Abstract

Bread undergoes physicochemical processes known as ‘staling’, which limits shelf life and quality. Despite the fact that several chemical emulsifiers have been employed to combat this issue, they may offer risks to human health. In this investigation, the effects of bioemulsan, a natural bioemulsifier (BE), on bread quality and staleness were examined. The yield of emulsan generated by Acinetobacter calcoaceticus RAG-1 was 1.49 g/L. The presence of clear zones around colonies, high emulsification value of 100%, and remaining surface tension below 40 mN/m after heating (at 250 °C for 15–20 min) verified emulsan thermal stability. BE-supplemented bread had a greater moisture percentage than the control, resulting in reduced crumb hardening and improved bread quality during storage as measured by moisture content. The first day after adding 0.5% emulsan, the hardness rose from 90.45 N (for the control) to 150.45 N. Texture analysis showed that although the hardness increased during storage, adding emulsan allowed obtaining bread with clearly softer crumb after 2 and 3 days of baking, especially at 0.5% level (from 215.6 N for the control to 150.5 N for 0.5% BE-enriched bread after 2 days, and from 425.7 to 210.25 N after 3 days). Based on the sensory evaluation results, emulsan did not lead to any unpleasant changes on bread organoleptic parameters. Therefore, using bioemulsifier RAG-1 as a green emulsifier and anti-staling agent found to be more promising.

Keywords: Emulsan, Bioemulsifier, Acinetobacter calcoaceticus, Bread staling, Flat bread

Introduction

Bread is a worldwide staple food containing an elastic network of hydrated gluten molecules, and complexes with gelatinized starch granules. They together form the breadcrumb (Ren et al. 2020). After baking, it goes through a variety of physicochemical changes that primarily affect crumb firmness and freshness, reduce shelf life and customer acceptability. These changes include the moisture redistribution process, the loss of sensory characteristics, and the crumb firming process. This generally called ‘staling’ that causes a huge economical loss to the industry (Fadda et al. 2014; Shu et al. 2022). Although the exact mechanism of staling is still unknown, starch retrogradation, water migration, and starch–gluten interactions are suggested as the most important reasons for it (Fadda et al. 2014). To tackle this, several anti-staling agents such as emulsifiers/surfactants, whit both lipophilic and hydrophilic properties, were widely used in bread making (Shu et al. 2022). They retard staling, and slow the rate of crumb firming by their direct and indirect interactions with the linear amylose and amylopectin fractions within the starch granule, via a lipophilic bonding that results in forming reversible starch/emulsifier inclusion complexes. In fact, amylose can form helices that incorporate fatty components. As the lipophilic part of an emulsifier is often a fatty acid, this lipid chain can be placed inside the helices as double pairs that are connected to each other by the hydrogen bond of the carboxyl group of fatty acid (Deffenbaugh 2019). Emulsifiers preferentially form a complex with amylose in the presence of both amylose and amylopectin. Since amylopectin, one of the elements that contribute to bread aging, cannot crystallize with amylose, the influence of emulsifiers on amylopectin will only be indirect. (Gudmundsson and Eliasson 1990). The lipophilic tails of the emulsifier can bind with the hydrophilic sites of protein in the gluten network, contributing to a better porosity, higher volumes and softer crumb texture. Moreover, extending the bread shelf life by preventing the moisture movement was obtained when emulsifiers were added (Ren et al. 2020). Unfortunately, many of these chemicals may have controversial health issues. For instance, the carcinogenic effects of potassium bromate were reported (Kurokawa et al. 1990). It is also considered that diacetyl tartaric acid ester of monoglycerides (DATEM) is responsible for heart fibrosis and adrenal overgrowth in rats (Rahman and Simsek 2020).

Bioemulsifiers (biosurfactants) are low toxic, high biodegradable, ecologically accepted, and effective in a wide range of extreme conditions, including temperature, pH and salinity compared to chemical emulsifiers (Tabatabaee et al. 2005). Several studies have been conducted to using biosurfactant (BS)/bioemulsifier (BE) in bread making industry. For example, the beneficial effect of rhamnolipid biosurfactants produced by Pseudomonas species on the functional properties of bread obtained by Van Haesendonck and Vanzeveren (2004). It was reported that the addition of Bacillus subtilis SPB1 lipopeptide emulsifier softened breadcrumb during 8 days of storage, mostly at 0.075% level (w/w), and decreased the rate of staling (Mnif et al. 2012). Mannosythritol lipids (MELs), generated by Pseudozyma aphides yeasts, were evaluated on bread in a different research by Shu et al. (2022) that examined the effects of glycolipid biosurfactant. In terms of hardness, springiness, cohesion, chumminess, chewiness, and resilience, the textural attributes of bread made from frozen dough reportedly saw a substantial improvement (Shu et al. 2022). It is a widespread phenomenon that Acinetobacter species produces extracellular bioemulsifiers (Phetrong et al. 2008). This genus includes numerous non-pathogenic environmental species, and some with pathogenic ability, especially A. baumannii, which often causes hospital infections. Acinetobacter genus produce a lipopolysaccharide responsible for lethal toxicity in mice, pyrogenicity in rabbits, and a positive reaction in the Limulus amoebocyte lysate test. The disease symptoms seen during Acinetobacter septicemia are likely caused by endotoxin generation in vivo (Bergogne and Towner 1996). The first Shiga toxin 2-producing Acinetobacter haemolyticus strain was reported in prior work by Grotiuz et al. (2006).

