Abstract

Fe-based materials have received more and more interests in recent years as candidates to fabricate bioresorbable stents due to their appropriate mechanical properties and biocompatibility. However, the low degradation rate of Fe is a serious limitation for such application. To overcome this critical issue, many efforts have been devoted to accelerate the corrosion rate of Fe-based stents, through the structural and surface modification of Fe matrix. As stents are implantable devices, the released corrosion products (Fe2+ ions) in vessels may alter the metabolism, by generating reactive oxygen species (ROS), which might in turn impact the biosafety of Fe-based stents. These considerations emphasize the importance of combining knowledge in both materials and biological science for the development of efficient and safe Fe-based stents, although there are still only limited numbers of reviews regarding this interdisciplinary field. This review aims to provide a concise overview of the main strategies developed so far to design Fe-based stents with accelerated degradation, highlighting the fundamental mechanisms of corrosion and the methods to study them as well as the reported approaches to accelerate the corrosion rates. These approaches will be divided into four main sections, focusing on (i) increased active surface areas, (ii) tailored microstructures, (iii) creation of galvanic reactions (by alloying, ion implantation or surface coating of noble metals) and (iv) decreased local pH induced by degradable surface organic layers. Recent advances in the evaluation of the in vitro biocompatibility of the final materials and ongoing in vivo tests are also provided.

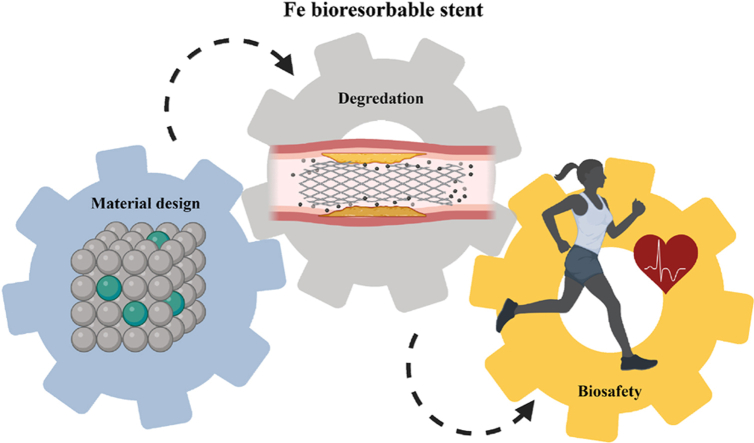

Graphical abstract

Design of Fe-based materials to balance degradation performance and biosafety of bioresorbable stents. Created with Biorender.

Highlights

-

•

The research background, interests and challenges of Fe-based bioresorbable stents has been introduced.

-

•

The design of Fe-based materials to accelerate corrosion rate, via surface and structural modification, has been reviewed.

-

•

The impact of degradation products on in vitro and in vivo biosafety has been introduced.

1. Introduction

Ischemic heart disease is the leading cause of death worldwide [1]. It accounted for 9,440,000 (8,820,000–9,960,000) deaths in 2021 [2]. Such a disease is mainly induced by narrowing (called stenosis) or occlusion of the arterial vessels. The common treatments are based on cardiovascular risk factors control and angioplasty by inserting and then inflating a tiny balloon temporarily, in order to widen the narrowed or obstructed arteries. It is often combined with the placement of a mesh tube, called stent, which helps prevent the artery from closing up again. However, a large number of patients suffer from restenosis after stent implantation. Recent studies suggested that in-stent restenosis could be due to the biological response (e.g. inflammation) triggered by the presence of the stent-based metallic platform injuring vascular wall [3]. To improve biocompatibility and prevent early restenosis, drug-eluting stents are currently used, because they are able to significantly induce an inhibition of neointimal proliferation. However, drug-eluting stents carry a higher thrombosis risk, mainly induced by delayed or absent endothelization of the stent struts, hypersensitivity, inflammatory and/or thrombotic adverse reactions [4].

Another promising approach is the use of bioresorbable stents (BRS), which avoid in-stent restenosis by self-degrading overtime. From the point of view of their physicochemical characteristics, the main requirements for bioresorbable stents are the preservation of their mechanical integrity for 3–6 months and their full degradation in 12–24 months [5]. In addition, the BRS must have biocompatibility and hemocompatibility properties allowing tissue regeneration and healing without inducing restenosis, thromboses or calcifications. However, the control of surface biocompatibility and degradation of bioresorbable stents still remains highly challenging, because few materials could fulfill both requirements. BRS based on biocompatible polymer of poly-l-lactide, has been commercialized and implanted in humans, but later withdrawn from sales due to the occurrence of restenosis effect similar to bare metal stents [6,7]. Besides, late shrinkage and non-uniform vessel support, induced by uneven degradation, was unveiled [7]. Mg alloys have been also explored as bioresorbable stents but they were degrading too fast. Indeed, within 4 months, the implanted Mg-based stents lost radial support due to reduced strut thickness, induced by surface erosion as the stent was absorbed [8]. Zn alloys demonstrate promising degradation rates and enhanced mechanical strength, largely due to alloying with elements such as Al, Li, Mg, Sr, Mn, and Ca [[9], [10], [11]], which allows for the creation of thin-strut stents comparable to modern stent-use CoCr alloys. Despite having different properties from strain-hardenable alloys traditionally used in stent and orthopedic devices, research is underway to balance strength and ductility in Zn alloys and adapt these properties for new stent design strategies. While chronic inflammation has been observed due to certain alloying elements [11], studies over the past five years affirm that Zn-based materials show potential for bioresorbable stents [9,[12], [13], [14], [15], [16]], albeit with considerable work needed for clinical application.

Fe and its alloys exhibit attractive mechanical properties, such as high strength, high elastic modulus, large ductility and important strain-hardening rate, combined with good biocompatibility, compared to Mg and Zn candidates. These advantages on mechanical properties enable thin strut design, low stent recoil and low risk of expansion fracture. A disadvantage of Fe stents is their slow degradation rate, as they remain virtually intact 53 months post-implantation [17], leading to prolonged retention times in the body. In order to improve the degradation rate, both metallurgical and surface strategies have been explored. The metallurgical approach to increase Fe degradation rate relies on two criteria which influence the corrosion susceptibility of the metal: (i) the addition of less noble alloying elements such as Mn within the solubility limit in Fe to make the Fe matrix more susceptible to corrosion [18]; and (ii) the addition of noble alloying elements to generate small and finely dispersed precipitates that act as cathodic sites towards the Fe matrix, inducing microgalvanic corrosion [19]. Another approach to increase Fe corrosion rate relies on surface coating by noble metals, such as Pt and Au microarrays [20,21], generating a multitude of galvanic cells on the surface. Recently, it was revealed that the biodegradation of Fe stents could be increased by surface coating of organic polylactide layers due to the decreased local pH induced by polylactide hydrolysis and alleviation of the passivation layer deposition [22]. As biosafety is the main concern in the development of new implantable devices, the biocompatibility of Fe-based BRS has been systematically evaluated in vitro and in vivo. The former includes direct- and indirect-contact (extracts and insert) tests using different cell lines, including animal ones such as mouse fibroblasts (3T3) or smooth muscle cell lines (VSMCs) and human cells in particular endothelial cells (HUVEC) [23]. The in vivo tests, carried out after the in vitro evaluation, are based on animal models such as rabbits, minipigs and juvenile domestic pigs and allow short or long term studies (from a few days to more than 4 years) [24]. As Fe-based materials attract more and more interests in the domain of BRS, a systematical review is necessary on the design, corrosion behavior and biosafety of such devices. Herein, we summarize and discuss the fundamental aspects of Fe-based BRS, including corrosion mechanism, materials design from material sciences point of view, in vitro, in vivo and clinical evaluations of Fe BRS.

2. Fundamentals aspects of Fe corrosion

Mechanism of Fe corrosion. The Fe corrosion is a redox reaction, summarized as an anodic reaction of Fe oxidation (Equation (1)) and a cathodic reaction of oxygen reduction (Equation (2)) in neutral or alkaline medium. For Fe implants, the pH value of the working conditions is 7.4 which corresponds to that of blood and that of most simulated body fluids (BSF) [25]. In BSF, the formed Fe2+ reacts with OH−, generating Fe(OH)2 (Equation (3)) which can be further oxidized to Fe(OH)3 (Equation (4)). During formation of hydroxides, the deposition of calcium and phosphorus layers also takes place. The corrosion rate is thus reduced after several days due to surface coverage of these layers [26]. The thermodynamics and kinetics of Fe corrosion, represented by the corrosion potential and rate, exhibit variation depending on the type of bioresorbable Fe materials designed. The structure, surface and working environment have great impact. As described in section 3, one can tailor Fe microstructure (e.g. defects and grain), matrix porosity, composition (by integration of other elements) or surface chemistry (by polymer coating) to make Fe easier and faster to be corroded. The working environment can also affect corrosion kinetics. As reported by Mei et al., for kinetic evaluation of a bioasorbable bare metal, increasing complexity of medium can lead to the decrease of corrosion rate [27]. For example, the corrosion rate might become lower in a medium containing various organic compounds and proteins, compared with a simple medium of inorganic ions [27]. However, if the material is optimized, the corrosion can be accelerated even in complex medium. For example, Fe corrosion became faster in presence of bovine serum albumin when the surface was coated by a thin layer of polyethyleneimine due to interaction of protein with polymer coating [28]. Therefore, it is important to investigate the corrosion rate during in vitro and in vivo environment. These aspects are introduced and summarized in section 4.

| Fe → Fe2+ + 2e− | (1) |

| O2 + H2O + 4e− → 4OH− | (2) |

| Fe2+ + 2OH− → Fe(OH)2 | (3) |

| 4Fe(OH)2 + O2 + 2H2O → 4Fe(OH)3 | (4) |

In the human body, the anodic reaction, namely, oxidation of Fe (Equation (1)) remains the same but the products participate in metabolism and undergo Fenton reaction that generates radicals [[29], [30], [31], [32]]. In aerobic condition, Fe2+ reacts with oxygen and forms superoxide anion (Equation (5)), followed by H2O2 generation (Equation (6)). The interaction of H2O2 and Fe2+ products hydroxyl radical (Equation (7)), known as Fenton reaction [[29], [30], [31], [32]], inducing oxidative stress [23].

| Fe2+ + O2 → Fe3+ + O2⦁- | (5) |

| Fe2+ + O2⦁- + 2H+ → Fe3+ + H2O2 | (6) |

| Fe2+ + H2O2 → Fe3+ + OH⦁ + OH− | (7) |

Therefore, for Fe-based BRS, the control of reactive oxygen species (ROS), here OH⦁ releasing and the improvement of biocompatibility is very important. The impact of such an effect toward biological process and biosafety will be discussed in detail in section 4.

