Abstract

Condition-based maintenance involves activities that are conducted based on the equipment's performance. Continuous monitoring of equipment will ensure that it will be maintained according to a relevant activity plan. This paper proposes a maintenance framework to analyze the application of statistical control charts for condition-based maintenance of electrical generators. The proposed framework consists of four components that collaboratively determine a performance threshold for a given piece of electrical equipment. Based on the slow progression and dynamics of mechanical failures, Long Short-term Memory (LSTM) and Useful Remaining Life (URL) models were used to assist in the maintenance decision-making process. The analysis is based on detecting the dynamics of the process parameters, including vibration, noise, and temperature, based on relevant control charts. With the help of experimental methodology, failures in the performance modes and defined modes are measured. Then empirical analysis reveals how control charts respond to failure detection. The results show that X-bar consistently demonstrates failure detection capability, while R charts sometimes fail when data deviates from normality.

Moreover, heat monitoring surpassed vibration and noise in failure detection, where temperature control charts successfully identified failure. The overall results support the significant role of statistical charts in decision-making regarding condition-based maintenance for electrical equipment like generators.

-

•

Application of statistical control charts for condition-based maintenance of electrical generators.

-

•

Detecting dynamics of the process parameters, including vibration, noise, and temperature, based on relevant control charts.

-

•

Long Short-term Memory (LSTM) and Useful Remaining Life (URL) models were used to assist in the maintenance decision-making process

Keywords: Condition-based maintenance, Statistical control charts, LSTM, URL

Method name: Statistical control charts for condition-based maintenance of electrical generators

Graphical abstract

Specifications table

| Subject area: | Engineering |

| More specific subject area: | Condition-based maintenance |

| Name of your method: | Statistical control charts for condition-based maintenance of electrical generators |

| Name and reference of original method: | Control Charts |

| Resource availability: | The data are available in this article |

Method details

Introduction

In modern-day industries, fault detection and maintenance are the most vital considerations for ensuring the safety and reliability of complex processes and mechanical equipment. High quality and excellent performance are always desirable goals for process engineers. Different maintenance strategies are utilized to enhance the quality of automated systems and processes. Condition-based maintenance (CBM) is an efficient and cost-effective preventive maintenance strategy compared to scheduled time-based maintenance schemes [1]. This technique promotes the early detection of faults and prevents complete failure of equipment. For example, [2] provided an alternative engine knock detection technique based on engine block vibration. A model of failure ranking and sorting in gas compression plants using the risk priority number was developed by [3]. Another work by [4] was done to evaluate the performability of the steam generation system of a coal-fired thermal power plant using Markov Chains.

A related work done by [5] proposes a statistical model based on control charts for analyzing the operational conditions of an internal combustion engine in a thermal power plant. Unlike conventional monitoring systems that only indicate nonconformities close to catastrophic failure, the proposed model continuously monitors the stress levels experienced by the machine during operation, providing predictive analysis of its operating conditions.

The fault detection strategy for CBM utilizes the measurable parameters of machines like temperature, noise, and vibration. In most cases, the theoretical analysis of the Fourier transform, RMS, or the crest factor analysis ascertains the system's health. This strategy's limitation is its applicability to specific mechanical components, inability to define a threshold for performance degradation, shortage to evaluate the overall system health, and computational complexity. Hence, to overcome the complex analysis and assess the general health of mechanical equipment, statistical control charts could be employed for decision-making for CBM. Statistical control charts are widely utilized in manufacturing industries to evaluate process variability and product conformance to specifications. With measurable parameters like vibration, the control charts could identify the systematic pattern or data points beyond the set threshold that shows the equipment's potential degradation.

The working principle of control charts applies to electrical generators by comparing the sound, vibration, and heat data with nominal values using statistical charts. The normalized data like mean and standard deviation of physical parameters could be obtained from the vendor's electrical generator manual or by benchmarking before putting it into the actual process. Any systematic performance pattern or deviation from the upper or lower thresholds is an alarming situation requiring rigorous analysis [6]. The signals in terms of acoustic sensors could be used for studying the wear mechanism of processes. Similarly, vibration monitoring could ensure the equipment's health using scalar indicators like Kurtosis or RMS. These indicators could prevent significant degradation of the health of the equipment.

The current study's motivation comes from the industrial requirements of fault detection and maintenance strategy to enhance any mechanical system's lifetime. Because equipment has many components, inspecting each element may require more effort, time, and money. Thus the health of the system can be evaluated through indirect parameters through statistical modeling. Also, in most cases, failures develop over time when the equipment fails; however, there is remaining useful life where there is no need for immediate reaction. This issue usually depends on failure type as well as failure severity.

