Abstract

Cells interact with their surrounding environment through a combination of static and dynamic mechanical signals that vary over stimulus types, intensity, space, and time. Compared to static mechanical signals such as stiffness, porosity, and topography, the current understanding on the effects of dynamic mechanical stimulations on cells remains limited, attributing to a lack of access to devices, the complexity of experimental set‐up, and data interpretation. Yet, in the pursuit of emerging translational applications (e.g., cell manufacturing for clinical treatment), it is crucial to understand how cells respond to a variety of dynamic forces that are omnipresent in vivo so that they can be exploited to enhance manufacturing and therapeutic outcomes. With a rising appreciation of the extracellular matrix (ECM) as a key regulator of biofunctions, researchers have bioengineered a suite of ECM‐mimicking hydrogels, which can be fine‐tuned with spatiotemporal mechanical cues to model complex static and dynamic mechanical profiles. This review first discusses how mechanical stimuli may impact different cellular components and the various mechanobiology pathways involved. Then, how hydrogels can be designed to incorporate static and dynamic mechanical parameters to influence cell behaviors are described. The Scopus database is also used to analyze the relative strength in evidence, ranging from strong to weak, based on number of published literatures, associated citations, and treatment significance. Additionally, the impacts of static and dynamic mechanical stimulations on clinically relevant cell types including mesenchymal stem cells, fibroblasts, and immune cells, are evaluated. The aim is to draw attention to the paucity of studies on the effects of dynamic mechanical stimuli on cells, as well as to highlight the potential of using a cocktail of various types and intensities of mechanical stimulations to influence cell fates (similar to the concept of biochemical cocktail to direct cell fate). It is envisioned that this progress report will inspire more exciting translational development of mechanoresponsive hydrogels for biomedical applications.

Keywords: cell therapy, hydrogel, mechanical stimulation, mechanomedicine, mechanotransduction

Cells communicate with their surroundings through both static and dynamic mechanical signals, which vary over stimulus type, intensity, location, and duration. Current knowledge on dynamic mechanical stimulations is limited compared to static ones. For this, researchers are now developing extracellular matrix‐mimicking biofunctional hydrogels that can replicate intricate static and dynamic mechanical profiles, enhancing the understanding of cellular complex interactions.

1. Introduction

The state and behavior of a cell are dynamic and they are a function of its intrinsic characteristics (e.g., genetic makeup, cytoskeletal contractility, and metabolic signaling pathways) and its interaction with the local environment.[ 1 , 2 ] The extracellular microenvironment consists of the extracellular matrix (ECM, neighboring cells, and a variety of biochemicals, such as hormones, growth factors, and cytokines).[ 3 ] In comparison to biochemical signals, the biophysical effects of ECM in modulating cellular fates remain poorly elucidated. Notably, the biological function of ECM extends beyond inert physical support, as it can impact functional behaviors in cells such as migration, proliferation, differentiation, and apoptosis via a series of mechanical cues.[ 4 , 5 ] However, many of these findings are based on overly simplistic models that typically involve culturing cells on 2D plastic or glass surfaces that have been modified with ECM components. Such systems are unable to recapitulate the native 3D context, resulting in poor biological and clinical relevance and translatability.[ 6 , 7 ] Materials that allow in vivo cell–matrix interaction are advantageous for decoding the complex relationship between ECM and cells, and be used as a model to translate basic science findings into advances in regenerative medicine, cancer therapies for instance.[ 8 , 9 , 10 ] In recent years, it has become evident that the ECM is more than just a passive mechanical support; it is also as an active regulator of fundamental cellular processes. While the ECM has a prominent influence over cellular processes, cells, in turn, are also continually changing ECM features by secreting ECM macromolecules or degrading the ECM network to remodel their external environment.[ 10 ] This bidirectional, interdependent interaction in which cells and matrix can affect each other is referred to as ‘dynamic reciprocity’.[ 11 ] Given the importance of ECM in determining cellular fates, a better understanding of cell–matrix interaction is necessary to delineate the influence of ECM on cells and vice versa, as well as to further exploit these mechanisms for tissue engineering.

A thorough understanding of the biofunctions of ECM in vivo is required for the proper design of an in vitro model to study ECM–cell interactions. The ECM serves at least five important roles. It provides i) structural support, ii) cell binding sites, iii) topographical cues, iv) porous geometries for nutrient and waste exchange, and v) tissue‐specific spatial and temporal organization to induce and maintain cellular functions.[ 12 ] These biophysical properties constitute the matrix mechanics that allows cells to sense and respond through mechanotransduction.[ 13 ] Mechanotransduction is typically characterized by cells binding to the surrounding matrix and applying tension across integrins, resulting in a cascade of downstream mechanosensing pathways that alter the genetic and epigenetic profile of cells and, eventually, cell fate.[ 14 , 15 ] On this note, ECM not only regulates cell behaviors, but it also undergoes dynamic structural remodeling when it interacts with resident cells.[ 10 ] While understanding how ECM can direct cellular processes (e.g., embryonic development, carcinogenesis, immune response) and maintain cell functions is critical, it is extremely difficult to replicate this interaction in vitro.[ 16 ]

Hydrogels are a desirable material for in vitro ECM recapitulation. They are highly hydrated and porous, allowing for a large aqueous compartment as well as excellent nutrient and gas permeability, similar to in vivo tissues.[ 12 ] In addition, the mechanical properties of hydrogels can be easily modified to suit a broad spectrum of tissues in the body (for example, matrix stiffness ranging from 50 Pa to 1 GPa, from the brain to bone tissue[ 17 ]), making them more physiologically relevant. Most importantly, many ECM proteins (e.g., laminin, collagen, fibronectin) and their associated protein derivatives (e.g., RGD, GFOGER, YIGSR) can be incorporated into the gel formulation to yield the gels properties that are similar to native ECM.[ 18 , 19 , 20 ] To study cell–ECM mechanocommunications using hydrogels, cells are typically cultured within gels with fixed mechanical properties. Mechanical properties include stiffness, strain, porosity, topography, and cell adhesivity have been extensively studied under static settings.[ 10 , 21 , 22 ] In addition to mimicking the dynamic structures of ECM, stimuli‐responsive hydrogels with variable mechanical properties modulated by changes in pH, temperature, light, and magnetic field are gaining popularity.[ 23 , 24 ] These stimuli‐responsive hydrogels have been shown in proof‐of‐concept studies to direct targeted cellular responses, and some have even led to appreciable outcomes for disease treatment.[ 25 ]

There are significant technical obstacles to replicate the native ECM in vitro. One of the major difficulties is simulating the native dynamic structural remodeling of ECM. Although some existing gel formulations, as described above, allow on‐demand self‐reconfiguration in response to external stimulations, these changes are typically one‐time only and irreversible (e.g., stiffening only).[ 26 ] Furthermore, ECM is of high heterogeneity and structurally anisotropic,[ 27 ] but most current hydrogel designs are mechanically identical in all dimensions, and thus unsuitable to realize spatial/temporal heterogeneity that occurs naturally in vivo. While there are hurdles, advances in material design and fabrication (e.g., additive manufacturing) have shown promise in creating in creating the next generation of hydrogels that are more structurally defined and controllable.[ 28 , 29 , 30 ] A better understanding of the mechanotransduction process will definitely aid in the development of new material design principle (gradient hydrogel).

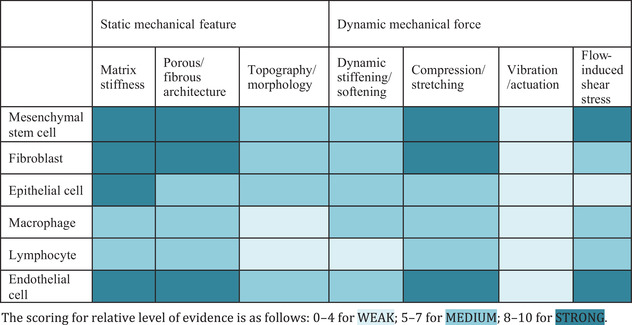

Here, we present a comprehensive overview of recent advances in hydrogel engineering for cell fate manipulation. First, we will discuss how mechanical stimuli can impact different cellular components and the underlying mechanobiology pathways. The principles of designing a mechanoresponsive hydrogel to modulate functions of different cell types are then described. To the best of our knowledge, this is the first comprehensive study summarizing cell mechanomodulation spanning both the fields of static and dynamic stimulations using hydrogel materials. Based on cellular differences in response to mechanostimulation (treated vs. control) and number of related published literature and citations from Scopus database, we categorize the rigor of evidence describing the impact of static and dynamic mechanical stimuli on clinically relevant cell types including mesenchymal stem cells, fibroblasts, epithelial cells, immune cells, and endothelial cells as ‘strong’, ‘medium’, and ‘weak’. We believe this classification will provide readers with evidence‐based recommendations on the type of mechanical stimuli to incorporate into their hydrogels for specific experimental goals. Besides, we highlight the synergistic effects of integrating multiple mechanical stimulations on different cell types to demonstrate the power of using a cocktail of different types and intensities of mechanical stimulations to influence cell fates, similar to the concept of biochemical cocktail to direct cell fate. We believe this progress report will inspire future breakthroughs in hydrogel engineering and mechanical stimuli with promising translational potential in biomedicine.

2. Mechanical Stimuli and Cell Behaviors

Human cells have a sense of ‘touch’, allowing them to ‘feel’ and ‘respond’ to the mechanical properties of their surroundings.[ 31 ] Living cells are largely influenced by the static and dynamic mechanical characteristics of their microenvironment (e.g., ECM) and the mechanical forces that surround them (e.g., shear force from blood flow).[ 32 , 33 , 34 ] In response to these mechanical cues, cells modify their behaviors to adapt to new microenvironment and achieve homeostasis. Mechanical stimuli have the ability to control virtually every aspects of cell behavior, including morphogenesis, proliferation, differentiation, migration, and gene/protein expression.[ 32 , 35 , 36 ] The behaviors are cell‐type specific, which means that different types of cells could react differently even when subjected to the same stimuli type and intensity. In this regard, mechanical cues are an important informational system for regulating cell behaviors in vivo. It also implies the potential of using a cocktail of different types and intensities of mechanical stimulations to influence cell fates, similar to the concept of biochemical cocktail to direct cell fate.

