Abstract

In underdeveloped nations, rice is frequently harvested at a relatively high moisture content and then dried under the open sun to a storage moisture content. However, direct UV exposure, rain, dust, premature drying, contamination, and open sun drying are all associated with problems like poor grains, discolorations, and cracking. Commercial mechanical dryer utilization is not practical in remote regions due to the absence of electrical service, high startup costs, and ongoing operating expenses. In this work, a pilot mixed-flow rice drier that ran on rice husk energy and solar energy to power the driving fan was designed, produced, and tested. The major parts of the dryer assembly that were conceived and created were the combustion chamber, heat exchanger, and mixed-flow dryer. The results of the trial revealed that the combustion chamber's average temperature was 347.3 °C, the drying air at the heat exchanger output, where the drying chamber was attached, was 63.3 °C, and the combustion chamber and heat exchanger's respective efficiencies were 52.4% and 14.9%. The mixed-flow dryer powered by rice has a significantly lower operating cost than a comparable dryer powered by electricity, petrol, and diesel. The study makes it evident that such a reasonably priced and effective rice dryer might significantly help small-scale rice producers to extend the storage duration and maintain the quality of their product.

Keywords: Rice dryer, Design, Development, Mixed-flow dryer, Rice-husk

1. Introduction

For the majority of people on Earth, rice is a crucial food and a source of nutrition [1]. These days, it is expanding across a wide range of nations, especially in Asia, where about half of the world's population receives daily food [2]. It is eaten as whole grain rice, rice flour, rice flakes, and puffed rice, with whole grain rice having the greatest consumption rate among them all [3]. In Ethiopia, rice farming is a more recent development than its use as a food crop. According to some data, the Fogera and Gambella regions saw the start of Ethiopia's rice farming in the early 1970s [4]. In Ethiopia's northern, northwest, and western regions, the Fogera, Gambella, Metema, and Pawe plains are currently developing into major rice-producing areas [4].

Rice production on the Fogera Plain helps to reduce food insecurity in the farming community and gives farmers opportunities for income and employment [5]. In the farming community, the rice harvest has a wide variety of uses. Many traditional meals and drinks, including Injera, Dabbo, Genffo, Kinchie, Shorba, Tella, and Katikalla, are made with it [6]. The Central Statistical Agency of Ethiopia reports that rice output is rising each year. The area covered by rice production in the last four production years has been 53106.79 ha, 63361.86 ha, 5757.72 ha, and 85288.87 ha, producing 1510183.30 quintals, 1718540.95 quintals, 1706301.01 quintals, and 2682235.14 quintals, respectively [[7], [8], [9], [10]]. In the production year of 2019/20 to 2020/21, there was a 48.13, 57.20, and 6.10% increase in area coverage, production quantity, and yield per hectare respectively in rice-producing areas [10].

Rice is commonly harvested with a moisture content of 20–30%; which needs drying to reduce the moisture content to 9–13% for safe storage [11,12]. Drying is the main unit operation to reduce the moisture content of the grain to a safe level for storage through the use of heat to prevent the growth of fungi, bacteria, and mold, as well as the development of insects and mites [13]. Delays in drying, partial drying, or inefficient drying all reduce grain quality. However, the unit process that requires the greatest energy is drying. Due to some factors, such as significant moisture content changes between harvest and storage, low drying temperatures, and little pre-treatment because of the sensitivity of agricultural products to thermal and mechanical stress, drying of agricultural products consumes a lot of energy [14]. Different kinds of drying methods are applied for the drying of agricultural products, such as open sun, solar, and artificial mechanical dryers. The open sun drying process dates back to ancient times when people used the sun under the open sky to preserve agricultural products [15] by leaving the product on the field for a long period before or after harvesting [16]. However, open sun drying takes a long time and is associated with issues like low-quality grains, discolorations, and cracking due to direct exposure to UV radiation, rain, dust, premature drying, and contamination resulting from poor handling facilities. Additionally, operating parameters like air velocity, relative humidity, drying temperature, and moisture content are uncontrolled [17] because drying is largely dependent on environmental factors, particularly solar radiation.

For both on- and off-farm drying, solar drying uses components like solar absorbers to harvest useable solar radiation energy and raise the temperature of the drying air. Solar drying uses less time and energy than open-air sun drying, preserves and enhances product quality, prevents environmental contamination, and enables the use of tiny drying spaces [14,17]. Depending on whether forced or natural convection is used to move the drying air, solar dryers are categorized as active or passive. Solar dryers are used in many different areas around the world but they are low-capacity dryers and take more drying time compared to artificial mechanical dryers. Different mechanical grain dryers are available, such as bin, batch, mixed-flow, cross-flow, counter/concurrent flow, rotary drum, fluidized bed, deep bed, spouted bed, and cabinet dryers [16,[18], [19], [20]]. Artificial mechanical dryers use energy sources other than solar radiation like biomass (wood rejects, rice husk), electric heaters, infrared and microwave, coal, diesel, chemicals, and other fuels for both on-farm and off-farm drying. Electricity access is limited in the rural part of most countries, and its cost is high in developing countries which makes it unsuitable for small-scale farmers. As a potential energy source, the calorific value of the rice husk was studied by different researchers [[21], [22], [23], [24]] and it lies between 6.8 and 17.5 MJ/kg. Regarding the specific energy consumption of different rice dryers designed by different researchers [20,22,25] and reviewed by Ref. [26], the heat value of rice husk shows that it is a good alternative energy source. The environmental impact to obtain 1 MJ from rice husk, including elements in the global warming, acidification, and eutrophication categories, is less than the impact observed when 1 MJ is generated from coal by 97%, 88%, and 80%, respectively [24].

Mixed-flow dryers are common in the drying of grains [12] and are energy-efficient [1,21,22]. The dryer has a relatively good contact between the drying air and the grain which increases the rate of heat and mass transfer between the grain and the drying air. A mixed-flow dryer works on both conduction and convection heat transfer modes. The drying characteristics and the efficiency of the dryer are highly dependent on the design, operation, grain thermophysical properties, and drying air properties [2,23,24,26]. Grain thermophysical property is highly related to the moisture content of the grain [27]. Drying air properties include relative humidity, temperature, and velocity. Mostly rice drying process is classified as low-temperature drying up to 40 °C, medium temperature up to 82 °C, and high-temperature drying above 82 °C. Drying air with relative humidity in the range of 50–80% is recommended [26]. The recommended drying air flow rate for small-scale grain dryers is in the range of 4.3–6 m3/min [25,27].

Energy-efficient mixed–flow dryer can be introduced as an alternative dryer for drying high-moisture paddy in subtropical countries to achieve high-quality milled rice [1]. In the past, many researchers tried to design, develop, and evaluate the performance of a mixed-flow grain dryer that uses different energy sources mostly electric heaters. Scholars design and develop different grain dryers using rice husk as an energy source for hot air generation and these researches showed that rice husk is an alternative solution to other expensive energy sources [[28], [29], [30], [31], [32], [33]]. develop and evaluated the performance of rice husk fueled shelf type dryers for corn, jackfruit, cassava, and rice drying. Generally, all the above researchers used a pipe-type heat exchanger to get the required drying temperature from the rice husk furnace and none of them tried a cross-flow heat exchanger. Sriwist et al. [1] developed and evaluated the performance of a mixed-flow rice dryer that uses an electric heater. Mondal et al. [26] design a mixed-flow rice dryer that uses an electric heater and evaluate its performance [[34], [35], [36], [37]]. developed and examined mixed-flow dryers for different grains by using different energy sources. Few researchers [34,36,38,39] tried to develop tray or shelf-type rice husk-fueled paddy dryers for corn, cassava, and jackfruit. Scientific information about the use of rice husk-fueled mixed-flow rice dryers with cross-flow plate heat exchangers is still missing.

The objective of this research is to design, develop and test a low-cost and small-scale mixed-flow rice dryer that uses rice husk as an energy source for hot air generation. The system uses a cross-flow plate heat exchanger and solar panels to drive fans/blowers for rural area farmers.

