Abstract

Cured-in-place pipes (CIPPs) are plastic liners manufactured inside existing damaged sanitary sewer, storm sewer, and water pipes that extend the service life of host pipes. This process often is conducted in neighborhoods and near roadways. Before, during, and after plastic manufacture, waste materials that include volatile materials are released into the air. Emissions from this manufacturing process can affect outdoor air quality and indoor air quality for buildings connected to the sewer system. We identified key issues and solicited stakeholder feedback to estimate and manage public health risks of CIPP-generated chemical air pollution. A work group representing 13 U.S. agencies and public health associations provided feedback and prioritized public health issues for action. To mitigate potential public and occupational health risks, additional testing and public health educational efforts were recommended. An improved understanding of CIPP chemical exposure pathways, as well as stakeholder needs and interests, is essential.

Introduction

Water infrastructure is critical to the health of communities, and its condition is connected to environmental justice (Schaider et al., 2019). By 2027, more than $300 billion will be needed to repair U.S. municipal water and sewer pipes (U.S. Government Accountability Office, 2016), which is more than 50% of the entire 2019 construction sector’s gross domestic product. Separate from public utilities, repair is required on more than 500,000 miles of sewer laterals owned by the property owners they serve (American Society of Civil Engineers, 2021). Repair costs have driven demand for innovative solutions that do not require pipe excavation, one of which is the cured-in-place pipe (CIPP) repair process (U.S. Environmental Protection Agency [U.S. EPA], 2022a).

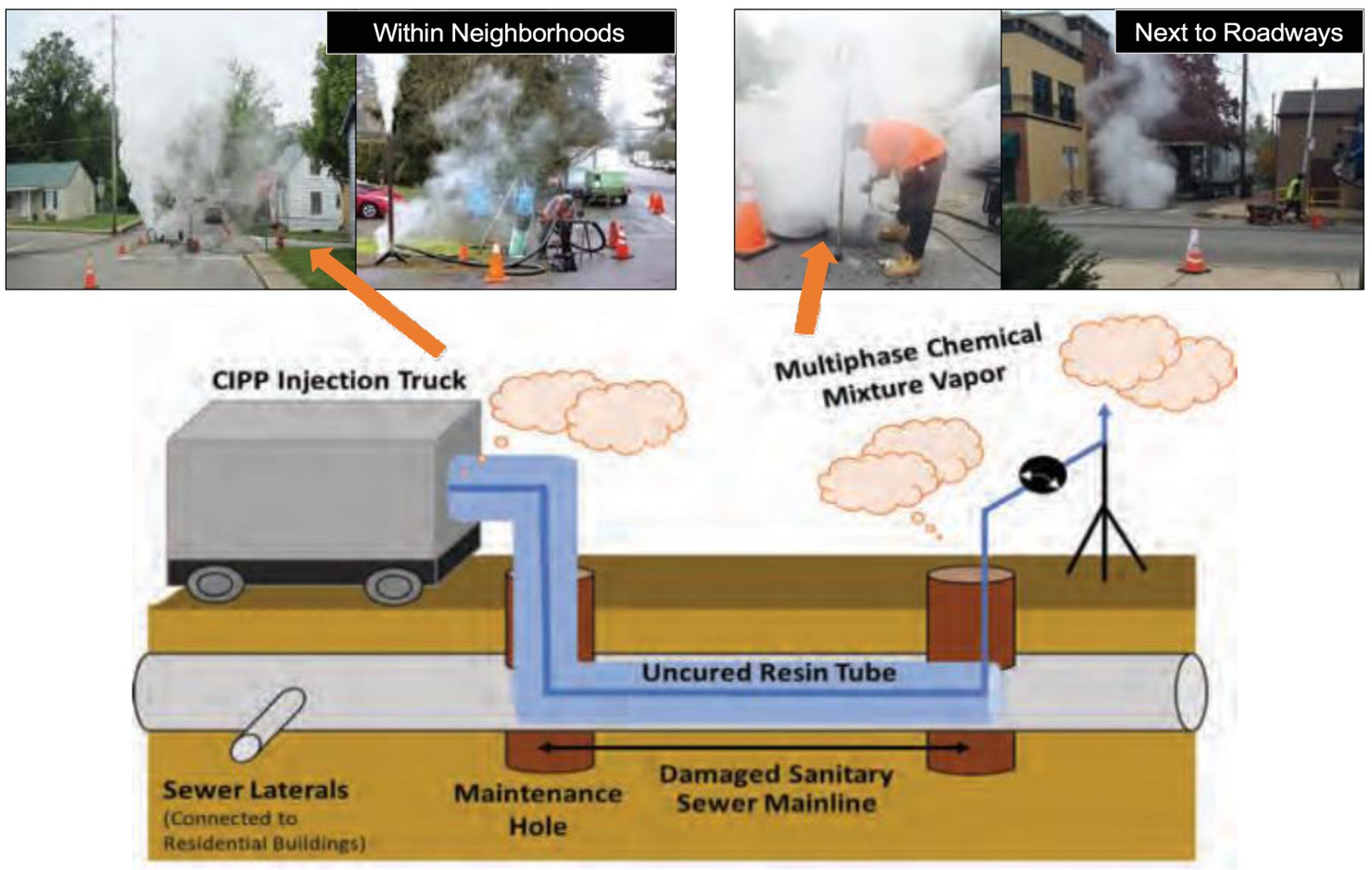

CIPPs are plastic liners manufactured inside existing damaged sanitary sewer, storm sewer, and drinking water pipes that extend the service life of the host pipes. CIPPs can be 20–90% less costly than other repair methods. Sometimes installers can manufacture the CIPP and move to the next work site within 1–2 hr. These advantages are driving the growing CIPP market, which is estimated to reach $3 billion by 2026. Health officials have responded to CIPP caused bystander chemical exposure incidents (Figure 1) both outdoors (LeBouf & Burns, 2019; LeBouf et al., 2021; Penders et al., 2012; U.S. Department of Labor, 2018; Wisconsin Department of Health and Family Services [WDHFS] & Agency for Toxic Substances and Disease Registry [ATSDR], 2005) and indoors (California Department of Public Health, 2017, 2018; Florida Department of Public Health, 2020; Virginia Department of Health, 2020). Exposures have occurred in neighborhoods, schools, residential buildings, office buildings, and other buildings as well as alongside roadways.

