Abstract

To ensure the stability of biologicals over their entire shelf-life, non-ionic surface-active compounds (surfactants) are added to protect biologics from denaturation and particle formation. In this context, polysorbate 20 and 80 are the most used detergents. Despite their benefits of low toxicity and high biocompatibility, specific factors are influencing the intrinsic stability of polysorbates, leading to degradation, loss in efficacy, or even particle formation. Polysorbate degradation can be categorized into chemical or enzymatic hydrolysis and oxidation. Under pharmaceutical relevant conditions, hydrolysis is commonly originated from host cell proteins, whereas oxidative degradation may be caused by multiple factors such as light, presence of residual metal traces, peroxides, or temperature, which can be introduced upon manufacturing or could be already present in the raw materials. In this review, we provide an overview of the current knowledge on polysorbates with a focus on oxidative degradation. Subsequently, degradation products and key characteristics of oxidative-mediated polysorbate degradation in respect of different types and grades are summarized, followed by an extensive comparison between polysorbate 20 and 80. A better understanding of the radical-induced oxidative PS degradation pathway could support specific mitigation strategies. Finally, buffer conditions, various stressors, as well as appropriate mitigation strategies, reagents, and alternative stabilizers are discussed. Prior manufacturing, careful consideration and a meticulous risk-benefit analysis are highly recommended in terms of polysorbate qualities, buffers, storage conditions, as well as mitigation strategies.

Keywords: Biotherapeutic formulations, Biologicals, Surfactants, Polysorbates, Tweens®, Oxidative degradation, Polysorbate stability, Oxidation

Graphical abstract

1. Polysorbates in biotherapeutic formulations

Recombinant proteins and antibodies are an emerging class of therapeutics in biopharmaceutical industry. In 2019, seven of the ten highest-selling drugs were biologics (five antibodies and two fusion proteins) (https://pharmaintelligence.informa.com, 2022; Strickley and Lambert, 2021), and in 2021 six of ten were biologics (https://www.drugdiscoverytrends.com/50-of-2021s-best-selling-pharmaceuticals/, 2022). Those biopharmaceuticals are delivered in a wide range of concentrations up to 200 mg·mL-1 (Garidel et al., 2017). Here, tight protein packing (less than a few nanometers) is accompanied by the disadvantages of molecular crowding, protein–protein interactions, and denaturation (Blaffert et al., 2018; Philo, 2009; Mahler et al., 2009). This phenomenon is even enhanced by the protein´s surface activity leading to partial unfolding, followed by e.g. particle formation (Patten and Schellekens, 2003; Van Beers et al., 2012). However, drug products with lower concentrations are also subjected to denaturation. Especially, the contact with different interfaces (e.g., plastic polymers, glass, liquid-air, or stainless steel) upon manufacturing and drug product filling may promote protein degradation (Basu et al., 2013; Britt et al., 2012; Brett Ludwig et al., 2010; Gerhardt et al., 2014). Other stress conditions include shaking, transport, pumping or freeze–thaw processes (Khan et al., 2015; Lougheed et al., 1983). To prevent these undesired effects, protein formulations are stabilized by non-ionic surfactants to ensure quality, safety, and efficacy of the final product (Brovč et al., 2020a; Rayaprolu et al., 2018). Polysorbates (PS) are the most widely used detergents in biopharmaceutical industry due to their low toxicity, high biocompatibility, and excellent stabilizing properties (Khan et al., 2015; Lougheed et al., 1983; Jones et al., 2018; Patapoff and Esue, 2009). They are by far the most used surfactants in biopharmaceutical products (Kishore et al., 2011a; Crommelin et al., 2019; Daugherty and Mrsny, 2006). Generally, two different PS – namely polysorbate 20 (PS20; Tween®20) and polysorbate 80 (PS80; Tween®80) – are used as an essential part of registered drug products for intravenous (i.v.), subcutaneous (s.c.), and intramuscular (i.m.) applications. Both surfactants are characterized by high hydrophilic–lipophilic balance (HLB) values in the range of 15 to 17 and low critical micelle concentration ranges (CMRs) (Knoch et al., 2021), allowing them to adsorb on surfaces at low concentrations. They are commonly used in ranges between 0.01 and 1 mg·mL-1 in drug products (Martos et al., 2017). These concentrations were determined by stress tests defining the lowest effective surfactant concentration preventing protein denaturation (Kishore, 2018). Alternative surfactants like poloxamer 188 (Kolliphor®P188), lecithin, sodium dodecyl sulfate, polyoxyl 35 castor oil (Cremophor®EL or Kolliphor®EL), and alkyl saccharides are also used in parental applications (Martos et al., 2017; Bollenbach et al., 2022; Ruiz et al., 2022).

Three main mechanisms are discussed for the beneficial impact of surfactants on protein stability: (i) surfactants compete with proteins at hydrophobic interfaces and provide protection against interfacial stress and protein aggregation as well as increasing formulation stability and ensuring biotherapeutic activity (Singh et al., 2017; Gerhardt et al., 2015; Mahler et al., 2005). (ii) As second mechanism, direct interactions with hydrophobic patches are reported (Khan et al., 2015; Mahler et al., 2005), however, direct binding of PS20 and PS80 to several mAbs was shown to be minimal to negligible, depending on the investigated mAb drugs (Khan et al., 2015; Singh et al., 2017; Garidel et al., 2009). (iii) The encapsulation in the micelle interior. However, due to the discrepancy in size and number of micelles in comparison to mAbs, this protection mechanism is relatively unlikely and not possible for PS (Garidel et al., 2021). The exact stabilization mechanism of non-ionic surfactants is still under investigation (Dwivedi et al., 2020). Recently PS20 was fractionated and the protein stabilization effect of specific fractions was investigated (Diederichs et al., 2023; Tomlinson et al., 2020).

Despite their benefits, many factors are influencing the intrinsic stability of PS, leading to various degradation reactions (Kerwin, 2008). Generally, two main degradation mechanisms are discussed: (i) chemical or enzymatic hydrolysis, and (ii) oxidation (Kerwin, 2008; Donbrow et al., 1978a). It is essential to elucidate the obstacles of PS degradation to ensure quality, efficacy, and safety of the drug product over its entire shelf-life (Kishore, 2018). However, the inherent complexity of PS as well as the varying impact between biopharmaceuticals on the extent of PS degradation cause major analytical challenges.

This review provides a general overview on PS20 and PS80 followed by a detailed description of the current scientific knowledge of polysorbate oxidation, degradation products, oxidation markers, key characteristics, effect of PS quality/grade on oxidation, formulation conditions, and the different stressors used in the literature. Additionally, mitigation strategies and future perspectives are discussed.

2. Structure and heterogeneity of polysorbate 20 and 80

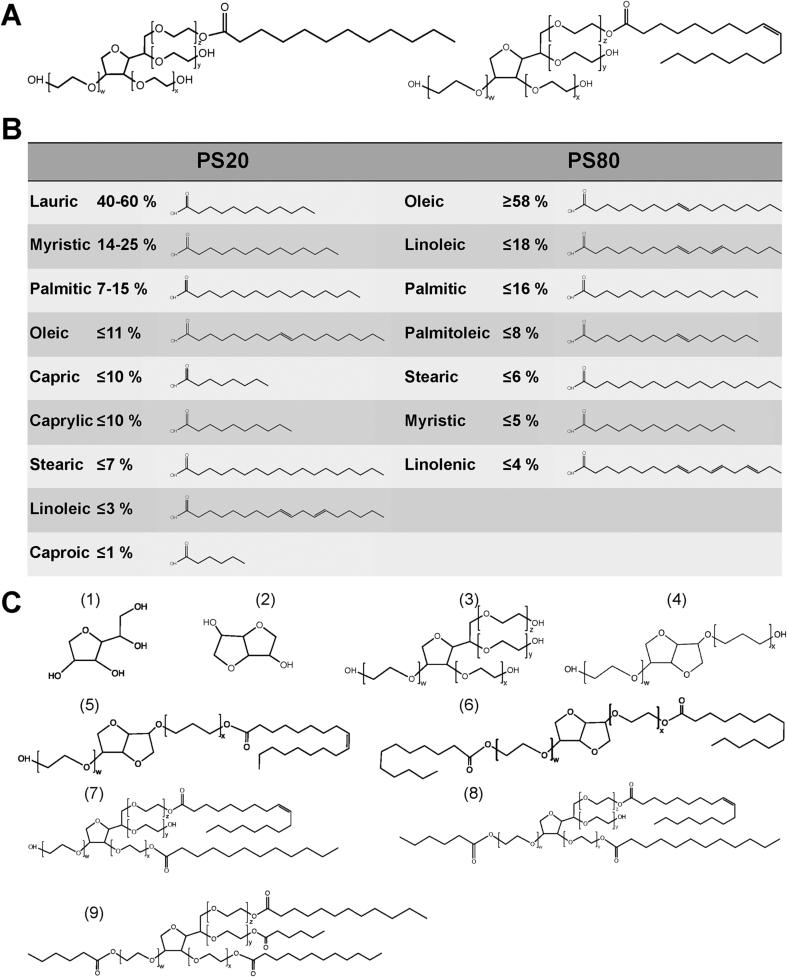

The heterogeneity of polysorbates can be derived from their synthesis and the used raw materials, starting with the dehydration of sorbitol to sorbitans and isosorbides, followed by esterification of fatty acids (FAs) and ethoxylation with ethylene oxide (Brovč et al., 2020b). The exact order of esterification and ethoxylation is not specified by the manufacturers, but usually requires high temperatures and anhydrous basic conditions (Kishore, 2018; Smidrkal et al., 2004). According to the pharmacopoeia, polysorbates are composed of a hydrophilic headgroup (sorbitan, isosorbide) esterified via up to four chains of approximately 20 polyoxyethylene (POE) moieties in total with up to four lipophilic fatty acids. The latter is adding complexity as a fatty acid composition ranging from caproic (C6:0) to linolenic acid (C18:3), depending on the polysorbate species, is esterified to the POE moieties. The actual PS is named after the most abundant FA, which is predominately monolaurate (C12:0) for PS20 (polyoxyethylene(20) sorbitan monolaurate) and mainly monooleate (C18:1) for PS80 (polyoxyethylene (20) sorbitan monooleate) (Kerwin, 2008). The expected structures of PS20 and PS80 are shown in Fig. 1A. Both structures only account for approximately 20 % (w/w) of the total material (Hewitt et al., 2011). The structures of the different fatty acids present in PS20 and PS80 are summarized in Fig. 1B. Acceptable ratios of the different fatty acids as well as other parameters such as impurities and peroxide values are defined by the pharmacopoeias (European pharmacopoeia (Ph. Eur.), United State pharmacopoeia (USP), Japanese pharmacopoeia (JP), British pharmacopoeia (BP), or Chinese pharmacopoeia (ChP)) (Evers et al., 2021). The amounts of peroxides of commercially available polysorbates for parenteral application are far below the limits of the pharmacopoeias. Nevertheless, Doshi and colleagues (2020) provided certificates of analysis for two different PS20 qualities, observing small differences between PS20 and PS80 as well as in different qualities and lots (Doshi et al., 2020a). Additionally, the raw material contains a certain amount of unesterified fatty acids (free fatty acids) and POE sorbitans and it was reported that up to approximately 28 % of PS20 corresponds to unesterified sorbitan-POE, depending on batch, quality, and vendor (Hewitt et al., 2008). Evers and colleagues (2021) presented values of unesterified fatty acids mostly below 5 % of hydrolysis, however, for C16 or C18 higher values (up to 20 %) were detected (Evers et al., 2021). The latter are ranging between 11 to 28 % (w/w) depending on the polysorbate species (Hewitt et al., 2011). The most abundant impurities as well as the di-, tri-, and tetraesters are illustrated in Fig. 1C.

