Abstract

Intelligent responsive packaging provides informative feedback or control the release of active substances like antimicrobial agents in response to stimuli in food or the environment to ensure food safety. This paper provides an overview of two types of intelligent packaging, information-responsive and intelligent controlled-release, focusing on the recent research progress of intelligent controlled-release antimicrobial packaging with enzyme, pH, relative humidity, temperature, and light as triggering factors. It also summarizes the current status of application in different food categories, as well as the challenges and future prospects. Intelligent controlled-release technology aims to optimize the antimicrobial effect and ensure the quality of food products by synchronizing the release of active substances with food preservation needs through sensing stimuli, which is an innovative and challenging packaging technology. The paper seeks to provide a reference for the research and industrial development of responsive intelligent packaging and controlled-release packaging applications in food.

Keywords: Responsive packaging, Controlled release, Triggers, Food packaging, Antimicrobial

Introduction

In the production and processing of foods, packaging has an essential function as the final part of the production process. Antibacterial active packaging, as an extension of traditional packaging, protects food from oxidation and microbial contamination based on the interactions between products, packaging and the environment, protects food from oxidation and microbial contamination to improve food with a better quality and longer shelf life (Wicochea-Rodriguez et al., 2019). However, microbial growth and reproduction are affected by the physiochemical properties of food and the environment. From this sense, the development of environmentally responsive controlled release antibacterial packaging is extremely important.

Intelligent responsive packaging is an emerging technology that can sense changes in the environmental conditions inside and outside the package and react when stimulated by the environment (Brockgreitens and Abbas, 2016). The way to improve the quality of food through real-time detection or timely release of active substances provides an effective way to meet the growing need for real-time information detection and quality guarantee of food products (Gao et al., 2019). By functions, intelligent responsive packaging can be divided into information-responsive and intelligent controlled release type. This review summarizes two kinds of intelligent responsive packaging, explores the latest research progress of intelligent controlled release packaging with microbial contamination and environmental factors as triggers, as well as its application in different categories of food, in order to provide reference for the research in the field of food preservation and food packaging.

Overview of intelligent responsive packaging

Triggers for intelligent responsive food packaging

Food is rich in nutrients, which is susceptible to be perishable and deteriorated by microorganisms. Scholars have carried out extensive discussions on the active packaging with antibacterial, antioxidant or other preservation functions, the release kinetics of active substances, and the ways to control their release rate (Chen et al., 2019a). Although many studies have proved that changing the component proportion of packaging materials, structure of film, adding microcapsule carriers, nanoparticles and other ways can increase the circuitous degree of release path and delay the effect of antibacterial agents. However, the release rate mainly relies on its diffusion in the packaging medium (Zhang et al., 2021a), rather than triggering the release of antimicrobials or controlling the release rate through the environmental stimuli of packaging.

Responsive packaging works by combining responsive materials with packaging systems (Gao et al., 2019). Such materials can respond to environmental stimuli to maintain or improve the quality of food products. Food, packaging and packaging headspace make up the microenvironment. During the storage period, contamination by pathogenic and spoilage bacteria will lead to changes in the biochemical properties of the food and fluctuations in the composition of the headspace in the packaging microenvironment. For example, bacteria, fruits and vegetables will produce carbon dioxide and organic acids due to respiration, as well as the metabolism of meat and seafood foods will generate biological press and volatile nitrogen compounds (Zhang et al., 2023). These metabolites cause a change in the composition of the gas in the package, which in turn alters the pH inside the package. In addition, some foods have their distinct pH value, like fresh juice (Heras-Mozos et al., 2023), fresh-cut fruits and vegetables (Heras-Mozos et al., 2022b). Therefore, their own properties can be used as triggers once they come into contact with packaging. Besides, the storage environment of food will also greatly affect the quality and safety of food. Food like baked goods is more sensitive to moisture and light. Freshly baked foods are usually free of bacteria and molds because of high temperature (Wang et al., 2023). However, the moisture in the headspace after cooling and packaging makes them susceptible to mold contamination, while light will also promote oxidative deterioration of fats and oils and destroy nutrients. Among the storage conditions, temperature is an important factor affecting food quality, and as the storage temperature increases, oxidative spoilage and microbial growth of food products are subsequently accelerated.

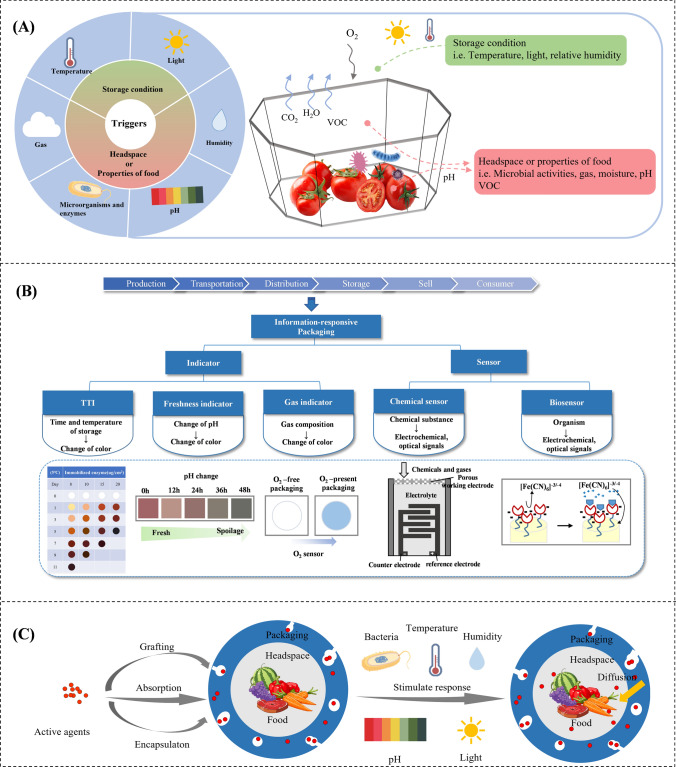

Therefore, as shown in Fig. 1(A), food properties associated with microbial growth and spoilage, packaging headspace, or storage environment conditions can be used as triggers. Changes in conditions prompt the package to provide informative or releasing feedback. Among them, the informative feedback is used to detect the quality and the security of the food and give cautions, while the releasing feedback is effective in improving the quality of the food by releasing active substances.

Fig. 1.

(A) Triggers for intelligent responsive packaging; (B) Classification of information-responsive packaging; (C) Schematic diagram of the release mechanism of intelligent controlled-release packaging (Zhang et al., 2021a; 2021b; 2021c)

Classification of intelligent responsive packaging

Information-responsive packaging

Information-responsive intelligent packaging combines intelligent devices or materials with packaging. It allows real-time monitoring of food quality or environment during distribution and provides signals to manufacturers, retailers and consumers about food quality and potential safety issues (Gao et al., 2019). Since food spoilage is usually along with physical or chemical changes, early detection of these changes can prevent the consumption of unsafe foods, and thus reduce the risk of foodborne illness (Cheng et al., 2022). Responsive packaging has been developed that can provide information on changes in food quality indicators such as microbial growth, temperature, gas, pH, etc. Different from traditional packaging, information responsive packaging has communication capabilities that can characterize the condition of food in a quantitative or qualitative way (Dodero et al., 2021).

Information-responsive packaging contains two types, including indicators and sensors according to its working principle (Fig. 1B). Furthermore, indicators can be divided into time-temperature indicator, freshness indicator and gas indicator on a macro level (Drago et al., 2020). Its working principle is to use the decomposition of lipids and proteins, fruits and vegetables and microbial metabolism produced by the chemical reaction with dyes, causing irreversible changes in dye color (López-Carballo et al., 2019; Tsai et al., 2021; Wu et al., 2021). Indicators can transform the change of quality index into color change, so as to directly and conveniently reflect the freshness of food.

Sensor-based packaging is to embed sensors into the packaging to output quantifiable signals in response to changes in quality indicators (Ghaani et al., 2016). Sensors usually include four parts: receptor (sensitive unit), conversion unit, signal processing element and signal display unit (Drago et al., 2020). After the receptor interacts with the detected substance, the signal is generated, which is processed by the conversion unit into usable analytical signals, then processed by the electronic components, and finally fed back on the display unit (Vanderroost et al., 2014). The most widely studied sensors in food packaging include chemical sensors and biosensors. Chemical sensors are mostly based on electrochemical or optical signal transduction methods to detect the presence of volatile chemicals and gases (Drago et al., 2020; Ren and Li, 2022). And for biosensors, the receptors of it are organisms or substances in organisms, such as microorganisms, enzymes, DNA, etc. Sensors reflect the freshness of food by detecting biological signals such as allergens and analytes (Drago et al., 2020; Poyatos-Racionero et al., 2018). However, intelligent devices like sensors are often complex and costly, and face the risk of potentially dangerous biochemicals. Thus, in-depth research is needed before sensor-based packaging enters the market on a large scale.

