,11

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

Here velocity is , T is used for temperature, C and are used for the solutal and nanoparticle concentration. Following are the Boundary condition used here

| (6) |

The coefficients used in equations (1–5) represent the following quantities : density of fluid, : viscosity, : effective thermal conductivity, : volumetric thermal expansion coefficient, : volumetric solutal expansion coefficient (depends on the density of solvent and solute and is taken as negative for denser solute than solvent), : density of nanoparticles. While the coefficient appearing in equations (3) and (4) are of Brownian diffusion coefficient is , the thermophoretic diffusion coefficient is , Dufour type diffusivity is , solutal diffusivity is of and sort type diffusivity concentrations are . g is the gravitational acceleration. The fluid heat capacity and nanoparticles' specific heat capacity are and , respectively. We had taken the problem where the transport of nanoparticles will not be affected by solute. Equations (3) and (5) are derived as in the papers by Buongiorno 10 and Kuznetsov and Neild. 15

By use of the Roseland approximation, the radiative thermal flux is

| (7) |

Here denoting constant named Steffen Boltzmann and denoting the coefficient of mean absorption. By using the Taylor series and ignoring higher-order terms, is extended about to yield . By employing equation (7), equation (3) diminishes and becomes

| (8) |

By taking into account Oberbeck–Boussinesq approximation and by linearization of the momentum equation is done by assuming the concentration of nanoparticles to be diluted along with a desirable choice for the reference pressure. Writing equation (2) as

| (9) |

The boundary layer approximation which is considered to be standard finds out centered on scale analysis is given by

| (10) |

| (11) |

| (12) |

| (13) |

| (14) |

Below, mentioned in equation (15), is thermal diffusivity, the ratio of nanoparticles, and fluid heat capacity.

| (15) |

It should be noted that in equation (11) the first appearing term present in the bracket is the upward buoyancy term because of the effect of thermal expansion, and here the third term of the square bracket is taken negative buoyancy term acting downward because of densities differences between nanoparticles and the fluid. One more worth noting point is that the second term present in the square bracket of equation (11) are buoyancy terms either negative or positive because of volumetric solutal expansion as also described above.

And in equation (12), thermal energy transport resulting from Brownian motion is described by the first term involved in the square bracket, and energy diffusion resulting from the thermophoretic effect is described by the second term. Likewise, interpretation is employed on the right side of equation (14) as by Buongiorno. 6 The momentum equation is employed along the y-axis and in free stream, Bernoulli's equation is employed, we have

| (16) |

| (17) |

By use of equation (15), equation (11) will become,

| (18) |

Stream function introduced here is

| (19) |

that satisfies the continuity equation (1) identically and shapes remaining equations (10–12) as (unsteady)

| (20) |

| (21) |

| (22) |

| (23) |

Similarity transformation

We are going to find out the similarity solution of equations (20–23) with aid of the boundary condition represented by equation (6). A dimensionless normal distance is introduced as

| (24) |

The suitable transformation quantities are given below that transform (20–23) into an ordinary differential equation

| (25) |

The reduced nonlinear ordinary differential equation by employing similarity transformation (24) and (25) are

| (26) |

| (27) |

| (28) |

| (29) |

Boundary conditions are

| (30) |

Here primes are used for differentiation regarding , dimensionless stream function is . , are dimensionless solutal concentrations and is used for dimensionless nanoparticle concentration. In the above equation (26), mixed convection parameter (Richardson parameter) is used which is in which and with shows assisting flow, shows opposing flow, and referred for forced convection flow. is a radiation parameter. A plus point is that mostly Richardson number Ri is used by researchers in literature. Intended for a better understanding of concepts, we used mixed convection parameter in the whole article. The other several parameters used are defined as

| (31) |

| (32) |

| (33) |

| (34) |

| (35) |

| (36) |

| (37) |

| (38) |

| (39) |

where represents Prandtl number, represents the regular double-diffusive buoyancy parameter, represents the nanofluids buoyancy ratio, represents the thermophoresis parameter, represents Brownian motion parameter, represents modified Dufour parameter, represents regular Schmidt number, M represents nanofluids Schmidt number, and represents Dufour-solutal Lewis number.

