Abstract

Fibrin is a promising natural polymer that is widely used for diverse applications, such as hemostatic glue, carrier for drug and cell delivery, and matrix for tissue engineering. Despite the significant advances in the use of fibrin for bioengineering and biomedical applications, some of its characteristics must be improved for suitability for general use. For example, fibrin hydrogels tend to shrink and degrade quickly after polymerization, particularly when they contain embedded cells. In addition, their poor mechanical properties and batch-to-batch variability affect their handling, long-term stability, standardization, and reliability. One of the most widely used approaches to improve their properties has been modification of the structure and composition of fibrin hydrogels. In this review, recent advances in composite fibrin scaffolds, chemically modified fibrin hydrogels, interpenetrated polymer network (IPN) hydrogels composed of fibrin and other synthetic or natural polymers are critically reviewed, focusing on their use for tissue engineering.

Keywords: Fibrin hydrogels in tissue engineering, fibrin-polymer composite scaffolds, PEGylated fibrin hydrogels, natural polymer-fibrin hydrogels, particles encapsulated in fibrin hydrogels

Introduction

Significant advances in molecular and cellular biology over the past two decades have greatly increased our understanding of the role of fibrin in wound healing, blood clotting, fibrinolysis, cellular-matrix interactions, inflammatory response, infection and neoplasia.1,2 Fibrin is composed of fibrinogen, which is a soluble protein derived from the liver. Following tissue damage, fibrinogen is converted to fibrin by thrombin, a clotting enzyme, at the site of bleeding. In 1943, Bailey et al. classified fibrinogen as a fibrous protein with keratin, myosin, and epidermin, based on an X-ray diffraction pattern generated by its coiled-coil structure. 3 It is a 340 -kDa glycoprotein that is normally present in human blood plasma at a concentration of 1.5–4 g/L and is required for several biological functions. 4 The interactive sites of fibrinogen produce fibrin polymerization, which implies a variety of biological functions, including interactions with platelets, leukocytes, fibroblasts, and endothelial cells, as well as binding to thrombin to control the activity of factor XIII (a coagulation protein). 5 Fibrin fibers are the main players because they serve as scaffolds for tissue regeneration and promote both cell migration and tissue ingrowth. In contrast, fibrin is not mechanically strong or stable enough to act as a stand-alone wound repair material. 6 To address this issue, multiple fibrin modifications using natural and synthetic materials with improved stability and medical efficacy are currently available. One strategy consists of combining living cells with polymeric scaffolds made of fibrin and synthetic materials, such as polyglycolic acid (PGA), polylactic acid (PLA), polycaprolactone (PCL), and polyvinyl alcohol (PVA), or natural polymers, such as hyaluronic acid, alginate, or collagen.

Hydrogels are the most common scaffolds used in tissue engineering because of their similar properties to those of the original living tissues, such as water-holding capacity, permeability, and viscoelasticity.7,8 Biocompatibility, biodegradation, affordability, ease of cell migration, and growth while providing mechanical support until new tissue is formed are some of the requirements that a scaffold material must fulfill. Natural materials are especially promising because they present properties similar to the original tissues and organs, such as biocompatibility and mechanical performance almost identical to that of the extracellular matrix (ECM), and also provide specific adhesion sites for cells. 9 Using naturally based hydrogels, researchers have created new scaffolds for cell seeding and growth, tissue regeneration strategies, and novel biomedical products. 10

Owing to the aforementioned properties, fibrin hydrogels have emerged as ingenious scaffolds because of their important role in blood coagulation during natural wound healing. In summary, fibrin properties include controllable and non-toxic degradation, excellent biocompatibility, and minimal inflammation, as it can be obtained from the patient’s own blood. Furthermore, fibrin properties can be tuned by varying the precursor proportions when polymerization is initiated. The ability of the fibrin hydrogel to rapidly gel and control its properties by tuning the fibrinogen concentration makes it ideal for cell encapsulation, cell carriers, and injectable biomaterials for tissue regeneration applications. For this reason, many fibrin-based products have been developed over the years for biomedical procedures as bioadhesives in surgeries for hemostasis, wound closure, or as sealants, which have been extensively analyzed in other review articles.5,11

Despite being frequently used as a biomaterial in numerous clinical and research applications, fibrin has some drawbacks related to its rapid degradation both in vivo and in vitro and its poorly understood shrinkage behavior and poor mechanical properties make it difficult to handle or even unsuitable for other biomedical applications.12,13 To solve these problems, during the past years a new experimental approach has emerged based on the development of improved fibrin scaffolds via fibrin modification and/or combination with other materials. In this article, we present recent advances in this field, their applications, particularly in different tissue engineering scenarios, and a discussion of their future challenges and opportunities.

Fibrinogen basics: Structure, polymerization, acquisition, and commercial use

Fibrinogen structure and fibrin polymerization

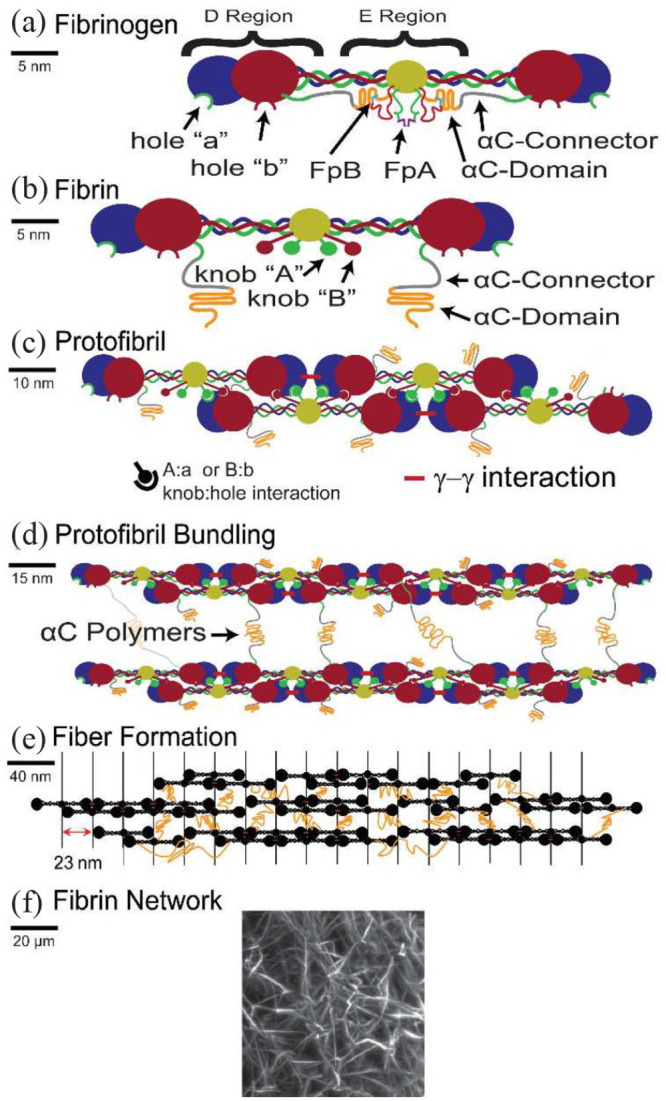

Fibrinogen is a glycoprotein secreted from the liver into the blood and is one of the most important components in hemostasis, as it acts as an adhesive protein for platelet aggregation, forming a fibrin clot for blood coagulation when vascular injury occurs. This fibrous (45 nm in length) and 340 KDa dimeric glycoprotein is composed of approximately 132 amino acids. The fibrinogen macromolecule is a symmetrical dimeric protein composed of three domains in which two identical regions (D-domains) are linked by the central E-domain. The hexameric molecule is made up of three pairs of different polypeptide chains known as α, β, and γ (Figure 1(a)). As Weisel et al. report, the nomenclature of the polypeptide chains arises from the designation of the small peptides that are cleaved from fibrinogen by thrombin to yield fibrin as fibrinopeptides A and B and the parent chains, without the fibrinopeptides, as α and β. 14 No peptides were cleaved from their gamma chains using thrombin. The two terminal D-domains are connected to the E-domain through five symmetrical disulfide bridges at the N-terminus by allelic coiled coils.

Figure 1.

Diagram of the fibrin structure and its polymerization process: (a) Structure of the fibrinogen macromolecule with D-domains and the central E-domain. The domains are linked by three pairs of different polypeptide chains: α, β and γ. (b) Fibrinogen is converted to fibrin monomer by thrombin. It cleaves fibrinopeptides A and B, exposing knobs A and B. (c) Then, the cleaved fibrinopeptides bind to holes a and b, respectively, known as the specific unions A:a and B:b, and form the protofibril molecule. (d) Protofibril bundling is formed by lateral aggregation of protofibrils, owing to interactions of the AC regions, and leading up to thick fibrin fibers. (e) Then, the branching and lateral aggregation of fibers form the fibrin network. (f) Image of a fiber network forming a gel obtained with a light sheet microscope. Reprinted from Belcher et al. 15

Fibrinogen is converted to a fibrin monomer by the cleavage of fibrinopeptides A and B by thrombin (Figure 1(b)). Thrombin is a serine protease with specificity for fibrinopeptides that are formed by the proteolysis of prothrombin by factor Xa in the presence of other factors and phospholipids. Thrombin enzymatically cleaves fibrinopeptide A (FPA) exposing a tripeptide (Gly-Pro-Arg) at the N-terminus of the alfa-chain known as “knob” A that is complementary to a “hole” a in the center region of the other fibrin monomer. 16 This specific union is known as A:a. Fibrinopeptide B cleavage occurs slower than that of FPA and is not necessary for fibrin polymerization, although it plays an important role in lateral aggregation. There is consensus that these electrostatic interactions are the foundation of fibrin polymerization and blood clot formation (Figure 1(c)).

