Highlights

-

•

Cavitation based pretreatment to improve the biological oxidation.

-

•

First study on CETP effluent containing pharmaceutical contaminants.

-

•

Comparison of different hybrid oxidation schemes as pretreatment.

-

•

Cavitation + Fenton is the best pretreatment resulting in maximum COD reduction.

-

•

Toxicity analysis confirmed no negative effects of cavitation based pretreatment.

Keywords: Common Effluent Treatment Plant, Process intensification, Acclimatized sludge, Biological oxidation, Acoustic Cavitation

Abstract

The current work investigates the efficacy of acoustic cavitation (AC) based pretreatment as a process intensification method for improving the conventional biological oxidation (BO) treatment of the effluent from common effluent treatment plant (CETP) mainly containing pharmaceutical compounds. The effluent acclimatized with cow dung-based sludge was utilized for the aerobic oxidation with an optimum condition of 1:3 ratio of sludge to effluent and 6 h as duration. COD reduction of 19.58% was achieved with the conventional biological oxidation, which was demonstrated to be improved by incorporating acoustic cavitation-based pretreatment approaches under optimized conditions of 125 W and 70% duty cycle for only AC as well as oxidant loadings as 1000 mg/L for H2O2, 250 mg/L Fe(II) with 1000 mg/L H2O2 for Fenton, 1000 mg/L for KPS and 0.5 L/min for the O3 during the combination approaches. The improved COD reduction after the use of pretreatment approaches followed by the BO of 6 h duration was 29.26%, 72.42%, 85.47%, 45.68% and 69.26% for the AC, AC + H2O2, AC + Fenton, AC + KPS and AC + O3 based approaches respectively. The toxicity assay of the effluent before and after every pretreatment approach using bacterial strains of Staphylococcus aureus and Pseudomonas aeruginosa ensured the biodegradability of the treated effluent as no toxic intermediates could be seen. Overall, the present work elucidated the effectiveness of acoustic cavitation-based pretreatment approaches for the improvement of conventional BO of CETP effluent.

1. Introduction

The improper discharge of organic pollutants by pharmaceutical industries contributes to a severe concern of environmental pollution due to the toxic nature of the compounds involved in the processing. The increased presence of organic recalcitrant and aromatic compounds present in the pharmaceutical effluent makes it challenging to treat the effluent to the prescribed discharge limits. Natural resources are widely exposed to pharmaceutical products due to their increased exploitation which adversely affects the ecosystem as a whole in the form of health and environmental hazards. The increased quantity of effluent generated in pharmaceutical industries and its bio-refractory nature are the major hurdle for conventional treatment approaches [1]. Also, the higher stability of bio-refractory organic pollutants in the pharmaceutical effluent due to their resistance to microbial activity makes them more hazardous. Even a trace amount of recalcitrant pollutants present in natural resources can lead to serious health issues such as toxicity, carcinogenicity and mutagenicity [2]. The stringent discharge norms enforced by the regulatory bodies have led to the need for process intensification of conventional wastewater treatment systems by employing novel methods to handle the complexity of the composition of waste streams generated in bulk drug industries. In recent decades, the need for alternative treatment approaches for bulk drug industries has gained significance [3], [4].

Due to the economic constraints, the small and medium scale industries struggle to carry out the whole sequence of effluent treatment enforced by the regulatory bodies in terms of primary, secondary and tertiary treatment. Considering these issues and as the majority of the pharmaceutical intermediate processing industry belongs to the small and medium scale industries, the application of Common Effluent Treatment Plant CETP) which acts as a unified treatment unit for the cluster of companies, is considered as a practical solution. The partially treated wastewater from small scale industries with their available facilities is subjected to further treatment in CETP and final disposal after meeting the discharge limits [5], [6]. Currently, the industrial effluent is being treated by conventional approaches in the CETPs and hence there are processing issues, especially when the cluster of companies have pharmaceutical industries in large proportion [7]. The heterogenicity in the collected influent in CETP, makes the conventional processes less capable of degrading the recalcitrant compounds present in it. The treatment of the effluent in CETPs generally involves aerobic oxidation in the presence of microorganisms, generally coined as biological oxidation. The activated sludge process is a widely utilized secondary treatment process for the treatment of industrial effluent for the degradation of pollutant molecules by organic matter in the presence of oxygen [8]. The amount of sludge formation, extended treatment time and inhibition of the active microorganisms in the sludge by bio-refractory pollutants present in the wastewater are counted as the major drawbacks of the conventional BO process [9], [10]. The limitations associated with the conventional BO can be rectified using proper process intensification approaches such as those based on effective pretreatment techniques.

Cavitation can be considered an effective option for the pretreatment of BO as it comprises the generation of highly reactive OH. radicals which attack the complex organic pollutants in the effluent with a non-selective nature and subsequently break them into harmless compounds under an optimized operation [11], [12], [13]. Acoustic cavitation results in degradation of organic compounds in wastewater through the formation of reactive hydroxyl radicals (•OH) during bubble collapse. The formed radicals initiate oxidation reactions, breaking down complex organic molecules into smaller fragments. With continued oxidation, the fragments mineralize into carbon dioxide (CO2), water (H2O), and other harmless inorganic compounds. Other oxidants, such as hydrogen peroxide (H2O2) and ozone (O3), can also contribute to degradation either by direct attack on the pollutants or by generation of enhanced quantity of hydroxyl radicals. Enhanced mass transfer promotes contact between pollutants and reactive species, facilitating their degradation. This process results in the transformation of organic recalcitrant compounds into simpler, less harmful substances, aiding in the conventional wastewater treatment. The combination of cavitation with other chemical oxidants and catalysts has the potential to significantly improve the efficiency of the BO. The cavitation based treatment approaches can be utilized as a plausible pretreatment method for the conversion of complex molecules into easily digestible intermediates and/or as a toxicity lowering pathway for the effluent stream to facilitate the conventional biological oxidation [14]. The main reason attributed to the use of pretreatment is that without pretreatment, BO would require long treatment time and result in a lower reduction in the COD values due to the difficulty in the biodegradation of recalcitrant organic pollutants present in the effluent streams [11]. Cavitation can be considered as a promising pretreatment strategy for BO due to its feasibility and generation of zero additional wastes under optimized conditions [15]. In addition to ultrasound based cavitation, hydrodynamic cavitation has also been reported as effective approach to treat effluents by oxidation of complex chemicals. Raut-Jadhav et al (2013) reported a degradation study of imidacloprid using HC in combination with H2O2, where a complete degradation of the pollutant was obtained within 45 min of treatment at an optimal molar ratio of 1:40 of pollutant to hydrogen peroxide [16]. Also, Korpe et al (2023) conducted a study on the treatment of tannery effluent using hybrid apporach of HC + PAA + FeSO4.7 H2O. A 72.36% COD reduction was observed within 100 min of treatment at optimal conditions [17].

