Abstract

Plastic food containers are being used popularly, generating a waste of about 115 million tons in Vietnam. Such waste is causing environmental and health issues. This study conducted a field survey with 250 local people and selected 59 samples out of 135 plastic food containers collected in Go Vap district, Vietnam. Collected plastic samples identified compositions were PET 13.6%, PP 28.8%, PS 16.9%, and 40.7% undefined plastics. Collected plastic samples were classified based on the plastic type using recycling code and quantitatively analyzed with X-ray fluorescence spectroscopy method to assess concentrations of Cd, Sb, Pb, Hg, Sn, Cr, Br, Cl, and S. Most of these collected plastic samples (91.5%) were found to contain 8/9 hazardous substances and most elements contained in these plastics were below their standard thresholds. These elements in plastic samples could be divided as the result into three hazard groups: (1) high hazard group (Sb, Cl, and S); (2) medium hazard group (Cr, Br and Hg); and (3) low hazard groups (Cd, Pb and Sn). Among substances in the high hazard group, element Sb was assessed for its migration because only Sb is regulated in Vietnam in QCVN 12-1: 2011/BYT. Substances of Cl, S, Cr, Br, and Hg (group 1, 2) do not have regulations related to the method of decontamination. Thus, additional health risks need to be assessed using the USEtox model. Finally, this study proposed a screening process to assess the risk of toxicity of elements contained in plastic food containers through ISO 31000:2018.

Supplementary Information

The online version contains supplementary material available at 10.1007/s43188-023-00194-0.

Keywords: Plastic food containers, Hazardous substances, Toxicity, Health risk assessment, LCIA

Introduction

Plastic is being used commonly in the world, having a total production of 368 million tons in 2019. The biggest end-use market is packaging plastic, accounting for 39.6% of total European plastic demand [22]. In fact, compared to metal and glass containers, plastic packaging, including hard and flexibles plastic materials, are preferred because of they are lighter and more durable. Therefore, various additives or low molecular weight chemical compounds are applied and mixed in the manufacturing processes of plastic food containers so that the resulting material is more durable with improved functional properties [5]. Currently, there are many concerns about the migration of chemicals from food packaging or plastic containers into food due to close contacts between containers and food. Therefore, humans are easily exposed to these chemicals that can have toxic and harmful effects on human health [20, 29].

Plasticizers, stabilizers, flame retardants, antioxidants, anti-microbial agents, and colorants are main additives in plastic materials, particularly food packaging materials [8, 21, 13, 16, 27]. Metallic elements contained in these additives can also migrate from the packaging material to food or beverage over the exposure or contact time, prticularly when there is an increase in temperature or mechanical stress [5]. Substances like Cd, Pb, and Hg comprise toxic components that can have adverse effects on human health, including but not limited to the liver, kidneys, lungs, cardiovascular system, and immune system, if exposed to them for a prolonged period. Colorants and stabilizers containing cadmium and lead are often used in colored polymers. Chromium is mainly used for polymers such as polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP). Although synthetic polymers are generally resistant to microbial attack, some microorganisms can use certain additives as an energy source in the presence of water. This phenomenon can be prevented by adding biocides such as As, Sb, and Sn during polymer production [7]. Additives such as compounds S, Br, and Cl are added to create fire resistance for polystyrene (PS) materials [3, 6, 18]. Antimony is commonly used as a flame retardant additive. It is also a catalyst involved in polymerization of polyethylene terephthalate (PET) [28].

In order to minimize the potential risk to consumers' health caused by the accumulation of substances present in plastic packaging and food containers, health and environmental regulatory bodies around the world, including those in Vietnam, have implemented regulations and requirements for plastic products used in contact with food. These regulations must be met by manufacturers before their products can be released into the market.

Directive 94/62/EC on packaging and packaging waste limits toxic metals such as Hg, Pb, Cr6+, and Cd in plastic materials with a maximum concentration of 100 mg/kg [9]. The RoHS Directive (Restriction of hazardous substances directive in electrical and electronic equipment 2002/95/EC) is a directive on the restriction of hazardous substances in electrical and electronic equipment. The RoHS directive stipulates a maximum of 0.1% for Pb, Hg, Cr6+, PBB, and PBDE and a maximum of 0.01% for Cd by weight of packaging plastics [30]. The EU food safety standard specifies that the maximum Sb concentration is 350 ppm [28]. National technical regulation QCVN 12-1:2011/BYT stipulates that the maximum concentration allowed for Cd and Pb is at 100 µg/g and the maximum migration concentration allowed of Sb is 0.05 µg/mL [31].

The aim of the present study was to analyze concentrations of hazardous substances contained in food-grade plastic and provide modeling results of a life cycle impact assessment (LCIA) to determine the impact of hazardous substances on human health and the ecosystem. LCIA is a tool of product life cycle assessment to understand and estimate the magnitude and significance of potential environmental impacts added in a product system throughout its life cycle [17]. Several LCIA impact assessment methods have been developed with different approaches to resolve issues related to environmental and human impacts. There are several LCIA methods for determining effects of hazardous substances on human health, including classical impact assessment methods or problem-oriented methods [such as CML (Centrum voor Milieukunde Leiden), EDIP (Environmental Design of Industrial Products), and TRACI (the Tool for the Reduction and Assessment of Chemical and other environmental Impacts)], damage-oriented methods (such as Eco-indicator 99, EPS 2000, and EI99 methods), and other research-based LCA methodologies including the USEtox model [1, 19]. The main purpose of this study was to perform a preliminary screening for concentrations of hazardous additives with possible adverse health effects containd in plastic food containers samples. For this study, the authors collected different plastic container products for food and characterized hazardous substances released from them after proper processing. Obtained data were then applied to LCIA’s USEtox model to determine impacts on human health and ecosystems. Finally, this study proposed a risk assessment screening process according to ISO 31000:2018.