Among Acinetobacter spp., A. Calcoaceticus RAG-1 was known as one of the earliest bacteria for producing polyanionic bioemulsifier called bioemulsan. It is a complex of an anionic heteropolysaccharide and protein (Johri et al. 2002).

In the literature, there is no report on the influence of bioemulsan produced by A. calcoaceticus in the bread making industry. Thus, the purpose of this study was to determine the effect of bioemulsifier RAG-1 on quality of “Barbari”, a type of Iranian flat bread, and evaluate the possibility of retarding staling.

Material and methods

Bacteria, culture conditions and material

Acinetobacter calcoaceticus RAG-1 (ATCC 31012) was donated by Persian Type Culture Collection (PTCC) was used as the biosurfactant-producing microorganism. The cells were maintained on a nutrient agar slant. After incubation at 30 °C for 24 h, the slants were stored at 4 °C. For the preculture, 1% of bacterial inoculums were used in nutrient broth medium, followed by incubation at 180 rpm and 30 °C for 17 h to reach stationary phase, and desired growth (Chamanrokh et al. 2010). Then, using a modified version of the medium reported in a previous study by Tabatabaee et al. (2005), bacteria were cultivated in 5000 ml Erlenmeyer flasks containing 1000 ml mineral salt solution. Soybean oil, as a source of energy and carbon, was added at a rate of 1%. The flasks were incubated for 72 h at 200 rpm and 30 °C in a Lab-Line incubator-shaker for culture (Tabatabaee et al. 2005). Commercial Triticum aestivum wheat flour (locally named Setareh); having 10.14% water content, 0.747% ash content, 12.76% protein content, 28.6% wet gluten, 68.10 gluten index, 24 (ml) sedimentation value, and 429 (s) falling number value (AACC 2000 methods: 08-07, 38-11, 56-11, 56-08, 46-12, 74-09) and extraction rate of 80% (weight of flour/100 kg clean wheat); salt and fresh compressed yeast were purchased from the local market. All chemicals, reagents and solvents used were of analytical grade which were procured from reputed companies.

Confirmation tests for emulsan production

Haemolytic activity

Haemolytics test is the first screening method for identification and isolation of biosurfactsnts/bioemulsifiers (Tabatabaee et al. 2005). It was measured by inoculating sheep blood agar. The lytic zones around the colony indicate lysis of erythrocytes, showing BS/BE production. It was examined by placing 70 µl of aqueous culture into a well containing 5,7,10 and 12% sheep blood agar. Plates were incubated at 30 °C for 48–72 h. Even though the existence of distinct clear zones surrounding A.calcoaceticus colonies may be linked to the synthesis of emulsan, supernatant was utilized for further screening techniques to support this conclusion. There were three copies of each experiment performed. (Jain et al. 1991).

Emulsification test

The emulsification activity was carried out by adding 0.5, 1, 1.5, and 2 ml of soy oil to 2 ml of the cultural liquid in a graduated screw cap test tube. Then, they were vortexed at high speed for 1 min using a vortex-GENIE. After 24 h, emulsification activity was determined as percentage of height of emulsified layer divided by total height of the liquid column (Chamanrokh et al. 2008).

Measurement of surface tension

Du-Nouy-Ring assay described by Bodour et al. (2003) was performed. The test was triplicated. Each time the water surface tension was measured as reference number.

Extraction and purification of emulsan

The emulsan was extracted using ammonium sulfate method. Hence, after incubation of culture broth, it was aseptically transferred into the centrifuge tubes and centrifuged for 40 min at 8000× g, and 4 °C to obtain cell-free supernatant. After performing confirmatory tests for bioemulsifier production, it was served for emulsan extraction. This procedure included adding ammonium sulfate to the supernatant and keeping it at 4 °C for 24 h, or around 50% saturation. Centrifugation at 8000 rpm for 40 min separated the precipitate, which was then suspended in 2 ml of phosphate-buffered solution and desalted using dialysis (Spectrum, MW cut-off 6000–8000 Da). Then, it was dried by lypophilization method. To remove residual impurities, we applied Soxhlet apparatus with ether (Chamanrokh et al. 2008; Johri et al. 2002). The emulsan yield was about 1.49 g/L. This crude powder was used as a bioemulsifier for incorporation into wheat bread formulas to perform this work.

Thermal analysis of emulsan

To evaluate the thermal stability of emulsan, the bioemulsifier solution was exposed to baking bread condition (15–20 min and 250 °C which is described by Iranian National Standardization Organization (INSO), No.5809), and then cooled to room temperature. Remaining activity was then determined by surface tension, emulsification activity and haemolytic test, which are famous diagnostic tests to screen and prove the activity of biosurfactants (Phetrong et al. 2008; Tabatabaee et al. 2005).