FIGURE 1.

Example of How Plastic Cured-in-Place Pipes (CIPPs) Are Manufactured Inside Damaged Pipes

Untreated CIPP plastic manufacturing waste is commonly discharged into the environment, a practice that is encouraged by the CIPP industry trade group, CIPP companies, engineering firms, and municipalities overseeing projects (Matthews et al., 2020; NASSCO, 2020). The waste contains a variety of toxicants and physical hazards (e.g., organic vapors, particulates, resin droplets, water saturated with volatile chemicals including hazardous air pollutants [HAPs]). Toxicants can travel to public spaces and buildings through sewer plumbing, cracks in foundations, windows, and doors as well as heating, ventilation, and air conditioning intakes. Bystander exposures resulting in hospitalizations have been reported in Australia, Canada, Finland, France, Netherlands, Poland, States of Guernsey, Sweden, the UK, and the U.S. (Noh et al., 2022a; Ra et al., 2019; Sendesi et al., 2020). Only recently have emergency responders received guidance on CIPP operations (Noh et al., 2022a). As health officials have begun to formally respond to and collaborate regarding CIPP health concerns (California Department of Public Health, 2018; Florida Department of Public Health, 2020; LeBouf & Burns, 2019; LeBouf et al., 2021; WDHFS & ATSDR, 2005), evidence-based information is needed for planning and response activities (See Supplemental Information). The goal of our study was to identify and assess public environmental and occupational health knowledge gaps associated with CIPP use. Specific objectives were to 1) conduct a literature review of current materials, practices, and regulations associated with waste discharge and 2) identify and prioritize research needs through a work group of government agencies and health associations. Our study results are intended to assist officials in understanding the chemicals, exposure pathways, and actions needed to make data-driven health protection decisions.

Methods

Literature Review and Approach

We reviewed CIPP-related peer-reviewed journal articles, gray literature, industry and government reports, and emergency responder incident reports. The review focused on five topics: 1) plastic manufacture and wastes, 2) sewers and buildings,3) chemical exposure and health effects, 4) quantitative chemical risk assessment, and 5) risk communication (Supplemental Figure 1). Information obtained was used as the basis for work group discussions.

Work Group Formation, Approach, and Research Team Dialogue

To identify existing public health knowledge gaps related to the CIPP procedure, six work group meetings were convened virtually between February 8 and May 10, 2021. More than 30 representatives from 13 U.S. federal, state, and city health agencies as well as public health associations participated (Supplemental Figure 1). Participants included environmental health specialists, toxicologists, epidemiologists, occupational health scientists, and emergency response specialists. Each meeting began with a presentation by a subject matter expert outlining current knowledge about a specific topic (30 min), followed by group discussion (30 min).

During meetings, participants asked questions, shared their own CIPP knowledge and experiences, and discussed existing evidence and information gaps. Each meeting resulted in the identification of key messages for CIPP related hazards, exposure assessment, and environmental health. The final meeting focused on potential public health risks, practices, and guidelines. After work group activities, the authors distilled the information to prioritize a public health action plan with the American Public Health Association, Association of State and Territorial Health Officials, and National Environmental Health Association.

Results

Practice, Pollutants, and Risk Cured-in-Place Pipe Practices

Many engineering and construction entities are involved in the proposal, conduct, and oversight of CIPP construction projects (Supplemental SI-2). Under a single project, multiple CIPPs can be manufactured in a single sewer system. To manufacture a CIPP, raw materials such as uncured resin with volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs) are delivered to the work site. An uncured tube of resin is then inflated against the wall of the damaged existing pipe (Supplemental Table 1). CIPP contractors inject air, steam, or water to keep the uncured resin tube pressed against the pipe wall during setup, curing, and cool down periods. For steam, pressures range from 20 to 552 kPa (3 to 80 psi). Different curing methods are used to polymerize uncured resin into a hard plastic; steam is the most popular method while hot water is applied in another method. Curing with UV light is the least popular due to its higher cost. Lastly, the ends of the new hard plastic are cut, and the contractor relocates to the next CIPP manufacturing site.

Chemicals Brought, Chemicals Created

Resin constituents and degradation products can be released into the air before, during, and after manufacture (Matthews et al., 2020; Noh et al., 2022b; Ra et al., 2018, 2019; Sendesi et al., 2017). More than 15 CIPP resins and 20 initiators have been used. For initiator compounds, more than 19 degradation products can be created during manufacture (Ra et al., 2018). Antioxidants, plasticizers, and solvents present in the resin sometimes are not reported on safety data sheets (Li et al., 2019). Reinforcement is used, such as polyethylene terephthalate fiber for thermally manufactured CIPPs and glass fiber for UVmanufactured CIPPs. Inorganic fillers may be present to reduce the amount of resin and material cost. Direct chemical analysis of styrene resins (i.e., polyester/vinyl ester resin, isophthalic based polyester resin, and vinyl ester resin) has revealed as many as 60 VOCs per resin, but only 1 to 4 VOCs were listed on the corresponding resin safety data sheets (Li et al., 2019; Noh et al., 2022b; Ra et al., 2019; Sendesi et al., 2017).

To date, approximately 40 organic compounds have been found discharged into the air because of CIPP manufacture (Matthews et al., 2020; Ra et al., 2019; Sendesi et al., 2017) and many more have been confirmed in the resins, found as residual inside the new CIPPs, and released into water. Air contaminants include HAPs, carcinogens, endocrine disrupting compounds, and other contaminants that can cause acute health effects (Supplemental Table 2).

