Abstract

Access to dependable and environmentally friendly energy sources is critical to a country's economic growth and long-term development. As countries seek greener energy alternatives, the interaction of environmental elements, temperature, and sunlight becomes more critical in utilizing renewable energy sources such as wind and bioenergy. Solar power has received much attention due to extraordinary efficiency advances. under this context, the present work focus on solar radiation and chemical processes in the presence of modified ternary hybrid nanofluids (THNFs) circulating over an exponentially stretched surface in both aiding flow (A-F) and opposing flow (O-F) circumstances. The primary objective of this investigation is to dive into the complicated dynamics of these structures, which are distinguished by complex interactions involving radiation, chemical reactions, and the movement of fluids. We construct reduced ordinary differential equations from the governing equations using suitable similarity transformations, which allows for a more in-depth examination of the liquid's behavior. Numerical simulations using the Runge–Kutta Fehlberg (RKF) approach and shooting techniques are used to understand the underlying difficulties of these reduced equations. The results show that thermal radiation improves heat transmission substantially under O-F circumstances in contrast to A-F conditions. Furthermore, the reaction rate parameter has an exciting connection with concentration levels, with greater rates corresponding to lower concentrations. Furthermore, compared to the O-F scenario, the A-F scenario promotes higher heat transfer in the context of a modified nanofluid. Rising reaction rate and solid fraction volume enhanced mass transfer rate. The rate of thermal distribution in THNFs improves from 0.13 to 20.4% in A-F and 0.16 to 15.06% in O-F case when compared to HNFs. This study has real-world implications in several fields, including developing more efficient solar water heaters, solar thermal generating plants, and energy-saving air conditioners.

Subject terms: Mathematics and computing, Applied mathematics, Chemical engineering

Introduction

Science and advanced methods as well as recent technology have played a prominent role in the production of power1, refrigeration and heating2, production3, applications in medicine4, pharmaceutical industries5. To operate effectively and functionally of these systems will depends on excellent thermal management systems6. Further, improving the power efficiency and minimizing the components will challenge the existing techniques. To overcome this a new concept of enhancing the thermal conductivity in working fluids by involving micro-scale nanoparticles was introduced by Hamilton and Crosser7. In 1995, Choi and Eastman8 conducted pioneering research on using nanoparticles (NPs) to improve liquid thermal conductivity. The resulting liquid formed is coined as nanofluid (NFs). These fluid shows gradual improvement in its thermal conductivity due to this NFs applications are found in9–12. Based on the applications, we can find some of the advantages of nanofluids with relevant to base liquid. The rate at which heat is exchanged in thermal systems may be increased by utilising a nanofluid because of its better thermal conductivity relative to the base liquid. Therefore, by employing nanofluids to increase the temperature transfer rate, the size of a thermal system may be lowered, meaning a more compact system with savings in material weight and cost. Nanofluids are more stable and can improve the transmission of heat more than carrier fluids can. In view of this, numerous researchers have examined and evaluated the usage of nanofluids in thermal transfer applications.

Sandeep et al.13 analyzed the flow characteristics of a chemically reactive Casson liquid over a convectively heated curved area. The results demonstrate that non-Newtonian fluids, in contrast to Newtonian fluids, have a much higher heat transfer rate under unequal heat sources and viscous dissipation conditions. Yasir et al.14 looked at the dynamics of ethylene glycol transporting copper and titania NPs over a stretchable/shrinkable curved structure, including a stability in their study. Because copper enhances porosity and titania functions as a photocatalyst, the study also emphasises the significance of these nanocomposites. Prasannakumara et al.15 explored the TPD (Thermophoretic particle deposition) in a bioconvective NFs flowing over an exponentially extended surface. The findings reveal that adding NPs in a carrier fluid will increases the heat transformation rate. Poojari et al.16 evaluated improved conveyance of heat in unsteady magneto- NFs circulation caused by a stochastic expanding surface with convective boundaries. They employed the Maxwell and Xue models of NFs in their research. According to the results, the Maxwell nano model predicts a far higher rate of thermal circulation than the Xue nano model predicts. Khan et al.17 evaluated the effect of mixed convection and radiation on the temperature transfer of a nanofluid in a slip flow through a bending sheet subject to activation energy and a binary reaction. Results reveal that the addition of nanoparticles slows the flow rate for both upper and lower branch solutions. Some of the works with different kinds of nanoparticles in base liquds are listed in18–21.

A specialised group of NFs known as HNFs (hybrid nanofluids) has arisen in recent years. An innovative kind of nanofluid, HNFs are made by dispersing many NP types in a single solvent. A specific material may not contain all desirable features necessary for a certain application; it may have excellent thermal or rheological capabilities. An owing to the synergistic effect, the HNFs is projected to have higher thermal conductivity than separate nanofluids. Recently, Nanda et al.22 studied the nonlinear/linear expandable surface containing joule impact, radiation with three dimensional movement of tangent hyperbolic liquid containing aluminium alloys. The influence of nanoparticles, the heat transfer rate in the nonlinear extended scenario is double that of the linear stretched case. Ramesh et al.23 examined the HNFs circulation across a nonlinear/linear stretched surface by considering TPD. In the study, linear situation, including nanoparticles augments heat propagation but decreases concentration while improving axial velocity in the nonlinear case. Yasir et al.24,25 explored the thermal performance of different kind of nanoparticles (SWCNT, CuO, MgO, Ag) with H2O and EG carrier liquids. Sulochana et al.26 examined the tangent hyperbolic liquid containing Mgo and Cuo nano sized particles in the presence of magnetic field. In the nanoparticle volume factor, the energy transmission rate in the nonlinear extending case is greater than the linear case.

Researchers are also investigating the inclusion of different NPs into HNFs, resulting in modified nanofluids. This novel class of functional liquids shows promise and is the topic of much investigation. Trihybrid nanofluids (TNFs), made up of three solid NPs combined with a carrier liquid, have been studied for their improved thermal conductivity and thermal expansion. Recently, Yook et al.27 used a multi-linear regression model to examine ternary hybrid nanoparticles' thermal and momentum transmission in a channel with varying permeabilities and porous walls. In their study they used three different cases of nanoparticle combination to examine the thermal performance. The results show that more rapid heat transmission is shown in mixtures of paraffin wax, sand, and AA7072. Madhukesh et al.28,29 examined the TNFs flow to examine the thermal and mass transfer analysis. The TNFs shows greater performance in these two aspects than HNFs and NFs. Animasaun et al.30 studied thermal examination of magnitudes of different kinds of nanoparticles with water as a base liquid. More thermal significant performance is achieved with smaller densities of the nanoparticles.

