Abstract

Aiming at the problem that it is difficult to popularize in Guizhou mining area due to high filling cost, taking 11071 working face of Panzhihua Coal Mine in Liupanshui as the research background, the idea and technology of strip interval filling mining are put forward. Through theoretical analysis and mechanical tests, the reasonable range of strip spacing distance and mechanical parameters of filling body were obtained. The FLAC3D simulation software is used to analyze the stress field, displacement field, and plastic zone of five kinds of design schemes, and the UDEC simulation software is used to carry out the filling mining of No.7 coal seam. The results show that the strip interval filling mining technology regards the empty roof area as a controllable underground spatial structure, and the single spatial stress field changes little. The load on the immediate roof is gradually transferred from the top of the empty roof area to the top of the filling body. The “filling body-direct roof” structure improves the self-bearing capacity of the immediate roof, and the overlying surrounding rock migration is controlled. With the increase of mining depth, it gradually tends to the original rock stress, and the control effect on surface subsidence is more significant. Finally, “filling 3 m interval 3 m” is determined as the optimal filling scheme. In the process of simulated filling mining, the peak stress in the stress concentration area of the front coal wall shows a trend of “increase-decrease-increase,” and the peak stress curve of the immediate roof in the middle of the stope changes from “increase-decrease ‘trend to’ increase-decrease-increase-decrease” trend. The rock layer near the immediate roof is in a stress concentration state in the coal wall area on both sides, and the middle part is not obvious.

Keywords: Strip interval filling mining, mechanical properties test, overlying strata migration, FLAC3D, UDEC

With the gradual depletion of coal resources in the central and eastern regions, western coal energy ushered in a long-term development opportunity. Guizhou Province, as a representative area, most of the coal mines are in the low-middle Mountain Ridge Landform, and the geological structure is extremely complex. At the same time, due to the long-term extensive management mode of coal mining enterprises, a series of environmental problems such as surface subsidence or mountain collapse, coal gangue pollution, and so on are becoming more and more prominent. Filling mining is a green mining method with high resource recovery, which can effectively control the movement of overlying strata and surface subsidence, and protect the surrounding environment of the mining area.1–3 At present, filling mining in the Guizhou mining area is difficult to promote, fundamental cost is too high. In view of the current problems faced by coal mine filling mining, a large number of scholars have found that strip filling mining can reduce filling costs.4–7

Many scholars at home and abroad have studied strip-filling mining by means of theoretical analysis, numerical simulation, and similarity simulation tests. Based on the control mechanism of key strata, Xu et al. 8 developed the strip (pier) filling coal mining technology in goaf. Sun 9 applied paste-filling mining technology to replace coal pillar by strip mining, so that the movement and deformation values of protected buildings on the ground were less than grade I damage standard of buildings, and the effect of preventing floor water damage was remarkable. Skrzypkowski 10 established the indoor numerical model and spatial numerical model of cemented paste filling body. For the first time, the double-sided strip method was used in the numerical simulation to study the four stages of cemented paste filling in the post-mining space of the deposit. On this basis, the compression coefficient was determined. Cui et al. 11 studied the acoustic emission characteristics and damage evolution process of coal mine filling body-coal pillar-filling body(BPB)composite samples by uniaxial compression test. It is concluded that the acoustic emission energy concentration area in the failure process of BPB composite samples is mainly distributed in the coal element, and the maximum acoustic emission energy value appears on the coal element. The decrease of the width of the filling body element in the BPB composite sample will reduce its binding force to the coal element. Jiang and Guo et al.12,13 carried out systematic research and industrial test on the replacement of strip coal pillar with paste filling and studied the space-time structure model and movement law of overlying strata in paste filling mining of strip coal pillar. Sun et al. 14 studied the mining under buildings. In order to ensure the safety of coal pillar and improve the recovery coefficient, theoretical analysis and numerical simulation were used to determine the coal pillar and mining width under different mining scenarios, and the stress distribution of the coal pillar and surface subsidence were discussed. Zhu et al. 15 put forward the short-longwall face-filling pillarless mining method, and deduced the theoretical calculation formula of coal pillar/filling zone width by Wilson theory. Xu et al.16–18 put forward the scientific concept of using CO2 and solid waste to develop filling body and inject it into goaf during strip filling mining, which can control the migration of overlying strata while storing CO2. Through physical similarity simulation tests and numerical simulation, it is verified that the developed carbon dioxide mineralized filling body can effectively control the migration of overlying strata and protect the overlying aquifer.

Most scholars study filling technology from the aspects of theoretical analysis, numerical simulation, and similarity simulation, but little focus on the optimization of filling process. Taking Liupanshui 11,071 working face of Panzhihua Coal Mine as the engineering background, this paper puts forward the technology of strip filling. The reasonable range of backfill width and spacer width and the mechanical parameters of backfill were determined by theoretical analysis and experiment, and the relevant results were verified by numerical simulation. Strip interval filling can control the overlying strata migration to a certain extent, reduce the surface settlement and reduce the cost of filling, which can provide reference for similar projects.

Engineering background

Panzhihua Coal Mine is located in Beipan River of Jichang Town, Shuicheng County. Mine design production capacity of 1.2 million tons/year, area 4.4488 km2, total resources 140 million tons, recoverable reserves 87.26 million tons, minable 19 layers. Coal seam dip angle 17° to 55°, average 32°. The mine is a coal and gas outburst mine, the hydrogeological condition is medium, and the hydrogeological type is medium type dominated by roof fissure water filling.

In total, 11,071 working face is located in the northeast of the main inclined shaft in the middle of the first mining area, Return airway roof elevation +945 to +913 m, transport roadway roof elevation +870 to +860 m. The strike length of 11,071 working face is about 300 m, length approximately 100 m. There are no other buildings except for the S212 road, Terrain elevation +950 to +1050 m, relative altitude difference of about 100 m, borehole comparison and geological correlation analysis are shown in Figure 1. Surface subsidence is easily caused by mining of 11,701 working face, resulting in the destruction of S212 Road, if the coal pillars, will result in a large waste of coal resources.