For steam-cured CIPP, waste discharged into air can be a complex multiphase mixture of partially cured resin, oligomers, particulates, VOC vapor, and VOCand SVOC-saturated water vapor (Sendesi et al., 2017). VOC vapor levels have been found to exceed 1,500 ppm, which is 4–5 orders of magnitude higher than the background of <0.1 ppm (Bourbour Ajdari, 2016; LeBouf & Burns, 2019; LeBouf et al., 2021; Matthews et al., 2020; Ra et al., 2018, 2019; Sendesi et al., 2017).

For steam CIPP air emissions, the total plume styrene level has been shown to reach 4,300 ppm (Sendesi et al., 2017). CIPP manufacture with hot recirculated water also emits VOCs into the air, but some CIPP industry representatives still refer to these emissions as “steam.” Chemicals are also released into the air during UV CIPP manufacture (LeBouf & Burns, 2019; Li et al., 2019). Pollution from hot water and UV CIPP has been less studied than pollution from steam CIPP. A laboratory investigation estimated thermal CIPP manufacture can discharge 6 to 20 tons of VOC vapor into the air per project (Sendesi et al., 2020). Air sampling data are limited, and investigators often assumed that styrene was the only chemical of concern.

Pollutant Fate and Transport in Sewers and Buildings

Chemicals can travel from CIPP manufacturing sites through sewers and enter buildings (Figure 1 and Supplemental SI-2). It was reported that styrene was detected 0.8 km downstream in a sewer of a CIPP installation and kilometers away above ground from another manufacturing site (RIVM, 2006). Building plumbing traps are designed to prevent sewer gases from directly venting into indoor air but their presence, design, and functionality is not guaranteed (Supplemental SI-2), allowing sewer gas entry into indoor air spaces (Pennell et al., 2013). As <10 kPa can displace a typical p-trap water seal, nearby CIPP activities can and have displaced water seals, allowing entry of chemicals (Noh et al., 2022a).

At present, the prediction of CIPP chemical locations and concentrations within sewer mains are difficult to determine. VOC sewer gas transport can be estimated using several factors, including liquid/gas mass transfer, vapor diffusion, sorption, and biodegradation (Roghani et al., 2021). For CIPP operations, mass transfer likely will govern transport in the sewer near the injection site. Away from that site (once background pressures return), other factors will become more important for transport. These farther distances would be consistent with hazardous waste vapor intrusion observations where VOC transport has been documented hundreds of feet within sewers (Roghani et al., 2018). The transport distance is dependent on the effectiveness of sewer ventilation and the VOC source strength. If the sewer is effectively ventilated and/or the VOC source is removed, VOC concentrations decrease, providing a means to reduce the exposure level.

Human Exposure, Health Effects, and Styrene

Lack of formal incident reporting has resulted in many CIPP emission exposures not being identified and logged (Sendesi et al., 2017). Incident review revealed that CIPP contractors frequently encourage exposed individuals to contact them instead of public health officials or medical professionals. Contractors provide incident risk information based on safety data sheets that do not list all chemicals that are used, created, and discharged into the air. No explicit CIPP incident response procedures or monitoring guidelines currently exist. CIPP waste releases have been treated as hazardous material releases, but most health and environmental departments lack expertise and/or equipment to respond. Chemicals released are regulated under the Clean Air Act, which was designed to protect public health and public welfare and also regulate emissions of hazardous air pollutants (U.S. EPA, 2022b). To date, Clean Air Act primacy agencies and U.S. EPA have not formally reviewed CIPP manufacture or the companies as a pollution source (Berlin, 2022).

Acute exposure to CIPP-related chemicals can prompt a variety of symptoms, including irritation of skin, eyes, nose, and the respiratory system; breathing difficulties; and neurological effects including headaches, dizziness, light-headedness, nausea, and loss of consciousness. Chronic symptoms associated with these chemical exposures currently are unknown. No studies were found that considered the duration or dose of CIPP-related chemical exposures. For workers, the potential cumulative effect of multiple VOCs present in combination may be greater than the measured exposure to styrene alone (WDHFS & ATSDR, 2005).

The greatest amount of human health information exists for styrene vapor, which is the most tested contaminant in the limited CIPP studies. Styrene vapor levels have ranged from the low 10s to potentially 1,824 ppm at work sites. Air quality model simulations have predicted levels exceeding 300 ppm indoors (Noh et al., 2022a). The acute reference exposure for residential and commercial building occupants is 4.9 ppm (California Department of Public Health, 2017). The U.S. EPA reference level and no-observed-adverseeffect-level are 0.23 and 8 ppm, respectively.

The Agency for Toxic Substances and Disease Registry (ATSDR) previously declared a public health hazard because styrene vapor levels (0.32 ppm) from a CIPP project exceeded its minimum acceptable chronic exposure level (0.06 ppm), resulting in an office building being contaminated for 3 months (WDHFS & ATSDR, 2005).

Few studies have investigated health effects from CIPP air pollution. Cell toxicity assessments of the waste discharged into the air exhibited differential toxicity in mouse cell lines representative of the pulmonary system (Kobos et al., 2019). Cytotoxicity, inflammation, and alterations in immune signaling were also observed. The researchers found that minor compounds, not just styrene, contributed to differential toxicity between the exposures. Although styrene is an important contributor to toxicity, continued focus solely on the styrene component of CIPP emissions has limited understanding of the human on reference dose, concentrations, and other information to conduct these assessments is lacking. Development of monolayer and organoid methods for in-laboratory assessments of toxicity and cellular response could be promising. Nationally, several states use ATSDR risk assessment tools, such as the Partnership to Promote Local Efforts to Reduce Environmental Exposure as a part of the Comprehensive Environmental Response, Compensation, and Liability Act. More work, however, is needed in understanding these risk assessment components to reliably address CIPP risks (Supplemental Table 3).

