Highlights

-

•

Sonicated potato flours have lower blue value and oil holding capacity.

-

•

Swelling power, water solubility, syneresis rate, and transparency were increased.

-

•

Ultrasound caused a decrease in RDS content but an increase in RS and SDS content.

-

•

Significant increase in T0, TC, decrease in ΔH was found in sonicated samples.

-

•

Crystalline patterns were not affected by ultrasound.

Keywords: Potato flour, Ultrasound, Physicochemical properties, Structural characteristics

Abstract

Ultrasound has been widely used for physical modifications of starch because of its effectiveness and environment friendliness; however, only a few reports have focused on the effect of varying ultrasonic treatments on the physicochemical properties of potato flour. In the present study, ultrasound at varying power levels (200, 300, 400, 500, and 600 W) and time intervals (20, 40, 60, 80, and 100 min) were used to obtain sonicated flour. Sonicated potato flour exhibited a significant (P < 0.05) decrease in blue value and oil holding capacity but an increase in swelling power, water solubility, syneresis rate, and transparency. Moreover, ultrasound decreased the RDS content while increasing RS and SDS contents. Thermal properties demonstrated significant (P < 0.05) increases in T0 (64.39℃–83.52℃) and TC (144.29℃–146.87℃) but a decrease in ΔH of the sonicated flour. SEM revealed wrinkles, less debris, and larger particle size at the surface of the sonicated flour. FTIR profiles of all samples exhibited similar characteristics peaks, but the sonicated flour had a higher R1047/1022 value. Additionally, ultrasound did not affect crystalline patterns, but it increased the crystallinity of the sonicated flour. Our study contributes to the understanding of physicochemical property changes of sonicated potato flour, which could have industrial applications.

1. Introduction

Potato is the fourth largest crop globally. According to the statistical data provided by the China Bureau of Statistics in 2021, the country’s potato production amounted to 1,830.9 million tons, predominantly used in the preparation of fresh and processed food items [1]. The consumption of potatoes has long been associated with promoting good health and enhancing human nutrition because of their rich content of carbohydrates, protein, dietary fiber, vitamins, minerals, and polyphenols [2], [3]. Potato can be processed into flour to extend its applications and shelf life. Potato flour with balanced nutrients and lower starch digestibility can be obtained through cooking, drying, grinding, and sieving [4], [5]. There is an increasing interest in developing potato-based food products, such as bread, snacks, noodles, and chips [6]. Studies have demonstrated that incorporating potato flour into steamed bread or noodles can enhance the nutritional value of the final product [7]. However, potato flour has poor processing characteristics and is unstable under various conditions. In this regard, the enhancement of processing properties through physical, enzymatic, or other modifications for better application in foods remains attractive to researchers.

The widespread use of ultrasonic treatment for food processing and preservation has resulted in higher throughput, shorter processing times, improved quality, and lower maintenance costs [8]. Ultrasound’s cavitation effect and mechanical vibration can cause cell wall disruption, molecular degradation, and free radical production [9]. Particularly, ultrasonic treatment is a nonthermal processing method widely used in the production of modified starch with fewer byproducts and no chemical residues. Ultrasound can alter the physical properties of food components, resulting in new structures or functions [6]. Studies have reported the effects of ultrasonic treatment on corn [10], wheat [11], potato [12], and rice [13] starches. Ultrasound can induce several changes in starches, such as decreased viscosity, increased transparency, and increases solubility [14]. Moreover, the ultrasonication effects on starch properties are quite complex, depending on the applied ultrasonic parameters, such as the power and time. Starch is the main component of potato flour. Numerous investigations have explored the properties of sonicated potato starch [14], [15]. However, the effect of ultrasound on the structure and physicochemical characteristics of potato flour has remained largely unknown.

Therefore, the present study investigated the effect of varying ultrasonic parameters, including ultrasonic power and time, on the functional, structural, and thermal properties of potato flour. The oil holding capacity, water solubility and swelling power, freeze–thaw stability, transparency, granule morphology, crystallinity, thermal characteristics, and in vitro digestibility were determined to explore potential applications of sonicated potato flour.

2. Materials and methods

2.1. Materials

Potatoes (Qingshu No.9) were acquired from Li household agriculture professional cooperative (Pujiang, China). Coomassie Brilliant blue G-250/R-250 and bovine serum albumin were obtained from Solarbio Life Science (Beijing, China). Other chemicals and reagents were purchased from Ke Long Chemical Reagent Co., Ltd (Chengdu, China).

2.2. Preparation of potato flour

Potato flour was prepared using a previous method [16]. Fresh potatoes were cleaned, peeled, sliced, and then steamed for 30 ∼ 40 min. The steamed potatoes were dried in an oven at 55℃ for 48 h. The dried potatoes were mashed, passed through a 100-mesh sieve, and sealed in zip-lock bags until use. The contents of moisture, ash, protein, fat, starch and reducing sugar were determined according to previous reports.

2.3. Ultrasound processing

Sonicated potato flour was prepared using an ultrasonic processor (JY92-IIN, Ningbo Scientz Biotechnology Co., Ltd., Ningbo, China) with adjustable power of up to 650 W at a frequency of 25 kHz. The temperature of the reactor was controlled at 25℃ with a low-temperature thermostatic bath (DC-2006, Ningbo Scientz Biotechnology Co., Ltd., Ningbo, China). Potato flour was dispersed with deionized water, followed by constant agitation for 2 min to get a homogeneous slurry (35%, w/v). Ultrasonic treatment was performed in pulse mode with a 5-s on and 5-s off cycle. A 6-mm probe was used, which was submerged at a depth of 2 cm in the slurry. The effects of varying ultrasonic power (200, 300, 400, 500, and 600 W) and ultrasonic time (20, 40, 60, 80, and 100 min) on the functional, digestive, and structural properties of potato flour were investigated. The detailed ultrasonic treatment conditions are shown in Table 1. The sonicated flour was washed with 50% ethanol (v/v) thrice. After centrifugation at 5000 × g for 10 min, the precipitate was dried in an oven at 40℃ for 24 h. Subsequently, the precipitate was ground to powder, sieved through a 100 mesh, and stored in airtight plastic containers for further analysis.

