Abstract

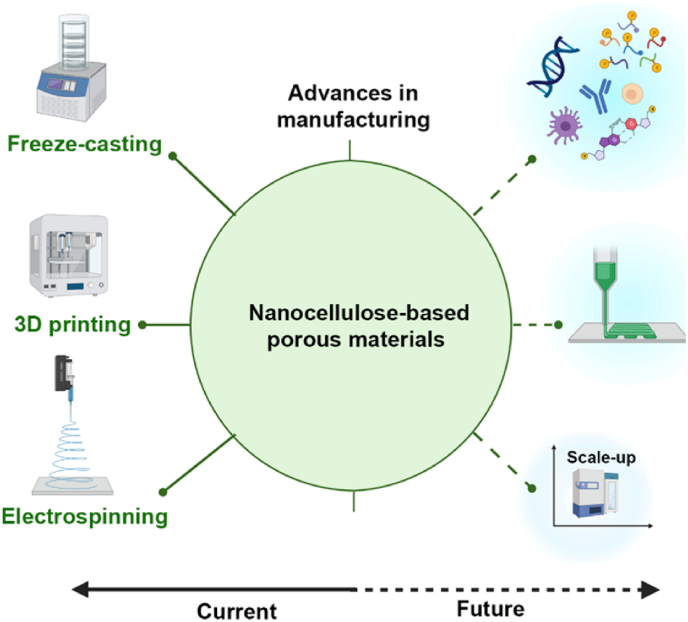

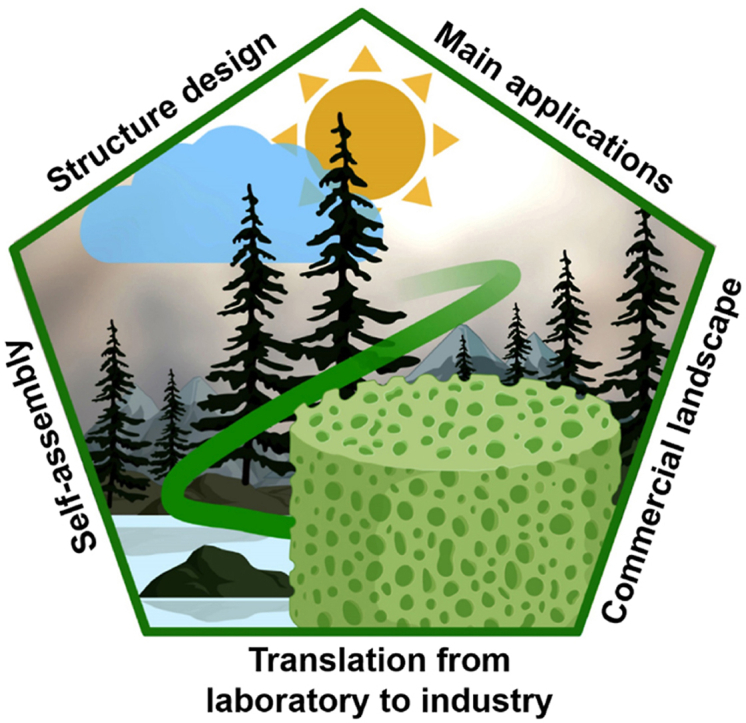

We review the recent progress that have led to the development of porous materials based on cellulose nanostructures found in plants and other resources. In light of the properties that emerge from the chemistry, shape and structural control, we discuss some of the most promising uses of a plant-based material, nanocellulose, in regenerative medicine. Following a brief discussion about the fundamental aspects of self-assembly of nanocellulose precursors, we review the key strategies needed for material synthesis and to adjust the architecture of the materials (using three-dimensional printing, freeze-casted porous materials, and electrospinning) according to their uses in tissue engineering, artificial organs, controlled drug delivery and wound healing systems, among others. For this purpose, we map the structure–property–function relationships of nanocellulose-based porous materials and examine the course of actions that are required to translate innovation from the laboratory to industry. Such efforts require attention to regulatory aspects and market pull. Finally, the key challenges and opportunities in this nascent field are critically reviewed.

Keywords: Cellulose nanofibrils, Cellulose nanocrystals, Regenerative medicine, Biomaterial, Sustainable materials, Green nanomaterials

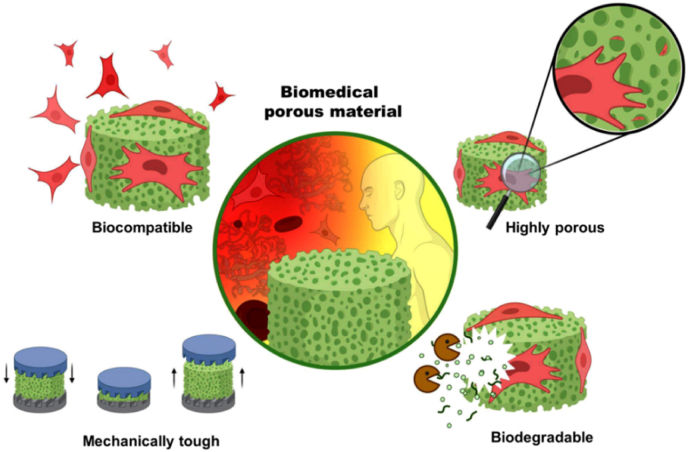

Graphical abstract

Highlights

-

•

Critical review of cellulose-based porous nanostructures in regenerative medicine.

-

•

Key concepts for engineering porous materials are presented.

-

•

Function-structure-property relationships at micro- and nano-scale are emphasized.

-

•

The commercialization pathway and regulatory challenges are highlighted.

1. Introduction

Polymeric materials are present in our daily lives in applications ranging from household products to airplane components [[1], [2], [3]]. A significant number of these polymers is derived from fossil hydrocarbons [4], which may be chemically unsafe in some contexts, for instance, either because they are generally harmful to wildlife and threatening aquatic ecosystems [5] or because the unintended release of chemicals used in their production, use, and disposal [6]. Moreover, because of their recalcitrant nature, low recycling rates, and poor waste management, nonbiodegradable materials have become a major concern [7,8]. Geyer et al. [9] estimated that approximately 8300 million metric tons of polymers were produced in 2017, and most of them were accumulated in landfills. If this trend continues, the adverse environmental problems will continue to increase by an order of magnitude by 2025 [10]. This global situation is troubling and has been the focus of the global policies [[11], [12], [13]]. In many actions, interdisciplinary research has shed light on bio-based and renewable resources to answer the dependence on fossil resources to prepare materials that find use in our daily lives [[14], [15], [16], [17], [18], [19]]. Recent breakthroughs concerning cellulose-based materials are increasingly relevant in these efforts, and it is anticipated that they may replace a fraction of the market of petroleum-based polymers [[20], [21], [22], [23], [24], [25], [26], [27]].

Cellulose is virtually an inexhaustible natural polymer responsible for the structural functions in plants. Hierarchically, the microfibrils of cellulose align in tightly packed assemblies held together by hydrogen bonds and van der Waal forces [[28], [29], [30]]. Deconstruction of such structure by mechanical, chemical, or combination of mechanical and chemical, or enzymatic processes results in fibrillated celluloses, cellulose nanofibrils (CNF) or cellulose nanocrystals (CNC) – collectively referred to as nanocelluloses [[31], [32], [33], [34]]. CNF and CNC are versatile materials for manufacturing multifunctional micro- and nano-scale lightweight and renewable building blocks useful for many applications [[35], [36], [37], [38]]. Such ability emerges from their unique assembly into hierarchical and multiphase systems, as summarized elsewhere [[39], [40], [41]]. However, some aspects, including the guidelines for the adoption of CNF and CNC to achieve synergistic integration into porous materials have not been fully understood. Moreover, the critical actions (i.e., regulatory aspects and market pull) that are required to translate innovation from the lab scales to industry were not considered in other review papers. Herein, we introduce recent advances in the construction of micro- and nano-scale porous structures based on CNF and CNC. We use the available knowledge on the assembly process to understand the design principles that take advantage of nanocellulose’s self-assembly features. We begin by briefly discussing the fundamental principles of nanocellulose chemistry and self-assembly. We then summarize the methods to integrate nanocellulose-based hierarchically porous structures, highlighting fundamental concepts and synthesis strategies. In particular, the critical features of surface interaction and wettability of CNF and CNC are discussed to modulate structure–properties relationship. This is accomplished from the design principles to the final performance in innovative applications in regenerative medicine. We conclude with an in-depth account on the future direction and opportunities for designing and fabricating such nanocellulose-based porous materials towards translation from laboratory to industry. This highly cross-disciplinary contribution will serve the scientific community, including those starting discoveries in the area of materials chemistry (e.g., self-assembly, cellulosic nanostructures, polymer nanocomposites, etc.), as well as practitioners interested in the translation, from innovation to commercialization. In sum, this review adds to current understanding of the nanocellulose-based porous materials engineering, paving the route for tailored design for versatile advanced applications, helping to overcome a major challenge that exists in the preparation of such materials, namely, achieving the control of design–performance relationship, as well as their commercialization.

2. Nanocellulose isolation, chemistry, and self-assembly

Nanocellulose isolation [[42], [43], [44]], chemistry [[45], [46], [47]], and self-assembly [44,48,49] have been discussed in depth in other review papers published in leading journals. Thus, these issues were not discussed in depth here. Briefly, nanocellulose isolation refers to the process of extracting and obtaining nanoscale cellulose structures from cellulose-rich sources [50]. Such process is a critical step in harnessing the potential of nanocellulose for a wide range of applications, and depending on the source, method, and chemicals used, the resulting nanocellulose can vary in structure and properties (i.e., crystallinity, morphology, aspect ratio, and surface chemistry) [51]. Nowadays, different methods have been used for isolating such materials [[52], [53], [54]], but the mechanical process and acid hydrolysis occupies an important position, representing the foremost route toward CNF and CNC isolation [[55], [56], [57]].

The chemistry on the surface of cellulose plays an important role in determining its properties and interactions with other materials. The abundant hydroxyl groups (–OH) enable modification of nanocellulose surfaces by catalytic [58], polymerizable [59], and ionic [60] groups, which are desirable to expand the application spectrum [61]. Surface functionalization of nanocellulose can also be achieved through coating processes, where a thin layer of another material is deposited onto the cellulose surface, imparting new properties such as barrier properties, adhesion, or optical characteristics [62,63]. By understanding and manipulating the surface chemistry, researchers can expand the potential of nanocellulose as a renewable and versatile material.