Intelligent controlled release packaging

Although information-responsive packaging can intuitively provide information about food freshness and changes in storage environment, etc., most of them just function as “diagnosis and indication”. Intelligent controlled release packaging can reduce the harmful effects of environmental fluctuations on food by releasing the active agents in the packaging. Brockgreitens and Abbas (2016) proposed the definition of intelligent controlled release packaging for the first time. They pointed out that intelligent controlled release packaging was a type of packaging that relied on changes in the stimulus response material (shrinkage, swelling, dissolution, changes in chemical function, or self-assembly) to trigger the release of active compounds (Brockgreitens and Abbas, 2016). The stimuli can be the properties of the headspace inside the package or the food (such as pH, water activity, gas composition, microorganisms and contaminants) or storage conditions, like temperature, relative humidity, light, etc. (Bruneau et al., 2019). When exposed to environmental stimuli, the packaging system releases active agents and controls its release rate so as to maintain or improve food safety and quality (Mousavi Khaneghah et al., 2018). For instance, water vapor generated by respiration of Agaricus bisporus gathered inside the package, which raised the relative humidity rapidly. Wu et al. (2022) prepared an aerogel of nanocellulose reinforced pectin that can rapidly absorb moisture inside the package. It led to the enlargement of pores and the disintegration of part of the structure, which allowed the dissolution of the loaded thymol to be released. This aerogel effectively avoided the effects of moisture accumulation and high humidity on the Agaricus bisporus. The loaded thymol also inhibited cell membrane damage and slowed down the aging of Agaricus bisporus. Wang et al. (2021) prepared a pectin-based antimicrobial hydrogel loaded with cinnamon essential oil as an inner package to replace commercial alcoholic freshness cards. The hydrogel could absorb the moisture produced by bread and accelerate the release of cinnamon essential oil as the hole wall of gel increased, significantly inhibiting the growth of molds. Compared to alcohol freshness cards, its natural essential oil smell is also more acceptable to consumers.

Intelligent controlled release packaging is an emerging technology in the field of food preservation and while targeted controlled-release technology based on response principles has been extensively studied and tested for drug delivery in biopharmaceuticals. Due to the differences between the cancer microenvironment and the healthy human physiological environment, pathological tissues have lower pH, overexpression of enzymes and over-reactive oxygen species, and these unique properties are associated with the growth of cancer (Zhou et al., 2022). The stimulus–response vectors that deliver drugs undergo structural changes precisely under the stimulation of the tumor microenvironment, thus effectively transporting and targeting the release of drugs.

Similarly, in the process of food transportation and storage, conditions such as light, temperature and humidity in the external environment always change, which will greatly affect the quality of food and lead to spoilage. In addition, when food spoils, the acidic or alkaline volatile compounds produced by microbial decomposition of carbohydrates, proteins and other nutrients will also change the pH when acidic or alkaline gases accumulated in the packaging. Packaging can rely on these changes to stimulate or control the release of active agent and the schematic diagram of its release mechanism was shown in Fig. 1(C). When stimulated by different environment factors, the physical structure of packaging materials swells or contracts, or the surface charge balance is damaged, which changes the molecular forces and spatial conformation of polymers, and thus releasing antibacterial agents, antioxidants and other active substances in a controllable manner (Tan et al., 2018; Zhang et al., 2021b).

Triggers of smart controlled release packaging

As mentioned above, the properties of the headspace of the food or food packaging and the conditions of storage environment can be used as triggers for intelligent controlled release packaging. The following is a discussion on the research progress of intelligent controlled release packaging in the field of food, which is triggered by enzymes secreted by bacteria and environmental conditions (pH, humidity, temperature, and light), and an analysis of their working mechanisms respectively.

Enzyme-response

Delivery and release systems that use enzymatic digestion as a responsive switch have attracted a lot of attention from the food and pharmaceutical industries. In the pharmaceutical industry, targeted release of drug is based on the principle of encapsulating a drug in an enzyme-sensitive carrier. For example, when a carrier containing ester bonds is hydrolyzed by human lipase, the carrier breaks, thus releasing the loaded drug. Similarly in the food industry, the enzymes that trigger the release of active substances are usually secreted by microorganisms themselves, such as cellulase, protease, and amylase. These enzymes can selectively cleavage the enzyme-sensitive linkage or breakdown specific biopolymers into subunit monomers, leading to disintegration of the polymer, which triggers the release of active agents (Aytac et al., 2021).

As shown in Fig. 2(A), the mechanism of controlled release of intelligent packaging based on enzymatic release control is divided into three types: (i) degradation and rupture of enzyme-sensitive polymers. When the polymer material comes into contact with specific hydrolytic enzymes, the enzyme-sensitive parts cleave which leads to degradation of the polymer; (ii) polymer is grafted with enzyme-sensitive bonds; and (iii) the active agents forms enzyme-sensitive bonds by grafting with the polymer (Rezaei et al., 2022). Under the effect of enzymes, the enzyme-sensitive bonds are broken which allows the release of active agents encapsulated or grafted.

Fig. 2.

(A) Mechanisms of enzyme cleavage of polymer chain segments that leads to release of active agents (Bruneau et al., 2019); (B) The pineapple exudated juice was used as triggers to induce the hydrolysis of imine bonds and the release of volatile antimicrobial agents from imine-chitosan films (Heras-Mozos et al., 2022a; 2022b); (C) A consumer-activated pH-responsive package for smoked salmon preservation (Boyacı and Yemenicioğlu, 2018); (D) An antibacterial corrugated cardboard to produce ClO2 and its application of strawberry preservation (Li et al., 2020); (E) Principles of light-responsive release systems and the application of nanocapsules as coatings in food packaging (Marturano et al., 2018)

The polymer like pectin and its derivative hypo methoxy-pectin can be used to develop targeted delivery systems for enzyme sensitive carriers. Stimulated by pectinase substances secreted by food-borne pathogens, the polymer matrix degrades to galacturonic acid, which triggers the continuous release of active substance and the activation of its antibacterial effect later. Min et al. (2022) prepared an antibacterial nanofiber membrane that responds to pectinase stimulation based on the enzyme hydrolysis principle and tested it on artificially inoculated citrus. The film could intelligently sense Aspergillus niger and accurately released thymol to inhibit its growth. However, natural pectin from natural sources belongs to high-methoxy pectin, in which most carboxylic acid groups are esterified by methanol and are non-ionizing. Low-methoxy pectin containing a higher proportion of free carboxylic acid groups is more conducive to electrostatic interaction with positively charged water-soluble lysozyme (Bayarri et al., 2014). Bayarri et al. (2014) studied the release of lysozyme in the medium added with pectinase, proving that the complex formed by low-methoxy pectin and lysozyme could release lysozyme in a controllable way, which could be used to protect food from lysozyme sensitive microorganisms.

For another, the antibacterial action of the fiber membrane responding to a single enzyme is limited, and the material with multiple enzyme stimulation can respond to more enzymes, and thus effectively inhibit more microorganisms. Aytac et al. (2021) prepared electrospinning fibers by using cellulose nanocrystals, zein and starch as substrates with the addition of free thyme essential oil. Thymol was released by diffusion and bio-based polymer degradation in the presence of cellulase, protease, and amylase, reaching 23% at platform, whereas in the buffer without enzymes, the fibers released thymol by diffusion with only 13% release.

Despite the advantages of specificity and efficiency of enzymatic release packaging, food applications are still limited by environmental conditions of storage, like temperature and moisture. Since the enzymatic reaction requires a certain activity of the enzyme, the enzyme activity is strongest at the optimum temperature for maximum breakage of enzyme-sensitive bonds between the polymer or polymer and the active substance (Bruneau et al., 2019). In contrast, enzyme activity is reduced or inactivated at low or high temperatures, making it difficult to break down the polymer. In the development of enzymatic controlled release antimicrobial packaging systems, most scholars (Bayarri et al., 2014; Dai et al., 2022; Sun et al., 2023) used 37 °C as the experimental temperature. This is due to the fact that this temperature is the optimum temperature for enzymes that are commonly broken down by bacteria, such as proteases, amylases, and pectinases (Reynolds et al., 2018). Moisture is another important factor affecting the enzymatic reaction. Usually, the enzyme activity increases non-linearly with increasing moisture activity (Touraine and Drapron, 1988), and the degree of enzymatic hydrolysis of polymers increases subsequently. Troller and Stinson (1978) found that the synthesis of enzymes such as protease, lipase, and catalase is inhibited in Staphylococcus aureus when the water activity decreases. Besides, water is one of the reaction substrates for enzymatic reactions, and a suitable water content in the packaging microenvironment can promote the reactions.

