Abstract

Notifications that related 1st degree burns to reflective striping and impermeable clothing elements did reach the investigators, while the mechanisms behind this phenomenon are still unclear. Material tests for thermal and evaporative resistance, and for heat transmission under dry and wet conditions at low radiation levels were done to evaluate the performance of protective clothing with and without printed logos or reflective striping. The results under the specified conditions showed reduction of heat loss capacity under impermeable elements from dry to wet conditions. Reflective surfaces, even when more impermeable, showed still lower heat transmission through the textile package than materials without striping under tested moisture and radiation combinations. It can be expected that the reported 1st degree burns were related to clothing design and tightness/fit rather than to reflective striping. However, due to the fine balance between clothing thermal and evaporative resistance, outer material emissivity, moisture quantity and location in clothing and applied radiation level, a different setup could lead to different results.

Keywords: Radiation, Moisture, Firefighter, Uniform, Thermal resistance, Evaporative resistance, Heat transmission

Introduction

Recent notifications reaching to the Netherlands Institute for Public Safety (NIPV) were concerned with 1st degree burns during firefighting exercises and clothing testing, and called for further examination. The reported incidents indicated a short-term (2–3 min) exposures to radiation levels of probably less than 8 kW/m2 but not specifying the exact power level. The available information referred only to the damage of the reflective striping and 1st degree burns at the upper and lower arms. During more recent observations of similar exercises, power in the range of 5–7 kW/m2 at the human position was sufficient to cause 1st degree burns. These field exercises were meant for training, and the measurements were only done as background information to ensure that wished levels of the exposure conditions were reached. Also, assuming that the used equipment corresponded to the standards1), then occurrence of above mentioned adverse events was not expected. At their occurrence, thus, all details were not noted down at once nor were all details available or parameters measured. At the same time the studies connecting technical measurements with the effect on human performance or degree of burns are scarce due to ethical considerations2,3,4), while officially published accident and injury data often stands alone without the technical clothing material specifications and environmental conditions description, e.g., similar as published by Kahn et al5). Thus, in related research we often have to rely on technical measurements and modelling6,7,8,9,10,11,12,13,14,15) in order to get indication of causal factors.

A recent modelling and validation paper by Malaquias et al.12) points out that precise conclusions about the influence of moisture on thermal performance under diverse heat exposures are hard to obtain and there exist contradictory results as different experimental set-ups and garments, measuring techniques, and protocols have been utilized. Thus, any comparison, and trends, between the studies can’t be conclusive. Their study evaluated risk for second degree burns in a clothing system with moisture located in different layers and concluded that reductions in thermal performance were due to moisture condensation near the skin, and the condensation caused scald burns. Their results showed that the final outcome strongly depends on the combination of moisture location in the clothing system layers and the applied radiation level. However, they did not focus on the possible effects of air gaps. Effect of air gaps have been discussed in several other studies10, 11, 14, 15). Largely it can be said that more and wider (>6–7 mm) air gaps increase thermal protective performance (TPP) of the clothing system16), while too wide and open air gaps may increase internal natural convection and pumping external air into clothing system and reduce TPP of the system17, 18) and may increase the risk for exposure to contaminated air in a polluted environment18,19,20,21).

Returning to the issues raised by firefighters on reflective striping then Chou et al.2) found that although the aluminized protective clothing had a similar clothing weight and thermal insulation as non-aluminized clothing, the physiological and subjective strains during exercise in radiant heat were the greatest under reflective layers, due to the greater evaporative resistance and lower water vapor permeability of the aluminized firefighters’ clothing. This was also a main conclusion from several measurement series under thermal radiation on heat and moisture transfer through clothing materials with various moisture permeabilities during a European Thermprotect study3). Although covering a wide range of conditions, and settling the relationships for heat and mass transfer from heat stress perspective22,23,24) that project used considerably lower radiation intensities, did not focus specifically on burn injury risks and short term exposure limits. At the same time, reflective layers are recommended for work under high radiation levels (depending on national regulations >4–8 kW/m2) in order to reduce burn injury risks9, 25). In this case the exposure to radiation is expected to be longer than a few seconds under flashover, while due to the impermeable nature of the material it is not recommended for long-lasting heavy work and exposure limits have to be clearly defined2).