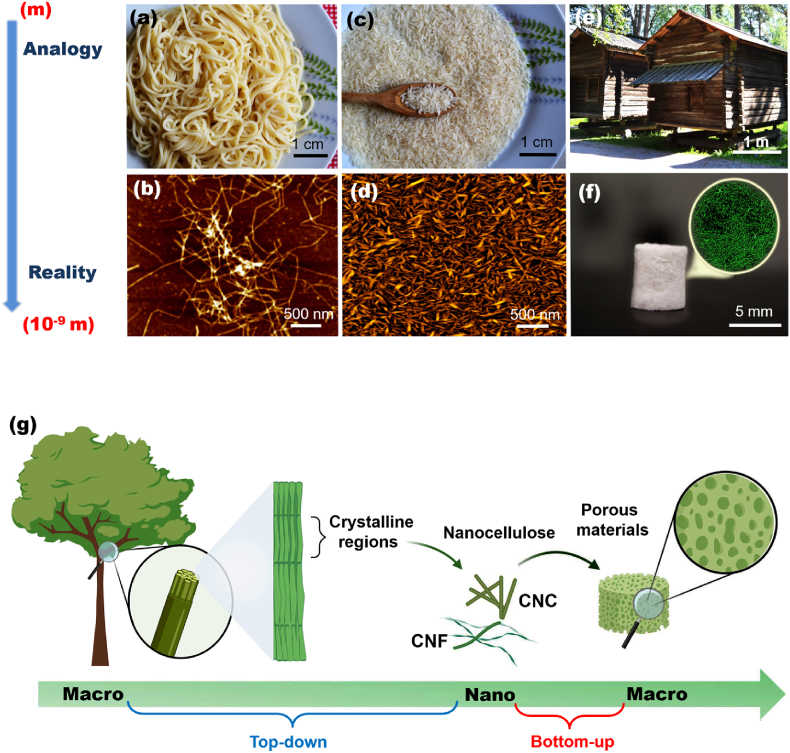

In contrast to CNF, which are plant nanofibers with a structure with high axial aspect ratio, measuring 5–500 nm in diameter and lengths of up to a few micrometers (Fig. 1a and b), CNC consists of a rod-like morphology (Fig. 1c and d), with lengths ranging from 100 to 1000 nm and diameter of 5–20 nm [64]. Other nanocelluloses properties include their crystallinity (especially for CNC) [65], versatility for surface modification [66,67], good mechanical properties (estimated elastic modulus and tensile strength in the range of 105–168 and 0.3–22 GPa, respectively) [68,69], and self-assembly ability [70]. This latter property has been extensively investigated for CNC [[71], [72], [73]]. Such self-assembly is driven by various intermolecular forces (e.g., hydrogen bonding and van der Waals interactions), which promote the alignment of nanocellulose [74]. This hierarchical organization process can be influenced by factors such as concentration, pH, temperature, and the presence of additives or surfactants [48,75]. By controlling the process, materials with desired characteristics (e.g., mechanical strength, optical properties, and responsiveness to environmental stimuli) can be can be achieved for different applications in the fields of packaging, tissue engineering, drug delivery, and sensors [44,49,76]. Other (bio)molecules (e.g., proteins [77]) and inorganic substances (e.g., transition metal oxide [78]) may also be used in the assembling processes [79] for fabricating functional materials [80].

Fig. 1.

(a) Spaghetti and (c) rice grains are visualized as analogues* to (b) CNF and (d) CNC that can be used in the construction of hierarchical structures, represented by a (e) traditional Finnish wooden house or (f) micro- and nanostructured cryogels. (g) Scheme to introduce the (a) top-down and bottom-up approaches to prepare nanocellulose-based porous functional materials. *Analogy for better understanding, differences must be taken into account, e.g., the flexibility of CNF is completely different from noodles.

Due to their outstanding properties, cellulose-based structures have been engineered, and promising results for different applications have been proposed [[81], [82], [83], [84]]. In particular, CNF and CNC have received a great deal of attention as precursors of porous structures (Fig. 1f). Two different approaches are used for the synthesis and production of cellulose materials, i.e., top-down and bottom-up methods [85]. Top-down is mainly related to the deconstruction of the larger cellulose structures (e.g., wood pulp or cellulose fibers) through physical or chemical treatment (e.g., mechanical disintegration, high-pressure homogenization, or chemical hydrolysis) to obtain nanoscale cellulose structures (i.e., CNC and CNF) [86]. On the other hand, bottom-up involves the assembly or synthesis of cellulose-based materials from such nanoscale cellulose structures [87]. In this approach, the materials are formed by self-assembly or controlled synthesis [88]. Overall, the choice of these approaches depends on the specific purpose and desired application [89]. Herein, we focus on bottom-up approach (Fig. 1g), where the extracted nanocellulose is assembled into porous functional materials.

3. Hierarchically porous materials - synthesis strategies and structure design

Nanocellulose-based porous structures are an emerging materials class and the integration with strategies used for their production enable designs with remarkable functions. In particular, we summarize the latest advances aimed at developing mechanical strength, porosity and orientation for uses in regenerative medicine. Herein, we highlight the fundamental concepts related to the strategies to achieve well-controlled nanocellulose-based porous materials, including three-dimensional (3D) printing, freeze-casted porous materials, and electrospinning.

3.1. Three-dimensional (3D) printing

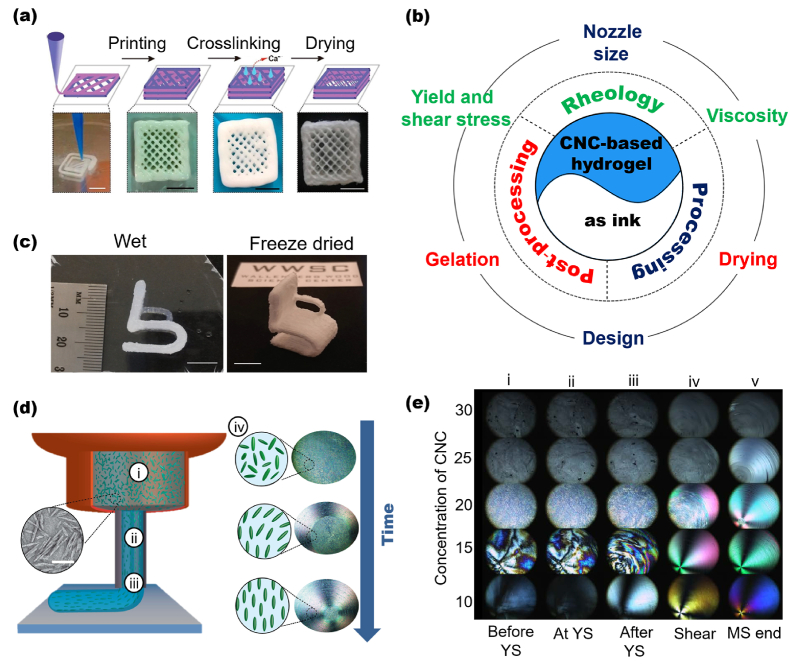

3D printing has been adopted as one of the main approaches for fabricating porous materials because it allows the preparation of complex structures that cannot be achieved with conventional manufacturing approaches [90,91]. The engineered porous materials are developed using computer-assisted technology and, generally, the 3D printing methods are primarily classified as extrusion, inkjet, laser-assisted, and UV-assisted printing [92]. Extrusion occupies an essential position among these methods due to its high throughput and compatibility with different inks [93]. The method is based on the extrusion of hydrogel inks which are then solidified as post-processing removes the solvent. A wide variety of natural and synthetic polymers can be employed as inks in 3D printing [94], including nanocellulose-based hydrogels. In this case, the nanocelluloses are seamlessly intertwined in a viscous hydrogel with both structural complexity and mechanical behavior modulated by the interaction of the cellulose chains, especially through crosslinking process (Fig. 2a) [95]. Adjusting the physicochemical parameters that affect nanocellulose-based hydrogel properties is one of the main strategies for preparing porous structures with shape fidelity and mechanical stability. Here, we review recent 3D printing innovations based on nanocellulose. Specific requirements that determine the printability of the hydrogel to achieve reliable fabrication of 3D constructs are illustrated in Fig. 2b and discussed next in more detail.

Fig. 2.

(a) 3D printed CNF-based cubic scaffolds (scale bar is 5 mm). (b) Main parameters that must be taken into account when preparing a material by 3D printing. Green: rheological properties (i.e., viscosity and shear stress); blue: processing (i.e., nozzle size and fabrication time); red: post‐processing (i.e., gelation and drying). (c) 3D printed small chair based on nanocellulose showing the high level of detail after freeze-drying. The scale bar corresponds to a 10 mm. (d) Scheme showing that 3D printing nozzles combined with shear and extensional flow can be used to tune the orientation of CNC. (di) CNC randomly organized; (dii) Aligned CNC due to maximized shear stresses through the nozzle; (diii) Final oriented extruded segment. (div) Alignment of CNC observed by polarized light imaging. (e) Alignment of a CNC as a function of concentrations and shear-stress. (ei) Before, (eii) at, and (eiii-iv) after yield stress (YS); (ev) at the end of the measurement. (a) Adapted from Ref. [95] with permission of Copyright 2019 American Chemical Society. (b) Inspired from Ref. [96]. (c) Adapted from Ref. [97] with permission of Copyright 2016 Wiley-VCH. (d–e) Adapted from Ref. [98] with permission of Copyright 2018 American Chemical Society.

The conversion of nanocellulose-based hydrogels into a dry 3D structure with good shape fidelity is one of the main challenges in 3D printing because cellulose chains can collapse upon drying, changing the printed form [97]. The rheological properties (i.e., viscosity, yield and shear stress), processing (i.e., nozzle size and design), and post‐processing (i.e., gelation and drying) are some of the main aspects to consider in the preparation of nanocellulose-based aerogels or porous materials by 3D printing [96].

Several 3D printing technologies can be used to manufacture synthetic heterogeneous nanocellulose-based porous materials such as stereolithography (SLA), digital projection lithography (DLP) and direct ink writing (DIW) [99,100]. Nanocellulose-based materials produced by DIW, an extrusion-based 3D printing approach, can be utilized in a wide range of materials of different sizes and geometries. The main challenges related to this technique relates to the development of viscoelastic inks that are ready for extrusion, and yet form self-supporting features after exiting the nozzle [101]. Thus, a printable ink should have shear thinning behavior; G′ >G″ with G′ of the order of few kPa and apparent yield stress of few hundred Pa [102].

The viscosity of inks can affect the printing fidelity and dictates its gelation, i.e., how quickly it needs to solidify [96]. Low zero-shear viscosity gives hydrogel inks a poor shape fidelity when printing and a slow gelling, leading to the collapse of the printed structure [103]. High viscosity inks may take less time to gelation, but very fast gelation can clog the needle during printing. In general, the hydrogel needs to be viscous enough to flow in the printer, becoming solid-like shortly after extrusion [104,105]. In this sense, the outstanding shear thinning properties of nanocellulose hydrogels allows flow from the needle when the stresses are present, but when deposited, a 3D structure made with relaxed hydrogel is formed [98]. Ink formulation must also be taken into account. For instance, a hydrogel with 5 wt% of CNC (low viscosity) and a hydrogel with 20 wt% CNC can polymerize both quickly (or in a very similar time) if a monomer and a photo-initiator were used [106].

Regarding cellulose chain collapse during gelation, it can also be controlled using different drying processes (e.g., air drying, solvent exchange before drying, and freeze-drying) [97,107] and/or through crosslinking [95,108]. In this sense, the high density of nanocellulose surface charges can tailor the gelation due to crosslinking [[109], [110], [111]]. Therefore, printed 3D structures with controlled architectures are preserved upon solidification (Fig. 2c). The combination of surface charged-nanocellulose and alginate can promote the crosslinking process, preparing post‐processed material with shape fidelity and sufficient mechanical stability [112]. The viscosity of the hydrogel can be conveniently controlled by nanocellulose concentration. Moreover, considering the relationship viscosity–gelation on fabrication time of the printed material, viscosity is also a key mechanism to control fabrication time [113].

Efforts to alter the hydrogel rheology – consequently, the mechanical behavior of the final material – have combined the nanocellulose with other polymers. Ajdary et al. [114] added CNF into poly(glycerol sebacate) (PGS) and polypyrrole (PPy) as an active component to alter the elasticity and flexibility of the printed material facilitating direct ink writing. Functional components such as carbon nanotubes [115,116], graphene [117], graphene oxide [118], and magnetic nanoparticles [119] have been added to the inks to open the development of 3D printed materials for different applications.