2.1. Mechanosensation of Different Cellular Components

By integrating multiple cellular structures (i.e., mechanosensors) and pathways, cells can probe mechanical cues and provide specific feedback.[ 37 , 38 ] The cytoskeleton is a dynamic network of interlinking filamentous proteins (i.e., filamentous actin, intermediate filament, and microtubule) in the cytoplasm that serves as the key structure for cell mechanobiological function (Figure 1A).[ 39 , 40 ] Cytoskeleton not only serves an internal scaffold as mechanical support of cell shapes and mechanical resistance to the deformation of plasma membrane, it also connects nuclear matrix to the ECM for mechanotransduction.[ 37 ] As previously demonstrated, filamentous actin (F‐actin) is the primary regulator and transmitter of external mechanical stimulation to cells.[ 41 ] In most eukaryotic cells, the F‐actin cytoskeleton drives cell morphogenesis changes in conjunction with the force exertion activity of myosin (an ATP‐consumed molecular motor). The process influences a diverse range of cellular processes such as cell adhesion, movement, and division by generating contractility and protrusion, thus enabling the cells to adapt to the sensed physical forces exerted on plasma membrane.[ 42 , 43 ]

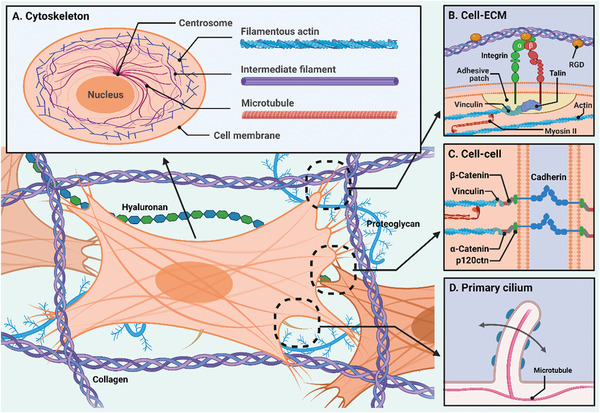

Figure 1.

Schematic illustration of key structures of cell mechanobiological functions. A) Cytoskeleton is the dynamic network of interlinking three filamentous proteins including filamentous actin, intermediate filament, and microtubule in cytoplasm, which is the key structure for mechanical sensing and cell structural support. B) The cell–extracellular matrix interaction is transmitted to cells through integrin on focal adhesion sites. C) Cadherin on adherens junctions forms efficient intracellular adhesion and mechanical force transmission. D) Primary cilium on the cell membrane probes and collects information about the surrounding environment.

As the barrier that separates the interior of cells from the exterior microenvironment, the cell membrane plays a crucial role in cell mechanosensation as well. On the lipid bilayer of cellular membrane, there are several mechanosensitive microstructures, molecules, proteins, and channels. Integrin, a transmembrane heterodimer consisting of α‐ and β‐chain subunits, is the primary cell‐adhesion receptor that binds to the matrix, forming focal adhesion sites.[ 15 ] It also serves as a transmembrane transmitter to the actin cytoskeleton (actin stress fiber) (Figure 1B). While one end of an integrin binds to ECM proteins for anchorage, the opposite end is usually connected to the cytoskeleton via linkage with cytoplasmic proteins like talin, filamin, vinculin, and actinin.[ 44 ] These cytoplasmic proteins bind directly to actin filaments, allowing integrins and their associated proteins to mediate ECM–cytoskeleton interactions.[ 45 ] When integrins bind to ECM proteins, they recruit other integrins to form a cluster which then assembles into focal adhesion complexes.[ 46 ] When the cell membrane is subject to external forces, the extracellular α‐chain of integrin, which binds to cell‐adhesion peptide motif such as RGD sequence (i.e., tripeptide arginine–glycine–aspartate), is activated via conformational switches.[ 15 ] The mechanical signals are then transmitted to the linked F‐actin cytoskeleton by the intercellular β‐chain subunit,[ 47 ] and the cellular internal force (e.g., contractility) can then transmit to the ECM via integrin‐based focal adhesion sites.[ 14 ] Mechanical cues (force transmission from the ECM) relayed by focal adhesion can directly influence cytoskeletal configuration and actin polymerization, causing gene expression and cellular responses to be perturbed.[ 48 ] It should be noted that structures of focal adhesion complexes are not static because they can dynamically disassemble and reassemble in response to cytoskeleton contractility.[ 49 ] In this case, the signals are sent in the reverse direction, which is intracellularly, to the focal adhesion site. Evidently, focal adhesion serves as an integrated signaling center for the transmission of mechanical, biochemical, and contextual cues, with signaling directed both inside‐out and outside‐in.

Aside from cell–ECM adhesion, cell–cell interaction (e.g., adheren junction, gap junction, etc.) is heavily involved in mechanosensation when cells are functionally clustered together and every single cell is mechanically affected by neighboring cells. For example, the establishment of cadherin‐based adherens junctions allows efficient intracellular adhesion and force transmission.[ 50 , 51 ] Furthermore, F‐actin‐binding proteins including α‐catenin and vinculin can modify the molecular conformation of cytoskeleton in response to transmitted force. Alternatively, F‐actin binding proteins can reorganize the cytoskeletal network by adjusting the actomyosin belts (myosin II) (Figure 1C). This may further induce force‐driven cell shape changes, collective cell migration, and tissue reorganization.[ 50 , 52 , 53 ] Other than membrane proteins and molecules, primary cilium is another important cellular mechanosensor located on the cell membrane (generally situated at the cell apical surface).[ 54 ] Primary cilium is the microtubule‐based flexible sensory ‘antennae’ that can probe and collect information about the surrounding environment (Figure 1D). For example, the primary cilium deforms in the presence of fluid flow and transmits mechanical information into the cell.[ 55 ]

Mechanosensitive ion channel is another essential force sensor present on the cell membrane. Since Hudspeth and Corey's seminal work in 1979,[ 56 ] a large number of mechanically activated ion channels have been discovered. The channels consist of several mechanosensitive integral membrane proteins whose molecular conformation can be altered in response to various external mechanical forces, most notably plasma membrane tension (Figure 2 ). These conformational changes alter the membrane permeability for specific ions, allowing them to enter the cell as mechanical signals that influence cell fates and behaviors.[ 38 , 57 ] For example, G‐protein‐coupled receptors (GPCRs) have been identified as mechanosensitive ion channels capable of detecting membrane stretching and responding to changes in conformation.[ 58 ] In addition, transient receptor potential ion channels (e.g., TRPC1, TRPV4, TRPP2),[ 37 , 59 ] piezo ion channels (e.g., Piezo1 and Piezo2),[ 60 ] two‐pore domain potassium (K2P) channels (e.g., TREK1, TREK2, TRAAK),[ 61 , 62 ] and degenerin/epithelial sodium ion (DEG/ENaC) channels[ 63 ] have also been found to be mechanosensitive. Furthermore, mechanically driven ion channel activation can result in the release of signaling molecules that remodels the surrounding matrix, thereby influencing neighboring cells behavior.[ 10 ]

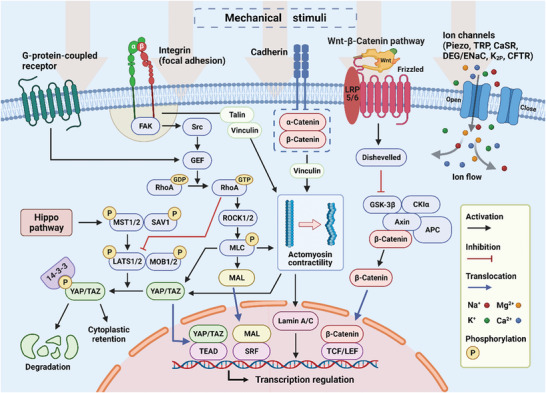

Figure 2.

Schematic illustration of cellular mechanotransduction pathways. Matrix mechanical features and external applied forces can influence cell behaviors. The mechanical signals are transduced to the nucleus by transmembrane proteins/macromolecules, ion channels, and cytoskeleton remodeling, and then trigger alternation of gene expression to tune cell fates and activities.

2.2. Cellular Mechanotransduction and Response

The cellular process by which cells integrate and convert mechanical stimuli into biochemical/molecular signals is referred to as mechanotransduction. When cells detect external forces on the cell surface, the signals can be rapidly transduced to the nucleus (through the membrane protein–cytoskeleton–nucleus axis) and trigger corresponding cellular behaviors, resulting in the formation of a robust cellular mechanoresponsive system. This force‐induced transduction also contributes to/partakes in protein conformational changes, such as the exposure of cryptic binding or signaling domains.[ 64 ] Cells mediate their behaviors primarily by altering their gene expression profiles.[ 65 ] Mechanosensors on the cell membrane detect mechanical cues, which are converted into biochemical signals in the cytoplasm before being relayed to the nucleus by effector proteins to regulate gene expression.