Risk Communication

Many mixed public messages about CIPP chemical exposures exist and communicating risk is challenging when emergent evidence is involved (Balog-Way et al., 2020). In addition to information uncertainty that typically bounds health-related hazards, guidance and policies may change regarding potential controls and other protective actions. These changes can erode stakeholder trust if engagement is not central to the communication process (Hoover et al., 2021). Because CIPP installations lack enforcement from the air pollution regulatory framework that is applied to other resin-reliant pollution-generating industries, minimal familiarity with the process and potential risks likely exists among those outside the industry.

Different levels of CIPP-related environmental health literacy (Hoover, 2019) exist among various stakeholder groups, and multiple communication tools are necessary (Table 1). In many cases, stakeholders and their potential roles in prevention and mitigation have yet to be identified, so health officials cannot create targeted, meaningful messages. By identifying and engaging key groups, health officials can ensure messages are delivered by trusted messengers through preferred communication channels.

TABLE 1.

Levels of Environmental Health Literacy Needed for Various Stakeholders

| Stakeholders | ||||||||

|---|---|---|---|---|---|---|---|---|

| Industry | Workers | Environmental Quality Officials | First Responders | Public Health Officials | Healthcare Professionals | People Near Work Sites | Elected Officials | |

| Create plans to prevent or mitigate the hazard | X | X | X | |||||

| Evaluate strategies to address the hazard | X | X | X | X | X | |||

| Analyze the rough probability of CIPP related exposures taking place | X | X | X | X | X | |||

| Apply information to avoid or mitigate CIPP related exposures | X | X | X | X | X | X | X | X |

| Understand why the exposures exist | X | X | X | X | X | X | X | X |

| Recognize the potential for CIPP-related exposures | X | X | X | X | X | X | X | X |

Note. CIPP = cured-in-place pipe.

Several frameworks exist for supporting public health practitioners in developing and deploying messages regarding potential CIPP exposure threats and prevention approaches (Supplemental Figure 2). The Crisis and Emergency Risk Communication Framework can be helpful for addressing emergency incidents, while best practices for risk communication can assist in longer-range health and environmental risks. The lack of detection methods and biomarker studies that can affect exposure and health risks are described in Supplemental SI-2.

Chemical Risk Assessment for the Public

Challenges arise when attempting to quantify a health risk involving exposure to a complex mixture such as CIPP emissions. These challenges stem mostly from limited toxicology knowledge and long-standing cumulative risk limitations. Further, CIPP exposures are also occurring beyond the occupational setting, with public exposures occurring in homes, schools, other large buildings, and even outdoors. Subsequently, the exposures represent poorly understood concentrations of a complex chemical waste with unknown risk outcomes. Various exposure scenarios described in Supplemental SI-2 define a complex set of exposures and exposure pathways that require assessment.

Cumulative risk over a resident’s location timeline, a worker’s lifetime, or other long-term exposures is a topic that has received no scrutiny for CIPP to date. Until cumulative risk data addressing inhibitory or acceleratory effects from combinations of chemicals produced by the emissions can be generated, risk assessment for CIPP exposures will be significantly challenged.

Subsequently, initial risk assessments will need to be single hazard-specific and use standard metrics such as the hazard quotient or lifetime excess cancer risk. Further complicating risk assessment is that information communication planning efforts (Sellnow et al., 2009). The U.S. EPA Strategy, Action, Learning, and Tools (SALT) framework provides additional guidance, from developing communication strategies to providing tools and resources for communicators.

Insights From Public Health Practitioners

Practices and Feedback

Feedback from public health officials was wide-ranging, and representatives had many questions about the complexity of CIPP health issues (Supplemental Table 4). Approximately 40–50% of officials had some knowledge of CIPP technology before participating. Some agencies directly responded to assistance requests from individuals who self-reported emission exposure. One organization conducted chemical air testing in response to a public request. Participants identified practitioner information needs that included the specific chemicals and concentrations brought on-site, the specific byproducts and concentrations released during manufacture, and potential chemical exposure differences among types of CIPP practices. Additionally, practitioners were interested in whether UV light curing was safer than the steam-based curing.

Inquiries were also made about if some available CIPP resins develop less-toxic emissions. Practitioners also sought guidance on real-time air sampling approaches. To better understand health concerns, participants inquired about available worker safety data, indoor air testing procedures, and building decontamination methods. Practitioners also inquired about roles and responsibilities regarding public communication about exposures as well as responsibility for consequences (i.e., human harm, building contamination), including if infrastructure owners could use contract language to limit waste discharge incidents.

Key Groups Needing Information and Incident Response Knowledge Gaps

The structural framework for preventing CIPP chemical exposures was identified as a shared responsibility across multiple organizations and sectors. Numerous audiences were identified as needing information before, during, and after a chemical exposure incident (Table 2). Emergency responders were identified as an important group needing information; however, agencies contacted were unable to participate. Practitioners identified that the public needs more information about potential health impacts of exposure. The work group noted environmental justice implications; while less expensive and faster infrastructure repair processes such as CIPP can work to a community’s advantage, the potential for exposure to affect marginalized populations was a concern.

TABLE 2.

Group Roles and Action Plans for Cured-in-Place Pipe-Related Stakeholders

| Roles | |

|---|---|

| Groups identified as having a role in chemical exposure and incident response | |

| Public works |

|

| Physicians and medical technicians |

|

| Emergency responders |

|

| Elected officials |

|

| Groups identified as having additional responsibilities before and after the construction project | |

| NIOSH/OSHA |

|

| Environmental regulators |

|

| Code officials |

|

| Industry and contractors |

|

| Researchers |

|

Note. ATSDR = Agency for Toxic Substances and Disease Registry; FEMA = Federal Emergency Management Agency; NIOSH = National Institute for Occupational Safety and Health; OSHA = Occupational Safety and Health Administration; PPE = personal protective equipment.

Overall, knowledge gaps associated with CIPP exposure response included:

What hazardous materials are generated before, during, and after CIPP manufacture?

How emissions distribute and migrate?

What specific health effects are related to exposure?

