Abstract

The four‐tiered NOVA food classification defines foods based on their degree of processing and ranges from native unprocessed foods to so‐called “ultra‐processed” foods. Recent publications have suggested that foods classified as ultra‐processed are unhealthy and contribute to the obesity epidemic. It is important to distinguish between formulation and processing of a food. In most cases it is the formulation more than the processing that results in foods that are not recommended as part of a healthy diet. Such “ultra‐formulated” foods are unhealthy because they are high in added sugar and other caloric sweeteners, refined flours saturated fats and salt to increase palatability. The understanding that processing and formulation are distinct will assist health professionals in identifying the types of foods that are unhealthy and contribute to overconsumption and obesity. It furthermore will help to destigmatize food technology and promote discussions amongst health professionals, food scientists, corporate scientists, government officials and the general public. Novel food processing techniques are urgently needed in times of population growth, climate change and war‐induced food shortages.

Keywords: formulation, MyPlate, NOVA food classification, processing, ultra‐formulated food, ultra‐processed food

Recent studies suggest that ultra‐processed foods are associated with obesity and other degenerative diseases such as diabetes, cancer, and cardiovascular disease. 1 , 2 A review by Zhang and Giovannucci 1 summarizes the increased global consumption of such foods and the evidence from population studies on the negative health consequences, including cause‐specific and all‐cause mortality, associated with consumption of ultra‐processed foods. From a review of the current literature, Harb et al. 3 concluded that there is a strong positive relation between high consumption of ultra‐processed foods and obesity. Aside from population studies, a short‐term clinical trial Hall and colleagues 4 reported that ultra‐processed diets resulted in an increase of about 500 kcal/day compared to unprocessed foods in 20 weight‐stable adults. Handakas et al. 5 found that consumption of ultra‐processed foods was associated with perturbation of many metabolic traits contributing to childhood obesity risk. More evidence of the negative effects of the popular consumption of ultra‐processed foods is produced daily.

What then are ultra‐processed foods? Monteiro and colleagues 6 define such foods as formulations made mostly or entirely from substances derived from foods and additives, with little if any intact unprocessed or minimally processed foods and produced using a series of processes commonly employing advanced equipment and technologies. Their formulations include processed culinary ingredients such as flours, sugars, oils, fats, salt; but also include specific isolated or modified components from food, such as lactose, casein, gluten, whey, hydrogenated or interesterified oils, hydrolyzed proteins, soya protein isolate, maltodextrin, invert sugar, high‐fructose corn syrup and a series of preservatives, colorants and flavors. 2 Some of these components may also be of non‐food origin. Specific processing techniques that Monteiro lists for ultra‐processed foods are extrusion, molding, pre‐processing used for frying, hydrolyzation and hydrogenation. 6 Monteiro 7 described a four‐tiered NOVA classification of foods 6 which include unprocessed/minimally processed foods (Group 1), processed culinary ingredients (Group 2), processed foods (Group 3) and ultra‐processed foods (Group 4).

The term “ultra‐processing” unnecessarily emphasizes the use of advanced, intensive processing techniques rather than the choices that food developers make in employing ingredients in formulating the foods of Group 4. Food processing by itself can help or harm the production of healthy foods 8 and advanced processing technologies, such as ultrafiltration, are used for foods and ingredients from Groups 1–3, often to prolong shelf life or make the processing more sustainable, but also to introduce new functionalities. Processes that are used for foods across several NOVA groups include operations such as drying, sorting, milling, crystallization, separation, mixing, blending, extrusion, baking, toasting, flaking, cooking, dispersing, molding, coating, foaming, whipping, shaping, freezing and spray‐ and freeze drying. It would be better to indicate the type of processing rather than assign them to a specific class of foods.

More advanced processing often brings important nutritional benefits. The lysine loss in spray‐dried milk powder is much lower than in roller‐dried milk powder. 9 Membrane‐concentrated juices have better retention of sensitive compounds than thermally evaporated juices. 10 In recent years, advanced technologies are being developed for the processing of products from Groups 1 and 3, as these often have lower energy and water requirements, often have a lower thermal impact on the product and thereby retain nutritional and taste profiles that are closer to the unprocessed foods.