One central example of gene‐regulated mechanotransduction pathway is the Hippo pathway (Figure 2).[ 66 , 67 ] The downstream effectors in the Hippo pathway and the mechanosensitive nuclear transcription factors are mechanoactuator proteins, Yes‐associated protein and transcriptional coactivator with PDZ‐binding motif (YAP/TAZ).[ 37 , 66 ] They serve as ‘mechanical memory keepers’ by mediating gene expression and remodeling chromatin in response to external stimuli in the same way that strong or weak mechanosensitive memories do.[ 68 ] When the Hippo is “switched‐on” after phosphorylation of MST1/2 by upstream effector, kinases LAT1/2 will be activated and induce phosphorylation of YAP/TAZ. Phosphorylated YAP/TAZ will be inactivated and either binds to 14‐3‐3 protein (cytoplastic retention) or degrades further. When subjected to external mechanical stimulation, signals are transmitted from membrane proteins (e.g., integrin, GPCR) to activate RhoA (transforming protein). The RhoA then inhibits LATS kinase activity (switches off the Hippo pathway) and downregulates LATS‐driven YAP/TAZ phosphorylation. This causes YAP/TAZ activation, and the proteins translocate into the nucleus (i.e., nuclear shuttling proteins), where they interact with TEAD factors to mediate gene expression.[ 44 , 67 , 69 , 70 , 71 , 72 ] As such, the location of YAP/TAZ is generally used to assess the level of mechanical signaling. For example, when cells experience low levels of mechanical stimulation (e.g., in soft ECM), most YAP/TAZ proteins are found in the cytoplasm; when cells are subjected to high levels of stimulation (e.g., in stiff ECM), many YAP/TAZ are found in the nucleus instead (i.e., nuclear localization). In addition to mechanotransduction, Hippo pathway also plays an important role in regulating cell behaviors (e.g., cell movement and growth) and is a key regulator in cancer progression, as discussed in published reviews.[ 70 , 73 , 74 ]

RhoA/ROCK pathway is another well‐researched pathway for cellular mechanotransduction (Figure 2). Under RhoA/ROCK pathway, the guanine nucleotide‐exchange factor (GEF) is activated and interacts with RhoA after the relevant membrane proteins receive external mechanical signals. In this process, GEF stimulates RhoA by catalyzing free nucleotide uptake (i.e., GDP to GTP).[ 75 , 76 ] Following that, RhoA‐GTP activates its downstream effectors, ROCK 1/2, which promotes phosphorylation of myosin light chain to induce actin stress fibers formation and actomyosin contraction. The induced intrinsic force from the cytoskeleton can directly influence transcription in the nucleus via nuclear lamina (e.g., lamin A) or activate transcription regulators (e.g., megakaryocytic acute leukaemia (MAL)) and translocate them into the nucleus.[ 36 , 77 ] SRF‐MAL, which is associated with serum response factor (SRF) in the nucleus, drives changes in gene expression and mediates cell behaviors. In addition to changes in gene expression, the cytoskeleton is altered during RhoA/ROCK pathway activation, which results in corresponding changes in cell morphology or motility. Interestingly, the transcription regulator YAP/TAZ is also stimulated in this process,[ 66 ] indicating the potential synergistic effect between Hippo and RhoA/ROCK pathways. This encourages further research into the interaction of various mechanotransduction pathways to better understand how they interact in response to external mechanical stimuli. Besides, Wnt‐β‐catenin pathway is another important route for cellular response to external mechanical cues. β‐catenin is not a mere structural protein in the cadherin adhesion complex, but rather a nuclear shuttling protein that, when activated, can translocate into the cell nucleus and bind to TCF/LEF (transcription factors) to regulate gene expression (Figure 2).[ 36 , 78 , 79 , 80 ]

In addition to cytoskeleton remodeling and gene expression alterations, changes in nuclear morphology, including shape and size, are prominent cellular responses to mechanical cues from the surrounding environment. Because the inner membrane of the nucleus is linked to the cytoskeleton, any mechanically induced cytoskeleton remodeling could lead to changes in nuclear morphology. For example, the nuclear size increases as microtubules polymerize, indicating a mechanosensitive response to the ECM stiffness.[ 81 ] Recently, it was discovered that a complex known as linker of the nucleoskeleton and cytoskeleton is capable of stretching nuclear pores by transducing ECM mechanical cues to nucleus via cytoskeleton.[ 82 , 83 ] As previously stated, nucleus‐bound physical transduction pathway through cytoskeleton is much faster than the typical mechanotransduction signal pathways (i.e., chemical signals).[ 84 ] As a result, the cell's initial response to mechanical stimuli is assumed to be purely mechanical, involving cytoskeleton remodeling and changes in nuclear shape.[ 37 ] Another important pathway for cellular response mechanotransduction is changes in secondary messenger signaling, such as calcium ion flow (Figure 2). Readers are encouraged to refer to published review papers for more information.[ 38 , 57 ]

2.3. Static and Dynamic Mechanical Stimuli

Mechanical stimuli, like biochemical/chemical signals, influence cellular function and growth in vivo.[ 36 ] They play vital roles in the regulation of cellular physiological processes at the molecular, cellular, and systemic levels. Static mechanical stimulus is a type of mechanical factor determined primarily by the physical properties of attached substrates, matrices, or scaffolds (e.g., ECM or artificial implant materials). The stiffness of matrix is a well‐known mechanical factor that influences cell behaviors.[ 85 ] Cells can sense stiffness through focal adhesion sites and transduce signals via membrane protein channels and the cytoskeleton. In the human body, a diverse range of cells and tissues reside in/on mechanical environments of varying stiffness, and the local stiffness of the matrix has a significant impact on cell behaviors.[ 86 ] For example, mesenchymal stem cell differentiation to osteoblasts or chondrocytes can be regulated by substrate stiffness, which is largely mediated by mechanosensitive integrin β1.[ 87 ] Creating an environment with appropriate stiffness has become a prerequisite for cell culture to achieve optimal cell growth and biofunctions for in vitro and in vivo work, inspired by the stiffness‐dependent attributes of the cell.[ 32 ] The stiffness of artificial matrix can be easily increased by raising material mass concentration, molecular weight, and crosslinking density.[ 12 , 88 ] It is well‐known that the tumor matrix, which contains cancer‐associated fibroblasts, has a higher rigidity than normal ECM, which contributes significantly to tumor growth and progression.[ 85 ] Therefore, enhanced tissue stiffness is regarded as a distinguishing feature of solid tumors.[ 89 ] Furthermore, porous structure are important mechanical properties of matrices because of their strong correlation with matrix stiffness. According to recent studies, the mesh size and porosity of the matrix could influence cell proliferation and mobility.[ 35 ] Lin et al. demonstrated that increasing the mesh size of hydrogel could promote cell growth.[ 90 ] Additionally, substrate surface topography, morphology, and fibrous architecture are other important static mechanical features to consider in cellular mechanobiology.[ 35 ]

Dynamic mechanical stimulus, or externally applied force, is another important type of mechanical factor in cell mechanobiology. Cells and tissues are constantly experiencing a variety of forces within the body such as dynamic pressure produced by blood flow, skin deformation, muscle stretching, and lung expansion, all of which are essential for maintaining proper body physiology. In comparison to the mechanical characteristics of matrix or substrate, dynamic mechanical stimulation is still a relatively new field, but it is attracting greater attention in recent years. Some emerging techniques, such as microfluidic platforms and hydrogel engineering have enabled researchers to study cell behaviors under various mechanical stimulations in a simplified and accurate manner.[ 34 , 91 , 92 ]

Flow shear stress is the physical force caused by the friction of fluid flow against the cell membrane (i.e., flow‐induced shear stress). In the human body, many tissues and adherent cells are subjected to mechanical shear force in the biofluidic systems (e.g., blood and lymphatic systems).[ 93 ] This mechanical stimulus has a significant impact on cell activity and adhesion. To illustrate, cells respond to shear forces by altering membrane properties (e.g., permeability), gene expression, cell behaviors, and even reorganizing the entire cell layer. In addition, abnormal flow‐induced shear stress has a significant impact on disease progression. For example, high wall shear stress from blood flow has been shown to improve the viability of human colorectal carcinoma cells due to increased intracellular signaling.[ 94 ] Dynamic compression and tension forces are essential dynamic mechanical stimuli[ 95 ] and they include external loading during human locomotion, and traction and adhesion forces during cell–cell/cell–ECM interactions. In recent years, a collection of studies has been conducted to investigate how tension force affects cell behavior, including YAP/TAZ nuclear localization,[ 96 ] cell mobility,[ 97 ] and cell adaptability.[ 98 ] Similar to shear stress, abnormal tissue tension can also drive tumor aggression and progression, which is extensively reviewed elsewhere.[ 99 , 100 ]

On the other hand, the effects of other in vivo mechanical stimuli, such as gravity, hydrostatic pressure, and osmotic pressure on cell behaviors cannot be overlooked. As cells in the body operate in complex mechanochemical environments, it is important to study how they respond to a combination of static and dynamic mechanical stimuli (i.e., mechanical cocktail).[ 32 ] Nonetheless, the effect of dynamic mechanical stimuli on cells is currently understudied. As a result, additional research should be conducted using biomaterials such as hydrogel, which will be described in greater detail in the following section.

3. Current Design Principles for Mechanoresponsive Hydrogels

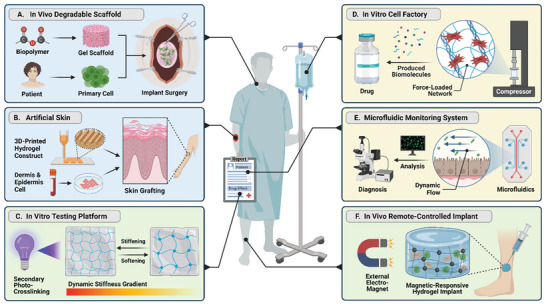

Hydrogels are described as 3D networks of highly crosslinked, hydrophilic polymers capable of absorbing solvents up to a few thousand heavier than their original weight.[ 101 ] They can be classified based on their material origins, preparation methods, types of precursors, crosslinking methods, biodegradability, ionic charges, physical properties, and responsiveness toward external stimuli.[ 102 ] Hydrogels have soft, highly hydrated properties similar to native tissue and ECM, and are capable of providing cells with an ideal environment to grow. Due to low interfacial tension, hydrogels have an exceptionally low affinity for proteins in body fluids which contributes to their high biocompatibility.[ 103 ] The unique, highly porous, interconnected network structure of hydrogel is also critical for gaseous exchange, cell locomotion, as well as mass transportation of nutrients and cellular waste.[ 104 ] Furthermore, the ability to tune hydrogels using a variety of methods has given researchers rigorous control over their mechanical and biochemical properties, thus bridging the gap between fabricated hydrogel scaffolds and native ECM with more realistic emulation of in vivo conditions (Figure 3 ). To date, specific cellular microenvironments or cell behaviors can be recreated by tuning the mechanical properties of hydrogel. It is also possible to recapitulate dynamic biophysical environment on a hydrogel platform using external devices such as a digital stretcher and microfluidic pump.

