Abstract

The study aimed to evaluate the potential use of spent coffee powder (SCP) and spent tea powder (STP) as bioactive supplements for sponge cake. To achieve this aim, we initially compared the chemical properties of spent tea and coffee powders with those of their raw forms. Subsequently, three supplemented cake blends were prepared (1, 2, and 3% of SCP and STP) to test the effect of their addition on the chemophysical characteristics, sensory attributes, and shelf life of the final products. Our results indicated that spent tea and coffee are prospective materials for polyphenols. Spent tea powder could retain up to 72% (theaflavin trigallate), while spent coffee powder could retain up to 63.9% (1-caffeoylquinic acid) of the identified compounds compared to the raw materials. Furthermore, spent tea and coffee powders contained high levels of dietary fiber (18.95 and 31.65 g/100 g dry weight) and the elements potassium (254.6 and 1218.2 mg/100 g of DW), phosphorus (189.8 and 161.3 mg/100 g of DW), calcium (904.1 and 237.8 mg/100 g of DW), and magnesium (158.8 and 199.6 mg/100 g of DW). In addition, the fortified samples with SCP and STP significantly enhanced the nutritional values while retaining good sensory qualities compared to those of the control sample. Moreover, cakes fortified with the highest concentrations of SCP and STP (3%) showed a significant decrease in malondialdehyde content (MDA; 17.7 and 18.0 μg/g) and microbiological counts (2.4 and 2.5 log cfu/g) compared to the control cake after 14 days of storage. These findings suggest that incorporating SCP and STP into cakes not only enhances their nutritional value but also extends their shelf life. By utilizing these waste products, we can contribute to a more sustainable and ecofriendly food industry.

Introduction

For many years, human development and population growth have been accompanied by the exhaustion and depletion of natural resources and the generation of a significant amount of agri-food waste due to following the linear economy model of “produce, use, then throw away”.1

Tea and coffee are the most consumed beverages around the world due to their pleasant aroma, health benefits, and even religious beliefs.2,3 They are rich in bioactive substances, and their consumption is linked to health benefits, including anti-inflammatory, antioxidant, antiviral, antiallergic, anticancer, and cardiovascular benefits.4,5 Furthermore, they could enhance memory, mood, and cognitive ability.6,7

For both products, around 10% of the dry weight is extracted during brewing in their infusions while around 90% is finally disposed into landfills.2,8 However, only low molecular weight components are extracted in their respective infusions while the spent coffee powders and tea leaves still retain considerable amounts of bioactive substances, including polyphenols, fibers, and essential elements.2,9−11

Currently, the awareness of the general farmers and consumers of terms including sustainable development and circular bioeconomy helped in mitigating this problem, and agri-food waste is now accepted as a valuable resource and re-entered the supply chain via recycling, valorization, energy recovery, and other uses.2,12−17 In this context, there have been studies on the use of used spent coffee and tea leaves in the field of livestock nutrition, agricultural compost, or production of biogas, or valorized for their bioactive molecules.2,13,18−21 However, there is a lack of research on the use of spent tea and coffee in the production of novel foods.22−24

It has been noted that research on natural functional food additives, including those that exhibit high antioxidant activity, has been developing rapidly in recent years. Consumers prefer antioxidants derived from natural plant sources versus possibly hazardous, manufactured chemicals.25−28 In this context, several studies have explored the effects of fortifying bakery products with coffee, tea, or their extracts on the technological and nutritional properties of the final products.29−33 However, to our knowledge, less effort is made to incorporate spent tea or Arabic coffee in making sponge cakes and to investigate their effects on the sensorial, technological, and shelf lives of the final products. Therefore, the current study aimed to (I) evaluate the use of byproducts of tea and Arabic coffee as a novel functional food ingredient in bakery goods; (II) study the impact of adding spent tea or Arabic coffee ground on the sensory qualities, nutritional values, and shelf life of the final product; and (III) validate our findings using chemometric methods. All in all, we aimed to provide normal households with easy-to-use methods to reduce their carbon footprint by utilizing their nutrient-rich food wastes to prepare diverse food concepts to their liking, social habits, and lifestyle.

Materials and Methods

Materials

Materials used were H2O2 30% (ultrapure for AA, CARLO ERBA Reagents GmbH, France); HNO3 65% (ICP grade); the element Ca, Na, K, Mg, P, Fe, Mn, Zn, Cu, Cd, Cr, Se, and Sr standards 1000 mg/L (ICP grade); n-hexane 100% (Sigma-Aldrich, USA); acetone and acetic acid (HPLC grade, CARLO ERBA Reagents GmbH, Germany); Folin-Ciocalteu Reagent 20% (Fluka, Milwaukee, Wisconsin, United States); acetonitrile (HPLC grade); ethanolamine 98%; trichloroacetic acid (TCA); DPPH, ABTS, BHT, Vit C 99.9%, and epigallocatechin gallate (Sigma-Aldrich, Germany); and gallic acid 98% (Fischer, UK).

The black tea and Arabic coffee used in this investigation were purchased from a local market in Saudi Arabia.

Methods

Preparation of Spent Coffee and Tea Powders

Bags of Arabic coffee or black tea were soaked in 100 mL of boiling distilled water for 10 min while being gently stirred. After this, spent coffee or tea was retrieved and repeatedly rinsed with distilled water to remove soluble and colored components. The solid was cleaned with distilled water and then dried in an oven for 24 h at 60 °C. The dried leaves were then pulverized and sieved into small particles less than 500 μm and kept at room temperature until used in polyethylene bags. After that, it was crushed into a fine powder in a laboratory mill, as described by Zuorro and Lavecchia.34

Cake Ingredients and Processing

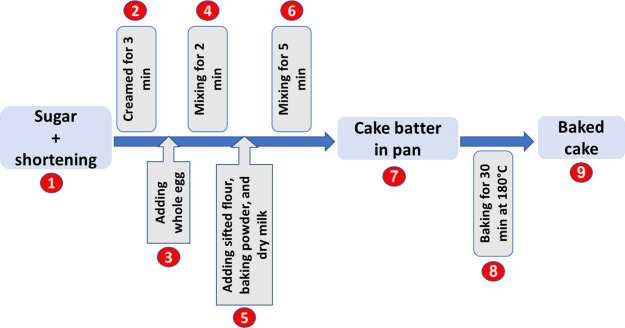

Cake samples were made using a modified approach of Ahmed35 using food-grade ingredients purchased from the local market. Table 1 summarizes the cake recipe and lists the various ratios of employed Arabic coffee or black tea powders used in this study. The control caking process followed the following scheme (Figure 1):

Table 1. Mixing Ratios of the Control and Substituted Cake Blendsa.

|

cake blends |

|||||||

|---|---|---|---|---|---|---|---|

| ingredients (g) | control | C-STP1 | C-STP2 | C-STP3 | C-SCP1 | C-SCP2 | C-SCP3 |

| wheat flour 72% | 100 | 99 | 98 | 97 | 99 | 98 | 97 |

| STP | 0 | 1 | 2 | 3 | 0 | 0 | 0 |

| SCP | 0 | 0 | 0 | 0 | 1 | 2 | 3 |

| sugar | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| shortening | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| fresh whole egg | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| dry milk powder | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| baking powder | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| vanillin | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Figure 1.

An illustration of the baking process of cake samples.

The formula’s flour was substituted with spent Saudi coffee or black tea powders at 1, 2, and 3% ratios to make the substituted cake batters. The mixing process was carried out in the same order as that for the control. After baking, the cake was taken out of the pans, cooled completely at room temperature, and then sealed in polyethylene bags for 14 days of storage. After the pans were removed, samples were obtained within 1 h and frequently at weekly intervals for examination.

Determination of the Physical Properties of Cake Samples

After 1 h of baking, the cake sample weight, volume, and specific volume were determined according to Randez-Gil et al.36 Furthermore, the tristimulus color scheme was used to determine the Hunter values L*, a*, and b* of all cake samples using a Minolta Calorimeter (CR-200, Japan) according to the method described by Francis.37

Sensory Evaluation of Cake Samples

The test was carried out according to the ethical guidelines of King Faisal University (approval number ETHICS834) by a sensory panel consisting of four females and six males (aged between 33 and 55 years old). They are well-trained and have no known illnesses, allergies, or intolerances to any of the ingredients used in our experiment. Cake samples were evaluated in two separate sessions in a well-lit and ventilated sensory room with an average temperature of 25 °C. During each session, 2 cm-thick slices labeled with three-digit randomized codes were served and the panelists were asked to perform visual and ortho- and retro-nasal evaluations of the samples for the attributes appearance, crust and crumb colors, crumb texture, taste, odor, and overall acceptability. The selection of these attributes and experimental design were according to our previous research.28,38 The panelist rated these attributes based on a 10-point numerical with a range between 0 “strongly dislike” and 10 “strongly like”. The panelists used water between samples to eliminate the residual taste according to the AACC 33-50.02 method.39

Microbiological Analysis

Ten grams of cake (crumb with crust) was removed and put into a sterile stomacher bag using aseptic procedures for the microbiological analysis procedure, which was carried out following Łopusiewicz et al.40 with a minor modification. A BagMixer (INTERSCIENCE, Saint-Nom-la-Brèteche, France) was used to blend the samples for 1 min after diluting them with 90 mL of sterile physiological saline (0.9%). The proper decimal dilutions were made in sterile buffered peptone water from Merck, Darmstadt, Germany. On Plate Count Agar (Merck, Darmstadt, Germany), total microbial counts were counted and cultured for 24 h at 37 °C in aerobic conditions. To identify molds and yeasts, 1 mL of diluted sample was spread-plated on potato dextrose agar and incubated aerobically for 72 h at 28 °C. By counting plates with 30–300 colonies, the number of microorganisms was counted in triplicate and the viable cell counts were expressed as log CFU/g of the materials.

Chemical Measurements

Before analysis, the three separate samples of cakes from each treatment were mixed to produce single consistent samples. After that, triplicates of each chemical measurement were performed on the unified samples.

Proximate Analysis

Dry matter (DM), total nitrogen, crude protein, ash and water-soluble ash fraction (WSAF), total carbohydrates, and reducing sugars were all assessed using the procedure described in A.O.A.C.41 Crude fiber was measured according to the manufacturer’s manual using a completely automated method (Foss Fibertec 8000, Denmark).

Element Analysis

Before analysis, 1 g from each sample was digested using H2O2 or 8 mL of HNO3 in a closed microwave digestion/extraction system (SINEO MDS-6G SMART, China).42 The mixtures were then chilled, filtered, and diluted with 25 mL of ultrapure water from the Milli-Q system (Millipore, France). Finally, elements were injected using an ASX-280 autosampler, and the elements were measured using a Shimadzu ICP-OES (9820 Series, Tokyo, Japan) fitted with an Argon AS 93plus autosampler to ensure the purity of the plasma and the carrier gas (purity >99.995%). Each element was quantified using a calibration curve fitted by its respective standard solution (calibration range from 0 to 10 mg/L).

Extraction and Determination of Phytochemicals

Two grams of each dried sample was mixed with a solvent system consisting of acetone/water/acetic acid (70/29.5/0.5; v/v/v), shaken for 2 h at 25 °C (Witeg shaking water bath, Wertheim, Germany), and centrifuged at 10,000g for 20 min at 20 °C (Hermel Z36HK, Germany), and finally the supernatant was collected. This procedure was repeated, and the supernatant was combined. The extract was then evaporated under low pressure and redissolved in acetonitrile to a final volume of 10 mL.

Total phenolic content was determined according to the method of Goffman and Bergman43 after minor modifications. 0.1 mL of the extract was mixed with 0.50 mL of deionized water and 0.25 mL of Folin–Ciocalteu reagent. After 5 min, 0.5 mL of 0.5 M ethanolamine was added to the mixture and the mixture was incubated for 90 min for color development. The absorbance was then measured at 760 nm using a Thermo Scientific Evolution 350 UV–vis spectrophotometer (Massachusetts, USA). The total phenolic concentration was expressed as gallic acid (GA)/100 g of sample dry weight (DW).

Determination of the total condensed tannins (TCTs) applied by precipitation of condensed tannins by polyvinyl poly pyrrolidone PVPP, and after that, TCT content was established by the difference between total polyphenols TP and the residual nonadsorbed or nontannin polyphenols RNAPC.44 One milliliter of PVPP (100 mg/mL) in deionized water was charged with 0.1 mL of sample, and then the mixture was vortexed for 1 min and incubated in a shaking water bath (Witeg, Wertheim, Germany) at 40 °C for 15 min. Then, the mixture was centrifuged at 4000 rpm for 5 min at 4 °C. The RNAPC was measured in 100 μL of the supernatant by Folin–Ciocalteu reagent as described in the TP measurement step. Epigallocatechin gallate was the reference standard, and the TCT was calculated from % (TP – RNAPC).

Determination of DPPH and ABTS Radical Scavenging Capacity

The 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging capability was calculated according to the method of Goffman and Bergman43 with some modifications. The phytochemical extract was mixed with 0.9 mL of DPPH solution (80 mg/L in 100% methanol) and incubated in darkness at room temperature for 30 min, and finally, the absorbance was measured at 517 nm. The percentages of DPPH radical scavenging activities in samples were estimated by using the following formula:

where Ablank denotes the absorbance of the blank and Asample denotes the absorbance of the sample.

The 2,2′-azino-bis ethylbenzthiazoline-6-sulfonic acid (ABTS) radical scavenging capability against BHT and Vit C was calculated according to the method of Re et al.45 with some modification, where potassium persulfate 2.45 mM and ABTS 7 mM were mixed at a 1:1 ratio (v/v) and incubated for 4 to 16 h to allow complete oxidation of ABTS. Before measurements, ABTS was diluted with ethanol, and then 0.9 mL was mixed with 0.1 mL of the test samples, the mixture was incubated for 1 min, and finally the absorbance was measured at 734. The following equation was used to determine the antioxidant activity of the tested samples and standards based on the decrease in absorbance at varied doses:

where Astandard denotes the absorbance of the standard and Asample denotes the absorbance of the sample.