Materials and methods

Survey methodology and sample collection

A survey was conducted in order to evaluate people's reactions and attitudes to the use of plastic packaging for food. The study used the Cochran's sample size formula (1977) to calculate the number of surveyed participants. Since the people who living in Go Vap district as the population size is unknown, the population proportion is known:

| 1 |

where e is acceptable sampling error (e = 0.05), p is the (estimated) proportion of the population which has the attribute in question, p = 0.1, z: the z-value, extracted from a z-table.

With 99% confidence, the z value is 2.58, (1) formula resulting in a sample size of 240, which is rounded up to 250. Data were obtained through face-to-face surveys of 250 participants who lived in Go Vap District, Ho Chi Minh City, Vietnam. Random sampling is used, and the interview ends after the required number of samples have been obtained. We select a group of people who commonly interact with plastic food packaging. They include salesmen who operate fast food restaurants in marketplaces and on the roadsides where plastic samples were collected, as well as students, office workers, and housewives who dropped inside these stores to pick up a takeaway. The questionnaire included the following: (1) socio-demographic characteristics such as gender, age, and occupation of participants, (2) habits of using food container materials, (3) habits of reusing plastic food containers, and (4) perceptions, awareness, and attitudes about toxic components in plastic food containers and their use.

Sample collection of plastic food containers was conducted with the survey in parallel. The aforementioned interviewees' homes or points of sale were visited to gather plastic samples. A total of 135 plastic samples were collected, including plastic food containers after being used by customers or owners of facilities. After the preliminary assessment, duplicate samples of their origin and shapes of collected plastic food containers were removed. The remaining 59 plastic samples were selected for next experiments (See Table S1).

Determination of hazardous components by X-ray fluorescence spectroscopy

To analyze hazardous elements contained in plastic food containers, this study used energy-dispersive X-ray spectroscopy (EDX) due to its several advantages over other methods of measuring elemental content [2, 11]. EDX measurement is simple, fast, safe, cost-effective, and less time-consuming for daily calibration than other methods such as atomic absorption (AA). After being collected, food plastic container samples were classified by recycling code for plastic (Resin identification code, Figure S1) [4] and watering for cleaning grease and food residue. Elemental concentrations of nine selected hazardous substances, including cadmium (Cd), antimony (Sb), lead (Pb), mercury (Hg), tin (Sn), chromium (Cr), bromine (Br), chlorine (Cl) and sulfur (S), were determined using an EDX-7000 (Shimadzu, Japan). Elemental concentrations of selected substances of each plastic sample were analyzed three times to ensure sample precision. Concentration results of selected hazardous elements were collated according to RoSH standard, Directive 95/62/EC, and EU Food Safety Standards and then classified into three different hazard groups:

High-hazard group: a group of hazardous substances with concentrations exceeding their safety standards;

Medium-hazard group: a group of hazardous substances with their concentrations ranging from 50 to 90% of the prescribed concentration based on safety standards;

Low-hazard group: a group of hazardous substances with concentrations lower than 20% of the prescribed concentration.

Migration test

For plastic food containers that contain elements from the high-hazard group, their safety levels were assessed using the migration test method in accordance with Vietnam's national technical regulations QCVN 12-1:2011/BYT-National technical regulation on safety and hygiene for synthetic resin implements, containers, and packaging in direct contact with food [31]. In this process, antimony (Sb) analysis was performed using atomic absorption spectroscopy, employing a test solution and a working standard antimony solution, and the results were compared.

Life cycle impact assessment by USEtox

USEtox is a well-known scientific consensus model developed by the USEtox Team and endorsed by the United Nations Environment Program (UNEP) and the Society for Environmental Toxicology and Chemistry (SETAC) Life Cycle Initiative to characterize "human toxicological and ecotoxicological impacts of chemical emissions and of chemicals in consumer products" in life cycle assessment (http://www.usetox.org). The potential impact of hazardous substances on human health and the environment was calculated using the following formula with USEtox model factors (2) [25, 26, 33].

| 2 |

where ISx was the impact point of element X in plastic food containers, Cx was the concentration of element X in the plastic food containers, M (kg) was the mass of each plastic sample, and CFx was the characterization factor (CF) or total cause for the corresponding element X. CFx characteristic factors were quantified through the model, resulting in migration data. The output of the USEtox model included a database of recommended and interim characterization factors, including human exposure parameters such as cancerous and noncancerous incidence and ecotoxicological impacts of chemicals. The unit is PAF·m3·day/kgemitted for ecotoxicity specific factor and cases/kgemitted for human toxicity. In this study, input data of the USEtox model are clearly described in Table 1.

Table 1.

Input description of USEtox model used in the study

| Factors | Factor description | Factors in the study |

|---|---|---|

| Mx | The quantity of each sample of waste plastics in kg | 0.0025 kg |

| Cx | The amount of metal x in the waste plastic | Analytical data of substances performed by the method of migration specified in the national technical regulation QVCN 12-1:2011/BYT |

| Landscape data | Landscape- and human-exposure relevant environmental characteristics | Southeast Asia |

| Substance data | The substance data describes the physical–chemical characteristics, degradation rates, toxicity, ecotoxicity, bioaccumulation factors and biotransfer factors of a substance | Substance data of elements Sb(III), Cr(III), Cr(VI) and Hg |

Results

Results of the questionnaire

A total of 250 survey questionnaires including 104 men and 146 women were used for analyzing the use or consumption behaviors of food containers, especially plastic materials. Students and office workers were the majority of those visiting locations (where samples are taken) to buy fast food (using plastic containers), hence survey participants between the ages of 20 and 29 had the highest proportion (41.2%). Survey participants aged over 40 years old, under 20 years old and 30–39 years old were 22%, 20% and 16.9%, respectively. Thus, the surveyed age range from 18 to 54 years old mainly falls representing the age group that determines most of the products consumed in the family. People of this age range has a lot of exposure to general knowledge and information exchange, reflecting an interest in products that pose a risk to health and the environment, specifically plastic food containers.