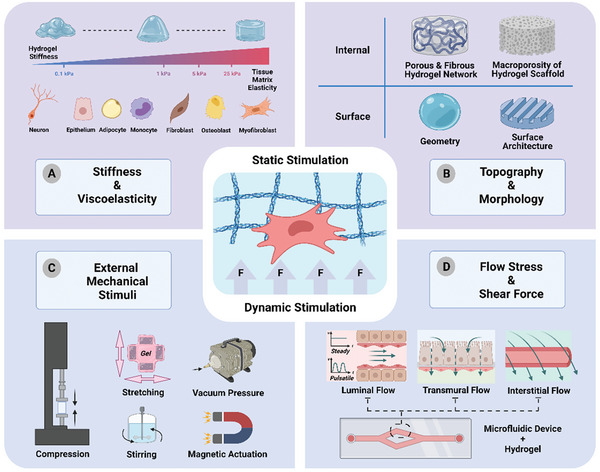

Figure 3.

Schematic illustration of static and dynamic mechanical stimulation for hydrogel materials. A) Through modulating stiffness, hydrogels can mimic specific tissue matrix elasticity to suit different cell types.[ 86 , 113 ] B) The topography and morphology of hydrogel such as internal structures (e.g., porous and fibrous hydrogel network and macroporosity of hydrogel scaffold) and surface structures (e.g., 3D hydrogel geometry, surface architecture) influence material physical features and cell behaviors. C) Dynamic mechanical stimuli exerted on hydrogel materials by external equipment, including compression, stretching, stirring, vacuum pressure, and magnetic field. D) Microfluidic device/hydrogel‐integrated platform provides flow‐induced shear stress and mimics different in vivo flow patterns (e.g., steady or pulsatile luminal flow, transmural flow, interstitial flow).[ 111 ]

3.1. 2D Conventional Substrate versus 3D Hydrogel Matrix

Cells alone may not sustain and undergo cellular functions unless they are supported by ECM, the external environment to which cells are bound in vivo. The ECM is a 3D heterogeneous network consisting of collagens, proteoglycans, elastin, and glycoproteins that assemble to provide structural support and act as a reservoir for bioactive molecules.[ 105 ] It should be pointed out that the “dimension” of matrix or substrate is also an important factor for cell growth. From a cell biology perspective, hydrogels could serve as a 3D matrix to better recapitulate in vivo microenvironment. The structural complexity and contact guidance that a 2D substrate (planar surface) can provide fair pale in comparison to a 3D environment. Cells can probe and detect differences in their surroundings in 2D or 3D, thereby transmitting corresponding mechanical and contextual cues by intracellular signaling pathways, which alter gene expression and result in distinctive cellular behaviors.[ 106 ] In a conventional approach, cell culture is performed on 2D substrates such as Petri dishes and silicone substrates. This, however, does not completely replicate the in vivo milieu and frequently leads to compromised histological observations.[ 107 ] The absence of 3D structural cues (e.g., porous structure) and physical supports (e.g., multidimensional force) commonly results in the formation of a disorganized layer of cells which do not differentiate and hierarchically assemble into functional tissue.[ 108 ]

Interestingly, the effects of mechanical stimulation also depend on the dimension of cell environment. The disparity of cellular responses between 2D and 3D microenvironments was well‐illustrated by a study conducted by Bisell and co‐workers, where human breast epithelial cells seeded in 3D basal membrane showed normal phenotypes and formed acini structures, whereas those cultured on 2D substrate exhibited tumorigenic features.[ 109 ] On the other hand, it has been shown that under 2D conditions, a stiff substrate promoted mesenchymal stem cell spreading and activated cell migration,[ 110 ] due to higher intracellular cytoskeleton tension, while under 3D conditions, a stiff matrix reduced cell spreading because of steric hindrance and adhesion site distribution.[ 82 ] Additionally, in some cases where cells originate from a flat surface like endothelial cells, 2D culture system might more accurately reconstitute in situ condition.[ 88 ] Increasingly, circumstances where 2D culture systems are being preferred are getting less popular, but they should be given due consideration depending on the scientific questions and applications.

3.2. Static Mechanical Stimulation of Hydrogel Materials

One big advantage of hydrogel material is that its static mechanical features including stiffness, porous microstructure, and topography, can be easily programmed to mimic the native microenvironment and to biophysically reprogram cells.

3.2.1. Stiffness

Stiffness is one of the most important mechanical features of hydrogel, which is commonly defined as the material's resistance to deformation when subjected to external mechanical forces.[ 111 ] In other words, stiffness is the indication of material softness or hardness. Stiffness of a material is generally quantified by elastic (or Young's) moduli. Physiologically, stiffness of ECM in tissue level varies from 0.1 kPa for brain tissue to 40 kPa in osteoid,[ 112 ] and different cell types preferentially grow on tissue matrix with specific elasticity (Figure 3A).[ 86 , 113 ] The stiffness differential of ECM can be well assimilated in hydrogel fabrication, and a myriad of studies have validated the significance of hydrogel stiffness in dictating cell spreading, adhesion, proliferation, differentiation, and migration.[ 114 , 115 ] Furthermore, substrate rigidity guides cell locomotion in a phenomenon known as durotaxis, in which most adherent cells preferentially migrate up the stiffness gradient.[ 116 , 117 ] A common method used to engineer a matrix with varying stiffness is by controlling the crosslinking condition, thereby controlling the substrate flexibility by changing its crosslinking density. Three common ways to manipulate the mechanical stiffness of hydrogel are: changing comonomer/monomer composition, altering crosslinking agent concentration, and modulating the polymerization‐induced condition (e.g., pH, temperature, reaction time, light intensity for photopolymerization).[ 118 ] Readers are encouraged to refer to published papers for the advantages and limitations of these approaches.[ 25 , 26 ]

3.2.2. Macroporosity of Hydrogel Network

Different from the inherent mesh size of hydrogel which is generally defined as the linear distance between two adjacent crosslinks and typically on the nanometer scale,[ 119 , 120 ] macroporous structure can be created and tailored by advanced fabrication techniques within bulk hydrogel scaffolds. Techniques such as solvent casting, freeze‐drying, phase separation, and gas foaming are frequently utilized to generate macroporosity.[ 121 ] The advent of 3D bioprinting technology has further simplified the process of introducing macropores into scaffold structures. Besides basic functions in regulating nutrient accessibility, gaseous exchange, and waste elimination in cell‐seeded matrix, these macropores offer several benefits, including ample space for cell growth and the circumvention of transport limitations associated with oxygen, nutrients, and growth factors. Additionally, through regulating cell morphology and assembly, they supply biophysical factors that modulate cellular behavior, and facilitates precise spatial control of pore distribution and interconnectivity, which is crucial for mimicking the native ECM and maintaining cell activities.[ 122 ] This level of control enables researchers to fine‐tune the hydrogel scaffolds to better replicate the physiological environment, thus leading to more successful in vitro/vivo experiments.

3.2.3. Topography

Native tissue microenvironments, such as the bone, blood vessel, cartilage, and nerve, have highly distinct surface or spatial topography patterns that serve as contact guidance to direct cell responses. According to their scale, topography structures can be classified as micro‐ or nanotopography (Figure 3B). Microtopography, in general, refers to topography features larger than 10 µm in size that influences the entire cell morphology.[ 123 ] In this respect, the actin cytoskeleton of a cell is responsible for sensing its surrounding structure microtopographical cues, to which it constantly adapts and remodels.[ 124 ] On the other hand, nanotopography is measured on a nanometer scale and commonly induces changes in cells via subcellular sensory components like integrin and its associated proteins and signaling pathways.[ 123 ] Many studies have shown that topographical features of engineered hydrogels such as sizes, thickness, patterns, and geometry, play important roles in regulating cell behaviors such as adhesion, migration, and differentiation. Despite the lack of clarity regarding the exact mechanism by which topographical clues are detected, it is believed that a mechanotransduction mechanism similar to normal mechanical stimuli, such as stiffness, plays an indispensable role in this regard. The mechanosensing of topography is unique as the topography is thought to impose a 3D spatial restriction to cell‐hydrogel adhesion sites.[ 125 ] As a result, the locations, intervals, and sizes of focal adhesion complexes for cell–matrix interaction are fitted to the spatial constraint imposed by the surface architecture. Variations in mechanical signals arising from spatial restriction are transmitted through integrins, and collectively stimulate intracellular signal cascading which leads to phenotypic transformation. To introduce topographical patterns on hydrogel scaffolds, micro‐ and nanopatterning technologies such as photolithography, electron beam lithography, soft lithography, and hot embossing are frequently adopted.[ 126 ]

