Abstract

Novel tissue regeneration strategies are constantly being developed worldwide. Research on bone regeneration is noteworthy, as many promising new approaches have been documented with novel strategies currently under investigation. Innovative biomaterials that allow the coordinated and well-controlled repair of bone fractures and bone loss are being designed to reduce the need for autologous or allogeneic bone grafts eventually. The current engineering technologies permit the construction of synthetic, complex, biomimetic biomaterials with properties nearly as good as those of natural bone with good biocompatibility. To ensure that all these requirements meet, bioactive molecules are coupled to structural scaffolding constituents to form a final product with the desired physical, chemical, and biological properties. Bioactive molecules that have been used to promote bone regeneration include protein growth factors, peptides, amino acids, hormones, lipids, and flavonoids. Various strategies have been adapted to investigate the coupling of bioactive molecules with scaffolding materials to sustain activity and allow controlled release. The current manuscript is a thorough survey of the strategies that have been exploited for the delivery of biomolecules for bone regeneration purposes, from choosing the bioactive molecule to selecting the optimal strategy to synthesize the scaffold and assessing the advantages and disadvantages of various delivery strategies.

Keywords: bioactive materials, biomolecules, biomolecule delivery systems, bone healing, bone regeneration, biomaterials, composites, scaffolds

Introduction

Advanced strategies for the regeneration of various tissue defects continue to emerge in plastic and reconstructive medicine and in dentistry. Millions of individuals suffer from bone loss each year; and although bone tissue naturally possesses high regeneration potential, its capacity to repair itself can be limited by secondary factors such as the extent of bone loss, the age and sex of the individual, and comorbidities. Bone defects typically resulting from extensive trauma, tumors, infections, inflammation, or degenerative disorders can be healed with advanced treatments.

The need for hard tissue regeneration biomaterials has substantially increased as the world’s population ages. Bone fractures, defects, and nonunions are a global healthcare problem. Moreover, fragility fractures, typically occurring in osteoporosis, located in wrists, hips, and vertebrae, can often be debilitating, put patients at an increased risk for a subsequent fracture, and can even be fatal among older adults.1 Worldwide, women over 50 years old have a 9.8–22.8% risk of fragility fractures.2 The Bone Health and Osteoporosis Foundation estimates that 3 million fractures and $25.3 billion in direct healthcare costs will arise annually by 2025. The total cost of care associated with osteoporotic fractures and nonunion fractions will reach $95 billion in 2040.3

The gold standard—allografts—is impeded by potential infection, limited availability, and a high nonunion rate with host tissues. Biomaterials that mimic bone tissue are becoming critical components of reconstructive approaches for cases where autogenous bone grafts are not obtainable. There are currently a large variety of bone matrices that can be used to treat bone loss. Among them, there are materials delivering natural or synthetic materials that are compatible with regenerative medicine. New matrices are being developed each year, and these are commonly coupled with growth factors (GFs) and other bone growth stimulants and infused with antibiotics to lower the risk of infection. On the other hand, the World Health Organization identifies antibiotic resistance as one of the biggest threats to global health, and their overuse in prophylaxis for bone should be limited.4 The search for composites with optimal biocompatibility and osteointegrative, osteoconductive, and osteoinductive properties is ongoing. Expectedly, such new generation of biomaterials must also allow the efficient recruitment of mesenchymal stem cells (MSCs) that will colonize the scaffold and differentiate into bone tissue with the desired shape, form, and durability.

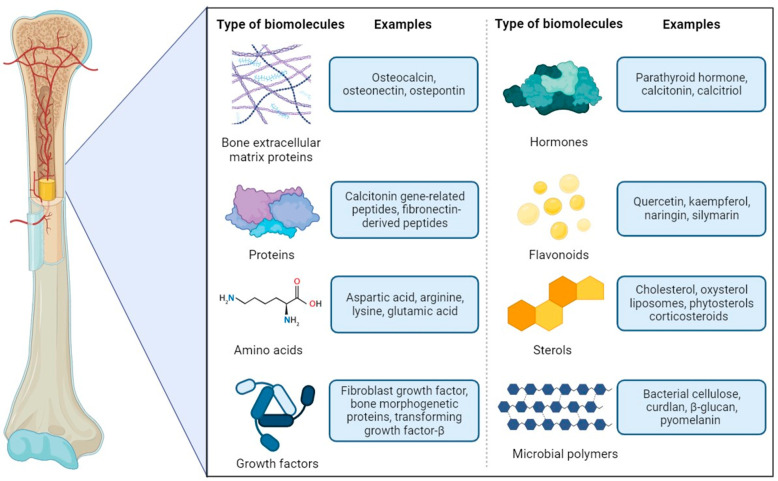

This paper reviews recent developments in using biomaterials and constructs for hard tissue repair and regeneration (Figure 1). The multidisciplinary group of chemists, material engineers, molecular biologists, biotechnologists, and microbiologists worked together to explore recent advances in vitro and in vivo research on the efficiency of bioactive molecules, their delivery platforms, and methods to produce polymeric materials. The first section of this review concentrates on bioactive components that support biocompatibility and bone regeneration using bone extracellular matrix (ECM), hormones, plant-derived flavonoids and sterols, peptides, amino acids, and microbial polymers. In the second section, we explore selected methods and pathways to produce materials and scaffolds, including polymers, inorganic fillers, and solvent-free techniques. Finally, we present the delivery methods that ensure the activity of the biomolecules, e.g., obtained by surface functionalization, controlled and stimuli-driven delivery, and gene-delivery systems. The last sections discuss recent advances, highlighting challenges and possible solutions in the design and application of biomaterials in bone tissue engineering.

Figure 1.

Types and examples of biomolecules used to support the regeneration of bone tissue.

Biomolecules Used for Bone Regeneration

Bone Extracellular Matrix (ECM) Proteins

Bone tissue mainly comprises cells mounted in a biomineral matrix.5 The extracellular matrix (ECM) is a complex and constantly changing biological environment with specific mechanical and biochemical properties. The ECM plays a crucial role in regulating cell adhesion, proliferation, responses to growth factors, and differentiation, ultimately affecting the mature bone’s functional characteristics. Osteoblast-lineage cells, including MSCs, osteoblasts, and osteocytes, can produce new bone when stimulated by the bone ECM, whereas osteoclasts can absorb bone.6 The structure of bone’s biomineral scaffold consists of around 70% of inorganic calcium hydroxyapatite (HA) crystals—Ca10(PO4)6(OH)2. The remaining 30% comprises organic elements, with collagens being the predominant proteinaceous components followed by noncollagenous proteins (NCPs), lipids, proteoglycan molecules, and other bone matrix proteins.7 Bone ECM proteins are vital factors in bone tissue’s mechanical strength and adhesive characteristics of bone tissue.8 Moreover, ECM mineralization is an essential and critical step in bone repair and reconstruction. Matrix mineralization, and the synthesis and secretion of type I collagen and NCPs by osteoblasts, are hallmarks of bone formation. The scaffold frame formed by the deposition of collagen fibers constitutes the structural basis of bone mineralization, whereas NCPs are involved in HA deposition. The ECM also plays a critical role in regulating cell adhesion, movement, and migration.9

As said above, collagens are the main structural proteins present in the ECM of bone tissue, constituting over 20% of bone mass and up to 90% of bone’s organic matrix.10 Type I collagen is the main collagen type implicated in bone mineralization; however, small quantities of type V collagen bound to HA crystals typically found in bone tissue. Collagen type III alongside with type V are thought to influence fibrillogenesis and fiber diameter of type I collagen. Collagen matrix organization is critical to maintain the optimal mechanical properties of the bone, and abnormalities in collagens hierarchical structures are associated with serious conditions, including osteogenesis imperfecta and Paget’s disease.11 Collagens, especially type I, are often used in bone replacement composites to improve their structural and functional properties.