We now present an overview of a few studies available in the literature on the utilization of acoustic cavitation as a pre-treatment for effluent treatment prior to biological oxidation so as to highlight the novelty of the work. Sangave and Pandit (2004) conducted a study on the enhancement of biodegradability of distillery wastewater using an ultrasound-based pretreatment approach. An ultrasonic bath operating at 22 kHz and 120 W power was used to treat 100 mL of the effluent. The COD reduction of the untreated effluent directly subjected to BO was 25%, which increased to 40% with the use of US pretreated effluent in the BO [18]. Gogate et al. (2020) reported another study on using ultrasound in combination with H2O2 for the pretreatment of municipal wastewater before subjecting to the BO. The authors reported that, for achieving 80% degradation in COD, 60 h of aerobic oxidation was required when untreated effluent was used directly, which got significantly decreased to 21 h when pretreatment based on AC + H2O2 combination was applied at 90 W US power and 200 mg/L H2O2 loading along with the utilization of modified activated sludge [19]. Another study on the treatment of tannery effluent by Saxena et al (2018) reported the enhancement in the biodegradability of the tannery effluent from a value of 0.12 to 0.27 after a pretreatment using alum based coagulation at 0.4 g/L loading followed by the AC at 750 W power for 120 min of treatment time [20]. In addition to these studies with actual industrial wastewater, some studies have also been carried out on simulated effluents. Ramteke and Gogate (2015) presented a detailed study on the degradation of wastewater containing ethylbenzene and p-nitrophenol using BO with activated sludge. The authors reported the improvement in biodegradation of the effluent after a pretreatment process based on the combination of AC and Fenton process at 200 mg/L loading of Fe(II) and 150 mg/L of H2O2 at acidic pH of 3 to 3.5. The biodegradability index improved from 0.15 to 0.3 for ethylbenzene containing wastewater, while for p-nitrophenol containing effluent, the enhancement in biodegradability index was from 0.2 to 0.35 [9]. Moradnia et al (2021) investigated a scientific study on the improvement of biodegradability of petroleum effluent mainly containing 2-Chlorophenol in it. The pretreatment using ultrasound in combination of persulfate at optimized operating conditions of pH as 2, 150 W as the power dissipation, 120 mg/L as persulfate loading, time of 65 min and initial loading of 2-Chlorophenol as 17 ppm resulted in an increase in biodegradability index from 0.14 to 0.57 [21]. The degradation of wastewater containing the antibiotic levofloxacin was investigated by Guo et al (2010) and it was reported that the BI of the wastewater improved from undesired value of < 0.3 to desired value of 0.41 after the pretreatment using ultrasound in combination with CCl4 [22]. It can be seen from the literature that the application of acoustic cavitation in combination with chemical additives as a pretreatment process for the biological oxidation of industrial effluents dealing with CETP or pharmaceutical industry are not investigated. The use of cavitation-based pretreatment as a process intensification method for conventional biological oxidation of pharmaceutical effluent degradation can offer several advantages [15], [22], [23] in terms of enhanced degradation efficiency of pollutants, reduced sludge accumulation, cost savings and environmental benefits, while intensifying the overall treatment process. In this work we hypothesize that, the combination of acoustic cavitation with AOPs followed by the subsequent biological oxidation could create a synergistic effect, improving pollutant removal rates and effluent quality. The current work focuses on the enhancement of biological oxidation of pharmaceutical industry based CETP effluent by means of AC + AOP based pretreatment approaches. The utilization of effluent acclimatized cow dung based sludge inoculum for the BO of effluent is another novel aspect presented in the current work with optimization into the loading for the biological oxidation of CETP effluent after AC + AOP based pretreatment approaches. The main objective of the study is to develop a better treatment scheme for the CETP effluent by involving acoustic cavitation in combination with chemical oxidants such as H2O2, Fenton, KPS and O3 as pretreatment methods at optimum operating conditions followed by BO. The kinetics involved in the biological oxidation as well as toxicity analysis of the pretreated effluent, have also been evaluated in the study.

2. Materials and methods

2.1. Materials

The industrial effluent for the study, predominantly containing pharmaceutical sector based pollutants was collected from a Common Effluent Treatment Plant (CETP), Mumbai, India [23]. The physicochemical properties of the effluent are represented in Table 1. Fresh cow dung for the preparation of the inoculum for biological oxidation (sludge) was collected from a dairy farm situated in Mumbai, India. Various chemicals of analytical reagent (AR) grade utilized for the COD analysis were silver sulphate (Ag2SO4), potassium dichromate (K2Cr2O7), ferrous ammonium sulphate ((NH4)2Fe(SO4)2·6H2O), mercuric sulphate (HgSO4), and concentrated sulfuric acid (H2SO4). Other chemicals (AR grade) used for the treatment process were hydrogen peroxide (H2O2, 30% v/v), potassium persulphate (K2S2O8), glucose (C6H12O6) and ferrous sulphate (FeSO4·7H2O). All the chemicals mentioned were procured from S.D. Fine Chem. Pvt. Ltd., Mumbai, India, and were used without any further purification. The oxygen concentrator and ozone generator utilized for the ozone-based experiments were obtained from Eltech Ozone Pvt Ltd, Mumbai, India. The deionized water used for attaining desired dilutions was obtained from the Millipore Milli-Q Gradient water purification unit. 0.1 N NaOH and 0.1 N H2SO4 solutions were utilized for modifying the pH according to the requirements.

Table 1.

Physiochemical properties of the CETP effluent.

| Property | |

|---|---|

| Initial COD | ∼950 mg/L |

| TDS | ∼ 4500 mg/L |

| pH | 8 |

| Appearance | Brownish black |

2.2. Experimental setup

2.2.1. Dual stepped ultrasonic horn

For the pretreatment of the CETP effluent, a dual stepped ultrasonic (AC) horn procured from M/s Dakshin, India was utilized for all experiments The geometrical details of the US horn have been well described in the previous work along with schematic representation [23]. US horn operates at a preset frequency of 22 kHz and a rated power dissipation of 250 W. All the experiments were conducted at a fixed volume of 200 mL of the effluent taken in a 250 mL glass beaker with 1:1 dilution of the effluent with DI water, since the availability of the industrial effluent was limited. The operating conditions of AC were restricted to 125 W input power and 70% duty cycle with 1 h of treatment time for comparing the efficacy of different treatment approaches. AC based pretreatment experiments were conducted at ambient conditions (30 ± 2 ◦C temperature). The reaction temperature was maintained by utilizing ice-water in the jacket throughout the experiment and a thermocouple was used for monitoring the temperature.

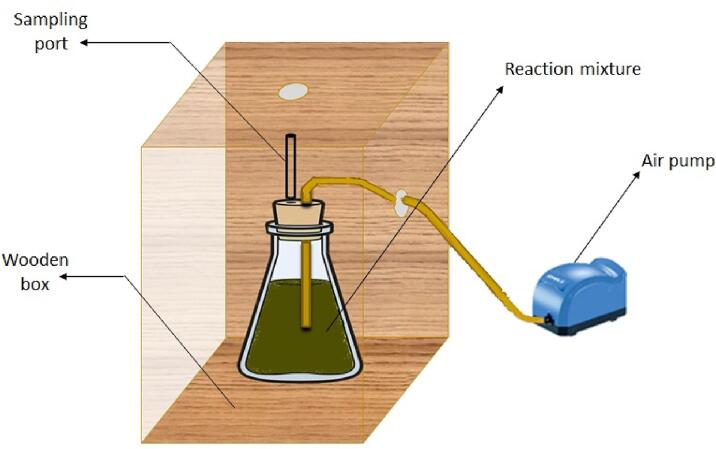

2.2.2. Biological oxidation setup

The biological oxidation experiments were performed in a 500 mL capacity glass conical flask, properly sealed using a rubber cork. Two openings were provided on the rubber cork, one for aeration of the reaction mixture for the oxidation experiments and the other for withdrawing samples periodically. An air pump was used for continuous supply of oxygen throughout the reaction. The schematic representation of the assembly has been illustrated in Fig. 1. The reactor assembly was kept in a wooden chamber to avoid the interference of light during the aerobic oxidation. At regular time intervals, samples were withdrawn through the sampling port and analyzed for COD.