Determination of Fe corrosion rate. The most common methods to evaluate corrosion rate (CR) are electrochemical and immersion test, as suggested by ASTM-G102-89 [33] and ASTM-G31-72 [34] standard protocols. The former provides corrosion information under controlled potential or/and current while the later without. Electrochemical measurements (operated in a three-electrodes system and controlled by a potentiostat), including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), are the most widely employed tests for fast evaluation of corrosion properties. The information obtained from electrochemical measurements are rich (such as open cycle potential, corrosion potential/current, resistance/capacitance, etc.), providing insights on corrosion mechanisms. The CR value can be calculated through analysis of the Tafel plot derived from the potentiodynamic polarization curve, using Equation (8) [35].

| CR = 3.72 × 10−3× icorr× EW / ρ | (8) |

Where the icorr is corrosion current density (A cm−2) derived from Tafel plot, EW the equivalent weight of iron (27.92 g/eq) and ρ the material density in grams per cubic centimeter (7.87 for Fe). The immersion test aims to estimate CR value by the weight loss of samples via Equation (9).

| CR = m / (S × t) | (9) |

Where m is the sample weight loss which can be directly weighted or calculated from released ion concentration, S surface area of sample and t immersion time. The static immersion test (ASTM-G31-72) is conducted by immersing the specimen into the bath at 37 °C. After n days (usually, n varies from 3 to 180 days), samples are removed from the bath, followed by washing and drying, for weighting. In addition, dynamic immersion tests can be also employed to evaluate CR [36]. Such a setup is designed to simulate blood flow in the coronary artery. The specimen is immersed into a fluidic system where the flow speed, sample wall shear stress, dissolved oxygen level and pH value are controlled.

Many factors affect the corrosion test results. For example, to obtain an accurate potentiodynamic polarization curve, the scan rate should not be too fast, usually at 0.166 mV s−1 [35,37] and 0.33 mV s−1 in literatures [21,38], but could be extended to 0.5 or 1 mV s−1 [26,39,40]. Higher total current density can be observed with increasing scan rate. In EIS, the frequency, generally ranging in 100 kHz - 10 mHz [41,42], should be adapted to the stability of the sample or to avoid sample surface deterioration in electrolyte and to reduce noises. For immersion tests, the ratio of solution volume to sample surface area is crucial [43], which should be 20 or 40 mL cm−2 as suggested by ASTM-G31-72. But the international standard organization (ISO10993-15) suggested keeping the ratio lower than 1 mL cm−2. In any case, the immersion solution volume should be adapted to sample oxidation properties, avoiding oxygen exhaustion and surface accumulation of corrosion products. In addition, immersion solution type has also an impact. It seems that the corrosion rate is lower in a medium containing complex components with respect to simple medium [27]. For example, the corrosion is decreased in a cell culture medium (that contains inorganic ions, organic compounds and proteins) with respect to that in NaCl solution [27]. For dynamic immersion tests, the flow rate simulating blood in the human body is set to 40 mL min−1 [44]. For Fe-based BRS, as reported by Liu et al., the wall shear stress (0.68 Pa), dissolved oxygen (2.8–3.2 mg L−1) and pH (7.34–7.45) should be considered as experimental parameters [36]. The CR value of a sample obtained by electrochemical measurement should display the same trend to that from static or dynamic immersion tests.

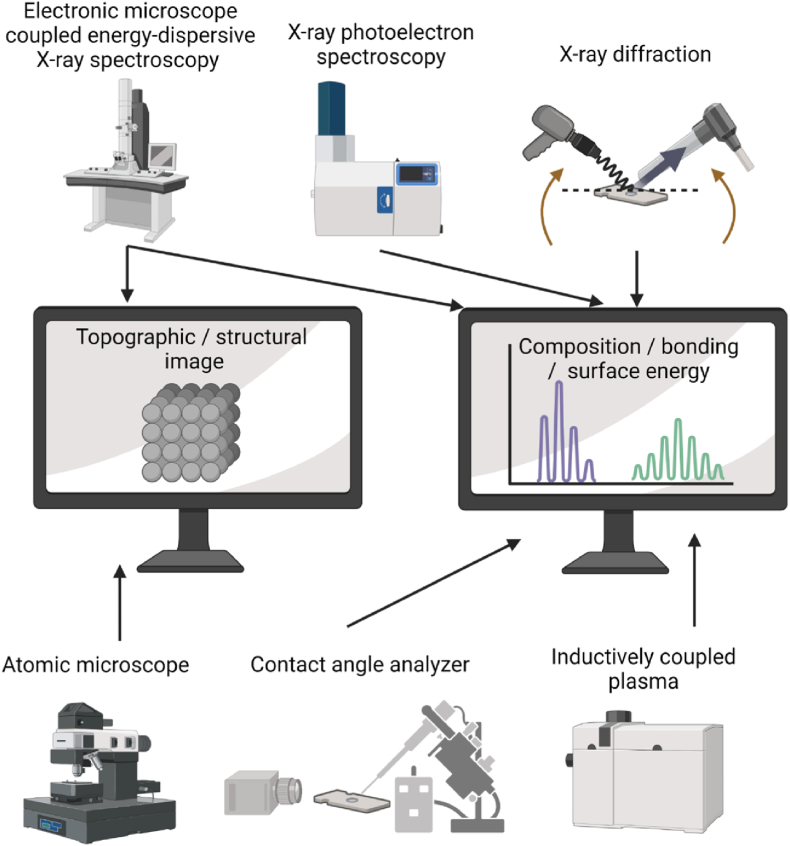

Characterization for fundamental studying of Fe corrosion. Surface and structure characterizations before and after corrosion tests are essential and necessary for fundamental studying of Fe corrosion and understanding the reaction mechanism. As shown in Fig. 1, the topographic or structural images with surface chemistry (composition, bonding and energy) should be collected and investigated to understand the corrosion behavior. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) has been widely applied for this purpose. This technique provides information on structure, surface morphology and composition. For example, porous Fe, with high surface roughness and high concentration of dislocations sites, have been fabricated to serve as BRS due to the accelerated CR [39]. As revealed by SEM images, the porous morphology of Fe scaffold can be confirmed. Another example is Ta-implanted Fe surface [45]. Such a material has been characterized by SEM-EDS, confirming the formation of surface nanoridges covered by Ta on Fe substrate. After corrosion tests, the specimen can be also analyzed by SEM-EDS, investigating surface topography (e.g. pitting or cracking) [45] and chemistry (e.g. corrosion products, passivation layer deposition) [46]. X-ray photoelectron spectroscopy (XPS) is also used for surface chemistry analysis. One example is Fe–Mn alloy that has been reported for improved biodegradation [47]. Using SEM and XPS, the topography and the formation of Fe and Mn oxides on the surface after laser ablation should be associated with increased degradation. In addition, X-ray diffraction (XRD), delivering crystalline structural information, has been applied to characterize surface components. For example, using XRD, one can verify the formation of alloy or oxide coating [42,48]. Atomic force microscopy (AFM) can also provide surface morphology, such as roughness [49]. Contact angle analyzer has been used for hydrophilicity of surface [50]. Inductively coupled plasma (ICP) could provide released iron concentration after corrosion tests [42]. Nowadays, Raman spectroscopy has emerged as an interesting surface analysis technique for developing BRS by offering a comprehensive understanding of surface composition and bonding information. Additionally, this method enables the generation of images with both spectral and spatial information, further enhancing its capabilities for surface characterization. It thus proved particularly useful in investigating the corrosion behavior of materials made of iron (Fe), offering valuable data for further analysis and understanding of the corrosion process/products [28].

Fig. 1.

The illustrative scheme of equipments for surface and structure analysis in the domain of Fe-based BRS. Created with Biorender.

3. Strategy to accelerate Fe corrosion

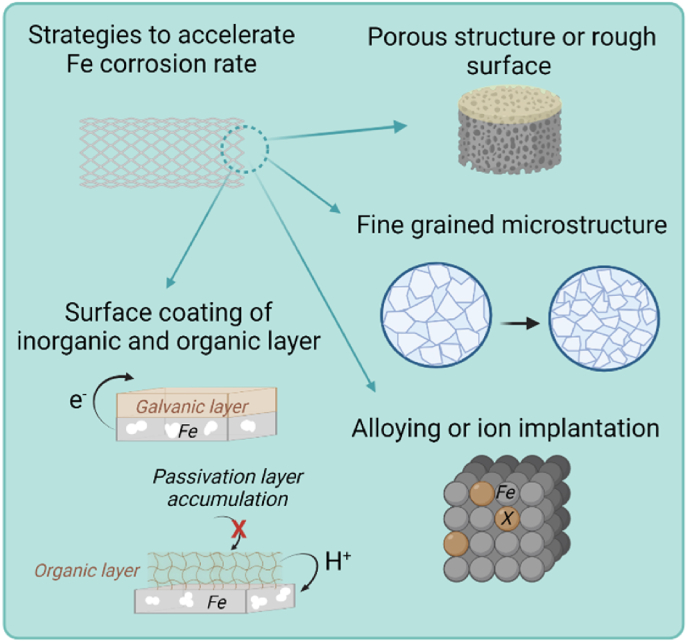

Various approaches can be employed to improve corrosion rate, as illustrated in Fig. 2.

-

(i)

Increasing Fe active surface area by enhancing roughness and porosity. Increased Fe surface roughness or porosity leads to increased electrochemical active surface area, inducing improved corrosion rates [39].

-

(ii)

Creating fine grained microstructure with higher volume of grain boundaries. This leads to an increased number of active sites, thereby increasing the susceptibility of corrosion attack [41].

-

(iii)

Alloying or ion implantation. Fe corrosion can be accelerated by introducing second phases into the matrix, e.g. Fe–Mn, Fe–W alloys [44,47]. Besides, surface ions implantation (such as Zn) has been reported for accelerated Fe corrosion [49].

-

(iv)

Surface coating of inorganic and organic layer. It could be a coating of an inorganic galvanic layer, with higher oxidation potential (such as Ta, Au, Pt, carbon, etc.) [20,21,45]; or, through organic coating to decrease local pH (e.g. polylactide), hydrolysis or/and inhabitation of the deposit of passivation layer during corrosion can be also employed to increase CR [22,51].

Fig. 2.

Illustrative scheme of the strategies to accelerate iron corrosion via (i) increasing surface porosity and roughness; (ii) Creating fine grained microstructure; (iii) alloying or ion implantation; and (iv) surface coating of microgalvanic layer or polymer to decrease local pH or/and inhabit of passivation layer deposition. Created with Biorender.

Approaches (i) and (ii) are respectively surface and structure strategies which are mainly used to accelerate corrosion of pure Fe stents; these two methods will be introduced in section 3.1. Methods (iii) and (iv) developed for bioresorbable stents on Fe-based alloys or composites, will be summarized in section 3.2 and section 3.3, respectively.

3.1. Increasing corrosion rate of pure fe

Tunable Fe surface morphology or/and microstructure engineering can increase the mechanical properties and corrosion rate by properly inducing porous structure, microstructural defects and grain refinement.