3.3. Dynamic Mechanical Stimulation of Hydrogel Materials

Aside from the hydrogel mechanical properties (i.e., static mechanical stimuli) mentioned above, cells residing in the native ECM experience dynamic mechanical stimulation such as mechanical stretching, compression, torsional force, and flow‐induced shear stress. Of late, it has been established that dynamic mechanical stimulation influences virtually all aspects of cell fates including proliferation, cell morphology, differentiation, and apoptosis, with the resulting effects varying depending on cell type, mechanical forces, and substrate conditions.[ 35 ] With more evidence supporting the need for appropriate dynamic mechanical stimulation in the study of mechanotransduction, it is critical to provide cells with spatial and temporal mechanical cues similar to those found in their natural environment.[ 31 ]

3.3.1. Mechanical Stretching/Compression (Stress)

Pneumatic actuations, motor‐driven methods, and magnetic actuations are common actuation methods used together with hydrogel systems to deliver local and global mechanical stimuli to cells (Figure 3C).[ 35 ] Depending on the setup, pneumatic actuation or motor‐driven stretcher/compressor can be used to apply cyclic stretching to adherent cells seeded on/in a stretchable matrix through positive or negative pressure.[ 127 , 128 ] This mechanical actuation can also cooperate with the aligned fiber structure, to synergistically regulate cell activities.[ 129 ] Despite its limitation of inhomogeneous strain distribution, simple configuration of pneumatic and motor‐driven actuation has enabled their widespread use in mechanobiology research, particularly with the commercially available Flexcell system, which yields improved strain profile.[ 130 ] In recent years, magnetic actuation is one of the most actively researched actuation methods due to its ability to induce well‐controlled mechanical stimulation without physically contacting the culture system.[ 131 , 132 ] Magnetic beads or nanoparticles, when combined with a magnetic tweezer, can produce localized mechanical stimuli on the subcellular scale, most notably on the cell plasma membrane.[ 133 ] Given the noncontact nature of magnetic actuation, this strategy holds promise for in vivo mechanotherapy. Additionally, global deformation of cell‐seeded substrate is attainable by integrating magnetic particles into micropillars, microcantilevers, or continuous soft substrate surfaces at a scale large enough to change whole cell morphology. Finally, magnetoresponsive hydrogel is an emerging strategy for dynamic mechanical stimulation of cells. The encapsulated magnetic beads or rods are attracted and controlled by an external magnetic field which exerts stress on surrounding cells.[ 132 ] Some of its advantages include high controllability, uniform force distribution reversible/flexible ON/OFF stimulation and noninvasiveness.

3.3.2. Flow‐Induced Shear Stress

Poly(dimethyl siloxane) (PDMS) microfluidic devices coupled with hydrogel‐based matrix are an excellent cell culture platform capable of generating various dynamic mechanical stimulation under well‐controlled conditions. Microfluidic devices, for example, are being used to provide quasi‐circumferential strain,[ 134 ] hydrostatic pressure,[ 135 ] and flow‐induced shear stress,[ 136 ] in order to simulate the physiological conditions of blood vessels and other tissues that are constantly stretched, compressed, or sheared (Figure 3D). Notably, in addition to their versatility and scalability, microfluidic devices can be modified to provide simultaneous biochemical signals or secondary mechanical forces in addition to primary stimulation, allowing for combinatorial effects to be studied. Another crucial aspect is that there is currently a lack of research examining the effects of flow‐induced shear stress on cells encapsulated within hydrogels. Rather, many studies use hydrogels as 2D or 2.5D (2D with a topographical surface which can partially change cell membrane curvature[ 137 ]) substrates, seeding cells onto hydrogel channels or substrates to investigate the impact of flow stress on cell behaviors. Endothelial cells, for example, experience fluid shear stress due to tangential friction between the basal surface of the endothelium and blood or lymphatic flow.

3.3.3. Dynamic Stiffening/Softening

The local properties of ECM are not constant, and their stiffness varies over time, influencing resident cells.[ 138 ] Over the last few decades, there has been an increase in interest in how ECM stiffness variation influences a plethora of cellular biological behaviors ranging from cell proliferation to metabolism and even pathological activities.[ 114 , 115 , 139 , 140 ] For example, as the tumor progresses, the ECM and surrounding tissue stiffen gradually due to changes in the structure and composition of the matrix.[ 141 ] Stiffness variations occur as a result of tissue/organ remodeling, such as break down and reformation of the ovarian matrix during menstruation. To investigate this, new dynamic hydrogel platforms have been developed to modulate the rigidity of the culture environment in a time‐dependent manner by manipulating external stimuli. Leveraging on biochemical factors (e.g., light and enzymatic stimuli for secondary crosslinking) or/and physical stimuli (e.g., pH, temperature, electricity, magnetic field for strain‐stiffening/softening), the matrix stiffness can achieve programmable increase or decrease, or even reservable and flexible stiffness variation for cell mechanotransduction studies.[ 26 ]

3.3.4. Dynamic Viscoelasticity

In addition to stiffness, the ECM exhibits dynamic viscoelastic properties, such as stress relaxation and creep, which result in time‐dependent responses to deformation or mechanical loading. Recent research has increasingly recognized the significance of matrix viscoelasticity in cellular activities and disease progression.[ 142 , 143 , 144 , 145 ] As a result, hydrogels with adjustable viscoelastic properties show enormous potential for replicating time‐dependent mechanics observed in native ECM, through which they can effectively regulate cellular behavior and direct cell fate. For a more comprehensive understanding of this topic, readers are encouraged to refer to other published review papers.[ 146 ]

4. Engineering Hydrogel for Cellular Mechanical Stimulation

Mechanical stimuli, such as hydrogel's inherent matrix properties or externally applied forces play an important role in modulating cell fates and behaviors. Mechanical cues can be used to activate cells and stimulate tissue growth, which is for new therapeutic approaches.[ 147 , 148 , 149 ] Hydrogels are ideal in vitro platforms for cell mechanobiology due to their ECM‐like structure and great biocompatibility.[ 10 , 150 , 151 , 152 ] Unlike traditional 2D/planar substrates, 3D architecture enables the hydrogel to provide more physiologically relevant conditions and to perform multidimensional mechanical stimulations on cells. More importantly, when used as surface attachments (e.g., wound site) or in vivo implants, these hydrogels can function as programmable cell‐loaded matrix or mechano‐bioreactor through external stimulation.[ 153 ] Notably, due to cell specificity, a single mechanical stimulus can result in markedly different behaviors in different cell types. This section will focus on hydrogel engineering to mechanically modulate cell types such as mesenchymal stem cells (MSCs), fibroblasts, epithelial cells and immune cells, which have been approved by the U.S. Food and Drug Administration (FDA) for therapeutic use. It also includes endothelial cells as a model cell type for understanding the impacts of shear forces on cells. In each subsection, we first present a stacked bar graph to demonstrate the disparity between static and dynamic mechanical stimuli (based on publication and citation numbers). We aim to draw attention to the paucity of research on the effects of dynamic mechanical stimuli on cells, highlighting the impact it could have on basic mechanobiology studies, cell manufacturing and mechanomedicine, and encouraging more interest in this area.

4.1. Mesenchymal Stem Cell

MSCs are fibroblastoid, multipotent adult stem cells that can be found in a variety of bone and adipose tissues. MSCs possess high cell proliferation, self‐renewal ability, and are sensitive to the surrounding environments.[ 82 ] Under specific biophysical or/and biochemical stimulation, MSCs can differentiate into adipocytes, osteoblasts, and chondrocytes, or transdifferentiate into non‐mesenchymal cell lineages and mesodermal cell lineages.[ 154 , 155 , 156 , 157 , 158 ] Their remarkable self‐renewal capabilities and lineage differentiation have drawn considerable attention in the realm of regenerative medicine. As of December 2022, there are over 1400 registered clinical trials using MSCs to investigate the therapeutic effect, including bone/cartilage repair, immunoengineering, and even the prevention or treatment of COVID‐19, listed on ClinicalTrials.gov.[ 159 ] Conventionally, culture medium with biochemical factors is used to induce MSC differentiation into targeted cell types. Nonetheless, this approach necessitates the addition of fresh differentiation culture medium on a regulate basis to avoid premature cell aging as the number of passages increases, and it is not suitable for in vivo differentiation for clinical purposes.[ 160 , 161 ] Recent studies have highlighted the potential of harnessing mechanoactivation to trigger MSCs proliferation, differentiation, and paracrine activities (e.g., growth factor and exosome) for clinical application including inducing MSCs‐derived bone tissue regeneration.[ 162 , 163 , 164 , 165 ] By programming physical properties of hydrogel scaffold (e.g., matrix stiffness and internal topography) and applying dynamic forces, researchers have discovered the widespread implications of mechanical stimuli on cell biofunctions (Figure 4A).

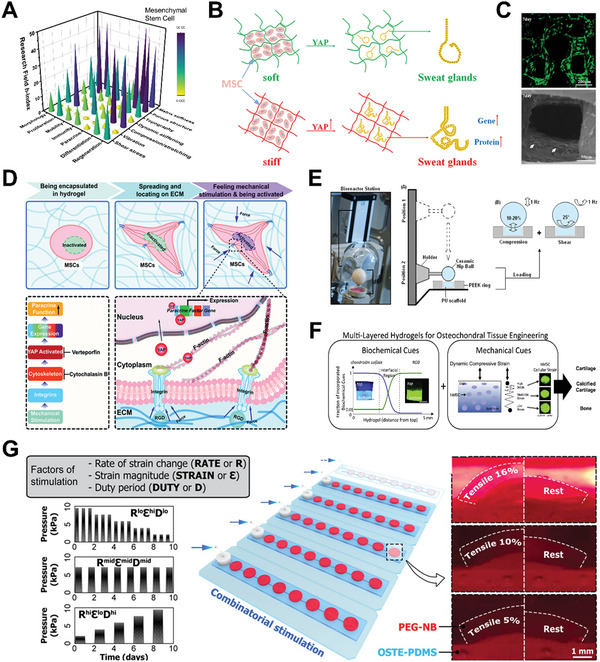

Figure 4.