Therefore, from this point of view, enzymatic release control technology is not suitable for all types of food products. For foods that are transported and stored under low temperature or frozen conditions, such as chilled meat, their freshness will be limited due to lower enzyme activity. Besides, foods with low water activity will also have low release of active agents to inhibit the growth of microorganisms due to lower enzyme synthesis.

pH-response

Fruits and vegetables have strong respiration after harvesting. Under normal circumstances, the acidic gas CO2 generated by respiration is absorbed by the water inside the package, which will cause changes in the pH of the headspace microenvironment of the package (King et al., 1991). In addition, microbial metabolism will also produce CO2 and volatile organic acids to aggravate the acidification of the headspace microenvironment (Kakiomenou et al., 1996). As food deteriorates from an edible state to a spoiled state, the acids will cause a drop in pH (Kim et al., 2016). Therefore, changes in the headspace microenvironment can be used as a trigger to design pH-responsive controlled release packaging. This technology was applied to the preservation of blackberries and successfully extended the shelf life of blackberries from the 3rd day to the 9th day (Heras-Mozos et al., 2021). The result demonstrates that the CO2 generated by the metabolism of fruits and vegetables is suitable as a trigger for pH response.

However, since the trigger of pH-controlled release packaging system depends on the change of microenvironmental gases, it cannot work at its optimal effect if the food is already spoiled. In order to develop packaging materials that match food preservation needs, the relationship between the laws of food spoilage, pH sensitivity of packaging and antimicrobial agent release rate needs to be explored in depth. Xu et al. (2011) exploited the dynamic balance between antimicrobial agent, moisture and organic acids, where moisture inside the package at the beginning of storage could facilitate the release of low concentrations of antimicrobial agent. Once spoiled, the organic acids produced by the microenvironment stimulated the release of antimicrobial agents at high concentrations and released more as the acidity increased. The strategy effectively avoids the problem of late release of antimicrobial agents that lower the effectiveness.

To design the pH-responsive release systems, there are two mechanisms: (1) Acid-sensitive chemical bonds (e.g., imine bonds and ester bonds) exist between the polymer and the active substance, and the chemical bonds are hydrolyzed under acidic conditions to achieve on-demand release; (2) polymers containing weak acid or weak base groups are protonated or deprotonated at different pH, resulting in disruption of the charge balance between the polymers, changes in the polymer structure, and release of the active agents (Rezaei et al., 2022).

Acid-sensitive chemical bonds

Imine bond, also known as Schiff-based structure, is formed by the dehydration condensation of the carbonyl group of aldehydes and ketones with the primary amine in the polymer (Zhu et al., 2023). It is acid-sensitive and hydrolyzes the covalent bond under acidic conditions, thus giving the polymer excellent pH responsiveness. Natural sources of aldehydes such as cinnamaldehyde, citral, and vanillin have excellent antibacterial properties and are good inhibitors of foodborne pathogens. Grafting natural aldehydes with polymers containing amino groups forms an acid-reversible Schiff base structure (Higueras et al., 2015). As shown in Fig. 2(B), after being stimulated by acidic substances, the imine bond between the antimicrobial agent natural aldehyde and the polymer breaks, and the small molecules of natural aldehyde volatilize from the surface of the packaging material to achieve the antimicrobial effect.

Chitosan is an excellent bio-based material for the preparation of imine bonds because of abundance of -NH2 in chitosan, which provides a large number of reactive sites for the formation of imine bonds. Besides, its green and non-toxic characteristics are also very suitable for food packaging. Heras-Mozos et al. (2022a) grafted trans-2-hexenal and citral onto the surface of amino-rich chitosan films to form imine bonds (Fig. 2B). The pineapple exudate could be used as triggers to induce the hydrolysis of imine bonds and the release of volatile aldehydes. Compared with PE films, the acid triggered chitosan films effectively extended the shelf life of pineapple, and had good antibacterial effect on Pineapple Wild Yeast. Fadida et al. (2015) prepared an antifungal composite film by grafting volatile hexanal with chitosan film. The film significantly reduced the fungal infection rate tenfold during post-harvest storage of wheat. In addition to direct grafting of antimicrobial agents, controlled release can also be achieved by encapsulating antimicrobial agent in an acid-sensitive carrier. Wang et al. (2022) prepared a pH-sensitive nanofiber carrier for loading and delivery of curcumin with LBL self-assembly technique. Schiff base bonding and electrostatic interactions between chitosan and anionic algal dialdehyde were used to enhance the sensitivity of curcumin to different pH conditions. Release experiments showed that the nanofibers released only about 25% of curcumin at pH 7.4 within 120 min, but the cumulative release of curcumin could be increased to 75% at pH 4.2. This encapsulation of the active substance with self-assembled pH-sensitive nanofibers also provides an effective solution strategy for the intelligent controlled release and delivery of antimicrobial agents in food packaging.

However, chitosan is limited by its crystal structure and strong hydrogen bonding between amino and hydroxyl groups, resulting in the films or powdered products prepared with low substitution degree and poor water solubility. Meanwhile, the preparation of chitosan-based materials in ethanol will also consume a lot of solvent (Heras-Mozos et al., 2023). Carboxymethyl modification of chitosan increases the water solubility of raw materials and products, and can dissolve in a wider pH range. The results of Abdel-Monem et al. (2020) demonstrated that the Schiff-base complexes prepared from carboxymethyl chitosan and salicylic aldehyde exhibit better swelling in acidic media, which may be attributed to the fact that the site blocking effect created by the aldehyde benzene ring reduces the attraction between adjacent chain segments of carboxymethyl chitosan. The reduced attraction leads to more solvent diffusion into the interior of the molecule and therefore increases the water absorption capacity of the Schiff-base complex.

Charge balance

Polymers containing weak base or acid groups (such as amines, carboxylic acids, and phosphoric acids) will undergo a conformational change due to pH changes that disrupt the charge balance of the system. This conformation may take the form of swelling or dissolution of the carrier, which controls the rate of release of the encased bioactive material. Natural polysaccharides such as carboxymethyl chitosan (Teng et al., 2013), alginate (Deng et al., 2020), amylose (Zhao et al., 2022) can be used as pH sensitive carriers. These anionic polymers are rich in carboxyl groups (-COOH), which deprotonate to the -COO− when the pH in solution is greater than the acidity coefficient pKa of the weak acid. The increased electrostatic repulsion leads to a larger pore size of the macromolecular network, allowing the release of the encapsulated antimicrobial agent.

Electrostatic complexation between proteins and anionic polysaccharides can be used to prepare hydrogels or films for delivery of active substances. Deng et al. (2020) prepared hydrogel particles for encapsulating lavender essential oil with casein and sodium alginate, and studied the effect of pH on the release of essential oil. At high pH, both casein and alginate molecules were negatively charged, and the strong electrostatic repulsion led to reduced cross-linking of molecular chains and reduced denseness of hydrogel structure, which enhanced the release rate of essential oils. The application of hydrogel particles as coatings on substrates can expand their application in food packaging. Streptococcus lactis is a polypeptide secreted by bacteria and has antibacterial properties. Lu et al. (2022) prepared an antibacterial hydrogel particle based on the electrostatic interaction of Streptococcus lactis with nanocellulose and coated it on paper for anti-microorganisms. When the pH of the environment was greater than the isoelectric point (pI = 8.8) of Streptococcus lactis, the electrostatic interactions between nanocellulose and Streptococcus lactis were progressively disrupted with increasingly swelling, which led to a higher release of antimicrobial lactococcin.

The above pH-responsive systems mainly rely on pH changes in the environment to spontaneously change the release rate of antimicrobial agents. However, in practical, environmental factors are complex and variable, which may lead to mis-touching. Thus pH-controlled packaging by consumers has higher accuracy for application. Boyacı and Yemenicioğlu (2018) designed a zein-based film based on charge balance to release lysozyme, and tested its effect on preservation of fresh beef and smoked salmon (Fig. 2(C)). Consumers could activate the packaging by acidizing lemon juice, so as to release the lysozyme released and inhibit the growth of listeria on the surface of meat. This method of activation allows consumers to open vacuum or air-conditioned packaging, and the remaining food can still maintain good quality which is suitable for consumers to operate in practice.