Fig. 1.

Schematic representation of biological oxidation reactor assembly.

2.3. Methodology

2.3.1. Aerobic oxidation.

Initially, aerobic oxidation of the CETP effluent was performed using cow dung based precursor inoculum (without any modification). Subsequently, effluent acclimatized cow dung based sludge was utilized for the treatment to check the efficacy of acclimatization for aerobic oxidation. The pH of the reaction mixture was maintained neutral (7 to 7.5) during the biological oxidation treatment of the effluent for pretreated and untreated CETP effluent to provide better incubation for the microorganism present in the reaction mixtures. BO experiments were performed for a fixed treatment time of 6 h.

2.3.2. Pretreatment of CETP effluent using acoustic cavitation

The optimized conditions of both stand-alone AC based approach and other hybrid AC + AOP based approaches were based on the previous study on treatment of the same CETP effluent [23]. The various pretreatment approaches such as AC, AC + H2O2, AC + KPS, AC + Fenton and AC + O3 were performed for 1 h duration at ambient conditions [23]. Except Fenton based approach, every other pretreatment was carried out at neutral pH and the treated effluent was subsequently utilized for the BO without further modifications. The AC + Fenton based pretreatment was investigated at acidic pH of 3 and was neutralized prior to the subsequent BO to avoid any problems to the microorganisms. A 5 mL of samples were withdrawn before and after each pretreatment method for analyzing COD value and toxicity content.

2.4. Analytical methods

A COD digester procured from Hanna Equipment Pvt Ltd., Mumbai, India was used to perform COD analysis. The final COD values were calculated by titrating the digested samples against freshly prepared ferrous ammonium solution of 0.3 N concentration [13] and using the calculation steps described in earlier work [21]. The total dissolved solids (TDS) present in samples were measured by means of TDS meter (model-254312-A01) procured from Thermo Scientific Ltd., India. The toxicity analysis of the pretreated and treated effluent was carried out using agar well diffusion method.

3. Results and discussion

3.1. Biological oxidation

The secondary treatment of wastewater involves the utilization of live microorganisms for biological oxidation. The metabolic characteristics of the microorganisms present in the harnessed biomass aid in the oxidation of organic pollutants to less harmful molecules [7]. The current study of BO of pharmaceutical drug based CETP effluent was carried out by utilizing novel cow dung based sludge inoculum. The extent of degradation of organic pollutants in the wastewater depends on various parameters like oxidation time, sludge characteristics, sludge loading and effluent characteristics. Considering this, it was thought important to optimize the treatment conditions for better degradation of pollutants in the effluent.

3.1.1. Cow dung-based sludge preparation

In the current study, the cow dung-based inoculum was utilized for the first time as sludge inoculum for the biological oxidation of the real industrial effluent from a CETP. The microorganisms present in cow dung have the ability to oxidize different contaminants leading to the treatment of the effluent. The freshly collected cow dung was mixed with water in a 1:1 (W/V) proportion to make it into a slurry form. The cow dung based slurry was vigorously mixed using an overhead stirrer for 10 min at 500 rpm speed for getting a uniform mixture. Then the coarse particles present in the cow dung based slurry were removed by screening it through a 0.3 mm aperture sieve. The filtered supernatant was collected and were utilized for the biological oxidation studies.

The supernatant after the filtration was diluted using water in 1:3 proportion with slurry to water ratio before using it for BO experiments. A nutrient mixture of 1% proportion of the cow dung based inoculum was introduced to the sludge on a weekly basis to preserve the microorganisms present in the sludge. The presence of live microorganisms in the sludge was confirmed using the nutrient agar plating method. Fig. 2 represents the plate containing active microorganisms, predominantly the bacteria present in the sludge, that can be useful for aerobic oxidation experimentations.

Fig. 2.

Microorganisms in cow dung based sludge isolated on nutrient agar.

3.1.2. Conventional biological oxidation

The biological oxidation using native cow dung based sludge was carried out using a 500 mL conical flask. To the 180 mL of untreated CETP effluent taken in the flask, ∼60 mL of cow dung based inoculum was introduced. The initial COD of the untreated effluent was ∼ 950 mg/L. During the aerobic oxidation, continuous aeration was achieved by means of an aquarium pump at a flow rate of 1.5 L/h. The oxidation time required for the BO might vary based on the pollutants present in the wastewater to be treated and the inoculum used for the BO. Gogate et al (2020) reported that, for municipal wastewater treatment using, activated sludge duration of 60 h was required using unfiltered activated sludge, while for the filtered sludge, the BO duration was reduced to 56 h [19]. Thanekar et al (2020) conducted a biological oxidation study for the treatment of wastewater containing mainly naproxen as pollutant and reported 7 days as the utilized time for aerobic oxidation of the effluent [24]. The analysis allowed to establish that it is important to optimize the treatment time required for the BO of CETP effluent using cow dung based inoculum. Considering this, the samples for COD analysis were withdrawn at 1 h time intervals, and it was observed that the extent of COD reduction obtained reached saturation at 6 h of treatment with a value of 10.74% as per the results presented in Fig. 3. The 6 h of treatment was hence applied for subsequent experiments for BO of CETP effluent, mainly to compare the efficacy of different approaches. In this set of experiment, the BO of CETP effluent were performed with raw cow dung based inoculum which, resulted in a lower COD reduction. With an objective to enhance the BO, the cow dung based sludge was preconditioned to the CETP effluent and then used in the study to improve the effectiveness of the BO process.

Fig. 3.

Extent of COD reduction using BO of CETP effluent based on the native cow dung based sludge (Operating conditions: Total volume ∼ 250 mL,1:3 sludge to effluent loading, pH 7, 6 h Treatment time).

3.1.3. Sludge acclimatization

Preconditioning the inoculum with the pollutants present in the wastewater can ensure the survival of incubated microorganisms in the sludge. If the sludge is not pre adapted to the effluent, it is important to acclimatize the same with proper conditioning protocols [25]. The native cow dung based sludge was acclimatized to the industrial effluent containing pharmaceutical pollutants for the improved efficacy of the biological oxidation process. The effluent collected at the outlet of the secondary treatment unit of the CETP was sequentially introduced to the cow dung based sludge to provide a better organic inoculum for the biological oxidation of the effluent. The physicochemical characteristics of the bioreactor outlet collected from the industry are depicted in Table 2. The acclimatization of the cow dung based sludge precursor inoculum with the bioreactor outlet from CETP was performed in three stages of 21 days duration.