Mechanical stimulation on mesenchymal stem cell (MSC) behaviors by hydrogel‐based platforms. A) 3D bar graph of mechanical stimulation on MSC for various cell activities and biomedical applications. The research conditions are evaluated based on h‐index of each field calculated by paper publication and citation data from Scopus. B) Schematic illustration of bioprinted stiffer hydrogels that can upregulate Yes‐associated protein (YAP) level and heighten the expression of sweat gland cell phenotype. Reproduced with permission.[ 178 ] Copyright 2020, Elsevier. C) Fluorescent and SEM images of MSC (green fluorescence or white arrows) spreading and growing in macroporous silk‐gelatin 3D hydrogel scaffold. Reproduced with permission.[ 122 ] Copyright 2021, Elsevier. D) Schematic illustration of mechanical stimulation from dynamic stiffening matrix. The stiffness stress is transmitted via cell cytoskeleton and induces YAP nuclear localization and ultimately potentiates paracrine response. Reproduced with permission.[ 82 ] Copyright 2020, the Royal Society of Chemistry. E) Schematic illustration of bioreactor operation for compression and shear forces to MSC‐seeded hydrogel. Reproduced with permission.[ 195 ] Copyright 2017, Springer Nature. F) Multilayer hydrogel with specific biochemical cues, matrix stiffness, and dynamic mechanical loading for osteochondral tissue engineering. Reproduced with permission.[ 197 ] Copyright 2015, Elsevier. G) Illustration and images of combinatorial mechanical stimulation patterns in combination with defined levels of rate of strain change, strain magnitude, and duty period. Reproduced with permission.[ 190 ] Copyright 2021, American Association for the Advancement of Science.

4.1.1. Internal Topography

Engineering geometric architectures has proven to be a successful method for regulating MSC fate. The shape and size of MSCs can be easily controlled by tuning matrix internal or surface microstructures.[ 166 ] Generally, a small and roundish matrix structure limits MSC flattening and hence promotes differentiation toward adipocytes lineage, whereas a larger matrix structure promotes cell spreading and thereby favors osteoblastic differentiation.[ 167 , 168 ] By capitalizing on electrospinning and other advanced hydrogel fabrication methods, various fibrous architectures can be fabricated in 3D scaffolds to mimic MSCs–matrix interaction. Several MSC studies using fibrous hydrogel have illustrated the effects of scaffold architecture on MSC activities, particularly cell proliferation, spreading,[ 169 ] and chondrogenic differentiation.[ 170 ] Furthermore, porous structure is another important geometric feature that influences MSC behaviors. Hydrogel macroporosity has been found to be directly implicated MSC growth under 3D conditions. In vitro, human MSCs seeded in porous hydrogel showed improved oxygenation and osteogenic lineage commitment, as well as early expression of alkaline phosphate and collagen type I.[ 171 ] Immunostaining revealed that the expression of HIF‐α in solid hydrogels was significantly higher than in porous hydrogels, indicating a greater degree of oxygen deprivation. When the macroporous hydrogel construct was transplanted into mice, it induced vascularization and promoted oxygenation of the embedded cells.

4.1.2. Stiffness

Matrix stiffness has a strong influence on stem cell differentiation. There is abundant evidence demonstrating that matrix stiffness regulates MSC differentiation toward bone, muscle or neuronal lineages when they are seeded on hydrogel matrices that are similar to the native stiffness of their respective tissues.[ 172 , 173 ] MSCs cultured on soft matrix preferentially undergo adipogenesis and chondrogenesis, whereas those cultured on stiffer matrix preferentially undergo osteogenesis.[ 143 , 174 ] Evidently, stiff substrate induces higher expression of smooth muscle cell markers, while soft substrate promotes the expression of chondrogenic markers but results in less cell spreading, fewer stress fibers, and lower proliferation rate.[ 175 ] The tension and its resulting cytoskeleton contractability, as well as the adhesion site transduction are considered the main factors contributing to the stiffness‐dependent differentiation (Figure 2).[ 176 ]

Similar to bulk hydrogels, the stiffness of 3D‐bioprinted matrix can affect MSCs differentiation as well. In recent years, tunable hydrogel‐based bioink and bioprinted matrices have been widely used in MSCs‐related bone engineering. For example, by leveraging on 3D‐printed hydrogel, Liu et al. observed a higher expression of osteogenic markers in stiffer hydrogels, indicating a stronger response of MSCs differentiation toward stiffer matrix.[ 177 ] Following that, they discovered that the stiffness of hydrogel‐based bioink can also regulate MSC differentiation toward sweat gland cells, potentially by upregulating YAP localization in the nuclei (Figure 4B).[ 178 ] 3D bioprinting can thus be utilized to configure microenvironments (i.e., stiffness‐gradient constructs) and direct desired MSC phenotypes.[ 179 ] Additionally, 3D bioprinting can introduce macropores within scaffold structure, which can provide adequate space for cell growth and overcome the transport restriction for oxygen, nutrient, and growth factors (Figure 4C).[ 122 ]

Matrix stiffness is also a potential modulator of redox metabolism in MSCs. Tay and co‐workers observed increased expression of intracellular ROS expression on softer substrates through the mechanotransduction pathway.[ 180 ] Consequently, the production of proangiogenic transcriptors was upregulated, as evidenced by higher expressions of vascular endothelial growth factor (VEGF) and basic fibroblast growth factor on softer matrix. This finding emphasizes the possibility of reprogramming MSCs redox metabolism by modifying material mechanical features for regenerative medicine using MSC‐derived secretome. In addition to MSCs, the proliferation and differentiation of some other stem cells such as adipose‐derived stem cells are reportedly affected by hydrogel matrix stiffness as well.[ 181 ]

4.1.3. Dynamic Stiffening

Aside from local static matrix stiffness, stiffness variation/gradient is another important modulator of MSC behaviors. MSC migration and differentiation can be directed by stiffness gradients within ECM or tissues caused by normal tissue variation (e.g., myocardium) or pathological conditions (e.g., myocardial infarction).[ 182 ] MSC cellular adhesion and spreading increased in a stiffness gradient gel via F‐actin assembly and vinculin recruitment.[ 183 ] Even with a shallow durotactic gradient, MSCs eventually migrate to the stiffer region and differentiate into a more contractile and myogenic phenotype, demonstrating the importance of mechanical tension in MSC growth and differentiation.[ 117 ] Changes in ECM stiffness also affect the paracrine function of MSCs, including VEGF, SDF‐1, and HGF. Compared to static stiffness, dynamic stiffening of the matrix is a more effective mechanical stimulation to activate encapsulated MSCs. By leveraging on the release of biomolecules, Lin et al. discovered that by using calcium ions release to stiffen alginate‐RGD hydrogel, MSCs displayed stronger YAP activation and paracrine function than those in hydrogel without dynamic stiffening.[ 82 ] This is because the soft matrix allows for early cell spreading, resulting in a stable cytoskeleton that helps MSCs to collect more mechanical signals when the matrix stiffens (Figure 4D).

It is noteworthy that static mechanical stimuli promote certain cell behaviors while limiting some others,[ 184 ] whereas dynamic stiffening can effectively regulate multiple cell activities across time through programmable material. This feature is beneficial for improving therapeutic outcomes in clinical applications as well as increasing biomolecule production. For example, it was discovered that MSCs cultured on soft gel substrate significantly improved the secretion of immunomodulatory factors but halted MSC proliferation, while stiff substrate resulted in enhanced proliferation and reduced replicative senescence without any secretome amplification. Hence, a novel approach would be to first introduce stiff substrate to promote MSC proliferation and follow it up with gel softening to improve secretory activities to produce a greater quantity of therapeutic secreted factors (e.g., VEGF). In addition to mechanical cues, dynamic stimulation can be relevant also to biochemical cues, such as changing ligand presentation on demand. Bian's group developed a dynamic hydrogel platform that provides magnetic tuning of RGD tether mobility within the hydrogel network, allowing stem cell behaviors to be regulated.[ 185 ] Furthermore, they also discovered that cancer cells with increased stemness and tumorigenicity exhibit dynamic controllable presentation of integrin ligands. This discovery emphasizes the potential impact of modulating ligand presentation on cell behavior and its implications for cancer research.[ 186 ] This demonstrates the importance of modulating the biochemical presentation of cell ligands on hydrogel/matrix for dynamic control of cell–matrix interactions, which has significant value for both fundamental research and practical applications.[ 3 ] Readers are encouraged to refer to published reviews elsewhere.[ 187 ]

4.1.4. Dynamic Loading

Applying external stress is another way of manipulating the dynamic mechanical features of MSC’s surrounding microenvironment. It was previously found that the effect of static matrix stiffness or constant mechanical stimulation gradually faded due to cell adaptation.[ 188 , 189 ] The application of dynamic loading is believed to alleviate the effects of cell adaptation by resetting cell mechanosensitivity and enhancing cellular mechanoresponses.[ 190 , 191 , 192 ] Through the use of an external bioreactor, incremental or cyclic strain is commonly applied to cell‐laden matrix as dynamic mechanical stimuli to regulate MSC behaviors. In particular, compression loading has been shown to enhance MSC chondrogenic differentiation, which is required for neocartilage formation.

