Abstract

Food printing using 3D, 4D, and 5D printing processes has received a lot of interest as a result of rising living standards and increased customer desire for new foods. In the food industry, 3D as well as 4D printing are extremely effective methods for additive manufacturing. The 3D printing technology produces flat objects with a variety of mechanical strengths. The strength of the object depends on the type of material used and the printing process. Printing structures with the most complex geometric, such as curved surfaces, necessitates the usage of supplementary material. The 4D printing procedure necessitates additional stimuli in order to adjust the aspect of the generated geometry. These obstacles can be addressed by employing 5D printing techniques, which prints the product in three motions and two rotational axes without the use of additional support material. These emerging innovations are likely to result in substantial advancements in all industries, including the manufacturing of high-quality food products. Food printing technology can be used to create long shelf-life products by printing food with protective coatings that prevent oxidation and degradation. Foods can also be printed in specific shapes or sizes to reduce surface area exposed to air. 6D printed objects can be created as a result of 5D printing because it is regarded as a by-product of 5D printing technology. 6D printing can save time and money by using the right processing parameters to create strong materials that are more sensitive to stimuli. 7D printing can enable more efficient production processes, reduce costs, and enable the development of products that are more complex and intricate than what is achievable with traditional manufacturing methods. The revolutionary change brought by food printing technologies in the field of applications, research and development, processing, advantages in food industry have been discussed in this paper.

Keywords: 3D food printing, 5D Food Printing, 7D, Food manufacturing

Introduction

By utilising non-traditional food sources like insects, high-fiber plant materials, and by-products from both plants and animals, Food printing technology will indeed increase the number of easily accessible food supplies. To achieve accurate and exact printing, three major areas must be thoroughly investigated: material qualities, processing parameters, and post-processing processes (Zhang et al., 2021). Food printing, often known as 3D food printing, is a novel technique that creates three-dimensional food creations from edible materials using a computer-controlled printer (Wang et al., 2017). This technology is used to create food items that are more aesthetically pleasing and have a longer shelf life than traditional food production methods. Food printing also has the potential to reduce food waste, as it allows for the production of food items that are the exact size and shape required for a specific recipe. 3D food printing is a process of using 3D printing technology to create food products (An et al., 2019). It involves using a 3D printer to extrude food-grade materials into a variety of shapes and sizes. The process allows chefs and food professionals to create food items with intricate designs, complex textures, and customized flavors. 3D food printing also offers the potential to reduce food waste, improve food safety, and create more sustainable food production. The technology is still in its early stages, but is growing in popularity and becoming more widely available. 4D printing is the outcome of 3D printing smart materials that respond to a variety of stimuli to create unique goods. Engineering, medical equipment, computer peripherals, food processing, and other areas have effectively used 4D printing (Leppiniemi et al., 2017). In the last two years, there has been a considerable rise in research on 4D, 5D, and 6D food printing. Furthermore, the principles, existing applications, and possible applications of the most recent technologies for additive manufacturing (5D and 6D printing) are studied and explored. 4D food printing uses are mostly concerned with producing appropriate colour, shape, flavour, and nutritional qualities of 3D printed items (Lind et al., 2017). 5D and 6D printing can produce very complicated shapes with enhanced power and less material than 3D and 4D printing. These technological advances are likely to result in substantial advancements in all industries in the future, including the manufacturing of high-quality food products that are currently impossible to make with present processing technology. The goal of this review is to determine the industrial possibilities of 4D printing as well as future innovation using 5D and 6D printing (Mantihal et al., 2017).

5D printing is a relatively new branch of additive manufacturing. In this technique, the print head as well as the printable product have five levels of versatility. It produces curved layers as opposed to flat layers. In this action, the print section spins whereas the printer head prints. As a result, rather than progressing through a straight phase as in 3D printers, printing following the curve path of the component being produced. The fundamental benefit of this technique is the capacity to create a part with a stronger curved layer (Zhao et al., 2020).

3D printing technology

A three-dimensional (3D) object is made by depositing consecutive layers of material directly onto a pre-designed file prepared by computer-aided design using (3D) printing, a type of incremental manufacturing technique. The use of 3D printing is widespread in a variety of industries, including engineering, biomedicine, equipment, and most recently, the food business (Ge et al., 2016). A compelling and intriguing business idea that has captured the interest of both entrepreneurs and the media is 3D printing of food (Yoon et al., 2019). Some 3D food printers are now commercially accessible; they are largely utilised for specialised tasks including printing decorations for bakeries, meals that are simple to eat for people with chewing/swallowing issues, and "pop up" restaurant experiences. There are signs that novel, more widely used applications, methods, and materials will be introduced during the next few years (Lipton et al., 2015). Extrusion printing has had an enormous impact on printing accuracy. This type of printing can produce prints with very high resolution and accuracy, as the plastic filament is precisely extruded onto the build plate. This accuracy allows for intricate designs and complex parts to be printed with ease. Also, the materials extruded can be tailored to the specific application, allowing for greater control over the print. This technology is a great benefit to the printing industry, as it provides a reliable and accurate printing process (Derossi et al., 2023).

3D printing applications are diverse and varied. They range from prototyping and concept modelling to production parts, medical and dental applications, and many more.

Prototyping: Rapid prototyping with 3D printing is utilised in the design process. It allows designers to quickly and easily create a physical representation of their design to test form, fit, and function.

Concept Modelling: 3D printing can be used to produce concept models that are used to evaluate ideas, explore different design options, or present an idea to others.

Production Parts: For low-volume production runs, Parts with geometric geometrical and high precision can be produced using 3D printing.

Medical & Dental Applications: 3D printing is used to produce medical and dental devices and implants, such as prosthetics, orthodontic braces, and dental crowns.

Architecture & Construction: 3D printing can be used to create scaled models of buildings and structures, as well as full-scale components such as walls and doors.

Education: 3D printing is used in the classroom to teach a variety of topics from anatomy to engineering.

Arts & Crafts: 3D printing is used to create art, jewellery, toys

3D food printing is an alluring new technology in food engineering, assesses capability and potential, and investigates problems connected to supply chain adjustments and the creation of business models.

Rapid Prototyping (RP) technologies, the first 3D printing predecessors, initially emerged into public view in the late 1980s. This is since the techniques were first designed as a quick and more economical way to produce prototypes for product development within industry. In May 1980, Dr. Kodama filed the first RP provisional patent in Japan. Dr. Kodama was a patent attorney; thus, it was unfortunate that when Charles Hull got the first invention for stereolithography equipment (SLA) in 1986, the full patent description was not filed just before application's one-year deadline (Liu et al., 2020). The five basic categories into which 3D bioprinting processes are typically divided are as follows: (a) laser-assisted, (b) inkjet, (c) stereolithography, (d) extrusion, and (e) microvalve-based bioprinting (Ravinder Reddy et al., 2018) (Fig. 1).

Fig. 1.

Extrusion based 3D food printing processing parameters

Technologies for printing 3D food and variables affecting printing precision and accuracy

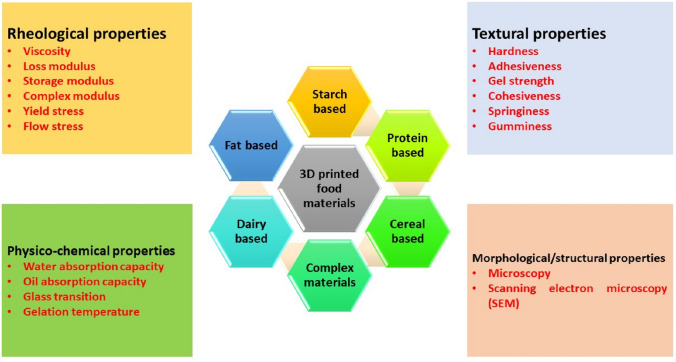

The precision and quality of printed items are affected by processing conditions, material properties, and post-processing techniques. Each 3D food printing technology having set of advantages and disadvantages.