This study aims to solve these issues by proposing a new framework that combines statistical tests, control charts, artificial intelligence, and URL for identifying the failure type and the useful remaining life of the equipment parts.

The contribution of this paper is that it provides a framework that is quite suitable for hazardous or remotely located systems for identifying different types of faults and their remaining lifetime of equipment parts such as nuclear reactors, submersible pumps, wind turbines, and confined spaces. Combining CBM based on statistical analysis and artificial intelligence LSTM will optimize maintenance resources, increase availability, and reduce maintenance costs.

Related works

The failure modes of electrical generators, one of the most common types of equipment in modern industry, of different categories are assessed through their process conditions. For example, the failure of a rolling bearing could occur due to contamination in the lubrication system, leading to increased noise and vibration of the rotating parts [7]. Secondly, filters that provide specific air-to-fuel ratios could clog over time, creating an imbalance in fuel performance. Thirdly, a burned spark plug could affect the generators' performance, such as misfire and idling [8]. Fourth, problems could occur in the modern internal combustion engines' air intake system with an air filter as one of the major components. Such problems could be detected using various feedback signals using sensors like accelerometers [9]. The mechanism of knocking and other faults could be detected indirectly through vibration and other sensors embedded in the mechanical parts of the combustion engines or generators. Thus, fault detection, isolation, and maintenance of internal combustion engines and electrical generators operating at accessible, remote, or hazardous places are essential.

The research field of Condition-based Maintenance (CBM) is rapidly evolving. Most scholars prefer CBM over time-based maintenance due to the early fault detection mechanism [10,11]. Moreover, CBM involves time-based maintenance and monitoring of the system's and components' health [12,13]. The CBM technique involves failure's prognostic effects for enhancing the system's life [13]. Jamshidi et al. [14] proposed a CBM technique for railway infrastructure to effectively control the equipment's degradation. The trains will keep running safely and reliably through a systematic plan for monitoring the problematic areas. Kumar et al. [15] researched the preventive maintenance domain for mechanical processes involving reciprocating or pivoting components. When maintenance is planned on equipment conditions, these parts will result in low vibration levels. The research reveals that almost 90% of all incidents happen due to the misalignment of mechanically rotating parts [15]. Their health monitoring through vibration, acceleration, and velocity could be ascertained, and timely actions could be taken.

The inspection schedules for CBM could be various depending on the process conditions. Some examples proposed in the research are continuous monitoring schedules, periodic monitoring schedules, and non-periodic schedules [16]. For offshore installations and power plants, the continuous monitoring mode is adopted for CBM due to operation in a stress-induced environment. The researchers proposed periodic monitoring for systems at inaccessible places like underground pipelines for health assessment of systems at regular intervals. Non-periodic maintenance is carried out on systems with low chances of failure in early phases. Thus, less frequent maintenance during the initial years of operation and more frequent maintenance are proposed with the aging effects of equipment [16]. Liu et al. [17] proposed a continuous-time stochastic model to inspect system states to prevent failures. CBM involves real-time system monitoring, thus considered more effective than traditional time-based scheduling. By minimizing unnecessary maintenance actions, operating costs are reduced. Tian et al. [18] determined several predictive models to estimate the remaining useful life. The models based on data-driven or model-drive techniques could be used for fault prognostics. Due to associated failure models, the equipment degradation behavior must be analyzed deeply [19]. Accurate information about equipment is crucial for proposing the correct approach for maintenance. Shin and Jun [20] proposed a comprehensive condition-based maintenance policy by predicting the abnormality of system states using indirect monitoring. They reviewed various CBM approaches and standards for a suitable replacement of parts of equipment actions before the occurrence of a fault. Zhao et al. [21] proposed an optimal CBM policy with delays for systems under continuous monitoring. The degradation dynamics of the system are modeled with the help of a stochastic process. They also proposed threshold analysis for equipment degradation to reduce maintenance costs. The research work of Zhu et al. [22] considered the problem of modeling and optimization of CBM for the deteriorating system in a dynamic environment. With the help of stochastic modeling using the Gamma process and Poisson arrival, they modeled wear deterioration and shock damage to the system within the dynamic environment.

The research literature on control charts provides various strategies for effective process monitoring. The effectiveness of control charts for assisting in the decision-making of CBM is proven [23]. Fávero and Belfiore [24] elaborated on how the process could be controlled when the product features vary due to random reasons. The variations in targeted quality characteristics like vibrations and noise could be judged effectively with the help of control charts. Similarly, Zhang et al. [25] analyzed the Weight Loss Function (WLC) control chart for condition monitoring of mechanical processes. Cassady et al. [26] claimed that statistical quality control methods could solve the problem of autocorrelation of data. With these methods' help, industrial processes' productivity is proven to increase [26]. Therefore, designing a predictive maintenance policy is essential to remove the process's troublesome aspects and prevent undesired mechanical equipment failures.