Fig. 1.

Structural heterogeneity of polysorbate. (A) Idealized structures of PS20 (left) and PS80 (right), with approximately w + x + y + z = 20 (26 experimentally determined, but dependent on quality and batch (Evers et al., 2020)), referring to the number of ethylene oxide moieties defined by the pharmacopeias. (B) Structures and content of various fatty acids in PS20 and PS80 arranged according to the relative occurrence as specified in the pharmacopoeia. (C) Compounds present in PS20 and PS80 including (1) sorbitan, (2) isosorbide, (3) POE sorbitan, (4) POE isosorbide, (5) POE isosorbide monoester, (6) POE isosorbide diester (7) POE sorbitan diester, (8) POE sorbitan triester, and (9) POE sorbitan tetraester. Fatty acids with double bonds are illustrated in the trans configuration to save space.

All in all, the complexity of polysorbate can be differentiated in: (i) diversity of POE, (ii) esterification degree, (iii) head group variation, and (iv) composition of fatty acids (Kishore, 2018). Additionally, impurities can vary, depending on the used raw materials. The rational in defining all components of polysorbate can be discussed, however, Evers and coworkers (2020) revealed in total a remarkable number of more than 600 compounds which could be assigned in PS20 determined via mass spectrometry (Evers et al., 2020).

3. Pharmacopoeia’s requirements and grades

The specifications for polysorbate qualities are described by the international pharmacopoeias – Ph. Eur., USP, JP, BP, and ChP – normally agreeing on the majority of requirements like FA composition (Table 1) (Martos et al., 2017; Kishore, 2018). Impurities and specific tests for the different pharmacopoeias are given in Table 2. Currently, different grades are available: (i) multicompendial (MC) grade and (ii) ultrapure grade. The MC grades can be subdivided into high purity (HP) and super refined (SR) qualities, and the latter is claimed by the manufacturers to possess lower peroxide, impurity, and endotoxin levels. For PS20, the MC grade defines a ratio of 40–60 % of lauric acid, whereas the oleic acid content of PS80 must be ≥58 %. For a more detailed description see Martos et al. (2017) (Martos et al., 2017). Additionally, ultra-pure grades with reduced heterogeneity in the fatty acid composition were developed, denoted as all-oleate (AO), with a content of ≥98 % oleic acid for PS80 and <0.5 % for all other fatty acids as well as with a content of ≥98 % lauric acid for PS20 denoted as all-laurate (AL) (Brovč et al., 2020b). Additionally, the endotoxin level is restricted to 0.012 EU (Martos et al., 2017). To the best of our knowledge, the AL grade has only been used for research purposes (Brovč et al., 2020b), as only a few companies offer these quality standards AL for PS20 and AO (comparable to ChP grade) for PS80. The storage and handling of polysorbate upon manufacturing and filling is crucial as well (Martos et al., 2017). The actual advantages and disadvantages of the different grades in respect to oxidative degradation will be summarized and scientifically evaluated in the following chapters.

Table 1.

Fatty acid composition as listed in the different pharmacopoeias (ChP: Chinese pharmacopoeia; JP: Japanese pharmacopoeia; Ph. Eur.: European pharmacopoeia; USP: United State pharmacopoeia) for PS20 and PS80. JP has no monograph specific for PS20. For USP only the differences to the other pharmacopeias are reported.

| Pharmacopeia | Polysorbate | Fatty acid | Percentage / % | USP / % | |

|---|---|---|---|---|---|

| Ph. Eur. / ChP | PS20 | Lauric acid | C(12:0) | 40–60 | |

| Myristic acid | C(14:0) | 14–25 | |||

| Palmitic acid | C(16:0) | 7–15 | |||

| Oleic acid | C(18:1) | ≤11 | |||

| Capric acid | C(10:0) | ≤10 | |||

| Caprylic acid | C(8:0) | ≤10 | |||

| Stearic acid | C(18:0) | ≤7 | ≤11 | ||

| Linoleic acid | C(18:2) | ≤3 | |||

| Caproic acid | C(6:0) | ≤1 | |||

| Pharmacopoeia | Polysorbate | Fatty acid | Percentage / % | ChP / % | |

|---|---|---|---|---|---|

| Ph. Eur. / JP / USP | PS80 | Oleic acid | (18:1) | ≥58 | ≥98 |

| Linoleic acid | C(18:2) | ≤18 | ≤0.5 | ||

| Palmitic acid | C(16:0) | ≤16 | ≤0.5 | ||

| Palmitoleic acid | C(16:1) | ≤8 | ≤0.5 | ||

| Stearic acid | C(18:0) | ≤6 | ≤0.5 | ||

| Myristic acid | C(14:0) | ≤5 | ≤0.5 | ||

| Linolenic acid | C(18:3) | ≤4 | ≤0.5 |

Table 2.

Impurities and specific tests for PS20 and PS80.

| Pharmacopoeia | Polysorbate | Ph. Eur. | USP | JP | ChP |

|---|---|---|---|---|---|

| Peroxide value / mEq·kg-1 | PS20 | ≤10 | ≤5 | - | ≤10 |

| PS80 | ≤10 | ≤10 | ≤10 | ≤3 | |

| Heavy metal / ppm | PS20 | ≤10a | ≤10 | - | ≤10 |

| PS80 | ≤10a | ≤10a | ≤20 | ≤10 | |

| Endotoxins / EU | PS20 | - | - | - | - |

| PS80 | - | - | - | 0.012 | |

| Acid value / mgKOH·g-1 | PS20 | ≤2 | ≤2 | ≤4 | ≤2 |

| PS80 | ≤2 | ≤2 | ≤2 | ≤1 | |

| Hydroxyl value / mgKOH·g-1acetylated | PS20 | 96–108 | 96–108 | - | 96–108 |

| PS80 | 65–80 | 65–80 | 65–80 | 65–80 | |

| Saponification value / mgKOH·g-1 | PS20 | 40–50 | 40–50 | 43–55 | 40–50 |

| PS80 | 45–55 | 45–55 | 45–55 | 45–55 | |

| Ethylene oxide / ppm | PS20 | ≤1 | ≤1 | - | ≤1 |

| PS80 | ≤1 | ≤1 | ≤1 | ≤1 |

Limits deleted since Ph. Eur. 9.0 and since 01.01.2018 (USP)

4. Degradation of polysorbates and their impact on biologicals

The degradation of PS can have a significant impact on the quality of the drug product by decreasing the efficient surfactant concentration or by the formation of degradants affecting protein or product stability (Kishore et al., 2011a). The formation of protein particles bears the risk of immunogenicity (Rosenberg, 2006; Carpenter et al., 2009; Moussa et al., 2016), whereas PS-related fatty acid particles or particles in general can affect the requirements of the pharmacopoeias (European Pharmacopeia. 10.5, 2022; Das, 2012). Two different degradation pathways can be distinguished: (i) chemical/enzyme-mediated hydrolysis and (ii) oxidation (Kerwin, 2008; Donbrow et al., 1978a; Brovč et al., 2020b; Smidrkal et al., 2004). The root causes promoting each mechanism are diverse, as well as the impacts on product quality. It is crucial to shed light on the different degradation pathways starting from early stages of formulation development to the determination of the product shelf-life (Martos et al., 2017). Therefore, a huge number of different techniques and methods were developed in the last decade to analyze and investigate the composition and the properties of polysorbate, ranging from fluorescence detection to reversed-phase high performance liquid chromatography (RP-HPLC) coupled to evaporative light scattering detection (ELSD), charged aerosol detection (CAD), and/or mass spectrometry (MS), to name a few (Garidel et al., 2009; Doshi et al., 2020a; Hewitt et al., 2008; Hewitt et al., 2008; Moussa et al., 2016; Borisov et al., 2015; Dixit et al., 2016; McShan et al., 2016; Tomlinson et al., 2015; Kovner et al., 2023; Wuchner et al., 2022a; Lippold et al., 2017; Khossravi et al., 2002; Dwivedi et al., 2018; Liu et al., 2022a; Saggu et al., 2015; Siska et al., 2015). Besides liquid chromatography with CAD/ELSD coupling, which is the most used analytical method as described by the industry perspective on the use and characterization of PS, the fluorescence micelle assay (FMA) is often used for quantification (Wuchner et al., 2022a). Here, the dye N-phenyl-1-naphthylamine (NPN) can partition in hydrophobic environments like micelles followed by a detectable increase in the fluorescence quantum yield, allowing to quantify micelles. Differences between quantification by FMA and HPLC-CAD/ELSD should be considered, as FMA is highly dependent on higher-order ester species with high hydrophobicity’s and less dependent on monoesters with less hydrophobicity’s. Thus, an increased or faster degradation of hydrophobic species (higher-order esters) may lead to an overrepresentation in PS loss during FMA, which is not detected in HPLC measurements (Lippold et al., 2017). Colorimetric techniques are also used, however, they may not always be able to indicate whether polysorbate has been degraded and thus should only be performed using careful consideration (Khossravi et al., 2002). For a more detailed description of the different approaches, see Dwivedi et al. (2018) and Liu et al. (2022) (Dwivedi et al., 2018; Liu et al., 2022a).

-

a.

Chemical and enzymatic-mediated hydrolysis

Ester bond hydrolysis can occur by chemical- or enzymatic-mediated hydrolysis, both releasing free fatty acids (FFA) (Tomlinson et al., 2015; Saggu et al., 2015; Siska et al., 2015). The subsequent formation of fatty acid particles in relation to the PS concentration is discussed as a major concern in the biopharmaceutical community (Glücklich et al., 2020; Cao et al., 2015). Chemical hydrolysis of PS can be promoted by acidic and alkaline conditions (Dwivedi et al., 2020; Bates et al., 1973; Roberts and Urey, 1939; Stefanidis and Jencks, 1993). Here, pioneering work was performed by Bates and coworkers (1973) studying polysorbate degradation at different pH values and temperatures, revealing an acid- and base-catalyzed reaction of PS80 below pH 3 and above pH 7.6, respectively (Bates et al., 1973). The hydrolysis rate was inversely proportional to the surfactant concentration, discussed as being attributed to micelle formation and inaccessibility of the ester group (Bates et al., 1973). Additionally, no significant effects upon different hydrocarbon chain lengths were observed for polysorbate 40 (PS40, polyoxyethylene(20) sorbitan monopalmitate), polysorbate 60 (PS60, polyoxyethylene(20) sorbitan monostearate), and PS80 (Bates et al., 1973). More recently, Dwivedi and colleagues (2020) investigated the chemical hydrolysis of PS20 and PS80 at acidic, neutral, and alkaline conditions at different temperatures via FMA and RP-HPLC-CAD Dwivedi et al. (2020). They demonstrated that both surfactants are more prone to degradation at alkaline conditions (pH >12), whereas the hydrolysis was neglectable at pH 7 and 40 °C for 48 h (Dwivedi et al., 2020). Additionally, PS80 was found to be less sensitive to chemical hydrolysis in comparison to PS20 (Dwivedi et al., 2020).