Humidity-response

Moisture in the food packaging microenvironment usually comes from the respiration of fresh food, the metabolism of microorganisms, and the infiltration of the external environment (Baghi et al., 2022). Polymers exhibit a high density of cohesion energy due to the high degree of intermolecular bonding by polymer polar groups (Lagaron et al., 2001). However, when moisture enters the polymer macromolecules, it can be attached to the polymer in different ways: (i) by hydrogen bonding to polar groups; (2) by hydrogen bonding to already bonded water molecules; and (3) by water in its free state (Lagarón et al., 2001). The hydrogen bonding formed by water and polar groups breaks the original hydrogen bonds between polymer molecules and reduces the cohesion of the polymer. Subsequently free water fills the remaining free volume of the polymer, and the process further increases the distance between molecular chains, weakens the intermolecular forces and increases the plasticizing effect. As the polymer molecular chain gap increases, the migration of small molecules of reactive substances becomes more flexible and escapes from the polymer more easily by diffusion (Vasile and Baican, 2021). With relative humidity as a trigger probe for response packaging, the antimicrobial active agent can be released in a controlled manner by microscopic changes in the polymer carrier structure, i.e. physical changes, or by activating chemical reactions.

Physical changes

As mentioned above, moisture can act as a plasticizer, increasing the gaps between polymer chain segments and decreasing the crystallinity of the polymer. Liang et al. (2022) demonstrated that moisture disrupted the ordered crystal structure of the Metal Organic Frameworks (MOFs), and the crystal surface was rough and cracked. In contrast, the crystal microstructure was clear and structurally intact when in a solution without moisture. In addition, Fujita (1961) developed a “free volume” theoretical model, which suggests that the diffusive motion of polymer chain segments and molecules depends mainly on the free volume available in the polymer system constructed by both. This means that the release rate of the active agent is related to the free volume distribution of the packaging polymer. The larger the free volume of the polymeric material, the larger the molecular chain spacing, the more favorable the movement of the polymeric chain segments, which increases the release rate of the active agent (Chen et al., 2019a).

Moisture-responsive controlled release packaging takes advantage of the feature that moisture changes the molecular gap of the polymer to release the encapsulated active agents. Moisture-responsive carriers are available in various forms, including films, beads, metal–organic backbones, micelles, cyclodextrins, etc. The binding of these carriers to the antimicrobial agent was shown in Fig. 3. When these carriers are exposed to different relative humidities, the material undergoes swelling or develops microporosity, which changes the release rate of the small molecule antimicrobial agent (Zhang et al., 2021c).

Fig. 3.

Schematic diagram of the binding of the antimicrobial agent to the carrier in a humidity-responsive system. (A) Beads; (B) HKUST-1 loaded with curcumin (Liang et al., 2022); (C) Core–shell structure of micelles; (D) Cyclodextrins form complexes with antimicrobial agents

Film

Hydrophilic polymers such as chitosan, alginate and soy protein are excellent materials for preparing moisture-responsive packaging. Changes in relative humidity will cause a transition in the glass transition temperature (Tg) of these polymers. At temperatures below Tg, the material is in a glassy state, while above Tg, the material is rubbery and viscoelastic (Arfa et al., 2007; Chalier et al., 2009). This state transition will increase the mobility of polymer molecular chains, and therefore lead to easier diffusion of active small molecules.

Chalier et al. (2009) explored the correlation between relative humidity and Tg in depth. The researchers verified that the release of active agents was closely related to the structural changes that occur in the soy protein matrix at different temperature and humidity. At 60% RH, when the soy protein matrix was in a glassy state, the diffusion rate of carvacrol was only 0.11 × 10−16 m2/s. With the increase of relative humidity, soy protein is obviously in the rubberized state or in the vitrification transition zone, and the diffusivity increases significantly to 7.5 × 10−16 m2/s at 100% RH. Similar release was observed in hydrophilic pectin based films (Wicochea-Rodriguez et al., 2019) and chitosan based films (Liu et al., 2017). In addition, some researchers also believe that there is competition between water and active substances for high-energy binding sites (Benbettaïeb et al., 2019). Water readily binds tightly to hydrophilic biopolymers and is difficult to be displaced as soon as it takes over the high-energy bonding site. Thus, when such hydrophilic bio-based materials are in high humidity environments or packaged foods with high levels of aqueous activity, such as fresh fruits and vegetables, the accumulation of moisture inside the package will facilitate the release of active substances (Zhang et al., 2021a).

Lee et al. (2021) prepared a hydrophilic PVA composite film loaded with cinnamaldehyde and explored its antimicrobial effect. The film swelled due to the absorption of water from the agar medium, facilitating the release of cinnamaldehyde into the headspace. The experimental group showed good bactericidal effect against both Gram-positive and Gram-negative bacteria compared to the control group without cinnamaldehyde. Wong et al. (2022) developed a humidity-triggered carvacrol release nanofiber with good antimicrobial preservation effect on strawberries with higher water activity. At the 3rd day, there was no mold growth on the surface of the nanofiber-packed strawberries, while the control group already had significant spoilage. These results demonstrate that in a humidity-responsive controlled-release packaging system, moisture promotes the release of the antimicrobial agent on one hand, and does not affect the effect of the antimicrobial agent on the other.

Beads

Polysaccharide hydrophilic polymers have gelatinous properties and can be prepared into micro beads containing active substances by ionic gel method. The hygroscopicity of beads is related to its porosity. As shown in Fig. 3(A), when the dried beads are put into food packaging, they will absorb water in the food and swell, and the water on the bead wall will stimulate hydration, resulting in tiny gaps on the bead wall (Sangsuwan and Sutthasupa, 2019), and gradually release volatile natural compounds onto the food surface to inhibit the growth of microorganisms. At present, scholars have prepared antibacterial beads based on chitosan-pectin (Sriwattana et al., 2023), and alginate (Sangsuwan and Sutthasupa, 2019) and have been successfully applied to the preservation of fresh grapes and refrigerated cooked food.

MOFs

MOFs is a new type of porous hydrophilic material with high surface area and adjustable pore size, which has great potential in moisture-triggered antibacterial active agent delivery systems. Incorporation of MOFs into the polymers can lock the metal ions by forming intense relationships between the metal nodes and the carboxyl and hydroxyl groups of the polymers, which can avoid the agglomeration of MOFs in an effective way (Liang et al., 2022). HKUST-1 is one of the first commercialized MOFs materials, and the biobased film prepared by combining HKUST-1 loaded with curcumin with carboxymethyl starch and poly(vinyl alcohol) has excellent humidity responsiveness (Fig. 3(B)) (Liang et al., 2022). Since water can disrupt the crystalline stability of HKUST-1, carboxymethyl starch, which is also hydrophilic, can adsorb water more efficiently, thus allowing a rapid release of curcumin from the structure. The bio-based film has promising applications in packaging fresh fruits with high water activity. Allyl isothiocyanate is a volatile small molecule food antimicrobial agent that may react with certain ingredients of food (e.g. water, peptides and amino acids) when added directly to food, resulting in the loss. Lashkari et al. (2017) developed a controlled-release system for MOFs-loaded allyl isothiocyanate. Under low relative humidity conditions, allyl isothiocyanate remains in MOFs and triggered the release of antibacterial agents at relative humidity above 95% RH.

Micelles

Micelles, consisting of amphiphilic segments, are self-assembled into a shell-core formation in water and can be used as nanocapsules for hydrophobic drugs or bioactive compounds. The hydrophilic blocks of micelles expand or degrade when exposed to moisture, so the release rate of the encapsulated bioactive substance can be controlled (Fig. 3(C)). Luo et al. (2022) studied the effect of different relative humidity on the release of cinnamon essential oil by poly (ethylene glycol)-poly (ε-caprolactone) (PEG-PCL) micelles. It was found that the release of essential oil from the paper sprayed with micellar solution was 72% at 75% RH for 7 days, while it was less at 15% RH and 35% RH, both lower than 35%. This may be due to the interactive effect of water and PEG, which promoted the breakdown of the PCL block copolymer, causing the release of essential oils.

Cyclodextrin

Cyclodextrin is an oligosaccharide with a cyclic conical structure, which is internally hydrophilic and externally hydrophobic (Fig. 3(D)). It is capable of creating host–guest containing complexes with a broad range of hydrophobic molecules and has been extensively studied in the delivery of antimicrobial agents. The relative humidity will significantly affect the release of guest compounds due to the difference of water solubility of cyclodextrins. When the cyclodextrin complex is exposed to high relative humidity, the interaction between the complexes is weakened, resulting in the passive release of antibacterial agents into the environment (Ayala-Zavala et al., 2008). This mechanism can be used to produce antibacterial active packaging to protect fruits and vegetables and other foods with high water activity from bacteria and fungi. Some of the current research status of cyclodextrin in humidity-responsive antibacterial systems are summarized in Table 1.