Osteocalcin (OC) is among the most abundant NCPs in the bone matrix. OC is a relatively small matrix protein dependent on vitamins D and K. Each OC molecule contains three γ-carboxyglutamic acid molecules with a strong affinity for Ca2+. The γ-carboxyglutamic acid moieties are responsible for the high affinity of OC for HA.12,13 Mature osteoblasts produce the 49 amino acids long OC protein, which is directly involved in the regulation of bone density. Moreover, OC promotes bone mineralization and formation and attracts osteoclast progenitors.14,15 OC is believed to influence the early stages of bone healing and regulate the activity of osteoblasts and hydroxyapatite binding.16−18 Previous studies demonstrated that OC could successfully enhance the adhesion of osteoblast-like cells on the surface of HA/collagen I containing materials in vitro.19 A study by Rammelt et al.20 noted the significantly faster replacement of woven bone by lamellar bone when HA/collagen I implants were enriched with OC compared to unmodified implants. This result indicates that OC accelerates de novo bone formation rather than increasing the formation of new bone.20

Another important NCP that can be used to tune the bone regeneration process is osteonectin, also known as secreted protein, acidic and rich in cysteine (SPARC) or BM-40.21,22 Osteonectin has a high affinity for collagen I and HA.23 Like OC, osteonectin is involved in bone matrix mineralization.24 It is also a modular protein that regulates cell behavior and can influence tissue remodeling, repair, development, and cell turnover.25 A study by Zhu et al.26 provided evidence that osteonectin regulates the mineralization process in osteoblasts and is a crucial component of the p38 signaling pathway. Osteonectin can also modulate bone density. Thus, it holds tremendous potential as a point for bone reconstruction and regeneration interventions.26

Osteopontin (OPN) is another ECM NCP that can be used in the bone regeneration process. OPN is a member of the small integrin-binding ligand family N-glycosylated proteins, along with bone sialoprotein (BSP), dentin matrix protein 1, and matrix extracellular phosphoprotein. OPN mediates the attachment of bone cells to the mineral crystal structure and regulates bone resorption and calcification. Moreover, OPN is active in biological processes, such as wound healing, immunological reactions, tumorigenesis, atherosclerosis, and angiogenesis.27 McKee, Pedraza, and Kaartinen28 suggested that OPN may have an essential role in bone regeneration processes after surgical cutting when bone debris (powder) is cleared by macrophage phagocytosis after OPN opsonization and a cement line (plane) is formed at the margins of the wound that integrates the newly repaired bone with the existing drilled bone.28 Furthermore, other studies have shown that the so-called “glue” effect of some NCPs (OPN, OC, osteonectin) plays a significant role in promoting the integration of collagen fibrils and apatites.7,29

Sun et al.30 indicated that NCPs could be extracted from bone ECM and successfully coupled to the surfaces of nanofibrous (NF) gelatin scaffolds. In vitro studies revealed that NF-gelatin-NCP scaffolds promoted the osteoblasts’ proliferation, differentiation, and mineralization. Importantly, in vivo calvarial bone defect experiments demonstrated that the scaffolds containing NCPs could recruit more host cells to the defect and regenerate more bone than the control scaffolds at 6 weeks postimplantation. Thus, integrating NCPs into scaffolds is a promising strategy for improving the bone regeneration process.30

Other important protein components of ECM include positive (e.g., Periostin) and negative (matrix Gla protein, bone Gla protein) regulators of bone formation, mineralization, and remodeling (thrombospondins and R-spondins);6 however, their potential application in functionalization of bone replacement scaffolds has yet to be fully investigated.

Peptides

Bone tissue engineering (BTE) and research on peptides have expanded significantly in recent years. The outcomes of these extensive studies have shown that several peptides can support and stimulate the bone healing response.31 The practical advantage of using peptides over proteins is that they can be produced with precise control of their chemical structures. Moreover, compared to proteins, peptides are also more resistant to denaturation caused by temperature or pH variations than proteins and are easier to manipulate during grafting. Bioactive peptides that can promote the regeneration of local bone defects can be mainly divided into ECM-derived peptides, and bone morphogenetic protein (BMP)-derived peptides.32

The most-studied ECM-derived peptides contain signaling domains, as they can connect to receptors on the surface of the cell membrane.33 Selected examples of ECM-derived peptides that have been used in bone repair and regeneration studies are shown in Table 1.

Table 1. In Vitro and In Vivo Studies That Have Reported the Osteogenic Effects of Bioactive Peptides in Bone Regeneration34.

| Bioactive peptide [Reference(s)] | Composition [number of amino acids] | Binding site/potential pathway(s) | Genes or proteins up-/downregulated by peptide | Function |

|---|---|---|---|---|

| ECM-Derived Peptides | ||||

| PepGen P-15 (P-15) [385−388] | 15 | Type I collagen binding sites | Upregulated: ALP, BMP-2, BMP-7; Runx2, COL1, OSTRX BSP, and integrin a2 | Promoted: extracellular matrix production; proliferation and osteogenic differentiation; cell attachment, migration, and survival |

| Arginine-glycine-aspartic acid (RGD) [389−392] | 3 | Integrin binding sites | Upregulated: ALP, RUNX2, osteocalcin, osteopontin, BSP, Sox9, Aggrecan, fibronectin, and collagen II | Promoted: Proliferation, mineralization, and osteogenic differentiation; cell attachment and survival |

| Ser-Val-Val-Tyr-Gly-Leu-Arg (SVVYGLR) [393−395] | 7 | RGD binding sites | Upregulated: integrin avb3 | Promoted: proliferation and neovascularization; angiogenesis and osteogenesis; adhesion, migration; tube formation of endothelial cells |

| Suppressed: NFAT, osteoclastogenesis-related mRNAs | ||||

| Glycine-phenylalanine-hydroxyproline-arginine (GFOGER) [396−399] | 4 | integrin a2b1 binding sites | Upregulated: integrin a2b1 binding | Promoted: differentiation, bone regeneration, and osseointegration |

| Collagen binding motif (CBM) [400, 401] | 28 | Collagen binding sites | Induced sustained activation of ERK; induced transactivation of SRE, CRE, and AP-1; induced expression of type X collagen | Promoted: bone-related cell adhesion and growth; osteogenic differentiation |

| Fibronectin-derived peptides (FN-derived peptides) [402−404] | 7 | – | – | Promoted: bone-related cell spreading; adhesion and mineralization |

| BMP-Derived Peptides | ||||

| P17-BMP-2 [405] | 17 | – | – | Promoted: bone repair; osteoblast differentiation and bone regeneration |

| P20-BMP-2 and P24-BMP-2 [406] | 20 and 24, respectively | – | Upregulated: OCN, Runx2, and collagen I | Promoted: osteogenesis and differentiation of MSCs into osteoblasts |

| BMP-7-derived peptide BFP-1 [407] | 15 | – | Upregulated: expression of CD44, CD47 and CD51 | Enhanced: Ca2p content in cells; ALP activity; bone regeneration |

| Other Peptides | ||||

| Calcitonin gene-related peptides (CGRPs) [61, 408−410] | 37 | Pathways: cAMP, Wnt, and AMPK-eNOS | Upregulated: expression of IGF-1, IGF-1 receptor and BMP-2 receptor; ALP, OC, and COLLA1 | Promoted: cell proliferation, osteogenic differentiation, and angiogenesis |

| Downregulated: apoptosis and inflammation | ||||

| Parathyroid hormone (1-34) (PTH 1-34) [411, 412] | 34 | Pathways: G(q)-signaling, b-arrestin recruitment, ERK 1/2 phosphorylation and phospholipase C | Upregulated: expression of Runx2 and COL2A1 | Promoted: cell proliferation and chondrogenesis |

| Downregulated: expression of ALP and BMP-2 | ||||

| Osteogenic growth peptides (OGPs) [413−415] | 14 | Pathways: G1 protein-MAPK and RhoA/ROCK | Upregulated: osteocalcin, collagen, BMP-2, ALP and mineralization TGF b1, TGF b2, TGF b3, FGF-2, IGF-I | Promoted: cell proliferation and osteogenic differentiation; cartilage-to-bone transition |

| Downregulated: adipogenic differentiation | ||||

| Thrombin peptide 508 (TP508) [389, 416] | 23 | Pathways: JAK/STAT, NF-κB, PDGF, PI3K/AKT, PTEN, and ERK/MAPK; cell cycle-G1/S checkpoint | Upregulated: expression of Runx2 and OPN | Promoted: cell proliferation and osteogenic differentiation; chemotaxis, angiogenesis and revascularization |

| Downregulated: apoptosis, the effect of hypoxia | ||||

| NEMO-binding domain peptide (NBD) [417, 418] | 6 | Pathway: NF-κB | Downregulated: TRAP activity, actin rings; RANKL-induced c-Src kinase activity | Promoted: osteogenic differentiation of cells |

| Downregulated: bone resorption | ||||

| Cell-penetrating peptide (CPP) [419, 420] | 30 | – | – | Transcription factor delivery of bone regeneration-related proteins or factors into cells |

| AcN-RADARADARAD-ARADA-CONH2 (RADA16-I 16) [421] | 16 | – | Upregulated: expression of Runx2 genes, ALP, and osteocalcin | Transcription factor delivery of bone-regeneration-related proteins or factors into cells |

Another group, the BMP-derived peptides (BMPs), are mostly GFs, which are responsible for inducing the formation of bone or cartilage.34 BMPs that promote the bone healing response are mainly derived from BMP-2, BMP-7, and BMP-9. Studies have shown that BMP-derived peptides induce the osteogenic differentiation of hMSCs and bone regeneration. Moreover, BFP-1 enhanced the Ca 2p content in cells and induced their alkaline phosphatase (ALP) activity.35 Selected examples of BMP-derived peptides that have been used for bone repair and regeneration studies are shown in Table 1.