Aerodynamics, plastic sheets preparation, processing of materials, wire drawing and environmental flows are some of the examples which draw the attention of exponential stretching sheet (E-SS). The study also draws an attention the impacts of this geometry and the movement of the surface on motion of the fluid and thermal distribution. Due to this many works are carried out on E-SS geometries. Prasannakumara et al.15 investigated the TPD, H-SS and movement of microorganisms over an E-SS using NFs. Alqahtani et al.31 examined a change in energy and mass due to the motion of a Casson hybrid nanofluid over an elongated stretching sheet. In their study thermal and slippage of velocity circumstances, the absorption of heat, viscous dissipation, thermal radiation, the Darcy impact, and thermophoresis diffusion impacts are studied. Carreau flow of Cu-water nanofluids through an exponentially permeable stretched thin surface with an MHD thermal boundary layer is quantitatively studied by Yousif et al.32. Souayeh and Ramesh33 studied the mobility of metallic ternary nanofluids (Ag–Au–Cu/H2O), taking into account a wide variety of phenomena like gyrotactic organisms, energy of activation, buoyancy forces, and thermal radiation, as they enacted through an exponentially extending sheet.

The mechanics of fluids and the transfer of heat combine at the interface, where thermal radiation plays a crucial role in determining liquid behavior. Without a medium, heat may be transferred from one place to another by means of electromagnetic waves; this process is governed by thermal radiation (T-R). Intricate studies are required to effectively characterize and forecast liquid behavior when T-R is included in the governing equations. To create effective thermal systems, such as solar panels, burning chambers, or spacecraft re-entry scenarios, it is necessary to have a firm grasp of these interactions. Yasir et al.34 looked into the effects of non-linear T-R and non-uniform H-SS on the movement of ethylene glycol in the presence of hybrid nanomaterials like Silicon dioxide and Titanium oxide. The results indicate that in both variants of the optimal solution, heat transmission improves as a result of an increase in the radiation effect. The effect of electromagnetic radiation and convective slippery conditions on second-grade nanofluids with high viscosity via permeable medium was studied by Jamshed et al.35. The study reveals that increasing radiation levels modify its temperature distribution and the Nusselt number. The consequences of heat production and absorption in the T-R mixed convective circulation of a hybrid nanofluid through an inclinically contracting interface were studied by Yasir et al.36. the study reveals that boosting thermal dispersion through a rise in T-R and Eckert numbers. Some recent works on T-R with TNFs are given in37,38.

In a chemical reaction, two or more chemicals undergo a transformation to produce a new compound. Chemical reactions (C-R) form the backbone of the discipline and perform an essential role in many other areas of science, industry, and daily life. They play a role in everything from combustion to metabolism to photosynthesis to the creation of new materials. The areas of health, materials research, energy generation, and environmental protection all stand to benefit greatly from a deeper understanding of, and ability to manipulate, chemical interactions. Khan et al.39 examined the time-dependent movement of non-Newtonian fluid, emphasizing thermal and solutal movement. The results demonstrate that an upsurge in the surface concentration of the catalyst enhanced the efficiency of both homogeneous and heterogeneous techniques. The impact of endothermic/exothermic C-Rs with activation energy on a wedge-shaped ternary hybrid nanofluid was studied by Sajid et al.40. The study reveals that C-R will upsurges rate of thermal distribution. Using a squeezed parallel infinite plate as a flow channel, Bilal et al.41 studied the characteristics of a fluctuating electroviscous TNFs. The study shows that as C-R values rise, the pace at which mass is allocated rises.

In all the above served literatures, the studies individually examined the impacts of T-R, chemical reaction, and porous medium over different geometries. No work is found to be studied by integrating all the above-mentioned impacts over E-SS in the presence of TNFs. Analyzing the resultant complicated system of ordinary differential equations requires the use of innovative numerical techniques like the Runge–Kutta Fehlberg (RKF) method and shooting algorithms. The major engineering coefficients are also covered in this study. The results have real-world applications in areas such as thermal engineering, manufacturing processes, and renewable energy infrastructure. Finally, the aim of the article provides answers to the following pertinent research questions:

How do several important variables affect both A-F and O-F cases?

What effect do changes in various parameters have on the rate of heat transfer and skin friction?

How change in chemical reaction constraint will interact with mass transfer rate?

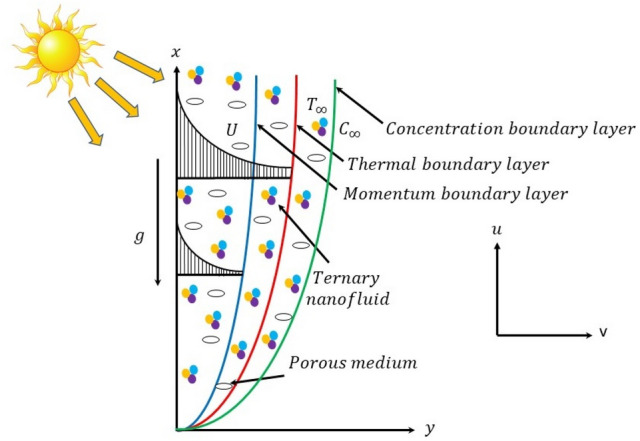

Mathematical modelling

The steady, two-dimensional, laminar and incompressible flow of THNF (combination of nanoparticles and base fluid), see Fig. 1. The sheet is stretching along x-direction and y-axis normal to it. The scenario of mutual assistance between the stretching-generated flow, thermally buoyant flow, and as well as the scenario of mutual antagonism between these two flows are studied. The sheet uniform velocity is represented by in the corresponding axis direction. Further, the sheets variable temperature is provided by . Here, , and denotes the wall, ambient and reference temperature of the sheet, respectively. It is also assumed that the variable concentration of the sheet is . In which; , and denotes the respective wall, ambient and reference concentration of the exponential surface of the sheet. However, is the variable chemical rate introduced into concentration equation42 and it is defined as . Meanwhile, at , the temperature and concentration at the surface of E-SS is denoted by and , respectively. The far field boundaries as are presented by the respective and . Based on these assumptions with boundary layer and Boussinesq approximations, the governing equations for the present problem are as follows: (see43–46):

| 1 |

| 2 |

| 3 |

| 4 |

Figure 1.

