Abstract

Introduction:

With the increasing drilling depth of shale formation, downhole collapse is a frequent occurrence, which often manifests as borehole wall caving.

Methods:

We used the deep shale of the Longmaxi Formation to conduct the mechanical loading and unloading experiments under different downhole working conditions and a theoretical evaluation method of borehole wall caving and instability was proposed.

Results and discussion:

As the confining pressure and axial load increased, the acoustic velocity increased. When a certain value was reached, the acoustic velocity of the rock mass had minimal changes. As the confining pressure continued to unload and decrease, the acoustic velocity decreased. At the moment of core failure, the acoustic velocity suddenly dropped. When the axial force of loading was constant, the unloading speed of confining pressure increased, and shale could easily be destroyed. The pressure at the well bottom changed rapidly, the likelihood of borehole wall failure increased.

Conclusion:

The deep shale has high brittleness. Under the bottom-hole pressure, the borehole wall rock was prone to brittle fracture failure along the parallel bedding surface. Under different working conditions, obvious changes could be observed in the pressure of the effective fluid column at the well bottom. The pressure changed rapidly, which, in turn, caused the rock at the well bottom to break down, thereby resulting in borehole wall caving. After tripping out and turning the pump off, the shale tensile stress in the upper and lower sidewalls of the horizontal well section was responsible for tensile caving.

Keywords: Deep brittle shale, mechanical properties, surge pressure, borehole wall caving, wellbore stability

Introduction

With the ability to increase the drilling depth of shale formation, the proportion of hard brittle shale in easily damaged shale can be as high as 66.66%.1,2 Due to the high content of brittle minerals in deep shale, downhole collapse is a serious and likely problem, which often manifests as borehole wall caving. From downhole imaging, it is evident that, in deep and ultradeep wells, fracturing occurs in the collapse section of the borehole wall; moreover, rock in the borehole wall is prone to collapse along the fracture line, and tensile failure of brittle rock occurs along with splitting. 3 In general, the borehole wall is relatively stable during the drilling process; stopping drilling and tripping are accompanied by the phenomena of sticking and touching resistance. Sticking and touching resistance are associated with borehole wall caving mainly due to fluctuations in the downhole equivalent circulation density (ECD), which, in turn, results in the development and closure of fractures/strata in the bedding formation. When the cracks reach a certain size, the borehole wall rock will break down, thereby leading to borehole wall caving.

Shamsuzzoha studied the influence of bedding on borehole instability using a linear elastic constitutive model and weak surface criterion. Assuming that borehole stability depends on well inclination, formation dip angle, angle of attack, azimuth, and the in situ stress state, Shamsuzzoha analyzed the influence of borehole orientation on the angle of attack under different formation dip angles, optimizing the borehole trajectory in the process. 4 According to Khan et al. the mechanical properties and strength anisotropy of stratified formation affect borehole instability more in inclined wells than in straight wells. When the anisotropy ratio is between 1.2 and 3.5, the influence of anisotropy should be considered when analyzing original in situ stress and borehole stability. 5 Lang et al. established a borehole stability model for stratified shale pressure failure, suggesting that it is not safe to drill along the bedding surface and that drilling at low angles reduces stability. 6 When Zhao et al. 7 studied the borehole stability of anisotropic stratified shale, they analyzed the stress state of a well with a large slope according to the elastic mechanics theory of porous media. By using dual coordinate transformation, the model of concentrated stress around the well distribution on the bedding surface can be obtained, and, accordingly, the influence of various factors on borehole stability can be comprehensively considered. Li et al. 8 used the MTS815 testing machine to conduct a triaxial compression test on gas-bearing shale, obtaining the failure mode and mechanical behavior under different stress conditions in the process. The failure mode of gas shale under low confining pressure is either the flerry or the double shear type, whereas under high confining pressure, the failure mode is mainly the single shear type. Moreover, brittleness increases with an increase in the content of brittle minerals in the shale mineral composition, which, in turn, increases the chance of fracture. Xu 9 collected experimental samples of continental shale in the Ordos Basin and turned them into standard samples with different bedding angles to study the fracture morphology, crack initiation stress, and crack rupture stress under different burial depths. The results suggest that when the continental shale in the Ordos Basin is buried at a depth of roughly 3000 m, the compression failure process does not include the fracture compaction stage and the elastic stage; additionally, plastic failure occurs. Moreover, the influence of bedding angle and burial depth on the crack initiation stress, crack rupture stress, and their ratio is particularly great, and the failure mechanism and fracture morphology of shale differ with different bedding angles and burial depths. Sun et al. 10 studied the influence of bedding direction on the dynamic load failure mode as well as the intensity and energy dissipation characteristics of shale. In essence, the dynamic load failure mode of shale with different bedding directions can be divided into three categories, namely, splitting tensile failure, shear failure, and mixed failure. For a small bedding angle and large bedding angle, splitting tensile failure occurs, whereas for medium bedding angles, mixed failure, and shear failure occur. To study the borehole stability of shale, Liang et al. 11 conducted a series of rock mechanics experiments under different confining pressure loading and unloading modes, coring angles, and fluid immersion. The results suggest that shale of the Longmaxi Formation in Sichuan Basin has high uniaxial compressive strength and brittleness. Moreover, the unloading action severely damaged the rock samples and increased the complexity of the damage mode. In essence, when the angle between the coring direction and the bedding surface was 15°, the compressive strength and cohesion were minimal; destruction was most severe when the angle was 45°. The compressive strength and cohesion of the rock samples were greatly reduced by fluid immersion, and the rock samples were mainly subjected to shear failure. Liang et al. 12 studied and analyzed the mineralogy, pore structure, sliding failure conditions, and rock mechanics of shale samples, demonstrating in the process that shale is a brittle fracture material with poor hydration capacity; moreover, a decrease in rock strength under the action of seepage can change the weak surface strength parameters. Overall, the occurrence of a weak surface, the number of weak surfaces, and water saturation significantly influence borehole stability during the drilling process. Li 13 established a prediction model for borehole failure with respect to the horizontal well of shale formation as well as a calculation model for horizontal well collapse pressure using coordinate conversion and weak surface slip failure theory. These can be used to analyze the effect of shale occurrence on the failure shape and collapse pressure of a horizontal well. In addition, they can be used to optimize the drilling direction of a horizontal well in shale formation to avoid rock sliding failure along the bedding surface as well as to prevent deterioration of borehole stability due to the shale bedding surface.