This study is the first report on evaluating the thermostability of emulsan produced by A. Calcoaceticus RAG-1 in bread baking condition.

Bread making

Bread investigated in this study was ‘‘Barbari’’, which is one of the most consumed Iranian flat bread. It was produced with wheat flour based on standard method described by Iranian National Standardization Organization (INSO), No.5809. On 100 g of flour (control dough), the essential ingredients were: 1–2 g of salt, 2 g of compacted yeast, and around 60–65 ml of water. Five levels of emulsan powder were added to the flour (0.05, 0.2, 0.5, 0.75, and 1%) on a basis of percent flour; these substitution levels were selected in accordance with the surfactant values employed in earlier experiments (Olusola Ajibade and Ademola Ijabadeniyi 2018; Arshad et al. 2019). Bread dough was then prepared by mixing all ingredients. Once it was formed, then separated into pieces of 600 g, hand-molded in a circular shape and rested for 10 min. One teaspoon of paste called Roomal (a boiled mixture consisting of 10 g flour and 200 ml water) was spread on them. The dough samples were then baked at 250 °C for 15–20 min. Then, bread was cooled down to room temperature for approximately 1 h. These samples were packed in sealed plastic bags at room temperature for 1, 2 and 3 days.

Moisture content of bread

To study the effect of emulsan on the moisture content of bread, the samples were stored for 1, 2 and 3 days (at 25 °C) in plastic bags. This factor was determined based on the AACC method 44-16 (2000).

Measurement of bread firmness (texture)

To determine the bread staling at 1, 2, and 3 days after preparation, the bread samples were prepared in slices, and stored in plastic bags at room temperature. The slices were submitted to a compression test during storage using an Instron Universal Testing Machine (HOUNSFIELD_H50KS, 500 N load cell), with a probe of 36 mm diameter, based on established method (AACC 2000: method 74-09). Bread firmness was calculated as the force (in N) needed to compress a slice of bread that was 25 mm thick by 25% from its center (Mohebbi et al. 2018). The mentioned firmness levels are the averages of three distinct assessments.

Organoleptic evaluation of bread

Organoleptic evaluation was performed by eight trained panelists using scales scoring 0 (lowest score) to 5 (highest) as described by Gharaie et al. (2015). In this review, overall organoleptic quality of bread was evaluated by considering the organoleptic characteristics, such as bread shape, bottom and upper surface properties, porosity, firmness and softness of texture, chewing ability, odor, flavor and taste.

Sensory evaluation of bread staling

Eight trained panelists evaluated sensory analysis of bread staling using the Iranian flat bread evaluation method described by Azizi et al. (2003) after 1, 2 and 3 days of baking. The results were also reported as a score from 0 to 5, with 5 being the highest value.

Statistical analysis

Experiments were carried out in triplicate and data were shown as mean ± SD. The results were statistically tested by ANOVA (Analysis of Variance), followed by Duncan’s test. It was differences significant at the level of P ≤ 0.05 in this work. Between the bread parameters the values of Pearson’s correlation coefficients (r) were calculated at the significance level of P ≤ 0.01. Statistical analysis of the data was performed using the SPSS version 18 (SPSS Inc., Chicago, IL, USA).

Results and discussion

Investigation of temperature effect on emulsan

The results of surface tension, emulsification and haemolytic activities, before and after heating in baking bread condition (temperature of 250 °C for 15–20 min) are shown in Table 1. According to the findings, surface tension was about 30 mN/m after heating and stayed below 40 mN/m, proving that the temperature tested had no effect on the emulsan’s surface activity (Walter et al. 2010). Additionally, according to the results, there were no apparent changes in emulsification activity at a temperature of 250 C, and a high emulsification value of almost 100% was reached. Based on this index, it can be concluded that Acinetobacter calcoaceticus not only is an appropriate candidate for production of surface-active compound, but its bioemulsifier shows thermal stability. In terms of haemolytic test evaluated in this study, the presence of definite clear zones around A.calcoaceticus colonies (Fig. 1) after exposure to bread baking temperature verified the good thermostability of emulsan. Therefore, the bioemulsifier extract from strain RAG-1 may have potential for use in bread formula.

Table 1.

Effect of heat treatment on emulsan activities

| Tests | Before heat treatment | After heat treatment |

|---|---|---|

| Surface tension (mN/m) | 29.2 | 30 |

| Diameter of haemolytic Zone (mm) | 2.4 | 2.2 |

| Emulsification activity (%) | 100 | 100 |

Fig. 1.