Group 4 food products essentially all result as formulations of processed ingredients. The choices made in formulating these such “ultra‐formulated” products are based on considerations of palatability, consumer acceptance and convenience, and marketing rather than being forced by processing. Group 4 products may require intense processing techniques, such as extrusion for breakfast cereals and snacks and deep drying for potato chips, but also may be the result of more simple processes, such as candy bars, that are produced using basic technologies such as mixing, shaping, and molding. Often, the ingredients that are used in these Group 4 products result from more intense processing and are often energy‐dense and nutritionally unbalanced. Ingredients include those of Group 2, but also further isolated and fractionated ingredients such as protein isolates, lipid fractions and flavors and emulsifiers isolated from food sources, modified ingredients, such as starch hydrolyzates and ingredients that are of other sources, including many emulsifiers and flavoring substances.

Group 4 products are not necessarily unhealthy. Infant formula, an often‐quoted example (see for example 7 ), can sustain newborn babies in the first half year of their lives, when breast milk is unavailable 11 and is considered safe and nutritious. The verdict on the health impact of meat analogs based on plant proteins is still out, as many are formulated with high salt and saturated fat contents but there is no reason they cannot be formulated with acceptable amounts of salt and saturated fats next to a high protein and fiber content and thus fit in a healthy diet in addition to being animal friendly and more sustainable than meat. 12

For Group 4 products, technology and formulation are often independent variables: while oil is needed to process potato chips, salt and flavorings can be added at will. Corn flakes can be produced without added sugar and other additives and are then categorized as Group 1. 8 Sugar can be added in any amount, and is usually applied by frosting, a simple process technology, and the resulting breakfast cereals are categorized as Group 4. Salt, sugar, fat and additives such as flavors and colorants can thus be added independent of the process, in particular for Group 4 foods. It is often the content of fat, sugar and salt that render Group 4 products unhealthy. Fat and sugar (incl. processed starches, such as high‐fructose corn syrup and maltodextrins) increase the energy density of the products without providing important micronutrients (“empty calories”). Colorants, flavors and additives, such as emulsifiers, are added to make these energy‐dense “ultra‐formulated” products more attractive but have few substantiated negative health consequences themselves.

Processing itself can have negative effects on nutrient availability of foods and thus on health. Overprocessing of grains can cause an increase in the glycemic index which can impact circulating glucose levels and hemoglobin A1C. 13 As a result of processing, quick oats and rolled oats have a higher glycemic index than steel cut oats. 13 Simple grinding of peanuts to make peanut butter can increase the absorption of fat and thus provide more kilocalories. 14 Fat absorption is even higher when consuming peanut oil. 14

Technology can also result in negative health effects. Chemical modification was applied to create solid fat (margarine) from vegetable oil, which was thought to be healthier than butter due to the lower cholesterol content and lower content of saturated fats. Unfortunately, this introduced trans‐fats that are now known to have negative health impacts. The recognition of this in the 1990s led to technology changes that resulted in production of partially hardened fats no longer containing trans fatty acids. 15

On the other hand, processing can improve the nutritional quality of foods. The bioavailability of lycopene, an antioxidant, is higher in tomato paste than in fresh tomatoes. 16 Adding air and water to food decreases the ratio of calories to volume which has an impact on energy intake. 17 , 18 Greek yogurt is more highly processed compared to regular yogurt but is considered healthier due to increased protein content and, in modern versions, reduced fat content. 19 Lactose can be filtered out of milk to make lactose free milk or to decrease the caloric content of milk‐based cocoa beverages. 20 , 21 Pasteurization of milk decreases the risk of foodborne illness and more healthy low‐fat milk results from the use of a fat separator. Food processing also renders foods such as beans non‐toxic by degradation of antinutritional factors and improves the digestibility of low digestible vegetables. Many foods are seasonal and have improved shelf life due to drying, pickling and fermentation. Also, foods with low palatability can become a versatile ingredient for culinary uses such as the dehusking and milling of wheat converting it to flour.

Formulation independently of processing can affect the quality of foods in either a positive or negative way. Salt, sugar, and fat are added to foods in Group 3 “Processed foods” and Group 4 “Ultra‐processed foods” of the NOVA system to improve palatability and to prolong the shelf life. Other additives such as coloring agents and flavors are also used to enhance the acceptability of foods, mainly those of Group 4. These formulated foods easily lead to overconsumption and are even labeled addictive by some and thereby promote obesity as well as other negative health consequences. 22 In contrast, certain non‐formulated, minimally processed foods in Category 1 such as high‐fat or cured meats are generally not recommended as part of a healthy diet due to their nutrient composition. Addition of certain oils such as olive oil to highly processed foods can improve their “health index.” 23 While low sodium soups are not highly processed, potassium chloride, monosodium glutamate, yeast extract or hydrolyzed soy are often added to improve palatability, providing a low sodium option for individuals needing to decrease their sodium intake.