The nozzle size is an additional factor that influences both drop volume and shear stress, and consequently, the printed material properties [120]. Hausmann et al. [98] showed that 3D printing nozzles combined with shear and extensional flow could be used as effective means to tune the orientation of CNC, therefore, affecting the manufactured material’s microstructure and properties. The authors observed that the CNC might be aligned during extrusion due to the shear stress imposed on the suspension (Fig. 2d). During printing, the nanocrystals randomly distributed in the cartridge are then aligned due to high shear stresses that exist through the nozzle, resulting in a final oriented extruded segment (Fig. 2di-iii). Such alignment of CNC can be observed by polarized light imaging (Fig. 2div), and it is a function of CNC concentrations and shear-stress (Fig. 2e). Gladman et al. [121] took advantage of the extensional and shear forces experienced during DIW to align CNF building blocks while printing. They demonstrated how to create bilayer architectures with programmable anisotropic swelling by controlling the printing parameters and CNF orientation within the filaments, opening opportunities to create soft materials for tissue engineering, biomedical devices and soft robotics.

3.2. Freeze-casted porous materials

Freeze casting is a versatile, cost-effective, and rapid method for fabricating well-controlled porous structures based on nanocelluloses. Freeze-casting is well-suited to produce porous materials by using, for example, nontoxic (and inexpensive) precursors, eliminating or reducing the usage of solvents, and decreasing production cost. Traditionally, the processing occurs by two main processes: controlled solidification of wet foam/gel and sublimation of the solvent (such as water) under reduced pressure.

-

(i)

Controlled solidification of wet foam/gel: First, a multi-phase dispersion containing nanocellulose in a liquid phase (usually water) is considered. Other solvents, including ethanol, can also be used as pore-creating agents. However, intermediate steps involving solvent exchange may be required [122]. A critical step is to ensure the separation of nanocellulose by the liquid phase because these particles serve as building blocks (walls of the porous material) in the process [123]. In general, the separation step occurs when the interfacial free energies satisfy the following criterion (Equation (1)):

| (1) |

where, , and are the interfacial free energies associated with the particle/solid, particle/liquid, and solid/liquid interfaces, respectively [123].

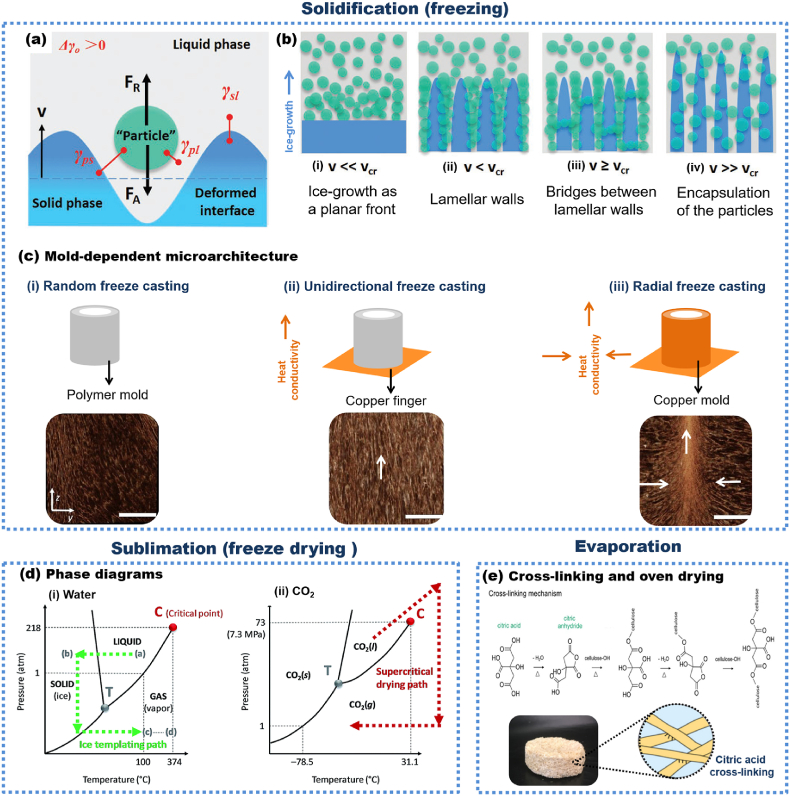

Phase separation occurs through solvent solidification (freezing). Thermodynamically, repulsive (FR) and attractive (FA) forces act on the particles at the liquid/solid interface during particulate suspensions (Fig. 3a). The final pore morphology of freeze cast materials is significantly affected by the relationship between freezing front velocity () and critical freezing front velocity , as illustrated in Fig. 3b and discussed by Shao et al. [123] Briefly, pores of freeze cast structures do not formed when freezing rates are very low (; Fig. 3bi). On the other hand, lamellar walls are obtained if (Fig. 3bii). When (Fig. 3biii), some nanocellulose can be entrapped by solid phase growth, yielding a different porosity scale than that observed otherwise. Finally, at very fast freezing rates (; Fig. 3biv), the encapsulation of nanocellulose within the ice front can occur [123]. The freezing process govern these freezing front velocities from freeze casting (i.e., in a freezer or liquid nitrogen) and the temperature gradient of mold material [124]. The columnar or lamellar morphologies can be achieved through unidirectional and radial freeze casting [125], whereas the size of the pores is scales with the solidification rate [126], given that fast freezing prevents the phases segregation [127]. Mariano et al. [128] tailored the porous orientation (Fig. 3c, white arrows) through heat conductivity of the mold material (i.e., freezing on copper is faster than polyethylene), which affect the ice-crystals growth direction, and the obtained porous structure.

Fig. 3.

(a) Forces acting on the particles at the liquid-solid interface during particulate in the vicinity of a freezing front. (b) Effect of freezing front velocity () and critical freezing front velocity on final pore morphologies of freeze cast material. (c) Mold-dependent microarchitecture of CNF-based cryogel - polyethylene copper molds (top) used for freezing CNF suspensions. X-ray microtomography reconstructions (μCT; bottom) of the obtained porous material (scale bar = 5 mm). (d) Phase diagrams of (di) water and (dii) carbon dioxide (CO2). (e) Cross-linked cellulose to prepare porous materials by evaporation in the oven. (a–b) Adapted from Ref. [123] with permission of Copyright 2020 Wiley-VCH. (c) Adapted from Ref. [128] with the permission of Elsevier. (d) Reproduced from Ref. [129] with permission from Copyright 2017 Royal Society of Chemistry. (e) Adapted from Ref. [130] with permission of Copyright 2020 American Chemical Society.

Importantly, along with pore tuning in terms of size and shape by freezing velocity, other variables offer opportunities to tailor the structure of freeze-cast materials. The generation of gas bubbles can achieve slight control of the size and shape of the formed pores through high-intensity stirring or air sparging [131]. In this sense, the porosity and orientation usually increase as bubbles and/or bubble orientation increase. The type of nanocellulose used (CNC, CNF) is critically important. Munier et al. [132] showed that unidirectional freezing of CNC dispersions leads to porous materials with the high alignment in the freezing direction. However, compared to the CNF (0.08 wt %), the concentration of particle concentrations should be increased using CNC (above 0.2 wt %), leading to 3D structures with high orientation. This behavior occurs because CNF forms a so-called “3D maze” of entangled nanofibrils at a very low solids content [133]. Such structure is especially beneficial where directional conduction is needed, e.g., for sunlight evaporators [134] and energy harvesting [135].

-

(ii)

Solvent Sublimation: The solidified solvent (suspension media) is removed by freeze-drying or supercritical drying (Fig. 3d) [129,136]. The process involves the removal of solidified suspension by lowering the pressure. No parameters have been reported to play a significant role in the development of micro- and macrostructures of the porous materials. In recent years, evaporation in ovens has been shown as alternative to replace freezing casting (solidification and sublimation). The mechanism of swelling and collapse for these porous materials involve unique cellulose-cellulose interactions [129]. The interaction forces between nanocellulose and solvent are essential to ensure the formation of distinct phases and to template removal by evaporation. During drying, the energetic cost of holding polymer chains separated should not be as significant as the energetic gain of the interaction due to hydrogen bonding between cellulose chains. Functional groups attached to the nanocellulose surface [137] and/or crosslinkers [138] can increase the energy cost for a collapsed conformation, allowing the preparation of porous materials based on nanocellulose with no need for freeze-casting. For instance, Ferreira et al. [130] prepared lignocellulosic foams by oven-drying sugarcane bagasse fibers cross-linked in the presence of citric acid (Fig. 3e).

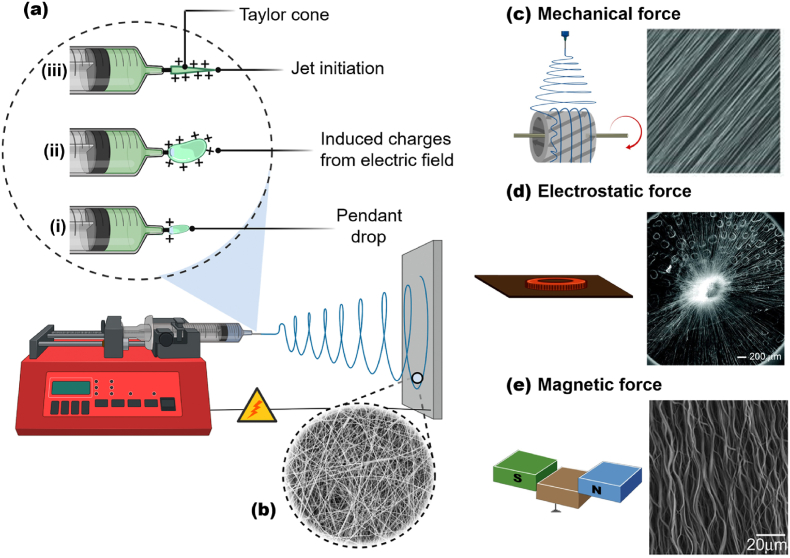

3.3. Electrospinning

Electrospinning is a versatile, simple, and useful technique that utilizes the electrostatic repulsion between surface charges of a polymer solution jet to fabricate micro- and nanofibers [139]. A generic electrospinning apparatus comprises a high-voltage power supply, a syringe, a syringe pump, and a grounded collector (Fig. 4a). Initially, surface-charged droplets (Fig. 4ai) are created by applying an electrical potential provided by a high-voltage power supply [140]. Then, the polymer solution is extruded from the syringe spinneret, generating a small conical droplet (Fig. 4aii), a Taylor cone [141]. Immediately, the droplet enters the “cone-jet” regime (Fig. 4aiii), and then the “whipping instability” regime, where the diameter of the jet is decreased over time while the solvent evaporates [142]. The final material is usually collected as a nonwoven mat composed of fibers with diameter from micrometers down to tens of nanometers (Fig. 4b). Pore structure and, especially, fiber orientation can be controlled by adjusting the experimental conditions, using rotating mandrel (Fig. 4c) [143,144], metallic materials (Fig. 4d) [145,146], and permanent magnets (Fig. 4e) [[147], [148], [149], [150]].

Fig. 4.

