Abstract

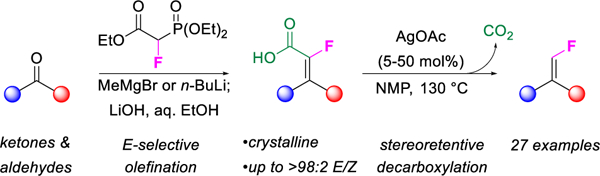

The synthesis of di- and trisubstituted vinyl fluorides with high isomeric purity remains a challenge for organic synthesis. While many methods exist to access these compounds, separation of the desired isomer from the minor isomer and/or starting materials often is difficult. Herein we report a practical method to access di- and trisubstituted vinyl fluorides via a selective Horner-Wadsworth-Emmons olefination/hydrolysis, which provides crystalline 2-fluoroacrylic acids in high (>98%) E-isomeric purity. A subsequent silver catalyzed stereoretentive decarboxylation provides the title substances with high isomeric purity and without the need for tedious chromatography to remove the minor isomer. The process was amenable to a variety of aldehydes and ketones and provided a diverse array of di- and trisubstituted vinyl fluorides. The sequence was applied to the synthesis of antibacterial and anti-inflammatory compounds.

Keywords: vinyl fluoride, olefination, decarboxylation

GRAPHICAL ABSTRACT

INTRODUCTION

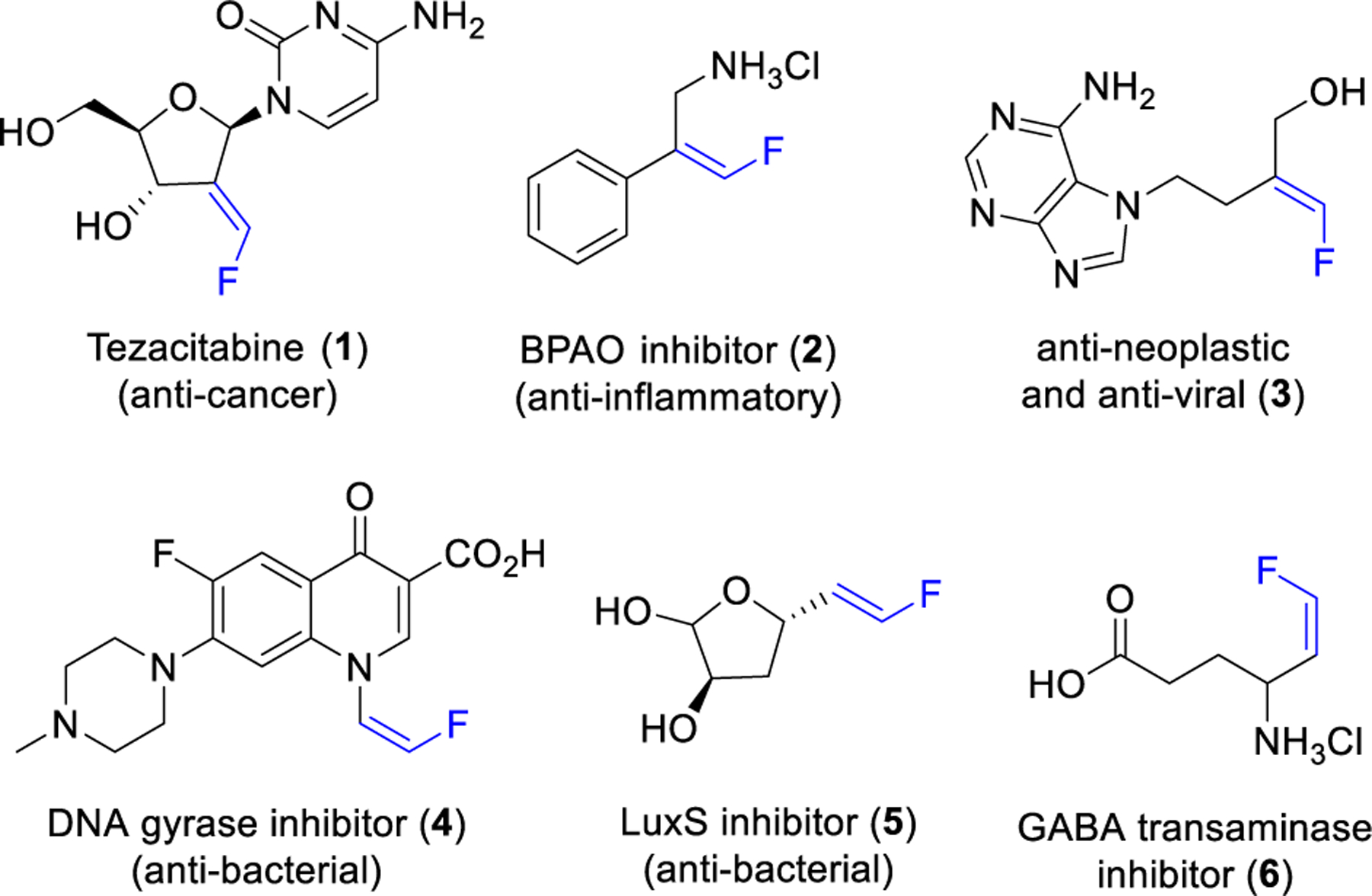

The incorporation of fluorine into organic molecules often results in advantageous modulation of physical properties.1 This has resulted in the growing presence of fluorine in pharmaceuticals,2 agrochemicals3 and organic materials.4 Among the plethora of fluorine containing functional groups, terminal monofluoroalkenes are of interest due to their applications in materials science, synthetic methodology and medicinal chemistry.5 Several biologically active compounds bearing trisubstituted (1-3) or disubstituted (4-6) terminal vinyl fluorides are shown in Figure 1.6

Figure 1.

Biologically active compounds containing terminal vinyl fluorides.

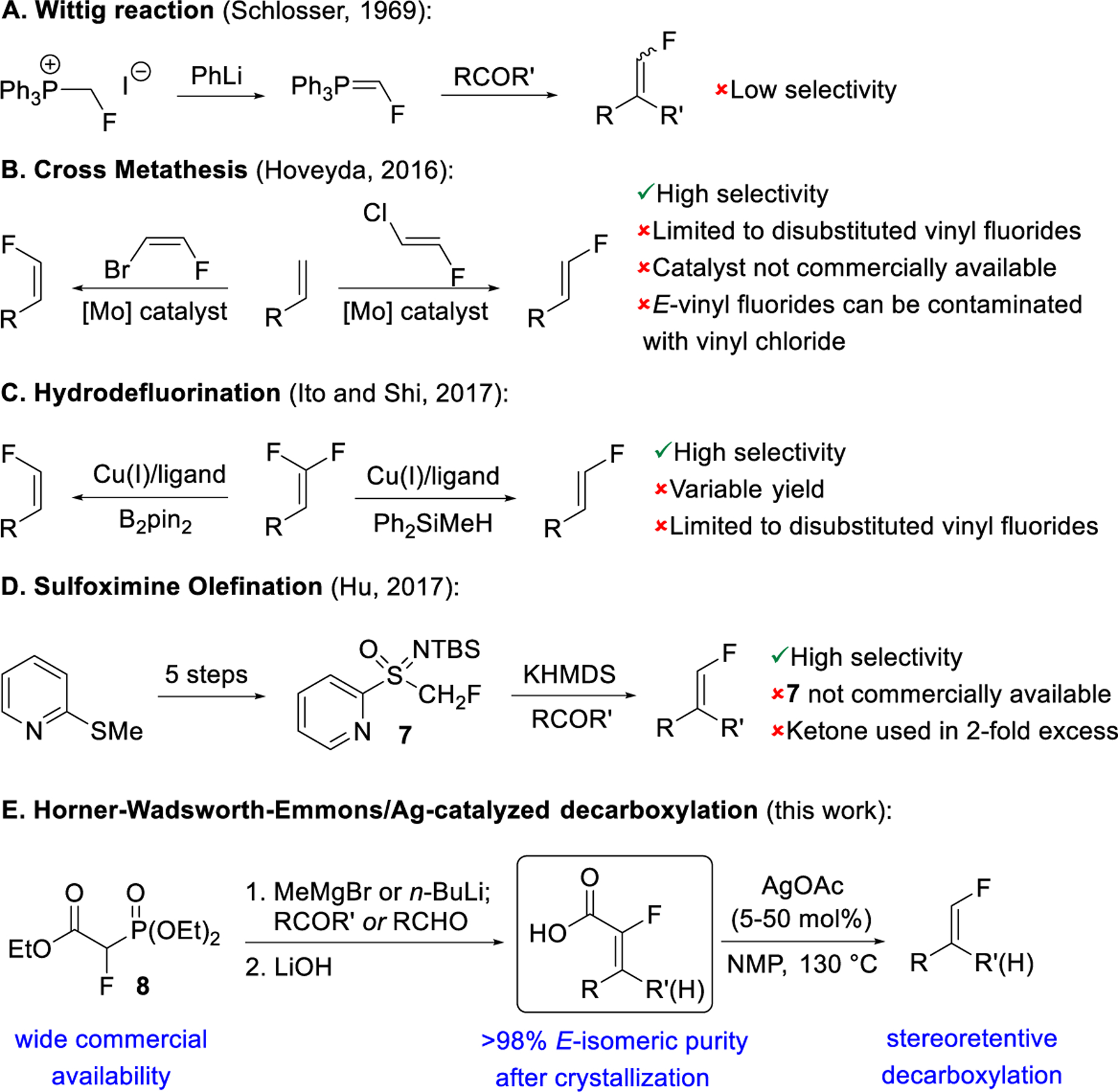

The geometry of the vinyl fluoride is often critically important to biological activity, and consequently synthetic methods to access these structures with high isomeric purity are desired.6b To support a recent drug development program, we required a safe and scalable route to trisubstituted terminal vinyl fluorides with high isomeric purity. A survey of the literature revealed a diverse set of approaches, but many raised concerns regarding safety and/or scalability. A selection of published protocols is shown in Figure 2. The Wittig reaction using a fluoromethyl triphenylphosphonium salt was first reported by Schlosser in 1969 (Figure 2A).7 Variations of this reagent were subsequently developed but generally provide low selectivities.8 In 2016, Hoveyda reported cross metathesis approaches to both Z and E disubstituted vinyl fluorides (Figure 2B).9 High selectivities were obtained, but the reaction required a non-commercially available catalyst and was limited to disubstituted products, and in the case of E-vinyl fluorides, a vinyl chloride byproduct was formed which could prove difficult to separate from the desired product.

Figure 2.

Selected methods for terminal vinyl fluoride synthesis (A-D) and our olefination/decarboxylation approach (E).

The hydrodefluorination of 1,1-difluoroalkenes (Figure 2C) was demonstrated by the groups of Ito and Shi in 2017 and can provide E or Z products depending on reaction conditions but is limited to disubstituted vinyl fluoride products.10 Hu and co-workers reported an olefination using fluoromethylsulfoximine 7 in 2017 (Figure 2D).11 This procedure gave high selectivity for both ketones and aldehydes. The non-commercial availability of the reagent 7 and its 5-step preparation, as well as the requirement to use 7 as the limiting reagent with the ketone in two-fold excess nonetheless presented obstacles to employing this process on large scale.11b The preparation and Horner-Wadsworth-Emmons (HWE) reaction of triethyl 2-fluorophosphonoacetate 8 were first reported by Machleidt and Wessendorf in 1964 (Figure 2E).12 The wide commercial availability and low cost of 8 made it an attractive reagent for introduction of the fluorovinyl group from a ketone or aldehyde starting material. We reasoned that if this olefination could be developed with high selectivity and coupled with stereoretentive decarboxylation of the derived carboxylic acid, it would constitute a practical route to vinyl fluoride products. Herein we report the development of this route to di- and trisubstituted terminal vinyl fluorides by a highly selective olefination of ketones or aldehydes using 8, subsequent hydrolysis to the crystalline α-fluoroacrylic acids, and stereospecific Ag-catalyzed decarboxylation.13

RESULTS AND DISCUSSION

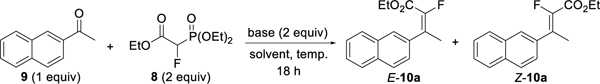

Initial work focused on optimization of the HWE reaction of acetonaphthone 9 with phosphonate 8 (Table 1). The base was screened first, using 2 equiv of 8 in THF at 0 °C. The use of n-BuLi or alkali metal HMDS derivatives gave modest selectivities around 85:15 favoring E-10a (entries 1–4). We next examined Grignard reagents as bases. In 1998, Sano reported the use of i-PrMgBr as base to give Z-selectivity in the reaction of 8 with aldehydes.14 In 2008, Davies described the highly E-selective reactions of non-fluorinated phosphonates with aldehydes using MeMgBr as base.15 When we applied alkyl Grignard bases to the reaction of 8 with ketone 9, a significant improvement in selectivity was observed (entries 5–8). i-PrMgCl gave a 96:4 E/Z ratio of 10a in 88% assay yield. Using MeMgCl gave a higher assay yield of 98% with similar selectivity (95:5, entry 6). The halide counterion had a slight effect on selectivity and yield, with MeMgBr (entry 7) being optimal at 96:4 selectivity and 97% yield. The use of dibutylmagnesium (entry 9) proceeded in high yield but decreased selectivity. The use of an alkylzinc bromide (entry 10) or dimethylzinc (entry 11) was less effective compared to Grignard reagents. A brief examination of other solvents (entries 12–15) showed none to be as effective as THF, although DME did provide high selectivity (97:3, entry 15). Finally, the effect of temperature was examined (entries 16–18). Lowering the temperature to –20 °C resulted in incomplete conversion, although with slightly increased selectivity (97:3, entry 16). Increasing the temperature to 40 °C gave the highest assay yield (99%, entry 17) while maintaining the selectivity observed at 0 °C (96:4) but increasing further to 50 °C resulted in a drop in assay yield and selectivity (entry 18). Thus, the optimal conditions were MeMgBr as base and THF as solvent at a reaction temperature of 40 °C (entry 17).16

Table 1.

Optimization of olefination reaction conditions.

| |||||

|---|---|---|---|---|---|

| entry | base | solvent | T (°C) | yield (%)a | E/Zb,c |

| 1 | n-BuLi | THF | 0 | 81 | 85:15 |

| 2 | LiHMDS | THF | 0 | 85 | 84:16 |

| 3 | NaHMDS | THF | 0 | 90 | 87:13 |

| 4 | KHMDS | THF | 0 | 73 | 86:14 |

| 5 | i-PrMgCl | THF | 0 | 88 | 96:4 |

| 6 | MeMgCl | THF | 0 | 98 | 95:5 |

| 7 | MeMgBr | THF | 0 | 97 | 96:4 |

| 8 | MeMgI | THF | 0 | 88 | 95:5 |

| 9 | Bu2Mg | THF | 0 | 98 | 92:8 |

| 10 | n-PrZnBr | THF | 0 | 44 | 85:15 |

| 11 | Me2Zn | THF | 0 | 81 | 93:7 |

| 12 | MeMgBr | toluene | 0 | 79 | 94:6 |

| 13 | MeMgBr | NMP | 0 | 66 | 91:9 |

| 14 | MeMgBr | 2-MeTHF | 0 | 79 | 93:7 |

| 15 | MeMgBr | DME | 0 | 79 | 97:3 |

| 16 | MeMgBr | THF | −20 | 86d | 97:3 |

| 17 | MeMgBr | THF | 40 | 99 | 96:4 |

| 18 | MeMgBr | THF | 50 | 93 | 95:5 |

Assay yield from 19F NMR using benzotrifluoride as internal standard.

E/Z ratio from 19F NMR of crude product.

Stereochemistry was confirmed by 1H-19F HOESY experiments.

Conversion of 9 to 10a from HPLC (220 nm).