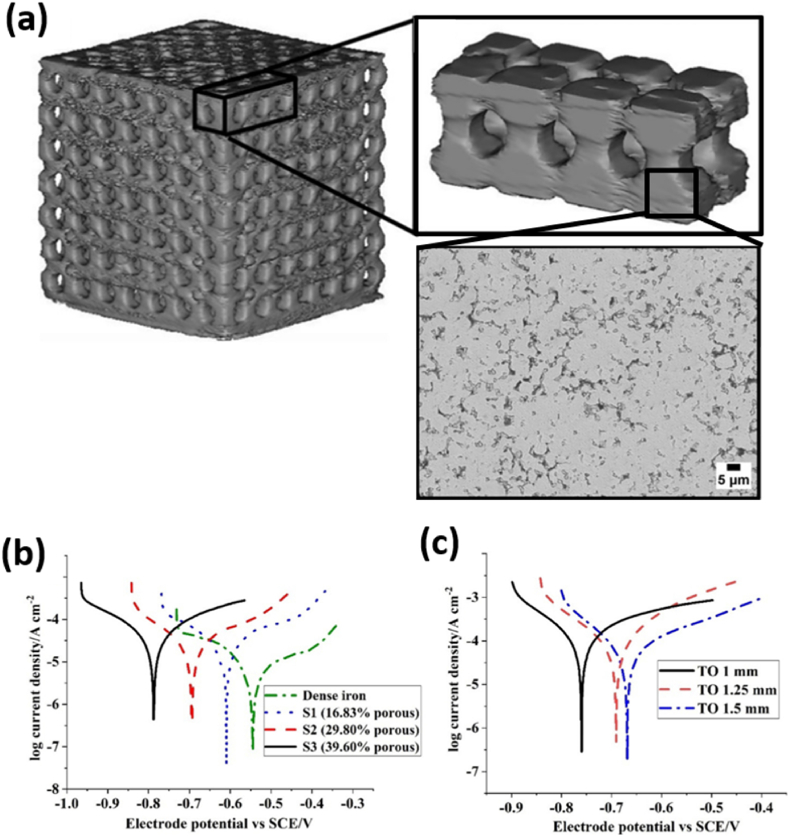

Porous Fe structure.Wegener et al. recently reported porous Fe implants fabricated by powder sintering technique. The animal test results demonstrated that the degradation of the implant was detected, and the porous Fe-based material is a promising candidate for self-degrading and high load bearing implant material [52]. In order to understand the influences of porous structure to corrosion rate, P. Sharma et al. have compared porous Fe scaffold samples having random microporous structure and topologically ordered porous structure (as shown in Fig. 3a) [39]. The manufacturing of the porous structures employed prefabricated moulds with different pore topologies to sinter Fe powder in the mould [53]. The potentiodynamic assessment results showed that the increase in random microporosity leads to higher corrosion susceptibility (Fig. 3b). As listed in Table 1, the corrosion potential was more negatively shifted on random porous Fe with the highest porosity (39.60 %) with highest corrosion current, with respect to less random porous samples (16.83 % and 29.80 % of porosity). And the reduction of the macropore (strut) size resulted in the same effect up to 2.5 times higher on corrosion rate (Fig. 3c, cf. CR value of topological ordered porous Fe samples in Table 1). The highest corrosion rate was recorded on topologically ordered porous iron scaffold (with 1 mm strut size), it was found about 17 times higher than that of non-porous Fe sample (Table 1). Similar results have been reported by N. E. Putra et al. [46] who showed that the presence of geometrically designed macropores and random micropores improved the in vitro corrosion rate of the scaffold as compared to the bulk counterpart. The porous Fe presented 7 % of mass loss after 28 days’ immersion test. It is worthy to note that the CR value from immersion test was 2.8 g m−2 day−1 at day 1, but declined to 1.1 g m−2 day−1 at day 28, probably due to surface accumulation of corrosion products (Table 1). Such a value (at day 28) is much higher than cast pure iron or porous iron in literatures (0.4–0.8 g m−2 day−1) [44,50,54]. The acceleration of degradation rate was also observed in the study in which topologically ordered porous structure was achieved by direct metal printing technique [40]. The electrochemical tests showed up to about 12 times higher rates of corrosion for this porous Fe sample (1.18 mm year−1) as compared to that of bulk Fe (0.1 mm year−1), see Table 1.

Fig. 3.

(A) Construction of 3D macroporous Fe structure from computerized tomography (CT) scan and SEM picture of microporous sample surface. Comparison of potentio-dynamic polarization curves for (b) dense and microporous Fe sample (S1–S3), (c) macroporous samples (TO) with different strut size. Adapted from Ref. [39], copyright 2019, Elsevier.

Table 1.

The mechanical and degradation properties of Fe-based materials.

| Ref. | Sample | Mechanical properties |

Degradation properties |

|||||

|---|---|---|---|---|---|---|---|---|

| Ultimate tensile stress/MPa | Tensile yield stress/MPa | Compressive yield stress/MPa | Ecorr/V | Jcorr/μA cm−2 | CRa/mm year−1 | CRb (immersion time)/g m−2 d−1 | ||

| Porous Fe | ||||||||

| [39] | Dense Fe (reference sample) | N.A. | N.A. | N.A. | −0.545 vs. SCE | 11.53 | 0.13 | N.A. |

| Random Porous Fe (16.83 % porosity) | N.A. | N.A. | N.A. | −0.609 vs. SCE | 42.96 | 0.50 | N.A. | |

| Random Porous Fe (29.80 % porosity) | N.A. | N.A. | N.A. | −0.694 vs. SCE | 65.51 | 0.76 | N.A. | |

| Random Porous Fe (39.60 % porosity) | N.A. | N.A. | N.A. | −0.738 vs. SCE | 83.97 | 0.98 | N.A. | |

| Topological ordered porous Fe (1 mm strut size, 45.63 % porosity) | N.A. | N.A. | N.A. | −0.760 vs. SCE | 193.34 | 2.25 | N.A. | |

| Topological ordered porous Fe (1.25 mm strut size, 59.99 % porosity) | N.A. | N.A. | N.A. | −0.691 vs. SCE | 115.87 | 1.35 | N.A. | |

| Topological ordered porous Fe (1.5 mm strut size, 80.97 % porosity) | N.A. | N.A. | N.A. | −0.669 vs. SCE | 73.34 | 0.85 | N.A. | |

| [46] | Porous Fe | N.A. | 7.2 (day 1) 9.4 (day 28) |

96 (day 1) 19 (day 28) |

−0.781 vs. Ag/AgCl (day 1) −0.676 vs. Ag/AgCl (day 28) |

8.0 (day 1) 3.5 (day 28) |

0.09 (day 1) 0.04 (day 28) |

2.8 (day 1) 1.1 (day 28) |

| [40] | Cold-rolled Fe (reference sample) | N.A. | N.A. | N.A. | N.A. | 8.6 (day 1) | 0.10 (day 1) | N.A. |

| Porous Fe | N.A. | 27.8 (day 1) 22.4 (day 28) |

N.A. | N.A. | 102.8 (day 1) | 1.18 (day 1) | N.A. | |

| Fine-grain Fe | ||||||||

| [35] | Pure Fe, annealed at 550 °C (reference sample) | 205 | 140 | N.A. | −0.732 vs. SCE | 14 | 0.16 | N.A. |

| E-Fe, annealed at 550 °C | 292 | 270 | N.A. | −0.776 vs. SCE | 44.3 | 0.51 | N.A. | |

| E-Fe | 423 | 360 | N.A. | −0.824 vs. SCE | 73.4 | 0.85 | N.A. | |

| [58] | Annealed Fe at 1100 °C | 274 | 104 | N.A. | Between −0.55 and −0.6 V vs. SCE | N.A. | 0.099c | 1.2 (day 1)e 1.3 (day 7)e |

| Annealed Fe at 1200 °C | 275 | 137 | N.A. | Between −0.55 and −0.6 V vs. SCE | N.A. | 0.101c | 3.0 (day 1)e 2.6 (day 7)e |

|

| Annealed Fe at 1300 °C | 279 | 139 | N.A. | Between −0.55 and −0.6 V vs. SCE | N.A. | 0.100c | 4.5 (day 1)e 2.6 (day 7)e |

|

| As-sprayed Fe | 84 | N.A. | N.A. | −0.70 vs. SCE | N.A. | 0.097c | 6.5 (day 1)e 3.8 (day 7)e |

|

| Alloyed Fe | ||||||||

| [61] | Fe | N.A. | N.A. | N.A. | −0.236 vs. SCE | 4.67 | N.A. | N.A. |

| Fe87Mg9Zn4 | N.A. | N.A. | N.A. | −0.305 vs. SCE | 3.97 | N.A. | N.A. | |

| Fe74Mg19Zn7 | N.A. | N.A. | N.A. | −0.773 vs. SCE | 7.87 | N.A. | N.A. | |

| Fe60Mg30Zn10 | N.A. | N.A. | N.A. | −0.832 vs. SCE | 9.72 | N.A. | N.A. | |

| [63] | Fe (reference sample) | N.A. | N.A. | N.A. | −0.594 vs. Ag/AgCl | 3.3 | 0.04 | 1.296 (day 30)d |

| Fe65Mn35 | N.A. | N.A. | N.A. | −0.747 vs. Ag/AgCl | 34.0 | 0.51 | 6.695 (day 30)d | |

| Fe65Mn35Ag1 | N.A. | N.A. | N.A. | −0.764 vs. Ag/AgCl | 57.8 | 0.96 | 19.01 (day 30)d | |

| [47] | Fe (reference sample) | N.A. | N.A. | N.A. | −0.735 vs. SCE | N.A. | 6.2 ⋅ 10−5 | N.A. |

| Polished Fe–Mn | N.A. | N.A. | N.A. | −0.699 vs. SCE | N.A. | 1.21 ⋅ 10−4 | N.A. | |

| Laser-textured Fe–Mn | N.A. | N.A. | N.A. | −0.755 vs. SCE | N.A. | 8.63⋅ 10−4 | N.A. | |

| [64] | Fe–30Mn (reference sample) | N.A. | N.A. | N.A. | −0.725 | 11.62 | 0.127 | 1.08 (day 30)d |

| Fe–30Mn prepared by continuous laser | N.A. | N.A. | N.A. | −0.776 | 10.85 | 0.114 | 1.01 (day 30)d | |

| Fe–30Mn prepared by nanosecond laser | N.A. | N.A. | N.A. | −0.596 | 18.54 | 0.136 | 1.27 (day 30)d | |

| Fe–30Mn prepared by femtosecond laser | N.A. | N.A. | N.A. | −0.903 | 69.22 | 0.179 | 1.51 (day 30)d | |

| [50] | Pure Fe | N.A. | 148 | N.A. | −0.324 vs. SCE | 0.871 | N.A. | 0.44 (Static, day 30)e 0.63 (dynamic, day 30)e |

| Fe–Pd | N.A. | 445 | 754 | −0.471 vs. SCE | 1.550 | N.A. | 0.74 (Static, day 30)e 1.63 (dynamic, day 30)e |

|

| Fe–Pt | N.A. | 503 | 785 | −0.545 vs. SCE | 6.698 | N.A. | 1.21 (Static, day 30)e 1.88 (dynamic, day 30)e |

|

| [48] | As-cast pure iron (reference sample) | N.A. | 140e | N.A. | −0.727 vs. SCE | 3.742 | 0.043 | 0.62 (Static, day 30)e 1.40 (dynamic, day 30)e |

| As-sintered pure ion (reference sample) | N.A. | 250e | N.A. | −0.860 vs. SCE | 6.018 | 0.071 | 0.70(Static, day 30)e 1.59 (dynamic, day 30)e |

|

| Fe–2Ag | N.A. | 210e | N.A. | −0.841vs. SCE | 10.19 | 0.120 | 0.72 (Static, day 30)e 1.74 (dynamic, day 30)e |

|

| Fe–5Ag | N.A. | 380e | N.A. | −0.856 vs. SCE | 12.17 | 0.140 | 0.90 (Static, day 30)e 2.06 (dynamic, day 30)e |

|

| Fe–10 Ag | N.A. | 200e | N.A. | −0.891 vs. SCE | 15.19 | 0.175 | 0.78 (Static, day 30)e 1.87 (dynamic, day 30)e |

|

| Fe–2Au | N.A. | 350e | N.A. | −0.809 vs. SCE | 14.97 | 0.174 | 0.73 (Static, day 30)e 1.73 (dynamic, day 30)e |

|

| Fe–5Au | N.A. | 250e | N.A. | −0.796 vs. SCE | 11.50 | 0.131 | 0.98 (Static, day 30)e 2.31 (dynamic, day 30)e |