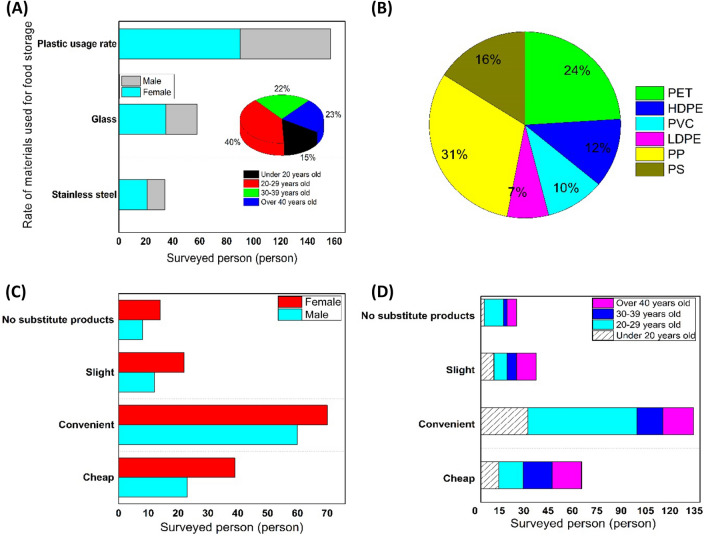

According to the survey, plastic is the most chosen material for food containers by both women and men, with 62.4% of participants choosing plastic, while only 23.2% and 13.3% of participants chose glass and stainless steel products, respectively (Fig. 1a). On a per-gender basis, 61.6% (90 out of 146) of women and 65.4% (68 out of 104) of men chose plastic food containers rather than food containers made of glass, stainless steel, or ceramic. Percentages of those choosing food containers made of glass, stainless steel, and ceramic were not significantly different between women and men. However, by age, the age group of 20–29 years old who chose plastic materials accounted for 40%, which was the highest percentage among age groups. This is because people in this age group are mostly students or office workers. Thus, the use of plastic food containers is more common for food products, particularly street food. The selection rate for plastic products as food containers was 22–23% for age groups of 30–39 or over 40 years old. The age group of under 20 years old had the lowest selection rate of 15% for plastic food containers. Regarding plastic types of food containers, PP had the highest proportion (31%), followed by PET (24%), PS (16%), and HDPE (12%). The rest of plastic food containers were LDPE and PVC types, accounting for a low percentage (< 10%) (Fig. 1b). The survey also showed that 52% of respondents preferred plastic food containers to other types of food containers such as glass and stainless steel products due to convenience of plastic food containers. Moreover, using plastic containers does not take time to clean or wash dishes. After using them, they could be just collected and thrown away as trash. Plus, it is easier to store take-away food instead of using expensive glass or steel containers or cups that could be easily broken and dented. This selection of plastic food containers was predominant in age groups of under 20 years and 20–29 years old. Other reasons such as low-cost and light properties of plastic food containers accounted for 24.8% and 13.6%, respectively. They were evenly distributed in surveyed age groups (Fig. 1c, d). With high mechanical strength and relative temperature resistance, plastic containers can hold almost any type of food. Plastic food containers just need to be carried in a bag, taking up very little space and effort to carry.

Fig. 1.

Survey of using food container materials by gender and age group (a), percentage of food containers according to plastic type (b), and reason of choosing plastic food container by gender and age (c, d)

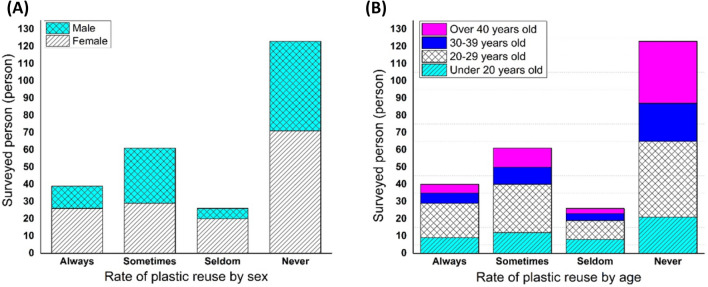

Figure 2a shows opinions about the reuse of plastic food containers. About half (49.2%) of respondents did not try to reuse plastic food containers because these containers were used on-site, at school, or work place and often thrown away after using. Some boxes of PS foam or thin plastic are easily damaged, making it difficult to reuse them. According to Chi-square test results (sig. ¼ 0.045 < 0.05), only the relationship between gender and plastic recycling habits was established in the three tested relationships between plastic recycling habits and gender, age, or occupation (See Table S2). Contrary to traditional thinking, males tended to reuse plastic containers more than females (43.7% vs. 38.1% for answer sometimes or always) (Table 2).

Fig. 2.

Survey on the level of reuse of plastic food containers by gender (a) and by age group (b)

Table 2.

Chi-square test results and significance response in the study

| Hypothesis | Chi-square test result | Response |

|---|---|---|

| There is no significant relationship between age and plastic recycling habits | 0.269 | Yes |

| There is a significant relationship between age and plastic recycling habits | No | |

| There is no significant relationship between gender and plastic recycling habits | 0.045 | No |

| There is a significant relationship between gender and plastic recycling habits | Yes | |

| There is no significant relationship between occupation and plastic recycling habits | 0.912 | Yes |

| There is a significant relationship between occupation and plastic recycling habits | No |

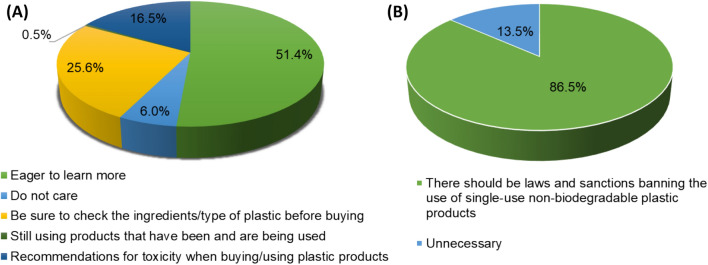

Most interviewees had heard that some plastic food containers might contain toxic or hazardous ingredients. In addition, the same respondents mentioned harmful effects of such toxic or hazardous substances with the potential to cause cancer, neurological diseases, respiratory diseases, and brain damage with health and environmental impacts. Regarding attitude using plastic food containers, 51.4% of the respondents were concerned. They wanted to get more information about the toxicity and adverse health effects of hazardous susbtances in plastic products. This suggests that they may be willing to modify their behavior based on the information they receive.