The literature investigating the problem of determination of degradation of equipment through indirect measures like measurement of noise and vibration is also worth reviewing. Conventional sensing mechanisms and evolving digital technology have assessed the degradation of industrial processes quite reliably. Physical properties, like vibration, noise, temperature, and acceleration, could be measured through various mechanisms. However, the main task lies in integrating physical mechanisms measurements with stochastic processes and probability charts for CBM in the overall preventive maintenance context.

This paper bridges the research gap by introducing an innovative framework that investigates the applicability of statistical tests, control charts, artificial intelligence (LSTM), and URL for identifying the fault type and its expected occurrence in electrical generators. Through measurement of vibration, noise, and temperature, the behavior of the generators will be indirectly assessed for degradation. The failure detection mechanism involves the comparison of the variability of control charts with mean values.

Research methodology

This Section presents the Long Short Term Memory Model – based Useful Remaining Life (LSTM-based URL) Model to identify the failure type and the useful remaining life for electrical generators. Fig. 1 presents the proposed LSTM-based URL framework that the maintenance department can use to identify any potential failure.

Fig. 1.

Proposed framework.

Fig. 1 comprises four main components. These components work collaboratively to convert the received vibration, temperature, and noise to identify failure type and its useful remaining life. The first component, statistical tests, verifies experimental results such as vibration, temperature, and noise obtained from electrical generators and ensures data fitness to parametric tests. These tests are summarized as follows:

-

•

Paired T-Test

Each experiment will be repeated twice for validation purposes and consistency. Thus, the results from trials 1 and 2 are compared using the paired t-Test to ensure no significant difference between the two data sets.

-

•

Correlation test

The purpose is to identify any possible correlation between vibration, noise, and temperature. Determining those factors' relationships will help in control chart interpretation and comparison. Pearson correlation test will be used.

-

•

Normality check

Normality is a crucial characteristic a given data set must possess before performing parametric tests like ANOVA and control charts. Probability plot tests will be performed as well as kurtosis and skewness tests.

-

•

ANOVA

This test was employed to prove the effect of the failure severity factor on the observed parameters and identify the existence of the failure effect.

These tests will be performed on the inputs to ensure data consistency and fitness. The verified data by this component will be sent to the second control charts component to early determine if the related part of the process is failed. Statistical control charts will be developed for early fault detection based on statistical measures of the observed vibration, noise, and temperature outputs. The type of failure is then determined and classified by the third LSTM component, in which different failure types (clogged filter failure, cooling fan failure, spark plug failure, and defective bearing failure) will be classified. Then, the similarity model, after receiving the failure type, will determine the useful remaining life (URL) of the failed part. These components are explained as follows. The output will be the relevant failure type along with its URL for each detected fault.

Experimental study, results & discussion

In this study, four common failures in electrical generators were fabricated separately, clogged filter failure, cooling fan failure, spark plug failure, and defective bearing failure. Each failure was made up suddenly and on three stages, stage 1, stage 2, and stage 3, representing mild, medium, and severe failure. Each stage lasts 20 min except for the cooling fan, where each stage lasts 30 min to ensure that the heat rise reaches its peak. The focus of the analysis will be made on one of the failures to avoid any results repeatability.