Fibrin polymerization proceeds from highly reactive fibrin monomers (with their FPA released) binding one to another, leading to a self-assembled half-staggered dimer structure. The first stage of polymerization involves the formation of a two-stranded trimer, in which the central region of one fibrin monomer fits the D regions of two different fibrin monomers through the aforementioned knob:hole A interaction. Oligomers grow longitudinally from the two-stranded trimer with the addition of more fibrin monomers until they reach a double-stranded protofibril – 600–800 nm in length. At this stage, the protofibrils begin to aggregate laterally, leading to thick fibrin fibers (Figure 1(d)).

The interaction between monomers occurs in a half-staggered manner, defining the molecular packing in the fibers, giving a periodicity of 22.5 nm, which is exactly half the fibrin monomer length. There is a thermodynamic mechanism that controls the diameter of the fibers, as protofibrils that are newly added to the surface of a fiber must be stretched as their path length increases. Therefore, lateral aggregation stopped when the protofibril stretching energy surpassed the bonding energy.

However, the mechanism underlying the lateral aggregation of protofibrils remains unknown. However, the self-assembly and protofibril origin imply that the interactions in lateral aggregation are weak and cooperative along the axis of the protofibril. Many publications have shown that the following structures and mechanisms besides not being necessary for fibrin polymerization, strongly influence on the final properties and architecture of fibrin clots: knobs ‘B and holes ‘b, the AC regions and the plasma transglutaminase factor XIIIa.17,18

These intermolecular interactions have been demonstrated to promote lateral aggregation. The B:b interactions have been shown to thicken fibrin fibers when compared to fibrinogens, where fibrinopeptides A and B were cleaved to fibrinogen. FPA was cleaved off, suggesting that B:b interactions favor the lateral aggregation of protofibrils. The AC domains enhance the mechanical stability of fibrin clots by promoting lateral aggregation. AC is a fibrinogen extension molecule that interacts with the center of the molecule. FpB cleavage by thrombin action triggers the release of AC, allowing weak intermolecular interactions between them. Specifically, factor XIIIa mechanically and proteolytically stabilizes fibrin clots by forming covalent bonds.

These intermolecular interactions have been demonstrated to promote lateral aggregation. The B:b interactions have been shown to thicken fibrin fibers when compared to fibrinogens, where fibrinopeptides A and B were cleaved to fibrinogen. FPA was cleaved off, suggesting that B:b interactions favor the lateral aggregation of protofibrils. The AC domains enhance the mechanical stability of fibrin clots by promoting lateral aggregation. AC is a fibrinogen extension molecule that interacts with the center of the molecule. FpB cleavage by thrombin action triggers the release of AC, allowing weak intermolecular interactions between them. Specifically, factor XIIIa mechanically and proteolytically stabilizes fibrin clots by forming covalent bonds.

The entire polymerization process, in which numerous proteins and molecules take part, ends with the formation of a 3D fibrous network that appears as an insoluble hydrogel (Figure 1(f)). The mechanical properties, microstructure, and behavior of this fibrin hydrogel depend on many conditions, such as the concentration of the molecules involved in the process or environmental parameters such as temperature or pH.1,14,19

Human fibrinogen acquisition

Human fibrinogen can be obtained in different ways. 20 Fresh frozen plasma (FFP) obtained from patients has extensive use in trauma and transfusions, with a fibrinogen concentration of 1–3 mg/ml.21,22 FFP, which is easily accessible, is the most commonly used source of fibrinogen. To produce FFP, whole blood from a single donor is split into its plasma and cellular components, which are then quickly frozen and stored at 18°C or lower. The contact activation (intrinsic) and tissue factor (extrinsic) clotting system soluble coagulation factors, as well as fibrinogen, were preserved by freezing. 23 Fresh plasma samples can be divided into three types depending on the number of platelets. These include platelet-rich plasma (PRP), platelet-free plasma (PFP), and platelet-poor plasma (PPP), the latter two of which are described as having low platelet concentrations in the literature.24,25 All these types of plasma are produced by sufficiently centrifuging patient blood, but several procedures and techniques have been developed to produce them with enhanced purity at a low cost. 26 The main difference is in the concentration of platelets, which is triggered by the presence of high levels of growth factors. PRP has at least 200 × 10−3 platelets/µL suspended in plasma; however, due to its inconsistent experimental results and poor reproducibility, other alternatives, such as PPP, should be investigated. 27 PPP applications, such as clot formation and wound healing in which platelet-released growth factor concentration is not essential, have recently been discovered and applied in several studies. D’Amico et al. explored the use of factor-decorated fibrin matrices containing platelet-derived growth factor-BB (PDGF-BB) and vascular endothelial growth factor-A (VEGF) together to promote therapeutic arteriogenesis and accelerate wound healing in diabetic mice. This study demonstrated that these matrices, loaded with growth factors and cytokines, stimulated angiogenesis and the formation of new blood vessels in diabetic wounds. 28 PPP is also cost-effective, appropriate for bulk production, and easily translatable, with only minimal regulatory requirements for Food and Drug Administration (FDA) certification.29–31

However, due to the risks associated with using a given blood product, including low total fibrinogen concentrations or considerable fluctuations in concentration across donor packets, FFP is not the optimal supply of fibrinogen. 32 Cryoprecipitation is used to obtain a higher fibrinogen concentration than that in FFP. 33 A cryoprecipitate is a human plasma-derived blood product. It contains factor VIII, von Willebrand factor (vWF), fibrinogen, fibronectin, and factor XIII. Currently, cryoprecipitates are most commonly used to replace fibrinogen in patients with chronic hypofibrinogenemia and hemorrhage. Cryoprecipitation is an excellent fibrinogen source frequently used in the United States and is obtained by thawing FFP, centrifugation, and resuspension of the precipitated proteins in plasma. Each unit of cryoprecipitate contained 200–300 mg of fibrinogen.34–36 Although fibrinogen levels can be adjusted, this can be performed with less accuracy than commercial fibrinogen, and the infusion volume is smaller than that of fresh-frozen plasma. Viral inactivation methods such as methylene blue or psoralen/ultraviolet light treatment are frequently used. However, thawing is necessary before infusion, and ABO compatibility is required. 37 This multi-donor blood product that requires large volumes, cross-matching, and thawing before administration, and is associated with possible pathogen transmission.

Commercial fibrin products

Commercial fibrinogen products are a good way to take advantage of this material for different clinical applications and are available as liquid fibrin glues, sealants, and fibrin patches.38,39 Patches can help blood clot, sealants can form a barrier whether blood is present, and glues can join tissues together. 40 Fibrin glues usually contain a freeze-dried concentrate of clotting proteins such as cryoprecipitate, mainly fibrinogen, factor XIII, fibronectin (sealant), and freeze-dried thrombin. In addition to being used clinically in a variety of surgical specialties, fibrin sealants also play a part in a number of research applications, such as drug delivery, tissue sealing, and hemostasis. 41

The FDA has approved five blood products based on fibrin for topical use. The functional elements of the sealant are fibrinogen and thrombin, which, upon administration, form hemostatic fibrin. FDA-approved products frequently contain these two components; however, the concentrations of fibrinogen and thrombin can be altered to meet specific demands for mechanical strength or to alter the dynamics of sealant polymerization. The blood products approved by the FDA are listed in Table 1 and can be divided into four main groups: 42,43 topical use, absorbable patches, fibrin lyophilization, and a device that produces fibrinogen and thrombin from human plasma.

Table 1.