As mentioned at the very start of the introduction, the specific situation when the reported burn injury occurred was not described in enough detail. However, one thing is clear that the 1st degree burn injury (reddening of the skin) was observed after the exercise, while reflective striping was pointed out as the cause of the burn injury. Due to this it was important to study the combined effects of moisture, heat radiation, and reflective stripes or impermeable print sections on heat transfer and temperatures’ increase on similar textile packages. Although, there have been several studies looking at the materials’ behaviour under radiation heat load, we could not find studies where the effect of locally applied clothing elements with different thermal properties, e.g., reduced moisture permeability and reflectivity, in clothing systems were analysed. Based on literature on complex behaviour of moisture under reflective layer and radiation2, 10,11,12, 22,23,24,25) and the field report assumptions, we had expectations that moisture collection under relatively impermeable but limited areas of reflective striping may increase heat transfer through textile material package and increase the temperature of the underlaying surfaces.

The aims of this study were to evaluate the impact of the low heat radiation on the performance of local clothing elements of the modern Dutch firefighter clothing material packages, such as printed logos and reflective striping, based on the heat transmission through selected materials and temperatures between material layers and on textile representing skin, and indicate the trends related to the presence of moisture under low heat radiation exposure.

Methods

The testing was carried out at the Thermal Environment Laboratory at Lund University, Sweden. The climatic (warm) chamber there allowed temperature settings from +5 to +55 °C, humidity adjustment from 10 to 90%. Air speed in the chamber could be adjusted from somewhat below 0.2 m/s to around 0.8 m/s. During the measurements the variation of air temperature was ± 0.1 °C, humidity ± 2% and air velocity <0.1 m/s.

Materials

Two pairs of material packages were compared:

• short sleeved polo shirts with knitted (Fig. 1a; abbreviated as 11) versus printed logo (Fig. 1b; abbreviated as 11A) and

Fig. 1.

The used materials: a) polo shirt with knitted logo (11); b) polo shirt with printed logo (11A); c) firefighter jacket areas without reflective striping (21B); d) firefighter jacket areas with reflective striping (21S). Here the materials are dressed on a cooled plate.

• the areas without (Fig. 1c; abbreviated as 21B) versus with reflective striping (Fig. 1d; abbreviated as 21S) of a firefighter jacket.

The knitted logo was of the same material as the rest of the shirt and knitted as a part of the same surface of the shirt while using just a different yarn colour. The knitted logo area, thus, had the same thermo-physiological properties for heat and mass transfer as the rest of the shirt. The printed logo area in the other polo shirt was less permeable and the textile fibres under the print did not stick out but were compressed by the print to the textile surface. The colour of the logos of the both shirts followed the same set requirements based on Pantone Colour System. The reflective striping on the jacket had been applied thermally.

The materials were the ones used in the new Dutch firefighters’ station wear (also known as operational uniform (OU)) polo shirt corresponding to ISO 2194226) requirements, and the new style turnout jacket that based on thermal properties corresponded to EN 4691) requirements. The polo shirt consisted of 60% modacrylic and 40% cotton with a material weight of 200 g/m2 (Narkonteks, size L weighed on average 346 g). The jacket composition was the following: the outer layer consisted of 100% aramid + AST (antistatic), middle layer of 100% aramid laminated with bi-component ePTFE membrane and lining of 100% aramid + AST (SIOEN, model 830 Twin/AS, size L weighed on average 1,794 g). In all cases, except thermal resistance measurements on hot plate, a layer of T-shirt material (60% modacrylic, 40% cotton, 190 g/m2, Narkonteks, size L weighed on average 182 g) was used under the tested clothing item material package as this is the minimal required underwear layer in the uniform. The reason for not using T-shirt during thermal resistance measurements was to minimize the effect of layers and air gaps, and being thus able to see the possible maximal differences in thermal resistance of the materials.

For the present measurements the exact material composition was not expected to have a major practical relevance as in these specific comparative cases the differences in thermal resistance and evaporative resistance and related heat transmission through material packages were expected to be created just by the material surface finishing, such as the printed logo or the application of reflective striping. In other respect, the materials in the respective material packages, either in polo shirt or jacket, were exactly the same. As the logo and the reflective striping areas were not enough large to cover the whole hot or cooled plate areas, then the materials were placed so that at least the test area of the plates was maximally covered. In the case of logo it covered about 1/3 of test area while reflective striping covered the whole test area, while parts of the guard zone were not fully covered by the striping.