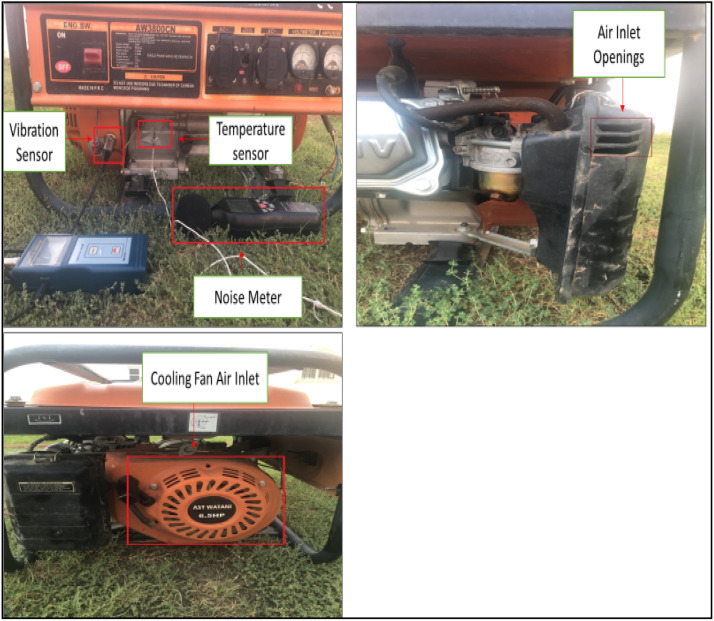

Fig. 2 presents the generator that has been considered for the experimental work along with the considered parts. The air inlet was closed with sticky tape in the experimental setup. The closure degree corresponded to filter blockage severity to mimic filter blockage. A similar approach was used to simulate cooling fan failure. Three experiments of mild, medium, and severely damaged spark plugs and defective bearings at the end of the shaft connected to the rotor were installed and left to run. Three defective spark plugs and three defective bearings were obtained from a mechanical workshop (scraped) specialized in electrical generator maintenance. The defect severity was assessed by the mechanic and classified as (mild or moderate or severe). The experiments were done for each failure (mild, moderate, severe) separately, for example, the mild defective spark is installed, then the generator is run and data collected, then the engine stopped and left to cool down. The same procedure was repeated for other failure types and severity.

Fig. 2.

Sensors set up diagram.

Every experiment was performed twice to verify the obtained results; however, only the first trial was used in the analysis. The data acquisition system was prepared after all required sensors are placed appropriately to measure and observe the factors. The sensors used in the experiment are described below:

-

•

Vibration sensor: Piezoelectric Accelerometer (Piezoceramic). The type model of the vibration sensor is A36D50AC Dynamic 4–20 mA Current Type Vibration Transmitter Piezoelectric Accelerometer for Industrial Monitor, manufactured by Yangzhou Xiyuan Electronic Technology Co.,Ltd.

-

•

Noise sensor: Condenser Type Sensor. The Model used is ST9604 manufactured by Doublepow.

-

•

Temperature sensor: Thermocouple. A probe type thermoucouble K-type with thread specification NPT 1/2′' manufactured by CGELE, China was used.

In this study, an accelerometer that uses velocity as a vibration measure was used. The velocity of vibration is defined as the speed to reach the peak, and the unit of velocity used is (mm/s). As far as the accelerometer's working theory is based on the piezoelectric effect, a piezoceramic material is used to generate a voltage when a force is exerted on it. The voltage generated is proportional to the exerted force.

Sound sensors' working theory is very similar to a vibration sensor. A component called the diaphragm vibrates when pressure disturbance occurs and converts those vibrations into electrical signals. Those electrical signals are converted to Decibels (dB) by using algorithmic conversion. A decibel is a unit that measures sound intensity.

There are mainly two categories of thermal sensors, contact, and non-contact sensors. In this study, a thermocouple was used to monitor the generator temperature. A thermocouple is a device that consists of a circuit made of two different types of conductors. Those conductors are connected at two junctions; the hot junction is placed on the targeted surface that we are interested in measuring its temperature. The cold junction is connected to the voltage-measuring device. When there is a difference between cold and hot junction temperatures, a voltage starts to generate and then is converted as the following (1 millivolt equals 1 Celsius). Its intensity is proportional to the temperature difference between the two junctions.

In normal conditions, the generator kept running for 480 min under regular condition operation to determine the Mean and Standard Deviation of the three factors: vibration, noise, and temperature. A moving-average line pattern indicates that the collected data show randomness and no trend in the data behavior, see Fig. 3 (Minitab>Stat>Time Series>Trend Analysis). A trend suggests that the mean and standard deviation are not constant, and there is a change in their values that depends on the deterioration process. Those values must be recalculated on a regular time interval proportional to the trend change. For instruments like an electrical generator designed to last for an extended period, an operational time of 480 min is considered a short period for the degradation process. At the same time, it is sufficient time to estimate the normal condition and standard deviation of the targeted parameters.

Fig. 3.

Trend analysis plot of vibration, noise, and temperature at normal condition.

The probability plots in Fig. 4 (Minitab>Graph>Probability Plot) indicate that vibration and noise do follow normal distribution while the temperature failed to do so at a 95% confidence level. However, according to the central limit theorem, temperature data can be assumed to follow a normal distribution. According to the descriptive statistics in Table 1 below (Minitab>Stat>Basic Statistics>Display Descriptive Statistics), it is worth mentioning that noise has the highest data spread among other variables. If the data depart from normality, skewness, and Kurtosis can conclude data fitness to parametric tests. Suppose the absolute values of Kurtosis and skewness are below the absolute value of 1.96 (Kim 2013); the data can be assumed to follow normal distribution regardless of normality test failure.

Fig. 4.

Probability plot of vibration, temperature, and noise at normal conditions.

Table 1.