Some of the other physical quantities used are skin coefficient is , local Nusselt number is , local regular Sherwood number is associated with solutal mass flux, local nanofluids Sherwood number is associated with nanoparticle mass flux are given by

| (40) |

| (41) |

| (42) |

| (43) |

Here shows shear stress of the wall, shows the heat flux of the wall, shows the solutal mass flux of the wall, and shows the nanoparticles' mass flux which is defined by

| (44) |

| (45) |

| (46) |

| (47) |

By use of similarity variables (25), we get

| (48) |

And is the local Reynolds number. The Sherwood numbers reduced Nusselt and reduced Nusselt is usually known as , , and can be written as

| (49) |

Method of solution

The ordinary differential equations (26–29) are numerically evaluated using the Keller–Box method (KBM) and the boundary conditions (30) in MATLAB, a powerful computational software package. This software holds the distinctive property of classifying the required governing system of equations and employing the most reliable numerical technique to make available precise solutions for the system. The intensely combined, nonlinear system of equations (20–23) with the aid of the boundary condition represented by equation (6) does not disclose analytical solutions in closed form. Other numerical techniques can solve the governing equation, but Keller's KBM is the most reliable implicit finite difference numerical technique for the computational examination of non-Newtonian boundary layer flow. This method is particularly useful in computational methods for viscous fluid dynamics. Some of the researchers who employed Keller's method are.11,38

Keller's method gives fast convergence and unconditional stability for intensely nonlinear flows involving four steps: (1) Reducing the nth-order partial differential system of the equation to n first-order equations, (2) Obtaining the Finite difference discretization of equations reduced in the first step, (3) nonlinear Keller algebraic equations are quasilinearized, (4) Block-tridiagonal elimination of obtained linearized Keller algebraic equations.

Let us consider the nth-order differential equation

| (50) |

where .

Along with boundary conditions

| (51) |

where .

Here the domain is denoted by and the boundary of the domain is denoted by . The boundary operator B could be the function of which is the case of second-order velocity slip in fluid flows for . This process of the KBM is requisite to reduce the nth-order differential equation (50) into the system of differential equations of the first order, which are given below

| (52) |

Discretizing the equation (24) by standard KBM and using the Jacobi method that gives

| (53) |

Equation (53) is used as explicit because there is only one unknown in each equation. To further employ the present method with the explicit procedure, some of the conditions are assumed, and their values are found out by using the computational software package called MATLAB. Commands can be switched with any algorithm that can be employed for finding the required missing initial conditions.

In our system, some different parameters are involved, that is, , , , , , , , , , , and . These equations formed a nonlinear system of equations by introducing a new dependent variable and then articulating in finite difference form along with consuming central differences. Because the system is nonlinear, it is linearized using Newton's method, then converted to matrix-vector form, and the block-tridiagonal elimination method is used to solve a subsequent linear system with boundary conditions, as described in the study of Cebeci and Bradshaw. 39 For maintaining necessary accuracy, the step size used in and edge's position of the boundary layer has been selected as suitable for several values of parameter involved. Depending on the different parameters used, we have taken the value of between 0.0005 and 0.005 and obtained numerical values for at least four decimal places that are independent of mesh. A satisfactory convergence criterion was found for a uniform grid of and get accuracy near 0.4 decimal points in almost all circumstances. On the other hand, the infinity boundary condition is achieved asymptotically for the boundary layer thickness .

Results and discussion

The KBM was used to solve the governing equations of the double-diffusive mixed convection boundary layer problem using the local similarity method. It is necessary to mention that the stagnation point mixed convection flow of a regular fluid headed toward a vertical plate involves the involvement of three parameters: two mixed convection parameters and a Prandtl number, which is dimensionless. 17 We have extended our study with the involvement of nine more parameters that are dimensionless and listed as: represents the regular double-diffusive buoyancy parameter, represents the nanofluids buoyancy ratio, represents the thermophoresis parameter, represents Brownian motion parameter, represents modified Dufour parameters, represents regular Schmidt number, M represents nanofluids Schmidt number, and represents Dufour-solutal Lewis number. So, we are having many choices for values of parameters. Now in this section, we are talking about graphical analysis of velocity, temperature, solutal concentration, and nanoparticle concentration boundary layer profiles with varying parameters.