(a) Traditional electrospinning apparatus containing a high-voltage power supply, a syringe with spinneret, a syringe pump, and a grounded collector. Schematic illustration of electrospun fibers preparation: (ai) formation of surface charged droplets (aii) extrusion of the solution from the syringe generating a tiny conical droplet. (aiii) “Cone-jet” regime where a fine jet initiates from the cone. (b) SEM images of electrospun fibers randomly oriented. Electrospinning set-ups, such as (c) mechanical, (d) electrostatic, and (e) magnetic forces to adjust pore structure and fiber orientation. The right column shows the aligned nanofibers prepared by different electrospinning set-ups. (a–b) Schematic diagram inspired from Ref. [140]. (c–e) Schematic diagram inspired from Ref. [149]. (c; right column) Adapted from Ref. [149] with permission of Copyright 2011 Wiley-VCH. (d; right column) Adapted from Ref. [145] with permission of Copyright 2010, American Chemical Society. (e; right column) Adapted from Ref. [147] with permission of Copyright 2010 Wiley-VCH.

For electrospinning, and from the macromolecular point of view, nanocellulose should be dispersed in water-soluble, high molecular weight polymers. However, the processing flexibility enables the preparation of nanocellulose-based fibers using hydrophobic polymers. In such method, an additional step (e.g., saponification with NaOH/ethanol and/or freeze-drying) might be needed, as well as some solvent can be required, depending on the polymer used [151,152]. The amount of nanocellulose is intimately linked to the material’s microstructure (e.g., diameter, thermal and mechanical properties of the electrospun fibers). Shi et al. [153] prepared electrospun nanofibers of PLA reinforced with CNC from a solvent mixture consisting of N,N′-dimethylformamide, and chloroform at room temperature. The authors observed that the addition of CNCs up to 5 wt% improved the in vitro degradation, tensile stress and young’s modulus, and heat resistance of CNC-based electrospun fibers while decreased their average diameter. In this sense, many authors have studied how the addition of nanocellulose affects the overall properties of electrospun nanofibers. For instance, CNC affects the viscosity and electrical conductivity of the CNC-polymer solution. In particular, CNC can increase the viscosity of the solution, probably due to the formed network structure of within the polymer solution [[153], [154], [155]]. In contrast, the negative charges of CNC produced by sulfuric acid hydrolysis can decrease the electrical conductivity of the polymer solution [156].

Regarding the mechanical properties of nanocellulose-based electrospun fibers, in general, the high extensibility of the fibers (compared to ceramics-based counterparts) is unfavorable to maintain the shape and pore size but particularly useful to provide mechanical resistance to the fiber mat. These properties can be controlled by factors including individual fibers composition (e.g., polymer matrix), mechanical percolation, and nanocellulose interfacial adhesion. Improved mechanical performance can be achieved by direct links between nanocellulose and the polymer due to percolation threshold and surface interaction [157]. To support high loads on the fiber’s long axis, the preparation of aligned fibers is another alternative [158]. This approach is powerful if a biomedical application is envisioned because aligned fibers positively affect cell functions [145,159,160]. Specifically, anisotropy in topography and structure can be highly desired for tendon/ligament, neural, and cardiac tissue engineering [144,161,162], where the fibrils are aligned parallel and/or perpendicularly interwoven [149]. Yin et al. [161] studied the effects of nanotopography (aligned or random poly(l-lactide)-based nanofibers) on the differentiation of human tendon stem/progenitor cells (hTSPCs). A higher expression in hTSPCs growing in aligned nanofibers was observed. Zong et al. [163] prepared fine-textured electrospun scaffolds for heart tissue constructs and observed modulation of tissue structure as a function of chemistry and geometry of the scaffold surface.

Molecules or nanoparticles can also be added during electrospinning. However, it is essential to keep in mind that such “fillers” also affect the viscosity of the suspension and, consequently, the electrospun fibers' diameter. Nano–biotherapeutic emulsion formulated with both CNF and CNC and multifunctional active compounds, e.g., vegetable oils with antibiotic and antioxidant properties [164] and polypeptide nanoparticles [165], have been used in electrospun nanofibers with synergistic properties, including drug loading and release [166].

3.4. Comparison of 3D bioprinting, freeze-casting, and electrospinning

We highlight the versatility of nanocellulose for the preparation of hierarchically porous materials. 3D bioprinting, freeze-casting, and electrospinning are compared in Table 1 considering manufacturing aspects.

Tables 1.

3D bioprinting, freeze-casting, and electrospinning in the context of manufacturing.

| Method | Advantages | Disadvantages |

|---|---|---|

| 3D printing |

|

|

| Freeze-casting |

|

|

| Electro-spinning |

|

|

3D printing has become a compelling and universal method to prepare sustainable and versatile functional porous material. Complex structures such as blood vessels and organs can be engineered. However, 3D printing is a multi-step solvent-based technique [167,168]. Moreover, the drawbacks of shape fidelity and there are risks of collapsing cellulose chains upon drying (during post-processing). On the other hand, freeze-casting has been used as an “easy and green route” to prepare well-controlled porous structures based on nanocellulose. In this method, solidification (freezing) is crucial for templating and fabricating various structures with tunable pore sizes. Further aligned porous structures can be obtainable through recently developed freeze-casting techniques, which facilitate the material functionality across multiple fields of application [123]. However, unlike 3D printing, high structural complexity, e.g., tissue-like materials, is still challenging to engineer by freeze-casting nanocellulose-based materials. Electrospinning gained much attention as a processing route for aligned nanofibrous mats. However, although control of pore structure and fiber orientation can be achieved by this technique, it does not yield 3D structures and is challenging to scale-up. However, some recent work has demonstrated scalable ultrathin fibers in areas relevant to this review [169].

In sum, the presented approaches are suitable to develop porous materials based on nanocellulose with distinct porosity range, especially meso (2–50 nm) and macro (>50 nm) porous. These synthesis routes have the potential to be scale-up for industrial applications. However, scaling-up while maintaining precise and simultaneous control of the overall properties (i.e., porosity over pore geometries, mechanical performance, chemical functionalities, etc.) is still challenging. For instance, small changes in mass and heat transfer, are difficult to control, affecting the structure and consequently the properties of the fabricated porous materials [170]. In contrast to bottom-up approaches, top-down synthesis is an alternative to prepare hierarchically porous materials, taking advantage of the natural hierarchical structure of cellulose-based materials [171]. This approach does not necessarily use nanocellulose, but it can decrease time demanding manufacturing costs and energy needs.

4. Applications of nanocellulose-based porous materials

In recent years, CNF and CNC have been used to prepare highly porous biomaterials – or scaffolds– for regenerative medicine. Tissue engineering, in particular, is an important field that supports the formation of repair tissue that closely mimics native tissues [172]. Of the many scaffolds currently utilized for tissue engineering, those based on nanocellulose are quite promising [20,173,174]. In general, scaffolds should transduce changes in the physiological environment into therapeutic response [[175], [176], [177]]. For this purpose, biomedical materials should be biocompatible, highly porous, mechanically tough, bioactive, and biodegradable (Fig. 5) [173,178,179].

Fig. 5.

Main requirements for scaffolds applied in tissue engineering.

The biocompatibility of the scaffolds means minimal toxicity (i.e., medical therapy without eliciting any undesirable local or systemic effects in the recipient) and favorable biological interactions with the surrounding tissue (i.e., bioactivity). From the perspective of the tissue scaffold, efforts have been made to increase the bioactivity while maintaining the porous structure and tenability. Such efforts have led to a new generation of nanocellulose-based composites scaffolds and exciting prospects for application in clinical settings.

Porous materials are classified into three categories according to the International Union of Pure and Applied Chemistry - IUPAC [180]: microporous (<2 nm), mesoporous (2–50 nm), or macroporous (>50 nm). For biomedical applications, the porosity of scaffolds is critical to provide sufficient space for cell functions (i.e., growth, migration, and proliferation). Moreover, damaged tissue repair is hindered due to the lack of scaffolds vascularization. Since 30–40 μm is the minimum porosity required for proper scaffold vascularization [181], larger pores (160–270 μm) facilitate vascularization and gas exchange and nutrient transport in the scaffold, hence macropores materials are more appropriate for this purpose. Unfortunately, increasing porosity to promote the suitable biomimetic microenvironment for cell functions and neovascularization might compromise the mechanical strength of the material [173]. Regarding compression, crosslinking can facilitate the preparation of porous materials with versatile deformation and shape recovery behavior.

The mechanical properties of scaffolds should mimic the properties of the surrounding environment [182]. In this context, low porosity imparts better scaffolds' mechanical stability and provides applications in hard tissues; meanwhile more porous (softer) materials are better suited for soft tissues. In all cases there is a need for balancing a suitable mechanical performance and facilitating the proper nutrient diffusion and cell migration. These features can be tailored by the scaffold manufacturing process or by using covalent crosslinkers such as tannic acid [183], citric acid [184], and commercial products such as Kymene™ [185].

Scaffold biodegradation is essential for biomedical applications. Ideally, the material should be biodegraded at the same rate as the new tissue grows. Although most species in vivo do not have enzymes that hydrolyze nanocellulose, hence, exogenous enzymes can be administered to overcome such limitations. Nanocellulose-based materials have been extensively utilized as scaffolds for biomedical applications because they are biocompatible, show low cytotoxicity, and have the right wettability for cell functions [186,187]. Moreover, the high water content gives wet material a structural similarity to the extracellular matrix [188]. In the next section we review examples of CNC- and CNF-based structures in biomedical applications.

4.1. CNC in regenerative medicine

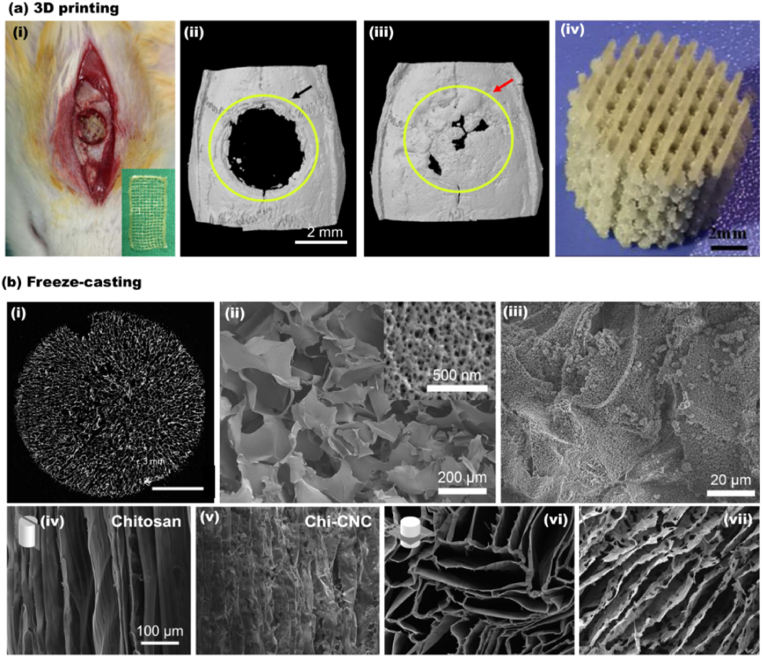

CNC has been employed to reinforce polymer matrices and to fabricate functional nanocomposites for bone and cartilage tissue engineering, dental composites, soft tissues, drug carriers, and wound healing applications [88]. 3D printing is particularly useful for fabricating customized tissue constructs, namely, simple biomimetic devices such as tissue-like materials (i.e., skin, bone, and cartilage). Also, the shear-induced alignment during hydrogel 3D printing facilitates the production of structures with controlled properties such as porosity and mechanical strength [98,102]. Such materials have been successfully fabricated and commercialized. Recently, Dutta et al. [189] developed 3D scaffolds based on alginate, gelatin, and CNC for bone tissue engineering. The CNC addition significantly increased the mechanical performance, mineralization efficiency, and the expression of osteo-specific gene markers. As shown in Fig. 6ai-iii, in vivo experiments with rat models demonstrated fast and high-density bone regeneration after three weeks of implantation. Patel et al. [190] prepared 3D printed compositions of alginate, gelatin, and CNC and achieved similar outcomes. Of relevance is CNC as a bio-based nucleation agent for bone repair purposes. For instance, Shuai et al. [191] demonstrated that the abundant hydroxyl groups in CNC interact with the poly-l-lactide (PLLA) molecular chains to increase the crystallization of the structure. Selective laser sintered of CNC/PLLA 3D scaffolds exhibited high fidelity (Fig. 6aiv), excellent biocompatibility, enhanced compressive modulus (351%), and strength (191%) compared with PLLA.