Descriptive statistics of vibration, noise, and temperature at normal condition.

| Variable | Mean | SE Mean | StDev | Minimum | Median | Maximum | Skewness | Kurtosis |

|---|---|---|---|---|---|---|---|---|

| Vibration | 81.255 | 0.0233 | 0.513 | 79.9 | 81.27 | 82.49 | −0.13 | −0.3 |

| Noise | 102.71 | 0.0817 | 1.8 | 98.4 | 102.7 | 108.1 | 0.18 | −0.21 |

| Temperature | 68.025 | 0.0422 | 0.929 | 65.4 | 68 | 72.1 | −0.04 | 0.27 |

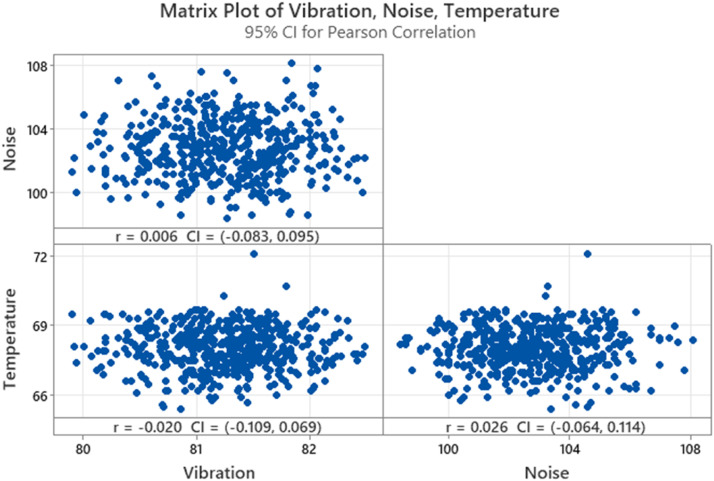

Fig. 5 presents the correlation matrix (Minitab>Stat>Basic Statistics>Correlation) of the three factors: Noise, Temperature, and Vibration. Since the r values are small, the Pearson correlation test suggests that there is no significant relationship between any two parameters meaning that each parameter behaves independently.

Fig. 5.

Correlation matrix of vibration, noise, and temperature at normal condition.

Control charts were produced only for the first trial (the second trial was used just for validating the output from the first one). Using Minitab software (Stat>Contro Charts> Variables Charts for Subgroups > Xbar-S), two control charts, one for the mean () and the other for the standard deviation (S), were produced for each variable only for trial 1.

The X&S control charts shown in Fig. 6 indicate that the process is in control and the data behave randomly and do not follow a specific pattern. Thus, nominal values can be estimated safely. Furthermore, by comparing control chart results with the trend analysis plot at normal conditions shown in Fig. 3, it can be concluded that there is no significant change in the parameters associated with operational time.

Fig. 6.

X&S control charts of vibration, noise, and temperature at normal condition.

The following sections present the experimental work and analysis of the faults studied, with details being highlighted for one of the serious faults, the clogged filter. The remaining faults will not be presented in detail to avoid repetition.

Clogged filter experiment

Correlation tests

The Pearson correlation matrix test, shown in Fig. 7, revealed a strong positive correlation among each pair of variables with R values greater than 0.7 for all the parameters.

Fig. 7.

Correlation matrix of vibration, noise, and temperature for clogged filter experiment.

Analysis of variance test

Table 2 shows ANOVA tests of the clogged filter experimental results. The null and alternative hypotheses can be stated as follows:

H0: Clogged filter does not affect the parameter (temperature, vibration, or noise)

H1: Clogged filter affects the parameter (temperature, vibration, or noise)

Table 2.

Analysis of variance test of clogged filter experiment stages.

|

According to the P-values, the null hypothesis for all parameters is rejected at a significance level of 0.05. Thus, we conclude that the filter blockage affects the mentioned parameters.

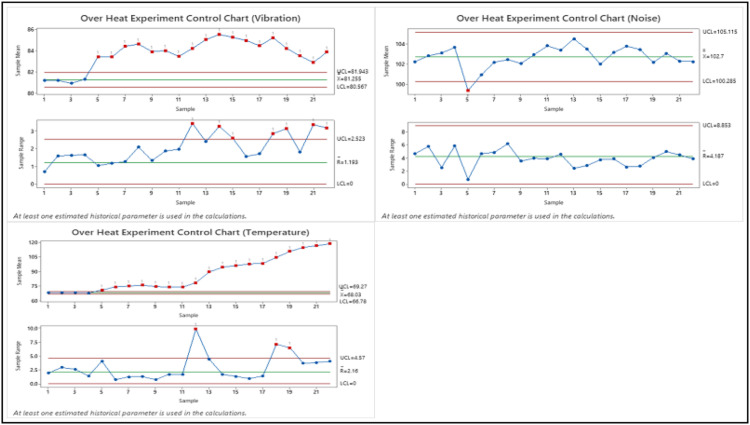

Control charts analysis

The vibration X-bar control chart could not detect the failure in stages 1 & 2; this was an expected result since the vibration results were relatively similar to regular condition operation with mean values of 81.341 and 80.9 for stages 1 and 2, respectively. The noise and temperature X-bar control charts successfully detected the instant after its occurrence, while the R chart failed to do so on most occasions, see Fig. 8.