2. Materials and methods

2.1. Description of the dryer

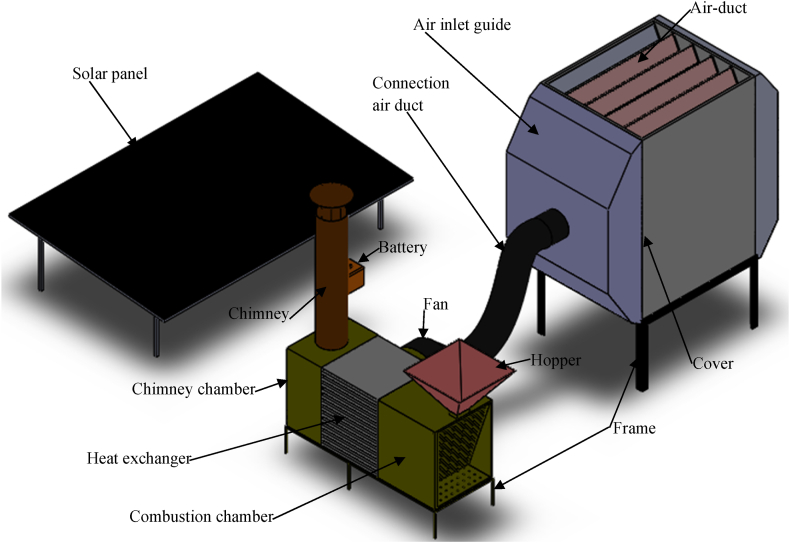

Fig. 1 below illustrates the three main parts of the proposed dryer. One is the drying chamber where the rice is dried and the moisture is removed; the second is the rice husk furnace where the rice husk is burned; and the third is the plate heat exchanger where the hot air from the furnace is used to heat the drying air. A drying compartment, a hot air pipe or duct system, a supporting frame, and an air intake guide are all included in the drying chamber's setup. The chimney chamber and chimney, hopper, supporting frame, fan, and solar panel to power the fan are among the system's additional parts.

Fig. 1.

The proposed rice husk-fueled mixed-flow rice dryer.

2.2. Design assumptions and consideration

In designing and testing the proposed dryer the following considerations and assumptions were made.

-

➢

To keep the cost of research and development to a minimum, the dryer's capacity was set at 30 kg per batch. It was capable enough to study the drying phenomenon, and [26,40] employed dryers of comparable size to examine the effectiveness of small-scale mixed-flow dryers.

-

➢

During the time that the rice was drying, the study area's average daily temperature was 22 °C and 70% relative humidity. The necessary values for the humidity ratio, specific volume, and enthalpies were then calculated for the specified temperature and relative humidity using the psychometric chart.

-

➢

The harvest moisture content of rice is in the range of 20–30% and to store rice safely and prevent difficulties with seed germination, the harvest moisture content of rice must be dried to a moisture content of 12% [18,41]. Hence, in this research, the initial and final moisture content of the paddy to be dried was assumed to be 30% and 12% respectively.

-

➢

The drying temperature was considered to be 43 °C to keep the germination properties of the rice [26,40].

-

➢

Row-to-row space between air ducts, subpar design, and subpar construction all contribute to uneven drying. To create a low-density air stream for even drying and homogeneous airflow, it is advisable to employ small air ducts with close horizontal and vertical spacing [42]. Hence, in designing the drying compartment, to create a uniform drying airflow, the length of the dryer, the width of the dryer, and horizontal and vertical air duct pitch were assumed to be 0.4 m, 0.4 m, 0.1 m, and 0.1 m respectively.

2.3. Design of the dryer

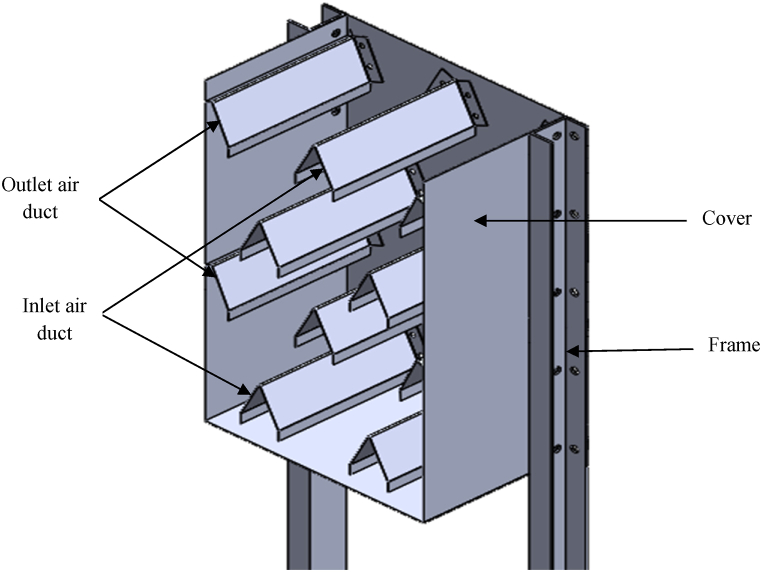

The determination of the dryer's overall size as well as the materials utilized to build the mixed-flow dryer is covered in this section. Fig. 2 below depicts the cross-section of the proposed mixed-flow dryer. Air outlet ducts were closed on the air inlet side and opened on the air outlet side of the dryer, whereas inlet air ducts are open on the air inlet side and closed on the air outlet side.

Fig. 2.

A sectional view of the mixed-flow dryer.

2.3.1. Design of air duct

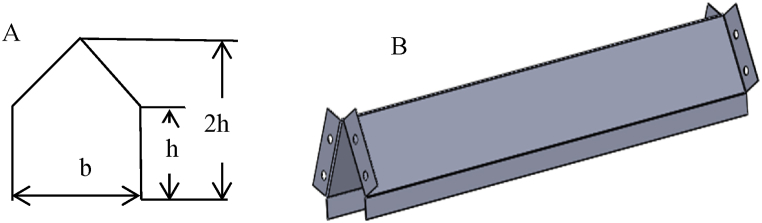

2.3.1.1. Air duct shape

There are various shapes for inverted “V" air duct designs. For this design, the air duct's shape depicted in Fig. 3 was used. This kind of air duct has a higher drying efficiency because it increases the surface area in contact with the paddy rice that needs to be dried. Previous research has also demonstrated that using this style of air duct “Fig. 3A” improved drying effectiveness [37] and the 3D model of the proposed air duct design in this study was shown in Fig. 3B below.

Fig. 3.

Proposed air duct shape A) Cross section, and B) 3D model.

Then, the height (h) and base (b) of the air duct is determined from equation (1) as follows,

| (1) |

2.3.1.2. Air duct dimensions

The length of the air duct is equal to the length of the dryer compartment which was assumed to be 0.4 m. The volume flow rate of the air must be determined to calculate the cross-sectional area of the air duct. In doing so the following parameters were determined.

-

➢

Humidity level (): it is represented by the mass of water removed during the drying process in kg and calculated simply by using initial moisture (mi), final moisture (mf), and mass of rice drying per batch (kg) as equation (2), the same formula were used by Refs. [43,44]. The initial moisture (mi), final moisture (mf), and mass of rice drying per batch (kg) were assumed to be 30%, 12%, and 30 kg respectively. This resulted in the removal of 6.1 kg mass of water (Ww) per batch of paddy rice drying.

| (2) |

-

➢

The energy required (Q): the amount of energy needed (Q) in KJ to remove water from the product is calculated using the mass of water removed from the product , latent heat (L), a mass of product to be dried (m), the specific heat of the product ( and change in temperature ( taking into account both the sensible heat and latent heat. Mostly sensible heat was insignificant in comparison to latent heat [43,45] and the heat requirement is calculated as in equation (3).

| (3) |

| (4) |

Where, = product temperature

-

➢

Product temperature can be determined from the drying temperature ( in (°C) and ambient temperature ( in (°C) using equation (5) as stated in Ref. [47].

| (5) |

-

➢

The temperature change was calculated using equation (6) from the air temperature entering the dryer (drying temperature (Td) and leaving the dryer (Tf).

| (6) |

-

➢

The temperature of the air leaving the dryer (Tf) was calculated using equation (7) as mentioned in Ref. [38].

| (7) |

-

➢

The volume of air required (): the total volume of air required () for removing the moisture was determined using equation (8) as given in Refs. [38,47].

| (8) |

-

➢

Where, is gas constant (287 J/kg K), is the specific heat of air at constant pressure (1005 J/kg k), is atmospheric pressure in N/m2 and L is latent heat in J/kg [47]. Atmospheric pressure was a function of altitude above sea level (z) and it could be determined as [48] by equation (9).

| (9) |

-

➢

Mass flow rate () of air needed for drying was calculated from the heat supplied by the drying air Q in kilocalories, humidity ratio H, drying, and final temperature respectively as in equation (10).

| (10) |

-

➢

Volume flow rate (): The volume flow rate () of air needed for drying is determined from the mass flow rate and specific volume as in equation (11).

| (11) |

-

➢

Where specific volume is determined from the psychometric chart. The time required for drying (t) in seconds was calculated from the volume of air required and volume flow rate as in equation (12).

| (12) |

-

➢

The velocity of air () required for drying was determined from the energy consumption equation as given in Refs. [43,49] using equation (13) or (14).

| (13) |

| (14) |

Following the above procedures, the following values were found.

-

➢

Mass of water removed (Ww) = 6.1 kg

-

➢

The heat energy required (Q) = 17397 KJ

-

➢

Mass of rice husk required = 3 kg

-

➢

The total volume of air required = 975 .

-

➢

The mass flow rate of air required = 0.1 kg/s

-

➢

The volume flow rate of air required = 0.0852 .