The lytic zone around the Acinetobacter calcoaceticus colony grown on blood agar after heating

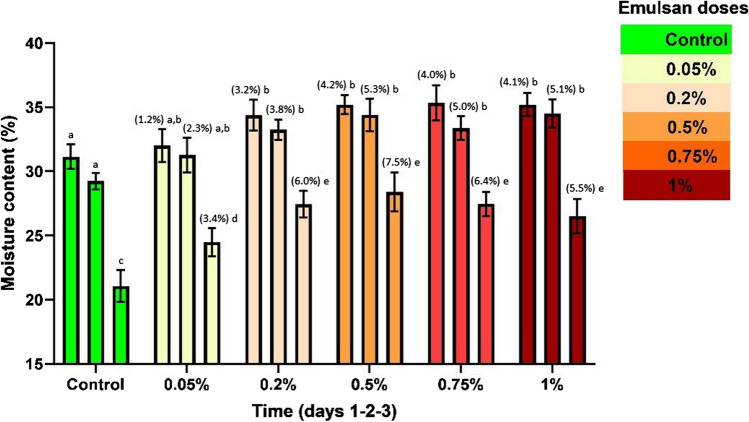

Influence of emulsan on bread moisture content

The effect of emulsan on the moisture content of bread is presented in Fig. 2. It was shown that the bread moisture content decreased during 3 days of storage. On the third day, this decline was significant (P ≤ 0.05). The transfer of water from gluten to the crystalline starch structure, which changed its structure from an amorphous state to a more stable crystalline one, may have caused moisture decrease (Stampfli and Nersten 1995). This could result in reduction of water mobility throughout the bread ageing. Therefore, water is not available as a plasticizer which cannot be felt organoleptically, which lead to crumb firmness and develop a drier mouth feel (Pateras 2007). In the study by Arshad et al. (2019) enriched bread with Calcium stearoyl-2-lactylate (CSL) and Sodium stearoyl-2-lactylate (SSL) emulsifiers, led to a significant increase in the moisture value of bread.

Fig. 2.

Effects of emulsan addition on bread moisture content. Note: Different letters indicate significant differences (P ≤ 0.05). Values in parentheses are the percentage of moisture increased in emulsan-enriched bread samples compare to control bread

The data in Fig. 2 obviously indicate that emulsan addition, except for those with 0.05% levels, led to significant increase in the bread moisture content than did the respective control sample (P ≤ 0.05). Furthermore, results showed that although by increasing level of emulsan the bread moisture content increased, there was no statistically significant difference between the incorporation of 0.2, 0.5, 0.75 and 1% levels (P > 0.05). These results are probably because, with addition of emulsan, this molecule is adsorbed onto the starch surface. In contrast to the control bread, the starch granules were unable to absorb the water produced by the gluten to the same degree. More water will be available as a result, resulting in softer breadcrumb and higher bread quality during storage. But this adsorption cannot be further improved when the emulsan concentration is more than 0.2% (Guarda et al. 2004; Stampfli and Nersten 1995). Therefore, as can be seen in the Fig. 2, with the addition of emulsan from 0.2 to 1%, although the moisture content gradually increases, it is not statistically significant and the bread samples containing 0.2, 0.5, 0.75 and 1% of emulsan are included in one statistical group (b). In fact, they had the same effect on moisture content. Thus, it sounds that fortification of flour with 0.5% RAG-1 bioemulsifier not only has a significant positive effect on bread freshness (P ≤ 0.05), but it will be more economical.

Evaluation of the emulsan addition on bread firmness

The effect of emulsan at different levels (0.05%, 0.2%, 0.5%, 0.75% and 1%) on bread firmness properties within 1, 2 and 3 days of storage was evaluated in Table 2. Based on the Table, an overall upward trend in hardness of bread was monitored by adding BE in the first day of baking. This result was consistent with the results of Cao et al. (2021), who reported that dough samples with added 1% chemical surfactant, diacetyl tartaric acid esters of monoglycerides, increased bread hardness. Another results obtained by Pomeranz et al. (1991), showed no significant effect on freshly baked bread softness by adding Monodiglycerides, Lecithin and Ethoxylated monoglycerides.

Table 2.

Crumb firmness (Force, N) and sensory evaluation of bread staling as affected by emulsan

| Sample | Crumb firmness (N) | Sensory scores of bread staling | ||||

|---|---|---|---|---|---|---|

| 1 day | 2 days | 3 days | 1 day | 2 days | 3 days | |

| Control | 90.45 ± 0.3541,c | 215.60 ± 0.2832,c | 425.70 ± 65.9023,c | 3.00 ± 1.001,a | 1.80 ± 0.8371,a | 2.00 ± 0.7072,a |

| 0.05% BE | 150.45 ± 0.4951,b,c | 205.30 ± 7.2132,b,c | 319.30 ± 70.0043,b,c | 2.60 ± 1.1401,a | 1.80 ± 0.4471,a | 1.40 ± 0.5482,a |

| 0.2% BE | 125.40 ± 6.9301,b,c | 190.40 ± 0.1412,b,c | 292.05 ± 73.3273,b,c | 2.40 ± 0.5481,a | 2.80 ± 1.9241,a | 1.40 ± 0.5482,a |

| 0.5% BE | 102.80 ± 3.3941,a | 150.50 ± 0.5662,a | 210.25 ± 28.4963,a | 2.40 ± 0.8941,a | 2.60 ± 1.5171,a | 2.00 ± 0.7072,a |

| 0.75% BE | 125.35 ± 7.4251,a,b | 180.60 ± 0.4242,a,b | 251.85 ± 43.7703,a,b | 2.40 ± 0.8941,a | 2.60 ± 1.1401,a | 2.20 ± 0.4472,a |

| 1% BE | 112.00 ± 2.4041,a,b | 170.30 ± 0.2832,a,b | 259.40 ± 68.8723,a,b | 3.20 ± 0.8371,a | 3.20 ± 0.8371,a | 1.80 ± 1.3042,a |

