Abstract

Current methods for feed formulation are based on minimizing costs, not maximizing profits. Complex models of bird growth and reproduction as functions of genetic, feed and other environmental variables are being developed, but their adaptation has been slow. The development of profit maximizing models will evolve to center on the production functions of broilers and layers. The production functions are the relationship between the value of products (mainly meat and eggs) and the cost of feed. The production function is the tool used to maximize profits subject to all the various inputs, not just feed or nutrition. The production function is subject to the law of diminishing returns. The most profitable output levels are those where the marginal value (price) of the meat or eggs is just equal to the marginal cost of the inputs including feed, housing, processing and all other costs. Anything that affects the production function, bird genetics, feed quality, housing and environment, will be considered to maximize profits for the poultry firm. The profit maximizing models of poultry firms will improve as various technical improvements are made: metabolizable energy to describe ingredients will evolve to net energy systems that consider that the heat production (and therefore energetic efficiency) of broilers is different depending on the ingredients used to formulate the feed and the environmental temperatures under which they are reared. Amino acid needs will include a method to find the birds' needs for the non-essential amino acids. “Digestible” amino acid assays will differentiate between digestion and absorption to best balance various sources. The carbohydrate fractions of feed ingredients will be determined to optimize the use of exogenous enzymes. The value of meat and egg co-products will reduce overall costs (e.g., organic fertilizer for crop enhancement). Future profit maximizing production models will be ever evolving processes where field conditions and results are continually being utilized to re-calibrate the technical models so that the management team can use them with cost and return projections to decide on the best choices of inputs and outputs.

Keywords: Feed formulation, Linear programming, Non-linear, Programming, Econometrics

1. Introduction

1.1. The past

The mechanics or process of feed formulation has changed very little since the 1950's. The nutritionist collects and combines three sets of data: the nutrient composition of the ingredients available, the minimum and maximum acceptable nutrient levels in the feed, and the prices of the ingredients. Computers are then used to find the least-cost combination of ingredients meeting the nutrient specifications. Oviedo-Rondon (2014) presented a very insightful list of reasons why this process is inefficient, outdated, and still used. Modeling of the technical and economic aspects of poultry meat and egg production should lead to more comprehensive processes for feed formulation and increased or maximized profits, but it has not been widely adopted.

1.2. The future

Modeling poultry growth and performance in order to maximize profits, while optimizing the environmental impact of chicken meat and egg production, would seem to be prudent. The word “optimizing” was used regarding poultry's environmental impact because co-products, manure and offal are important sources of soil enriching compounds, not just contaminants to be disposed of. Poultry production must be regarded as a part of the agricultural ecosystem, providing organic materials for grazing livestock, etc. Such models should be helpful and perhaps even necessary for companies to remain competitive as world populations increase and resources are spent.

As Oviedo-Rondon (2014) pointed out, various models have been developed but failed to gain widespread acceptance. The models are, for the most part, very good attempts to advance from least-cost models of feed formulation to maximum-profit models. Models all suffer from similar problems that limit their usefulness as they center around: 1) how they model nutrient “requirements” when there really are none, only profit-maximizing nutrient levels; 2) their methods of approaching economic profit maximizing; and 3) their reliance on inappropriate technical properties of feed and the environment.

This paper will first deal with the changing paradigms necessary to move from least-cost to maximum profit models. The basic economic techniques of decision making for feed formulators to make a move from least cost to maximum profit models will be explained. Then we will describe several areas where the biology and feed formulation need to be re-evaluated to reduce the error in models to improve the outcomes of economic modeling for meat and egg production. The environmental costs of production should be included in these models to maximize the sustainability of poultry production.

The main biological areas that need to be addressed are as follows. (1) The use of metabolizable energy (ME) in modeling broiler and layer performance is inadequate. ME overestimates the amount of energy that birds get from feed ingredients. ME measures the difference between the amount of energy ingested and the amount of energy excreted over a given period of time. But the origins of the energy contained in the excreta are difficult to determine (feed, turnover cells from the gut, microbial). It is also a measurement that accounts for nutrients totally burned or oxidized, as opposed to utilized. The objective of animal production is to not oxidize as many nutrients as possible but to deposit them in the carcass or egg. There should be a shift from ME to net energy (NE). (2) NE measures the energy that is utilized for maintenance and production, such as tissue deposition and reproduction. But NE is not the sole characteristic of feed ingredients; rather it is the reflection of the interaction that occurs when the bird consumes certain feed. It is determined by the amount of heat produced during metabolic processes, which, in turn, is affected by feed constituents and the environment in which they are reared. Fortunately, today's poultry production environments are largely controlled, although the growth of free-range production means NE research will need to examine the environmental influence of production on heat increment. NE is an important next step for feed formulation because of its magnitude. Approximately 25% to 30% of ME is lost as heat increment (Kleiber 1975). This loss is similar to the amount of fecal and urinary energy lost from the total energy of feed, i.e., gross energy, when ME is obtained. (3) Digestible amino acid measurements as currently implemented have two major shortcomings. Digestibility is clearly age dependent, and the major methodologies for measuring digestibility in chicks and older stocks differ considerably (Khalil et al., 2023). Thus, a) digestibility as a function of age needs to be researched and added to future models, and b) digestibility measurements need to take into account the level of amino acids in the assay diets. Measurements taken in digestibility assays should be reconciled with the typical feeding levels to have appropriate values for feed formulation. (4) The non-essential amino acids are ignored in most feed formulation models. It is important to lower the protein level in diets in order to achieve some welfare objectives, such as reduced excreta moisture and gas emissions (sulfur dioxide and ammonium, for instance). There is now strong evidence suggesting that some of the so-called non-essential or dispensable amino acids, such as glycine and serine, have become essential (Hillier et al., 2019). Therefore, these amino acids need to be represented mathematically to properly balance diets. (5) The carbohydrate fractions of most ingredients need to be known to best determine the effects of various digestive enzymes and interactions with other nutrients. This is essential for future feed formulation because non-starch polysaccharides (NSP) make up the bulk of fiber, which is currently represented by the highly inaccurate crude fiber. The structures and functions of these NSP and other carbohydrates, such as resistant starch as well as various oligosaccharides, must be explored in order to determine their nutritional roles with or without glycanases. (6) The batch-to-batch variation in ingredient composition needs to be known so that the costs of supplying nutrients to different proportions of batches, or flocks can be understood. How to be sure that more than half the birds are getting enough of each nutrient or if that is cost effective?

1.3. Obstacles and opportunities of change

The reasons Oviedo-Rondon (2014) gave for the slow adaptation of modeling in feed formulation included a lack of education and understanding of profit maximizing approaches by nutritionists. Being responsible for the major input in poultry meat and egg production, feed, it might be assumed that nutritionists necessarily have some understanding of economics. They set the minimum and maximum levels of all the nutrients, determining to a large extent, the profitability of the company (or at least the contribution of live production). In reality, poultry nutritionists rarely have a good (or any) background in production economics. They are much more likely to have studied and researched veterinary science and molecular biology than economics. The move to profit maximizing strategies must include the nutritionist sharing responsibilities with other specialists. In the future, with maximum profit formulation models, nutritionists will be one member of a business team, jointly responsible for nutrient levels, feeding programs, environmental conditions, products produced, etc. The teams will likely include specialists in production economics, business management, marketing, environmental engineering, veterinary medicine and animal welfare.

Maximum profit models require a different thought process, or paradigm. The necessary shift is from trying to find the lowest level of nutrients that result in maximum performance (genetic potential), to understanding and describing the responses to different nutrients. From a statistical perspective, it is from regarding nutrient levels as continuous variables instead of class variables. From an econometric perspective, the needed change is from regarding responses to nutrients as non-linear, diminishing marginal returns problems instead of spline models with breakpoints.

1.4. Change with the information age

The present information age is a time when details about the environment of poultry production facilities are observed and recorded and available to be related to performance outcomes. There are enormous amounts of data on things like temperature, humidity, and photoperiod just waiting to be related to growth rates, feed intake and processing yields. Large amounts of analytical data on feed ingredient composition are being collected and are available to be related to bird performance under different environmental conditions. Some data is there, it just needs proper analyses and presentation to help maximize overall technical and economic efficiencies of poultry production. Profit maximizing formulation should become an iterative process where the results of each production cycle are compared to model projections and the model projections are adjusted to better fit the latest observed data and thus better predict future performance. The use of current prices in profit maximizing models will be replaced with each company's best prediction of costs and returns based on current prices and yearly cyclical prices and any other relevant or expected influences. So the era of big data has arrived, and it is imperative to start putting in place a strategy to take advantage of the large volume of data becoming available so that profit-maximizing models will be effectively used to achieve sustainable production in the future.

1.5. Need for research and change in terminology: amino acids, balanced protein, and protein requirements

The area of protein nutrition may be particularly confusing to students and practitioners alike because of the way the jargon of animal nutritionists has evolved. For instance, it is common to discuss amino acid digestibility, but amino acids are not digested in digestibility assays, proteins are. And amino acid digestibility is the product of protein digestion and amino acid absorption (or disappearance) in in vivo assays. It is still common to see protein requirements listed for poultry, but we know requirements per se do not exist. Balanced protein is discussed, but it is not protein that must be balanced, it is amino acids. Interestingly, “balanced protein” usually refers to a mixture of intact proteins and free amino acid salts. It is prudent, both in the present and the future, to refer to high amino acid ingredients instead of high protein ones, responses to balanced amino acids instead of balanced protein, and total amino acid requirements instead of crude protein requirements. Total amino acid requirements are for the sum of the essential, excess essential and non-essential amino acids. Total amino acids in an ingredient or diet have been referred to as true protein levels of feeds and those may be used interchangeably to facilitate communication with people in other branches of nutrition. In this review, the use of the term protein has been eliminated as much as possible to reflect how feed formulation will be practiced in the future.