Table 1.

Ultrasonic treatment conditions.

| Sample | Power (W) | Time (min) |

|---|---|---|

| Native flour | – | – |

| UPF-P200 | 200 | 40 |

| UPF-P300 | 300 | 40 |

| UPF-P400 | 400 | 40 |

| UPF-P500 | 500 | 40 |

| UPF-P600 | 600 | 40 |

| UPF-T20 | 400 | 20 |

| UPF-T40 | 400 | 40 |

| UPF-T60 | 400 | 60 |

| UPF-T80 | 400 | 80 |

| UPF-T100 | 400 | 100 |

2.4. Functional properties

2.4.1. Blue value

The blue value was determined using a previous method with little modification. Briefly, 2.5 g of sonicated potato flour was homogenized with 500 mL of water for 2 min. Approximately 4 mL of the mixture was mixed with 25 mL of iodine solution (0.04%). The blue value was expressed as the absorbance measured at 620 nm with distilled water as blank.

2.4.2. Oil holding capacity

The oil holding capacity of potato flour was determined according to a centrifugal procedure as described by Chiranthika et al. [17]. In a centrifuge tube, 0.5 g of samples were suspended in 5 mL of oil and mixed for 1 min using a vortex mixture. The mixture was centrifuged at 3000 × g for 10 min at room temperature. The supernatant was poured carefully into a tared evaporating dish. The oil holding capacity was calculated using the following equation:

2.4.3. Water solubility and swelling power

The water solubility and swelling power were determined as described by Chiranthika et al. [17] with little modification. In a 50-mL centrifuge tube, 0.1 g of potato flour was mixed with 10 mL of deionized water. The mixture was heated for 30 min (with periodic vertexing) at 95℃, cooled to room temperature in a tap water bath, and centrifuged at 2500 × g for 30 min. The weight of the precipitate was measured (m2). Meanwhile, the supernatant was carefully poured into a weighing bottle and dried in an oven at 105℃ to constant weight (m1). The water solubility and swelling power of potato flour were calculated using the following equations:

where m is the initial weight of the sample; m1 is the weight of dissolved potato flours; m2 is the weight of the precipitate.

2.4.4. Freeze-thaw stability

In a 50-mL centrifuge tube, 0.1 g of potato flour was mixed with 10 mL of deionized water. The mixture was heated for 30 min (with periodic vertexing) at 95℃, cooled to room temperature in a tap water bath, and centrifuged at 2500 × g for 30 min. The weight of the precipitate was measured (m2). Meanwhile, the supernatant was carefully poured into a weighing bottle and dried in an oven at 105℃ to constant weight (m1). The water solubility and swelling power of potato flour were calculated using the following equations [18]:

where, W0 is the weight of gelatinized potato flours and Wp is the weight of precipitate, respectively.

2.4.5. Transparency

The transparency of potato flours was measured using a method described by Wang et al. [19]. Approximately 0.5 g of potato flour was mixed with 50 mL of deionized water. The mixture was heated for 30 min at 95℃ with constant stirring and then cooled to room temperature. The transmittance (%) was measured at 640 nm with a UV/Vis spectrophotometer (Meipuda instruments Co., Ltd., Shanghai, China).

2.5. In vitro digestibility

The in vitro digestibility of potato flours was measured using a method of Englyst et al. [20]. Typically, 200 mg of potato flour was mixed with 15 mL of sodium acetate buffer (pH 5.2). The gelatinized sample was obtained by boiling the mixture for 30 min. After cooling to room temperature, 10.0 mL of α-amylase from the pancreas containing amyloglucosidase (15 U/mL) was added. The mixture was incubated at 37℃ for 120 min, and then 4.0 mL of 99% ethanol was added with vigorous stirring. After centrifugation (1500 × g for 10 min), the supernatant was collected. The amount of glucose from the hydrolysis was quantified using the DNS (3,5- Dinitrosalicylic acid) method. Rapidly digestible starch (RDS) (fractions digested within 20 min), slowly digestible starch (SDS) (fractions digested between 20 and 120 min), and resistant starch (RS) (fractions remained after 120 min) were calculated using the following equations:

where, G20 is the glucose content after 20 min of digestion, G120 is the glucose content after 120 min of digestion, FG is the glucose content before digestion, and TS is the starch content in potato flour.

2.6. Thermal properties

The thermal properties of each sample were measured through differential scanning calorimetry (DSC) (Q2000, TA Instruments, USA) as described by Wang et al. [21]. The samples (5 mg) were transferred to an aluminum pan and sealed. An empty aluminum pan was used as a reference. The pans were heated from 20℃ to 250℃ at a rate of 10℃/min. The gelatinization parameters of samples such as the temperatures at the beginning (T0), peak (Tp), and conclusion (Tc), as well as the enthalpy change (ΔH), were measured.

2.7. Scanning electron microscopy (SEM)

The morphological characteristics of native and sonicated potato flour (UPF-P200, UPF-P300, UPF-P400, UPF-P500, UPF-P600) were obtained using the Sigma 300 SEM (ZEISS, German). Each sample was gently spread on the double-sided sticky tape fixed to a copper stub. The samples were observed at 10-kV accelerating voltage after coating with gold–palladium [21].