Fig. 6.

CNC containing 3D composites generated by 3D printing and freeze-casting. (a) 3D printed composite: (ai) The digital photograph of in vivo surgical examination with 3D printed CNC containing composite (CNC/Alg/Gel). The bone regeneration after 3 weeks in rat calvaria defect model. (aii) the negative control, and (aiii) the healed section [189]. (aiv) High fidelity 3D printed PLLA/CC composite [191]. (b) The 3D structures obtained by freeze-casting. (bi) A 2D slice of macroporous CNC structure. (bii) The cross-section SEM image of the macroporous aerogel at low and higher magnification (indicating the mesoporous CNC flakes). (biii) HA formation and coverage of CNC aerogel after CaCl2 pre-treatment and submersion in SBF for 7 days [122]. SEM images of a longitudinal cross-section of (biv) chitosan and (bv) chitosan-CNC scaffold frozen at the cooling rate of 10 °C/min. The SEM images of a transverse cross-section of (bvi) chitosan and (bvii) chitosan-CNC froze at a similar cooling rate of 10 °C/min (ai-iii) Adapted from Ref. [189] with permission of Copyright 2021 Elsevier. (aiv) Adapted from Ref. [191] with permission of Copyright 2020 Elsevier. (bi-iii) Adapted from Ref. [122] with permission of Copyright 2019 Elsevier. (biv-vii) Adapted from Ref. [192] with permission of Copyright 2019 American Chemical Society.

The freeze casting method has been used to prepare biomedical materials based on CNC. Scaffolds based on surface-modified CNC with sulfate (S) and phosphate (P) half ester group were developed by freeze-casting for bone tissue engineering. S–CNC freeze-casted scaffold was 89% porous, while P–CNC presented slightly less porosity (83%). Both CNC porous scaffolds were viable with Saos-2 cells and displayed hydroxyapatite growth in two weeks (Fig. 6bi-iii). The sulfated freeze-casted scaffolds demonstrated about 50% higher bone volume fraction than P–CNC after 12 weeks of implantation in Long Evans rats [122]. In another example, Yin et al. [192] studied equal mixed ratios of biocompatible chitosan and CNC for fabricating freeze-casted scaffolds for tissue engineering. The porosity, alignment of the pores, and mechanical performance were tunable by controlling the cooling rate during freeze-casting (Fig. 6biv-vii). It was also shown that blends of CNF and CNF improved the mechanical performance compared with that produced with neat CNC [192].

Other than 3D printing and freeze casting, CNC containing cast functional samples have been reported for biomedical applications. Athinarayanan et al. [193] developed HA/CNC nanocomposite from Phoenix dactylifera biomass and eggshell. HAP 10–50 nm crystals surrounded the 100–200 nm CNC and the structures exhibited nontoxic and biocompatible properties. This investigation highlights biomass valorization towards functional bioactive structures that can regenerate and rejuvenate bone microstructure. Al-Sabah et al. [194] studied the cast alginate/nanocellulose compositions for cartilage tissue engineering to study the impact of sterilization and CaCl2 crosslinking on the overall network construction and organization. The pore size enlarged, and the overall porosity decreased when the crosslinker concentration increased from 0.1 M to 1 M. Although the UV, autoclave, and ethanol immersion sterilization techniques demonstrated negligible differences in porosity and pore size, the Alginate/CNC composites displayed more than two times higher modulus when sterilized in ethanol.

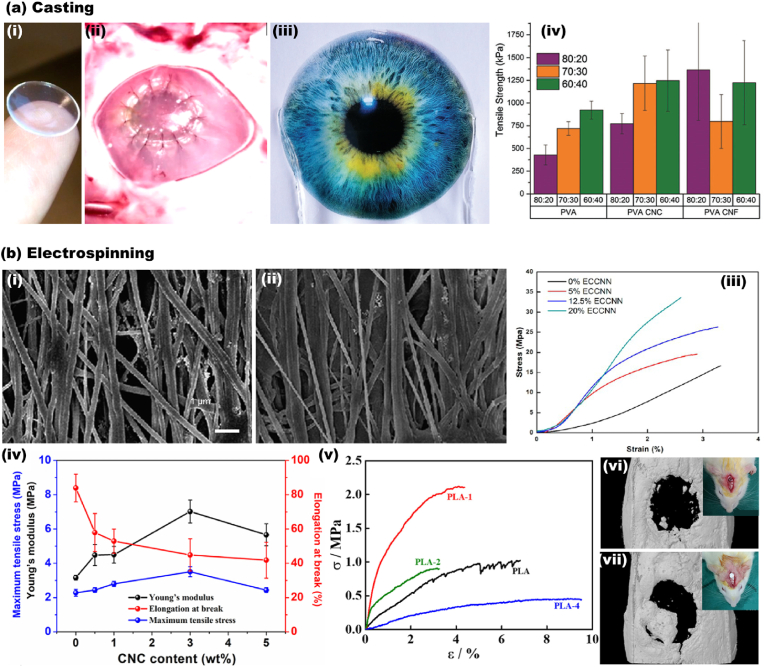

In other uses, Tummala et al. [195,196] fabricated high water content (93%) CNC-PVA contact lenses, Fig. 7ai-iv. The CNC reinforced contact lenses demonstrated excellent properties, including optical transparency (>95%), hyperelastic rubber-like mechanical performance, oxygen permeability (66 × 10−11 [(cm2/s) (mL O2/mL × mm Hg)]), and biocompatibility. The properties of the obtained soft tissue mimicked the cornea’s constituents and were comparable with commercial contact lenses.

Fig. 7.

CNC containing 2D composites produced by casting and electrospinning. (a) Casted structures. (ai) Casted PVA/CNC transparent hydrogel sheet in the form of self-standing contact lenses. (aii) Ex vivo implantation of the contact lenses to the porcine cornea [196]. (aiii) Coverage of the transparent CNC/CNF sheet on the lower half of the printed image. (aiv) The mechanical performance of the CNC/CNF sheet compositions and solvent ratios (DMSO/water) [195]. (b) Electrospun 2D composites. SEM images of electrospun cotton/CNC composites in (bi) 0% CNC and (bii) 20% CNC. (biii) The stress-strain curve demonstrating the mechanical performance of cotton/CNC electrospun structures [197]. (biv) The mechanical performance of electrospun PBS/CNC bio-nanocomposite in various CNC concentrations of (0–5 wt%) [198]. (bv) The stress-strain curve of electrospun PLA/CNC composite containing varying CNC amounts (0–4 wt%). In vivo surgical examination after 3 weeks in rat calvarial defect for the (bvi) negative control and the (bvii) repaired sample [199]. (ai-ii) Adapted from Ref. [196] with permission of Copyright 2016 American Chemical Society. (aiii-iv) Adapted from Ref. [195] with permission of Copyright 2017 Royal Society of Chemistry. (bi-iii) Adapted from Ref. [197] with permission of Copyright 2014 American Chemical Society. (biv) Adapted from Ref. [198] with permission of Copyright 2018 Elsevier. (bv-vii) Adapted from Ref. [199] with permission of Copyright 2020 Elsevier.

Biomedical ultrathin fibers based on CNC have been developed through the electrospinning technique. Zhou et al. [155] prepared electrospun nanofibrous maleic anhydride grafted poly(lactic acid) (MPLA) reinforced with CNC. First, MPLA was prepared, and then freeze-dried CNC was added to a mixture of chloroform and DMF (volume ratio 8/2). The authors observed that the addition of CNC (5 wt%) increased the material’s thermal stability (heat resistance) and tensile strength while decreasing in vitro polymer degradation. Moreover, such nontoxic scaffold was able to support cell proliferation. He et al. [197] fabricated CNC reinforced all-cellulose nanocomposites by an electrospinning device equipped with a rotating drum to obtain aligned nanofibrils, Fig. 7bi-ii. The addition of 20% of CNC to the cellulose dope (cotton dissolved in LiCl/DMAc) improved the elastic modulus and tensile strength by 171% and 101%, respectively (Fig. 7biii). Human dental follicle cells exhibited high viability to the electrospun scaffold and proliferated on both microstructure’s surface and bulk.

Huang et al. studied the CNC reinforcement of polybutylene succinate (PBS) electrospun nanocomposites. The addition of 3 wt% CNC improved the hydrophilicity of the nanocomposite and enhanced the modulus, tensile strength, Fig. 7biv. The PBS/CNC scaffolds were viable with fibroblast cells, and nanocomposites biodegradation increased from 4.5% for pure PBS to more than 13% for the CNC-containing sample. Patel et al. [199] studied the potential of poly(lactic acid) and CNC compositions. The strong interaction of CNC and polymer chains resulted in higher thermal stability and mechanical properties (Fig. 7bv). Also, cell adhesion and proliferation significantly improved, and a higher expression of osteogenic gene markers was noticed for the composite. After 3 weeks, the in vivo result confirmed the potential of PLA/CNC as osteoconductive biomaterial for bone tissue regeneration (Fig. 7bvi-vii).

Cellulose acetate (CA) has been used in cellulose-based materials by electrospinning [151,152]; however, post-processing such as saponification with NaOH/ethanol and/or freeze-drying may be required. Joshi et al. [152] prepared multilayered cellulose scaffolds for bone tissue engineering. A 2D electrospun mat was prepared and modified into a 3D cellulose sponge using gas foaming, which allowed the biomimetic mineralization of the material and enhanced cell proliferation and attachment. In the method proposed by Li et al. [151], electrospun cellulose nanofibers (CelluNF) were first fabricated using CA, and then their surface was modified by a phosphorylation reaction. The authors observed the formation of HA covering the nanofibers, showing potential for bone tissue engineering. Table 2 summarizes some of the recent efforts in CNC-based structures developed for regenerative medicine produced by 3D printing, freeze-casting, casting, and spinning.

Table 2.