While it is known that protein “requirements” per se do not exist, there are still questions involving amino acid nutrition that will be answered in the future. (1) The role of non-essential or conditionally essential amino acids will be elucidated. In early work, it was demonstrated that glutamic acid gave better responses than other, or mixtures of other, non-essential amino acids (Maruyama et al., 1976). Most studies on the role of non-essential amino acids leave the question of what the proper controls should be when determining quantities of conditionally essential amino acids. (2) The role of the conditional amino acid cystine, or cysteine, in sulfur containing amino acid nutrition will be clarified. Sasse and Baker (1974) demonstrated that chicks would respond better to cystine than methionine when fed purified diets. Apparently, there is a cysteine requirement since maximum growth cannot be achieved with methionine alone. Are there differences in meal-fed versus continuously-fed birds in the ability of cysteine to be synthesized from methionine in a timely manner? The authors did not emphasize that finding, but it was clear from the data. Can other amino acids be synthesized in a timely manner in continuously fed (24 h photoperiod) but not meal fed (approximately 16 h photoperiod) birds? (3) The role of peptides in “protein requirements” and nutrition needs further clarification (Gilbert et al., 2008). Protein digestion is not always broken down to amino acids for absorption; rather some peptides are absorbed directly. Beyond the role of bioactive peptides (BP) in regulating metabolism (Sánchez and Vázquez, 2017), the nature of “peptide requirements” is not known. Since these peptides often consist of both essential and non-essential amino acids, it is speculated that there may be specific ratios of certain amino acids that drive many life functions. Therefore, our definition of “essential” and “non-essential” amino acids is highly arbitrary.

2. The goals and approaches to feed formulation

2.1. The present technical paradigm

Linear, least cost feed formulation models remain the typical method for formulating poultry feeds (Oviedo-Rondon, 2014). Least-cost linear programs solve a series of inequalities like “the amounts of the ingredients must be equal to 100%”, and “the proportion of digestible lysine in soybean meal times the amount of soybean meal plus the proportion of digestible lysine in corn times the amount of corn must be at least 1.25%”, etc. A few new features were added over the years, like calculations of shadow prices and multi-blending. Shadow prices tell the minimum price that an ingredient will appear at in the solution, and multi-blending solves several feed problems simultaneously to determine which feed(s) an ingredient in limited supply should be used in.

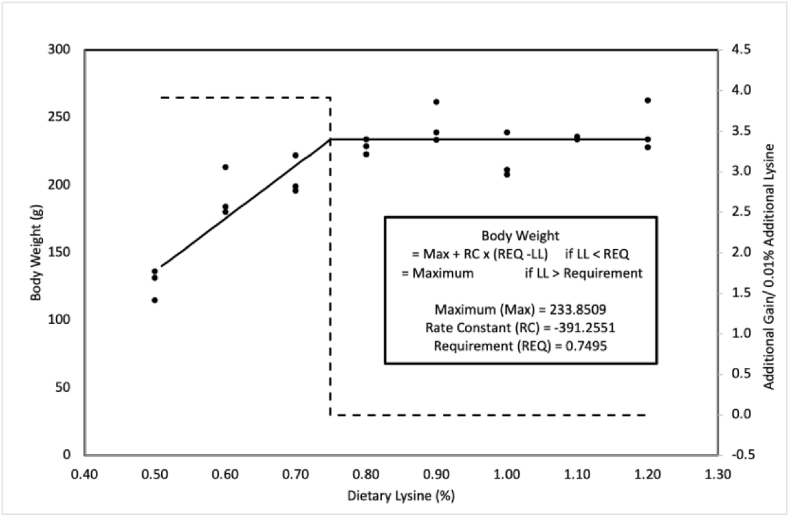

Nutritional requirements are determined as the least amount of nutrients resulting in the maximum technical efficiency (Pesti et al., 2009). The most common model used in determining nutrient requirements is the “broken-line linear model” (Fig. 1). This model may be the most intuitive. It assumes that each additional amount of lysine given is utilized at the same rate until the “requirement” is reached (the dashed line). At or above the requirement, there is no additional response to increasing amounts of lysine until it becomes toxic. Linear, least-cost feed formulation programs currently in use require a single value for each nutrient restriction, be it a minimum, maximum, or both. They therefore require models giving a single “requirement” (or maximum). These models are fine for inexpensive nutrients like iodine or thiamine. For such inexpensive nutrients, the “requirement” value is increased by some margin of safety to specify the practical feeding level in the feed.

Fig. 1.

An example of using the broken-line linear plot to estimate nutritional requirements. The body weight response to increasing levels of dietary lysine is from Sterling et al. (2003). The chick's lysine requirement is the amount at the break point where the lines meet.

For inexpensive nutrients like the vitamins and trace minerals, the broken-line model (Fig. 1) is usually thought of as adequate. For nutrients without much batch-to-batch ingredient variation, the level of the nutrient at the break point plus some “safety margin” is fed. This is often 10% but may be increased if considerable batch-to-batch variation is known or the nutrient is subject to oxidation during feed processing, etc.

2.2. The future technical paradigm

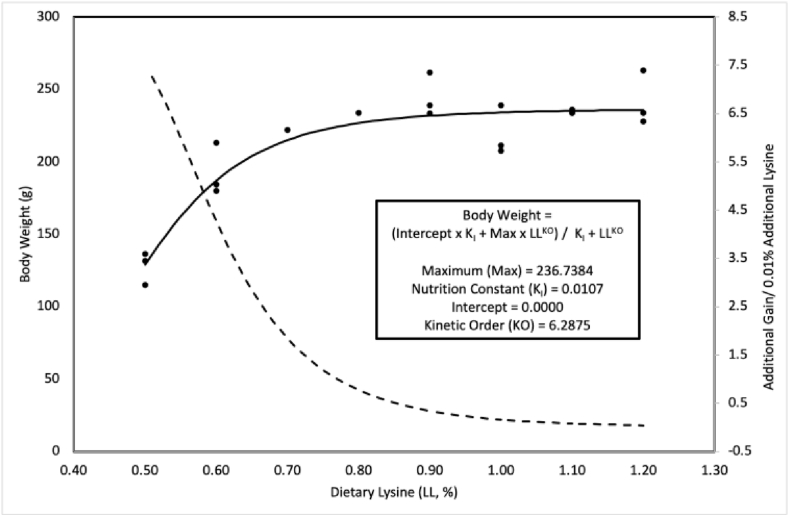

A more rational model is the Saturation Kinetics Model of Morgan et al. (1975) (also called the Morgan-Mercer-Flodin or MMF model; Fig. 2). The Saturation Kinetics Model is a superset of the Michalaes-Menten model of enzyme kinetics. It assumes that there is some rate-limiting, enzyme catalyzed reaction that is limiting growth when sub-optimal levels of any nutrient are fed. The shape of the curve is the same as for any enzyme catalyzed reaction, except that an intercept and kinetic order of the response at the origin is added to the enzyme kinetics model. A big difference between these models, and how they are applied in practice, is the expected marginal efficiency of the nutrient in question. The Saturation Kinetics Model follows the law of diminishing marginal returns (or productivity). As each increment of the nutrient is added to the feed, the response is less than the previous one. This response is expected to infinity, since a maximum response is never achieved, only approached. Similarly, the marginal efficiency never reaches zero (the dashed line).

Fig. 2.

The Saturation Kinetics Model of nutritional responses fitted to the data of Sterling et al. (2003). The solid line represents the growth response to lysine, while the dashed line represents the marginal efficiency.

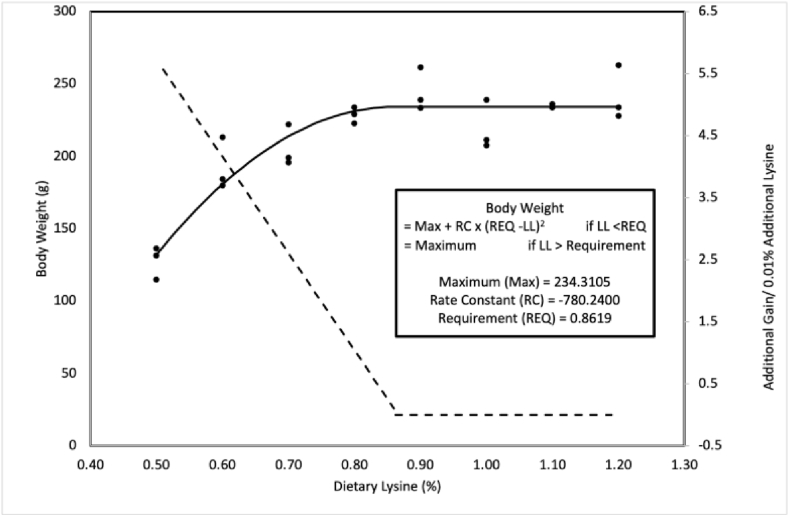

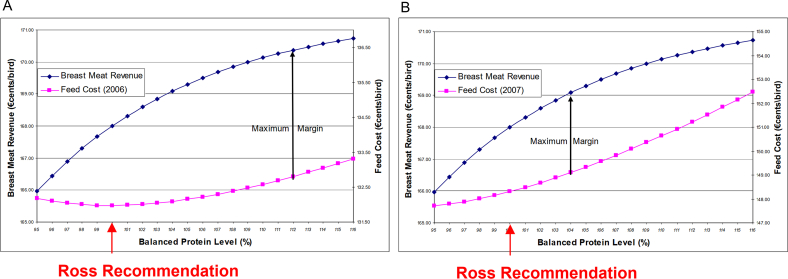

A compromise model, the ascending quadratic with plateau model, is also sometimes applied to nutritional response data (Pesti et al., 2009). Unlike the Saturation Kinetics Model, it has a clearly defined “requirement” for maximum performance, like the broken-line linear model. It also has a plateau. Most nutritionists expect there to be some range of nutrients that can be fed above the “requirement” that neither improves the response nor results in toxicity, the plateau. A model with a diminishing-returns ascending segment and a plateau therefore seems to be the most appropriate model for many nutrients (Fig. 3). For more expensive nutrients, the “requirement” models are not adequate since their responses follow the Saturation Kinetics Model (or a very similar one). The concept of feeding to maximize profits and not just satisfy “requirements” was best illustrated in a technical bulletin from Ross Breeders (Fig. 4).

Fig. 3.

The broken-line quadratic model fitted to the data of Sterling et al. (2003).

Fig. 4.

An application of profit maximizing strategies to broiler production based on a non-linear relationship between the balanced total amino acid level (referred to as balanced protein level in the figures) of the feed and returns from breast meat (Waller, 2007).

The key features of such models are: 1) the flexibility to feed different nutrient levels as costs and returns change to maximize profits, and 2) the acceptance that there is no one “requirement” for all nutrients. The reality is that there are different feeding levels that result in perfectly healthy birds with different characteristics, and maximum growth does not necessarily mean maximum profits. Birds fed higher amino acid levels grow faster on less feed and have more carcass yields due to less carcass fat (Lemme et al., 2008). The response to increasing energy levels is somewhat similar, except that birds fed higher energy levels grow faster on less feed but have lower carcass yields due to increased carcass fat.