Table 1.

Researches on cyclodextrins in humidity-responsive antimicrobial systems

| Antibacterial agent | Microorganism | Relative humidity | Result of release | References |

|---|---|---|---|---|

| Allyl isothiocyanate | Botrytis cinerea | 25%, 50%, and 97% | The release amounts were 1%, 59%, and 100%, respectively | Muñoz-Shugulí et al. (2022) |

| Methyl salicylate | NA | 27%, 57%, and 95% | At 25 °C, the reaction rate k increased with the increase of relative humidity | Lee et al. (2020) |

| Cinnamaldehyde and eugenol | Bacillus | 35%, 75%, and 100% | No antimicrobial agent was detected at 35% RH, and the release amounts were 3.2 μg/g and 7.38 μg/g at 75% RH and 100% RH, respectively | Herrera et al. (2019) |

| Carvacrol | Staphylococcus aureus and Escherichia coli | 43%, 53%, and 90% | When RH increased from 43 to 90%, diffusion coefficient of carvacrol increased by 24.09 × 10−15 m2/s | Laura (2015) |

| Thyme essential oil | Alternaria alternata | 0%, 3%, 33%, 66%, 96%, and 100% | At each RH, about 15% of agent was released, and at the highest RH, almost 76% was released | Del Toro-Sánchez et al. (2010) |

| Zanthoxylum bungeanum essential oil | S. aureus | 40%, 60%, and 80% | Under the relative humidity of 40%, 60% and 80%, the retention of oil was 91.93%, 65.31 and 41.23% after 10 days, respectively | Qin et al. (2022) |

| Thyme oil, sorbic acid, and nisin | Escherichia coli | 50% and 95% | The concentration reached at 7.5 ppm after 4 h for the 95% RH, significantly lower than 11.5 ppm level for the 50% RH condition | Aytac et al. (2021) |

| Carvacrol | NA | 40% and 75% | The release rate was about 45 times higher than that observed at 40% RH | Liu et al. (2021) |

| Allyl sulfide | NA | 6%, 40%, 54%, and 73% | Under high RH, the complex absorbed a large amount of water, resulting in rapid release of flavor and collapse of wall material | Nguyen and Yoshii (2018) |

Cyclodextrin has two advantages as a release system. First of all, stability: natural antimicrobial essential oils are volatile, and this fluidity and instability can lead to loss of volatile compounds during processing (e.g. film extrusion at high temperatures and shear) and in storage as well (Chen et al., 2019a); Secondly, controlled release. The release rate of essential oil can be adjusted by controlling the relative humidity of the environment to avoid the adverse effects of the high concentration of essential oil in the package on the flavor and smell of food (Ayala-Zavala et al., 2008).

Chemical reactions

In addition to changing the physical structure of the polymer, moisture also binds to specific substances, activating chemical reactions that target the release of antibacterial agents. Chlorine dioxide (ClO2), a gas with a broad spectrum of bacteriostatic properties, is formed from the decomposition of sodium chlorite in the presence of acidity and moisture (Li et al., 2020; Ray et al., 2013; Saade et al., 2018). ClO2 shows strong adsorption and penetration to microbial cell walls. It can penetrate inside the microorganism and achieve disinfection and sterilization by reacting with oxygen-containing compounds and proteins on the cell membrane (Ren et al., 2023).

Since fruits and vegetables produce water and organic acids when they are metabolized or attacked by microorganisms, the continuous release of acid gas and moisture accumulates in the packaging, which changes the humidity and pH of the internal microenvironment. Based on this principle, scholars designed a corrugated cardboard with sodium chlorite and applied it to the preservation of strawberries (Li et al., 2020). As shown in Fig. 2(D), Strawberries produced moisture continuously due to respiration, which stimulated the decomposition reaction of sodium chlorite coated on the corrugated carton, so as to produce ClO2 with antibacterial effect. In comparison with the control group, the decay rate and weight loss rate of strawberries packed in coated cartons were reduced to 21.88% and 6.84%, respectively, and the apparent color, hardness and nutrient content were preserved as well. By adding diatomaceous earth into the coating solution, the release rate was also effectively delayed. In addition, Ray et al. (2013), Saade et al. (2018) prepared humidity-responsive release ClO2.The film and smart label of ClO2 can effectively reduce the level of bacteria on the surface of agricultural products, improve food quality and extend the shelf life.

Therefore, moisture can both change the release rate of antimicrobial agents by adjusting the microstructure and promote the production of antimicrobial agents through chemical reactions to exert antimicrobial effects.

Temperature-response

Temperature, one of the important conditions affecting the growth of microorganisms, is also an easily controlled stimuli. During the circulation and storage process, if the external temperature is not properly controlled, it will lead to the rapid growth of foodborne microorganisms and food spoilage. Therefore, intelligent packaging that can release antimicrobials or antioxidants in response to temperature changes has a good application prospect.

Thermosensitive polymers exhibit the ability to react to thermal changes and can form into hydrogels, films, interpenetrating network polymers, and micelles (Rezaei et al., 2022). Poly(n-isopropylacrylamide) (PNIPAM), of excellent temperature sensitivity, contains a hydrophilic amide group and a hydrophobic isopropyl-side chain. The change of temperature will destroy the hydrophilic–hydrophobic equilibrium of the polymer and show the volumetric phase transition behavior of expansion–contraction (Fuciños et al., 2014). When the temperature rises above the lower critical solution temperature (LCST), the hydrogen bond formed by amide bond is destroyed, and the hydrophobic interaction between hydrophobic groups is significantly enhanced, resulting in phase transition of hydrogel network. Based on the unique thermal sensitivity and biocompatibility of PNIPAM, some scholars combined volatile plant polyphenols, plant essential oils and other antibacterial agents with PNIPAM to develop an antibacterial delivery system. These materials have been proven to have excellent temperature-responsive release properties, and restrain the growing of food-borne bacteria, which provides a new solution for food quality and freshness preservation. The application of PNIPAM in food antimicrobial delivery systems is listed in Table 2.

Table 2.

Application of PNIPAM in food antimicrobial delivery systems

| Core component | Delivery system | Temperature | Result of release | References |

|---|---|---|---|---|

| Natamycin | Film | 10 °C and 37 °C | The amount of release increased significantly at 37 °C and was almost non-release at 10 °C | Fuciños et al. (2014) |

| Thymol | Film | 4 °C, 15 °C, and 25 °C | When the release was in equilibrium, the release time at 4 °C was 18 h longer than that at 25 °C | Li et al. (2022a; 2022b) |

| Cinnamon essential oil | Film | 20 °C and 40 °C | At 20 °C, the release of essential oil was greatly inhibited, while at 40 °C, the release reached 64 ± 11% within 24 h | Douaki et al. (2022) |

| Hexal, trans-2-hexenal | Nanoparticle | 25 °C and 40 °C | With the increase of temperature, the release of essential oil increased significantly from 25 to 70% | Ma et al. (2022) |

| Ag ions | Coating | 4 °C and 37 °C | At 37 °C, the 3D grid structure on the coating was destroyed resulting in Ag ions being blocked in the polymer | Li et al. (2022a; 2022b) |

| ZnO nanoparticles | Nanofiber | 28 °C and 32 °C | A decreasing release by increasing the temperature because of globular hydrophobic conformation | Hosseini-Alvand and Khorasani (2023) |

| Pimaricin | Nanohydrogels | 10 °C and 37 °C | The values of diffusion exponent n were 0.80 ± 0.04 and 0.66 ± 0.04 at 10 °C and 37 °C | Fuciños et al. (2015) |

| Nile red (NR) | Microcapsule | Increased to 50 °C | When temperature increased, the particles transformed to a collapsed state inducing NR molecules’ diffusion | Chen et al. (2020) |

But sometimes it is difficult to rely solely on natural temperature changes to meet the packaging needs of specific occasions or specific products, while materials with temperature changes induced by other factors have more accurate response. Douaki et al. (2022) applied thermoelectric Poly(3,4-ethylenedioxythiophene)-poly (styrenesulfonate) (PEDOT:PSS) and temperature sensitive PNIPAM coatings to a fiber mat respectively which was impregnated with essential oil. After applying the proper voltage, the thermoelectric coating sensed an increase in temperature and allowed the release of essential oils only when the temperature exceeds the LCST. Whereas under normal storage conditions, the PNIPAM layer obstructed the release of the essential oil.