Fibrin products approved by FDA.

| Product | Company | Principal components | Form | Indication | Ref. |

|---|---|---|---|---|---|

| Topical use | |||||

| ARTISS | Baxter Healthcare Corp. | Fibrinogen (67–106 mg/mL), thrombin (2.5–6.5 IU/mL), CaCl2 (36–44 µmol/mL), factor XIII and aprotinin (2250–3750 KIU/mL) | Spray set | Adhesive for autologous skin grafts and as face-lift for facial rhytidectomy surgeries | Yamamoto and DeJoseph 44 |

| EVICEL | Omrix Biopharmaceutical Ltd. | Fibrinogen (55–85 mg/mL) and thrombin (800–1200 IU/mL) | Spray or syringe | Hemostatic agent for liver, vascular, and general surgeries | Ofikwu et al. 45 |

| FIBRIN SEALAN/Vistaseal | Instituto Grifols/Ethicon | Fibrinogen (80 mg/mL) and thrombin (500 IU/mL) | Spray or in a syringe | Hemostatic agent for vascular surgeries; also approved by the European Medicines Agency (EMA) | Beudert et al. 43 |

| RAPLIXA | The Medicines Co. | Fibrinogen (79 mg/g) and thrombin (699 IU/g) | Spray | Hemostatic agent for general surgeries | McKeage 46 |

| TISSEEL | Baxter Healthcare Corp. | Fibrinogen (67–106 mg/mL), thrombin (400–625 IU/mL), factor XIII (0.6–5 IU/mL) and aprotinin (2250–3750 KIU/mL) | Spray set | Hemostatic agent for cardiopulmonary bypass, splenic injuries, and general injuries, and as sealant in colonic anastomosis | Siedentop et al. 47 |

| Absorbable patches | |||||

| EVARREST | Ethicon | Fibrinogen (8.6 mg/cm2) and thrombin (37.5 U/cm2) | Patch | Hemostatic agent for retroperitoneal, intra-abdominal, pelvic, noncardiac thoracic surgeries and adult liver surgeries | Matonick and Hammond 48 |

| TachoSil | Nycomed Danmark ApS (2019 Ethicon) | Fibrinogen (3.6–7.4 mg/cm2) and thrombin (1.3–2.7 U/cm2) | Patch | Hemostatic agent for cardiovascular and neurological surgeries; also approved by the European Medicines Agency (EMA) | Simo et al. 49 |

| Fibrin lyophilization products | |||||

| RiaSTAP | CSL Behring GmbH | Lyophilized fibrinogen (18–26 mg/mL) | Hemostatic agent for acute bleeding episodes in patients with congenital fibrinogen deficiency | 50 | |

| Fibryna/Fibryga | Octapharma Pharm. Prod. | Lyophilized fibrinogen (120 mg/mL) | Hemostatic agent for treatment of acute bleeding episodes in adults and adolescents with congenital fibrinogen deficiency | Roberts et al. 51 | |

| Device that produces fibrinogen and thrombin from human plasma: | |||||

| Cryoseal | ThermoGenesis | A device to produce fibrinogen and thrombin from human plasma (autologous fibrinogen) | Foams spray and drop tips for application | Adjunct to hemostasis during liver resection | Doria and Vaccino 52 |

The use of these fibrin-based products has significantly reduced pain and the duration of hospital stay by lowering the appearance of postoperative hematomas. 53 Fibrin sealants reduce the cost and time required for these operations.

The aforementioned properties and use of fibrin as a hemostatic agent in various fields of surgery have drawn attention to this material as a hydrogel in 3D cell culture by tissue engineering researchers.

The use of fibrin hydrogels in tissue engineering: Challenges

Fibrin hydrogels are formed by the polymerization of fibrin monomers, leading to a fibrous structure. Fibrin hydrogels are commonly used in tissue engineering because of their biocompatibility, structural similarity to native tissues, their ability to transport properties, tunable properties, and capacity to deliver drugs and growth factors. The porosity and viscoelastic mechanical properties that mimic the extracellular matrix (ECM), along with the predetermined cell-binding sites in fibrin, result in good cell adhesion, spreading, proliferation and migration. 54 Moreover, specific proteins can bind to fibrin, which plays an active role in interacting with cells. As a fibrous scaffold, it provides a temporal substrate; cells secrete plasminogen and matrix metalloproteinases (MMPs) that mediate fibrinolysis and subsequent degradation of the hydrogel. However, there are still numerous limitations, such as shrinkage of the hydrogel during formation, low mechanical stiffness, batch-to-batch variability, and rapid degradability. Thus, research efforts are required to improve fibrin performance by modifying it with diverse polymers in many different ways and creating new scaffolds for cell seeding.

Fibrin hydrogel degradation

Fibrin hydrogels can be degraded by two different mechanisms, which decrease their effectiveness and chances of successful engraftment in tissue engineering.

First, degradation is caused by cells that are present in fibrin hydrogels; when these cells proliferate, they produce plasmin, which is secreted by a variety of cell types, including endothelial cells.55,56 However, the lifespan of fibrin is limited by rapid fibrinolysis that occurs when plasminogen is present. The use of inhibitors that block the active site of plasmin serine proteases, such as tranexamic acid or epsilon-aminocaproic acid, can help reduce the effect of plasminogen.

The second degradation mechanism is the activation of matrix metalloproteinases (MMPs) through proteolytic and esterolytic reactions, which contribute to the remodeling of the extracellular matrix and serve as a negative feedback mechanism for the matrix degradation response. The use of aprotinin, which inhibits MMPs, prevents the breakdown of fibrin, and promotes the accumulation of extracellular matrices, is a way to reduce this effect.57,58

The rate of fibrin hydrogel degradation can be tuned by the addition of protease inhibitors, such as aminocaproic acid and aprotinin, or by modifying the precursor concentrations of the biomolecules involved in polymerization.59–61 These degradation processes enable proper tissue development as scaffolds are exchanged by cells, and the degradation rate is different for different cell lineages seeded in the scaffold. Different sources of stem cells affect degradation at different rates, which has strong implications for the development of artificial tissues and organs. 62 The rate of hydrogel degradation is crucial for obtaining viable tissues. Controlling this parameter is not always intuitive as it appears to be due to fibrinolysis. The derived products play an important role in the chemical signaling of cells, healing processes, angiogenesis, and stimulation of migration. 63 The rate of hydrogel degradation is crucial for obtaining viable tissues. Controlling this parameter is not always intuitive as it appears to be due to fibrinolysis. The derived products play an important role in the chemical signaling of cells, healing processes, angiogenesis, and stimulation of migration. 64 In most cases, fibrin hydrogels dissolve completely before the tissue is obtained. An increase in hydrogel stability is achieved by adjusting the fibrinogen concentration. 57 Ahmed et al. found that a combination of aprotinin and galardin (MMP inhibitor) hydrogels can last up to 5 weeks, whereas pure fibrin hydrogels degrade completely in 7 days owing to cell activity. 69 In the specific case of retinal pigment epithelium transplantation, it would be interesting to exploit the fast degradation rate of fibrin. 65 For these reasons, fibrinogen-based hydrogels have been used in recent years for different tissue engineering applications, for example, as a scaffold for the culturing of muscle, adipose, cartilaginous, liver, bone, or ocular cells; for wound repair and skin regeneration therapies; or even as a treatment for neurodegenerative diseases and fertility preservation strategies.66,67

Although the use of fibrin could be promising in all tissue regeneration strategies, it could have side effects; for example, in the treatment of cardiac or skin tissue lesions, it might produce undesirable fibrous scars.68,69 Fibrous scars are characterized by the excessive deposition of extracellular matrix components, particularly collagen, which leads to impaired tissue function and limited regenerative potential. The formation of fibrous scars during fibrin-based tissue regeneration can be attributed to several factors. First, the inflammatory response derived from the fibrin degradation products activates fibroblasts, which are responsible for collagen synthesis.70,71 Second, fibrin-derived peptides can induce the expression of profibrotic factors such as transforming growth factor-beta (TGF-β), platelet-derived growth factor, and connective tissue growth factor, further promoting fibrosis.70,72,73 Finally, the mechanical properties of fibrin-based scaffolds, including stiffness and porosity, can influence cellular behavior and tissue remodeling, thereby potentially increasing scar formation.

Fibrin hydrogel contraction

The tendency of fibrin hydrogels to contract, particularly when embedding cells, is one of the aforementioned drawbacks, according to the conclusions of numerous studies.30,74–76 For example, Montero et al. analyzed the contraction behavior of plasma-derived fibrin hydrogels and found that these scaffold contractions in the presence of fibroblasts depend on the fibrinogen concentration and compromise the development of skin tissue culture. 75 They concluded that in fibrin hydrogels, there is a lack of attachment to the culture insert, which causes shrinking in the z-axis and complicates their clinical use and surgical handling. Murphy et al. demonstrated that NaCl and fibrinogen affect hydrogel contraction when cultivating mesenchymal stem cell spheroids. 77 According to Yue et al., this could impede the advancement of customized tissue reconstruction techniques. 78 In recent years, the use of fibrin in combination with synthetic or natural polymers has been investigated as a potential solution to this issue.79–81 Other potential solutions include the use of solid scaffolds and their chemical modifications.