How can officials better engage and control CIPP-related exposure incidents?

What are the best risk assessment and communication strategies? Primary, secondary, and tertiary prevention and mitigation actions identified are shown in Table 3.

TABLE 3.

Strategies for Preventing and Mitigating Exposures Based on Literature Review and Work Group Feedback

| Prevention Stage | Issues and Gaps | Key Steps | Stakeholders |

|---|---|---|---|

| Primary | Utility practice | Require waste capture and/or treatment, thereby limiting discharge; develop pollutant monitoring or controlling guidelines of the overall CIPP practice | Health officials, industry, regulatory agencies |

| Curing technology | Investigate emissions released from nonstyrene-based CIPP products | Industry, researchers | |

| Secondary | Measurement technology | Evaluate real-time monitoring equipment for atmospheres impacted by CIPP-caused emissions and provide information to stakeholders | Health officials, NIOSH, industry, firefighters, researchers |

| VOC pathways | Require prevention of waste leaving the work site and air testing to confirm prevention method was effective | Health officials, NIOSH, industry, code officials | |

| Public exposure | Notify the nearby population to contact the health department to report exposures | Health officials, industry, firefighters | |

| Occupational exposure | Conduct air testing; provide air testing results to stakeholders; notify workers to contact NIOSH or OSHA with concerns | Health officials, NIOSH, industry | |

| Incident response | Conduct training to improve the safety of workers overseeing a project or responding to an incident | Health officials, firefighters | |

| Plumbing system | Recognize building plumbing can have sewer connections that building owners, pipe owners, and contractors are unaware of; encourage water seals in drains but acknowledge water seals might not prevent chemical entry | Industry, code officials, NIOSH | |

| Tertiary | Generated wastes | Examine the composition of emitted wastes; identify the secondary contamination of the emission (e.g., micrometer and nanometer plastic formation) | Health officials, industry, academic researcher |

| Mitigation technology | Examine the applicability of emission capture and/or contaminant removal at the CIPP work site (granular activated carbon filtration was proposed during work group sessions) | Health officials, industry | |

| Toxicity and health effects | Determine which chemicals and concentrations are present near and away from work sites; determine the toxicological impact of different resins and installation conditions; compare air concentrations to public exposure levels; determine if the matrix effect is important; provide triage advice to firefighters and health officials | Health officials, NIOSH, industry | |

| Emergency management | Determine the efficacy of available real-time testing devices for atmospheres impacted by CIPP-caused emissions; provide triage advice to firefighters and health officials | Health officials, emergency responders | |

| Risk assessment | Identify risk of chemical mixtures generated from installation; determine the appropriate risk assessment tool for CIPP installations | Health officials, NIOSH, industry | |

| Health equity | Recognize some infrastructure is located in lower socioeconomic areas; recognize people might not reach out for help even if they are exposed or harmed | Health officials, firefighters, physicians |

Note. CIPP = cured-in-place pipe; NIOSH = National Institute for Occupational Safety and Health; OSHA = Occupational Safety and Health Administration; VOC = volatile organic compound.

Prioritized Actions of Public Health Associations to Mitigate Health Risks and Improve Knowledge

Representatives from public health associations identified several priorities for followup work (Supplemental Table 4). In terms of CIPP manufacture and waste, a better understanding of how to minimize emissions and vapor transport pathways in sewers was recommended. Understanding chemical transport was deemed a high priority for routine conditions (without pressure) and during CIPP manufacture (with pressure). Practitioners desired information and tools to help predict potential health effects given exposure details. Other priorities included better understanding how and when municipalities notify residents of CIPP and what health advice to provide after an exposure.

Public health associations frequently proposed educational activities (i.e., conferences, newsletters, blog posts) as a means for sharing new knowledge. A multi-association effort was proposed in which evidence-based public health practice and emergency incident response information could be posted on a website. Brief educational modules for public health professionals that incorporate CIPP definitions, general hazards and risks, and complaint case studies also were recommended. Development of informational materials (e.g., health department fact sheets, a frequently asked questions (FAQ) list, research progress updates) was mentioned. The creation of a downloadable mobile phone app was proposed so that populations could report CIPP use, emission discharges into air, and exposures (i.e., detection of odor or symptoms). All association representatives sought better documentation of chemical exposures nationwide.