Figure 1.

Well top–down comparison diagram and related schematic diagram.

Strip interval filling mining method

Strip interval filling mining technology principle

The general idea of strip interval filling mining is filling with mining and interval filling. The filling body replacement strip coal pillar, at the same time control surface subsidence, reduces the environmental pollution and the amount of filling costs. The overall process of working face strip interval filling mining is shown in Figure 2. The specific technical steps are as follows:

Figure 2.

Whole process of strip interval filling mining on working face. (a) Divide strips. (b) Charging strips 1, 3, 5. (c) Mining strip 2, strip 4. (d) Strip 2, 4 form goaf.

①First, the open-off cut, return air channel and transport channel of the traditional working face are formed, and the mining and filling unit is divided into five mining strips along the direction of parallel channel, as shown in Figure 2(a). ②Mining-filling strips are arranged at intervals, and then an auxiliary transport roadway is tunneled along the pre-mined filling strip. When the auxiliary transport roadway is tunneled to a certain distance from the open-off cut, a small open-off cut of the strip is formed in advance, and an open-off cut coal pillar is reserved, as shown in Figure 2(b), stoping strip 1, 3, 5, and timely filling the rear goaf after mining, strip 1 using “U” type ventilation, strip 3 and strip 5 using “Z” type ventilation. ③After the stoping and filling of the 1, 3, and 5 strips, after the filling body reaches a certain strength, the auxiliary transportation roadway is excavated along one side of the filling body, when the auxiliary transportation roadway is excavated to a certain distance from the open-off cut, the small open-off cut of the strip is formed in advance, and the coal pillar of the open-off cut is retained. Then, the second and fourth strips are mined, and the “Z” type ventilation is used for the second and fourth strips. as shown in Figure 2(c). ④At the end of the second and fourth strip mining, all caving is used to deal with the goaf, as shown in Figure 2(d).

heoretical analysis on stability of strip interval filling

Mining strip width

(1) Calculation by beam fracture. The general idea of strip interval filling mining is filling with mining and interval filling, replacing strip coal pillar by filling body. Therefore, in the process of strip filling mining, there is no large-scale goaf, and the strip roof rock beam is approximately fixed beam state. When the roof rock beam is simplified to a fixed beam, its mechanical model is shown in Figure 3. 19

Figure 3.

Mechanical model of strip roof fixed rock beam.

For rock beam with unit width, the normal stress σ and shear stress xy at any point A in the beam are

| (1) |

| (2) |

In the formula, M and X are the bending moment and shear force of the section where point A is located, y is the distance from point A to the neutral axis of the section, “h” is the thickness of the beam, and “l” is the length of the filling zone/coal pillar. The maximum bending moment and shear stress Qmax occur at both ends of the beam, calculated as:

| (3) |

| (4) |

The maximum tensile stress max and the maximum shear stress on this section are:

| (5) |

| (6) |

When the maximum tensile stress Q max reaches the ultimate tensile strength RT or the maximum shear stress reaches the ultimate shear strength RS ultimate shear strength RS of the main roof, the main roof will crack. At this point, the limit span a1T and a1S under the constraint of the maximum tensile stress and the maximum shear stress are, respectively:

| (7) |

| (8) |

(2) Calculation by plate fracture. The four sides of the strip roof rock beam are supported by the filling strip/coal pillar, so the roof rock layer can be regarded as a fixed plate around it. According to the structural model of the surrounding clamped plate, when the top plate is in the limit hanging state, the four clamped edges form a negative bending moment zone, and the maximum principal bending moment Mmax occurs in the middle of the long clamped edge. According to the Marcus modified solution, 15

| (9) |

In the formula: “u” is the Poisson's ratio of the basic vertex ; “q” is the basic top weight and its overlying load, is the geometric shape parameter of the goaf, and “a” is the width of the mining strip.

The relationship between bending moment and stress satisfies the following:

| (10) |

The equations (9) and (10) are combined to obtain the calculation formula of the limit span a3T of the basic roof fracture under the boundary condition of the surrounding fixed support:

| (11) |

In order to ensure the sufficient stability of the strip roof strata, when determining the limit width of the mining strip, the calculation results of equations (7), (8), and (11) should be considered comprehensively, and the minimum value should be taken as the limit width of the mining strip :

| (12) |

According to the periodic weighting step of the adjacent working face, here, l is 10 m, the overlying strata load, the average bulk density of the overlying strata γ is 25 kN/m3. Combined with the site, the thickness of the main roof is 5.0 m, and the Poisson’s ratio u is 0.25, which are brought into equations (3)–(11), respectively, and a1T, a2S, a3T are : 10, 10, 13.5, from equation (12), a is 10 m. The limit width of mining strip is 10 m.

Coal pillar/filling strip width

According to Wilson theory, 20 when the width of the goaf on both sides of the strip coal pillar/filling strip is less than 0.6H (Figure 6), the load Fs of unit length strip coal pillar/filling belt is:

| (13) |

Figure 6.

Triaxial mechanical properties test of filling body.

In the formula: is the average bulk density of overlying strata, H is the mining depth, b is the width of coal pillar/filling zone. Under the gravity pressure of the upper composite rock beam, some areas on both sides of the coal pillar/filling zone are in plastic deformation state, and the middle area is in elastic state, which is often called “elastic core” coal pillar. A large number of studies have shown that the vertical stress inside the strip coal pillar/filling belt is inverted “saddle shape”, and the vertical stress can be approximately replaced by isosceles trapezoid load, 21 as shown in the red trace in Figure 4.

Figure 4.

Load distribution when the width of mined-out sides of the coal pillar/filling zone is less than 0.6H.