Velocity for assisting and opposing flow

The impact of , , , , , and on the velocity is explained in Figures 2–5. The impact of is shown in Figure 3. It is clear that except for opposing flow which gives a reverse trend with , the dimensionless velocity increases in the case of regular double-diffusive buoyancy parameter . The impact of is shown in Figure 4. In the case of assisting flow, the existence of solute in fluid rises with a small modification in hydrodynamic boundary layer thickness. Furthermore, in Figure 4 when boundary ratio is increasing then dimensionless velocity also increases. Due to the thermophoresis force, ratio of the nanoparticle in nanofluids to the thermal diffusion can be defined by the thermophoresis parameter . It is fact that solid particles present in the fluid are experienced by a force having an opposite direction to that of the gradient of temperature. Because of this, the movement of the nanofluids is from hot to cold. The wall temperature is much than the ambient temperature whenever is positive. In the specified condition of the problem, an increment of thermophoresis parameter give reductions in the dimensionless velocity as illustrated in Figure 3. The ratio of the nanoparticle diffusion because of Brownian motion influence on thermal diffusion is represented by the Brownian parameter . When the Brownian parameter is positive, the boundary layer concentration of the nanoparticles is less than the concentration of nanoparticles on the wall surface. Through a rise in the Brownian motion parameter , the thermal transport also increases because of the buoyancy effect which comes out due to the gradient of nanoparticle concentration.

Figure 2.

Impact of M on for assisting flow and opposing flow .

Figure 5.

Impact of on for assisting flow and opposing flow .

Figure 3.

Impact of on for assisting flow and opposing flow .

Figure 4.

Impact of on for assisting flow and opposing flow .

The two important slip mechanisms, thermophoresis, and Brownian motion in the laminar flow of nanofluids, which provide relative velocity in between nanoparticles, show two conflicting effects on the dimensionless velocity. Using the same parameter value, it is clear that the decrease in thermophoresis is far more significant than the increase in Brownian motion. As it was pointed out before by Buongiorno, 10 our results also show that the results of thermophoresis are much more practical than the results of Brownian motion in the nonhomogeneous model of mass, momentum, and heat transfer of the nanofluids with solute dissolved in them. In comparison between opposing and assisting flows, the dimensionless velocity in the boundary layer is established to be greater in the case of assisting flows. The increase in the mixed convection parameter causes an appropriate rise in flow velocity.40,41 It is seen that the governing equations (26) and (27) have mixed convection parameters, velocity increases with an increase in due to the Grashof number which increases the acceleration of the fluid. Also, buoyancy force increases the acceleration and pressure gradient of the fluid resulting increase in the velocity and production.

Temperature profile for assisting and opposing flow

The impact of , , , , , and on the dimensions is depicted in Figures 6–9. It is clearly interpreted except for opposing flow with , the dimensionless velocity increases in the case of regular double-diffusive buoyancy parameter . The effect of is very low if we compare Figures 2 and 6 on the dimensionless temperature as this parameter occurs in momentum equation (26). With an increase in the thermophoresis coefficient, an increase occurs in the diffusion of nanoparticles also their movement away from the hot wall force happens. Subsequently, an increase in the value of gives an increase in temperature at the boundary layer Figure 6.

Figure 6.

Impact of on for assisting and opposing flow.

Figure 9.

Impact of k on for assisting and opposing flow.

Figure 8.

Impact of on for assisting and opposing flow.

The increase in Brownian motion parameter results in a rise in the degree of temperature Figure 7. It is depicted that when thermophoresis effects and Brownian diffusion rises, this results in making the thermal boundary layer thicker. It results in a decrease in wall transfer of heat rate and temperature gradient. The impact of and k on dimensionless temperature is shown. There is an inverse relationship between the Prandtl number and thermal conductivity lower the higher will be thermal conductivity and heat energy diffuses better than momentum.

Figure 7.