When asked if they would continue using products containing toxic or hazardous elements that are harmful to health, 25.6% of respondents said they would consider carefully about plastic component information before buying. It suggested they could be more picky about their purchases.

Moreover, 16.5% of the respondents mentioned that they would tell others about the unsafe plastic products, which could lead to a word-of-mouth campaign about avoiding toxic plastic products (Fig. 3a).

Fig. 3.

Consumer attitudes and perceptions about the use of these products (a) and requirements for developing laws/regulations about the use of single-use plastic containers (b)

However, it is concerning that 6% of participants indicated that they would not worry about plastic components or their toxicity information, and 0.5% would continue to use these products despite the awareness of the potential risks. These findings suggest that while awareness about the potential hazards of plastic food containers is high, not all respondents were willing to change their behavior to avoid using plastic containers that contain hazardous substances.

The results of Fig. 3b suggest that a vast majority of the interviewees are in favor of laws and sanctions that would ban the use of single-use non-biodegradable plastic products. This indicates that raising awareness among people who use plastic containers about the negative impact of plastic waste on the environment can lead to increased support for legislative measures to address the issue. By informing the public about human toxicological and ecotoxicological impacts from exposure to toxic or hazardous substances released from food plastic food containers, individuals may be more willing to support or advocate for regulatory interventions to minimize the use of single-use non-biodegradable plastic products, especially in Vietnam.

In conclusion, raising awareness among plastic container users about the study's findings of toxicological risks from plastic food containers, indicating strong support for a ban on single-use non-biodegradable plastic products, can promote a better understanding of the importance of reducing plastic waste and foster greater support for legislative interventions to address the issue.

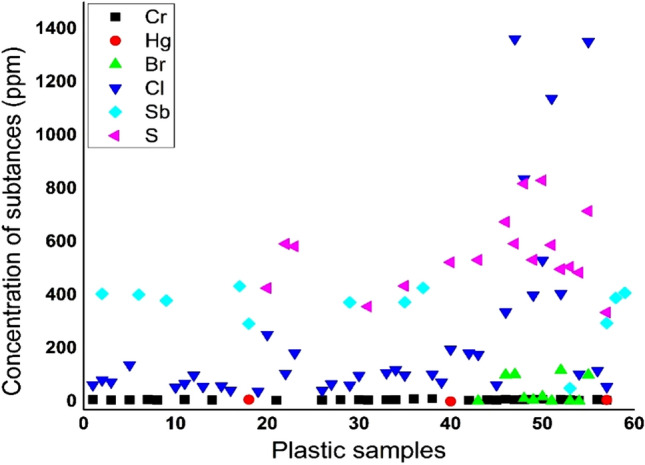

Concentrations of substances in food containers

The selected samples for concentration analysis of hazardous substances contained in the collected plastic food containers were 59 food-grade plastic samples, including those containing PET (n = 8), PP (n = 17), and PS (n = 10). The large fraction of these 59 samples was X plastic (n = 24), which was defined as a plastic with plastic classification number and code not known or not easily identified from its appearance in this study. From EDX analysis of the 59 collected food plastic samples, Hg, Cr, Br, Sb, Cl, and S elements were detected, whereas Cd, Pb, and Sn were not detected. Figure 4 and Table S3 show concentration distribution of detected substances. Concentrations of Cl, S, and Sb were much higher than those of the remaining components. High chlorine concentrations were detected from 38 samples, including 3 PET, 12 PP, 9 PS, and 14 X plastic samples. In particular, chlorine in 8 samples showed significantly higher concentrations (above 300 ppm) than other elements, with the highest chlorine level of 1361.87 ppm (M28). Exposure to or contact with compressed liquid chlorine may cause frostbite of the skin and eyes. It can easily produce hypochlorous acid which is corrosive. Such acid can damage cells in the body on contact. According to WHO (World Health Qrganization), the guideline value for free chlorine in drinking-water derived from a NOAEL (no-observed-adverse-effect level) is 15 mg/kg of body weight per day. Its TDI (tolerable daily intake) is 150 µg/kg of bodyweight with the application of an uncertainty factor of 100. Its guideline value in drinking-water is 55 mg/liter with an allocation of 100% of the TDI to drinking-water [34]. Released fractions or levels might vary depending on plastic food container, food packaging process, and various conditions such as food contact time, food composition, and food temperature in plastic containers. Currently, an allowable concentration limit of chlorine has not yet been set or regulated for food plastic packaging or container. Results about these high chlorine contents in the present study call for attention to chlorine regulation issue to minimize or prevent from adverse health effects caused by the use of plastic food containers.

Fig. 4.

Distribution of toxic elements in collected plastic samples of food containers

The second finding of interest is chromium (Cr). It was detected in 28 of 59 plastic samples, including 8 PP, 8 PS, and 11 X plastic samples: 8 PP samples of M1-1, M3-1, M4 (plastic cup), M5-1, M7-1, M9-1, M13-1, and M36-1 (plastic bowl); 8 PS samples of M27, M28, M29, M30, M31, M33, M34-1, and M34-2 featured in foam food containers; and 11X samples of plastic cups and plastic boxes. Chromium concentration mainly fluctuated in the range of 4.45–8.53 ppm on PP and PS, except for M22-1 and M23-1 with concentrations of 9.47 ppm and 10.27 ppm in X plastic, respectively. However, Cr concentrations in all investigated plastic samples used for food containing purposes in this study were detected within the regulated safe limit of 100 ppm specified in the directive 94/62/EC.

Sulfur (S) concentrations in 18 out of 59 samples exceeded 300 ppm. Sulfur was detected in 2 PET samples (M21-2 and M36-2 of plastic lids), 3 PP samples (M12-2, M13-2, and M14 of lunch boxes), 3 X plastic samples (M19-1, M24-1, and M25-2), and 10 PS samples. PS in most samples had high concentrations above 400 ppm. In particular, M31 had the highest concentration of 830.83 ppm. PP and X plastic samples showed average concentrations of sulfur, ranging from 356.65 to 592.07 ppm. However, PET samples had the lowest S concentrations among different plastic groups tested.