Characterization of the Individual Phenolics Using UPLC-MS/MS

Characterization of the individual phenolics was according to El-Beltagi et al.28 For measurements, 20 μL of each extract was injected and the separation was achieved using a Waters ACQUITY UPLC–I class using an ACQUITY UPLC BEH column (C18 1.7 μm–2.1 × 100 mm). The flow rate was 0.8 mL min–1, and the mobile phase consisted of a binary gradient of 0.5% formic acid in deionized water (A) and 100% methanol (B) at 0.8 mL/min at 25 °C. The gradient used was as follows: 0 min, 15% B; 0 to 15 min, linear gradient to 15% B; 15 to 25 min, linear gradient to 25% B; 25 to 35 min, linear gradient to 50% B; 35 to 50 min, linear gradient to 75% B; 50 to 55 min, linear return to 15% B; and 55 to 57 min, isocratic at 100% B to re-equilibrate. The identification was achieved by using Xevo TQD MS (Milford, Massachusetts, U.S.A). Argon was used as a collision cell gas inlet at 7 psi, and nitrogen pressure was at 60 psi. The MS was set to an atmospheric pressure ESI source (negative ion mode). The electrospray capillary voltage was set to 3000 V, with a nebulizing gas flow rate of 12 L/h and a drying gas temperature of 300 °C. The mass spectrometry data was acquired in the scan mode (mass range m/z 100–1000). Data interpretation was achieved by MassLynx v4.1 software, where the mass metabolite spectral library compared mass spectral data. The metabolite library identifies and validates molecules using high mass accuracy MS/MS spectra, Rt, and isotopic data.

MDA Determination by TBARS

For this test, malonaldehyde content (MDA) from cake samples using trichloroacetic acid and measured using thiobarbituric acid reagent according to Vyncke,46 and the absorbance was measured at 525 and 560 nm.

Statistical Analysis

According to Mahmoud and Magdy47 and Mahmoud et al.,48 the data was prepared for statistical analysis by being tested for outliers, normalized, and calculated z-scores when it was discovered to be normally distributed. To examine the differences between samples based on the means and standard deviations of triplicates for each of the variables and 10 in another variable, a one-way ANOVA was conducted, followed by Duncan’s test. The XLSTAT 2022 (Addinsoft, Paris, France) spreadsheet program was used for principal component analysis (PCA). Finally, heatmap-based hierarchical clustering was performed using the web tool “Morpheus Open” (last accessed on: May 22, 2023).

Results and Discussion

Characterization of Raw Materials

Proximate Analysis

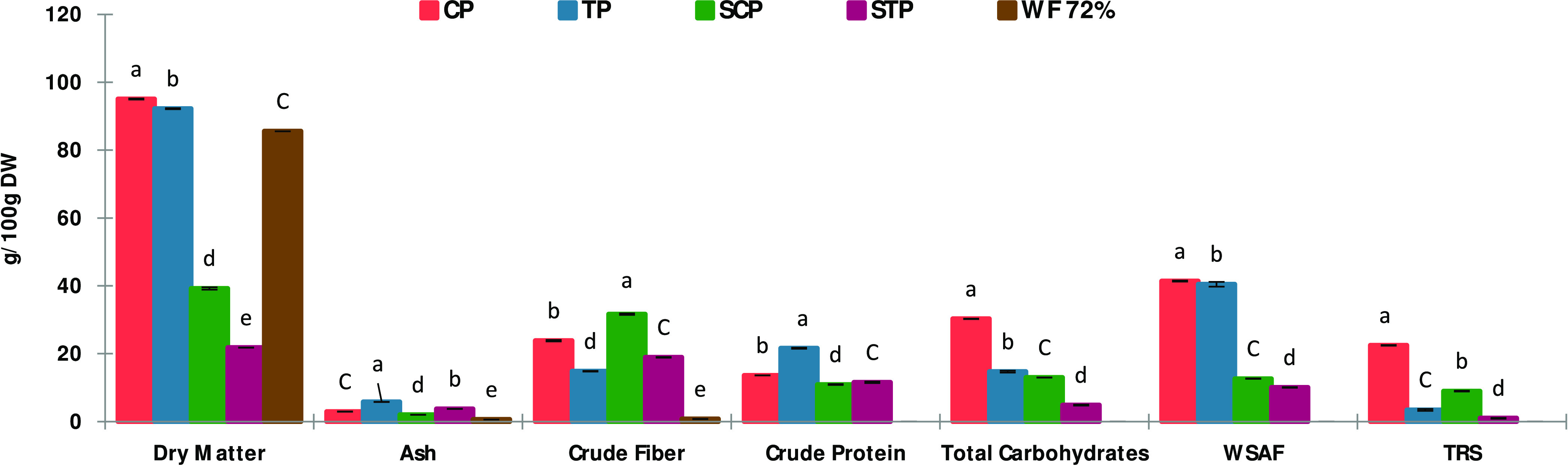

Figure 2 reports the approximate chemical analysis of coffee powder (CP), tea powder (TP), spent coffee powder (SCP), spent tea powder (STP), and wheat flour (WF 72%). Generally, raw tea powder and coffee ground have higher proximate contents compared to their spent forms, where coffee powder has the highest concentration of gray matter (95.11 g/100 g DW), total carbohydrate (30.29 g/100 g DW), WSAF (41.41 g/100 g DW), and total reducing sugar (22.48 g/100 g DW). On the other hand, tea powder has the highest crude protein and ash levels (21.60 and 5.79 g/100 g DW, respectively). It is noted that spent materials possessed lower proximate components compared to their forms. This difference can be attributed to the hydrophilic properties of these chemicals, which facilitate their extraction at high temperatures when brewing coffee grounds and tea powder. Consequently, the concentrations of these compounds decrease during the brewing process.49,50 The only exception was spent coffee powder, which has the highest crude fiber among all samples (31.65 g/100 g DW).

Figure 2.

Proximate composition of the raw materials. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. CP: coffee powder; TP: tea powder; SCP: spent coffee powder; STP: spent tea powder; WF 72%: wheat flour 72% extraction; WSAF: water-soluble ash fraction; TRS: total reducing sugar.

Mineral Composition

Generally, the results of ICP-OES indicated that all raw materials (tea powder, coffee powder, spent coffee, and tea powders) have higher macro and trace element contents than wheat flour (Table 2). When comparing the unused materials, tea powder has the highest concentrations of Ca (670.3 mg/100 g DW), P (239.6 mg/100 g DW), Mn (54.2 mg/100 g DW), and Zn (2.0 mg/100 g DW) whereas coffee ground contained the highest amounts of K (1874 mg/100 g DW), Mg (225.2 mg/100 g DW), and Sr (1.5 mg/100 g DW). Finally, wheat flour has the highest Na concentration (119.3 mg/100 g DW).

Table 2. Macro and Trace Elements of Raw Materialsa.

| minerals mg/100 g DW | WF (72%) | TP | CP | STP | SCP |

|---|---|---|---|---|---|

| Ca | 30.0 ± 19.1e | 670.5 ± 0.4b | 170.0 ± 0.01d | 904.5 ± 0.5a | 237.8 ± 0.3c |

| K | 140.0 ± 0.9e | 771.0 ± 0.7c | 1874.0 ± 0.01a | 254.6 ± 0.7d | 1218.2 ± 0.1b |

| Mg | 125.0 ± 0.8e | 170.0 ± 0.6c | 225.0 ± 0.1a | 158.8 ± 0.2d | 199.5 ± 0.6b |

| P | 0.10 ± 0.00e | 240.0 ± 0.6a | 215.0 ± 0.4b | 189.8 ± 0.3c | 161.3 ± 0.1d |

| Na | 119.0 ± 0.4a | 15.8 ± 0.5b | 8.66 ± 0.07c | 15.0 ± 0.02b | 8.87 ± 0.2c |

| Fe | 1.0 ± 0.00c | 11.2 ± 0.06b | 0.011 ± 0.00d | 15.6 ± 0.2a | 0.012 ± 0.0d |

| Mn | 0.50 ± 0.007d | 53.9 ± 0.4a | 3.25 ± 0.004c | 50.2 ± 0.2b | 3.20 ± 0.1c |

| Zn | 0. 60 ± 0.00c | 2.0 ± 0.001a | 1.08 ± 0.01b | 1.84 ± 0.1a | 1.06 ± 0.02b |

| Cu | 0.0001 ± 0.00c | 2.5 ± 001b | 0.001 ± 0.00c | 2.86 ± 0.06a | 0.001 ± 0.00c |

| Cr | 0.00 ± 0.00c | 0.10 ± 0.00b | 0.00 ± 0.00c | 0.103 ± 0.001a | 0.00 ± 0.00c |

| Cd | 0.00 ± 0.00 | 0.000 ± 0.00 | 0.00 ± 0.00 | 0.004 ± 0.00 | 0.00 ± 0.00 |

| Sr | 0.00 ± 0.00b | 0.003 ± 0.00b | 1.50 ± 0.00a | 0.001 ± 0.00b | 1.48 ± 0.03a |

The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each column. CP: coffee powder; TP: tea powder; SCP: spent coffee powder; STP: spent tea powder; WF 72%: wheat flour 72% extraction.

Spent tea powder contains more amounts of Ca, Fe, and Cu (904.1, 15.6, and 2.9 mg/100 g DW, respectively) than the raw tea. Similarly, spent coffee contained higher K and Mg (237.8 and 1218 mg/100 g of DW, respectively) than the raw coffee. The increase in the concentration of these elements might be attributed to the loss of the total weight of the samples, e.g., loss of dry matter, ash, and caffeine, during brewing.49,50

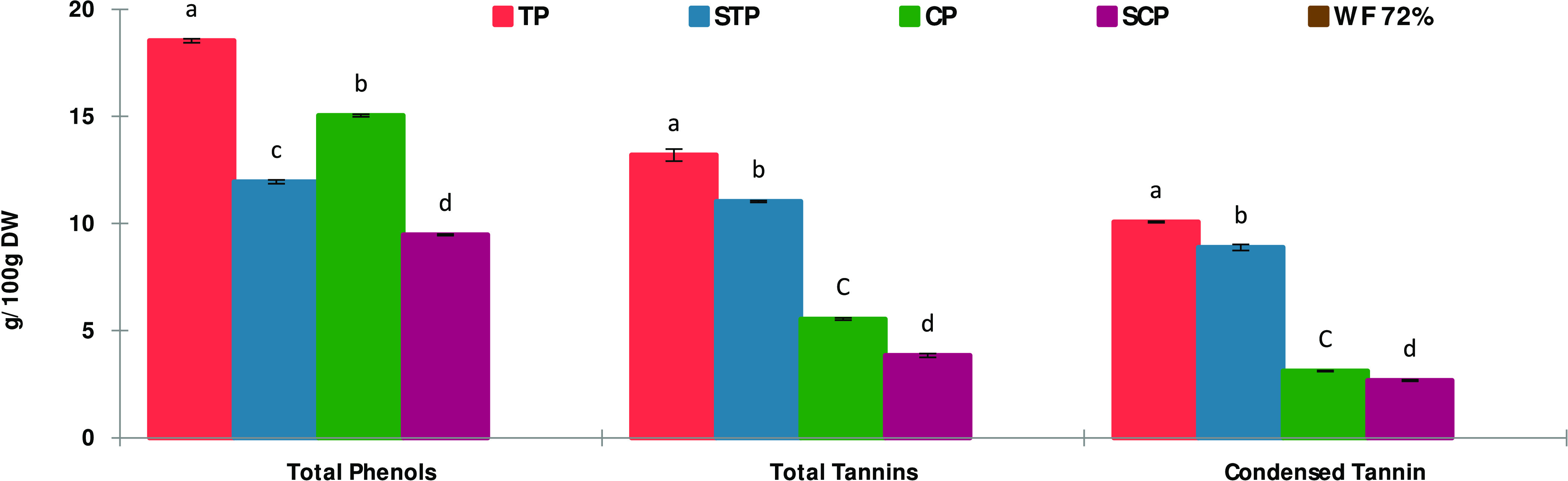

Total Secondary Metabolites

The secondary metabolites of the raw materials are displayed in Figure 3. Our findings showed that raw materials varied depending on their total phenol, tannin, and condensed tannin concentrations. In comparison to the other samples, tea powder had the greatest levels of total phenols (18.5 g/100 g DW), total tannins (13.2 g/100 g DW), and condensed tannins (10.1 g/100 g DW). Coffee powder had the highest levels of total phenols (15.1 g/100 g DW). Additionally, STP has greater levels of total phenols (12.0 g/100 g DW), total tannins (11.1 g/100 g DW), and condensed tannins (8.9 g/100 g DW) as compared to spent coffee powder.

Figure 3.

Secondary metabolites of raw materials. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. CP: coffee powder; TP: tea powder; SCP: spent coffee powder; STP: spent tea powder; WF 72%: wheat flour 72% extraction.

Individual Secondary Metabolites

UPLC-tandem MS was used for the identification and quantification of the phenolic contents of the coffee powder, tea powder, spent coffee powder, and spent tea powder ethanolic extracts, as shown in Table 3 and Figures S1 and S2. A total of 15 compounds were identified in TP, while epigallocatechin and gallocatechin gallate were absent in the chromatogram of spent tea powder; on the other hand, three compounds were detected in coffee powder and spent coffee powder. The quantity of all detected phenolic compounds is reduced in spent tea or coffee compared with their quantity in tea powder or coffee powder. The residual quantities of theaflavin, gallocatechin, GA epicatechin, and theaflavin were found to be 72.96, 71.07, 55.81, 44.85, and 33.9%, respectively. From these prominent results, we can deduce first the considerable percentage of phenolic compounds retained in the spent tea powder and second the possible antioxidant activity of the spent tea powder. Similarly, 63.94% of 1-caffeoylquinic acid was retained in the spent coffee powder. From the obtained results, most tea powder and spent tea powder compounds belong to the phenolic acids and theaflavins group while coffee powder and spent coffee powder compounds belong to the phenolic acids group.