pH-induced ester cleavage is unlikely in comparison to enzyme-mediated hydrolysis, as biopharmaceuticals are typically formulated at pH values between 5 and 7 and at storage temperature of 2–8 °C (Dwivedi et al., 2018). In particular, the presence of host cell proteins (HCPs) as impurities in the final product is described as the main root cause for enzymatic PS degradation (Kishore et al., 2011b; Borisov et al., 2015; McShan et al., 2016; Siska et al., 2015; Roberts and Urey, 1939; Stefanidis and Jencks, 1993; Glücklich et al., 2021; Hall et al., 2016; Zhang et al., 2021; Rupp et al., 2010; Li et al., 2022; Zhang et al., 2020; Chen et al., 2020; Kovner et al., 2023; Roy et al., 2021; Graf et al., 2021). These PS-degrading enzymes are classified as esterases or lipases and multiple PS-degrading enzymes were studied so far to gain fingerprints or characteristics of various lipases, as demonstrated exemplarily by McShan and coworkers (2016) (McShan et al., 2016). The analytical toolbox for identifying and quantifying the PS-degrading enzymes is essential to comprehend and mitigate the enzymatic hydrolysis of PS (Li et al., 2022). A wide range of analytical methods was developed, ranging from PS purity and content analysis over enzymatic activity assays to mass detection (Li et al., 2022). However, each HCP possesses its own substrate specificity, enzymatic optimum, and impact on PS degradation, prohibiting common guidelines and strategies. For instance, certain lipases degrade primarily higher-order esters implying a higher risk for particle formation as more individual FAs are released (Doshi et al., 2020b). Furthermore, insolubility limits of released fatty acids from PS are dependent on temperature, pH, PS concentration, and PS quality, which vary between final drug products (Glücklich et al., 2020; Doshi et al., 2015).

Different analytical methods are used to detect the hydrolytic degradation of PS. In addition to chromatographic methods, the titration of the formed fatty acid can be used, however, the apparent pKa of long chain fatty acid depends strongly on the local environment and can range from “4.2 to 10.2” (Heider et al., 2016). The degree of protonation/deprotonation has a strong impact on the hydrophilicity and solubility of the fatty acids (Heider et al., 2016). Oleic acid phase separates from water in the protonated, uncharged form, but it becomes water soluble and micelle-forming in its deprotonated anionic form (Heider et al., 2016).

Different mitigation strategies were applied to prevent enzymatic PS degradation, such as specific inhibitors (Zhang et al., 2020), cell line development via knockouts (Chiu et al., 2017; Chen et al., 2020; Kol et al., 2020,Dovgan et al., 2021), additional upstream development (harvest time, cell density, media optimization) (Li et al., 2022), adjustment/optimization of purification steps (resin, elution, buffers, and general optimizing purification steps), or improved formulation (PS type and grade, buffer system, and excipients) (Roy et al., 2021). For a more detailed description of enzymatic PS degradation, see Li et al. (2022) (Li et al., 2022).

-

b.

Oxidative degradation

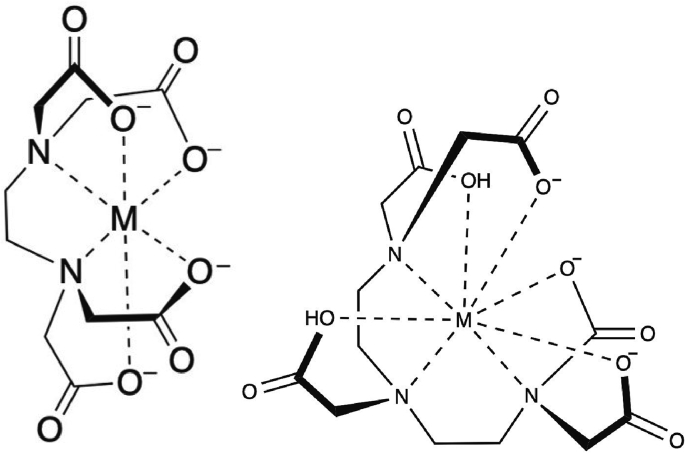

Oxidative degradation of PS occurs at typical pharmaceutical conditions like pH values ranging from 5 to 7 and at temperatures between 5 and 25 °C (Donbrow et al., 1978a; Donbrow et al., 1978b; Hamburger et al., 1975). Donbrow and colleagues (1978) are pioneers in the field of polysorbate oxidation, which is portrayed as a three-phase process (Donbrow et al., 1978a). Starting with the initiation phase, oxidation can be accelerated by e.g., light exposure or transition metals in the presence of oxygen, which are common factors during pharmaceutical production processes, resulting in peroxide formation, or can be triggered by residual peroxides itself (Kerwin, 2008; Donbrow et al., 1978a; Singh et al., 2012; Larson et al., 2020). It has been demonstrated that catalysts such as copper sulfate can shorten the oxidative initiation time and increase the peroxide formation rate (Donbrow et al., 1978a). In this context, it should be mentioned that copper has presumably minor importance for the pharmaceutical industry compared to, for instance, iron, which is present nearly ubiquitously. Origin of residual H2O2 or organic peroxides may be the raw materials or the manufacturing/filling process, as H2O2 is a commonly used disinfectant agent in manufacturing environment (Sterchi, 2001; Corveleyn et al., 1997; Krishna et al., 2000). Therefore, stress tests conducted using H2O2 are certainly of practical relevance. As described above, the required peroxide limit stated in the certificate of analysis (<1 mEqO2·kg-1) for PS80 is 10-fold lower than the limit defined in the pharmacopeias (<10 mEqO2·kg-1) (Mittag et al., 2022). H2O2 can form hydroxyl radicals (OH•) for instance via the Fenton (Eq. 1) or Haber–Weiss reaction (Eq. 2), so that in the presence of redox-active metals, tiny impurities in the ppb range (as they occur during pharmaceutical production processes) are sufficient to cause significant effects (Phaniendra et al., 2015). Mittag and colleagues (2022) reported the presence of OH•, R•, RO•, and ROO• in bulk and 10 % (w/v) PS80 solutions measured via EPR spectroscopy and spin trapping. In bulk materials primarily ROO• and RO• were detected, whereas in 10 % (w/v) aqueous PS80 solutions mainly OH• was found, independent of PS80 quality and grade (Mittag et al., 2022).

| (1) |

| (2) |

Elevated temperatures accelerate oxidation of PS, and they are for instance used as accelerated stress conditions in pharmaceutical industry (Donbrow et al., 1978a).

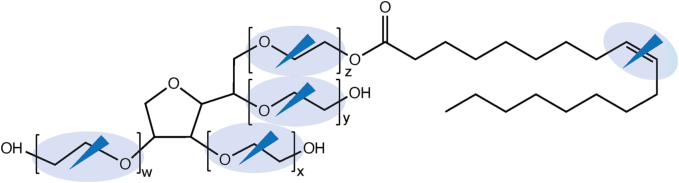

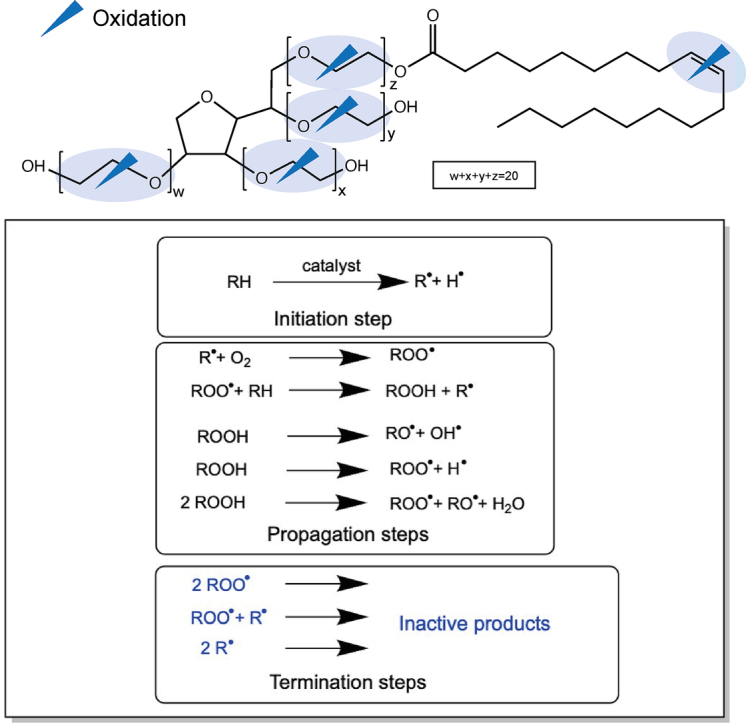

Polysorbates provide multiple potential reaction sites for oxidation such as (i) the POE moieties, also resulting in free fatty acid to a low extent, and (ii) the unsaturation site (double bond) of the fatty acid as illustrated in Fig. 2 (Donbrow et al., 1978a; Zhang et al., 2017; Yao et al., 2009).

Fig. 2.

Exemplary scheme for PS80 with its potential oxidation reaction sites (blue arrow and blue shadow).