Bromine (Br) was detected in 11 plastic samples, with concentrations ranging from 1.58 to 117.37 ppm. Among these 11 samples with Br detected, 10 were PS samples. This is because PS is considered to have a very high fire hazard. Thus, bromine compounds are mostly added as flame retardants into PS [18]. Currently, Vietnam does not have proper regulations about the concentration of Br in plastic. Considering that the RoHS standard of Br is 1000 ppm, detected bromine concentrations seemed to be lower than the standard. However, caution still should be exercised in the use of these materials.

Only three samples showed mercury (Hg) detection, including two PET samples of M12-1 and M36-2 (food container lids) and one X sample (plastic container). The RoHS standard and Directive 94/62/EC of Hg both stipulate a safety threshold of < 100 ppm for Hg. Detected Hg concentrations (with the highest of 7.34 ppm) were within the safe limit. However, mercury also needs to be paid more attention, particularly considering that Vietnam currently does not have a legal standard regulating the concentration of mercury in food plastic materials.

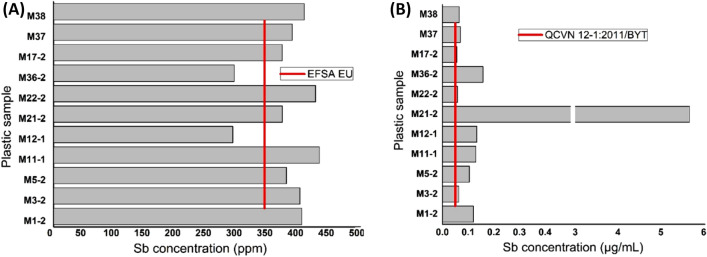

Antimony (Sb) was detected in all 8 PET samples and 3 X plastic samples (M17-2, M37 and M38). Antimony is often used as a flame retardant additive and a catalyst involved in the polymerization reaction in PET plastic. Previous studies have also shown the presence of Sb in PET resins, with concentrations ranging from 150 to 300 ppm [10, 14, 24]. Compared with EU food safety standards (EFSA EU), 9 out of 11 samples containing Sb exceeded the safety standard of 350 ppm. In particular, M11-1 (PS) showed the highest Sb concentration of 433.3 ppm, which was 1238 times higher than the standard (Fig. 5a). It may cause a potential risk to human health. Many studies have proven that antimony can migrate from materials to food under the influence of temperature and storage time. Antimony migration may lead to adverse health impacts such as cancer, cardiovascular, immune response, and endocrine disorder in human [14].

Fig. 5.

Antimony (Sb) concentrations detected in some obtained plastic samples by EDX (a) and by migration test (b)

Based on results described above, substance groups contained in plastic food containers investigated in this study can be classified into three main hazard groups:

High hazard group, including Sb, Cl, and S elements, which can be classified as a group with high-value screen-measured concentrations by EDX. In particular, Sb element in 9 samples out of 11 exceeded its EU safety standard of 350 ppm. Although their detected concentrations of Cl and S substances were quite high, currently there are no specific regulations on their safe concentrations.

Medium hazard group, including Hg, Cr, and Br substances, with their concentrations ranging from 50 to 90% of the prescribed level by the corresponding standard specified on the Directive 95/2/EC and the RoHS standards, 100 ppm for Hg and Cr and 1000 ppm for Br. Currently, measured concentrations of the substances Hg, Cr, and Br in the plastic food containers investigated in this study were much lower than their prescribed levels.

Low hazard group, including substances Cd, Pb, and Sn not detected in the investigated plastic food containers of the current study using the EDX-7000 screening for element detection.

Migration test

The screening results for hazardous substances in plastic food containers were analyzed and included Sb, Hg, Cr, the halogen group (Br, Cl), and non-metallic S. The detection of these elements was done through Energy Dispersive X-ray fluorescence spectroscopy. All the analyzed elements were found to be within their safe limits specified by EFSA, except for Sb which exceeded its limit. PET containers were found to contain Sb in concentrations that surpassed the allowable limit specified by QCVN 12-1: 2011/BYT in Vietnam. It is worth noting that Sb in plastic food containers has the potential to leach into food while packaging and storing, particularly hot food for a prolonged time. Therefore, it is advisable to avoid reusing these types of plastic food containers.

The concentrations of Cl and S elements were also found to be high. Thus, the migration test was used to assess the potential for toxicity accumulation from food resins into the human body. Although concentrations of Cl and S are quite high, there are currently no regulations about their safe thresholds. Thus, the current study tried a migration test for these two substances to assess their potential toxicity. Sb element was assessed for its migration in a group of substances with high levels of risk in this study.

Nine out of 11 samples of plastic food containers samples showed Sb exceeding its EU safety standard of 350 ppm. Therefore, Sb was classified into the high hazard group with a high level of risk in this study. It was also assessed with the migration test. Most of the plastic food containers with Sb detected were PET plastic, a widely used plastic for single-use water and beverage bottles. Many studies have shown that element Sb can migrate from plastic to food under the influence of temperature and storage time [5, 10, 12, 14, 15]. Concentration of Sb is currently regulated as QCVN 12-1: 2011/BYT in Vietnam, which specifies the maximum concentration of Sb migration. The allowed maximum limit of Sb specified in QCVN 12-1:2011/BYT is 0.05 µg/mL. As shown in Fig. 5b, all samples containing Sb exceeded its allowable limit. For example, all tested PET samples exceeded its level, ranging from 1.18 to 3.16 times higher than the allowable limit, with concentrations ranging from 0.059 to 5.67 µg/mL. All tested X plastic samples also exceeded its allowable limit, with concentrations ranging from 0.056 to 0.07 µg/mL.