-

➢

Theoretical drying time required = 3 h and 11 min

The volume of the air duct was calculated from equation (16) using the area and length, first by determining the area of air duct using equation (15) from the volume flow rate and air velocity as follows.

| (15) |

| (16) |

The final width (w) of the dryer takes into account the width and the number of air ducts; nevertheless, to make the dryer smaller or more compact, it is assumed that the width and length of the dryer are equal. The number of air ducts in the row was calculated by employing equation (17) as follows;

| (17) |

While the number of the air duct in the column was calculated by applying equation (18) below;

| (18) |

The number of air duct columns will be determined after determining the height of the drying compartment in section 2.3.2. The shape of the air duct was inverted ‘V’ and considered a triangle and its size was determined based on the area of the single air duct.

Since the total area of the air duct was known, the single duct area used for the air inlet was determined using equation (19) by dividing the total area by half of the total number of air ducts.

| (19) |

The overall air duct dimensions become.

-

➢

Air duct size (base x height) = 0.07 × 0.1 m

-

➢

Length of air duct = 0.4 m

-

➢

Total number of air ducts = 18

2.3.2. Design of drying chamber

From the relations of bulk density and moisture content (M) % wet basis of paddy as given by Ref. [44], using equation (20) the bulk density was estimated to be 691.1 kg/m3.

| (20) |

The volume of the drying chamber (V) is estimated from the relationship of bulk density and mass of rice (m) drying per batch using equation (21) and adding the total volume of the air duct. It was assumed that the drying capacity was 30 kg per batch. The drying chamber's volume was determined to be 0.0434m3 for a bulk density of 691.1 kg/m3 and a mass of 30 kg.

| (21) |

To use the straightforward volume and area relations of equation (22) to determine the base area, the length (l) of the drying compartment was assumed to be 0.4 m. The drying compartment's base area was determined to be 0.1085 m2. Additionally, it was believed that the dryer's width (w) would be 0.4 m, resulting in an estimated dryer height (h) of 0.64 m. As a result, the drying compartment's overall measurements are 0.4 m 0.4 m 0.64 m.

| (22) |

2.4. Design of furnace and heat exchanger

In this section, the overall size determination of the furnace, paying particular attention to the combustion chamber, heat exchanger, chimney, insulation thickness of the combustion chamber, and air pipes is discussed. Fig. 4 below depicts the complete assembly of the furnace; the hopper in this configuration is an optional feature and not a necessary part.

Fig. 4.

Furnace assembly.

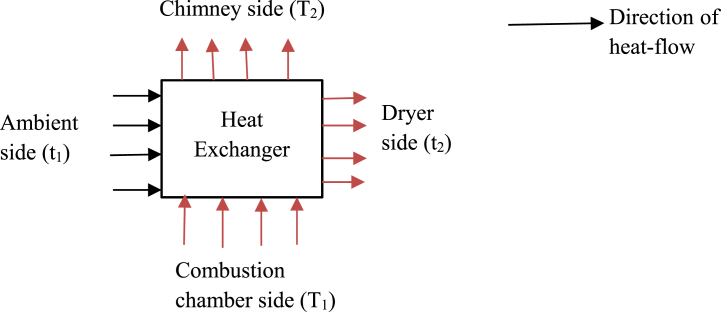

To reduce the overall size of the furnace the heat exchanger should be compact. The cross-flow plate heat exchanger was chosen for this study because, among the several types of heat exchangers, it was versatile, affordable, efficient, and employs a series of thin plates [45]. The area of the heat exchanger (A) was calculated using equation (23) from the required heat using the same method as [50,51]:

| (23) |

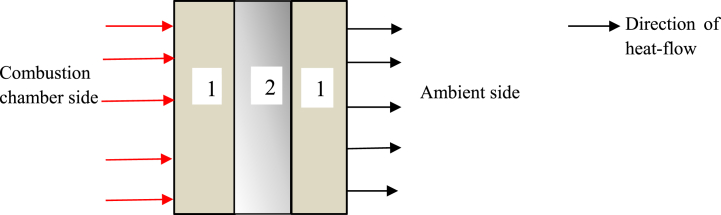

Where, Q = heat required for drying, U = overall heat transfer coefficient, F = correction factor for cross-flow heat exchanger, = log mean temperature difference. While Log mean temperature difference was calculated using equation (24) as suggested by Refs. [50,51] where, is hot air inlet temperature, is hot air outlet temperature, is cold air inlet temperature, and is cold air outlet temperature as shown in Fig. 5 below specifically for this study.

| (24) |

Fig. 5.

Temperature distribution in the heat exchanger.

Equations (25), (26) used to find P and R parameters to read correlation factor (F) from graph as stated by Ref. [51];

| (25) |

| (26) |

To determine the length and width, the area of one plate ( was calculated employing equation (27) from the number of plates ( and the area of the heat exchanger (A) as follows [45];

| (27) |

The length, width, and overall height must all be equal for the heat exchanger to be compact and cube-shaped. The heat exchanger height and the quantity of heat exchanger plates were used to calculate the distance between the heat exchanger plates applying equation (28) as follows:

| (28) |

Since the width and height were known and the combustion chamber was merged with the heat exchanger, the width and height of the heat exchanger are also used for the combustion chamber as well, and only the length was left unknown. To determine the length (L) of the combustion chamber the maximum capacity was considered. The volume of the required combustion chamber was calculated by equation (30) first and substituted into equation (29) to determine the length as stated by Ref. [50] as follows:

| (29) |

| (30) |

Taking the density of rice husk from Refs. [24,52], a mass of rice husk, height, and width and substituting it into the above equations (29), (30) gives the length of the combustion chamber. However, taking into account space for combustion, air space movement, and hopper assembly, in addition to the fact that grate type downward draught furnace was best [53], the length may be slightly longer than calculated. For chimney construction, the length is merely assumed based on the amount of space available and the overall size of the furnace.

Insulation thickness determination: The next point to be considered in the furnace design was its insulation. Thermal insulation was required to minimize the undesired flow of heat from the furnace or used to improve energy efficiency [54]. Low thermal conductivity, non-corrosive, non-toxic, non-flammable, readily accessible, and cost-effectiveness are all desirable qualities in thermal insulation material. Wood dust and wood ash due to their low thermal conductivity 0.015w/m°C [55], availability, and low cost was used for furnace insulation and fiberglass was used for air pipe insulations from the heat exchanger to the dryer chamber.

Determination of the critical insulation thickness becomes hard since the chamber was a cube in shape. Therefore, a simple technique was used by considering heat loss. 10% of the energy required was considered as a loss in the energy determination section and from the 10% let's assume half or 5% has occurred in the combustion chamber. Additionally, because the chamber was shaped like a cube this 5% loss was divided among the cube's five sides because one of them was required to move hot air to the heat exchanger. Therefore, there has been a 1% heat loss on each side of the combustion chamber. The arrangements of the furnace construction material (mild steel from the material selection) and insulation was shown in Fig. 6 below.

Fig. 6.

Arrangements of the combustion chamber cover 1) Mild steel sheet and 2) Wood ash.

The heat transferred through a wall was determined using equation (31) as suggested by Ref. [55],

| (31) |

Where, K = thermal conductivity of the material (0.015w/m°C), A = cross sectional area (m2), = temperature difference (°C), and X = thickness of a wall. From the above equation, the only unknown is the thickness of the wall, and by substituting values and a heat transfer rate it can be determined.

Following the above procedure, the critical dimensions of the furnace become.

-

➢

Furnace size (length x width x height) = 1 × 0.3 × 0.3 m

-

➢

Furnace insulation thickness = 0.04 m

-

➢

Heat exchanger plate spacing = 0.015 m

-

➢

Heat exchanger number of plates = 20

2.5. Fan selection

The energy consumption by blower/fan () to move the air was determined by applying equation (32) from air velocity (v) in KW similar to Refs. [43,56] as;

| (32) |

Determining the necessary airflow rate, pressure head, and power requirement is necessary for drying fan selection. Based on these figures, the appropriate manufacturer was chosen and the fan was selected [16]. Axial and centrifugal fans were used in the drying of grains. Axial fans were chosen because they were appropriate for the operation, readily available on the local market, and met the process's needs for power and volume flow rate. According to Atungulu & Sadaka [16], the axial fan is inexpensive, does not overload, and has the highest static pressure output. The power (P) required in watts (W) to drive the fan was determined by using the following equation (33) as proposed by Refs. [57,58];

| (33) |

Where, g = gravitational acceleration (9.81 m/s2), ղ = fan efficiency, = air flow rate and = pressure head in (m water column) and calculated by equation (34) as recommended by Ref. [48] as follows considering dynamic pressure head ( equation (35) and static pressure head ( equation (36) as follows;

| (34) |

| (35) |

| (36) |

Where, v = air speed (m/s), = air density (kg/m3), = drying product thickness (m) = air pressure (pa), n = molecular weight of air (kg/kmol), R = universal gas constant (J/kmol K) and = air temperature leaving the dryer (K). The efficiency of commercial industry fans ranges from 70 to 85% [59]. Therefore, a minimum efficiency was used for optimum fan selection. Based on the calculations made, the fan size (based on power requirement) should be above 24.5 W. A 30 W solar panel was used as a power source to drive the fan.