Extrusion printing and the elements that influence printing accuracy

Extrusion-based printing, also known as Fused deposition modelling (FDM), was primarily created to make plastic items. During the food printing processing, the molten material or slurry is continuously ejected out of a moving nozzle tip, where it cools and adheres to the preceding layers. This printing can be used to print on chocolate as well as soft materials such as dough, casseroles, cheese, and meat paste (Mao et al., 2016). Although a wide range of soft materials have been deposited using this method, their inherent susceptibility to distortion and warping places restrictions on their ability to be deposited into intricate and delicate shapes. To manufacture delicate and elaborate geometries even during the soft-material casting method, extra structural components must be printed to support the product geometry. The last step requires physical removal of the supporting constructions. This method takes a lot of time, which will decrease printing speed and increase material costs (Martínez-Monzó et al., 2019). There are various things that may be to blame for this, but printing quality and precision. 1) Extrusion process 2) material properties such as transition temperature, melting and gelling properties 3) Extrusion rate, nozzle diameter, and tip height are examples of processing variables. 4) Procedures for post-processing (Momeni et al., 2017).

Screw -based extrusion, air pressure-based extrusion, and Syringe -based extrusion are 3D food printing employs three extrusion processes. Food ingredients are put into the sample feeder and then transferred to the nozzle tip by a rotating screw inside the screw-based extrusion process (Mulakkal et al., 2018). Food ingredients can be continually put in the hopper throughout the extrusion operation to realise continuous printing. However, because food slurries with high viscosities and mechanical strengths are not ideal for screw-based extrusion, Mechanical strength is lacking in printed samples required to support the following deposited layers, resulting in poor resolution and severe distortion. Are using the air pressure-based extrusion technique to print liquid or low viscous materials, in which food products are propelled to the nozzle by air pressure. High viscosity and mechanically robust food ingredients may be printed using the syringe-based extrusion device, making it likely that complex 3D structures can be created using this method. It should be emphasised, however, that syringe- and Ongoing feeding of food items during printing is not possible with air pressure extrusion (Oliver et al., 2016).

Selective laser sintering (SLS) and its impact on printing accuracy

There in selective laser sintering (SLS) technique, a strong laser is used to layer-by-layer fuse granules into a three-dimensional framework. By screening cross sections on the top of each layer, the laser selectively combines the powder. After scanning each cross-section, the layer of powder is lowered and a fresh powdered layer is applied on top. Until the desired structure is complete, this process is repeated (Xiao et al., 2020). The unfused powder is then taken out and reused for the subsequent printing. The process is very accurate and can produce complex parts with very tight tolerances. It is also capable of producing parts with intricate details and textures. SLS is often used for prototyping, low volume production, and customized, one-off parts. It is also used in the medical, automotive, and aerospace industries. The accuracy of SLS printing is very good, as the laser can precisely control the size and shape of the parts. The parts created by SLS are typically very precise, with tight tolerances, and no visible signs of deformation or warping. This accuracy comes from the use of a laser which is able to precisely control the size and shape of the parts. The laser heats the powder particles as it passes over them, and the particles are fused together to create the desired shape. The accuracy of SLS printing is also improved using a closed-loop control system. This system measures the layer-by-layer build-up of powder and adjusts the laser intensity, scanning speed, and layer thickness accordingly. This ensures that the laser beam can precisely sinter the desired shape or contour with minimal distortion and minimal material waste. The accuracy of SLS printing is further improved using specialized 3D printing software which can create detailed 3D models that can be accurately printed. This software also allows for the use of advanced algorithms to minimize post-processing and ensure that the result is as accurate as possible. The accuracy of SLS printing is also improved using multiple laser sources. This allows for the use of different laser wavelengths and power levels which can be used to sinter different material types and thicknesses. This further increases the accuracy of the printed part. SLS printing has also allowed for the rapid and cost-effective production of complex parts and components. This is due to the reduced cost of prototyping and the ability to quickly produce accurate parts. This has allowed manufacturers to produce components and parts that would have traditionally been considered too complex or costly to produce. Overall, SLS printing has had a major impact on the accuracy and efficiency of 3D printing. It has allowed manufacturers to produce parts with complex geometries that would have been impossible to produce with traditional methods. The process is also able to be used with a variety of materials, including plastics and metals, which allows for a wide range of applications. The accuracy of SLS 3D printing is high, as it can print parts that can be used in a variety of industries, including automotive, aerospace, medical and industrial. The accuracy of SLS printing is further improved by the ability to create multiple parts at once, as well as the ability to accurately print thin walls and complex geometries. The accuracy of SLS printing is also improved by its ability to produce parts quickly, with minimal waste of material. Overall, SLS printing has had a major impact on the accuracy and efficiency of 3D printing and has been instrumental in the development of many new products and applications (Smykov, 2023). SLS has been widely used in the fabrication of metals and ceramics, however there are several barriers to its use in the food industry. (1) appropriate powdered material that can be fused together during the fabrication process without the material itself decomposing (2) the use of a variety of food products to create different edible objects (An et al., 2019). SLS enables the precise fabrication of free-standing, complex, 3D structures, but the material selections are limited to powders such as sugar, fat, or flour granules. To spread the usage of this technique in traditional foods, the range of food items available must be expanded. SLS printing precision and accuracy are strongly reliant on material qualities and quantitative and qualitative data collection (laser types, laser strength, laser spot diameter, and so on (Nordlund et al., 2018). Additional post-processing for the printed objects may be required in selective laser sintering, such as the removal of surplus food material powder to improve surface qualities and additional heating to enhance mechanical strength (Pallottino et al., 2016).