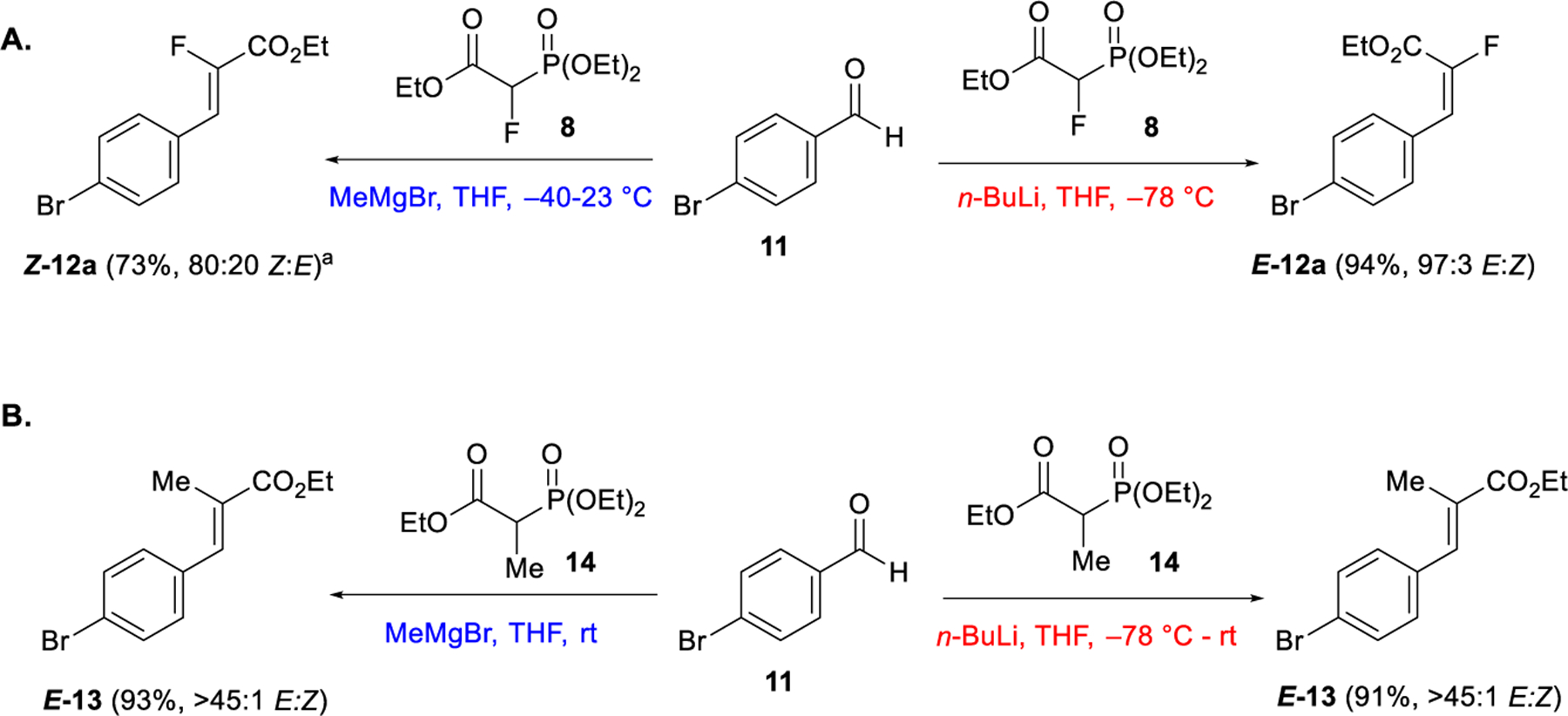

Applying the reaction conditions developed for ketones to the olefination of 4-bromobenzaldehyde 11 showed moderate (80:20) selectivity favoring the Z-isomer (Scheme 1A).13a Alternatively, the use of n-BuLi as base at low temperature (–78 °C) gave the E-isomer with high selectivity (98:2).17 The stereochemistry was confirmed by 1H–19F HOESY experiments and single crystal X-ray structure analysis of the derived acid of Z-12a (vide infra). By contrast, olefination of 11 with triethyl-2-phosphonopropionate 14 gave the product E-13 in >45:1 E-selectivity using either MeMgBr or n-BuLi as the base (Scheme 1B).

Scheme 1.

Olefination of aldehyde 11 with 8 and 14 using MeMgBr or n-BuLi as base. aAfter purification >98:2 Z:E.

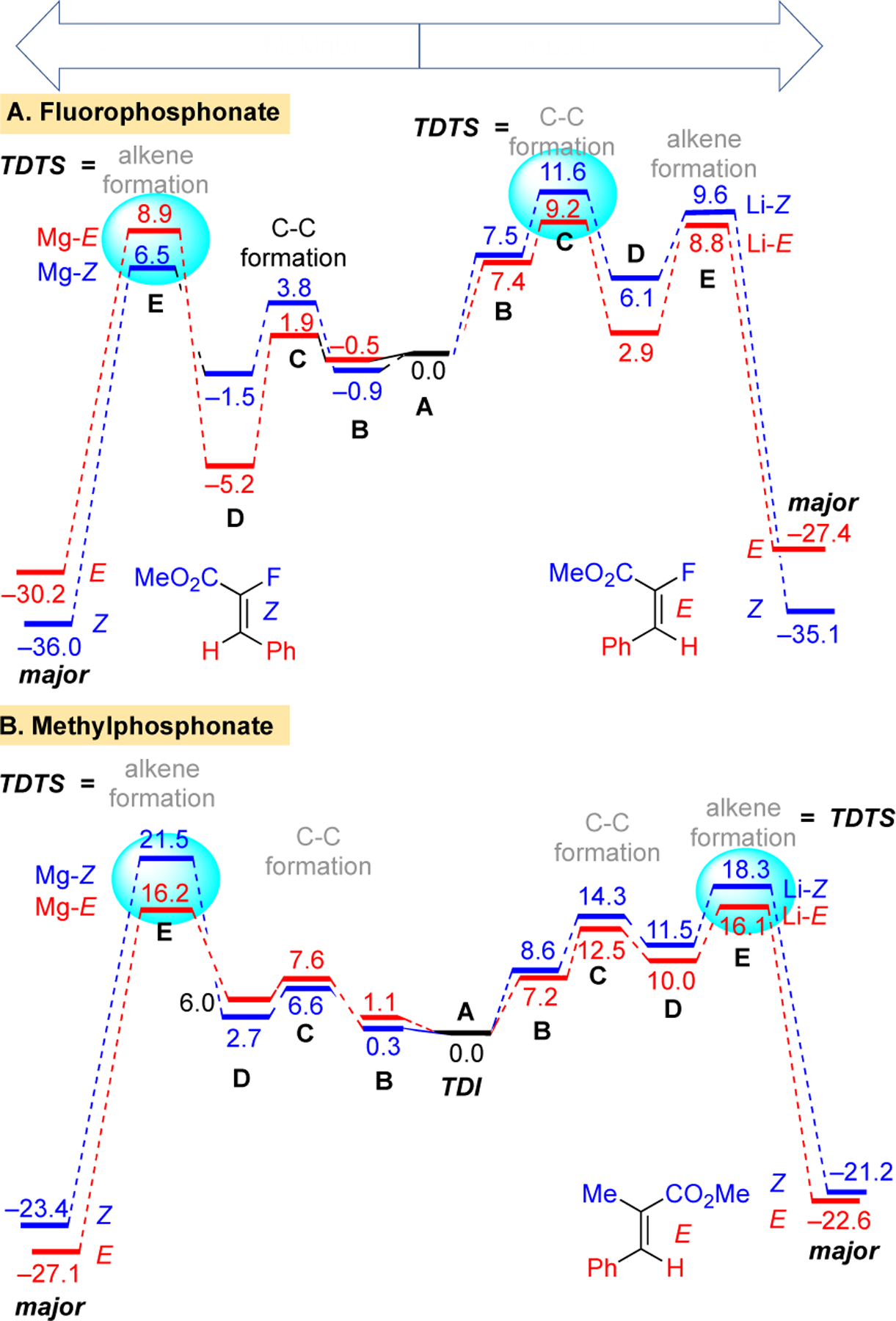

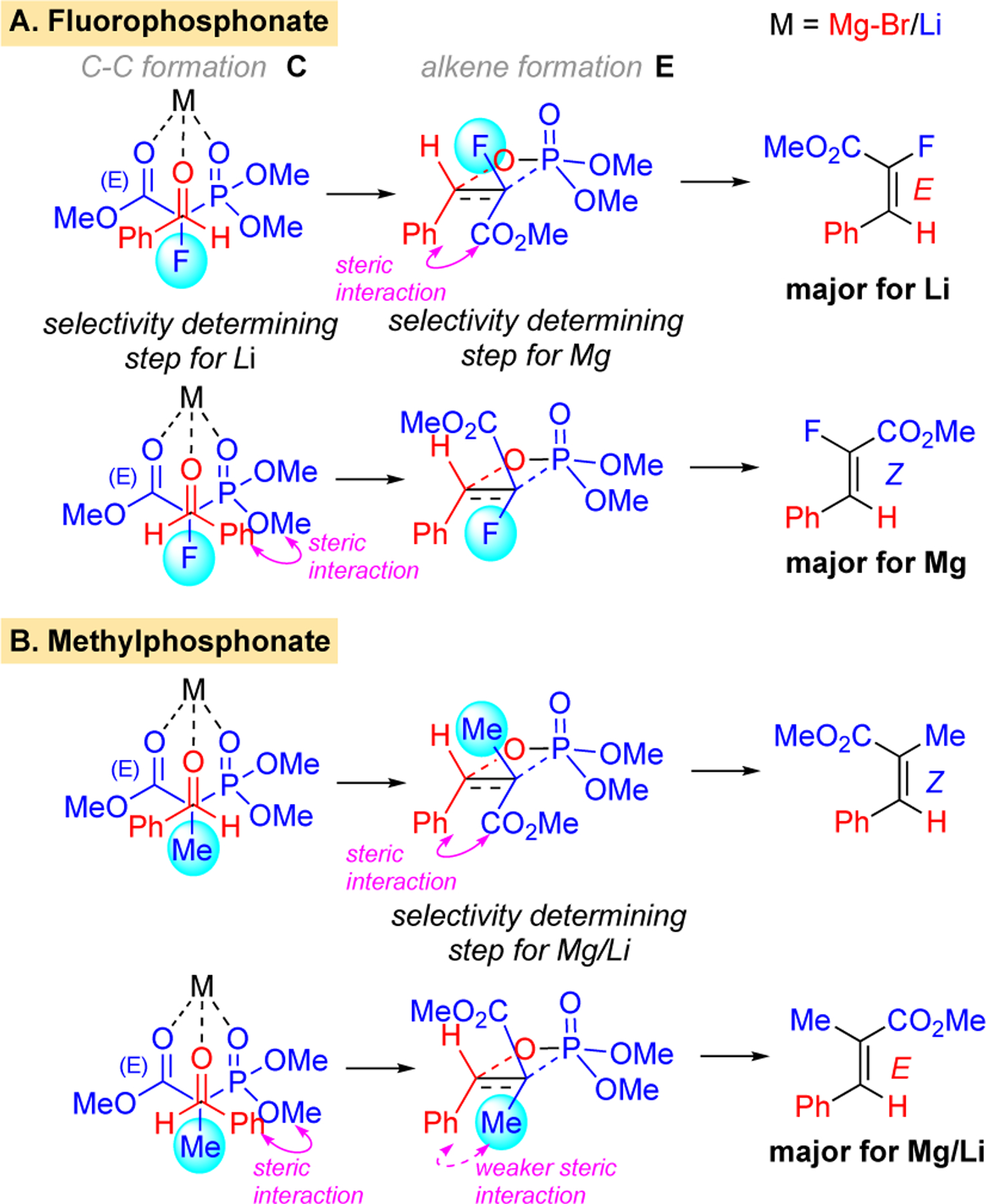

The basis for the E/Z selectivity, especially the changes with different bases, was investigated computationally. Calculations were performed with Gaussian18 B3LYP-D3/6–31G(d,p)19 with an SMD20 solvation model. The energy diagram for reaction of the lithium and magnesium phosphonates are shown in Figure 3. Coordination of solvent to the Li or BrMg counterions was required to account for the observed trends. Specifically, two THF molecules remained coordinated throughout the reaction. The substrates (A) undergo a precoordination to form B followed by a transition state C for addition of the anion to the aldehyde via a staggered transition state where the metal coordinates the oxygens of the ester, phosphonate, and aldehyde (Scheme 2). The adduct D, then proceeds to a four-membered transition state E (Scheme 2) which gives rise to formation of the alkene.

Figure 3.

Relative Gibbs free energy (kcal/mol) profile diagram of the formation of olefin from the Mg/Li fluoro- and methyl-phosphonates (SMD(THF)/B3LYP-D3/6–31G**).

Scheme 2.

Reaction pathways of PhCHO with 2-fluoro and 2-methyl phosphonoacetates.

For the reactions of stabilized ylides, the initial addition of the anion is reversible and the selectivity-determining step is typically elimination from the oxaphosphetane via transition state E.21 For the α-methylphosphonate 14, this expected trend holds for both the lithium and bromomagnesium phosphonates (Figure 3B) and the E-isomer is the major adduct from each (Scheme 1B). The transition state E has fewer steric interactions en route to the E-isomer as the larger groups (-CO2Me, -Ph) are trans disposed (Scheme 2B). There are, however, some notable differences between the two pathways. The barrier for the addition of the methyl-substituted phosphonate anion to the aldehyde is significantly higher for the lithium case which can be attributed to the lower Lewis acidity of lithium (NBO charge +0.88) vs magnesium (NBO charge +1.69).

For the α-fluorophosphonate 8, the turnover determining transition state (TDTS) differs depending on the metal counterion employed. With MeMgBr, the expected trend holds in that alkene elimination via E is selectivity determining (left side of Figure 3A) and leads to the Z-isomer with the larger groups (-CO2Me, -Ph) trans disposed. In this case, steric interactions are again minimized in the oxaphosphetane transition state E (bottom of Scheme 2A). With n-BuLi, the selectivity determining step for α-fluorophosphonate 8 is transition state C (right side of Figure 3A). Steric interactions are minimized in the staggered approach that ultimately leads to the E-isomer (Scheme 2A).

This change of selectivity determining transition state for the fluoro-substituted phosphonates was investigated further. For the initial addition of the anion to the aldehyde, the barrier is again significantly higher for the lithium vs the magnesium case due to greater Lewis acidity of the latter. However, the barriers are generally lower for the fluoro-substituted phosphonate than for the methyl-substituted phosphonate anion. Apparently, the lower nucleophilicity of the fluoro-substituted phosphonate (NBO charge on enolic carbon: F = –0.32 ± 02, Me = –0.76 ± 01) is offset by the greater steric size of the methyl vs fluoro group. This substituent enters into particularly close proximity to the aldehyde groups due to the non-parallel approach of the phosphonate anion along the Dunitz-Bürgi angle to engage π* of the aldehyde. A distortion interaction analysis highlights this effect (see Supporting Information) where the aldehyde undergoes greater distortion with the methyl-substituted phosphonate anion (average = 14.9 kcal/mol) vs the fluoro analog (average = 7.8 kcal/mol).

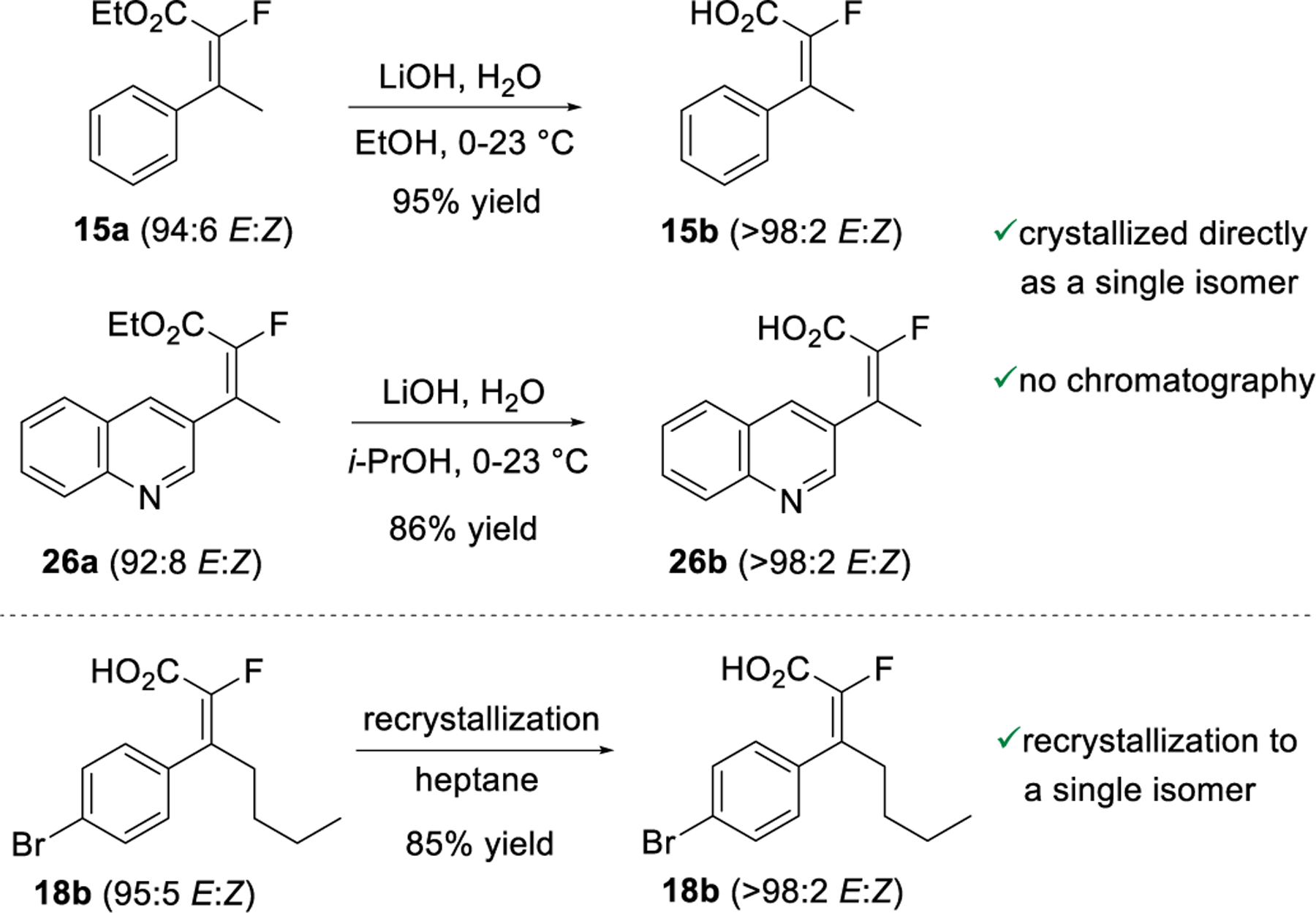

The hydrolysis of esters in the products from the above reactions was performed using LiOH in aqueous EtOH or i-PrOH, and upon completion of the reaction, acidification usually resulted in crystallization of the product acids in high yield and often with increased isomeric purity (up to >98:2 E/Z).22 For example, hydrolysis of esters 15a and 26a gave the corresponding acids 15b and 26b as single E-isomers on acidification (Scheme 3). Alternatively, the acids could be recrystallized to achieve the desired purity: acid 18b of 95:5 isomeric purity was upgraded to the pure E-isomer (>98:2) after a recrystallization from heptane. This favorable property of the α-fluoroacrylic acids eliminated the need for chromatography for removal of the minor isomer.