There are all sorts of other considerations besides dietary nutrient levels that need to be included in future formulation models. The composition and value of the manure may be critical when modeling responses to dietary total amino acid levels, while pellet quality may become important when modeling responses to dietary energy levels, etc.

2.3. The present economic paradigm

Least-cost linear programming is about making inexpensive feed. That is, the cheapest feed for the technical restrictions it is given. There is no connection between possible alternative technical restrictions and economics, except to compute the least-cost solution. Linear programs are not used to choose the technical restrictions that maximize profits. Parametric linear programming shows the effects of a series of nutrient levels or ingredient prices on feed costs, but they are not typically set up to relate feed cost to performance objectives. Nutritional requirement experiments are usually designed and interpreted by finding the nutrient level yielding a response not significantly different from the maximum response. This level is usually chosen to be the best feeding level. In Fig. 1 this could be 0.70% or even 0.60% lysine despite that the requirement using a regression technique yields a requirement of 0.75% lysine. However, “not significantly different from” does not mean “the same as”. Feeding 0.70% lysine to birds expected to respond like those in Fig. 1 may be expected to respond like those above 0.75% lysine (“not significantly different from” believers) or to respond like those fed 0.70% lysine (regression model believers). The real question is whether it is economical to feed an extra 0.05% lysine to produce an extra 19.5 g of body weight.

2.4. The future economic paradigm

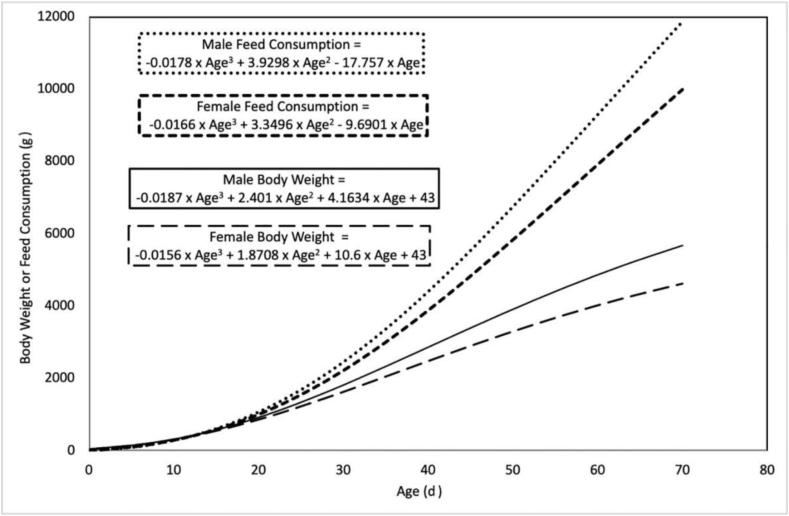

Once the paradigm switch is made from least-cost linear models to maximum-profit non-linear models, nutrition and feed formulation are just a part of complex models of broiler or layer profit maximizing strategies. The nutritionist must then be a part of the production management team and not an independent profit center responsible for making all feeding decisions. Feeding decisions that determine growth rates will necessarily involve the nutritionist responsible for the feed, but also the production manager who has to coordinate housing temperatures, marketing managers who determine what size(s) of birds are most profitable and processing managers who need to schedule birds for slaughter, etc. There may even be different objectives to the overall process depending on the limiting factors for the particular enterprise. If floor space is limiting production, maximizing profits per unit area per year may be the overall objective; if processing is limiting production, maximizing profits per shackle may be the overall objective, etc. Economic decisions will be centered around to production function of the birds. The production function is derived from the growth curves in the case of broilers (Fig. 5).

Fig. 5.

Technical broiler performance expectations for a hypothetical flock grown in 2022.

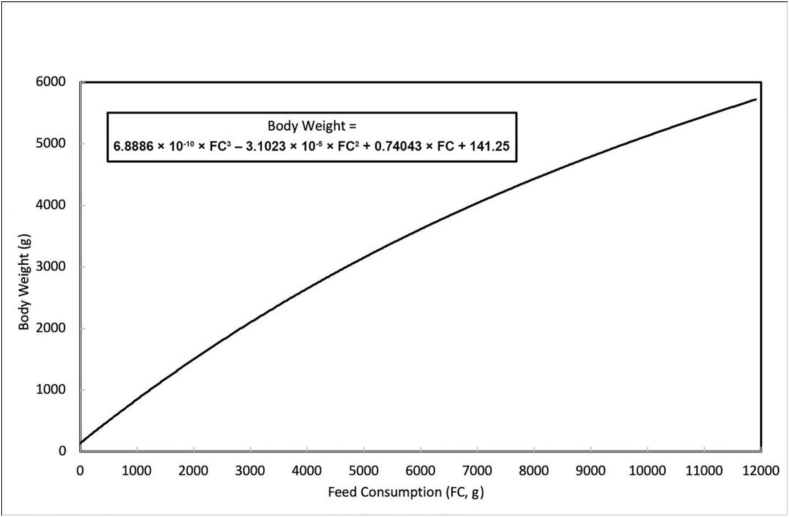

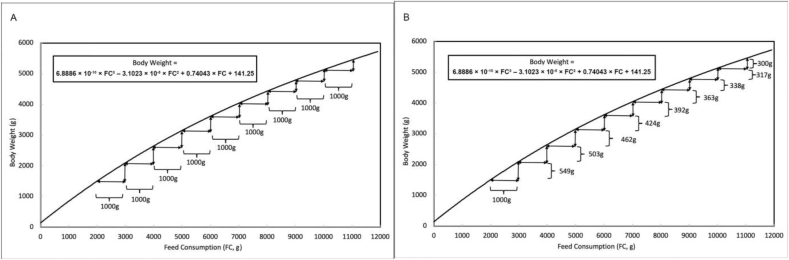

The production function of broilers (Fig. 6) should be the center of profit maximizing models for broiler meat production. There should be a different production function for each set of circumstances that broilers are grown under (specific genetics and environmental conditions). This production function relates how much live broiler meat is produced from feed that is consumed. The production function is used to determine the size of the bird that maximizes profits, based on, but not necessarily minimizing, feed costs.

Fig. 6.

The production function of a flock of male broilers grown in 2022, based on the expected performance data in Fig. 5.

The production function is interpreted as shown in Fig. 7. For each unit of feed that is consumed, smaller and smaller amounts of body weight are produced. The most profitable amount of feed to give is then chosen when the cost of the feed is just equal to the value of the broiler that is produced.

Fig. 7.

The marginal analysis of example production functions from Fig. 6. Adding the next (marginal) amount of feed results in diminishing amounts of salable broilers. (A) Inputs (costs) are depicted in the graph on the left and (B) outputs (returns) in the graph on the right.

All the factors that affect the production function may be important in determining the maximum profit feed. The balanced dietary total amino acid level affects the production function as shown in Fig. 4. Other factors that affect the production function include environmental temperature, relative humidity and air speed, bird genetics, carcass composition, etc. Anything that impacts the growth of the bird impacts the production function and will need to be added to more comprehensive models. Since birds are rarely sold live, the most obvious thing that needs to be added to profit maximizing models is carcass yields. Dietary balanced total amino acid levels and dietary energy levels affect carcass and parts yields. The best diet to feed may therefore be dependent on whether whole birds or parts are being sold (Costa et al., 2001). To determine the best amount of feed for the example in Fig. 5, Fig. 6, Fig. 7, a marginal analysis may be conducted (Table 1).

Table 1.

| Female |

Male |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Age, d | Body weight, g | Feed consumed, g | Returns, $ | Costs, $ | Returns over feed costs, $ | Marginal returns, $ | Age, d | Body weight, g | Feed consumed, g | Returns, $ | Costs, $ | Returns over feed costs, $ | Marginal returns, $ |

| 22 | 1,016 | 1,231 | 2.031 | 0.862 | 1.169 | 0.061 | 22 | 1,098 | 1,322 | 2.195 | 0.925 | 1.270 | 0.074 |

| 23 | 1,087 | 1,347 | 2.173 | 0.943 | 1.230 | 0.061 | 23 | 1,181 | 1,454 | 2.363 | 1.018 | 1.345 | 0.075 |

| 24 | 1,159 | 1,467 | 2.319 | 1.027 | 1.292 | 0.061 | 24 | 1,267 | 1,591 | 2.535 | 1.114 | 1.421 | 0.076 |

| 25 | 1,234 | 1,592 | 2.467 | 1.114 | 1.353 | 0.061 | 25 | 1,356 | 1,734 | 2.711 | 1.214 | 1.497 | 0.076 |

| 26 | 1,309 | 1,721 | 2.618 | 1.204 | 1.414 | 0.061 | 26 | 1,446 | 1,882 | 2.891 | 1.317 | 1.574 | 0.077 |

| 27 | 1,386 | 1,853 | 2.772 | 1.297 | 1.474 | 0.061 | 27 | 1,538 | 2,035 | 3.075 | 1.425 | 1.651 | 0.077 |

| 28 | 1,464 | 1,990 | 2.928 | 1.393 | 1.535 | 0.060 | 28 | 1,631 | 2,193 | 3.263 | 1.535 | 1.728 | 0.077 |

| 29 | 1,543 | 2,131 | 3.087 | 1.492 | 1.595 | 0.060 | 29 | 1,727 | 2,356 | 3.454 | 1.649 | 1.805 | 0.077 |

| 30 | 1,624 | 2,276 | 3.247 | 1.593 | 1.654 | 0.059 | 30 | 1,824 | 2,524 | 3.648 | 1.766 | 1.881 | 0.077 |

| 31 | 1,705 | 2,424 | 3.409 | 1.697 | 1.713 | 0.059 | 31 | 1,922 | 2,696 | 3.845 | 1.887 | 1.958 | 0.076 |

| 32 | 1,787 | 2,576 | 3.573 | 1.803 | 1.770 | 0.058 | 32 | 2,022 | 2,873 | 4.044 | 2.011 | 2.033 | 0.076 |

| 33 | 1,869 | 2,731 | 3.739 | 1.912 | 1.827 | 0.057 | 33 | 2,123 | 3,054 | 4.246 | 2.138 | 2.108 | 0.075 |

| 34 | 1,953 | 2,890 | 3.906 | 2.023 | 1.883 | 0.056 | 34 | 2,225 | 3,239 | 4.450 | 2.268 | 2.183 | 0.074 |

| 35 | 2,037 | 3,052 | 4.074 | 2.137 | 1.937 | 0.054 | 35 | 2,328 | 3,429 | 4.656 | 2.401 | 2.256 | 0.073 |