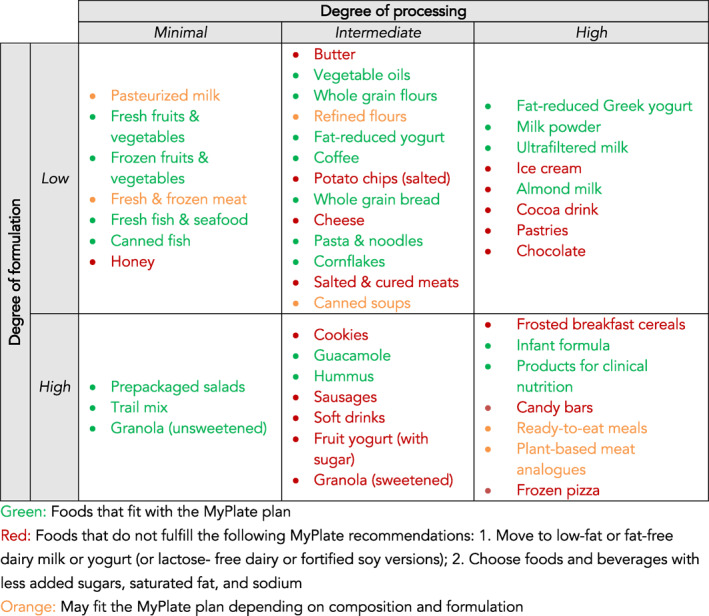

Recognizing the importance of both processing and formulation as parameters that independently impact the nutritional and dietary characteristics of foods, a food matrix that explicitly recognizes these two parameters is presented (Table 1). In Table 1, the MyPlate (https://www.myplate.gov/) recommendations to color code if a food fits in a healthy diet were used. Foods that are considered healthy or unhealthy occur all over the matrix, whereby the prevalence of unhealthy foods increases with the degree of processing, and specifically, with the degree of formulation. As argued above, this is often a conscientious choice to make such “ultra‐formulated” foods more palatable and attractive rather than being driven by the process and often has to do with the addition of sugar (or other caloric sweeteners such as high fructose corn syrup), (saturated) fats and salt to intermediate and highly processed foods.

TABLE 1.

Food processing‐formulation matrix

|

The cells of the food processing‐formulation matrix do not map one‐to‐one with the groups of the NOVA classification, but there is certainly a correspondence between the two systems. Minimally processed foods of both simple and complex formulations mostly align with Group 1 from the NOVA system, with several important exceptions including coffee and milk powder, which in our system are classified as of an intermediate degree of processing and highly processed, respectively, but of simple formulation. Group 2 processed culinary ingredients, such as butter, flour and vegetables oils are of an intermediate degree of processing and, by their nature as ingredients, of simple formulation. Honey, which in the NOVA system is a Group 2 ingredient, is here classified as a minimally processed food of simple formulation. Processed foods of Group 3 of the NOVA system mostly match those of the intermediate processing category.

The case becomes more interesting for Group 4, the ultra‐processed foods in the NOVA classification. This group not only encompasses the foods that in our system are high processed and that are highly formulated. Several also fit in the category of foods that, while highly processed foods, are of a reasonably simple formulation. This includes pastries, such as plain croissants, most ice cream and plain dark chocolate. Several Group 4 foods are furthermore of an intermediate degree of processing and have either a simple formulation, such as plain, salted potato chips, or a complex formulation, such as cookies, soft drinks and sweetened fruit yogurt. Foods that in the NOVA system are classified in Group 4 ultra‐processed foods are thus mostly, but not exclusively, highly processed and highly formulated. Furthermore, while many of these foods do not fit with the MyPlate recommendations, there are important exceptions such as milk powder, infant formula and possibly plant‐based meat analogs that can be part of a healthy diet. Finally, many foods that are highly processed and of simple formulation fit with the MyPlate recommendations, including fat‐reduced Greek yogurt, milk powder, ultrafiltered, lactose‐reduced milk and various vegan milk analogs.

Technology and specific formulations can result in inexpensive, easily prepared, or ready‐to‐eat foods that are highly palatable, low in essential nutrients and energy dense and that are thus undesirable as part of the daily diet. Such foods are often aggressively marketed and may outcompete food production by small local producers potentially leading to unsustainable practices. Demonizing ultra‐processed foods because of the processing rather than their unhealthy formulation could however undermine public acceptance of processing as essential for the development of nutritious foods that are affordable, sustainable, safe from foodborne illness and easily stored and transported. Discussing formulations separately from processing also gives a direction for developing more wholesome foods and may facilitate a more open discussion between nutritionists, public health researchers and food technologists.