The impact of binder jetting printing parameters on printing accuracy

Binder jetting printing, commonly known as inkjet 3D printing, was first described by Sachs, Haggerty, Cima, and Williams (1994). (3DP). Powdered materials were placed layer by layer throughout this procedure, and the adhesive was then selectively expelled onto each material at specified places according to the information file for the object being made (Rutzerveld, 2014). The binder fuses current cross-sections to previously fused cross-sections. The unfused material always supports the fused sections during the manufacturing process, allowing the construction of delicate and difficult structures. Unbound powder is then removed and recycled for future use (Zeijderveld, 2018). By adjusting the composition of the binder, binder jetting technology can create multicoloured 3D edible things as well as intricate and delicate 3D structures. The edible binder has an impact on its extensive use in the food industry, particularly in the realm of traditional cuisine enjoyed in daily life. Unfortunately, the structural material is confined to powder items. (Leist & Zhou, 2016). The particle feed rate affects the amount of material deposited onto the build platform and thus influences the accuracy of the printed parts. If the feed rate is too high, the particles will be deposited too quickly and can overlap, leading to inaccuracy. On the other hand, if the feed rate is too low, not enough material will be deposited and the parts will be underfilled. The binder feed rate also influences the accuracy of the parts. If the feed rate is too low, not enough binder material will be deposited, resulting in an underfilled part. On the other hand, if the feed rate is too high, the binder material can form clumps and cause an overfilled part. By controlling the binder feed rate, the user can achieve the desired part accuracy. The infill pattern and infill density also influence the accuracy of the part. Generally, a higher infill density will result in a more accurate part. However, if the infill density is too high, the binder material can form clumps, resulting in an overfilled part. The layer height of the part also affects the accuracy of the part. If the layer height is too low, the binder material may not be adequately deposited, resulting in an underfilled part. If the layer height is too high, the binder material may form clumps, resulting in an overfilled part. Finally, the curing temperature and time of the part also influence the accuracy of the part. If the curing temperature is too low, the binder material may not be fully cured, resulting in an inaccurate part. If the curing time is too long, the binder material may form clumps, resulting in an overfilled part. By controlling the binder jetting printing parameters, the user can achieve the desired part accuracy (Yilmaz et al., 2023). By adjusting the binder feed rate, infill pattern, infill density, layer height, and curing temperature, the user can improve the part accuracy and consistency. This can be done by controlling the speed at which the binder is fed into the part, the type of infill pattern used, the amount of binder applied, the layer height, and the curing temperature. The binder feed rate affects the amount of binder that is applied to each layer of the part and therefore affects the accuracy of the part. If the feed rate is too high, not enough binder is applied and the part may be too weak. If the feed rate is too low, too much binder is applied and may lead to warping. The infill pattern affects the part's strength and accuracy. Different infill patterns produce different results, such as a hollow part, a solid part, or a lattice pattern. A hollow part is usually the least accurate, while a solid part is the most accurate. The infill density affects the part's strength and accuracy. If the infill density is too low, the part may be weak and lack accuracy. If the infill density is too high, the part may be too heavy and lack accuracy. The layer height affects the accuracy of the part. If the layer height is too high, the part can be distorted and its features can become less accurate. It is therefore important to keep the layer height as low as possible. On the other hand, if the layer height is too low, the printing time increases significantly and the part can become too brittle. Thus, an optimal layer height must be established in order to obtain the desired accuracy. The binder jetting printing speed also has an influence on the accuracy of the parts. If the printing speed is too high, the layers may not be fused properly and the part may be distorted. Slower printing speeds allow for better accuracy and a higher quality part. The binder jetting printing temperature also affects the accuracy of the part. If the temperature is too high, the parts can become distorted, and if it is too low, the parts may not be fused properly. It is therefore important to select the optimal temperature for the material being printed to ensure the desired accuracy. The binder jetting printing resolution also affects the accuracy of the part. If the resolution is too low, the features on the part may not be accurately reproduced. Higher resolutions allow for higher accuracy and a better finish on the part (Mummaleti et al., 2023). Finally, the binder jetting printing orientation also has an important impact on the printing accuracy. The orientation of the component can affect the flow of the binder, which in turn can affect the accuracy of the printed components. When the component is printed in a vertical orientation, the gravity can influence the flow of the binder, which can lead to variations in the thickness of the component. When the component is printed in a horizontal orientation, the flow of the binder can be more consistent and thus lead to more accurate prints. Thus, binder jetting printing parameters such as component orientation should be carefully considered when printing components for accuracy (Yu et al., 2023).

Inkjet printing and its impact on printing accuracy

Inkjet printing on food surfaces such as cookies, cakes, and pizza directs a spray of particles from a thermal or piezoelectric nozzle to locations for surface filling or graphic ornamentation. Inkjet printing processes are classified into two types: ongoing jet printing and drop-on-demand printing. In a continuous jet printer, ink is continuously expelled out via a piezoelectric crystal that vibrates at a constant frequency (Lanaro et al., 2017). To attain the desired flowability, some conductive compounds are added to the ink. Under the pressure of a valve, ink is discharged from the heads of a drop-on-demand printer. Drop-on-demand systems have slower printing rates than ongoing jet systems, but the produced images have higher resolution and precision (Kuang et al., 2019). Inkjet printing often works with low viscosity materials that lack the mechanical stability to support 3D structures. The printing of two-dimensional graphics is typically done using this method. From the standpoint of printing precision and accuracy, the compliance of the ink with the surface layer, the viscosity and rheological properties of the ink, the temperature, and the production pace are all critical aspects (Kokkinis et al., 2015).

Application of 3D food printing in some specific food areas

Military and space food

Due to several factors, The US Army is quite interested in using 3D food printing in military rations. (1) Meals may be produced on-demand in the battlefield thanks to this technology; (2) Individual meals can be tailored and personalised nutrition and energy needs of soldiers; and (3) this method might increase the food's shelf life keeping them as raw materials as opposed to finished products will save material (Kim et al., 2018). NASA sought for using 3D food printing to meet food security, nutritional consistency, and meal acceptance requirements for lengthy space flights while using the fewest resources possible for the spacecraft. Currently, NASA's food system is unable to provide meals that are both nutrient-dense and have a five-year shelf life for lengthy missions since the usual cooking procedures used to prepare the individual packaged foods result in their loss of micronutrients over time (Jun, 2016). Resources on the spacecraft will be heavily devoted to the refrigeration equipment. Additionally, the current space food system was unable to satisfy each astronaut's unique nutritional and energetic needs. In order to design a food system that meets the nutritional and personalised requirements of each astronaut for extended space missions, 3D printing will be employed to produce important nutrients, structure, and texture, and inkjet printing will be employed to deliver micronutrients, flavour, and smell (Khoo et al., 2015). The macronutrient stocks will be kept in dry sterile containers, while the liquid micronutrients and flavourings will be kept in sterile packs. During food preparation, the macronutrient constituents will be directly given to the printer after being combined with water or oil and flavouring and texture modifiers applied at the print head. When the necessary patterns and shapes are achieved, the mixes are extruded (Jun, 2016).

Elderly food

The issue of ageing is one that many nations, including Japan, Sweden, and Canada, are grappling with. Chewing and swallowing issues affect 15%–25% of seniors over the age of 50 and up to 60% of nursing home residents. People with this disease are frequently given bland "porridge-like meals," which might make them lose their appetite and possibly lead to nutritional deficits. The PERFORMANCE project, financed by the European Union (EU), aims to develop an automated production procedure, and provide customised and specifically textured food utilising 3D printing technology (He et al., 2020). Scientists working on the project have imitated the flavour and texture of real meals by creating simulations of them, including gnocchi and peas. These foods are not only enjoyable for the elderly to eat, but also easy for them to swallow due to their soft, pureed texture. Individualised nutritional meals can be created for each person based on their age, physical condition, and nutritional and energy needs (Blaeser et al., 2016). A few nursing homes in Germany offered printed soft meals to elderly patients who had trouble chewing and swallowing. More delicious 3D-printed dishes composed of peas, mashed potatoes, and broccoli have been introduced to the market, and a thousand organisations around the nation now provide this kind of food daily (Blutinger et al., 2019).

Confectionary market

The world consumes a lot of sweets, which make up a sizable share of the food market. Sweets are the primary focus of most of the top businesses and research facilities for 3D food manufacturers, including Hershey, ChocEdge, and 3D Systems. Research compares various confectionary or sweets printing equipment. In collaboration with Hershey, a leader in the creation of chocolate and sweets, 3D Systems, one of the major producers of industrial-grade 3D printers, has created the Cocojet, an extrusion-based chocolate printer that can print a variety of designs in chocolate (Campbell et al., 2014). The University of Exeter's scientists created ChocCreator, the first industrial chocolate printer. Hans Fouche created an 8-nozzle Cheetah chocolate 3D printer and used it to test out various chocolate flavours. While most of the 3D chocolate is currently produced using melt-extrusion-based printers, four students from the University of Waterloo named 3D Chocolateering devised inexpensive selective laser sintering-based printers to produce 3D chocolate sculptures using chocolate powder (Chen et al., 2019). The 3D Systems ChefJet Pro can print sweets or food decorations that are aesthetically pleasing and savoury utilising a variety of food components, such as cheese, sugar, and chocolate. This technology has been used to build intricate structures like wedding cakes, other sugar sculptures, and interlocking candies. Additionally, the ChefJet Pro's four print heads allowed it to produce multi-color structures like multi-colored cocktail decorations (Kholgh Eshkalak et al., 2020).