Fig. 8.

X & R control charts for vibration, noise, and temperature for clogged filter experiment.

Correlation test

The purpose of this test is to detect any potential relationships between heat, noise, and vibration, as defined in Section III. According to the R-value of the Pearson linear correlation model, shown in Fig. 9, there is a slight correlation between noise, temperature, and vibration. This suggests that the engine heat rise does not significantly affect its noise and vibration.

Fig. 9.

Correlation matrix of vibration, noise, and temperature for overheat experiment.

Probability plot and descriptive statistics

Applying the Anderson- Darling normality test, all parameters deviate from normality with a significance level of 0.05%, as shown in Fig. 10. The degree of skewness and Kurtosis is considered relatively small; thus, the data satisfy the fitness assumption for parametric testing, see Table 3.

Fig. 10.

Probability plot of vibration, noise, and temperature for overheat experiment.

Table 3.

Skewness and kurtosis of vibration, noise, and temperature for overheat experiment.

| Variable | N | Skewness | Kurtosis |

|---|---|---|---|

| Vibration | 90 | 0.20 | 0.59 |

| Noise | 90 | −0.36 | −0.87 |

| Temperature | 90 | 0.32 | −1.37 |

Analysis of variance test

Table 4 shows that all the ANOVA tests' P-values are less than the significance level of 0.05%. It can be concluded that the null hypothesis that assumes all the means of all of the parameters stages are equal is false. It can be inferred that the cooling fan's damage degree affects at least one of the variables.

Table 4.

Analysis of variance test of overheat experiment.

|

Control chart analysis

The X-bar control chart of vibration and temperature perfectly detected the cooling fan failure due to the change of their mean values relative to the standard condition value. The noise X-bar chart falls short in observing the failure on all occasions since the rapid increase in temperature did not affect the generator significantly. Additionally, the R chart had infrequently discriminated the cooling fan breakdown event (see Fig. 11).

Fig. 11.

X & R control charts for vibration, noise, and temperature for overheat experiment.

Fault tests overall discussion

The purpose of this Section is to discuss the outputs of the clogged filter failure compared with cooling fan failure, spark plug failure, and defective bearing failure.

The cooling fan fault's correlation test shows a slight correlation between noise, temperature, and vibration. This suggests that the engine heat rise does not significantly affect its noise and vibration. The Pearson correlation test shows no correlation between vibration and noise for the spark plug fault. At the same time, there is a medium negative correlation between vibration versus temperature and noise versus temperature. For the bearing fault, the Person correlated test shows a strong positive relationship between vibration and temperature. In contrast, the relationship between noise versus temperature and noise versus vibration is a moderate positive.

The probability plots for both cooling fan and spark plug failures show that all the parameters failed to follow normal distribution at a 95% confidence level. However, the Kurtosis and skewness are less than the absolute value of two. Thus, parametric tests can be performed regardless of normality test failure. For the bearing failure, the normality test performed on all data sets, Vibration, and Temperature data sets, shows a lack of normality with a P value < 0.05. In comparison, Noise data sets are normally distributed since the P-value is 0.075. However, the skewness and Kurtosis of vibration and temperature are less than the value of 2. Hence we can assume that data sets are not very skewed, and parametric tests may apply.

For the ANOVA test, the cooling fan failure results show that P-values are less than the significance level of 0.05%. Thus, it can be concluded that the null hypothesis that assumes all the means of all parameter stages are equal is false. Based on that, it can be inferred that the cooling fan's damage degree affects at least one of the variables. The ANOVA summary of the spark plug fault experiments shows that the obtained P-value is less than the significance level of 0.05. Thus, the null hypothesis is false, and a conclusion can be drawn that a change between each stage corresponds to spark plug damage severity. Finally, the bearing fault ANOVA analysis indicates that the P-value is almost Zero; hence, the null hypothesis is rejected in favor of the alternative hypothesis that damage severity affects the observed parameters.

Control charts analysis

For the first fault, the X-bar control chart of vibration and temperature perfectly detected the cooling fan failure due to the change of their mean values relative to the standard condition value. The noise X-bar chart falls short in observing the failure on all occasions since the rapid increase in temperature did not affect the generator significantly. Additionally, the R chart had infrequently discriminated the cooling fan breakdown event. The X-bar control chart successfully detected the failure for all three parameters for the second fault. Almost all the data in the X-bar fall outside control limits. Again, the R-chart was not successful in distinguishing failure in all parameters. Finally, for the bearing fault, the X-bar chart detected failure upon its occurrence in all trials and for all parameters where all points fall beyond the upper control limit. This was due to the increment of parameter values corresponding to high friction due to the damaged bearing. The R chart detected the failure only in vibration and, on some occasions, in temperature while ultimately failing in the noise variable. The inability of the R chart in the case mentioned above is thought to be due to the low spread of noise data.