Table 3. LC-Tandem MS Identification of Phenolic Compound Content in Tea Powder (TP), Spent Tea Powder (STP), Coffee Powder (CP), and Spent Coffee Powder (SCP)a.

| amount

(mg/g) |

|||||||

|---|---|---|---|---|---|---|---|

| compound name | ret. time (min) | [M + H]− | base beak (m/z) | TP | STP | % of residual components in STP | |

| 1 | gallic acid | 5.174 | 169 | 125 | 12.1311 | 6.7698 | 55.81 |

| 2 | gallocatechin | 5.370 | 305 | 125 | 13.3357 | 9.4743 | 71.04 |

| 3 | epigallocatechin | 6.008 | 193 | 134 | 11.6923 | Nd | 0.00 |

| 4 | catechin | 7.864 | 289 | 289 | 10.9873 | 0.7757 | 7.06 |

| 5 | chlorogenic acid | 8.280 | 353 | 353 | 11.6469 | 0.8362 | 7.18 |

| 6 | caffeic acid | 9.948 | 197 | 135 | 11.7437 | 1.1396 | 9.70 |

| 7 | epigallocatechin gallate | 11.045 | 457 | 287 | 12.2593 | 1.4659 | 11.96 |

| 8 | epicatechin | 12.382 | 289 | 289 | 80.1692 | 35.9521 | 44.85 |

| 9 | gallocatechin gallate | 12.548 | 457 | 287 | 120.4337 | Nd | 0.00 |

| 10 | epicatechin gallate | 15.726 | 441 | 169 | 30.3867 | 1.3820 | 4.55 |

| 11 | catechin gallate | 17.748 | 441 | 169 | 11.1799 | 1.6092 | 14.39 |

| 12 | ellagic | 19.690 | 301 | 257 | 11.0955 | 1.9654 | 17.71 |

| 13 | quercetin-3-O-galactoside | 21.484 | 463 | 301 | 12.1586 | 1.3008 | 10.70 |

| 14 | theaflavin | 23.733 | 563 | 563 | 60.0017 | 20.3382 | 33.90 |

| 15 | theaflavin trigallate | 24.062 | 1019 | 867 | 110.7092 | 80.7743 | 72.96 |

| amount mg/g |

|||||||

|---|---|---|---|---|---|---|---|

| compound name | ret. time (min) | [M + H]− | base beak m/z | CP | SCP | % of residual components in SCP | |

| 1 | 1-caffeoylquinic acid | 1.910 | 353 | 173 | 171.1329 | 109.4265 | 63.94 |

| 2 | 3-feruloylquinic acid | 12.072 | 367 | 177 | 60.3371 | 14.5921 | 24.18 |

| 3 | 3,4-dicaffeoylquinic acid | 12.832 | 515 | 353 | 310.0614 | 40.7680 | 13.15 |

Residual components % calculated from STP or SCP concentration based on the corresponding TP or CP concentration.

The most abundant compounds in tea powder were gallocatechin gallate (120.4 mg/g), theaflavin trigallate (110.7 mg/g), epicatechin (80.2 mg/g), theaflavin (60.0 mg/g), and epicatechin gallate (30.4 mg/g). In addition, the most abundant compounds in spent tea powder were theaflavin trigallate (80.8 mg/g), epicatechin (36.0 mg/g), theaflavin (20.3 mg/g), gallocatechin (9.5 mg/g), and GA (6.8 mg/g). In this context, Moldoveanu and Oden51 indicated that GA, epigallocatechin gallate, epicatechin gallate, epigallocatechin, epigallocatechin, and epicatechin are the most common phenolics in tea samples. In another study, Jeszka-Skowron et al.52 indicated that 5-, 4-, and 3- caffeoylquinic acids are the most abundant phenolics in coffee Arabica and Robusta.

Furthermore, Ramdani53 compared the phenolic profile of raw and spent black tea profiles and indicated that the number of compounds and their concentrations were higher in the raw tea than in its spent form. However, the author indicated that spent tea powder still presented considerable amounts from these compounds and promoted their ability to present nutritional values upon consumption.

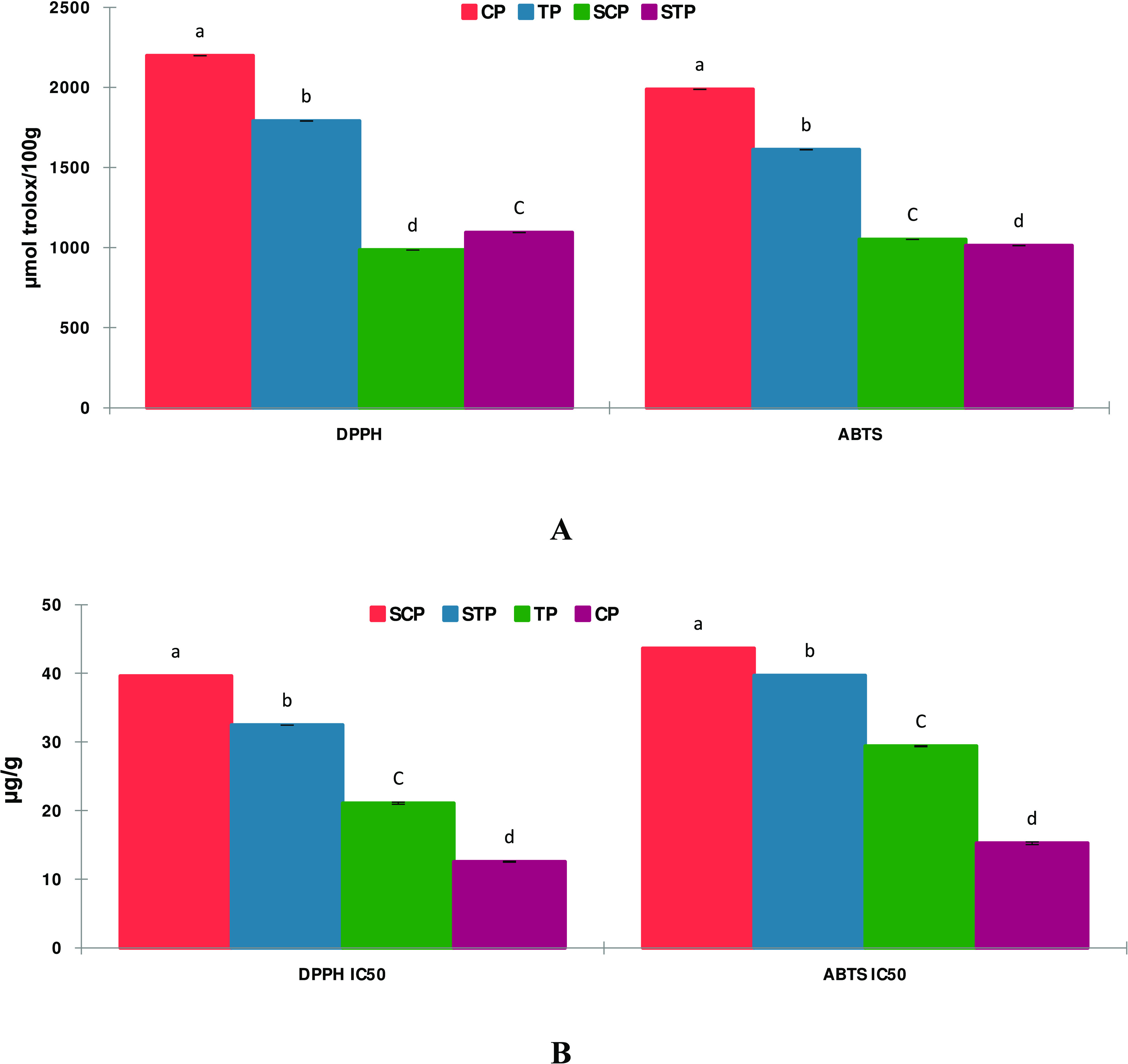

Antioxidant Activity

The Trolox equivalent antioxidant capacity of raw materials was tested by using the DPPH and ABTS assays (Figure 4 A). The most pronounced increases in DPPH (2197.9 and 1790.5 μmol Trolox/100 g DW) and ABTS (1988.3 and 1988.3 μmol Trolox/100 g DW) were detected in coffee and tea powder, respectively. In addition, spent tea powder has higher DPPH activity (1093.7 μmol Trolox/100 g of DW) than spent coffee powder while spent coffee powder has higher ABTS activity (1051.2 μmol Trolox/100 g of DW) than spent tea powder (Figure 5A). ROS scavenging (IC50) is related to antioxidant activity, and the lower the IC50, the greater the antioxidant activity of the sample. The lower IC50 of DPPH (12.6 and 21.1 μg/g) and ABTS (15.3 and 29.4 μg/g) were detected in CP and TP, respectively (Figure 4B).

Figure 4.

Antioxidant activity of raw materials (A) and IC50 (B) compared to standard antioxidants expressed in μmol Trolox/100 g. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. CP: coffee powder; TP: tea powder; SCP: spent coffee powder; STP: spent tea powder; WF 72%: wheat flour 72% extraction.

Figure 5.

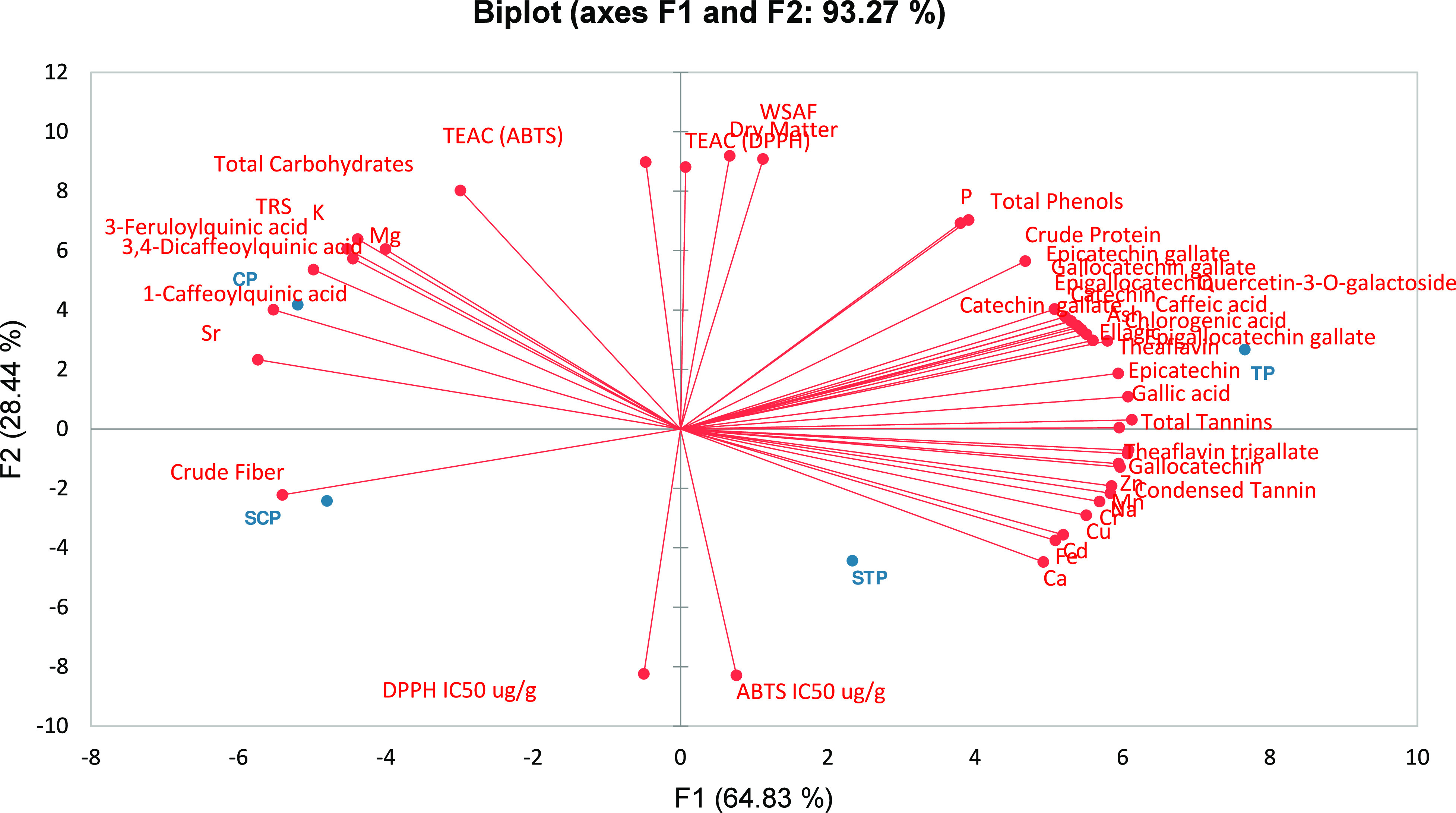

PCA biplot showing the variation between raw and spent tea and coffee.

Overall Evaluation of Raw Materials

The PCA was performed first to establish a comparison between the raw and spent tea and coffee powders and then to understand the possible effects after the inclusion of their spent form in the cake at different addition levels. When examining the characteristics of raw and spent pure tea and coffee powders, two principal components have explained 93.2% of the variation among samples (Figure 5), where the first principal component (PC1) differentiates samples based on their source (tea vs coffee) while the second principal component (PC2) differentiates between treatments (raw vs spent). The raw samples generally showed higher proximate and phenolic contents and higher antioxidant activities. This implies that the preparation conditions (diffusion time and temperature) facilitated the extraction of these components. Furthermore, the release of phenolic compounds from the matrix reduces spent powders’ antioxidant capacities.