4D food printing technology

Massachusetts Institute of Technology (MIT) professor Tibbits first put up the idea of 4D printing in 2013. The advancement of 3D printing into 4D printing, which adds "space–time axis" based on 3D coordinate axes, is known as 4D printing. The use of 4D printing technology in industries including aerospace, automotive, soft robots, biomedicine, and others is encouraged by the availability of intelligent materials like shape memory alloy (Chen et al., 2019). Contrary to shape memory alloy, the food materials used to make printing inks are typically not intelligent materials. Currently, 4D printing technology in the food industry is implemented by combining multiple food components (recombined food) according to a predetermined formula and structural design. Shape, nutrition, taste, feel, colour, and other attributes of printed goods can result in predictable changes in response to specific stimuli (water, heat, magnetic field, light, pH, etc.). The printing of food in four dimensions is significant and has certain advantageous qualities (Cotabarren et al., 2019). Due to its potential to offer distinctive appearance, nutrition, ease of swallowing, and other benefits, 3D food printing has become a popular issue in research. A development of 3D printing is 4D printing. Thankfully, unlike 3D printing, 4D printing can build suspended structures such as blooming flowers. Eating becomes more intriguing as flowers go from being closed to blossom, which draws more attention from customers like picky kids. Food that is printed using 4D technology offers fresh concepts for creating interactive dishes and improves the relationship between customers and food components (Comber et al., 2012) (Fig. 2).

Fig. 2.

Similarity between 3D/4D food printing and bioprinting

Additional feature of 4D printing over 3D printing the fact that the printed product's flavour, nutrition, or colour can be provided whenever the person eats it somewhat than when it is kept. 3D-printed items, on the other hand, have sensory or nutritional qualities diminish over time. Keeping structural changes under control while drying is advantageous when making some nutritious snacks. For instance, the curvature of potato chips contributes to their crispier mouthfeel. The items have a crunchy feel thanks to the 4D printing and drying process. As printing technology has advanced and gained popularity, it can be integrated into the production process to allow automatic production (Wang et al., 2017).

Conditions for 4D food Printing technology

4D printing may build dynamic structures with outside signals and interaction mechanisms with the help of 3D model creation. The fundamental ingredients of 4D food printing are 3D printers, printing technology, inks, building system, and stimulants (water, heat, magnetic field, light, pH, etc.) that enable the controlled and predictable evolution of the printed goods over time (Dai et al., 2019). Many researchers have adjusted printers and printing programs as technology has improved to make 3D printing better suitable for 4D food printing. The main focus of this review is how to gradually migrate from 3D printing to 4D printing in the food company from three perspectives: printing software, printers, and inks (Martínez-Monzó et al., 2019).

Printers

The key printer types utilised in 3D food printing are diffuse deposition modelling (FDM), stereolithography, straight ink writing, inkjet, digital light treatment, and selective laser melting (Teng et al., 2019). Because of its high universality, low cost, and ease of usage, FDM is presently the most extensively utilised technique for 4D food printing. Intelligent materials and design are critical parts of 4D food printing. Intelligent materials and design are important ingredients of 4D food printing. As a result, 4D printed food should be created with meticulous attention to the mechanism, expected behaviour, and necessary parameters in accordance with the properties of the material. In order to accomplish multi-material printing, use a variety of inks, and create more intricate and detailed structures, printers must use these techniques. The printing of multi-material modules is a major aspect of 4D food printing since it increases adaptability and functionality. Multi-material printers can build hierarchical structures by integrating two or three distinct materials in a single printing structure (Dick et al., 2019). Certain food-related polymers, such as ethyl cellulose, can respond effectively to external stimulation; nevertheless, these materials have printing conditions that necessitate printer changes (Eshkalak et al., 2020). Currently, the printer is integrated with other devices like a cooling table, laser, and microwave. The capability of infrared or laser technology to move alongside the printing nozzle enables precise local heating while also exposing different portions of the printed object to varying degrees of heat treatment, benefiting heat-induced property changes such as deformation (Tao et al., 2019). Modifications in microwave power or substance formulation, such as changing salt or sugar contents, can modify the dielectric characteristics of the food ingredients used in microwave printers, which can subsequently affect the rate at which heat is collected and alter the qualities of the printed product (Gao et al., 2016).

Printing software

Creating a 3D model containing several pieces of information—such as substance, structure, stimulation signals, and so on—and then replicating the printing process as well as the model's deformation, discoloration, or other characteristics behaviours are the general tenets of 4D food printing research. Sliced from the multi-information optimised 3D model, the printing process is guided by the slicing programme (Ramesh et al., 2018). Following the production of the printed product, the appropriate assessment approaches and tools are explored in order to evaluate the changeable adjustments. In other words, the printing technology, process simulation, numerical modeling, and slicing software all impact the quality of 4D food printing (Ge et al., 2016). Forward design and reverse design are the two primary components of 4D intelligent software at the moment. Forward design is the process of predicting final changes based on the structures, properties, and stimulation of the materials. It is fundamental research that seeks to understand ideas, theories, and connections. In order to adapt to external stimuli, flowers are gifted with the ability to They have control over the fundamental asymmetry of their different tissues and cell walls. This is a reverse construction, which is essentially a bionic design (He et al., 2020). 4D food printing is a technique that requires the use of sophisticated software, hardware, and materials, allowing for more intricate and complex designs than traditional food printing. It allows for the creation of custom food shapes and textures, as well as the potential to tailor ingredients to individual dietary needs. Also enables precise control over the shape and design of food items, allowing for more intricate details that cannot be achieved with traditional food printing methods. It can produce an array of different food items in a variety of shapes and sizes, offering more options for consumers. 4D food printing is faster and more efficient than traditional food printing, allowing for quicker production of food items in large quantities. By simulating the printing process and optimising its physical parameters (such as viscosity, pressure, homogeneity, etc.), 4D simulation programming software can lower the likelihood of printing failure (Ratish Ramanan & Mahendranet, 2021) (Fig. 3).

Fig. 3.

Characteristics of 3D food printing technology that are being researched

Printing inks

Food-related substances for printing technology are becoming increasingly popular in the last ten years. Chocolate, bread, cheese, a combination of fruits and vegetables, hydrocolloid, meat, protein, starch, and algae are examples of food ingredients used in printing. The ability of materials to be printed is a requirement for the development of 4D food printing (Shin et al., 2017). More crucially, food ingredients can alter their characteristics in response to external stimulus. Soy protein isolate, starch gels, or hydrogel solutions are all options (gelatin, sodium alginate, pectin, xanthan gum, carrageenan, konjac gum, etc.) are the major ingredients used in 4D food printing (Ghazal et al., 2019). Through the coding design of their constituent parts and structural elements, regulated alterations in response to external stimulus can be achieved (uniform distribution, gradient distribution, or special pattern). Protein (soy protein isolate), hydrogels, and starch gels are used in 4D food printing technology as well as current printing technology issues and solutions to those issues, will be covered in the part that follows (Zarek et al., 2016).

Applications for 4D printing and problems needing attention

In order to achieve successful printing, it is important to keep in mind the factors listed below. 4D food printing is a new technology in the food industry.