Discussion

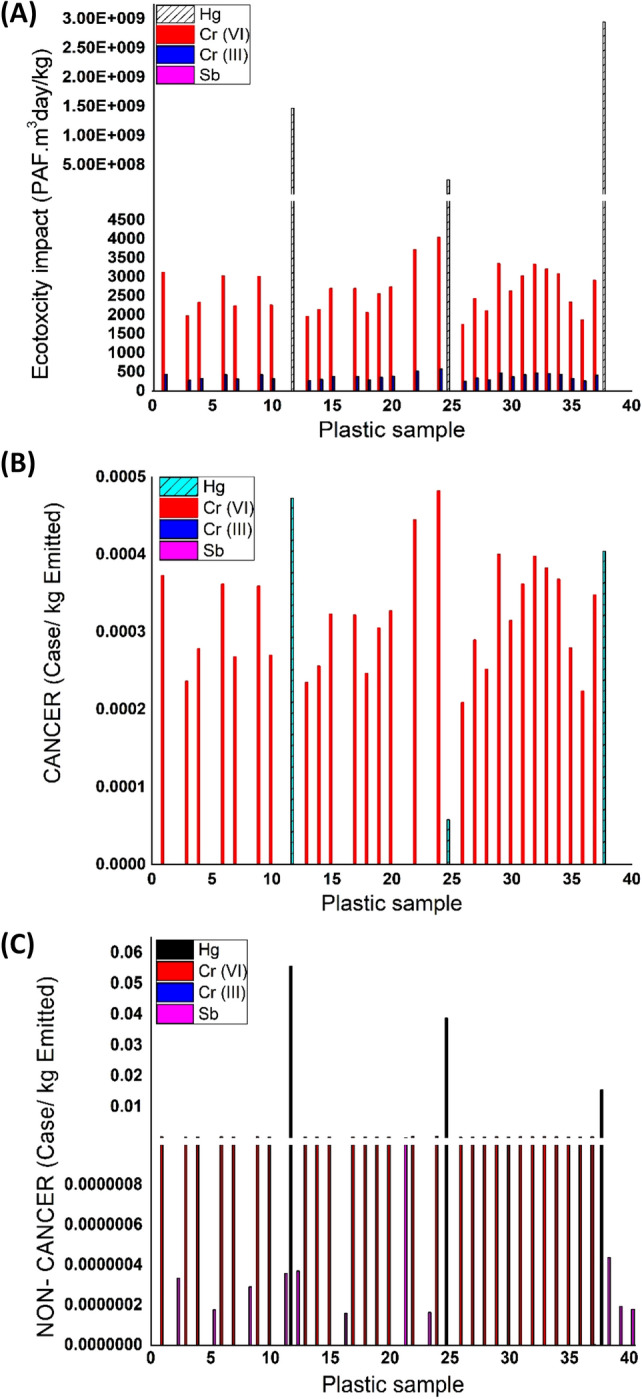

Life cycle impact assessment by USEtox

The resulting migration information of Sb was included in the LCIA model using USETox to assess risks of hazardous substances contained in plastic food containers. However, substances such as S, Br, Cl, Hg, and Cr do not currently have migration regulations. Therefore, it was assumed that these substances’ concentrations measured by EDX analysis were completely migrated to food for risk assessment. Sb, Hg, and Cr components are known to be very toxic or carcinogenic [23, 28, 32]. Therefore, they were focused on in this study to evaluate their risk using the USEtox model. Chromium applied in the USEtox the model included both Cr(III) and Cr(VI) species.

Figure 6 shows the impact of hazardous substances (Hg, Cr and Sb) identified in plastic food containers using the USEtox LCIA model. Detailed calculations for each metal in terms of emission concentration in air, water, and soil are shown in Fig. S2 and S3. It was found that Hg was the most ecotoxic element, followed by Cr(VI), Cr(III), and Sb (Fig. 6a). These results indicate that Hg element tends to become a significant carcinogen in the PET plastic group (Fig. 6b). Element Cr(VI) can affect human health due to its carcinogenicity [32]. It was detected in most food plastic samples, especially in the X plastic group. Sb and Cr(III) are not classified as Group 1 (known human carcinogen) or Group 2A (probable human carcinogen) carcinogenic agents. Figure 6c shows that element Hg has a risk of causing non-cancerous diseases. It tends to be show a risk of cancer when both PET samples have high levels of mercury. Cr(VI) also has a significant risk of causing non-cancerous diseases. Results also indicate that elements Sb and Cr(III) are causative agents of non-cancerous diseases at low levels.

Fig. 6.

Results of USEtox LCIA model showing average impacts of Hg, Cr, and Sb identified in food plastic containers—related to emission concentrations in air, water and soil with a ecotoxicological impacts, b Human cancer and, c non-cancerous diseases

Results from screening and removal were used to assess potential human health risks of substances through the USEtox LCIA model. USEtox model results showed that three substances could be applied in the model, including Sb, Hg, and Cr.

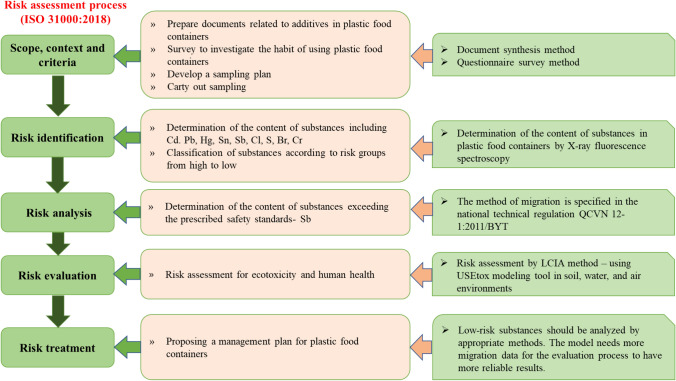

An operational framework of risk assessment process by ISO 31000:2018 on plastic food containers

The object of a risk assessment (RA) was determined to be food-grade plastic and additives contained in the plastic by the method of collecting assets related to the object. The first step of RA is to survey and collect survey method for determining the context and scope of the research. Achieved survey results included the collection and identification of process information on plastic food containers and information related to food container problems surrounding people whom are often in contact with plastic. Through the survey, this study found that the use of plastic products for food packaging or containers was very frequently chosen and the reuse of plastic was quite high at 49.2%. The use rate of plastic containers for hot food was also high at 44%. These data indicate that plastic food containers have great potential to cause health risks if they are regularly used and reused for hot food for a long time.