Compressing MSC‐seeded hydrogel with TGF‐1 increased chondrogenic gene expression (i.e., Sox‐9, aggrecan, and collagen type II) and ECM production.[ 193 ] Specifically, a duration of 2.0–2.5 h appeared to be optimal for chondrogenic differentiation. A shorter duration is inadequate to stimulate the encapsulated cells whereas a longer duration causes cell–cell signaling to level off, limiting the stimulation effect. In addition, this study also highlighted the significance of TGF‐β to MSC chondrogenesis, and that dynamic compression may have enhanced the transport of TGF‐β into the hydrogel.[ 194 ] Nevertheless, some other studies have demonstrated that external force alone, without exogenous biochemical factors, can significantly induce and maintain MSC chondrogenesis. For example, a combination of compression and shear forces for 21 days in a hydrogel bioreactor (Figure 4E) without exogeneous factors can facilitate chondrogenic differentiation with an increased chondrogenic gene and protein expression (e.g., sulphated glycosaminoglycans and collagen II).[ 195 ]

The benefits of dynamic mechanical stimulation shed light on the field of MSCs‐based tissue engineering including cartilage regeneration or repair. As such, many researchers have explored techniques like in vitro biochemical/biomechanical chondrogenic preconditioning and in situ MSCs‐laden scaffold implants. For example, Lin et al. implanted MSCs‐seeded hydrogel treated with chondrogenic induction medium and 14 days of dynamic compressive loading into osteochondral‐defected animal models and discovered that the mechanical condition promoted neocartilage formation.[ 196 ] Steinmetz et al. used a sequential photopolymerization method to develop a multilayer hydrogel that comprises a soft, cartilage‐like layer of chondroitin sulfate with low RGD concentrations, a stiff bone‐like layer with high RGD concentrations, as well as an intermediate interfacial layer for cartilage and bone compound tissue regeneration.[ 197 ] Compared to MSCs cultured statically in differentiation media, dynamic mechanical stimulation increased the expression of collagen type II in the cartilage‐like layer, collagen type X in the interfacial layer, as well as collagen type I in the bone‐like layer and mineral deposits localized to the bone layer (Figure 4F). Aside from compression, interstitial flow is another potential factor triggering osteogenesis in stiff bone‐like layer, as previous studies has shown that flow‐induced shear stress may potentiate the osteogenic differentiation of MSCs via TAZ activation.[ 198 ] In these works, the static preculture (commonly culture several days without mechanical stimulation) is required before applying dynamic loading. In the absence of preculturing, compression‐induced MSC chondrogenic differentiation was reduced due to the poor adaptation to the new matrix environment and insufficient acquisition of nutrient or biochemical signals.[ 199 , 200 ] Similar to compression, stretching or tensile stress can influence MSC fate. Liu et al. discovered that increasing the duty period and strain magnitude synchronously can most effectively improve MSC matrix production (Figure 4G).[ 190 ]

4.1.5. Vibration

Vibration has been reported to promote ontogenetic differentiation of MSC via mechanotransduction pathways. Vibration is exerted on muscles and bones during daily physical activities such as walking and running. This phenomenon has been shown to affect bone mass and skeleton strength.[ 161 , 201 , 202 ] As a result, researchers begin to take advantage of the unique property of vibration to promote MSC activities, particularly osteogenesis. For example. Mehta et al. encapsulated hMSCs in PEGDA gel microspheres and stimulated them with low‐magnitude, high‐frequency vibration. They discovered that low (0.3 g) and medium (3.0 g) accelerations enhanced osteogenesis in MSCs while high accelerations (6.0 g) inhibited osteogenesis due to cell apoptosis and reduced bone resorption.[ 173 ]

The native mechanical microenvironment of MSCs is highly intricate and contains multiple mechanical cues that have to be coordinated for delicate control of MSC activities and functions.[ 203 , 204 ] Systematic and combinatorial approaches, which included multiple static or dynamic mechanical stimulation (i.e., mechanical cocktail), provide more predictive regulation of MSC mechanoresponses. For example, Grolman et al. demonstrated that ECM plasticity and dynamic force loading can affect MSC phenotypes and spreading through a biphasic relationship dependent on cell intrinsic forces.[ 205 ] Despite the fact that a large number of external devices for force‐loading purposes have been developed, translating them into clinical applications involving osteo‐chondrogenesis remains difficult. In this regard, magnetic and ultrasonic mechanical stimulation are attractive strategies due to their remote actuation and noninvasive nature.[ 35 ] Another major obstacle to current MSC‐based research is its inconsistent experimental or clinical results. Currently, several studies have illustrated the effects of mechanical stimulation, but these results often appeared to be inconsistent, probably caused by differences in cell source species (i.e., mice and human), cell types/subpopulation (MSC is a highly heterogeneous cell population with multiple subsets), and culture conditions.[ 166 ] It is therefore important to optimize and standardize MSC source and culture conditions to improve the reproducibility of experiments. This is also meaningful for future MSC autologous cell extraction and therapy in the clinic. Some other features including seeding cell density,[ 206 ] cell–matrix interaction (e.g., ECM reconstruction),[ 36 , 82 ] synergistic promotion with biochemical factors (e.g., TGF‐β),[ 175 ] and hydrogel crosslinking rate,[ 207 ] are associated with the effect of MSC mechanobiological‐based control.

4.2. Fibroblast

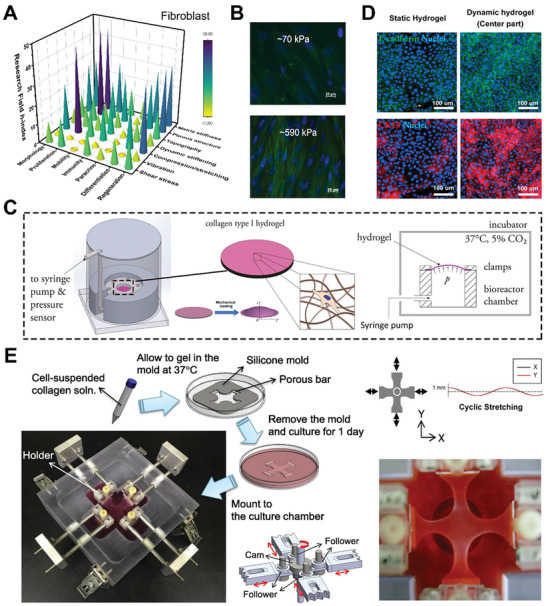

Fibroblast is a type of mesenchymal cell that constitutes a majority of the stroma, especially in connective tissues. They are typically spindle‐shaped, elongated morphologies with a flat oval nucleus. As of December 2022, there were over 1100 registered clinical trials using fibroblasts to investigate the therapeutic effect, the majority of which most were for skin regeneration or transplantation for a variety of disease/indications such as wrinkles correction (LAVIV, Rosmir), diabetic foot ulcer (DERMAGRAFT), mucogingival condition (GINTUIT), and deep partial‐thickness burns (STRATAGRAFT). For example, DERMAGRAFT, a fibroblast‐derived dermal substitute which is composed of fibroblasts, ECM, and a bioabsorbable scaffold, is approved for the treatment of full‐thickness diabetic foot ulcers. Inactivated fibroblasts exist in a quiescent state with low secretion and contractile activity. When activated fibroblasts (e.g., proto‐myofibroblast and myofibroblast) are stimulated by extracellular biochemical and mechanical cues, they secrete ECM macromolecules (e.g., collagen, glycosaminoglycan, proteoglycan), growth factors, cytokines, and chemokines.[ 208 , 209 ] Fibroblasts can also remodel and compact their surrounding matrix, particularly the collagen construct, via pseudopodia extensions (usually several tens of µm within a matter of hours).[ 210 ] Material mechanical properties and external dynamic stress have been shown to have a significant impact on fibroblast behavior (Figure 5A).

Figure 5.

Mechanical stimulation on fibroblast cell behaviors by hydrogel‐based platforms. A) 3D bar graph of mechanical stimulation on fibroblast for various cell activities and biomedical applications. The research conditions are evaluated based on h‐index of each field were calculated by paper publication and citation data from Scopus. B) Fluorescent staining indicates that fibroblasts, which cultured in matrix with higher stiffness, express more α‐smooth muscle actin (α‐SMA). The cells are detected by staining the cell nucleus (blue DAPI) and α‐SMA (fluorescent green). Reproduced with permission.[ 213 ] Copyright 2012, Elsevier. C) Schematic illustration of dynamic pump‐based bioreactor that applies tension to deform installed hydrogels. Reproduced with permission.[ 227 ] Copyright 2021, Elsevier. D) Whole‐mount staining for E‐cadherin and CK19 expression suggests that dynamic forces can promote the early maturation of the dermo–epidermal skin substitute. Adapted with permission.[ 227 ] Copyright 2021, Elsevier. E) Schematic and working procedure of the cyclic four‐arm stretcher. The fibroblast‐seeded hydrogel is installed in the chamber and stretched by dynamic actuator system. Adapted with permission.[ 231 ] Copyright 2018, Elsevier.