2.6. Amount of rice husk required per batch of drying

Since the efficiency of the majority of combustion appliances was 90% [60] and 90–95% [53], it was important to take loss into account to obtain the final amount of energy/heat needed [26]. Again, since the heat source was rice husk, we must determine how many kg were needed to produce this heat. This could be done by using equation (37) as [50], where HV is the rice husk's heating value and m is its mass. Equation (13) above previously determined the amount of energy needed. Using equation (37) the amount of rice husk required for a batch of drying is about 3 kg.

| (37) |

2.7. Manufacturing of the dryer

The dryer was manufactured from locally available material using basic workshop tools. The supporting frame should be rigid and strong and manufactured from structural steel. The drying compartment, air duct, air inlet guide, hopper, and the body of the furnace were manufactured at 1.5 mm thick mild steel. Air pipes or connection ducts are used as a transport system for drying air from the heat exchanger to the dryer. To avoid losses, it should not be much longer and constructed from mild steel sheet metal.

The heat exchanger is used for the exchange of heat energy between the ambient air and the rice husk flue gasses and is constructed from aluminum sheet metal. The chimney chamber and chimney are used for the exhaust of rice husk flue gasses after losing their heat energy in the heat exchanger and are constructed from mild steel sheet metal. The fan is used to energize the drying air and increase its pressure and velocity and they are standard and bought from the market based on the design capacity. Finally, the solar panel and the solar battery are used to drive the circulation fan. It is standard and bought from the market based on the capacity of the fan.

The materials listed above are selected based on the following criteria. Availability of the materials in the local market and different food safety standards are followed to select the material. But the food product is rice with its husk the reaction of the food with the metal is neglected since the white rice is covered by its husk during the drying process and only the availability of the material in the local market, suitability of the material for the working condition and operation, its strength, and cost of the material considered.

2.8. Testing and evaluation of the dryer parts

2.8.1. Experimental setup

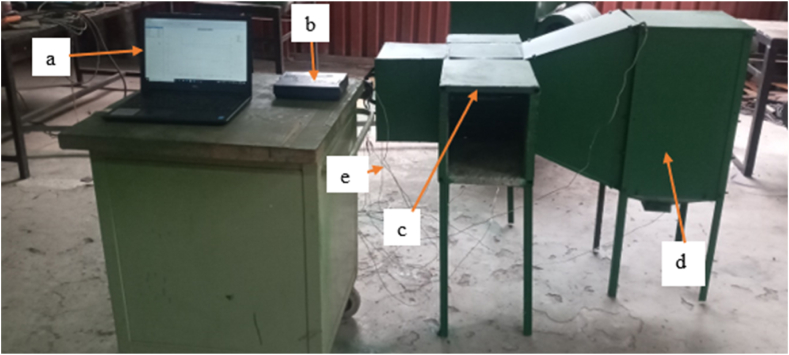

Thermocouple was used to measure the temperature of the mixed-flow dryer and the rice husk furnace at different locations based on the experimental setup. K type thermocouples with the following characteristics were used: fast response, small size, and widest operating temperature ranges (−270 to 1260 °C with an accuracy of ±1.5 °C), and it can work in rugged environmental conditions & various atmospheres. Grant (2020 Series) SQUIRREL DATA LOGGER (logger type 2F8 serial number KS1511008) was used to record the temperature and relative humidity of the dryer and furnace at the locations where the thermocouple was installed. The velocity and flow rate of air during the drying process was measured using Kestrel 5500 Weather Meter digital anemometer (with a speed measuring range of 0.6 m/s to 40 m/s with sensitivity or resolution of 0.1 m/s). A Digital Electronic Price Computing Scale balance with a maximum capacity of 40 kg with a sensitivity of 0.002 kg was used to measure the mass of the samples that includes the initial mass of the sample, the final mass of the sample and the mass of rice husk used for fuel. The experimental setup is shown in Fig. 7 below.

Fig. 7.

Experimental setup a) Laptop, b) Data logger, c) Furnace, d) Dryer, and e) Thermocouple.

2.8.2. Experimental procedure

A series of preliminary tests were carried out before the actual test to calibrate the experimental apparatus and regulate the feed rate of the rice husk. Then, after adding the measured amount of rice husk to the combustion chamber, the suction fan at the chimney starts and waits a few minutes for the heat exchanger to heat up before turning on the drier fan. The drier then received 30 kg of rice with a measured starting moisture content. During the test, the moisture content is measured at the 10-min interval as necessary and the time interval is decided by the test personally based on his interest. If the rice husk burned, fresh rice husk was applied, this time with known mass. The burning process was stopped and the drier fan was allowed to continue cooling the rice once the desired final moisture content was attained. The beginning mass of the rice to be dried, its initial moisture level, and the mass of the rice husk are all input parameters for this test. The experiment should be performed a minimum of three times following ISO standards.

2.8.3. Sample characteristics

The grain used for the experiment was rice (Oryza sativa L.) NERICA-4 variety. The most extensively used upland cultivar, NERICA-4, is grown in more than ten sub-Saharan African nations. Upland NERICA cultivars provide favorable yields, mature quickly (in 75–100 days), and are resilient to significant regional pressures. Farmers, especially women farmers, value upland NERICAs' early maturation because it gives them access to food throughout their “hunger period” while they wait for other crops to be harvested. Compared to other types, some NERICA cultivars have roughly 25% more protein. The average measured physical properties of the sample NERICA-4 at a moisture content of 12% (wb) are length 9.13 mm, width 2.76 mm, thickness 1.98 mm, geometric mean diameter 3.68 mm, arithmetic mean diameter 4.62 mm, surface area 38.4 mm2, volume 26.74 mm3, bulk density 0.64 g/cm3, sphericity 40.35%, aspect ratio 0.3, porosity 37.92%, 1000grain weight 24 g, and angle of repose 39.22°. More detailed information about NERICA-4 about other physio-morphological properties and chemical compositions could be found in Refs. [61,62]. The sample of NERICA-4 is shown in Fig. 8 below.

Fig. 8.

NERICA-4 rice variety color and shape. (For interpretation of the references to color in this figure legend, the reader is referred to the Web version of this article.)

3. Result and discussion

3.1. Design parameters

The mass flow rate of air found in this research 0.1 kg/s lies in the recommended mass flow rate of air 0.02–0.9 kg/s for the optimum dying process [47]. It was higher than the airflow rate recommended by Satria et al. [63], and sufficiently close to the airflow rate recommended by Refs. [26,40], and approximately equal to that of the value obtained by Ref. [1]. The drying process has the biggest impact on product quality. If the time is too short, the rice will crack, and if the time is too long, it will require more time and energy. Therefore, the projected drying time of 3 h and 11 min in this study was acceptable, and a similar trend was found in Ref. [33]. Uneven drying is caused by poor design, construction, and row-to-row air duct spacing. This study used a tiny air duct that was only 0.07 m by 0.1 m in dimension. By supplying a low-density air stream, relatively small air ducts and close spacing can generate relatively homogeneous airflow and consistent drying [42]. The designed air duct size was almost similar to the design of Mondal et al. [40], which was 0.06 m by 0.09 m. No row-to-row spacing is produced when the height of the dryer and the number of air duct rows are taken into account [37], used the same design in which zero row-to-row spacing was applied.

3.2. Performance evaluation

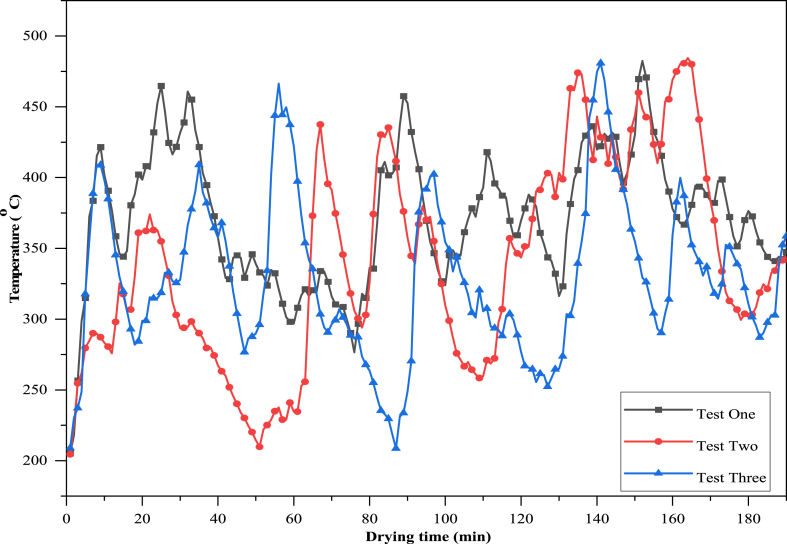

3.2.1. Temperature distribution

The test was performed three times with the dryer loaded and the outcomes are presented in Fig. 9 below. Fig. 9 below demonstrates that the combustion chamber outlet temperature was variable, which results in extremely low, unstable, or fluctuating combustion chamber efficiency. The main reason behind this fluctuation was the varying moisture level in the rice husk and the erratic fan speed. The combustion chamber outlet temperatures for the experiment ranged from 205.2 °C to 482.4 °C with an average of 372.2 °C for test one, from 204.5 °C to 484.4 °C with an average of 341.0 °C for test two, and from 208.7 °C to 480.8 °C with an average of 328.7 °C for test three. With a mean temperature of 347.3 °C, a standard deviation of 58.3 °C, and a standard deviation error of 4.2 °C, the total average temperature was 347.3 °C at the combustion chamber outlet. The temperature measured in the chimney had ranges of 78.9 °C–168.5 °C with an average of 142.4 °C for the first test, from 71.3 °C to 151.0 °C with an average of 125.9 °C for the second test, and from 74.0 °C to 115.4 °C with an average of 101.3 °C for the third test, with an average of 123 °C and standard deviation errors of 1.3 and standard deviation of 18 °C, respectively.

