Abstract

The quality and the safety of the foods that are served at fast foods restaurants and their effect on the consumer health could become a matter of concern during COVID-19. Therefore, the objectives of this study were i) to evaluate the quality and safety of raw foods, suitability and availability of manufacturing places, physical facilities, drinking water and waste management system, and processing conditions, and ii) to assess the knowledge, attitudes, practices regarding food safety and hygienic practices among food handlers at fast foods restaurants in the different universities in Jordan during COVID-19. The study was conducted in 12 fast foods restaurants of 3 different universities in Jordan which are located in different places in Jordan. A desirable practice was given a score of one while no score will be allotted for an undesirable practice through using a standard questionnaire for all the food establishments. This was used to compare with the maximum score obtainable for that relevant operation and the percentage scores was calculated for each operation. Analysis of Variance (ANOVA) of the data was performed to study the significant differences at P ≤ 0.05 in all the evaluated properties among the food establishments in the different universities. The results showed that low percentage scores were obtained with 68%, 75%, 32% and 56% for the production area, waste management, product evaluation (chemical, microbial) and food safety program application, respectively. Also, it was found that there were insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in all the safety properties. This means that all the food establishments in all the universities suffer from the same problems with the same degree. As a conclusion, more work should be done to produce safe food in the different food establishments that were studied in the different universities.

Keywords: Food safety, Fast foods, KAP, Hygienic practices, Food handlers

1. Introduction

WHO estimated that 33 million of healthy lives are lost due to eating unsafe food globally each year [1]. The main factors behind the foodborne illnesses are cross contamination, poor storage conditions, insecure food sources, food mishandling, poor personal hygiene, and improper cooking [2]. Preventing COVID-19 is all about hand washing, wearing facemasks, keeping a safe distance from each other and quarantine in addition to that different vaccines are in the process of production. It is tempting to speculate that this COVID-19 infection may also become an issue in different food establishments. During COVID-19 period, food safety was the most important part of the food chain [3]. This may relate to possibility of contamination with COVID-19 during food preparation, holding, serving and delivering different foods to the consumers. The unsafe employee's practices may increase the susceptibility of spreading the disease. SARS-CoV-2 was found to be stable at −20 °C for 3 weeks on salmon filets, chicken, and pork [4]. In addition to that, it was found that the contamination of a food with SARS was reduced by 4 log colony forming units (CFU)/g by cooking at 63 °C for 4 min [5]. Therefore, there is an urgent need to examine knowledge, attitudes, and practices (KAP) regarding food safety during the era of the COVID-19 pandemic. According to the different researches, KAP has improved during this public health crisis [[6], [7], [8], [9], [10]]. Providing safe foods to the consumer during this period is a matter of challenge in different foods establishments and mainly in fast food restaurants. Fast foods restaurants offer a wide variety of foodstuffs that are fresh and very tasty, generally semi nutritious, available quickly and reasonably priced. However, the quality and safety of these foods and their effect on the consumer health could become a matter of concern. Before the pandemic, about 59% of food employees in the military hospital in Jordan were found to be incorrectly following food hygiene practices [11]. No study has critically evaluated the quality, safety and the acceptability of the foods that are served at these fast foods restaurants in some famous and traditional restaurants during the COVID-19.

Food safety is one of the most important aspect that should be considered in food preparation process starting from the raw materials receiving, pre preparation, preparation, storage and food serving and distribution steps. Ensuring food safety during COVID-19 is an important issue in maintaining public health (Nutrition Foundation of India [12]. Food deliveries and eating out of the homes is becoming one of the most important phenomena that increased rapidly during the last periods. Fast food restaurants and cafeterias boast an impressive selection of foodstuffs that not only satisfy cravings but also embody an enticing attitude of freshness, delectable flavors, swift service, and pocket-friendly prices [13,14]. However, the quality and the safety of these foods and their effect on the consumer health could become a matter of concern if essential preparation steps and hygienic practices are not followed during their preparation and their subsequent storage until sale [15]. Therefore, it is essential to apply all the hygienic and sanitary practices at all steps of food production and preparation [16]. Implementation of food quality and food safety monitoring program by food service establishments would dramatically improve the level of food quality and safety [17,18]. These improvements will be reflected on the degree of the foods acceptability that is served in these restaurants. There are only shreds of evidence regarding the duration of coronavirus survival on different contact surfaces and in foods under certain conditions which suggests the need for advanced studies in understanding the risk of COVID-19 spread associated with food and food packages. Research trials are required to find a link between the ingestion of food contaminated with SARS-CoV- [19,20].