Porous materials based on cellulose nanocrystals (CNC) and applied in regenerative medicine.

| Materials | Fabrication Method | Cell type | Application | Experimental conditions | Observations | Ref. |

|---|---|---|---|---|---|---|

| CNCa) | 3D printing | – | Tissue engineering | Nozzle diameter of 410 μm (22G), a flow rate of 70–120%, and a printing speed of 10–80 mm/s | Shear-induced alignment oriented the nanocrystal from 61 to 76% in the extrusion direction. Pore size: between 80 and 2125 μm. | [200] |

| CNC-chitosan | 3D printing | MC3T3-E1 pre-osteoblast | Bone tissue engineering | Nozzle diameter 610 μm (20 G), Extrusion pressure 12–20 kPa. Cell density 5 million/mL. The bioprinted scaffolds were incubated in DMEM in a 24-well tissue culture plate at 37 °C for 24 h. | The degree of shrinkage ranged between 30 and 34%. The scaffolds enhanced the osteogenic differentiation and collagen formation in ECM. | [201] |

| PLLA-CNC | 3D printing | MG-63 human osteosarcoma | Bone tissue engineering | The selective laser sintering optimized parameters were the spot size ∼200 μm, the laser power 7 W, the scanning speed 200 mm/s, and layer thickness of 150 μm. | The addition of 3 wt% CNC (nucleating agent) enhanced the compressive strength and modulus by 190% and 350%. | [191] |

| Alginate-gelatin-CNC | 3D printing | human bone-marrow-derived mesenchymal stem cells | Bone tissue engineering | Nozzle diameter 200 μm (27 G), printing pressure of 80–600 kPa, printing speed of 8 mm/s, printing temperature of 30 °C, print-bed temperature 6 °C | Effective load transfer from the polymer matrix to CNC (due to the larger interconnected network) significantly improved the mechanical performance. | [190] |

| Alginate-gelatin-CNC | 3D printing | Human bone marrow-derived mesenchymal stem | Tissue engineering | Cellulose nanocrystals (CNCs) from cotton pulps (10–20 nm width, 50–400 nm length, 12% solid content, crystalline index >70%), Nozzle diameter 200 μm (27 G), printing pressure of 100–500 kPa, printing speed of 5 mm/s, printing temperature of 35 °C, print-bed temperature 4 °C | CNC containing structures display enhanced mineralization efficiency and cell proliferation compared with the control sample | [189] |

| PEGDA-CNC | 3D printing | – | Tissue engineering | The digital light processing parameters included the projector intensity of 18 mW/cm2, the exposure time of each layer was 4 s, the thickness of each cured layer (curing layer thickness) was set at 100 μm | The properties of digitally light processed 3D composites can be tailored by curing time and layer thickness | [202] |

| Gelatin-bioactive glass- CNC | Freeze casting | L929-fibroblast | Bone tissue engineering | The structure was put into a refrigerator. under −20 °C for 24 h, and then lyophilized at −57 °C and 0.05 bar for 48 h | The addition of CNC, even in small amounts, has a considerable effect on the mechanical performance | [203] |

| Cross-linked CNC | Freeze casting | Saos-2 | Bone tissue engineering | All suspensions were frozen at −4 °C overnight to turn the suspension into a cryo-gel. The cryo-gels were then transferred into anhydrous ethanol for 5 days to form alco-gels. The alco-gels were placed inside of a critical point dryer and solvent exchanged with supercritical CO2 and gradually depressurized to ambient conditions to produce CNC aerogel. | No collapse of cryo-gels was observed during the solvent exchange, thereby making incremental ethanol exchanges unnecessary. Formation of hydroxyapatite layers, the proliferation of bone-like cells in vitro, and bone regeneration in vivo | [122] |

| Hydroxyapatite–CNC–silk fibroin | Freeze casting | MC3T3-E1 | Bone tissue engineering | The scaffolds were freeze-dried for 24 h in 48-well plate. Then the scaffolds were immersed in 90% (v/v) aqueous methanol solution for 30 min to induce a structural transition that generated the water-insoluble scaffolds. | The average pore size and porosity of the scaffolds were 110 ± 7.3 mm and 90 ± 6.2%, respectively. The calvarial bone defect in rat was healed during 12 weeks of scaffold implantation | [204] |

| PVA-ovalbumin–CNC– HA | Freeze casting | – | Bone tissue engineering | The polymer solution was poured into 24-well plate, and freezed at −40 °C for 12 h, followed by drying under vacuum at similar temperature for 5 days. | Most optimal composition PVA/OVA/CNCs/n-HA (20:05:10:15) exhibited promises for short term bone regeneration | [205] |

| Alginate- gelatin- CNC | Freeze casting | Mesenchymal stem | Cartilage tissue engineering | The scaffolds were freeze-dried at −75 °C for 24 h | Nanocomposites with 96% porosity with a modulus of 0.5 GPa (higher than natural cartilage) | [206] |

| CNC/CNF-alginate | Freeze casting | L929-fibroblast | Tissue repair and wound healing | The samples were frozen in liquid nitrogen (−196 °C) for 5 min, followed by a freeze-drying step at −50 °C for 48 h. The dried materials were then added to a bath of CaCl2 at 2 wt % for 24 h. Then, the gels were washed with distilled water and were frozen with liquid nitrogen and freeze-dried again. | ECM biomimetic structure with promising mechanical properties, bioadhesion, cytocompatibility | [207] |

| CNC/CNF-chitosan | Freeze casting | – | Tissue regeneration | The slurry was poured in a polytetrafluoroethylene tube and was sealed with a copper mold (bottom section). The mold was then placed on liquid nitrogen. The molds were equilibrated to 4 °C for 10 min before a cooling rate of either 10 or 1 °C/min was applied until the mold reached a temperature of −150 °C. The frozen slurries for 72 h at 0.008 mbar and a coil temperature of −85 °C. | Obtaining structures with high porosity and surface area with controllable pore alignment | [192] |

| CNC/CNF-PVA | Casting | Human corneal epithelial | Soft contact lenses and cornea regeneration implants | The cast gels were placed at −20 ᵒC for 24 h followed by at least 48 h dialysis with deionized water. | Structures with higher water content and biocompatibility compared with commercial contact lenses | [195,196] |

| Dental glass ionomer cement- CNC | Casting | – | Dental composites | In addition to 0.4 wt% CNC, the compressive strength and tensile strength improved by 110% and 161%, respectively. | [208] | |

| Crosslinked CNF/CNC-alginate | Casting | Human naso-septal chondrocytes | Cartilage tissue engineering | Crosslinking was performed at room temperature using 0.1 M, 0.5 M or 1.0 M calcium chloride (CaCl2). | Different crosslinking and sterilization conditions had a considerable impact on the microstructure architecture. | [194] |

| PCL-CNC | Casting and extrusion | Mouse preosteoblast | Bone tissue engineering | Prior to extrusion the caster films were placed in vacuum oven at 40 °C for 24 h | By the addition of 10 wt% CNC, the stiffness was doubled, and the ultimate tensile strength increased by 60% | [209] |

| HA-CNC | Casting | human mesenchymal | Bone tissue engineering | The hybrid structure was dried at ambient condition | The CNC-based nanohybrids from agro-waste were biocompatible, nontoxic, and it enhanced the calcium nodule growth | [193] |

| Cellulose acetatepropionate-CNC | Casting | – | Tissue engineering | After casting the suspension, a 0.3 T magnetic field was applied for 1 h at room temperature and the structures were kept for another 1 h without the magnetic field | Alignment of CNC under weak magnetic field effectively enhanced the mechanical performance (even at 0.2 wt% CNC addition) | [210] |

| Rosin-g-CNC | – | – | Antimicrobe structures | – | Strong and medium antibacterial activity was observed against Gram-negative and Gram-positive bacteria, respectively | [211] |

| Porphyrin-CNC | – | M. smegmatis, E. coli and S. aureus bacteria strains | Antimicrobe structures | – | Development of photobacterial materials with high efficiency against Gram-negative, Gram-positive, and mycobacterium | [212] |

| Polyrhodanine-CNC | – | HeLa (ATCC CCL-2) | Antimicrobe structures | – | Core-sheath antimicrobial nanoparticles with killing efficiency of over 95% E.coli and B. subtilis | [213] |

| CNF–CNC | Electrospinning | Human dental follicle | Artificial organ | The operating voltage of 20 kV, flow rate 0.03 mL/min, A steel rotating collector (6 cm in diameter) wrapped with aluminum foil was placed 10 cm away. The tangential velocity of the collector was set at 300 m/min | All cellulose nanocomposite with high fiber alignment. | [197] |

| PBS-CNC | Electrospinning | 3T3 fibroblast | Tissue engineering | The operating voltage of 20 kV, flow rate 1.0–2.0 mL/h and the distance between the electrodes was 18 cm. | The in vitro degradation displayed to increase from 4.5% for pure PBS to about 14% for PBS-CNC (3 wt% CNC) during 28 days. | [198] |

| PLA | Electrospinning | – | Short-term applications in the tissue engineering | The operating voltage of 15 kV, flow rate 1.5 mL/h and the distance between the electrodes was 20 cm. The obtained fibers were collected as mats, and were vacuum-dried at 80 °C for 24 h. | Improvement in heat resistance, tensile stress, young’s modulus, In vitro degradation | [153] |

| PAN-CNC | Electrospinning | – | Dental composites | The operating voltage of 17.2 kV, flow rate 2.0 mL/h and the distance between the electrodes was 20 cm. | The addition of 3 wt% CNC resulted in a significant increase in flexural and fracture strength. | [214] |

| PLA-CNC | Electrospinning | Human bone marrow-derived mesenchymal stem | Bone tissue engineering | The operating voltage 16 kV, distance between the electrodes 15 cm, and rolling speed of the collector was 2000 rpm. | Excellent biocompatibility and promising osteoinductivity was obtained according to in vivo studies during three weeks | [199] |

| PEG-g–CNC–PLA | Electrospinning | Human mesenchymal stem cells | Bone tissue engineering | The operating voltage of 20 kV, flow rate 0.5 mL/h and the distance between the electrodes was 15 cm, and 18 G blunt stainless-steel needle. The obtained fibers were collected as mats and were vacuum-dried at 80 °C for 24 h. | The addition of PEG improved the biocompatibility of the composite | [215] |

| MAH-g-PLA | Electrospinning | Adipose-derived mesenchymal stem | Bone tissue engineering | The operating voltage of 15 kV, flow rate 1.5 mL/h and the distance between the electrodes was 20 cm, The obtained fibers were collected as mats and were vacuum-dried at 80 °C for 24 h. | Improvement in heat resistance and tensile strength. Reduction in vitro degradation rate. Capable of supporting cell proliferation. | [155] |

| PCL-CNC | Electrospinning | – | Controlled drug delivery | The operating voltage of 17 kV, flow rate 0.9 mL/h and the distance between the electrodes was 16 cm. | Addition of CNC enhanced the tensile strength and modulus by 46% and 47% | [216] |

| Alginate- gelatin- CNC | Injectable hydrogel | 3T3 fibroblast/MC3T3-E1 osteoblast | Bone regeneration | Injection with 18 G nozzle followed by the addition of 10.5 mL 0.05 M ZnSO4 (ionic crosslinking). | The presence of CNC enhanced the hydrogel/cell interactions | [217] |

CNC, cellulose nanocrystal; PLLA, Poly-l-lactic acid; PEGDA, Poly(ethylene glycol)diacrylate; PVA, Polyvinyl alcohol; HA, Hydroxyapatite; CNF, Cellulose nanofibrils; PCL, Polycaprolactone; PBS, Polybutylene succinate; PLA, Polylactic acid; PAN, Polyacrylonitrile; PEG, Polyethylene glycol; MAH, Maleic Anhydride. ECM, extracellular matrix.