Discussion

System Realignment

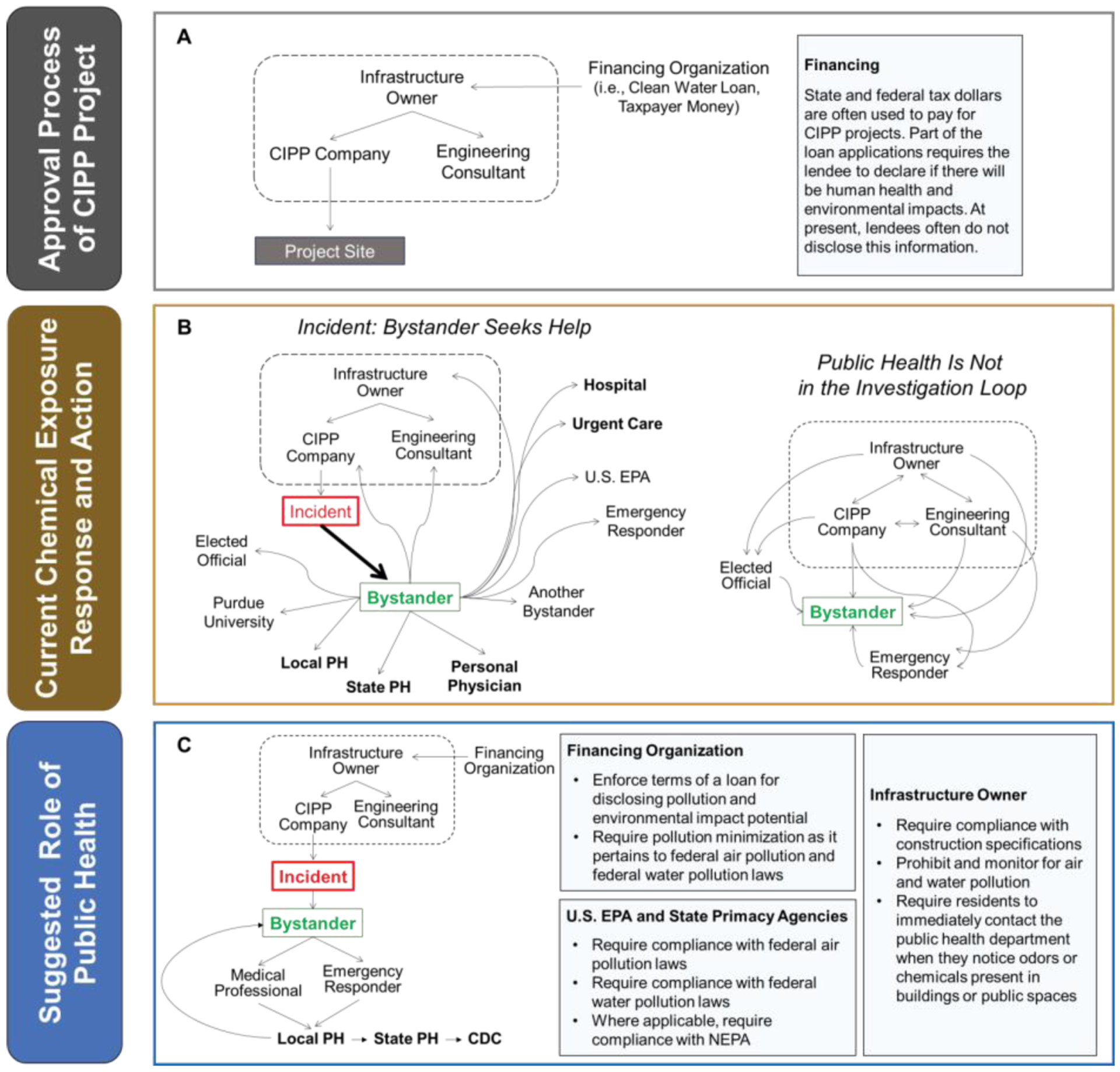

There is an acute lack of systems-level knowledge on protecting the public from harm when CIPP is implemented, and thus explicit participation of public health professionals is needed (Figure 2A, 2B). Environmental regulatory oversight of CIPP air discharges has yet to be implemented, unlike in other composite manufacturing industries (U.S. EPA, 2020). The social amplification of a risk framework indicates health officials who lack direct experience with or lack lines of communication about CIPP likely are unaware of the exposure risks (Penders et al., 2012). Community stakeholders and the general public also lack sufficient knowledge of CIPP emissions to recognize and avoid exposure hazards.

FIGURE 2.

Current Cured-in-Place Pipe (CIPP) Practice, Measures, and Suggested Desired System

The use of handouts and mailers by CIPP contractors, infrastructure owners, and consulting engineers has diverted exposure notifications away from health departments. By removing chemical evidence from buildings before emergency responders arrive, improperly using air-testing devices, or using devices that provide erroneous information, some CIPP companies and municipalities might reduce the chance of victims seeking medical assistance.

Although past CIPP emission exposures have posed immediate health hazards, the CIPP industry (and municipalities distributing their literature) compares building occupant styrene exposures to “strawberries” and “coffee,” both of which naturally contain styrene. Their messaging potentially creates an interpretive disconnect by presenting often desirable (rather than risk-laden) images. Evidence also indicates CIPP workers and companies are not informed about all chemicals that were contained and/or generated through the CIPP manufacture (Supplemental Table 2). This lack of understanding impedes deployment of critical controls to eliminate or substitute hazards and formulate engineering solutions that isolate people from hazards, implement administrative controls, and use personal protective equipment and actions (Morris & Cannady, 2019). A system realignment is strongly recommended so that public health officials can act on behalf of the population by participating in oversight and response (Figure 2C).

Considering the limitations and widespread practice of waste discharge to the environment, public health agencies and emergency responders should approach CIPP emission exposure settings as uncontrolled hazardous material releases. Respiratory protection for health officials and emergency responders can be necessary due to documented and predicted styrene levels at work sites and in buildings (Noh et al., 2022a). Individuals experiencing exposure-related symptoms should be removed from the exposure source and seek medical assistance. Additionally, odors and symptoms should be reported to the local health department.

Due to CIPP emission complexity (i.e, containing numerous components beyond VOCs), unique toxicity and health concerns arise that could present more robustly in susceptible populations. Beyond waste management, the general public and CIPP contractors should be educated and systematic communication among relevant stakeholders should be initiated.

Conclusion

To further understand and address the human health risks posed by CIPP sewer projects, we recommend the following changes for policy, practice, and future research:

Educate health departments about CIPP risks, appropriate response, and public notification practices using media to reach a broader audience.

Develop public health guidelines for preventing and responding to CIPP-related incidents. Address inadequate practices by: 1) identifying risks from the chemical exposure and countermeasures for infants, older adults, or anyone who is immunocompromised; 2) expanding safety data sheets to ensure they list all the material composition; and 3) generating capture policies for CIPP-generated chemical waste.

Evaluate the circumstances and conditions where CIPP manufacturing sites or companies require air pollution permits to protect the public from HAP exposures and environmental degradation.

Chemically characterize the materials brought on-site, created, and discharged by CIPP manufacturing sites (i.e., quantity and composition of the wastes, transport pathways of the wastes, public health risks).

Evidence shows that CIPP has been utilized with little consideration of the public health risks it can cause. As it is the mission of public health to protect the well-being of populations—and chemical exposures will continue to occur—public health stakeholders should examine and define their roles for chemical incident prevention and mitigation.