Change in colour

The presence of plant pigments in various chemical forms and pH levels is the main cause of the colour shift in the recombined meal. Anthocyanin, for instance, exhibits a red colour in an acidic environment and a green colour in an alkaline environment; curcumin exhibits a yellow hue in an acidic or neutral environment and a red colour in an alkaline environment (He et al., 2021). This increases customer connection by enabling 3D printed food to gradually change hue to a more appetising shade in response to internal or external stimulus (4 dimensions). Simply said, buyers want food to automatically become discoloured (Hertafeld et al., 2019). To successfully discolour the recombined starch gel system including colours, It is critical to understand how starch content affects water systems, printing, and textural features. The increased starch content is useful for retaining the shape of the printed object while slowing the rate of colour change due to the slower rate of water movement and the incorporation of starch into anthocyanin. The present discolouration has the disadvantage of progressing slowly. In addition to additional stimulation such as heat, using a printer to change the distribution of food components or building system can assist minimise the time required for discoloration (Guo et al., 2021).

Change in shape

Deformation characteristics in 4D food printing include bending, deformation, linear or nonlinear development, and surface curl. Shapes can be transformed from 1 to 1D, 2D to 2D, 3D to 3D, and much more. The change from 2 to 3D is particularly noticeable in the food industry. Dehydration and moisture content are currently important factors in food deformation. The quantity and orientation of shape change are determined by changes in the properties and spatial organisation of two or more materials. Now, dehydration and water absorption play a major role in food deformation. The differences in the characteristics and the amount and orientation of shape change are determined by the spatial arrangement of two or more materials (Gibson et al., 2015).

Deformation induced by water absorption

Water stimulation is one of the reasons of distortion in 4D food printing. The printing framework is made up of an expandable hydrophilic active ingredient and a stiff material. The material expands and generates forces that alter its shape. The complicated deformation behaviour can be obtained by carefully arranging the hard material and expanding material. The deformation generated by the two materials' dissimilar characteristics under the activation of water absorption should also take into account the adhesion between the two materials. Otherwise, two materials with low adhesion can easily be separated in water, which prevents deformation from occurring. In addition to the material's capacity to adhere well on its own, factors like thickness and printers that can spray adhesive also contribute to solving the issues (Gladman et al., 2016).

Deformation induced by dehydration

A moisture gradient is the result of the printed sample losing water. The printed sample deforms as a result of tension and strain brought on by the moisture gradient. Food is frequently dried using microwaves, infrared light, and hot air, and each of these techniques affects how much printed samples deform. Due to inadequate thermal penetration, hot air-drying results in a greater bending angle than the other two drying techniques. Greater differences in the distribution of moisture in the food matrix are caused by less heat penetration. Additionally, the primary cause of the deformation brought on by dewatering is the rate of dehydration. Because of the product's increased hardness, higher dehydration rates result in delayed deformation and a reduced bending angle. Even inappropriate water evaporation causes cavities and fissures. The internal structure of the printed samples, including the filling rate and filling angle, also appears to be a significant contributor to the degree of dehydration-induced deformation (Gu et al., 2018). Researchers discovered that as filling angle increased, the final degree of bending or torsion reduced. Researchers also discovered that the unintended enlargement of samples was caused by the higher filling density, which prevented water vapour from leaving (Severini et al., 2018).

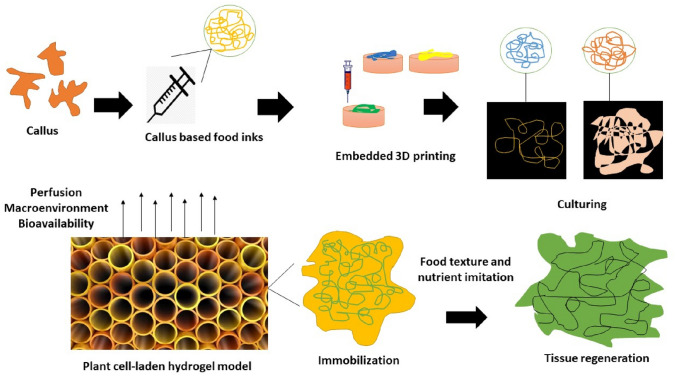

Nutritional change

One of the 4D biotechnological printing types that has a wide potential for creating functional tissue structures and managing medication delivery is the maturity of manufactured tissue structures. Inks and cells are swapped out for food-grade ingredients in a process that is inspired by 4D biotechnological printing. When the right circumstances (temperature, humidity, light, etc.) are present, edible cells will develop in an edible substrate. It is possible for printed things with plant or animal cells to form tissue-like structures that imitate the nutrients found in real food (Zhao et al., 2020). This is advantageous for older people who have trouble swallowing it as well as the accompanying passion for fake meat. When printing food in four dimensions, the following things need to be considered: Cell-based printing matrices must be biocompatible before printing in order to promote cell growth and show adequate printability. Now, the most prevalent matrix is made of infuser water colloids including such gelatin, xanthan gum, agar, and so on. Because the porosity of the gel structure enables uninterrupted nutrient delivery and oxygen to the fixed cultured cells, the matrix design (such as a lattice scaffold pattern) is critical. The arrangement of shear stress and speed on the cells while printing affects their vitality. The mechanical properties of the gel after printing are insufficient to enable cell growth (Yoon et al., 2019).

Flavour change

The flavour alteration of 4D food can only be realised with the help of printing technology. Since printing technology makes it possible for food stuffs to have a fair layout, which improves the chemical process of flavour, and because of the different structural design, which helps the flavour alteration more uniform or reduces the chance of unpleasant changes such as expansion (Godoi et al., 2016). Currently, there are primarily two methods for achieving the flavour shift in 4D food. The first is that printers reasonably disperse the ratio and various food ingredients that give food its delightful flavour, and that the pH or microwave stimulus causes the correct flavour change. The flavour alteration could become more uniform with microwave treatment. When a microwave serves as the stimulus for flavour alterations, Internal structure filling speed and microwave process time should be considered. Instructions for developing one-of-a-kind, nutritious 3D-printed foods that can be created ahead of time and then take on the proper flavour when consumed have been supplied through study. There is almost no flavour loss when done this manner (Guo et al., 2021).

Opportunities in the sector of 4D Printing technology

Considering the many elements of 4D food printing technology discussed above, few discussions can be included like Improving the connection between organizational context and stimulation. One of the primary meanings of printing is to design the internal structure of food. To achieve the goal of 4D printing more successfully, it is suggested that the harmony here between inner structure and stimulant of printed food be included in future research. Creating fresh printing circumstances. Now, 4D food printing technology is reliant on traditional 3D printing technologies and tools. The utilized as a way of substance performance-function should be built to meet the requirements of deformation, conformational changes, and variable function of food materials. Furthermore, as advanced materials and technology emerge, there will surely be new challenges in mimicking 4D printing. New finite element simulation models and methods must be created in order to accomplish accurate simulation. Developing test and check procedures for the printed samples. It is important to research the online monitoring technology for critical 4D printing process factors including dimensional accuracy and stimulation of each layer. Additionally, it is important to investigate the rules governing how various printing process factors affect property accuracy as well as the rules governing how the internal and external properties of printed samples vary over time. Innovative adjustments to properties. It is important to support and connect research into intelligent food materials to the real food sector. For instance, vanilla is a common seasoning for ice cream and chocolate. At pH levels 2 to 8, vanilla is activated, and pH levels 9 and 10 are inhibitory. To achieve 4D food printing, it is necessary to study new stimulation elements (such as light, electromagnetic fields, osmotic dehydration, or combinations thereof) in conjunction with the characteristics of food components and printing structure. More crucially, it should be possible to produce simultaneous appearance of several properties (such as colour, form, flavour, etc.), and these changes should be repeatable (Jiang et al., 2021).