The electrical stimulation device of miniaturization is easy to adjust the operating voltage and release antibacterial agent accurately. Furthermore, it’s helpful to connect the packaging material with the sensor that provides the power supply signal according to the food deterioration for realizing the construction of a new temperature-controlled release method.

Thermosensitive polyurethane (TSPU) is also an excellent temperature-sensitive material whose mainchain includes a soft segment of a thermally reversible phase and a hard segment of a stationary phase (Zhou et al., 2010). The soft segment of the molecular chain has an obvious phase transition in a certain temperature range, which causes in a sudden change in the free volume and permeability (Chen et al., 2019b; Zhou et al., 2010). The food packaging film prepared by TSPU is temperature-sensitive and can sense changes in the outside world, providing the possibility for intelligent release of antibacterial agents and antioxidants. Dong et al. (2020) found that the pore size of urethane-based films increased near the phase transition temperature, and the antimicrobial release rate increased significantly from 0.6 to 2.2%. The pore size of the polymer can be controlled by adjusting the temperature so as to control the release. Functional materials based on the temperature-sensitive characteristics of TSPUs have been extensively studied, but a single temperature-switched TSPU film can provide a relatively narrow range of stimulation temperatures. Chen et al. (2019b) mixed different soft segments of TSPUs, The antioxidant films with double temperature switches (35.26 °C, 56.98 °C) were prepared, and the essential oil of rosemary was encapsulated in nano liposome to prevent the essential oil volatilization. The film’s temperature switch is matched with the temperature range (35–55 °C) where lipid oxidation is likely to occur in food, so it can provide protection for food in circulation and storage at high temperature.

From a physical point of view, the principle of temperature-controlled release packaging is due to a change in the volume or pore size of the material, which changes the permeability at a microscopic level. However, no matter what trigger is used to achieve controlled release, the diffusion rate of the molecule is closely related to the activation energy. The activation energy describes the sensitivity of the diffusion process to changes in temperature. The higher the temperature, the more the molecular motion increases and the easier it diffuses out of the carrier. Strictly speaking, temperature cannot trigger the release of a substance, because the active substance will continue to diffuse faster or slower regardless of the ambient temperature, and the release rate increases significantly near the phase transition temperature (Bruneau et al., 2019) However, the characteristics of temperature-sensitive materials can be relied upon to preservation for foods circulating in specific conditions.

Light-response

In the process of food storage and transportation, light often leads to the degradation of food nutrients, especially the oxidation and rancidity of oil. Light-responsive intelligent packaging has great potential in food preservation, because compared with other factors, light can induce the release of active substances without contact. Light energy includes different wavelength ranges such as UV-C (100–280 nm), UV-B (280–315 nm), UV-A (315–400 nm), visible light (400–780 nm), or near infrared (NIR) (780–2500 nm) (Lam et al., 2022). The release rate can also be controlled by adjusting the intensity, wavelength and duration of light, so the light-responsive packaging has the advantages of flexibility and remote control (Bruneau et al., 2019).

Azobenzene, stilbene and spiropyran are common photosensitive molecules. Their photosensitivity is due to the fact that the molecule has two isomers that can be converted to each other. Under light conditions, the molecule is photo-isomerized and the molecular conformation is rearranged. Azobenzene and stilbene exhibit a change in molecular symmetry from a thermally stable trans orientation (E) to a less favorable cisorientation (Z); Spiropyranol is induced by irradiation to undergo a ring-opening reaction to form an isomerized thiocyanate form (Marturano et al., 2017). In terms of microscopic and macroscopic phenomena, isomerization is typically combined with molecular-level changes in physical characteristics (e.g., polarity, adhesivity, and absorptivity) and macromolecular changes in material characteristics (e.g., thickness, wettability, and stability) (Xiao et al., 2017). The principle of azobenzene, stilbene and spiropyranan as response switches and the research on the light-responsive release system are summarized in Table 3. Therefore, based on the structural properties of photosensitive molecules, a way of releasing antimicrobial agents using a light-triggered carrier can be proposed. As shown in Fig. 2(E), this approach is to fix light-sensitive molecules such as azobenzene in the pores of the carrier shell layer and change the permeability of the carrier after illumination to control the release rate of antimicrobial agent more effectively. Marturano et al. (2018) prepared nanocapsules by microemulsion interfacial polycondensation method, and embedded azobenzene molecules into the nanocapsules shell. Under ultraviolet light (λmax = 360 nm), the light-responsive release of thyme essential oil was successfully achieved. In addition to the single light response, Razavi et al. (2020) prepared light-sensitive micelles as well as temperature-sensitive based on the temperature sensitivity of PNIPAM. The intelligent release system can adjust the release rate of guest molecules at different wavelengths and temperatures. Although the researcher took the drug doxorubicin as an object, the micellar packaging of food as a non-contact material also shows potential in the food industry.

Table 3.

Principle and research of light-responsive system

| Light-sensitive molecule | Principle of light-sensitivity | Core compound | Result of release | References |

|---|---|---|---|---|

| Azobenzene | Thyme essential oil | After UV irradiation, thyme oil concentration was eightfold higher than that of unirradiated films | Marturano et al. (2019a) | |

| Sandela 803 | When irradiated by light, 8.19% of Sandela 803 was released after 10 days, while only 1.57% without irradiation | Ji et al. (2019) | ||

| Coumarin-6 | Natural light was induced by a rapid release of coumarin-6, resulting in 50% release after 2 min of exposure | Marturano et al. (2019b) | ||

| Stilbene |  |

Vanillin | With 35 min of UV irradiation, vanillin was released rapidly at first 20 min | Bandeira et al. (2015) |

| Spiropyranan | Doxorubicin (DOX) | With 2 days of UV irradiation, DOX release was 90–100% | Razavi et al. (2020) |

Application of intelligent controlled release packaging in food preservation

Fruit and vegetable preservation

CO2 and moisture released by continuous respiration of fruits and vegetables after picking make the environment inside the packaging more acidic. At the same time, acidic gases such as acetic acid and hydrogen sulfide, which are produced when carbohydrates are broken down by bacteria during the spoilage process, also reduce the pH of the microenvironment in the headspace of the package (Ayala-Zavala et al., 2008). Therefore, the water and acid gas produced by metabolism can be used as triggers to design the fresh-keeping package of fruits and vegetables that is responsive to humidity and pH. Many scholars have recently designed freshness indicators based on the feature that the change of CO2 level of metabolites during storage causes the pH change of environment. As mentioned before, this kind of indicators can easily and intuitively display the changing information of fruit and vegetable quality through visual changes, but most of them just play the “indication” role. How to use the characteristics of pH and humidity changes to achieve controlled release, and extend the shelf life of fruits and vegetables, is important in the field of fruit and vegetable preservation. As shown in Table 4, here lists some intelligent controlled release packaging systems applied in fruit and vegetable preservation which are triggered by fruits and vegetables themselves or changes of environment conditions.

Table 4.

Application of intelligent controlled release packaging system in fruit and vegetable preservation

| Fruit and vegetables | Active agent | Triggers | Preservation effect | References |

|---|---|---|---|---|

| Pineapple | Salicylaldehyde | pH | The exudate of the pineapple triggered the release of salicylaldehyde and delayed the surface oxidative browning of the pineapple chunks | Heras-Mozos et al. (2022a; 2022b) |

| Blackberry | Trans-2-hexenal | pH | Had good antibacterial effect on Penicillium and Bostonia cinerea, and extended the shelf life of blackberry from 3 to 12 days | Heras-Mozos et al. (2021) |

| Avocado, dragon fruit | Curcumin | Moisture | Only mild oxidation with the experimental group on the 6th day, and n bacterial infection observed | Liang et al. (2022) |

| Apple | 1-MCP | Moisture | Inhibited the production of ethylene and prolonged the shelf life of apples | Ariyanto et al. (2019) |

| Agaricus bisporus | Thymol | Moisture | Maintained the moisture in the package to 97%, significantly extended the storage time of Agaricus bisporus by 5 days | Wu et al. (2022) |

| Grape | Clove essential oil | Moisture | On the 21st day, mold was first observed on grape surface in the control group, while no mold growth was observed in the experiment group | Sangsuwan and Sutthasupa (2019) |

| Strawberry | Cinnamon essential oil | Moisture | At the end of storage, the decay rate was only 24%, 59% decrease compared to the control | Luo et al. (2022) |

Fresh-cut pineapple exudate, fresh-squeezed juice, etc. are mildly acidic liquids and can be used as triggers of pH-sensitive system. The modified chitosan film developed by Heras-Mozos et al. (2022a) had good antibacterial effect on E. coli, S. cerevisae and Pineapple wild yeast. Based on the Schiff-base structure, this material relied on the acidic substances of fruits and vegetables to stimulate the release of natural aldehydes antibacterial agents and to achieve the effect of antibacterial and fresh-keeping. The nanofiber pad prepared by Wong et al. (2022) had outstanding encapsulation efficiency and allowed for regulated release of carvacrol at different RH. After placing the fiber mats in high humidity strawberry packages, the yeast and mold populations on the surface of the strawberries were reduced and the shelf life of the strawberries was extended by 2 days. In addition to antibacterial agents, 1-MCP ethylene inhibitors also help keep the fruit fresh by reducing its respiratory strength. Ariyanto et al. (2019) developed a novel fruit paper packaging in which the rate of 1-MCP release from coated paper is related to the relative humidity in moist air. The coated paper reduced the amount of ethylene released, maintained pulp firmness, and reduced titratable acidity during storage.