|

| Fe–10Au | N.A. | 350e | N.A. | −0.779 vs. SCE | 8.833 | 0.098 | 0.87 (Static, day 30)e 1.72 (dynamic, day 30)e |

|

| [60] | M-Fe | N.A. | N.A. | N.A. | −0.673 vs. SCE | 5.84 | 0.137 | 2.57d |

| E-Fe | N.A. | N.A. | N.A. | −0.701 vs. SCE | 5.93 | 0.139 | 3.48d | |

| Fe–Zn (7.2 wt%) | N.A. | N.A. | N.A. | −0.798 vs. SCE | 9.85 | 0.231 | 5.31d | |

| Fe–Zn (4.6 wt%) | N.A. | N.A. | N.A. | −0.818 vs. SCE | 13.76 | 0.323 | 5.77d | |

| Fe–Zn (2.1 wt%) | N.A. | N.A. | N.A. | −0.761 vs. SCE | 10.15 | 0.238 | 4.56d | |

| Fe–Zn (2.3 wt%) | N.A. | N.A. | N.A. | −0.857 vs. SCE | 7.68 | 0.180 | 13.6d | |

| [19] | solution- heat- treated low carbon steel (reference sample) | 900 | 700 | N.A. | N.A. | N.A. | N.A. | 0.86 (day 1)e 0.58 (day 2)e |

| Fe–10Mn with heat treatments (reference sample) | 1300 | 650 | N.A. | N.A. | N.A. | N.A. | 3.97 (day 1)e 2.50 (day 2)e |

|

| Fe–10Mn–1Pt with heat treatments | 1450 | 850 | N.A. | N.A. | N.A. | N.A. | 6.68 (day 1)e 9.05 (day 2)e |

|

| [66] | Fe | N.A. | N.A. | 320 | −0.97 vs. SCE | 0.58 | 0.007 | N.A. |

| Fe–30Mn | N.A. | N.A. | 94 | −1.11 vs. SCE | 0.60 | 0.007 | N.A. | |

| Fe–30Mn–Ag | N.A. | N.A. | 130 | −1.10 vs. SCE | 0.89 | 0.012 | N.A. | |

| [62] | Fe | N.A. | N.A. | N.A. | −0.533 vs. SCE | 6.21 | 0.078e | 1.84 (day 28)d,e |

| Fe/0.3CNTs | N.A. | N.A. | N.A. | −0.595 vs. SCE | 7.28 | 0.090e | 2.05 (day 28)d,e | |

| Fe/0.6CNTs | N.A. | N.A. | N.A. | −0.628 vs. SCE | 12.83 | 0.160e | 2.27 (day 28)d,e | |

| Fe/0.9CNTs | N.A. | N.A. | N.A. | −0.683 vs. SCE | 17.55 | 0.225e | 3.20 (day 28)d,e | |

| Fe/1.2CNTs | N.A. | N.A. | N.A. | −0.712 vs. SCE | 19.95 | 0.241e | 3.30 (day 28)d,e | |

| Ion implanted Fe | ||||||||

| [68] | Pure Fe (reference sample) | N.A. | N.A. | N.A. | −0.582 vs. SCE | 2.340 | 0.027c | 0.09 (day 3)e 0.49 (day 15)e 0.48 (day 30) |

| Zn-implanted Fe | N.A. | N.A. | N.A. | −0.901 vs. SCE | 8.001 | 0.098c | 0.35 (day 3)e 0.68 (day 15)e 0.60 (day 30) |

|

| [49] | Fe (reference sample) | N.A. | N.A. | N.A. | −0.648 vs. SCE | 2.19 | N.A. | N.A. |

| Zn–Fe-5 | N.A. | N.A. | N.A. | −0.722 vs. SCE | 26.07 | N.A. | N.A. | |

| Zn–Fe-10 | N.A. | N.A. | N.A. | −0.727 vs. SCE | 21.07 | N.A. | N.A. | |

| Zn–Fe-40 | N.A. | N.A. | N.A. | −0.713 vs. SCE | 2.01 | N.A. | N.A. | |

| [45] | Fe (reference sample) | 180 (week 0)e 148 (week 12)e 122 (week 40)e |

N.A. | N.A. | −0.728 vs. SCE | 4.920 | 0.057 | N.A. |

| Nano Ta–Fe | 176 (week 0)e 170 (week 12)e 177 (week 40)e |

N.A. | N.A. | −0.754 vs. SCE | 13.836 | 0.161 | N.A. | |

| Fe with inorganic surface coating | ||||||||

| [21] | Pure Fe (reference sample) | N.A. | N.A. | N.A. | −0.699 vs. SCE | 9.642 | 0.112 | 1.485 (day 42) |

| Fe with Pt disc arrays (Φ20 μm × S5 μm) | N.A. | N.A. | N.A. | −0.763 vs. SCE | 17.698 | 0.206 | 3.456 (day 42) | |

| Fe with Pt disc arrays (Φ4 μm × S4 μm) | N.A. | N.A. | N.A. | −0.886 vs. SCE | 19.754 | 0.223 | 3.824 (day 42) | |

| [20] | Pure Fe (reference sample) | N.A. | N.A. | N.A. | −0.579 vs. SCE | 2.461 | 0.029 | 0.917 (day 30) |

| Fe with 200 × 200 μm2 Au disc | N.A. | N.A. | N.A. | −0.627 vs. SCE | 9.325 | 0.108 | 1.184 (day 30) | |

| Fe with 50 × 50 μm2 Au disc | N.A. | N.A. | N.A. | −0.575 vs. SCE | 12.66 | 0.147 | 1.134 (day 30) | |

| Fe with (fully coated) 0 × 0 μm2 Au disc | N.A. | N.A. | N.A. | −0.665 vs. SCE | 10.71 | 0.124 | 1.417 (day 30) | |

| Fe with organic surface coating | ||||||||

| [69] | Porous Fe (reference sample) | N.A. | 0.22 | 0.28 | −0.71 vs. Ag/AgCl | 2.33 | 0.11 | 7.127 (week 4)d |

| PLGA coated porous Fe | N.A. | 0.65 | 0.71 | −0.73 vs. Ag/AgCl | 5.18 | 0.42 | 16.41 (week 4)d | |

| PLGA infiltrated porous Fe | N.A. | 0.38 | 0.42 | −0.78 vs. Ag/AgCl | 9.84 | 0.72 | 138.7 (week 4)d | |

| [51] | Bare Fe (reference sample) | N.A. | N.A. | N.A. | −0.50 vs. SCE (day 0)e −0.80 vs. SCE (day 5)e −0.79 vs. SCE (day 10)e −0.84 vs. SCE (day 28)e |

8.2 (day 0)e 3.5 (day 5)e 3.0 (day 10)e 2.5 (day 28)e |

N.A. | N.A. |

| PMMA-coated Fe (reference sample) | N.A. | N.A. | N.A. | −0.36 vs. SCE (day 0)e −0.87 vs. SCE (day 5)e −0.96 vs. SCE (day 10)e −0.94 vs. SCE (day 28)e |

2.1 (day 0)e 1.0 (day 5)e 2.0 (day 10)e 2.7 (day 28)e |

N.A. | N.A. | |

| PLA-coated Fe (reference sample) | N.A. | N.A. | N.A. | −0.51 vs. SCE (day 0)e −0.93 vs. SCE (day 5)e −0.94 vs. SCE (day 10)e −0.98 vs. SCE (day 28)e |

8.2 (day 0)e 10.3 (day 5)e 11.0 (day 10)e 14.0 (day 28)e |

N.A. | N.A. | |

TS = tensile strength; YS = yield strength; CS = ultimate compressive strength; Ecorr = corrosion potential; Jcorr = corrosion current density; SCE = saturated calomel electrode.

N.A. = not analyzed.

Data from electrochemical test

Data from immersion test.

Data converted from g m−2 day−1 (= 0.0463 mm year−1).

Data converted from mm year−1 (= 21.6 g m−2 day−1).

Data estimated from figures.

The reason for the accelerated CR on porous structure can be attributed to the increased specific surface area which is in direct contact with the electrolyte. Since the porous material is less dense than the bulk one, for implants of the same size, the one made by porous material presents less mass to be degraded. Moreover, the corrosion rate, characterized by mass loss per unit surface area per duration, is also increased by porous structure which accelerates the degradation process in addition to the two above advantages. The mechanism has been suggested that the microporous structure resulted in intricate paths which were conducive to corrosion [39]. As a confinement effect in crevice corrosion, these paths slow the movement of corrosion species resulting in a local rise of acidity. It is also suggested that the reason could be attributed to the occurrence of an autocatalytic process in the micropores as an anode, and the cathodic reduction reaction occurred on Fe scaffold surface outside the micropores. Thus, to maintain the charge neutrality, the Cl− ions from the electrolyte were attracted inside the micropores, thereby resulting in the rapid dissolution of Fe. For bioresorbable application in cardiovascular implants, for instance the vascular stent, porous Fe shows advantages on dissolution rate regulation and important potential on drug-carrying and eluting. However, the challenges on mechanical properties, such as ductility and fatigue resistance, present in the stent expansion process and the maintenance of structural integrity during the artery healing process where radial support is indispensable. In numerous studies documented in Tables 1 and it has been consistently found that both tensile and compressive stresses are significantly lower in porous Fe compared to its bulk pure form. For porous Fe, the tensile yield stresses fluctuate within the range of 7.2–27.8 MPa. This is markedly below the tensile yield stress exhibited by bulk Fe, which is around 140 MPa. Typically, a decrease in mechanical strength necessitates an increase in implant size to ensure sufficient supportive force. Nevertheless, this poses a challenging dynamic as the dimensions of implants, such as the strut thickness in cardiovascular stents, significantly impact both the healing process and long-term clinical outcomes. Take modern coronary stents as an example, their thickness can be as little as 75 μm, a feature designed to optimize clinical outcomes. However, this necessitates an alloy tensile strength exceeding 400 MPa. The balance between the porous structure of the implant and its mechanical properties becomes an intricate problem in biomedical engineering.

Surface/structural grain refinement can be achieved via mechanical deformation method such as shot peening technique. The technique uses small spherical particles of high hardness striking the material surface at high velocity in order to create dimple-like local plastic deformation sites. The overlapping dimples form a continuous surface layer with high residual stress and high density of dislocations. The original grain structure of the alloy can therefore be refined to a level depending on the time and energy of the peening process. Bagherifard et al. have achieved accelerated corrosion and improved mechanical performance of pure iron through surface grain refinement [41]. They reported that severe shot peening could notably increase the surface roughness and grain refinement. The surface hardness has been largely increased due to the high density of dislocations and compressive residual stresses. It also showed that high concentration of micro cracks was observed on the top layer. The cracks are considered favorable to promote pure iron's degradation. But their influences to the mechanical properties were not evaluated.