Scheme 3.

Hydrolysis of esters to crystalline acids and recrystallization to upgrade isomeric purity.

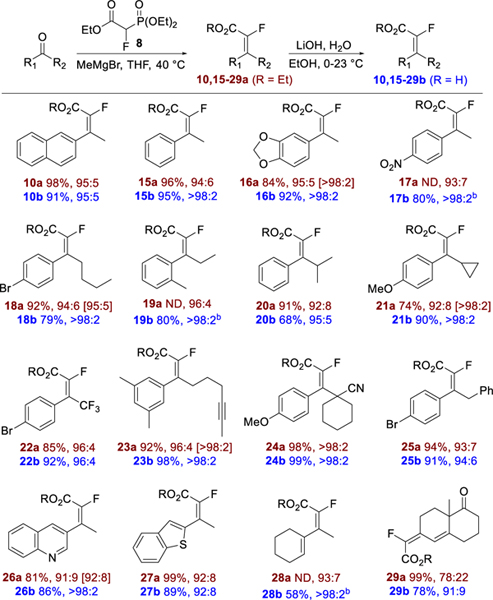

With the optimal reaction conditions in hand, the scope of the olefination/hydrolysis was explored (Table 2). For a variety of aryl alkyl and heteroaryl alkyl ketones, the olefination proceeded with E/Z selectivity of ≥90:10, with the highest selectivity observed for the sterically hindered 24a (single E-isomer). The olefination proceeded with uniformly high selectivity for electron poor (17a and 22a) and electron rich (16a and 21a) substrates. The olefination of vinyl alkyl ketones resulted in dienes 28a and 29a, with lower selectivity for the less sterically differentiated substrate 29a. The acids were often obtained as pure E-isomers (E/Z >98:2 by 19F NMR) after crystallization from the reaction mixture on acidification. For substrates 17b, 19b and 28b, the olefination and hydrolysis steps were telescoped (unpurified ester was taken directly into hydrolysis) and the overall yield of acid from ketone is given.

Table 2.

Scope of olefination/hydrolysis of ketones.a

|

For olefination products, yield of purified product, reaction E/Z selectivity, and E/Z isomeric purity of purified product [brackets] are given. When E/Z selectivity was the same for the reaction and purified product, no bracketed ratio is given. For carboxylic acid products, yield of purified product is given followed by E/Z isomeric purity of product. E/Z ratio from 19F NMR of crude product (esters) and isolated product (acids). For detailed reaction conditions, see the Experimental Section.

Unpurified ester taken directly into hydrolysis. Yield of acid is the overall yield from ketone.

The olefination/hydrolysis sequence was next applied to a selection of aldehydes (Table 3). As observed for olefination of aldehyde 11, the use of n-BuLi gave uniformly high E-selectivity for aryl, heteroaryl and alkyl aldehydes.15 The application of MeMgBr as base for olefination gave complimentary results, favoring the Z-isomers Z-12a and Z-30a and with modest selectivity (80:20 and 83:17, respectively). As observed for the ketone substrates, hydrolysis of the esters usually resulted in single E-isomers after isolation by crystallization directly from the reaction mixtures.

Table 3.

Scope of olefination/hydrolysis of aldehydes.a

|

For olefination products, yield of purified product, reaction E/Z selectivity, and E/Z isomeric purity of purified product [brackets] are given. When E/Z selectivity was the same for the reaction and purified product, no bracketed ratio is given. For carboxylic acid products, yield of purified product is given followed by E/Z isomeric purity of product. E/Z ratio from 19F NMR of crude product (esters) and isolated product (acids). For detailed reaction conditions, see the Experimental Section.

Olefination was performed using MeMgBr as base.

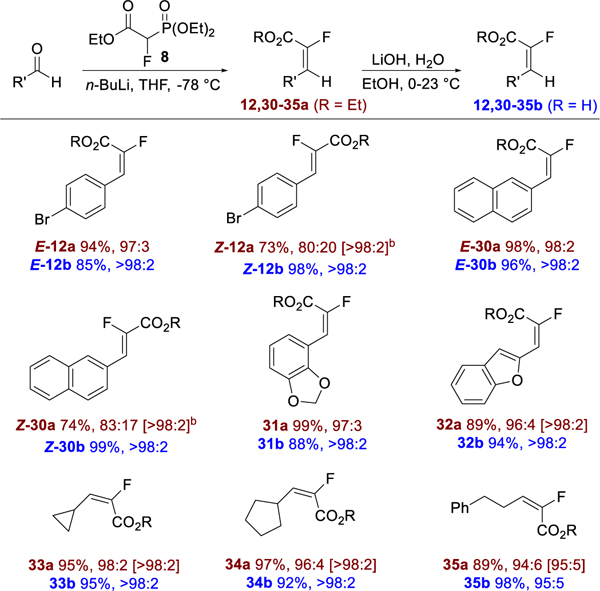

Single crystal X-ray structures were obtained for acids E-16b and Z-12b (Scheme 4) which confirmed the geometry assignments of the olefins.

Scheme 4.

X-ray crystal structures of acids E-16b and Z-12b

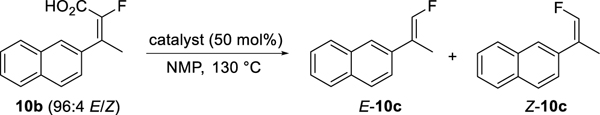

The decarboxylation of three α-fluoroacrylic acids was reported in 1967 by Elkik using a mixture of Cu powder and CuSO4 (36 mol % Cu in total) in quinoline at 205–210 °C.23 Subsequent to Elkik’s pioneering work, only stoichiometric decarboxylations have been reported.24 With the hopes of identifying milder conditions with lower temperature and catalyst loading, we embarked on a screen of catalysts for decarboxylation, using 10b of 96:4 E/Z purity as substrate (Table 4).25 For the initial screen, 50 mol % of catalyst was used in NMP (3 volumes) at 130 °C, with the reaction progress and the E/Z ratio of the product determined by HPLC analysis. Of the Cu catalysts screened, Cu2O was most effective, giving full conversion after 24 h with a slight drop in isomeric purity (94:6, entry 1). Silver salts are well known to promote decarboxylation, and a screen of various Ag salts gave some excellent results.26 Ag(I) salts with low pKa counterions gave low conversions (entries 6–8), but with retention of the starting olefin isomer ratio. AgNO3 gave complete conversion after just 1.5 h, but with significant erosion of isomeric purity (76:24, entry 9). The more basic catalysts Ag2CO3 and Ag2O (entries 10–11) also gave full conversion in 1.5 h and with only slight loss of geometric integrity (95:5 and 94:6, respectively). AgOAc proved to be the optimal silver catalyst, giving full conversion in 1.5 h with no loss of isomeric purity (entry 12). The use of Pd, Fe or Ir catalysts was ineffective (entries 13–15). Interestingly, Rh(nbd)2BF4 gave a moderate conversion after 24 h and with increased isomeric purity (99:1, entry 16). The Wilkinson catalyst, however, gave no reaction (entry 17).

Table 4.

Decarboxylation catalyst screen.

| |||||

|---|---|---|---|---|---|

| entry | catalyst | Conversion (%)a | E/Zb | ||

| 1 h | 4 h | 24 h | |||

| 1 | Cu2O | - | 28 | 100 | 94:6 |

| 2 | CuO | - | 0 | 1 | 87:13 |

| 3 | Cu(OAc)2 | - | 1 | 45 | 94:6 |

| 4 | CuOAc | - | 0 | 0 | - |

| 5 | CuTCc | - | 5 | 50 | 95:5 |

| 6 | AgOTs | - | 8 | 21 | 96:4 |

| 7 | AgBF4 | - | - | 25 | 96:4 |

| 8 | AgOTf | 5 | - | 27 | 96:4 |

| 9 | AgNO3 | 100d | - | - | 76:24 |

| 10 | Ag2CO3 | 100d | - | - | 95:5 |

| 11 | Ag2O | 100d | - | - | 94:6 |

| 12 | AgOAc | 100 d | - | - | 96:4 |

| 13 | Pd(OAc)2 | - | 0 | 0 | - |

| 14 | Fe(acac)3 | - | 0 | 0 | - |

| 15 | [Ir(cod)Cl]2 | - | 0 | 0 | - |

| 16 | Rh(nbd)2BF4 | - | 15 | 55 | 99:1 |

| 17 | Rh(PPh3)3Cl | - | 0 | 0 | - |

Conversion of 10b to 10c as measured by HPLC (220 nm).

E/Z ratio from HPLC.

Copper(I) thiophene-2-carboxylate.

Conversion after 1.5 h.

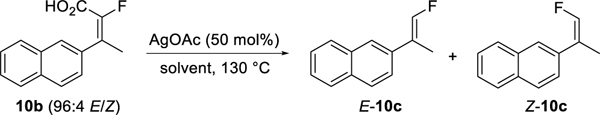

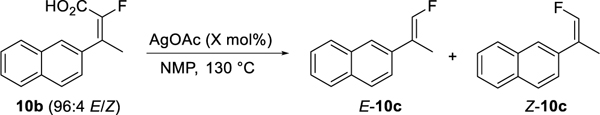

We next performed a solvent screen using the optimal catalyst AgOAc with a 50 mol % loading (Table 5). DMAc and DMSO were effective solvents for the reaction, but with slight reduction in isomeric purity (entries 2 and 3). The use of quinoline and pyridine gave a slower reaction but with retention of isomeric integrity (entries 4 and 5). The reaction proceeded but very slowly in 1-pentanol (entry 6). Decarboxylation was significantly retarded in propionic acid due to competitive binding to Ag (entry 7). Low conversion was observed in xylene due to the poor solubility of the catalyst (entry 8).

Table 5.

Decarboxylation solvent screen.

| |||||

|---|---|---|---|---|---|

| entry | solventa | Conversion (%)b | E/Zc | ||

| 2 h | 4 h | 24 h | |||

| 1 | NMP | 100 | - | - | 96:4 |

| 2 | DMAc | 100 | - | - | 95:5 |

| 3 | DMSO | 100 | - | - | 94:6 |

| 4 | quinoline | 90 | 100 | - | 96:4 |

| 5 | pyridine | 75 | 98 | 100 | 96:4 |

| 6 | 1-pentanol | - | 12 | 51 | 96:4 |

| 7 | propionic acid | 0 | 1 | 7 | 98:2 |

| 8 | p-xylene | 0 | 3 | 3 | 97:3 |

Three volumes of solvent relative to 10b.

Conversion of 10b to 10c as measured by HPLC (220 nm).

E/Z ratio from HPLC.

Finally, the loading of AgOAc was optimized (Table 6). Using 15 or 10 mol % catalyst, the reaction reached complete conversion after 1 h (entries 1 and 2). Lowering further to 5 mol % (entry 3) resulted in high but incomplete conversion after 1 h, with the reaction reaching completion by 2 h. The use of only 2.5 mol % catalyst drastically slowed the reaction, with it stalling at 22% conversion after 1 h (entry 4). Increasing the concentration of the reaction by using two instead of three volumes of NMP did not enable complete conversion with 2.5 mol % catalyst (entry 5) but with 5 mol % complete conversion was achieved in 1 h (entry 6). In all cases, isomeric purity was fully retained.

Table 6.

Catalyst loading optimization for decarboxylation.

| |||||

|---|---|---|---|---|---|

| entry | mol % AgOAc | Conversion (%)a | E/Zb | ||

| 1 h | 2 h | 3 h | |||

| 1 | 15.0 | 100 | - | - | 96:4 |

| 2 | 10.0 | 100 | - | - | 96:4 |

| 3 | 5.0 | 96 | 100 | - | 96:4 |

| 4 | 2.5 | 22 | 22 | 22 | 96:4 |

| 5 | 2.5c | 23 | 23 | 23 | 96:4 |

| 6 | 5.0 c | 100 | - | - | 96:4 |

Conversion of 10b to 10c as measured by HPLC (220 nm).

E/Z ratio from HPLC.

Two volumes of NMP instead of three volumes.

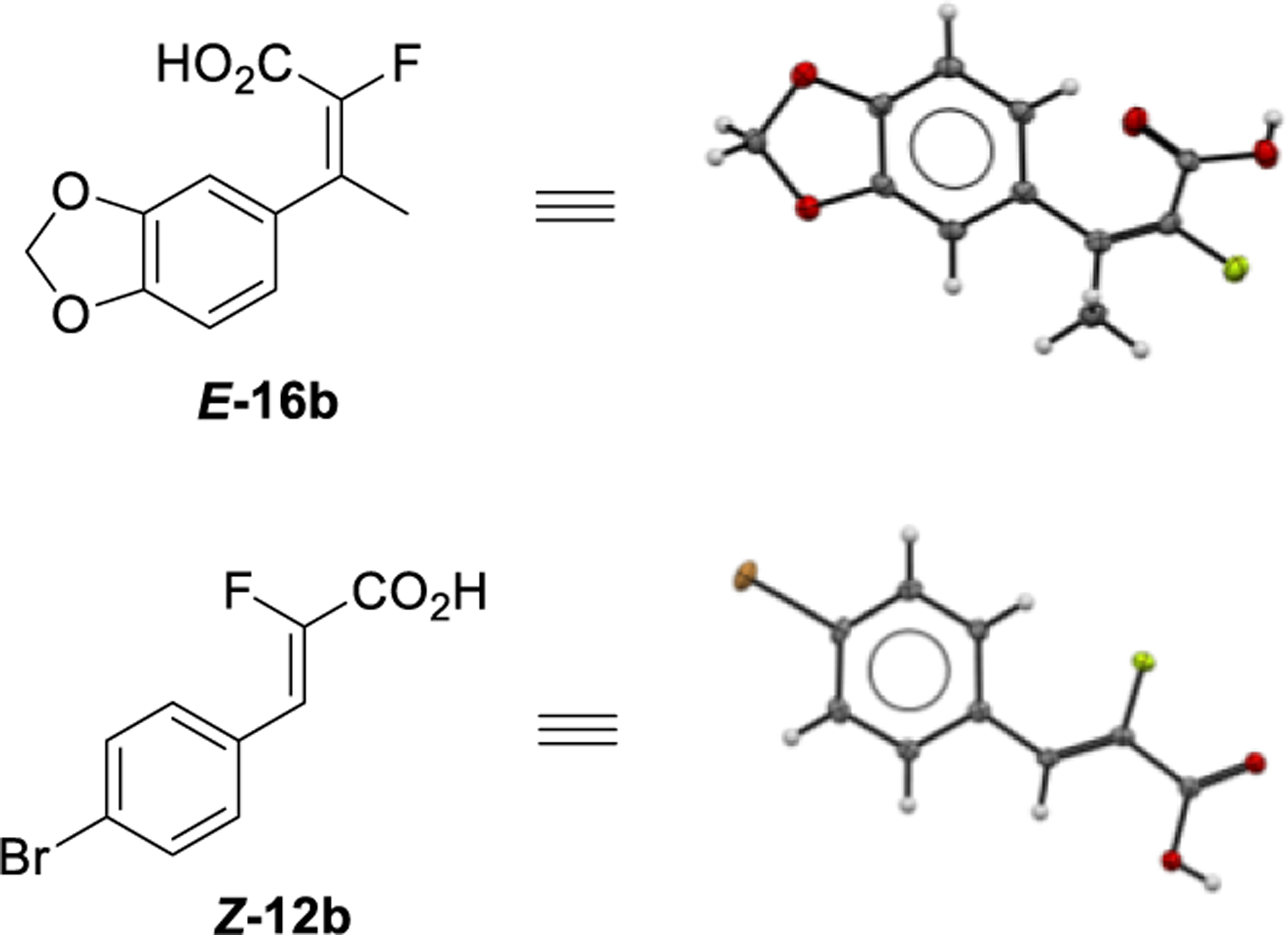

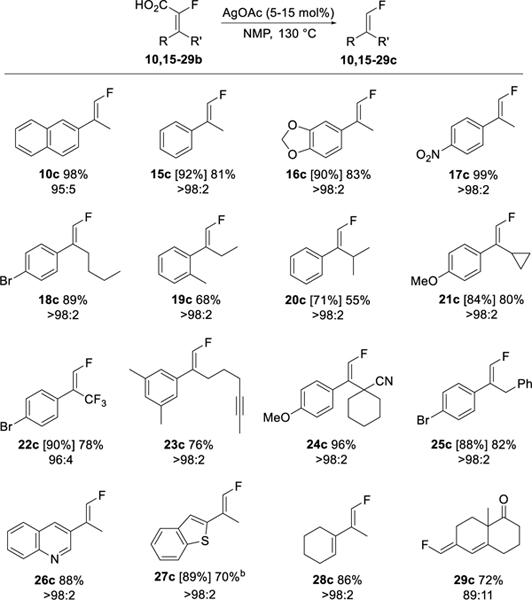

The decarboxylation was then applied to the α-fluoroacrylic acid substrates using the optimized reaction conditions (Table 7). A variety of aryl, heteroaryl and vinyl substituted α-fluoroacrylic acids underwent decarboxylation to yield the corresponding trisubstituted vinyl fluorides in good yields. In all cases except 27c, the isomeric purity of the starting acrylic acid was completely preserved in the trisubstituted vinyl fluoride product. In the case of 27c, the isomeric purity decreased from 92:8 to 81:19 during the decarboxylation. We attribute this anomaly to interaction of the thiophilic silver catalyst with the sulfur atom of the thiophene ring. Notably, the decarboxylation was not perturbed by the presence of other groups known to coordinate or react with silver, such as an aryl bromide (18c, 22c, 25c), an alkyne (23c), a nitrile (24c), and a quinoline nitrogen (26c). The reaction also gave access to unusual terminal monofluoro 1,3-dienes (28-29c).