Poor mechanical properties

Compared to other polymers, fibrin exhibits remarkable and distinctive viscoelastic properties that affect its structural, biological, physical, and chemical properties. The mechanical properties of fibrin are critical to its function and determine how it responds in treatments, such as tissue clotting, wound healing, and disease prevention and treatment. Information regarding the structural functions of clot stability is required to understand the role of fibrin hydrogels. The fibrin structure can be described as a branched network in which the mechanical properties are governed by both single fibers and their ensembles. This network also includes changes in the fiber orientation as well as stretching, bending, and buckling. According to Guthold et al., the quantity and configuration of double-stranded, half-staggered protofibrils affect the characteristics of individual fibrin fibers. 82

The stiffness of a fiber can be measured using its Young’s modulus; a higher value indicates a stiffer fiber. The elastic modulus (slope of the stress-strain curve), which indicates how elastic a material is in relation to strain, changes if it is nonlinearly elastic. 82 According to research, uncrosslinked and crosslinked fibrin fibers have Young’s moduli of 1.7 ± 1.3 and 14.5 ± 3.5 MPa, respectively. 83 These values were obtained through laser tweezer flexion experiments, which involved pulling the fibers and measuring their elastic moduli. Similar results were obtained using other independent methods such as stretching experiments, in which the elastic moduli were measured by pulling a bead in the direction of the fiber axis. With this method, the elastic modulus of uncrosslinked fibers was 1.9 ± 1.8 MPa, while that of crosslinked fibers was 11.5 ± 5.1 MPa. Because the fibers are not homogeneous and isotropic, and the experiments are different, these findings are not comparable to those obtained with flexion experiments, but all of these findings provide the basis for understanding the development of clot elasticity.82,83

It has been reported that native heart tissue has a Young’s modulus of up to 67 kPa, and native esophageal tissue has a Young’s modulus of 60 kPa in terms of tissues and hydrogels, when the tensile properties of each scaffold are measured with a uniaxial monotonic material tensile test machine.84,85 In contrast, the typical fibrin hydrogels have Young’s moduli ranging from 0.94 to 6.49 kPa for fibrinogen concentrations of 0.5–3.0 mg/mL. Higher fibrinogen concentrations, such as those present in commercially available fibrin-based adhesives, were measured using a uniaxial monotonic material tensile test machine. Hydrogels that had been developed with 30 and 70 mg/mL of fibrinogen improved in Young’s modulus by 27.5 and 14.6 kPa when they were crosslinked with CaCl2. 84 However, at high fibrinogen concentrations, the cells were unable to spread, proliferate, or ultimately survive.

The Young’s modulus of fibrin is of the same order of magnitude (1–10 MPa) as that of other soft biological fibers with the same stiffness and high extensibility, such as spider silk (Araneus Flag silk) with 3 MPa, myofibrils (sarcomere) with 1 MPa or elastin (bovine ligament) with 1 MPa. 82 However, we observed low extensibility and stiff fibers with higher orders of magnitude such as crosslinked, self-assembled collagen at 5000–7500 MPa, tendon collagen (mammalian tendon) at 160–7500 MPa, or actin at 1800–2500 MPa.

Understanding the mechanical interactions when cells are embedded is difficult because they present mechanical heterogeneities at the microscale and as a function of time. 86 Advances in cartilage tissue repair were achieved by Kim et al. analyzed the chondrogenic differentiation of human adipose-derived stem cells by modifying the fibrinogen and thrombin concentrations, which compromised cell behavior through changes in hydrogel stiffness. 87 Stabilization of fibrin hydrogels by the addition of alginate has also been attempted; however, bone marrow stem cells seem to differentiate and proliferate better in fibrin, highlighting the complex task of improve fibrin in-vitro performance. 88

In addition, fibrin hydrogels, as biomaterials, also influence angiogenesis because their microstructure strongly modifies neovascularization. For example, Tanaka et al. demonstrated that fibrin hydrogels induce macrophages, which opens up several other avenues for anti-inflammatory regenerative therapies. 89 Recently, some research groups have developed strategies for using fibrin as an adhesive between cells to obtain complex tissue constructs. 90

Batch-to-batch variability

Batch-to-batch variation in fibrin hydrogel properties is a significant challenge that can potentially lead to serious consequences if not properly addressed. According to Nair et al., there is a wide range of variation in reproducibility when using different batches of fibrinogen and thrombin, as well as day-to-day variation when using the same batch of fibrinogen. 91 These variations could result from changes in the preparation techniques or fibrinogen sourcing. The swelling of hydrogels from various fibrinogen batches can be studied to identify batch-to-batch variations and understand how hydrogel mechanics change over time. In other words, measuring the amount of water released from the hydrogel at different times is a method for determining the hydrophilicity of the polymer network between the hydrogels. 92 Furthermore, differences in the absolute shear moduli of fibrin hydrogels demonstrate relatively high batch-to-batch variations during polymerization. 93 According to the results of these studies, batch-to-batch variations play a major role in determining the hydrogel fabrication properties and how they change over time. 92

These differences are also notable in the fibrin glues. To create a fibrin clot and induce early hemostasis in the treated area, the glue mimics the final stage of the physiological blood coagulation cascade. In some studies, fibrin glues were prepared from pooled plasma, and the differences in the mechanical and biological properties of the resulting clots were due to batch variabilities.13,94 Remarkably, there are fewer variations between commercially produced fibrin glues that are standardized than between single-donor fibrin glues that suffer from batch-to-batch variability.

Other fibrin limitations

Several studies have reported less-known limitations of fibrin in hydrogels. For example, Gruber et al. indicated that fibrin hydrogel-seeded disk cells do not express aggrecan or chondroitin-6-sulfotransferase, which have crucial functions in tissue engineering. 95 In addition, Demol et al. demonstrated experimentally and computationally that limitations in oxygen mass transfer are responsible for cell density gradients within fibrin hydrogels and concluded that cell culture in fibrin hydrogels can lead to complete anoxia in the carrier center for realistic values of oxygen diffusion and consumption. 96 Moreover, despite the fact that fibrin sealants are effective in oral surgery, they suffer from the following disadvantages 97 : poorly reproducible rheological characteristics; a tendency to trigger the production of coagulation factor inhibitors (especially factor V) related to bovine thrombin, which results in postoperative coagulopathies; and the need for patients to visit the blood bank several days before a surgical procedure. Furthermore, using an infected fibrin clot as a model, Ma et al. demonstrated that the common blood-borne pathogen Staphylococcus epidermidis could affect the mechanical and structural properties of blood clots in in vitro models. 98 Kambic HE et al. added a new limitation of fibrin, and the design of tissue-engineered arrays in innervated fibrin matrices only facilitated the growth of vascular structures with the additional support of fibroblasts and keratinocytes, and their matrices within cells in vitro also showed poor mechanical properties. 99 Finally, Billiet et al. reported low and inhomogeneous mechanical strength, which restricted the porosity and insufficient interconnectivity of the pore distribution, as well as the presence of organic solvent residues, which can pose significant constraints in terms of toxicity risks and carcinogenic effects. 100

To a lesser extent, fibrin hydrogel properties can be varied by changing the thrombin concentration and modifying its mechanical and shrinkage properties. 101 Buffers that are known to be inert, such as HEPES, strongly modify the fibrin microstructure, leading to more transparent hydrogels. 102 Even the salinity of the precursor fibrin hydrogel plays a key role on how the hydrogel will behave. 103 In addition, fibrin hydrogels have been supplemented with proteins to enhance the bioactivity of cells, which also affects fibrin polymerization and the microstructure of the hydrogels. 104

Another drawback is the use of different crosslinking strategies to modify fibrin degradation and mechanical properties because of the cytotoxicity and inflammatory responses of some crosslinkers. It is important to consider specific requirements when selecting an appropriate crosslinking method for fibrin modification. For example, chemical crosslinkers, such as glutaraldehyde, have been explored with the aim to enhance the mechanical properties of fibrin. Glutaraldehyde crosslinking, such as tetranitromethane crosslinking, also improves mechanical strength, allowing for the modulation of mechanical properties and degradation rate, but it has been shown to be cytotoxic and pro-inflammatory.105,106 Moreover, carbodiimide crosslinking also forms stable covalent bonds between fibrin molecules, showing a drastic change in the hydrogel morphology. The swelling rate decreases, degradation increases, and Young’s modulus increases when the concentration of the crosslinker increases. However, growth factors showed lower release, and cytotoxicity assays demonstrated that by increasing the crosslinker concentration, cytotoxicity was observed.107,108 Alternative methods for the enzymatic crosslinking of glutaraldehyde include thrombin, transglutaminase, genipin or horseradish peroxidase (HRP). 105 Transglutaminases with high biocompatibility do not sufficiently crosslink plasma proteins. 105 In contrast, thrombin can crosslink plasma proteins to a satisfactory degree, providing an alternative crosslinker for fibrin hydrogels. Another alternative is the use of genipin as a fibrin crosslinker. For example, Gamboa-Martínez TC et al. demonstrated the cellular viability of an in vitro culture with genipin as a crosslinker. 109 Moreover, the content of primary amino groups in hydrogels crosslinked with genipin did not exceed that of the samples crosslinked with thrombin. 105 Finally, horseradish peroxidase has shown promise for modifying the mechanical properties of fibrin microthreads while preserving their biocompatibility. To optimize crosslinking strategies, parameters such as the crosslinker concentration, reaction time, and temperature must be carefully evaluated. Long-term biocompatibility studies should be conducted to assess the effects of crosslinking on cell behavior, inflammatory responses, and overall tissue integration.

For these reasons, over the past few years, researchers have focused on improving fibrin performance by modifying it with diverse polymers in various ways, which will be discussed below. The goal was to obtain scaffolds with adequate properties for specific biomedical applications without losing the biological properties of fibrin.