Fig. 9.

Experimental combustion chamber temperature.

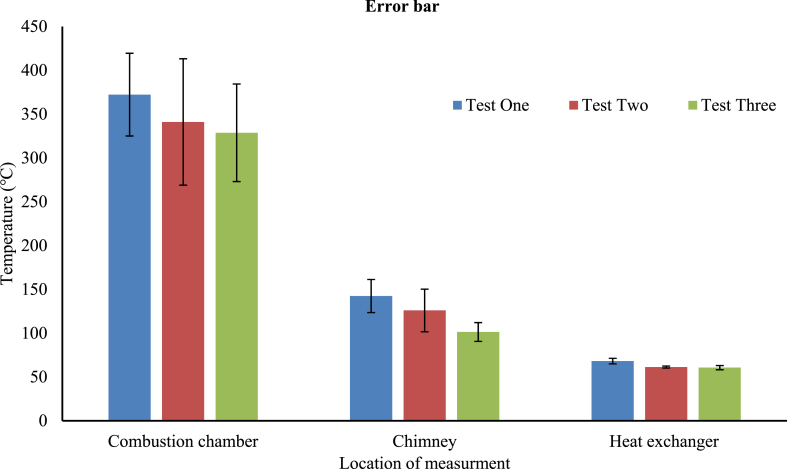

The variation of the data is shown in Fig. 11 below for each measuring locations of combustion chamber, chimney and heat exchanger outlet to the dryer for each of the three tests using an error bar. For a 95% confidence for each measured data, the confidence of interval of the data around the mean for the combustion chamber was for test one, for test two, and for test three with an overall average of °C. The corresponding value for the chimney was for test one, for test two, and for test three with an overall average of °C. This shows that most of the measured data lie around the mean at both combustion chamber and chimney data measurement locations.

Fig. 11.

Deviation of measured temperature from the mean for each test.

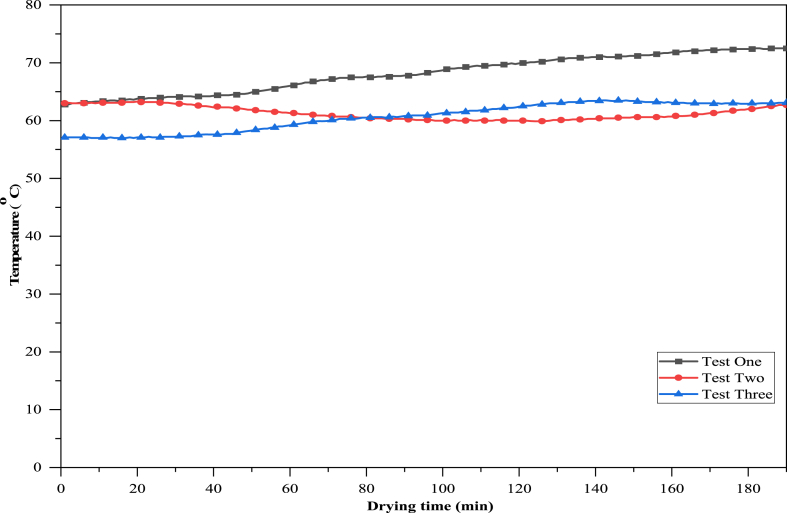

The heat exchanger outlet temperature of the drying air that was fed to the dryer has an average minimum of 57 °C, an average maximum of 72.5 °C, and an overall average of 63.3 °C (Fig. 10). The minimum recorded temperature was 62.8 °C, 59.9 °C, and 57.0 °C respectively for test one, test two, and test three. The higher temperature measured was 72.5 °C, 63.3 °C, and 63.5 °C for test one, test two, and test three, respectively. The average recorded temperature for each test was 68.1 °C, 61.3 °C, and 60.7 °C respectively for test one, test two, and test three with an average of 63.3 °C. The recorded temperature data at the heat exchanger outlet to the dryer shows an average agreement with a Standard Deviation of 2.2 °C and a Standard Deviation Error of a Mean of 0.2 during the test. The heated air from the heat exchanger was fed to the dryer through the connection duct and the temperature feed to the dryer shows a reduction compared to the heat exchanger outlet this showed that a significant amount of heat energy was lost through the connection duct due to insufficient insulation.

Fig. 10.

Heat exchanger outlet temperature.

The variation of the measured data is shown in Fig. 11 below, the deviation of the measured data from the mean for the heat exchanger was very small. For the 95% confidence, the measured data was for test one, for test two and for test three with an overall average of .

3.2.2. Energy consumption

The energy consumed during the three experimental tests varied depending on the continuity of the energy supply. The first experimental test drying process consumed 2.405 kg of rice husk, the second test took 1.895 kg of rice husk, and the third consumed 3.146 kg of rice husk. During the first drying experimental test the average moisture content of rice was reduced from 20.3% (wb) to 11.8% (wb) in the middle section of the dryer for a drying time of 2.43 h. The second experimental test reduced the average moisture content from 20.9% (wb) to 14.8% (wb) in the middle section of the dryer for a drying time of 1.17 h. For the third drying experiment, test the average initial moisture content was reduced from 21.6% (wb) to 12.4% (wb) in the middle section of the dryer for a drying time of 3.17 h. The energy needed per mass of water removed was calculated using the drying time and the mass of rice husk consumed. In tests one, two, and three of the drying experiment, on average, 2.89 kg, 2.14 kg, and 3.15 kg of water were eliminated. By dividing the heating value of the rice husk by the mass of rice husk consumed throughout the three experiments, the energy used was calculated. As a result, the total energy used during the experiment—including losses from the furnace, unburned rice husk, losses from the heat exchanger, connecting duct, and waste heat released into the environment through the chimney—was 36.7 MJ, 28.92 MJ, and 48.01 MJ for tests one, two, and three, respectively. This revealed that for each test, 12700 kJ/kg of water for the first test, 12740 kJ/kg of water for the second test, and 15241 kJ/kg of water for the third test were spent per kilogram of water eliminated. The energy consumed per drying hour was 15103 kJ/h, 24718 kJ/h, and 15145 kJ/h for test one, test two, and test three respectively including losses in the furnace, unburned rice husk, losses in the heat exchanger, connection duct, and released to the environment through the chimney. The minimum, maximum, and average energy output from the heat exchanger or the useful energy generated from the heat exchanger were 3707.3 kJ/h, 11128.9 kJ/h, and 7607.9 kJ/h, respectively.