Geometric representation of the problem.

The boundary conditions (BCs) are

| 5 |

| 6 |

The last term in Eq. (2) specifies the effect of buoyancy force which has a negative and positive sign, where this positive sign refers the buoyancy assisting flow and the negative sign refers the case of buoyancy opposing flow. Moreover, in Eq. (3) the term is given by (Rosseland approximation), see47. Additionally, expressing the term as a linear function of and ignoring the higher order terms, we get . Finally, the equation become as . By using the below suitable similarity (see44):

| 7 |

Using Eq. (7) in Eqs. (2–4), one obtains the form as:

| 8 |

| 9 |

| 10 |

with boundary conditions are:

| 11 |

| 12 |

From the above equations the non-dimensionless parameters are tabulated in Table 1.

Table 1.

List of dimensionless influential parameters.

| Sl. No | Symbol | Name of the parameter | Special case |

|---|---|---|---|

| 01 | Mixed convection parameter |

O-F case A-F case |

|

| 02 | Prandtl number | ||

| 03 | Radiation parameter | ||

| 04 | Reaction rate parameter | ||

| 05 | Schmidt number | ||

| 06 | Porous permeability constraint | ||

| 07 | |||

| 08 | |||

| 09 | |||

| 10 | |||

Nanofluid and its correlations are discussed by many researchers. The first model of thermal conductivity of the nanofluids proposed by Maxwell model48. Later, Yu and Choi49 considered the nanoliquid layer and proposed new thermal conductivity. By considering Brownian motion and aggregation, Xuan50 proposed new thermal conductivity of the nanoliquids. Some of the other thermophysical correlations of the nanofluids are given in the works of4,51–53.

Thermophysical properties of TNFs used in the present study are given as follows (see54)

In the above expressions when , the properties reduce to HNFs and in the absence of , the properties reduce to requisite posited NFs.

Gradients

The important engineering factors such as , and are described as follows:

| 13 |

and

| 14 |

The expression for (Sherwood number) is given as:

| 15 |

In the above equations, , and are expressed as,

| 16 |

By using (15) in (13–14), we get

| 17 |

| 18 |

| 19 |

where is called the local Reynolds number.

Methodology

The employing computational approaches, where the simplified governing Eqs. (8–10) and BCs are addressed using the RKF-4555 approach and shooting procedures56. We turn the revised equations into a first-order system via introducing new variables. In order to transform the system of equations into first order, we will select, , , , , , and . Hence, the equations become as:

| 20 |

| 21 |

| 22 |

and the BCs are

| 23 |

To solve the IVP defined by Eqs. (20)–(22) and BCs in (23), a quantitative approach called the RKF-45 order method is applied. The shooting procedure is utilized with carefully selected error tolerance of and step size value of correspondingly, to ensure that BCs at infinity are satisfied. For obtaining mathematical estimates, the built-in MATLAB program called bvp4c solver is implemented. It involves substituting parameters and , considering properties mentioned in Table 2. Graphical representation of the results generated for each constraint by varying each parameter while keeping the remaining values constant. In order to validate the numerical code for , a comparison is made between the findings of present study and formerly published research. The findings, as presented in Table 3, demonstrate a satisfactory level of agreement between the outcomes of the two datasets.

Table 2.

The NPs and thermophysical properties taken from the works of54.

| Material | ||||

|---|---|---|---|---|

| Aluminium oxide | 3970 | 0.85 | 40 | 765 |

| Silver | 6500 | 1.89 | 18 | 540 |

| Titanium Oxide | 4250 | 0.9 | 8.9538 | 686.2 |

| Water | 997.1 | 21 | 0.613 | 4179 |

Table 3.

Validation is performed by comparing the results with values for a selection of the limiting cases.

The algorithm of the RKF -45 is given below (see55):

The current methodology can be implemented by the following six steps:

Results and discussion

The flow of THNF across an ESS in the presence of a permeable medium is examined in this work. The modelling takes into account the impact of chemical reactions and renewable (solar) radiation. The dimensionless equations are formed from a collection of suitable similarity variables to simplify the consider task. Several critical elements are uncovered using this technique, and their impact on the profiles is visually depicted and briefly described.