At present, knowledge is lacking with respect to the mechanical properties and failure modes of shale under different conditions. In particular, the mechanism behind horizontal well borehole wall tensile caving instability requires further study. Accordingly, in this paper, using deep shale in a block from China, mechanical loading under downhole working conditions is conducted. In doing so, the influence of loading and unloading speed is analyzed on the mechanical property parameters of rock, and a theoretical evaluation method of borehole wall tensile caving instability in the horizontal well of deep brittle shale is established.

Materials and methods

Materials

The research object consists of underground shale core of the Longmaxi Formation in a block in China, with an average depth of more than 3500 m. X-ray diffraction (XRD) equipment was used to test the mineral composition and content distribution. The reservoir rocks were mainly clay and quartz (roughly 40%) and contained small amounts of plagioclase, calcite, and dolomite. The clay minerals were mainly illite and chlorite, with a small amount of andreattite; the mixed layer ratio was low, and the average brittleness index was as high as 60%. This kind of shale has high mechanical strength brittleness as well as weak hydration and expansion capacity, which means that microcracks are easily produced under high stress and external force.

In the process of horizontal well drilling in this area, downhole collapse and obstruction problems often occur in the deviating section and horizontal section. From the recovered cores and blocks, it was evident that the formation section contained thin layers with developed low-angle bedding fractures. In addition, the cores were relatively broken and loose with poor integrity and developed calcite filling strips. This means that the rocks are prone to fracture along the interface, as shown in Figure 1.

Figure 1.

Underground core photos of the Longmaxi Formation.

The microstructure characteristics of shale in the Longmaxi Formation were tested with scanning electron microscopy, as shown in Figure 2.

Figure 2.

Microstructure of underground core of the Longmaxi Formation (at 500× magnification).

With a scanning electron microscope magnification of 500 times, it can be seen from Figure 2(a) that the micro-fractures in the shale of Longmaxi formation are relatively well developed and run through the entire visual field, with the maximum width of the micro-fractures being about 20 µm. Figure 2(b) shows that the shale of Longmaxi formation is well stratified and has obvious stratified structure. Combined with XRD diffraction test results, it is generally found that this type of shale has high hardness, strong brittleness, and weak hydration expansion capacity. Under high stress and external force, the rock sample is prone to produce micro-cracks and slip failure along the bedding cracks.