Considering the plastic zone, the maximum load Fp that the coal pillar/filling pillar can withstand is:

| (14) |

In the formula, is the strength of coal pillar / filling pillar, is the width of plastic zone of filling strip, and its calculation formula is 22 :

| (15) |

In the formula, M is the height of coal pillar/filling column, A is the lateral pressure coefficient, d is the mining disturbance coefficient (generally 1.5–3.0), K is the maximum stress concentration coefficient on the coal pillar/filling column, α is the coal seam dip angle, and are the cohesion and internal friction angle of coal pillar/filling column and roof and floor, respectively.

To ensure the stability of coal pillars, it is necessary to meet Fp>Fs, That is

| (16) |

That is, the width b of the strip coal pillar or filling zone should satisfy equation (17)

| (17) |

Strip interval filling mining does not leave coal pillars. Except for the small coal pillars left as the connecting roadway, each mining strip will experience the transformation of “coal pillar →goaf →filling body” in its life cycle. Therefore, the filling width b is generally equal to the strip mining width a. While designing the width of strip mining, the stability of this width strip coal pillar/filling belt is checked by equation (12). When it ≤ a, you can set b= a, when b>a, it is necessary to reduce the width of strip mining a, and then calculate the width of strip coal pillar/filling belt by formula (17) until b ≤a is satisfied, and set b=a.

Through theoretical calculation, the limit width a of strip mining is 10 m. In order to make the underground production safer, the strip mining width a should be less than 10 m. According to the general situation of the project, the average buried depth of the 11,071 working face is 75 m, which is brought into equation (13). The calculated final compressive strength of the filling body is not less than 3.7 MPa. In order to maintain the long-term stable bearing capacity of the filling body, the safety factor is 1.5–2, and the final compressive strength of the filling body is preliminarily designed in the range of 5.55–7.4 MPa.

Design of strip interval filling mining scheme

According to the analysis of the above theory, the width b of the filling zone is equal to the width a of the strip mining, and it is reasonable to control the hanging length of the roof in the range of 10 m, so a=b < 10 m is preliminarily determined. Considering the underground safety and “continuous mining and filling” technology, the strip interval filling scheme is shown in Table 1.

Table 1.

Strip interval filling mining scheme.

| Mining scheme | Scheme 1 | Scheme 2 | Scheme 3 | Scheme 4 | Scheme 5 |

|---|---|---|---|---|---|

| Not filling | Interval 3 m filling 3 m | Interval 6 m filling 6 m |

Interval 9 m filling 9 m | Fully filled |

Mechanical properties and parameter determination of filling body

Testing material

The coal gangue used in this experiment was taken from the Panzhihua gangue pile in Liupanshui, Guizhou. According to the preliminary exploration test, the particles were broken and screened. The fine aggregate size was 0–5 mm and the coarse aggregate size was 5–15 mm. Fly ash is taken from a thermal power plant in Guizhou. The particle size of fly ash is about 3–1500 μm, and most of them are between 10 and 200 μm, which can be mixed with coal gangue as fine aggregate.23,24 Cement is the main cementing material of solid waste gangue filling body. Cement adopts ordinary Portland cement PO42.5, and other auxiliary materials also include lime, early strength agent, water reducing agent and so on.

Specimen preparation and test scheme

Standard specimen preparation

According to the concrete test block preparation standard (GB/T50080-2002) preparation of gangue gypsum filling material test research, the test used filling body are prepared with reference to the above standard, as shown in Figure 5.

Figure 5.

Preparation process of specimen.

Test scheme

After the paste-filling material meets the requirements of underground fluidity and filling strength, industrial experiments can be carried out. When the filling slurry is filled into the goaf, after the filling paste is formed, the filling body is in a three-way stress state, so as to measure the mechanical parameters of the filling body for numerical simulation analysis. In this paper, the RMT-150C rock mechanics test system is used to carry out triaxial compression, uniaxial compression, and tensile tests on the filling specimens with a ratio of 80% slurry mass concentration, 12% cement addition, and 25% fly ash addition. The size of the specimens is Φ50 mm × 100 mm compressive standard specimen and Φ50 mm × 40 mm tensile standard specimen, as shown in Table 2.

Table 2.

Filling body mechanics test standard specimen.

| Serial number | Sample number | Dimension/mm | Experiment type |

|---|---|---|---|

| 1 | Y1S.1 | 49.9×102.8 | Triaxial compression |

| 2 | Y1S.2 | 49.5×101.9 | Triaxial compression |

| 3 | Y1S.3 | 49.5×97.5 | Triaxial compression |

| 4 | Y1L.4 | 49.5×40.0 | Brazilian splitting test |

| 5 | Y1L.5 | 49.8×38.0 | Brazilian splitting test |

| 6 | Y1L.6 | 49.8×38.0 | Brazilian splitting test |

Test results

The conventional triaxial compression test with confining pressure of 1 MPa was carried out on RMT-150C rock servo test system. Measured by the triaxial test, the average triaxial compressive strength is 7.45 MPa, greater than the previous measured uniaxial compressive strength of 6.8 MPa, and the critical point of stress–strain curve is not obvious in the triaxial stress state. The cohesion is 3.2 MPa, the internal friction angle is 27°, and the tensile strength of the paste specimen is tested by the Brazilian splitting method. The average tensile strength is 1.05 MPa. Combined with the analysis results of the previous uniaxial experiment, the elastic modulus is 11 GPa, the Poisson’s ratio is 0.125, and the bulk modulus and shear modulus are 1.05 GPa. Mechanical parameters test experiment, as shown in Figure 6.