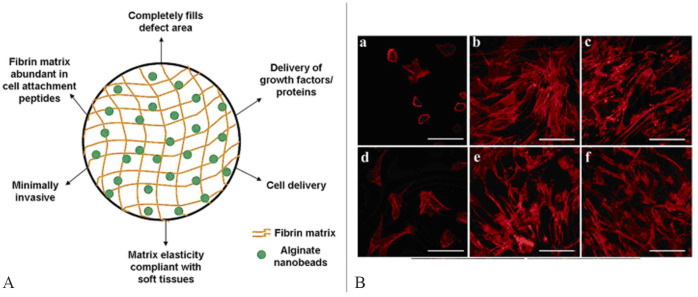

Advances in the design of fibrin-based matrices with improved properties

To solve those problems in the wide use of fibrin hydrogels in tissue engineering, some advances were researched and studied that aimed to improve the fibrin hydrogels properties. The first solution is the incorporation of polymer solid composites, where fibrin hydrogels are injected into porous solid scaffolds. The resulting fibrin-polymer solid composite scaffolds have shown great potential in tissue engineering, particularly in cartilage, cardiac tissue, skin, bone, and other tissues, where mechanical stabilization is improved, thereby providing biocompatibility. In addition, the incorporation of synthetic polymers, such as pegylated fibrin and PVA-fibrin hydrogels, among others, have also been researched and studied. These hydrogels provide additional structural support and modulate the biochemical and mechanical properties of the scaffolds. One notable advancement is the incorporation of natural polymers, owing to their compatibility with fibrin hydrogels. Natural polymers, such as collagen, alginate, hyaluronic acid, laminin, elastin, and agarose, have been incorporated into fibrin matrices to enhance specific properties, mimic the native ECM of target tissues, and regulate cell behavior to promote tissue repair and wound healing. Additionally, by incorporating particles into the fibrin matrix, it is possible to introduce specific functionalities such as controlled drug release, improved mechanical properties, and enhanced cell adhesion. These particle-incorporated fibrin hydrogels offer a versatile platform for targeted and localized therapy delivery as well as improved tissue engineering outcomes. These widely studied solutions aim to develop advanced biomaterials that promote tissue repair in damaged or diseased tissues.

Fibrin-polymer solid composite scaffolds

In this section, we discuss previous attempts to incorporate fibrin hydrogels into solid polymeric scaffolds. Synthetic polymeric scaffolds have been used because of their controllable mechanical properties, degradation rates that mimic those of real living tissues, easy handling, production, and low availability in most cases. They are typically obtained as porous scaffolds in the form of sponges and microfibers to culture cells in a 3D structure. Inside these scaffolds, cells proliferate and migrate over the surface of the pores or fibers, similar to a 2D culture; however, these polymers do not permit the development of cells or the expression of genes for differentiation or migration. On the other hand, fibrin is a complex biomaterial with some drawbacks regarding its mechanical properties and long-term stability but with outstanding cell signaling as RGD (arginine–glycine–aspartic acid) motifs that enhance cell adhesion and proliferation.

The synergy between both materials arises from the production of hybrid materials that take advantage of their good properties. Typically, the fabrication of these types of composite scaffolds proceeds by first obtaining a synthetic polymeric scaffold in which a fibrin precursor solution containing cells is infiltrated or poured over the porous scaffold, as shown in Figure 2. The three most common strategies to form fibrin-based hybrid scaffolds are phase-separation freeze-drying scaffold processing, the electrospinning scaffold technique and 3D printed scaffolds with porous, fibrous, and filamentous morphologies. Once the scaffold is produced using one of these strategies (a, b, and c in Figure 2), a fibrin precursor solution containing cells is injected into the solid scaffold and fibrin gelation occurs. 110 Using these procedures, a hybrid material was obtained from fibrin and a synthetic polymeric material.

Figure 2.

Scheme of fibrin-based hybrid scaffold formation in two steps: the fabrication of different solid scaffolds using different strategies (a, b, and c). (a) fibrin precursor solution containing cells is injected into the solid scaffold, and subsequent fibrin gelation occurs. A freeze-drying scaffold processing by phase separation: A polymer with a solvent is frozen to form a freeze-dried scaffold because of solvent sublimation. The resulting scaffold exhibits a porous morphology. (b) Electrospinning scaffold: A polymer with a solvent is dosed using a syringe on a collector drum with a determined electric current entailing solvent evaporation and the formation of a solid polymer fiber mesh. The formed scaffold exhibits a fibrous morphology. (c) 3D printed scaffold: a scaffold is designed in software, and the 3D printer reproduces the design layer by layer using needles loaded with a polymer that acts as bio-ink. The resulting scaffold exhibits a filamentous morphology. The left part of the image was adapted from Roacho-Pérez et al. 110

Applications in cartilage tissue engineering

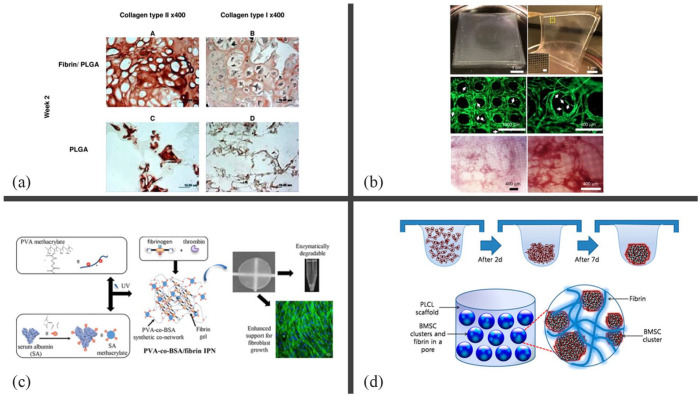

Fibrin-based hybrid materials have frequently been used as cartilage tissue scaffolds because of their enhanced mechanical properties and promotion of cell differentiation. Lee et al. enhanced cell retention and distribution within a macroporous polyurethane scaffold by combining chondrocytes with a fibrinogen solution. 117 However, the authors used aprotinin to delay fibrin degradation, and the scaffold did not maintain phenotypic conditions after 4 weeks. Recently, Sha’ban et al. discovered that chondrocytes produce more ECM due to the presence of more type II collagen and glycosaminoglycan in poly(lactic-co-glycolic acid) (PLGA) scaffolds with infiltrated fibrin after 3 weeks, compared to PLGA with no fibrin (Figure 3(a)). 111 Li C et al. also used a porous PLGA scaffold filled with fibrin gel, in which chondrocytes maintained a round shape, in contrast to the elongated shape of pure PLGA after 4 weeks. 112 In an in vivo analysis, Sha’ban et al. demonstrated that the hybrid scaffold was still improved to obtain cartilaginous tissue 4 weeks after implantation. 113 The authors suggested the incorporation of cell growth factors and other biomolecules to confer bioactivity to the hybrid system, with the aim of improving its ability to induce chondrocyte differentiation in other cell types.

Figure 3.

Applications of fibrin-polymer solid composite scaffolds in different tissues engineering. (a) Analysis of in vitro constructs using immunohistochemistry of fibrin/PLGA, which demonstrated strong immunopositivity of collagen type II, and PLGA, with minimal collagen type II expression, after 2 weeks. The immunopositivity of both constructs for collagen type I was moderate. Reprinted from Sha’ban et al. 111 (b) Micropillar array of poly (dimethylsiloxane) (PDMS) at square mesh (5 × 5 cm) (top images) with poured fibrin gel, which guided organization of the cells and produced angiogenic sprouts (white arrows) during 2 weeks of in vitro culture (middle images), and demonstrated a high degree of vascularization after 2 weeks of subcutaneous implantation in SCID-Beige mice (bottom images). Reprinted from Song et al. 114 (c) Research of scaffolds of polyvinyl alcohol (PVA) with serum albumin (SA), as a degradation agent by enzymes, at different concentrations. PVA and SA were previously methacrylated before being copolymerized into PVA-SA scaffolds via free radical copolymerization. Finally, fibrin gel with fibroblasts was infiltrated and polymerized by thrombin, resulting in enzymatically degradable IPNs. It promotes cell growth and mimics the physiological microenvironment of tissues. Reprinted from Bidault et al. 115 (d) Design for PLCL-fibrin scaffold fabrication in cartilage using stromal cells from rabbit bone marrow. Clusters of cells were aggregated using a hanging drop method and added inside the scaffolds using fibrin-gel infiltration. Reprinted from Lee et al. 116

A PLGA scaffold filled with fibrin sponges (obtained by freeze-drying) seems to increase water absorption and was characterized by Wei et al. to observe adipose-derived stem cell differentiation promoting cartilage regeneration in vivo. 117 Sukri NM et al. seeded rabbit bone marrow mesenchymal stem cells (BMSCs) on a PLGA/fibrin scaffold, in which the cells produced chondrogenic matrices but lacked signaling factors to induce chondrogenesis in vitro. 118 These investigations demonstrate the promising use of fibrin as a mesenchymal cell carrier to promote chondrogenesis in a hybrid scaffold with appropriate mechanical stability as a cartilage scaffold. Therefore, Lee et al. recently developed a hybrid poly (lactide-co-caprolactone)/fibrin scaffold in which fibrin was used to disperse BMSCs aggregates to achieve mature cartilaginous tissues. 116 Cell aggregation in combination with hybrid scaffolds improved chondrogenesis in vivo and cartilage-specific genes such as sulfated glycosaminoglycan (sGAG), collagen, and lacunae.