5D Food printing

5D printing of food products has become increasingly popular in recent years. This technology allows for the automated production of food products such as pizzas, cakes, and doughnuts. The process begins with the selection of a digital model of the desired food product. Once the model is chosen, the food ingredients are added and the 3D printer builds the food layer by layer. This process allows for precise customization of food products, allowing for the creation of unique and delicious dishes. Additionally, this technology can be used to create aesthetically pleasing food products, as the 3D printing process can create intricate details on food items. 5D printing of food products also offers several advantages over traditional methods of food production, such as improved efficiency, reduced wastage, and shorter production times. The introduction of eatable ink printing (2D/3D/4D) technique has resulted in significant innovation in the food business. Rheology accelerates development since it allows researchers and scientists to which was before the print quality of edible inks, duplicate the ideal print result, and put it into real industry applications. Japan and the United States developed biodegradable inks for food printing in the early twenty-first century (Wilson et al., 2021). Then, edible ink printing progressed from 2 to 4D printing, with culinary applications spanning from ornamentation to food intelligence. And now, 5D printing, the most recent advanced manufacturing technology, is being used to build tough and intricately formed items, with the potential to produce the most complicated and twisted food shapes with less material. The concept of 5D printing is a novel technological advancement utilised to construct complex and difficult-to-shape goods with excellent physical qualities (Pant et al., 2021). 5D printing is a blended technology that combines subtractive and additive manufacturing methods. It entails printing extremely complicated structures with three movement axes (X, Y, and Z) as well as two rotational axes. The printing head is represented by the X, Y, and Z axes, while the two rotational axes represent the printer's printing bed. Mitsubishi Electric Research Laboratories (MERL) pioneered 5D printing in 2016. The MERL study team used a 5D printer to experiment with producing pressure caps. They discovered that the 5D printed cap (3.7 MPa) has greater tensile stability than with the 3D printed framework (0.1 MPa). 5D printing is an additive manufacturing process in which an object is created layer by layer using a light-sensitive resin. A 3D printer heats the resin to a liquid state and then directs light, usually a laser, to selectively cure the resin in specific areas. As the object is built up layer by layer, more layers of liquid resin are added. The light cures the resin and hardens it in the desired shape. The process is repeated until the object is complete. The result is a 3D object with a high degree of detail, accuracy, and strength. 5D printing provides the benefits of a 3D printer with the added benefit of being able to produce a product with multiple layers of materials. This allows for the creation of objects with more intricate details and unique properties. This technology has the potential to be used in 5D printing of foodstuff and food packaging materials. 5D printing technology can be used to create food products with complex shapes, such as ball-shaped sweets items, beveled edge chips, or nibbles (Muthurajan et al., 2021). It can also be utilised in food packaging to create nuanced and complicated boxes, and tableware such as glasses and bowls that require extra support material in 3D printing can be manufactured utilising 5D printing technology. It has been discovered that the application of 5D printing appears to be particularly successful in the fields of healthcare and vehicle where curved or complex structures needing great strength are required. The notion of 5D printing was proposed for structural knowledge and functional creation, and it was claimed that 5D printing adds two dimensions, which are the distance measurement and the modification and regeneration of function level, with possible application in biological function tissue (Nida et al., 2021). The biggest benefit of 5D printing is clearly its strength and power, as it can easily exceed the limitations of 3D and 4D processing techniques (Zhao et al., 2021) (Figs. 4, 5).

Fig. 4.

Digitized nutrition control in food piece design

Fig. 5.

Schematic representation of the types of materials used for 4D printing

Applications and advantages of 5D printing in various fields

Food industry

5D Food printing is a novel manufacturing technology. The sample and the ready to print item have five degrees of freedom in this process. It creates curved layers rather than flat layers. The print portion rotates while the printed head prints in this process. As a result, rather of progressing through an item relating as in 3D printers, printing follows the curved line of the item being formed (Chen et al., 2022). The ability to manufacture a part with a thicker curved layer is the primary advantage of this technology. In terms of food uses, because 5D printing requires a high capacity to create subtle and captivating goods with soft and curved food constructions, as well as food with adequately construction purposes and intricate shape, the rheology characteristics of pertinent eatable inks for 5D printing are crucial and will influence the printing effects. While 3D/4D printing technology cannot touch the dinner table, 5D printed food should be highly stable during storage at diverse temperatures, transportation by various vehicles, and long/short-distance distribution to the dining table. Better rheological properties of edible inks would also aid to preserve the natural attributes (such as unique flavour) of food items and reduce nutrient loss due to the compactness of the ink matrix (Liu et al., 2017). The formulations of consumable inks are crucial and may fulfil demanding standards for specifying the edible ink composition, altering the potency and printability of 5D printing. 5D printing accommodates curved levels and generates concave constructions or curved stacking with outstanding quality and precision, while all the while adhering to design constraints. Edible ink's fluidity and rheological qualities are essential for printing concave structures or curved layers from many dimensions, which may necessitate the use of various inks for each dimension. Improper rheological properties can end up causing inks to have troubles extruded plastic from the spout or have extremely negatively ongoing fast flowability; likewise, dimension pairing is closely related to the ink asset as well as the viscosity, while poor permeability can cause decomposition, miscibility, or smudginess in printed products (He et al., 2020). Shearing thinning is also required for 5D printing consumable inks, especially when the parameters work simultaneously. The sheer of eatable inks from highly viscous to porosity and permeability under shear rate will add value to sleek extruding and successful collaborative effort to form magnificent products; however, when shearing behaviour is inappropriate under shear rate, it will result in numerous imperfections and faults in the printed products. The construction of 5D printed items is complex, with different regions having varying structure strengths (Liu et al., 2021). The storage and loss, complicated yield point, elastic modulus, and yield stress derived from sinusoidal testing are commonly used to assess mechanical strength and 5D printing's ability to maintain shape integrity. Choosing biopolymers is critical and tough in order to fulfil the comprehensive procedures by 5 axes during further research of 5D printing for development. The expense is also high due to the complex and expensive equipment. 5D printing requires additional research and the collaboration of numerous sectors, including rheological characteristics, mathematics, technology, biology, and so on, to promote the growth of the food sector. 5D printing of food inks has the potential to boost consumer attractiveness, meet a diverse range of customer tastes, and fill market segments. 5D printing in food includes the application of laser-sintering 3D printing to manufacture food items with complicated shapes, such as custom-made chocolates or detailed cakes. It can also be used to make food moulds for pastries, cakes, and other bakery items (Nida et al., 2021). 5D printing may be used to produce complex food structures from edible ingredients such as proteins and carbohydrates, allowing for the creation of new and fascinating textures in food products. Finally, 5D printing can be utilised to generate food products with tailored nutritional profiles, such as personalised meal plans or even customised supplements (Williams, 2021).

5D printing has enabled scientists to manufacture custom-made meals for individuals that are matched to their exact nutritional demands. This might be a significant nutritional breakthrough, as it could give tailored diets for patients suffering from allergies or other ailments. Improved food safety where 5D printing can generate food with a uniform, constant shape and size, any potential contamination is easier to identify (Song et al., 2019). Furthermore, 5D printing can be utilised to make food with a longer shelf life and fewer food waste, resulting in less food waste and enhanced food safety. Food may be produced with more precision using 5D printing, which can help reduce the risk of contamination, food illness, and allergens. Increased food variety: 5D printing allows for the creation of food items that would otherwise be difficult or impossible to produce, such as custom-shaped cookies or elaborate decorations on cakes (Dankar et al., 2018). Furthermore, 5D printing allows for the creation of food with a larger spectrum of flavours, textures, and colours. Reduced food waste: Because 5D printing can make food items with specified portion sizes and shapes, it can reduce food waste. Additionally, 5D printing can be used to create food with a longer shelf-life, resulting in fewer spoilage and wasted food. Reduced cost of production: 5D printing can create food with a shorter production time, which can reduce the cost of production. 5D printing can create complex shapes that are impossible to achieve through traditional methods, which can open up new possibilities for creative food design. Increased efficiency: 5D printing can create food with less wastage, which can help reduce the amount of food that goes to waste. Improved nutritional value: 5D printing can create food with more nutritional value, as it can precisely control the amounts of nutrients and vitamins added to food (Shi et al., 2022).