Table 7.

Silver catalyzed decarboxylation of α-fluoroacrylic acids to trisubstituted vinyl fluorides.a

|

Assay yields from 19F NMR versus PhCF3 are given in brackets, isolated yields are given with no brackets. E/Z isomeric purity of isolated product is given under yields. Isomeric purity determined by 19F NMR.

E/Z ratio degraded from 92:8 to 81:19 during the reaction. The minor isomer was removed by chromatography. For detailed reaction conditions, see the Experimental Section.

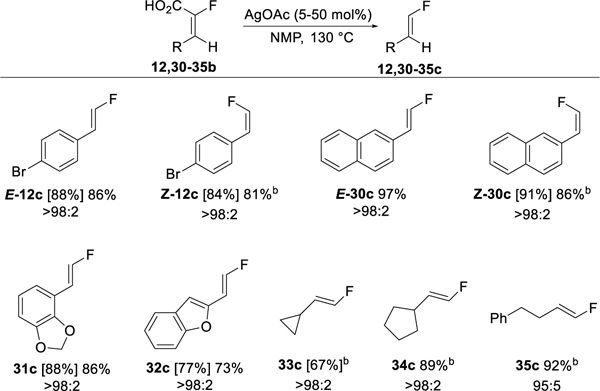

The decarboxylation was applied to aldehyde-derived α-fluoroacrylic acids with similar success (Table 8). Both aryl and alkyl substituted fluoroalkenes were amenable to the decarboxylation. The pure E and pure Z isomers of 12b and 30b were converted to the corresponding vinyl fluorides with the isomeric purity completely maintained. Decarboxylation of E-12b and E-30b was facile with only 5 mol % catalyst loading whereas the reaction of isomeric Z-12b and Z-30b required 50 mol % of AgOAc and higher dilution due to lower solubility of the corresponding Ag carboxylate intermediates. Higher reaction temperature (140–145 °C) and increased catalyst loading was also required for efficient decarboxylation of alkyl substituted fluoroacrylic acids (33–35b).

Table 8.

Silver catalyzed decarboxylation of α-fluoroacrylic acids to disubstituted vinyl fluorides.a

|

Assay yields from 19F NMR versus PhCF3 are given in brackets, isolated yields are given with no brackets. E/Z isomeric purity of isolated product is given under yields. Isomeric purity determined by 19F NMR. For detailed reaction conditions, see the Experimental Section.

AgOAc loading of 50 mol %.

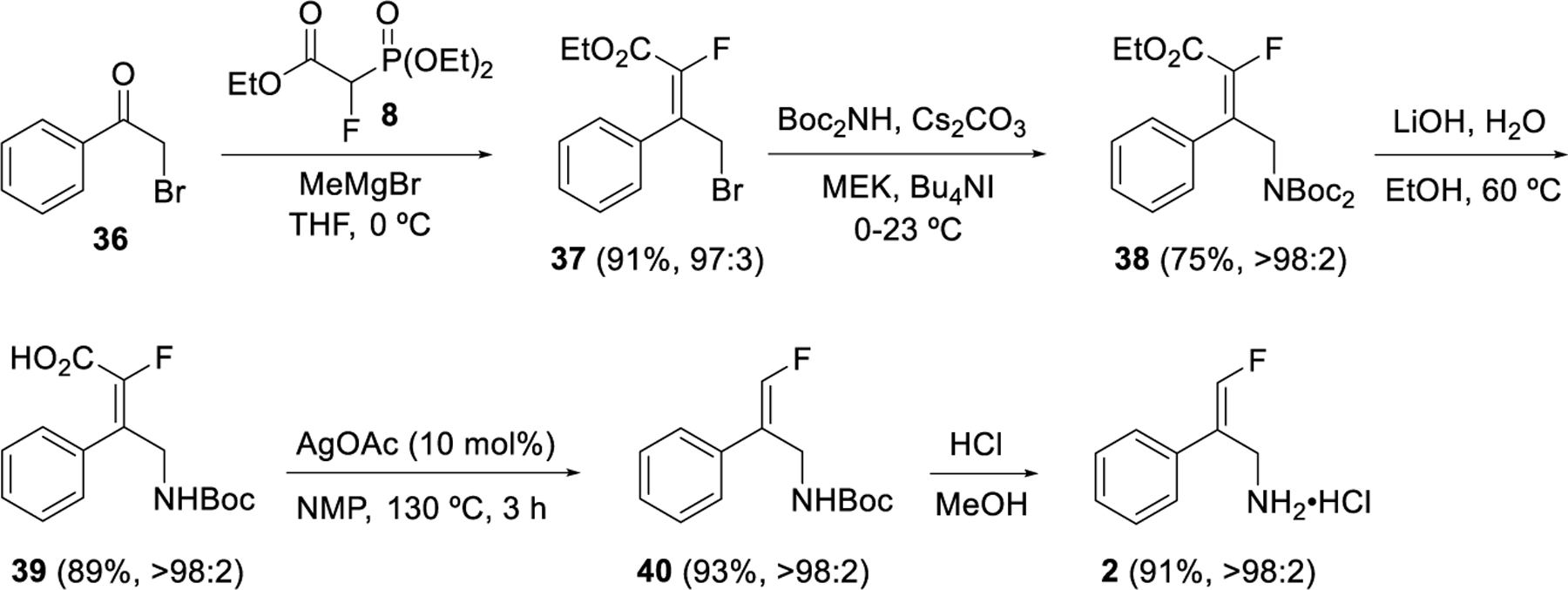

The overall method as described above was applied to the synthesis of the BPAO inhibitor 2 (Scheme 5).6b Olefination of bromoacetophenone 36 gave the ester 37 with a 90:10 Z/E reaction selectivity which was upgraded to a 97:3 Z/E after purification. Displacement of the bromide with di-tert-butyliminodicarboxylate gave 38, which was converted to the mono-Boc acid 39 with aqueous LiOH. The minor E-isomer of 39 was not detectable in the product due to isolation of both 38 and 39 by crystallizations which effectively purged the minor isomer. Decarboxylation of 39 gave a 93% yield of 40 with complete retention of geometric purity. Finally, Boc deprotection yielded the target compound 2 in high yield.

Scheme 5.

Application of HWE/hydrolysis/decarboxylation to the synthesis of BPAO inhibitor 2.

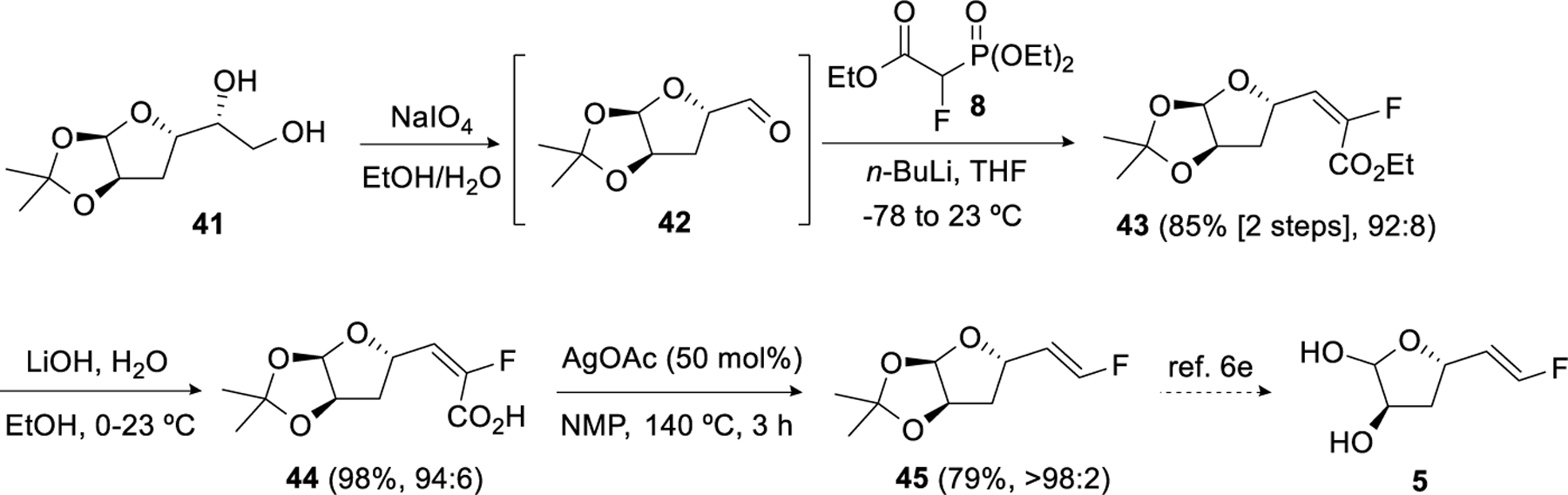

The protocol was also applied to the synthesis of an intermediate en route to LuxS inhibitor 5 (Scheme 6).6e Periodate cleavage of diol 4127 in EtOH/water gave the aldehyde 42 along with its ethyl hemiacetal. This mixture was taken directly into the olefination with 8 using n-BuLi as base to provide ester 43 with 92:8 E/Z selectivity in 85% yield from 41. Hydrolysis gave the acid 44 (E/Z = 94:6), which upon decarboxylation furnished 45 in 79% yield and as a single isomer after purification. Compound 45 can be converted to 5 by literature methods.6e

Scheme 6.

Application of HWE/hydrolysis/decarboxylation to the formal synthesis of LuxS inhibitor 5.

CONCLUSION

In summary, a HWE olefination/hydrolysis/decarboxylation sequence has been developed for the preparation of di- and trisubstituted terminal monofluoroalkenes. The olefination reaction exhibits high E-selectivity for ketone substrates using MeMgBr as base and for aldehyde substrates using n-BuLi as base. Upon hydrolysis, the derived α-fluoroacrylic acids are crystalline solids which may be isolated by direct crystallization from the reaction mixture upon acidification, often with an upgrade in isomeric purity. The acids can also be recrystallized to upgrade isomeric purity if necessary. A silver catalyzed decarboxylation was developed which proceeds with retention of olefin configuration under relatively mild reaction conditions. Importantly, the reagent 8 used for the HWE olefination is inexpensive and widely available. This protocol provides a practical method for accessing α-fluoroacrylic acids and terminal di- and trisubstituted vinyl fluorides with high geometric purity without recourse to difficult chromatography for separation of isomers.

EXPERIMENTAL SECTION

General Information.

All starting materials, reagents and solvents were purchased from commercial sources and used as received unless otherwise noted. For reactions requiring heating, an oil bath was used as the heat source. 1H, 19F and 13C NMR spectra were recorded using Bruker DRX 400 or 500 MHz spectrometers. 1H and 13C chemical shifts are referenced to internal solvent resonances (CHCl3 1H, δ = 7.26 ppm; CDCl3 13C, δ = 77.0 ppm) and reported relative to SiMe4; multiplicities are indicated by s (singlet), d (doublet), t (triplet), q (quartet), qn (quintet), m (multiplet) and brs (broad signal). Coupling constants, J, are reported in Hertz. Structural assignments were made with additional information from gCOSY, gHSQC, and gHMBC experiments. Flash chromatography was performed on a Combi-Flash automated system with silica columns. High-resolution accurate mass (HRAM) was performed on both a Thermo LTQ FT-ICR mass spectrometer using DART source ionization in positive/negative ion modes and on a Thermo Scientific Exactive GC/MS using positive ion electron ionization (EI). Melting points were measured using a differential scanning calorimeter TA instrument DSC 2500.

General Procedure for Horner-Wadsworth-Emmons Reaction of Ketones with Triethyl 2-fluoro-2-phosphonoacetate and MeMgBr in THF.

A round bottom flask is charged with triethyl 2-fluoro-2-phosphonoacetate (1.7–4.5 equiv) and THF (0.3 M rel to ketone substrate). The solution is cooled to 0 to −5 °C. MeMgBr (3.4 M in 2-MeTHF, 1.7–4.5 equiv) is then added dropwise maintaining internal temperature below 10 °C. The reaction mixture is warmed to rt and stirred for 10 min, then heated to 40 °C and stirred for another 10 min. A solution of ketone (1.0 equiv) in THF (1 M) is added dropwise, and the reaction mixture is stirred for 0.5–3 h. After reaction is complete, judged by HPLC or GC analysis, the mixture is cooled to rt. The reaction mixture is quenched with 10% aq. NH4Cl solution and extracted with EtOAc. Organic phase is dried over MgSO4, filtered, and concentrated under reduced pressure. The residue is purified by silica gel column chromatography.

Ethyl (E)-2-fluoro-3-(naphthalen-2-yl)but-2-enoate (10a).

The reaction between acetonaphthone 9 (10.0 g, 58.75 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (23.8 mL; 117.50 mmol; 2.0 equiv) and MeMgBr (33.8 mL, 117.50 mmol, 3.48 M in 2-MeTHF, 2.0 equiv) was run at 40 °C for 30 min. 19F NMR of the crude: mixture of stereoisomers in 20.6:1 (95:5) dr. The product was obtained as a colorless oil after purification by silica gel column chromatography eluting with 0–5% EtOAc in hexanes (14.90 g, 98% yield, mixture of stereoisomers in 20.9:1 (95:5) dr). 1H NMR (400 MHz, CDCl3) δ 7.90–7.79 (m, 3H), 7.69 (d, JHF = 1.0 Hz, 1H), 7.55–7.47 (m, 2H), 7.35 (dd, J = 8.4 Hz, J = 1.7 Hz, 1H), 4.06 (q, J = 7.1 Hz, 2H), 2.27 (d, J = 4.5 Hz, 3H), 0.97 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.5 (d, J = 36.1 Hz), 144.5 (d, J = 252.3 Hz), 135.8 (d, J = 5.5 Hz), 132.9, 132.6, 131.2 (d, J = 17.2 Hz), 127.8, 127.59, 127.52, 126.2 (d, J = 3.3 Hz), 126.12, 126.07, 125.7 (d, J = 3.0 Hz), 60.9, 19.2 (d, J = 6.5 Hz), 13.5; 19F NMR (376.5 MHz, CDCl3) δ −123.1 (d, JHF = 4.4 Hz); Z-isomer: −125.3 (s). HRMS (DART) calcd for C16H16O2F [M+H]+: 259.1129, found 259.1129.

Ethyl (Z)-3-(4-bromophenyl)-2-fluoroacrylate (Z-12a).

The reaction between 4-bromobenzaldehyde (4.25 g, 22.97 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (7.0 mL; 34.46 mmol; 1.5 equiv) and MeMgBr (9.90 mL, 34.46 mmol, 3.40 M in 2-MeTHF, 1.5 equiv) was run at −40 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 4.0:1 (80:20) dr. The product Z-12a was obtained as a white solid after purification by silica gel column chromatography eluting with 0–2% MTBE in hexanes (4.60 g, 73% yield, single Z-isomer (>98:2 dr)). mp 62.1–63.6 °C; 1H NMR (400 MHz, CDCl3): δ 7.56–7.46 (m, 4H), 6.85 (d, JHF = 34.7 Hz, 1H), 4.35 (q, J = 7.1 Hz, 2H), 1.38 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 161.1 (d, J = 34.2 Hz), 147.4 (d, J = 269.1 Hz), 132.0, 131.6 (d, J = 8.3 Hz), 130.0 (d, J = 4.4 Hz), 124.0 (d, J = 3.9 Hz), 116.3 (d, J = 4.7 Hz), 62.0, 14.2; 19F NMR (376.5 MHz, CDCl3) δ −124.0 (d, JHF = 34.7 Hz). NMR spectra matched reported data.30

Ethyl (E)-3-(4-bromophenyl)-2-fluoroacrylate (E-12a).