In addition to ECM- and BMP-derived peptides, other peptides like calcitonin gene-related peptide (CGRP), parathyroid hormone, osteogenic growth peptides, or cell-penetrating peptides have also been studied concerning their potential to induce bone regeneration (Table 1).34

Traditional bone graft can be substituted with injectable self-healing hydrogel loaded with peptides: osteogenic KP and angiogenic QK, which were designed from BMP2 and VEGF, respectively, to improve osteogenic differentiation and vascularization. Both peptides: KP and QK seemed to act synergistically by promoting bone formation in rat calvaria.36

Although biomaterials support healing processes, their modification with peptide sequences can improve antimicrobial, proangiogenic, and immunomodulatory properties. New peptides with biofunctional activities are being discovered.37 Thus, various scientific groups38−41 employed genomics to identify new short peptides, indicating their immunomodulatory properties toward keratinocytes, periodontal ligament cells, or endothelial cells in the context of regeneration, cytokine secretion, cell apoptosis, or viability. Also, peptides are frequently incorporated into biomaterials to improve the repairing of cardiovascular tissue.37

Amino Acids

Amino acids are the building blocks of proteins. Polar and charged amino acids (AAs) are abundant in NCPs and involved in bone HA mineralization. The acidic domains of NCPs (e.g., OPN, bone sialoprotein, dentin matrix protein 1, and dentin phosphophoryn) are rich in negatively charged AAs, such as aspartic acid (Asp), glutamic acid (Glu), and phosphoserine (PSer). Such negatively charged AAs play a critical role in controlling HA nucleation and growth, and they also take part in bone and dentine HA mineralization. Positively charged AAs, such as arginine (Arg) and lysine (Lys), are involved in HA nucleation within ECM proteins such as collagen.42,43 Moreover, Arg and Lys may accelerate the process of bone fracture healing by improving collagen synthesis and local blood supply and supplementing GFs. In addition, Glu, Arg, and Lys boost bone mineral density (BMD) by stimulating growth hormone (GH) production.44

Since amino acids containing amino groups can be used as aminolysis agents for biomaterials, three amino acids such as Ser, Gly, and Lys can be used to modify PLLA by surface modification to obtain nanofiber scaffolds. As shown by Zhang et al.,45 a modification of PLLA nanofiber scaffolds with Ser, Gly, and Lys helped to improve the hydrophilic properties of such biomaterials, as well as to lower the pressure resistance of modified scaffolds.

GFs

The role of GFs has been widely recognized in the bone repair process. GFs are released by cells in the inflamed area. Those polypeptides regulate the events that occur during wound healing.46,47 The term growth factors refers to a class of polypeptide hormones that stimulate a wide range of cellular events, such as cell proliferation, chemotaxis differentiation, and ECM protein production. GFs can act locally and systematically to stimulate cell growth and function in several ways. Their activity is mainly regulated by binding to ECM receptors. Tissue repair animal model studies have provided evidence that GFs, such as epidermal growth factor (EGF), transforming growth factor (TGF)-α, TGF-β, platelet-derived growth factor, and fibroblast growth factor (FGF), are the key agents involved in the wound healing process. More importantly, studies have shown that a lack of any of these mediators at the injured site hampers the healing process. Thus, exogenous GFs are considered potent supplements in wound healing, serving as the foundation for upcoming regenerative therapies.48

One of the families of growth factors that have been well-studied in bone regeneration is the family of BMPs. These proteins belong to the TGF-β superfamily and have been extensively studied in preclinical and clinical investigations of bone regeneration, including bone defects and spinal fusion. BMPs have been shown to be closely related to the processes of bone formation and regeneration.49 In the human genome, 20 genes encode functional BMPs.50 Bone regeneration is, in part, a recapitulation of embryonic development. Key steps during bone morphogenesis are progenitors/stem cell chemotaxis and their proliferation and differentiation. The mechanism of action of BMPs involves signaling in all of these steps (chemotaxis, proliferation, and differentiation of osteoprogenitor cells) and, thus, the induction of bone formation by these cells. Thus, recombinant BMPs 2 and 7 have been approved by the Food and Drug Administration (FDA) for spine fusion, fracture healing, and oral surgery.34,49

FGF2, or basic FGF (bFGF), is the most common FGF used in regenerative medicine, including bone regeneration,51 and its levels are increased in acute wounds. FGF2 plays a role in granulation tissue formation, re-epithelialization, and tissue remodeling. It may also regulate the synthesis and deposition of various ECM components, increase keratinocyte mobility during re-epithelialization, promote fibroblast migration, and stimulate collagenase production.52 In addition, FGF2 was shown to promote angiogenesis.53

One of the most essential parts of the fracture healing/bone regeneration process is the state of the local vasculature. Thus, VEGF substantially stimulates local vascular regeneration in the fracture area. It has been shown that VEGF can increase MSC chemotaxis and stimulate osteoblast differentiation and proliferation. Therefore, VEGF plays a crucial role in new bone formation. In vitro studies have reported that VEGF stimulates the growth of vascular endothelial cells, which are the basic units of arteries, veins, and lymphatic systems. Notably, angiogenesis plays a critical role in endochondral ossification and, thus, the transformation of avascular cartilage tissue into vascular bone tissue. VEGF is released during this process by hypertrophic chondrocytes and causes the ingrowth of metaphyseal blood vessels through cartilage tissue and the formation of new bone.54

Chen and Wu et al.55 showed that applying stromal-derived factor-1α (SDF-1α) and TGF-β1 to damaged cartilage can promote the migration and chondrogenic differentiation of MSCs. SDF-1α is a chemokine and the ligand of C–X–C chemokine receptor type 4 (CXCR-4) that induces stem cell recruitment and migration. TGF-β1 is a critical regulator of the chondrogenic differentiation of MSCs. Studies have reported that combining SDF-1α and TGF-β1 has a synergistic effect on enhancing in vitro chondrogenic potential and in vivo cartilage regeneration.55

Hormones (Cofactors)

The proper functioning of the endocrine system sustains skeleton development. Hormones are signaling molecules that act distal to their production site (the endocrine effect). They also regulate the synthesis and action of local factors, which directly affect cellular metabolism (autocrine and paracrine effects). Among the most critical hormones in bone formation-related processes are thyroid hormones, parathyroid hormone (PTH), calcitonin, calcitriol, androgens, estrogens, progesterone, insulin, glucocorticoids, and GH;13 and among these, the most important are GH and calciotropic hormones (PTH, calcitonin, and metabolites of vitamin D).

Thyroid hormones have opposite effects on bone. They stimulate the synthesis and mineralization of the osteoid matrix by osteoblasts and stimulate resorption by increasing the number and function of osteoclasts. The clinical outcome of the latter effect is bone loss in hyperthyroidism.56

Calcium homeostasis is controlled by PTH through its direct actions on the bone and the kidneys and indirect actions on the intestine.57 PTH is a signaling molecule shown to have the potential to enhance bone regeneration in significant bone defects. The potential of PTH lies in its anabolic effect on bone. The FDA has approved a treatment for osteoporosis that encompasses daily injections of PTH, which increases BMD and bone volume. Therefore, PTH may promote bone regeneration and be an alternative to autografts and BMPs to treat large segmental defects and nonunions.58 In a human case study documenting treatment with internal fixation, external fixation, and autograft combined with BMP-7 administration, the nonunion persisted unless the patient was supplemented with PTH 1-84.59

Calcitonin is an inhibitor of bone resorption that reduces the number and activity of osteoclasts. Nonetheless, calcitonin appears to have only a transient effect, as osteoclasts seem to become nonresponsive to calcitonin within a few days.60In vivo studies have shown that CGRP also plays a role in bone development, metabolism, and repair. CGRP is a 37 residue peptide generated in specific neurons by alternative splicing of the calcitonin gene. In vitro studies have demonstrated that CGRP may stimulate osteoblast proliferation, differentiation, and maturation in osteoblast cell lines and bone marrow MSCs.61

Calcitriol is a steroid hormone that promotes bone mineralization. It increases the intestinal absorption of calcium and phosphate; thus, its activity is beneficial for the growth of the skeleton.60,62

Sex hormones can also affect bone in numerous ways. Among others, androgens have an anabolic effect on bone by stimulating osteoblast receptors. Androgen deficiency has been associated with lower BMD, and testosterone administration to younger individuals was found to increase overall bone mass. Consistent with these findings, women with excess androgens also have higher bone densities than women with low/average levels of these hormones. Estrogens have a dual effect on bone metabolism. They favor bone formation by increasing the number and improving the function of osteoblasts; however, they also reduce resorption. Studies have shown that estrogens can increase the level of osteoprotegerin (OPG), which inhibits resorption. Thus, estrogens may play an essential role in the regulation of osteoclastogenesis. Moreover, progesterone has an anabolic effect on bone tissue. This effect may be direct, through the osteoblasts that possess hormone receptors, or indirect, through competition for the osteoblastic receptors of glucocorticoids.60,63 Scientific evidence has shown that high doses of glucocorticoids may have a catabolic effect on bone. This effect may be due to the inhibition of insulin-like growth factor (IGF-I) synthesis by osteoblasts and direct suppression of BMP-2 and Cbfa1, critical factors in osteoblastogenesis. In contrast, it has been demonstrated that glucocorticoids have an osteogenic capacity at physiological doses that promotes osteoblastic differentiation.64