| 36 | 2,121 | 3,218 | 4.243 | 2.252 | 1.990 | 0.053 | 36 | 2,432 | 3,623 | 4.864 | 2.536 | 2.328 | 0.072 |

| 37 | 2,206 | 3,386 | 4.412 | 2.370 | 2.042 | 0.052 | 37 | 2,537 | 3,821 | 5.074 | 2.675 | 2.399 | 0.071 |

| 38 | 2,291 | 3,558 | 4.582 | 2.490 | 2.092 | 0.050 | 38 | 2,642 | 4,023 | 5.284 | 2.816 | 2.468 | 0.069 |

| 39 | 2,377 | 3,732 | 4.753 | 2.612 | 2.141 | 0.048 | 39 | 2,748 | 4,229 | 5.496 | 2.960 | 2.536 | 0.068 |

| 40 | 2,462 | 3,909 | 4.924 | 2.737 | 2.187 | 0.047 | 40 | 2,854 | 4,438 | 5.709 | 3.107 | 2.602 | 0.066 |

| 41 | 2,547 | 4,089 | 5.094 | 2.863 | 2.232 | 0.045 | 41 | 2,961 | 4,651 | 5.922 | 3.256 | 2.666 | 0.064 |

| 42 | 2,633 | 4,272 | 5.265 | 2.990 | 2.275 | 0.043 | 42 | 3,068 | 4,868 | 6.136 | 3.407 | 2.728 | 0.062 |

| 43 | 2,718 | 4,457 | 5.435 | 3.120 | 2.315 | 0.041 | 43 | 3,175 | 5,087 | 6.349 | 3.561 | 2.788 | 0.060 |

| 44 | 2,802 | 4,644 | 5.605 | 3.251 | 2.354 | 0.038 | 44 | 3,282 | 5,311 | 6.563 | 3.717 | 2.846 | 0.058 |

| 45 | 2,887 | 4,834 | 5.774 | 3.384 | 2.390 | 0.036 | 45 | 3,388 | 5,537 | 6.777 | 3.876 | 2.901 | 0.055 |

| 46 | 2,971 | 5,026 | 5.942 | 3.518 | 2.423 | 0.033 | 46 | 3,495 | 5,766 | 6.990 | 4.036 | 2.953 | 0.053 |

| 47 | 3,054 | 5,220 | 6.108 | 3.654 | 2.454 | 0.031 | 47 | 3,601 | 5,998 | 7.202 | 4.199 | 3.003 | 0.050 |

| 48 | 3,137 | 5,417 | 6.274 | 3.792 | 2.482 | 0.028 | 48 | 3,707 | 6,233 | 7.413 | 4.363 | 3.050 | 0.047 |

| 49 | 3,219 | 5,615 | 6.438 | 3.93 | 2.508 | 0.025 | 49 | 3,812 | 6,471 | 7.624 | 4.530 | 3.094 | 0.044 |

| 50 | 3,300 | 5,814 | 6.600 | 4.070 | 2.530 | 0.022 | 50 | 3,916 | 6,712 | 7.832 | 4.698 | 3.134 | 0.040 |

| 51 | 3,380 | 6,016 | 6.760 | 4.211 | 2.549 | 0.019 | 51 | 4,020 | 6,955 | 8.040 | 4.868 | 3.171 | 0.037 |

| 52 | 3,459 | 6,219 | 6.919 | 4.354 | 2.565 | 0.016 | 52 | 4,122 | 7,200 | 8.245 | 5.040 | 3.205 | 0.034 |

| 53 | 3,537 | 6,424 | 7.075 | 4.497 | 2.578 | 0.013 | 53 | 4,224 | 7,448 | 8.448 | 5.213 | 3.235 | 0.030 |

| 54 | 3,614 | 6,630 | 7.228 | 4.641 | 2.587 | 0.009 | 54 | 4,325 | 7,698 | 8.649 | 5.388 | 3.261 | 0.026 |

| 55 | 3,690 | 6,838 | 7.379 | 4.786 | 2.593 | 0.006 | 55 | 4,424 | 7,950 | 8.848 | 5.565 | 3.283 | 0.022 |

| 56 | 3,764 | 7,046 | 7.528 | 4.933 | 2.595 | 0.002 | 56 | 4,522 | 8,203 | 9.043 | 5.742 | 3.301 | 0.018 |

| 57 | 3,836 | 7,256 | 7.673 | 5.079 | 2.593 | −0.002 | 57 | 4,618 | 8,459 | 9.236 | 5.922 | 3.315 | 0.014 |

| 58 | 3,907 | 7,467 | 7.815 | 5.227 | 2.588 | −0.006 | 58 | 4,713 | 8,717 | 9.426 | 6.102 | 3.324 | 0.009 |

| 59 | 3,977 | 7,679 | 7.953 | 5.375 | 2.578 | −0.010 | 59 | 4,806 | 8,976 | 9.612 | 6.283 | 3.329 | 0.005 |

| 60 | 4,044 | 7,892 | 8.089 | 5.524 | 2.564 | −0.014 | 60 | 4,897 | 9,237 | 9.794 | 6.466 | 3.328 | 0.000 |

| 61 | 4,110 | 8,105 | 8.220 | 5.673 | 2.546 | −0.018 | 61 | 4,987 | 9,499 | 9.973 | 6.650 | 3.324 | −0.005 |

| 62 | 4,174 | 8,319 | 8.347 | 5.823 | 2.524 | −0.022 | 62 | 5,074 | 9,763 | 10.148 | 6.834 | 3.314 | −0.010 |

| 63 | 4,235 | 8,533 | 8.471 | 5.973 | 2.497 | −0.027 | 63 | 5,159 | 10,028 | 10.318 | 7.019 | 3.298 | −0.015 |

| 64 | 4,295 | 8,748 | 8.590 | 6.124 | 2.466 | −0.031 | 64 | 5,242 | 10,294 | 10.484 | 7.206 | 3.278 | −0.020 |

| 65 | 4,352 | 8,963 | 8.704 | 6.274 | 2.430 | −0.036 | 65 | 5,322 | 10,561 | 10.645 | 7.393 | 3.252 | −0.026 |

| 66 | 4,407 | 9,179 | 8.814 | 6.425 | 2.389 | −0.041 | 66 | 5,400 | 10,829 | 10.801 | 7.580 | 3.221 | −0.032 |

| 67 | 4,459 | 9,394 | 8.919 | 6.576 | 2.343 | −0.046 | 67 | 5,476 | 11,098 | 10.952 | 7.768 | 3.183 | −0.037 |

| 68 | 4,509 | 9,610 | 9.018 | 6.727 | 2.291 | −0.051 | 68 | 5,548 | 11,367 | 11.097 | 7.957 | 3.140 | −0.043 |

| 69 | 4,557 | 9,826 | 9.113 | 6.878 | 2.235 | −0.056 | 69 | 5,618 | 11,637 | 11.237 | 8.146 | 3.091 | −0.049 |

| 70 | 4,601 | 10,041 | 9.202 | 7.029 | 2.174 | −0.062 | 70 | 5,685 | 11,908 | 11.370 | 8.335 | 3.035 | −0.056 |

Table 1 is presented in terms of days of age of the broilers and feed consumed to that date as commonly presented in management guides. It could easily have been presented in terms of total feed consumed in 1, 10, 50 or 100 g increments. This table was based on feed at $0.70/kg and broilers at $2.00/kg. The objective of this simplified model is to maximize returns over feed costs for one flock. Simply by looking down the marginal returns column to see when it changes from positive to negative, the days to market to maximize profits can be found.

In this example, profits per bird were calculated. In more comprehensive models, profits will be modeled relative to the limiting resource of the firm. If housing space is limiting output, then profits should be maximized per unit of floor space per year. Since nutrition impacts growth rate, it will be an important factor in determining the days to market, space allotment per bird and number of lots of birds that can be grown in each house each year. If processing space is limiting a firm's output, then bird size becomes a critical determinant of necessary growth rates and nutrient levels. Marketing is also important in determining what size bird to grow. Models based on the production function can determine if the birds should be grown at the lower or upper end of acceptable carcass sizes for sales. Maximum profit feed formulation will require close cooperation amongst the various managers of each poultry firm.

2.5. The present extra-nutritional paradigm

The nutritionist's duties have been expanded to include “extra-nutritional” aspects of the diet. The ramifications of feed pelleting and post-pelleting spray applications on feed consumption and uniformity of consumption are well established areas within the nutritionist's realm of responsibilities. The achievement of good pellet quality is presently more an art than a science. The economic interpretation of maintaining pellet quality is more qualitative than quantitative. The relationship between the cost of making good quality pellets is rarely related to the advantages of pelleting in a meaningful way. Similarly, antioxidants to preserve the nutrients and exogenous enzymes capable of improving the digestion of various nutrients are feed components naturally included in formulations by nutritionists. With restrictions on the use of feeding low-levels of antibiotics, maintaining gut health through the feeding of prebiotics, probiotics or specific combinations of the two (synbiotics), nutritionists are finding they have even more extra-nutritional responsibilities.

2.6. The future extra-nutritional paradigm

The pelleting process of the future will move from an art to a science. The cost of factors affecting pellet manufacturing and the beneficial and detrimental effects of pelleting will be quantified: The effects of each ingredient on pelleting, and especially energy use in pelleting, will be quantified. The total amino acid and carbohydrate fractions of the ingredients will be determined and related to their ability to form acceptable pellets. This will allow for the Pellet Quality Factor to be an absolute instead of relative factor (Abdollahi et al., 2013; Farahat, 2015). The energy to pellet feeds will become expensive enough to bring pelleting's value into question and justify research into all the variables affecting pellet quality and durability in terms of costs and returns. The questions that will be answered will include the costs of pelleting versus the value of improved growth and feed consumption, reduction in dustiness, water consumption and especially pathogen reduction. The cost of more hygienic (more energy consuming) pelleting versus increased destruction of pathogens and nutrients will be quantified (Lynch, 2022) allowing cost benefit and risk analyses. Producers will ask questions like “What is the risk of bacterial contamination of feed causing clinical disease?” and “Is it worthwhile to pay for pasteurizing conditions that destroy nutritional moieties of the feed?” The answers can only be found through the cooperation of nutritionists with health specialists and specialists in risk management.