Supplementary Material

Acknowledgements:

The authors thank the following agencies for their work group participation: American Public Health Association, Association of State and Territorial Health Officials, California Department of Public Health, Centers for Disease Control and Prevention, Colorado Department of Public Health and Environment, Florida Department of Public Health, Indiana State Department of Health, Michigan Department of Health and Human Services, National Environmental Health Association, National Institute for Occupational Safety and Health, Pennsylvania Department of Health, U.S. EPA, and Virginia Department of Health.

Appreciation is also extended to Yana Genchanok and Alexis Cain at U.S. EPA and Professor Azizur Molla at Grand Valley State University for their feedback and support.Any opinions expressed in this article are those of the author(s) and do not necessarily reflect the official positions and policies of the participating organizations. This research was supported by the National Institute of Environmental Health Sciences (R03 1R03ES030783–01, 1R01 ES032396-01, P42 ES007380), U.S. EPA (R5XA 00E02898), and National Science Foundation (CBET-2129166, CBET-1452800).

Contributor Information

Yoorae Noh, Lyles School of Civil Engineering, Purdue University.

Jonathan H. Shannahan, School of Health Sciences, Purdue University.

Anna G. Hoover, Department of Preventive Medicine and Environmental Health, University of Kentucky University of Kentucky Superfund Research Center.

Kelly G. Pennell, Department of Civil Engineering, University of Kentucky University of Kentucky Superfund Research Center.

Mark H. Weir, Division of Environmental Health Sciences, College of Public Health, The Ohio State University Sustainability Institute, The Ohio State University.

Andrew J. Whelton, Lyles School of Civil Engineering, Division of Ecological and Environmental Engineering, Purdue University.

References

- American Society of Civil Engineers. (2021). 2021 report card for America’s infrastructure. https://infrastructurereportcard.org/wpcontent/uploads/2020/12/National_IRC_2021-report.pdf

- Balog-Way D, McComas K, & Besley J (2020). The evolving field of risk communication. Risk Analysis, 40(S1), 2240–2262. 10.1111/risa.13615 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Berlin M (2022, January 10). DC Water plans summer start for Soapstone sewer work as the community voices concerns. Forest Hills Connection. https://www.foresthillsconnection.com/news/after-the-community-raised-air-pollution-concerns-dc-water-isdelaying-soapstone-sewer-work/ [Google Scholar]

- Bourbour Ajdari E (2016). Volatile organic compound (VOC) emission during cured-in-place-pipe (CIPP) sewer pipe rehabilitation [Doctoral dissertation, University of New Orleans]. Scholar-Works@UNO. https://scholarworks.uno.edu/cgi/viewcontent.cgi?article=3300&context=td [Google Scholar]

- California Department of Public Health. (2017). Cure-in-place pipe (CIPP): Additional consideration for municipalities. https://bit.ly/3AkA21w

- California Department of Public Health. (2018). CIPP safety alert:Vapor migration into buildings. https://bit.ly/3ThgPpW

- Florida Department of Public Health. (2020). Cured-in-place-pipe (CIPP). http://www.floridahealth.gov/environmental-health/hazardous-waste-sites/_documents/final_fdoh_cipp.pdf

- Hoover AG (2019). Defining environmental health literacy. In Finn S & O’Fallon L (Eds.), Environmental health literacy (pp. 3–18). Springer, Cham. 10.1007/978-3-319-94108-0_1 [DOI] [Google Scholar]

- Hoover AG, Heiger-Bernays W, Ojha S, & Pennell KG (2021). Balancing incomplete COVID-19 evidence and local priorities: Risk communication and stakeholder engagement strategies for school re-opening. Reviews on Environmental Health, 36(1), 27–37. 10.1515/reveh-2020-0092 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kobos L, Sendesi SMT, Whelton AJ, Boor BE, Howarter JA, & Shannahan J (2019). In vitro toxicity assessment of emitted materials collected during the manufacture of water pipe plastic linings. Inhalation Toxicology, 31(4), 131–146. 10.1080/08958378.2019.1621966 [DOI] [PMC free article] [PubMed] [Google Scholar]

- LeBouf RF, & Burns DA (2019). Evaluation of exposures to styrene during ultraviolet cured-in-place pipe installation (Report No. 20180009–3334). U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. https://www.cdc.gov/niosh/hhe/reports/pdfs/2018-0009-3334_revised032019.pdf [Google Scholar]

- LeBouf RF, Burns DA, Ranpara A, & Kobos L (2021). Evaluation of exposures to styrene during cured-in-place pipe liner preparation and during pipe repairs using hot water and steam (Report No. 2019–0080-3379). U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. https://www.cdc.gov/niosh/hhe/reports/pdfs/2019-0080-3379.pdf [Google Scholar]

- Li X, Ra K, Nuruddin M, Sendesi SMT, Howarter JA, Young-blood JP, Zyaykina N, Jafvert CT, & Whelton AJ (2019). Outdoor manufacture of UV-cured plastic linings for storm water culvert repair: Chemical emissions and residual. Environmental Pollution, 245, 1031–1040. 10.1016/j.envpol.2018.10.080 [DOI] [PubMed] [Google Scholar]

- Matthews E, Matthews JD, Alam S, Eklund S, Hassan H, Banjara A, Hossain G, Howell J, & Kraft J (2020) NASSCO CIPP emissions phase 2: Evaluation of air emissions from polyester resin CIPP with steam cure.