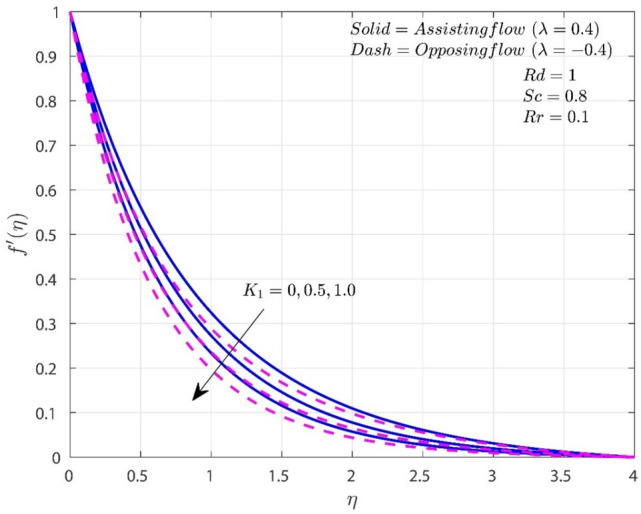

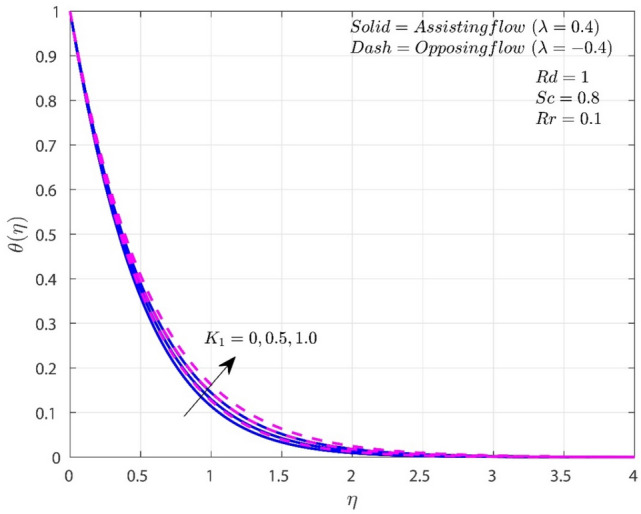

The variation of on , , and in both A-F and O-F situations are shown in Figs. 2, 3, 4. In both flow circumstances, the velocity falls as rises (see Fig. 2). This is happening due to the reason that the greater frictional force caused by higher porosity values, the system is more resistive and fluid flow is constrained. Potential drop in the fluid velocity is observed, and this results in higher resistance. Additionally, when rises, the fall in for O-F is more noticeable than the case of A-F. In both situations, higher porosity values also lead to higher profiles. Temperature is improved by increasing because it thickens the thermal boundary layer (TBL). This finding is consistent with the reasonable assumption that higher improves heat retention and transmission within the liquid. In addition, when is present, heat transmission in circumstances with O-F is greater than in situations with A-F. Rise in the values of will improves the concentration for both A-F and O-F cases as shown in Fig. 4. Improvement in will improves the frictional force which results improvement in the concentration boundary layer (CBL). Consequently, the level of concentration shows significant improvement for the O-F case than the A-F case.

Figure 2.

Variation of on .

Figure 3.

Variation of on .

Figure 4.

Variation of on .

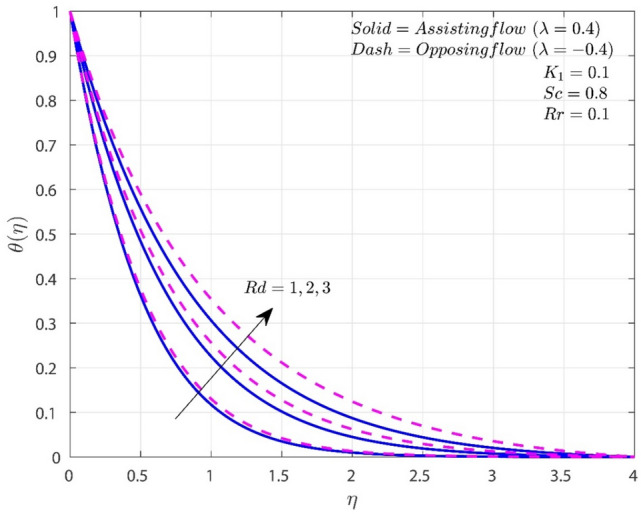

Figure 5 reveals the variation of on thermal profile. An increase in will enhances thermal distribution for both A-F and O-F cases. has an inverse relationship with the mean absorption coefficient, which drops as the value of increase. The buoyancy force is reduced, as a result, of conductive heat transmission, which proves to be more efficient compared to radiative heat transfer. In fact, a higher thermal dispersion is achieved with increased heat transfer to operating fluids through a higher value. Furthermore, gradual improvement in temperature of fluid is observed as the values are set to be high, and the fluid becomes more heated. Following that, heat transmission significantly increases. In the presence of , the O-F shows high thermal distribution than A-F case.

Figure 5.

Variation of on .

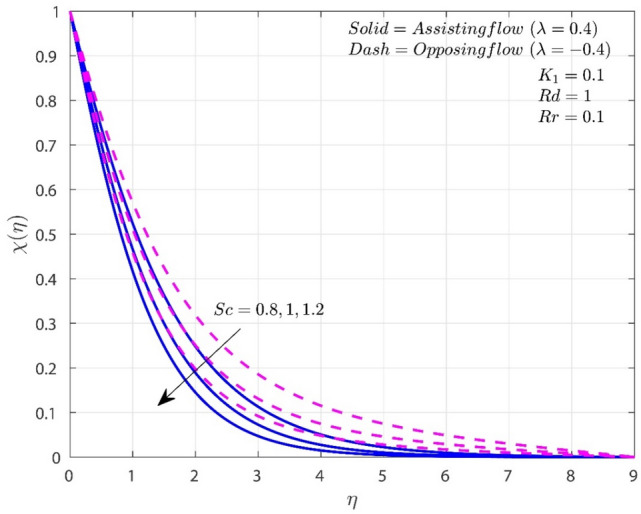

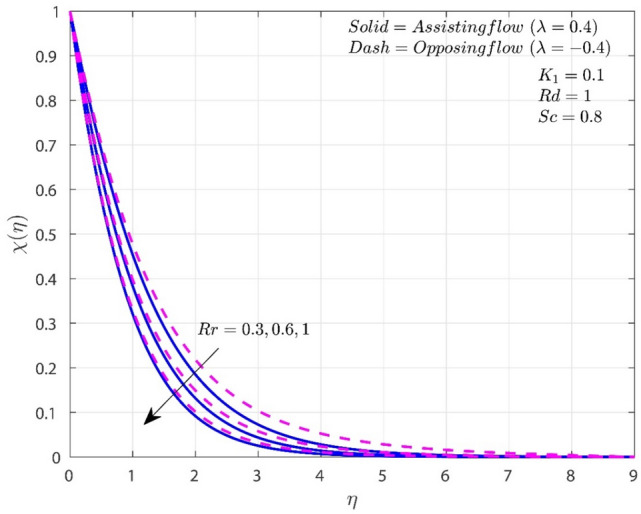

The impact of on the profile is observed in Fig. 6. In both scenarios, increasing lowers the concentration. Increased values of improves the mass diffusion coefficient, which lead to a reduction in concentration. This implies that the fluid's capacity to convey velocity is comparatively more effective than its capacity to convey mass or concentration. Consequently, the predominance of fluid motion supersedes mass transfer, leading to less efficient dispersion of concentration gradients arising from the origin. In comparison to the O-F situation, concentration is reduced in the A-F case.

Figure 6.

Variation of on .

Figure 7 shows how the variance of changes with various values. In both situations, increasing values cause the concentration to drop. Higher indicates that the transformation of reactants into products is taking place at an accelerated rate causes lower CBL. When is present, the O-F case concentrates less than the A-F case.

Figure 7.

Variation of on .