Gut health will be managed without the use of antimicrobial additives. This will require the formulator and their colleagues to have ever increasing understandings of various feed additives on the market and their functions. Besides the traditional non-nutritional feed additives, future feed formulation will include components designed to improve the development of gut and overall bird production and health. Scientists are really only beginning to understand the importance of extra-nutritional feed components on gut health on the performance of broilers and layers. The microbiota gut–brain axis (GBA) will be understood for growing and reproducing birds. It is now only beginning to be elucidated in humans (Carabotti et al., 2015). Eventually, the GBA will be understood and influenced to optimize bird performance. It is now known that neuro-immuno-endocrine mediators influence the GBA and how the gut develops and maintains gastrointestinal homeostasis including immune functions. A better understanding of the GBA will lead to improved use of pre-and pro-biotics and BP (Sánchez and Vázquez, 2017). BP are short chain (3 to 20 residues) amino acid polymers that are derived from both plant and animal proteins during enzymatic hydrolysis during digestion. They are well known in humans and other mammals.

Sánchez and Vázquez (2017) illustrated “BP play a significant role in human health by affecting the digestive, endocrine, cardiovascular, immune, and nervous systems.” BP may be classified as nutraceuticals, products derived from feed ingredients that contain some health promoting properties. Bioinformatics will play an important role in determining how various genotypes react to the various pro- and pre-biotics that may be available. Genetic differences in how birds respond to colonization by various microbes will be used for genetic selection. The effects of specific microbes in the gastrointestinal tract of birds on the development of the gastrointestinal, antioxidant and immune systems will become important. These microbes may be colonizing bacteria or disease challenge including vaccinations. Genetic selection in the presence of different feed ingredients with various levels of BP will result in ever more productive poultry. Future nutritionists will necessarily interact more with specialists in engineering, microbiology and health.

2.7. The present feed and the environmental impact paradigm

The use of crystalline amino acids to better balance feeds and avoid excessive intact protein feeding will continue to increase. From its beginnings with crystalline methionine in the 1950's the practice has grown as more economical ways of manufacturing crystalline amino acids have been developed. Enzymes, like phytase, have been added to feeds to reduce costs, and they have also reduced wastes that end up in the litter. Used litter and droppings have often been regarded as unfortunate by-products that must be gotten rid of. For many decades, nutritionists in dry climates, especially in winter, have added extra salt to their diets to add litter moisture and control poultry house dust. More recently, formulators have added compounds to their feeds for fly control. In some countries, there are limits to the amount of chemicals that can be added to avoid polluting the environment. The maximum amounts of extra-nutritional or pharmacological levels of nutrients like copper and zinc are controlled by law in some countries.

2.8. The future feed and the environmental impact paradigm

Dietary supplements like probiotics, Yucca schidigera and biochar have been shown to help reduce the environmental impact of poultry production (Ahmed et al., 2014; Kalus et al., 2020; Nahm, 2007; Saeed et al., 2018). The use of those and similar products are expected to increase in the future.

Animal welfare management will become increasingly important, like housing space, clean and dry animal house environments low in ammonia level, and public amenity considerations, like dust and odor emissions. Again, feed formulation needs to take these into account, which means not only the formulator needs to consider nutrients present in the feed that are available to the animal, but they also pay attention to the undigested components that could potentially become available when treated in situ or end up in the excreta with unknown environment outcomes.

In the future, used litter and droppings will be regarded as part of the sustainable ecosystem that needs to be fully exploited to maximize profits. Poultry producers will determine where the nutrients in their ingredients came from and what is needed by the soils they will fertilize and crops derived from them. The carbon in all plants comes directly from the atmosphere in the previous year and so should have a neutral carbon footprint. Similarly, the nitrogen in legumes comes directly from the atmosphere the year before and should therefore have a neutral nitrogen footprint. Phosphorus, calcium and many trace minerals are needed by the next generation of crops and therefore have the ability to replace inorganic forms as fertilizers and have value. The economic impact of waste nitrogen excretion will depend on how it is regarded (Table 2). If nitrogen can be sold to replace chemical fertilizers, it will have a positive value and increase the size of birds that maximize producer profits. A high value on manure nitrogen will tend to favor raising larger birds to maximize profits (compare the most profitable age to raise male broilers in Table 2; 63 days and 4.235 kg/bird when excreta nitrogen has value, and 49 days and 3.219 kg/bird when excreta nitrogen has a cost, with those in Table 1, 59 days and 4.806 kg/bird). Birds with poorer feed utilization efficiency and nitrogen efficiency will be the most profitable. On the other hand, if litter nitrogen is regarded as a waste product that is taxed or producers pay to be taken away, overall profitability will be reduced, and the most profitable age to raise birds to will be decreased. In this scenario, it will be most economical to use smaller birds that have greater gain per unit of feed and nitrogen, 49 days and 3.219 kg (Table 2). To further add value to meat and egg production, two aspects will be considered: 1) nitrogen trapping in the litter will become more economical as litter amendments are added to bind uric acid directly or ammonia after bacterial fermentation; and 2) nitrogen will also be removed from the air leaving poultry house. The production function balances environmental concerns, resulting in the most overall profitable production.

Table 2.

Results of a multiple lot model of broiler production including a value for selling or paying to dispose of litter nitrogen.

| Age, d | Body weight, g | Feed consumed, g | Nitrogen excreted, g | Nitrogen in excreta valued at 0.05 $/kg |

Nitrogen in excreta valued at −0.05 $/kg |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manure nitrogen value, $ | Returns, $ | Costs, $ | Returns over feed costs, $ | Marginal returns, $ | Manure nitrogen value, $ | Returns, $ | Costs, $ | Returns over feed costs, $ | Marginal returns, $ | ||||

| 40 | 2,462 | 3,909 | 9.77 | 0.49 | 5.412 | 2.737 | 2.676 | 0.069 | −0.49 | 4.435 | 2.737 | 1.699 | 0.025 |

| 41 | 2,547 | 4,089 | 10.22 | 0.51 | 5.606 | 2.863 | 2.743 | 0.067 | −0.51 | 4.583 | 2.863 | 1.721 | 0.022 |

| 42 | 2,633 | 4,272 | 10.68 | 0.53 | 5.799 | 2.990 | 2.809 | 0.066 | −0.53 | 4.731 | 2.990 | 1.741 | 0.020 |

| 43 | 2,718 | 4,457 | 11.14 | 0.56 | 5.992 | 3.120 | 2.872 | 0.064 | −0.56 | 4.878 | 3.120 | 1.758 | 0.017 |

| 44 | 2,802 | 4,644 | 11.61 | 0.58 | 6.185 | 3.251 | 2.934 | 0.062 | −0.58 | 5.024 | 3.251 | 1.773 | 0.015 |

| 45 | 2,887 | 4,834 | 12.09 | 0.60 | 6.378 | 3.384 | 2.994 | 0.060 | −0.60 | 5.169 | 3.384 | 1.785 | 0.012 |

| 46 | 2,971 | 5,026 | 12.57 | 0.63 | 6.570 | 3.518 | 3.051 | 0.057 | −0.63 | 5.313 | 3.518 | 1.795 | 0.009 |

| 47 | 3,054 | 5,220 | 13.05 | 0.65 | 6.761 | 3.654 | 3.107 | 0.055 | −0.65 | 5.456 | 3.654 | 1.802 | 0.007 |

| 48 | 3,137 | 5,417 | 13.54 | 0.68 | 6.951 | 3.792 | 3.159 | 0.053 | −0.68 | 5.597 | 3.792 | 1.805 | 0.004 |

| 49 | 3,219 | 5,615 | 14.04 | 0.70 | 7.140 | 3.930 | 3.209 | 0.050 | −0.70 | 5.736 | 3.930 | 1.806 | 0.001 |

| 50 | 3,300 | 5,814 | 14.54 | 0.73 | 7.327 | 4.070 | 3.257 | 0.047 | −0.73 | 5.873 | 4.070 | 1.803 | −0.003 |

| 51 | 3,380 | 6,016 | 15.04 | 0.75 | 7.512 | 4.211 | 3.301 | 0.044 | −0.75 | 6.008 | 4.211 | 1.797 | −0.006 |

| 52 | 3,459 | 6,219 | 15.55 | 0.78 | 7.696 | 4.354 | 3.343 | 0.041 | −0.78 | 6.141 | 4.354 | 1.788 | −0.009 |

| 53 | 3,537 | 6,424 | 16.06 | 0.80 | 7.878 | 4.497 | 3.381 | 0.038 | −0.80 | 6.272 | 4.497 | 1.775 | −0.013 |

| 54 | 3,614 | 6,630 | 16.58 | 0.83 | 8.057 | 4.641 | 3.416 | 0.035 | −0.83 | 6.400 | 4.641 | 1.758 | −0.016 |

| 55 | 3,690 | 6,838 | 17.09 | 0.85 | 8.234 | 4.786 | 3.448 | 0.032 | −0.85 | 6.525 | 4.786 | 1.738 | −0.020 |

| 56 | 3,764 | 7,046 | 17.62 | 0.88 | 8.408 | 4.933 | 3.476 | 0.028 | −0.88 | 6.647 | 4.933 | 1.714 | −0.024 |

| 57 | 3,836 | 7,256 | 18.14 | 0.91 | 8.580 | 5.079 | 3.500 | 0.025 | −0.91 | 6.766 | 5.079 | 1.686 | −0.028 |

| 58 | 3,907 | 7,467 | 18.67 | 0.93 | 8.748 | 5.227 | 3.521 | 0.021 | −0.93 | 6.881 | 5.227 | 1.654 | −0.032 |

| 59 | 3,977 | 7,679 | 19.20 | 0.96 | 8.913 | 5.375 | 3.538 | 0.017 | −0.96 | 6.994 | 5.375 | 1.618 | −0.036 |

| 60 | 4,044 | 7,892 | 19.73 | 0.99 | 9.075 | 5.524 | 3.551 | 0.013 | −0.99 | 7.102 | 5.524 | 1.578 | −0.040 |

| 61 | 4,110 | 8,105 | 20.26 | 1.01 | 9.233 | 5.673 | 3.560 | 0.009 | −1.01 | 7.207 | 5.673 | 1.533 | −0.045 |

| 62 | 4,174 | 8,319 | 20.80 | 1.04 | 9.387 | 5.823 | 3.564 | 0.004 | −1.04 | 7.307 | 5.823 | 1.484 | −0.049 |

| 63 | 4,235 | 8,533 | 21.33 | 1.07 | 9.537 | 5.973 | 3.564 | 0.000 | −1.07 | 7.404 | 5.973 | 1.431 | −0.054 |

| 64 | 4,295 | 8,748 | 21.87 | 1.09 | 9.683 | 6.124 | 3.559 | −0.005 | −1.09 | 7.496 | 6.124 | 1.372 | −0.058 |

| 65 | 4,352 | 8,963 | 22.41 | 1.12 | 9.824 | 6.274 | 3.550 | −0.009 | −1.12 | 7.584 | 6.274 | 1.309 | −0.063 |

| 66 | 4,407 | 9,179 | 22.95 | 1.15 | 9.961 | 6.425 | 3.536 | −0.014 | −1.15 | 7.666 | 6.425 | 1.241 | −0.068 |

| 67 | 4,459 | 9,394 | 23.49 | 1.17 | 10.093 | 6.576 | 3.517 | −0.019 | −1.17 | 7.744 | 6.576 | 1.168 | −0.073 |

| 68 | 4,509 | 9,610 | 24.03 | 1.20 | 10.220 | 6.727 | 3.493 | −0.024 | −1.20 | 7.817 | 6.727 | 1.090 | −0.078 |

| 69 | 4,557 | 9,826 | 24.56 | 1.23 | 10.341 | 6.878 | 3.463 | −0.029 | −1.23 | 7.885 | 6.878 | 1.007 | −0.083 |

| 70 | 4,601 | 10,041 | 25.10 | 1.26 | 10.457 | 7.029 | 3.429 | −0.035 | −1.26 | 7.947 | 7.029 | 0.918 | −0.089 |