Restaurant owners and workers have been significantly affected by food safety regulations during COVID-19 which have governed the activities of both employees and consumers. Therefore, our main objective in this study was to evaluate quality, safety and the acceptability of the foods, suitability and availability of manufacturing places, physical facilities, drinking water, waste management system, processing conditions, and food safety knowledge and hygienic practices of food handlers at these fast foods restaurants in the different universities in Jordan during COVID-19. The specific objectives included obtaining a general profile of the food handlers, food material, the hygiene practices, surface sanitation, food safety knowledge, the safety steps that are followed during food production, packaging and distribution. The study was conducted in 12 fast foods restaurants of 3 different universities in Jordan which are located in different places (Jordan University of science and technology, University of Jordan and the Hashemite University).

2. Materials and methods

2.1. The procedure

The study was conducted in 12 major fast food restaurants which are located in 3 different Universities in Jordan (Jordan University of science and technology, University of Jordan and the Hashemite University). This study was based on the willingness of the concerned restaurants, cooperation promised by the restaurant personnel to participate in the study and the easy accessibility of the restaurants. Catering operations and food material handling practices were evaluated and recorded by the University Safety Officer, along with a professor from the Nutrition department and a Lab instructor. These evaluations were conducted by the University Safety Officer, along with professors from the Nutrition department and the lab professor. Information were obtained on various aspects of layout such as procedures for buying and receiving of raw materials, storage of raw materials at different conditions, preparation (vegetables washing, soaking, thawing) and preparation of food items (cooking, frying, salad preparation), serving and holding while serving, dishwashing of equipment and utensils, and left over management. Personal hygiene (hand washing, using gloves), personal observations were also recorded. The temperature was monitored by using thermometer in all the preproduction, production and storage steps. A desirable practice was given a score of one while no score will be allotted for an undesirable practice through using a standard questionnaire for all the food establishments (Appendix 1). The scores average and the standard deviations for each evaluated step of the different 12 fast food establishments were calculated. This was used to compare with the maximum score obtainable for that relevant operation and the percentage scores was calculated for each operation. A pretested observation checklist was administered to facilitate recording of personal hygiene practices of the individual food handlers and for all the practices that are performed in the different food establishments.

In general, all the following variables were evaluated (According to Appendix 1).

-

1

Evaluation of different raw food products in all universities campuses food servings locations, which include: Milk and milk products, dry products, fruits and vegetables, meat and meat products, and oil products).

-

2

Evaluations of different manufacturing places (space and cleaning), which include: Adequate space, clean and dry place, ventilated place, pre-production safety, and production safety.

-

3

Evaluations of different physical facilities, water availability and waste management, which include: Physical facilities, water supply, and waste management.

-

4

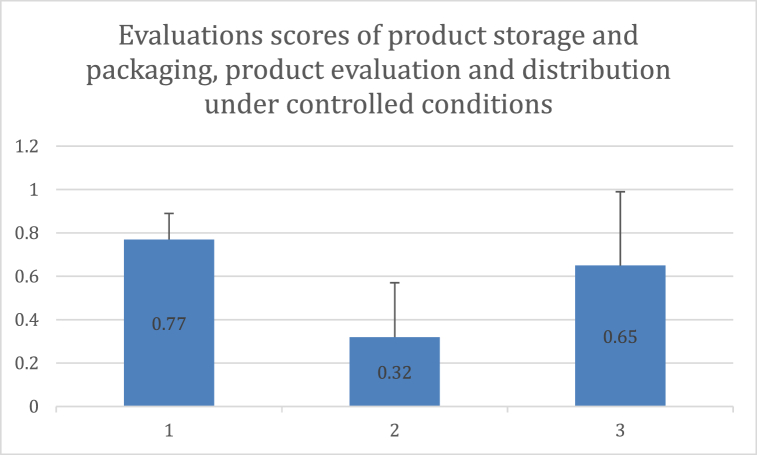

Evaluations of product storage and packaging, and distribution under controlled conditions, which include: Product storage and packaging, product evaluation, and product distribution under controlled conditions.