4.2.1. Stiffness

Many recent studies using hydrogel models have demonstrated that matrix stiffness could regulate fibroblastic cell behaviors and phenotypes. Jiang et al. designed a stiffness‐controllable hydrogel by modifying DNA crosslinking, and they demonstrated that fibroblasts seeded in the material could change morphologies in response to different rigidity.[ 211 ] Similar results were observed in Yeung et al. where fibroblasts cultured on soft gel were round in shape while those cultured on stiffer gel were of elongated morphologies with articulated stress fibers.[ 212 ] Chia et al. revealed that upon exposure to TGF‐β, fibroblasts cultured on rigid polyethylene glycol (PEG) hydrogels exhibited a higher expression of α‐smooth muscle actin (α‐SMA) fibers compared to those on soft PEG hydrogels (Figure 5B).[ 213 ] Interestingly, stiff matrix promoted fibroblast proliferation[ 214 ] and transdifferentiation into myofibroblast,[ 215 ] a type of activated phenotype that provides contractile forces during wound closure.[ 216 ] As a result of this discovery, novel wound healing strategies have been developed and tested. For example, high stiffness hydrogel‐based wound dressing was found to induce fibroblast proliferation, enhance stress fiber formation as well as upregulate key mediators of wound inflammation (e.g., interleukin‐10).[ 217 , 218 ] However, stiff matrix‐induced fibroblast/myofibroblast transition may cause fibrotic pathologies including valvular stenosis.[ 219 , 220 ] In high‐stiffness matrix (i.e., pathological conditions), fibroblasts can also differentiate into carcinoma‐associated fibroblasts, which is a key component of tumor ECM that contributes to tumorigenesis.[ 221 , 222 ]

4.2.2. Macroporosity of Hydrogel Network and Scaffold

Macroporous structure of a hydrogel matrix is another important mechanical property that influences fibroblast behavior. In this context, Choi et al. fabricated gelatin hydrogel scaffolds with different macroporous structures through 3D printing technique. Evidently, cells cultured in the larger pores proliferated faster than those in smaller ones.[ 223 ] This finding suggested that a hydrogel scaffold with the appropriate porous structure could support fibroblast proliferation and migration. Given the close relationship between stiffness and mesh size, it is hypothesized that both properties have synergistic effects on fibroblast cellular behaviors.[ 224 ] While the pore architecture of hydrogel may have a significant impact on cellular processes, fibroblasts residing within the construct could in turn manipulate the mechanical properties,[ 210 , 225 ] particularly the stiffness of hydrogel. Based on Ahearne et al., fibroblasts altered the elastic modulus of the hydrogel by applying contractile forces, resulting in matrix contraction or compaction (i.e., modulus increase) while releasing MMP to reduce gel mechanical strength.[ 226 ] Following that, changes in the surrounding matrix would have a negative impact on cell movement, viability, and actin expression. A mechano‐feedback loop exists between the fibroblast and the surrounding matrix, in which the mechanotransduction channels and cytoskeleton of fibroblast are strongly affected by the surrounding, while the fibroblasts release biomolecules (e.g., cytokines, chemokines, ECM macromolecules) and exert forces on the matrix.

4.2.3. Dynamic Compression/Stretching

As the key components of connective tissues and organs (e.g., skin), fibroblasts are subjected to a variety of dynamic forces, such as tension from neighboring cells/surrounding matrix and stress from physical exercises. These applied forces play critical roles in regulating the cell behavior of fibroblasts. Researchers have developed a number of devices/systems for applying external forces to hydrogels in order to observe how the applied forces affect fibroblast cell behaviors. For example, Wahlsten et al. created a dynamic bioreactor to introduce cyclic deformation to fibroblast‐seeded collagen hydrogel (Figure 5C).[ 227 ] The results showed that when fibroblasts were cultured under dynamic mechanical stress, the number of fibroblasts increased by 75%, and the direction of hydrogel deformation influenced fibroblast orientation. Similar results were found in the work of Balestrini and Billiar, which discovered that intermittent stretching (i.e., dynamic mechanical force) applied on fibroblast‐populated fibrin gel could increase cell number due to increased mechanotransduction pathway and collagen secretion under hydrogel compaction, while continuous force (i.e., static mechanical force) had no significant impact.[ 228 ] More importantly, they demonstrated that dynamic mechanical loading on fibroblast‐seeded matrix could promote the production of human dermo–epidermal skin substitutes (Figure 5D), which could be used in skin graft and reconstructive surgery. Hu's group developed a four‐arm hydrogel stretcher that uses biaxial/uniaxial mechanical constraints to stimulate fibroblast‐seeded construct (Figure 5E).[ 229 , 230 , 231 ] In the presence of cyclic biaxial stretching, fibroblasts had an elongated, spindle‐shaped morphology with increased α‐SMA expression, whereas cells seeded in the unstretched gels had a spherical morphology with low α‐SMA expression. This mechanoactivation also has an important contribution in ECM remodeling and tissue development. Lee et al. demonstrated that incrementally increasing stretching significantly increased the mRNA expression of collagen type I.[ 231 ] Nevertheless, because a force threshold affects fibroblast collagen production, the applied force should be within the appropriate range.[ 232 ]

The aforementioned studies provide new insight into the behaviors of mechano‐stimulated fibroblasts. However, some limitations must be addressed in order to promote the clinical translation of fibroblastic mechanotherapy. However, external mechanical stimulation has both positive and negative effects on cellular behaviors, which is a significant limitation. A recent study revealed an inverse relationship between fibroblast proliferation and collagen synthesis, implying that cyclic force enhanced collagen production but could possibly hinder cell proliferation simultaneously.[ 233 ] In addition, inappropriate mechanical forces may jeopardize the mechanical landscape of ECM by increasing tissue stiffness, resulting in abnormal cellular behaviors. Hence, to achieve the desired mechanostimulation with minimal side effects, the hydrogel mechanical characteristics and magnitude/range of mechanical forces applied on targeted fibroblasts must be quantified precisely. Although some crucial parameters such as stretch parameters[ 228 ] and matrix (i.e., hydrogel) remodeling metrics[ 234 ] have been investigated thoroughly, more holistic and comprehensive research is required for further clinical validation. Furthermore, it is critical to understand the complex relationship between various mechanical stimuli, including the synergistic effects and dominant factors that determine cellular behaviors. As shown in Figure 5A, current mechanobiology research on fibroblasts focuses a lot on material static mechanical features, especially on stiffness. However, Wahlsten et al. discovered that cyclic stress on hydrogel is the dominant mechanical factor promoting fibroblast proliferation, whereas hydrogel stiffness only plays a relatively minor role.[ 227 ] Similarly, Petersen et al. discovered that gel scaffold stiffness has only a transient impact on fibroblast cell behaviors, whereas the effect of mechanical stimulation was preserved over time.[ 235 ] Henceforth, more emphasis should arguably be placed on externally applied forces for the application of fibroblast in skin tissue engineering. Interestingly, many mechano‐induced cell behaviors and mechanisms remain unknown. As an example, it is still unclear how different mechanical stimuli trigger fibroblasts to differentiate into myofibroblasts and more research is needed to elucidate the specific mechanisms.

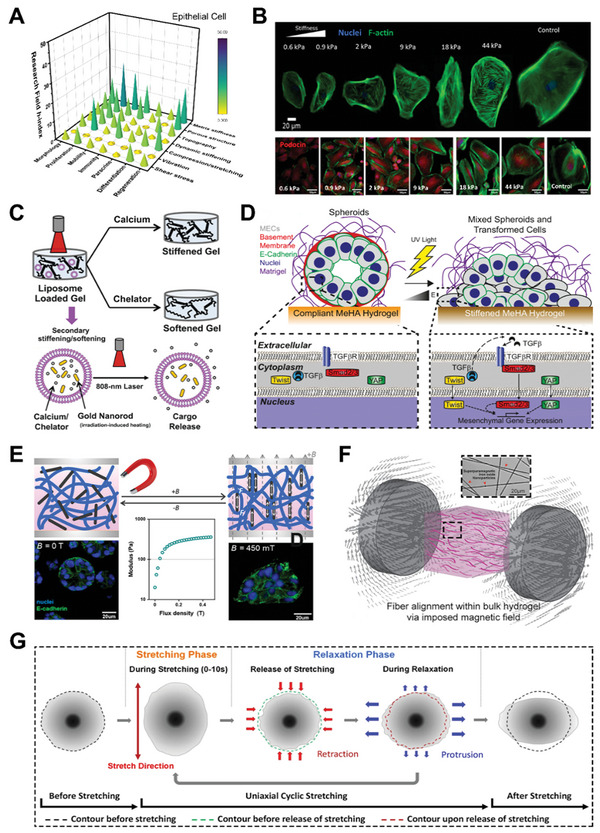

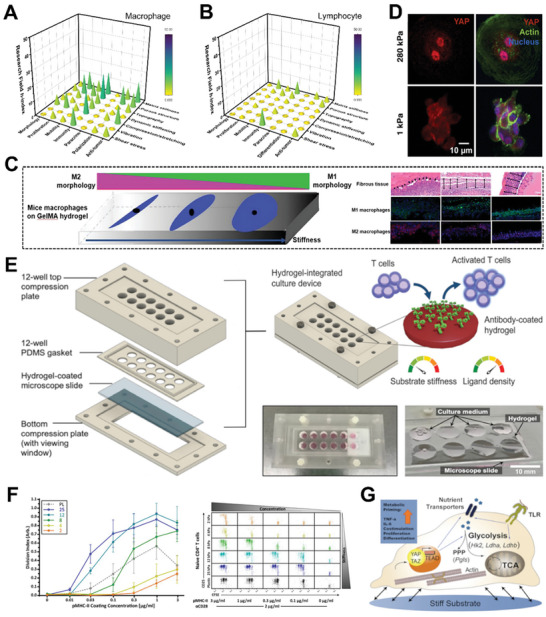

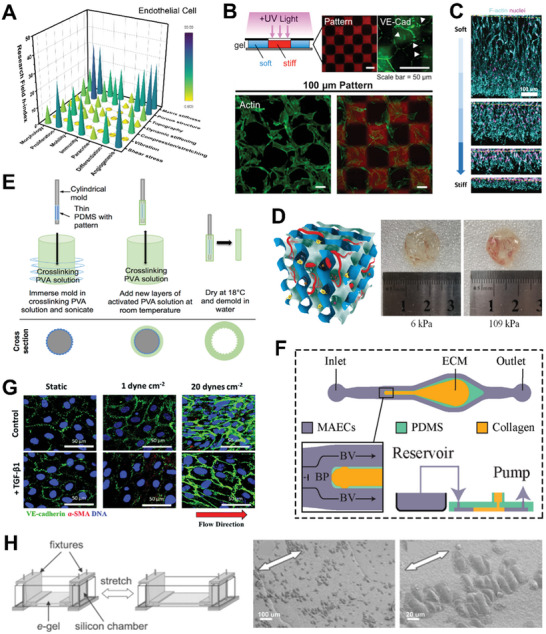

4.3. Epithelial Cell