Methods

To obtain the variation law behind the tensile caving instability of the horizontal well of brittle shale under downhole pressure, the influence of complex load changes at the borehole wall bottom was experimentally tested. Due to the deep well depth in this block, the difficulty and cost of coring was large, and the number of cores was limited. Accordingly, a total of six downhole cores were selected. To eliminate the influence of differences in the core compressive strength caused by core heterogeneity, XRD was conducted, and cores with similar mineral composition and content were selected. According to GB 23561.1-2009 (Methods for Determining the Physical Properties of Coal and Rock), the rock samples were transformed into specimens with a length 50 mm and diameter of 25 mm, after which the cores were placed in a drying oven and were baked for 24 h at 105°C. 14 The samples with obvious heterogeneity and defects were then screened through microscopic observation. Finally, an acoustic wave testing device was used to screen the rock samples; those that met the standards were selected. The selected cores are presented in Table 1.

Table 1.

Core information after screening.

| No | Corenumber | Core description | Length(mm) | Diameter(mm) | VS(km/s) | VP(km/s) |

|---|---|---|---|---|---|---|

| 1 | 09 | No fracture | 37.89 | 25.16 | 3.10 | 5.30 |

| 23 | No fracture | 43.08 | 25.10 | 3.08 | 5.31 | |

| 10 | No fracture | 47.06 | 25.30 | 3.06 | 5.28 | |

| 2 | 15 | Fracture development | 51.75 | 25.11 | 2.55 | 3.81 |

| 1 | Fracture development | 50.22 | 25.05 | 2.53 | 3.82 | |

| 3 | Fracture development | 49.25 | 24.95 | 2.57 | 3.80 |

Mechanical properties under different unloading confining pressure speeds

The borehole wall is prone to collapse if the drilling tripping speed is too fast. Accordingly, the rate of change in the confining pressure affects the stability of the borehole wall. 15 Figure 3 shows the pressure on the borehole wall in the field. A triaxial test instrument was used to conduct the unloading confining pressure tests.

Figure 3.

Schematic of confining pressure loading and unloading experiments.

P-wave and S-wave velocity during mechanical loading

During the loading and unloading experiment, dynamic variation in the P-wave and S-wave velocity was tested considering that rock type and structure affect the propagation speed of the said waves. Since the propagation speed of the rock skeleton is greater than that of the gas, the looser the rock is, the more cracks it will contain and the lower the wave speed. 16 Therefore, the effect of mechanical loading on the mechanical properties of borehole wall rock can be indirectly evaluated by comparing the acoustic time of the rock samples.

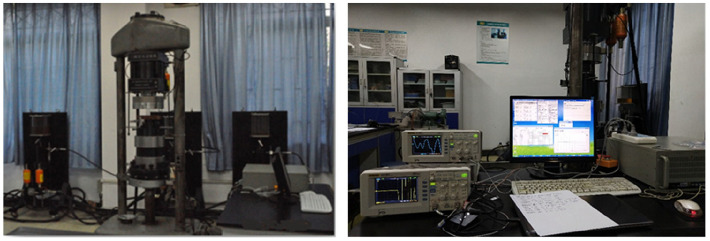

The triaxial equipment used in this study was the 600KN MTS triaxial mechanical loading testing machine from the State Key Laboratory, Southwest Petroleum University. The technical indicators consisted of the following: pore pressure of 0–100 MPa, confining pressure of 0–100 MPa, temperature of 0°C–150°C, maximum axial load of 0–1000 kN, and a deformation range of ±2.5 mm in the axial and radial directions. To ensure experimental accuracy, the pressure was 0.01 MPa, the liquid volume was 0.01 cc, and deformation was 0.001 mm. The available core sizes included 1, 1.5, and 2 in. Acoustic testing sensors were installed at both ends of the gripper by sufficient modifications, which were then connected to the acoustic testing equipment. During the triaxial loading and unloading experiment, the dynamic change process of the P-wave and S-wave velocity of the core was recorded using the acoustic acquisition software. Figure 4 shows the triaxial experimental testing machine and acoustic testing system.

Figure 4.

Triaxial mechanical experiment machine and acoustic testing system.

During the experiment, the confining pressure of each group was set to a value of 20 MPa (downhole formation pressure) with the same rate, and then the axial load of the triaxial instrument was loaded to the set value with the same rate. The aim was to study the influence of different confining pressure unloading rates on rock mechanical properties. Prior to the unloading confining pressure experiment, the compressive strength of original rock samples in Group 1 (Core 9) and Group 2 (Core 15) under a confining pressure of 20 MPa was tested; this was used as a reference standard for the required axial load during the unloading confining pressure experiment. During the unloading confining pressure for Core 2 and Core 10 in Group 1 and Core 1 and Core 3 in Group 2, the axial force loaded by the triaxial instrument was 50% of the compressive strength of Core 9 and Core 15. It should be noted that to ensure the integrity of the cores as well as to observe the change law of the unloading confining pressure experiment, it is necessary to prevent the core from being crushed in advance due to excessive axial force. The specific experimental steps are outlined below.