-

5

Evaluation of food handlers and personal hygiene practices, which include: Personal appearance, personal undesirable activities during the work, personal hygienic practices that are followed, and toilet conditions.

-

6

Evaluation of food safety knowledge and equipment's availability, which include: Food safety knowledge, and equipment availability.

Statistical analysis: Analysis of Variance (ANOVA) of the data was performed to study the significant differences in all the evaluated properties among the food establishments in the different universities that were used in the study by using a Statistical Analysis System (SAS) (2003) program. RCD design was followed. The least Significant Difference (LSD) test was used for mean separation. The results were considered significant at P ≤ 0.05.

3. Results

3.1. Evaluation of different food products in all universities campuses food serving locations

The evaluation scores of different food products in all universities campuses food serving locations can be shown in Fig. 1. The highest evaluation percentage was obtained for the meat and meat products which was 90%. The evaluation includes the following parameters: meat temperatures which is about (4–6 °C), the package cleanness, sensory properties and the expiration date. This result is very critical in determining the quality and the safety of these products since most of the health concerns are related to meat and meat products consumption. Moreover, there was insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in the safety evaluation scores of these products. The lowest evaluation percentage was obtained for the milk and milk products which was 77%. The evaluation includes: milk temperatures which is about (4–6 °C), the package cleanness, sensory properties and the expiration date. Also, this result is very critical in determining the quality and the safety of these products since most of the pathogenic microorganisms can be transmitted through consumption of contaminated milk and milk products. The dry products, fruits and vegetables and the oil products evaluation percentage are located in between the other previous mentioned products as can be seen in Fig. 1. These results can be considered as good indicators for the advantages of doing this study. Actually, more information and training should be given for all the employees in the different food establishments about the quality and the safety of the different food products that are going to be used for either direct consumption or in the production and preparation.

Fig. 1.

Evaluation score of different food products (1: Milk and Milk products, 2: Dry products, 3: Fruit and vegetables, 4: Meat and Meat products, 5: Oil products in all universities campuses food servings locations). Multiply the results by 100 to be changed into %.

4. Evaluations scores of different manufacturing places (space and cleaning) in different universities to produce safe food products

It was found that the average percentages for the space, cleaning, and ventilation of the different places that are used for food manufacturing are 72%, 77% and 77%, respectively, as can be seen in Fig. 2. At the same time, it was found the percentage evaluation of preproduction step condition to produce safe food is 81% which include washing and sanitizing of the raw materials, covering of the raw material and the place should be free from any objectionable odors. Also, the percentage of evaluation of the production area is 68% which include: production surfaces cleaning, the products covering and temperature monitoring. Moreover, there was insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in the space and cleaning. All of these results can be used to indicate that more work should be done efficiently to produce safe food. The critical point that is need to be modified and monitored is the production step.

Fig. 2.

Evaluations scores of different manufacturing places (space and cleaning) in all universities campuses food servings locations to produce safe food products (1: Adequate space, 2: Clean, 3: Ventilation, 4: Preproduction safety, 5: production safety). Multiply the results by 100 to be changed into %.

5. Evaluations scores of different physical facilities, water availability and waste management

As can be seen in Fig. 3 that the percentage scores for the physical facilities, water availability and waste managements are 81%, 81% and 75%, respectively. These results are good indictors that more work should be done to improve the process of producing safe foods. These facilities are so important in determining the quality and the safety of the different food items. Moreover, there was insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in the physical facilities, water availability and waste management.

Fig. 3.