Presented data are mean values ± SD

Different letters/numbers in the same column or in the same line indicate significant differences (P ≤ 0.05) according to Duncan’s multiple range test. R. BE: Bioemulsifier. Five-point hedonic scale ratings: 5 = like extremely and 0 = dislike extremely

From obtained texture results (Table 2), it could be noticed that the firmness values of all bioemolsifier-supplemented breadcrumbs, after 2 and 3 days of storage, were significantly lower than the control (P ≤ 0.05). Nevertheless, the hardening of each sample increased significantly during storage. Among the various concentrations of emulsan, bread prepared using 0.5% showed very less value of firmness during all storage days.

The rise in crumb hardness, which has a direct impact on the bread's quality and customer acceptability, is one of the most often utilized signs of bread staling (Rahman and Simsek 2020). Concerning to Pearson table (Table 3), there is a significant (P ≤ 0.01) and negative correlation between the firmness amount and bread quality (r = − 0.681), and organoleptic parameters. Therefore, higher bread firmness decreases the quality, and sensory characteristics of bread. In this way, it seems that bread supplemented with 0.5% bioemulsifier was in good quality after 2 and 3 days of storage when compared to the reference bread.

Table 3.

Pearson correlation between bread characteristics

| Bread characteristics | Quality | Crumb firmness | Form and shape | Bottom surface | Upper surface | Firmness and softness | Chewing ability | Porosity | Odor, flavor and taste |

|---|---|---|---|---|---|---|---|---|---|

| Quality | 1 | − 0.681** | 0.057 | 0.150 | 0.314 | 0.331 | 0.336 | 0.494 | 0.341 |

| Crumb firmness | − 0.681** | 1 | − 0.533 | − 0.315 | − 0.109 | 0.099 | − 0.162 | − 0.312 | − 0.293 |

| Bread shape | 0.057 | − 0.533 | 1 | 0.850* | 0.295 | − 0.112 | 0.398 | 0.474 | 0.434 |

| Bottom surface | 0.150 | − 0.315 | 0.850* | 1 | 0.656 | 0.338 | 0.773 | 0.797 | 0.761 |

| Upper surface | 0.314 | − 0.109 | 0.295 | 0.656 | 1 | 0.902* | 0.768 | 0.633 | 0.847* |

| Firmness and softness | 0.331 | 0.099 | − 0.112 | 0.338 | 0.902* | 1 | 0.711 | 0.533 | 0.768 |

| Chewing ability | 0.336 | − 0.162 | 0.398 | 0.773 | 0.768 | 0.711 | 1 | 0.953** | 0.968** |

| Porosity | 0.494 | − 0.312 | 0.474 | 0.797 | 0.633 | 0.533 | 0.953** | 1 | 0.894* |

| Odor flavor and taste | 0.341 | − 0.293 | 0.434 | 0.761 | 0.847* | 0.768 | 0.968** | 0.894* | 1 |

*: Correlation is significant at the 0.05 levels

**: Correlation is significant at the 0.01 levels

It was shown that the overall staling process mainly results from two separate phenomena. First was in terms of moisture migration from the crumb to the crust. The latter because of the cell wall material firming associated with starch re-crystallization during storage (Pateras 2007).

The anti-staling ability of emulsifiers on retardation of bread was hypothesized as being the result of (1) preventing starch from taking up water and promoting moisture migration from crumb to crust by their blocking of moisture migration from gluten to starch (2) forming a complex with linear amylose, and a possible inhibition of the amylopectin re-crystallization by doing some complex with its outer linear branches (Rao et al. 1992).

The breadcrumb softening effect of different chemical surfactants, such as sodium stearoyl-2-lactylate (SSL), diacetyl tartaric acid esters of monoglycerides (DATEM), glycerol monostearate (GMS), and distilled glycerol monostearate (DGMS) was reported in previous studies (Azizi and Rao 2005; Pateras 2007; Sheikholeslami et al. 2021).

The current work is the first to describe the beneficial effects of an anti-staling additive made by Acinetobacter calcoaceticus RAG-1, a polymeric bioemulsifier. The bread that had been exposed to emulsan showed softer crumbs after 2 and 3 days of storage, notably at a 0.5% level, according to our overall findings. This determined how well this naturally occurring emulsifier retarded staling.