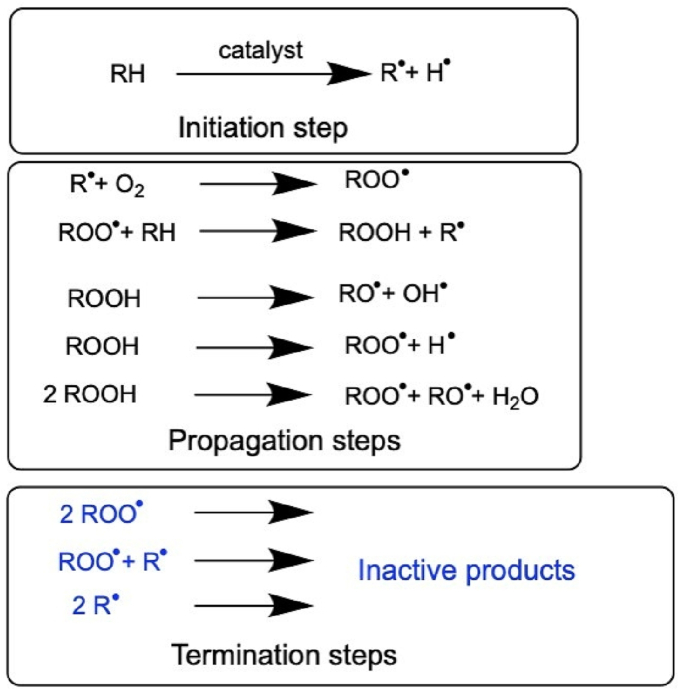

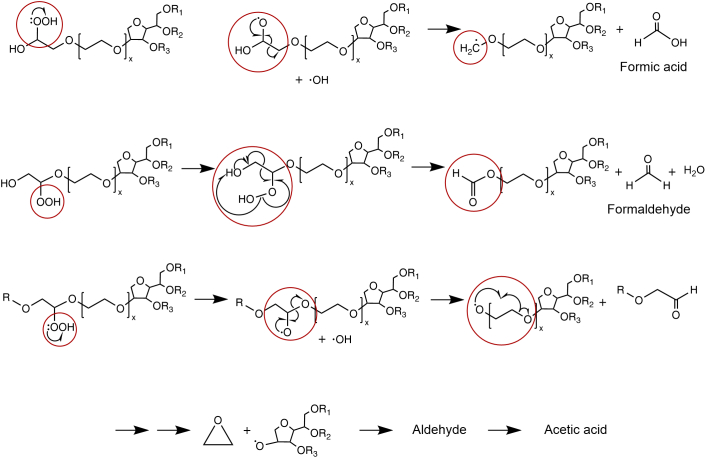

As shown in Fig. 3, oxidation is described by a radical initiation, propagation, and termination reaction (Kerwin, 2008; Kishore et al., 2011b; Dulog and Storck, 1966), similar to most polyoxyethylene systems (Donbrow et al., 1978a). Initially, an alkyl radical can be formed, promoted by e.g., light, temperature, metal traces, or residual peroxides followed by the propagation reaction with molecular oxygen. Here, Ha et al. (2002) detected an increased peroxide formation with increased temperature and light for 20 % (w/v) PS80 solutions (Ha et al., 2002). The resulting hydroperoxide is driving the reaction forward. Nevertheless, such high polysorbate concentrations are not commonly applied in pharmaceutical industry. Other free radicals are generated by homolytic or heterolytic peroxide cleavage before individual radicals are quenching each other leading to the radical termination reaction (Donbrow et al., 1978a). Another possibilities for termination are the lack of substrate or the presence of antioxidants. Molecular oxygen is essential for the oxidation, and thus, oxygen removal results in a lower initial increase in peroxides or even in prevention of peroxide formation and oxidation processes (Ha et al., 2002). The radical scheme is depicted in Fig. 3, and a more detailed mechanistic description of the POE radical-mediated oxidation is shown in Fig. 4. Different scenarios can be distinguished depending on the “location of the radical” within the POE group or within the different POE monomers in the POE chain (dependent on the hydrogen abstraction of another radical). Formic acid is formed by starting the radical-induced degradation from an alkoxyl radical (RO•) at the end of a POE chain (compare Fig. 4A), whereas initiation from a hydroperoxide (ROOH) at the terminus of the POE chain can result in the formation of an ester, formaldehyde, and water due to a six-membered intramolecular decomposition (compare Fig. 4B) (Decker and Marchal, 1974). The remaining ester will be further hydrolyzed to formic acid. There are multiple reactions possible (compare Fig. 3), as the hydroperoxide can also be homo- or heterolytically cleaved, resulting in an alkoxy radical or a peroxyl radical. In contrast, a radical reaction within the POE chain creates acetaldehyde and finally acetic acid via an epoxide intermediate (Fig. 4C) (Dulog and Storck, 1966).

Fig. 3.

Radical-induced oxidative degradation of general polyoxyethylene units with an alkyl residue R. The radical reaction scheme can be divided into initiation, propagation, and termination steps. This figure is adapted from Donbrow et al. (1978) (Donbrow et al., 1978a).

Fig. 4.

Radical-induced oxidative degradation of polyoxyethylene (POE) moieties in polysorbates. The variety of products is dependent on different factors such as the position of the attacked POE chain or C-atom within the POE chain, leading to the formation of different degradation products such as (A) formic acid, (B) formaldehyde, (C) acetic acid. This figure is adapted from Kishore et al. (2011) and Dwivedi et al. (2018) (Kishore et al., 2011a; Dwivedi et al., 2018). The reaction sites are marked by brown circles.

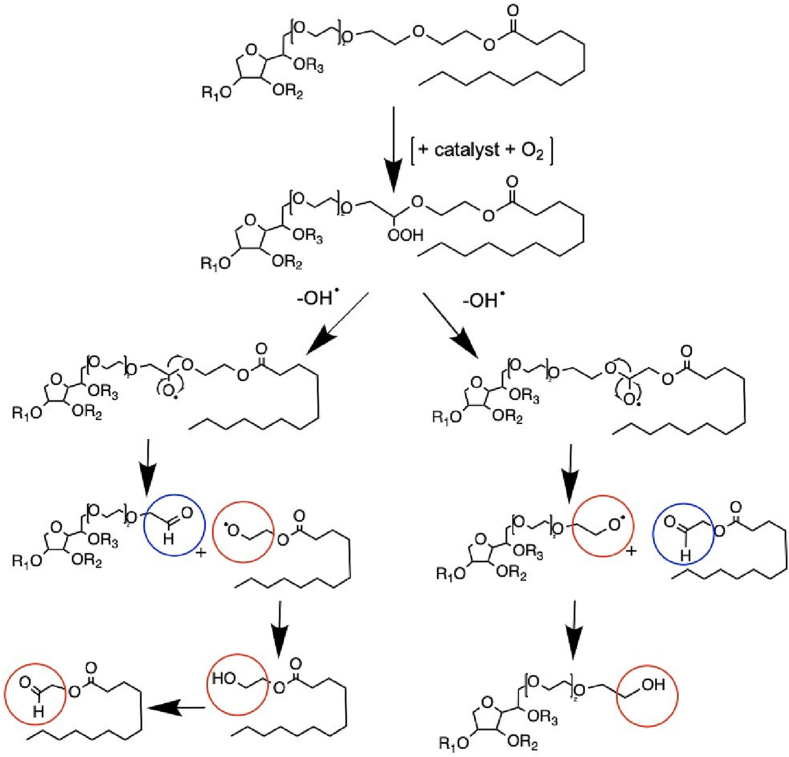

Under the consideration of an actual polysorbate monoester, radical-induced oxidation of the POE chain will result in short-chain POE esters of fatty acids and POE sorbitans/isosorbides. Potential mechanistic illustrations are given in Fig. 5 (adapted from Dahotre et al. (2018)) (Dahotre et al., 2018). Donbrow and colleagues (1978) claimed that it is challenging to break the terminal hydroxyl groups, requiring strongly acidic conditions with harsh oxidizing agents (Donbrow et al., 1978a). However, such instability may occur by reaction with a hydroperoxide radical in the α- or ß-position to the terminal hydroxyl group leading to C-C or C-O cleavage, forming the corresponding short-chain acids as degradation products (Donbrow et al., 1978a).

Fig. 5.

Two potential mechanisms for radical-induced oxidative degradation of the polyoxyethylene (POE) moieties in polysorbate leading to the formation of aldehydes (left) and alcohols (right). This figure is adapted from Dahotre et al. (2018) (Dahotre et al., 2018).

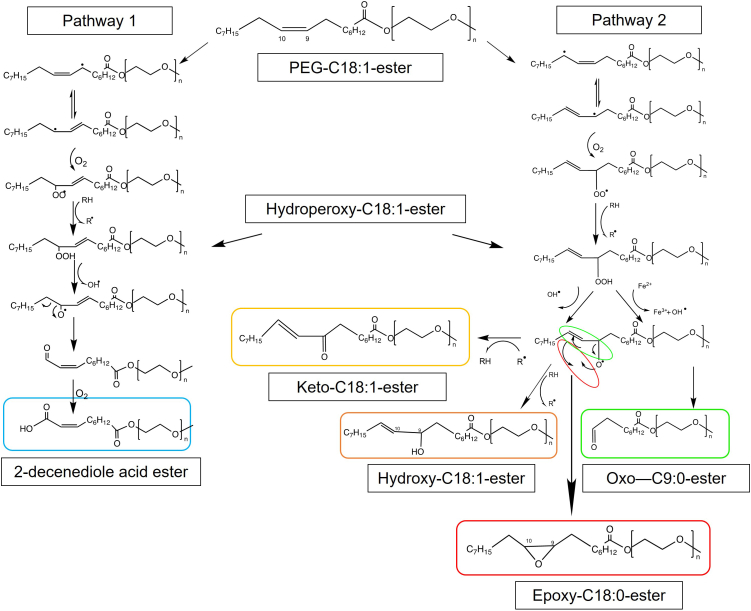

Finally, oxidative degradation can occur on the hydrocarbon site of unsaturation (Yao et al., 2009), as shown in Fig. 6. This pathway is more relevant for PS80 as it contains at least 58 % unsaturated fatty acids (only considering oleic acid), whereas PS20 comprises at least 86 % saturated fatty acids (European Pharmacopeia. 10.5, 2022). Nevertheless, PS20 can include up to 11 and 3 % oleic acid and linoleic acids, respecitvely (European Pharmacopeia. 10.5, 2022). The basis of the susceptibility of PS80 for oxidative degradation is based on electron transfer followed by hydrogen atom abstraction. The enthalpy for H-atom extraction by a hydroperoxyl radical strongly depends on the mesomeric stabilization of the radical intermediate. Unsaturated and especially multi-unsaturated fatty acids have a higher degree of delocalization regarding the mesomeric stabilization of the radical intermediate and therefore, are more prone to oxidation (Pratt et al., 2011; Ding et al., 2022). In addition, the formation of carbon centered radicals – oxygen complexes have been described as important intermediate species (Pratt et al., 2011). New insights on the oxidation of oleic acid have been published already several years ago and also very recently (Ding et al., 2022; Porter, 1986). According to the experimental results of Ding et al. (2022), isomerization of allyl, analogous to β-fragmentation, is one of the pathways to form multiple hydroperoxides (Ding et al., 2022). Nevertheless, different oxidation stages strongly affect both reactions. While hydroperoxides accumulate, β-fragmentation is taking a leading part (Ding et al., 2022). In contrast, allyl isomerization primarily appears when hydroperoxide is decomposed in large quantities (Ding et al., 2022). In total, the H-atom abstraction energy is estimated to be more favorable in the vicinity of a double bond or between double bonds than near an ethylene oxide group (Yao et al., 2009). In oils a corelation between degree of unsaturation and oxidative susceptibility could be established (Musakhanian et al., 2022). The alkyl radical in the vicinity of the double bond is reacting with molecular oxygen and H-atom abstraction (see Fig. 6A). Subsequent, homolytic cleavage of the hydroperoxide results in the formation of an alkyl radical, which can react with another radical in a termination reaction or in the formation of alkenes, aldehydes, or ketones via scission of the C-C bond (Kishore, 2018). Additionally, radicals can react with double bonds by direct reaction with similar rates as the hydrogen abstraction (see Fig. 6B) (Yao et al., 2009; Denisov, 2005).

Fig. 6.

Radical-induced oxidative degradation of polysorbate via the unsaturation site of the fatty acid. (A) Reaction with molecular oxygen in the vicinity of the double bond and (B) reaction of peroxyl radicals with double bonds. This figure is adapted from Yao et al. (2009) and Kishore (2018) (Kishore, 2018; Yao et al., 2009).

Thereby, various degradation products are formed ranging from alkenes, aldehydes, and ketones to short carboxylic acids, fatty acids, and POE esters of fatty acids (Hvattum et al., 2012). Especially fatty acid esters with short POE chains are of major concern for fatty acid particle formation, as they possess similar solubility characteristics as fatty acids, due to their short hydrophilic headgroup (Kishore et al., 2011a). Kishore and coworkers (2011) determined the logP value of various components of oxidative degraded PS20 and PS80 revealing more sparsely soluble degradants for PS20 (Kishore et al., 2011a). This change in hydrophilic-to-hydrophobic ratio results in change of the critical micelle concentration (CMC) and change of the cloud point (Donbrow et al., 1978a). Additionally, the resulting aldehydes may be harmful in respect to protein stability and may also affect the human body in a toxic manner (Lopachin and Gavin, 2014).