The fine-grain Fe thin foil can be formed by electrochemical deposition of pure Fe onto a metallic substrate in ferrous chloride–calcium chloride aqueous solution. Moravej et al. has characterized the corrosion rate, mechanical properties and microstructure of pure Fe foil by electroforming technique [35]. Equiaxial fine grains at 4 μm in size with strong (111) fiber texture was found in the as-electroformed sample (E-Fe). The ultimate tensile stress and tensile yield stress witnessed a remarkable increase, reaching respective values of 432 MPa and 360 MPa. When compared to pure Fe, which has an ultimate tensile stress of 205 MPa and a tensile yield stress of 140 MPa, the E-Fe sample exhibits a significantly enhanced mechanical strength. This improved strength shows great potential for stent design, enabling the creation of thin-strut stents comparable in thickness to modern versions (approximately 75 μm) as previously mentioned. In this state, the corrosion potential was negatively shifted of 110 mV; and corrosion current density was ca. 5-foder higher, with respect to pure Fe. The corrosion rate was increased (0.85 g m−2 day−1) over 5 times due to the high internal stress and electroforming defects when compared to conventional pure Fe samples (0.16 g m−2 day−1, data summarized in Table 1). After being annealed to retain ductility, the corrosion rate was considerably reduced to 0.51 g m−2 day−1 because of the grain growth and the elimination of internal stress and structural defects. The ultimate tensile stress and tensile yield stress were found to decrease to 292 MPa and 270 MPa respectively, which points to a reduction in the alloy's strength as a result of thermal treatments performed at 550 °C. At this particular temperature, the material experiences recovery and likely partial recrystallization. These processes contribute to a decrease in dislocation density, defects, and internal stress. Generally, it's worth noting that, aside from the E-Fe sample, Fe after annealing with lower refinement defects or internal stress can demonstrate enhanced ductility. However, this comes at the cost of reduced corrosion rate and mechanical strength, leading to a delicate equilibrium between strength and ductility.

One should notice that the grain refinement mentioned in these literature [35,41] has shown that grain size reduction with structural defects due to the processes. The defects, including dislocations and surface cracks, and internal stress are key outcomes of the mechanical grain refinement, serves as a potent promoter for augmenting corrosion rates. However, in the recrystallized pure Fe, it has been shown proportional relationship between grain size and corrosion rate due to the removal of refinement induced defects, as reported in Ref. [55]. Therefore, after thermal treatment such as recrystallization, pure Fe with finer grain without refinement defects or internal stress can show reduction of corrosion rate when comparing to larger grains.

Techniques such as Equal-Channel Angular Pressing (ECAP) and High Pressure Torsion (HPT), used for causing severe plastic deformations, can dramatically refine the grain structure and lead to a significant density of structural defects. The intricate details of these techniques are reviewed in the referenced article [56]. It's worth highlighting the research on Fe–Mn–C alloys, which, after ECAP, exhibited the development of an ultrafine-grained structure [57]. This refinement enhanced the alloys' strength without compromising their biocompatibility. The corrosion rate was found to be 2.8–3 times higher compared to pure iron. It should be noted that the alloy in the study demonstrated limited hemocompatibility (hemolysis ∼7%) due to its high Mn content. Severe Plastic Deformation (SPD) treatments have shown promising effects on enhancing mechanical properties and reducing corrosion rates. However, SPD techniques do have certain limitations. Specifically, they encounter challenges when it comes to fabricating certain shapes like thin-walled tubes or ultrafine wires, which are crucial for stent applications.

Additive manufacturing is an emerging fabrication method that holds potential for the processing of biodegradable Fe, making it possible to achieve various surface finishing and complex geometric designs. An in-depth review of the advancements in manufacturing and processing can be found in this recent article [56]. One of the additively manufacturing techniques, to obtain Fe surface with desired defects and grain refinement for degradation, is called cold gas dynamic spraying [58]. It is a high-pressure powder processing technique, utilizing compressed gas to propel metal powder at a large temperature range. The powder impacts the substrate at a high velocity, the particles deform, adhere to the substrate and form a coating. The microstructure can reach grain sizes in the micron to submicron range, resulting in improvement of corrosion rate. It has been shown in the same study that further increase in corrosion rate were obtained after increasing annealing temperature (cf. Table 1, sample treated at 1100 °C, 1200 °C and 1300 °C), based on results of electrochemical tests. Post-annealing, there was an observed increase in the ultimate tensile stress, which elevated to approximately 274–279 MPa. The tensile yield stress fell within the range of 104–139 MPa. These values are similar to those of pure Fe in its annealed state, suggesting a similar load-bearing performance. It was suggested that the acceleration may be attributed to microgalvanic corrosion, due to increased precipitate concentration induced by annealing. The intermetallic phase has been observed and they could act as a cathode in an anodic Fe-based matrix. It is worth noting that the corrosion rate for as-sprayed Fe was higher than annealed ones (Table 1, immersion test results), which should be related to increased porosity and poor interparticle bonding. This resulted in severe corrosion around particle boundaries, probably reducing radial strength and stiffness of stent and leading to premature failure of vessel remodeling.

3.2. Alloying and ion implantation to accelerate Fe corrosion

Alloying is the most common method to tailor metal physico-chemical properties. It can be a solid solution of metal elements, in which components are compatible and form a unique phase (single crystal structure), as defined by IUPAC (International Union of Pure and Applied Chemistry). It could also be a mixture of metallic phases, namely, two or more solutions forming a microstructure of different crystals within the metal. For Fe-X alloys, by alloying with X = Cr, Ni, Mo, Cu, Ti, V, and Si, the corrosion resistance of inox can be improved [36]. Various techniques have been reported for Fe-X alloys manufacturing. Research laboratories typically employ methods such as vacuum induction melting, arc-melting, and powder sintering to fabricate small quantities of alloys for property testing [56]. Desired alloy compositions are achieved by repeated remelting of a carefully weighted mixture of pure elements or through the use of master alloys. To improve the quality of the final alloys, a combination of different melting techniques can be applied. Emerging additive manufacturing techniques, such as laser or electron beam methods, can also be employed to create alloys (not using pre-alloyed powders). This is achieved by using a mixture of pure element powders to attain the desired composition or a gradient thereof. However, techniques that utilize powders can often contain higher amounts of impurities, such as oxygen, carbon, or nitrogen. This is due to the large specific surface of the powder, and the inherent challenge of preventing contamination. Despite these points, powder-based techniques permit structural porosity and geometric complexity, aspects that conventional melting and casting methods can struggle with. The choice of the appropriate fabrication technique is closely tied to the research purpose. For studies investigating the relationship between chemical composition and properties, non-powder techniques are preferred to minimize influences from impurities, composition inhomogeneity, and structural defects. Conversely, research with a higher tolerance for impurities can fully leverage the flexibility offered by powder-based techniques for factors beyond mere chemical composition.

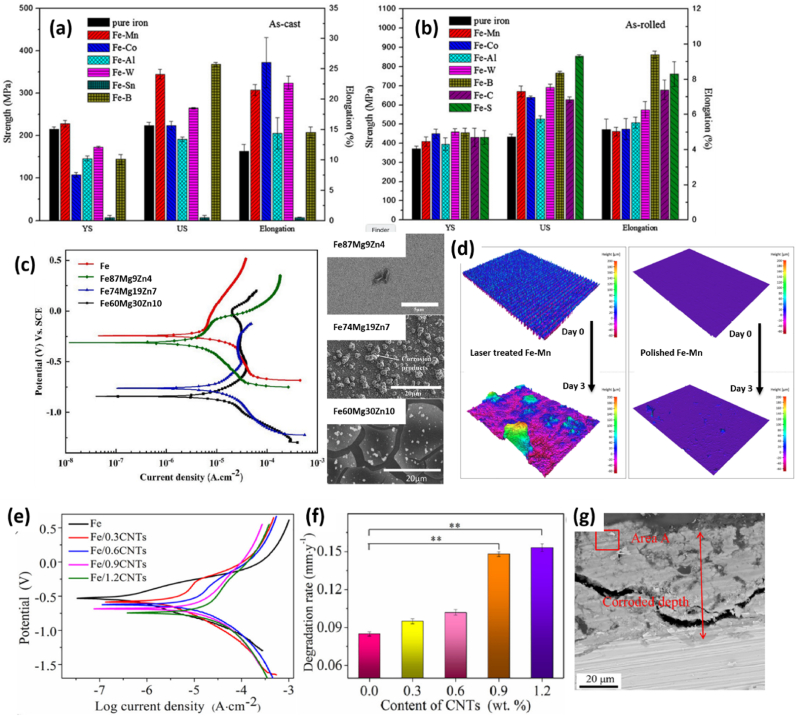

As-rolled and as-cast Fe-X (X = Mn, Co, Al, W, Sn, B, C and S) alloys have been studied in Zheng's group [36]. Their results showed that, except Sn, all the other alloying elements could result in the strain hardening effect, i.e. the stress increase from yield to ultimate strength of iron (Fig. 4a and b). Actually, if these two values are very close (for example the pure iron, cf. Fig. 4a and b), the fracture could easily take place during expansion of the stent [59] due to premature necking effect, i.e. the strong strain localization led by lack of strain-hardening. Therefore, the increased difference between yield and ultimate strength in Fe-X alloying favors future application as coronary stents mechanical properties. The elongation values for Fe-X alloys (except Fe–Sn) are higher or comparable to pure iron. It indicates that these alloys can exhibit enough ductility to allow plastic deformation of the stent, which is required to permanently expand the stent to a larger diameter in order to re-open the narrowed artery and importantly to bear the radial force exerted from the expanded artery. These results provide insights on mechanical properties of Fe-based alloys, facilitating the selection of proper materials for stent. The corrosion rate of Fe-X (X = Mn, Co, Al, W, B, C and S) has been investigated by electrochemical, static and dynamic immersion tests. The CR values, derived from electrochemical tests for Fe-X (X = Co, Al, W, B C and S), and those from static immersion tests for Fe-X (X = Co, W, C, S), are increased (but in the same magnitude) with comparison of pure iron. However, the results from dynamic immersion tests show a reduced corrosion rate for Fe-X (X = Mn, Co, Al, W, B, S), and only as-rolled Fe–C exhibits increased CR value. Other researchers reported also increased corrosion on Fe-X binary alloys, such as Fe-Zn [60], Fe–W, Fe-Carbon nanotubes (CNTs) [38] and porous Fe–W layer on Fe skeleton [44]. Therefore, alloying is a promising strategy to accelerate the corrosion Fe, but more efforts should be devoted to increase corrosion rate to a higher magnitude.

Fig. 4.

The yield (YS), ultimate (US) strength and elongation values of (a) as-cast and (b) as-rolled Fe and Fe-X (X = Mn, Co, Al, W, Sn, B, C and S) alloys. Adapted from Ref. [36], copyright 2011, Elsevier. (c) The potentio-dynamic polarization curves and SEM images after static immersion tests of 24 h for Fe, Fe87Mg9Zn4, Fe74Mg19Zn7 and Fe60Mg30Zn10 alloys. Adapted from Ref. [61] copyright 2022, Elsevier. (d) 3D height image representing the surface topography of laser-textured and polished Fe–Mn sample before and after 3 days of immersion. Adapted from Ref. [47] copyright 2018, Elsevier. (e) Polarization curve for Fe and Fe/CNTs alloys (0.3–0.9 wt% CNTs contents). (f) Corrosion rate from 28 days' immersion tests for Fe/CNTs samples and (g) SEM image for Fe/1.2CNTs sample after immersion test. Adapted from Ref. [62], copyright 2019, Elsevier.