Impact of on for assisting and opposing flow.

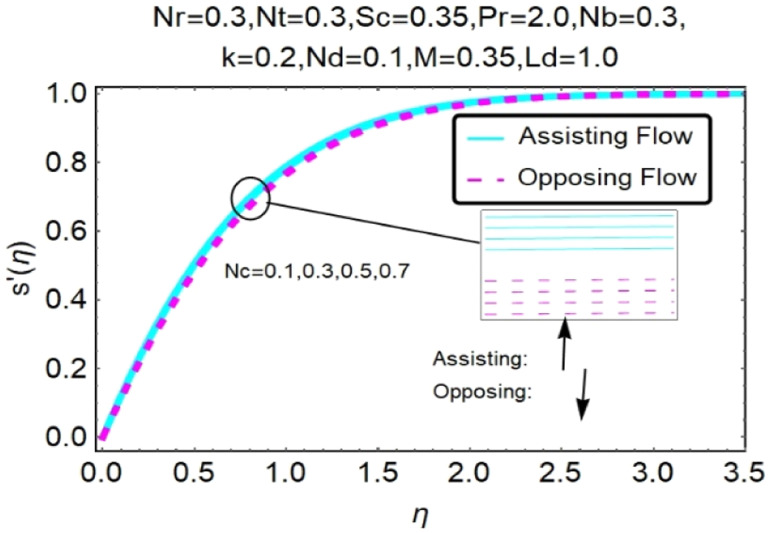

Solutal concentration profile for assisting and opposing flow

The impact of , , and on solutal concentration is depicted in Figures 10–13. It is clearly interpreted that when the buoyancy parameter of regular double-diffusive increases the solutal concentration decreases in the case of larger and smaller Dufour-solutal Lewis number .

Figure 10.

Impact of M on for assisting and opposing flow.

Figure 13.

Impact of on for assisting and opposing flow.

Figure 11.

Impact of on for assisting and opposing flow.

Figure 12.

Impact of on for assisting and opposing flow.

Also, in the case of large impact of on dimensionless solutal concentration becomes weak. And along this, the solutal concentration seems to be greater for bigger Dufour-solutal Lewis numbers resulting in overrunning nearer to the surface. In an assisting flow regime with an increase of , the dimensionless solutal concentration decreases and has a reverse trend in the case of opposing flow regimes.

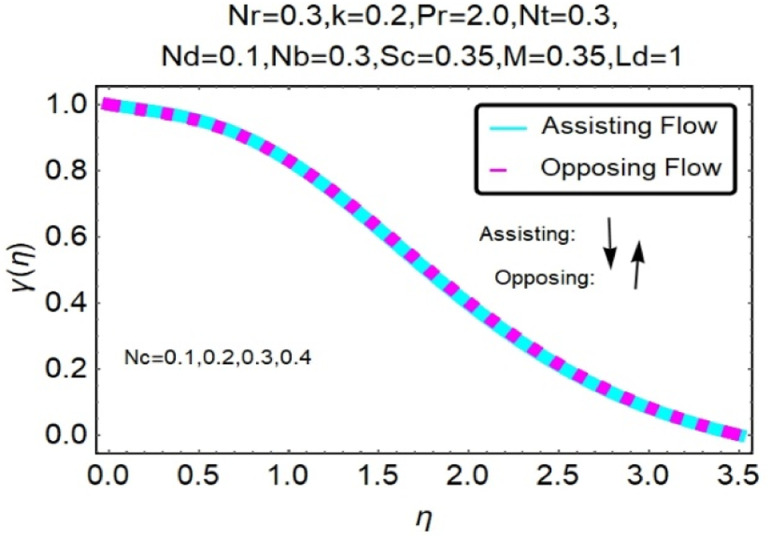

Nanoparticle concentration profile for assisting and opposing flow

The impact of , , and on the nanoparticle concentration is shown in Figures 14–16. As the parameter of Brownian motion rises, the concentration of nanoparticles decreases at the wall whereas the reverse trend is shown in the case of thermophoresis parameter . These two nanofluid parameters pave a path for overrunning the dimensionless nanoparticles nearer to the wall. It is important to note that when a surface that is hot resists the particles of sub-micron size then the nanoparticle concentration boundary later moves away from the surface because of the thermophoresis. This means the thickening of the boundary layer as shown in Figure 15. By increasing the buoyancy parameter of regular double-diffusive the concentration of nanoparticles decreases.