As previously discussed, tissue engineering also faces the problem of contraction of the scaffold during the culture of anatomically shaped structures. Cells tend to contract hydrogel scaffolds, especially when they are embedded inside, owing to proliferation, migration and cell mediated degradation.119,120 To address this, Visscher et al. designed a 3D printed PCL cage around a fibrin hydrogel that completely inhibited matrix contraction after 28 days in the presence of chondrocytes, perichondrocytes, and adipose-derived stem cells. 121 Setayeshmehr et al. lyophilized a mixture of devitalized costal cartilage matrix and aminated PVA, which was crosslinked in different ways, to embed a fibrin adipose-derived mesenchymal stromal cell (ASC) hydrogel. 122 Combining these materials allows cells to differentiate and prevents cell-mediated contractions. Research results and developments suggest the use of a combination of materials with the intention of fulfilling all properties and requirements for a specific tissue culture. Recently, a hybrid scaffold composed of a 3D-printed PCL lattice structure was coated with fibrin and ECM, which resulted in enhanced cell viability. 123

Applications in cardiac tissue engineering

Fibrin-based hybrid materials are frequently used in cardiovascular tissue engineering. For example, Pankajakshan et al. and Gundy et al. enhanced the expansion, proliferation, and survival of human umbilical vein endothelial cells and human coronary artery smooth muscle cells, respectively, using combinations of a solvent-cast PCL scaffold and a warp-knit PLA textile with a fibrin hydrogel, respectively.124,125 Generally, the tissues to be regenerated in vitro tend to be very complex, which means that the current design of scaffolds is a complicated task that requires a combination of different materials. Each type of material has its disadvantages. Hybridization plays an important role in balancing the properties of the hybrid material to approximate those of the original organ or tissue. Microvascular meshes with functional blood vessels have been obtained by Song et al. using a micropillar array of polydimethylsiloxane (PDMS) in which they poured a fibrin gel and this combined patterned scaffold guided the cell organization and prevented the matrix from shrinkage (Figure 3(b)). 114 Recently, multiscale hybrid scaffolds made of fibrin hydrogels, electrospun PCL fibers, and alginate hydrogels have been mechanically conditioned to support different types of cells in co-cultures to promote cardiovascular tissue and blood-vessel formation. 126

Applications in skin tissue engineering

Scaffolds for skin tissue can be created by combining fibrin and synthetic polymers using a variety of methods, such as electrospinning or physical blending.127,128 Studies using these scaffolds for wound healing demonstrated that a nanofiber wound dressing containing fibrin can be prepared using a coaxial electrospinning technique, which was tested in animal models. 129 The coaxial structure of the nanofibers allows for the encapsulation and controlled release of fibrin, which promotes angiogenesis and accelerates wound healing. The nanofiber dressing exhibited excellent biocompatibility and demonstrated enhanced wound healing capabilities, including increased cell migration and proliferation, as well as improved vascularization at the wound site. 130 Bidault et al. developed and tested a scaffold containing fibrin and PVA for the growth of fibroblast. 131 PVA was combined with a fibrin hydrogel and crosslinked by free-radical polymerization inside the scaffold after modification with methacrylate groups. According to this study, the scaffold had excellent mechanical properties such as tensile strength and elasticity because of the synergistic interactions between fibrin and PVA. In addition, these scaffolds provide an environment conducive to fibroblast growth, which may be helpful in wound healing. The self-supporting nature of scaffolds allows them to be easily handled and placed on complex wounds. Another approach is to add different PVA of serum albumin (SA) at different concentrations to allow the material to be degraded by enzymes (Figure 3(c)). 115 The PVA–SA co-networks were synthesized by free radical copolymerization of polyvinyl alcohol (PVAm) and serum albumin (SAm), both previously modified with methacrylate functions. The fibrin gel was then added to the solution and polymerized using CaCl2 and thrombin. This study demonstrated that by adjusting the crosslinking density and composition of IPN, the degradation rate of the biomaterial could be controlled.

Another polymer frequently used to create scaffolds into which polymerized fibrin solution is injected is poly(lactide-co-glycolide) (PLGA). Fibrous PLGA/fibrin scaffolds have demonstrated potential as substitutes for the skin. When combined with fibrin, PLGA, a biodegradable polymer, provides benefits, such as improved mechanical properties, controlled degradation, and support for cell adhesion and proliferation. PLGA/fibrin scaffolds have shown potential as skin substitutes. 132 Fibrin increased tensile strength while decreasing elongation at break. Direct and indirect 3-(4,5-dimethylthiazol-2-yl)−2,5-diphenyl-2H-tetrazolium bromide (MTT) assays were performed on the scaffolds, and the incorporation of fibrin improved cell adhesion and viability. Therefore, PLGA/fibrin is a promising material for use as a skin substitute. PLGA/fibrin scaffolds have also been used in wound healing models. In particular, a bilayer scaffold comprising an electrospun PLGA/fibrin membrane and a fibrin hydrogel layer was investigated. To produce a skin substitute, Bastidas et al. developed an electrospun membrane and fibrin hydrogel layer on a rat skin model. Keratinocytes were grown on electrospun membranes, and fibroblasts were grown in a fibrin hydrogel layer. The study showed that the scaffolds induced collagen deposition, granulation tissue growth, and epithelial tissue remodeling. The fibrous structure of the scaffold closely resembled the architecture of native skin, facilitating dermal cell infiltration and promoting the formation of new tissue. 133

Another interesting approach involves the healing effect of a fibrin-based scaffold loaded with platelet lysates in full-thickness skin wounds. 134 This study focused on treating full-thickness skin wounds with a fibrin-based scaffold loaded with a platelet lysate. Platelet-derived growth factors and cytokines, which have strong regenerative properties, are present in platelet lysates. Platelet lysates can potentially be used to treat diabetic foot ulcers because they accelerate reepithelialization and increase collagen deposition, thereby improving wound healing.

Furthermore, poly(ether)urethane-polydimethylsiloxane (PU-PDMS) scaffolds can be combined with fibrin to control the delivery of proangiogenic growth factors for the formation of new blood vessels. 135 The controlled release of proangiogenic growth factors from the scaffold improves vascularization in the surrounding tissue, resulting in better wound healing. The composite scaffold enabled targeted angiogenic stimulation and the formation of functional vasculature within the regenerated tissue by precisely regulating the release kinetics of these growth factors.

These scaffolds provide a biomimetic microenvironment that closely resembles the natural composition and architecture of skin. They promote cell adhesion, migration, and proliferation, while providing mechanical support and regulating the release of bioactive factors.

Applications in bone tissue engineering

Fibrin offers various scaffolding options for bone tissue engineering. Moreover, synthetic polymers incorporated into scaffolds, such as PLGA, polycaprolactone (PCL), or PVA, support cellular processes and have favorable mechanical properties that contribute to cellular viability. Studies on bone repair in scaffolds with interconnected pore structures that mimic the native bone microenvironment and promote cell infiltration and nutrient diffusion have been the main focus of the current literature. The incorporation of fibrous or nanofibrous structures improves cell adhesion and proliferation, and fibrin creates a biocompatible and biodegradable matrix. The scaffolds are typically made with PCL, PVA, and PLGA, among other materials, and are produced using the methods mentioned before, then, the fibrin precursor solution containing cells will be infiltrated or poured over the porous scaffold.136–139 For instance, Lee et al created an engineered cartilage scaffold complex with cells. 117 By using a gel-pressing technique, they engineered poly (lactide-co-caprolactone) (PLCL) scaffolds, and rabbit bone marrow stromal cells (BMSCs) clusters were added using fibrin-gel infiltration (Figure 3(d)). For up to 8 weeks, they implanted the scaffold into nude mice in order to differentiate chondrocytes, maintain their phenotypes, and increase glycosaminoglycan (GAG) production. All results show that the fibrin-based scaffold successfully repaired segmental bone defects, highlighting its potential as a clinically relevant approach for bone defect treatment. A 3D freeze-dried scaffold made of PVA and fibrin was developed for application in bone repair. The creation of platelet-rich fibrin (PRF)-loaded nano-biphasic calcium phosphate (nBCP)/PVA composites was researched. 140 This demonstrates how low-temperature Robocasting, a form of additive 3D printing, can be used to produce 3D printed BCP/PVA/PRF scaffolds with desired internal structures and bioactive factors to enhance segmental bone repair.

Another approach for bone repair is the use of biodegradable scaffolds. Mesenchymal stem cells and fibrin glue were injected into a biodegradable tricalcium phosphate (TCP) scaffold developed by Yamada et al. for bone repair. The scaffold acts as a carrier for mesenchymal stem cells (MSCs) and facilitates targeted delivery to damaged tissue. 141 The combination of MSCs, fibrin glue, and biodegradable scaffolds improved bone regeneration.