Material measurements for total thermal and evaporative resistance

The tests were carried out on a non-standard hot/wet plate (Fig. 2)27). As the design of the used hot plate follows the principles of a sweating manikin construction, then our testing and calculations procedures followed the recommendations of related literature and standards28,29,30). However, as the measuring setup, methodology and conditions were kept the same for all test series then the results allow for comparison of these material package pairs. The testing plate was kept at 34°C. During thermal resistance tests the air temperature in the climatic chamber was kept at 20°C and air velocity at 0.2 m/s. During evaporative resistance testing the air temperature was kept the same as the plate temperature, i.e., 34°C, and air velocity was 0.4 m/s. Relative humidity in the chamber during the evaporative resistance tests was 25%.

Fig. 2.

Hot/wet plate. Wet plate picture represents the start of surface wetting from the water nozzles. Before the tests the whole surface was also sprayed in order to ensure the even wetness of the surface already at the very start of the measurement.

Before testing the clothing pieces were conditioned at room temperature corresponding to the standard conditions. During the testing they were checked by weighing to ensure that they had the same mass as after the preconditioning period. Dry conditions (thermal resistance) were tested with all textile layers confirmed to be dry. Wet measurements (evaporative resistance) started with saturated “skin” and saturated T-shirt layer. The “skin” was wetted by spraying and the T-shirt was wetted in warm tap water. Excess water was pressed out so that no dripping occurred. The T-shirt weight was checked after wetting on a weighing scale (ICS425k-15LA/f, ± 0.1 g, Mettler-Toledo (Albstadt) GmbH, Germany) in order to ensure approximately the same water content for each test. The data was acquired when stable heat loss levels for thermal and evaporative resistance measurements were achieved and kept for at least 20 min, meaning that heat loss and evaporation were constant under the set conditions, and/or stable temperatures (for cooled plate tests) were reached. Commonly the temperatures stabilized in 10–15 min after the test start, and the tests were run totally for 40–60 min. Each condition was tested twice. If the difference between double determinations would be higher than 4% then additional tests were performed until the requirement was met. Commonly only two tests were needed per test condition.

Tests on cooled plate with a solar lamp

The method is described in detail in earlier studies31, 32). The schematic view of the cooled plate setup is shown in Fig. 3. With this method the heat transmission through the textile materials and absorbance into the underlaying materials simulating human tissue was measured. The cooled plate itself consisted of an insulating material. The plate was covered with aluminium sheet for even temperature distribution. Between the round measuring area and the rest of the plate there was a 5 mm gap in order to avoid heat transfer from the central measuring area to the side areas. The aluminium plate was covered with a cotton textile simulating “skin” that was glued to the aluminium surface. Under the measuring area a space was carved out to locate coiled silicon tubing that was connected to a peristaltic pump (an 8-channel Gilson Minipuls, Pretech Instruments). Silicon tubing was in direct contact with the aluminium plate. Setting of the flow rate should be done depending on the expected transmission or heat radiation intensity. In this study the water flow was set to 9.84 g/min. Knowing the flow, inlet and outlet temperatures the heat transmitted through material package to the water can be calculated. The inlet water was placed in thermos and was kept at 25°C. The pump, inlet water and sensory equipment were all shielded from the solar lamp beam.

Fig. 3.

Schematic view of cooled plate system.

The solar lamp (Thorn lamp) was positioned at 2.47 m from the cooled plate surface and the lamp intensity was checked at 3 distances with 2 separate pyranometers (Fig. 4). As the solar lamp is a point source and the intensity is reducing also sideways then 9 measuring points over the test surface were used to calculate average intensity. 9 point average heat load was 940 W/m2, corresponding to about the level of solar load under clear sky on a summer day. The average intensity at the centre point where the temperature measurements of the clothing layers’ and “skin” surface was performed was 1,141 W/m2.

Fig. 4.

Solar lamp intensity in W/m2 at different distances from the lamp.

The tests with the solar lamp were performed at room temperature. Air velocity during the tests was <0.2 m/s. Solar lamp tests were done on a vertical surface. For example, the difference with a study by Barker et al.33) was that even when setting the layers close to the plate as possible there was no gravity effect pressing the layers down, i.e., possible, although undefined airgaps were expected to be larger than on horizontal surface, thus, corresponding better with the real use situation. This was different from thermal and evaporative resistance measurements on hotplate where the materials were tested on horizontal surface27). Two tests per material package were planned. The criteria for additional tests and wetting the textile skin and T-shirt were the same as described for hot plate tests. Commonly only 2 tests were needed per condition. After the initial period the change in temperature was not observed, indicating that the surface was still as wet and the evaporation rate stayed stable. The temperatures became stable depending on the condition within the first 10–30 min. Therefore, all tests were run for at least 40 min and the last 10 min of the stable state were used for calculations.