On the other hand, the spent sample possessed higher elemental composition than their respective raw samples. We postulate that these elements were presented in pound forms within the cells and released after heat treatment. This finding is supported by the results of Dobrinas et al.54 when examining the transfer rate of elements Fe and Cu from the different tea leaves into their infusions and reported that, depending on the temperature, infusion time, and tea type, this rate could vary between 0.67 and 122.5%.

Chemical and Physical Characteristics of the Final Products

Proximate Analysis of Cakes

According to the proximate analysis, the control cake had the highest DM content (71.03 g/100 g DW) of all the samples (Table 4). In contrast, cakes made with different levels of spent coffee and tea powders contain higher ash and crude fiber contents, in which the cakes made with the addition of 3% spent coffee and tea powders showed the most significant increases in ash (4.08 and 4.13 g/100 g of DW) and crude fiber (1.10 and 0.69 g/100 g of DW), respectively. Previous reports indicated that adding spent coffee and teas to bakery products improved their fiber and ash contents compared to the control.24,55−57

Table 4. Proximate Composition of Cake Samplesa.

|

cake blends |

|||||||

|---|---|---|---|---|---|---|---|

| parameters(g/100 g DW) | control | C-STP1 | C-STP2 | C-STP3 | C-SCP1 | C-SCP2 | C-SCP3 |

| dry matter | 71.1 ± 0.04a | 68.2 ± 0.2e | 68.6 ± 0.03d | 68.9 ± 0.01d | 69.1 ± 0.3c | 70.1 ± 0.01b | 70.2 ± 0.01b |

| ash | 3.85 ± 0.1b,c | 4.04 ± 0.02a | 4.08 ± 0.01a | 4.11 ± 0.03a | 3.78 ± 0.01c | 4.04 ± 0.02a,b | 4.06 ± 0.02a |

| crude fiber | 0.12 ± 0.001g | 0.31 ± 0.001f | 0.50 ± 0.00d | 0.69 ± 0.00c | 0.44 ± 0.001e | 0.76 ± 0.003b | 1.07 ± 0.03a |

The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each column. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Mineral Composition of Cakes

Compared to control cakes, the findings showed that all macro- and trace elements, except Na, considerably increased in cakes prepared with the addition of spent coffee and tea powders at various concentrations (Table 5). Among fortified cake samples, the cakes made with the addition of 3% spent coffee and tea powders showed the most substantial increases in macro and trace elements. In contrast, Cr and Cd were not found in any of the cake samples and Se had no significant effect on any of the samples. Reports have indicated that fortifying bakery products with coffee or tea can significantly increase their elemental contents including Ca, K, and Mg.58,59

Table 5. Macro Elements and Trace Elements of Cake Samplesa.

|

cake

blends |

|||||||

|---|---|---|---|---|---|---|---|

| minerals(mg/100 g DW) | control | C-STP1 | C-STP2 | C-STP3 | C-SCP1 | C-SCP2 | C-SCP3 |

| Ca | 156.7 ± 0.001g | 170.3 ± 0.05c | 183.8 ± 0.03b | 201.5 ± 0.2a | 160.0 ± 0.04f | 163.6 ± 0.004e | 167.1 ± 0.02d |

| K | 132.6 ± 0.02g | 135.8 ± 0.08f | 139.1 ± 0.08e | 142.7 ± 0.2d | 150.4 ± 0.02c | 168.2 ± 0.03b | 186.0 ± 0.03a |

| Mg | 63.4 ± 0.1g | 65.3 ± 0.02f | 67.1 ± 0.06d | 69.3 ± 0.2b | 66.0 ± 0.1e | 68.5 ± 0.2c | 70.8 ± 0.03a |

| P | 117.5 ± 0.09g | 120.6 ± 0.2e | 123.4 ± 0.1c | 126.6 ± 0.2a | 120.1 ± 0.003f | 122.5 ± 0.07d | 125.0 ± 0.09b |

| Na | 297.5 ± 0.05a | 297.2 ± 0.05a,b | 296.9 ± 0.7a,b | 296.6 ± 0.2b,c | 297.5 ± 0.7a | 296.7 ± 0.06b,c | 296.5 ± 0.3c |

| Fe | 1.24 ± 0.3d | 1.52 ± 0.04c | 1.76 ± 0.05b | 1.99 ± 0.02a | 1.29 ± 0.01d | 1.33 ± 0.01d | 1.29 ± 0.01d |

| Mn | 0.264 ± 0.04d | 1.00 ± 0.01c | 1.71 ± 0.06b | 2.39 ± 0.3a | 0.28 ± 0.001d | 0.34 ± 0.001d | 0.38 ± 0.001d |

| Zn | 0.861 ± 0.07a | 0.846 ± 0.01a | 0.91 ± 0.06a | 0.912 ± 0.03a | 0.84 ± 0.001a | 0.86 ± 0.001a | 0.85 ± 0.001a |

| Cu | 0.006 ± 0.00d | 0.050 ± 0.001c | 0.09 ± 0.00b | 0.143 ± 0.001a | 0.006 ± 0.00d | 0.006 ± 0.00d | 0.006 ± 0.001d |

| Se | 0.009 ± 0.00a | 0.012 ± 0.004a | 0.01 ± 0.00a | 0.01 ± 0.00a | 0.009 ± 0.00a | 0.009 ± 0.00a | 0.009 ± 0.001a |

| Cr | 0.00 ± 0.00 | 0.002 ± 0.00 | 0.01 ± 0.00 | 0.005 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Cd | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Sr | 0.00 ± 0.00d | 0.00 ± 0.00d | 0.00 ± 0.00d | 0.00 ± 0.00d | 0.02 ± 0.00c | 0.04 ± 0.00b | 0.08 ± 0.00a |

The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each column. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

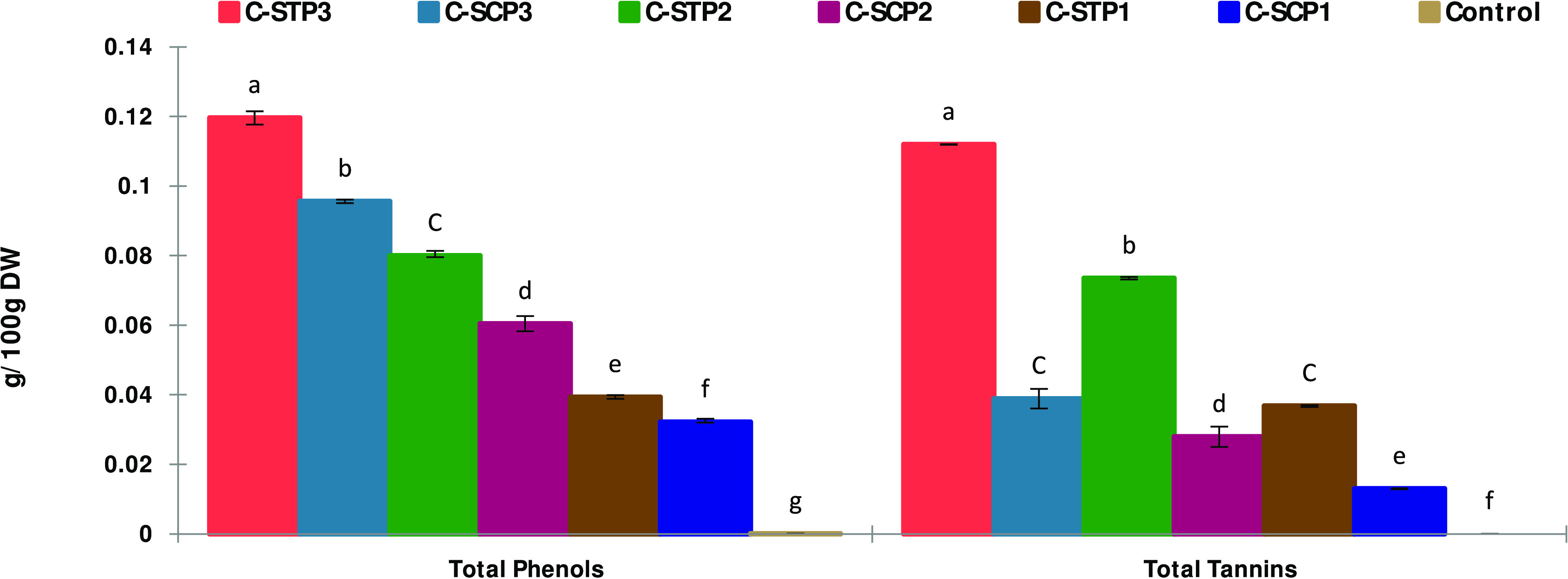

Total Secondary Metabolites

In baked goods, samples of cakes supplemented with 1, 2, and 3% spent tea and coffee powder showed an increment in the total phenols and total tannin content compared to the control cakes. The levels of total phenols and total tannins were greater in samples fortified with STP. The highest concentrations of phenols (0.12 and 0.10 g/100 g DW) and tannins (0.11 and 0.04 g/100 g DW) were detected in cakes fortified with 3% spent tea and coffee powder, respectively (Figure 6).

Figure 6.

Secondary metabolites of cake samples. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Our results are comparable to those of Koh et al.,60 who found that the tannin level of all the cookies made with spent tea powder was much higher than that of the control cookies. The high tannin content of the spent tea powder may be blamed for this. Due to the oxidation process used in their manufacture, which causes organic matter to break down and release tannins, spent tea powder had greater tannin content.61 The tannin concentrations of the cookie samples produced by the addition of spent coffee and tea powders were noticeably low in the current study. The heat breakdown of tannin during baking may be to blame for this.62 According to the findings, all of the cookies’ tannin concentration was within the allowed level for their antinutritional effect when consumed by humans.60

Spent coffee powder had a total phenolic content that was 23.5 times higher than wheat flour.63 In addition, the spent coffee powder had the highest total phenolic content. All the bread and bakery products fortified with spent coffee powder had higher total phenolic content as compared with 100% wheat-based bread.10,58 Phenolic substances are essential for maintaining human health.28

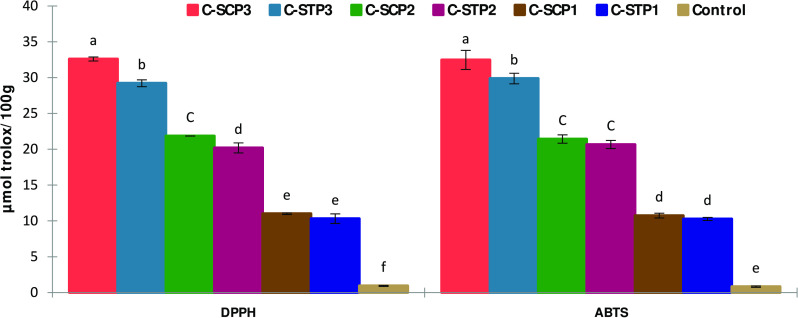

Antioxidant Activity

The Trolox equivalent antioxidant capacity of cake samples was tested by using the DPPH and ABTS assays (Figure 7). Furthermore, all cake samples showed a significant increase in DPPH and ABTS activity compared to control cakes. The higher concentrations of ABTS (32.5 and 29.9 mol Trolox/100 g DW) and DPPH (32.6 and 29.2 mol Trolox/100 g DW) were found in cakes fortified with 3% spent coffee and tea powders, respectively.

Figure 7.

Antioxidant activity of cake samples compared to standard antioxidants expressed in μmol Trolox/100 g. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Previous studies attributed the antioxidant capacities of coffee and tea to their phenolic contents.7,13,64 Our findings indicate that the residual phenolic compounds in spent tea or coffee could survive the heat treatment, thus exhibiting antiradical activity in cake samples fortified with STP or SCP. Previous reports showed similarities with our findings, where various bakery goods fortified with raw tea or coffee powders, their extracts, or their spent forms presented higher antioxidant activities compared to the controls.29,57,63−65

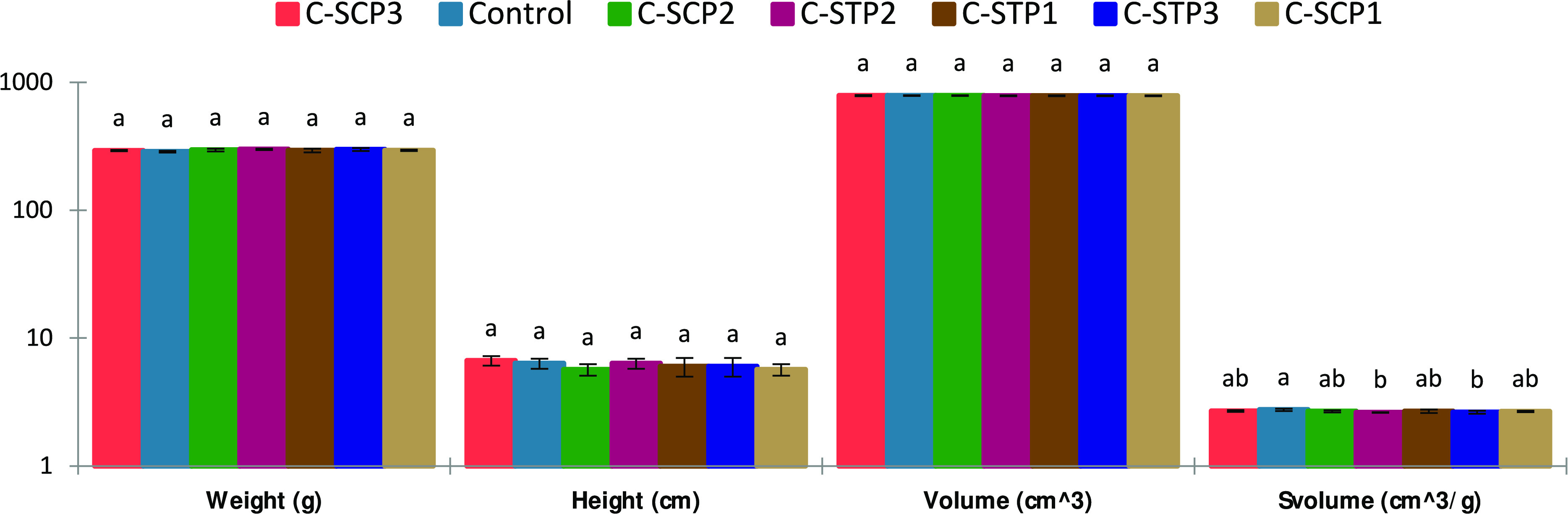

Physical Analysis

The physical features of the fortified cake samples with varying spent tea and coffee powder concentrations (1, 2, and 3%) are shown in Figure 8. The data show that there are nonsignificant effects between all samples and control cakes in weight (g), height (cm), volume (cm3), and specific volume (cm3/g) except for 2 and 3% spent tea powder, which showed a significant decrease in the specific volume (cm3/g).