4.2. CNF in regenerative medicine

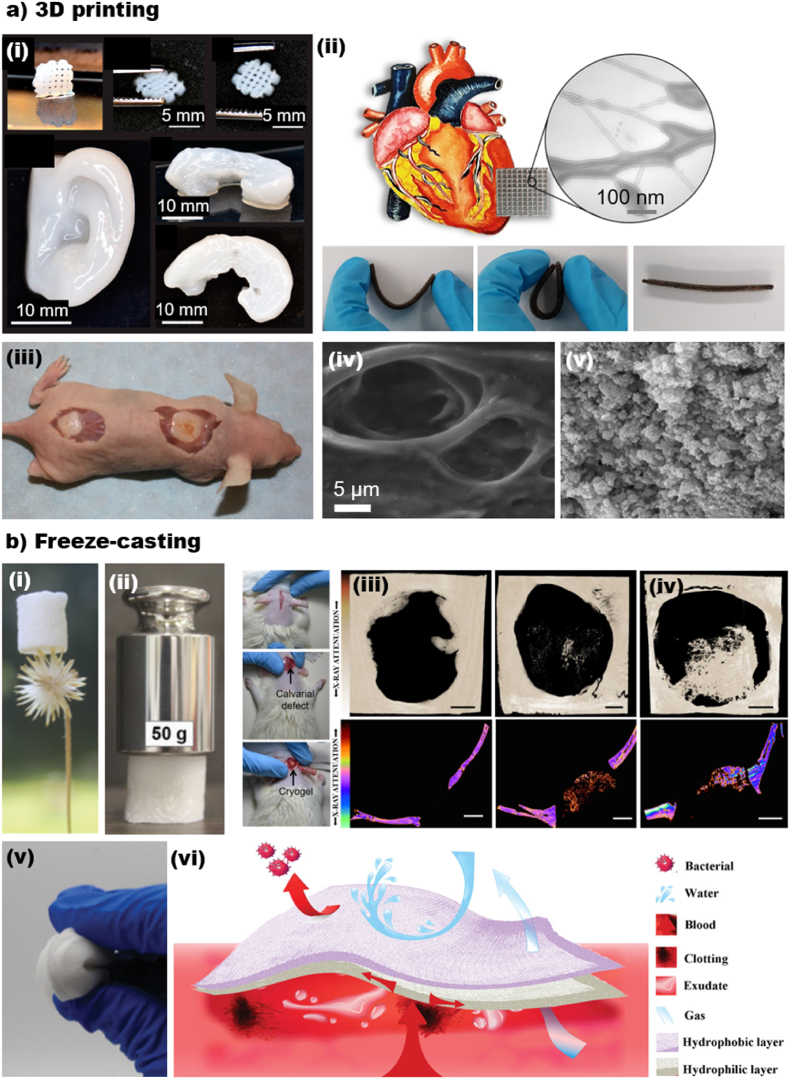

CNF-based structures have been reported for regenerative medicine. CNF aqueous suspension is similar to the extracellular matrix (ECM) and demonstrates sufficient mechanical stability for secondary cell culture purposes, even in their pure form and with no addition of polymers/particles [[218], [219], [220]]. However, to obtain properties beyond biocompatibility and cell interaction, polymers or (nano)particles are added to CNF suspension to fabricate hybrid or composite materials, allowing the incorporation of additional functionalities or the enhancement of specific properties [221,222]. In this sense, nanocellulose can be combined with bioactive materials, such as metallic or magnetic (nano)particles [223], quantum dots [224], bioactive glass [225] and so on [226]. Such particles can be easily integrated into the nanocellulose matrix by surface functionalization, electrostatic interactions or simply mixing during the scaffold preparation process, providing unique functionalities, such as antimicrobial activity [227], imaging capabilities [228], and stimuli-responsive behavior [229,230]. Thus, the successful hybridization of nanocellulose with bioactive nanoparticles holds great promise for a wide range of biomedical applications. In this direction, Markstedt et al. [112] prepared 3D bioprinted shapes resembling cartilage tissues using a bio-ink consisting of CNF and alginate at room temperature and low pressure (critical features to work with living cells). The authors successfully printed an ear and a meniscus (Fig. 8ai) with good shape fidelity and showed biocompatibility and suitability for cell culture (human nasoseptal chondrocytes - hNC).

Fig. 8.

CNF containing 3D composites generated by 3D printing and freeze-casting. (ai) 3D printed small grids (7.2 × 7.2 mm2) with shape recovery behavior, 3D printed human ear, and 3D printed sheep meniscus [112]. (aii) Electrically conductive, elastic, drug-loaded cardiac patch based on TOCNF/PGS/PPy. Shape recovery and flexibility of the cardiac patch [232]. (aiii-iv) The SEM images of CNF-based structure (aiii) before and (aiv) after mineralization for bone tissue engineering application [233]. (bi-ii) Light-weight and strong composite based on CNF and bioactive glass (CNF/BG) for bone tissue engineering. The (biii) negative control and the (biv) the rat calvarial regeneration after 56 days of scaffold implantation of CNF/BG [225]. (bv-vi) Janus flexible sponges based on CNF for wound healing application and treatment of hemorrhagic wounds [234]. (ai) Adapted from Ref. [112] with permission of Copyright 2015 American Chemical Society. (aii) Adapted from Ref. [232] with permission of Copyright 2020 Wiley-VCH. (aiii-iv) Adapted from Ref. [233] with permission of Copyright 2018 American Chemical Society (bi-iv) Adapted from Ref. [225] with permission of Copyright 2019 Royal Society of Chemistry. (bv-vi) Adapted from Ref. [234] with permission of Copyright 2020 Wiley-VCH.

Ajdary et al. [114] combined poly(glycerol sebacate) (PGS), polypyrrole (PPy), and 2,2,6,6-tetramethylpiperidine-1-oxyl radical-oxidized nanocellulose (TOCNF) to prepare cardiac patches with good elasticity, flexibility, and electrical conductivity for treatment of cardiovascular diseases (Fig. 8aii). The samples were prepared by 3D printing, followed by freeze-drying. The scaffolds performed as a mechanical support for cells and promoted reorganization into functional tissue. Moreover, the slow degradation of the printed scaffold could prevent the burst release of drugs, which is suitable for long-term delivery for therapies. Kuzmenko et al. [231] fabricated other CNF-carbon nanotubes (CNT) conductive hydrogels for neural guideline application. In their work, shear-thinning inks of CNF/CNT were mixed and 3D printed to form thin guidelines of less than 1-mm diameter. The neural guidelines displayed electrical conductivity and exhibited high viability with neural cells.

Several studies have demonstrated the high potential of 3D printable CNF/alginate compositions for cartilage tissue engineering applications [112,194,207,233,[235], [236], [237]]. For instance, Möller et al. [236] bioprinted cell-laden CNF/alginate scaffolds to investigate the clinical relevance for chondrogenesis. The cell-containing samples retained their integrity up to 60 days in vivo and displayed potential for cartilage reconstruction application. However, cell-laden inks are usually affected by the imposed shear during the printing process, and the challenges to reproduce a structure with comparable mechanical properties to natural human cartilage still exist. Abouzeid et al. [233] studied crosslinked CNF/alginate compositions for bone tissue engineering. The equal mass ratio of CNF and alginate demonstrated compressive strength of 455 MPa (87 MPa for pure CNF) and modulus of 1511 MPa (135 MPa for pure CNF) after crosslinking. After 14 days of mineralization, the hydroxyapatite content of the scaffold was evaluated to be around 20% with the average crystal size of 25.4 nm (Fig. 8aiii-iv).

CNF freeze-casting has also been a facile approach to develop scaffolds for tissue engineering applications. For example, Carlström et al. [238] investigated compositions of crosslinked CNF and gelatin for bone tissue regeneration and tuned the biodegradation rate of gelatin when combined with CNF. The compositions exhibited higher mechanical properties and lower degradation rates. After crosslinking, the porosity decreased from ca. 90% for pure CNF to 70% for CNF/gelatin, while the surface area of the composite more than doubled.

Ferreira et al. [225] developed bioactive, biocompatible, and strong freeze-casted cryogels from CNF and bioactive glass for bone tissue regeneration (Fig. 8bi). The low-density cryogels comprised 80% bioactive glass and 20% CNF on a dry basis and resisted high compressive loads, up to over 1250 times cryogels' original weight (Fig. 8bii). The cryogels displayed remarkable performance in vivo with no damage to the excretory environment and effective bone formation during 56 days of the examination (Fig. 8biii-iv). Tang et al. [239] studied the compositions of CNF/polyethylene glycol diacrylate (PEGDA) for cartilage tissue engineering. CNF was performed as supporting material in their work and facilitated the structure with mechanical integrity and high porosity of up to 90% (porosity less than 10% in pure PEGDA). This enhancement in the porosity significantly impacted the cell viability and proliferation of the NIH 3T3 cells on CNF/PEGDA scaffolds.

Beyond bone and cartilage tissue engineering, CNF-based freeze-casted scaffolds have been applied for skin tissue regeneration and wound healing purposes. To illustrate, Ghafari et al. [240] produced CNF/polyvinyl alcohol (PVA) bilayers inspired from the dermis and epidermis in the skin top layers. The first skin mimic layer, dermis, comprised 0.4 wt% CNF and 0.1 wt% PVA, and the second layer, epidermis, was made from 1.4 wt% CNF and 0.35 wt% PVA. As in the actual skin, the first layer had less bulking density and higher water uptake. The overall porosity of dermis and epidermis biomimetic structures were more than 95% and 88%, respectively, and both layers provided a suitable microenvironment for fibroblasts and keratinocyte cells to adhere and proliferate. Cheng et al. [234] combined cross-linked CNF/organosilanes and chitosan to prepare Janus sponges, which showed high effectiveness for treating hemorrhagic wounds. The Janus sponges displayed a shape-memory and remarkable flexibility in wet conditions. Compared to the common gauze, the Janus sponges displayed 49% blood loss reduction, indicating potential for wound dressing (Fig. 8bv-vi).

As indicated earlier, electrospinning is a promising technique to obtain porous interconnected structures. CNF has been used as a bio-based reinforcing agent in combination with polymers such as PLA, PBS, etc. For example, Abudula et al. [241] produced PLA/PBS/CNF electrospun nanofibers for vascular tissue engineering purposes. The CNF addition tuned the nanofiber diameter to around 270 nm and resulted in more homogeneous fiber morphology than pure PLA and PBS. CNF-containing composites absorbed antibacterial enzyme lysozyme and exhibited a higher biodegradation rate in the presence of Proteinase K enzyme. Joshi et al. [152] investigated the saponified electrospun cellulose acetate nanofibers post-treated with sodium borohydride solution. The post-treatment enhanced the porosity and decreased the packing of the nanofibers to form 3D spongy scaffolds with enhanced hydroxyapatite mineralization and cell interactions. Table 3 summarizes the recent efforts in CNF/CNF-based structures developed for regenerative medicine.

Table 3.