LSTM model training result

The model shows an accuracy of 98.5% and a loss function value of 1.5%, as seen in Fig. 12. The model training process stopped at iteration number 168. A random noise of 10% was added to the validation data to verify the robustness of the model.

Fig. 12.

LSTM model training result.

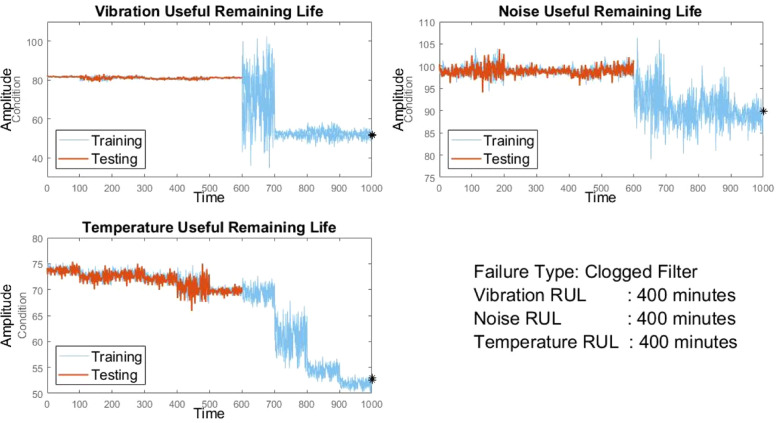

For validating the pairwise similarity model, the URL pairwise similarity model theory finds the nearest data group, then calculates the useful remaining life based on the median values of training data. Vibration data sets of clogged filter trials 1 and 2 were selected to validate the URL model, Fig. 13. Trial 1 group was used as testing data, and trial two was mixed with 99 irrelevant data sets. The model successfully excluded irrelevant data sets and calculated URLs based on the trial #2 groups.

Fig. 13.

Testing URL model.

The integration of LSTM with URL models uses run-to-failure data to calculate useful remaining life. Due to data limitation, it was assumed that the end of stage 3 of all experiments is the failure point where the machine completely shuts down. In order to integrate the URL with the classification model, a Matlab code was embedded in the LSTM model.

The LSTM model first classifies what type of failure is occurring, then use the similarity model to select a similar group data set, and then useful remaining life is calculated. The testing data sample size was selected to be 600 observations, and URL model data was set to be 1000 observations. Hence, it is observable that all URL values are 400 min. See Fig. 14 for the LSTM and URL output for the clogged filter failure as a sample of results.

Fig. 14.

LSTM & URL output for clogged filter failure.

Conclusion

This study considered the application of control charts for proposing an efficient scheme for condition-based maintenance policy. A framework was proposed to predict the failure type and its expected occurrence. The electrical generator operation was considered the prototype, whose process parameters of vibration, noise, and temperature were used as the main process outcomes for detecting failures. The normal mean and standard deviations were used for designing X-bar and R-control charts. Four common failures of the electrical generators were considered for testing the sensitivity of the control charts. The X-bar control chart detected the failure successfully in ten out of twelve cases, while the R chart failed in most cases (may be due to departure from normality). By comparing the X-chart of vibration, noise, and temperature, the control chart of temperature is most accurate in failure determination. It is concluded that the X-bar chart successfully detects faults, but it does not tell the machine's fault type or useful remaining life. Integrating the similarity model and LSTM shows that the overall CBM scheme will provide optimal electrical generator utilization.

More sophisticated and interactive methodologies could be developed for future work to include other factors and non-parametric data outputs.

Ethics statements

The work does not involve animal or human subjects. Additionally, no data from social media platforms are involved in the work.

CRediT authorship contribution statement

Mohammad A. Shbool: Conceptualization, Methodology, Writing – review & editing. Badi Alanazi: Methodology, Investigation, Formal analysis, Writing – review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability

Data will be made available on request.