Finally, one should be careful in distinguishing fact from opinion in Monteiro's classification. While processed culinary ingredients can be used to prepare “delicious dishes and meals” 7 in the hands of a skilled cook, cooking skills have waned in past decades to such an extent that some Group 4 products, such as “instant” sauces, 7 may for many of us actually be helpful in maintaining a healthy diet as they can be added in modest amounts to plain cooked, healthy fare and thereby increase the pleasure of eating. Furthermore, the use of “sophisticated and attractive packaging, usually made of synthetic materials” 7 is not limited to Group 4 foods, but they are also used widely for products from Groups 1–3. Think of strawberries in clamshells, cheese packaged in plastic foil, vegetable oil and milk in plastic bottles. And these packages get more and more sophisticated and attractive all the time, with easy open lids, colorful labeling, and advanced material properties leading to longer shelf life and a more appealing tactility. The excessive quantities of synthetic packaging that are used create major problems, relating to waste, recycling, and use of scarce resources, but this is independent of the healthfulness of the foods they are used for.

The world's daily food supply is and will remain critically and increasingly dependent on the processing of foods and ingredients. With future population growth, climate change and the need for agricultural practices to become more sustainable, continued innovation in food processing is essential to guarantee a sustainable, healthy, and abundant food supply. While many types of processing can have negative effects, food processing does not need to result in only unhealthy foods, but rather constitutes a critical and essential component of our food system. Ensuring public trust in food processing technology is undermined by the categorization of ultra‐processed foods without more nuanced understanding of the factors that determine the nutritional value (positive or negative) of these foods.

AUTHOR CONTRIBUTIONS

Allen S. Levine and Job Ubbink conceived, discussed, wrote, and edited the content of this perspective.

CONFLICT OF INTEREST

ASL is a board member of the Minnesota State Fair Foundation. JU receives royalties for two books (Columbia University Press and Elsevier book). He received consulting fees from Buhler, Inc. (training workshop). He has received funds in 2022 for program review at two Universities. He has several patents.

ACKNOWLEDGMENTS

ASL has no grants or contracts to report. JU acknowledges partial financial support from the Minnesota Agricultural Experiment Station (hatch project MIN‐18‐141) and the University of Minnesota.

Levine AS, Ubbink J. Ultra‐processed foods: processing versus formulation. Obes Sci Pract. 2023;9(4):435‐439. 10.1002/osp4.657

REFERENCES

- 1. Zhang Y, Giovannucci EL. Ultra‐processed foods and health: a comprehensive review. Crit Rev Food Sci Nutr. 2022:1‐13. 10.1080/10408398.2022.2084359 [DOI] [PubMed] [Google Scholar]

- 2. Juul F, Deierlein AL, Vaidean G, Quatromoni PA, Parekh N. Ultra‐processed foods and cardiometabolic health outcomes: from evidence to practice. Curr Atherosclerosis Rep. 2022;24(11):849‐860. 10.1007/s11883-022-01061-3 [DOI] [PubMed] [Google Scholar]

- 3. Harb AA, Shechter A, Koch PA, St‐Onge MP. Ultra‐processed foods and the development of obesity in adults. Eur J Clin Nutr. 2022. 10.1038/s41430-022-01225-z [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4. Hall KD, Ayuketah A, Brychta R, et al. Ultra‐processed diets cause excess calorie intake and weight gain: an inpatient randomized controlled trial of ad libitum food intake. Cell Metab. 2020;32(4):690. 10.1016/j.cmet.2020.08.014 [DOI] [PubMed] [Google Scholar]

- 5. Handakas E, Chang K, Khandpur N, et al. Metabolic profiles of ultra‐processed food consumption and their role in obesity risk in British children. Clin Nutr. 2022;41(11):2537‐2548. 10.1016/j.clnu.2022.09.002 [DOI] [PubMed] [Google Scholar]

- 6. Monteiro CA, Cannon G, Moubarac JC, Levy RB, Louzada MLC, Jaime PC. The UN Decade of Nutrition, the NOVA food classification and the trouble with ultra‐processing. Publ Health Nutr. 2018;21(1):5‐17. 10.1017/s1368980017000234 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7. Monteiro CA, Cannon G, Lawrence M, Costa Louzada ML, Pereira Machado P. Ultra‐processed Foods, Diet Quality, and Health Using the NOVA Classification System. FAO; 2019. [Google Scholar]