In this study, the identification of potential hazards was conducted through screening of hazardous substances contained in plastic food containers measured by Energy Dispersive X-ray fluorescence spectrometer (EDX-7000). This method is simple and safe because samples are measured directly without needing a digestion step. It is also more cost-effective than other analytical methods. Through the screening processes of element information (concentration and toxicity) obtained after analysis by EDX-7000 with a comparison with plastic-related legal standards, including RoHS standards, Directive 94/62 EC, and Food Safety standards, study results indicate that elements in plastic samples can be divided into three hazard groups: (1) high hazard group (Sb, Cl, and S); (2) medium hazard group (Cr, Br and Hg); and (3) low hazard groups (Cd, Pb and Sn).

For substances classified into the high hazard group after the screening process, their risks were analyzed through the exposure method (concentration investigation by EDX and migration test in this study for example) to assess their ability to accumulate toxic substances in the human body. In this study, among substances in the high hazard group, element Sb was assessed for its migration. It was chosen because in the sample screening process, almost all plastic samples containing Sb exceeded its safety threshold prescribed for PET plastic, a type of plastic widely used in food containers.

However, in the high hazard group of substance classified in the above step, only Sb is regulated in Vietnam in QCVN 12-1: 2011/BYT. Thus, the maximum concentration of Sb contamination was chosen as the basis to assess its ability to accumulate toxicity from plastic food containers into the human body. Substances of Cl, S, Cr, Br, and Hg do not have regulations related to the method of decontamination. Thus, these substances were only subjected to screening analysis using EDX-7000. However, it is difficult to identify or estimate their safety level.

Through the USEtox model, Hg and Cr(VI) were found to be highly toxic substances, while Sb and Cr(III) substances were found to have a relatively low potential for ecological toxicity and human health compared to Hg and Cr(VI). However, this model is mainly applicable to the problem of assessing the toxicity of E-waste plastics because e-plastics are mainly exposed to humans through pathways in the USEtox LCIA model [25, 26]. The limitation of this model was that data on temperature conditions, food contact time, and physicochemical issues were not directly applied in the model. Thus, evaluation through this model needs more data on temperature and storage time to ensure high accuracy of the model.

The final step of the process is to propose a risk management option. Although hazardous substances Cd, Pb, and Sn were not detected in plastic food containers during EDX screening, they should be investigated using more appropriate methods. These substances were considered to have a low risk. However, they might have a high risk in other studies.

In this study, only Sb can be decontaminated. Other substances also need to be decontaminated, regardless whether they are in the high, medium, or low risk group. This is because these substances have potential risk to human health. All possible emitted substances in food plastics (such as 9 hazardous substances, including cadmium (Cd), antimony (Sb), lead (Pb), mercury (Hg), tin (Sn), chromium (Cr), bromine (Br), chlorine (Cl) and sulfur (S) in this study) need to have an impact assessment process with LCIA models, especially the USEtox model. This is because toxicity research about plastic food containers using this model has not been established yet. In addition, the USEtox model is still limited in the application of data on migration conditions, such as temperature, storage time, and physicochemical environment of hazardous substances contained in plastic food containers. Figure 7 summarizes the risk assessment screening process of plastic food containers according to ISO 31000:2018.

Fig. 7.

Summary of the risk assessment screening process of plastic food containers according to ISO 31000:2018

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

The author would like to thank the Industrial University of Ho Chi Minh City, the Institute for Science, Technology and Environmental Management for creating conditions to complete the study.

Author contributions

NTLB and NTTT analyzed and interpreted the main data and was a major contributor in writing the manuscript. NTNT and VDK were responsible for data curation. B-KL took responsibility for writing—reviewing the manuscript. All authors read and approved the final manuscript.

Funding

Not applicable.

Data availability

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

Declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

References

- 1.Acero AP, Rodriguez C, Ciroth A (2017) LCIA methods: impact assessment methods in life cycle assessment and their impact categories. Version 1.5.6. Green Delta, pp 1–23

- 2.Adel Ismael Chaqmaqchee F. Comparison of various plastics wastes using x-ray fluorescence. Am J Mater Synth Process. 2017;2:24. doi: 10.11648/j.ajmsp.20170202.12. [DOI] [Google Scholar]

- 3.Alekseev AA, Osipchik VS, Sukhinina OA. Properties of chlorinated polystyrene. Int Polym Sci Technol. 2001;28:76–78. doi: 10.1177/0307174x0102800419. [DOI] [Google Scholar]

- 4.ASTM - American Society for Testing and Materials (2014) D7611 standard practice for coding plastic manufactured articles for resin identification. 10.1520/D7611_D7611M-13

- 5.Bhunia K, Sablani SS, Tang J, Rasco B. Migration of chemical compounds from packaging polymers during microwave, conventional heat treatment, and storage. Compr Rev Food Sci Food Saf. 2013;12:523–545. doi: 10.1111/1541-4337.12028. [DOI] [PubMed] [Google Scholar]

- 6.Braun U, Eisentraut P, Fuchs S, Deglmann P. Sulphurous additives for polystyrene: Influencing decomposition behavior in the condensed phase. J Appl Polym Sci. 2015;132:41665. doi: 10.1002/app.41665. [DOI] [Google Scholar]

- 7.Campanale C, Massarelli C, Savino I, et al. A detailed review study on potential effects of microplastics and additives of concern on human health. Int J Environ Res Public Health. 2020;17:1212. doi: 10.3390/ijerph17041212. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Cherif Lahimer M, Ayed N, Horriche J, Belgaied S. Characterization of plastic packaging additives: food contact, stability and toxicity. Arab J Chem. 2017;10:S1938–S1954. doi: 10.1016/j.arabjc.2013.07.022. [DOI] [Google Scholar]

- 9.European Parliament and the Council of the European Union (1995) Directive 95/62/EC of the European Parliament and of the Council of 13 December 1995 on the application of open network provision (ONP) to voice telephony