The reaction between 4-bromobenzaldehyde (3.0 g, 16.21 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (4.93 mL; 24.32 mmol; 1.5 equiv) and n-BuLi (9.0 mL, 24.32 mmol, 2.71 M in hexanes, 1.5 equiv) was run at −78 °C to −20 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 35.5:1 (97:3) dr. The product E-12a was obtained as a colorless oil after purification by silica gel column chromatography eluting with 0–2% MTBE in hexanes (4.14 g, 94% yield, mixture of stereoisomers in 34.5:1 (97:3) dr). 1H NMR (400 MHz, CDCl3) δ 7.50–7.44 (m, 2H), 7.38–7.31 (m, 2H), 6.81 (d, JHF = 21.9 Hz, 1H), 4.26 (q, J = 7.1 Hz, 2H), 1.26 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.3 (d, J = 35.7 Hz), 147.2 (d, J = 257.6 Hz), 131.3 (d, J = 3.1 Hz), 131.2, 129.9 (d, J = 9.7 Hz), 122.9, 120.4 (d, J = 26.8 Hz), 61.8, 13.9; 19F NMR (376.5 MHz, CDCl3) δ −115.9 (d, JHF = 21.9 Hz), Z-isomer: −124.0 (d, JHF = 34.7 Hz). NMR spectra matched reported data.28

Reaction of triethyl 2-phosphonopropionate (14) with 4-bromobenzaldehyde. Ethyl (E)-3-(4-bromophenyl)-2-methylacrylate (E-13).

Using MeMgBr as base:

The reaction between 4-bromobenzaldehyde (1.00 g, 5.40 mmol, 1 equiv) and reagent prepared from triethyl 2-phosphonopropionate (1.74 mL; 8.11 mmol; 1.5 equiv) and MeMgBr (2.33 mL, 8.11 mmol, 3.48 M in 2-MeTHF, 1.5 equiv) was run at −40 °C with warming to rt. 1H NMR of the crude: >45:1 dr. The product E-13 was obtained as a colorless oil after purification by silica gel column chromatography eluting with 2–5% EtOAc in hexanes (1.35 g, 93% yield). Using n-BuLi as base: The reaction between 4-bromobenzaldehyde (1.00 g, 5.40 mmol, 1 equiv) and reagent prepared from triethyl 2-phosphonopropionate (1.74 mL; 8.11 mmol; 1.5 equiv) and n-BuLi (3.24 mL, 8.11 mmol, 2.50 M in hexanes, 1.5 equiv) was run at −78 °C with warming to rt. 1H NMR of the crude: >45:1 dr. The product E-13 was obtained as a colorless oil after purification by silica gel column chromatography eluting with 2–5% EtOAc in hexanes (1.33 g, 91% yield). NMR spectra for E-13 prepared by both methods matched reported data.29

Ethyl (E)-2-fluoro-3-phenylbut-2-enoate (15a).

A round bottom flask was charged with triethyl 2-fluoro-2-phosphonoacetate (591 μL, 2.91 mmol, 1.7 equiv) and THF (4.9 mL). The solution was cooled to 0 to −5 °C. MeMgBr (985 μL, 2.91 mmol, 2.96 M in Et2O, 1.7 equiv) was added dropwise maintaining internal temperature below 10 °C. The reaction mixture was warmed to rt and stirred for 10 min, then heated to 40 °C and stirred for another 10 min. A solution of acetophenone (200 μL, 1.71 mmol, 1.0 equiv) in THF (1.7 mL) was added dropwise, and the reaction mixture was stirred for 15 min. The mixture was cooled to rt, quenched with sat. aq. NH4Cl solution (10 mL) and extracted with EtOAc (2 × 10 mL). The organic phase was dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was analyzed by quantitative 19F NMR which showed a mixture of stereoisomers in 15.5:1 (94:6) dr. The residue was purified by silica gel column chromatography eluting with 0–2% EtOAc in hexanes to afford 15a as a colorless liquid. Mixture of stereoisomers in 15.9: 1 (94:6) dr (341.6 mg, 96% yield). 1H NMR (500 MHz, CDCl3) δ 7.40–7.30 (m, 3H), 7.23–7.14 (m, 2H), 4.05 (q, J = 7.2 Hz, 2H), 2.15 (d, JHF = 4.4 Hz, 3H), 1.03 (t, J = 7.2 Hz, 3H); 13C{1H} NMR (125 MHz, CDCl3) δ 160.5 (d, J = 36.2 Hz), 144.2 (d, J = 251.7 Hz), 138.5 (d, J = 5.5 Hz), 131.3 (d, J = 17.0 Hz), 128.0, 127.7, 127.3 (d, J = 3.1 Hz), 60.9, 19.2 (d, J = 6.6 Hz), 13.5; 19F NMR (470 MHz, CDCl3) δ −123.9 (s). NMR spectra matched reported data.30

Ethyl (E)-3-(benzo[d][1,3]dioxol-5-yl)-2-fluorobut-2-enoate (16a).

The reaction between 1-(benzo[d][1,3]dioxol-5-yl)ethan-1-one (3.0 g, 18.28 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (8.15 mL; 40.21 mmol; 2.2 equiv) and MeMgBr (11.6 mL, 40.21 mmol, 3.48 M in 2-MeTHF, 2.2 equiv) was run at 40 °C for 2 h. 19F NMR of the crude: mixture of stereoisomers in 17.9:1 (95:5) dr. The product 16a was obtained as a colorless liquid after purification by silica gel column chromatography eluting with 2–8% EtOAc in hexanes (3.88 g, 84% yield, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 6.78 (d, J = 7.9 Hz, 1H), 6.70–6.60 (m, 2H), 5.96 (s, 2H), 4.10 (q, J = 7.1 Hz, 2H), 2.10 (d, JHF = 4.5 Hz, 3H), 1.12 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.5 (d, J = 35.8 Hz), 147.3, 147.2, 144.3 (d, J = 252.6 Hz), 131.9 (d, J = 5.8 Hz), 131.0 (d, J = 17.6 Hz), 121.0 (d, J = 3.2 Hz), 108.2 (d, J = 3.3 Hz), 108.0, 101.1, 70.0, 19.3 (d, J = 6.4 Hz), 13.7; 19F NMR (376.5 MHz, CDCl3) δ −123.4 (q, JHF = 4.5 Hz). HRMS (DART) calcd for C15H19O2BrF [M+H]+: 329.0547, found 329.0550.

Ethyl (E)-3-(4-bromophenyl)-2-fluorohept-2-enoate (18a).

The reaction between 1-(4-bromophenyl)pentan-1-one (3.0 g, 12.44 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (6.31 mL; 31.10 mmol; 2.5 equiv) and MeMgBr (9.15 mL, 31.10 mmol, 3.40 M in 2-MeTHF, 2.5 equiv) was run at 40 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 17.1:1 (94:6) dr. The product 18a was obtained as a colorless liquid after purification by silica gel column chromatography eluting with 5% MTBE in hexanes (3.77 g, 92% yield, mixture of stereoisomers in 20.5:1 (95:5) dr). 1H NMR (400 MHz, CDCl3) δ 7.50–7.45 (m, 2H), 7.06–6.99 (m, 2H), 4.05 (q, J = 7.1 Hz, 2H), 2.60–2.40 (m, 2H), 1.41–1.23 (m, 4H), 1.06 (t, J = 7.1 Hz, 3H), 0.93–0.79 (m, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.3 (d, J = 36.2 Hz), 144.2 (d, J = 254.1 Hz), 136.1 (d, J = 5.8 Hz), 134.4 (d, J = 17.1 Hz), 131.1, 129.5 (d, J = 3.1 Hz), 121.6, 61.0, 32.0 (d, J = 4.8 Hz), 28.7 (d, J = 2.0 Hz), 22.2, 13.59, 13.56; 19F NMR (376.5 MHz, CDCl3) δ −124.3 (t, JHF = 3.5 Hz); Z-isomer: −124.2 (s). HRMS (DART) calcd for C15H19O2BrF [M+H]+: 329.0547, found 329.0550.

Ethyl (E)-2-fluoro-4-methyl-3-phenylpent-2-enoate (20a).

The reaction between isobutyrophenone (3.0 g, 20.2 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (10.26 mL, 50.6 mmol, 2.5 equiv) and MeMgBr (17.1 mL, 50.6 mmol, 2.96 M in Et2O, 2.5 equiv) was run at 40 °C for 30 min. 19F NMR of the crude: mixture of stereoisomers in 11.6:1 (92:8) dr. The product 20a was obtained as a colorless oil after purification by silica gel column chromatography eluting with 0–5% EtOAc in hexanes (4.37 g, 11.6:1 (92:8) dr, 91% yield). 1H NMR (400 MHz, CDCl3) δ 7.41–7.29 (m, 3H), 7.11–7.03 (m, 2H), 3.98 (q, J = 7.1 Hz, 2H), 3.31 (dsept, J = 7.0 Hz, JHF = 0.5 Hz 1H), 1.02 (d, J = 7.0 Hz, 6H), 0.96 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.7 (d, J = 36.9 Hz), 143.7 (d, J = 253.0 Hz), 139.8 (d, J = 14.0 Hz), 134.7 (d, J = 5.6 Hz), 128.3 (d, J = 3.2 Hz), 127.5, 127.2, 60.8, 28.9 (d, J = 5.1 Hz), 20.1 (d, J = 2.0 Hz), 13.4; 19F NMR (376.5 MHz, CDCl3) δ −126.2 (d, JHF = 5.0 Hz); Z-isomer: −121.3 (s). NMR spectra matched reported data.30

Ethyl (E)-3-cyclopropyl-2-fluoro-3-(4-methoxyphenyl)acrylate (21a).

The reaction between cyclopropyl(4-methoxyphenyl) ketone (4.0 g, 22.70 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (19.6 mL; 96.48 mmol; 4.25 equiv) and MeMgBr (27.7 mL, 96.48 mmol, 3.48 M in 2-MeTHF, 4.25 equiv) was run at 70 °C overnight. 19F NMR of the crude: mixture of stereoisomers in 11.0:1 (92:8) dr). The product 21a was obtained as a white solid after purification by silica gel column chromatography eluting with 1–5% EtOAc in hexanes (4.46 g, 74% yield, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 6.95–6.87 (m, 2H), 6.87–6.79 (m, 2H), 3.99 (q, J = 7.1 Hz, 2H), 3.79 (s, 3H), 2.29–2.10 (m, 1H), 1.00 (t, J = 7.1 Hz, 3H), 0.83–0.70 (m, 2H), 0.44–0.31 (m, 2H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.3 (d, J = 35.1 Hz), 159.0, 145.2 (d, J = 251.6 Hz), 136.9 (d, J = 13.4 Hz), 129.9 (d, J = 3.2 Hz), 124.6 (d, J = 5.1 Hz), 113.1, 60.6, 55.0, 13.6, 11.7 (d, J = 9.4 Hz), 4.8 (d, J = 1.2 Hz); 19F NMR (376.5 MHz, CDCl3) δ −131.2 (s). HRMS (DART) calcd for C15H18O3F [M+H]+: 265.1235, found 265.1235.

Ethyl (Z)-3-(4-bromophenyl)-2,4,4,4-tetrafluorobut-2-enoate (22a).

The reaction between 1-(4-bromophenyl)-2,2,2-trifluoroethan-1-one (4.0 g, 15.81 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (8.0 mL; 39.52 mmol; 2.5 equiv) and MeMgBr (11.6 mL, 39.52 mmol, 3.40 M in 2-MeTHF, 2.5 equiv) was run at 40 °C for 30 min. 19F NMR of the crude: mixture of stereoisomers in 25.8:1 (96:4) dr. The product 22a was obtained as a colorless liquid after purification by silica gel column chromatography eluting with 5% MTBE in hexanes (4.56 g, 85% yield, mixture of stereoisomers in 25.8:1 (96:4) dr). 1H NMR (400 MHz, CDCl3) δ 7.59–7.52 (m, 2H), δ 7.18–7.09 (m, 2H), 4.10 (q, J = 7.1 Hz, 2H), 1.06 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 158.7 (d, J = 34.5 Hz), 149.6, (dq, J = 285.1 Hz, J = 2.4 Hz), 131.6, 131.0 (d, J = 3.4 Hz), 127.5 (d, J = 2.5 Hz), 123.9, 121.6 (q, J = 275.4 Hz), 120.5 (dq, J = 32.9 Hz, J = 9.4 Hz), 62.6, 13.3; 19F NMR (376.5 MHz, CDCl3) δ −107.3 (q, J = 24.3 Hz), −60.5 (d, J = 24.3 Hz); Z-isomer: δ −105.7 (q, J = 10.0 Hz), −58.5 (d, J = 10.0 Hz). HRMS (DART) calcd for C12H10O2BrF4 [M+H]+: 340.9795, found 340.9796.

1-(3,5-Dimethylphenyl)hept-5-yn-1-one.

To a suspension of Mg turnings (489.5 mg, 20.13 mmol, 1.04 equiv) in THF (5 mL) was added 1,2-dibromoethane (63 µL, 0.73 mmol, 0.04 equiv) and the mixture was heated to 50 °C and stirred for 15 min. A solution of 1-bromo-3,5-dimethylbenzene (2.63 mL, 19.36 mmol, 1 equiv) in THF (20 mL) was then added dropwise maintaining steady solvent boiling. After complete addition the reaction mixture was stirred at 50 °C for 30 min. The resultant Grignard reagent was titrated with salicylaldehyde phenylhydrazone: 0.765 M solution was obtained. Grignard reagent (13.8 mL, 10.56 mmol, 1.0 equiv.) was added dropwise to a solution of 2-methyl-3-oxocyclohex-1-en-1-yl trifluoromethanesulfonate31 (3.0 g; 11.62 mmol; 1.1 equiv) in THF (20 mL) at 0 °C. The mixture was stirred at 0 °C for 10 min and then warmed to room temperature and stirred for additional 30 min. The reaction mixture was quenched with 10% aq. NH4Cl solution and extracted with MTBE (2 × 30 mL). Combined organic extracts were dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was purified by silica gel column chromatography eluting with 5–30% EtOAc in hexanes to afford the title ketone as a pale yellow oil (1.56 g, 63% yield). 1H NMR (400 MHz, CDCl3) δ 7.58 (s, 2H), 7.19 (s, 1H), 3.06 (t, J = 7.3 Hz, 2H), 2.37 (s, 6H), 2.29–2.21 (m, 2H), 1.90 (apparent quintet, J = 7.0 Hz, 2H), 1.78 (t, J = 2.5 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 200.3, 138.1, 137.1, 134.5, 125.8, 78.5, 76.3, 37.4, 23.5, 21.2, 18.3, 3.4. HRMS (DART) calcd for C15H19O [M+H]+: 215.1430, found 215.1431.

Ethyl (E)-3-(3,5-dimethylphenyl)-2-fluoronon-2-en-7-ynoate (23a).

The reaction between 1-(3,5-dimethylphenyl)hept-5-yn-1-one (1.50 g, 7.00 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (3.3 mL; 16.10 mmol; 2.3 equiv) and MeMgBr (4.6 mL, 16.10 mmol, 3.48 M in 2-MeTHF, 2.3 equiv) was run at 40 °C for 2 h. 19F NMR of the crude: mixture of stereoisomers in 22.0:1 (96:4) dr. The product 23a was obtained as a colorless liquid after purification by silica gel column chromatography eluting with 0–2% MTBE in hexanes (1.95 g, 92% yield, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 6.94 (s, 1H), 6.74 (s, 2H), 4.04 (q, J = 7.1 Hz, 2H), 2.63–2.53 (m, 2H), 2.31 (s, 6H), 2.18–2.08 (m, 2H), 1.76 (t, J = 2.5 Hz, 3H), 1.62–1.48 (m, 2H), 1.03 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.6 (d, J = 36.6 Hz), 144.3 (d, J = 252.4 Hz), 137.3, 136.7 (d, J = 5.3 Hz), 134.8 (d, J = 15.7 Hz), 129.3, 125.5 (d, J = 3.0 Hz), 78.2, 75.9, 60.8, 31.7 (d, J = 5.2 Hz), 26.3 (d, J = 2.1 Hz), 21.1, 18.5, 13.5, 3.3; 19F NMR (376.5 MHz, CDCl3) δ −124.9 (s). HRMS (DART) calcd for C19H24O2F [M+H]+: 303.1755, found 303.1755.

Ethyl (Z)-3-(1-cyanocyclohexyl)-2-fluoro-3-(4-methoxyphenyl)acrylate (24a).