The possible approaches to achieve faster corrosion of Fe-X alloy could be: (i) increase of alloying content. For example, Fe alloying with 20–35 wt% of Mn (Fe80Mn20 and Fe65Mn33 alloy) could be 2-times faster than pure Fe, induced by formation of numerous pits (by galvanic corrosion) on the entire surface [18]. Besides, Fe65Mn35 alloy exhibits also improved corrosion rate (5-fold higher, Table 1) compared with Fe [63]. Interestingly, the addition of Ag (1 wt%) in the alloy could boost corrosion rate, achieving 15-times more rapid than Fe. Another example is increasing alloyed Mg and Zn contents [61]. As listed in Table 1, the corrosion potential and current density of Fe60Mg30Zn10 alloy is respectively lower and higher than reference Fe, Fe87Mg9Zn4 and Fe74Mg19Zn7 due to a uniform degradation behavior. As shown in Fig. 4c, more corrosion products and surface cracks can be observed on Fe60Mg30Zn10 after immersion tests. (ii) Modification of surface morphology. As reported by Donic et al., the corrosion can be significantly accelerated (over 10-folds, Table 1) on a laser-textured Fe–Mn surface with respect to Fe (cf. Fig. 4d) due to increased surface area and formation of Mn-containing oxides on the surface (e.g. Fe2O3 and FeO) [47]. It is worth to note that the surface Fe oxides layer has been reported for favoring Fe degradation [42]. Sun et al. have also observed increased corrosion rate on pulsed-laser modified Fe–Mn surfaces [64] (Table 1). (iii) Alloying with noble metals, such as Pt, Pd, Au, Ag, to establish micro-galvanic corrosion [48,50]. These materials usually have smaller grain size with respect to pure Fe, showing a large number of corrosion pits with uniform distribution on the surface after immersion tests. Compared to pure Fe, the corrosion rate enhancement can be achieved 1.4–3.5 folds (Table 1). As shown in Table 1, the ultimate tensile stress was 445 MPa and 503 MPa, respectively for Fe–Pd and Fe–Pt alloys. Compared with Fe (148 MPa), the mechanical strengths are improved. The compressive yield stress of Fe–Pd and Fe–Pt was 745 MPa and 785 MPa, indicating a strength level higher than the currently used high-strength alloy (CoCr L605) in thin-strut coronary stents. For Fe–Ag and Fe–Au alloys (cf. Table 1), the tensile yield stress was in the range of 200–350 MPa, comparable to as-sintered Fe (250 MPa) and higher than as-cast Fe, showing less strengthening effect from Ag or Au additions than expected. (iv) Alloying with an element more susceptible to corrosion, such as Mn, Zn, etc., can reduce the potential of Fe alloys and thus increase corrosion rate. Among these elements, Zn has attracted large interests due to its biocompatibility [60]. In addition, when the content of Zn in Fe is higher than the equilibrium concentration, it might form supersaturated solid solution, increasing Gibbs free energy and thus corrosion sensibility of Fe alloys [60]. As reported in literature [60], the corrosion rate of Fe–Zn alloys (Zn content of 2.1–7.2 wt%) could be 1.3–2.3 higher than reference Fe (Table 1). (v) Multi-component alloys to create intermetallic corrosion. For example, the addition of Pd or Ag in Fe–Mn alloys to generate multiple galvanic reactions between Fe–Mn phase and secondary phase (Pd, Ag) [19,65,66]. As listed in Table 1, the degradation of ternary Fe–10Mn–1Pd can be 3.6-times faster than binary Fe–10Mn, and 15.6-times than reference Fe. Similarly, the corrosion of Fe–30Mn–Ag is accelerated 1.7-fold with comparison of Fe–30Mn and Fe. From Table 1, the ultimate tensile stress and tensile yield stress of Fe–10Mn–1Pd were increased to 1450 MPa and 650 MPa, higher than Fe–10Mn and reference carbon steel, demonstrating very promising strength properties for designs minimizing alloy volume in load-bearing bioresorbable implants. (vi) Alloying with nanostructured carbon, such as carbon nanotubes (CNTs). According to literature [62], the merits of CNTs can be concluded as their higher standard potential than Fe with excellent conductivity and large surface area, which can generate multiple and efficient Fe galvanic corrosion in nanoscale. In this work, the corrosion potential of Fe/CNTs, derived from polarization curves (Fig. 4e) was negatively shifted by −62 mV, −95 mV, −150 mV and −179 mV with the increase of CNTs content (0.3–0.9 wt%), compared with Fe (Table 1). The corrosion current is also increased after alloying with CNTs (Table 1). After 28 days' immersion test, as shown in Fig. 4f and Table 1, the CR value is gradually increased in function of CNTs content. The SEM image (Fig. 4g) of Fe/1.2CNTs (1.2 wt% of CNTs) sample exhibited thick corrosion layers (confirmed by EDX analysis in area A in Fig. 4g) with corrosion holes and cracks due to localized corrosion.

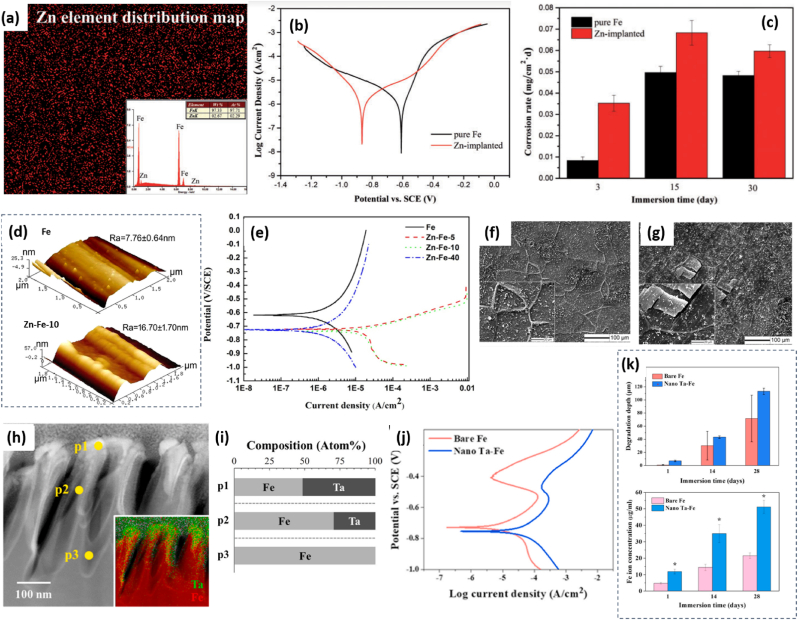

Ion implantation. Another alternative approach to enhance Fe corrosion rate is surface alloying by ion implantation. Such a technique aims to modify surface physical, chemical, or electrical properties of materials. Briefly, the ions are electrostatically accelerated to a high energy and then impinge onto a target substrate. The average penetration of ions in depth, called ions range, usually varies from 10 nm to 1 μm [67]. This technique, widely used in semiconductor device manufactory, has attracted interests for BRS fabrication. The idea is to modify the Fe surface by metals with lower corrosion potential, generating a galvanic layer on the surface. Recently, Zn and Ta have been reported as ion implantation sources to improve the corrosion rate of Fe [45,49,68]. Huang et al. have homogeneously implanted Zn (2.67 wt%; 2.29 at.%) onto Fe (Fig. 5a) with ions range of 60 nm based on SEM-EDX and Auger electron spectroscopy [68]. The highest Zn content of 11 at.% appeared at 30 nm in depth. The ZnO presented on the surface (< 7 nm) whereas Fe–Zn solid solution was claimed beneath. As derived from polarization curves (Fig. 5b), the corrosion potential of Zn-implanted Fe was negatively shifted to −0.901 V, with comparison of pure Fe at −0.582 V (see Table 1). The corrosion current was 3.4-fold higher after Zn implantation. The smaller transfer resistance was measured on Zn-implanted Fe, using EIS, indicating the faster corrosion rate with respect to pure Fe. The static immersion tests showed significantly (over 3 times) higher CR value than pure Fe for the first 3 days, but such a difference reduced gradually at day 15 and day 30 (Fig. 5c). Later, Wang et al. reported similar results on Zn-implanted Fe [49]. They found an outmost surface of Fe2O3/ZnO oxides after implantation, and the depth of Zn varying in 40–60 nm depending on ion doses. The surface roughness after treatment was increased, as shown in Fig. 5d. The corrosion potential from potentiodynamic polarization curve (Fig. 5e) was negatively shifted from −0.648 V to around −0.7 V after implantation (Table 1), independent to ion doses (sample Zn–Fe-5, Zn–Fe-10, Zn–Fe-40, corresponding to Zn dose = 5 × 1016 ions/cm2, 10 × 1016 ions/cm2 and 40 × 1016 ions/cm2). However, the most intense corrosion current density could be achieved on Zn–Fe-5 (ca. 26.07 μA cm−2) and Zn–Fe-10 (ca. 21.07 μA cm−2) samples, which is 10-fold increased than Fe (ca. 2.19 μA cm−2) and Zn–Fe-40 (ca. 2.01 μA cm−2) (Table 1). After 9 days’ static immersion tests, the surface morphology was investigated by SEM. As shown in Fig. 5f, grain boundaries and some white precipitates presented on the pure Fe surface, whereas thick corrosion layers with large cracks were detected on Zn–Fe-10 sample (Fig. 5g). This indicates faster corrosion rate on Zn-implanted samples. Another example is Ta ions implanted Fe [45]. The implantation of Ta ions generates surface nano-galvanic couples and thus accelerate Fe degradation. As shown in SEM and EDX map Fig. 5h, the Ta was mostly dispersed at the top region of nanostructured Fe (nanoridges). The ion contents in 3 points in depth (P1, P2 and P3) was listed in Fig. 5i, confirming ca. 50 at.% of Ta distribution on the outmost surface, ca. 30 at.% at ca. 120 nm in depth and 0 at.% at ca. 300 nm under the surface. As summarized in Table 1, the corrosion potential derived from Fig. 5j shifted toward a more negative direction by −26 mV after implantation, and the corrosion current density was increased from 4.92 μA cm−2 for Fe to 13.84 μA cm−2 for Ta–Fe. The electrochemical corrosion rate was more than 2-times higher on Ta–Fe with respect to Fe sample. After a static immersion test, as depicted in Fig. 5k, the released Fe ion concentration was 51.0 μg/mL, which was 228% higher than that of bare Fe (22.4 μg/mL) on Day 28. It is worthy to note that the release of Ta ions was not detected during this period. By analysis of the samples after immersion (using SEM), the corrosion depth on Ta–Fe is much higher than on Fe along the entire immersion test (Fig. 5k). One should note that the variation of this value is smaller in Ta–Fe, mainly because of its uniform degradation behavior rather than Fe. The tensile strength (cf. Table 1) could keep constant on Ta–Fe after 12 and 40 weeks of immersion in simulated body fluid, showing more stable mechanism properties than the reference Fe where this value was decreased by about 32%. The value of ultimate tensile stress of Ta–Fe can be kept in the range of 170–177 MPa during 40 weeks, while the value of reference Fe dropped from 180 MPa in week 0–122 MPa in week 40 (Table 1). This fact showed stable mechanical stability of Ta–Fe sample.

Fig. 5.

(A) The EDX mapping of Zn ion implanted Fe; (inset) the mass and atomic contents of Fe and Zn in the mapping area. (b) Polarization curves and (c) static immersion tests for pure and Zn-implanted Fe. Adapted from Ref. [68] copyright (2016), Oxford University Press. (d) AFM image with surface roughness (Ra) values for pure and Zn-implanted Fe (Zn–Fe-10 sample, ion dose = 10 × 1016 ions/cm2). (b) Polarization curves and SEM images for (f) Fe, (g) Zn–Fe-10 sample after 9 days immersion test. Adapted from Ref. [49] copyright 2017, Elsevier. (h) SEM image and (inset) EDX map for Ta–Fe sample. (i) The atomic composition of Fe and Ta at P1, P2 and P3 points in the SEM image. (j) Polarization curves, (k) analysis of average degradation depth and released Fe ion concentration during static immersion tests for Fe and Ta–Fe sample. Adapted from Ref. [45] copyright 2022, Elsevier.