Evaluations scores of different physical facilities, water availability and waste management in all universities campuses food servings locations to produce safe food products (1: physical facilities, 2: water availability, 3: waste management. MULTIPLY THE RESULTS BY 100 TO BE CHANGED INTO %.

Waste management is one of the most important factor that should be controlled to produce safe food. The waste management includes such as the presence of garbage bins and lid, disposable bags, self-closing garbage bins, and many other parameters that are mentioned in Appendix 1. As can be seen in Fig. 3, the waste management got the lowest score compare to the physical facilities which includes such as lite and ventilation, the presence of sinks and water, the availability of clean equipment and many others (Appendix 1). The availability of supply water and the type of water that is used in the food establishment can be considered as one of the main factors that influence the safety of the establishments and its products.

6. Evaluations scores of product storage and packaging, product evaluation and distribution under controlled conditions

The percentage evaluation scores were 77%, 32% and 65% for the product storage conditions packaging evaluation, product evaluation (chemical, microbial and sensory), distribution and serving of the food after the production stage, respectively, as can be seen in Fig. 4. Moreover, there was insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in the product evaluation and distribution under controlled conditions.

Fig. 4.

Evaluations scores of product storage and packaging, product evaluation and distribution under controlled conditions in all universities campuses food servings locations to produce safe food products (1: product storage and packaging, 2: product evaluation, 3: product distribution). MULTIPLY THE RESULTS BY 100 TO BE CHANGED INTO %.

The lowest evaluation score was found for the product evaluation which was 32%. Product evaluation step is very critical step in determining the quality and the safety of the food products. Most of the food establishments that were studied do not do any chemical and microbial evaluation of their products before its serving. Some of the establishments do a certain type of sensory evaluation. This step needs to be improved in the most food establishments in the different universities. In addition to the food packaging and its distribution and serving under controlled condition should be improved.

7. Evaluation scores of food handlers and personal hygiene practices

As can be seen in Fig. 5 that the percentage scores for the personal appearance, undesirable activity during the work, hygienic practices and toilet conditions are 79%, 72%, 75% and 74%, respectively. Moreover, there was insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in the food handlers and personal hygienic practices.

Fig. 5.

Evaluations scores of food handlers and personal hygiene practice in all universities campuses food servings locations to produce safe food products (1: personal appearance, 2: undesirable activity during the work, 3: hygienic practices, 4: toilet conditions). MULTIPLY THE RESULTS BY 100 TO BE CHANGED INTO %.

These values are so important in giving an idea about the hygienic practices that are followed by the employees during doing their job which will directly reflect the level of the food safety that is going to be consumed by the consumers. Many types of pathogenic microorganism can be transmitted to the food through the employees if they do not follow the hygienic practices in the food production. Therefore, it is so important to train the employees about these practices. These results show that more information and knowledge should be giving for the employees about the hygienic practices such as personal appearance (such as: shaving regularly, keep nails short, clean uniform, wearing gloves during serving … etc., Appendix 1). Also, some undesirable activities were found to be done during the food handling and serving by the employees (such as: combing hair, blowing nose, sneezing, coughing, cleaning ear … etc. (Appendix 1). In

Addition to that some other activities were done by the employees and were monitored during the evaluation such as visiting toilet, handling money, smoking and cleaning without sufficient hand washing with soap. Doing all these activities will give the chance for the pathogenic microorganisms to be transmitted to the food. Moreover, it was found that the toilet conditions were not acceptable (such as absence of soap, sanitizers, dryer … etc.). Therefore, all evaluation scores were low compare to the maximum and acceptable values.

7.1. Evaluation scores of food safety knowledge and Equipment's availability

As can be seen in Fig. 6 that the percentage scores for the food safety knowledge and equipment's availability are 56% and 77%, respectively. Moreover, there was insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in the food safety knowledge and equipment availability.

Fig. 6.

Evaluations scores of scores for the food safety knowledge and equipment's availability in all universities campuses food servings locations to produce safe food products (1: food safety knowledge, 2: equipment's availability). MULTIPLY THE RESULTS BY 100 TO BE CHANGED INTO %.