Preservation of meat products

Meat and meat products are excellent resources of high-quality protein, but meat products are prone to spoilage. Because the acidic environment, high water activity, and easily accessible nutrients are ideal for the growth of spoilage microorganisms such as Staphylococcus, Micrococcus, filamentous Bacillus, Pseudomonas and lactic acid bacteria (Bhattacharya et al., 2022). The chitosan/pectin microspheres prepared by Sriwattana et al. (2023) released more antibacterial essential oil into food packaging under high humidity conditions, inhibited the growth of Bacillus cereus and Pseudomonas, and extended the shelf life of refrigerated deli meat products from 7 to 24 days. Boyacı and Yemenicioğlu (2018) designed pH-responsive lysozyme releasing packaging material based on charge balance principle for preservation of beef, mutton and smoked salmon. The film is controlled by consumers using acidified lemon juice to activate the lysozyme, which can effectively inhibit the growth of listeria on the surface of meat products. By contrast, Zhang et al. (2023) used electrospinning to prepare Eudragit L100-based nanofiber padding, which can be used directly to keep cold meat fresh without human activation. This was due to the increase in pH caused by ammoniacal substances generated by protein decomposition and the deprotonation of the carboxyl group of the polymer, which increased the repulsion of the molecular chain and accelerated the release of cinnamon essential oil. The fibrous padding can effectively inhibit Escherichia coli and Staphylococcus aureus, and extended the shelf life of fresh meat by 3 days.

Preservation of baked foods

Baked goods such as bread, cake and moon cake are rich in oil. High temperature and light conditions will promote the oxidation of oil rancid, resulting in unpleasant smell. At the same time, baked foods have very strict requirements for moisture because the moisture in the packaging is easy to cause the growth of bacteria, yeast and mold, resulting in the decrease of freshness (Qian et al., 2021). Wang et al. (2021) prepared kappa–carrageenan hydrogels that can control the release rate of cinnamon essential oil based on relative humidity. The packaging significantly inhibited the growth of mold on bread slices. After 3 days, the number of mold colonies on bread surface was only 22 CFU/g, while the number of mold colonies in the control group was 225 CFU/g, far exceeding the upper limit of safe edible value of bread (105 CFU/g). The oxidation rate of fats in food is closely related to temperature; the higher the temperature, the quicker the release of oxidation rancidity. Therefore, packaging based on temperature response release will contribute to the quality of baked goods and reduce the degree of lipid oxidation. Some scholars have reported that a temperature-sensitive TPSU-based film could be designed as packaging material for Cantonese mooncakes (Dong et al., 2020). Compared with the commercially available PE film, this film had excellent preservation effect, slowing the rate of peroxide value increase in the packaging, and prolonging the shelf life of mooncakes to 28 days. However, the shelf life of Cantonese mooncakes packed with PE film was only 21 days, due to the rapidly increasing peroxide value and total plate counts.

Challenges and perspectives of responsive packaging

As mentioned above, intelligent responsive packaging has shown great potential in ensuring food quality and reducing foodborne pathogen contamination, and can fulfill the function of providing information on food quality or improving food quality based on environmental changes. In particular, intelligent controlled release packaging can trigger the release of appropriate antibacterial and antioxidant active substances or change the release rate through the environment to further guarantee the quality and safety of food.

In recent years, intelligent controlled release technology has made certain scientific and technological achievements and progress in the field of food packaging, but the research is still in its infancy. The future exploration and application are still faced with the following challenges:

The accuracy and sensitivity of packaging technology. Triggers are very important for intelligent controlled release packaging. Sensitivity of triggers determines whether the packaging can accurately release a certain amount of active substances as expected. Incorrect information identification will lead to a mismatch between the release rate and the growth rate of bacteria. If the release is too fast, it is difficult to achieve long-lasting bacteriological inhibition, while if the release is too slow, the minimum inhibitory concentration cannot be reached, and even the deterioration of food will be exacerbated (Chen et al., 2019a). Therefore, in order to ensure the preservation effect of food packaging, appropriate trigger mechanism should be selected for the design of antibacterial packaging system according to the characteristics of specific food objects. But due to the complexity of real food, most controlled release experiments presently used food packaging simulation solution or different pH buffer as the release medium to study the release kinetics of active agents. Only a small number of scholars (Heras-Mozos et al., 2022b; Heras-Mozos et al., 2023; Li et al., 2020; Saade et al., 2018) took the characteristics of food itself as the triggers, and analyzed the release statistics of active agents from a quantitative perspective. Therefore, how to study the release kinetics in real food, and how to explore the accuracy and sensitivity of response technology are the difficulties and pain points in the development of controlled release packaging.

The choice of packaging materials. The development of intelligent controlled release packaging usually uses responsive materials to respond to environmental conditions. Besides, materials made for food packaging should be safe, green and non-toxic. Some of the chemical synthetic response materials mentioned above, such as PINPAM, polyurethane, etc., may pose potential threats to food safety and quality. In order to avoid packaging toxicity and cross-contamination, green non-toxic, natural sources of materials such as chitosan, sodium alginate, protein, etc., have been broadly applied to the development of bio-based food packaging materials. If intelligent controlled release technology is combined with bio-based packaging materials, it will promote the development of food packaging towards intelligent direction to a certain extent.

Legal and regulations. Controlled release packaging has shown great potential in food preservation, but its commercial application is still limited by laws and regulations. In 2009, the European Food Safety Authority (EFSA) established Regulation (EC) No 450/2009, which authorizes the use of active and intelligent packaging in food firstly, provided that the packaging can improve the safety, quality and prolong the shelf life of the food (Yildirim et al., 2018). This means that the packaging material can reasonably come into contact with the food and transfer some ingredients into the food (Restuccia, 2010). The main problem of food contacted materials is that the migration and dissolution of harmful substances (such as plasticizers, fillers, ink and other substances in packaging materials) will cause harm to the health of consumers (Szczepańska et al., 2018). Therefore, in order to ensure the safety of packaging materials, intelligent controlled release packaging needs to focus on exploring whether triggers will lead to the accidental migration of inedible parts, and evaluate its safety by establishing relevant laws and testing standards before its commercialization (Dodero et al., 2021).

Packaging cost. Although the foregoing has provided insight into the potential value of smart controlled release technologies in food products, there is still the limitation of packaging cost when it comes to real commercial applications. For most food products, the cost of packaging should not exceed 10% of the total cost (Ghaani et al., 2016). Due to the incorporation of innovative controlled release technologies, packaging costs will inevitably increase. On the one hand, stimuli-responsive packaging materials, such as PINPAM and MOFs may be inherently costly. Besides, the elaborate and complex preparation process of stimuli-responsive nanocarriers may also make the manufacturing cost increase. On the other hand, considering the characteristics of specific food products, it is also necessary to explore and verify the main issues on release laws and mechanisms, antibacterial effects, etc., which is a complex and time-consuming process (Dainelli et al., 2008).

Intelligent packaging is a novel technology in food preservation and one of the future directions of food packaging development. Stimuli-responsive carriers have great potential in intelligent controlled-release food packaging, which can respond to changes in temperature, pH, and humidity in the environment to release antimicrobial agents (Brockgreitens and Abbas, 2016). Currently, bio-based materials such as chitosan, cellulose, plant proteins and essential oils of natural origin have attracted a great deal of scholarly attention. Integration of stimuli-responsive carriers with safe, non-toxic, biodegradable packaging materials is the direction of research focused on this technology in food preservation. Liang et al. (2022) encapsulated curcumin in moisture-sensitive MOFs material and then co-blended the film with carboxymethyl starch and PVA. The packaging film still had moisture-responsive release characteristics and antimicrobial effect, which proved that the technology is feasible to be applied in intelligent controlled-release packaging for food. Second, in the era of globalization, consumers are very concerned about the reliability of new packaging technologies (Dainelli et al., 2008; Drago et al., 2020). Incorrect identification of stimuli in the packaging microenvironment can lead to food spoilage or waste. The current simulated conditions have a large range of variation in triggers, while changes in the microenvironment of real food during storage may not be sufficient to stimulate the packaging. Therefore, suitable trigger factors need to be selected according to the characteristics of different foods and explored towards the direction of precise and stable release in future research and applications. In addition, the processability of the packaging and the activity of the antimicrobial agent should also be taken into consideration. When the antimicrobial agent is added to the packaging material, it is also necessary to consider the antimicrobial effect of the antimicrobial agent and whether there is an effect on the processing performance, mechanical properties and appearance morphology of the film when designing smart antimicrobial packaging.