Figure 14.

Impact of on for assisting and opposing flow.

Figure 16.

Impact of on for assisting and opposing flow.

Figure 15.

Impact of on for assisting and opposing flow.

Table discussion

Lastly, by use of different nondimensional flow parameters, the velocity, temperature, and concentration were found numerically as well as skin friction, Nusselt number, and Sherwood number. Following are the default values used for the computation in Table 1, that is, for assisting flow and for opposing flow: and for various Prandtl numbers . It is worth mentioning that we had provided comparisons of our results with previous results obtained in Dinarvand et al., 11 yet to prove the validity of our results and found out to be in great resemblance as shown in Tables 1 and 2. The dimensionless skin friction coefficient, Nusselt number , Sherwood number , and Sherwood number are calculated for several parameters with Prandtl numbers . Table 3 present numerical values of Sherwood number Sh for several parameters.

Table 1.

Comparison of for various Prandtl numbers when .

| Present results | Dinarvand et al. 11 | |||

|---|---|---|---|---|

| Assisting flow | Opposing flow | Assisting flow | Opposing flow | |

| 4.218462 | ||||

Table 2.

Comparison of for various Prandtl numbers when .

| Pr | ||||

|---|---|---|---|---|

| Present results | Dinarvand et al. 11 | |||

| Assisting flow | Opposing flow | Assisting flow | Opposing flow | |

Table 3.

Numerical values of Sherwood number for several parameters when .

| Assisting flow | Opposing flow | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | |||||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | |||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – |

It is reflected that the skin fraction shows positive variations in the case of assisting flow as seen in Table 4 with increasing the value of several parameters while showing a reverse trend on the value of the parameter in the case of opposing flow. Also, it is concluded that the heat transfer rate shows the highest effect. The Nusselt number shows decreasing variation in the case of assisting flow and in the case of opposing flow when both Brownian motion and thermophoresis coefficient increase as seen in Table 5 and shows a mixed trend on increasing value of several parameters. The ratio of buoyancy of nanofluids has more impact than the increasing impact of the modified Dufour parameter. The Sherwood number shows positive variation in the rate of mass transfer in the case of assisting flow and in the case of opposing flow as seen in Table 6 when the thermophoresis coefficient increases and shows a reverse trend in increasing values of another various parameter. It is important to mention that negative will be the value of the reduced Sherwood number, and higher will be the concentration of nanoparticles and solute with the wall surface of the fluid.

Table 4.

Numerical values of skin fraction for several parameters when .

| Assisting flow | Opposing flow | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Table 5.

Numerical values of Nusselt number for several parameters when .

| Assisting flow | Opposing flow | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | |||||

| – | – | – | – | – | – | – | – | – | ||

| – | – | – | – | – | – | – | – | – | ||

| – | – | – | – | – | – | – | – | – |

Table 6.

Numerical values of Sherwood number for several parameters when .

| Assisting flow | Opposing flow | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | ||||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – | |||

| – | – | – | – | – | – | – | – |

Conclusion

In this article, the KBM is used for the numerical study of the double-diffusive unsteady mixed convective flow of nanofluids over a vertical surface. The model of nanofluids having a binary base fluid includes thermophoresis and Brownian motion effects. A solution is obtained that depends on 11 dimensionless parameters. In the presented analysis of the double-diffusive mixed convection model, four boundary layers are considered: the solutal, the thermal, the hydrodynamic, and the nanoparticle concentration. Following is the main conclusion coming from this analysis of the assisting flow regime:

The thickness in the hydrodynamic boundary layer occurs with a rise in , , and which gives justification for reducing values of coefficient of skin friction and reveres in the case of and .

The increasing value of parameters , , and increases the thickness of the boundary layers whereas decreases with the value of and .

It is observed that the behavior of decreasing function shows by reduced Nusselt number for , , and and behavior of increasing function for , , and .