References

- 1.Nistane V.M., Harsha S.P. Failure evaluation of ball bearing for prognostics. Procedia Technol. 2016;23(179–186):3rd. [Google Scholar]

- 2.Ismail M.M., Fawzi M., Taweekun J., Leevijit T. Engine knock detection for a multifuel engine using engine block vibration with statistical approach. MethodsX. 2021;8 doi: 10.1016/J.MEX.2021.101583. Jan. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Faris M.H.M., Elhussein E., Ali H.O. A method for failures grouping and priority ranking case study: operating gas compression plant. MethodsX. 2021;8 doi: 10.1016/J.MEX.2021.101268. Jan. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Malik S., Verma S., Gupta A., Sharma G., Singla S. Performability evaluation, validation and optimization for the steam generation system of a coal-fired thermal power plant. MethodsX. 2022;9 doi: 10.1016/J.MEX.2022.101852. Jan. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Vilas Boas F.M., et al. Condition monitoring of internal combustion engines in thermal power plants based on control charts and adapted nelson rules. Energies. 2021;14(16):4924. doi: 10.3390/EN14164924. 2021, Vol. 14, Page 4924Aug. [DOI] [Google Scholar]

- 6.De la Torre-Gutiérrez H., Pham D. A control chart pattern recognition system for feedback-control processes. Expert Syst. Appl. 2019;138 [Google Scholar]

- 7.Chang Z., Jia Q., Yuan X., Chen Y. Main failure mode of oil-air lubricated rolling bearing installed in high speed machining. Tribol. Int. 2017;112:68–74. [Google Scholar]

- 8.Zulfattah Z.M., et al. Effect of bio-based lubricant towards emissions and engine breakdown due to spark plug fouling in a two-stroke engine. J. Clean. Prod. 2019;221:215–223. [Google Scholar]

- 9.Naber J.D., Blough J.R., Frankowski D., Goble M., Szpytman J.E. Analysis of combustion knock metrics in spark-ignition engines. SAE Trans. 2006:223–243. [Google Scholar]

- 10.Yang S.K. A condition-based preventive maintenance arrangement for thermal power plants. Electr. Power Syst. Res. 2004;72(1):49–62. [Google Scholar]

- 11.Ahmad R., Kamaruddin S. An overview of time-based and condition-based maintenance in industrial application. Comput. Ind. Eng. 2012;63(1):135–149. [Google Scholar]

- 12.Heng A., Zhang S., Tan A.C.C., Mathew J. Rotating machinery prognostics: state of the art, challenges and opportunities. Mech. Syst. Signal Process. 2009;23(3):724–739. [Google Scholar]

- 13.Jardine A.K.S., Lin D., Banjevic D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006;20(7):1483–1510. [Google Scholar]

- 14.Jamshidi A., et al. A decision support approach for condition-based maintenance of rails based on big data analysis. Transp. Res. Part C Emerg. Technol. 2018;95:185–206. [Google Scholar]

- 15.Kumar S., Goyal D., Dang R.K., Dhami S.S., Pabla B.S. Condition based maintenance of bearings and gears for fault detection–a review. Mater. Today Proc. 2018;5(2):6128–6137. [Google Scholar]

- 16.Alaswad S., Xiang Y. A review on condition-based maintenance optimization models for stochastically deteriorating system. Reliab. Eng. Syst. Saf. 2017;157:54–63. [Google Scholar]

- 17.Liu B., Wu S., Xie M., Kuo W. A condition-based maintenance policy for degrading systems with age-and state-dependent operating cost. Eur. J. Oper. Res. 2017;263(3):879–887. [Google Scholar]

- 18.Tian Z., Jin T., Wu B., Ding F. Condition based maintenance optimization for wind power generation systems under continuous monitoring. Renew. Energy. 2011;36(5):1502–1509. [Google Scholar]

- 19.Baglee D., Jantunen E. Can equipment failure modes support the use of a condition based maintenance strategy? Procedia CIRP. 2014;22:87–91. [Google Scholar]

- 20.Shin J.H., Jun H.B. On condition based maintenance policy. J. Comput. Des. Eng. 2015;2(2):119–127. [Google Scholar]

- 21.Zhao X., He S., He Z., Xie M. Optimal condition-based maintenance policy with delay for systems subject to competing failures under continuous monitoring. Comput. Ind. Eng. 2018;124:535–544. [Google Scholar]

- 22.Zhu W., Fouladirad M., Bérenguer C. Condition-based maintenance for a deterioration system with shock in dynamic environment. IFAC Proc. 2012;45(20):504–509. [Google Scholar]

- 23.Montgomery D.C. John Wiley & Sons; 2020. Introduction to Statistical Quality Control. [Google Scholar]

- 24.Fávero L.P., Belfiore P. Academic Press; 2019. Data Science For Business and Decision Making. [Google Scholar]

- 25.S. Zhang, J. Mathew, L. Ma, Y. Sun, and A.D. Mathew, “Statistical condition monitoring based on vibration signals,” 2004.

- 26.Cassady C.R., Bowden R.O., Liew L., Pohl E.A. Combining preventive maintenance and statistical process control: a preliminary investigation. IIE Trans. 2000;32(6):471–478. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.