The data were analysed with simple t-tests in MS Excel. The statistical significance was set to p<0.05.

Results and Discussion

Total thermal and evaporative resistance

As can be seen in Fig. 5, the printed logo shows lower total thermal resistance (0.102 m2K/W) than that of knitted logo (0.115 m2K/W, difference 11%). This was also the case for reflective striping (0.226 m2K/W) being lower than without reflective striping (0.237 m2K/W, difference close to 5%). It is logical that the printed logo and applied reflective stripes reduce the total thermal resistance due to surface resistance reduction as the loose fibres over that surface are pressed to the surface by applying logo or the striping (Fig. 5).

Fig. 5.

Total thermal and total evaporative resistances of the material packages.

The absolute difference in total thermal resistance was not very big: 0.012 and 0.011 m2K/W for polo and the jacket, respectively. This, by experience, can be considered laying below the physiologically detectable difference. At the same time, considering the method accuracy, then all the presented differences were statistically significant both for measured thermal and evaporative resistances.

The difference in total evaporative resistance showed greater differences than that of total thermal resistance (Fig. 5). The total evaporative resistance of the polo shirt with the printed logo was 24.8 m2Pa/W, being 49% higher than that of the shirt with the knitted logo (15.1 m2Pa/W). This difference is even more significant when considering that only about 1/3 of the test surface was covered by the logo. Total evaporative resistance under the stripes (50.4 m2Pa/W) was almost double as high as for the jacket area without reflective striping (27.4 m2Pa/W). The differences would become even clearer if to subtract the evaporative resistance of the skin and air layer from the total values that together were of the magnitude of about 10 m2Pa/W, and to compare only the material evaporative resistances.

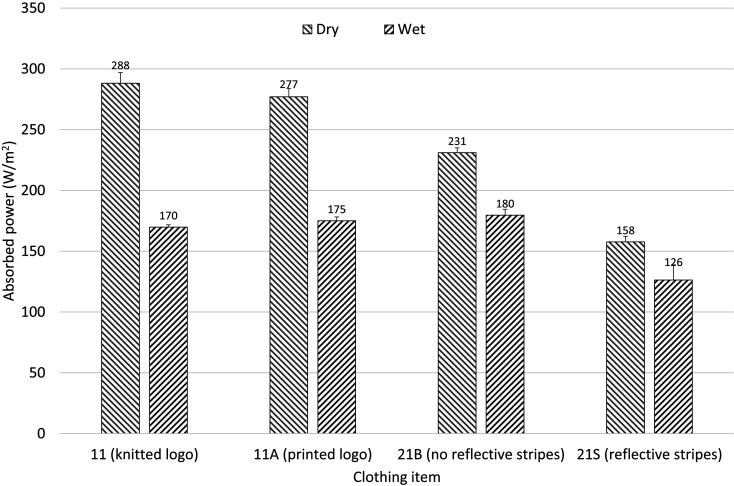

Absorbed power by the cooled plate

The absorbed power (Fig. 6) shows the heat that reached into the plate and was transported away (based on in and out temperatures and the water flow rate through the plate). In the case of knitted versus printed logo and jacket areas without versus with reflective stripes it means that under specified heat load over the whole measuring surface (940 W/m2) in dry conditions 31 vs. 29 and 25 vs. 17% of the applied power was transmitted through the textile packages. In the wet conditions these numbers were 18 vs. 19 and 19 vs. 13% for knitted versus printed logo and jacket areas without versus with reflective stripes, respectively.

Fig. 6.

Absorbed power by the cooled plate (=transmitted power through the material package) under mean heat load of 940 W/m2 over the measuring surface.

For polo shirts the statistical difference of the heat transmission values was not significant for neither dry nor wet conditions. As we can see in the dry condition, more heat passes through the knitted than through the printed surface. The air velocity was <0.2 m/s. With a higher air velocity the picture could have been different with possible stronger wind cooling that can pass through the knitted material. At the same time the change from dry to wet conditions shows stronger heat transmission drop for knitted logo (lower evaporative resistance, 118 W/m2), than for printed logo (higher evaporative resistance, 102 W/m2). This difference in change (16 W/m2) indicates statistically significant difference (p<0.05) between the type of the logo with more favourable thermo-physiological performance of the shirt with a knitted logo for the tested conditions.