But not only the degradation products, also the generation of reactive oxygen species (ROS) are critical, as they are oxidizing the protein product as well as other formulation components (Yao et al., 2009; Hipper et al., 2021; Ehrenshaft et al., 2015; Michaeli and Feitelson, 1994). ROS are defined as reactive chemicals formed from O2 including free radicals (HO•, O2•−, HOO•), but also H2O2, hydroperoxide (ROOH) or singlet oxygen (1O2). The reactivity of different ROS is quite different. OH-radicals are highly reactive and only the diffusion limits its reactivity (k >109 M–1⋅s–1) (Finkelstein et al., 1980; Goldstern et al., 2004; Hawkins and Davies, 2014). In contrast, peroxyl-radicals and superoxide radicals are less reactive with reaction constants 6 to 9 orders of magnitude lower and might therefore undergo further reactions at later time points and different locations (Mittag et al., 2022; Finkelstein et al., 1980; Goldstern et al., 2004; Hawkins and Davies, 2014; Haywood, 2013; Buettner and Mason, 1990). Nevertheless, the exact mechanism of oxidation is not fully understood so far (Borisov et al., 2015). To determine the types of radicals involved in oxidative PS degradation, NMR, or EPR measurements were conducted (Mittag et al., 2022; Doyle et al., 2019).

5. Oxidation of polysorbate

Recently, an industry perspective of 16 globally acting companies was published, highlighting that PS degradation was observed through both hydrolysis (69 %) and oxidation (63 %) in at least one of their biopharmaceutical products (Wuchner et al., 2022a; Wuchner et al., 2022b). To elucidate the challenges of PS degradation, it is essential to differentiate between hydrolytic and oxidative degradation to guide appropriate mitigation strategies. Many methods like RP-HPLC coupled with CAD (Fekete et al., 2010; Christiansen et al., 2011), ELSD (Hewitt et al., 2008; Nayak et al., 2012), or FMA (Brito Rui and Vaz, 1986) were established to determine the PS content in formulations, however, they fail to clearly distinguish the main root cause of PS degradation. In the following chapter, degradation products and oxidation markers determined by MS or 1H-NMR are summarized to evaluate the root cause of PS degradation. Other indicators for oxidative degradation are the presence of peroxides (relative stable intermediate of oxidation), which were detected upon oxidative processes (Donbrow et al., 1978a; Ha et al., 2002). Additionally, shifts to more acidic pH values in weakly-buffered systems can be observed, due to the short-chain acid degradation products like for instance formic acid and acetic acid (Donbrow et al., 1978a). ROS are intermediates in the oxidation process and two assays are commonly used to monitor ROS and correlate them with PS oxidation: (i) the ROS content (every ROS oxidizing Fe2+ to Fe3+ is determined) is investigated using a dye complex consisting of Fe3+ and xylenol orange under acidic conditions (FOX assay), and (ii), the content of H2O2 is examined with the aid of horseradish peroxidase (AmplexTM Red assay) (Doshi et al., 2020a; Ha et al., 2002; Kranz et al., 2019). Another possibility to assess the root cause of degradation are specific reaction conditions like the addition of stressors, placebo formulations, or other conditions allowing only oxidation to occur (Bollenbach et al., 2022; Singh et al., 2017; Roy et al., 2021). To tackle oxidation-mediated degradation, formulations can be exposed to stress factors, which were developed to investigate the decomposition process as well as to identify degradation products (ICH Guideline Stability Testing, 1996). These stress conditions include exposure of polysorbates to evaluate the impact of e.g. temperature, iron or transition metals (Brovč et al., 2020a; Liu et al., 2022a; Hvattum et al., 2012; Kranz et al., 2019; Gopalrathnam et al., 2018; Schröter et al., 2021; Bensaid et al., 2022; Doyle et al., 2019; Kranz et al., 2020; Klair et al., 2021; Prajapati et al., 2022), H2O2 (Kishore et al., 2011a; Kranz et al., 2019; Peters et al., 2022), light exposure (Ha et al., 2002; Doyle et al., 2019; Doshi et al., 2021a; Singh et al., 2012; Agarkhed et al., 2013; Prajapati et al., 2020, Prajapati et al., 2022, Larson et al., 2020; Lei et al., 2021), or 2,2-azobis(2-amidinopropane) dihydrochloride (AAPH) (Borisov et al., 2015; Larson et al., 2020; Zhang et al., 2017; Schröter et al., 2021; Zhang et al., 2018), all promoting the formation of radicals resulting in oxidative degradation. As oxidation of polysorbates can occur at: (i) the POE moieties, which can also result in free fatty acids and (ii) the existing double bonds (Donbrow et al., 1978a; Zhang et al., 2017; Yao et al., 2009), it is discussed whether PS80 or PS20 or different subspecies are most susceptible to oxidative degradation (compare Fig. 5 and Fig. 6). Subsequently, we will summarize oxidative degradation products, elaborate key characteristics of oxidative-mediated PS degradation in respect to different PS types and grades, followed by an extensive comparison between PS20 and PS80 and their grades. Finally, we will summarize current available stress studies of polysorbate to provide a common picture of the different stress conditions as well as suitable mitigation strategies and reagents.

-

a.Degradation products and oxidative markers

-

I.Degradation products

-

I.

Technologies detecting the degradation products, such as liquid chromatography coupled to mass spectrometry (LC-MS), or 1H-NMR are suitable to track oxidation (Kishore et al., 2011b; Khossravi et al., 2002; Hvattum et al., 2012; Ilko et al., 2015; Zhang et al., 2015). These methods focus on detecting established oxidation markers and/or relevant degradation products such as aldehydes or ketones, short-chain acids, shortened POE chains, or short-chain POE fatty acid esters to verify oxidative behavior (Kishore et al., 2011a; Evers et al., 2020; Zhang et al., 2017; Dahotre et al., 2018; Hvattum et al., 2012; Kranz et al., 2020). Formaldehydes as oxidative degradation products, may be formed through C-C bond cleavage by hydroperoxides or free radicals (compare Fig. 5) (Kerwin, 2008). A broad overview of degradation products was provided by Kishore et al. (2011), analyzing PS20 and PS80 by stir-bar-assisted sorption extraction gas chromatography-mass spectrometry (SBSE-GC-MS) (Kishore et al., 2011a). In general, degradation products were divided into five groups: (i) ketones (C5-C15), (ii) aldehydes (C5-C15), (iii) furanones (C5-C9), (iv) fatty acids (C10-C14), and (v) fatty acid esters (C12-C16). Formic acid, acetic acid, acetaldehyde, and formaldehyde were found originating to arise from β-scission of alkoxy radicals, by a six-membered intramolecular decomposition, or might be generated via an epoxy intermediate (compare Fig. 4) (Kishore et al., 2011a). Many different aldehydes like decanal, nonanal, octanal, and hexanal (to name a few) were generated as secondary products from hydroperoxides by oxidation of the double bond of unsaturated oleic, linoleic, or linolenic acids. By analyzing protein formulations stored for 20 months at 25 °C, they detected primarily C10-C16 fatty acids and fatty acid esters for PS20, indicating oxidative scission of the POE chain (Kishore et al., 2011a). In contrast, C8-C9 fatty acids and the lack of oleic acid were found in PS80 samples, suggesting cleavage at the double bond (Kishore et al., 2011a). Some of those degradation products like short-chain POE monoesters have also been found by Hvattum and colleagues (2012), by using LC-MS with argon as collision gas for collision-induced dissociation (CID) and 1H-NMR spectroscopy (Hvattum et al., 2012). Using CID-MS they could compare PS80 species esterified with different fatty acids before and after incubation at 40 °C for 8 weeks. C18:1 and C18:2 species were investigated more closely, showing that C18:2 species were nearly-completely degraded after 8 weeks at 40 °C to circa 30 % and 8 % for POE sorbitan and POE isosorbide/POE esters, whereas C18:1 species degraded to approximately 86 % and 80 % for POE sorbitan and POE isosorbide/POE esters for the same conditions. Additionally, they observed oxidation products of oleic acid, such as sorbitan/isosorbide/POE esters of hydroxyl-C18:1 (C18:1-OH), epoxy-C18:0, or keto-C18:1, as well as short-chain POE esters of C18:1 (Hvattum et al., 2012). Borisov and coworkers (2015) revealed degradation products of PS20 and PS80 after stressing with AAPH at 40 °C (Borisov et al., 2015). For PS20 and PS80 5 mM and 1.5 mM AAPH for 40 h and 12.5 h were used, respectively. Comparable to Hvattum et al. (2012), they used LC-MS with CID to investigate fragments of the different fatty acids in PS20 and PS80. For PS80, 9-oxononanoic acid (oxo-C9:0), keto-C18:1, hydroxyl-C18:1, epoxy-C18:0, hydroperoxyl-C18:1, and shorter POE versions (result of ether bond scission) of them were found as degradation products, whereas for PS20 mainly shorter POE chain derivatives were observed (Borisov et al., 2015). Additionally, free fatty acids can be generated by oxidation, however, their concentration is notably lower in comparison to hydrolytic degradation (Zhang et al., 2017). Here, Zhang and coworker (2017) developed an UPLC-MS method to differentiate between hydrolysis and oxidation via 18O-labeling technique, where they were able to detect free lauric acid and POE-laurate after oxidative degradation with 1.5 mM AAPH at 40 °C (Zhang et al., 2017). Two mechanisms were proposed, (i) starting with H-abstraction from the C-H bond on the POE chain immediately adjacent to the ester bond (α-C-H bond) and (ii) H-abstraction from the ß-C-H group. Hydrogen abstraction from the ß-C-H group is proposed to be the more favored mechanism based on the higher bond dissociation energy for the C-H bond immediately adjacent to the ester bond, and as there has to be a ratio of 16O:18O of free lauric acid of 3:1, in case of α-C-H abstraction, which could not be detected experimentally (Zhang et al., 2017).

-

II.