3.2.3. Efficiency

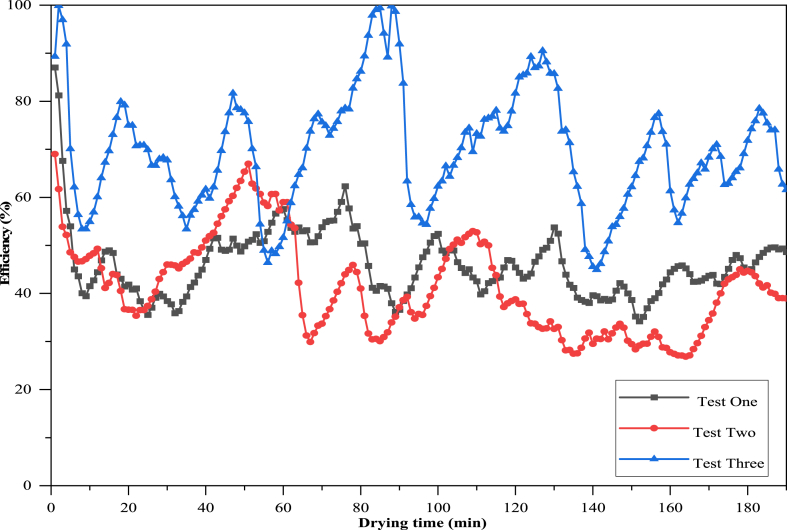

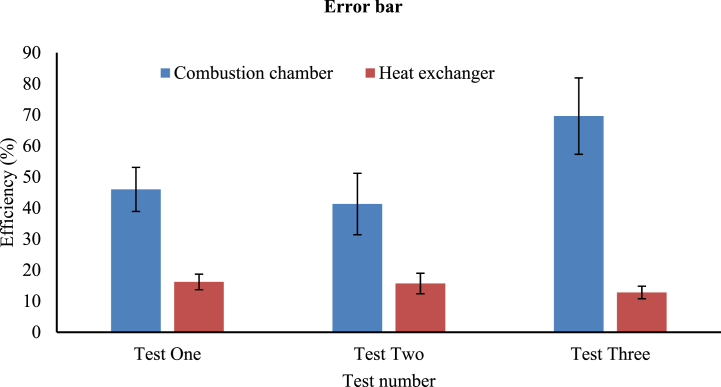

The energy contained in the rice husk and the energy discovered at the combustion chamber exit were used to calculate the combustion chamber efficiency (Fig. 12). The initial moisture level of the rice husk, the non-constant rice husk feed rate to the boiler, and the erratic fan airflow were the causes of the fluctuation in the combustion chamber efficiency. According to test 1, the combustion chamber's observed minimum, maximum, and average efficiencies were 34.2%, 87.0%, and 46%, with a standard deviation of 7.11%. For test 2, the corresponding minimum, maximum and average values were 26.9%, 69.0%, and 41.3% with a standard deviation of 9.92%. For test 3 it was 45.0%, 99.9%, and 69.6% with a standard deviation of 12.3% respectively. The overall average combustion chamber efficiency was 52.4%. The analytical combustion chamber efficiency was 95.4%. With little modification of the variables, the analytical result was close to the reported combustion chamber or furnace efficiency values from other studies [50,51]. Fig. 14 indicates the deviation of the measured combustion chamber efficiency from the mean for the three tests. For a 95% confidence, the confidence interval of the measured efficiencies for the combustion chamber around the mean is for test one, for test two, and for test three respectively with an overall average of . This shows that the measured efficiencies were lying around the mean of the measured data.

Fig. 12.

Instantaneous combustion chamber efficiency.

Fig. 14.

Deviation of the combustion chamber and heat exchanger efficiency from the mean for each test.

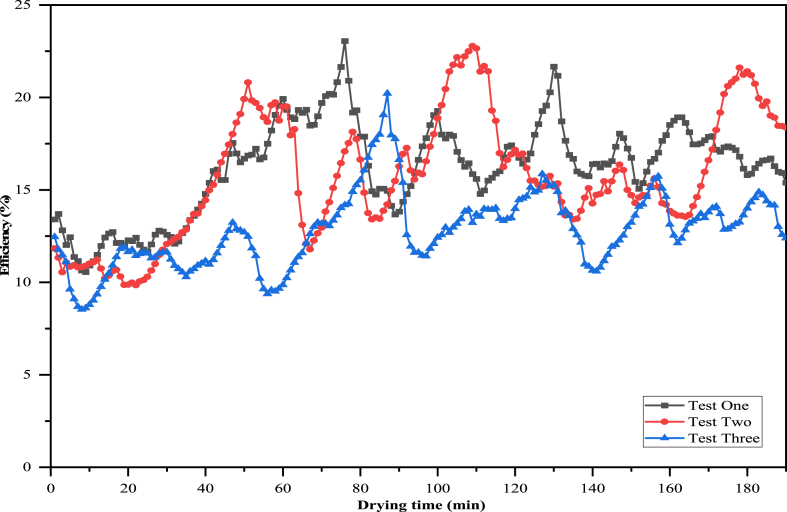

As shown in Fig. 13, similar to the combustion efficiency the heat exchanger efficiency was unsteady. That was due to the fluctuating temperature and flow rate of the hot air from the combustion chamber. For test one, the minimum, maximum, and average heat exchanger efficiency was 10.6%, 23.1%, and 16.2% respectively. For test two, the minimum, maximum, and average efficiency were 9.8%, 22.8%, and 15.7% respectively. For the third test, 8.5%, 20.2%, and 12.8% were the minimum, maximum, and average efficiencies respectively. The average heat exchanger efficiency across all experiments was 14.9%, with a standard deviation of 2.63%. Due to the suction fan's incapacity and instability, the heat exchanger's construction material, the significant heat loss of exhaust air to the atmosphere, and the deposition of ashes on the surfaces of the heat exchanger, the efficiency of the heat exchanger was relatively low.

Fig. 13.

Instantaneous heat exchanger efficiency.

Fig. 14 shows the deviation of the measured heat exchanger efficiency from the mean for the three tests. For a 95% confidence, the confidence interval of the measured efficiencies for the heat exchanger around the mean was for test one, for test two, and for test three respectively with an average of . This shows that the measured efficiencies are lying around the mean of the measured data.

The overall efficiency of the furnace was determined by multiplying the combustion chamber and heat exchanger efficiencies. The average combustion chamber and heat exchanger efficiency from the three tests was 52.4% and 14.9% respectively, with an overall furnace efficiency of 7.8%. Because of the uneven burning of the rice husk, the moisture present in the rice husk, the feeding rate, and the placement of the furnace fan assembly, the furnace was not as efficient and effective as expected or forecasted. However, compared to the research conducted by Ref. [32], they reported an energy conversion efficiency of 6.17%, and the energy conversion efficiency of the furnace in this study was higher.

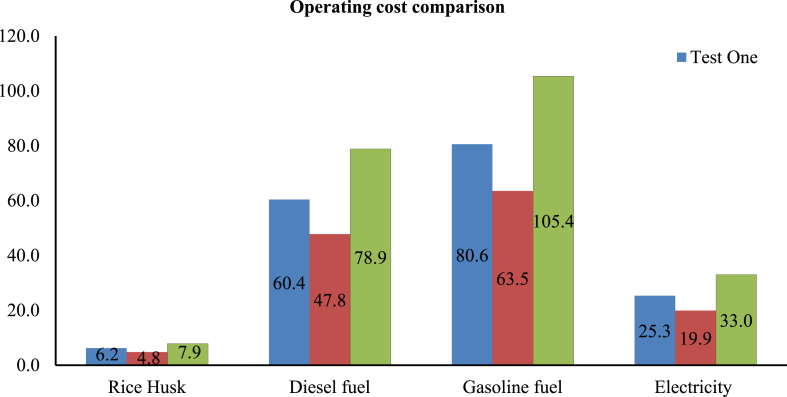

3.3. Operating cost

Operating cost determination is very important for any equipment design. The fuel used for this experiment is rice husk and the mass of the rice husk used for each test was known. The current price of rice husk in the local market of Wereta town is 2.5 ETB (Ethiopian Birr) per kg. So, from the energy consumption, we know the mass of rice used for each test is 2.405 kg, 1.895 kg, and 3.146 kg and the operating cost become 6.2 ETB, 4.8 ETB, and 7.9 ETB respectively for test one, test two and test three respectively. While the current price of diesel fuel in Ethiopia is 62.89 ETB per liter, gasoline fuel is 73.57 ETB per Liter and electricity price is varied depending on the monthly consumption in KWh and based on the energy consumed in this research the tariff price is 2.481 ETB/KWh. According to information from the Bureau of Transportation Statistics, diesel fuel delivers 38,290 KJ of energy per liter, whereas gasoline delivers 33,526 KJ. The running costs for tests one, two, and three would be 0.96, 0.76, and 1.254 L of diesel fuel, respectively, if we converted the energy used to a liter of diesel fuel. For tests one, two, and three, the operating costs would be 60.37 ETB, 47.8 ETB, and 78.86 ETB, respectively. For test one, test two, and test three, the fuel consumption for petrol is 1.095, 0.863, and 1.432 L accordingly, and the corresponding operation costs are 80.56 ETB, 63.5 ETB, and 105.35 ETB.

To determine the electrical operating cost, first, the energy consumed for each test was converted to KWh, and then the KWh was multiplied by the tariff, the operating cost became 25.31 ETB, 19.92 ETB, and 33.01 ETB for test one, test two, and test three respectively. Fig. 15 below illustrates the variation in operating cost concerning heat energy sources to operate the pilot mixed-flow rice dryer. The dryer with rice husk had the lowest operating costs, with petrol being the most expensive. Most manufacturers who employ mechanical dryers and researchers like [1,23,26] use expensive fuels like electricity, natural gases, or other types of fuel that could be substituted or supplemented by more affordable energy sources like rice husk. The rice husk mixed-flow dryer that was designed and developed in this study with some improvement in efficiency is a good alternative for small-scale rice-producing farmers. Rice husk is available in excess in those rice-producing areas.

Fig. 15.

Mixed-flow rice dryer operating cost comparison.