The cores were placed in the triaxial experimental kettle chamber along with the acoustic sensor. The triaxial chamber was sealed and filled with hydraulic oil.

In the software, the experimental confining pressure for each core group was set as 20 MPa. The axial force was set then as 50% of the compressive strength of the original rock samples in Group 1 and Group 2, and the confining pressure and axial force were maintained for 30 s.

After 30 s, the axial load was maintained, and the unloading confining pressure velocity of Core 23 in Group 1 and Core 1 in Group 2 was set as 0.0333 MPa/s (according to the unloading velocity of confining pressure from 20 to 0 MPa in 10 min). The unloading confining pressure velocity of Core 10 in Group 1 and Core 3 in Group 2 was set as 0.0667 MPa/s (according to the unloading velocity of confining pressure from 20 to 0 MPa in 5 min).

The values of residual confining pressures were tested separately in the event of core failure.

Experimental test of shale tensile strength

The tensile caving of borehole rock mentioned in this paper refers to that the pressure of borehole drilling fluid column is less than the pore pressure of formation. When the pressure difference exceeds the tensile strength of rock, the tensile caving of borehole wall will occur. Therefore, four downhole cores were selected, and the tensile test was also carried out with the 600 kN MTS triaxial mechanical loading testing machine.

Results and discussion

Tables 2 and 3 present the experimental results.

Table 2.

Triaxial experimental results of original rock samples.

| No | Length(mm) | Diameter(mm) | Confining pressure(MPa) | Compressivestrength (MPa) | Elasticmodulus(MPa) | Poisson’sratio |

|---|---|---|---|---|---|---|

| 09 | 37.89 | 25.16 | 20 | 120 | 2,3026.9 | 0.149 |

| 15 | 51.75 | 25.11 | 20 | 80 | 2,0968 | 0.162 |

Table 3.

Experimental results of unloading confining pressure.

| Corenumber | Axial compressionloading(kN) | Confining pressureloading(MPa) | Axial compressionloading time (s) | Confiningpressureloading time (s) | Axialcompressionloadingrate(kN/s) | Confiningpressureloadingrate(MPa/s) | Unloadingconfiningpressurerate(MPa/s) | Residual confining pressure(MPa) |

|---|---|---|---|---|---|---|---|---|

| 23 | 60 | 20 | 300 | 120 | 0.2 | 0.167 | 0.033 | 3.3 (rockbroken) |

| 10 | 60 | 20 | 300 | 120 | 0.2 | 0.167 | 0.067 | 5.7 (rockbroken) |

| 1 | 40 | 20 | 360 | 180 | 0.11 | 0.11 | 0.033 | 2 (rockbroken) |

| 3 | 40 | 20 | 360 | 180 | 0.11 | 0.11 | 0.067 | 4.8 (rockbroken) |

Figure 5 shows the experimental stress–strain results under different unloading confining pressure rates.

Figure 5.

Experimental results of unloading confining pressure: (a) core 10 (unloading speed of 0.067 MPa/s), (b) core 23 (unloading speed of 0.033 MPa/s, (c) core 3 (unloading speed of 0.067 MPa/s), and (d) core 1 (unloading speed of 0.033 MPa/s).

Changes in acoustic velocity reflect the dynamic change rule behind the microstructure of rock mass. As the confining pressure and axial load increase, the rock mass is compacted, and the acoustic velocity increases. When a certain value is reached, the acoustic velocity of the rock mass has minimal changes. As the confining pressure continues to unload and decrease, the rock mass is slowly destroyed and cracks appear, and the acoustic velocity decreases. At the moment of core failure, the acoustic velocity suddenly drops. Experiments with different unloading pressure rates show that when the axial force of loading is constant, the unloading speed of confining pressure increases, and shale can easily be destroyed. In other words, the pressure at the well bottom changes rapidly, and, accordingly, the likelihood of borehole wall failure increases.

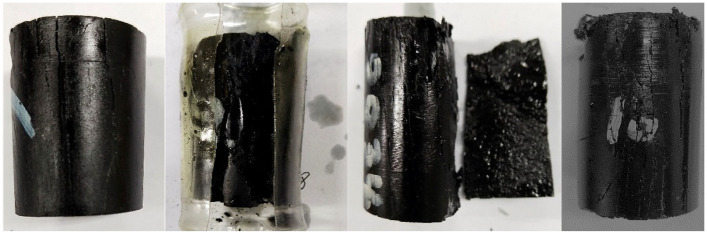

The core photos of the rock samples after the unloading confining pressure test are shown in Figure 6:

Figure 6.