Another hormone that might be involved in the bone regeneration process is insulin. It has been proposed that insulin could stimulate osteoblast differentiation, which would enhance the production of OC, and subsequently, OC may be able to stimulate pancreatic β cell proliferation and skeletal muscle insulin sensitivity. It is still uncertain whether insulin stimulates bone directly or indirectly by increasing muscle work and, therefore, skeletal loading.65,66

Flavonoids

New strategies are constantly being developed to promote the natural healing of bone lesions or regeneration. Medicinal plants are essential sources of compounds such as phytochemicals, vitamins, and other nutrients, and such compounds derived from plants may enhance bone healing. Phytochemicals, especially flavonoids, may improve bone health due to their antioxidant and anti-inflammatory properties. Moreover, due to their inhibition of osteoclast cells and increased proliferation of osteoblasts, these compounds might help prevent bone loss and reduce inflammatory processes without producing the undesirable side effects of allopathic drugs.67

Flavonoids can be divided into various classes based on their chemical structure.68 Recent reports have shown that the flavonols quercetin and kaempferol can reduce bone resorption in vitro by directly targeting mature osteoclasts via the estrogen receptor (ER). Quercetin has anti-inflammatory properties and has been found to inhibit the proliferation of human adipose tissue-derived stromal cells and promote their differentiation into osteoblasts. Thus, quercetin can promote osteoblast differentiation and inhibit osteoclastogenesis, so it might be considered a potential drug for bone diseases and regeneration.69

In traditional Chinese medicine, another flavonoid, naringin, is commonly used to treat osteoporosis and bone disorders. Studies have shown that naringin may promote the proliferation of bone marrow stromal cells (BMSCs), enhance the levels of BMPs, and increase the expression of bone markers (ALP, OCN, and OPN). It has also been demonstrated that naringin can abolish osteoclastogenesis and bone resorption by inhibiting RANKL-induced NF-κB and ERK activation70−74

Hesperidin, whose effect on bone metabolism has been studied in rats, has been shown to improve femoral strength in adult rats and the total metaphyseal and diaphyseal BMD at the femur in young rats. However, poncirin (a flavanone glycoside) enhances the gene expression of the osteogenic transcription factor Runx2 and a transcriptional coactivator with a PDZ-binding motif (TAZ) and upregulates the expression of bone markers such as ALP and OCN in C3H10T1/2 cells. Hesperidin also promotes bone mineral deposition in BMSCs.69

Silymarin (Smn) is another active polyphenolic flavonoid that has been used primarily due to its antioxidant and anti-inflammatory properties. By regulating the bone formation, Smn has been shown to be effective in treating bone fractures and osteoporosis. In in vitro and in vivo models, Smn directly affected cell adhesion, proliferation, and matrix secretion and the expression of osteogenic markers such as Col I, OCN, and Runx2. Notably, an enhanced regenerative process that provides more significant bone matrix deposition and tissue organization has been observed in in vivo models testing the activity of Smn.73

Plant Sterols

It has been suggested that phytosterols may affect osteoblast proliferation and differentiation. Cissus quadrangularis (Vitaceae family, plant kingdom) is a plant species indigenous to southern Asia and Africa that has been widely studied in bone regeneration research.74Cissus quadrangularis extract (CQE) contains steroids that are considered positive stimulants of osteoblasts and bone growth and is used as a composite modification designed for bone healing. To date, alginate O-carboxymethyl chitosan (O-CMC) or poly(ε-caprolactone) PCL/HA composites have been modified with CQE to study their effect on osteoblasts. Composites with CQE cause a significant increase in peptide absorption; peptides are absorbed by the composite due to the electrostatic interactions between the protein and composite surface. Cellular research indicates that these biomaterials enhance cell attachment to the composite surface and cell spreading throughout the composite. Cell proliferation increased significantly after only 72 h of stimulation, but it was suggested that CQE further enhances cell proliferation as the contact time increases. ALP, a marker of osteoblast differentiation, was significantly increased compared to that in the unmodified composite, and the effect grew over time. Moreover, the increase in ALP over time correlates with the significant increase in biomineralization by osteoblasts in the presence of a composite containing CQE compared to an unmodified composite (hydroxyapatite was detected by chemical analysis).75−77 However, the mechanism of CQE has yet to be determined, and more research is needed.

Seaweeds are marine plants that are widely present in Asian diets. Seaweeds have been studied for several years due to their bioactivity and potential use as pharmaceutical agents. One compound found in seaweed that has been studied is fucosterol, which is thought to affect bone regeneration.78 Studies have investigated the use of fucosterol in osteoblast cell culture and ovariectomized female rats (an animal model of osteoporosis). Interestingly, the obtained results indicated that fucosterol increased ALP activity, mineralization, and bone density and significantly increased bone cell proliferation. On the other hand, it was suggested that fucosterol might decrease osteoclast differentiation and affect bone resorption, maintaining bone homeostasis, which is the balance between bone mineralization and resorption. Fucosterol can also enhance the production of OC and the reduction in CTx. Moreover, the effect of fucosterol was compared to that of estradiol, which has been presented as a postmenopausal osteoporosis therapy factor, and in many cases, fucosterol was superior.79,80

Studies have shown that phytohormones may play a role in bone regeneration. β-Ecdysterone is a steroid hormone found in plants such as Achyranthe bidentata. β-Ecdysterone-mediated stimulation of osteoblasts results in significantly increased ALP levels and OPN activity. Moreover, β-ecdysterone may enhance mineralization and bone tissue formation in vitro. Gene sequencing analysis showed that genes involved in the BMP pathway were upregulated by β-ecdysterone. In vivo studies on the effect of β-ecdysterone on bone regeneration were performed using rat femurs. Four and eight weeks after bone defect initiation and β-ecdysterone injection, micro-CT imaging showed changes in the bone that were typical of healing; moreover, the bone density had significantly increased. Finally, a significant increase in the level of BMP-2 expression was detected, and this result was confirmed by an immunohistochemistry assay.81

Oxysterols

Oxysterols are small, cholesterol-derived molecules naturally occurring in human and animal tissues and blood circulation that have been reported to be osteoinductive factors.82

20S-Hydroxycholesterol and 22S-hydroxycholesterol are compounds formed during the oxidation of cholesterol. Studies indicate that these compounds may affect the differentiation of osteogenic cells both in vitro and in vivo.83 In the context of alveolar bone regeneration, oxysterols were shown in vitro and in vivo to significantly enhance ALP activity, mineralization, and calcium ion levels needed for proper regeneration. Oxysterols also promote increased osteogenic gene and protein (OCN or Runx2) expression. In addition, oxysterols stimulate an increase in Hedgehog pathway activation in which proteins such as Smo (a Hh receptor) or Gli1 (a transcription factor) are involved. In vivo studies performed on rats showed progressive bone formation 10 and 15 days after extraction using micro-CT imaging and histological analysis; however, immunohistochemical analysis showed increased expression of ALP and OCN. In these studies, the promotion by oxysterols was at a level comparable to that of BMP-2.84 The above-mentioned studies align with the in vitro research performed by Kwon, Lee, Hwang, and Heo.85 Additionally, Aghaloo et al.86 performed in vivo studies on rats with poly(lactic-co-glycolic acid) (PLGA) scaffolds coated with oxysterols, and Johnson et al.87 performed studies on rats with collagen sponges containing various types of oxysterols (Oxy34 and Oxy49). All of the above-mentioned studies indicated that treatment prompted increased factors involved in bone regeneration.

Oxy49 is an oxysterol examined as a potential factor that can promote bone regeneration. In vivo studies performed using a rabbit cranial bone defect model and a collagen sponge containing Oxy49 showed increased expression of the osteogenesis markers COL1, OSX, OPN, and OCN. Additionally, the activity of ALP, the level of OC, and the mineralization process significantly increased. Finally, micro-CT analysis showed precise bone regeneration and density intensification after a collagen sponge containing Oxy49 was implanted into the cranium.82

Oxysterols are still being examined as relatively new compounds in bone regeneration. In addition to 20S-hydroxycholesterol, 22S-hydroxycholesterol, Oxy34, and Oxy49, studies on oxysterols have also included Oxy4, Oxy 18, and Oxy21, and all of these compounds may successfully promote osteogenesis. Notably, the potential of oxysterols is comparable to or even better than that of BMP-2.88

Liposomes

Liposomes are lipid-based biocompatible vesicles widely used in therapies for bone healing to deliver drugs/bioactive particles and act as stimuli-responsive factors. Scaffolds containing liposomes have been proven to enhance bone regeneration. They help with the delivered molecule’s solubilization, bioactive stabilization, or bioavailability. Liposomes combined with factors that promote bone healing enhance osteogenesis. Liposomes can deliver oxysterols, and the combination of these two factors enhances osteoregenerative processes both in vitro and in vivo.89 Recently, novel liposomal nanocarriers, stereosomes, were developed and examined as agents to improve molecular stability. Lee et al.90 produced and studied stereosomes containing 20S-hydroxycholesterol and purmorphamine coated on PLGA and polydiacetylene (PDA) layers that can activate bone regeneration by enhancing the Hedgehog signaling pathway, which is crucial for effective osteogenesis. Applying this stereosome resulted in a synergistic increase in ALP activity and level of mineralization in cells. Moreover, the studied biomolecules caused significant increases in the expression levels of genes involved in osteogenesis (ALP, Runx2, OCN, OPN, Col1, and Gli1). In vivo research performed on mice confirmed the cell study results, and micro-CT and histological analysis showed an increase in bone regeneration and mineralization in stereosome-treated animals compared to that in controls. Immunohistochemical analysis indicated enhanced expression of the osteogenic markers Runx2 and OCN. Research by Lee and colleagues90 is in-line with that of Cui et al.83 on stereosomes containing 20S-hydroxycholesterol and sterylamine.