Approaching the performance of the striping on the jacket in the same way we can see significant differences between all jacket conditions: dry-wet and with-without reflective striping. The jacket areas seem to work due to evaporative resistance differences in a similar way as the polo shirts, however the observable effect is larger as stripes did cover test plate’s measuring surface completely and not only about 1/3 of it. Additional dimension is added by the reflectivity of the stripes as they reflect away considerable amount of heat. In the jacket tests the absorbed heat is less than in the polos due to higher thermal resistance in dry condition. The reflective properties of the striping still dominate under wet conditions resulting in the lowest uptake of heat. The results from hot/wet plate (Fig. 5) support the results from the cooled plate, and the changes related to dry vs. wet tests. The results showed that the difference between the jacket areas with and without the reflective stripes reduced in the wet conditions. This change was also statistically significant showing a bigger reduction of heat transmission in the material without reflective striping (=lower evaporative resistance). We have to consider that presently only the skin and the T-shirt were saturated. If the jacket materials were also saturated, then the situation may change.

Surface temperatures at the centre point of the cooled plate

As material properties (Fig. 5), also the temperature data (Fig. 7) confirms the results of heat absorbance/transmission − higher thermal resistance and lower emissivity leads to less heat transmission and lower surface temperatures, while higher evaporative resistance that reduces heat loss from the wet surface starts to counteract the positive effect of insulation and lower emissivity on reducing heat transmission through material package to the test surface under radiation. The results are also in line with the earlier studies22, 24).

Fig. 7.

Surface temperatures on the “skin” and garment package layers at the centre point of the cooled plate under specified radiation load (1,141 W/m2).

Result interpretation

As Barker et al.33) indicated then the combination of the radiation and moisture in the material package, and even so in the clothing system, is a complex issue to handle. The outcome depends on the moisture content and saturation levels in various layers of the material package/clothing system, radiation levels, body motion and clothing ventilation. Thus, also the results of the present study are only valid for the specific test conditions and generalizations for practical use should be made only within the context of other related research.

Our specific results indicate that in dry conditions the material with the printed logo has lower thermal resistance and higher heat losses (=slightly less absorbance of heat and lower “skin” temperature) than the knitted one. This may be related to somewhat higher observed reflectivity of the printed surface and lower thermal resistance of the surface (loose fibres are compressed to the surface by the print). In wet conditions the higher evaporative resistance of the printed logo contributes to the lower evaporative heat loss, demonstrating the change towards the advantage of the knitted logo in the tested conditions. It should be remembered that printed logo was too narrow and did not cover all test surface (the rest was knitted material), i.e., if looking at printed material part only, then the differences in wet conditions between printed and knitted could be even bigger. However, in reality the print does not cover the whole shirt area either and will minimally affect the person’s total heat balance. Measured surface temperatures (Fig. 7) show a similar trend as absorbance of the heat (Fig. 6).

In a similar way the measurements of EN 469 jacket areas without and with reflective stripes show quite similar thermal resistance but higher evaporative resistance for the material part with reflective stripes. Here the observed reflectivity of the striping material is much higher than in the case of a printed logo, and lower heat absorbance and surface temperatures under reflective material are maintained during the tests under heat radiation even when moisture is added. At the same time the absolute differences between material packages without and with reflective stripes were diminished when saturated “skin” and T-shirt were used. It has to be considered again that this is valid under the tested conditions. With higher or lower radiation, or more layers, e.g., jacket, saturated or dry T-shirt, the outcome could be different.

General discussion

He et al.8) studied higher radiation intensities (7–17 kW/m2) and paid special attention on the effects of reflective trim. Our results were more or less in line with their results—thus with reflective trim the 2nd degree burn time was longer than without it and the heat reaching skin sensor was much lower under the layers with reflective trim. Under reflective trim the power to skin reached the stable state, while under the material without reflective trim the heat flux into the skin sensor kept rising until the end of the exposure8). Also, these results indicated that a reflective layer as such couldn’t be a (main) cause of the reported problem described in the introduction. However, it has again to be remembered that heat transfer under combined moisture and radiation conditions in various clothing layers is a very complex phenomenon7, 12, 13, 33) and not necessarily reflects the situation that led to the reported 1st degree skin burns.