The combination of fibrin with other natural polymers in an injected solution is a novel approach. The use of alginate or collagen, for example, in combination with fibrin, improves the gelation properties, encapsulation, controlled release, or mechanical properties to improve the scaffold’s viability and regeneration.13,142 For example, fibrin-alginate hydrogels can be injected into a poly-ε-caprolactone (PCL) scaffold to treat bone defects. 143 The scaffold has proangiogenic properties because it promotes blood vessel formation and nutrient supply. The mechanical support, bioactivity, and controlled-release characteristics were provided by a combination of PCL, fibrin, and alginate. Additionally, Zhou et al. created alginate-fibrin microbeads to be injected into scaffolds for bone tissue engineering to promote the fast release of stem cells. 144 This study emphasized the importance of cell release kinetics from the scaffold and its influence on cell viability and functionality.

These microbeads had excellent mechanical properties that were comparable to those of natural bone, was biocompatible, allowed the controlled release of bioactive molecules, permitted osteoconductivity and osteoinductivity, and allowed the scaffold to be gradually replaced by new bone. 145 Kohli et al. used calcium phosphate to investigate the potential of composite scaffolds made of fibrin, alginate, and calcium phosphate for bone tissue engineering applications. The combination of the proangiogenic and osteogenic properties of these scaffolds provides an approach for promoting bone regeneration. 146

Other applications in tissue engineering

The possibility of increasing the range of applications of different blends of materials and cell types has led to the development of new hybrid materials that can be used for different cell culture lineages. For instance, a mixture of PCL and calcium monophosphide (CaP) can be used to 3D print lattice scaffolds in which a cell-laden fibrin hydrogel can infiltrate, promoting the proliferation and differentiation of mesenchymal stem cells to the osteogenic lineage. 147 Hokugo et al. incorporated PGA fibers into a fibrin hydrogel and lyophilized the entire construct. The addition of fibers suppresses cell-mediated contraction and does not affect fibroblast viability, showing promise for applications in skin or soft tissue engineering. 148 Using fibrin hydrogels as cell carriers is interesting when homogenizing cell cultures and ensuring cell proliferation in a urethral scaffold that mimics the biomechanical properties of native tissue using blends of PCL and PLCL. 149 The incorporation of a Smart Matrix on the surface of a plasma-polymerized PDMS membrane led to promising results in the preparation of a product for pressure sore treatment or as a dermal scaffold. 150

In renal tissue-engineered models, a PGA electrospun construct was filled with a fibrin precursor solution and gelled inside podocytes and glomerular endothelial cells, modifying its mechanical properties and increasing the long-term proliferation rates of cells. 151 A similar hybrid material made of wet-spun PCL fibers was used to culture human osteosarcoma to produce a hybrid scaffold for hard-tissue engineering. 152 These examples demonstrate versatility in terms of developing or regenerating different tissues and organs, paving the way for personalized regenerative medicine.

Synthetic polymers—fibrin hydrogels

As a different strategy, some authors have modified the properties of fibrin hydrogels. Two strategies can be envisioned for introducing synthetically functionalized polymers during fibrin polymerization. In one case, the synthetic polymer forms a network apart from that formed by fibrin, leading to the formation of an interpenetrating polymer network (IPN), in which both networks coexist simultaneously. In another case, the synthetic polymer interacts with fibrinogen or fibrin monomers to modify the native fibrin network, for example, by polyethylene glycol (PEGylation).

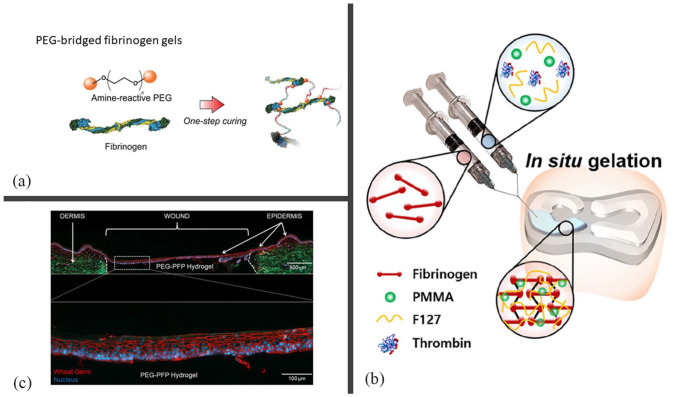

Typically, fibrin participates in the formation of an IPN by forming one of the networks via thrombin activation, whereas the synthetic polymer bears acrylate groups to form its own network via UV-activated polymerization (Figure 4(b)). Polyethylene glycol (PEG) and polyvinyl acetate (PVA) were used to enhance the mechanical properties of IPN, rehydration ratios, and stability. However, the use of UV light and acrylates in combination with cells is a concern in terms of cell viability, and in some cases, excess acrylates inhibit fibrin polymerization.131,153 An IPN based on enzymatic activation (thrombin) and Michael-addition crosslinking between a thiol and an amphiphilic block copolymer (Tetronic T904) was developed by Zhang et al. for the controlled release of non-viral genes. 154 The degradation ratio was controlled by modulating the T904/fibrinogen ratio, which in turn modulated the transfection level.

Figure 4.

Modification of fibrin hydrogels by synthetic polymers. (a) Process of the formation of a PEGylated hydrogel. First, PEG is functionalized to react in the presence of the amine groups of a protein. Then, the di-functional PEG is added to the fibrinogen leading to a new type of fibrin hydrogel (reprinted from Roberts et al. 51 ). (b) Scheme of an IPN formation of fibrinogen with Pluronic® F-127 (F127) and poly(methy)methacrylate (PMMA) polymers, thanks to thrombin. The hydrogel is formed by a dual-syringe system which dispenses a Fb/F127/PMMA solution and thrombin and fills a meniscal region, (reprinted from An et al. 155 ). (c) The top part shows a polyethylene glycol-platelet free plasma hydrogel treated 4 mm ex vivo explant that was cultured for 14 days. It is stained with wheat germ (red) to visualize the plasma membrane and counterstained with DAPI for nuclei (blue). At the bottom, an enlarged epidermis formed over the PEG-PFP hydrogel is shown (reprinted from Stone et al. 29 ).

Acylate-bearing PEG is used extensively to obtain IPNs in combination with bovine serum albumin (BSA) modified with methacrylate groups (mBSA). Kuten Pella O et al. combined PEGylated albumin and fibrinogen to obtain hydrogels for drug delivery systems, in which it was possible to control the mechanical properties, biocompatibility, and drug release by controlling the PEG, fibrinogen, and albumin content, respectively. 156 Similarly, mPVA and mBSA were combined to obtain IPNs in the presence of fibrin, leading to more stable gels in terms of mechanical properties and degradation, whereas cell viability was enhanced owing to the presence of BSA in comparison with the aforementioned studies on mPVA. 115 As these PEG-BSA IPNs modify the hydrogel microporosity, they could hamper the cellular infiltration required to obtain cultured 3D functional tissues in-vitro; therefore, Gsib et al. proposed further research on obtaining modified fibrin hydrogels with controlled porosity. 157 IPNs modified by these methods are promising because their mechanical properties and biodegradability can be easily tuned by changing their composition, which makes them a good material choice for tissue engineering applications. 158

To avoid these complications in IPN hydrogels, scientists have identified alternative ways to obtain fibrin-based IPNs using different strategies. Recently, Loebel et al. used a combination of supramolecular and covalent networks to enhance the mechanical properties of hydrogels while promoting the proliferation and spreading of cells by means of the dynamic nature of the supramolecular network. 159 As in previous studies, the covalent network was composed of PEGDA and fibrinogen, whereas the supramolecular network was made of hyaluronic acid functionalized with either cyclodextrin or adamantane. Gsib et al. developed an IPN; however, instead of forming both networks simultaneously, they performed it in a sequential manner. They first obtained a hydrogel composed of PEG-BSA, as in previous studies, and lyophilized it to obtain a microporous construct that was subsequently filled with the hydrogel precursor solution to develop a fibrin network in the pores of the previous one. 160 Thus, they avoided the aforementioned porosity modifications while obtaining an enhanced fibrin-based hydrogel.

As real examples for applicability Recently, injectable hydrogel systems based on fibrin have been developed for meniscal regeneration using two different approaches to improve the properties of fibrin. Unlike previous examples, Kim et al. incorporated polyethylene oxide (PEO) or Pluronic F127 (P-F127) as an injectable hydrogel into a fibrinogen solution to form a semi-IPN in the defect area. The incorporation of free PEO in the fibrin hydrogel improved the mechanical properties and apparently enhanced the tissue regeneration and the quality of this regenerated tissue after 12 weeks in rabbits. 161 In contrast, the incorporation of P-F127 and polymethyl methacrylate (PMMA) microbeads into fibrin formulations seems to enhance the mechanical properties, degradation, and tissue regeneration ratios, but particularly improves shear stress to facilitate hydrogel administration in damaged areas. 155 How ever, free PEO, P-F127, and PMMA microbeads were released from the hydrogel with unknown effects when used in vivo. Therefore, further studies are required to confirm these findings.