Most of the food establishments lack of any types of food safety programs such as Good manufacturing practices or hazard analysis and critical control points. Therefore, food safety knowledge score is very low. However, this problem can be resolved by doing some workshops for the employees to give them the chance in applying those systems at their establishments to reduce any possibility of food contaminations and reduce the health hazards that may affect the consumers.

8. Discussion

More information and knowledge should be giving for the employees about the hygienic practices because the evaluation score was only 75% from the total score. Some undesirable activities were found to be done during the food handling and serving by the employees (such as: combing hair, blowing nose, sneezing, coughing, cleaning ear … etc. In addition to that, some other activities were done by the employees and were monitored during the evaluation such as visiting toilet, handling money, smoking and cleaning without sufficient hand washing with soap. Moreover, it was found that the toilet conditions were not acceptable (such as absence of soap, sanitizers, dryer … etc.). Therefore, all evaluation scores were low compare to the maximum and acceptable values. In different other studies, it was found that the majority of the food handlers belonged to the low socioeconomic group and over 80% of the employees were untrained; none of the cooks had received any formal training and had learnt the job by experience [14]. Actually, these reasons could be the main reason behind the low scores values compare to the maximum values. In the same study [14], it was found that none of the employees washed their hands with soap after smoking/eating touching waste foods/performing any cleaning operations/handling money. Also, it was found that there was a positive significant association between education and personal hygiene of food handlers in Bijapur city [21]. All of these factors may lead to increase the possibility of the cross contaminations in any food establishment [22]. found that insufficient washing hands, lack to use hygienic towels for hand drying leads to faults in hygiene practices management. In a study done by Ref. [23] in Brazil showed that 13 schools from 15 (87%) were classified as poor on the basis of the total scores obtained in terms of layout, utensils and equipment maintenance, employee personal hygiene practices, quality of raw and RTE foods, production flow, food handler practices and quality control. In another study, it was found that only 20% of workers possessed good knowledge, 56% had positive attitudes, and 55% had good practices. In general, it was observed that the precautions and preventive measures put in place during the pandemic improved the application of key food safety regulations within their workplaces [24]. Also, more training is required to prevent the spread of COVID-19 and foodborne pathogens via the application of good hygienic practices that improve food safety, reducing illnesses and food waste while maintaining food security and economic sustainability. Also, in fast food restaurant it was found that 31% of the workers working in food and drink establishments in Southwest Ethiopia had poor knowledge about COVID-19, while only 28% had strong knowledge [25]. However, according to Ref. [24] only 35% of workers know that the hand washing duration period is at least 20 s. It has been indicated that hand hygiene is more important than any other steps during cleaning and disinfecting food surfaces in terms of controlling the spread of pathogens. That is because hands are considered the main reason for spreading pathogenic microorganisms [26]. In another study in Malaysia, it was found that the food handlers had sufficient level of knowledge (80.5%), attitude (87.4%) and practice (90.1%) [27].

According to study done by Ref. [28], it was found that more than 95% of participants gathered information regarding food safety through various media. These findings indicate that people has felt the need to learn more information during the corona outbreak, and getting this information naturally has led to increased knowledge, attitude, and, as a result, better hygienic practice performance.

These results are good indicators that poor hygienic practices are followed in the fast food restaurants in different countries. All of these results are in agreement with the results that are obtained in this study.

9. Conclusions

A general profile of the food handlers, food material, the hygiene practices, surface sanitation, of various foodstuffs that are served some major fast food restaurants in 12 different locations at 3 different Universities in Jordan has been achieved during COVID-19. The highest evaluation percentage was obtained for the meat and meat products which in the average of all the Universities was 90%. The percentage of evaluation of the production area is 68% which include: production surfaces cleaning, the products covering and temperature monitoring. The waste management got the lowest score which was 75% compare to the other facilities parameters. Food evaluation (Chemical, microbial and sensory) after the production has been studied, the lowest evaluation score was found for the product evaluation which was 32Therefore, food safety knowledge score is very low 56% in the average for all food establishments that have been studied in all the different universities Finally, there were insignificant differences at P ≤ 0.05 among different food serving establishments in different universities in all the safety properties Therefore, foodservice establishments owners should concentrate on the procedures and the instructions that should be followed in order to have a sustainable safe food with high quality.