3.3. Surface coating of inorganic and organic layer

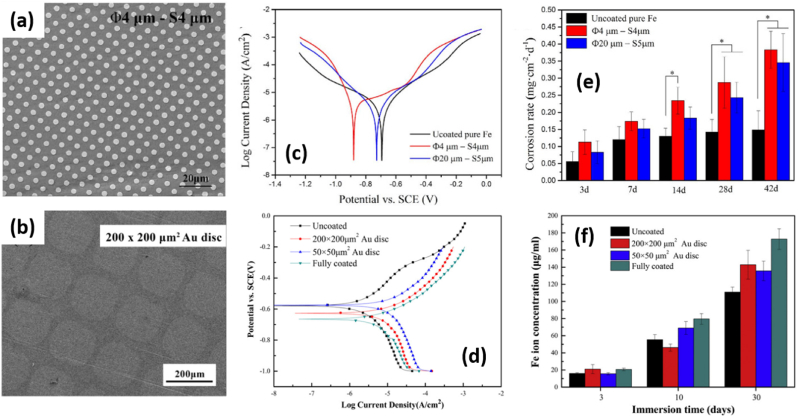

Coating of inorganic layer. The control of surface topography is an efficient approach to increase Fe corrosion. In this case, the surface of Fe is usually patterned by a galvanic layer. For example, Pt or Au disc arrays have been coated on Fe by lithography [20], as shown in Fig. 6a (Pt arrays) and Fig. 6b (Au arrays). In both works, Fe was coated with different sizes of noble metal layers to study the impact of the layer morphology. The Pt circles discs with Φ20 μm × S5 μm (Φ20 μm = diameter of the platinum discs, S5 μm = the space between two nearest platinum discs) and Φ4 μm × S4 μm were prepared [21]. The quasi-circular template with 200 mesh (200 × 200 μm2) and 400 mesh (50 × 50 μm2) were used for Au arrays deposition [20]. From the results derived from polarization curves (Fig. 6c and d), the corrosion potential of both Pt- and Au-coated Fe was negatively shifted, and corrosion current was increased, with respect to the reference Fe sample (see data summarized in Table 1). These facts indicated that the corrosion rate was enhanced. According to static immersion tests, the CR value for Pt-coated Fe was improved ca. 2–3 folds (Fig. 6e, Table 1) within 28 days, one can also observe the disc size affecting corrosion speed: the smaller Pt size (Φ4μm × S4μm) the faster corrosion rate. The Au-coated Fe released ca. 1.3–1.7 times more Fe ions than bare Fe (Fig. 6f). It seems that the Au disc size has negligible effect on the CR values, since more released Fe ions were detected on 50 × 50 μm2 sample than 200 × 200 μm2 one at day 10, but the tendency was inverse at day 30. The Au fully coated Fe showed the fastest degradation at day 10 and day 30 in immersion tests. The corrosion behavior of Au-coated Fe is summarized in Table 1. It is worth noting that both Pt and Au coating was observed gradually peeling off during immersion test, and no more Pt or Au can be detected at the end of immersion test. This could be explained as gradually expansion of Fe corrosion beneath galvanic layer, finally leading to the falling-off of coating.

Fig. 6.

SEM images of (a) Pt- (discs diameter of 4 μm; the space of 4 μm between two nearest platinum discs) and (b) Au-coated (prepared by a quasi-circular template with 200 × 200 μm2 size) Fe. Dynamic-potentio polarization curves for (c) Pt- and (d) Au-coated Fe. (e) The corrosion rate values from static immersion tests for 42 days for Pt-coated Fe. (f) Released Fe ion concentration during 30 days immersion test for Au-coated Fe. (a, c, e) Adapted from Ref. [21] copyright 2016, Springer Nature. (b, d, f) Adapted from Ref. [20] copyright 2015, Elsevier.

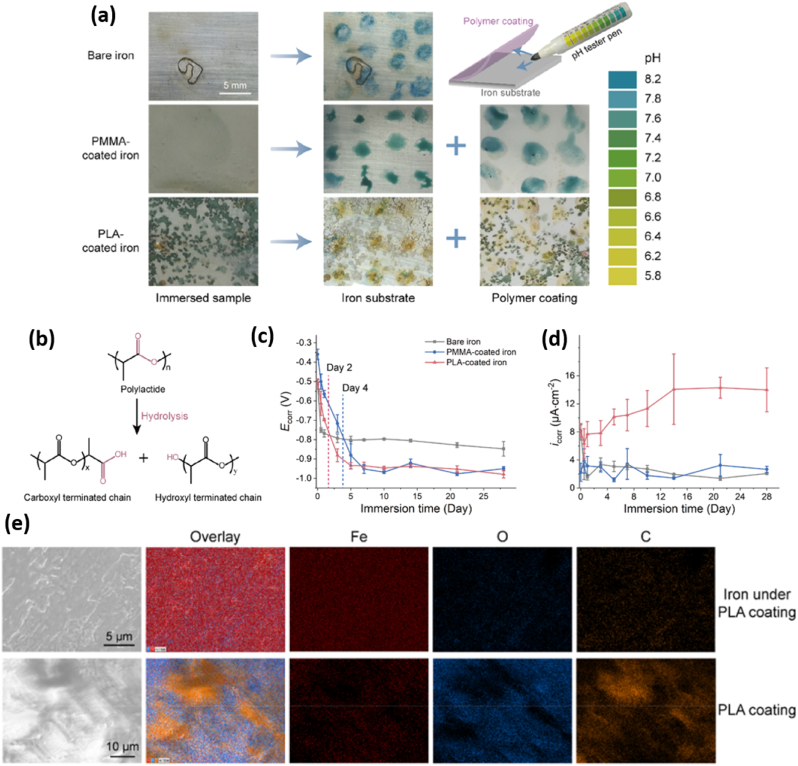

Coating of organic layer. In 2015, poly (lactic-co-glycolic acid) (PLGA) infiltrated and coated porous iron was reported for increased corrosion rate over bare porous samples (Table 1), which might be applied as temporary medical implants [69]. The mechanical properties (see ultimate tensile and yield stress in Table 1) of PLGA treated porous Fe was only slightly increased, compared with no-treated porous Fe. This demonstrates that the surface modification had limited impact on mechanical properties of Fe matrix. Later in 2018, surface deposition of polylactide (PLA) was also published for acceleration of Fe corrosion [22]. The mechanism could be attributed to (i) local pH decreasing and (ii) inhibition of passivation layer formation [51,69] induced by PLA surface layer. Compared with bare Fe and poly (methyl methacrylate) (PMMA) coated surfaces, the local pH of PLA-coated Fe was decreased (Fig. 7a), which should be related to degradation (hydrolysis) of PLA (Fig. 7b). From day-by-day polarization results (Fig. 7c), the corrosion potential and current of PLA-coated Fe were respectively higher and lower than bare one at day 0 (see Ecorr and Jcorr values in Table 1). After 5 day's immersion in Hank's solution, the PLA-coated sample showed lower corrosion potential with respect to the uncoated one, indicating PLA-functionalized sample should be easier corroded. Besides, the corrosion current became higher, demonstrating higher CR value than bare Fe (Fig. 7d). Compared with nondegradable PMMA-coated sample, the Fe corrosion was obviously faster on PLA-coated Fe since day 0 (namely, lower Ecorr and higher Jcorr values for PLA-coated Fe, Table 1). After immersion tests, no Ca and P elements were detected on the surface of iron and the interior surface of the PLA coating (Fig. 7e). In addition, no peeling of PLA was reported after immersion test of 28 days, indicating robust coating on Fe surface.

Fig. 7.

(A) Local pH on the surface of bare iron, in the interfaces of PMMA- and PLA-coated iron after 24 h immersion in Hank's solution. (b) Illustration of hydrolysis of PLA. Corrosion (c) potential and (d) current, derived from polarization curves, for bare, PMMA- and PLA-coated Fe after immersion in Hank's solution. (e) SEM and EDX mapping for PLA-coated iron after immersion (72 h in Hank's solution). Adapted from Ref. [51], copyright 2019, American Chemical Society.

3.4. Overview of mechanical properties of Fe-based materials with accelerated corrosion

As listed in Table 1, mechanical properties of bulk Fe alloys and structure/surface engineered pure Fe, e.g. porous Fe, fine-grain Fe, ion-implanted Fe and coated Fe, exhibit considerable differences under tensile tests as well as compressive tests. The tensile yield stress of pure Fe is about 150 MPa at room temperature, but the alloyed Fe can reach up to 850 MPa under the same test condition. The fact demonstrates that the Fe-based materials are highly tunable on the mechanical strength because Fe system can benefit from various strengthening effects such as solution strengthening, precipitation strengthening, thermomechanical strengthening and microstructural engineering. The large range of mechanical strength provides possibilities for Fe-based materials to answer to different mechanical requirements for different implant applications. For load bearing implants such as cardiovascular stent, high tensile strength and excellent fatigue resistance are required to withstand the radial pressure from the artery. The high strength Fe can reduce the size of the implant to provide enough force, which in turn reduces the requirement of dissolution rate because of the reduction of the Fe volume to be dissolved. Therefore, the strength of different Fe materials via different processing technologies summarized in Table 1 may affect correspondingly the geometrical design of the implant, thus influencing the optimal dissolution rate for the total absorption of the implant in a given duration.

4. Biosafety of Fe-based stent

The development of new metallic resorbable stents requires an exhaustive study of their biocompatibility throughout the entire degradation process. To consider their clinical application, Fe-based devices should not generate toxic degradation products (neither soluble nor insoluble), should not interfere with blood homeostasis and should not cause chronic inflammatory responses.

Since Fe is present in tissues and blood under physiological conditions (45–55 mg Fe/kg bw), it was postulated that corrosion by-products of Fe stents will not cause systemic toxicity and that will instead be metabolized and safely excreted by natural mechanisms. In the physiological environment under aerobic conditions, the redox reaction of Fe2+ to Fe3+ exhibits a favorable redox potential (+772 mV) [70].

This oxidation enables many fundamental biochemical cellular reactions and transforms iron into an essential element. The produced extracellular Fe3+ is practically insoluble and is carried by the specific iron chelators, as transferrin (Tf) towards the cell membrane. Then, through the cellular uptake mediated by the TfR1 receptor, it is transported into the endosomes. However, the total iron-binding capacity of plasma transfer proteins is limited and the presence of excess iron poses a threat to cells and tissues; its toxicity is largely based on its ability to catalyze the generation of radicals. Moreover, the redox reactions of iron constitute a potential danger since they are at the origin of the production of reactive oxygen species (ROS) which, in high concentrations, lead to a cellular oxidative stress. Therefore, the concentration of iron must be tightly controlled and the degradation process from the Fe based-stents should not release excessive amounts of iron in a short period.

4.1. Biocompatibility studies

-

1)

Cellular studies in contact with iron under in vitro static and dynamic conditions

In vitro studies are not representative of in vivo conditions of tissues in contact with stent material; however, when suitable models are used, they provide a first step to assess biocompatibility.