Analysis of overlying strata migration law of strip interval filling mining based on finite difference method

Establishment and assignment of model

According to the geological data and numerical simulation modeling criteria, the 11,071 working face has a strike length of 300 m and a working face length of 100 m. There are undulating parts on the surface above the working face. In order to eliminate the influence of boundary conditions, 50 m protective coal pillars are set on both sides of the strike and tendency. The model has a strike length of 400 m, a tendency length of 200 m, and a non-surface undulating height of 115 m. At the same time, there is a valley of 150 m in the middle of the strike, and a peak of 50 m on both sides of the strike direction. Combined with the advancing direction of the working face and the surface topography, the mining stage is divided into three stages: valley (50–125 m), valley bottom (125–275 m) and back valley (275–350 m). Combined with the mechanical parameters of coal and rock mass and the mechanical parameters of filling body, see Table 3. Mohr-Coulomb strength criterion is used to solve the constitutive relation of this model.25,26 The model material is assigned and the boundaries are constrained.27,28 Six monitoring lines were set up at 6, 12, 24, 36, 48 m above the coal seam and the ground surface, and the measuring points were evenly arranged on each monitoring line to monitor the displacement and stress changes. The numerical simulation model and measuring line arrangement of 11,071 working face are shown in Figure 7.

Table 3.

Mechanical parameters table of coal rock mass and filling strip.

| Lithologic | Thickness (m) |

Density (kg·m−3) |

Shear modulus (GPa) | Bulk modulus (GPa) |

Cohesion (MPa) |

Tensile strength (MPa) |

Friction (°) |

|---|---|---|---|---|---|---|---|

| Siltstone | 5.0 | 2460 | 8.13 | 10.83 | 2.75 | 1.84 | 38.0 |

| Silty mudstone | 3.4 | 2417 | 5.70 | 10.76 | 1.18 | 1.46 | 35.0 |

| Coal | 3.0 | 1460 | 0.93 | 2.12 | 0.50 | 0.35 | 24.0 |

| Mudstone | 1.5 | 2250 | 2.27 | 4.39 | 4.90 | 3.80 | 25.2 |

| Muddy siltstone | 9.2 | 2400 | 3.80 | 5.00 | 4.00 | 2.50 | 35.0 |

| Epipedon | ` | 1960 | 0.098 | 0.28 | 0.85 | 0.35 | 25.0 |

| Fine sandstone | 3.0 | 2600 | 11.20 | 15.28 | 3.10 | 3.48 | 42.0 |

| Filling body | 2560 | 1.05 | 1.05 | 3.20 | 1.05 | 27.0 |

Figure 7.

Numerical model and line layout.

The mining schemes in Table 3 are simulated respectively, and the displacement, stress and plastic zone of the immediate roof under five conditions of direct caving, interval 3 m filling 3 m, interval 6 m filling 6 m, interval 9 m filling 9 m and full filling are analyzed. Strip interval filling mining schematic, as shown in Figure 8.

Figure 8.

Strip interval filling mining schematic diagram.

Numerical simulation results

(1) Displacement field analysis under different schemes. It can be seen from the displacement of Figure 9 that the filling mining has obvious effect on roof control. When the filling is not taken, the maximum subsidence of the direct roof of the goaf in the middle of the stope reaches 2.4 m; when “full filling” scheme is adopted, the maximum subsidence of immediate roof is about 3 mm; when the “interval 9 m filling 9 m” filling scheme is adopted, the maximum direct roof subsidence is about 15 mm ; when the “interval 6 m filling 6 m” filling scheme is adopted, the maximum direct roof subsidence is about 9 mm, which is 40% lower than the “interval 9 m filling 9 m” scheme. When the “interval 3 m filling 3 m” filling scheme is adopted, the maximum direct roof subsidence is about 6 mm, which is 60% lower than the “interval 9 m filling 9 m” scheme.

Figure 9.

Displacement cloud diagram under each scheme. (a) caving method. (b) fully filled. (c) Interval 9 m Filling 9 m. (d) Interval 6 m Filling 6 m. (e) Interval 3 m Filling 3 m.

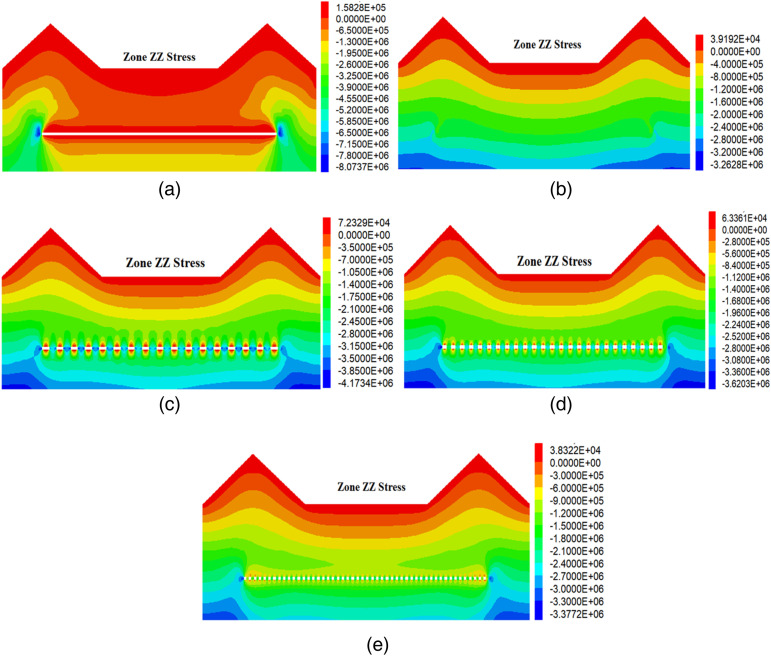

(2) Stress field analysis under different schemes. It can be seen from the stress distribution in Figure 10 that when the filling mining is not used, the stress concentration occurs on both sides of the coal wall of the stope, the maximum stress is about 8 MPa, and the overlying strata are in a state of pressure relief, which conforms to the stress distribution of the overlying strata in the “three zones” theory. When the stope is fully filled, stress concentration occurs on both sides of the coal wall of the stope, the maximum stress is only 3.2 MPa, and the overlying strata are still in the original rock stress state. When interval strip filling mining is adopted, with the increase of the filling strip spacing, the stress concentration occurs on both sides of the edge of the filling body, and the edge may be damaged, which is not conducive to the long-term stability of the filling bearing body. The area with stress of 0 appears above the empty roof area, and the stress concentration on both sides of the edge of the filling body in the area below the mountain is more serious.