Liposomes were formerly studied as effective agents to deliver the bone morphogenetic protein BMP-2 gene to the bone fracture site, which resulted in enhanced bone regeneration.91 Currently, liposomes are successfully being used both as individual carriers of biomolecules and as additions to scaffolds.92

Statins

Statins are well-known drugs used to lower LDL cholesterol levels and prevent the development of atherosclerosis. Almost 20 years ago, it was reported that hypercholesterolemic patients undergoing statin therapy had a reduced risk of bone fracture. Researchers have thus started investigating how BMD and turnover change after statin therapy and how statins may affect bone regeneration. Montagnani et al.93 examined 30 women suffering from postmenopausal hypercholesterolemia. The studied group was treated with simvastatin daily for 1 year. During that time, the group did not receive any treatment that would affect bone metabolism (calcitonin, calcium, and vitamin D). Blood samples were collected every 3 months, and serum calcium, phosphate, and ALP levels were measured. Moreover, bone resorption and mineral density were assessed. The obtained results indicated that the treated patients had significant increases in total and bone ALP levels over time and BMD in the lumbar spine and femoral neck. In the same year, Ayukawa, Okamura, and Koyano94 performed a study on rats in which titanium implants were installed in the tibias, and a daily dose of simvastatin was given. The bone contact ratio and bone density measurements showed significant increases in the experimental group compared to that in the control group, which was not treated with simvastatin. Histological analysis showed newly formed bone and abundant bone trabeculae in the treated animals. Wong and Rabie95 investigated whether adding statins accelerates osteogenesis in rabbits. After implantation of a collagen sponge combined with simvastatin into the calvarial fracture, the expression levels of VEGF, BMP-2, and Cbfa1 were enhanced and resulted in earlier osteoinduction and neovascularization. Wong and Rabie96 also performed histological analysis to identify new bone formation that occurred 5 days after implantation of a simvastatin-modified collagen sponge.

Importantly, simvastatin is not the only statin compound studied in the context of bone regeneration. Moriyama et al.97 investigated whether local fluvastatin application promotes osteogenesis after PLGA implantation into rat tibiae. Tibias were used for histological analysis 1, 2, and 4 weeks after implantation, indicating a significant amount of osteoid bone and increased mineralization. Masuzaki et al.98 showed by histological analysis that, after fluvastatin-modified PLGA microsphere implantation into rat tibiae, bone formation was amplified, and the bone implant contact significantly increased. Additionally, the level of OCN, a bone metabolism marker, was significantly higher 2 and 4 weeks after implantation. Research by Rakhmatia, Ayukawa, Furuhashi, and Koyano99 aligns with previous studies. Rats implanted with fluvastatin-modified carbonate apatite showed enhanced bone formation and bone volume by micro-CT analysis. Moreover, histological analysis confirmed these results and indicated significant intensification of bone mineralization.

In addition, in vitro research indicated that statins regulate the OPG/RANKL/RANK pathway. Statins can inhibit bone resorption, ROS generation, or osteoclastogenesis. Additionally, statins may affect osteogenesis promoters, such as BMP-2, TGF-β, or ALP. Statin-stimulated cells exhibited increased expression of the osteogenic genes Runx2 and OCN and the osteogenic proteins Runx2, OCN, and OPN.100

Microbial Biopolymers

Bacteria and microscopic fungi produce natural polymers as part of their intrinsic physiology to create a mechanical protective layer that surrounds their cells. These polymers store molecules necessary for proper metabolism functions and create a biofilm that protects their cells from the harmful effects of the environment. Microorganisms can synthesize various types of biopolymers with different monomer compositions, molecular weights, 3D configurations, and cross-linking arrangements that can be tailored for specific applications in BTE.101 Microbial polymers are synthesized from enzymatic reactions that link monomers, such as sugars, amino acids, or hydroxy fatty acids, to create high molecular weight molecules. Microorganisms can produce various classes of biopolymers with potential biomedical applications, such as polysaccharides, polyamides, polyesters, and polyphosphates.102

Bacterial cellulose (BC) is a linear homopolysaccharide biopolymer produced by many Gram-negative bacterial genera, such as Komagataeibacter (formerly Gluconacetobacter), Agrobacterium, Acetobacter, Burkholderia, Erwinia, Pseudomonas, and Rhizobium.103,104 BC is synthesized from glucose in the periplasmic space of bacterial cells by cellulose synthase, and its chemical structure is composed of β-d-glucopyranose units linked by β-1,4 glycosidic bonds. The biocompatibility, biodegradability, high crystallinity, porosity, and tensile strength with mechanical robustness make BC an interesting biopolymer that can be used in designing modern biomaterials for the targeted regeneration of bone tissue.103

Bassi et al.105 showed that intracranial implantation of a BC membrane led to bone neoformation and vascularization at the defect site and confirmed the activity of key ossification markers such as OC and OPN 60 days after biomaterial implantation.105 BC is used by itself and in combination with other bioactive factors in designing biomaterials for bone regeneration. Hydrogels made from BC modified with gold nanoparticles significantly increased the activity of ALP, OC, and OPN in cell culture models and led to the formation of apatite deposits. In contrast, in a rabbit model, these hydrogels showed that new bone tissue with high mineral density had been formed.106 Similar conclusions were drawn by Kheiry et al.,107 who showed that modifying BC with fisetin contributes to the increase in ALP activity and the concentrations of OC and OPN in mesenchymal cells subjected to osteogenic differentiation.107 Nanocomposites of BC modified with hydroxyapatite (HA), the main inorganic compound responsible for the mechanical properties of bones, promoted the proliferation and maturation of mesenchymal cells into osteocyte precursors and effectively contributed to the neoformation of bone tissue after implantation.108 Unmodified BC does not have antibacterial properties; however, its porosity and good ability to biofunctionalize with molecules such as antibiotics, silver nanoparticles, lysozyme, or cationic surfactants can be used to design biomaterials that reduce the risk of postimplantation infections.109,110

Another example of microbially produced polymers with potential for use in bone regeneration are β-glucans. β-Glucans are heterogeneous groups of polysaccharide polymers composed of d-glucose monomers linked by (1 → 3), (1 → 4), or (1 → 6) glycosidic bonds. The cell walls of grains, bacteria, fungi, and yeast are a natural source of this biopolymer. The most well-known β-glucans synthesized by microbes are the linear (1 → 3) and branched (1 → 3;1 → 6) β-glucans found in Saccharomyces cerevisiae. The physiochemical and biological properties of β-glucans strongly depend on the source, extraction method, polymer chain length, and extent of purification.111,112

One of the fundamental problems in achieving an appropriate level of osseointegration with an implant is the excessive bone resorptive activity of osteoclasts. There is substantial scientific evidence to conclude that polycan, a β-glucan derived from Aureobasidium pullulans, reduces the number of active osteoclasts and inhibits the secretion of pro-osteolytic cytokines such as interleukin-1β (IL-1β) and tumor necrosis factor-α (TNF-α). β-Glucan, which is part of the S. cerevisiae cell wall, contributed to the downregulation of receptor activator for nuclear factor κB ligand (RANKL) and the upregulation of OPG, which resulted in the inhibition of bone loss in a mouse model.113 The suppressive activity of β-glucan derived from baker’s yeast against RANKL has also been demonstrated by Hara et al.114 Stimulation of mouse bone marrow cells with S. cerevisiae β-glucan inhibited differentiation from maturing osteoclasts by downregulating the nuclear factor of activated T cells 1 (NFATC1), which was caused by the suppression of NF-κB signaling and c-fos expression.114 β-Glucan can not only inhibit osteoclast activity but also be used as a polymer when designing biocomposites modified with a ceramic phase. Biocomposites composed of (1 → 3) β-glucan and HA meet important physicochemical requirements, such as the ability to undergo thermal sterilization without damaging the polymer structure, good porosity, flexibility, and self-adaption to the defect shape.115 Modifying such composites by adding HA-containing carbonate ions (CHA) increased the solubility and decreased the crystallinity of the ceramic phase, as well as intensified the attachment, proliferation, and differentiation of osteoblasts. In rabbit models, 6 months after implantation, the CHA/β-glucan composite contributed to the increased formation of new cortical bone and intensified mineralization at the implantation site.116