Author contribution statement

Mahmoud Abughoush: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Amin N. Olaimat: Conceived and designed the experiments; Performed the experiments.

Murad A. Al-Holy, Maher Al-Dabbas: Conceived and designed the experiments; Analyzed and interpreted the data.

Sajid Alavi, Laith Abu - Ghoush: Analyzed and interpreted the data; Wrote the paper.

Sofyan Maghaydah: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Imranul Choudhury: Performed the experiments; Wrote the paper.

Mohammad Nour: Performed the experiments; Analyzed and interpreted the data.

Data availability statement

The data that has been used is confidential.

Declaration of competing interest

No Conflict of interst.

Footnotes

Supplementary data related to this article can be found at https://doi.org/10.1016/j.heliyon.2023.e18936.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- 1.Who . World Health Organization; 2015. Estimating the Burden of Foodborne Diseases. World Health Organization.https://www.who.int/activities/estimating-the-burden-of-foodborne-diseases [cited 2022Nov28] [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Who . World Health Organization; 2015. Food Safety: what You Should Know. World Health Organization.https://apps.who.int/iris/handle/10665/160165 [cited 2022Nov28] [Google Scholar]

- 3.Galanakis M., Aldawoud I.M., Galanakis C.M. Safety of foods, food supply chain and environment within the COVID-19 pandemic. Trends Food Sci. Technol. 2020;102:293–299. doi: 10.1016/j.tifs.2020.06.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Fischer R.J., Morris D.H., Van Doremalen N., Sarchette S., Matson M.J., Bushmaker T., Yinda C.K., Seifert S.N., Gamble A., Williamson B.N. Effectiveness of N95 respirator decontamination and reuse against SARS-CoV-2 virus. Emerg. Infect. Dis. 2020;26:2253–2255. doi: 10.3201/eid2609.201524. ([CrossRef] [PubMed]) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.The French Agency for Food . 2020. Environmental and Occupational Health & Safety (ANSES). ANSES's Recommendations on Food, Shopping and Cleaning; the French Agency for Food, Environmental and Occupational Health & Safety (ANSES): Maisons-Alfort, France.https://www.anses.fr Available online: accessed on 27 March 2022. [Google Scholar]

- 6.Hatabu A., Mao X., Zhou Y., Kawashita N., Wen Z., Ueda M. Knowledge, attitudes, and practices toward COVID-19 among university students in Japan and associated factors: an online cross-sectional survey. PLoS One. 2020;15(12) doi: 10.1371/journal.pone.024435020. Available from: [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Mayurnikova L., Koksharov A., Krapiva T. Food safety practices in catering during the coronavirus COVID-19 pandemic. Foods and Raw materials. 2020;8(2):197–203. doi: 10.21603/2308-4057-2020-2-197-203. [Internet] Available from: [DOI] [Google Scholar]

- 8.Luo Y., Chen L., Xu F., Gao X., Han D., Na L. Investigation on knowledge, attitudes and practices about food safety and nutrition in the China during the epidemic of Corona virus disease. Publ. Health Nutr. 2019;24(2):267–274. doi: 10.1017/S1368980020002797. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Ranaei V., Pilevar Z., Hosseini H. Food safety practices in covid-19 pandemic. Journal of Food Quality and Hazards Control. 2020;7(3):116–118. [Google Scholar]

- 10.Omar S. 2020. Hygienic Food Practice Among Food Workers in Jordanian Food Factories during Pandemic Crisis: COVID-19: Comparative Study. Research Square. [DOI] [Google Scholar]

- 11.Luo Y., Chen L., Xu F., Gao X., Han D., Na L. Investigation on knowledge, attitudes and practices about food safety and nutrition in the China during the epidemic of CORONA virus disease 2019. Publ. Health Nutr. 2020;24:267–274. doi: 10.1017/S1368980020002797. ([CrossRef]) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.NFI. National . Nutrition Foundation of India; New Delhi: 2003. Workshop on Food Safety. [Google Scholar]

