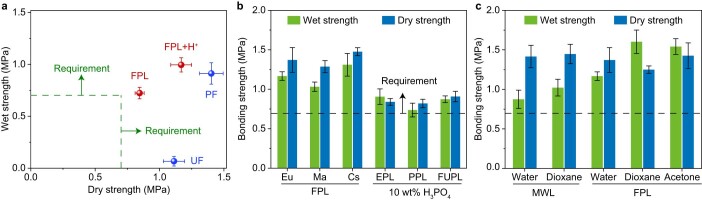

Extended Data Fig. 9. Comparison of UF and PF resins as well as a variety of lignin adhesives in adhesion performance.

a, Comparison of adhesion performances of FPL adhesives and conventional PF and UF resin adhesives. Lignin adhesive preparation in a lignin (or UF or PF)/water = 1: 2 (w: w); hot-pressing conditions: 150 °C, 8 min, 1.5 MPa, and a glue application level of 100 g·m−2. Compared to the three-layer plywoods bonded with PF and UF resin adhesives, FPL adhesive showed comparable adhesion strength. b, Lignin adhesives prepared from different feedstocks protected with formaldehyde as well as eucalyptus lignin protected with other aldehydes. Eu: eucalyptus; Ma: Masson pine; Cs: corn stover; FPL: formaldehyde-protected lignin; EPL: ethyl aldehyde-protected lignin; PPL: propionaldehyde-protected lignin; FUPL: furfural-protected lignin; MWL, milled wood lignin. The H3PO4 loading was on the basis of lignin. c, Lignin adhesives prepared via mixing FPL with different solvents. Lignin adhesive preparation in b and c: lignin/water (or solvent) = 1: 2 (w: w), pH = 7; hot-pressing conditions in b and c: 190 °C, 8 min, 1.5 MPa, and a glue application level of 100 g·m−2.