An example of a linear bacterial (1 → 3) β-glucan that has aroused interest in the design of new biocomposites for targeted bone tissue regeneration is Curdlan, which is produced by Alcaligenes faecalis.117 Curdlan limited osteoclast differentiation by suppressing NFATC1 activation via downregulation of the Syk kinase signaling pathway, which is responsible for osteoclast differentiation, maturation, and bone lytic activity.113,118 Curdlan can be modified to make highly elastic and biocompatible hydrogels or biocomposites. Curdlan/whey protein isolate/hydroxyapatite biomaterials showed a high cytocompatibility level and promoted OC production in an in vitro model of human osteoblasts.119 The addition of Curdlan to a chitosan/HA scaffold improved the porosity, water uptake capability, and biocompatibility of the composite and enhanced human osteoblast survival and proliferation on the scaffold, which are crucial to start the implant osseointegration process.120 Toullec et al.121 reported that Curdlan–chitosan scaffolds were not cytotoxic and improved cell migration on the surface of the biocomposite; however, further studies are required to demonstrate the positive effect of this biomaterial on bone tissue regeneration.121

Bacterial exopolysaccharides (BEPSs), such as gellan and alginate, are classified as high molecular weight carbohydrate polymers and are secreted by cells into the external environment. BEPSs perform various physiological functions and can be adapted to the needs of regenerative medicine due to their unusual physicochemical properties.122 Gellan isolated from Sphingomonas paucimobilis was incorporated into a composite in the form of a gum, and the addition of HA increased the adhesion of human adipose-derived stem cells to the surface.123 Alginate secreted by Pseudomonas aeruginosa is being studied for use in bone tissue regenerative medicine as a carrier of GFs. The delivery of BMP-2 and BMP-7 using an alginate biomaterial enhanced the differentiation of bone marrow-derived stem cells to osteoblasts, and codelivering the BMP-2 and VEGF released from the alginate gels improved the reconstruction of bone defects.124

Another interesting biopolymer produced by P. aeruginosa is pyomelanin, a black–brown pigment formed by the oxidative polymerization of homogentisic acid.125 The use of melanin polymers, such as pyomelanin, seems to be an economical and affordable way to improve the physicochemical and osteoinductive properties of newly designed biocomposites.126 Important premises indicating the need to investigate the role of pyomelanin as a modulator of bone tissue regeneration processes are the studies of Yoo et al.,127 who showed that melanin isolated from Gallus gallus domesticus promoted the in vitro proliferation and differentiation of osteoblastic MG-63 cells through BMP-2 signaling and inhibited osteoclast formation.127

Methods to Prepare Polymeric Materials and Scaffolds for BTE

The structure of human bone is complex and capable of bearing mechanical loads and resisting deformation.128 Bone is also involved in multiple vital processes, including maintaining homeostasis and regulating blood pH.129 Taking into consideration the complexity of bone structure, materials suitable for BTE should be capable of bearing mechanical loads, biocompatible, osteoconductive (allowing cells to move along the scaffold and slowly produce new bone),130 osteogenic (stimulating bone growth),130 and osteoinductive (stimulating stem cells to differentiate toward osteoblasts).130 A novel biomimetic approach to designing a biodegradable scaffold that propagates osteoconductivity for bone and cartilage tissue applications includes replicating the ECM131 and providing suitable conditions for tissue regeneration.

There is a diverse range of materials that are applicable for BTE. These materials include polymeric materials, bioceramics, and preferably tailored composite materials that meet the requirements for the above-mentioned properties. Currently, several methods are known for producing polymer scaffolds, polymer–ceramic scaffolds, and multicomponent materials used in BTE. Methods of producing materials for BTE can be divided into two main groups: those obtained by solvent techniques and those obtained by techniques involving plasticization of the polymer material. This paper considers the most important and popular techniques for manufacturing three-dimensional scaffolds with potential applications in BTE, emphasizing polymer and composite scaffolds.

Polymers, Inorganic Fillers, and Composites

Polymeric materials are promising structural materials for scaffold preparation in BTE and usually act as a composite matrix and an active compound carrier (at least two ingredients). These macromolecules can be divided into those that are naturally derived and those that are synthetic. The former group includes polysaccharides, such as alginate,129 chitosan129,132 and hyaluronic acid,133,134 protein-based collagen,135,136 and gelatin,132,137 which are capable of forming hydrogels as well as a variety of cellulose-based biofibers.138

The application of natural polymers in bone regeneration systems minimizes the negative immunological response resulting from their high biocompatibility.139 The main disadvantage of this group of materials is their low mechanical resistance, especially considering the load-bearing requirements in BTE, as concluded by Swetha et al.140

Synthetic polymers are more amenable to chemical modification. For example, the presence of functional groups can allow the facile binding of cellular proadhesive ligands such as arginine–glycine–aspartic acid (RGD).141 On the other hand, natural collagen has an RGD sequence already incorporated into its structure. Synthetic polymers generally have higher mechanical resistance than natural polymers. Significant representatives of this group in BTE include poly(l-lactic acid) (PLLA),142,143 poly(ε-caprolactone) (PCL),144,145 poly(ethylene glycol) (PEG),146 and the emerging polymer poly(glycerol sebacate) (PGS).147

The role of inorganic ceramic materials has been significant in developing BTE since the 1990s.148,149 Among the most important compounds are crystalline hydroxyapatite (HA), β-tricalcium phosphate (β-TCP), and amorphous bioglasses. The modern approach to using ceramics in BTE involves their stimulation of osteogenesis by releasing active ions150 (e.g., Ca2+ in the case of HA) and the ability to act as a mechanical support in the composite with a high compressive modulus.151 Such compounds should be resorbable over time.

HA and β-TCP are composed of calcium phosphate and therefore resemble the inorganic phase of human bone. Calcium phosphate-based substances play a vital role in biomineralization, which is essential to strengthen the osteogenic capability of the scaffold.152,153 Bioglasses constitute the other class of ceramics in BTE, which are materials composed of Si2O, Ca2O, and P2O5 and can enhance osteogenesis more rapidly than calcium phosphates.154

Composite materials are based on at least two constituents and possess properties from each phase. Basic BTE composite materials are made of a polymeric matrix and an inorganic filler. Preparing composites aims to combine the desired features of both materials.

Pathways to Obtain BTE Composite Scaffolds

There is a broad array of techniques to manufacture and form BTE scaffolds. These techniques depend on the desired geometry, presence, and distribution of the filler, and most importantly, the chemical characteristics of the substrates. In terms of biodegradability, porosity is of vital importance. The degradation medium (e.g., water) can infiltrate scaffolds more freely if voids (pores) are present compared to water infiltration into the bulk material. Moreover, in thermosetting polymers such as PGS,155 the degradation time can be adjusted by altering the curing time of the polymer bulk.156 Porous scaffolds naturally promote osteoconductivity toward the inner layers of the scaffold. Therefore, the synthesis of porous materials is an important subject in BTE.

Electrospinning

The most facile method to manufacture highly porous nonwoven fibers in BTE is electrospinning.157 This technique utilizes an electric current to deposit the polymer solution on the substrate to form a fiber. Electrospinning has attracted attention due to its ability to mimic the tissue ECM and the wide range of materials that are applicable for spinning. The components of electrospinning systems for BTE include a thermoplastic polymer solution, such as PLA or PCL, with a combination of collagen, chitosan, silk, gelatin, hydroxyapatite, or β-TCP. The significance of such systems in terms of bone regenerative medicine is comprehensively described in a review paper by Jang, Castano, and Kim.158

The electrospinning method can produce two-dimensional fiber networks. However, there are more effective methods for creating three-dimensional structures that can mimic the complexity of bone tissue. In bone tissue engineering, creating porous and hierarchical structures is important, which is difficult to achieve with electrospinning. Electrospinning requires optimizing many parameters, such as voltage, solution flow, and distance between the needle and collector.159 The need to experiment and adjust these parameters can take time and lead to trial and error. In addition, electrospinning is a manufacturing process that is not highly repeatable. The electrospinning process uses organic solvents and/or chemicals that can be potentially toxic to cells and the body.160 It is necessary to ensure adequate elimination of these substances to avoid negative effects on the biocompatibility and functionality of scaffolds. Fiber produced by electrospinning often has a very low density and mechanical strength compared to natural bone tissue. This can lead to poor structural stability of the scaffold and limit its use in stressed areas. Manufacturing homogeneous composite materials is also a challenge for electrospinning.

Thermally Induced Phase Separation (TIPS)

TIPS is one of the most popular methods to obtain three-dimensional scaffolds for BTE. In this technique, the polymer needs to be homogeneously dissolved in a solvent with a high melting temperature (Tm) due to the subsequent freeze-drying process (1,4-dioxane is one of the most popular solvents in TIPS with Tm = 11.8 °C161). Afterward, a ceramic filler such as bioglass or apatite can be introduced to the polymer solution162 and dispersed by stirring or ultrasonication.163 After a suitable solution is obtained, a freeze-drying process is performed to remove the solvent from the composite matrix and generate pores. The main limitation of this method is the thermolability of the solvent used for scaffold preparation. On the one hand, the solvent should dissolve the polymer, and on the other hand, the solvent should be easily removed from the scaffold by lyophilization.