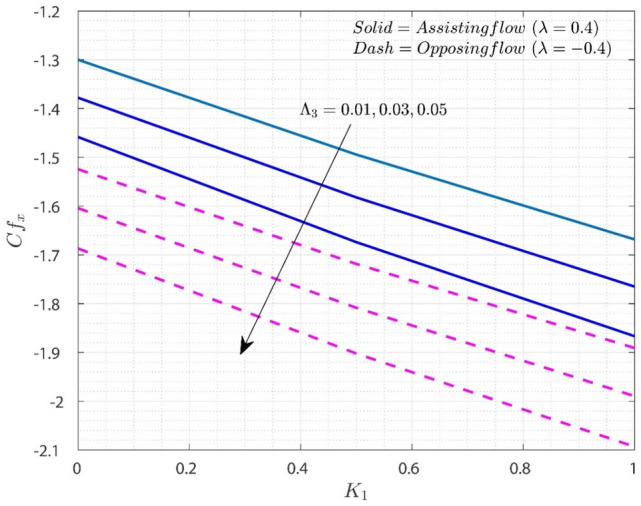

Figures 8 and 9 indicate how the key engineering interests of and vary with different dimensionless restrictions. Figure 8 depicts the fluctuation of on for various values of for both flow situations. The graph shows that increasing the value of decreases the friction drag force in both flows. The increase in values will resist the flow of the liquid. The addition of to the scale of enhances the MBL thickness. This results in a reduction in surface drag force. In the O-F situation, is much lower than in the A-F example. Figure 9 depicts the fluctuation of on Rd as values vary. The rise in the value of and will increase the thermal transfer rate.

Figure 8.

Variation of on for numerous values of .

Figure 9.

Variation of on for numerous values of .

The elevation in the values of improves the rate of heat transfer due to presence of . Increment in also improves the TBL which results in improvement of . is more in A-F case than O-F case.

Figure 10 displays the variation of with change in the values of and for both A-F and O-F scenarios. As the values of escalates, the rate of transformation of reacting substances into outputs is accelerated further. On the other hand, will also improves the thickness of the CBL due to improvement in the surface area. A-F case shows greater rate of mass distribution than O-F.

Figure 10.

Variation of on for numerous values of .

Further, Table 4 shows the computational values of , and for both A-F and O-F cases in the presence of various dimensionless constraints. Table 5 displays the change in the percentages of , and for both A-F and O-F cases in comparison with TNFs and HNFs. The tabulated outcome shows that TNFs shows gradual improved performance in all the constraints in comparison with HNFs.

Table 4.

Computed numerical results of , and for several constraints which are dimensionless with .

| 0.01 | 0.1 | 1 | 0.1 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.01 | 1.34078 | 1.56529 | 3.79998 | 3.71445 | 0.57882 | 0.56448 | |||

| 0.03 | 1.42065 | 1.64722 | 3.81106 | 3.72716 | 0.57837 | 0.56445 | |||

| 0.05 | 1.50363 | 1.73236 | 3.82315 | 3.74099 | 0.57815 | 0.56441 | |||

| 0.1 | 1.34078 | 1.56529 | 3.79998 | 3.71445 | 0.57882 | 0.56448 | |||

| 0.5 | 1.49431 | 1.71858 | 3.72790 | 3.63569 | 0.56452 | 0.54976 | |||

| 1.0 | 1.66825 | 1.89092 | 3.64578 | 3.54638 | 0.54996 | 0.53503 | |||

| 1 | 1.34078 | 1.56529 | 3.79998 | 3.71445 | 0.57882 | 0.56448 | |||

| 2 | 1.31687 | 1.59441 | 4.71124 | 4.50619 | 0.58289 | 0.55889 | |||

| 3 | 1.30019 | 1.61737 | 5.41062 | 5.04916 | 0.58625 | 0.55341 | |||

| 0.1 | 1.33903 | 1.59390 | 3.80193 | 3.67524 | 0.57882 | 0.56448 | |||

| 0.3 | 1.33903 | 1.59390 | 3.80193 | 3.67524 | 0.70613 | 0.69459 | |||

| 0.5 | 1.33903 | 1.59390 | 3.80193 | 3.67524 | 0.81475 | 0.80504 | |||

Table 5.

Comparative analysis of change in , and for dimensionless constraints in the case of A-F and O-F.

| 0.1 | 1 | 0.1 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 2.92% | 2.59% | 0.12% | 0.15% | 0.04% | 0.01% | |||

| 1.0 | 2.87% | 2.58% | 0.11% | 0.13% | 0.04% | 0.005% | |||

| 1.5 | 2.84% | 2.57% | 0.09% | 0.12% | 0.04% | 0.001% | |||

| 1.0 | 2.98% | 2.61% | 0.13% | 0.16% | 0.05% | 0.01% | |||

| 3.0 | 1.74% | 2.50% | 14.7% | 8.08% | 0.50% | 0.04% | |||

| 5.0 | 1.37% | 2.41% | 20.4% | 15.06% | 0.73% | 0.11% | |||

| 0.2 | 2.98% | 2.61% | 0.13% | 0.16% | 0.04% | 0.01% | |||

| 0.4 | 2.98% | 2.61% | 0.13% | 0.16% | 0.03% | 0.01% | |||

| 0.6 | 2.98% | 2.61% | 0.13% | 0.16% | 0.02% | 0.007% | |||

The rate of change in the percentage of skin friction, Nusselt number and Sherwood number in the presence of TNF and HNF are presented in Table 5. To obtain , and the formulas are given below:

| 24 |

| 25 |

| 26 |

Final remarks

The idea of this study is to investigates the transfer of heat and mass on ESS by considering the influence of A-F and O-F with ternary hybrid nanofluid. It also incorporates T-R, chemical reaction, and porous medium. Utilizing RKF-45 the numerical solutions are found for reduced ODEs. Graphs are utilized to illustrate the important dimensionless limitations. The key findings of this work are as follows:

The velocity profile declines with higher impacts of the porosity parameter while the temperature and concentration profiles boosted up.

The augmentation of the solar radiation parameter decelerates the velocity, thermal distribution, and temperature gradients. This indicates that reducing thermal radiation flux decelerates the thickness of TBL while increasing the thickness of the MBL.

For increasing thermal radiation and , the heat transfer rate augmented. In general, the radiation parameter enriches the thermal conductivity, as a consequence, the heat transfer improves.