2.8. Fourier transform infrared spectroscopy (FTIR)

FTIR spectra of native and sonicated potato flour (UPF-P200, UPF-P300, UPF-P400, UPF-P500, UPF-P600) The dried samples were finely mixed with KBr (1:100, w/w), ground, and pressed into tablets. The sheet samples were located on a sample table, and the spectra were recorded over a wave number range of 400–4000 cm−1 at a resolution of 4 cm−1 [22].

2.9. X-ray diffraction (XRD)

The crystalline type and relative crystallinity (RC) of native and sonicated potato flour were acquired using an X-ray diffractometer (D8 Advance, Bruker, USA) equipped with Cu-Kα radiation (λ = 0.154 nm). Samples were recorded at 40 kV and 40 mA with a scanning rate of 4.0°min−1 in the diffraction angle (2θ) range of 5°–60° [22].

2.10. Statistical analysis

All experiments were conducted in triplicates, and results are expressed as mean ± standard deviation. The related data was statistically analyzed using analysis of variance (ANOVA). Significant differences (P < 0.05) were determined using Duncan’s test (P < 0.05) with SPSS software, version 22.0 (SPSS Inc., Chicago, USA).

3. Results and discussion

3.1. Chemical composition of native potato flour

We analyzed the basic ingredients of native potato flour. The flour had the highest concentration of starch (60.85 g/100 g), followed by protein (7.53 g/100 g), moisture (4.69 g/100 g), ash (1.23 g/100 g), fat (0.63 g/100 g), and reducing sugar (0.37 g/100 g).

3.2. Effect of ultrasound on functional properties of potato flour

3.2.1. Blue value

The effect of different ultrasonic parameters on the blue value of potato flour was investigated, and the results are illustrated in Fig. 1. The blue value represents the ability of free starch in potato flour to combine with iodine. The greater the value, the stronger the ability to combine with iodine. As shown in Fig. 1, the blue value of sonicated sample was lower than that of the native flour, and the higher the ultrasonic power, the lower the blue value, indicating that ultrasound decreased the combination ability of potato flour with iodine. As clarified by Izabella et al. [23], the blue value was evidence of resistant starch development. If the absorbance is close to zero, the starch has transformed into resistant starch.

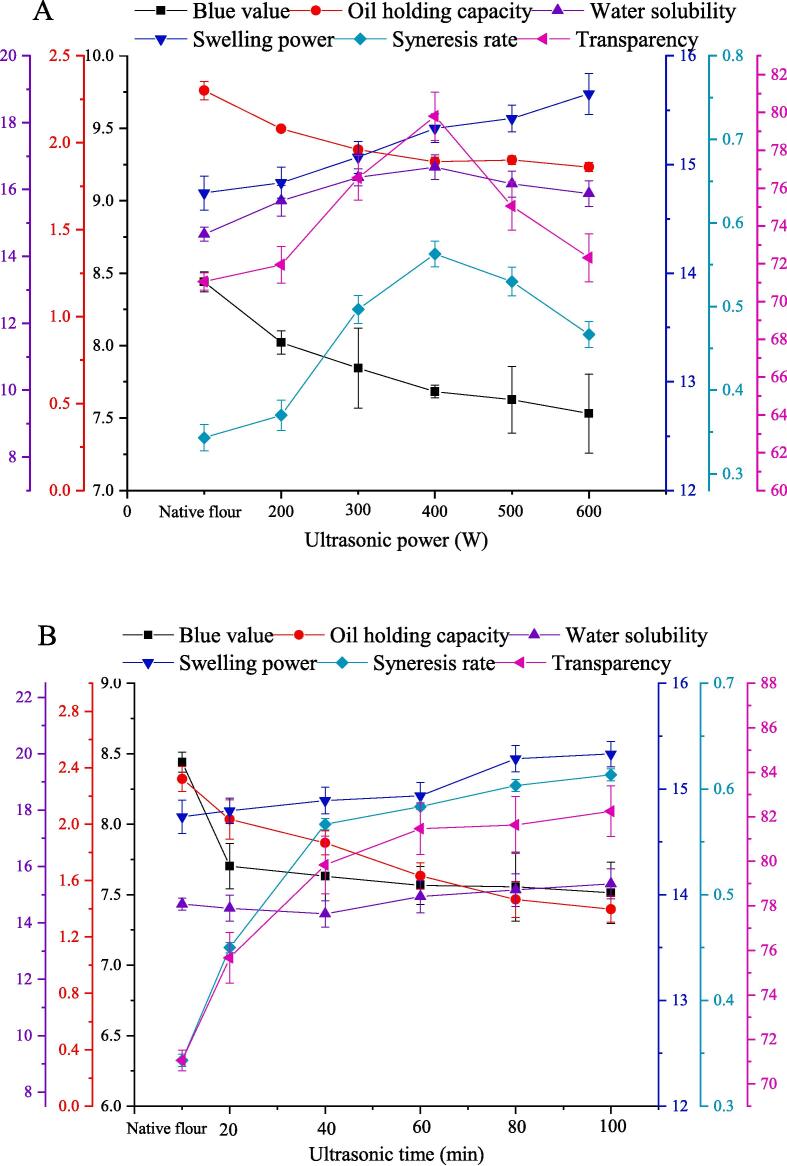

Fig. 1.

Effect of different ultrasonic treatments on the physicochemical characteristics of potato flour. (A) Ultrasonic power; (B) ultrasonic time.

3.2.2. Oil holding capacity

Oil holding capacity (OHC) is the ability to bind with oil during applications, thereby preserving product flavor [17], [24]. As shown in Fig. 1, ultrasound decreased the OHC of potato flour, which might be due to the increased particle size, resulting in a decreased surface area of modified flour in contact with oil. The entrapment of oil within the loosely arranged amylose-amylopectin architecture might be responsible for the higher OHC of native flour [25]. However, the decreased oil absorption of modified flour makes it a good choice for low-fat food processing.