By increasing and the solutal dimensionless mass transfer rate shows a decreasing trend.

By increasing the values of the parameters and the rate of dimensionless nanoparticle mass transfer is observed to be reduced and increased with .

It is worth noting that all these conclusions for assisting flow regime results have reverse effects for increasing nanofluids parameter for opposing flow regime.

Future studies can be conducted by changing nanofluid geometries and adding other factors to increase understanding in the literature and make advances at the industrial level. Moreover, this article will hopefully help supplement different nanofluid flow applications, mainly in nuclear accelerators and reactors, flow meters, MHD generators, cooling system designs, the automobile industry, nanodrug delivery, and cancer treatment.

Author biographies

Ammara Islam is a research scholar in the field of applied mathematics.

Zafar Mahmood is a senior scholar and Lecturer affiliated with Hazara University Pakistan.

Umar Khan is Assistant Professor and affiliated with Hazara University Pakistan.

Appendix

Nomenclature

solutal concentration

ambient solutal concentration

friction coefficient

Brownian diffusion coefficient

thermophoretic diffusion coefficient

temperature (K)

velocity (ms−1)

thermal diffusivity

ambient temperature (K)

time (s)

dimensionless nanoparticle concentration

specific heat capacitance at constant pressure (J kg−1 K−1)

fluid's heat capacitance (J K−1 m−3)

nanofluids Schmidt number

dimensionless velocity

thermal conductivity (W m−1 K−1)

Nusselt number (nondimensional)

Prandtl number (nondimensional)

unsteadiness parameter

gravitational acceleration (ms−2)

Dufour Lewis number

buoyancy ratio of nanofluid

parameter of Brownian motion

double-diffusive buoyancy parameter

thermophoresis parameter

modified Dufour parameter

skin coefficient

local regular Sherwood number

local nanofluid Sherwood number

Cartesian coordinates

Greek Symbols

similarity variables

dimensionless temperature

dynamic viscosity (kg m−1 s−1)

kinematic viscosity (m−2 s−1)

density of fluid (kg m−3)

volumetric thermal expansion coefficient

volumetric solutal expansion coefficient

density of nanoparticles

nanoparticle concentration

ambient nanoparticle concentration

stream function

mixed convection parameter

dimensionless solutal concentration

Superscript

differentiation with respect to

Footnotes

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Funding: The author(s) received no financial support for the research, authorship, and/or publication of this article.

ORCID iDs: Ammara Islam https://orcid.org/0000-0002-9813-161X

Zafar Mahmood https://orcid.org/0000-0003-1866-1432

Umar Khan https://orcid.org/0000-0002-9183-6115

References

- 1.Bahiraei M. A comprehensive review on different numerical approaches for simulation in nanofluids: traditional and novel techniques. J Dispers Sci Technol 2014; 35: 984–996. [Google Scholar]

- 2.Bahiraei M, Hangi M. Flow and heat transfer characteristics of magnetic nanofluids: a review. J Magn Magn Mater 2015; 374: 125–138. [Google Scholar]

- 3.Dinarvand S, Hosseini R, Pop I. Unsteady convective heat and mass transfer of a nanofluid in Howarth’s stagnation point by Buongiorno’s model. Int J Numer Methods Heat Fluid Flow 2015; 25: 1176–1197. [Google Scholar]

- 4.Khalili S, Dinarvand S, Hosseini Ret al. et al. Magnetohydrodynamic stagnation point flow toward stretching/shrinking permeable plate in porous medium filled with a nanofluid. Proc Inst Mech Eng Part E J Process Mech Eng 2014; 228: 309–319. [Google Scholar]

- 5.Mahmood Z, Alhazmi SE, Alhowaity Aet al. et al. MHD mixed convective stagnation point flow of nanofluid past a permeable stretching sheet with nanoparticles aggregation and thermal stratification. Sci Rep 2022; 12: 1–26. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Lemont, IL: Argonne National Laboratory, 1995. [Google Scholar]