4. Conclusion

A mixed-flow rice husk-fueled rice dryer was created, built, and tested using resources that were readily available in the study area. The intended drier had a 30 kg capacity and a drying duration of 3 h and 11 min, reducing the moisture content of the rice from 30% (wb) to 12% (wb). The trial findings demonstrated the designed mixed-flow rice husk-fueled rice dryer's capacity to quickly obtain the desired moisture content. The average lowest, maximum, and average temperatures measured in the combustion chamber throughout the three tests are 204.5 °C, 484.4 °C, and 347.3 °C, respectively. The average lowest, maximum, and average temperatures of the drying air at the heat exchanger's outflow were 57 °C, 72.5 °C, and 63.3 °C, respectively. The developed furnace combustion chamber has an average 52.4% efficiency with a minimum efficiency of 34.2% and a maximum efficiency of 99.9%. The average lowest and highest efficiencies of the heat exchanger are 8.5% and 23.1%, respectively, with a mean efficiency of 14.9%. In comparison to other energy sources (electricity, petrol, and diesel), the operational cost of rice husk for mixed-flow dryers was comparatively quite low. Overall, the experimental findings demonstrated that mixed-flow dryers are the most effective drying techniques for quickly reducing high moisture paddy to the acceptable storage moisture content. It was also shown that rice husk was a potential energy source for the drying process heat source and other applications with less smoke pollution when compared to wood, other fuels, and biomass. The cost of the prototype rice husk-fueled mixed flow rice dryer totaled 64,213 ETB (Ethiopian Birr), which included the cost of the materials, the cost of fabrication tools, and the cost of labor. The study discovered that such a low-cost and only marginally efficient rice dryer might dramatically extend the storage length and quality (reduce postharvest losses) of rice as well as the income and food security of small-scale farmers. The paper proposes future research on the dryer's economic viability and on reducing the variables noticed in (feed rate, fan flow rate, and rice husk feed moisture content).

Author contribution statement

YABEBAL CHEKOLE MIHRET: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Mulugeta Admasu Delele: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Solomon Tekeste Hailemesikel: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This research did not recive any specific grant from funding agencies in the public, commerccial, or not-for-profit-sectors.

Data availability statement

The data that has been used is confidential.

Additional information

No additional information is available for this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Sriwiset S., Chiawchanwattana C., Laohavanich J. Designing of the small mixed-flow dryer and studying of hot air distributions. Eng. Appl. Sci. Res. 2021;49(1):81–87. doi: 10.14456/easr.2022.9. [DOI] [Google Scholar]

- 2.Xie R., et al. Structures, microstructures, physical and chemical properties of different rice grains. Phase Transitions. 2019;0(0):1–11. doi: 10.1080/01411594.2019.1566827. [DOI] [Google Scholar]

- 3.Rehal J., Kaur G.J., Singh A.K. Influence of milling parameters on head rice recovery : a review. Int. J. Curr. Microbiol. Appl. Sci. 2017;6(10):1278–1295. doi: 10.20546/ijcmas.2017.610.152. [DOI] [Google Scholar]

- 4.Alemu D., Tesfaye A., Assaye A., Addis D. A historical analysis of rice commercialisation in Ethiopia : the case of the Fogera Plain. APRA Work. Pap. 2018;18:1–7. [Google Scholar]

- 5.Gebrekidan H., Seyoum M. Effects of mineral N and P fertilizers on yield and yield components of flooded lowland rice on Vertisols of Fogera Plain, Ethiopia. J. Agric. Rural Dev. Tropics Subtropics. 2006;107(2):161–176. [Google Scholar]

- 6.Tefera A., Sentayehu A., Leta T. Advances in Rice Research and Development in Ethiopia, No. February. Ethiopian Institute of Agricultural Research; 2019. Association and path coefficient analyses of yield and Yield_related traits in rainfed lowland rice (oryza sativa L.) genotypes in northwestern Ethiopia; pp. 99–112. [Google Scholar]

- 7.Csa F. Addis Ababa; Ethiopia: 2018. Agricultural Sample Survey 2017/2018: Report on Area and Production of Major Crops. [Google Scholar]

- 8.Csa F. Addis Ababa; Ethiopia: 2019. Agricultural Sample Survey 2018/2019: Report on Area and Production for Major Crops. [Google Scholar]

- 9.Csa F. Addis Ababa; Ethiopia: 2020. Agricultural Sample Survey 2019/20: Report on Area and Production of Major Crops. [Google Scholar]

- 10.Csa F. Addis Ababa; Ethiopia: 2021. Agricultural Sample Survey 2020/2021: Report on Area and Production of Major Crops. [Google Scholar]

- 11.Hemhirun S., Bunyawanichakul P. Cross-flow paddy dryer application using an infrared gas burner. Int. J. Adv. Res. Eng. Technol. 2020;11(6):204–214. doi: 10.34218/IJARET.11.6.2020.019. [DOI] [Google Scholar]

- 12.Cao C.W., Yang D., Liu X., Liu Q. Research on modeling and simulation of mixed-flow grain dryer. Dry. Technol. 2014;A:565–572. doi: 10.1080/07373930701290951. [DOI] [Google Scholar]

- 13.Parde S.R., Jayas D.S., White N.D.G. Grain drying : a review. Sci. Aliment. 2003;23:589–622. [Google Scholar]

- 14.Mellmann J., Weigler F., Scaar H. Research on procedural optimization and development of agricultural drying processes. Dry. Technol. 2018;0(0):1–10. doi: 10.1080/07373937.2018.1494186. [DOI] [Google Scholar]

- 15.Sharma A., Chen C.R., Lan N.V. Solar-energy drying systems : a review. Renew. Sustain. Energy Rev. 2009;13:1185–1210. doi: 10.1016/j.rser.2008.08.015. [DOI] [Google Scholar]

- 16.Atungulu G.G., Sadaka S. Rice, ElsevierInc. In Corporation with AACC International. 2019. Postharvest technology: rice drying; pp. 473–515. [Google Scholar]

- 17.Kalita P., Deka T.J., Das S., Das D., Kataki R. Design, development and performance evaluation of a fluidized bed paddy dryer. J. Energy Environ. Sustain. 2018;6:18–23. [Google Scholar]

- 18.Cesd P.U. Paddy Drying. 2013;Version 2:1–51. [Google Scholar]

- 19.Vijayavenkataraman S., Iniyan S., Goic R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012;16(5):2652–2670. doi: 10.1016/j.rser.2012.01.007. [DOI] [Google Scholar]

- 20.Yahya M., Fudholi A., Sopian K. Energy and exergy analyses of solar-assisted fluidized bed drying integrated with biomass furnace. Renew. Energy. 2017;105:22–29. doi: 10.1016/j.renene.2016.12.049. [DOI] [Google Scholar]

- 21.Armynah B., Atika, Djafar Z., Piarah W.H., Tahir D. The 2nd International Conference on Science. ICOS); 2018. Analysis of chemical and physical properties of biochar from rice husk biomass; pp. 1–8. [DOI] [Google Scholar]

- 22.Nizamuddin S., et al. Upgradation of chemical, fuel, thermal, and structural properties of rice husk through microwave-assisted hydrothermal carbonization. Environ. Sci. Pollut. Res., no. April. 2018 doi: 10.1007/s11356-018-1876-7. [DOI] [PubMed] [Google Scholar]

- 23.Kargbo F.R., Xing J., Zhang Y. Property analysis and pretreatment of rice straw for energy use in grain drying : a review. Agric. Biol. J. N. Am. 2010;1(3):195–200. [Google Scholar]

- 24.Quispe I., Navia R., Kahhat R. Life Cycle Assessment of rice husk as an energy source. A Peruvian case study. J. Clean. Prod. 2019;209:1235–1244. doi: 10.1016/j.jclepro.2018.10.312. [DOI] [Google Scholar]

- 25.Bepary R.H., Wadikar D.D., Patki P.E. Engineering properties of rice-bean varieties from north-east India. J. Agric. Eng. 2018;55(3):32–42. [Google Scholar]

- 26.Mondal H.T., Sayed K., Shiplu P., Sen K.P., Roy J., Sarker S.H. Performance evaluation of small scale energy efficient mixed flow dryer for drying of high moisture paddy. Dry. Technol. 2019;0(0):1–10. doi: 10.1080/07373937.2018.1518914. [DOI] [Google Scholar]

- 27.Bhushan B., Raigar R.K. Influence of moisture content on engineering properties of two varieties of rice bean. J. Food Process. Eng. 2020:1–10. doi: 10.1111/jfpe.13507. [DOI] [Google Scholar]

- 28.Alit I.B., Susana I.G.B. Evaluate the thermal performance of the dryer using a perforated wall furnace-heat exchanger for drying. World J. Adv. Eng. Technol. Sci. 2021;2(2):84–90. doi: 10.30574/wjacts. [DOI] [Google Scholar]

- 29.Alit I.B., Susana I.G.B. Drying performance of jackfruit dodol using rice husk energy on household in lombok, Indonesia. Front. Heat Mass Transf. 2021;17 doi: 10.5098/hmt.17.15. [DOI] [Google Scholar]