Figure 10.

Stress cloud diagram under each scheme. (a) Caving method. (b) Fully filled. (c) Interval 9 m Filling 9 m. (d) Interval 6 m Filling 6 m. (e) Interval 3 m Filling 3 m.

When the width of the strip and the filling spacing is 9 m, there are more areas where the stress is 0 above the empty top area, and the stress concentration on both sides of the edge of the filling body is larger. The vertical stress is as high as 3.2–3.5 MPa, and the vertical stress in the middle of the filling body is 2.4–2.8 MPa, when the width of the strip and the filling spacing is 6 m, the area where the stress is 0 above the empty top area is reduced, and the stress concentration on both sides of the filling body edge is reduced. At this time, the vertical stress in the middle of the filling body is the largest, and the vertical stress in the middle of the filling body is 2.2–2.6 MPa, when the strip width and filling spacing are 3 m, only a small range of zero stress zone appears at the bottom of the immediate roof under the mountain area, and the stress concentration on both sides of the edge of the filling body is further reduced. The maximum vertical stress in the middle of the filling body is reduced, and the vertical stress is 1–1.4 MPa, indicating that the reasonable filling spacing ensures an empty roof.

(3) Analysis of plastic zone under different schemes. As can be seen from the distribution of plastic zone in Figure 11, when the strip width and filling spacing is 9 m, the range of direct roof plastic zone is the largest, and the plastic zone of nearly 1 m appears on both sides of the filling strip edge, which is difficult to ensure the long-term stability of the filling support. When the width of the strip and the filling spacing is 6 m, the plastic zone of the immediate roof is relatively reduced, and the plastic zone below the mountain area is larger than the central area of the stope. There is no damage on both sides of the edge of the overall filling strip in the stope, which basically ensures the long-term stability of the filling support. When the strip width and filling spacing is 3 m, only the direct roof below the mountain area produces tensile and shear failure, and there is no plastic zone in the middle of the stope, which is conducive to the long-term stability of the filling support.

Figure 11.

Plasticity distribution diagram under each scheme. (a) Interval 9 m Filling 9 m. (b) Interval 6 m Filling 6 m. (b) Interval 3 m Filling 3 m.

The numerical simulation shows that taking the displacement field as the entry point, the direct roof subsidence during strip interval filling is slightly larger than that during full filling, showing a “wave” type subsidence, and the foothill area is the largest subsidence area, which is greater than the central area of the valley bottom. With the decrease of filling strip spacing, “wave” type subsidence gradually stabilized; taking the stress field as the breakthrough point, with the decrease of the filling strip spacing, the overall stress concentration degree of the stope decreases, and the stress concentration position gradually shifts to the middle of the filling body. The area with stress of 0 above the empty roof area gradually disappears, and the bearing capacity of the immediate roof to the overlying strata is significantly improved, so as to achieve a stable state. Affected by the surface load, the area where the stress in the empty top area under the mountain is 0 is more obvious, and the stress concentration on both sides of the edge of the filling body is greater; taking the plastic zone as the breakthrough point, with the decrease of the filling strip spacing, the tensile and shear failure of the immediate roof gradually disappear, weakening the influence of the surface load, which is more conducive to the stability of the “filling strip-direct roof” composite structure.

Based on the above analysis, it can be seen that the strip interval filling mining technology regards the empty roof area as a controllable underground space structure, and its single space stress field changes little. The stress of the immediate roof is gradually transferred from the top of the empty roof area to the top of the filling body, which improves the self-bearing capacity of the immediate roof, and the movement of the overlying surrounding rock is controlled. As the elevation rises, it gradually tends to the original rock stress, and the control effect on the surface subsidence is more significant, which is close to the control effect of all filling mining on the overlying strata and the surface. Finally, “filling 3 m interval 3 m” was determined as the optimal filling scheme.

Evolution law of surrounding rock stress and fracture in mining stage based on discrete element numerical simulation

This time, the UDEC discrete element simulation software was used to simulate the optimal scheme “interval 3 m filling 3 m” mining stage, observe the roof condition and fracture development during the mining period, and analyze the direct roof stress change law during the filling mining stage.

Simulation design

Using discrete element numerical simulation software, combined with the geological conditions and mechanical parameters of the mine, a calculation model is established. The model takes the horizontal direction as the X axis and the vertical direction as the Y axis. The model strike is 400 m long, No.7 coal seam is 75–115 m from the surface, the valley bottom is 115 m high from the bottom of the model, and the mountain is 165 m from the bottom of the model. The distribution of the simulated strata is consistent with that of the coal strata in Table 3. There are 8 inflection points in the model, which are (0,0), (0115), (62.5,165), (125,115), (275,115), (337.5,165), (400,115) and (4000) in a clockwise direction. The coal strata above the main roof are simplified, and the strata with smaller thicknesses are classified into the thicker strata. In the case of ensuring that the error is as small as possible, it is conducive to modeling operations. The rate of the left and right sides and the bottom of the model is set to 0, the gravity acceleration is set to 9.8 m/s2, and 50 m coal pillars are reserved on the left and right sides of the model to eliminate the influence of the model boundary on the model excavation results, as shown in Figure 12.

Figure 12.

UDEC numerical simulation model.

Filling mining is carried out on the working face. The filling scheme is “interval 3 m filling 3 m” strip interval filling. This simulation is excavated from the left boundary of 50 m, advancing 300 m. During the period, the surface transitions from the mountain area to the flat surface area, and then from the flat surface area to the mountain area. Each filling stops 30–60 m, and the roof condition and fracture development are observed.29,30 In order to further analyze the condition of the immediate roof, four monitoring points were set at 0, 6, 12, and 18 m of the overlying strata to monitor the stress change of the overlying strata.