Porous materials based on cellulose nanofibrils (CNF) and applied in regenerative medicine.

| Material | Fabrication Method | Cell type | Application | Experimental conditions | Observations | Ref. |

|---|---|---|---|---|---|---|

| CNFa TOCNF Acetylated CNF |

3D printing | H9c2 cardiomyoblast | Cell culturing scaffolds | Nozzle diameter of 410 μm, 630 μm, and 840 μm, extrusion pressure of 35–55 kPa, print speed 5–12 mm/s | High biocompatibility with cardio myoblasts and induced cell proliferation for 21 days | [218] |

| CNF-alginate- lignin particles | 3D printing | HepG2 Hepatocellular carcinoma cell line | Soft tissue engineering | Nozzle diameter of 410 μm (22 G), print speed 11.5 mm/min. The scaffolds were crosslinked in 90 mM CaCl2, stored at ambient conditions for 2 h, or in 1 × DPBS + solution for 1 week at 4 °C | The shear-thinning behavior of CNF did not alter due to addition of up to 25% LPs. Good cell viability regardless of the lignin content (LP/CNF ratio 0–25 w/w %) | [242] |

| PGS-PPy-TOCNF | 3D printing | H9c2 cardiomyoblast | Treatment of cardiovascular diseases | Nozzle diameter of 840 μm (18G). After 3D printing, the samples were frozen overnight at −18 °C followed by freeze-drying for 48 h, at −49 °C and 0.05 mbar. Then, the sample was cured for 48 h in a vacuum oven at 120 °C | Porosity of 78 ± 2%, electrical conductivity of 34 ± 2.7 mS cm−1, Young’s Modulus 0.6 ± 0.16 MPa, high biocompatibility with cardiomyoblasts and induced cell proliferation for 28 days |

[114] |

| CNF-CNT | 3D printing | HPACC, human neuroblastoma | Neural guidelines | Nozzle diameter of 300 μm, printing pressure 65 kPa, print speed 10 mm/s | Viability, proliferation, and attachment of cells to the guidelines with less than 1 mm diameter and 3.8 × 10−1 S cm−1 conductivity | [231] |

| Cross-linked TOCNF-alginate | 3D printing | – | Bone tissue engineering | Nozzle diameter of 500 μm, printing pressure of 50 kPa, printing speed 16 mm/s. The structures were post-crosslinked in 0.5 M CaCl2 for 20 min. | Successful ex vivo mineralization of HA up to 20% in the scaffold made from an equal ratio of CNF and alginate. The compressive strength and elastic modulus ranged from 87 to 455 MPa, and 135–1511 MPa, respectively. | [233] |

| CNF | 3D printing | – | Tissue engineering | Nozzle diameter 200–510 μm | 4D shape-morphing mesoscale structures that are initiated upon hydration. Young’s Modulus in longitudinal and Transverse direction 1267 ± 201 and 1011 ± 39, respectively. | [121] |

| polyurethane-CNF | 3D printing | NIH 3T3 mouse skin fibroblasts and human fibroblasts | Tissue engineering | Nozzle diameter 160 μm, Printing pressure 50–200 kPa, printing speed 7–10 mm/s | Waterborne PU and CNF developed high fidelity structures with high cell proliferation. The compression storage modulus decreased from 1.57 MPa at day 0–0.91 MPa at day 28. | [243] |

| Cross-linked CNF | 3D printing | Mouse embryonic fibroblast | Cell culture scaffold | The smallest tested concentration of CaCl2 (0.22 wt%) was better for the cells. The higher stability of the structures by cooling and crosslinking steps that favor cell viability. | [220] | |

| Cross-linked CNF-alginate | 3D printing | Human nasoseptal chondrocytes | Cartilage tissue engineering | Nozzle diameter 300 μm, Printing pressure 20–60 kPa, printing speed 10–20 mm/s | Shapes resembling an ear and a meniscus with high fidelity and stability were successfully printed. Viability of 73% and 86% after 1 and 7 days of 3D culture. | [112] |

| CNF-alginate | 3D printing | human nasal chondrocytes, human bone marrow-derived mesenchymal stem | Cartilage tissue engineering | Cell density 10 million/mL | Effective cartilage synthesis occurred in cell-laden 3D constructs with promising mechanical properties hand high fidelity. | [236] |

| CNF-alginate | 3D printing | human nasal chondrocytes | Cartilage tissue engineering | Cell density 20 million/mL, nozzle diameter 150 μm | Excellent stability of shape and size that supports the redifferentiation of cells. | [235] |

| TOCNF- Aloe vera | 3D printing | – | Tissue engineering | Nozzle diameter 630 μm | Development of fully bio-based hydrogels with high stability and excellent viscoelastic properties. Porosity higher than 80–95% and a high-water uptake capacity of up to 46 g/g. Tensile modulus of 4.95–73.44 kPa | [244] |

| CNF–CaCO3 | 3D printing | – | Controlled drug release | Nozzle diameter 1.21 mm | Achieving controlled drug release that mimicked the colons condition | [245] |

| CNF-alginate | 3D printing | L929 mouse fibroblast | Wound healing | Nozzle diameter 580 μm, printing speed 3 mm/s | CNF from sugarcane bagasse residue has efficient biocompatibility | [237] |

| Cross-linked CNF-GelMA | 3D printing | 3T3 fibroblast | Wound healing | Precision tips (25G, and 30G), printing pressure 65–80 kPa, printing speed 16–32 mm/s | A facile approach to obtain high cell compatibility and proliferation. Mechanical strength in the range of 2.5–5 kPa | [246] |

| Cross-linked TOCNF | 3D printing | Human dermal fibroblasts | Wound healing | Nozzle diameter 200 μm, printing pressure 50 kPa, printing speed 8 mm/s | Higher rigidity of the scaffold improves cell proliferation. Mechanical strength in the range of 3–8 kPa | [219] |

| CNF- Peptide | 3D printing | – | Wound healing | Nozzle diameter 410–840 μm, printing pressure 100–350 kPa, printing speed 10 mm/s | Obtaining structures with programmable actuation and texture with controlled mechanical and antimicrobial properties | [247] |

| CNF- bioactive glass | Freeze casting | MC3T3-E1 cells | Bone tissue engineering | Light-weight bio-active cryogels that promote ion release (Si, Ca, P, Na). Cryogel compression strength range 11 ± 1 to 24 ± 1 kPa | [225] | |

| Cross-linked gelatin-CNF | Freeze casting | Human bone marrow mesenchymal stem | Bone tissue engineering | The samples were frozen at −20 °C followed by freeze-drying for 24 h | Different crosslinking methods did not have an adverse biological effect on cells, and the composite promoted cell differentiation | [238] |

| CNF-PEGDA | Freeze casting | NIH 3T3 mouse embryonic fibroblast | Cartilage tissue engineering | The samples were frozen at −80 °C for 24 h followed by freeze-drying at −68 °C for 48 h | Structure with about 90% porosity and 1–3 MPa mechanical strength. | [239] |

| CNF-PVA | Freeze casting | Fibroblast cells and keratinocytes | Skin tissue engineering | A novel, integrated skin mimics bilayer structures (mimicking Epidermis and Dermis). Elongation at break range of 52 ± 7 to 91 ± 1. Young’s modulus range of 0.04–8.3 ± 1.8 kPa and porosity of 77 ± 7.3% | [240] | |

| TOCNF | Freeze casting | U937 cell | Tissue engineering | The structures were frozen at −20 °C for 24 h and then freeze-dried for 24 h | Production of considerably less inflammatory cytokines than gelatin according to in vivo test | [249] |

| Cross-linked CNF/organosilanes and chitosan | Freeze casting | Human skin fibroblasts | Hemostatic dressing | The hydrophilic layer was frozen at −80 °C, and after permeation of the hydrophobic layer, the Combination structure was freeze-dried for 36 h at −50 °C. |

Effective bleeding control with nearly 50% less blood loss | [234] |

| CNC/CNF-alginate | Freeze casting | L929-fibroblast | Tissue repair and wound healing | The samples were frozen in liquid nitrogen (−196 °C) for 5 min, followed by a freeze-drying step at −50 °C for 48 h. The dried materials were then added to a bath of CaCl2 at 2 wt % for 24 h. Then, the gels were washed with distilled water and were frozen with liquid nitrogen and freeze-dried again. | ECM biomimetic structure with promising mechanical properties, bioadhesion, cytocompatibility | [207] |

| CNC/CNF-chitosan | Freeze casting | – | Tissue regeneration | The slurry was poured in a polytetrafluoroethylene tube and was sealed with a copper mold (bottom section). The mold was then placed on liquid nitrogen. The molds were equilibrated to 4 °C for 10 min before a cooling rate of either 10 or 1 °C/min was applied until the mold reached a temperature of −150 °C. The frozen slurries for 72 h at 0.008 mbar and a coil temperature of −85 °C. | Obtaining structures with high porosity and surface area with controllable pore alignment | [192] |

| Crosslinked CNF/CNC-alginate | Casting | Human naso-septal chondrocytes | Cartilage tissue engineering | Crosslinking was performed at room temperature using 0.1 M, 0.5 M or 1.0 M calcium chloride (CaCl2). | Different crosslinking and sterilization conditions had a considerable impact on the microstructure architecture. | [194] |

| PLA-PBS- CNF | Electrospinning | Dermal fibroblasts | Vascular tissue engineering | The operating voltage of 20 kV, flow rate 0.5 mL/h and the distance between the electrodes was 12 cm. | ECM mimic microstructure with excellent cell proliferation and attachment on the composites | [241] |

| CNF–CNC | Electro-spinning | Human dental follicle | Artificial organ | The operating voltage of 20 kV, flow rate 0.03 mL/min, A steel rotating collector (6 cm in diameter) wrapped with aluminum foil was placed 10 cm away. The tangential velocity of the collector was set at 300 m/min | All cellulose nanocomposite with high fiber alignment and indentation modulus of 2492 ± 61.6 MPa | [197] |

| Cellulose acetate | Electro-spinning** | Osteoblast | Bone tissue engineering | The operating voltage of 17 kV, flow rate 1.0 mL/h and the distance between the electrodes was 15 cm. Then, the fabricated mats were dried at 40 °C for 24 h. | Biomimetic mineralization, enhanced cell proliferation, and attachment. The apparent density of 0.26 g/mL | [152] |

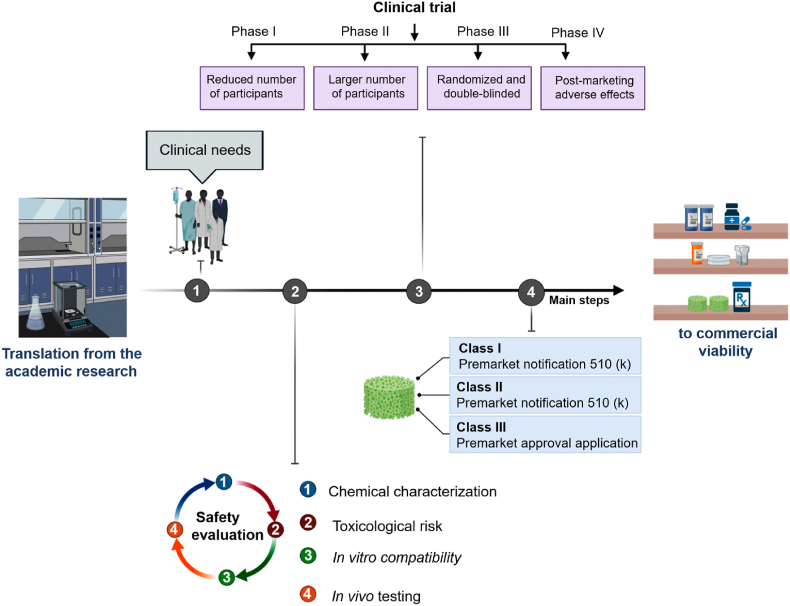

| Cellulose acetate | Electro-spinning | – | Bone tissue engineering | Formation of HA covering the nanofibers. Specific surface areas of the composite were 51.08 m2/g. The CelluNF/HAp composites had mesopores in a range of 2–18 nm, and large amount of micropores in a range of 1.03–2.0 nm | [151] |