Table 2.

Characteristics of CETP bioreactor outlet.

| Property | |

|---|---|

| pH Appearance |

7 ± 0.3Greenish black (clear liuid) |

| TDS | ∼4500 mg/L |

| Initial COD | ∼500 mg/L |

Initially, the cow dung based sludge was introduced to CETP bioreactor outlet, i.e. 5 mL of the cow dung slurry was introduced into 10 mL of bioreactor outlet followed the addition of a diluent of 35 mL of water containing nutrients. The mixture was incubated in an orbital shaker at 110 rpm speed and 37 °C temperature for 7 days. For the second stage incubation, ∼50% of the already prepared solution was taken, i.e. 25 mL of 7 days incubated solution and 5 mL of cow dung-based slurry was added, followed by the addition of 20 mL of water containing nutrients. The solution was kept for incubation in the orbital shaker at same conditions as earlier for another 7 days period. For the final stage of preconditioning of sludge, the 14 days inoculated sludge was taken as ∼ 90% by volume, i.e., 45 mL to which a 5 mL of cow dung based slurry was introduced and the mixture was kept in an orbital shaker at the prescribed conditions for 7 more days. Based on this protocol, an ample amount of sludge was acclimatized by repeating the same procedure, which can be used for a whole set of biological oxidation. The inoculum was maintained at 37 °C with periodic addition of nutrients to maintain the microbial consortium alive in it. The physicochemical characteristics of the effluent acclimatized cow dung based sludge are represented in Table 3.

Table 3.

Characteristics of the effluent acclimatized cow dung based sludge.

| Property | |

|---|---|

| TDS | ∼ 11 (%) |

| pH Appearance |

7 ± 0.5 Greenish black |

| Initial COD | ∼300 mg/L |

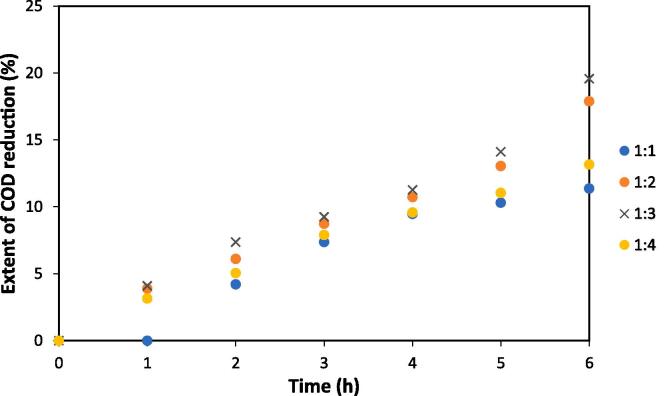

3.1.4. Optimization of sludge loading

The amount of sludge introduced to the effluent for BO also need to be optimized to ensure better biodegradation activity leading to a possibly higher extent of degradation of pollutants present in the wastewater during BO [9]. In order to investigate the effect of sludge loading , biological oxidation experiments at various sludge to effluent loading proportions ranging from 1:1 to 1:4 were conducted. Every reaction was carried out in a 500 mL conical flask with approximately 50% occupancy of the reaction mixture. The results obtained are represented in Fig. 4 where the best loading condition observed was 1:3 sludge to effluent loading proportion. Use of the best loading condition resulted in a maximum of 19.58% COD reduction of the effluent, followed by 1:2, 1:4 and 1:1 sludge to effluent proportions with 17.89%, 13.16% and 11.37% COD reduction, respectively. At the optimum loading of 1:3 proportion of sludge to effluent loading, it was also seen that the COD reduction demonstrated a first order kinetics with the value of rate constant as 3.33 × 10-2h−1. The optimum loading of sludge is dependent on the specific system under investigation. Gogate et al. (2020) reported 10% loading of activated sludge as optimum for the treatment of municipal wastewater using aerobic oxidation [19]. Neczaj and Kacprzak (2007) conducted a study on the enhancement of landfill leachate treatment in a sequential batch reactor (SBR) using sludge collected from a municipal wastewater treatment plant and reported an optimum sludge loading of 4 g/L as the best treatment conditions [26]. The comparison with the literature allowed to establish the specific dependency of the optimum sludge loading on the system in question, also elucidating the importance of the current work.

Fig. 4.

Effect of sludge loading on BO (Operating conditions: Total volume ∼ 250 mL, pH 7, 6 h Treatment time).

3.2. Intensified BO using AC based pretreatment

In order to investigate the efficacy of various pre-treatment approaches in altering the performance of biological oxidation, the pretreated effluent using various approaches based on acoustic cavitation, was subjected to subsequent aerobic oxidation.

3.2.1. Pretreatment of effluent using AC based approaches

The treatment of pharmaceutical industry based CETP effluent using only AC and hybrid AC + AOP techniques was utilized as a pretreatment approach prior to the subsequent biological oxidation of the effluent. According to the previous work reported on the same CETP effluent using AC based on the dual stepped horn, the optimized treatment conditions were 125 W as the operating power, 70 % as the duty cycle and 60 min as the treatment time, ambient temperature conditions and volume of 200 mL of the effluent [23]. The same optimized conditions were used in the current work during the pretreatment. The standalone AC based pretreatment of the effluent resulted in a COD reduction of 9.47%. Combined cavitation and oxidant based AOP approaches offer economical, sustainable and promising pretreatment prospects. Thus, hybrid pretreatment approaches of combined AC with various chemical oxidant based AOPs were also incorporated to enhance the COD reduction. At already optimized loading conditions, chemical additives such as H2O2, KPS, Fenton and O3 were incorporated along with AC for the improved pretreatment of CETP effluent. The COD reduction obtained for each treatment approach at optimum loading conditions of oxidants is represented in Table 4. The best pretreatment approach observed was AC in combination with Fenton reagent, where an 83.58% reduction in COD was observed with the addition of 250 m/L of Fe(II) along with 1000 mg/L H2O2 at pH 3. The Fenton based pretreatment has maximum catalytic activity in the acidic pH range from 2.5 to 3.5 [27]. During the Fenton based treatment, FeSO4 release Fe(II) ions, which, when combined with the optimum quantity of H2O2 aids the generation of highly reactive ˙OH radicals instantaneously under acidic conditions [13]. The ferric hydroxo complex formed during the process is also effectively broken down by the cavitating effects leading to a further increase in the generation of hydroxyl radicals, and also might be responsible for the subsequent coagulation of chemicals. The precipitation/coagulation during the Fenton based pretreatment also leads to better removal efficiencies [28], [29]. AC in combination with other oxidants also resulted in significantly higher COD reduction compared to the only AC based approach. AC in combination with ozone resulted in a COD reduction of 51.88%, whereas AC + H2O2 and AC + KPS based pretreatment at 1000 mg/L oxidant loading resulted in a COD reduction of 39.89% and 33.68%, respectively. Among various pretreatment approaches, AC + Fenton based pretreatment was observed as the best treatment approach in terms of maximum COD reduction.

Table 4.