Core photos after unloading confining pressure test.

The rock samples after unloading pressure test were taken out for observation, and it was found that there were many cracks in the rock, and the fracture characteristics of the rock were very obvious. The alternating load controlled the development characteristics of bedding fracture angle, and the rock samples were mainly subjected to tensile splitting failure along the bedding cracks.

The tensile test results are shown in Table 4 below:

Table 4.

Shale tensile test results.

| No | Length (mm) | Diameter (mm) | Core description | Tensile strength (MPa) |

|---|---|---|---|---|

| 01 | 47.88 | 25.13 | No fracture | 7.91 |

| 02 | 51.75 | 25.12 | No fracture | 8.03 |

| 03 | 50.31 | 25.012 | Fracture development | 4.02 |

| 04 | 48.32 | 24.98 | Fracture development | 4.11 |

It is found that the tensile strength of the shale matrix is significantly higher than that of the shale with fractures, and the shale with stratified fractures mainly suffers slippage failure along the bedding fractures.

Theory

For shale gas reservoirs, the bedding is almost parallel, and bedding permeability and mechanical strength are different compared with the shale matrix. Therefore, when evaluating the effective stress field and borehole stability of horizontal shale gas wells, it is necessary to consider the spatial anisotropy of mechanical strength as well as the bedding permeability. This problem is referred to as the transverse isotropic mechanical problem. Indeed, in a certain spatial direction, pore permeability and mechanical strength have the same characteristics.

Tensile caving instability refers to tensile stress acting on a rock that exceeds the tensile strength, resulting in tensile caving. For horizontal well borehole wall rock tensile caving, it refers to the borehole drilling fluid column pressure is less than the formation pore pressure, when the pressure difference exceeds the tensile strength of the rock, it will cause the borehole wall tensile caving, as shown in Figure 7.

Figure 7.

Borehole wall caving diagram of bedding shale horizontal section.

The condition of caving block in the borehole wall is that the radial stress (effective stress ) of the rock in the borehole wall is tensile stress, and the tensile stress is greater than the tensile strength of the rock. This can be expressed as follows 17 :

| (1) |

Where denotes the radial stress (MPa), Pw denotes the hydrostatic column pressure (MPa), a denotes the effective stress coefficient, PP denotes the static pore pressure of the formation (MPa), and St denotes the tensile stress (MPa).

For formation containing stratification and fractures, it is necessary to study the normal principal stress acting on the stratified or fracture surface to determine whether the borehole wall will break down along the stratification or fracture. When this normal principal stress is greater than the tensile strength of the bedding or fracture, the borehole wall will collapse, as shown in Figure 8.

Figure 8.

Schematic of stress on stratigraphic crack in the horizontal well of stratified shale.

It is assumed that the rectangular coordinate system of in situ stress field ( ) is IGS, and the rectangular coordinate system along the bedding plane (xs-ys-zs) is SGS, the angle between the bedding or fracture tendency and the direction of the maximum horizontal principal stress is , and the inclination of the bedding or fracture plane is . Figure 9 shows the spatial relationship between the in situ stress field and the bedding/fracture in the Cartesian coordinate system.

Figure 9.

Spatial relationship between the in situ stress field and the stratified coordinate system.

According to the spatial transformation relation of two coordinate systems, the original long coordinate system of in situ stress is taken as a reference. The in situ stress field coordinate system rotates at an angle of along the axis of , and then rotates at an angle of along the axis of , then the rectangular coordinate system of bedding plane (xs-ys-zs) can be obtained.

Combined with the spatial relationship between the in situ stress field and the rectangular bedding plane coordinate system, the spatial Cartesian coordinate transformation relationship between the in situ stress field IGS coordinate system and the rectangular bedding plane SGS coordinate system can be expressed as follows 18 :

| (2) |

It is assumed that the rectangular coordinate system along the axis stress field of the inclined well ( ) is BGS, and the spatial relationship between it and the in situ rectangular coordinate system IGS is shown in Figure 10. The rectangular coordinate system of the in situ stress field rotates by an angle around the axis, and then by an angle around the axis to obtain the rectangular coordinate system along the axis of the inclined borehole ( ).

Figure 10.

Spatial schematic of the in situ stress field and inclined well track.

Combined with the spatial relationship between the in situ stress field and the rectangular coordinate system of the crooked hole, the Cartesian coordinate transformation relationship between the IGS coordinate system of the in situ stress field and the rectangular BGS coordinate system of the crooked hole can be expressed as follows:

| (3) |

To evaluate the rock caving and collapse of the inclined borehole wall, it is necessary to establish the cylindrical coordinate system along the axis of the crooked hole ( ). Figure 11 shows the spatial relationship between the rectangular coordinate system and the cylindrical coordinate system along the axis of the crooked hole. By rotating an angle θ along Zb in the rectangular inclined well BGS coordinate system, the cylindrical coordinate system of any position around the inclined well can be obtained.