Figure 8.

Physical properties of cake samples fortified with spent tea and coffee powder. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Our results are similar to those of Mashkour et al.,65 who found that while the volume of all sponge cakes fortified with green tea powder significantly decreased, there were no significant differences between any of the examined samples for weight. Gas is created, and the vapor pressure is increased during baking. The gluten network holds gas during the rising and heating stages. As a result, the gluten matrix responsible for retaining gas was weakened when green tea powder was used in place of flour in a cake, which has an impact on the volume.66 Additionally, there was no discernible difference in sample weight between the cakes fortified with spent tea and coffee powder. Therefore, the volume of these cakes was mostly responsible for the increase in hardness.57 In addition, there are no significant differences in weight and volume in bread fortified with spent coffee ground.67

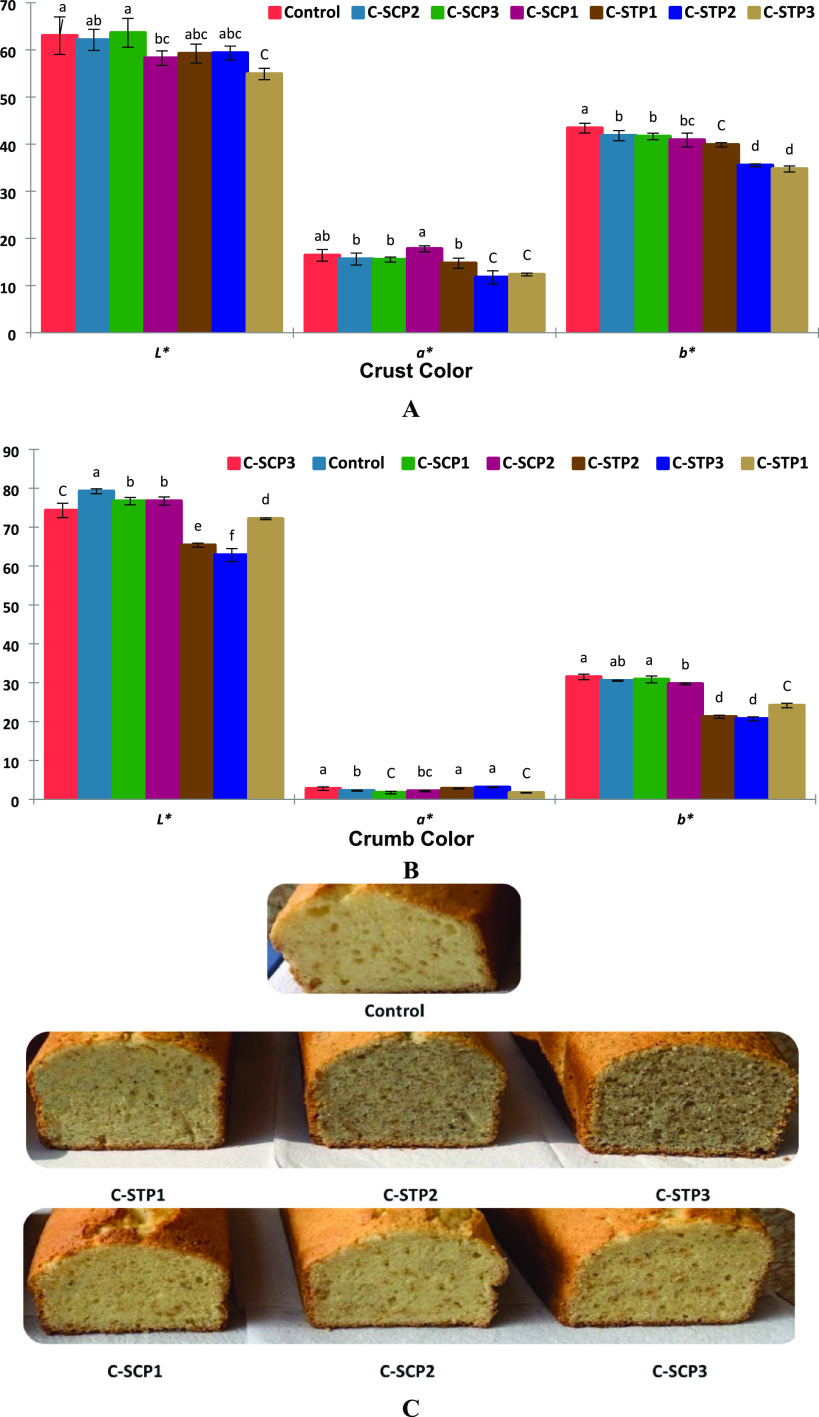

Another crucial aspect of a product’s quality is its color, which has an impact on the overall acceptability of cookies by consumers. Our findings demonstrated that apart from cakes fortified with 1% spent coffee powder and 3% spent tea powder, all samples significantly decreased the crust’s brightness (L*) compared to control cakes (Figure 9A–C). However, all cake samples, except for those fortified with 2 and 3% STP, did not significantly differ in their levels of redness (a*). All cake samples displayed a considerable reduction in yellowness (b*) when compared to that of control cakes (Figure 9A). Additionally, compared to control cakes, the crumb color’s brightness (L*) dramatically decreased in all cake samples. However, all cake samples, except those prepared by adding 1% spent tea and coffee powder, showed a substantial rise in redness (a*) compared to that of control cakes. In terms of yellowness (b*), cake samples fortified with 1, 2, and 3% spent coffee powder showed no significant difference, while cake samples fortified with 1, 2, and 3% spent tea powder exhibited a substantial reduction compared with control cakes (Figure 9B).

Figure 9.

Crust color (A), crumb color (B), and baked control and fortified cake samples. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively. Lightness (L*), redness (a*), and yellowness (b*).

These findings concur with Ali et al.,56 who discovered that adding spent coffee grounds to wheat flour at levels 2, 4, and 6% lowered the L* and b* values but raised the a* value in contrast to control biscuits. Because there was less light dispersion, the brightness (L*) decreased as the concentration of dark spent coffee grounds increased. It is generally known that an increase in a* coincides with an increase in redness at the start of the Maillard reaction, a nonenzymatic browning process.26 This is because the brown color is too dark to be seen, related to the rise of a* value and the reduction of b* value.68 Additionally, the L*, b*, and a* values of the spent tea powder-infused cookies were much lower than those of the control cookies, showing that the inclusion of spent tea powder gave the cookies a darker hue.60 These might be related to the original color of spent tea powder due to spent tea powder containing high amounts of phenols, making it darker in color than wheat flour. Tea leaves go through an enzymatic oxidation process that is catalyzed by polyphenol oxidase during the making of tea. Fresh tea leaves initially contain colorless catechins that, through oxidation, turn into theaflavins and thearubigins with a reddish-brown coloring. Eventually, the tea leaves take on a dark-brown hue.69 The oxidation reaction that tea pigments and polyphenol compounds underwent during baking, along with the participation of sucrose in the caramelization process, may be responsible for the color shift of baked cakes.57

Evaluation of Shelf Life

Sensory Analysis

Control and supplemented cake samples were evaluated for their appearance, crust and crumb color, texture, taste, odor, and overall impression during different storage periods (0, 7, and 14 days) (Table 6). The data showed that all sensory analysis in control cake and cake fortified with spent coffee and tea powders decreased significantly with increasing storage period. Moreover, all samples fortified with 1, 2, and 3% of spent tea powder showed a significant decrease in all sensory analyses compared to the control cake during the 0-day storage period. In addition, crumb color, texture, and overall quality significantly decreased in cakes fortified with 3% spent coffee powder compared to control cake in a 0-day storage period. Moreover, cakes fortified with 3% spent tea and coffee powders showed a significant decrease in crust color and overall compared to the control cake during the storage period of 7 days. In addition, the crust and crumb of the cakes prepared with the addition of 3% spent tea powder decreased significantly compared to the control cake. Generally, all samples had an insignificant effect on odor except 3% spent tea powder, which showed a significant decrease compared to the control cakes.

Table 6. Sensory Evaluation of Sponge Cake Fortified with Different Levels of Spent Coffee or Tea during Different Storage Periodsa.

| time | sample | appearance | crust color | crumb color | texture | taste | odor | overall |

|---|---|---|---|---|---|---|---|---|

| day 0 | control | 9.7 ± 0.5a | 9.4 ± 0.5a | 9.3 ± 0.6a | 8.9 ± 0.7a | 8.9 ± 0.7a | 9.0 ± 0.8a | 9.2 ± 0.7a |

| C–STP1 | 8.7 ± 0.6b,c | 8.1 ± 0.8c,d | 8.2 ± 0.9c,d | 7.5 ± 1.2c,d | 7.6 ± 0.9b–d | 8.4 ± 0.1a,b | 8.0 ± 0.9c–e | |

| C–STP2 | 8.3 ± 0.6c,d | 8.5 ± 0.9b,c | 8.5 ± 0.5b,c | 7.9 ± 0.7b,c | 7.8 ± 1.0b,c | 8.7 ± 0.9a | 8.2 ± 1.0b–d | |

| C–STP3 | 8.2 ± 1.0c,d | 8.1 ± 0.8c–e | 8.1 ± 1.0c–e | 6.8 ± 1.1d–g | 7.4 ± 1.1c,d | 6.9 ± 1.1d–g | 7.0 ± 0.6g–i | |

| C–SCP1 | 9.3 ± 0.9a,b | 9.3 ± 0.9a | 9.1 ± 0.7a,b | 8.5 ± 0.7a,b | 8.9 ± 0.7a | 8.8 ± 0.7a | 8.8 ± 0.4a,b | |

| C–SCP2 | 9.2 ± 0.7a,b | 9.2 ± 0.6a | 9.4 ± 0.5a | 8.7 ± 1.3a,b | 8.8 ± 0.7a | 8.7 ± 0.9a | 8.8 ± 0.7a,b | |

| C–SCP3 | 9.1 ± 0.8a,b | 8.9 ± 0.7a,b | 8.6 ± 0.5b,c | 8.0 ± 1.5b,c | 8.3 ± 0.6a,b | 8.3 ± 0.6a,b | 8.5 ± 0.5b,c | |

| day 7 | control | 7.4 ± 0.9e–h | 7.8 ± 0.6d–f | 7.6 ± 0.8d–g | 7.5 ± 0.7c,d | 7.3 ± 0.6c,d | 7.5 ± 0.8c,d | 7.7 ± 0.5d–f |

| C–STP1 | 7.4 ± 0.9e–h | 7.2 ± 0.6f,g | 7.4 ± 0.8e–g | 6.8 ± 0.6d–g | 6.9 ± 0.7d–g | 7.3 ± 0.6c–f | 7.3 ± 0.6f–h | |

| C–STP2 | 7.1 ± 0.7f–i | 7.4 ± 0.5f,g | 7.5 ± 0.5d–g | 6.9 ± 0.7d–g | 7.0 ± 0.6d–f | 7.9 ± 0.5b,c | 7.6 ± 0.7d–g | |

| C–STP3 | 6.9 ± 0.9g–j | 7.0 ± 0.6g,h | 7.5 ± 0.5d–g | 6.4 ± 0.9e–h | 6.9 ± 0.9d–g | 6.8 ± 0.6d–g | 6.6 ± 0.5i–k | |

| C–SCP1 | 8.0 ± 0.6c–e | 7.9 ± 0.7c–f | 7.8 ± 0.4d–f | 7.3 ± 0.6c,d | 7.8 ± 0.7b,c | 7.5 ± 0.5c,d | 7.5 ± 0.5e–h | |

| C–SCP2 | 7.7 ± 0.5d–f | 7.8 ± 0.6d–f | 7.6 ± 0.5d–g | 7.3 ± 0.9c–e | 7.5 ± 0.5c,d | 7.7 ± 0.6b,c | 7.6 ± 0.5d–g | |

| C–SCP3 | 7.6 ± 0.5d–g | 7.4 ± 0.7d–g | 7.2 ± 0.7f,g | 7.1 ± 0.8c–f | 7.2 ± 0.6c–e | 7.4 ± 0.5c–e | 6.9 ± 0.5h–j | |

| day 14 | control | 6.1 ± 0.5k,l | 6.2 ± 0.4i | 6.2 ± 0.7i | 6.3 ± 0.6f–h | 6.1 ± 0.7h | 6.2 ± 0.6g,h | 5.9 ± 0.7k,l |

| C–STP1 | 6.3 ± 0.8j–l | 6.3 ± 0.6i | 6.1 ± 0.3i | 6 ± 0.4g,h | 6.2 ± 0.6g,h | 6.3 ± 0.6g,h | 5.9 ± 0.9l | |

| C–STP2 | 6.4 ± 0.7i–l | 7.4 ± 0.5e–g | 6.9 ± 0.9g,h | 6.1 ± 0.7g,h | 6.2 ± 0.4g,h | 6.4 ± 0.8g,h | 6.2 ± 0.7k,l | |

| C–STP3 | 5.9 ± 0.7l | 7.0 ± 0.6g,h | 6.9 ± 0.9g,h | 5.6 ± 0.5h | 6.0 ± 0.6h | 5.7 ± 0.6h | 5.8 ± 0.4l | |

| C–SCP1 | 6.6 ± 0.8i–l | 6.4 ± 0.5h,i | 6.3 ± 0.6h,i | 6.1 ± 0.5g,h | 6.5 ± 0.8e–h | 6.3 ± 0.5g,h | 6.2 ± 0.6k,l | |

| C–SCP2 | 6.7 ± 0.6h–k | 6.4 ± 0.7h,i | 6.1 ± 0.5i | 6.2 ± 0.7f–h | 6.4 ± 0.7f–h | 6.6 ± 0.5f,g | 6.3 ± 0.6j–l | |

| C–SCP3 | 6.3 ± 0.6j–l | 6.2 ± 0.6i | 5.8 ± 0.6i | 6.0 ± 0.6g,h | 6.1 ± 0.6h | 6.7 ± 0.8e–g | 6.0 ± 0.6k,l |