The shear stress and mass transfer rate decelerate with superior influences of but the heat transfer rate remarkably uplifts.

When compared to HNFs, the rate of heat distribution in THNFs goes from 0.13% to 20.4% and from 0.16% to 15.06%, respectively, for the case of A-F and as well as for the case of O-F.

The current research is relevant in several applications like capacitors, biofuel, batteries, nanomaterials, and power storage etc. By captivating the following distinct impact such as the ternary nanofluid flow over an inclined stretching/shrinking surface, mass suction/injection, convective boundary conditions, Two-phase model and Newtonian heating is also possible to consider in the extended work of this problem.

Acknowledgements

The author would like to extend his appreciation to the support of Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2023R163), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia. Also, the researchers would like to thank the Deanship of Scientific Research at King Khalid University for funding this work through large group Research Project under grant number RGP2/130/44.

List of symbols

Temperature (K)

Wall temperature (K)

Far-field temperature (K)

Reference temperature (K)

Thermal radiation heat flux

Mean absorption coefficient

Permeability of porous medium

Porous permeability parameter

Velocity

Nusselt number

Dimensionless concentration profile

Reaction rate parameter

Diffusion

Concentration

Wall concentration

Dimensionless velocity profile

Length

Thermal conductivity

Specific heat

Prandtl number

Radiation parameter

- and

Velocity components

- and

Coordinates

Skin friction

Local Reynolds number

Schmidt number

Acceleration due to gravity

Grashof number

Far-field concentration

Reference concentration

Greek symbols

Stream function

Thermal expansion

Kinematic viscosity

Stefan–Boltzmann constant

Dynamic viscosity

Variable chemical rate ()

Mixed convection parameter

Dimensionless temperature profile

Similarity variable

Solid volume fraction

Density

Subscripts

Modified nanofluid

Nanofluid

Solid particles

Hybrid nanofluid

Fluid

Author contributions

Conceptualization, J.K.M. and U.K.; methodology, B.C.P.; software, J.K.M., and U.K.; validation, B.C.P., K.V.N., N.B.K, S.E., and A.M.H.; formal analysis, J.K.M., and U.K.; investigation, B.C.P., and U.K.; resources, B.C.P, S.E., and N.B.K.; data curation, J.K.M, S.E., and J.S.C.; writing—original draft preparation, B.C.P., U.K., and K.V.N.; visualization, A.A.; supervision, K.V.N., and B.C.P.; project administration, A.M.H. and S.E.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Rezania A, Rosendahl LA, Andreasen SJ. Experimental investigation of thermoelectric power generation versus coolant pumping power in a microchannel heat sink. Int. Commun. Heat Mass Transf. 2012;39:1054–1058. doi: 10.1016/j.icheatmasstransfer.2012.07.010. [DOI] [Google Scholar]

- 2.Ghanbarpour M, Khodabandeh R, Vafai K. An investigation of thermal performance improvement of a cylindrical heat pipe using Al2O3 nanofluid. Heat Mass Transf. 2017;53:973–983. doi: 10.1007/s00231-016-1871-9. [DOI] [Google Scholar]

- 3.Khanafer K, Vafai K. Analysis of turbulent two-phase flow and heat transfer using nanofluid. Int. Commun. Heat Mass Transf. 2021;124:105219. doi: 10.1016/j.icheatmasstransfer.2021.105219. [DOI] [Google Scholar]

- 4.Khanafer K, Vafai K. A critical synthesis of thermophysical characteristics of nanofluids. Int. J. Heat Mass Transf. 2011;54:4410–4428. doi: 10.1016/j.ijheatmasstransfer.2011.04.048. [DOI] [Google Scholar]

- 5.Muneeshwaran M, Srinivasan G, Raja B, Wang C-C. Investigation of heat and mass transfer behavior of mannitol during vial freeze-drying. J. Therm. Anal. Calorim. 2022;147:2393–2404. doi: 10.1007/s10973-021-10635-3. [DOI] [Google Scholar]

- 6.Bi J, Vafai K, Christopher DM. Heat transfer characteristics and CHF prediction in nanofluid boiling. Int. J. Heat Mass Transf. 2015;80:256–265. doi: 10.1016/j.ijheatmasstransfer.2014.09.019. [DOI] [Google Scholar]

- 7.Hamilton RL, Crosser OK. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fund. 1962;1:187–191. doi: 10.1021/i160003a005. [DOI] [Google Scholar]

- 8.Choi, S. U. S. & Eastman, J. A. Enhancing thermal conductivity of fluids with nanoparticles. https://www.osti.gov/biblio/196525 (1995).

- 9.Saidur R, Leong KY, Mohammed HA. A review on applications and challenges of nanofluids. Renew. Sustain. Energy Rev. 2011;15:1646–1668. doi: 10.1016/j.rser.2010.11.035. [DOI] [Google Scholar]

- 10.Devendiran DK, Amirtham VA. A review on preparation, characterization, properties and applications of nanofluids. Renew. Sustain. Energy Rev. 2016;60:21–40. doi: 10.1016/j.rser.2016.01.055. [DOI] [Google Scholar]

- 11.Taylor R, et al. Small particles, big impacts: A review of the diverse applications of nanofluids. J. Appl. Phys. 2013;113:011301. doi: 10.1063/1.4754271. [DOI] [Google Scholar]

- 12.Kasaeian A, et al. Nanofluid flow and heat transfer in porous media: A review of the latest developments. Int. J. Heat Mass Transf. 2017;107:778–791. doi: 10.1016/j.ijheatmasstransfer.2016.11.074. [DOI] [Google Scholar]

- 13.Sandeep N, Sulochana C, Ashwinkumar G. Understanding the dynamics of chemically reactive Casson liquid flow above a convectively heated curved expanse. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022;236:11420–11430. doi: 10.1177/09544062221115084. [DOI] [Google Scholar]

- 14.Yasir M, Khan M, Sarfraz M, Abuzaid D, Ullah MZ. Exploration of the dynamics of ethylene glycol conveying copper and titania nanoparticles on a stretchable/shrinkable curved object: Stability analysis. Int. Commun. Heat Mass Transf. 2022;137:106225. doi: 10.1016/j.icheatmasstransfer.2022.106225. [DOI] [Google Scholar]

- 15.Prasannakumara BC, Madhukesh JK, Ramesh GK. Bioconvective nanofluid flow over an exponential stretched sheet with thermophoretic particle deposition. Propuls. Power Res. 2023;12:284–296. doi: 10.1016/j.jppr.2023.05.004. [DOI] [Google Scholar]

- 16.G. Poojari, A., B., R., N., S. & Sulochana, C. Enhanced heat transmission in unsteady magneto-nanoliquid flow due to a nonlinear extending sheet with convective boundary conditions. Numer. Heat Transf. Part A: Appl.0, 1–22 (2023).