Organoleptic evaluation of bread containing emulsan

The emulsan was added to the bread recipe at five levels and eight trained panelists performed the sensory evaluation of fresh bread. It can be seen from the Table 3 that, there is a positive correlation between quality and all bread organoleptic characteristics. Table 4's sensory ratings also demonstrate that adding a bioemulsifier almost enhanced various organoleptic qualities, such as bread form, bottom/upper surface characteristics, chewability, and porosity, but these improvements were not statistically different from the control (P > 0.05). Furthermore, based on the Table 4, score improvement was observed for the odor, flavor and taste for all samples containing bioemulsifier, probably due to the fact that in addition to preserving the natural flavor of bread, it hides the little fermented flavor caused by the yeast (Maleki and Milani 2013).

Table 4.

Organoleptic properties of bread samples as affected by emulsan

| Characteristics | Dosage (%) | |||||

|---|---|---|---|---|---|---|

| Control | 0.05 | 0.2 | 0.5 | 0.75 | 1 | |

| Bread shape | 3.8 ± 1.304a | 4.1 ± 0.652a | 4.6 ± 0.894a | 4.3 ± 0.837a | 4.3 ± 758a | 4.1 ± 1.025a |

| Bottom surface property | 3.5 ± 1.0607a | 3.7 ± 0.9083a | 4.2 ± 0.9747a | 3.7 ± 1.0954a | 3.8 ± 1.3038a | 3.9 ± 0.8944a |

| Upper surface property | 3.7 ± 1.789a | 3.7 ± 0.975a | 4.2 ± 0.975a | 3.75 ± 1.299a | 3.4 ± 0.822a | 4.2 ± 0.758a |

| Firmness and softness of texture | 3.4 ± 1.294a | 3.4 ± 0.894a | 3.5 ± 0.707a | 3.3 ± 0.837a | 3.1 ± 0.894a | 3.7 ± 0.837a |

| Chewing ability | 2.9 ± 1.475a | 3.4 ± 0.822a | 3.7 ± 0.908a | 3 ± 0.935a | 3.2 ± 0.837a | 3.9 ± 0.894a |

| Porosity | 3 ± 1.225a | 3.5 ± 0.866a | 4 ± 1.173a | 3.2 ± 1.037a | 3.7 ± 0.671a | 4.3 ± 758a |

| Odor, flavor and taste | 2.8 ± 1.095a | 3.3 ± 0.837a | 3.6 ± 1.140a | 3.1 ± 0.742a | 3 ± 1.000a | 3.8 ± 0.908a |

All values are given as the mean of sensory scores ± standard deviation. Means followed by the same small letters in the same line are not significantly different (P > 0.05) according to Duncan’s multiple range test. R. Five point hedonic scale ratings: 5 = like extremely and 0 = dislike extremely

Concerning to degree of firmness and softness, it could be observed that bread texture sensory attributes improved when 1% emulsan was added, whereas all bread samples were almost similar to the control.

Bacillus subtilis biosurfactant addition was examined in a prior work by Mnif et al. (2012) to enhance the quality of bread. They came to the conclusion that adding 0.075% biosurfactant increased bread slice area, enhanced bread look, and produced higher crumb quality.

Although there was no significant difference between samples, overall organoleptic scores rose by adding emulsan, and panelists preferred the appearance properties of bread containing bioemulsifier to bread without this compound. Therefore, using this biomolecule did not lead to any unfavorable changes on bread sensorial parameters, even bread containing it was of better quality.

Sensory evaluation of bread staling

Eight trained panelists carried out sensory analysis of bread staling during 1, 2 and 3 days of storage (Table 2). No significant differences of sensory staling scores in bread between the first and second days of aging were noted (P > 0.05), whereas the mean of each of the bread scores decreased significantly after 3 days of storage (P ≤ 0.05). These results confirm the previous one from crumb moisture content. As it was expected sensory score of bread staling decreased with moisture content reduction.

The current findings (Table 2) demonstrate that the addition of emulsan in the first day of storage lowered the sensory scores of bread staling (apart from 1% BE), although the drop was not statistically significant (P > 0.05). This was linked to the Instron instrument's measurement of crumb hardness on the first day of aging.

After 2 days of baking, almost all bread fortified with emulsan showed higher scores than did the respective control bread. This increase was observed for 0.5 and 0.75% levels of BE on the third day of storage. However, these differences were not significant (P > 0.05). This result is consistent with the results of the freshly bread organoleptic properties.

Conclusion

This study showed that Acinetobacter calcoaceticus RAG-1 bacterium produce a polymeric bioemulsifier that can be highly beneficial for application in the bread making industry. Based on obtained results, the addition of emulsan, especially at 0.5% level, allowed obtaining bread with the softer crumb, and higher moisture content during 3 days of storage. The sensory panelists also approved of the bread's quality after it had been treated with RAG-1, a bioemulsifier. Overall, the experimental findings from this study supported emulsan's ability to prevent staling, suggesting that it might find widespread use as a natural emulsifier and anti-staling agent in other wheat-based products. Nonetheless, to make emulsan as effective food additive, further experiments and future researches should be done prior to the practical use of this bioemulsifier in food industry.

Acknowledgements

The authors wish to thank all technicians and staff at the biochemical laboratory of Tehran University, especially Mrs. chamanrokh; without the valuable help of these colleagues this study could not have been completed.