- Morris GA, & Cannady R (2019). Proper use of the hierarchy of controls. Professional Safety, 64(08), 37–40. https://onepetro.org/PS/article-abstract/64/08/37/33643/Proper-Useof-the-Hierarchy-of-Controls [Google Scholar]

- NASSCO. (2020). Guideline for the safe use and handling of styrenebased resins in cured-in-place pipe. https://www.nassco.org/wp-content/uploads/2021/02/Safe-Handling-and-Use-of-Styrene_Specification-Guideline-_−2020-2.pdf

- Noh Y, Boor BE, Shannahan JH, Troy CD, Jafvert CT, & Whelton AJ (2022a). Emergency responder and public health considerations for plastic sewer lining chemical waste exposures in indoor environments. Journal of Hazardous Materials, 422, Article 126832. 10.1016/j.jhazmat.2021.126832 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Noh Y, Odimayomi T, Sendesi SMT, Youngblood JP, & Whelton AJ (2022b). Environmental and human health risks of plastic composites can be reduced by optimizing manufacturing conditions. Journal of Cleaner Production, 356, Article 131803. 10.1016/j.jclepro.2022.131803 [DOI] [Google Scholar]

- Penders S, Melendrez D, Abusaba K, Kampbell NE, Donaldson BM, & Weaver CM (2012). Environmental effects of cured-inplace pipe repairs. Caltrans Division of Research and Innovation. http://worldcat.org/title/903661269 [Google Scholar]

- Pennell KG, Scammell MK, McClean MD, Ames J, Weldon B, Friguglietti L, Suuberg EM, Shen R, Indeglia PA, & Heiger-Bernays WJ (2013). Sewer gas: An indoor air source of PCE to consider during vapor intrusion investigations. Groundwater Monitoring & Remediation, 33(3), 119–126. 10.1111/gwmr.12021 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ra K, Sendesi SMT, Howarter JA, Jafvert CT, Donaldson BM, & Whelton AJ (2018). Critical review: Surface water and stormwater quality impacts of cured-in-place pipe repairs. Journal–American Water Works Association, 110(5), 15–32. 10.1002/awwa.1042 [DOI] [Google Scholar]

- Ra K, Sendesi SMT, Nuruddin M, Zyaykina NN, Conkling EN, Boor BE, Jafvert CT, Howarter JA, Youngblood JP, & Whelton AJ (2019). Considerations for emission monitoring and liner analysis of thermally manufactured sewer cured-inplace-pipes (CIPP). Journal of Hazardous Materials, 371, 540–549. 10.1016/j.jhazmat.2019.02.097 [DOI] [PubMed] [Google Scholar]

- RIVM (Rijksinstituut voor Volksgezondheid en Milieu, Netherlands National Institute for Public Health and the Environment). (2006). Sewer renovation with stocking methods: Backgrounds in the information sheet (Report Number 609021038/2006).

- Roghani M, Jacobs OP, Miller A, Willett EJ, Jacobs JA, Viteri CR, Shirazi E, & Pennell KG (2018). Occurrence of chlorinated volatile organic compounds (VOCs) in a sanitary sewer system: Implications for assessing vapor intrusion alternative pathways. Science of the Total Environment, 616–617, 1149–1162. 10.1016/j.scitotenv.2017.10.205 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Roghani M, Li Y, Rezaei N, Robinson A, Shirazi E, & Pennell KG (2021). Modeling fate and transport of volatile organic compounds (VOCs) inside sewer systems. Groundwater Monitoring & Remediation, 41(2), 112–121. 10.1111/gwmr.12449 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schaider LA, Swetschinski L, Campbell C, & Rudel RA (2019). Environmental justice and drinking water quality: Are there socioeconomic disparities in nitrate levels in U.S. drinking water? Environmental Health, 18, Article 3. 10.1186/s12940-018-0442-6 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sellnow TL, Ulmer RR, Seeger MW, & Littlefield RS (2009). Best practices for risk communication. In Effective risk communication: A message-centered approach (pp. 19–31). Springer. 10.1007/978-0-387-79727-4_2 [DOI] [Google Scholar]

- Sendesi SMT, Noh Y, Nuruddin M, Boor BE, Howarter JA, Youngblood JP, Jafvert CT, & Whelton AJ (2020). An emerging mobile air pollution source: Outdoor plastic liner manufacturing sites discharge VOCs into urban and rural areas. Environmental Science: Processes & Impacts, 22(9), 1828–1841. 10.1039/d0em00190b [DOI] [PubMed] [Google Scholar]

- Sendesi SMT, Ra K, Conkling EN, Boor BE, Nuruddin M, Howarter JA, Youngblood JP, Kobos LM, Shannahan JH, Jafvert CT, & Whelton AJ (2017). Worksite chemical air emissions and worker exposure during sanitary sewer and stormwater pipe rehabilitation using cured-in-place-pipe (CIPP). Environmental Science & Technology Letters, 4(8), 325–333. 10.1021/acs.estlett.7b00237 [DOI] [Google Scholar]

- U.S. Department of Labor, Occupational Safety and Health Administration. (2018). Citation and notification of penalty (Inspection No. 1274028). https://engineering.purdue.edu/CIPPSafety/resources/OSHA-Region5-CIPP-Fatality-Notification-of-Penalty-2018.pdf [Google Scholar]

- U.S. Environmental Protection Agency. (2020). 85 FR 15960: National emission standards for hazardous air pollutants: Boat manufacturing and reinforced plastic composites production risk and technology review. https://www.govinfo.2020-03-20/2020-04661

- U.S. Environmental Protection Agency. (2022a, March 8). EPA releases new memo outlining strategy to equitably deliver clean water through President Biden’s Bipartisan Infrastructure Law. https://strategy-equitably-deliver-clean-water-through

- U.S. Environmental Protection Agency. (2022b). Clean Air Act standards and guidelines for foam, fiber, plastic and rubber products. https://www.epa.gov/stationary-sources-air-pollution/clean-airact-standards-and-guidelines-foam-fiber-plastic-and

- U.S. Government Accountability Office. (2016). Water infrastructure: Information on selected midsize and large cities with declining populations (GAO-16–785). https://www.gao.gov/products/gao-16-785 Virginia Department of Health. (2020). Styrene. https://www.vdh.virginia.gov/environmental-health/styrene/ [Google Scholar]

- Wisconsin Department of Health and Family Services, & Agency for Toxic Substances and Disease Registry. (2005). Health consultation: Schlitz Park Office Building, Milwaukee, Milwaukee County, Wisconsin. https://stacks.cdc.gov/view/cdc/82830 [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.