- 13.Kashyap S., Sharma S., Sundararaj P., Gupta S. WHO Biennium Project Report, Government of India; 2004. Determinants of Healthy Eating Inyoung Girls Attending College and Promoting Healthy Lifestyles in Them. [Google Scholar]

- 14.Gupta H., Sharma S., Sundararaj P. Assessment of microbiological quality of foodstuffs served in college cafeterias. Qual. Assur. Saf. Crop Foods. 2011;3:148–167. [Google Scholar]

- 15.Who . WHO Global Strategy for Food Safety: Safer Food for Better Health. Food Safety Department, World Health Organization; Geneva: 2002. Major issues in food safety; pp. 1–27. [Google Scholar]

- 16.Davies Rf N.I.N. In: Food Safety in Public Catering. Bhat R.V., Rao N.R., editors. National Institute of Nutrition, Indian Council of Medical Research; Hyderabad: 1992. Food safety in public catering in developing countries; pp. 1–7. [Google Scholar]

- 17.Gangahar P. Food safety and quality management. In: Foods and Nutrition Update: 2000. Challenges Ahead eds Sharma S., Sundararaj P. pp. 236–250, Phoenix Publishing House Pvt Ltd, New Delhi.

- 18.Who . 2005. WHO Guidelines on Hand Hygiene in Health Care. [Google Scholar]

- 19.Giorgi L., Lindner L.F. The contemporary governance of food safety: taking stock and looking ahead. Qual. Assur. Saf. Crop Foods. 2009;1:36–49. [Google Scholar]

- 20.Olaimat A., Shahbaz H., Fatima N., Munir S., Holly R. Food safety during and after the era of COVID-19 pandemic. Front. Times. 2020 doi: 10.3389/fmicb.2020.01854. Microbiol. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Udgiri R.S., Masali K.A. A study on health status of food handlers employed in food establishments in Bijapur city. J. Community Med. 2007;32:131–132. [Google Scholar]

- 22.Park A., Lee S.J. Fault tree analysis on handwashing for hygiene management. Food Control. 2009;20:223–229. [Google Scholar]

- 23.Santana G.N., Almeida R.C.C., Fereira J.S., Almeida P.F. Microbiological quality and safety of meals served to children and adoption of good manufacturing practices in public school catering in Brazil. Food Control. 2009;20:255–261. [Google Scholar]

- 24.Olaimat A.N., Al-Nabulsi A.A., Nour M.O., Osaili T.M., Alkhalidy H., Al-Holy M., Ayyash M., Holley R.A. The effect of the knowledge, attitude, and behavior of workers regarding COVID-19 precautionary measures on food safety at foodservice establishments in Jordan. Sustainability. 2022;14(13):8193. doi: 10.3390/su14138193. [DOI] [Google Scholar]

- 25.Qanche Q., Asefa A., Nigussie T., Hailemariam S., Duguma T. Knowledge of COVID-19 and preventive behaviors among waiters working in food and drinking establishments in southwest Ethiopia. PLoS One. 2021;16 doi: 10.1371/journal.pone.0245753. ([CrossRef]) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Yannas F. FDA: Silver Spring; MD, USA: 2020. FDA's Perspective on Food Safety and Availability during and beyond COVID-19.https://www.fda.gov/food/conversations-experts-food-topics/fdas-perspective-food-safety-and-availabilityduring-and-beyond-covid-19 Available online: accessed on 6 December 2020. [Google Scholar]

- 27.Saiaipullizan S., Abd Mutaleb S., Sedek R. Negeri Sembilan; Malaysia: july 2018. Knowledge, Attitude and Practice of Food Utensils Hygiene Amongst Food Handlers in Kuala Pilah; pp. 1527–1533. sains malaysiana 47(7) [DOI] [Google Scholar]

- 28.Salehi A., Salmani F., Norozi E. Knowledge, attitudes and practices of Iranian people about food safety and hygiene during covid-19 pandemic. BMC Publ. Health. 2022;22:1148. doi: 10.1186/s12889-022-13559-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data that has been used is confidential.