- 10.Franz R, Welle F. Contamination levels in recollected PET bottles from non-food applications and their impact on the safety of recycled PET for food contact. Molecules. 2020 doi: 10.3390/molecules25214998. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Goodlaxson B. Studies to evaluate methodologies used for determining heavy metal content in polyethylene terephthalate food packaging. Ames: Iowa State University; 2017. [Google Scholar]

- 12.Guerreiro TM, de Oliveira DN, Melo CFOR, et al. Migration from plastic packaging into meat. Food Res Int. 2018;109:320–324. doi: 10.1016/j.foodres.2018.04.026. [DOI] [PubMed] [Google Scholar]

- 13.Hahladakis JN, Velis CA, Weber R, et al. An overview of chemical additives present in plastics: migration, release, fate and environmental impact during their use, disposal and recycling. J Hazard Mater. 2018;344:179–199. doi: 10.1016/j.jhazmat.2017.10.014. [DOI] [PubMed] [Google Scholar]

- 14.Haldimann M, Alt A, Blanc A, et al. Migration of antimony from PET trays into food simulant and food: determination of Arrhenius parameters and comparison of predicted and measured migration data. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2013;30:587–598. doi: 10.1080/19440049.2012.751631. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Hansen E, Nilsson NH, Lithner D, Lassen C (2014) Hazardous substances in plastic materials. The Danish Environmental Protection Agency, Denmark. https://www2.mst.dk/Udgiv/publications/2014/12/978-87-93283-31-2.pdf

- 16.Hauser R, Calafat AM. Phthalates and human health. Occup Environ Med. 2005;62:806–818. doi: 10.1136/oem.2004.017590. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Jolliet O, Saade-Sbeih M, Shaked S, et al. Environmental life cycle assessment. Boca Raton: CRC Press; 2015. [Google Scholar]

- 18.Ketov AA, Krasnovskikh MP, Maksimovich NG. Transformations of chlorinated organic additives in polystyrene in the course of oxidative pyrolysis. Russ J Appl Chem. 2013;86:1563–1568. doi: 10.1134/S1070427213100145. [DOI] [Google Scholar]

- 19.Menoufi KAI. An overview on Life Cycle Impact Assessment ( LCIA ) methodologies: state of the art. Lleida: Universitat de Lleida; 2011. [Google Scholar]

- 20.Muncke J, Andersson AM, Backhaus T, et al. Impacts of food contact chemicals on human health: a consensus statement. Environ Health A Glob Access Sci Source. 2020;19:25. doi: 10.1186/s12940-020-0572-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Pivonello C, Muscogiuri G, Nardone A, Garifalos F, Provvisiero DP, Verde N, De Angelis C, Conforti A, Piscopo M, Auriemma RS, Colao A. Bisphenol A: an emerging threat to female fertility. Reprod Biol Endocrinol. 2020;18:22. doi: 10.1186/s12958-019-0558-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Plastics Europe (2020) Plastics—the Facts 2020. Plastics Europe Association of Plastics Manufactures. https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/

- 23.Rodrigues MO, Abrantes N, Gonçalves FJM, et al. Impacts of plastic products used in daily life on the environment and human health: what is known? Environ Toxicol Pharmacol. 2019;72:103239. doi: 10.1016/j.etap.2019.103239. [DOI] [PubMed] [Google Scholar]

- 24.Shotyk W, Krachler M. Contamination of bottled waters with antimony leaching from polyethylene terephthalate (PET) increases upon storage. Environ Sci Technol. 2007;41:1560–1563. doi: 10.1021/es061511+. [DOI] [PubMed] [Google Scholar]

- 25.Singh N, Duan H, Ogunseitan OA, et al. Toxicity trends in E-Waste: a comparative analysis of metals in discarded mobile phones. J Hazard Mater. 2019;380:120898. doi: 10.1016/j.jhazmat.2019.120898. [DOI] [PubMed] [Google Scholar]

- 26.Singh N, Duan H, Tang Y. Toxicity evaluation of E-waste plastics and potential repercussions for human health. Environ Int. 2020;137:105559. doi: 10.1016/j.envint.2020.105559. [DOI] [PubMed] [Google Scholar]

- 27.Singh P, Saengerlaub S, Wani AA, Langowski HC. Role of plastics additives for food packaging. Pigment Resin Technol. 2012;41:368–379. doi: 10.1108/03699421211274306. [DOI] [Google Scholar]

- 28.Snedeker SM (2014) Antimony in food contact materials and household plastics: uses, exposure, and health risk considerations. In: Snedeker SM (ed) Toxicants in food packaging and household plastics. Molecular and integrative toxicology. Springer, London, pp 205–230. 10.1007/978-1-4471-6500-2_8

- 29.Thompson LA, Darwish WS. Environmental chemical contaminants in food: review of a global problem. J Toxicol. 2019;2019:2345283. doi: 10.1155/2019/2345283. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.UK Office for Product Safety and Standards (2021) Guidance regulations: restriction of hazardous substances (RoHS). GOV.UK. https://www.gov.uk/guidance/rohs-compliance-and-guidance. Accessed 2 Oct 2021

- 31.Vietnam Ministry of Health (2011) QCVN 12-1:2011/BYT National technical regulation on safety and hygiene for synthetic resin Implement, container and packaging in direct contact with foods

- 32.Wang Y, Su H, Gu Y, et al. Carcinogenicity of chromium and chemoprevention: a brief update. Onco Targets Ther. 2017;10:4065–4079. doi: 10.2147/OTT.S139262. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Westh TB, Hauschild MZ, Birkved M, et al. The USEtox story: a survey of model developer visions and user requirements. Int J Life Cycle Assess. 2015;20:299–310. doi: 10.1007/s11367-014-0829-8. [DOI] [Google Scholar]

- 34.World Health Organization (2003) Chlorine in Drinking-water. Background document for preparation of WHO Guidelines for drinking-water quality. World Health Organization, Geneva (WHO/SDE/WSH/03.04/45)

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data generated or analyzed during this study are included in this published article [and its supplementary information files].