3.2.3. Swelling power and solubility

Swelling power is one of the most important characteristics of starch. As shown in Fig. 1, the swelling power of modified flour increased with increasing sonicated power and time, which might be attributed to the cavitation-induced increase in temperature. When the modified flour was exposed to high temperatures, the internal matrices of starch changed from an ordered state to a disintegrated state, thereby increasing the swelling power. The characteristics of amylopectin are indicative of the degree of swelling power because it has a 3D branched structure providing space to hold more water [14].

The water solubility of the sonicated flour showed a similar trend. The solubility of the sonicated flour increased with increasing sonicated power and time, which may be attributed to the hydrolysis of starch granules caused by ultrasonic treatment. Increased ultrasonic power and time enhance the exposure of hydrogen bonds because of the degradation of potato flour, which induced an increase in the solubility of starch granules.

3.2.4. Freeze-thaw stability

The freeze–thaw stability of starch, which decides its application in frozen food products, indicates the syneresis degree of frozen foods after thawing; the lower the syneresis rate, the better the freeze–thaw stability. As shown in Fig. 1, ultrasonic treatment increased the syneresis rate, indicating that ultrasound decreases the freeze–thaw stability of modified flour, which may be attributed to the increased interaction of amylose-amylose and amylose-amylopectin during freezing, exuding more water [26]. Furthermore, the syneresis rate increased with the ultrasonic power in the range of 200–400 W but decreased after 400 W, which may be attributed to the protein in potato flour. High-intensity ultrasonic treatment could increase the water-holding capacity of protein, and correspondingly, the water-holding capacity of potato flour is also enhanced [27].

3.2.5. Transparency

As shown in Fig. 1, sonication leads to enhanced transparency of the modified potato flour, which had been confirmed in starches derived from diverse sources, such as potato, rice, and sweet potato. According to Zhu et al. [28], ultrasonication increased the water solubility of potato starch and reduced the number of granule remnants, resulting in better hydration of starch chains and an increase in light transmission. Moreover, with the ultrasonic power increased, the transparency of modified flour increased to a peak value at 400 W, after which it decreased. Larger expanded particle size and an increase in amylopectin content tend to increase transparency [29].

3.3. In vitro starch digestibility of potato flour affected by ultrasound

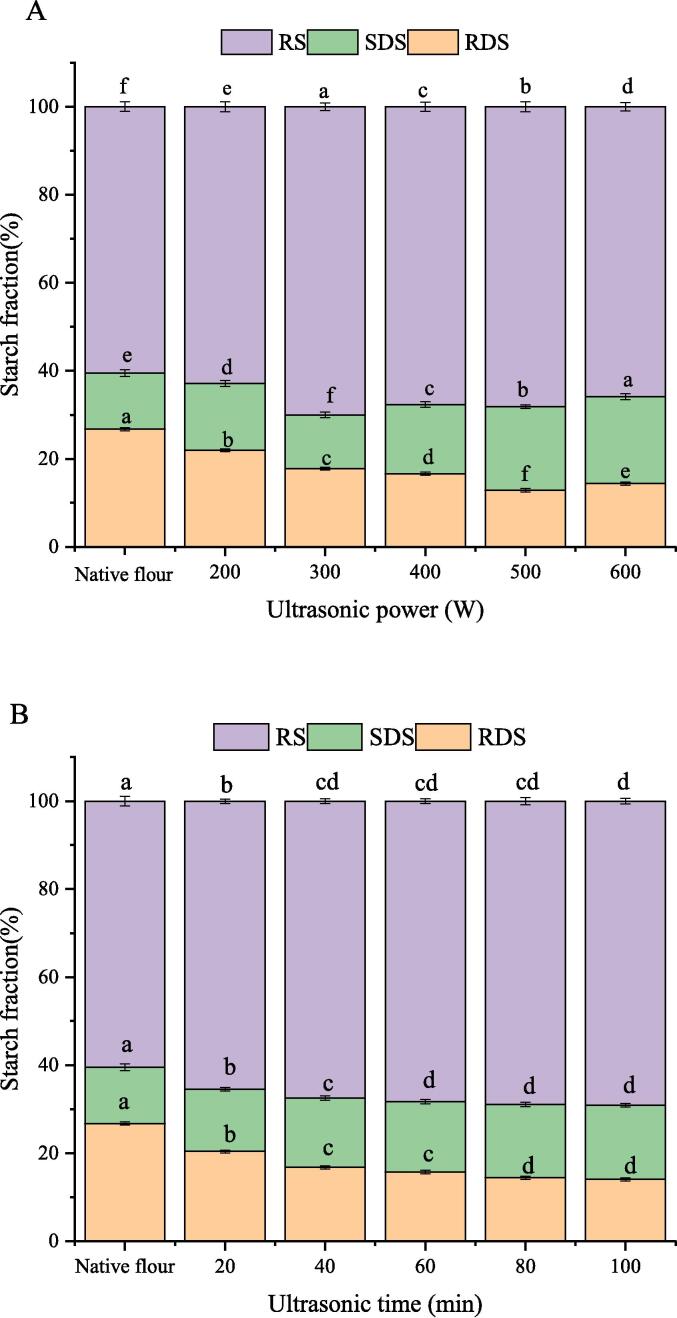

Fig. 2 presents the RDS, SDS, and RS levels in native and modified potato flours. Ultrasonic power significantly (P < 0.05) increased the RS and SDS contents but decreased the RDS contents of potato flour. The relationship between RS contents and ultrasonic power showed a rising trend before 300 W and a decreasing trend after 300 W. The peak value (70.01%) was obtained at 300 W. Low ultrasonic power at 200–300 W induced an increase in RS content from 60.51% to 70.01%, which might be attributed to the retrogradation of starch, reducing its susceptibility to enzyme hydrolysis [30]. However, higher ultrasonic power decreased RS content to 65.86%, which might be due to the faster collapse of bubbles caused by the more cavitation of higher ultrasonic power, making the starch granules more readily to break [30].