Figure 11.

Schematic of spatial relationship between rectangular coordinate system of the inclined well and the cylindrical coordinate system.

Combined with the spatial relationship between the oblique rectangular coordinate system and the cylindrical coordinate system, the spatial Cartesian coordinate transformation relationship between the rectangular coordinate system and the cylindrical coordinate system along the axis of the inclined well can be expressed as follows:

| (4) |

Combining the distribution of the in situ stress field and the relationship of the spatial angle and Cartesian coordinate transformation, the normal principal stress on the fracture/bedding surface at any spatial distribution angle can be evaluated to determine whether the borehole wall will collapse along the said surface.

Assuming that the principal stress of the in situ stress field is known, the distribution matrix of the in situ stress field can be expressed as follows:

| (5) |

Combined with the spatial Cartesian coordinate transformation relationship, the magnitude distribution of the circum-borehole stress field in the cylindrical coordinate system along the axis of the inclined borehole can be expressed as follows:

| (6) |

Combined with the three-dimensional spatial distribution of the fracture/bedding surface and the spatial angle relationship with the in situ stress field, the spatial Cartesian coordinate transfer formula can be used to obtain the stress field distribution of the circum-borehole fracture/bedding surface for different well types:

| (7) |

The formula can be used to calculate the principal stress ( ) and shear stress ( ) acting on the fracture/bedding surface, where is the normal principal stress acting on the fracture/bedding surface. Combined with the criterion of tensile caving instability, the critical state of tensile caving in the fracture/bedding surface can be expressed as follows:

| (8) |

When the normal principal stress acting on the fracture/bedding surface is tensile stress, and when the tensile stress is greater than the tensile strength between fractures, the borehole wall will collapse along the cracks.

Taking a well as an example, the downhole complexity was mainly associated with the difficulties encountered when the pump was switched on, and the drill pipe was lifted. To accurately evaluate the variation in the ECD of the bottomhole under downhole complexity, the effective ECD of a downhole was evaluated under normal drilling, stopping drilling, and tripping out conditions, and the dynamic change law behind the effective fluid column pressure was identified. The basic parameters of the well are shown in Table 5.

Table 5.

Basic input parameters.

| Basicparameter | Parametervalue | Basicparameter | Parametervalue | Basicparameter | Parametervalue | Basicparameter | Parametervalue |

|---|---|---|---|---|---|---|---|

| Measureddepth/verticaldepth | 4604.52 m/4372 m | OD ofpipe | 139.7 mm | ID ofpipe | 125.4 mm | Drillingfluiddensity/ρ | 2.15 g/cm3 |

| OD ofPDCbit/Dbit | 215.9 mm | ID of drill collar | 140 mm | OD ofdrill collar | 178 mm | PlasticviscosityPV/η | 58 MPa s |

| Deliveryvolume/Q | 29 L/s | Trippingvelocity | 0.5 m/s | Pumpingpressure | 28 MPa | φ600/φ300 | 90/80 |

Based on the basic parameters in Table 5 and the established calculation model, the ECD values of the downhole under tripping out, stopping drilling, and normal drilling conditions are evaluated, as shown in Table 6.

Table 6.

Calculation results of effective ECD at the well bottom under different working conditions.

| Working condition | Mud densityadded value(g/cm3) | Bottom-holepressureadded value(MPa) | Bottom-holeeffectiveequivalentdensity(g/cm3) | Bottom-holeeffectivefluid columnpressure (MPa) |

|---|---|---|---|---|

| Stopping drilling | 0 | 0 | 2.15 | 94 |

| Tripping out | −0.02 | −0.87 | 2.13 | 93.13 |

| Normal drilling | +0.128 | +5.59 | 2.278 | 99.59 |

From Table 6, it is evident that the speed of tripping is strictly controlled on site. The effect of exciting pressure on the bottom-hole effective equivalent density is 0.02 g/cm3, and the added value of bottom-hole pressure is 0.87 MPa. A relatively large difference can be seen between normal drilling and stopping drilling with respect to the ECD of the circulating drilling fluid. During normal drilling, the added value of drilling fluid density is 0.128 g/cm3, and the added value of effective bottom-hole fluid column pressure is 5.59 MPa.