Fracture evolution characteristics of overlying strata

In the process of filling and mining in No.7 coal seam, the strip filling body has a good supporting effect on the immediate roof. Only the false roof gangue falls in the empty roof area under the mountain body, and the concentration of cracks under the mountain area is higher than that under the flat surface area. The degree of concentration is large, but there are no obvious penetrating cracks, no obvious subsidence of the roof rock layer, and no obvious change of the overlying rock layer, which ensures the stability of the support body and the overlying rock layer structure, as shown in Figure 13.

Figure 13.

Roof condition and fissure development degree of strip interval filling stoping stage. (a) Filling mining 30 m roof condition diagram. (b) Filling mining 90 m roof condition diagram. (c) Filling mining 210 m roof condition diagram. (d) Filling mining 300 m roof condition diagram. (e)Fracture development in filling stage.

It can be seen from Figure 13 that in the filling and mining stage of No.7 coal seam, the empty roof area is regarded as a controllable spatial structure, and the stress on the immediate roof is gradually transferred from the upper part of the empty roof area to the upper part of the filling body. After the stress redistribution, a stress increase area is formed above the filling body. When the strength limit of rock or rock mass joints is exceeded, damage cracks will appear, so the cracks on both sides of the empty roof area are densely distributed.

When the filling mining is 9 m, the cracks begin to develop, the distribution is sparse, and the height is small. With the continuous advancement of the working face, when the filling mining reaches 30 m, the fracture distribution becomes denser, a few cracks penetrate each other, and a small range of separation cracks appear in the pseudo-roof, indicating that a small amount of gangue falls from the pseudo-roof under the mountain. When filling stoping at 150 m, the fracture height basically does not change, and the fracture development under the mountain is relatively denser than the flat surface (valley bottom) area ; when the filling is recovered to 300 m, the fracture distribution law does not change.

From the above analysis, it can be seen that in the process of mining, the existence and expansion of cracks are symmetrically distributed in the area under the mountain. With the deepening of mining distance, the expansion of cracks is concentrated near the stope, and does not extend upward, which poses little threat to safety production. It shows that the disturbed filling body and the roof strata are deformed synergistically, and the filling body and the filling body and roof and floor are compacted. The filling body with small interval space has a strong limiting effect on the roof and floor of the coal seam, which can effectively control the deformation of the roof and floor.

Stress evolution characteristics of filling stope

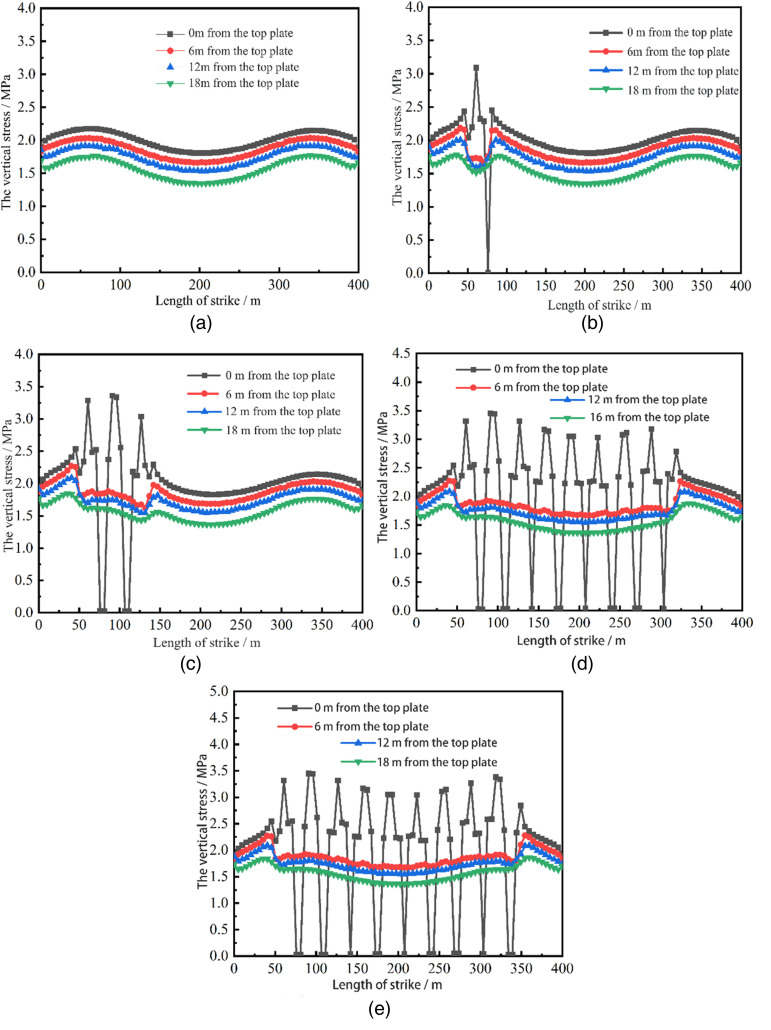

It can be seen from Figure 14 that in the unmined stage, the original rock stress at the same elevation is distributed in an “M” type, and the original rock stress in the surface area of the mountain is higher.

Figure 14.

Stress monitoring curve of overlying strata in the mining stage. (a) Original rock stress state (not mined). (b) Backfill mining 30 m. (c) Backfill mining 90 m. (d) Backfill mining 210 m. (e) Backfill mining 300 m.