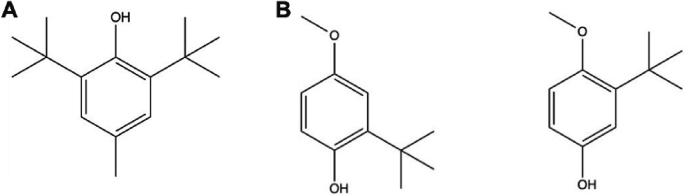

Oxidation markers

With the improved knowledge of oxidative degradation, oxidation markers were detected and used. Generally, it can be distinguished between ‘universal markers’ which can be applied for both polysorbate species or markers which are specific for PS20 or PS80 (Table 3). Here, Dahotre and colleagues (2018) identified an aldehyde derivate of fatty acid esters as result of the POE chain scission, which can be derivatized to analytically monitor PS20 oxidation (Dahotre et al., 2018). Theoretically, this approach should be applicable for PS80 as well, as it detects the ether bond scission of the POE chain, although it was not verified for PS80 in their study. Some of the already mentioned degradation products were summarized by Kranz et al. (2020), however, also additional oxidation markers were identified via LC-MS by stressing PS20 and PS80 in the presence and absence of protein with 10 ppb Fe2+ at 40 °C (Kranz et al., 2020). As universal markers they revealed peroxyl derivatives and glycolic acid esters of POE with varying chain length (6-10 POE units), which can be found in PS20 (MC/AL) and PS80 (MC/AO) (Kranz et al., 2020). Furthermore, specific markers for PS20 (MC/AL) like POE-laurates with a terminal esterified glycolic acid moiety with POE chain length of 1-6 (or more) units and oxo-lauric acid derivates were observed (Kranz et al., 2020). However, the exact position of the keto group was not defined, allowing different isomers to be present (Kranz et al., 2020). The novel degradation markers as well as the already published degradation products for PS80 summarized by Kranz and colleagues (2020) are listed in Table 3. Acids such as the aforementioned formic acid (Donbrow et al., 1978a; Donbrow et al., 1978b; Brovč et al., 2020a), glycolic acid, and acetic acid were for instance found by Brovč et al. (2020) (Brovč et al., 2020a). They used UPLC coupled to UV detection after derivatization with 2-nitrophenylhydrazine to identify formic acid, acetic acid, glycolic acid, and propionic acid as well as formaldehyde, acetaldehyde, propanal, and acetone after stressing polysorbates at 50 °C for 2 months in histidine buffer. Elevated levels of acetaldehyde, acetone, and propanal could be detected, whereas acetaldehyde is most likely formed by oxidative scission of POE units, while acetone and propanal are more likely generated by the oxidation of oleic acid (Brovč et al., 2020a). Additionally, they found 1,9-nonanedioic acid as degradation product of PS80 (Brovč et al., 2020a). Schröter et al. (2021) used 2,4-dinitrophenyl hydrazine (DNPH) for derivatization of 4-hydroxynonenal, being a result of poly-unsaturated fatty acid degradation (Schröter et al., 2021). Their derivation assay of carbonyls with DNPH leads to hydrazones that can be detected by LC-MS. By applying different stress conditions for 5 weeks they obtained ppb concentrations of 4-hydroxynonenal in 10 % (w/v) PS80 solutions of different grades, varying in the butylhydroxytoluene (BHT) concentration (Schröter et al., 2021).

Table 3.

Oxidation markers or specific degradation products for polysorbate 20 and 80. Published oxidation markers or specific degradation products of PS20 and PS80 are summarized below. Not all identified degradation products are summarized. Only derivates, which are reported as oxidation markers or specific degradation products are listed.

| Oxidation marker | Marker type | Applied stress | Molecular weighta / g·mol-1 | Putative structure | Referencesb |

|---|---|---|---|---|---|

| PEGx10 peroxide | Universal | 10 ppb Fe2+ & 40 °C | 474.2676 | Kranz et al. (2020) (Kranz et al., 2020) | |

| PEGx9 glycolic acid ester | Universal | 10 ppb Fe2+ & 40 °C | 472.2520 |  |

Kranz et al. (2020) (Kranz et al., 2020) |

| Glycolic acid ester-PEGx2-laurate | PS20 | 10 ppb Fe2+ & 40 °C | 346.2355 | Kranz et al. (2020) (Kranz et al., 2020) | |

| 12-oxo-lauric acid | PS20 | 10 ppb Fe2+ & 40 °C | 214.1569 | Kranz et al. (2020) (Kranz et al., 2020) | |

| 9-oxo-C9:0-ester† | PS80 | 1.5 mM AAPH | 1418.8232† | Borisov et al. (2015) (Borisov et al., 2015) | |

| Hydroxy-C18:1-ester† | PS80 | 40 °C | 1544.9641† |  |

Hvattum et al. (2012) (Hvattum et al., 2012) |

| Hydroperoxyl-C18:1-ester† | PS80 | 1.5 mM AAPH | 1560.959† |  |

Borisov et al. (2015) (Borisov et al., 2015) |

| Keto-C18:1-ester† | PS80 | 40 °C | 1542.9484† |  |

Hvattum et al. (2012) (Hvattum et al., 2012) |

| Epoxy-C18:0-ester | PS80 | 40 °C | - |  |

Hvattum et al. (2012) (Hvattum et al., 2012) |

| 1,9-nonanedioic acid‡, ⨁ | PS80 | 50 °C | - | Brovč et al. (2020) (Brovč et al., 2020a) | |

| 2-decenedioic acid-ester‡ | PS80 | Stored under air | - |  |

Liu et al. (2022) (Liu et al., 2022a) |

Molecular weight is given for the original structure and not for the measured adduct.

Reference, which first reported and verified the degradation product.

Kranz et al. (2020) provided already published oxidation markers from Borisov et al. (2015) and Hvattum et al. (2012) including their molecular weights: esters of 9-oxo-C9:0, hydroxy-C18:1, hydroperoxyl-C18:1, and keto-C18.

Specific degradation products not reported as oxidation markers.

1,9-nonanedioic acid is esterified to sorbitan-POE.

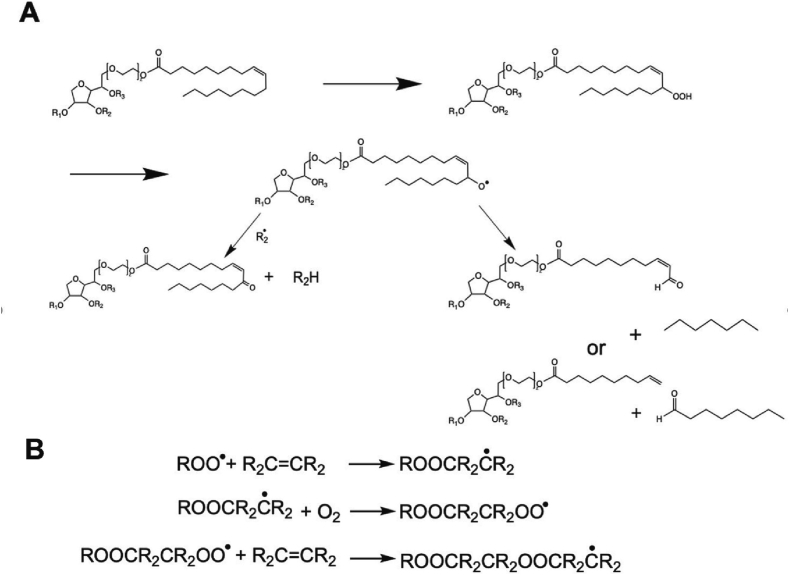

Li et al. (2022) postulated degradation pathways for PS80 and its major degradants (see Fig. 7). Many oxidation markers such as esters of oxo-C9:0, hydroxy-C18:1, epoxy-C18:0, and keto-C18:1 are presented by Li et al. (2022). They stressed polysorbates with Fe2+ at elevated temperatures in the absence of nitrogen followed by analysis via LC-MS (see Fig. 7) (Liu et al., 2022a). These markers were also described previously (compare Table 3) (Borisov et al., 2015; Hvattum et al., 2012), however, 2-decenedioic acid esters were found as novel degradation products of PS80 (Liu et al., 2022a). Additionally, two degradation pathways for oxidative degradation of PS80 including the found degradation products were postulated, starting with a hydrogen abstraction of oleic acid and distinguishing in the position of the radical in the vicinity of the double bond. In pathway 1 (see Fig. 7), the radical is formed on C8 of the oleic acid, followed by isomerization, O2 addition at C10, and formation of esters of hydroperoxyl-C18:1 (C10 position). Subsequently, the peroxide is cleaved resulting in an alkoxy radical (C10) and finally in esters of 2-decenedioic acid. Pathway 2 starts with hydrogen abstraction and radical formation on C11 of the oleic acid, followed by isomerization, O2 addition at C9, formation of hydroperoxyl-C18:1 (C9), and resulting in an alkoxy radical of oleic acid at C9. Here, different reactions are distinguished resulting in esters of either oxo-C9:0, hydroxy-C18:1, keto-C18:1, and epoxy-C18:0 (compare Fig. 7).

-

b.

Key characteristics for the oxidation of polysorbates

Fig. 7.

Two possible oxidative degradation pathways of PS80 postulated and adapted based on identified degradation products from Liu et al. (2022) (Liu et al., 2022a).

The most common oxidation mechanism involves radical-induced cleavage of the ether bonds within the POE sidechains, which is characteristic for polysorbate oxidation, but could also occur within other surfactants having POE sidechains (Kishore et al., 2011a; Donbrow et al., 1978a; Borisov et al., 2015; Larson et al., 2020). The free radical reactions naturally shorten the POE chain, impacting surface activity, CMC, and cloud points of PS20 (quality not stated) by changing the ratio between hydrophilic and hydrophobic parts as has been shown by induced oxidation by incubating polysorbate at 25, 40, 60, and 70 °C (Donbrow et al., 1978a). Nevertheless, Larson et al. (2020) observed a neglectable change in the CMC measured via pyrene fluorescence after PS80 (PS quality not stated in the paper) oxidation with AAPH, whereas higher values for the surface pressure isotherms in histidine buffer of the oxidized PS80 (approximately 18 mN·m-1 after 50 min) were detected in comparison to untreated PS80 (approximately 15 mN·m-1 after 50 min) by Langmuir trough (Larson et al., 2020).

To determine whether oxidation has occurred in a particular pharmaceutical formulation, guidance can be obtained using the key characteristics listed in this section (see also Table 4).

-

I.

pH shifts

Table 4.

Summarized key characteristics of oxidative PS degradation. Different characteristics are evaluated between PS20 and PS80 with positive (+) for true, negative (-) for false, (+/-) for controversial (not distinct), or with (n.a.) for not applicable.

| Key characteristic | PS20 | PS80 | References |

|---|---|---|---|

| pH shifts (weakly-buffered systems) | + | + | Donbrow et al. (1978) (Donbrow et al., 1978a) |

| Preferred degradation of higher-order esters | + | +/- | Kranz et al. (2019) (Kranz et al., 2019), Kranz et al. (2020) (Kranz et al., 2020), Zhang et al., (2017) (Zhang et al., 2017), Borisov et al. (2015) (Borisov et al., 2015), Liu et al. (2022) (Liu et al., 2022a), Zhang et al. (2018) (Zhang et al., 2018), Bensaid et al. (2022) (Bensaid et al., 2022), Lippold et al. (2017) (Lippold et al., 2017), Brovč et al. (2020) (Brovč et al., 2020a) |

| Species of lower hydrophobicity appearing in the chromatogram | - | + | Kranz et al. (2020) (Kranz et al., 2020), Kranz et al. (2019) (Kranz et al., 2019), Borisov et al. (2015) (Borisov et al., 2015), Lippold et al. (2017) (Lippold et al., 2017), Brovč et al. (2020) (Brovč et al., 2020a), Liu et al. (2022) (Liu et al., 2022a) |

| Dominant degradation of longer chain fatty acid esters | + | n.a. | Borisov et al. (2015) (Borisov et al., 2015), Zhang et al. (2018) (Zhang et al., 2018) |

| Competition of protein and PS oxidation | + | + | Brovč et al. (2020) (Brovč et al., 2020a), Bensaid et al. (2022) (Bensaid et al., 2022), Gopalathram et al. (2018) (Gopalrathnam et al., 2018) |