Acoustic cavitation based pretreatment of CETP effluent.

| Treatment approach | Oxidant loading(ppm) | Extent of COD reduction (%) |

|---|---|---|

| AC alone | – | 9.47 |

| AC + H2O2 | 1000 | 39.89 |

| AC + Fe(II) + H2O2 | 1:5 | 83.58 |

| AC + KPS | 1000 | 33.68 |

| AC + O3 | 0.5 g/h | 51.68 |

Similar results can be seen in the literature for the acoustic cavitation based pretreatment applied for the industrial wastewater, but to a limited extent and not for the CETP based pharmaceutical industry effluent. Ramteke and Gogate (2015) studied the biological oxidation of wastewater containing ethylbenzene and p-nitrophenol as model pollutants, and reported that AC in combination with Fenton at optimum operating condition of 2000 mg/L Fe(II) loading with 1500 mg/L loading of H2O2 at pH 3 was the best pretreatment method yielding about 55–70% reduction in COD [9]. Moradnia et al (2021) conducted a study on the treatment of petroleum effluent containing mainly 2-Chlorophenol. The treatment of effluent containing 2-Chlorophenol at a loading of 17 ppm with ultrasound in combination with persulfate at optimized operating conditions of pH of 2, 150 W power, 120 mg/L as the persulfate loading and time of 65 min resulted in a reduction efficiency of 90.92% [21].Gogate et al. (2020) also studied the BO of municipal wastewater by utilizing ultrasound based pretreatment approach. The optimum pretreatment conditions based on ultrasonic cavitation for the treatment of municipal wastewater were observed as 90 W power dissipation, 70% duty cycle, and of 200 mg/L dosage of H2O2, resulting in ∼ 24.9% reduction in COD. During the subsequent BO using modified activated sludge, the duration of oxidation got significantly reduced from 60 h to 21 h with US + H2O2 pretreatment given to the effluent [19].

3.2.2. BO of AC pretreated CETP effluent

For the confirmation of enhanced biodegradation, when the wastewater is pretreated prior to the conventional biological oxidation based on any possible conversion of the recalcitrant or bio refractory organic constituents present in the untreated effluent into simpler molecules, the pretreated CETP effluent using different approaches was further subjected to biological oxidation. The extent of oxidation for each pretreated effluent was compared with the oxidation obtained for the untreated effluent. Fig. 5. depicts the data obtained for the residual COD for each treatment approach before and after biological oxidation. It was observed that maximum COD reduction (as indicated by least residual COD value) was obtained for BO treatment after AC + Fenton based pretreatment, with the actual COD reduction as 85.47%. On the other side, the COD reduction of untreated CETP effluent after BO using effluent acclimatized cow dung-based sludge was only 19.58%. The BO of CETP effluent after other hybrid pretreatment approaches such as AC + H2O2, AC + KPS and AC + O3, also resulted in higher COD reductions of 72.42%, 45.68% and 69.26%, respectively compared to the untreated effluent.

Fig. 5.

Comparison of the different pretreatment approaches applied for intensification of BO process.

The kinetics of the oxidation process has also been analyzed, and the obtained data for rate constants are represented in Table 5. BO of the CETP effluent followed a first order reaction kinetics based on data fitting for the following equation.

Table 5.

Kinetics data for the BO of CETP effluent.

| Pretreatment Approach | %COD reduction after pretreatment | Over all %COD reduction |

Rate constant (×102) h−1 |

R2 |

|---|---|---|---|---|

| AC alone | 9.47 | 29.26 | 4.32 | 0.9584 |

| AC + H2O2 | 39.89 | 72.42 | 11.79 | 0.9083 |

| AC + Fenton | 83.58 | 85.47 | 2.45 | 0.8817 |

| AC + KPS | 33.58 | 45.68 | 3.66 | 0.9691 |

| AC + O3 | 51.68 | 69.26 | 7.64 | 0.9508 |

| Untreated WW | – | 19.58 | 3.33 | 0.9707 |

The maximum rate of COD reduction was achieved for BO performed after AC + H2O2 based pretreatment process with a maximum value of rate constant of 11.79 × 10-2 h−1. A COD reduction of 39.89% after the AC + H2O2 based pretreatment significantly increased to 72.42% after subsequent BO. The pretreatment process based on AC + O3 process showed the next best rate of COD reduction with a first order rate constant of 7.64 × 10-2 h−1. AC + Fenton based pretreatment process followed by BO exhibited a maximum reduction in the COD compared with the initial COD value but there was a marginal change in the oxidation rate for the BO with a first order rate constant of 2.45 × 10-2 h−1. Unlike other pretreatment methods, in the case of AC + Fenton based pretreatment of the effluent followed by BO, the actual COD reduction in the case of BO after the pretreatment was marginal (83.58% of reduction in COD after AC + Fenton got improved to 85.47% after BO). The trend can be attributed to the much higher COD reduction obtained in the case of AC + Fenton based pretreatment carried out at acidic pH of 3, which results in the formation of intermediates that are refractory towards the biological oxidation or inhibit the activity of sludge. It was also observed that in the case of BO of the effluent subjected to the Fenton based pretreatment, the COD reduction reached its maximum in 3 h of aerobic oxidation, which implies the maximum degradability of oxidizable organic pollutants present in the effluent. Overall, it can be said that AC + Fenton based pretreatment approach is observed as the best pretreatment method in terms of overall COD reduction, while the AC + H2O2 based pretreatment is the best method in terms of maximum extent of enhancement in BO with highest value of first order rate constant.

Based on the nature of the effluent, combinations of pretreatment technique employed, and the characteristics of the sludge inoculum utilized, the efficiency of the biological oxidation may vary depending on the applied cavitation based pretreatment approaches. According to Ramteke and Gogate (2015), US + Fenton based pretreatment approach was reported as a promising pretreatment process for the treatment of wastewater containing ethylbenzene and p-nitrophenol with an increment in biodegradability index from 0.15 to 0.36 using 40 min of pretreatment [9]. For the treatment of tannery waste effluent using BO reported by Saxena et al (2018), the combination of ultrasound and chemical coagulation (0.4 g/L alum) based pretreatment approach resulted in the enhancement in the biodegradability of the effluent from 0.12 to 0.27 [20]. For the treatment of municipal wastewater reported by Gogate et al (2020), ultrasound in combination with H2O2 based treatment approach resulted in better extent of COD reduction with a decrease in treatment time from 56 h to 30 h. The biodegradability index got improved from 0.33 to 0.6 upon AC + H2O2 pretreatment of municipal wastewater [19]. It can be thus said that the improvements in the BO are dependent on the type of effluent and also the applied pretreatment approach, which confirms the importance of current work.