In general, progress has been made in research on food packaging based on conditions such as enzymes, pH, temperature, humidity and light to trigger the release of antimicrobial agents. The advantage of intelligent responsive packaging lies in the stimuli inside and outside the packaging can change the release behavior. Especially the release system with the characteristics of real food as the triggers can be more specific and targeted. But due to the complex situation of real food, it is difficult to simulate the release environment with a single food simulation solution and to study the release kinetics in real food to develop controlled release packaging. In addition, limited by laws and regulations and the high cost of controlled release technology, there is still a long way to go for the research and development and commercial application of intelligent controlled release packaging. But in the long run, this packaging system will have a significant impact on improving food quality, reducing food waste, avoiding foodborne diseases, and has great application potential in the food industry.

Acknowledgements

This work is supported by Special Funds for Fundamental Scientific Research Funds of Central Universities (JUSRP21115); Independent Research Project Funding Project of Jiangsu Key Laboratory of Advanced Food Manufacturing Equipment Technology (FMZ201902).

Author contributions

TH: investigation and writing of manuscript. SM: project administration. FW: conceptualization and validation. LW: project administration, writing—review and editing. All authors reviewed and commented on manuscript.

Declarations

Conflict of interest

The authors declare no conflicts of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Tianmeng Hou, Email: 6210810010@stu.jiangnan.edu.cn.

Shufeng Ma, Email: msf971516@jiangnan.edu.cn.

Feijie Wang, Email: 7220809010@stu.jiangnan.edu.cn.

Liqiang Wang, Email: wlqcom@jiangnan.edu.cn.

References

- Abdel-Monem RA, Khalil AM, Darwesh OM, Hashim AI, Rabie ST. Antibacterial properties of carboxymethyl chitosan Schiff-base nanocomposites loaded with silver nanoparticles. Journal of Macromolecular Science, Part A. 2020;57:145–155. doi: 10.1080/10601325.2019.1674666. [DOI] [Google Scholar]

- Arfa A, Chrakabandhu Y, Preziosi-Belloy L, Chalier P, Gontard N. Coating papers with soy protein isolates as inclusion matrix of carvacrol. Food Research International. 2007;40:22–32. doi: 10.1016/j.foodres.2006.07.011. [DOI] [Google Scholar]

- Ariyanto HD, Chiba M, Oguma K, Tatsuki M, Yoshii H. Release behavior of 1-methylcylopropene coated paper-based shellac solution in response to stepwise humidity changes to develop novel functional packaging for fruit. Packaging Technology and Science. 2019;32:523–533. doi: 10.1002/pts.2468. [DOI] [Google Scholar]

- Ayala-Zavala JF, Del-Toro-Sánchez L, Alvarez-Parrilla E, González-Aguilar GA. High relative humidity in-package of fresh-cut fruits and vegetables: advantage or disadvantage considering microbiological problems and antimicrobial delivering systems? Journal of Food Science. 2008;73:R41–R47. doi: 10.1111/j.1750-3841.2008.00705.x. [DOI] [PubMed] [Google Scholar]

- Aytac Z, Xu J, Pillai SKR, Eitzer BD, Xu T, Vaze N, Ng KW, White JC, Chan-Park MB, Luo Y, Demokritou P. Enzyme- and relative humidity-responsive antimicrobial fibers for active food packaging. ACS Applied Materials & Interfaces. 2021;13:50298–50308. doi: 10.1021/acsami.1c12319. [DOI] [PubMed] [Google Scholar]

- Baghi F, Gharsallaoui A, Dumas E, Ghnimi S. Advancements in biodegradable active films for food packaging: effects of nano/microcapsule incorporation. Foods. 2022;11:760. doi: 10.3390/foods11050760. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bandeira NAG, Tylkowski B, Bogdanowicz KA, Giamberini M, Bo C. An atomistic insight into light-sensitive polymers with methylstilbene building blocks. Polymer International. 2015;64:935–941. doi: 10.1002/pi.4868. [DOI] [Google Scholar]

- Bayarri M, Oulahal N, Degraeve P, Gharsallaoui A. Properties of lysozyme/low methoxyl (LM) pectin complexes for antimicrobial edible food packaging. Journal of Food Engineering. 2014;131:18–25. doi: 10.1016/j.jfoodeng.2014.01.013. [DOI] [Google Scholar]

- Benbettaïeb N, O’Connell C, Viaux A, Bou-Maroun E, Seuvre A-M, Brachais C-H, Debeaufort F. Sorption kinetic of aroma compounds by edible bio-based films from marine-by product macromolecules: effect of relative humidity conditions. Food Chemistry. 2019;298:125064. doi: 10.1016/j.foodchem.2019.125064. [DOI] [PubMed] [Google Scholar]

- Bhattacharya D, Nanda PK, Pateiro M, Lorenzo JM, Dhar P, Das AK. Lactic acid bacteria and bacteriocins: novel biotechnological approach for biopreservation of meat and meat products. Microorganisms. 2022;10:2058. doi: 10.3390/microorganisms10102058. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Boyacı D, Yemenicioğlu A. Expanding horizons of active packaging: design of consumer-controlled release systems helps risk management of susceptible individuals. Food Hydrocolloids. 2018;79:291–300. doi: 10.1016/j.foodhyd.2017.12.038. [DOI] [Google Scholar]

- Brockgreitens J, Abbas A. Responsive food packaging: recent progress and technological prospects. Comprehensive Reviews in Food Science and Food Safety. 2016;15:3–15. doi: 10.1111/1541-4337.12174. [DOI] [PubMed] [Google Scholar]

- Bruneau M, Bennici S, Brendle J, Patrick D, Limousy L, Pluchonc S. Systems for stimuli-controlled release: materials and applications. Journal of Controlled Release. 2019;294:355–371. doi: 10.1016/j.jconrel.2018.12.038. [DOI] [PubMed] [Google Scholar]

- Chalier P, Arfa AB, Guillard V, Gontard N. Moisture and temperature triggered release of a volatile active agent from soy protein coated paper: effect of glass transition phenomena on carvacrol diffusion coefficient. Journal of Agricultural and Food Chemistry. 2009;57:658–665. doi: 10.1021/jf802254p. [DOI] [PubMed] [Google Scholar]

- Chen X, Chen M, Xu C, Yam KL. Critical review of controlled release packaging to improve food safety and quality. Critical Reviews in Food Science and Nutrition. 2019;59:2386–2399. doi: 10.1080/10408398.2018.1453778. [DOI] [PubMed] [Google Scholar]

- Chen X, Long Q, Zhu L, Lu L-X, Sun L-N, Pan L, Lu L-J, Yao W-R. A double-switch temperature-sensitive controlled release antioxidant film embedded with lyophilized nanoliposomes encapsulating rosemary essential oils for solid food. Materials. 2019;12:4011. doi: 10.3390/ma12234011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen Y, Wei W, Zhu Y, Luo J, Liu R, Liu X. Synthesis of temperature/pH dual-stimuli-response multicompartmental microcapsules via pickering emulsion for preprogrammable payload release. ACS Applied Materials & Interfaces. 2020;12:4821–4832. doi: 10.1021/acsami.9b20999. [DOI] [PubMed] [Google Scholar]

- Cheng H, Xu H, Julian McClements D, Chen L, Jiao A, Tian Y, Miao M, Jin Z. Recent advances in intelligent food packaging materials: principles, preparation and applications. Food Chemistry. 2022;375:131738. doi: 10.1016/j.foodchem.2021.131738. [DOI] [PubMed] [Google Scholar]

- Dai J, Hu W, Yang H, Li C. Controlled release and antibacterial properties of PEO/casein nanofibers loaded with thymol/β-cyclodextrin inclusion complexes in beef preservation. Food Chemistry. 2022;382:132369. doi: 10.1016/j.foodchem.2022.132369. [DOI] [PubMed] [Google Scholar]