When the filling stoping is 30 m, the stress reduction zone and the stress increase zone appear at the bottom of the immediate roof. The stress increase phenomenon appears on the immediate roof of the left coal wall of the open-off cut. The maximum vertical stress at the bottom of the immediate roof reaches 2.43 MPa. There is a small range of stress reduction zone in the empty roof area on the right side of the open-off cut, and the degree of stress reduction is not obvious. With the increase of the strike length, the peak stress of 3.15 MPa and the valley value of 0.1 MPa appear again. The peak value is at 60 m and the valley value is at 75 m, that is, the central position of the stope. After 90 m, a small range of stress increase zone appears, with a peak value of 2.43 MPa, and then enters the original rock stress zone.

When the filling recovery is 90 m, the range of stress reduction zone and stress increase zone at the bottom of the immediate roof increases, the peak stress of the left coal wall of the open-off cut increases, and the maximum vertical stress at the bottom of the immediate roof reaches 2.6 MPa.There is still a small range of stress reduction zone in the empty roof area on the right side of the open-off cut, the degree of stress reduction is not obvious, and then the stress begins to rise. In addition to the peak stress of the open-off cut coal wall, with the increase of the strike length, there are three stress peaks and two stress valleys in the middle. The first stress peak is still at the 75 m position, but the peak value increases by 0.15 MPa; the second peak stress is the maximum vertical stress of 3.4 MPa, located in the center of the stope, namely the direction of 95 m; the third stress peak is low, reaching 3.08 MPa, and the two stress valleys are 0.2–0.5 MPa ; at the position of 140 m, the range of stress increasing zone increases, the peak value is 2.6 MPa, and then it enters the original rock stress zone.

When the filling mining is 210 m, the range of stress reduction zone and stress increase zone at the bottom of the immediate roof increases, and the peak stress of the left coal wall of the open-off cut remains unchanged, which is still 2.6 MPa. In addition to the peak stress of the open-off cut coal wall, with the increase of the strike length, there are 7 stress peaks and 6 stress valleys successively. The overall stress peak does not change, and the overall stress valleys are 0.2–0.5 MPa.At this time, the peak stress in the middle is not the maximum value, and several stress peaks still show a trend of “increase-decrease”. The range of stress increasing zone decreases again after 260 m, and then enters the original rock stress zone.

When the filling recovery is 300 m, the range of stress reduction zone and stress increase zone at the bottom of the immediate roof increases, and the peak stress of the left coal wall of the open-off cut remains unchanged, which is still 2.6 MPa. In addition to the peak stress of the coal wall, with the increase of the strike length, there are 10 stress peaks and 9 stress valleys in the middle, and the overall stress field has not changed significantly. The overall stress valleys are between 0.2 and 0.5 MPa. At this time, the peak stress in the middle is the minimum peak stress, the vertical stress value is 3.07 MPa, and several stress peaks still show a trend of “increase-decrease-increase-decrease”. After 350 m, the range of stress increasing zone rises again, the peak stress reaches 2.7 MPa, and then enters the original rock stress zone.

In summary, with the continuous advancement of the filling working face, the stress concentration area and stress peak value of the coal wall in front of the working face show a trend of “increase-decrease-increase”. The stress curve of the immediate roof in the middle of the stope shows a gradual “cycle”. The stress peak curve changes from “increase-decrease” trend to “increase-decrease-increase-decrease” trend. The stress valley value is 0.2–0.5 MPa, and no zero stress zone appears. The rock strata with elevation close to the immediate roof are in a state of stress concentration in the coal wall area, and the middle part is not obviously relieved. With the increase of the height of the overlying strata, the rock strata tend to the original rock stress area.

Conclusion

(1) Through theoretical analysis, combined with the site, the hanging roof is controlled within 10 m, which is conducive to the safety of underground production. The strip spacing should be less than 10 m, and the compressive strength of the filling body is not less than 3.7 MPa.

(2) The numerical simulation software FLAC3D is used to simulate the five design schemes respectively. The “filling body-direct roof” structure improves the self-bearing capacity of the direct roof, and the overlying surrounding rock migration is controlled. With the rise of elevation, it gradually tends to the original rock stress, and the control effect on surface subsidence is more significant, which is close to the control effect of all filling mining on overlying strata and surface. Finally, “filling 3 m interval 3 m” is determined as the optimal filling scheme.

(3) In the filling mining stage of No.7 coal seam, the monitoring results of the monitoring line (the bottom of the immediate roof) 0 m away from the immediate roof (the bottom of the immediate roof) have a large amplitude, and the other three lines have no obvious change. It can be seen that during the filling mining process, the stress concentration area and the stress peak value of the front coal wall show a trend of “increase-decrease-increase”. The stress curve of the immediate roof in the middle of the stope shows a gradual “cycle”, and the stress peak curve changes from the trend of “increase-decrease” to the trend of “increase-decrease-increase-decrease”. The stress valley values are 0.2–0.5 MPa, and there is no zero stress zone. The rock strata near the immediate roof are in a state of stress concentration in the coal wall area on both sides, and the middle is in an unobvious pressure relief state. With the increase of the height of the overlying strata, the rock strata tend to the original rock stress area, which ensures the stability of the underground space structure and the overlying strata.

Author biographies

Chang Luo is a postgraduate student at Guizhou University. He mainly engaged in coal mine filling mining research.

Ping Liu, master, is an associate professor at Guizhou University. She mainly engaged in coal mine filling mining research.

Yichao Jia is a doctoral student at Guizhou University. He mainly engaged in coal mine filling mining research.

Zhen Cheng is a postgraduate student at Guizhou University. He mainly engaged in coal mine filling mining research.

Fangling Gao is a postgraduate student at Guizhou University. She mainly engaged in coal mine filling mining research.

Xinkang Huang is a postgraduate student at Guizhou University. He mainly engaged in coal mine filling mining research.

Footnotes

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Funding: The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was supported by the Guizhou Science and Technology Fund, (grant number Qiankehe Foundation 1Z047).