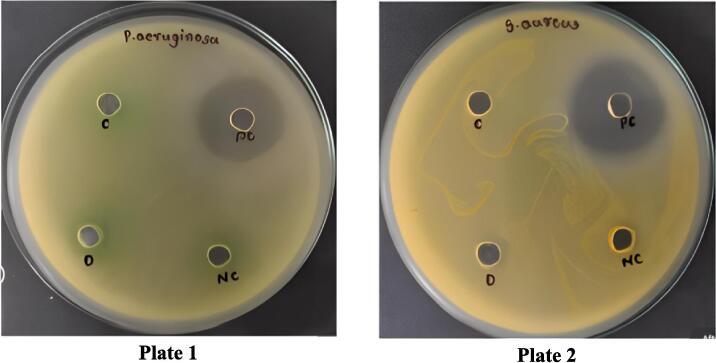

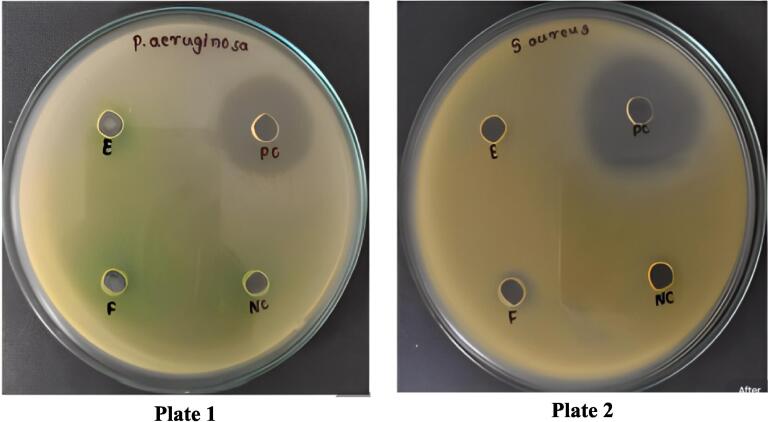

3.3. Toxicity assay

The presence of recalcitrant pollutants in the pharmaceutical industrial effluent might inhibit the microbial activity during the wastewater treatment due to the toxicity, which in turn affects the efficacy of further biological treatment processes [30], [31], [32]. Generally, the change in toxicity of industrial effluent during various treatment techniques greatly depends on many parameters such as the physio-chemical nature of the recalcitrant compounds, types of reactive species, the structure of organic pollutants, formation of various reaction intermediates, the concentration of chemical reactant species, residual oxidants and heterogeneous catalysts utilized for the treatment [33]. The toxicity of industrial effluent might get altered during or after the use of advanced oxidation processes, irrespective of the treatment approach employed among various AOPs. According to the literature, there was no common trend reported on changes in the toxicity of effluent after treatment [34] Since various factors such as pH, additive loading, treatment time etc., alter the toxic nature of effluent, it was thought essential to check the toxicity of the effluent sample before and after pretreatment using various cavitation based AOPs to ensure the absence of formation of the toxic intermediates during the treatment. The toxicity assay of pretreated effluent could be considered as a feasibility test for subsequent secondary treatment (biological treatment) in the downstream processes.

In the current study, the toxicity assay of effluent samples after treatment using different processes under optimized conditions was conducted prior to the biological oxidation study. The effluent sample before any pretreatment approach was also used for the toxicity analysis. The collected samples were filtered and centrifuged to remove any contaminants and taken for further study based on the agar well diffusion method for analyzing the toxicity towards the bacterial strains, Staphylococcus aureus and Pseudomonas aeruginosa as Gram positive and Gram negative test cultures, respectively. The untreated sample before AC treatment and the AC pretreated samples are depicted as A and B, respectively (Fig. 6). In the case of hybrid treatment of AC in combination with other chemical oxidants like H2O2, Fenton, KPS and O3, the untreated samples (prior to the pretreatment) were represented as C, E, G and I, while the corresponding pretreated samples were depicted as D, F, H and J for AC + H2O2, AC + Fenton, AC + KPS and AC + O3 based processes, respectively (Fig. 7, Fig. 8, Fig. 9, Fig. 10) for better comparison. For every sample, PC represents positive control, and NC represents negative control in the images of cultured agar plates as illustrated in Fig. 6 to Fig. 10. For both the strains of Staphylococcus aureus and Pseudomonas aeruginosa, Chloramphenicol was utilized as the positive control and sterile distilled water was chosen as the negative control. The test organisms were grown in Mueller Hinton broth providing an incubation period of 24 h at 37 °C and then utilized for the toxicity assay. The optical densities of the cultures were adjusted using 0.5 McFarland standard followed by mixing of the cell suspension to give a final density of 1 × 106 CFU/ml and then taken for toxicity analysis. Test culture containing Mueller Hinton agar plate was taken and introduced into wells of the plates with the help of a cork borer. The wells are introduced in such a way that each plate contains two samples and two controls. For the toxicity analysis, 0.1 mL of each sample was loaded into the respective wells and the plates were incubated at 37 °C for 24 h. Plates were examined for the presence of any toxicant by checking the presence of a zone of inhibition around the respective sample wells. The positive control Chloramphenicol exhibited a definite and strong zone of inhibition for both the gram positive and gram negative bacterial strains indicating toxicity. In the case of positive control, for Staphylococcus aureus, the zone of inhibition measured was 22 mm as diameter, while for Pseudomonas aeruginosa, it was 18 mm. Conversely, the negative control showed the absence of any inhibition zone, confirming the nontoxic nature. The positive control and negative controls were considered as references to compare the toxicity of respective samples before and after various pretreatment approaches. By comparing the positive control in Fig. 7, Fig. 8, Fig. 9, Fig. 10, it can be elucidated that all the samples of the effluent exhibited nontoxic behaviour against the bacterial strain mentioned, as the growth of both Staphylococcus aureus and Pseudomonas aeruginosa were not inhibited in the case of both untreated and AC based pretreated samples at different optimized conditions. By comparing the samples with the negative control in Fig. 7, Fig. 8, Fig. 9, Fig. 10, the absence of toxins can be confirmed due to the absence of a zone of inhibition. The toxicity analysis of pre and post treated samples after AC, AC + H2O2, AC + Fenton, AC + KPS and AC + O3 based pretreatment approaches confirmed no toxicity during the process as per the results depicted in Fig. 7, Fig. 8, Fig. 9, Fig. 10, respectively. Thus, AC based pretreatment approaches can be counted as pretreatment with no negative effect on microbial activity. It implies the better feasibility of cavitation based pretreatment approaches as a promising process intensification strategy prior to biological oxidation.

Fig. 6.

Toxicity analysis for untreated (A) and ultrasound pretreated (B) samples using different bacterial strain (plate1) Pseudomonas aeruginosa and (plate 2) Staphylococcus aureus.

Fig. 7.

Toxicity analysis for untreated (C) and AC + H2O2 pretreated (D) samples using different bacterial strain (plate1) Pseudomonas aeruginosa and (plate 2) Staphylococcus aureus.

Fig. 8.

Toxicity analysis for untreated (E) and AC + Fenton pretreated (F) samples using different bacterial strain (plate1) Pseudomonas aeruginosa and (plate 2) Staphylococcus aureus.

Fig. 9.

Toxicity analysis for untreated (G) and AC + KPS pretreated (H) samples using different bacterial strain (plate1) Pseudomonas aeruginosa and (plate 2) Staphylococcus aureus.

Fig. 10.

Toxicity analysis for untreated (I) and AC + O3 pretreated (J) samples using different bacterial strain (plate1) Pseudomonas aeruginosa and (plate 2) Staphylococcus aureus.