Fig. 2.

Effect of different ultrasonic treatments on the in vitro digestibility of potato flour. (A) Ultrasonic power; (B) ultrasonic time. Means followed by different letters indicate statistical difference (P < 0.05).

RDS can be digested rapidly, leading to a rapid increase in blood sugar levels. RS and SDS, on the other hand, have no and slow digestive characteristics in the small intestine, respectively. RS can ferment in the large intestine to produce short-chain fatty acids, which can prevent colorectal cancer, promote the growth of probiotic microorganisms, reduce blood sugar and blood lipid, inhibit fat accumulation, and promote mineral absorption [29], [31]. As shown in Fig. 2, the RDS and SDS contents of sonicated potato flour decreased, while the RS contents increased, indicating that ultrasonic treatment can reduce the digestion rate of potato flour, making it a suitable option for type Ⅱ diabetics.

3.4. Thermal properties

DSC analyses were conducted to evaluate the effect of ultrasound on the gelatinization and retrogradation properties of potato flour (Table 2). Results showed that significant (P < 0.05) increases in T0 (64.39℃–83.52℃) and TC (144.29℃–146.87℃) were observed in modified flours. As reported by Yang et al. [32], the increase in T0 is due to the dissolution of the weak crystalline structures in starch granules caused by ultrasound. Moreover, the ΔH of sonicated samples (46.8 J/g) was significantly lower (P < 0.05) than that of the native flour (70.47 J/g), which might be related to the disruption of ordered double-helical structures in crystalline regions of potato starch caused by energy released from the collapsing bubbles in ultrasonic treatment [15].

Table 2.

Thermal parameters of native and sonicated potato flours.

| Samples | To (°C) | TP (°C) | TC (°C) | △H (J/g) |

|---|---|---|---|---|

| Native flour | 64.39 ± 0.75a | 111.14 ± 0.11b | 144.29 ± 0.46a | 70.47 ± 0.23b |

| Sonicated flour | 83.52 ± 0.61c | 111.81 ± 0.38b | 146.87 ± 0.28b | 46.8 ± 0.17a |

Note: To is the gelatinization onset temperature, TP is the gelatinization peak temperature, TC is the gelatinization end temperature, and ΔH is the gelatinization heat threshold.

Different lowercase letters on the same column indicate significant differences between samples, P < 0.05.

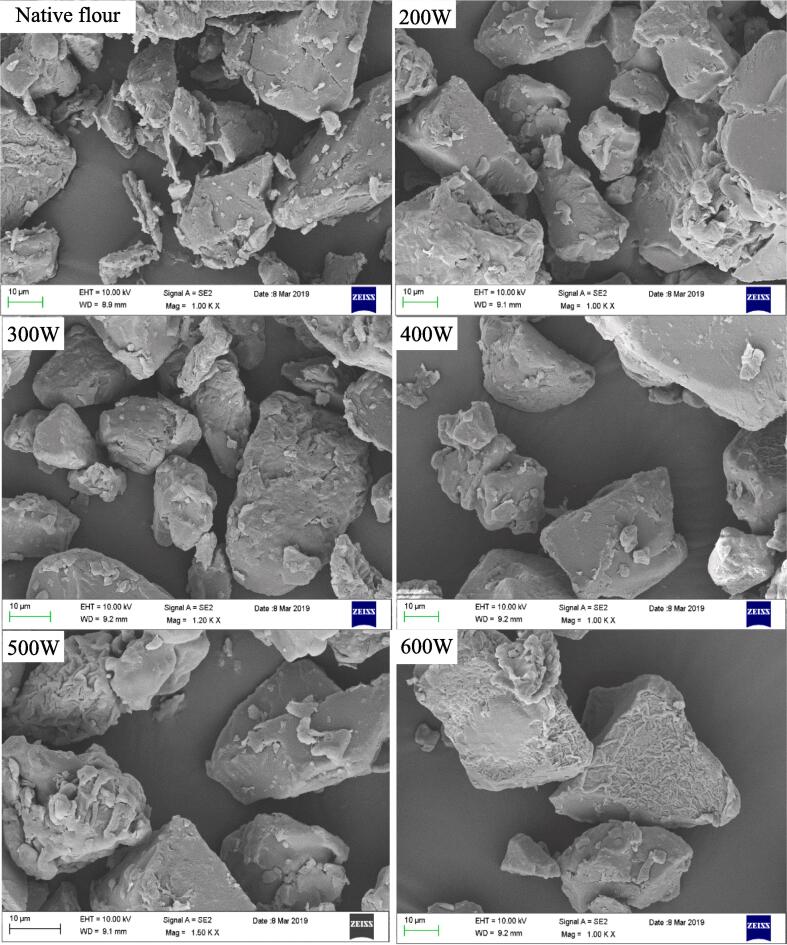

3.5. Morphology of samples

As shown in Fig. 3. The native flour had irregular shapes, such as lumps, fragments, and flocs, and the surface is smooth or uneven, or obvious cracks because of the heating process used to prepare potato flour, which destroyed the structure of starch particles. Sonicated potato flours displayed a rough surface with obvious wrinkles, less debris, and larger particle size. In another study [33], ultrasound led to the formation of some wrinkles on the surface of potato starch, which was similar to our results.

Fig. 3.

SEM micrographs of native and sonicated potato flours.