PEGylated—fibrin hydrogels

PEG is frequently used to obtain modified hydrogels with enhanced cell-culture properties. Basically, difunctionalized PEG is added to a fibrin precursor solution that reacts with native fibrinogen, leading to a new type of fibrin hydrogel. This process is known as PEGylation, and the material is referred to in the literature as a PEGylated fibrin scaffold (Figure 4(a)). Generally, PEG is functionalized with benzotriazole carbonate, succinimidyl glutarate, and acrylate groups to react in the presence of the amine groups of the protein, as in the case of fibrinogen, leading to stable urethane (carbamate), amide, or Michael addition bond, respectively.162,163 These modifications of native fibrinogen before fibrin polymerization increase the long-term stability, mechanical response, and hydrophilicity of fibrin hydrogels. Different cell types, regenerative approaches, and strategies have been tested using PEGylated fibrin hydrogels, which appear to promote cell migration and proliferation without affecting cell viability, or even improve it in some cases.164,165 For example, Figure 4(c) shows re-epithelialization of a 4 mm ex vivo explant into the skin, showing an epidermis completely formed over a wound with a polyethylene glycol-platelet-free plasma (PEG-PFP) hydrogel. Typically, a 1:10 (PEG:fibrin) molar ratio is used for fibrin modification, as this was found to be the best formulation without causing a delay in the gel time. 163 Typically, bifunctional PEGs with an average molecular weight of 3400 Da are used to better control the PEG/fibrinogen ratio. As PEG-fibrin can be modified prior to gelation it can be placed in wounds or injected into damaged areas acting as a vehicle for cells or growth factors.166–168 PEG-fibrin and PEG-PFP hydrogels have been used to heal burn wounds in pigs, preventing wound contraction and reducing the number of neutrophils and macrophages. 30 The same authors investigated wound healing strategies in vitro to test biomaterials on discarded human skin. They found that PEG-PFP hydrogels re-epithelialized the wound area faster and enhanced keratinocyte proliferation, migration, and differentiation compared to collagen and PEG-fibrin hydrogels.

As confirmed by Shpichka et al. using small-angle X-ray scattering (SAXS), the addition of bifunctional PEG to fibrinogen increases the oligomeric species at the beginning of polymerization, thus modifying the hydrogel structure and behavior. 169 Commonly, fibrin hydrogels modified by PEGylation have a microporous structure instead of the native fibrous structure, which is dependent on the fibrinogen:PEG ratio, and increases the storage modulus, transparency of the hydrogel, and vascularization in wounds for full-thickness skin regeneration. 31 Furthermore, Shpichka et al. suggested that the anchoring of PEG to different sites of fibrin molecules could increase cell migration owing to the masking effect of RGD moieties. Gorkun et al. related the formation of capillary- and tubular-like structures of cells inside the hydrogel to the change in microstructure and the aforementioned masking effect. 170 PEGylation also increases the long-term stability of fibrin hydrogels by reducing their degradation rates, thus opening new strategies in ovarian tissue engineering. 171

Because PEGylation is simple to perform, new strategies to understand and improve fibrin hydrogel properties have emerged in recent years. Recently, Pal et al. synthesized bi- or tetra-functionalized biodegradable crosslinkers based on PEG and polypropylene glycol (PPG) for blood plasma modification, which enhanced the mechanical properties and shortened the gel time without compromising the toxicity of plasma-based hydrogels. 172 In addition, Leon-Valdivieso et al. have functionalized PEG with peptides that react specifically to “a” and “b” knobs introducing defects during the fibrin polymerization inside the fibrin fibers. Through this modification, the authors softened the mechanical properties of the gel and studied its effect on fibroblast migration and colonization. 153

PVA—fibrin hydrogels

Polyvinyl alcohol (PVA) is a synthetic polymer belonging to a family of polyvinyl compounds. It is formed by polymerizing vinyl acetate and hydrolyzing it to remove the acetate groups, resulting in polyvinyl alcohol. PVA is a water-soluble polymer with excellent film-forming and adhesive properties. 127

PVA combined with fibrin improves the properties of fibrin hydrogels for wound healing, regeneration, and tissue engineering for several reasons. PVA is a synthetic polymer known and used for excellent mechanical properties including tensile strength and elasticity. When combined with fibrin, which is a natural biopolymer with low mechanical strength, PVA improves the overall mechanical stability of the composite material. This is particularly important for wound dressings and scaffolds because it provides structural integrity and supports healing tissue. 173 Another reason is moisture retention; PVA has hydrophilic properties and maintains a moist environment, which provides a favorable microenvironment for cell migration, proliferation, and tissue regeneration. 174 The biocompatibility and synergistic effects of PVA-based wound dressing materials, which lead to improved cell adhesion, proliferation, and tissue regeneration, combined with the previously mentioned advantages of fibrin, provide a versatile platform for wound healing and tissue engineering applications. Although fibrin contributes to the biocompatibility and biological activity of the composite, PVA improves the mechanical stability, moisture retention, and controlled drug release properties of the material. 173

The synthetic fibrin hydrogel formation of PVA was performed using chemical methods. Xu et al. investigated the effects of adding freeze-dried granule-lyophilized platelet-rich fibrin (G-L PRF) to a PVA hydrogel for wound healing applications. 175 The results demonstrated that the combination of PRF and PVA enhanced cell proliferation, angiogenesis, and wound closure. The incorporation of PRF provided a favorable microenvironment for cell adhesion, migration, and proliferation, whereas the PVA hydrogel acted as a scaffold, providing mechanical stability and facilitating controlled drug release.

When fibrin and PVA are combined, chemical crosslinking can be used to create a stable hydrogel. This method involves the use of crosslinking agents to covalently bond the fibrin and PVA networks. Epichlorohydrin, boric acid, aldehydes, and heavy metal compounds that form complexes with PVA molecules are examples of commonly used crosslinkers. 128 Emulsion template-based fabrication of fibrin/PVA scaffolds for skin tissue engineering was studied. 176 Fibrin and PVA were combined in an emulsion in which one phase was dispersed as droplets within the other phase. Subsequently, glutaraldehyde was used to crosslink the emulsion to create a scaffold structure with interconnected pores, which can be used for skin tissue engineering applications. These results demonstrated that the fibrin/PVA hydrogels possessed interconnected porous structures that were favorable for cell infiltration and nutrient diffusion. Fibrin hydrogels used for skin tissue engineering applications incorporate fibrin to promote cell adhesion and proliferation.

Other synthetic—fibrin hydrogels

Hydrogels made of methacrylated fibrin (MA-fibrin) are an alternative method for synthesizing synthetically modified fibrin hydrogels. Methacrylate groups are added to fibrin molecules to produce methacrylated fibrin. With this modification, fibrin can be crosslinked via photopolymerization to create a stable hydrogel. An innovative biomedical hydrogel was created by Haneen et al. for 3D cell culture or as a biodegradable delivery matrix for in vivo implantation.176,177 Methacrylic anhydride (MAA) was used to denature methacrylate fibrinogen in solution through light-activated free-radical polymerization in the presence of macromolecular crosslinking polymers. The study showed that in 3D cultures of human dermal fibroblasts, hydrogels offer a biocompatible environment that supports cell adhesion, proliferation, and differentiation. Hydrogels also have the potential to act as carriers of therapeutic agents with controlled release, opening up opportunities for precise delivery in tissue engineering and regenerative medicine.

Furthermore, fibrin can be modified by poly(N-isopropylacrylamide) (PNIPAAm), resulting in the formation of a nanogel. 178 PNIPAAm is a thermoresponsive polymer that undergoes a reversible phase transition near the body temperature. “Smart” hydrogels that can go through gel-sol transitions in response to temperature changes can be made by incorporating PNIPAAm into fibrin hydrogels. Owing to its high drug-loading capacity, the authors developed a nanogel system that could deliver two different therapeutic agents: one for promoting angiogenesis and tissue regeneration and the other for inhibiting fibrosis. As a result of the incorporation of PNIPAAm into fibrin hydrogels, this method simultaneously promotes tissue repair and reduces fibrosis.

Another interesting approach involves the use of polyacrylic acid (PAA)- modified fibrin hydrogels. PAA is an electroresponsive polymer that can be incorporated into fibrin hydrogels to introduce electricity-dependent swelling and drug release properties. Because of its increased electrical sensitivity, PAA-modified can to convert environmental stimuli, such as electrical energy, into mechanical forces. This allows for the creation of mechanically stimulating hydrogel-based smart devices that are electrosensitive and biocompatible. 179 Based on these findings, the hydrogel functions as a mechanical pump that guides the alignment of smooth muscle cells under electrical stimulation and facilitates their infiltration and distribution throughout the structure.

Natural polymers—fibrin hydrogels

In recent years, new approaches have been developed to improve fibrin properties by combining fibrin with natural polymers.

Fibrin-collagen hydrogels

Collagen is a major component of the extracellular matrix (ECM) in many tissues and organs and plays a key role in tissue development and function. 180 This material exhibits low immunogenicity, porosity, high permeability, biocompatibility, and biodegradability. However, its poor mechanical properties require crosslinking or modification with natural or synthetic polymers or inorganic materials. Collagen-based materials show higher cell adhesion and proliferation in vitro and are widely combined with fibrin matrices for tissue engineering applications. Earlier studies demonstrated that fibrin-collagen composite networks displayed extra stiffness and durability, improved elasticity, and permissive endothelial network formation in vitro and in vivo, providing support for their use instead of purified collagen and fibrin. 181