Dentistry surgery

The use of 5D printing in dentistry surgery is an emerging trend in the medical world. It offers dentists an opportunity to create detailed, custom dental implants and prosthetics that are more precise and cost-effective than traditional methods. The technology has a wide range of applications, including the fabrication of precise dental models and the production of dental prosthetics (Nanda et al., 2021). 5D printing is also being used to create dental implants that are customized to the patient's anatomy, resulting in a better fit and improved comfort. In addition, 5D printing can be used to create customized dental crowns, bridges, and other prosthetics. In the future, the technology is expected to play an even greater role in dentistry surgery, as it promises to reduce costs, improve accuracy, and shorten production times. 5D printing technology is becoming increasingly important in dentistry surgery. This innovative technology allows for the creation of 3D models of teeth, jaws, and other anatomically correct parts of the mouth, which can then be used to create more accurate and precise dental prostheses (Nida et al., 2021). 5D printing also allows to produce custom-made dental implants, which are more comfortable and aesthetically pleasing than traditional implants. Additionally, 5D printing can help reduce the cost of dental surgery by eliminating the need for multiple visits and procedures. With its ability to produce highly accurate and intricate structures, 5D printing is rapidly becoming an essential part of dentistry surgery (Liu et al., 2021).

Orthopaedic surgery

5D printing in orthopaedic surgery is an emerging technology that has tremendous potential for revolutionizing the way surgeons treat orthopaedic patients. It has the potential to improve the accuracy, speed and cost of orthopaedic surgery by enabling surgeons to create custom-made implants and devices tailored to the individual patient’s needs. 5D printing in orthopaedic surgery can also enable surgeons to create customized implants that are designed to fit a patient’s exact anatomy, which can lead to better outcomes and fewer complications. 5D printing can also help to reduce the amount of time required for surgery, as well as provide greater control over the surgical process (Jaspin et al., 2021). In addition, 5D printing can enable surgeons to create implants that are more durable and able to withstand long-term wear and tear. Finally, 5D printing in orthopaedic surgery can reduce the cost of procedures, as custom-made implants may be cheaper to produce than traditional implants. 5D printing is an important tool in orthopaedic surgery. It allows surgeons to create custom implants and tools for specific surgeries. This technology can be used to make highly precise, patient-specific implants that are tailored to fit the individual’s anatomy. It also allows surgeons to create tools that are specifically designed for the procedure, allowing for more precise and efficient surgery. 5D printing can reduce the risk of complications, such as implant rejection or infection, by providing a more precise fit (He et al., 2020). 5D printing can reduce costs by eliminating the need for expensive off-the-shelf implants. It is an invaluable tool for orthopaedic surgeons, providing them with the ability to create custom implants and tools for specific surgeries (Teng et al., 2021).

Bioprinting technology

Five-dimensional (5D) printing is a relatively new type of 3D printing technology that uses a fourth or fifth dimension—time or energy, respectively—to create complex, dynamic 3D structures. This technology enables the printing of objects that can change shape and size over time when exposed to certain environmental conditions. 5D printing can be used in a variety of industries, including bioprinting (Williams, 2021). Bioprinting is a type of 3D printing that involves the use of living cells, tissue, and biomaterials to create 3D structures. This technology is used to develop medical implants and prosthetics, organoids, and tissue structures for research purposes. The use of 5D printing in bioprinting technology has the potential to open up new possibilities in the field of regenerative medicine, allowing for the creation of complex, dynamic 3D structures with living cells. 5D printing can also be used to create scaffolds for tissue engineering, allowing for the development of tissue structures with a greater degree of control and accuracy. 5D printing can be used to create patient-specific tissue structures, allowing for the development of personalized medical treatments (He et al., 2020). Five-dimensional (5D) printing is a cutting-edge technology that is revolutionizing the field of bioprinting. It provides an efficient platform for the fabrication of complex three-dimensional (3D) structures with precise control over the physical and chemical properties of the material. This technology allows for the printing of living cells, biopolymers materials, and bioinks with intricate microstructures, enabling the fabrication of functional tissue constructs with high structural integrity. 5D printing has the potential to revolutionize the field of bioprinting by providing a platform for the construction of functional 3D structures with precise control over the physical and chemical properties of the material. The ability to manipulate the physical and chemical properties of the material allows for the fabrication of complex structures with specific biological and mechanical properties. 5D printing can be used to create a range of different cell types, allowing for the construction of tissue-like structures with improved structural integrity. The potential applications of 5D printing in bioprinting are vast and could lead to the development of sophisticated medical devices such as implants, prostheses, and tissue-engineered organs (He et al., 2021). 5D printing could be used to create personalized treatments for patients, as well as enabling the printing of complex biological structures. 5D printing technology has the potential to revolutionize bioprinting, as it can be used to print multiple layers of materials with different properties in a single step (Guo et al., 2021). This could be used to create complex 3D-printed living tissues, organs, and other biological structures. Compared to traditional 3D printing techniques, 5D printing offers greater control over the shape, size, and complexity of the printed structures. 5D printing could enable the printing of intricate vascular networks as well as the addition of cell types and other components to the printed structures. 5D printing could be used to print living tissues, organs, and other complex biological structures. Furthermore, this technology could be used to create personalized treatments tailored to the individual needs of each patient (Dickey, 2016).

6D printing

6D printing, in contrast hand, is emerging and mostly occurs on the research scale, with rapidly growing demand from researchers and businesses across a wide range of industries. It is the offspring of a five-axis printer that employs fused layer infrastructure and skilled and smart materials under stimulating conditions. The use of consumable inks in conjunction with a 6D printer is crucial for attaining the printing goal and impact (Chen et al., 2021a; b). In addition to 5D printing rheology problems, rheological properties may have an impact in real 6D printing by aiding in the development of good 6D printing consumable ink formulations, modelling the procedure, and helping in the identification of the necessary processing parameters. With a theoretically robust structure, the seismic design of 6D-printed samples is evaluated emphasis on scientific in a similar way as 5D printing. The temperature capability and values – of modern fabrics for 6D printing may be increasingly important in 6D printing rheology (Ghazal et al., 2019). This is since (1) smart materials may contain special active groups, and components would only maintain structural stability and function as expected at the appropriate temperature; and (2) the 6D printed sophisticated materials-based edible inks are made up of varying thicknesses of two distinct polymer composites, which will unquestionably bend when exposed to heat/temperature (Vancauwenberghe et al., 2019). As smart materials improve, 6D printed objects can be created as a result of 5D printing. It is thought to be a result of 5D printing technology (Shanthamma et al., 2021). 6D printing has the potential to be useful in the food industry. These domains are underdeveloped and have great economic and research promise (Sathe, 2017). The present expense of 6D printing in culinary purposes is owing to (1) unique consumable ink with high barriers to entry and high standards matching 5 axes, and (2) costly and difficult equipment (Phuhongsung et al., 2020). The primary benefit of 6D printing is that it combines the elevated structures of 5D printing with the ability to change structure, coloration, and flavour over time in response to 4D printing inputs, resulting in more durable and more efficient objects (Reddy et al., 2018) (Tables 1, 2).