Taking the Longmaxi Formation at a depth of 4604.52 m as an example, the drilling fluid density is 2.15 g/cm3, the pore pressure coefficient is 2.14, and the pore pressure is 93.6 MPa, the maximum horizontal ground stress was 2.7 MPa/(100 m), the minimum horizontal ground stress was 2.25 MPa/(100 m), and the overburden pressure was 2.5 MPa/(100 m). The variation law behind the borehole wall tensile caving instability of the horizontal well under the conditions of tripping out, stopping drilling and pump off, and pumping for circulation was examined for both dense formation without fractures and formation with stratified fractures, the results of which are shown in Figures 12 and 13, respectively.

Figure 12.

Borehole wall tensile caving instability in dense shale formation without fractures: (a) tripping out, (b) stopping drilling and pump off, and (c) pumping for drilling.

Figure 13.

Determination of borehole wall tensile caving instability in stratified shale formation with fractures: (a) tripping out, (b) stopping drilling and pump off, and (c) pumping for drilling.

By comparing Figures 12 and 13, it is evident that when the formation is dense without fractures, or when the effective plugging property of the drilling fluid is 100%, the formation maintains the original formation pressure state, there is no seepage migration nor pressure transfer between the borehole and the stratum, and the borehole does not collapse nor chip; otherwise, stratification and fractures are evident in the formation, and seepage and pressure transfer are present between the borehole and the stratum under differential pressure at the well bottom. After pumping and spud in, the effective pressure difference at the well bottom is the largest, resulting in a rapid increase of pore pressure near the borehole wall. When the pumping and drilling stop, the additional pressure at the well bottom disappears, the pressure equivalent density of the effective liquid column at the well bottom reaches a minimum, and some of the rock in the borehole wall is under tensile stress. When the tensile stress exceeds the tensile strength of the shale rock itself, the borehole is under tension; accordingly, caving is a possibility. As shown in Figure 13, rock in the upper and lower borehole wall of the horizontal well will be subjected to tensile stress after tripping out and stopping the pump. This produces a small range of possible tensile caving. The zone of caving is in the bedding shale with a thickness of 2–3 cm.

Conclusions

Based on the deep shale of a block in China, the simulation experiment scheme of mechanical loading under downhole conditions was developed, the influence of loading and unloading speed on the mechanical parameters of rock was analyzed, and the theoretical evaluation method of borehole wall tensile caving instability in the horizontal well of deep brittle bedding shale is established and the following conclusions were drawn.

The deep shale of the Longmaxi Formation is mainly composed of clay and quartz with a high content of brittle minerals and a developed bedding fracture in the sample cores. Under the bottom-hole pressure, the borehole wall rock is prone to brittle fracture failure along the parallel bedding surface.

The tripping out speed influences the pressure of effective fluid column at the bottom of the horizontal section of the deep shale gas. When the pump is stopped, the pressure of effective fluid column at the well bottom is reduced as well as the support confining pressure on the borehole wall rock, which, in turn, induces rock collapse and caving along the bedding plane.

When the tripping out velocity is slower than 0.4 m/s, the variation range of the effective ECD at the well bottom is roughly 0.02 g/cm3. When the tripping out velocity is faster than 0.4 m/s, the variation range of the effective fluid column pressure at the well bottom increases. Differences exist in the effective supporting confining pressure of the borehole wall rock under different tripping out velocities. The likelihood of borehole wall rock collapse increases with an increase in the tripping out speed. When the rock samples were damaged, the speed of the unloading confining pressure increased from 0.033 to 0.067 MPa/s, and the remaining confining pressure increased from 3.3 to 5.7 MPa, resulting in an increase of 0.056 g/cm3 in the equivalent density of the bottom-hole collapse pressure.

Improving the effective plugging property of the drilling fluid has a twofold effect, that is, it reduces the pressure penetration effect of the drilling fluid along the fracture/bedding surface and increases the effective support force of the drilling fluid to the borehole wall rock. It is necessary to optimize the rheological property of drilling fluid and improve the carrying capacity in boreholes. At the same time, it is necessary to carry out comprehensive optimization according to the formation fracture width and the characteristics of the plugging agent.

Author biographies

Yu Fan is a Senior Engineer who is mainly engaged in shale gas engineering technology research and management.

Shuai Cui is a PhD who is mainly engaged in wellbore stability and rock mechanics research.

Houbin Liu is a Professor who is mainly engaged in wellbore stability and rock mechanics research.

Pengcheng Wu is a Senior Engineer who is mainly engaged in shale gas drilling technology research.

Xudong Wang is a Senior Engineer who is mainly engaged in shale gas drilling technology research.

Chengxu Zhong is a Senior Engineer who is mainly engaged in shale gas drilling technology research.