From a welfare perspective, the amount of floor space birds is allowed needs to be considered. That requires different analyses. If the number of chicks that can be hatched or birds that can be processed is limiting the output (profits) of a firm, then the type of analyses in Table 1, Table 2 is the most appropriate. But when housing space limits the profitability of an enterprise, then the analyses must change. Calculations of profitability must consider the number of chicks to be placed in the house based on their age at processing, the kilogram of broilers per square meter and the downtime between flocks (Table 3). The broiler age to maximize profits in the example in Table 1 for the single lot model was 56 days or 3.764 kg/bird for females. For the multiple lot model in Table 3, with the particular chick costs used, the best weight to raise birds to was only 39 days or 2.377 kg. With the multiple lot model used to create Table 3, changing the specified kilogram broilers per square meter of floor space has a big effect on overall returns over feed cost, but no effect on the broiler age to maximize profits. When the floor space allocation in Table 3, 24 kg/m2, was changed to 20 kg/m2, the age to maximize profits would still be 39 days, but overall returns over feed and chick costs would be reduced from $63.27 to $52.73/m2.

Table 3.

Results from a multiple lot model of female broiler production.

| Age, d | Body weight, g | Feed consumed, g | Number of broilers, per m2 | Batches, per year | Number of broilers, per m2 per year | Broiler costs, $/year | Broiler weight, kg/m2 per year | Feed consumed, kg/m2 per year | Total returns, $ | Total costs, $ | Returns over feed and chick costs, $ | Marginal returns, $ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 1,624 | 2,276 | 14.78 | 9.13 | 134.98 | 175.48 | 219.15 | 307.19 | 438.300 | 390.512 | 47.788 | 4.859 |

| 31 | 1,705 | 2,424 | 14.08 | 8.91 | 125.42 | 163.05 | 213.80 | 304.03 | 427.610 | 375.865 | 51.745 | 3.957 |

| 32 | 1,787 | 2,576 | 13.43 | 8.70 | 116.81 | 151.86 | 208.71 | 300.91 | 417.429 | 362.495 | 54.934 | 3.189 |

| 33 | 1,869 | 2,731 | 12.84 | 8.49 | 109.05 | 141.76 | 203.86 | 297.85 | 407.721 | 350.254 | 57.467 | 2.533 |

| 34 | 1,953 | 2,890 | 12.29 | 8.30 | 102.02 | 132.62 | 199.23 | 294.85 | 398.455 | 339.015 | 59.439 | 1.972 |

| 35 | 2,037 | 3,052 | 11.78 | 8.12 | 95.64 | 124.33 | 194.80 | 291.92 | 389.600 | 328.671 | 60.929 | 1.490 |

| 36 | 2,121 | 3,218 | 11.31 | 7.94 | 89.83 | 116.78 | 190.57 | 289.06 | 381.130 | 319.126 | 62.005 | 1.076 |

| 37 | 2,206 | 3,386 | 10.88 | 7.77 | 84.54 | 109.90 | 186.51 | 286.28 | 373.021 | 310.298 | 62.723 | 0.718 |

| 38 | 2,291 | 3,558 | 10.47 | 7.61 | 79.71 | 103.62 | 182.63 | 283.57 | 365.250 | 302.118 | 63.132 | 0.409 |

| 39 | 2,377 | 3,732 | 10.10 | 7.45 | 75.28 | 97.86 | 178.90 | 280.95 | 357.796 | 294.523 | 63.273 | 0.141 |

| 40 | 2,462 | 3,909 | 9.75 | 7.31 | 71.21 | 92.58 | 175.32 | 278.40 | 350.640 | 287.458 | 63.182 | −0.091 |

| 41 | 2,547 | 4,089 | 9.42 | 7.16 | 67.48 | 87.72 | 171.88 | 275.94 | 343.765 | 280.876 | 62.888 | −0.293 |

| 42 | 2,633 | 4,272 | 9.12 | 7.02 | 64.04 | 83.25 | 168.58 | 273.55 | 337.154 | 274.735 | 62.419 | −0.469 |

| 43 | 2,718 | 4,457 | 8.83 | 6.89 | 60.86 | 79.12 | 165.40 | 271.25 | 330.792 | 268.997 | 61.796 | −0.623 |

| 44 | 2,802 | 4,644 | 8.56 | 6.76 | 57.93 | 75.30 | 162.33 | 269.03 | 324.667 | 263.629 | 61.038 | −0.758 |

| 45 | 2,887 | 4,834 | 8.31 | 6.64 | 55.21 | 71.77 | 159.38 | 266.90 | 318.764 | 258.602 | 60.162 | −0.876 |

| 46 | 2,971 | 5,026 | 8.08 | 6.52 | 52.69 | 68.50 | 156.54 | 264.84 | 313.071 | 253.889 | 59.183 | −0.980 |

| 47 | 3,054 | 5,220 | 7.86 | 6.41 | 50.35 | 65.46 | 153.79 | 262.87 | 307.579 | 249.467 | 58.112 | −1.071 |

| 48 | 3,137 | 5,417 | 7.65 | 6.30 | 48.18 | 62.64 | 151.14 | 260.97 | 302.276 | 245.316 | 56.960 | −1.152 |

| 49 | 3,219 | 5,615 | 7.46 | 6.19 | 46.16 | 60.01 | 148.58 | 259.16 | 297.153 | 241.416 | 55.736 | −1.223 |

| 50 | 3,300 | 5,814 | 7.27 | 6.09 | 44.27 | 57.55 | 146.10 | 257.42 | 292.200 | 237.751 | 54.449 | −1.287 |

| 51 | 3,380 | 6,016 | 7.10 | 5.99 | 42.51 | 55.27 | 143.70 | 255.77 | 287.410 | 234.305 | 53.105 | −1.344 |

| 52 | 3,459 | 6,219 | 6.94 | 5.89 | 40.87 | 53.13 | 141.39 | 254.19 | 282.774 | 231.065 | 51.709 | −1.396 |

| 53 | 3,537 | 6,424 | 6.78 | 5.80 | 39.33 | 51.14 | 139.14 | 252.69 | 278.286 | 228.019 | 50.267 | −1.442 |

| 54 | 3,614 | 6,630 | 6.64 | 5.71 | 37.90 | 49.27 | 136.97 | 251.27 | 273.938 | 225.155 | 48.783 | −1.484 |

| 55 | 3,690 | 6,838 | 6.50 | 5.62 | 36.55 | 47.52 | 134.86 | 249.92 | 269.723 | 222.463 | 47.260 | −1.523 |

| 56 | 3,764 | 7,046 | 6.38 | 5.53 | 35.29 | 45.87 | 132.82 | 248.66 | 265.636 | 219.934 | 45.702 | −1.558 |

| 57 | 3,836 | 7,256 | 6.26 | 5.45 | 34.10 | 44.33 | 130.84 | 247.47 | 261.672 | 217.561 | 44.110 | −1.592 |

| 58 | 3,907 | 7,467 | 6.14 | 5.37 | 32.99 | 42.89 | 128.91 | 246.35 | 257.824 | 215.336 | 42.487 | −1.623 |

| 59 | 3,977 | 7,679 | 6.04 | 5.29 | 31.95 | 41.53 | 127.04 | 245.32 | 254.087 | 213.252 | 40.835 | −1.653 |

| 60 | 4,044 | 7,892 | 5.93 | 5.22 | 30.96 | 40.25 | 125.23 | 244.36 | 250.457 | 211.304 | 39.154 | −1.681 |

| 61 | 4,110 | 8,105 | 5.84 | 5.14 | 30.04 | 39.05 | 123.46 | 243.47 | 246.930 | 209.485 | 37.445 | −1.709 |

| 62 | 4,174 | 8,319 | 5.75 | 5.07 | 29.17 | 37.92 | 121.75 | 242.67 | 243.500 | 207.792 | 35.708 | −1.736 |

| 63 | 4,235 | 8,533 | 5.67 | 5.00 | 28.35 | 36.86 | 120.08 | 241.94 | 240.164 | 206.219 | 33.945 | −1.763 |

| 64 | 4,295 | 8,748 | 5.59 | 4.94 | 27.58 | 35.86 | 118.46 | 241.30 | 236.919 | 204.765 | 32.154 | −1.791 |

| 65 | 4,352 | 8,963 | 5.51 | 4.87 | 26.86 | 34.91 | 116.88 | 240.73 | 233.760 | 203.424 | 30.336 | −1.818 |

There are very important differences between the single lot and multiple lot models of broiler production. In the single lot model, the kilogram of broiler and feed consumption increased with the age of the bird at processing. In the multiple lot model, just the opposite was true, as bird age increased, the kilogram broiler produced and feed consumed per square meter decreased. With the single lot model as the price of feed increased, using less feed would tend to maximize profits, so smaller birds would be processed, and conversely. With the multiple lot model as the price of feed increased using less feed would tend to maximize profits, so larger birds would be processed, and conversely. This illustrates the importance of choosing the correct model when projecting profitability. When the incubator or processing space is limiting the profitability of a company, the single lot model is appropriate. When housing space is limiting the profitability of a company, the multiple lot model is appropriate. One practical application of this phenomenon is that if a market requires a certain range of bird (or rather carcass) weights, with the single lot model with some set of costs and returns it may be most economical to produce birds on the higher end of the acceptable range; but with the multiple lot model it would be most economical to produce at the lower end of the acceptable weight range. With both models the production function is the center of the model, but how it is applied is most important. The examples in Table 1, Table 2, Table 3 are most appropriate for a live bird market. For most commercial producers who process their birds, yields would need to be added, and the objective would change from live weight returns over feed and chick costs to meat and byproduct value returns over all costs.