- 17.Khan U, et al. Features of radiative mixed convective heat transfer on the slip flow of nanofluid past a stretching bended sheet with activation energy and binary reaction. Energies. 2022;15:7613. doi: 10.3390/en15207613. [DOI] [Google Scholar]

- 18.Sandeep, N., Babu, R. S., Nanda, P. & Ashwinkumar, G. P. Enhanced heat transmission in conical slip flow of Walter’s-B nanofluid. Int. J. Mod. Phys. B 2450096 (2023). 10.1142/S0217979224500966.

- 19.Sandeep N, Nanda P, Ashwinkumar GP. Transpiration effect on Falkner-Skan bioconvective mixed nanoliquid flow above a poignant wedge. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2023;237:1793–1805. doi: 10.1177/09544062221134387. [DOI] [Google Scholar]

- 20.Yasir M, Ahmed A, Khan M. Carbon nanotubes based fluid flow past a moving thin needle examine through dual solutions: Stability analysis. J. Energy Storag. 2022;48:103913. doi: 10.1016/j.est.2021.103913. [DOI] [Google Scholar]

- 21.Madhukesh JK, et al. A model development for thermal and solutal transport analysis of non-Newtonian nanofluid flow over a riga surface driven by a waste discharge concentration. Water. 2023;15:2879. doi: 10.3390/w15162879. [DOI] [Google Scholar]

- 22.Nanda P, Sandeep N, Sulochana C, Ashwinkumar GP. Enhanced heat transmission in methanol-based AA7072/AA7075 tangent hyperbolic hybrid nanofluid flow along a nonlinear expandable surface. Numer. Heat Transf. Part A: Appl. 2023;83:711–725. doi: 10.1080/10407782.2022.2157916. [DOI] [Google Scholar]

- 23.Ramesh GK, Madhukesh JK, Khan U, Hussain SM, Galal AM. Inspection of hybrid nanoparticles flow across a nonlinear/linear stretching surface when heat sink/source and thermophoresis particle deposition impacts are significant. Int. J. Mod. Phys. B. 2023;37:2350008. doi: 10.1142/S021797922350008X. [DOI] [Google Scholar]

- 24.Yasir M, Khan M, Alqahtani AS, Malik MY. Numerical study of axisymmetric hybrid nanofluid MgO-Ag/H2O flow with non-uniform heat source/sink. Alex. Eng. J. 2023;75:439–446. doi: 10.1016/j.aej.2023.05.062. [DOI] [Google Scholar]

- 25.Yasir M, Hafeez A, Khan M. Thermal conductivity performance in hybrid (SWCNTs-CuO/Ehylene glycol) nanofluid flow: Dual solutions. Ain Shams Eng. J. 2022;13:101703. doi: 10.1016/j.asej.2022.101703. [DOI] [Google Scholar]

- 26.Sulochana C, Savita & Ashwinkumar, G. P. Joule heating effect on the MHD flow of tangent hyperbolic mixed nanofluid embedded with MgO and CuO nanoparticles. Int. J. Ambient Energy. 2023;44:1904–1913. doi: 10.1080/01430750.2023.2198531. [DOI] [Google Scholar]

- 27.Yook S-J, et al. Heat and momentum diffusion of ternary hybrid nanoparticles in a channel with dissimilar permeability’s and moving porous walls: A Multi-linear regression. Case Stud. Therm. Eng. 2023;47:103133. doi: 10.1016/j.csite.2023.103133. [DOI] [Google Scholar]

- 28.Madhukesh JK, Sarris IE, Prasannakumara BC, Abdulrahman A. Investigation of thermal performance of ternary hybrid nanofluid flow in a permeable inclined cylinder/plate. Energies. 2023;16:2630. doi: 10.3390/en16062630. [DOI] [Google Scholar]

- 29.Madhukesh, J. K., Sarris, I. E., K, V., Prasannakumara, B. C. & Abdulrahman, A. Computational analysis of ternary nanofluid flow in a microchannel with nonuniform heat source/sink and waste discharge concentration. Numer. Heat Transf. Part A: Appl.0, 1–18 (2023).

- 30.Animasaun IL, Al-Mdallal QM, Khan U, Alshomrani AS. Unsteady water-based ternary hybrid nanofluids on wedges by bioconvection and wall stretching velocity: Thermal analysis and scrutinization of small and larger magnitudes of the thermal conductivity of nanoparticles. Mathematics. 2022;10:4309. doi: 10.3390/math10224309. [DOI] [Google Scholar]

- 31.Alqahtani AM, et al. Heat and mass transfer through MHD Darcy Forchheimer Casson hybrid nanofluid flow across an exponential stretching sheet. ZAMM – J. Appl. Math. Mech./Zeitschrift für Angewandte Mathematik und Mechanik. 2023;103:e202200213. doi: 10.1002/zamm.202200213. [DOI] [Google Scholar]

- 32.Yousif MA, Ismael HF, Abbas T, Ellahi R. Numerical study of momentum and heat transfer of MHD carreau nanofluid over an exponentially stretched plate with internal heat source/sink and radiation. HTR. 2019;50:1. [Google Scholar]

- 33.Souayeh B, Ramesh K. Numerical scrutinization of ternary nanofluid flow over an exponentially stretching sheet with gyrotactic microorganisms. Mathematics. 2023;11:981. doi: 10.3390/math11040981. [DOI] [Google Scholar]

- 34.Yasir M, Khan M, Alqahtani AS, Malik MY. Mass transpiration effect on rotating flow of radiative hybrid nanofluid due to shrinking surface with irregular heat source/sink. Case Stud. Therm. Eng. 2023;44:102870. doi: 10.1016/j.csite.2023.102870. [DOI] [Google Scholar]

- 35.Jamshed, W. et al. Electromagnetic radiation and convective slippery stipulation influence in viscous second grade nanofluid through penetrable material. ZAMM – J. Appl. Math. Mech./Zeitschrift für Angewandte Mathematik und Mechanik e202200002.