Yingfeng Meng is a Professor who is mainly engaged in the teaching and research of reservoir protection and underbalanced drilling technology.

Footnotes

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Funding: The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was supported by the Science and Technology Special Project of CNPC Southwest Oil and Gas Field Branch “Research on Optimal and Fast Drilling Technology of Deep Shale Gas Horizontal Wells in Luzhou and Yuxi Blocks” (grant number XNS25JS2019-34); and the CNPC Field Test Project of Major Engineering Technology “Key Technology Research and Test for Effective Exploitation of Deep Shale Gas” (grant number 2019F-31).

ORCID iD: Houbin Liu  https://orcid.org/0000-0003-4849-9720

https://orcid.org/0000-0003-4849-9720

References

- 1.Yu KK. Reservoir characteristics of upper permian leping formation shale in Pingle depression. Geol China 2016; 43(2): 520–530. [Google Scholar]

- 2.Wang JH, Yan JN, Su SL. A new method for evaluating borehole stability of hard brittle shale. Oil Drill Prod Technol 2006; 28(2): 28–30. [Google Scholar]

- 3.Liu XJ, Jian X, Liang LX, et al. Investigation of the physico-chemical and mechanical properties of hard brittle shales from the Shahejie Formation in the Nanpu Sag, northern China. J Geophys Eng 2017; 14(3): 445–455. [Google Scholar]

- 4.Shamsuzzoha M. Analysis of borehole failure related to bedding plane. Master Thesis. University of Stavanger, Norway, 2011. [Google Scholar]

- 5.Khan S, Ansari SA, Han H, et al. Importance of Shale Anisotropy in Estimating In-Situ Stresses and Wellbore Stability Analysis in Horn River Basin. Canadian Unconventional Resources Conference, 2011. [Google Scholar]

- 6.Lang J, Li S, Zhang J. Wellbore stability modeling and real-time surveillance for deepwater drilling to weak bedding planes and depleted reservoirs. SPE/IADC Drilling Conference and Exhibition, 2011. [Google Scholar]

- 7.Zhao K, Deng JG, Wei BH, et al. Borehole stability of highly-deviated well in bedding shale. Sci Technol Eng 2013; 13(5): 1147–1149. [Google Scholar]

- 8.Li AQ, Chen M, Jin Y. Experimental research on failure modes and mechanical behaviors of gas-bearing shale. Chinese J Rock Mech Eng 2012; 31(S2): 3763–3771. [Google Scholar]

- 9.Xu D. Failure mechanism of continental shale with different bedding angles under coupling effects of temperature and confining pressure. Sci Technol Eng 2012; 31(S2): 3763–3771. [Google Scholar]

- 10.Sun QP, Zhang ZZ, Li PC, et al. Study on the bedding effect and damage constitutive model of black shale under dynamic loading. Chinese J Rock Mech Eng 2019; 38(7): 1319–1331. [Google Scholar]

- 11.Liang LX, Zhuang DL, Liu XJ, et al. Study on mechanical properties and failure modes of longmaxi shale. Chinese J Underground Space Eng 2017; 13(1): 108–116. [Google Scholar]

- 12.Liang C, Chen M, Jin Y, et al. Wellbore stability model for shale gas reservoir considering the coupling of multiweakness planes and porous flow. J Natural Gas Sci Eng 2014; 21(21): 364–378. [Google Scholar]

- 13.Li XF. Effects of shale formation occurrence on horizontal wellbore failure. Drill Prod Technol 2016; 39(5): 14–16. [Google Scholar]

- 14.GB/T 23561.9-2009. Methods for determination of physical and mechanical properties of coal and rock – Part 9: method for determination of triaxial strength and deformation parameters of coal and rock. General administration of quality supervision, inspection and quarantine of the People’s Republic of China, China Standardization Administration, 2009. [Google Scholar]

- 15.Li XZ, Shao ZS, Qin CZ. Study on rock crack damage and confining pressure effects on shear fracture band. Rock Soil Mech 2019; (11): 4249–4258. [Google Scholar]

- 16.Ding PB, Di BR, Wei JX, et al. Velocity and anisotropy influenced by different scale fractures: experiments on synthetic rocks with controlled fractures. Chinese J Geophys 2017; 60(4): 1538–1546. [Google Scholar]

- 17.Chen M, Jin Y, Zhang GQ. Petroleum engineering rock mechanics. Beijing: Science Press, 2008. [Google Scholar]

- 18.Lee H, Ong SH, Azeemuddin M, et al. A wellbore stability model for formations with anisotropic rock strengths. J Petrol Sci Eng 2012; 96–97: 109–119. [Google Scholar]