2.9. The present feed and environmental conditions paradigm

Currently, producers try to adjust the birds' environment to maximize performance levels. Temperature adjustments have been crude attempts to maintain some optimal level of profitability without direct cost and returns analyses. For instance, in the American contract system of broiler production, the company supplies the feed but the contract grower supplies the fuel to warm the house. It is well understood that when the birds are kept in cooler conditions they may eat more and thus grow faster but use more feed per unit of meat produced. Various schemes have been used to resolve the conflict between the company and grower regarding the feed efficiency of the birds: The conflict is (at least partially) resolved by the companies giving feed efficiency bonuses to their growers. These bonuses are payments for achieving a specified level of efficiency. What is not considered in a practical way is precisely what the costs of feed versus fuel are, and how temperature affects consumption and growth rate.

2.10. The future feed and environmental conditions paradigm

In the future, producers will determine the profit maximizing conditions to minimize overall energy usage in broiler and egg production. The energy to maintain environments with different temperatures, air movement, humidity and lighting programs will be modeled. Feed energy costs in each environment will be modeled as well. For any market requirement, the size bird with the lowest overall feed and environmental energy costs will be chosen. Models like the one developed for broilers and broiler housing interactions (Timmons, 1986) will be developed for modern conditions and continuously updated and re-calibrated with conditions and growth performance for each broiler and layer flock.

This problem is much more complex than might be initially obvious. The effects of temperature are modified by a number of factors that will be included in models. Heat loss by the birds directly affects environmental temperature and humidity and changes rapidly with age, feather cover, activity (lighting schedule), and even the surface area of the birds: Genetics, bird age, feather growth and/or loss, relative humidity, and air movement all contribute and interact for finding the most economical temperature for broilers (Timmons, 1986) and layers (McDonald, 1978).

To determine the most economical temperature to keep birds at, two closely related problems need to be modeled and solved. The first is the fuel and insulation trade-off for broiler and egg production need to be known (Costantino et al., 2021; Küçüktopcu and Cemek, 2019; Zerjal et al., 2021).

Many good models of broiler house energy expenditures were developed after the last energy crisis in the 1970's, but they need to be updated. Once the amount of insulation is specified and the average climate for a barn is known, the relationship between broiler or layer performance and housing temperature, humidity and airspeed will be modeled for profit maximization.

2.11. The present traceability of feed used to produce meat or eggs paradigm

Feed mills have on-site storage facilities capable of holding large quantities of grains and other ingredients. Feed bins with capacities of up to 7,600 tonnes of grain can hold only one type of grain. Such monuments to inflexibility limit the formulators' ability to substitute grains and other ingredients when prices are favorable. Deliveries of each ingredient from various sources must be mixed together when they arrive at the feed mill. Some analytical values for ingredients arriving at feed mills are determined and used to determine the price to be paid. These analytical values are sometimes added to historical databases that are used in feed formulation.

2.12. The future traceability of feed used to produce meat or eggs paradigm

The purpose of feed formulation will not end at producing a nutritionally balanced, animal welfare friendly and environmentally sound feed. Rather, the consumer will have the right to trace back what was used in feed to produce the meat or eggs they purchase from their local supermarket. Whether required by various governmental entities or not, traceability will become an integral part of the feed formulation process. As batches of feed are identified upon delivery at the feed mill, they will be sampled and stored separately or with similar batches. Simply segregating ingredients by those above and below average for critical nutrients will greatly improve the uniformity of finished feeds (Alhotan et al., 2014). Purchasing agents will coordinate with formulators the purchase of the most economical ingredients without restriction due to storage facilities. In addition to being available for consumers, knowledge of what is in each batch of finished feed will be related to bird performance on each farm. The feed ingredient and nutrient data will be used to improve models of feed intake and growth expectations. Data from each batch of feed and farm results will continuously improve profit maximizing and formulation models. The ability to predict growth rates from each farm will be useful for other purposes like scheduling processing times to have the best flocks processed to meet each day's marketing needs.

3. Changes in the biological paradigm

3.1. Digestible amino acids present paradigm

In the middle of the 20th century, amino acid requirements were mainly determined by adding synthetic amino acids to a basal diet low in the amino acid in question. It was recognized that the synthetic amino acids were utilized with near 100% absorbed, while some of the amino acids in intact proteins were somewhat lower. Assays with chicks and roosters were developed to measure “digestible” amino acids. The term “digestible” as used is really the product of the digestion (or rather the liberation of the amino acids in the digestion of the protein) and absorption of the free amino acids. Databases of amino acid digestibility values of feed ingredients have been compiled by several companies. Some values are based on assays with chicks, others with assays with roosters. The values from the two digestibility assay systems are highly correlated (R2 = 0.978; Tahir and Pesti, 2012), but those from mature birds are about 14.4% higher than those with chicks. The level of the amino acid in the ingredient was found to be a significant factor in contributing to amino acid digestibility in both systems. It is known that some oilseed meals have fiber fractions that interfere with their own amino acid absorptions in swine diets (Messad et al., 2016). Such interactions are ignored and digestibility values are considered to simply be additive with no interactions between ingredients. The effect of age on amino acid digestibility has also been demonstrated using the same assay: Adedokun et al. (2008) observed an overall increase in amino acid digestibility of 8.3% between 5 and 21 days of age (83.4% vs. 75.1%; P < 0.0001 by our re-calculation). They also found highly significant differences between the methods of endogenous amino acid correction of 2.8% (P < 0.0001 by our re-calculation, Table 4). Eight specific problems with digestible amino acid assays have been pointed out by Adedokun et al. (2011): In addition to the method of correcting for endogenous losses and bird age, diet minerals, intestinal bacteria, sampling area, level of intake, proportion of energy source, ingredient specific endogenous losses and difficulties in quantitating dietary markers are all potential sources of error in digestible amino acid assays. There has been a general consensus that it is advantageous to have one “standardized” method for digestible amino acid assays, despite the understanding that there are serious problems with any method in combination with some specific ingredients.

Table 4.

Analysis of variance for broiler amino acid digestibility from Adedokun et al. (2008).

| Source | DF | SS | Mean square | F value | Pr > F |

|---|---|---|---|---|---|

| Model | 29 | 47970.2305 | 1654.1459 | 128.93 | <0.0001 |

| Error | 320 | 4105.6253 | 12.8301 | ||

| Corrected total |

349 |

52075.8558 |

|||

|

Source |

DF |

Type III SS |

Mean square |

F value |

Pr > F |

| Ingredient | 5 | 19556.8676 | 3911.3735 | 304.86 | <0.0001 |

| AA | 17 | 6124.2455 | 360.2497 | 28.08 | <0.0001 |

| Age | 1 | 3365.9114 | 3365.9114 | 262.35 | <0.0001 |

| Correction method1 | 1 | 709.8925 | 709.8925 | 55.33 | <0.0001 |

| Age × Ingredient | 5 | 4984.9504 | 996.9901 | 77.71 | <0.0001 |

DF = degrees of freedom; SS = sum of squares; Type Ⅲ SS = Type Ⅲ sum of squares.

Correction method = protein free diet versus highly digestible protein diet.

3.2. Digestible amino acids future paradigm

Amino acid digestibility values in the future will be refined to account for differences in bird age. Adjustments will be made to account for differences due to assay conditions and amino acid levels. Digestibility values will reflect the level that the amino acid is at in the finished feed. Fully and poorly digested ingredients will be properly described by chick and hen assays, accounting for digestion and absorption along the entire digestive tract. Interactions and influences of one ingredient's components on the digestibility of amino acid from other ingredients will be taken into account in feed formulation models. Different methods to discover digestible amino acid values will be used to show the appropriate values for each individual ingredient.

3.3. The present carbohydrate feeding paradigm

A large portion of feed ingredients is still largely ignored in feed formulation except through their contributions to ME. Neither the composition nor the quantity of the carbohydrates in feed ingredients is adequately described. Carbohydrates are the major source of energy in poultry diets but mainly in the form of starch. Whereas NSP, as the main part of fiber that come in numerous different forms and structures, are not well digested in poultry. In fact, NSP contribute the largest proportion of undigested feed component in broiler chickens (Kim et al., 2022). The fate of NSP in the gastrointestinal tract of poultry is important for managing poultry gut health because it depends on the age of the bird, the use of enzymes and the type of NSP molecules present. The use of appropriate enzymes can alleviate problems associated with soluble NSP, like arabinoxylans and beta-glucans, but it can also lead to the production of prebiotics in situ, which can enhance gut health (Morgan et al., 2020).

3.4. The future carbohydrate feeding paradigm

The actions and interactions of carbohydrates will only be properly understood after their levels in feed ingredients are better known and their chemical structures properly elucidated. The use of exogenous carbohydrate digesting enzymes will only be optimized after the composition of feed ingredients is better understood. Another important point to make is that, the current use of crude fiber in feed formulation does not capture most of the soluble NSP and some lignin in feed. This makes feed formulation inaccurate because nutrients contained in the feed do not add up to 100%, as they should.

3.5. Measuring energy values of feeds present paradigm

Today, the apparent metabolizable energy (AME) assay corrected for nitrogen retention using growing broilers is the most widely used system for feed formulation globally. AME determinations on batches of ingredients have been reported to be both accurate and repeatable across laboratories (Bourdillon et al., 1990a, 1990b). While the ME system has enjoyed great utility in the poultry industry for decades, some questions and idiosyncrasies remain. Table values often do not indicate if they were obtained using roosters or growing chicks. They also may not indicate if there has been a correction for nitrogen retention. The effects of anti-nutritional factors from one ingredient on others are ignored. Of greater importance is the fact that ME does not give a complete picture of the net amount of energy (NE) actually available for maintenance and growth.