Author contributions

All authors (HS, HR, MMA, and MSA) made significant contributions to study design, acquisition, analysis, or interpretation of data; participated in drafting the article or revising it; agreed to submit to this journal; and agreed to be accountable for all aspects of the work.

Funding

This article extracted from the MSc thesis of Hanieh Sadeghi. The authors wish to thank the Science and Research branch of Islamic Azad University of Tehran, for financially supporting this project.

Availability of data and material

Data and material presented in this manuscript are transparent to declare.

Code availability

Not Applicable.

Declarations

Conflict of interest

The authors have no conflicts of interests to declare.

Ethics approval

Not Applicable.

Consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Hanieh Sadeghi, Email: haxsadeghi@yahoo.com.

Hamid Rashedi, Email: hrashedi@ut.ac.ir.

Mahnaz Mazaheri Assadi, Email: mahnazmazaheri@gmail.com.

Mahdi Seyedin Ardebili, Email: Mahdi_seyedain@yahoo.com.

References

- Approved methods of the American association of cereal chemists (2000), 10 the edn. methods 44-16, USA: AACC

- Arshad N, Ahmad A, Nadeem M, Amir RM, Arshad MS. Reporting the utilization and perspectives of different surface active agents for bread making. Food Sci Technol. 2019;40:312–321. doi: 10.1590/fst.11619. [DOI] [Google Scholar]

- Azizi MH, Rao GV. Effect of surfactant gels on dough rheological characteristics and quality of bread. Crit Rev Food Sci Nutr. 2005;44(7–8):545–552. doi: 10.1080/10408690490489288. [DOI] [PubMed] [Google Scholar]

- Azizi MH, Rajabzadeh N, Riahi E. Effect of mono-diglyceride and lecithin on dough rheological characteristics and quality of flat bread. LWT Food Sci Technol. 2003;36:189–193. doi: 10.1016/s0023-6438(02)00201-3. [DOI] [Google Scholar]

- Bergogne-berezin E, Towner KJ. Acinetobacter spp. as nosocomial pathogens: microbiological, clinical, and epidemiological features. Clin Microbiol Rev. 1996;9(2):148–165. doi: 10.1128/CMR.9.2.148. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bodour AA, Drees KP, Maier RM. Distribution of biosurfactant-producing bacteria in undisturbed and contaminated arid southwestern soils. Appl Environ Microbiol. 2003;69(6):3280–3287. doi: 10.1128/AEM.69.6.3280-3287.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cao Y, Jiang L, Suo W, Deng Y, Zhang M, Dong S, et al. Influence of emulsifiers and enzymes on dough rheological properties and quality characteristics of steamed bread enriched with potato pulp. Food Chem. 2021;360:130015. doi: 10.1016/j.foodchem.2021.130015. [DOI] [PubMed] [Google Scholar]

- Chamanrokh P, Assadi MM, Noohi A, Yahyai S. Emulsan analysis produced by locally isolated bacteria and Acinetobacter calcoaceticus RAG-1. Iran J Environ Health Sci Eng. 2008;5(2):101–108. [Google Scholar]

- Chamanrokh P, Assadi MM, Amoabediny G, Rashedi H. Cleaning oil-contaminated vessel by emulsan producers (Autochthonous bacteria) Iran J Environ Health Sci Eng. 2010;7(3):209–222. [Google Scholar]

- Deffenbaugh LB. Emulsifier-Carbohydrate Interactions. In: Hasenhuettl G, Hartel R, editors. Food emulsifiers and their applications. 3. Berlin: Springer; 2019. pp. 65–100. [Google Scholar]

- Fadda C, Sanguinetti AM, Del Caro A, Collar C, Piga A. Bread staling: Updating the view. Compr Rev Food Sci Food Saf. 2014;13(4):473–492. doi: 10.1111/1541-4337.12064. [DOI] [PubMed] [Google Scholar]

- Gharaie Z, Azizi MH, Barzegar M, Aghagholizade R. Effects of hydrocolloids on the rheological characteristics of dough and the quality of bread made from frozen dough. J Texture Stud. 2015;46(5):365–373. doi: 10.1111/jtxs.12136. [DOI] [Google Scholar]

- Giannone V, Lauro MR, Spina A, Pasqualone A, Auditore L, Puglisi I, et al. A novel α-amylase-lipase formulation as anti-staling agent in durum wheat bread. LWT-Food Sci Technol. 2016;65:381–389. doi: 10.1016/j.lwt.2015.08.020. [DOI] [Google Scholar]

- Grotiuz G, Sirok A, Gadea P, Varela G, Schelotto F. Shiga toxin 2-producing Acinetobacter haemolyticus associated with a case of bloody diarrhea. J Clin Microbiol. 2006 doi: 10.1128/JCM.00407-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guarda A, Rosell CM, Benedito C, Galotto MJ. Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocoll. 2004;18:241–247. doi: 10.1016/S0268-005X(03)00080-8. [DOI] [Google Scholar]