pH shifts in unbuffered polysorbate solutions as key characteristic of polysorbate oxidation was first shown nearly half a century ago (Donbrow et al., 1978a). Here, Donbrow and coworkers (1978) evaluated 3 % (w/v) PS20 (quality not stated in the paper) oxidation reactions by determining cloud points, pH values, peroxide values, and surface tensions after storage at elevated temperature ranging from 25 to 70 °C depending on the experiments with or without Cu2+ (10-4 M) or after addition of NaCl (Donbrow et al., 1978a). They demonstrated three phases of oxidation and revealed that catalysts like copper sulfate or light (daylight vs. darkness) are shortening the induction phase and accelerating peroxide formation rate as well as decreasing the cloud point and pH value for unbuffered PS solutions (Donbrow et al., 1978a). Within 10 days at 25 °C and exposed to daylight, the pH value decreased by more than 1 pH unit, whereas it drops by more than 3 pH units at 60 or 70 °C (Donbrow et al., 1978a). Nevertheless, it is important to note that such high temperatures do normally not occur during production processes. For different temperatures higher peroxide numbers (mEq·kg-1 surfactant) after light exposure were detected spectrophotometrically (Donbrow et al., 1978a; Azaz et al., 1973). Peroxide numbers >5 mEq·kg-1 surfactant are reported as autoxidation, showing a characteristic kinetic pattern with a strong increase to a maximum peroxide number value and a subsequent decrease (Donbrow et al., 1978a). Hence, they revealed that low peroxide values cannot directly be interpreted as lack of oxidation, as there is a general consumption and generation of peroxides depending on the timeframe of the oxidation process (Donbrow et al., 1978a). Initially, the rate of peroxide formation was higher than the rate of peroxide decomposition, whereas at some point the process reverses (the higher the peroxide concentration, the higher the likelihood for peroxides to react with other peroxides in decomposition reactions), and peroxides may be below the detection limit, which is in the micromolar range for the used method (Donbrow et al., 1978a; Azaz et al., 1973). Additionally, the thermal stability of peroxides has to be taken into account. Here, Ha and colleagues (2002) reported a complete loss of peroxides originated from a 20 % (w/v) PS80 solution (MC) in vacuum after 6 weeks at 60 °C and a reduction to 50 % at 40 °C after 4 weeks analyzed via the FOX assay (Ha et al., 2002). Again, the high polysorbate concentration and temperature applied in the presented study are extreme stress conditions.

-

II.

Preferred degradation of higher-order esters

Another key characteristic of oxidative degradation is that PS polyesters are significantly more affected by oxidation than monoesters as reported by various stress tests with either H2O2, AAPH, temperature, or iron (Borisov et al., 2015; Lippold et al., 2017; Liu et al., 2022a; Zhang et al., 2017; Kranz et al., 2019; Bensaid et al., 2022; Zhang et al., 2018; Kranz et al., 2020; Brovč et al., 2020c). Via CAD, Kranz and colleagues (2019) showed that higher-order esters of PS20 HP completely disappear after treatment with 10 ppb Fe2+ at 40 °C after seven days. Here, free POE moieties as indicator for monoester degradation only slightly increase, whereas for PS80 HP mono- and polyesters degrade in nearly similar rates with a slightly faster kinetic for higher-order esters. These findings of PS80 degradation were accompanied by a huge increase in free POE species up to 250 % (relative to t0) after nearly two weeks at 40 °C (Kranz et al., 2019). These findings were supported as well as extended by a second study of Kranz et al. (2020), showing similar behavior of PS20 AL and PS80 AO in respect to PS20 MC and PS80 MC, respectively (Kranz et al., 2020). Other research groups confirmed higher degradation of polyesters for PS20 AL or MC by forced oxidation via AAPH at elevated temperatures (Zhang et al., 2017; Zhang et al., 2018) as well as nearly similar degradation of mono- and polyesters for PS80 (quality not defined in the paper) using iron and temperature stress (Borisov et al., 2015). For PS80 (MC and ChP), Liu and colleagues (2022) reported using LC-MS that polyesters degraded more rapidly than monoesters for Fe2+-induced degradation at 25 °C (Liu et al., 2022a). Similarly, Bensaid et al. (2022) reported a prominent decrease in polyester and a less extensive degradation of monoester in PS80 MC in the presence of mAb (20 mg·mL-1) for stressing with 20 ppb Fe2+ in 10 mM histidine buffer pH 6.0 and 10 % (v/w) sucrose (Bensaid et al., 2022). Whereas, a common opinion about higher oxidation-induced polyester degradation is reported for PS20, some controversial is found for PS80. It is important to emphasize that higher-order esters can be degraded in monoesters, increasing the monoester fraction successively, potentially blurring the small difference for PS80 (Borisov et al., 2015). As only Kranz and colleagues (2019/2020) measured free POE moieties in parallel they could verify faster degradation of polyesters in PS20 as well as only slightly higher degradation of higher-order ester for PS80 (Kranz et al., 2019, Kranz et al., 2020). The other studies only checked on mono-, di-, tri-, and tetraesters or their rates and found similar results. Nevertheless, it should be emphasized that for instance for sorbitan-POE-laurate, a cleavage in only one chain of POEs would result in a detectable change via CAD, whereas for higher-order esters like tetraesters or triesters a change in every POE chain or in 3 of 4 POE chains would result in a detectable change via CAD, as the fatty acids were cleaved.

-

III.

Emerging of species with lower hydrophobicity

Another key characteristic for oxidative PS80 degradation is the appearance of multiple new species in the chromatograms with low hydrophobicity after forced oxidation (Brovč et al., 2020a; Borisov et al., 2015; Lippold et al., 2017; Liu et al., 2022a; Kranz et al., 2019; Kranz et al., 2020). The presence of double bonds is discussed as origin resulting in oxidation degradation products of oleic acid (Borisov et al., 2015; Liu et al., 2022a; Kranz et al., 2020). Liu et al. (2022) suggested, for instance, keto-oleic acid or hydroperoxyl-oleic acid with in-source water loss after performing LC-MS with CID as more hydrophilic degradation products of oleic acid for two of the early eluting species (Liu et al., 2022a). However, also other products were discussed as described above (see Fig. 7) (Liu et al., 2022a).

-

IV.

Dominant degradation of longer chain fatty acid esters

Additionally, Borisov and coworkers (2015) revealed a stronger degradation of PS species esterified to longer FA chains in comparison to shorter ones (Borisov et al., 2015). For instance, POE sorbitan mono-caprate (C10:0) esters are more resilient to oxidative stress with AAPH after 19 h and 40 h, respectively, compared to POE sorbitan mono-stearate (18:0) esters (Borisov et al., 2015). These results were supported by Zhang et al. (2018), demonstrating reduced APPH induced degradation of laurates in comparison to stearates and revealing another key characteristic of polysorbate oxidation (Zhang et al., 2018). Exact rationales behind the preferred oxidation of longer fatty acid POE sorbitans are unknown, however, preferential ether bond scission within the esterified POE chain were argued due to different arrangements of the POE chain (Borisov et al., 2015).

-

V.

Competition of protein and PS oxidation

Another characteristic is the "competitive" oxidation between polysorbate and the protein present in formulations (Brovč et al., 2020a; Gopalrathnam et al., 2018; Bensaid et al., 2022). Brovč and colleagues (2020) investigated the degradation of PS80 AO (0.2 mg·mL-1) formulated in 20 mM histidine chloride buffer pH 6.5 in the presence of four different mAbs (10 mg·mL-1) at 50 °C for 1 month. In all cases less PS80 oxidation in comparison to the placebo formulation was observed, with even neglectable oxidation of PS for two of the four mAbs (Brovč et al., 2020a). A mAb concentration dependent effect was shown by Bensaid et al. (2022), as less PS80 MC oxidation was observed with increasing protein concentration ranging from 10 to 140 mg·mL-1, although the samples were stressed with 50 ppb iron at 40 °C (Bensaid et al., 2022). The protective effect of protein on PS80 (quality not defined) oxidation was also reported by Gopalrathnam et al. (2018), as no PS80 oxidation was observed for samples containing mAb >40 mg·mL-1 for the storage of 10 month at 25 °C (Gopalrathnam et al., 2018). As active pharmaceutical ingredients are typically formulated in high protein concentrations, there are stochastically more protein molecules in the solution compared to surfactant molecules, which would result in higher protein oxidation for diffusion driven oxidation (OH• radicals). For example, there are >6 times more mAb molecules in a formulation with 0.2 mg·mL-1 (∼0.16 mM) polysorbate 20 and 150 mg·mL-1 (∼1 mM) antibody (Mw PS20 ∼1227 g·mol-1 and Mw mAb ∼150,000 g·mol-1). Therefore, the likelihood for radicals to attack an antibody molecule will be higher as finding a surfactant molecule based on solely stochastically assumptions. Oxidation of the protein is not intended as it can influence the drug efficacy, but it has been observed multiple times (Brovč et al., 2020a; Gopalrathnam et al., 2018; Bensaid et al., 2022). However, the presence of polysorbate itself results in increased oxidation of the proteins as shown for instance by Ha et al. (2002), Lam et al. (2011), and Klair et al. (2021) to name a few (Ha et al., 2002; Klair et al., 2021; Lam et al., 2011).

-

c.

Is PS80 more prone to oxidation than PS20?

It is usually claimed that PS80 is more susceptible to oxidative degradation compared to PS20, due to the higher ratio of esterified unsaturated fatty acids (Brovč et al., 2020a; Kishore et al., 2011a; Kishore et al., 2011b; Borisov et al., 2015; Liu et al., 2022a; Larson et al., 2020; Yao et al., 2009; Hvattum et al., 2012). However, an in-depth comparison between both polysorbate types in a concentration dependent manner and under pharmaceutical relevant conditions, is currently not available in the literature. This chapter will elaborate and summarize the public available conducted studies that examined the different degradation of PS20 compared to PS80.

A study that pursued the question which surfactant might be more susceptible on oxidative processes, was conducted by Yao et al. (2009), using the difference in reaction heats for H-absorption by hydroperoxyl radicals to demonstrate that the oxidation is energetically favored in the vicinity of the unsaturated site rather than at the POE units (Yao et al., 2009). After stressing with AAPH at 40 °C, differences in oxidizability constants between PS80 and PS20 (the authors used highest Sigma Aldrich grade at that time) of 2.65 were reported (Yao et al., 2009). It should be mentioned that quite high concentrations of PS80 and PS20 were used, ranging between 0.5 and 5.0 % (w/v) as well as between 0.5 and 4.0 % (w/v), respectively (Yao et al., 2009). However, they concluded that two-thirds of the oxidation occurs in the vicinity of the unsaturated fatty acid ester groups of PS80, as otherwise the oxidizability constants should be identical for PS20 and PS80, when oxidation is only occurring at the identical amounts of POE subunits. In PS20, oxidation is mainly occurring at the POE groups, based on the small amounts of unsaturated fatty acids (Yao et al., 2009). The different heats of reaction for H-absorption by hydroperoxyl radicals illustrates that unsaturated fatty acids are more affected by oxidation compared to POE units. Likewise, it seems logical that there would be differences in the oxidizability constants, which had to be the same for PS20 and PS80 if they had identical degradation kinetics.