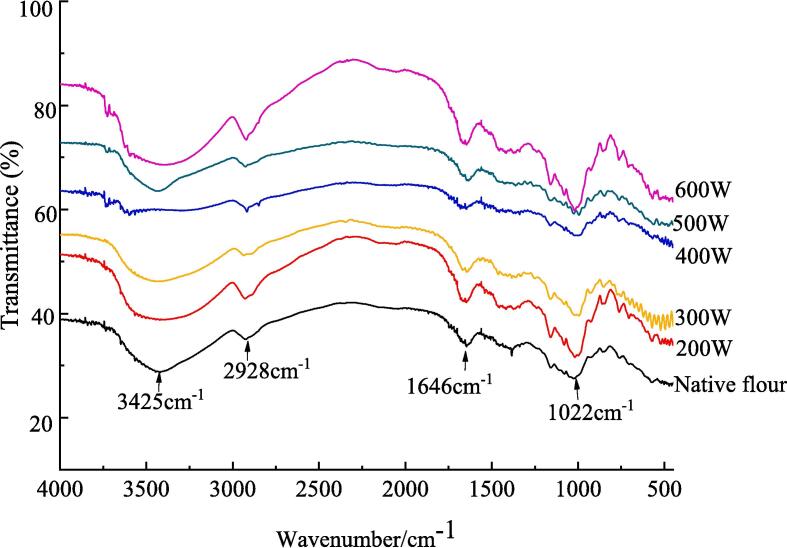

3.6. FTIR

FTIR can provide valuable information regarding structural characteristics, such as double helical order, helicity, and chain conformation. As shown in Fig. 4, the FTIR spectra of native and sonicated potato flours exhibited similar characteristics peaks at 3425 cm−1, 2928 cm−1, and 1646 cm−1, representing O–H vibration stretching, C–H deformation vibrations of glucose, and bending vibration of O–H in the water molecule and amorphous, respectively. The peaks at 1047 and 1080 cm−1 were related to the order structures of starch granules, whereas the FTIR band at 1022 cm−1 was reported to have a linkage to the amorphous regions [34]. The ratio of absorbance at 1047 and 1022 cm−1 (R1047/1022) can be used to describe the amount of ordered structure in starch [14]. According to Fig. 4, sonicated samples exhibited higher values of R1047/1022, suggesting that short-range order was strengthened [15]. However, there was no significant difference (P > 0.05) at variable power levels.

Fig. 4.

FT-IR spectra of native and sonicated potato flours.

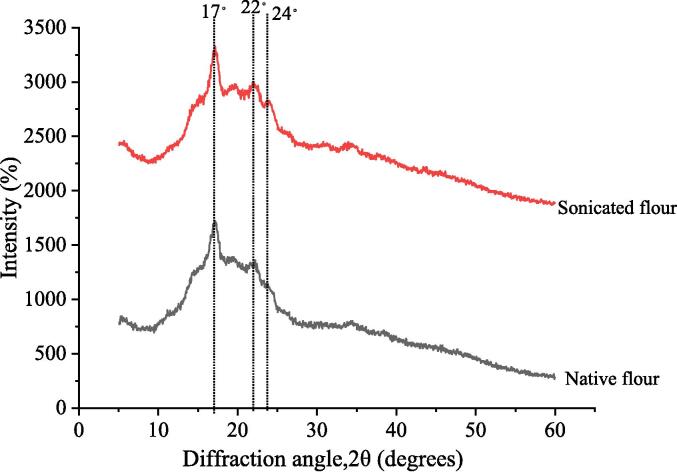

3.7. XRD

XRD was used to analyze the crystalline, amorphous, or semi-crystalline nature starch granules. X-ray diffraction patterns of native and sonicated potato flour are shown in Fig. 5. Native potato flour exhibited strong peaks at 2θ values of 17◦ and weak peaks at 15◦, 19◦, and 22◦, suggesting that the starch granules have B-type crystalline patterns. The XRD profile of the sonicated flour was similar to that of native potato flour, with a strong peak at 17◦, and weak peaks at 15◦, 19◦, 22◦, and 24◦. The increase of peak intensity at 17◦, 22◦, and 24◦ indicated an increase in crystallinity, which may be due to the promotion of sub-crystal crystallization by ultrasonic wave [35].

Fig. 5.

X-ray diffractograms of native and sonicated potato flours.

4. Conclusions

The present study investigated the effects of sonicated potato flour at various power levels and time intervals. Ultrasonic treatment significantly affected the functional and thermal properties of potato flour. Compared with the native flour, the sonicated samples had lower blue value and oil holding capacity but higher swelling power, water solubility, syneresis rate, and transparency. Ultrasonication decreased the RDS content while increasing the RS and SDS concentrations. Compared with the native flour, micrographs of the sonicated samples exhibited rough surfaces with obvious wrinkles, less debris, and larger particle size. Additionally, FTIR revealed higher values of R1047/1022 for sonicated samples, suggesting the strengthening of short-range order. Furthermore, ultrasonication did not affect the crystalline patterns but increased the crystallinity of sonicated samples. Our findings suggest that controlled ultrasonication can be used to alter the physicochemical characteristics of potato flour, which could be used to develop new products with more beneficial effects.