The reaction between 1-(4-methoxybenzoyl)cyclohexane-1-carbonitrile32 (1.0 g, 4.11 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (3.75 mL, 18.5 mmol, 4.5 equiv) and MeMgBr (5.31 mL, 18.5 mmol, 3.48 M in 2-MeTHF, 4.5 equiv) was run at 40 °C for 18 h. 19F NMR of the crude: single stereoisomer (>98:2 dr). The product 24a was obtained as a colorless oil after purification by silica gel column chromatography eluting with EtOAc in hexanes (1.33 g, 98% yield, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 7.01 (d, J = 8.5 Hz, 2H), 6.90 (d, J = 8.5 Hz, 2H), 4.01 (q, J = 7.1 Hz, 2H), 3.82 (s, 3H), 2.12–1.97 (m, 2H), 1.83–1.64 (m, 5H), 1.49–1.33 (m, 2H), 1.18–1.03 (m, 1H), 1.02 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 159.9 (d, J = 35.3 Hz), 159.6, 147.0 (d, J = 269.0 Hz), 132.2 (d, J = 9.5 Hz), 129.9 (d, J = 3.5 Hz), 125.1 (d, J = 5.8 Hz), 120.6, 113.6, 61.5, 55.1, 41.6 (d, J = 1.7 Hz), 34.3 (d, J = 2.1 Hz), 24.6, 22.7, 13.5; 19F NMR (376.5 MHz, CDCl3) δ −111.4 (s). HRMS (DART) calcd for C19H23O3NF [M+H]+: 332.1657, found 332.1657.

Ethyl (E)-3-(4-bromophenyl)-2-fluoro-4-phenylbut-2-enoate (25a).

The reaction between 1-(4-bromophenyl)-2-phenylethan-1-one (4.0 g, 14.54 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (5.9 mL; 29.08 mmol; 2.0 equiv) and MeMgBr (8.4 mL, 29.08 mmol, 3.48 M in 2-MeTHF, 2.0 equiv) was run at 40 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 13.2:1 (93:7) dr. The product 25a was obtained as a colorless liquid after purification by silica gel column chromatography eluting with 0–5% MTBE in hexanes (4.94 g, 94% yield, mixture of stereoisomers in 13.3:1 (93:7) dr). 1H NMR (400 MHz, CDCl3) δ 7.40–7.31 (m, 2H), 7.27–7.13 (m, 3H), 7.06–6.97 (m, 2H), 6.84–6.75 (m, 2H), 4.05 (q, J = 7.1 Hz, 2H), 3.79 (d, JHF = 3.6 Hz, 2H), 1.04 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (125 MHz, CDCl3) δ 160.4 (d, J = 36.2 Hz), 144.3 (d, J = 255.8 Hz), 136.3 (d, J = 2.5 Hz), 135.6 (d, J = 5.3 Hz), 132.8 (d, J = 17.0 Hz), 131.0, 129.7 (d, J = 3.1 Hz), 129.1 (d, J = 1.1 Hz), 128.5, 126.7, 121.8, 61.3, 38.6 (d, J = 5.1 Hz), 13.6; 19F NMR (376.5 MHz, CDCl3) δ −123.3 (t, JHF = 3.2 Hz); Z-isomer: −122.6 (s). HRMS (DART) calcd for C18H17O2BrF [M+H]+: 363.0391, found 363.0391.

Ethyl (E)-2-fluoro-3-(quinolin-3-yl)but-2-enoate (26a).

The reaction between 1-(quinolin-3-yl)ethan-1-one (4.0 g, 23.37 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (8.1 mL; 39.72 mmol; 1.7 equiv) and MeMgBr (11.7 mL, 39.72 mmol, 3.40 M in 2-MeTHF, 1.7 equiv) was run at 40 °C for 30 min. 19F NMR of the crude: mixture of stereoisomers in 9.8:1 (91:9) dr. The product 26a was obtained as a light brown oil after purification by silica gel column chromatography eluting with 40% MTBE in hexanes (4.88 g, 81% yield, mixture of stereoisomers in 11.3:1 (92:8) dr). 1H NMR (400 MHz, CDCl3) δ 8.67 (d, JHF = 2.2 Hz, 1H), 8.04 (d, J = 8.5 Hz, 1H), 7.91 (d, JHF = 2.1 Hz, 1H), 7.72 (d, J = 8.1 Hz, 1H), 7.63 (ddd, J = 8.5 Hz, J = 6.9 Hz, J = 1.4 Hz, 1H), 7.47 (ddd, J = 8.1 Hz, J = 6.9 Hz, J = 1.0 Hz, 1H), 3.96 (q, J = 7.1 Hz, 2H), 2.17 (d, JHF = 4.5 Hz, 3H), 0.88 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 159.9 (d, J = 35.7 Hz), 149.6 (d, J = 2.9 Hz), 147.1, 145.0 (d, J = 255.4 Hz), 133.7 (d, J = 3.5 Hz), 131.3 (d, J = 5.4 Hz), 129.4, 129.0, 127.9 (d, J = 5.4 Hz), 127.6, 127.1, 126.7, 61.1, 19.0 (d, J = 6.4 Hz), 13.4; 19F NMR (376.5 MHz, CDCl3) δ −120.4 (q, JHF = 4.5 Hz); Z-isomer: −123.7 (s). HRMS (DART) calcd for C15H15O2NF [M+H]+: 260.1081, found 260.1082.

Ethyl (E)-3-(benzo[b]thiophen-2-yl)-2-fluorobut-2-enoate (27a).

The reaction between 1-(benzo[b]thiophen-2-yl)ethan-1-one (4.0 g, 22.70 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (9.2 mL; 45.39 mmol; 2.0 equiv) and MeMgBr (13.0 mL, 45.39 mmol, 3.48 M in 2-MeTHF, 2.0 equiv) was run at 40 °C for 30 min. 19F NMR of the crude: mixture of stereoisomers in 10.9:1 (92:8) dr. The product 27a was obtained as a pale yellow oil after purification by silica gel column chromatography eluting with 2–8% EtOAc in hexanes (5.97 g, 99% yield, mixture of stereoisomers in 10.9:1 (92:8) dr). 1H NMR (400 MHz, CDCl3) δ 7.84–7.79 (m, 1H), 7.78–7.72 (m, 1H), 7.40–7.29 (m, 2H), 7.25 (s, 1H), 4.16 (q, J = 7.1 Hz, 2H), 2.25 (d, JHF = 4.7 Hz, 3H), 1.11 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.2 (d, J = 35.7 Hz), 145.5 (d, J = 257.6 Hz), 140.1, 139.3, 138.9 (d, J = 6.7 Hz), 124.5, 124.3, 123.9 (d, J = 21.6 Hz), 123.64, 123.63 (d, J = 3.5 Hz), 122.0, 61.4, 19.3 (d, J = 6.4 Hz), 13.7; 19F NMR (376.5 MHz, CDCl3) δ −116.9 (q, JHF = 4.7 Hz); Z-isomer: −116.4 (q, JHF = 3.2 Hz). HRMS (DART) calcd for C14H14O2FS [M+H]+: 265.0693, found 265.0694.

Ethyl (E)-2-fluoro-2-(4a-methyl-5-oxo-4,4a,5,6,7,8-hexahydronaphthalen-2(3H)-ylidene)acetate (29a).

The reaction between Wieland-Miescher ketone (4.0 g, 22.44 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (8.2 mL; 40.40 mmol; 1.8 equiv) and MeMgBr (11.6 mL, 40.40 mmol, 3.48 M in 2-MeTHF, 1.8 equiv) was run at −40 °C for 30 min. 19F NMR of the crude: mixture of double bond isomers in 3.47:1 (78:22) dr. The product 29a was obtained as a colorless oil after purification by silica gel column chromatography eluting with 3–10% EtOAc in hexanes (5.98 g, 99% yield, mixture of double bond isomers in 3.44:1 (78:22) dr). 1H NMR (400 MHz, CDCl3) δ 7.09 (s, 1H), 4.26 (q, J = 7.1 Hz, 2H), 2.84–2.71 (m, 1H), 2.71–2.56 (m, 2H), 2.49–2.34 (m, 2H), 2.34–2.20 (m, 1H), 2.11–1.99 (m, 1H), 1.92–1.74 (m, 2H), 1.71–1.56 (m, 1H), 1.38–1.25 (m, 6H); 13C{1H} NMR (100 MHz, CDCl3) δ 212.7, 161.2 (d, J = 33.7 Hz), 151.2 (d, J = 12.4 Hz), 142.0 (d, J = 252.9 Hz), 129.5 (d, J = 18.1 Hz), 118.6 (d, J = 2.5 Hz), 61.0, 50.2, 37.9, 32.0, 28.7 (d, J = 1.6 Hz), 24.0, 23.6 (d, J = 1.4 Hz), 19.5 (d, J = 8.1 Hz), 14.1; 19F NMR (376.5 MHz, CDCl3) δ −129.6 (m); Z-isomer: −132.5 (d, JHF = 4.2 Hz). HRMS (DART) calcd for C15H20O3F [M+H]+: 267.1391, found 267.1392.

Ethyl (Z)-2-fluoro-3-(naphthalen-2-yl)acrylate (Z-30a).

A round bottom flask was charged with triethyl 2-fluoro-2-phosphonoacetate (7.79 mL, 38.42 mmol, 1.5 equiv) and THF (80 mL). The solution was cooled to −10 °C. MeMgBr (11.0 mL, 38.42 mmol, 3.48 M in 2-MeTHF, 1.5 equiv) was added dropwise maintaining internal temperature below 10 °C. The reaction mixture was warmed to rt and stirred for 10 min, then cooled to −78 °C. A solution of 2-naphthaldehyde (4.0 g, 25.61 mmol, 1.0 equiv) in THF (23 mL) was added dropwise, and the reaction mixture was linearly warmed to rt over 2 h. The mixture was quenched with sat. aq. NH4Cl solution (50 mL) and extracted with MTBE (2 × 30 mL). Organic phase was dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was analyzed by quantitative 19F NMR: mixture of stereoisomers in 4.82:1 (83:17) dr. The residue was purified by silica gel column chromatography eluting with 0–2% MTBE in hexanes to afford the product Z-30a as a white solid (4.64 g, 74% yield, single Z-isomer (>98:2 dr)). mp 68.4–70.5 °C; 1H NMR (400 MHz, CDCl3) δ 8.10 (s, 1H), 7.91–7.75 (m, 4H), 7.57–7.46 (m, 2H), 7.09 (d, JHF = 35.3 Hz, 1H), 4.38 (q, J = 7.1 Hz, 2H), 1.41 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 161.4 (d, J = 34.2 Hz), 147.1 (d, J = 267.8 Hz), 133.5 (d, J = 1.9 Hz), 133.1, 130.7 (d, J = 8.1 Hz), 128.7 (d, J = 4.6 Hz), 128.5, 128.4, 127.6, 127.2, 126.8 (d, J = 8.5 Hz), 126.5, 117.6 (d, J = 4.6 Hz), 61.9, 14.2; 19F NMR (376.5 MHz, CDCl3) δ −125.2 (d, JHF = 35.3 Hz). Both 1H and 13C NMR spectra matched reported data.33

General Procedure for Horner-Wadsworth-Emmons Reaction of Aldehydes with Triethyl 2-fluoro-2-phosphonoacetate and n-BuLi in THF. Ethyl (E)-2-fluoro-3-(naphthalen-2-yl)acrylate (E-30a).

A round bottom flask was charged with triethyl 2-fluoro-2-phosphonoacetate (5.84 mL, 28.81 mmol, 1.5 equiv) and THF (50 mL). The solution was cooled to −78 °C. n-BuLi (10.63 mL, 28.81 mmol, 2.71 M in hexanes, 1.5 equiv) was added dropwise maintaining internal temperature below 0 °C. The reaction mixture was warmed to rt and stirred for 10 min, then cooled to −78 °C. A solution of 2-naphthaldehyde (3.0 g, 19.21 mmol, 1.0 equiv) in THF (26 mL) was added dropwise, and the reaction mixture was linearly warmed to 10 °C over 2 h. The mixture was quenched with sat. aq. NH4Cl solution (50 mL) and extracted with MTBE (2 × 30 mL). The organic phase was dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was analyzed by quantitative 19F NMR: mixture of stereoisomers in 40.0:1 (98:2) dr. The residue was purified by silica gel column chromatography eluting with 0–2% MTBE in hexanes to afford product E-30a as a white solid (4.59 g, 98% yield, mixture of stereoisomers in 40.0:1 (98:2) dr. mp 31.3–32.7 °C; 1H NMR (400 MHz, CDCl3) δ 7.95 (s, 1H), 7.89–7.79 (m, 3H), 7.60 (dd, J = 8.5 Hz, J = 1.6 Hz, 1H), 7.56–7.47 (m, 2H), 7.08 (d, JHF = 22.4 Hz, 1H), 4.28 (q, J = 7.1 Hz, 2H), 1.25 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.5 (d, J = 36.1 Hz), 147.0 (d, J = 255.1 Hz), 133.1, 132.8, 129.5 (d, J = 3.5 Hz), 128.3 (d, J = 9.5 Hz), 128.2, 127.6, 127.4, 127.0 (d, J = 2.1 Hz), 126.7, 126.3, 121.5 (d, J = 26.3 Hz), 61.6, 13.8; 19F NMR (376.5 MHz, CDCl3) δ −116.5 (d, JHF = 22.4 Hz); Z-isomer: −125.2 (d, JHF = 35.3 Hz). Both 1H and 13C NMR spectra matched reported data.33

Ethyl (E)-3-(benzo[d][1,3]dioxol-4-yl)-2-fluoroacrylate (31a).

The reaction between benzo[d][1,3]dioxole-4-carbaldehyde (3.0 g, 19.98 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (6.08 mL; 29.97 mmol; 1.5 equiv) and HexLi (12.5 mL, 29.97 mmol, 2.40 M in hexanes, 1.5 equiv) was run at −78 °C to −30 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 34.8:1 (97:3) dr. The product 31a was obtained as a colorless oil after purification by silica gel column chromatography eluting with 5–7% EtOAc in hexanes (4.90 g, >99% yield, mixture of stereoisomers in 36.1:1 (97:3) dr). 1H NMR (400 MHz, CDCl3) δ 7.03–6.97 (m, 1H), 6.84–6.73 (m, 3H), 5.94 (s, 2H), 4.26 (q, J = 7.1 Hz, 2H), 1.25 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.3 (d, J = 36.0 Hz), 148.1 (d, J = 257.1 Hz), 147.1, 145.7 (d, J = 2.7 Hz), 122.6 (d, J = 2.6 Hz), 121.1, 113.9 (d, J = 27.9 Hz), 113.3 (d, J = 9.9 Hz), 108.7, 100.9, 61.6, 13.8; 19F NMR (376.5 MHz, CDCl3) δ −115.4 (d, JHF = 20.7 Hz), Z-isomer: −123.9 (d, JHF = 35.5 Hz). HRMS (DART) calcd for C12H12O4F [M+H]+: 239.0714, found 239.0715.

Ethyl (E)-3-(benzofuran-2-yl)-2-fluoroacrylate (32a).

The reaction between benzo[b]furan-2-carboxaldehyde (5.0 g, 34.21 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (10.4 mL; 51.31 mmol; 1.5 equiv) and n-BuLi (18.9 mL, 51.31 mmol, 2.71 M in hexanes, 1.5 equiv) was run at −78 °C to −20 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 21.6:1 (96:4) dr, 98% yield. The product 32a was obtained as a pale yellow oil after purification by silica gel column chromatography eluting with 0–3% MTBE in hexanes (7.1 g, 89% yield, single stereoisomer (>98:2 dr). 1H NMR (400 MHz, CDCl3) δ 7.80 (s, 1H), 7.62 (d, J = 7.7 Hz, 1H), 7.46 (dd, J = 8.3 Hz, J = 0.8 Hz, 1H), 7.34 (ddd, J = 8.3 Hz, J = 7.2 Hz, J = 1.3 Hz, 1H), 7.28–7.21 (m, 1H), 6.89 (d, JHF = 21.9 Hz, 1H), 4.41 (q, J = 7.1 Hz, 2H), 1.42 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.3 (d, J = 33.7 Hz), 154.9 (d, J = 2.3 Hz), 146.9 (d, J = 262.0 Hz), 147.5 (d, J = 10.6 Hz), 128.8, 125.8, 123.1, 121.9, 111.8 (d, J = 7.1 Hz), 111.5 (d, J = 33.5 Hz), 111.1, 61.9, 14.1; 19F NMR (376.5 MHz, CDCl3) δ −116.5 (d, JHF = 21.9 Hz). HRMS (DART) calcd for C13H12O3F [M+H]+: 235.0765, found 235.0766.

Ethyl (E)-3-cyclopropyl-2-fluoroacrylate (33a).