Bröde et al.22) studied the combined effects of moisture and radiation. In their study various outer layers and underwear were combined, while the applied radiation levels were lower than in the present study. They22) showed lower heat gain in reflective (here the whole garment was aluminized) vs. non-reflective garments in dry conditions. So our results are confirmed by their study. They also showed the difference in heat gain change when wet tests were compared to dry ones. In their setup they used PVC material for the impermeable suit. However, the heat gain under specified conditions was still much less than reduction of the heat load by the reflective layer in dry conditions. Again the measurements of the present study are confirmed by their results22), while for relating the results to the reported injury and in order to interpolate these results to different number of layers, moisture content and higher radiation combinations, we need to know parameters of the specific situation when the reported injury took place.

Fu et al.6) studied radiation effects (2–3 kW/m2) on a sweating (100–300 g/m2/h) thermal manikin. As for the present study on a cooled plate and the study of Fu et al.6) on the manikin, the exposures were long and were not reflecting human skin temperatures in reality. We can just compare the setups. The effects of reflective areas or permeability of clothing were not specifically studied while the effect of moisture lowered the temperatures in each layer6). Also, their results support the statements that under different moisture level and radiation combinations the balance of the higher or lower temperatures in different layers and at skin may change. Fu et al.6) also tried to explain the mechanisms why skin burns often occur in the shoulder area, and concludes that in addition moisture and radiation effect, this area is often compressed and conduction is turned into an important heat transfer pathway. By elimination of other direct causal factors by the present study then the same mechanism as suggested by Fu et al.6) can be suspected as the major cause of the 1st degree burns observed in the field. This would lead to a question if the design of the used firefighter jacket was too tight, allowing for easy compression of the layers and minimizing air gap, and in this way opening conductive pathway from radiation heated outer layers through the moist layers to the skin.

In any case, in order to apply the research results in the practice and eliminate future risks of any (potential) health and safety incidents, then it is very important that a medical record and/or an incident report on accident or near accident is prepared that specifies the exact injury location, and makes sure that the person is available for an interview and the clothing (the complete clothing set used at that incident/experiment) with detailed technical specification will be available for inspection. Preferably, if the data allows, the comparison of risk analysis should be done based on the number of the cases and their severity, in order to decide on further steps related to the requirements/limit values.

Considering that the used methods were able to discriminate performance differences of elements applied to the clothing then it may be of future interest to use them for specific clothing material package testing. Nowadays many new materials are developed to improve water vapour or water permeability or resistance, fire resistance, etc. of the protective fabrics34,35,36). These do often show superior results for the materials at micro level. The methods described in this paper can be used for simple and quick evaluation of the thermo-physiological impact of complete clothing material packages with such modern surface finishes, including air gaps, for selection of the best combination to fill the protective purpose in expected environments.

Conclusions

The results from the specific conditions (low radiation and saturated skin and next to skin clothing layers) indicate that neither the material as such nor the striping could be the reason for 1st degree burns reported from the field. The problem could be related to the clothing design. Due to natural working postures a fashionable, relatively tight fitting design allows further compression of the clothing material layers at upper arm level, and by eliminating the insulating air layers, it can lead to the reported 1st degree skin burns. However, as we have neither got nor tested the specific clothing set or the jacket that was used in the specific situations, then more far going conclusions can’t be drawn.

In the future it would be interesting to study the borderlines at which levels of wetness and radiation combinations the situation shifts from one to another side, e.g., where the positive effect of the reflective stripes might be counterbalanced by the increased evaporative resistance, or at which moisture levels and air gap widths of the clothing package layers the variation of radiation may lead to burns. Considering possibilities for any smart solutions for avoiding burn injuries then defining such borderlines would allow with simple measurements triggering the protective functions of the advanced gear.

Besides that, in future proper thermal physiological evaluation of protective clothing for the fireservices could be positively contribute to avoid health and safety effects during undefined testing of clothing by firefighters.

Acknowledgments

We would like to thank Dr. Chuansi Gao from Lund University, Sweden for facilitating the possibilities to use their thermal environment laboratory, and Dr. Emiel den Hartog from North Carolina State University for fruitful discussions, commenting and giving the first feedback on the initial draft of this paper.