CRediT authorship contribution statement

Xiaoyan Hou: Formal analysis, Data curation, Writing – original draft. Xiaowan Li: Methodology, Investigation. Jianlong Li: Data curation, Formal analysis, Writing – review & editing. Jun Cong: Resources, Software. Lingyan Jiang: Resources, Software. Guanghui Shen: Validation, Visualization. Anjun Chen: Conceptualization, Resources. Zhiqing Zhang: Supervision, Project administration.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

We thank Home for Researchers editorial team (www.home-for-researchers.com) for language editing service.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

References

- 1.Liu X., Ma Q., Cheng D., Zhang F., Li Y., Wang W., Wang J., Sun J. Preparation and characterization of type 3 resistant starch by ultrasound-assisted autoclave gelatinization and its effect on steamed bread quality. Ultrason. Sonochem. 2023;92 doi: 10.1016/j.ultsonch.2022.106248. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.King J.C., Slavin J.L. White potatoes, human health, and dietary guidance. Adv. Nutr. 2013;4:393S–401S. doi: 10.3945/an.112.003525. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Koch M., Naumann M., Pawelzik E., Gransee A., Thiel H. The importance of nutrient management for potato production part i: plant nutrition and yield. Potato Res. 2020;63:97–119. doi: 10.1007/s11540-019-09431-2. [DOI] [Google Scholar]

- 4.Gong S., Li W., Yu Y., Gu X., Zhang W., Wang Z. Dynamic changes of proton populations in potato flours during fermentation and their relationship with digestibility and functional properties. Food Chem. 2020;313 doi: 10.1016/j.foodchem.2020.126161. [DOI] [PubMed] [Google Scholar]

- 5.Pu H., Wei J., Wang L., Huang J., Chen X., Luo C., Liu S., Zhang H. Effects of potato/wheat flours ratio on mixing properties of dough and quality of noodles. J. Cereal Sci. 2017;76:236–242. doi: 10.1016/j.jcs.2017.06.020. [DOI] [Google Scholar]

- 6.Cui R., Zhu F. Effect of ultrasound on structural and physicochemical properties of sweetpotato and wheat flours. Ultrason. Sonochem. 2020;66 doi: 10.1016/j.ultsonch.2020.105118. [DOI] [PubMed] [Google Scholar]

- 7.Yang X., Ru X., Sun Z. Effects of sodium chloride and freeze–thaw cycling on the quality of frozen cooked noodles made of potato flour. J. Food Process Pres. 2022;46:16733. doi: 10.1111/jfpp.16733. [DOI] [Google Scholar]

- 8.He R., Pan Y.-G., Shang W.-T., Zhong G., Huang W.-Y., Xiang D., Pan F., Zhang W.-M. Ultrasonic-assisted binding of canistel (Lucuma nervosa A.DC) seed starch with quercetin. Ultrason. Sonochem. 2023;96:106417. doi: 10.1016/j.ultsonch.2023.106417. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Zhang X., Mi T., Gao W., Wu Z., Yuan C., Cui B., Dai Y., Liu P. Ultrasonication effects on physicochemical properties of starch-lipid complex. Food Chem. 2022;388 doi: 10.1016/j.foodchem.2022.133054. [DOI] [PubMed] [Google Scholar]

- 10.Zhang S., Li Q., Zhao Y., Qin Z., Zheng M., Liu H., Liu J. Preparation and characterization of low oil absorption corn starch by ultrasonic combined with freeze-thaw treatment. Food Chem. X. 2022;15 doi: 10.1016/j.fochx.2022.100410. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Sujka M. Ultrasonic modification of starch–impact on granules porosity. Ultrason. Sonochem. 2017;37:424–429. doi: 10.1016/j.ultsonch.2017.02.001. [DOI] [PubMed] [Google Scholar]

- 12.Kaul S., Kaur K., Kaur J., Mehta N., Kennedy J.F. Properties of potato starch as influenced by microwave, ultrasonication, alcoholic-alkali and pre-gelatinization treatments. Int. J. Biol. Macromol. 2023;226:1341–1351. doi: 10.1016/j.ijbiomac.2022.11.246. [DOI] [PubMed] [Google Scholar]

- 13.Shifeng Y., Yongchun Z., Yin G., Ying Z., Tianying S., Yan J., Xiqun Z. Effects of ultrasound processing on the thermal and retrogradation properties of nonwaxy rice starch. J. Food Process Eng. 2013;36:793–802. doi: 10.1111/jfpe.12048. [DOI] [Google Scholar]

- 14.Raza H., Ameer K., Ma H., Liang Q., Ren X. Structural and physicochemical characterization of modified starch from arrowhead tuber (Sagittaria sagittifolia L.) using tri-frequency power ultrasound. Ultrason. Sonochem. 2021;80:105826. doi: 10.1016/j.ultsonch.2021.105826. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Zhang B., Xiao Y., Wu X., Luo F., Lin Q., Ding Y. Changes in structural, digestive, and rheological properties of corn, potato, and pea starches as influenced by different ultrasonic treatments. Int. J. Biol. Macromol. 2021;185:206–218. doi: 10.1016/j.ijbiomac.2021.06.127. [DOI] [PubMed] [Google Scholar]

- 16.Buzera A., Gikundi E., Orina I., Sila D. Effect of pretreatments and drying methods on physical and microstructural properties of potato flour. Foods. 2022;11:507. doi: 10.3390/foods11040507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Chiranthika N.N.G., Chandrasekara A., Gunathilake K.D.P.P. Physicochemical characterization of flours and starches derived from selected underutilized roots and tuber crops grown in Sri Lanka. Food Hydrocoll. 2022;124 doi: 10.1016/j.foodhyd.2021.107272. [DOI] [Google Scholar]

- 18.Xie F., Yuan C., Zhang H., Wu Y., Ai L. Structure-function relationship between galactomannans and their effects on freeze-thaw stability, retrogradation, and texture of corn starch gels during cold storage. Food Chem. 2023;398:133915. doi: 10.1016/j.foodchem.2022.133915. [DOI] [PubMed] [Google Scholar]

- 19.Wang W., Zhou H., Yang H., Zhao S., Liu Y., Liu R. Effects of salts on the gelatinization and retrogradation properties of maize starch and waxy maize starch. Food Chem. 2017;214:319–327. doi: 10.1016/j.foodchem.2016.07.040. [DOI] [PubMed] [Google Scholar]