Table 1.

Functions of 5D and 6D printing in various industries

| Industry/areas | 5D printing | 6D printing | References |

|---|---|---|---|

| Pharmaceutical/medical |

It can quickly print the sophisticated Orthopaedic implants that require a lot of strength during the patient's actual operation, and it is also useful in surgical planning, learning, and teaching It enables the creation of prosthetic body parts with complex shapes, such as legs, arms, and lower jaws, which require a great level of strength |

It can be utilised to create clever and effective implants for complex medical problems that would be impossible to create with 4D or 5D printing independently It has the potential to be used to create higher-performing, lower-cost medical materials for prostheses, orthopaedics, and dental implants |

Ramesh et al. (2018) |

| Automobile and construction components |

It may be used to construct complicated and curving houses It can aid in the precise or flawless production of a model of a vehicle or object's part or compound |

When dynamic alterations of these elements are required and useful, it can be employed to develop smart and effective car and construction components | Ratish Ramanan and Mahendranet (2021) |

| Food industries |

5D printing can create the most intricate and curved food shapes while using less material and having more robustness than 3D printing 5D printing could be a perfect alternative for creating food product containers and handling equipment that involve the construction of complicated geometries that fit the geometry of the product, decreasing its susceptibility to harm on production lines |

6D printing could be utilised to create smart and dynamic food stuffs with increased strength and complicated and curved geometries that retain their characteristic shape throughout handling chains It is capable of generating smart wrapping for food products that is both sturdy and lightweight while utilizing less material |

Xiao et al. (2020) |

| Bioprinting | 5D printing can produce the most complicated and curved bioprinting materials with great strength, which may aid in the preservation of their specific structure and mechanical qualities after printing, whereas 3D printing cannot | 6D printing can be utilised to create curved and smart dynamic bio-ink structures that are stronger, require less material, and outperform 4D printed bio-inks | Xun et al. (2015) |

| Industries and aerospace engineering | It can be used to make the most intricate and curved parts for aerospace engineering that demand a lot of strength |

6D printing could be utilised in self-adapting and self-repairing systems and goods, such as pipelines that can alter widths and qualities in response to water pressure by using smart materials and a five-axis printer that really can follow pipe curves It can develop innovative and curved substances that can reconfigure in reaction to temperature changes |

Yamamura et al. (2021) |

Table 2.

Various printing operations and required printing materials

| Methods | Stereolithography (SLA) | Inkjet printer | Selective laser sintering (SLS) |

Fused deposition model (FDM) |

Laminated object manufacturing (LOM) |

References |

|---|---|---|---|---|---|---|

| Principle | Curing of defined photo resin layers by ultraviolet radiations | Powder & liquid binding, polyjet technology that enable inkjet printing of photoresins | By using laser heating of powder particles is done | Molten thermoplastics are extruded | Cutting of heated, adhesive coated sheet material using laser/razor | Zarek et al. (2016) |

| Materials used | Epoxy or acrylate based resins with proprietary photo initiators, support material | Photoresins, plastic powder particles (50–100 µm in diameter) | Powdered PVC, ABS, resin, metals, PC, nylon, polyester, ceramic powders | Wax blends, PS, nylon, PC, ABS, metals/ceramics (with binder) | Adhesive coated polymer, cellulose, paper and metal sheets | Zeijderveld et al. (2018) |

| Solvent compatibility | Most of the polymer materials are able to absorb small organic molecules, organic or aqueous solvents which results in welling of the bulk material | – | For some chemical applications, paper or cellulose may not be amenable | Zhao et al. (2021) | ||

| Resolution (XY/Z) | 70–250/1–10, < 1 with two photon polymerization | 20–50/50 | 50/1–2 | 250/50 | 10/100 | Zhang et al. (2021) |

Applications and advantages of 6D printing in various fields

Food industry

Combination of different printing methods Because 6D printing combines the strengths of 5D printing with the strengths of 4D printing; it has the potential to add value to much more inventive food, serve more organisations (army, astronauts, and excursions), adjust accordingly to more impacts to the suitable and easily transferring and hauling characteristics of 6D goods, apply in having to print biologically active food packaging utensils, and so on. Accelerate the aircraft industry by concentrating efforts on the creation of specialised goods for hostile environments. 6D printing can produce intelligent foods with any filling type and reduced infill densities while using fewer resources, which is consistent with the concept of current intelligent civilization (Ghazal et al., 2021). One promising method of 6D printing in the food industry would be custom-made food items like as cookies, pastries, and other desserts. Instead of carefully carving out each form with a cookie cutter, 3D printing may be used to manufacture unique shapes and patterns quickly and accurately. The technique might be used to print food with complex characteristics such as mouthfeel or flavour. This might be tremendously useful for creating custom-made delights that look and taste exactly how the consumer demands (Derossi et al., 2018).

Medical field

Six-dimensional (6D) printing has the potential to revolutionize the medical field by providing a more precise, cost-effective, and efficient way to produce medical equipment, prosthetics, and implants. 6D printing uses computer-aided design (CAD) software to create 3D models, which are then printed in layers of material. This process allows for precise customization of the product, resulting in a device that fits perfectly with the patient's body. 6D printing also produces a device that is lighter and stronger than traditionally manufactured products. In addition, 6D printing can reduce costs by eliminating the need for costly molds and casts (Dankar et al., 2018). 6D printing has the potential to reduce the time it takes to manufacture medical devices, meaning that patients can receive their devices much more quickly. This could also lead to improved patient outcomes, since they will have access to the device at a much earlier stage. 6D printing can also be used to create customized medical devices that are tailored to the exact needs of a patient, which could result in improved comfort and function (Das et al., 2019). 6D printing could reduce the cost of medical devices, since the cost of production would be drastically reduced. 6D printing could also reduce the need for traditional manufacturing processes, which are often wasteful and inefficient. All these benefits make 6D printing a valuable tool for medical professionals and patients alike (Shanthamma et al., 2021).

Bioprinting technology

6D printing is an important tool for bioprinting technology. It allows for the precise control of biological materials, such as cells and proteins, during the printing process. This enables the creation of complex 3D structures with intricate details such as channels, pores, and microenvironments. 6D printing allows for more accurate and complex designs than traditional 3D printing methods, which are limited in the range of biological materials that can be used. 6D printing enables the precise control of different parameters such as the printing speed, temperature, pressure, and the size of the printed objects. This makes it possible to create objects with desired properties, such as drug release profiles, tissue viability, and bioactivity (Chen et al., 2021a; 2021b). 6D printing technology also has the potential to provide 3D printed organs and tissues, which could revolutionize the field of regenerative medicine. This technology can enable the precise 3D printing of complex tissue architectures with defined microenvironments, providing a unique platform to precisely control the behavior of different cell types and scaffold materials (Cortés et al., 2017). This could lead to new treatments for a range of diseases, such as cancer, cardiovascular diseases, and even neurological conditions. By facilitating the development of regenerative therapies, 6D printing could reduce the risk of organ rejection, as well as the need for immunosuppressant medications. 6D printing could also enable the production of personalized medical devices, including prostheses and implants. By combining 3D printing with nano- and micro-printing technologies, 6D printing could be used to create structures with precise geometries and architectures that are not achievable with 3D printing alone. This could also be used to create novel medical devices for the diagnosis and treatment of diseases (Yamamura et al., 2021).

Industries and aerospace engineering