- 7.Alqahtani B, Mahmood Z, Alyami MAet al. et al. Heat and mass transfer analysis of MHD stagnation point flow of carbon nanotubes with convective stretching disk and viscous dissipation. Adv Mech Eng 2022; 14: 1–17. [Google Scholar]

- 8.Mahmood Z, Iqbal Z, Alyami MAet al. et al. Influence of suction and heat source on MHD stagnation point flow of ternary hybrid nanofluid over convectively heated stretching/shrinking cylinder. Adv Mech Eng 2022; 14: 1–17. [Google Scholar]

- 9.Mahmood Z, Khan U. Nanoparticles aggregation effects on unsteady stagnation point flow of hydrogen oxide-based nanofluids. Eur Phys J Plus 2022; 137: 1–28.34909366 [Google Scholar]

- 10.Buongiorno J. Convective transport in nanofluids. ASME J Heat Transfer 2006; 128: 240–250. [Google Scholar]

- 11.Dinarvand S, Hosseini R, Abulhasansari Met al. et al. Buongiorno’s model for double-diffusive mixed convective stagnation-point flow of a nanofluid considering diffusiophoresis effect of binary base fluid. Adv Powder Technol 2015; 26: 1423–1434. [Google Scholar]

- 12.Bachok N, Ishak A, Pop I. Boundary-layer flow of nanofluids over a moving surface in a flowing fluid. Int J Therm Sci 2010; 49: 1663–1668. [Google Scholar]

- 13.Nield DA, Kuznetsov AV. The Cheng–Minkowycz problem for natural convective boundary-layer flow in a porous medium saturated by a nanofluid. Int J Heat Mass Transfer 2009; 52: 5792–5795. [Google Scholar]

- 14.Khan WA, Pop I. Boundary-layer flow of a nanofluid past a stretching sheet. Int J Heat Mass Transfer 2010; 53: 2477–2483. [Google Scholar]

- 15.Kuznetsov AV, Nield DA. Natural convective boundary-layer flow of a nanofluid past a vertical plate. Int J Therm Sci 2010; 49: 243–247. [Google Scholar]

- 16.Bahiraei M, Hosseinalipour SM, Hangi M. Laminar forced convection of a water-TiO2 nanofluid in annuli considering mass conservation for particles. Chem Eng Technol 2013; 36: 2057–2064. [Google Scholar]

- 17.Bahiraei M, Hosseinalipour SM, Hangi M. Prediction of convective heat transfer of Al2O3-water nanofluid considering particle migration using neural network. Eng Comput 2014; 31: 843–863. [Google Scholar]

- 18.Malvandi A. The unsteady flow of a nanofluid in the stagnation point region of a time-dependent rotating sphere. Therm Sci 2015; 19: 1603–1612. [Google Scholar]

- 19.Tamim H, Dinarvand S, Hosseini Ret al. et al. Unsteady mixed convection flow of a nanofluid near orthogonal stagnation point on a vertical permeable surface. Proc Inst Mech Eng Part E J Process Mech Eng 2014; 228: 226–237. [Google Scholar]

- 20.Ramachandran N, Chen TS, Armaly BF. Mixed convection in stagnation flows adjacent to vertical surfaces. ASME J Heat Transfer 1988; 110: 373–377. [Google Scholar]

- 21.Devi CDS, Takhar HS, Nath G. Unsteady mixed convection flow in stagnation region adjacent to a vertical surface. Wärme-und Stoffübertragung 1991; 26: 71–79. [Google Scholar]

- 22.Lok YY, Amin N, Campean Det al. et al. Steady mixed convection flow of a micropolar fluid near the stagnation point on a vertical surface. Int J Numer Methods Heat Fluid Flow 2005; 15: 654–670. [Google Scholar]

- 23.Ishak A, Nazar R, Pop I. Mixed convection on the stagnation point flow toward a vertical, continuously stretching sheet. ASME J Heat Transfer 2007; 129: 1087–1090. [Google Scholar]

- 24.Ishak A, Nazar R, Arifin NMet al. et al. Dual solutions in magnetohydrodynamic mixed convection flow near a stagnation-point on a vertical surface. ASME J Heat Transfer 2007; 129: 1212–1216. [Google Scholar]