The data is represented as the mean ± SD of 10 replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each column. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Our results are similar to the results of Daniel,58 who found that there were noticeable color changes between the control and bread enriched with spent coffee grounds. The color acceptability of the bread declined when the amount of spent coffee ground was increased; this was likely because of the spent coffee ground’s dark coloring. The aroma and texture of white bread and bread with 10, 8, and 6% spent coffee ground incorporations were similar. Most of the volatile aromatic chemicals in coffee are lost or removed during the brewing process’s aqua phase, lowering the aromatics level in the spent coffee grounds. This might not result in any discernible aroma differences. Additionally, the texture of the biscuits with the additions appear to be substantially identical to the control without any discernible variations, which may be due to the stronger emulsifying activity and stability of spent coffee grounds, as previously reported by Ali et al.56 and Ballesteros et al.9 However, the overall acceptance of the investigated biscuits revealed no significant differences, making spent coffee grounds a functional component with considerable potential to be employed in biscuit products.56 Additionally, there were no significant changes between the control and sponge cakes fortified with 10 and 20% green tea powder in terms of the colors of the crust and crumb, sweetness, flavor, texture, and overall like scores.57

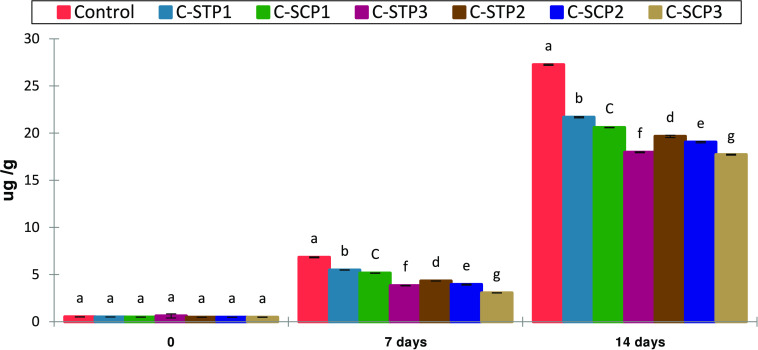

Thiobarbituric Acid Reactive Substances (TBARS)

The data in Figure 10 demonstrate that TBARS has significantly increased in both the control cakes and cakes fortified with various concentrations of 1, 2, and 3% of spent coffee and tea powders with increasing storage period from 0 to 14 days. Additionally, compared to the control cakes, the addition of various concentrations of SCP and STP resulted in a considerable drop in TBARS. Cakes fortified with 3% spent coffee powder showed the greatest decrease in TBARS over the course of the various storage times.

Figure 10.

Levels of TBARS in cakes fortified with spent coffee and tea powder over 14 days of storage. The data is represented as the mean ± SD of three replicates. According to Duncan’s test at p ≤ 0.05, the different letters represent the significance inside each bar. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

These results are compatible with those of Kozłowska et al.,70 who found that the durability of the fat increased with the length of the induction time. Compared to the control sample, the lipid fraction’s stability was increased in sponge fat cake fortified with 1% green tea extract. Tea catechins are capable of neutralizing free radicals and chelating metal ions. They stop the free radical chain reaction during lipid peroxidation by trapping hydroxyl radicals and superoxide anions.71

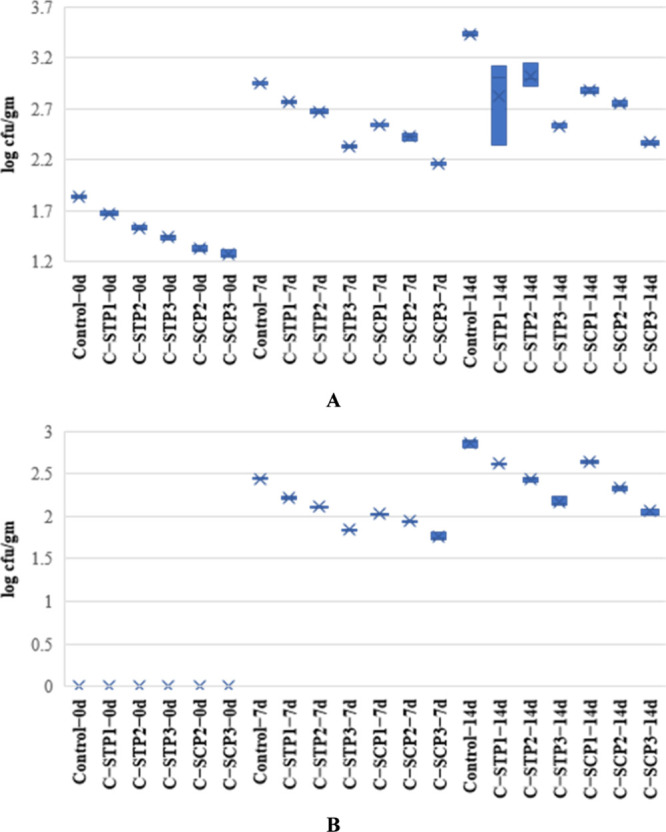

Microbiological Analysis

To guarantee that the cake samples were safe for human consumption, microbiological testing was done. The data in Figures 11A,B and Table S1 show that the total bacterial account, total mold, and yeast increased significantly in control cakes and cakes fortified with spent coffee and tea powders during storage for 7 and 14 days compared to the 0-day storage. Moreover, cakes fortified with different concentrations of SCP and STP showed a significant decrease in the total bacterial account, total mold, and yeast compared to control cake during each storage period.

Figure 11.

Total bacterial count (A) and total mold and yeast count (B) per log cfu/g and in sponge cake fortified with different levels of spent coffee or tea during different storage periods. The data is represented as the mean ± SD of three replicates. C-SCP1, C-SCP2, and C-SCP3: cakes with the addition of 1, 2, and 3% spent coffee powder, respectively; C-STP1, C-STP2, and C-STP3: cakes with the addition of 1, 2, and 3% spent tea powder, respectively.

Nevertheless, it should be noted that some microbes were found because the cakes were not made and stored in completely sterile settings. The primary ingredient in traditional cake and bakery making, flour is frequently tainted with germs from cereal grains.72 In addition to grain contamination, other factors that affect raw material microbial colonization include the state of the milling equipment, packing, and storage facilities. They can form when the flour moisture content rises above 15%, and as a result, the quality of the gluten degrades, changing its organoleptic qualities, increasing its acidity, and losing its baking properties. Flour contains a variety of microflora in addition to molds.40 In addition, the inclusion of spent coffee grounds in the formulations of the biscuits and spent tea grounds in the formation of cookies did not increase the microbial count, indicating that the food item has good microbiological quality.60

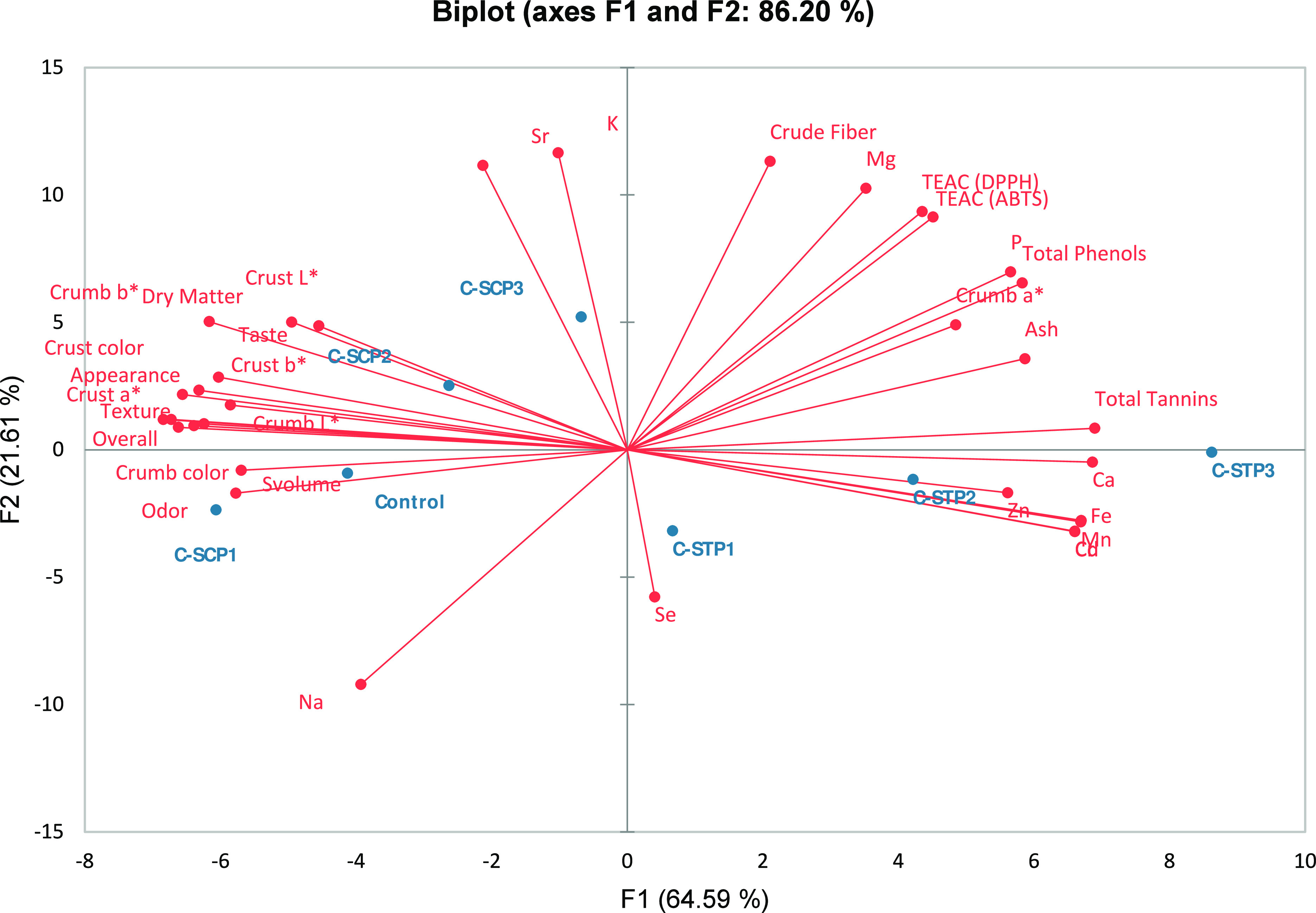

Overall Evaluation of Cake Samples

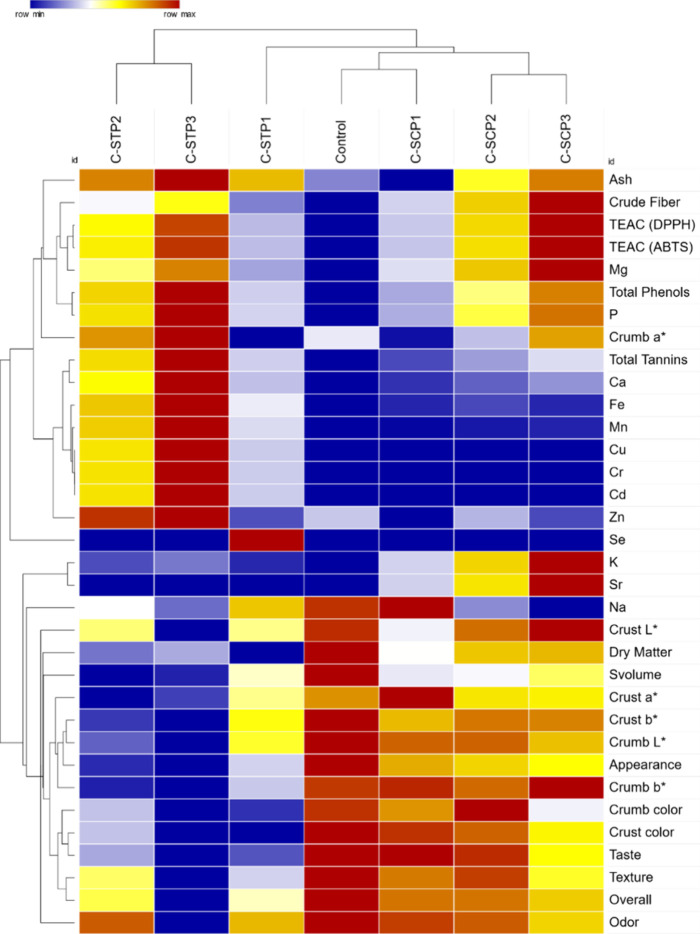

The overall evaluation of the fortified cake samples was established using the heatmap-based hierarchical test (Figure 12). The test indicated that samples and their variables were clustered into two groups. The control sample along with all the coffee-fortified samples (cake with 1, 2, and 3% coffee powder) and cake with 1% spent tea powder are clustered together, while cake with 2 and 3% spent tea powder are clustered in a second group.

Figure 12.