The reaction between cyclopropane carboxaldehyde (2.13 mL, 28.53 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (8.7 mL; 42.80 mmol; 1.5 equiv) and HexLi (17.8 mL, 42.80 mmol, 2.40 M in hexanes, 1.5 equiv) was run at −78 °C to −30 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 40.7:1 (98:2) dr. The product 33a was obtained as a colorless volatile liquid after purification by silica gel column chromatography eluting with 4–7% Et2O in pentane (4.28 g, 95% yield, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 5.27 (dd, JHF = 20.3 Hz, J = 10.9 Hz, 1H), 4.31 (q, J = 7.1 Hz, 2H), 2.52–2.39 (m, 1H), 1.34 (t, J = 7.1 Hz, 3H), 1.02–0.89 (m, 2H), 0.56–0.43 (m, 2H); 13C{1H} NMR (100 MHz, CDCl3) δ 161.5 (d, J = 34.4 Hz), 146.6 (d, J = 246.3 Hz), 129.6 (d, J = 21.8 Hz), 61.2, 14.1, 8.4 (d, J = 7.2 Hz), 8.1 (d, J = 1.1 Hz); 19F NMR (376.5 MHz, CDCl3) δ −127.1 (dd, JHF = 20.3 Hz, JHF = 1.8 Hz). HRMS (DART) calcd for C8H12O2F [M+H]+: 159.0816, found 159.0816.

Ethyl (E)-3-cyclopentyl-2-fluoroacrylate (34a).

The reaction between cyclopentane carboxaldehyde (2.72 mL, 25.47 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (7.75 mL; 38.21 mmol; 1.5 equiv) and HexLi (15.9 mL, 38.21 mmol, 2.40 M in hexanes, 1.5 equiv) was run at −78 °C to −30 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 23.6:1 (96:4) dr. The product 34a was obtained as a colorless volatile liquid after purification by silica gel column chromatography eluting with 4–7% EtOAc in hexanes (4.58 g, 97% yield, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 5.81 (dd, JHF = 21.8 Hz, J = 10.4 Hz, 1H), 4.27 (q, J = 7.1 Hz, 2H), 3.47–3.32 (m, 1H), 1.97–1.83 (m, 2H), 1.74–1.53 (m, 4H), 1.39–1.18 (m, 5H); 13C{1H} NMR (100 MHz, CDCl3) δ 161.1 (d, J = 35.7 Hz), 146.2 (d, J = 250.7 Hz), 128.6 (d, J = 16.5 Hz), 61.2, 36.2 (d, J = 4.8 Hz), 33.6 (d, J = 2.2 Hz), 25.3, 14.0; 19F NMR (376.5 MHz, CDCl3) δ −124.4 (d, JHF = 21.8 Hz), Z-isomer: −132.0 (d, JHF = 33.5 Hz). HRMS (DART) calcd for C10H16O2F [M+H]+: 187.1129, found 187.1129.

Ethyl (E)-2-fluoro-5-phenylpent-2-enoate (35a).

The reaction between 3-phenylpropionaldehyde (2.97 mL, 22.36 mmol, 1 equiv) and reagent prepared from triethyl 2-fluoro-2-phosphonoacetate (6.8 mL; 33.54 mmol; 1.5 equiv) and HexLi (14.0 mL, 33.54 mmol, 2.40 M in hexanes, 1.5 equiv) was run at −78 °C to −30 °C for 1 h. 19F NMR of the crude: mixture of stereoisomers in 15.1:1 (94:6) dr. The product 35a was obtained as a pale yellow liquid after purification by silica gel column chromatography eluting with 5–7% EtOAc in hexanes (4.44 g, 89% yield, mixture of stereoisomers in 17.6:1 (95:5) dr). 1H NMR (400 MHz, CDCl3) δ 7.35–7.27 (m, 2H), 7.25–7.18 (m, 3H), 5.94 (dt, JHF = 21.3 Hz, J = 8.0 Hz, 1H), 4.30 (q, J = 7.1 Hz, 2H), 2.91–2.82 (m, 2H), 2.81–2.74 (m, 2H), 1.35 (t, J = 7.1 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 161.8 (d, J = 35.8 Hz), 147.3 (d, J = 252.2 Hz), 140.6, 128.4, 126.1, 122.3 (d, J = 18.6 Hz), 61.3, 35.2 (d, J = 2.3 Hz), 27.1 (d, J = 5.1 Hz), 14.1; 19F NMR (376.5 MHz, CDCl3) δ −121.7 (d, JHF = 21.3 Hz), Z-isomer: −129.6 (d, JHF = 33.1 Hz). NMR spectra matched reported data.30 HRMS (DART) calcd for C13H16O2F [M+H]+: 223.1129, found 223.1130.

General Procedure for Ester Saponfication.

To a solution of ethyl ester (1 equiv) in EtOH (~0.5 M) was added a solution of LiOH•H2O (2.0 equiv) in water (volume ratio EtOH/H2O = 2:1) at 0 °C. The reaction mixture was warmed to r.t and stirred until completion as determined by HPLC or GC. The reaction mixture was diluted with water and cooled to 10 °C. Conc. HCl (2.2 equiv) was added dropwise maintaining internal temperature below 25 °C. The resultant slurry was warmed to rt and diluted further with water. The slurry was filtered and the solid was washed with 25 wt.% EtOH in H2O. The solid was dried to afford the carboxylic acid product.

(E)-2-Fluoro-3-(naphthalen-2-yl)but-2-enoic acid (10b).

Saponification of ester 10a (15.1 g, 58.07 mmol, 20.9:1 (95:5) dr) in EtOH/water afforded carboxylic acid 10b as a white solid (12.1 g, 21.1:1 (95:5) dr, 91% yield). mp 170.3–171.6 °C; 1H NMR (400 MHz, MeOH-d4) δ 7.85–7.77 (m, 3H), 7.68 (s, 1H), 7.49–7.42 (m, 2H), 7.31 (dd, J = 8.5 Hz, J = 1.7 Hz, 1H), 5.13–4.75 (brs, 1H), 2.20 (d, J = 4.5 Hz, 3H); 13C{1H} NMR (100 MHz, MeOH-d4) δ 163.7 (d, J = 36.5 Hz), 146.2 (d, J = 250.5 Hz), 137.5 (d, J = 5.6 Hz), 134.6, 134.3, 132.8 (d, J = 17.6 Hz), 129.1, 128.7 (2C), 127.6 (d, J = 3.2 Hz), 127.3 (2C), 127.1 (d, J = 2.9 Hz), 19.6 (d, J = 6.9 Hz); 19F NMR (376.5 MHz, MeOH-d4) δ −123.5 (q, JHF = 4.4 Hz); Z-isomer: −124.6 (s). HRMS (DART) calcd for C14H12O2F [M+H]+: 231.0816, found 231.0816.

(E)-3-(4-Bromophenyl)-2-fluoroacrylic acid (E-12b).

Saponification of ester E-12a (1.05 g, 3.85 mmol, 34.5:1 (97:3) dr) in EtOH/water afforded carboxylic acid E-12b as a white solid (0.80 g, > 98:2 dr, 85% yield). mp 149.1–150.6 °C; 1H NMR (400 MHz, CDCl3) δ 10.05–8.94 (brs, 1H); 7.55–7.43 (m, 2H), 7.40–7.29 (m, 2H), 6.97 (d, JHF = 21.8 Hz, 1H); 13C{1H} NMR (100 MHz, CDCl3) δ 164.7 (d, J = 36.8 Hz), 145.9 (d, J = 253.9 Hz), 131.45, 131.43 (d, J = 3.6 Hz), 129.1 (d, J = 9.2 Hz), 123.6; 123.5 (d, J = 26.8 Hz); 19F NMR (376.5 MHz, CDCl3) δ −116.3 (d, JHF = 21.8 Hz). HRMS (DART) calcd for C9H7O2BrF [M+H]+: 244.9608, found 244.9609.

(Z)-3-(4-Bromophenyl)-2-fluoroacrylic acid (Z-12b).

Saponification of ester Z-12a (4.53 g, 16.59 mmol, > 98:2 dr) in EtOH/water afforded carboxylic acid Z-12b as a white solid (3.97 g, > 98:2 dr, 98% yield). mp 226.5–227.5 °C; 1H NMR (400 MHz, MeOH-d4) δ 7.56 (apparent s, 4H), 6.94 (d, JHF = 35.0 Hz, 1H) 5.32–4.69 (brs, 1H); 13C{1H} NMR (100 MHz, MeOH-d4) δ 164.0 (d, J = 35.3 Hz), 149.1 (d, J = 265.5 Hz), 133.2, 133.0 (d, J = 8.3 Hz), 131.8 (d, J = 4.3 Hz), 124.9 (d, J = 3.9 Hz), 117.3 (d, J = 4.8 Hz); 19F NMR (376.5 MHz, MeOH-d4) δ −124.7 (d, JHF = 35.0 Hz). NMR spectra matched reported data.34

(E)-2-Fluoro-3-phenylbut-2-enoic acid (15b).

To a solution of ethyl ester 15a (5.85 g, 28.09 mmol; 1 equiv) in EtOH (60 mL) was added a solution of LiOH•H2O (2.36 g; 56.19 mmol; 2.0 equiv) in water (40 mL) at 0 °C. The reaction mixture was warmed to r.t and stirred for 2 h. After reaction completion the reaction mixture was diluted with water (50.0 mL) and cooled to 10 °C. Conc. HCl (5.1 mL; 61.81 mmol; 2.2 equiv) was added dropwise maintaining internal temperature below 25 °C. The resultant slurry was warmed to rt. Water (50.0 mL) was added dropwise, and the slurry was stirred for another 0.5 h. The slurry was filtered and the solid was washed with 25 wt.% EtOH in H2O (2 × 15 mL). The solid was dried on a Buchner funnel for 2 h and then at 50 °C in a vacuum oven overnight to afford carboxylic acid 15b as a white solid (4.81 g, 95% yield, >98:2 dr). mp 131.8–133.4 °C; 1H NMR (400 MHz, CDCl3) δ 10.46–9.19 (brs, 1H), 7.40–7.30 (m, 3H), 7.38–7.28 (m, 3H), 7.20–7.11 (m, 2H), 2.16 (d, JHF = 4.5 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 165.2 (d, J = 36.6 Hz), 143.3 (d, J = 248.6 Hz), 137.7 (d, J = 5.1 Hz), 135.0 (d, J = 17.0 Hz), 128.2, 128.1, 127.3 (d, J = 3.1 Hz), 19.9 (d, J = 6.6 Hz); 19F NMR (376.5 MHz, CDCl3) δ −124.1 (q, JHF = 4.5 Hz). HRMS (DART) calcd for C10H10O2F [M+H]+: 181.0659, found 181.0660.

(E)-3-(Benzo[d][1,3]dioxol-5-yl)-2-fluorobut-2-enoic acid (16b).

Saponification of ester 16a (3.7 g, 14.67 mmol, >98.2 dr) in 2-PrOH/water afforded carboxylic acid 16b as a white solid (3.0 g, >98.2 dr, 92% yield). mp 161.2–163.1 °C; 1H NMR (400 MHz, CDCl3) δ 6.76 (d, J = 8.0 Hz, 1H), 6.73–6.63 (m, 2H), 5.91 (s, 2H), 5.44–4.64 (brs, 1H), 2.08 (d, JHF = 4.6 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 163.9 (d, J = 36.6 Hz), 148.9, 148.8, 146.0 (d, J = 250.0 Hz), 133.6 (d, J = 5.9 Hz), 132.5 (d, J = 17.9 Hz), 122.4 (d, J = 3.2 Hz), 109.5 (d, J = 3.2 Hz), 109.0, 102.6, 19.6 (d, J = 6.8 Hz); 19F NMR (376.5 MHz, CDCl3) δ −123.5 (q, JHF = 4.3 Hz). HRMS (DART) calcd for C11H10O4F [M+H]+: 225.0558, found 225.0558.

General Procedure for Telescoped Horner-Wadsworth-Emmons Reaction and Ester Saponification. (E)-2-Fluoro-3-(4-nitrophenyl)but-2-enoic acid (17b).

A round bottom flask was charged with triethyl 2-fluoro-2-phosphonoacetate (1.04 mL, 5.15 mmol, 1.7 equiv) and THF (8 mL). The solution was cooled to 0 to −5 °C. MeMgBr (1.74 mL, 5.15 mmol, 2.96 M in Et2O, 1.7 equiv) was then added dropwise maintaining internal temperature below 10 °C. The reaction mixture was warmed to rt and stirred for 10 min, then heated to 40 °C and stirred for another 10 min. A solution of 4-nitroacetophenone (500 mg, 3.03 mmol, 1.0 equiv) in THF (4 mL) was added dropwise, and the reaction mixture was stirred for 15 min. The reaction mixture was cooled to rt and concentrated under reduced pressure to minimum volume. 2-PrOH (10 mL) was added, and the mixture was concentrated again. The reaction mixture was diluted with 2-PrOH (5 mL) and cooled to 10 °C. A solution of NaOH (726.6 mg; 18.17 mmol; 6 equiv) in H2O (1.2 mL) was added, and resultant slurry was warmed to rt and stirred at rt for 1 h. Conc. HCl (1.6 mL; 19.70 mmol; 6.5 equiv) was added, and the reaction mixture was slowly concentrated under reduced producing a yellow precipitate of the product. The mixture was filtered, and the filter cake was washed twice with water (5 mL) and then with heptane (5 mL). The solid was dried on a Buchner funnel for 1 h then at 50 °C in a vacuum oven overnight to afford crude acid 17b (yellow solid, 636.7 mg, 93% yield). Crude acid was obtained as 12.7:1 (93:7) mixture of E/Z isomers (19F NMR). Its stereochemical purity was increased by recrystallization as follows. Crude acid 17b (970.0 mg) was dissolved in 2-PrOH (3.00 mL) at 70 °C. Heptane (18 mL) was slowly added at 70 °C. The reaction mixture was gradually cooled to rt and the resultant slurry was stirred for 2 h. The slurry was filtered, and the filter cake was washed with a minimum amount of 2-PrOH/heptane mixture (6:1 v/v), then with heptane (5 mL). The solid was dried in high vacuum to afford the acid (yellow solid, 609.7 mg, single isomer (>98:2 dr)). The mother liquor was concentrated and the residue was recrystallized from 2-PrOH (800 μL) and heptane (6 mL) following the same procedure to afford the second crop of product (yellow solid, 220 mg, >98:2 dr). Combined mass: 829.7 mg, 86% yield, 80% overall yield from 4-nitroacetophenone. mp 192.9–194.4 °C; 1H NMR (400 MHz, MeOH-d4) δ 8.20 (d, J = 8.2 Hz, 2H), 7.46 (d, J = 8.2 Hz, 2H), 5.63–4.34 (brs, 1H), 2.15 (d, JHF = 3.8 Hz, 3H); 13C{1H} NMR (100 MHz, MeOH-d4) δ 162.9 (d, J = 35.8 Hz), 148.8, 146.4 (d, J = 255.0 Hz), 147.3 (d, J = 5.9 Hz), 130.9 (d, J = 19.2 Hz), 130.2 (d, J = 3.2 Hz), 124.4, 19.1 (d, J = 6.8 Hz); 19F NMR (376.5 MHz, MeOH-d4) δ −122.2 (q, JHF = 3.8 Hz). HRMS (DART) calcd for C10H7O4NF [M-H]–: 224.0365, found 224.0364.

(E)-3-(4-Bromophenyl)-2-fluorohept-2-enoic acid (18b).

Saponification of ester 18a (3.0 g, 9.11 mmol, 20.5:1 (95:5) dr) in 2-PrOH/water afforded crude carboxylic acid as an off-white solid (2.56 g, 93% yield). The crude acid was recrystallized from heptane to afford 18b as a single stereoisomer (2.18 g, 85% recovery, 79% overall yield, >98:2 dr). 1H NMR (400 MHz, CDCl3) δ 11.44–10.75 (brs, 1H), 7.52–7.40 (m, 2H), 7.07–6.92 (m, 2H), 2.72–2.31 (m, 2H), 1.53–1.09 (m, 4H), 1.05–0.67 (m, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 165.5 (d, J = 36.9 Hz), 143.2 (d, J = 250.5 Hz), 138.2 (d, J = 17.0 Hz), 135.4 (d, J = 5.4 Hz), 131.3, 129.3 (d, J = 3.0 Hz), 122.2, 32.7 (d, J = 4.8 Hz), 28.7 (d, J = 1.9 Hz), 22.3, 13.6; 19F NMR (376.5 MHz, CDCl3) δ −124.8 (t, JHF = 3.4 Hz); Z-isomer: −124.6 (s). HRMS (DART) calcd for C13H15O2BrF [M+H]+: 301.0234, found 301.0234.

(E)-2-Fluoro-3-(o-tolyl)pent-2-enoic acid (19b).