References

- 1.EN 469:2005/A1:2006. Protective clothing for firefighters − Performance requirements for protective clothing for firefighting activities. CEN, Brussels.

- 2.Chou C, Tochihara Y, Ismail MS, Lee JY. (2011) Physiological strains of wearing aluminized and non-aluminized firefighters’ protective clothing during exercise in radiant heat. Ind Health 49, 185–94. [DOI] [PubMed] [Google Scholar]

- 3.Havenith G, Holmér I, Meinander H, den Hartog E, Richards M, Broede P, Candas V. (2006) Assessment of thermal properties of protective clothing and their use. THERMPROTECT: final technical report, EU-project, contract G6RD-CT-2002-00846.

- 4.Heus R, Kingma BRM, van Berlo BMA, Mol D, Daanen HAM, Kuklane K. (2022) The protective performance of process operators’ protective clothing and exposure limits under low thermal radiation conditions. Biology (Basel) 11, 1222. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Kahn SA, Patel JH, Lentz CW, Bell DE. (2012) Firefighter burn injuries: predictable patterns influenced by turnout gear. J Burn Care Res 33, 152–6. [DOI] [PubMed] [Google Scholar]

- 6.Fu M, Weng W, Yuan H. (2015) Combined effects of moisture and radiation on thermal performance of protective clothing: experiments by a sweating manikin exposed to low level radiation. Int J Cloth Sci Technol 27, 818–34. [Google Scholar]

- 7.Guan M, Psikuta A, Camenzind M, Li J, Mandal S, Rossi RM, Annaheim S. (2019) Effect of perspired moisture and material properties on evaporative cooling and thermal protection of the clothed human body exposed to radiant heat. Text Res J 89, 3663–76. [Google Scholar]

- 8.He H, Yu Z, Zhang C, Li M. (2021) Thermal protective performance of firefighters clothing under low intensity radiation heat exposure. AUTEX Res J 21, 234–41. [Google Scholar]

- 9.Heus R, Denhartog EA. (2017) Maximum allowable exposure to different heat radiation levels in three types of heat protective clothing. Ind Health 55, 529–36. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Lu Y, Li J, Li X, Song G. (2013) The effect of air gaps in moist protective clothing on protection from heat and flame. J Fire Sci 31, 99–111. [Google Scholar]

- 11.Li J, Lu Y, Li X. (2012) Effect of relative humidity coupled with air gap on heat transfer of flame-resistant fabrics exposed to flash fires. Text Res J 82, 1235–43. [Google Scholar]

- 12.Malaquias AF, Neves SF, Campos JBLM. (2022) The impact of water on firefighter protective clothing thermal performance and steam burn occurrence in firefighters. Fire Saf J 127, 103506. [Google Scholar]

- 13.Mandal S, Mazumder NUS, Agnew RJ, Song G, Li R. (2021) Characterization and modeling of thermal protective and thermo-physiological comfort performance of polymeric textile materials—a review. Materials (Basel) 14, 2397. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Song G. (2007) Clothing air gap layers and thermal protective performance in single layer garment. J Ind Text 36, 193–205. [Google Scholar]

- 15.Wang YY, Lu YH, Li J, Pan JH. (2012) Effects of air gap entrapped in multilayer fabrics and moisture on thermal protective performance. Fibers Polym 13, 647–52. [Google Scholar]

- 16.Ghazy A, Bergstrom DJ. (2011) Influence of the air gap between protective clothing and skin on clothing performance during flash fire exposure. Heat and Mass Transfer/Waerme- und Stoffuebertragung 47, 1275–88. [Google Scholar]

- 17.Chen YS, Fan J, Qian X, Zhang W. (2004) Effect of garment fit on thermal insulation and evaporative resistance. Text Res J 74, 742–8. [Google Scholar]

- 18.Psikuta A, Mert E, Annaheim S, Rossi RM. (2018) Local air gap thickness and contact area models for realistic simulation of human thermo-physiological response. Int J Biometeorol 62, 1121–34. [DOI] [PubMed] [Google Scholar]

- 19.Bouskill LM, Havenith G, Kuklane K, Parsons KC, Withey WR. (2002) Relationship between clothing ventilation and thermal insulation. AIHA J (Fairfax, Va) 63, 262–8. [DOI] [PubMed] [Google Scholar]

- 20.Hill J, Hanley J .(2015) Fluorescent Aerosol Screening Test (FAST) Test Report. RTI International, RTI Project 0212534.112. https://responderwipes.com/wp-content/uploads/2016/07/RTI_Test_Report-FAST-Jan2015.pdf. Accessed August 24, 2022.