- 8. Ubbink J. Soft matter approaches to structured foods: from “cook‐and‐look” to rational food design? Faraday Discuss. 2012;158:9‐35; discussion 105‐124. 10.1039/c2fd20125a [DOI] [PubMed] [Google Scholar]

- 9. Mehta BM, Deeth HC. Blocked lysine in dairy products: formation, occurrence, analysis, and nutritional implications. Compr Rev Food Sci Food Saf. 2016;15(1):206‐218. 10.1111/1541-4337.12178 [DOI] [PubMed] [Google Scholar]

- 10. Jiao B, Cassano A, Drioli E. Recent advances on membrane processes for the concentration of fruit juices: a review. J Food Eng. 2004;63(3):303‐324. 10.1016/j.jfoodeng.2003.08.003 [DOI] [Google Scholar]

- 11. Martin CR, Ling PR, Blackburn GL. Review of infant feeding: key features of breast milk and infant formula. Nutrients. 2016;8(5):279. 10.3390/nu8050279 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12. Bohrer BM. An investigation of the formulation and nutritional composition of modern meat analogue products. Food Sci Hum Wellness. 2019;8(4):320‐329. 10.1016/j.fshw.2019.11.006 [DOI] [Google Scholar]

- 13. Wolever TMS, Johnson J, Jenkins AL, Campbell JC, Ezatagha A, Chu Y. Impact of oat processing on glycaemic and insulinaemic responses in healthy humans: a randomised clinical trial. Br J Nutr. 2019;121(11):1264‐1270. 10.1017/s0007114519000370 [DOI] [PubMed] [Google Scholar]

- 14. Levine AS, Silvis SE. Absorption of whole peanuts, peanut oil, and peanut butter. N Engl J Med. 1980;303(16):917‐918. 10.1056/nejm198010163031605 [DOI] [PubMed] [Google Scholar]

- 15. Ng YT, Voon PT, Ng TKW, et al. Interesterified palm olein (IEPalm) and interesterified stearic acid‐rich fat blend (IEStear) have No adverse effects on insulin resistance: a randomized control trial. Nutrients. 2018;10(8):1112. 10.3390/nu10081112 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16. Kamiloglu S, Demirci M, Selen S, Toydemir G, Boyacioglu D, Capanoglu E. Home processing of tomatoes (Solanum lycopersicum): effects on in vitro bioaccessibility of total lycopene, phenolics, flavonoids, and antioxidant capacity. J Sci Food Agric. 2014;94(11):2225‐2233. 10.1002/jsfa.6546 [DOI] [PubMed] [Google Scholar]

- 17. Osterholt KM, Roe LS, Rolls BJ. Incorporation of air into a snack food reduces energy intake. Appetite. 2007;48(3):351‐358. 10.1016/j.appet.2006.10.007 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18. Rolls BJ, Bell EA, Waugh BA. Increasing the volume of a food by incorporating air affects satiety in men. Am J Clin Nutr. 2000;72(2):361‐368. 10.1093/ajcn/72.2.361 [DOI] [PubMed] [Google Scholar]

- 19. Moore JB, Horti A, Fielding BA. Evaluation of the nutrient content of yogurts: a comprehensive survey of yogurt products in the major UK supermarkets. BMJ Open. 2018;8:e021387. 10.1136/bmjopen-2017-021387 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20. Corgneau M, Scher J, Ritie‐Pertusa L, et al. Recent advances on lactose intolerance: tolerance thresholds and currently available answers. Crit Rev Food Sci Nutr. 2017;57(15):3344‐3356. 10.1080/10408398.2015.1123671 [DOI] [PubMed] [Google Scholar]

- 21. McCain HR, Kaliappan S, Drake MA. Invited review: sugar reduction in dairy products. J Dairy Sci. 2018;101(10):8619‐8640. 10.3168/jds.2017-14347 [DOI] [PubMed] [Google Scholar]

- 22. Gearhardt AN, Schulte EM. Is food addictive? A review of the science. Annu Rev Nutr. 2021;41(1):387‐410. 10.1146/annurev-nutr-110420-111710 [DOI] [PubMed] [Google Scholar]

- 23. Heden TD, Chen C, Leland G, et al. Isolated and combined impact of dietary olive oil and exercise on markers of health and energy metabolism in female mice. J Nutr Biochem. 2022;107:109040. 10.1016/j.jnutbio.2022.109040 [DOI] [PMC free article] [PubMed] [Google Scholar]