- 20.Englyst K.N., Englyst H.N., Hudson G.J., Cole T.J., Cummings J.H. Rapidly available glucose in foods: an in vitro measurement that reflects the glycemic response. Am. J. Clin. Nutr. 1999;69:448–454. doi: 10.1093/ajcn/69.3.448. [DOI] [PubMed] [Google Scholar]

- 21.Wang H., Xiao N., Wang X., Zhao X., Zhang H. Effect of pregelatinized starch on the characteristics, microstructures, and quality attributes of glutinous rice flour and dumplings. Food Chem. 2019;283:248–256. doi: 10.1016/j.foodchem.2019.01.047. [DOI] [PubMed] [Google Scholar]

- 22.Vela A.J., Villanueva M., Solaesa Á.G., Ronda F. Impact of high-intensity ultrasound waves on structural, functional, thermal and rheological properties of rice flour and its biopolymers structural features. Food Hydrocoll. 2021;113 doi: 10.1016/j.foodhyd.2020.106480. [DOI] [Google Scholar]

- 23.Kwaśniewska-Karolak I., Mostowski R.A. The influence of storage conditions on the staling rate and starch retrogradation in wheat rolls packaged in a modified atmosphere. J. Microbiol. Biotechnol. Food Sci. 2019;8:1188–1193. doi: 10.15414/jmbfs.2019.8.5.1188-1193. [DOI] [Google Scholar]

- 24.Biswal A.K., Lenka C., Panda P.K., Yang J., Misra P.K. Investigation of the functional and thermal properties of mahua deoiled cake flour and its protein isolate for prospective food applications. Food Sci. Technol. 2021;137 doi: 10.1016/j.lwt.2020.110459. [DOI] [Google Scholar]

- 25.Biswas P., Das M., Boral S., Mukherjee G., Chaudhury K., Banerjee R. Enzyme mediated resistant starch production from indian fox nut (Euryale ferox) and studies on digestibility and functional properties. Carbohydr. Polym. 2020;237 doi: 10.1016/j.carbpol.2020.116158. [DOI] [PubMed] [Google Scholar]

- 26.Das A., Sit N. Modification of taro starch and starch nanoparticles by various physical methods and their characterization. Starch-Starke. 2021;73:2000227. doi: 10.1002/star.202000227. [DOI] [Google Scholar]

- 27.Hu H., Fan X., Zhou Z., Xu X., Fan G., Wang L., Huang X., Pan S., Zhu L.e. Acid-induced gelation behavior of soybean protein isolate with high intensity ultrasonic pre-treatments. Ultrason. Sonochem. 2013;20(1):187–195. doi: 10.1016/j.ultsonch.2012.07.011. [DOI] [PubMed] [Google Scholar]

- 28.Zhu F. Impact of ultrasound on structure, physicochemical properties, modifications, and applications of starch. Trends Food Sci. Tech. 2015;43:1–17. doi: 10.1016/j.tifs.2014.12.008. [DOI] [Google Scholar]

- 29.Hao Z., Xu H., Yu Y., Han S., Gu Z., Wang Y., Li C., Zhang Q., Deng C., Xiao Y., Liu Y., Liu K., Zheng M., Zhou Y., Yu Z. Preparation of the starch-lipid complexes by ultrasound treatment: exploring the interactions using molecular docking. Int. J. Biol. Macromol. 2023;237 doi: 10.1016/j.ijbiomac.2023.124187. [DOI] [PubMed] [Google Scholar]

- 30.Xiao Y., Wu X., Zhang B., Luo F., Lin Q., Ding Y. Understanding the aggregation structure, digestive and rheological properties of corn, potato, and pea starches modified by ultrasonic frequency. Int. J. Biol. Macromol. 2021;189:1008–1019. doi: 10.1016/j.ijbiomac.2021.08.163. [DOI] [PubMed] [Google Scholar]

- 31.Chan C., Wu R., Shao Y. The effects of ultrasonic treatment on physicochemical properties and in vitro digestibility of semigelatinized high amylose maize starch. Food Hydrocoll. 2021;119 doi: 10.1016/j.foodhyd.2021.106831. [DOI] [Google Scholar]

- 32.Yang Q., Lu X., Chen Y., Luo Z., Xiao Z. Fine structure, crystalline and physicochemical properties of waxy corn starch treated by ultrasound irradiation. Ultrason. Sonochem. 2019;51:350–358. doi: 10.1016/j.ultsonch.2018.09.001. [DOI] [PubMed] [Google Scholar]

- 33.Wang S., Hu X., Wang Z., Bao Q., Zhou B., Li T., Li S. Preparation and characterization of highly lipophilic modified potato starch by ultrasound and freeze-thaw treatments. Ultrason. Sonochem. 2020;64 doi: 10.1016/j.ultsonch.2020.105054. [DOI] [PubMed] [Google Scholar]

- 34.Flores-Silva P.C., Roldan-Cruz C.A., Chavez-Esquivel G., Vernon-Carter E.J., Bello-Perez L.A., Alvarez-Ramirez J. In vitro digestibility of ultrasound-treated corn starch. Starch-Stärke. 2017;69:1700040. doi: 10.1002/star.201700040. [DOI] [Google Scholar]

- 35.Shabana S., Prasansha R., Kalinina I., Potoroko I., Bagale U., Shirish S.H. Ultrasound assisted acid hydrolyzed structure modification and loading of antioxidants on potato starch nanoparticles. Ultrason. Sonochem. 2019;51:444–450. doi: 10.1016/j.ultsonch.2018.07.023. [DOI] [PubMed] [Google Scholar]