- 21.Joshi A, Psikuta A, Bueno MA, Annaheim S, Rossi RM. (2021) Effect of movement on convection and ventilation in a skin-clothing-environment system. Int J Therm Sci 166, 106965. [Google Scholar]

- 22.Bröde P, Kuklane K, Candas V, Den Hartog EA, Griefahn B, Holmér I, Meinander H, Nocker W, Richards M, Havenith G. (2010) Heat gain from thermal radiation through protective clothing with different insulation, reflectivity and vapour permeability. Int J Occup Saf Ergon 16, 231–44. [DOI] [PubMed] [Google Scholar]

- 23.Bröde P, Kuklane K, Candas V, den Hartog EA, Griefahn B, Holmér I, Meinander H, Nocker W, Richards M, Havenith G. (2008) Heat transfer through protective clothing under symmetric and asymmetric long wave thermal radiation. Z Arbeitswiss 62, 237–300. [Google Scholar]

- 24.Havenith G, Bröde P, den Hartog E, Kuklane K, Holmer I, Rossi RM, Richards M, Farnworth B, Wang X. (2013) Evaporative cooling: effective latent heat of evaporation in relation to evaporation distance from the skin. J Appl Physiol 114, 778–85. [DOI] [PubMed] [Google Scholar]

- 25.Meinster J .(2016) Handreiking inzake maximaal toelaatbare niveaus van warmtestraling voor korte inzet (maximaal 5 minuten) van (bedrijfs)brandweerpersoneel en operators bij industriële bedrijven. Landelijk Expertisecentrum Brandweer BRZO (in Dutch). [Google Scholar]

- 26.ISO 21942:2019. Station uniform for firefighters. ISO, Geneva.

- 27.ISO 11092:2014. Textiles − Physiological effects − Measurement of thermal and water-vapour resistance under steady-state conditions (sweating guarded-hotplate test). ISO, Geneva.

- 28.ASTM F2370-22 (2022) Standard test method for measuring the evaporative resistance of clothing using a sweating manikin. ASTM International, West Conshohocken.

- 29.EN 17528:2022 (2022) Clothing−Physiological effects − Measurement of water vapour resistance by means of a sweating manikin. CEN, Brussels.

- 30.Wang F. (2017) Measurements of clothing evaporative resistance using a sweating thermal manikin: an overview. Ind Health 55, 473–84. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.JögÅrd H. (2004) Solenergitransmission i textila material (Transmission of solar energy in textiles). Kandidatexamen vid Institutionen Textilhögskolan. Hogskolan BorAs 2004, 1 (in Swedish). [Google Scholar]

- 32.Kuklane K .(2014) Cooled plate tests on textile materials in simulated cockpit under “solar radiation”. In proceedings of Ambience14 & 10I3M, Scientific Conference for Smart and Functional Textiles, Well-Being, Thermal Comfort in Clothing, Design, 10th Meeting on Thermal Manikins and Modelling (10I3M), Tampere, Finland. [Google Scholar]

- 33.Barker RL, Guerth-Schacher C, Grimes RV, Hamouda H. (2006) Effects of moisture on the thermal protective performance of firefighter protective clothing in low-level radiant heat exposures. Text Res J 76, 27–31. [Google Scholar]

- 34.He H, Liu J, Wang Y, Zhao Y, Qin Y, Zhu Z, Yu Z, Wang J. (2022) An ultralight self-powered fire alarm e-textile based on conductive aerogel fiber with repeatable temperature monitoring performance used in firefighting clothing. ACS Nano 16, 2953–67. [DOI] [PubMed] [Google Scholar]

- 35.Yu Z, Liu J, He H, Ma S, Yao J. (2021) Flame-retardant PNIPAAm/sodium alginate/polyvinyl alcohol hydrogels used for fire-fighting application: preparation and characteristic evaluations. Carbohydr Polym 255, 117485. [DOI] [PubMed] [Google Scholar]

- 36.Yu Z, Zhao Y, Liu J, Wang Y, Qin Y, Zhu Z, Wu C, Peng J, He H. (2022) Advancement in cellulose-based multifunctional high conductive PNIPAAm/PPy hydrogel/cotton composites for EMI shielding. Cellulose 29, 6963–81. [Google Scholar]