A round bottom flask was charged with triethyl 2-fluoro-2-phosphonoacetate (6.8 mL, 33.63 mmol, 2.5 equiv) and THF (50 mL). The solution was cooled to 0 to −5 °C. MeMgBr (11.4 mL, 33.63 mmol, 2.96 M in Et2O, 2.5 equiv) was then added dropwise maintaining internal temperature below 10 °C. The reaction mixture was warmed to rt and stirred for 10 min, then heated to 40 °C and stirred for another 10 min. A solution of 2-methylpropiophenone (2.0 mL, 13.45 mmol, 1.0 equiv) in THF (10 mL) was added dropwise, and the reaction mixture was stirred for 30 min. An aliquot of reaction mixture was analyzed by quantitative 19F NMR: ester 19a was formed as a mixture of stereoisomers in 96:4 dr. The reaction mixture was cooled to rt and concentrated under reduced pressure to a minimum volume. 2-PrOH (20 mL) was added, and the mixture was concentrated again. The reaction mixture was diluted with 2-PrOH (10 mL) and cooled to 10 °C. A solution of NaOH (4.30 g; 107.6 mmol; 8 equiv) in H2O (10 mL) was added, and resultant slurry was warmed to rt and stirred at rt overnight. conc. HCl (9.4 mL; 114.3 mmol; 8.5 equiv) was added, and the reaction mixture was slowly concentrated under reduced pressure giving a biphasic mixture (water/oil). EtOAc (30 mL) was added and the layers were separated. The aqueous phase was extracted with EtOAc (2 × 10 mL). Combined organic extracts were dried over MgSO4 and concentrated under reduced pressure to an oil. The oil was treated with 3 M NaOH (9.0 mL; 26.9 mmol; 2 equiv.) and the mixture was extracted with MTBE (20 mL). The aqueous phase was acidified with 3 M HCl (9.9 mL; 29.6 mmol; 2.2 equiv) at 10 °C which resulted in formation of a slurry. The slurry was filtered and the filter cake was washed with water. The solid was dried on a Buchner funnel for 2 h then at 50 °C in vacuum oven overnight to afford crude acid 19b as an off white solid (2.78 g, 99% yield). Crude acid was obtained as 96.5:3.5 mixture of E/Z isomers (19F NMR). The crude acid was recrystallized from a hot (65 °C) mixture of heptane (10 mL) and IPAc (0.5 mL) to afford 19b as a white solid (2.25 g, 81% recovery, 80% overall yield from 2-methylpropiophenone, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 11.57–9.26 (brs, 1H), 7.25–7.07 (m, 3H), 6.93 (d, J = 7.4 Hz, 1H), 2.78–2.56 (m, 1H), 2.52–2.28 (m, 1H), 2.19 (s, 3H), 1.00 (t, J = 7.6 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 165.2 (d, J = 37.0 Hz), 143.3 (d, J = 249.3 Hz), 139.5 (d, J = 15.3 Hz), 135.8 (d, J = 5.1 Hz), 134.7 (d, J = 2.6 Hz), 130.0, 127.8, 127.4 (d, J = 3.3 Hz), 125.4, 25.8 (d, J = 5.5 Hz), 19.3, 11.1 (d, J = 2.0 Hz); 19F NMR (376.5 MHz, CDCl3) δ −126.8 (s). HRMS (DART) calcd for C12H14O2F [M+H]+: 209.0972, found 209.0973.

(E)-2-Fluoro-3-(o-tolyl)pent-2-enoic acid (19b).

A round bottom flask was charged with triethyl 2-fluoro-2-phosphonoacetate (6.8 mL, 33.63 mmol, 2.5 equiv) and THF (50 mL). The solution was cooled to 0 to −5 °C. MeMgBr (11.4 mL, 33.63 mmol, 2.96 M in Et2O, 2.5 equiv) was then added dropwise maintaining internal temperature below 10 °C. The reaction mixture was warmed to rt and stirred for 10 min, then heated to 40 °C and stirred for another 10 min. A solution of 2-methylpropiophenone (2.0 mL, 13.45 mmol, 1.0 equiv) in THF (10 mL) was added dropwise, and the reaction mixture was stirred for 30 min. An aliquot of reaction mixture was analyzed by quantitative 19F NMR: ester 19a was formed as a mixture of stereoisomers in 96:4 dr. The reaction mixture was cooled to rt and concentrated under reduced pressure to a minimum volume. 2-PrOH (20 mL) was added, and the mixture was concentrated again. The reaction mixture was diluted with 2-PrOH (10 mL) and cooled to 10 °C. A solution of NaOH (4.30 g; 107.6 mmol; 8 equiv) in H2O (10 mL) was added, and resultant slurry was warmed to rt and stirred at rt overnight. conc. HCl (9.4 mL; 114.3 mmol; 8.5 equiv) was added, and the reaction mixture was slowly concentrated under reduced pressure giving a biphasic mixture (water/oil). EtOAc (30 mL) was added and the layers were separated. The aqueous phase was extracted with EtOAc (2 × 10 mL). Combined organic extracts were dried over MgSO4 and concentrated under reduced pressure to an oil. The oil was treated with 3 M NaOH (9.0 mL; 26.9 mmol; 2 equiv.) and the mixture was extracted with MTBE (20 mL). The aqueous phase was acidified with 3 M HCl (9.9 mL; 29.6 mmol; 2.2 equiv) at 10 °C which resulted in formation of a slurry. The slurry was filtered and the filter cake was washed with water. The solid was dried on a Buchner funnel for 2 h then at 50 °C in vacuum oven overnight to afford crude acid 19b as an off white solid (2.78 g, 99% yield). Crude acid was obtained as 96.5:3.5 mixture of E/Z isomers (19F NMR). The crude acid was recrystallized from a hot (65 °C) mixture of heptane (10 mL) and IPAc (0.5 mL) to afford 19b as a white solid (2.25 g, 81% recovery, 80% overall yield from 2-methylpropiophenone, single stereoisomer (>98:2 dr)). 1H NMR (400 MHz, CDCl3) δ 11.57–9.26 (brs, 1H), 7.25–7.07 (m, 3H), 6.93 (d, J = 7.4 Hz, 1H), 2.78–2.56 (m, 1H), 2.52–2.28 (m, 1H), 2.19 (s, 3H), 1.00 (t, J = 7.6 Hz, 3H); 13C{1H} NMR (100 MHz, CDCl3) δ 165.2 (d, J = 37.0 Hz), 143.3 (d, J = 249.3 Hz), 139.5 (d, J = 15.3 Hz), 135.8 (d, J = 5.1 Hz), 134.7 (d, J = 2.6 Hz), 130.0, 127.8, 127.4 (d, J = 3.3 Hz), 125.4, 25.8 (d, J = 5.5 Hz), 19.3, 11.1 (d, J = 2.0 Hz); 19F NMR (376.5 MHz, CDCl3) δ −126.8 (s). HRMS (DART) calcd for C12H14O2F [M+H]+: 209.0972, found 209.0973.

(E)-2-Fluoro-4-methyl-3-phenylpent-2-enoic acid (20b).

Saponification of ester 20a (4.37 g, 18.49 mmol, 11.6:1 (92:8) dr) in EtOH/water afforded carboxylic acid 20b as a white solid (3.38 g, 11.6:1 (92:8) dr, 88% yield). The product was recrystallized from IPAc (1V) and heptane (15 V) to improve stereochemical purity to 18.4:1 (95:5) dr (2.61 g, 77% recovery, 68% overall yield). E-isomer: 1H NMR (400 MHz, CDCl3) δ 11.15–9.85 (brs, 1H), 7.36–7.27 (m, 3H), 7.06–6.97 (m, 2H), 3.29 (dsept, J = 7.0 Hz, JHF = 0.8 Hz, 1H), 1.00 (d, J = 7.0 Hz, 6H); 13C{1H} NMR (100 MHz, CDCl3) δ 160.5 (dd, J = 37.5 Hz, J = 7.1 Hz), 142.8 (d, J = 250.1 Hz), 143.3 (d, J = 14.0 Hz), 133.9 (d, J = 5.3 Hz), 128.0 (d, J = 3.1 Hz), 127.7, 127.6, 29.4 (d, J = 5.1 Hz), 20.0 (d, J = 2.0 Hz); 19F NMR (376.5 MHz, CDCl3) δ −126.7 (s); Z-isomer: −121.3 (s). HRMS (DART) calcd for C12H14O2F [M+H]+: 209.0972, found 209.0973.

(E)-3-Cyclopropyl-2-fluoro-3-(4-methoxyphenyl)acrylic acid (21b).

Saponification of ester 21a (4.36 g, 16.50 mmol, >98.2 dr) in EtOH/water afforded carboxylic acid 21b as a white solid (3.51 g, >98.2 dr, 90% yield). mp 157.2–158.9 °C; 1H NMR (400 MHz, CDCl3) δ 12.06–10.81 (brs, 1H), 6.96–6.84 (m, 2H), 6.84–6.74 (m, 2H), 3.79 (s, 3H), 2.45–1.96 (m, 1H), 0.94–0.71 (m, 2H), 0.53–0.30 (m, 2H); 13C{1H} NMR (100 MHz, CDCl3) δ 165.2 (d, J = 35.9 Hz), 159.2, 144.3 (d, J = 247.2 Hz), 140.7 (d, J = 13.3 Hz), 129.8 (d, J = 3.1 Hz), 123.8 (d, J = 4.8 Hz), 113.3, 55.1, 12.3 (d, J = 9.4 Hz), 5.4; 19F NMR (376.5 MHz, CDCl3) δ −131.2 (s). HRMS (DART) calcd for C13H14O3F [M+H]+: 237.0922, found 237.0922.

(Z)-3-(4-Bromophenyl)-2,4,4,4-tetrafluorobut-2-enoic acid (22b).

Saponification of ester 22a (3.0 g, 8.80 mmol, 25.8:1 (96:4) dr) in 2-PrOH/water afforded carboxylic acid 22b as an off-white solid (2.52 g, 25.8:1 (96:4) dr, 92% yield). 1H NMR (400 MHz, MeOH-d4) δ 7.60–7.53 (m, 2H), δ 7.24–7.16 (m, 2H), 5.46–4.94 (brs, 1H); 13C{1H} NMR (100 MHz, MeOH-d4) δ 161.3 (d, J = 34.3 Hz), 152.2, (dq, J = 284.3 Hz, J = 2.6 Hz), 132.8, 132.7 (d, J = 3.4 Hz), 129.4 (d, J = 3.2 Hz), 124.8, 123.5 (q, J = 274.7 Hz), 121.0 (dq, J = 32.4 Hz, J = 9.7 Hz); 19F NMR (376.5 MHz, MeOH-d4) δ −107.5 (q, J = 24.0 Hz), −61.6 (d, J = 24.0 Hz); Z-isomer: δ −105.6 (q, J = 10.3 Hz), −59.8 (d, J = 10.3 Hz). HRMS (DART) calcd for C10H4O2BrF4 [M-H]–: 310.9336, found 310.9336.

(E)-3-(3,5-Dimethylphenyl)-2-fluoronon-2-en-7-ynoic acid (23b).

Saponification of ester 23a (1.90 g, 6.28 mmol, >98.2 dr) in EtOH/water afforded carboxylic acid 23b as a white solid (1.68 g, >98.2 dr, 98% yield). mp 88.3–90.3 °C; 1H NMR (400 MHz, CDCl3) 6.95 (s, 1H), 6.74 (s, 2H), 2.66–2.54 (m, 2H), 2.30 (s, 6H), 2.17–2.06 (m, 2H), 1.75 (t, J = 2.5 Hz, 3H), 1.58–1.47 (m, 2H); 13C{1H} NMR (100 MHz, CDCl3) δ 165.2 (d, J = 37.0 Hz), 143.3 (d, J = 248.8 Hz), 138.5 (d, J = 15.7 Hz), 137.6, 136.0 (d, J = 5.0 Hz), 129.8, 125.4 (d, J = 2.8 Hz), 78.1, 76.2, 32.4 (d, J = 5.2 Hz), 26.3 (d, J = 1.7 Hz), 21.2, 18.6, 3.4; 19F NMR (376.5 MHz, CDCl3) δ −125.1 (s). HRMS (DART) calcd for C17H18O2F [M-H]–: 273.1296, found 273.1295.

(Z)-3-(1-Cyanocyclohexyl)-2-fluoro-3-(4-methoxyphenyl)acrylic acid (24b).

Saponification of ester 24a (1.1 g, 3.32 mmol, >98.2 dr) in EtOH/water afforded carboxylic acid 24b as a white solid (1.0 g, >98.2 dr, 99% yield). mp 156.5–157.6 °C; 1H NMR (400 MHz, CDCl3) δ 10.73–8.78 (brs, 1H), 6.96 (d, J = 8.6 Hz, 2H), 6.87 (d, J = 8.6 Hz, 2H), 3.82 (s, 3H), 2.12–1.92 (m, 2H), 1.82–1.61 (m, 5H), 1.48–1.30 (m, 2H), 1.18–0.97 (m, 1H); 13C{1H} NMR (100 MHz, CDCl3) δ 163.9 (d, J = 36.2 Hz), 159.8, 146.0 (d, J = 266.2 Hz), 135.3 (d, J = 9.3 Hz), 129.6 (d, J = 3.4 Hz), 124.4 (d, J = 5.4 Hz), 120.3, 113.8, 55.2, 42.0 (d, J = 1.7 Hz), 34.2 (d, J = 1.9 Hz), 24.5, 22.7; 19F NMR (376.5 MHz, CDCl3) δ −111.9 (s). HRMS (DART) calcd for C17H19O3NF [M+H]+: 304.1344, found 304.1344.

(E)-3-(4-Bromophenyl)-2-fluoro-4-phenylbut-2-enoic acid (25b).

Saponification of ester 25a (4.75 g, 13.08 mmol, 13.3:1 (93:7) dr) in EtOH/water afforded carboxylic acid 25b as a white solid (3.95 g, 14.9:1 (94:6) dr, 91% yield). mp 139.1–141.5 °C; 1H NMR (400 MHz, CDCl3) 9.57–8.49 (brs, 1H), 7.40–7.33 (m, 2H), 7.27–7.15 (m, 3H), 7.04–6.96 (m, 2H), 6.83–6.74 (m, 2H), 3.81 (d, JHF = 3.6 Hz, 2H); 13C{1H} NMR (100 MHz, CDCl3) δ 164.9 (d, J = 37.0 Hz), 143.3 (d, J = 252.6 Hz), 136.2 (d, J = 16.7 Hz), 135.9 (d, J = 2.4 Hz), 134.8 (d, J = 5.0 Hz), 131.2, 129.6 (d, J = 3.1 Hz), 129.1, 128.6, 126.9, 122.3, 39.1 (d, J = 5.0 Hz); 19F NMR (376.5 MHz, CDCl3) δ −123.7 (t, JHF = 3.3 Hz); Z-isomer: −122.9 (s). HRMS (DART) calcd for C16H13O2BrF [M+H]+: 335.0078, found 335.0078.

(E)-2-Fluoro-3-(quinolin-3-yl)but-2-enoic acid (26b).

Saponification of ester 26a (4.70 g, 58.07 mmol, 11.3:1 (92:8) dr) in 2-PrOH/water afforded carboxylic acid 26b as a white solid (3.60 g, >98:2 dr, 86% yield). 1H NMR (400 MHz, DMSO-d6) δ 8.76 (d, JHF = 2.0 Hz, 1H), 8.30 (d, JHF = 1.4 Hz, 1H), 8.02 (d, J = 8.4 Hz, 1H), 7.97 (d, J = 8.0 Hz, 1H), 7.82–7.71 (m, 1H), 7.67–7.57 (m, 1H), 4.65–2.66 (brs, 1H), 2.21 (d, JHF = 4.4 Hz, 3H); 13C{1H} NMR (100 MHz, DMSO-d6) δ 161.1 (d, J = 35.4 Hz), 150.2 (d, J = 2.6 Hz), 146.6, 145.2 (d, J = 253.8 Hz), 134.0 (d, J = 3.4 Hz), 131.7 (d, J = 5.8 Hz), 129.7, 128.6, 128.2, 127.6 (d, J = 19.1 Hz), 127.1, 126.9, 19.0 (d, J = 6.4 Hz); 19F NMR (376.5 MHz, DMSO-d6) δ −119.2 (q, JHF = 4.4 Hz); Z-isomer: −121.6 (s). HRMS (DART) calcd for C13H11O2NF [M+H]+: 232.0768, found 232.0769.

(E)-3-(Benzo[b]thiophen-2-yl)-2-fluorobut-2-enoic acid (27b).

Saponification of ester 27a (4.97 g, 18.80 mmol, 10.9:1 (92:8) dr) in EtOH/water afforded carboxylic acid 27b as a pale yellow solid (3.96 g, 10.9:1 (92:8) dr, 89% yield). mp 140.6–142.7 °C; 1H NMR (400 MHz, MeOH-d4) δ 7.81–7.77 (m, 1H), 7.75–7.70 (m, 1H), 7.34–7.27 (m, 2H), 7.26 (s, 1H), 5.45–4.58 (brs, 1H), 2.20 (d, JHF = 4.7 Hz, 3H); 13C{1H} NMR (100 MHz, MeOH-d4) δ 163.2 (d, J = 36.1 Hz), 147.4 (d, J = 256.3 Hz), 141.7, 141.1, 140.3 (d, J = 6.8 Hz), 125.8, 125.6, 125.1 (d, J = 3.1 Hz), 124.9, 123.1, 19.6 (d, J = 6.8 Hz); 19F NMR (376.5 MHz, MeOH-d4) δ −117.2 (q, JHF = 4.7 Hz); Z-isomer: −115.3 (q, JHF = 3.1 Hz). HRMS (DART) calcd for C12H8O2FS [M-H]–: 235.0235, found 235.0234.

(E)-3-(Cyclohex-1-en-1-yl)-2-fluorobut-2-enoic acid (28b).