Heatmap-based hierarchical test of control and fortified cake samples with tea or coffee. The intensities of the colors indicated the rates of the measured variables from blue (the lowest value) to dark red (the highest value).

From the first cluster, and based on the measured variables, the control sample is differentiated by the highest rates of crust L* and b* and crumb L* colors, two sensory attributes (appearance and overall), dry matter, and specific volume. On the other hand, it possessed the lowest concentrations of crude fiber, total phenols, total tannins, the elements P and Ca, and the lowest antioxidant capacity. Furthermore, cake with 1% spent coffee powder is differentiated by the lowest ash and Zn with the highest crust a*. In contrast, cake with 1% spent tea powder is differentiated by the highest Se concentration and the lowest DM and crumb a* level. Finally, cake with 3% spent tea powder is differentiated by the lowest odor, overall, texture, and Crust L values while having the highest total phenol, total tannins, crumb b, and the elements P, Ca, Fe, Mn, Cu, Cr, and Cd. As for the second cluster, cake with 3% coffee powder is differentiated by the highest contents of crude fiber; the elements Mg, K, and Sr; the color parameters crust L* and crumb b*; and the highest antioxidant activity. On the other hand, it possessed the lowest contents of the elements Fe, Mn, Cu, Cr, Cd, Se, and Na.

As for the fortified cake samples, principal components 1 and 2 explained 86.2% of the variation between samples (Figure 13), where PC1 differentiates samples based on their fortification type (tea vs coffee). Based on the measured variables, the proximate components (crude fiber and ash), the phytochemicals (total phenols and tannins), and elements (Ca, Mg, P, Zn, Fe, Mn, Se, and Cu) showed a higher tendency toward samples that were fortified with spent tea. On the other hand, the coffee-fortified cake samples showed comparable sensory attributes to the control samples and higher color rates (crust a*, L*, and b* along with crumb L* and b*), and higher concentrations from dry matter and the elements Sr, K, and Na.

Figure 13.

PCA biplot of control and fortified cake samples with tea or coffee.

Contrary to the TEAC results of free tea and coffee powders, samples fortified with spent tea showed antioxidant activities (both by DPPH and ABTS) higher than those of the coffee-fortified cake samples. Previous studies indicated that the antioxidant activity of different tea samples is significantly correlated with their total phenolic content and their concentration from elements including Fe, Cu, and Mg within certain limits, and they attributed that to the interaction between these elements with the polyphenolic content in tea, which resulted in a mutual increase in their activity.4,54 In another study focused on the relationship between antioxidant activity and the elemental composition of green coffee, the researchers realized an increase in the antioxidant activities of the brews that have the highest Mn concentrations.52 Furthermore, including metallic ions Mg, Cl, Zn, and K helped reserve the color of grape puree and peas.73,74 To test this theory, we performed a matrix Pearson-based correlation between the elemental and phytochemical contents of raw and spent tea and coffee powders and their respective cake samples and their measured TEAC values, as assessed by DPPH and ABTS (Table 7). The results indicated a positive correlation between the TEAC values, the total phenolic contents, and the elements Mg and P (p < 0.05). Furthermore, both elements were correlated with the total phenolic contents (p < 0.05). However, the excess concentration of these elements might be attributed to reducing the bioavailability of phenolic compounds due to the formation of metal-phenolic complexes, while free metals could act as prooxidants.75

Table 7. Pearson Correlation between TEAC Values and the Total Phenolic and Elemental Contentsa.

| DPPH | ABTS | Mg | P | |

|---|---|---|---|---|

| DPPH | 0.999 | 0.988 | 0.961 | |

| ABTS | 0.999 | 0.983 | 0.969 | |

| total phenols | 0.948 | 0.957 | 0.892 | 0.998 |

Based on these results, we could attribute the increase in antioxidant activities of the tea-fortified cake samples compared with the coffee-fortified cake samples, contrary to their pure powder, to the following: (I) having higher total phenolic contents, (II) having a richer phenolic profile (11 identified compounds) that might have a synergistic interaction between them, and (III) having higher Mg and P contents, and altogether boasted the ability of the phenolic content to survive the heat treatment and deliver the measured residual antioxidant capacities.

Conclusion and Future Perspectives

In conclusion, evaluating spent coffee and tea powders as bioactive supplements for sponge cake showed promising results. Both spent tea and coffee powders were rich sources of bioactive compounds, including polyphenols, and retained high levels of important dietary elements. By incorporation of spent tea and coffee powders into the sponge cake blend, the nutritional value of the cake can be enhanced, providing additional health benefits to consumers. The presence of bioactive compounds in the powders also contributes to the potential antioxidant activity and reduction of peroxide production and delays microbial growth during storage. Finally, further research could explore the potential applications of leftover coffee and tea powders in other food products such as bread or snacks. Additionally, investigating the economic feasibility of large-scale utilization of these waste products would be beneficial in determining their viability for commercial production.

Ethical Statement

Our study was carried out in consideration of both the Declaration of Helsinki and work safety protocols established at King Faisal University (approval number ETHICS834). Written consent was obtained from all sensory panelists who participated in our study.

Acknowledgments

We would like to express our gratitude to the Deputyship for Research and Innovation, Ministry of Education in Saudi Arabia for generously funding this research project. We further extend our gratitude to the expert sensory panel of KAU.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acsomega.3c03747.

(Figure S1) Chromatogram of polyphenolic compounds of tea powder extract and spent tea powder extract; (Figure S2) chromatogram of polyphenolic compounds of coffee powder extract and spent coffee powder extract; (Table S1) total bacterial and mold and yeast count per log cfu/g in sponge cake fortified with different levels of spent coffee or tea during different storage periods (PDF)

Author Contributions

Conceptualization, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; methodology, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; software, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; formal analysis, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; investigation, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; resources, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; data curation, S A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; writing—original draft preparation, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; writing—review and editing, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; visualization, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; supervision, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; project administration, A.R.A.; N.K.A.; K.M.A.R.; H.I.M.; M.A.A.M.; and H.O.E.; funding acquisition, A.R.A. All authors have read and agreed to the published version of the manuscript.

This research work was supported and funded by the Deputyship for Research and Innovation, Ministry of Education in Saudi Arabia (Project number INST 121).

The authors declare no competing financial interest.

Supplementary Material

References

- Mir-Cerdà A.; Nuñez O.; Granados M.; Sentellas S.; Saurina J. An Overview of the Extraction and Characterization of Bioactive Phenolic Compounds from Agri-Food Waste within the Framework of Circular bioeconomy. TrAC, Trends Anal. Chem. 2023, 161, 116994. 10.1016/j.trac.2023.116994. [DOI] [Google Scholar]

- Sermyagina E.; Mendoza Martinez C. L.; Nikku M.; Vakkilainen E. Spent Coffee Grounds and Tea Leaf Residues: Characterization, Evaluation of Thermal Reactivity and Recovery of High-Value Compounds. Biomass Bioenergy 2021, 150, 106141. 10.1016/j.biombioe.2021.106141. [DOI] [Google Scholar]

- Wang S.; Zeng T.; Zhao S.; Zhu Y.; Feng C.; Zhan J.; Li S.; Ho C.-T.; Gosslau A. Multifunctional Health-Promoting Effects of Oolong Tea and Its Products. Food Sci. Hum. Wellness 2022, 11 (3), 512–523. 10.1016/j.fshw.2021.12.009. [DOI] [Google Scholar]

- Klepacka J.; Tońska E.; Rafałowski R.; Czarnowska-Kujawska M.; Opara B. Tea as a Source of Biologically Active Compounds in the Human Diet. Molecules 2021, 26 (5), 1487. 10.3390/molecules26051487. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang L.; Ho C.; Zhou J.; Santos J. S.; Armstrong L.; Granato D. Chemistry and Biological Activities of Processed Camellia Sinensis Teas: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2019, 18 (5), 1474–1495. 10.1111/1541-4337.12479. [DOI] [PubMed] [Google Scholar]

- Borota D.; Murray E.; Keceli G.; Chang A.; Watabe J. M.; Ly M.; Toscano J. P.; Yassa M. A. Post-Study Caffeine Administration Enhances Memory Consolidation in Humans. Nat. Neurosci. 2014, 17 (2), 201–203. 10.1038/nn.3623. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alamri E.; Rozan M.; Bayomy H. A Study of Chemical Composition, Antioxidants, and Volatile Compounds in Roasted Arabic Coffee. Saudi J. Biol. Sci. 2022, 29 (5), 3133–3139. 10.1016/j.sjbs.2022.03.025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Akbayrak S.; Özçifçi Z.; Tabak A. Activated Carbon Derived from Tea Waste: A Promising Supporting Material for Metal Nanoparticles Used as Catalysts in Hydrolysis of Ammonia Borane. Biomass Bioenergy 2020, 138, 105589. 10.1016/j.biombioe.2020.105589. [DOI] [Google Scholar]

- Ballesteros L. F.; Teixeira J. A.; Mussatto S. I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. 10.1007/s11947-014-1349-z. [DOI] [Google Scholar]

- Murthy P. S.; Madhava Naidu M. Sustainable Management of Coffee Industry By-Products and Value Addition—A Review. Resour., Conserv. Recycl. 2012, 66, 45–58. 10.1016/j.resconrec.2012.06.005. [DOI] [Google Scholar]

- Martinez-Saez N.; García A. T.; Pérez I. D.; Rebollo-Hernanz M.; Mesías M.; Morales F. J.; Martín-Cabrejas M. A.; Del Castillo M. D. Use of Spent Coffee Grounds as Food Ingredient in Bakery Products. Food Chem. 2017, 216, 114–122. 10.1016/j.foodchem.2016.07.173. [DOI] [PubMed] [Google Scholar]

- Mukherjee A.; Okolie J. A.; Niu C.; Dalai A. K. Experimental and Modeling Studies of Torrefaction of Spent Coffee Grounds and Coffee Husk: Effects on Surface Chemistry and Carbon Dioxide Capture Performance. ACS Omega 2022, 7 (1), 638–653. 10.1021/acsomega.1c05270. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Abdeltaif S.; SirElkhatim K.; Hassan A. Estimation of Phenolic and Flavonoid Compounds and Antioxidant Activity of Spent Coffee and Black Tea (Processing) Waste for Potential Recovery and Reuse in Sudan. Recycling 2018, 3 (2), 27. 10.3390/recycling3020027. [DOI] [Google Scholar]

- Iriondo-DeHond A.; del Pilar Salazar M.; Domènech L. G.; Montoya J. E. Z.; del Castillo M. D.; Campos-Vega R.; Oomah B. D. Coffee Proteins: Functional Food Ingredients with Molecular Effects for Sustainable Health. Mol. Mech. Funct. Food 2022, 382–403. 10.1002/9781119804055.ch11. [DOI] [Google Scholar]

- Lee W. h.; Choi S. R.; Kim J. G. Spent Coffee Grounds as Eco-Friendly Additives for Aluminum–Air Batteries. ACS Omega 2021, 6 (39), 25529–25538. 10.1021/acsomega.1c03533. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chand M.; Barthwal S.; Rawat A. S.; Khanuja M.; Rawat S. Enhancing Photocatalytic Efficiency of Spent Tea Leaf Powder on ZnIn2S4 Incorporation: Role of Surface Charge on Dye Degradation. ACS Omega 2023, 8, 17880–17890. 10.1021/acsomega.3c00955. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gora E. H.; Saldana S. G.; Casper L. M.; Coll Sijercic V.; Giza O. A.; Sanders R. L. Effect of Exhausted Coffee Ground Particle Size on Metal Ion Adsorption Rates and Capacities. ACS Omega 2022, 7 (43), 38600–38612. 10.1021/acsomega.2c04058. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bonilla-Hermosa V. A.; Duarte W. F.; Schwan R. F. Utilization of Coffee By-Products Obtained from Semi-Washed Process for Production of Value-Added Compounds. Bioresour. Technol. 2014, 166, 142–150. 10.1016/j.biortech.2014.05.031. [DOI] [PubMed] [Google Scholar]

- Atelge M. R.; Atabani A. E.; Abut S.; Kaya M.; Eskicioglu C.; Semaan G.; Lee C.; Yildiz Y. Ş.; Unalan S.; Mohanasundaram R.; Duman F.; Kumar G. Anaerobic Co-Digestion of Oil-Extracted Spent Coffee Grounds with Various Wastes: Experimental and Kinetic Modeling Studies. Bioresour. Technol. 2021, 322, 124470. 10.1016/j.biortech.2020.124470. [DOI] [PubMed] [Google Scholar]

- Gammoudi N.; Nagaz K.; Ferchichi A. Potential Use of Spent Coffee Grounds and Spent Tea Leaves Extracts in Priming Treatment to Promote In Vitro Early Growth of Salt-and Drought-Stressed Seedlings of Capsicum Annuum L. Waste Biomass Valorization 2021, 12, 3341–3353. 10.1007/s12649-020-01216-w. [DOI] [Google Scholar]

- Kondo M.; Hidaka M.; Hirano Y.; Kita K.; Jayanegara A.; Yokota H. Nutrient Digestibility, Fecal Output of Fractionated Proteins, and Ruminal Fermentation Parameters of Goats Fed a Diet Supplemented with Spent Green Tea and Black Tea Leaf Silage. Anim. Sci. J. 2022, 93 (1), e13681 10.1111/asj.13681. [DOI] [PubMed] [Google Scholar]

- Nguyen N. D. T.; Phan T. T. H.; Tran T. T. T.; Ton N. M. N.; Vo D. L. T.; Le V. V. M. Enzymatic Treatment of Spent Green Tea Leaves and Their Use in High-Fibre Cookie Production. Food Technol. Biotechnol. 2022, 60 (3), 396–405. 10.17113/ftb.60.03.22.7474. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Arı Akın P.; Tayfun K. E.; Tamer U.; Boyacı İ. H. Use of Tea Fibers as a Source of Dietary Fiber in Wheat Flour and Bread. Cereal Chem. 2021, 98 (5), 1049–1058. 10.1002/cche.10444. [DOI] [Google Scholar]