Methodological approaches based on the addition of Fe3+ solutions into the cell culture media were used to simulate the Fe corrosion products and to study their effects on the cell viability. By this method it was shown a significant decrease in the mitochondrial activity (> 2 mM of Fe3+) and lipid peroxidation correlated to the Fe3+concentration on CHO–K1 cells [71]. The absence of toxicity of iron solutions incubated 1–3 days on endothelial cells was reported for the concentrations < 50 mg/mL [72].

However, the Fe degradation compounds released from medical devices are generally studied following ISO 10993-5 by direct or indirect contact tests [73]. The ISO 10993-5 standard references the conditions for obtaining the released products (cm2 or mg of samples/mL extractant), the cytotoxicity tests and the choice of cell lines [73]. Preconized cell lines are often from rodents, such as BALB/3T3 (CCL-163™) fibroblasts, J774A.1 macrophages (TIB-67™) or CHO–K1 (CCL-61™) epithelial cell line, that are not representative for the study of stent surrounding tissues but recommended for toxicology evaluations. Few studies have assessed human models relevant to vascular stent applications, such as human endothelial cells HUV-EC-C (CRL-1730), or primary cells as smooth muscle cells (SMC) and adipose tissue-derived stem cells (ADSCs).

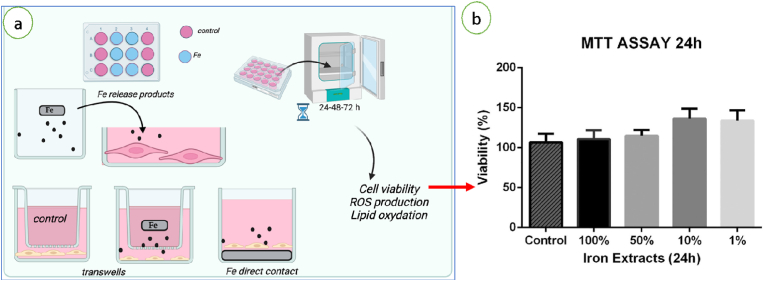

Assessments of the cytotoxicity of compounds released during Fe corrosion are often performed by placing Fe samples in physiological buffer or culture medium and, at the endpoints, the released products are added to the cells (Fig. 8a). Another methodological approach evaluates compounds released from Fe samples placed in culture inserts. These supports have a permeable polymeric membrane (polyethylene terephthalate, polyvinylidene difluoride or nitrocellulose among others) with pores of variable size allowing the diffusion of soluble compounds (Fig. 8a). The cell viability is measured after incubation times (in general comprise between 24 and 72 h) by the evaluation of the metabolic enzymatic activity using test as MTT ((3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide), Alamar blue etc. (Fig. 8) [36,72,74]. Others parameters as morphology, reactive oxygen species (ROS) production [29], gene expression [75] and cell proliferation are also evaluated. There is a consensus regarding the absence of toxicity of the soluble iron degradation products on several types of cells as fibroblasts [48,[75], [76], [77]], CHO–K1 [71], human endothelial cells [38,72], smooth muscle cells [35,36] and ADSCs (Fig. 8b) [74]. These studies showed that the cellular metabolic activity was not affected by the presence of soluble degradation products after 24–72 h. However, a reduction in cell proliferation was reported on smooth muscle cells, which was considered as a positive point, since these cells are the main responsible for in-stent restenosis [35,78].

Fig. 8.

Schematic representation of in vitro tests for the biocompatibility evaluation of Fe samples (a) MTT test of ADSCs for indirect contact evaluation of iron released products (b). Adapted from Ref. [74] for (b), copyright 2021, Elsevier.

Direct contact tests between iron surfaces and cells evaluate the impact of solid residues produced during corrosion on the fate of cells and tissues. A toxic effect of solid particles produced during iron corrosion was reported on L929 [79], CHO–K1 [71] and BALBc 3T3 fibroblasts [76]. It was recently shown that direct contact of endothelial cells (HUVECs, and Human Aortic) and SMCs (Human Coronary Artery and Human Aortic) with the Fe° as microparticles (50–800 mg/mL) alters cell viability after 24 h of culture for the high range of concentrations. However, contact with soluble release products from the same samples did not lead to changes in cell viability [29].

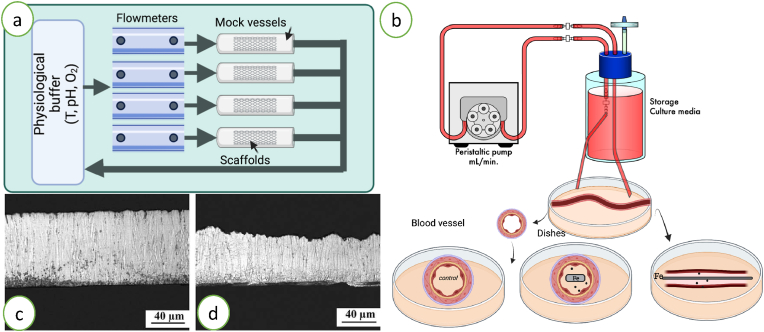

Almost all of the in vitro evaluations are carried out in culture dishes under static conditions, in these conditions the released Fe ions and ROS can accumulate to a very high concentration. Thus, the local concentration of Fe ions and ROS on the surface of iron samples may be even higher than it will be in vivo when the stents are subjected to blood flow. To better mimic in vivo conditions, a dynamic environment such as a bioreactor with a dynamic medium circulation system might be more effective in assessing cytotoxicity and corrosion parameters. Thereby, ex vivo studies (Fig. 9) under simulated blood flow conditions are developed to consider the influence of shear stress and flow conditions on stents surfaces or to assess the material degradation in dynamic conditions [80]. These systems use mock vessels (Fig. 9a) or whole arteries (Fig. 9b) in order to take into account the complexity of the tridimensional structure of tissues. Dynamic perfusion systems consist in a flask containing the perfusion medium connected to a peristaltic pump to control the flow rate and temperature. The arteries (whole or cut into rings) are placed in culture dishes connected to the system and their viability and morphology are assessed in contact of iron samples at different endpoints. By this method it has been shown modifications on iron surfaces due to physiological flow leading to a higher degradation rate under dynamic conditions [35] (Fig. 9c and d).

-

2)

Influence of physiological parameters on the Fe corrosion

Fig. 9.

Illustration of dynamic systems for the evaluation of iron samples. Mock vessels (a) or arteries (b) under simulated physiological flow. Adapted from Ref. [80]. Degradation under static (c) or dynamic (d) conditions of iron surfaces. Adapted from Ref. [35], 2010, Elsevier.

Some parameters of the Fe corrosion evaluation in physiological media, merit to be analyzed. The pH and the ionic concentrations of the simulating physiological fluids are calculated to be closed as possible to those of blood plasma. However, these media often do not contain proteins which are critical components of plasma. It was shown that the use of culture medium containing 10% fetal bovine serum as an extraction vehicle reduced the formation of corrosion products from a nitrided iron stent [79]. Proteins can react with both soluble and insoluble components released during Fe corrosion, but also proteins interact with the surface of the stent and create a layer of adsorbed proteins, as is the case with all devices after implantation [81,82]. The adsorption of proteins to the surface leads to changes in the rate of corrosion and influences the composition of the microenvironment close to the implant conditioning the response of the surrounding tissues. The adsorbed protein layer forms a barrier between the metal surface and the environment leading to inhibition of iron degradation. It was reported that after 7 days of immersion in culture medium without serum, iron samples showed zones completely corroded on the surface and solid deposits in zones close to the sample. The addition of fetal calf serum significantly decreased this corrosion rate [71,76]. The preconditioning of samples in culture medium (2 h–28 days) before contact with cells was carried out to simulate the different stages of iron degradation in the presence of serum proteins and showed a correlation between the preconditioning time and the increase in the thickness of the iron layer degradation [83]. The authors showed that this degradation layer, whose composition was complex, led to a decrease in the release of ions and showed a positive effect on cell survival at longer culture times, 7 or 28 days [83]. Furthermore, the O2 and CO2 concentrations in the culture system were shown to influence the rate of iron corrosion. Some researchers [17] pointed out a direct correlation between the iron corrosion rate and the local O2 concentration. Regarding the CO2 content, the tests carried out in culture incubators showed lower % than in the tissues, and therefore does not reflect the in vivo conditions. It has been shown that the high CO2 content leads to an important diminution in the rate of Fe degradation [84].

-

3)

Reactive oxygen species produced during Fe corrosion in physiological environment induce cellular changes

Oxidative stress on surrounding tissues is another aspect that must be considered on Fe devices. During iron degradation under aerobic conditions and neutral pH, Fe2+ and H2O2 generated participate to the production of HO• radicals, one of most damaging reactive oxygen species (ROS). ROS refers to the extremely reactive molecules and free radicals derived from molecular oxygen produced during aerobic respiration and cellular metabolism as normal byproduct [85]. Moderate amounts of ROS have beneficial effects on several physiological processes like the reduction of malignant pathogens, wound healing, and tissue repair processes by acting as signaling molecules [86,87]. In contrast, ROS overproduction disrupts the body homeostasis inducing oxidative tissue damage.

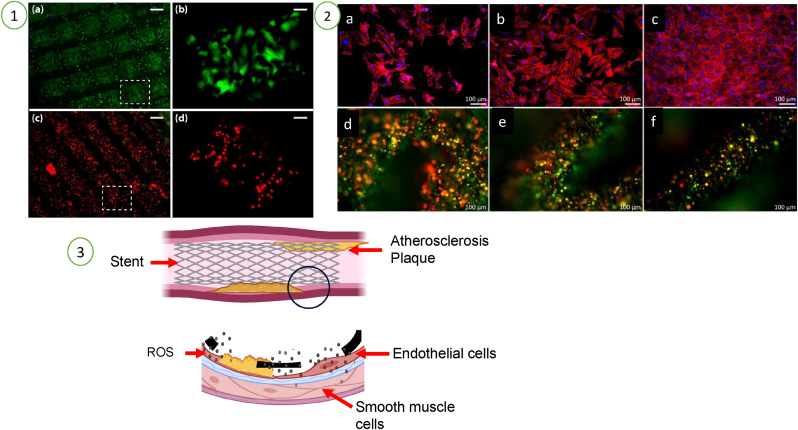

An overload of iron ions due to excessively rapid corrosion will produce a large amount of ROS by the Fenton reaction, and will induce a cascade of oxidation of cell membrane lipids leading to cellular oxidative stress and Ferroptosis [88]. Under in vitro physiological conditions the presence of HO• due to the corrosion of Fe was demonstrated [23]. A deleterious role of HO• on human endothelial cells and SMCs cultured in direct contact with iron powders was confirmed by the authors; they showed that the catalase addition protected cells from the oxidative stress generated by the iron corrosion [29]. An ex vivo model of arterial rings directly exposed to an iron rod in the lumen of the artery was developed by the same group to mimic endothelium-stent contact. With this experimental design, they showed a deleterious impact on the endothelium of arteries caused by the presence of HO• ions released during Fe corrosion, followed by a decrease in the enzymatic activity of eNOS and then an inhibition of the production of NO [29]. The protective role of serum in the environment close to stents was highlighted in an in vitro study using fetal bovine serum added to the HUVECs exposed to iron powder. The authors also evidenced in vitro the blocking of produced ROS during the Fe corrosion by the serum components [89]. To assess the behavior of cells that are in vivo involved in the resorption of degradation debris, macrophages were cultured in contact with rings of pure Fe [90]. As the metal degraded, a deposit of insoluble degradation products accumulated near the Fe° ring and in the same area the macrophages showed alterations in morphology and decreased viability, motility and mobility [90].