ORCID iD: Chang Luo https://orcid.org/0000-0003-1502-1632

References

- 1.Yang Y, Zhang M, Hu Get al. et al. Simulations of goaf surface subsidence via filling control. PLoS One 2022; 17: e0261740. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Zhang Q, Wang Z, Zhang Jet al. et al. Integrated green mining technology of "coal mining-gangue washing-backfilling-strata control-system monitoring"-taking Tangshan Mine as a case study. Environ Sci Pollut Res Int 2022; 29: 5798–5811. [DOI] [PubMed] [Google Scholar]

- 3.Shen Z, Jixiong Z, Hao M. Overlying strata movement coordinated with the compression ratio of backfilling solid in ultra-close coal seams. J Min Saf Eng 2019; 36: 712–718. [Google Scholar]

- 4.Bian Z, Miao X, Lei Set al. et al. The challenges of reusing mining and mineral-processing wastes. Science 2012; 337: 702–703. [DOI] [PubMed] [Google Scholar]

- 5.Zhu X, Guo G, Liu H, et al. Research on the stability evaluation model of composite support pillar in backfill-strip mining. Math Probl Eng 2020; 2020: 1–11. [Google Scholar]

- 6.Yansen HUAI, Wenyong LIU, Qian-ming LU. Technology study of coal mine filling on low-cost control. Coal Technol 2016; 35: 22–24. [Google Scholar]

- 7.Jialin X, Dayang X, Weibin Z. Present situation and prospect of filling coal mining technology. Min Technol 2011; 11: 24–30. [Google Scholar]

- 8.Jialin X, Dayang X, Wei-bin Z. Partial filling mining technology based on key strata control. J Min Saf Eng 2019; 1: 69–76. [Google Scholar]

- 9.Xikui S. Research on paste backfilling mining technology of coal mining under buildings, water bodies and railways. Coal Sci Technol 2021; 49: 218–224. [Google Scholar]

- 10.Skrzypkowski K. 3d Numerical modelling of the application of cemented paste backfill on displacements around strip excavations. Energies 2021; 14: 7750. [Google Scholar]

- 11.Cui B, Feng G, Bai J, et al. Acoustic emission characteristics and damage evolution process of backfilling body–coal pillar–backfilling body composite structure[J]. Bull Eng Geol Environ 2022; 81: 1–16. [Google Scholar]

- 12.Jiang N, et al. Modeling study on the influence of the strip filling mining sequence on mining–induced failure. Energy Sci Eng 2020; 8: 2239–2255. [Google Scholar]

- 13.Guo G, et al. A new method to control the regional strata movement of super-thick weak cementation overburden in deep mining. Stavební Obzor-Civ Eng J 2022; 31: 153–168. [Google Scholar]

- 14.Sun W, Zhang Q, Luan Y, et al. A study of surface subsidence and coal pillar safety for strip mining in a deep mine. Environ Earth Sci 2018; 77: 627. [Google Scholar]

- 15.Mengbo Z, Lang L, Shuangming W. Short- and long-walls backfilling pillarless coal mining method. J Min Saf Eng 2022; 39(09): 1116–1124. [Google Scholar]

- 16.Xu YJ, Ma LQ, Ngo IHet al. et al. Continuous extraction and continuous backfill mining method using carbon dioxide mineralized filling body to preserve shallow water in northwest China. Energies 2022; 15: 3614. [Google Scholar]

- 17.Xu YJ, Ma LQ, Ngo IHet al. et al. Prediction of the height of water conductive fractured zone under continuous extraction and partial backfill mining method—A case study. Energies 2022; 14: 6582. [Google Scholar]

- 18.Xu Y, Ma L, Ngo Iet al. et al. Prediction of the adaptability of using continuous extraction and continuous backfill mining method to sequestrate CO2 —A case study. Minerals 2022; 12: 936. [Google Scholar]

- 19.Min-gao Q, Pinwu S. Xu Jialin ground pressure and strata control. Xuzhou: China University of Mining and Technology Press, 2003. [Google Scholar]

- 20.Wei G. Study on the width of the non-elastic zone in inclined coal pillar for strip mining. Int J Rock Mech Min Sci 2014; 72: 304–310. [Google Scholar]

- 21.Prassetyo SH, et al. New coal pillar strength formulae considering the effect of interface friction. Int J Rock Mech Min Sci 2019; 123: 104102. [Google Scholar]

- 22.Das AJ, et al. Assessment of the strength of inclined coal pillars through numerical modelling based on the ubiquitous joint model. Rock Mech Rock Eng 2019; 52: 3691–3717. [Google Scholar]

- 23.Jiang N, Zhao J, Sun X, et al. Use of fly-ash slurry in backfill grouting in coal mines. Heliyon 2017; 3: e00470. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Ahmaruzzaman M. A review on the utilization of fly ash. Prog Energy Combust Sci 2010; 36: 327–363. [Google Scholar]

- 25.DU x, FENG G, QI T, et al. Roof stability analyses of “water-preserved and water-stored” coal mining with constructional backfill mining. J China Coal Soc 2019; 44: 821–830. [Google Scholar]

- 26.XIE W, YIN S, SHI Z. The key problem study about gob-side entry retaining in top-coal caving mining face. J China Coal Soc 2004; 29: 146–149. [Google Scholar]

- 27.Zhang C, et al. Coal pillar failure analysis and instability evaluation methods: a short review and prospect. Eng Fail Anal 2022; 138: 106344. [Google Scholar]

- 28.Li P, Tan Z, Yan L. A shaft pillar mining subsidence calculation using both probability integral method and numerical simulation. Comput Model Eng Sci 2018; 117: 231–249. [Google Scholar]

- 29.Liu W, et al. Characteristics analysis of roof overburden fracture in thick coal seam in deep mining and engineering application of super high water material in backfill mining. Geotech Geol Eng 2019; 37: 2485–2494. [Google Scholar]

- 30.Wang H, et al. Roof-breaking mechanism and stress-evolution characteristics in partial backfill mining of steeply inclined seams. Geomatics Nat Hazards Risk 2020; 11: 2006–2035. [Google Scholar]