- Gudmundsson M, Eliasson A-C. Retrogradation of amylopectin and the effects of amylose and added surfactant/emulsifiers. Carbohydr Polym. 1990;13:295–315. doi: 10.1016/0144-8617(90)90061-V. [DOI] [Google Scholar]

- Iranian National Standardization Organization (INSO) Cereal and Cereal Products-Barbari Bread. No. 5809, 2003

- Jain D, Collins-Thompson D, Lee H, Trevors J. A drop-collapsing test for screening surfactant-producing microorganisms. J Microbiol Methods. 1991;13(4):271–279. doi: 10.1016/0167-7012(91)90064-W. [DOI] [Google Scholar]

- Johri A, Blank W, Kaplan D. Bioengineered emulsans from Acinetobacter calcoaceticus RAG-1 transposon mutants. Appl Microbiol Biotechnol. 2002;59(2):217–223. doi: 10.1007/s00253-002-0994-8. [DOI] [PubMed] [Google Scholar]

- Kurokawa Y, Maekawa A, Takahashi M, Hayashi Y. Toxicity and carcinogenicity of potassium bromate-a new renal carcinogen. Environ Health Perspect. 1990;87:309–335. doi: 10.1289/ehp.9087309. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maleki G, Milani JM. Effect of guar gum, xanthan gum, CMC and HPMC on dough rhealogy and physical properties of Barbari bread. Food Sci Technol Res. 2013;19(3):353–358. doi: 10.3136/fstr.19.353. [DOI] [Google Scholar]

- Mnif I, Besbes S, Ellouze R, Ellouze-Chaabouni S, Ghribi D. Improvement of bread quality and bread shelf-life by Bacillus subtilis biosurfactant addition. Food Sci Biotechnol. 2012;21(4):1105–1112. doi: 10.1007/s10068-012-0144-8. [DOI] [Google Scholar]

- Mohebbi Z, Homayouni A, Azizi MH, Hosseini SJ. Effects of beta-glucan and resistant starch on wheat dough and prebiotic bread properties. J Food Sci Technol. 2018;55(1):101–110. doi: 10.1007/s13197-017-2836-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Olusola Ajibade B, Ademola Ijabadeniyi O. Effects of pectin and emulsifiers on the physical and nutritional qualities and consumer acceptability of wheat composite dough and bread. J Food Sci Technol. 2018 doi: 10.1007/s13197-018-3457-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pateras IMC. Bread spoilage and staling. Berlin: Technology of breadmaking. Springer; 2007. pp. 275–298. [Google Scholar]

- Phetrong K, H-Kittikun A, Maneerat S. Production and characterization of bioemulsifier from a marine bacterium, Acinetobacter calcoaceticus subsp. anitratus SM7. Songklanakarin J Sci Technol. 2008;30(3):297–305. [Google Scholar]

- Pomeranz Y, Huang M, Rubenthaler G. Steamed bread. III. Role of Lipids. Cereal Chem. 1991;68(4):353–356. [Google Scholar]

- Rahman MM, Simsek S. Go clean label: replacement of commercial dough strengtheners with hard red spring wheat flour in bread formulations. J Food Sci Technol. 2020;57(10):3581–3590. doi: 10.1007/s13197-020-04390-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rao PA, Nussinovitch A, Chinachoti P. Recoverability of bread crumb during storage. Cereal Chem. 1992;69(6):613–618. [Google Scholar]

- Ren Y, Linter BR, Linforth R, Foster TJ. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020;11(6):5333–5345. doi: 10.1039/D0FO00115E. [DOI] [PubMed] [Google Scholar]

- Sheikholeslami Z, Mahfouzi M, Karimi M, Ghiafehdavoodi M. Modification of dough characteristics and baking quality based on whole wheat flour by enzymes and emulsifiers supplementation. Lwt Food Sci Technol. 2021;139:110794. doi: 10.1016/j.lwt.2020.110794. [DOI] [Google Scholar]

- Shu Q, Wei T, Liu X, Liu S, Chen Q. The dough-strengthening and spore-sterilizing effects of mannosylerythritol lipid-A in frozen dough and its application in bread making. Food Chem. 2022;369:131011. doi: 10.1016/j.foodchem.2021.131011. [DOI] [PubMed] [Google Scholar]

- Stampfli L, Nersten B. Emulsifiers in bread making. Food Chem. 1995;52(4):353–360. doi: 10.1016/0308-8146(95)93281-U. [DOI] [Google Scholar]

- Tabatabaee A, Assadi MM, Noohi A, Sajadian V. Isolation of biosurfactant producing bacteria from oil reservoirs. Iran J Environ Health Sci Eng. 2005;2(1):6–12. [Google Scholar]

- Van Haesendonck I, Vanzeveren ECA (2004) Rhamnolipids in bakery products. International Application Patent (PCT) WO. 40984

- Walter V, Syldatk C, Hausmann R. Screening concepts for the isolation of biosurfactant producing microorganisms. Adv Exp Med Biol. 2010;1:1–13. doi: 10.1007/978-1-4419-5979-9_1. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data and material presented in this manuscript are transparent to declare.

Not Applicable.