- 30.Alit I.B., Susana I.G.B. The utilization of rice husk with furnace modification based on the heat exchanger pipe type for sustainable energy of traditional drying. Int. J. Mech. Prod. Eng. Res. Dev. 2020;10(4):285–394. doi: 10.24247/ijmperdaug202025. [DOI] [Google Scholar]

- 31.Susana I.G.B., Yudhyadi I.G.N.K., Alit I.B., Mirmanto M., Okariawan I.D.K. Effect of hole spacing and the number of pipes on dryer box temperature. Int. J. Mech. Eng. Technol. 2017;8(11):1029–1035. [Google Scholar]

- 32.Guanco J.B., Casinillo L.F. Performance evaluation of a rice hull-fueled cabinet food dryer. Recoletos Multidiscip. Res. J., no. June. 2018:23. –38. [Google Scholar]

- 33.Sutrisno A. Designing rice dryer with A capacity of 1000 Kg/hour using rice husk heater. J. Mech. Eng. Mechatronics. 2021;6(1):42–52. [Google Scholar]

- 34.Wang D., Lee Y. Performance evaluation of reversible air flow drying in circulating dryer. Int. J. Adv. Chem. Engg., Biol. Sci. 2017;4(1):185–190. doi: 10.15242/IJACEBS.C0417022. [DOI] [Google Scholar]

- 35.Stanescu G., Risso M. Optimization of continuous mixed-flow grain dryers by constructal theory. Int. J. Heat Technol. 2016;34(1):S151–S160. doi: 10.18280/ijht.34sp0120. Special Issue. [DOI] [Google Scholar]

- 36.Oksanen T. Controlling airflow in recirculating mixed flow batch dryer with double bed mode. Comput. Electron. Agric. 2018;149:133–138. doi: 10.1016/j.compag.2017.07.018. [DOI] [Google Scholar]

- 37.Yahya M., Fahmi H., Hasibuan R. Experimental performance analysis of a pilot-scale biomass-assisted recirculating mixed-flow dryer for drying paddy. Int. J. Food Sci. 2022;2022:1–15. doi: 10.1155/2022/4373292. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Abubakar S., Umaru S., Kaisan M.U., Umar U.A., Ashok B., Nanthagopal K. Development and performance comparison of mixed-mode solar crop dryers with and without thermal storage. Renew. Energy. 2018:1. doi: 10.1016/j.renene.2018.05.049. –37. [DOI] [Google Scholar]

- 39.Sileshi S.T., Hassen A.A., Adem K.D. Drying kinetics of dried injera (dirkosh) using a mixed-mode solar dryer. Cogent. Eng. 2021;8(1956870):1–19. doi: 10.1080/23311916.2021.1956870. [DOI] [Google Scholar]

- 40.Mondal H.T., Hossain A., Sheikh A.M., Akhtaruzzaman M., Sarker S.H. Energetic and exergetic investigation of a mixed flow dryer : a case study of maize grain drying. Dry. Technol. 2020;0(0):1–15. doi: 10.1080/07373937.2019.1709077. [DOI] [Google Scholar]

- 41.Oli P., Ward R., Adhikari B., Torley P. Parboiled rice: understanding from a materials science approach. J. Food Eng. 2014;124:173–183. doi: 10.1016/j.jfoodeng.2013.09.010. [DOI] [Google Scholar]

- 42.Weigler F., Mellmann J., Franke G., Scaar H. Experimental studies on a newly developed mixed-flow dryer. Dry. Technol. 2013;31(15):1736–1743. doi: 10.1080/07373937.2013.806929. [DOI] [Google Scholar]

- 43.Ye L., El-mesery H.S., Muzamal M., Shi Y., Zicheng H., Alshaer W.G. Analysis of energy and specific energy requirements in various drying process of mint leaves. Case Stud. Therm. Eng. 2021;26(101113):1–13. doi: 10.1016/j.csite.2021.101113. [DOI] [Google Scholar]

- 44.Ashfaq S., Ahmad M., Munir A. Design, development and performance evaluation of a small-scale solar assisted paddy dryer for on farm processing. Mehran Univ. Res. J. Eng. Technol. 2016;35(2):217–228. [Google Scholar]

- 45.Mota F.A.S., Carvalho E.P., Ravagnani M.A.S.S. Heat Transfer Studies and Applications. INTECH; 2015. Modeling and design of plate heat exchanger; pp. 165–199. [Google Scholar]

- 46.Hossain M.Z., Hossain M.A., Awal M.A., Alam M.M., Rabbani A.H.M.M. Design and development of solar dryer for chilli drying. Int. J. Res. 2015;2(1):1–17. [Google Scholar]

- 47.Forson F.K., Nazha M.A.A., Akuffo F.O., Rajakaruna H. Design of mixed-mode natural convection solar crop dryers : application of principles and rules of thumb. Renew. Energy. 2007;32:2306–2319. doi: 10.1016/j.renene.2006.12.003. [DOI] [Google Scholar]

- 48.Bagheri N., Keyhani A., Mohtasebi S.S., Alimardani R., Rafiee S., Mansoori G.H. Design, construction and evaluation of a fan speed controller in a forced convection solar dryer to optimize the overall energy efficiency. J. Agric. Sci. Technol. 2011;13:503–515. [Google Scholar]

- 49.Mutuli G.P., Mbuge D.O. Drying characteristics and energy requirement of drying cowpea leaves and jute mallow vegetables. Agric. Eng. Int. CIGR J. 2015;17(4):265–272. [Google Scholar]

- 50.Ali A., et al. Development of a low-cost biomass furnace for greenhouse heating. Sustainability. 2021;13(5152):1–16. doi: 10.3390/su13095152. [DOI] [Google Scholar]

- 51.Cengel Y.A., Ghajar A.J. fifth ed. McGraw-Hill; 2015. Heat and Mass Transfer: Fundamentals and Applications. [Google Scholar]

- 52.Zou Y., Yang T. Rice Bran and Rice Bran Oil. Elsevier Inc.; 2019. Rice husk, rice husk ash and their applications; pp. 207–246. [Google Scholar]

- 53.Bautista E.U., Aldas R.E., Gagelonia E.C. Proceedings of an International Conference Held at the FAO Regional Office for Asia and the Pacific. Bangkok; Thailand: 1978. Rice hull furnaces for paddy drying : the philippine rice research institute s experience; pp. 253–260. 17-20 October 1995. [Google Scholar]

- 54.Tsilingiris P.T. Wall heat loss from intermittently conditioned spaces-The dynamic influence of structural and operational parameters. Energy Build. 2006;38(8):1022–1031. doi: 10.1016/j.enbuild.2005.11.012. [DOI] [Google Scholar]

- 55.Carvill J. Thermodynamics and heat transfer. Mech. Eng. Data Handb. 1993:102–145. doi: 10.1016/B978-0-08-051135-1.50008-X. [DOI] [Google Scholar]

- 56.Motevali A., Minaei S., Khoshtagaza M.H. Evaluation of energy consumption in different drying methods. Energy Convers. Manag. 2011;52(2):1192–1199. doi: 10.1016/j.enconman.2010.09.014. [DOI] [Google Scholar]

- 57.Marine M., Manual E.S., Leese H. The design of a closed-type- impeller blower for a 500kg capacity rotary furnace. AU J. Technol. 2008;12(1):50–56. [Google Scholar]

- 58.Myaing K.T., Win H.H. Design and analysis of impeller for centrifugal blower using solid works. Int. J. Sci. Eng. Technol. Res. 2014;3(10):2138–2142. [Google Scholar]

- 59.Hussein J., Hassan M., Kareem S., Filli K. Design, construction and testing of a hybrid photovoltaic (PV) solar dryer. Int. J. Eng. Res. Sci. 2017;3(5):1–14. doi: 10.25125/engineering-journal-ijoer-may-2017-4. [DOI] [Google Scholar]

- 60.Feldmeier S., Schwarz M., Wopienka E., Pfeifer C. Categorization of small-scale biomass combustion appliances by characteristic numbers. Renew. Energy. 2021;163:2128–2136. doi: 10.1016/j.renene.2020.10.111. [DOI] [Google Scholar]

- 61.Tefera S., Aragaw M., Molla T. Agro-morphological and physiochemical studies of upland rice (Oryza sativa L.) varieties for variability with yield and quality-related parameters in south Gondar district, Ethiopia. Heliyon. 2023;9(4) doi: 10.1016/J.HELIYON.2023.E15186. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Abera A.A., Tadesse E.E., Abera B.B., Satheesh N. Effect of rice variety and location on nutritional composition, physicochemical, cooking and functional properties of newly released upland rice varieties in Ethiopia. Cogent Food Agric. Jan. 2021;7(1) doi: 10.1080/23311932.2021.1945281. [DOI] [Google Scholar]

- 63.Satria D., Haryadi, Austin R., Kurniawan B. Design of drying chamber and biomass furnace for sun- biomass hybrid rice-drying machine. Sustain. Energy Adv. Mater. 2016;50015(1717):1–7. doi: 10.1063/1.4943490. AIP conf. proc. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data that has been used is confidential.