- 36.Yasir M, Khan M, Alqahtani AS, Malik MY. Heat generation/absorption effects in thermally radiative mixed convective flow of Zn−TiO2/H2O hybrid nanofluid. Case Stud. Therm. Eng. 2023;45:103000. doi: 10.1016/j.csite.2023.103000. [DOI] [Google Scholar]

- 37.Adnan & Ashraf, W. Heat transfer mechanism in ternary nanofluid between parallel plates channel using modified Hamilton-Crossers model and thermal radiation effects. Geoenergy Sci. Eng.225, 211732 (2023).

- 38.Nasir S, et al. Heat transport study of ternary hybrid nanofluid flow under magnetic dipole together with nonlinear thermal radiation. Appl. Nanosci. 2022;12:2777–2788. doi: 10.1007/s13204-022-02583-7. [DOI] [Google Scholar]

- 39.Khan M, et al. Variable heat source in stagnation-point unsteady flow of magnetized Oldroyd-B fluid with cubic autocatalysis chemical reaction. Ain Shams Eng. J. 2022;13:101610. doi: 10.1016/j.asej.2021.10.005. [DOI] [Google Scholar]

- 40.Sajid T, et al. Trace of chemical reactions accompanied with Arrhenius energy on ternary hybridity nanofluid past a wedge. Symmetry. 2022;14:1850. doi: 10.3390/sym14091850. [DOI] [Google Scholar]

- 41.Bilal M, et al. Numerical analysis of an unsteady, electroviscous, ternary hybrid nanofluid flow with chemical reaction and activation energy across parallel plates. Micromachines. 2022;13:874. doi: 10.3390/mi13060874. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Sravanthi CS, Gorla RSR. Effects of heat source/sink and chemical reaction on MHD Maxwell nanofluid flow over a convectively heated exponentially stretching sheet using homotopy analysis method. Int. J. Appl. Mech. Eng. 2018;23:137–159. doi: 10.1515/ijame-2018-0009. [DOI] [Google Scholar]

- 43.Ferdows M, Khan MS, Alam MM, Sun S. MHD mixed convective boundary layer flow of a nanofluid through a Porous medium due to an exponentially stretching sheet. Math. Probl. Eng. 2012;2012:e408528. doi: 10.1155/2012/408528. [DOI] [Google Scholar]

- 44.Mukhopadhyay S, Gorla RSR. Effects of partial slip on boundary layer flow past a permeable exponential stretching sheet in presence of thermal radiation. Heat Mass Transf. 2012;48:1773–1781. doi: 10.1007/s00231-012-1024-8. [DOI] [Google Scholar]

- 45.Sajid M, Hayat T. Influence of thermal radiation on the boundary layer flow due to an exponentially stretching sheet. Int. Commun. Heat Mass Transf. 2008;35:347–356. doi: 10.1016/j.icheatmasstransfer.2007.08.006. [DOI] [Google Scholar]

- 46.Manzur M, Khan M, Rahman M. Mixed convection heat transfer to cross fluid with thermal radiation: Effects of buoyancy assisting and opposing flows. Int. J. Mech. Sci. 2018;138–139:515–523. doi: 10.1016/j.ijmecsci.2018.02.010. [DOI] [Google Scholar]

- 47.Rosseland, S. Astrophysik: Auf Atomtheoretischer Grundlage. (Springer Berlin Heidelberg, 1931). 10.1007/978-3-662-26679-3.

- 48.Maxwell, J. C. A Treatise on Electricity and Magnetism. (Clarendon Press, 1873).

- 49.Yu W, Choi SUS. The role of interfacial layers in the enhanced thermal conductivity of nanofluids: A renovated Maxwell model. J. Nanopart. Res. 2003;5:167–171. doi: 10.1023/A:1024438603801. [DOI] [Google Scholar]

- 50.Xuan Y, Li Q, Hu W. Aggregation structure and thermal conductivity of nanofluids. AIChE J. 2003;49:1038–1043. doi: 10.1002/aic.690490420. [DOI] [Google Scholar]

- 51.Koo J, Kleinstreuer C. A new thermal conductivity model for nanofluids. J Nanopart Res. 2004;6:577–588. doi: 10.1007/s11051-004-3170-5. [DOI] [Google Scholar]

- 52.Krieger IM, Dougherty TJ. A Mechanism for Non-Newtonian Flow in Suspensions of Rigid Spheres. Trans. Soc. Rheol. 1959;3:137–152. doi: 10.1122/1.548848. [DOI] [Google Scholar]

- 53.Brinkman HC. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 2004;20:571. doi: 10.1063/1.1700493. [DOI] [Google Scholar]

- 54.Ramesh, G. K., Madhukesh, J. K., Das, R., Shah, N. A. & Yook, S.-J. Thermodynamic activity of a ternary nanofluid flow passing through a permeable slipped surface with heat source and sink. Waves Random Complex Media 1–21 (2022).

- 55.Mathews, J. H. & Fink, K. K. Numerical Methods Using Matlab. (Pearson Education, Limited, 2010).

- 56.Mohamad, A. A. & Benselama, A. M. Numerical Methods For Engineers: A Practical Approach. (World Scientific, 2022).

- 57.Bidin, B. & Nazar, R. Numerical Solution of the Boundary Layer Flow Over an Exponentially Stretching Sheet with Thermal Radiation.

- 58.Abd El-Aziz M. Viscous dissipation effect on mixed convection flow of a micropolar fluid over an exponentially stretching sheet. Can. J. Phys. 2009;87:359–368. doi: 10.1139/P09-047. [DOI] [Google Scholar]

- 59.Magyari E, Keller B. Heat and mass transfer in the boundary layers on an exponentially stretching continuous surface. J. Phys. D: Appl. Phys. 1999;32:577. doi: 10.1088/0022-3727/32/5/012. [DOI] [Google Scholar]

- 60.Ishak A. MHD boundary layer flow due to an exponentially stretching sheet with radiation effect. Sains Malaysiana. 2011;40:391–395. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.