In the TIPS technique, an additional porogen, such as NaCl162,164 or a sugar,165 can be introduced to increase pore size by more than 100 μm. The porogen can subsequently be removed (washed away) from the matrix after lyophilization (e.g., TIPS followed by salt leaching (TIPS-SL)). This method gives the possibility of obtaining highly porous scaffolds (up to 98%)162 with an interconnected pore morphology.166 The porosity and internal structure can be tuned by altering the polymer solution concentration, filler content, amount of porogen, and particle size.167 There are a variety of polymer/filler compositions that have been fabricated by TIPS and reported for BTE applications. For example, PLLA/β-TCP nanocomposite scaffolds143 or PGS-based scaffolds168 can be fabricated by TIPS-SL.

The TIPS (TIPS-SL) process requires the use of organic solvents, which can affect the scaffold’s biocompatibility.169 Some of these solvents can be toxic to cells, which can limit the use of scaffolds in the context of tissue engineering. The TIPS process can be time-consuming (at least a few days) and requires precise control of temperature, time, and other parameters. This can lead to longer production times and increased costs. Producing scaffolds with adequate porosity and interconnected pores is crucial for bone tissue regeneration.170 However, the TIPS process can be difficult to control in terms of the porosity. It can be difficult to achieve uniform pore sizes and shapes, which can affect the scaffold’s effectiveness in regenerating bone tissue. The use of the TIPS-SL technique only partially solves the problem, as the pore size is increased, but at the same time, a material with lower strength parameters is obtained.171

Solvent-Free Techniques

3D Printing (3DP)

3DP techniques consist of slicing a computer-aided design (CAD) model into layers and its subsequent manufacture. This paper will cover only the method by which BTE scaffolds can be obtained, including techniques such as selective laser sintering (SLS),172 fused deposition modeling (FDM)/fused filament fabrication (FFF),173 and stereolithography (SLA),174 which are based on different operation principles. However, these methods are additive manufacturing techniques, which are, among other techniques, used to prepare scaffolds or implants for bone regeneration. There are a variety of biodegradable polymer/ceramic systems for BTE that have been manufactured by means of 3DP (Table 2). The major advantage of 3DP when manufacturing scaffolds for biomedical applications is the possibility to obtain a reproducible and well-defined architecture that meets the needs of patients.

Table 2. Applications of the Techniques by Which BTE Scaffolds Are Prepareda.

| Formation technique | Composition | Remarks | Biological activity | References |

|---|---|---|---|---|

| Electrospinning | PLA/PGS | Mat for cardiovascular diseases | Cardiomyocyte morphology similar to that in the natural environment | (422) |

| PLLA, PLLA/HA, PLLA/collagen/HA | Composites for bone tissue engineering | hFOB 1.19 cells had a higher proliferation rate and increased ALP activity in a PLLA/collagen/HA system | (423) | |

| PCL/PGS | The different solvents used for fiber preparation showed no cytotoxicity | Human cardiomyocytes, cytotoxicity | (424) | |

| TIPS | PLLA/β-TCP | Interconnected, hierarchical pore structures with a high porosity and compressive modulus in comparison to pristine PLLA scaffolds | Enhanced osteoblast (MG-63 cell) proliferation, penetration, and ECM deposition | (143) |

| PDLLA/45S5 bioglass | Anisotropic, bimodal pore architecture, >90% porosity | – | (425) | |

| PLGA/HA | Mechanical properties and water sorption enhanced by HA addition | Significantly higher rabbit MSC proliferation on the PLGA/HA scaffold in comparison to that on the pure PLGA scaffold | (426) | |

| FFF | PDA-coated PLA scaffold | Facile route for BTE scaffold manufacturing: FDM printing + immersion coating; the PLA scaffold was more hydrophobic than the PDA-coated scaffold | PDA-coated PLA scaffolds allowed hADSC cells to adhere and grow better than the unmodified PLA scaffolds | (176) |

| PCL | Indicates PCL is an important allogenic material in the field of reconstructive craniofacial surgery | Successful reconstruction of craniofacial defects regarding new bone formation | (178) | |

| PLA | PLA maintained a semicrystalline structure even though the polymer chains were shortened and thermal degradation profile had changed | Printed PLA scaffolds were proven to be biocompatible and allowed bone cell colonization | (427) | |

| SLS | PCL/HA | Gradient architecture with interconnected porosity and the desired mechanical properties | Excellent biocompatibility, induction of osteochondral repair in vivo | (428) |

| CaP/PHBV and CHAp/PLLA | Sintered scaffolds with a biodegradable osteoconductive calcium phosphate matrix; gradual decrease in mechanical properties after immersion in PBS | In SaOS-2 cell culture, CaP facilitated ALP expression on both materials; no significant difference in proliferation or ALP activity between the CHA/PLLA nanoscaffold and PLLA scaffold | (429) | |

| PVA | Periodic, porous architecture; PVA is vulnerable to high laser power for SLS | Successful growth and adaptation of MG-63 cells | (184) | |

| SLA | PCL/HA | Gradient architecture with interconnected porosity and the desired mechanical properties | Excellent biocompatibility, induction of osteochondral repair in vivo | (428) |

| CaP/PHBV and CHA/PLLA | Sintered scaffolds with osteoconductive calcium phosphate and a biodegradable matrix; gradual decrease in mechanical properties after immersion in PBS | In SaOS-2 cell culture, CaP facilitated ALP expression on both materials; no significant difference in proliferation or ALP activity between the CHA/PLLA nanoscaffold and PLLA scaffold | (429) | |

| PVA | Periodic, porous architecture; PVA is vulnerable to high laser power for SLS | Successful growth and adaptation of MG-63 cells | (184) | |

| Melt mixing/extrusion | PLLA/HA | Composites were extruded and patterned using a femtosecond laser | Human osteoblasts (ATCC CRL-11372 cells) were cultured on the laser-modified surface | (430) |

| PLLA/HA | Composites extruded using co-rotating twin-screw extruder and irradiated using a CO2 laser | Not tested | (431) | |

| PLLA | PLLA foil extruded using a conical single screw extruder and irradiated using a UV laser | Not tested | (432) | |

| PLLA/HA | Composites extruded using a co-rotating twin-screw extruder | Human adipose-derived stromal cells (hASCs) | (433) |

Abbreviations: poly(d,l-lactide), PDLLA; poly(lactic-co-glycolic acid), PLGA; calcium phosphate, CaP; carbonated hydroxyapatite, CHA; poly(hydroxybutyrate–cohydroxyvalerate), PHBV; phosphate-buffered saline, PBS; alkaline phosphatase, ALP; poly(vinyl alcohol), PVA.

3D printing processes are most often conducted at high temperatures (SLS, FFF/FDM) due to thermoplastic materials being processed at temperatures as high as 160–200 °C.175 For this reason, the introduction of bioactive particles, which are often sensitive to temperature, is difficult. The use of UV irradiation for cross-linking during the 3D printing (SLA) process degrades the polymer from which the scaffold is made.176

FDM/FFF

An operating principle of FDM/FFF is extrusion on a thermoplastic filament (usually 1.75, 2.85, or 3.0 mm in diameter) through a nozzle, followed by deposition on the printing bed. After a layer is delivered, the extruder moves upward, and the next layer is laid. The resolution of the printout is mainly affected by the extrusion rate, motor speed, and nozzle diameter. The main advantages of FDM are the simplicity of the process and high printing efficiency. On the other hand, the main limitation involves the thermoplastic characteristics of the material with the existence of a molten phase. Additionally, the process is relatively slow and has low accuracy. Moreover, complex geometries require auxiliary supports, which are removed during postprocessing. The filament for FFF is produced by means of melt extrusion.