Comparison with the literature revealed that similar inferences were reported by Thanekar et al. (2020), elucidating the importance of toxicity analysis prior to the biological oxidation for the degradation of the dimethoate (pesticide) containing effluent. The toxicity analysis of the HC + Fenton based pretreated wastewater was investigated by making use of Pseudomonas aeruginosa and Bacillus subtilis bacterial strains. The study confirmed nontoxic intermediate formation during the degradation of dimethoate using the cavitation based hybrid treatment approach [35]. Barik et al (2016) also reported the absence of formation of any toxic intermediates during the degradation of 4-chloro 2-aminophenol by carrying out toxicity analysis utilizing various bacterial strains like L. aerocolonigenes, P. aureofaciens,B. licheni-formis and A. eutrophus [36]. Toxicity analysis of US pretreated real textile effluent was reported in the study conducted by Nachiappan et al (2012). For the toxicity analysis of the effluent before and after Sono-Fento-Sorption (SFS) treatment, the disc diffusion susceptibility test was performed using Escherichia coli. The test elucidated the toxicity removal using the combined hybrid SFS pretreated biodegradation of the textile real effluent [37]. A study conducted by Gonze et al. (1998) reported the reduction in toxicity of ultrasound pretreated wastewater containing sodium pentachlorophenate (NaPCP). The toxicity analysis after the US pretreatment were conducted in two stages, the preliminary step being performed with the exposure of marine bacteria (Vibrio fischeri) and the reduction quantified in the next step using daphnids (Daphnia magna) which proved US treatment is efficient in reducing the toxicity and enhancing the biodegradability [38].

4. Conclusions

The current study mainly illustrated the effectiveness of intensification of conventional biological oxidation using hybrid cavitation based techniques for the treatment of CETP effluent containing mainly pharmaceutical pollutants. The biological oxidation was investigated for a duration of 6 h by utilizing effluent acclimatized cow dung based sludge. The extent of COD reduction with conventional biological oxidation was only 19.58%. The improvement in BO was achieved by the application of effective pretreatment using combination of AC with other chemical oxidant based approaches such as AC, AC + H2O2, AC + Fenton, AC + KPS, and AC + O3 followed by 6 h aerobic oxidation that resulted in higher reduction in COD with actual values of 29.26%, 72.42%, 85.47%%, 45.68% and 69.26% respectively. Among all pretreatment approach AC + Fenton process resulted in the highest COD reduction of 83.58%, although the subsequent BO reached saturation within 3 h of aerobic oxidation with a final COD reduction of 85.47%. The AC + H2O2 based approach was the best pretreatment technique in terms of enhancing the efficacy of COD reduction as COD reduction after pretreatment as 39.89% enhanced to 72.42% after the biological oxidation of the effluent using cow dung acclimatized sludge. The toxicity assay of effluent elucidated the absence of toxic intermediates generated during the cavitation based pretreatment which can definitely improve subsequent biological oxidation even at commercial level. Overall, the process intensification of conventional BO with AC based pretreatment approaches was successfully demonstrated with enhanced efficacy of the process for the treatment of CETP effluent containing pharmaceutical effluents.

Funding

Authors would like to acknowledge the funding of Department of Science and Technology, New Delhi, India under Water Technology Initiative scheme (Reference No.: DST/TM/WTI/WR/2K17/110).

CRediT authorship contribution statement

N.J. Lakshmi: Methodology, Investigation, Writing – original draft. Parag R. Gogate: Supervision, Writing – review & editing. Aniruddha B. Pandit: Supervision, Writing – review & editing, Project administration.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

Data will be made available on request.

References

- 1.Naddeo V., Belgiorno V., Kassinos D., Mantzavinos D., Meric S. Ultrasonic degradation, mineralization and detoxification of diclofenac in water: optimization of operating parameters. Ultrasonics sonochemistry. 2010;17(1):179–185. doi: 10.1016/j.ultsonch.2009.04.003. [DOI] [PubMed] [Google Scholar]

- 2.Imran H. Wastewater monitoring of pharmaceutical industry: treatment and reuse options. Electronic Journal of Environmental, Agricultural and Food Chemistry. 2005;4(4):994–1004. [Google Scholar]

- 3.Rosen M., Welander T., Löfqvist A., Holmgren J. Development of a new process for treatment of a pharmaceutical wastewater. Water Science and Technology. 1998;37(9):251–258. [Google Scholar]

- 4.Kumar K., Kumar P., Babu M. Performance evaluation of waste water treatment plant. International Journal of Engineering Science and Technology. 2010;2(12):7785–7796. [Google Scholar]

- 5.Sahithya D.D., Lakshmi C. Performance evaluation study of an effluent treatment plant in pharmaceutical industry. International Research Journal of Engineering and Technology. 2016;3(8):67–77. [Google Scholar]

- 6.Ramteke P.W., Awasthi S., Srinath T., Joseph B. Efficiency assessment of Common Effluent Treatment Plant (CETP) treating tannery effluents. Environmental monitoring and assessment. 2010;169(1-4):125–131. doi: 10.1007/s10661-009-1156-6. [DOI] [PubMed] [Google Scholar]

- 7.Metcalf L., Eddy H.P., Tchobanoglous G. McGraw-Hill; New York: 1991. Wastewater engineering: treatment, disposal, and reuse. [Google Scholar]

- 8.Bramucci M., Nagarajan V. Bacterial communities in industrial wastewater bioreactors. Current opinion in microbiology. 2006;9(3):275–278. doi: 10.1016/j.mib.2006.04.005. [DOI] [PubMed] [Google Scholar]

- 9.Ramteke L.P., Gogate P.R. Removal of ethylbenzene and p-nitrophenol using combined approach of advanced oxidation with biological oxidation based on the use of novel modified prepared activated sludge. Process Safety and Environmental Protection. 2015;95:146–158. [Google Scholar]

- 10.Ramteke L.P., Gogate P.R. Synthesis and characterization of modified activated sludge for biological oxidation with isolation studies and performance evaluation. Separation and Purification Technology. 2015;141:179–187. [Google Scholar]

- 11.Bhat A.P., Gogate P.R. Cavitation-based pre-treatment of wastewater and waste sludge for improvement in the performance of biological processes: A review. Journal of Environmental Chemical Engineering. 2021;9(2):104743. [Google Scholar]

- 12.Oller I., Malato S., Sánchez-Pérez J. Combination of advanced oxidation processes and biological treatments for wastewater decontamination—a review. Science of the total environment. 2011;409(20):4141–4166. doi: 10.1016/j.scitotenv.2010.08.061. [DOI] [PubMed] [Google Scholar]

- 13.Lakshmi N.J., Gogate P.R., Pandit A.B. Treatment of acid violet 7 dye containing effluent using the hybrid approach based on hydrodynamic cavitation. Process Safety and Environmental Protection. 2021;153:178–191. [Google Scholar]

- 14.Gogate P.R. Treatment of wastewater streams containing phenolic compounds using hybrid techniques based on cavitation: A review of the current status and the way forward. Ultrasonics sonochemistry. 2008;15(1):1–15. doi: 10.1016/j.ultsonch.2007.04.007. [DOI] [PubMed] [Google Scholar]

- 15.Thanekar P., Panda M., Gogate P.R. Degradation of carbamazepine using hydrodynamic cavitation combined with advanced oxidation processes. Ultrasonics sonochemistry. 2018;40:567–576. doi: 10.1016/j.ultsonch.2017.08.001. [DOI] [PubMed] [Google Scholar]