3.6. Measuring energy values of feeds future paradigm

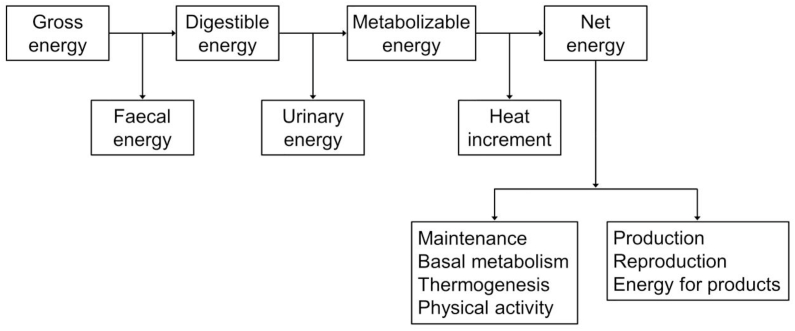

NE is defined as the energy consumed minus that excreted and “wasted” as heat as shown in Fig. 8 (Larbier and Leclercq, 1994). The use of NE for production values may be advantageous in formulation as energy for necessary basal metabolism, heat for body temperature regulation, and heat increment would be taken into account.

Fig. 8.

Partition and flux of energy in poultry.

The heat increment of feeding (HI) is defined as the heat produced by an animal in excess of that associated with basal or fasting metabolism. Different ingredients and combinations of ingredients generate more or less heat as their nutrients are digested and metabolized. In growing chicks, the relative efficiency of energy utilization for carbohydrate, fat and protein (total amino acids) has been determined to be 100%, 113% and 78%, respectively (De Groote, 1974). Intuitively, this means that the ME system overvalues the productive energy value of protein or high total amino acid meals and undervalues fat or ingredients with a high fat content. Prediction equations for estimating HI and NE can be generated based on the chemical composition of the diets and/or digestibility of various feed components. Such equations are now available for pigs (Noblet et al., 1994), ruminants (Ferrell and Oltjen, 2008) and poultry (Barzegar et al., 2019; Wu et al., 2019).

The argument for the use of NE in poultry is simple: the industry does not use gross energy or GE, rather it uses ME in feed formulation because approximately 30% of the feed energy is lost in the excreta (faeces and urine together); similarly, approximately 30% of the ME is lost before dietary energy starts to be used for production, i.e., NE, due to heat increment loss during metabolism. This 30% loss of ME depends on the ingredients used to formulate the feed.

3.7. Non-essential amino acids present paradigm

The proximate analysis system for evaluating feed was first developed in 1866 in Weende, Germany and has thus been called the Weende method, or proximate analysis. It characterized the composition of feed ingredients as either moisture, ash, crude fiber, lipid, nitrogen containing (crude protein) or the residual, nitrogen-free extract. Crude protein was accepted as containing 16% nitrogen, based on dairy products. Feeds and animals' requirements were considered in terms of crude protein until the early 20th century when good analytical techniques for quantitating the various amino acids in proteins were developed. It was then determined that animals require about 22 amino acids for protein synthesis. Animals can synthesize about 12 amino acids from amino nitrogen, but the other 10 are required to come from the diet. Formulating on the basis of crude protein was considered archaic. Requirement lists often included minimums for crude protein to provide enough amino nitrogen for the synthesis of non-dietarily essential amino acids, although this was rarely stated as the reason. Formulators would sometimes include a minimum level of some amino acid (not available in synthetic form) to maintain total amino acid levels without directly specifying a total amino acid requirement (since there is no crude protein requirement per se). There were many attempts to quantify the non-essential amino acid requirements, but none was widely accepted. Requirements for the essential amino acids are usually indexed to lysine levels when total nitrogen (crude protein) or total amino acid levels change.

3.8. Non-essential amino acids future paradigm

The problem with estimating a requirement for the 10 or so non-essential amino acids is that they can be provided by the non-essential amino acids in the feed or the excesses of all the essential amino acids in the feed. There are two possible improvements to the present system: (1) Computers may someday simply sum the excesses of all the essential amino acids in the feed ingredients and use those values to determine the potential amounts of non-essential amino acids that could be synthesized by the consuming birds. (2) The total amino acid (or true protein) level may be calculated from the amino acids in a feed (Sriperm et al., 2011). The total amino acid level of a feed is the sum of the dietarily required amino acids, excesses of the dietarily required amino acid and the non-essential amino acids. The total amino acid levels of thousands of feed ingredient samples are determined each year, so the values are already available. The total amino acid (or true protein) content of each feed ingredient can be easily determined by summing the amino acid levels. Requirements for the essential amino acids will be indexed to the total amino acid level of the diet to provide adequate and balanced levels of the essential amino acids and non-essential amino acids (Alhotan and Pesti, 2016). With either system there may need to be an adjustment for a very small amount of non-protein nitrogen that can be used to synthesize some non-essential amino acids (Lemme et al., 2019).

3.9. Balanced total amino acid and energy present paradigm

It was once thought that birds eat to satisfy their energy need, so all other nutrients could be provided in proportion to dietary energy (NRC, 1994). This concept works quite well for layers who maintain strict energy balance and gain little weight over the course of their productive lifetimes. This allows for excellent energy and feed consumption prediction equations for layers (McDonald, 1978). However, the concept does not work for broilers who have the capacity to alter both their growth rates and their body composition depending on the levels of total amino acids and energy they are offered (NRC, 1994). Currently, amino acid and protein requirements are listed for different classes and ages of birds. It is obvious that requirements (in percentages) for maximum growth rate and feed utilization efficiency decrease with time. As a result, feeding periods have been as small as practical. Although researchers generally determine requirements for certain ages of birds, practical diets are formulated for the first 500 g of feed, next kilogram feed, etc.

3.10. Balanced total amino acid and energy future paradigm

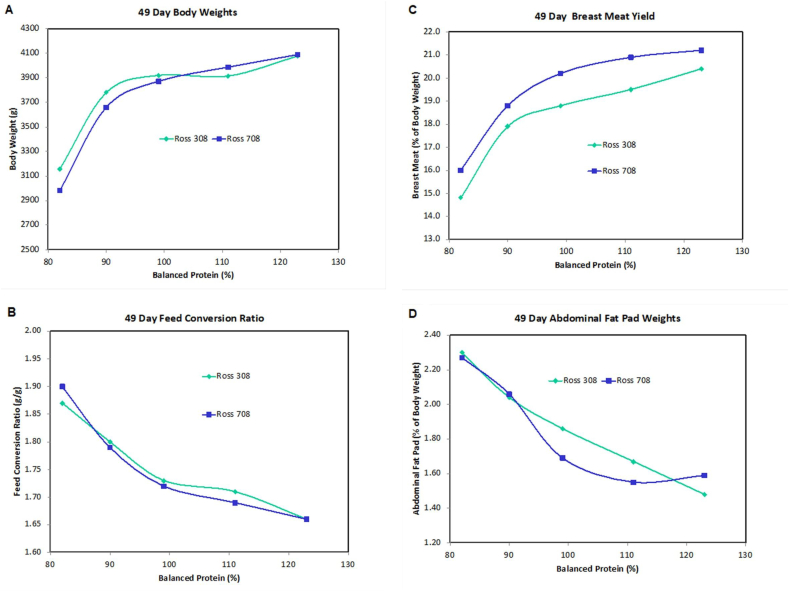

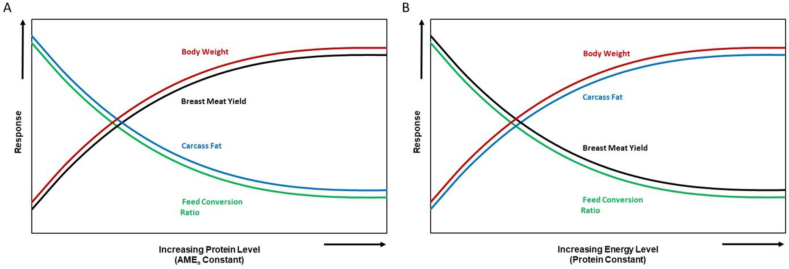

The broiler chickens' responses to dietary total amino acid and energy levels have been confirmed many times; an excellent example is shown in Fig. 9, Fig. 10. Increasing dietary energy results similarly to increasing balanced total amino acids in some respects and just the opposite in others. Increasing both total amino acids and energy levels results in improved growth and feed efficiency. Increasing dietary total amino acids level results in increases in lean body growth, while increasing dietary energy level increases body lipids (Fig. 10). The important thing to appreciate is that there are no break-points in these response curves that could be called “requirements”. In the future, producers will make choices of dietary total amino acids and energy levels based on costs and returns for most ages of birds. For starter feeds, growth and feed efficiency responses may not be as important as influencing the gut brain axis to influence gut health, optimizing immune responses, and building strong bones. Subsequently, the emphasis will be placed directly on the costs of inputs and the value of products and co-products produced.

Fig. 9.

Responses of different Ross strains to balanced dietary total amino acids (labeled protein by the authors). Drawn from the data of Lemme et al. (2008).

Fig. 10.

Comparison of the effects of increasing dietary (A) total amino acids (protein) and (B) energy levels. These are theoretical curves. The actual response lines will vary depending on genetic stock, and environmental conditions including temperature, humidity, litter conditions and atmospheric gasses such as carbon dioxide and ammonia levels.

The increase in growth and decrease in feed conversion ratio from feeding higher levels of dietary total amino acids result from a higher proportion of amino acids being deposited in the carcass and less being oxidized to uric acid and water. Thus more of the energy in the amino acids is retained, less is wasted. Increased growth and decreased FCR from feeding higher levels of dietary energy result from increased fat deposition in the carcass and less energy being expended in eating (similar to pelleting). Broiler chickens are very interesting creatures in that as they are selected for higher growth rates, they naturally become fatter. It is only through careful genetic selection that their carcass fat can be controlled. Depending on the selection criteria employed, some broilers may increase growth rate with higher total amino acid levels, while others maintain growth rates but increase feed utilization efficiency (Leclercq and Guy, 1991; Smith et al., 1998; Smith and Pesti 1998). Despite genetic selection for fast growth and feed efficiency, broilers can still change their carcass composition when different levels of total amino acids and energy are fed.

3.11. The present concept of precision feed formulation

Moss et al. (2021) discussed the possibility of precision nutrition and feed formulation. Their focus was on an adaptive system of determining daily requirements on a shed by shed basis adapted to the microenvironment of each farm. They pointed out that “Precision nutrition requires a well-characterized nutrient database together with a set of properly defined nutrient requirements, which may require some investment to achieve the accuracy and capacity required.” Moss et al. (2021) are striving for precision in a very imprecise environment.