Polymers for BTE applications include thermoplastic materials such as PCL, poly(vinyl alcohol) (PVA), and polylactides. This technique provides the possibility of introducing a ceramic phase into the blend177 for superior osteoconductivity. Furthermore, the infill architecture of the FDM printout affects the in vivo behavior of the scaffold, as the honeycomb internal structure of the FDM scaffold has been indicated to increase bone ingrowth.178

SLS

The SLS operation principle is based on layer-by-layer fusing/sintering of particles on a powder bed by heat generated from a laser beam.179 By means of rollers, the printing bed is coated with a preset layer of powder, which is sintered according to the CAD model. The printing bed moves downward incrementally, and the process repeats until the final printout is completed.179

The SLS technique is limited by the ability of the particles to absorb the wavelength of laser light as well as the laser energy density. System optics and resolution also affect the final structure and porosity of the material. Particle size, sphericity, and chemical characteristics are of vital importance for materials submitted for SLS. Usually, microspheres with a defined size (20–80 μm) for use in the SLS process are produced by emulsion solvent evaporation.180,181 However, one can purchase presynthesized SLS powders, such as PCL (CAPA 6501, Solvay Caprolactones, Warrington, Cheshire, UK), poly(hydroxybutyrate–cohydroxyvalerate) (PHBV) (ICI, UK), or PVA (Nippon Synthetic Chemical Industry Co. Ltd., Japan). Among the wide array of biodegradable materials for SLS, PVA is of particular interest due to its flexibility and semipermeability, which can allow oxygen and nutrient exchange, which is necessary for the cellular culture on the scaffold to thrive.182

The SLS process requires the material to have a low melting point and be able to form intermolecular bonds after exposure to a laser.183 The main advantage of using SLS scaffolds for BTE is the possibility of obtaining a porous structure that mimics the bone ECM. The overall porosity of the SLS printout can be higher than anticipated due to the formation of micropores in the scaffold.184 On the other hand, this technology is expensive and requires a complex modeling procedure.

SLA

The SLA approach in additive manufacturing utilizes ultraviolet (UV) light to trigger selective photopolymerization. The printing procedure involves submerging the printing bed in the photopolymer reservoir with subsequent layer-by-layer exposure to UV radiation in accordance with the CAD model. The SLA method is comparable to SLS; however, SLA uses a liquid prepolymer. After the layer is photocured, the printing bed slides down, and the process is repeated until the last layer is irradiated.185 SLA material diversity is limited by the requirements of biodegradability and lack of cytotoxicity. Materials for SLA scaffold-based tissue engineering include derivatives of PEG acrylate, PEG methacrylate, PVA, and modified polysaccharides, such as hyaluronic acid and dextran methacrylate, in addition to poly(propylene fumarate) (PPF) and PCL-based resins.186

For biomedical applications, the properties of SLA resins can be adjusted; for example, reducing the percentage of DEF in the PPF resin increases the viscosity of the solution and promotes cross-linking, which results in a final product with superior mechanical properties.187 However, a higher degree of polymer cross-linking affects the degradation rate. Lower cross-linking degree facilitates degradation. It is a vital parameter considering the resorption of biomaterial in vivo.

Melt Mixing

Melt mixing is the most important continuous method by which polymer/filler composites are obtained. One type of melt mixing is the twin-screw co-rotating extrusion (TSCE). TSCE is the most effective means to distribute filler in the polymer matrix and enables even filler distribution, even on the nanoscale.188 TSCE utilizes an instrument that consists of a motor, heated cylinder, screws, hopper, die, and control equipment (thermocouple, pressure sensor). Two screws are installed inside the cylinder on a shaft and rotate in the same direction. These screws are made of configurable sections (mixing and conveying sections) that can be arranged in various configurations.189 A preprepared material in the form of a granule or powder is dosed into the first zone of the extruder (feeding zone). Screws, rotating with speeds usually ranging from several dozen to a few hundred, plasticize, transport, and homogenize the material to the extruder head. After this process, the material in the form of a filament is allowed to cool down (using a water bath or in air) and pelletized. The advantages of this method are the fast homogenization and good dispersion of the filler. Disadvantages of this method include thermal degradation of the polymer during the process, the need for a relatively high amount of the polymer for extrusion, and large losses during processing. Extrusion is not actually a scaffolding manufacturing method, but is a preliminary method used to homogenize composite components. The material is obtained in the form of pellets or filaments and in this form is used for 3D printing.

Methods to Deliver Bioactive Molecules

Bone Regeneration Biomolecule Delivery Platforms and Release Strategies

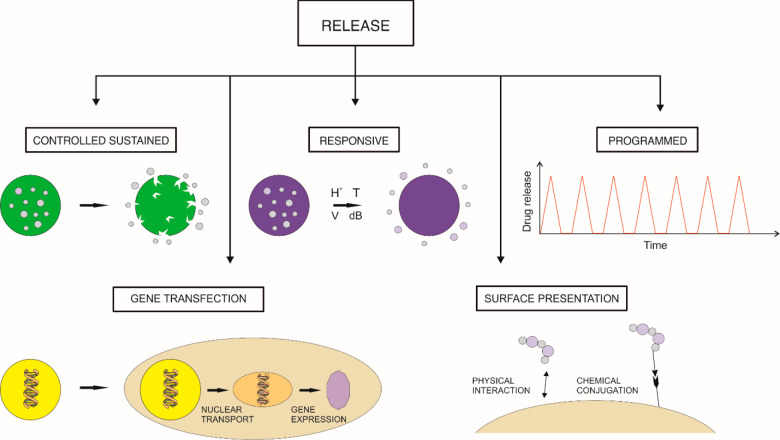

Bone regeneration involves multiple stages, including the inflammatory phase, callus formation phase, callus removal/bone deposition phase, and bone remodeling.8 Each phase is driven by different biochemical signals, which have to be delivered at a specific time in a coordinated and sequential manner.190 To achieve the best therapeutic outcome, orthopedic implants loaded with bioactive factors should release these factors at a dose and time that reflects this physiological pattern. Biomolecule dosing should also be tailored to the patient’s clinical status, i.e., cause, location, and severity of bone defect, age, and presence of coexisting conditions. A number of biomolecule delivery platforms and release strategies have been proposed to provide treatment options customized to different types of biofactors and for different types of bone defects. The platforms developed to date provide a wide range of dosing profiles that depend on the implant material, structure and size, biomolecule immobilization technique, and amount and spatial distribution of the biomolecules. Biomolecule delivery platforms can be categorized into five main types: surface-functionalized, controlled/sustained release, preprogrammed release, stimuli-responsive, and those for gene delivery, as depicted in Figure 2.

Figure 2.

Strategies for the delivery of bioactive agents in bone regeneration.

Surface-Functionalized Delivery Platforms

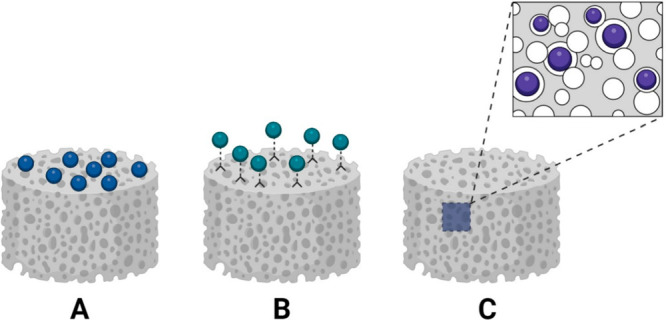

Surface-functionalized implants are being intensively explored in bone regenerative medicine191−193 as delivery platforms for BMPs,194−196 platelet-derived growth factor (PDGF),197 TGF-β,198 and vitamins D and K.199 During the fabrication of surface-functionalized implants, biomolecules are introduced onto the implant surface by physical adsorption,200,201 chemical conjugation,191,192 or ligand–receptor binding.

Physical adsorption (Figure 3A) occurs when biomolecules attach to the scaffold material via electrostatic, hydrophobic, van der Waals interactions, or hydrogen bonding.200 The release kinetics of biomolecules immobilized by physical adsorption depends on their affinity for the implant material and can be controlled by environmental conditions such as temperature and pH. To enhance biomolecule adsorption to biomaterials, their surface can be pretreated with charged molecules such as amino acids (e.g., serine, asparagine) or acids (e.g., pyrophosphoric acid,202,203 mercaptosuccinic acid204). Charged biomaterial surfaces can selectively attract molecules of interest (e.g., lysozyme,205 BMP-2206), while oppositely charged molecules are repulsed. Physisorption has been widely used to immobilize osteoinductive biomolecules (e.g., BMP-2,194,195 PDGF,197 TGF-β198]) in a variety of scaffolds, including collagen and gelatin sponges,207 poly(glycolic acid) meshes, poly(d,l-lactide) scaffolds,208 hydroxyapatite,206,209 tricalcium phosphate ceramics, and others. This technique has also been used to fabricate INFUSE Bone Graft from Medtronic (an absorbable collagen sponge soaked with BMP-2) for recombinant BMP-2 delivery, which is currently the only FDA-approved BMP-2 product that is commercially available. However, the major limitations of materials functionalized via physisorption include poor drug retention and limited control over the biomolecule release rate due to weak biomolecule bonding. This type of materials typically suffer from burst release,210 which is defined as a sudden initial release of a drug bolus resulting from its rapid desorption from the material surface. The main risk of burst release is the overdose of a therapeutic molecule in the immediate postimplantation period, which is usually associated with reduced drug absorption and rapid drug depletion. Supraphysiological doses of BMP-2 have also been shown to cause serious side effects such as spine swelling, neck edema, tumor formation, osteolysis, and ectopic bone formation,211 which remain among the biggest challenges of the current clinical approaches to bone healing based on BMPs.211

Figure 3.

Physical and chemical strategies to immobilize bioactive compounds on biomaterials: (A) physical adsorption, (B) covalent binding, and (C) entrapment in a polymer matrix.