A different approach was pursued by Kishore and colleagues (2010) investigating oxidation of PS20 MC and PS80 MC raw materials via thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) over a temperature range from 25 to 400 °C (Kishore et al., 2011b). By combining TGA and DSC loss/gain in weight as well as the thermodynamic heat loss/gain profiles they extracted information on oxidation. Additionally, they compared Span-80 (sorbitan ester of oleic acid) and PS80 to verify the influence of the unsaturated oleic acid upon oxidation. They revealed that thermal oxidation of PS80 is dominated by the POE chain, although it is initiated at the olefinic site (Kishore et al., 2011b). PS80 raw material showed slightly higher peroxide rates and slightly more degradation than PS20 due to the degree of unsaturation, however, the overall degradation profiles were comparable for storage at 40 °C for 24 weeks (Kishore et al., 2011b). In a second study, they compared degradation products of PS20 and PS80 via MS and were able to differentiate in POE oxidation (formation of formates) as well as in scission in the vicinity of the double bond (alkyl aldehydes, alkanes, and dicarboxylic acids) (Kishore et al., 2011a; De Sainte, 2009). GC-MS analysis of PS20 and PS80 detected hexane, pentane, and heptanal as well as butanal, pentanal, hexanal, and heptanal, respectively (Kishore et al., 2011a). Thus, while these results demonstrate oxidation occurring at the unsaturated fatty acid site, they unfortunately did not show whether oxidation is a more severe problem at PS80 compared to PS20.

Borisov and coworkers (2015) demonstrated that after stressing with the artificial radical initiator AAPH, a higher oxidative susceptibility of unsaturated fatty acids is observed (Borisov et al., 2015). The degradation product oxo-nonanoic acid was detected by LC-MS, originating from oxidation of the oleic acid (Borisov et al., 2015). Additionally, pseudo first-order rates for the decomposition of POE sorbitan esters were determined after stressing with AAPH, revealing higher rates for unsaturated fatty acids (Borisov et al., 2015). They clearly showed a faster oxidation of oleic acid species (PS80), however, the impact under pharmaceutical conditions, without additional stressors was not investigated.

Comparing PS20 and PS80 of different vendors and in different buffer systems, Brovč et al. (2020) observed higher degradation in PS80 relative to PS20 at 50 °C in some conditions, suggesting unsaturated fatty acids causing the difference (Brovč et al., 2020a). The detection of the degradation products like 1,9-nonanedioic acid additionally revealed oxidation at the double bond of oleic acid (Brovč et al., 2020a). Nevertheless, this observation was less obvious for all tested conditions, as some grades of PS80 revealed slower oxidation kinetics than PS20, as after one month more PS80 content was measured in comparison to PS20.

Liu et al. (2022) also reported that the oxidation of PS80 MC or AO mainly occurs at the double bond of unsaturated fatty acids (Liu et al., 2022a). They developed an LC-MS detection method to distinguish the degradation products of different PS80 grades and vendors by distinct fingerprints due to variations in the fatty acid compositions (Liu et al., 2022a). By monitoring specific degradation products such as 9-oxononanoic acid, keto-oleic acid, and 2-decenedioic acid species, after stressing PS80 MC or AO with 50 ppb iron at 25 °C, they demonstrated that the oxidation primarily occurs at the double bond of unsaturated fatty acids, since the POE structures remained intact (Liu et al., 2022a). Saturated fatty acid derivatives, such as POE palmitic acid monoesters showed higher stability (Liu et al., 2022a). These results were supported by Hvattum and colleagues (2012) reporting higher susceptibility of PS80 after temperature stress, by observing complete degradation of C18:2 after 8 weeks at 40 °C via LC-MS. (Hvattum et al., 2012) For the oleic acid a decrease of 20 % was monitored in short-chain POE esters and C18:1 oxidation products, however, the overall degradation rate was reported to be comparable to other esterified FAs (Hvattum et al., 2012). It needs to be clarified whether the entire degradation of C18:2 is indeed responsible for the overall accelerated degradation of PS80.

Larson and coworker (2020) stressed their PS80 samples with AAPH, showing that peroxyl radicals mainly attack PS80 on the double bond and in fact showed higher degradation, if higher amounts of double bonds like linoleic or linolenic acids were involved (Larson et al., 2020). Nevertheless, degradation products derived from both, the unsaturated fatty acids and POE units (Larson et al., 2020).

Although, there are many studies reporting and demonstrating oxidation of PS80 on the unsaturation site based on degradation products of oleic or linoleic acid, less is known about a direct comparison between PS20 and PS80 under pharmaceutical relevant conditions (without additional stressors). Or to rephrase it, is the difference of PS20 and PS80 oxidation relevant for the pharmaceutical industry and are products stored at 5 °C drastically affected? Up to now, only Kishore and colleagues (2010) measured a slightly higher peroxide formation in PS80, however, the degradation comparison between PS20 and PS80 over 24 weeks at 40 °C was nearly similar, making a conclusive statement rather difficult (Kishore et al., 2011b). Furthermore, Brovč et al. (2020) compared PS20 and PS80 from different manufactures, buffers, as well as at different pH values (pH 5.5 and 6.5) and could show that after 2 months a lower PS concentration can be monitored for PS80 (mainly in histidine chloride and sodium succinate buffer) (Brovč et al., 2020a). However, recently Kranz and colleagues (2020) observed similar polyester degradation of PS20 AL and PS80 AO, despite the higher oleic acid content of the all-oleate quality (Kranz et al., 2020). The question regarding PS20 or PS80 being the better surfactant is quite complex as it depends on many factors. To sum it up, although higher oxidation of the unsaturated fatty acids was demonstrated, there are currently not enough data to clearly show that PS80 is more prone to oxidation under pharmaceutical relevant conditions like temperatures of 5 °C. For an exact comparison, type and degree of stress should be considered as well.

-

d.

Impact of polysorbate 20 and 80 qualities on oxidation

-

I.

Purer polysorbate grades – PS20 AL and PS80 AO

While in recent years much effort has been spent on developing and commercializing purer or less heterogeneous polysorbates, studies published so far have not demonstrated any relevant advantage regarding oxidative polysorbate degradation. It seems that the functionality of PS is still not understood, as even poorer performance was reported (Brovč et al., 2020a; Doshi et al., 2020a; Liu et al., 2022a; Kranz et al., 2019; Bensaid et al., 2022; Kranz et al., 2020).

Due to the current issues and the intrinsic heterogeneity of PS, purer grades were developed, like PS20 AL and PS80 AO with higher amounts of the corresponding fatty acids. To identify advantages and disadvantages of this new polysorbate grades towards oxidative degradation, studies were conducted comparing different polysorbate qualities. Several studies demonstrated a faster oxidative degradation of the PS20 AL and PS80 AO grades after exposure to H2O2 or iron (Liu et al., 2022a; Kranz et al., 2019; Bensaid et al., 2022; Kranz et al., 2020). For instance, Kranz and colleagues (2019/20) investigated the oxidation behavior of the ultrapure polysorbates PS20 AL and PS80 AO in comparison to the MC grades of PS20 and PS80, respectively (Kranz et al., 2019; Kranz et al., 2020). They induced oxidative degradation by spiking Fe2+ or H2O2 at 40 °C (Kranz et al., 2019; Kranz et al., 2020). In the presence of H2O2 a greater loss in PS20 MC and AL as well as PS80 MC and AO concentration was observed in comparison to samples formulated in the absence of H2O2 (Kranz et al., 2019). By monitoring the polyester fractions of the different polysorbates, a slightly higher susceptibility was observed for the PS20 AL variant, whereas a drastically higher degradation was exhibited for the PS80 AO grade in comparison to their MC grades (Kranz et al., 2019). A similar behavior was detected for 10 ppb Fe2+ and 40 °C, with even faster degradation in comparison to the presence of just H2O2 (Kranz et al., 2019). Supporting results were obtained in their second study (Kranz et al., 2020). By tracking oxidation markers after oxidation stress, faster degradation for the ultrapure grades was confirmed (Kranz et al., 2020). This observation is matching with results from other studies, detecting higher oxidative susceptibility of the ultrapure grades (Brovč et al., 2020a; Liu et al., 2022a; Kranz et al., 2019; Bensaid et al., 2022; Kranz et al., 2020). Liu et al. (2022) investigated PS80 MC against ChP quality (AO) after exposure to 50 ppb Fe2+ at RT and hypothesized that the faster PS80 AO degradation is based on the approximately 10 % increased unsaturated fatty acids content (Liu et al., 2022a). Faster degradation of PS80 AO was also indicated by Brovč et al. (2020), investigating different PS80 grades from different vendors in various buffers (Brovč et al., 2020a). Similar behavior was observed in the presence of proteins, as Bensaid et al. (2022) stressed PS80 AO and MC grade in the presence of 20 mg·mL-1 mAb with 5 ppb Fe2+ at elevated temperatures and analyzed the PS degradation as well as the Met255 oxidation (Bensaid et al., 2022). Samples of the ultrapure grades (PS80 AO) exhibited faster PS decomposition as well as Met255 oxidation after 3 months at 25 °C and 1 month at 40 °C (Bensaid et al., 2022). Although many studies revealed higher susceptibility for oxidative degradation of ultrapure polysorbate qualities, protein protection against mechanical stress was not affected by the different qualities (Grabarek et al., 2020). For instance, Grabarek et al. (2020) exposed PS80 MC and AO to various mechanical stress conditions with no distinguishable differences in mAb functionality (Grabarek et al., 2020).

-

II.

PS20 HP vs. PS20 SR

Up to the authors knowledge, only one study compared polysorbate of HP and SR quality (Doshi et al., 2020a). Here, Doshi and coworkers (2020) showed that PS20 SR grade is more susceptible for oxidation than the corresponding HP quality, arguing with higher values of PS20 degradation, protein oxidation, and peroxide formation (Doshi et al., 2020a). Generally, it is reported by Doshi et al. (2020) by comparing the certificate of analysis that PS20 SR possesses a reduced content of stearate (6.3 % in PS20 HP vs. 1.1 % in PS20 SR) and correspondingly more myristate (18.5 % in PS20 HP vs. 22.5 % in PS20 SR). Also the additional proprietary flash chromatography of SR shows reduced content of impurities such as peroxides or aldehydes (Doshi et al., 2020a; Smaltz, 2013). Additionally, it was demonstrated for three different lots by ICP-MS that PS20 SR contains less transition metals like iron or chromium (4-8 ppb iron, <1-1.5 ppb chromium) in comparison to PS20 HP (11-15 ppb iron, 1-3 ppb chromium) (Doshi et al., 2020a). Therefore, the authors actually expected a higher susceptibility of PS20 HP, if only these data were considered. They tested the performance of 0.03 % (w/v) PS20 SR and HP in eight mAb formulations in histidine acetate buffer at pH 5.5 and monitored PS degradation, protein oxidation, and protein aggregation for different time periods at 2-8, 25, and 40 °C (Doshi et al., 2020a). The formulations containing PS20 HP demonstrated lower M252 oxidation, lower HMWs formation, as well as lower PS20 degradation mitigated by the presence of 10 mM methionine (Doshi et al., 2020a). The observed differences were explained by the faster peroxide formation of PS20 SR at 40 °C with PS20 HP showing a lag phase of approximately one week, monitored via the fluorometric Amplex® UltraRed HRP assay (Doshi et al., 2020a). The slight variation in oleate esters between PS20 SR and HP could also be a rationale behind the differences, however, it could not be definitively proven (Doshi et al., 2020a). This comparison of PS20 SR and HP demonstrates that a purified grade not necessarily possesses improved oxidation stability performance.