- Hussein A.; Ali H.; Bareh G.; Farouk A. Influence of Spent Coffee Ground as Fiber Source on Chemical, Rheological and Sensory Properties of Sponge Cake. Pak. J. Biol. Sci. 2019, 22 (6), 273–282. 10.3923/pjbs.2019.273.282. [DOI] [PubMed] [Google Scholar]

- Elkatry H. O.; Ahmed A. R.; El-Beltagi H. S.; Mohamed H. I.; Eshak N. S. Biological Activities of Grape Seed By-Products and Their Potential Use as Natural Sources of Food Additives in the Production of Balady Bread. Foods 2022, 11, 1948. 10.3390/foods11131948. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Elkatry H. O.; El-Beltagi H. S.; Ramadan K. M. A.; Ahmed A. R.; Mohamed H. I.; Al-Otaibi H. H.; Mahmoud M. A. A. The Chemical, Rheological, and Sensorial Characteristics of Arabic Bread Prepared from Wheat-Orange Sweet Potatoes Flour or Peel. Foods 2023, 12 (8), 1658. 10.3390/foods12081658. [DOI] [PMC free article] [PubMed] [Google Scholar]

- El-Beltagi H. S.; Mohamed H. I.; Abdelazeem A. S.; Youssef R.; Safwat G. GC-MS Analysis, Antioxidant, Antimicrobial and Anticancer Activities of Extracts from Ficus Sycomorus Fruits and Leaves. Not. Bot. Horti Agrobot. Cluj-Napoca 2018, 47 (2), 493–505. 10.15835/nbha47211405. [DOI] [Google Scholar]

- El-Beltagi H. S.; Ahmed A. R.; Mohamed H. I.; Al-Otaibi H. H.; Ramadan K. M. A.; Elkatry H. O. Utilization of Prickly Pear Peels Flour as a Natural Source of Minerals, Dietary Fiber and Antioxidants: Effect on Cakes Production. Agronomy 2023, 13, 439. 10.3390/agronomy13020439. [DOI] [Google Scholar]

- Bajerska O.; Mildner-Szkudlarz S.; Jeszka J.; Szwengiel A. Catechin Stability, Antioxidant Properties and Sensory Profiles of Rye Breads Fortified with Green Tea Extracts. J. Food Nutr. Res. 2010, 49 (2), 104–111. [Google Scholar]

- Azuan A. A.; Mohd Zin Z.; Hasmadi M.; Rusli N. D.; Zainol M. K. Physicochemical, Antioxidant and Sensory Characteristics of Cookies Supplemented with Different Levels of Spent Coffee Ground Extract. Food Res. 2020, 4 (4), 1181–1190. 10.26656/fr.2017.4(4).058. [DOI] [Google Scholar]

- Gomes W. P. C.; Pires J. A.; Teixeira N. N.; Bortoleto G. G.; Gutierrez E. M. R.; Melchert W. R. Effects of Green Coffee Bean Flour Fortification on the Chemical and Nutritional Properties of Gluten-Free Cake. J. Food Meas. Charact. 2022, 16 (5), 3451–3458. 10.1007/s11694-022-01469-0. [DOI] [Google Scholar]

- Meerasri J.; Sothornvit R. Novel Development of Coffee Oil Extracted from Spent Coffee Grounds as a Butter Substitute in Bakery Products. J. Food Process. Preserv. 2022, 46 (7), e16687 10.1111/jfpp.16687. [DOI] [Google Scholar]

- Ngan H.-L.; Ip S.-Y.; Wang M.; Zhou Q. Comparative Study of Sensory and Physicochemical Characteristics of Green-Tea-Fortified Cupcakes upon Air Frying and Oven Baking. Foods 2023, 12 (6), 1266. 10.3390/foods12061266. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zuorro A.; Lavecchia R. Adsorption of Pb (II) on Spent Leaves of Green and Black Tea. Am. J. Appl. Sci. 2010, 7 (2), 153. 10.3844/ajassp.2010.153.159. [DOI] [Google Scholar]

- Ahmed A. R. Influence of Chemical Properties of Wheat-Lupine Flour Blends on Cake Quality. Am. J. Food Sci. Technol. 2014, 2 (2), 67–75. 10.12691/ajfst-2-2-4. [DOI] [Google Scholar]

- Randez-Gil F.; Prieto J. A.; Murcia A.; Sanz P. Construction of Baker’s Yeast Strains That Secrete Aspergillus Oryzae Alpha-Amylase and Their Use in Bread Making. J. Cereal Sci. 1995, 21 (2), 185–193. 10.1016/0733-5210(95)90034-9. [DOI] [Google Scholar]

- Francis F. J.Colorimetry of Foods. In Physical Properties of Foods; Peleg M., Bagly E. B. Eds.; The AVI Publishing Company Inc.: Westort,Connecticut,USA, 1983; pp 105–123. [Google Scholar]

- Ijah U. J. J.; Auta H. S.; Aduloju M. O.; Aransiola S. A. Microbiological, Nutritional, and Sensory Quality of Bread Produced from Wheat and Potato Flour Blends. Int. J. Food Sci. 2014, 2014, 671701. 10.1155/2014/671701. [DOI] [PMC free article] [PubMed] [Google Scholar]

- AACC AACC Approved Methods of Analysis, 11th Ed. Method 54–21. Rheological Behavior of Flour by Farinograph: Constant Flour Weight Procedure. Cereals & Grains Association, St. Paul, MN, U.S.A; St. Paul. Minnesota, USA., 2002.

- Łopusiewicz Ł.; Kowalczewski P. Ł.; Baranowska H. M.; Masewicz Ł.; Amarowicz R.; Krupa-Kozak U. Effect of Flaxseed Oil Cake Extract on the Microbial Quality, Texture and Shelf Life of Gluten-Free Bread. Foods 2023, 12 (3), 595. 10.3390/foods12030595. [DOI] [PMC free article] [PubMed] [Google Scholar]

- A.O.A.C Association of Official Analytical Chemists. Official Methods of Analysis. AOAC International: Arlington; VA, USA, 2010. [Google Scholar]

- Marin B.; Chopin E. I. B.; Jupinet B.; Gauthier D. Comparison of Microwave-Assisted Digestion Procedures for Total Trace Element Content Determination in Calcareous Soils. Talanta 2008, 77 (1), 282–288. 10.1016/j.talanta.2008.06.023. [DOI] [PubMed] [Google Scholar]

- Goffman F. D.; Bergman C. J. Rice Kernel Phenolic Content and Its Relationship with antiradical Efficiency. J. Sci. Food Agric. 2004, 84 (10), 1235–1240. 10.1002/jsfa.1780. [DOI] [Google Scholar]

- Galvão M. A. M.; Arruda A. O. de; Bezerra I. C. F.; Ferreira M. R. A.; Soares L. A. L.. Evaluation of the Folin-Ciocalteu Method and Quantification of Total Tannins in Stem Barks and Pods from Libidibia Ferrea (Mart. Ex Tul) LP Queiroz. Braz. Arch. Biol. Technol. 2018, 61, 10.1590/1678-4324-2018170586 [DOI]

- Re R.; Pellegrini N.; Proteggente A.; Pannala A.; Yang M.; Rice-Evans C. Antioxidant Activity Applying an Improved ABTS Radical Cation Decolorization Assay. Free Radical Biol. Med. 1999, 26 (9–10), 1231–1237. 10.1016/S0891-5849(98)00315-3. [DOI] [PubMed] [Google Scholar]

- Vyncke W. Evaluation of the Direct Thiobarbituric Acid Extraction Method for Determining Oxidative Rancidity in Mackerel (Scomber Scombrus L.). Fette, Seifen, Anstrichm. 1975, 77 (6), 239–240. 10.1002/lipi.19750770610. [DOI] [Google Scholar]

- Mahmoud M. A. A.; Magdy M. Metabarcoding Profiling of Microbial Diversity Associated with Trout Fish Farming. Sci. Rep. 2021, 11 (1), 421. 10.1038/s41598-020-80236-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mahmoud M. A. A.; Magdy M.; Tybussek T.; Barth J.; Buettner A. Comparative Evaluation of Wild and Farmed Rainbow Trout Fish Based on Representative Chemosensory and Microbial Indicators of Their Habitats. J. Agric. Food Chem. 2023, 71, 2094. 10.1021/acs.jafc.2c07868. [DOI] [PubMed] [Google Scholar]

- Mussatto S. I.; Machado E. M. S.; Martins S.; Teixeira J. A. Production, Composition, and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol. 2011, 4, 661–672. 10.1007/s11947-011-0565-z. [DOI] [Google Scholar]

- Cruz R.; Cardoso M. M.; Fernandes L.; Oliveira M.; Mendes E.; Baptista P.; Morais S.; Casal S. Espresso Coffee Residues: A Valuable Source of Unextracted Compounds. J. Agric. Food Chem. 2012, 60 (32), 7777–7784. 10.1021/jf3018854. [DOI] [PubMed] [Google Scholar]

- Moldoveanu S. C.; Oden R. Antioxidant Character and Levels of polyphenols in Several Tea Samples. ACS Omega 2021, 6 (15), 9982–9988. 10.1021/acsomega.0c05818. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jeszka-Skowron M.; Stanisz E.; De Peña M. P. Relationship between Antioxidant Capacity, Chlorogenic Acids and Elemental Composition of Green Coffee. LWT 2016, 73, 243–250. 10.1016/j.lwt.2016.06.018. [DOI] [Google Scholar]

- Ramdani D.Evaluation of Tea and Spent Tea Leaves as Additives for Their Use in Ruminant Diets; Newcastle University, 2014. [Google Scholar]

- Dobrinas S.; Soceanu A.; Popescu V.; Carazeanu Popovici I.; Jitariu D. Relationship between Total Phenolic Content, Antioxidant Capacity, Fe and Cu Content from Tea Plant Samples at Different Brewing Times. Processes 2021, 9 (8), 1311. 10.3390/pr9081311. [DOI] [Google Scholar]

- Kiefl J.; Kohlenberg B.; Hartmann A.; Obst K.; Paetz S.; Krammer G.; Trautzsch S. Investigation on Key Molecules of Huanglongbing (HLB)-Induced Orange Juice Off-Flavor. J. Agric. Food Chem. 2018, 66 (10), 2370–2377. 10.1021/acs.jafc.7b00892. [DOI] [PubMed] [Google Scholar]

- Ali H. S.; Mansour A. F.; Kamil M. M.; Hussein A. M. S. Formulation of Nutraceutical Biscuits Based on Dried Spent Coffee Grounds. Int. J. Pharmacol. 2018, 14 (4), 584–594. 10.3923/ijp.2018.584.594. [DOI] [Google Scholar]

- Lu T.-M.; Lee C.-C.; Mau J.-L.; Lin S.-D. Quality and Antioxidant Property of Green Tea Sponge Cake. Food Chem. 2010, 119 (3), 1090–1095. 10.1016/j.foodchem.2009.08.015. [DOI] [Google Scholar]

- Daniel T.Use of Spent Coffee Ground (SCG) as Ingredient in Bread Formulation; Addis Ababa University: 2018. [Google Scholar]

- Timoshenkova I.; Moskvicheva E.; Fedinishina E.; Bernavskaya M.. Use of Green Tea for the Production of Sponge Cake. In E3S Web of Conferences; EDP Sciences: 2020; Vol. 161, p 1091. [Google Scholar]

- Koh W. Y.; Lim X. X.; Tan T. C.; Mamat H.; Kobun R.; Rasti B. Utilising Spent Tea Leaves Powder as Functional Ingredient to Enhance the Quality of Non-Gluten Shortbread Cookies. Foods 2023, 12 (7), 1557. 10.3390/foods12071557. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dhillon B.; Awasthi T.; Sodhi N. S.; Sogi D. S.; Jaiswal S. A Comparative Study to Investigate the Effects of Addition of Milk and Sugar on Total polyphenol, Flavonoid, Catechin and Tannin Contents of Green and Black Teas Consumed in India. J. Food Meas. Charact. 2021, 15 (5), 4652–4658. 10.1007/s11694-021-01036-z. [DOI] [Google Scholar]

- Sokač T.; Gunjević V.; Pušek A.; Tušek A. J.; Dujmić F.; Brnčić M.; Ganić K. K.; Jakovljević T.; Uher D.; Mitrić G. Comparison of Drying Methods and Their Effect on the Stability of Graševina Grape Pomace Biologically Active Compounds. Foods 2022, 11 (1), 112. 10.3390/foods11010112. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Trà T. T. T.; Yên V. T. N.; Thu N. T. A.; Nguyêt T. N. M.. Use of Wheat Flour and Spent Coffee Grounds in the Production of Cookies with High Fiber and Antioxidant Content: Effects of Spent Coffee Grounds Ratio on the Product Quality. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: 2021; Vol. 947, p 12044. [Google Scholar]

- Erskine E.; Gültekin Subaşı B.; Vahapoglu B.; Capanoglu E. Coffee phenolics and Their Interaction with Other Food phenolics: Antagonistic and Synergistic Effects. ACS Omega 2022, 7 (2), 1595–1601. 10.1021/acsomega.1c06085. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mashkour M.; Azari A.; Hashemi Shahraki M.; Raeisi M.; Ebrahimi M. Effect of Green Tea Powder on Physicochemical Properties and Glycemic Potential of Sponge Cake. J. Food Qual. 2022, 2022, 1065710. 10.1155/2022/1065710. [DOI] [Google Scholar]

- Kim J. H.; Lee H. J.; Lee H.-S.; Lim E.-J.; Imm J.-Y.; Suh H. J. Physical and Sensory Characteristics of Fibre-Enriched Sponge Cakes Made with Opuntia Humifusa. LWT 2012, 47 (2), 478–484. 10.1016/j.lwt.2012.02.011. [DOI] [Google Scholar]