- 25.Ishak A, Nazar R, Bachok Net al. et al. MHD mixed convection flow near the stagnation-point on a vertical permeable surface. Phys A Stat Mech Appl 2010; 389: 40–46. [Google Scholar]

- 26.Dinarvand S, Abbassi A, Hosseini Ret al. et al. Homotopy analysis method for mixed convective boundary layer flow of a nanofluid over a vertical circular cylinder. Therm Sci 2015; 19: 549–561. [Google Scholar]

- 27.Makinde OD, Khan WA, Khan ZH. Buoyancy effects on MHD stagnation point flow and heat transfer of a nanofluid past a convectively heated stretching/shrinking sheet. Int J Heat Mass Transfer 2013; 62: 526–533. [Google Scholar]

- 28.Tamim H, Dinarvand S, Hosseini Ret al. et al. MHD mixed convection stagnation-point flow of a nanofluid over a vertical permeable surface: a comprehensive report of dual solutions. Heat Mass Transfer 2014; 50: 639–650. [Google Scholar]

- 29.Khan WA, Aziz A. Double-diffusive natural convective boundary layer flow in a porous medium saturated with a nanofluid over a vertical plate: prescribed surface heat, solute and nanoparticle fluxes. Int J Therm Sci 2011; 50: 2154–2160. [Google Scholar]

- 30.Mahdy A. Soret and Dufour effect on double diffusion mixed convection from a vertical surface in a porous medium saturated with a non-Newtonian fluid. J Nonnewton Fluid Mech 2010; 165: 568–575. [Google Scholar]

- 31.Subhashini SV, Samuel N, Pop I. Double-diffusive convection from a permeable vertical surface under convective boundary condition. Int Commun Heat Mass Transfer 2011; 38: 1183–1188. [Google Scholar]

- 32.Khan ZH, Khan WA, Sheremet MAet al. et al. Irreversibilities in a triple diffusive flow in various porous cavities. Chinese J Phys 2021; 73: 239–255. [Google Scholar]

- 33.Raizah Z, Aly AM. Double-diffusive convection of a rotating circular cylinder in a porous cavity suspended by nano-encapsulated phase change materials. Case Stud Therm Eng 2021; 24: 100864. [Google Scholar]

- 34.Nield DA, Kuznetsov AV. The Cheng–Minkowycz problem for the double-diffusive natural convective boundary layer flow in a porous medium saturated by a nanofluid. Int J Heat Mass Transfer 2011; 54: 374–378. [Google Scholar]

- 35.Tizakast Y, Kaddiri M, Lamsaadi M. Double-diffusive mixed convection in rectangular cavities filled with non-Newtonian fluids. Int J Mech Sci 2021; 208: 106667. [Google Scholar]

- 36.Moderres M, Benmalek T, Sofiane Aet al. et al. Double-diffusive natural convection in a cavity with an inner cylinder wrapped by a porous layer. Therm Sci 2022; 26: 1841–1853. [Google Scholar]

- 37.Alomari MA, Al-Farhany K, Said NMet al. et al. Numerical investigation of double-diffusive mixed convection in a split lid-driven curvilinear cavity. Int Commun Heat Mass Transfer 2022; 138: 106322. [Google Scholar]

- 38.Iqbal Z, Mehmood R, Azhar Eet al. et al. Impact of inclined magnetic field on micropolar Casson fluid using Keller box algorithm. Eur Phys J Plus 2017; 132: 1–13. [Google Scholar]

- 39.Cebeci T, Bradshaw P. Physical and computational aspects of convective heat transfer. New York, NY: Springer Science & Business Media, 2012. [Google Scholar]

- 40.Ferdows M, Uddin MJ, Afify AA. Scaling group transformation for MHD boundary layer free convective heat and mass transfer flow past a convectively heated nonlinear radiating stretching sheet. Int J Heat Mass Transfer 2013; 56: 181–187. [Google Scholar]

- 41.Mahdy A. Unsteady mixed convection boundary layer flow and heat transfer of nanofluids due to stretching sheet. Nucl Eng Des 2012; 249: 248–255. [Google Scholar]