- 16.Raut-Jadhav S., Saharan V.K., Pinjari D., Sonawane S., Saini D., Pandit A. Synergetic effect of combination of AOP's (hydrodynamic cavitation and H2O2) on the degradation of neonicotinoid class of insecticide. Journal of Hazardous Materials. 2013 Oct;15(261):139–147. doi: 10.1016/j.jhazmat.2013.07.012. [DOI] [PubMed] [Google Scholar]

- 17.Korpe S., Rao P.V., Sonawane S.H. Performance evaluation of hydrodynamic cavitation in combination with AOPs for degradation of tannery wastewater. Journal of Environmental Chemical Engineering. 2023;11(3):109731. [Google Scholar]

- 18.Sangave P.C., Pandit A.B. Ultrasound pre-treatment for enhanced biodegradability of the distillery wastewater. Ultrasonics Sonochemistry. 2004;11(3–4):197–203. doi: 10.1016/j.ultsonch.2004.01.026. [DOI] [PubMed] [Google Scholar]

- 19.Gogate P.R., Thanekar P.D., Oke A.P. Strategies to improve biological oxidation of real wastewater using cavitation based pre-treatment approaches. Ultrasonics sonochemistry. 2020;64:105016. doi: 10.1016/j.ultsonch.2020.105016. [DOI] [PubMed] [Google Scholar]

- 20.Saxena S., Rajoriya S., Saharan V.K., George S. An advanced pretreatment strategy involving hydrodynamic and acoustic cavitation along with alum coagulation for the mineralization and biodegradability enhancement of tannery waste effluent. Ultrasonics Sonochemistry. 2018;44:299–309. doi: 10.1016/j.ultsonch.2018.02.035. [DOI] [PubMed] [Google Scholar]

- 21.Moradnia M., Noorisepehr M., Salari M., Darvishmotevalli M. Optimization of 2-chlorophenol removal using ultrasound/persulfate: Prediction by RSM method, biodegradability improvement of petrochemical refinery wastewater. Arabian Journal for Science and Engineering. 2022;47(6):6931–6939. [Google Scholar]

- 22.Guo W., Shi Y., Wang H., Yang H., Zhang G. Intensification of sonochemical degradation of antibiotics levofloxacin using carbon tetrachloride. Ultrasonics sonochemistry. 2010;17(4):680–684. doi: 10.1016/j.ultsonch.2010.01.004. [DOI] [PubMed] [Google Scholar]

- 23.Lakshmi N.J., Agarkoti C., Gogate P.R., Pandit A.B. Acoustic and hydrodynamic cavitation-based combined treatment techniques for the treatment of industrial real effluent containing mainly pharmaceutical compounds. Journal of Environmental Chemical Engineering. 2022;10(5):108349. [Google Scholar]

- 24.Thanekar P., Garg S., Gogate P.R. Hybrid treatment strategies based on hydrodynamic cavitation, advanced oxidation processes, and aerobic oxidation for efficient removal of naproxen. Industrial & Engineering Chemistry Research. 2019;59(9):4058–4070. [Google Scholar]

- 25.Thanekar P., Murugesan P., Gogate P.R. Improvement in biological oxidation process for the removal of dichlorvos from aqueous solutions using pretreatment based on Hydrodynamic Cavitation. Journal of Water Process Engineering. 2018;23:20–26. [Google Scholar]

- 26.Neczaj E., Kacprzak M. Ultrasound as a pre-oxidation for biological landfill leachate treatment. Water science and technology. 2007;55(12):175–179. doi: 10.2166/wst.2007.406. [DOI] [PubMed] [Google Scholar]

- 27.Guo Y., Xue Q., Zhang H., Wang N., Chang S., Wang H., Pang H., Chen H. Treatment of real benzene dye intermediates wastewater by the Fenton method: characteristics and multi-response optimization. RSC advances. 2018;8(1):80–90. [Google Scholar]

- 28.Umar M., Aziz H.A., Yusoff M.S. Trends in the use of Fenton, electro-Fenton and photo-Fenton for the treatment of landfill leachate. Waste management. 2010;30(11):2113–2121. doi: 10.1016/j.wasman.2010.07.003. [DOI] [PubMed] [Google Scholar]

- 29.Feng F., Xu Z., Li X., You W., Zhen Y. Advanced treatment of dyeing wastewater towards reuse by the combined Fenton oxidation and membrane bioreactor process. Journal of Environmental Sciences. 2010;22(11):1657–1665. doi: 10.1016/s1001-0742(09)60303-x. [DOI] [PubMed] [Google Scholar]

- 30.Ahmed J, Thakur A, Goyal A. Industrial wastewater and its toxic effects. Chapter in Biological Treatment of Industrial wastewater. Ed. Shah, M. Royal Society of Chemistry, London, 2022.

- 31.Cleuvers M. Aquatic ecotoxicity of pharmaceuticals including the assessment of combination effects. Toxicology letters. 2003;142(3):185–194. doi: 10.1016/s0378-4274(03)00068-7. [DOI] [PubMed] [Google Scholar]

- 32.Shah N.S., Rizwan A.D., Khan J.A., Sayed M., Khan Z.U.H., Murtaza B., Iqbal J., Din S.U., Imran M., Nadeem M., Al-Muhtaseb A.H., Muhammad N., Khan H.M., Ghauri M., Zaman G. Toxicities, kinetics and degradation pathways investigation of ciprofloxacin degradation using iron-mediated H2O2 based advanced oxidation processes. Process Safety and Environmental Protection. 2018;117:473–482. [Google Scholar]

- 33.Wang J., Wang S. Toxicity changes of wastewater during various advanced oxidation processes treatment: An overview. Journal of Cleaner Production. 2021;315:128202. [Google Scholar]

- 34.Antonio da Silva D., Pereira Cavalcante R., Batista Barbosa E., Machulek Junior A., César de Oliveira S., Falcao Dantas R. Combined AOP/GAC/AOP systems for secondary effluent polishing: optimization, toxicity and disinfection. Separation and Purification Technology. 2021;263:118415. [Google Scholar]

- 35.Thanekar P., Lakshmi N.J., Shah M., Gogate P.R., Znak Z., Sukhatskiy Y., Mnykh R. Degradation of dimethoate using combined approaches based on hydrodynamic cavitation and advanced oxidation processes. Process Safety and Environmental Protection. 2020;143:222–230. [Google Scholar]

- 36.Barik A.J., Kulkarni S.V., Gogate P.R. Degradation of 4-chloro 2-aminophenol using combined approaches based on microwave and photocatalysis. Separation and Purification Technology. 2016;168:152–160. [Google Scholar]

- 37.Nachiappan S., Muthukumar K. Pretreatment of textile effluent by ultrasound based hybrid methods for the enhancement of biodegradability. Journal of Scientific and Industrial Research. 2012;71:757–765. [Google Scholar]

- 38.Gonze E., Fourel L., Gonthier Y., Boldo P., Bernis A. Wastewater pretreatment with ultrasonic irradiation to reduce toxicity. Chemical Engineering Journal. 1999;73(2):93–100. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.