Abstract

The in situ stress plays a crucial role in variations in coal permeability, hydraulic fracturing behavior, and accordingly coalbed methane (CBM) productivity. As the depth increases, the effects of in situ stress will become more prominent. In the Shizhuang block, present-day stress magnitude and permeability of coals at depths >800 m were measured with multiple-cycle hydraulic fracturing and injection falloff test, respectively. The results show that most seams are under pressure reservoirs with pressure gradient <0.9 MPa/100 m. Horizontal stress magnitudes and gradients tend to increase (800–1200 m) and then decrease (>1200 m) with increasing depth. Strike-slip fault stress regimes are predominant, while seams with depth >1400 m are subjected to a normal fault stress regime. Coal permeability tends to decrease gradually with depth and tends to be convergence to 0.01 mD. Considering extremely low permeability of these deep seams, hydraulic fracturing must be applied to create seepage channels for gas and water drainage. Although the high horizontal stress difference in deep seams is favorable for the generation of longer and simple hydraulic fractures, there is no obvious relations between fracture length and gas productivity as poor-support fractures and limited sand migration distance. The current hydraulic fracturing missed the variable stress regimes and permeability at various depth, but used the similar fracturing schemes, leading to significant reduction in gas productivity with depth. Using the high viscosity fracturing fluid, great sand volume, big injection rate, and low sand concentration are recommended for hydraulic fracturing. Single-branch horizontal well with staged fracturing show better applicability for deep CBM extraction.

1. Introduction

In situ stress refers to the stress conditions existing in the subsurface before any mining or engineering activities take place. These conditions encompass the three principal stress components: vertical stress (σv), minimum horizontal stress (σh), and maximum horizontal stress (σH).1,2 These stresses play a crucial role in determining the stability and behavior of coal seams during mining operations. Vertical stress is the stress component that acts vertically downward due to the depth and the weight of the overlying rock strata.4–6 The horizontal stresses occur in a horizontal direction and are influenced by tectonic forces and rock movements.7 According to the Anderson faulting criteria, three types of the stress regime are generally classified, including normal, strike-slip, and reverse faulting stress regimes.8

The magnitude and orientation of the in situ stress can vary depending on the geological setting and tectonic forces present in the region.9–12 Geological structures like faults and folds can introduce additional stress components and alter the stress distribution within the coal seam.13 Understanding the in situ stress conditions is essential for designing and implementing mining and hydraulic fracturing operations.14,15 In situ stress can affect the coal permeability by altering the fractures and pathways.16,17 More specifically, it can cause the closure of fractures and microcracks within the coal matrix and thereby significantly reduce the permeability of the seam.18,19 Meanwhile, in situ stress plays a crucial role in determining the success and effectiveness of the fracturing process, governing the initiation and propagation of fractures and affecting the complexity of the fracture network.20–22 A low horizontal stress difference can lead to more complex fracture networks with multiple branches, while a high horizontal stress difference may result in simpler, more planar fractures.23,24

Techniques such as stress measurements using hydraulic fracturing, borehole imaging, or stress relief methods are employed to determine the present-day in situ stress.25,26 Each technique has its advantages and limitations, and hydraulic fracturing is widely applied in stress measurements in deep seams. In this work, in situ stress measurements were conducted in deep seams (>800 m) in the Shizhuang block of the southern Qinshui basin in China. With the measured data, the in situ stress distribution and its influence on coal permeability, hydraulic fracturing stimulation, and coalbed methane (CBM) extraction were systemically analyzed. Finally, optimization suggestions are proposed to improve CBM recovery rates in deep seams.

2. Geological Settings

The Qinshui Basin is located in the southeastern part of Shanxi Province, China and is one of the largest coal-rich basins in China (Figure 1a27). The eastern boundary of the Qinshui Basin is marked by the uplift of the Taihang Mountains, while the western boundary connects to the Lvliang Mountains, and the southern boundary is adjacent to the Zhongtiao Mountains. Overall, it extends along a long axis in the NNE direction (Figure 1b,27).

Figure 1.

(a) Location of the Qinshui basin in China; (b) location of the Shizhuang block in the Qinshui basin (modified after7). Reprinted (adapted or reprinted in part) with permission from Chen, S.; Tang, D.; Tao, S.; Xu, H.; Li, S.; Zhao, J.; and Fu, H. In situ stress measurements and stress distribution characteristics of coal reservoirs in major coalfields in China: Implication for coalbed methane (CBM) development. International Journal of Coal Geology2017, v. 182, pp 66–84. Copyright [2017] [Elsevier]; (c) stratigraphic column of coal-bearing strata (modified after29). Reprinted (adapted or reprinted in part) with permission from Li, Y.; Zhang, C.; Tang, D.; Gan, Q.; Niu, X.; Wang, K.; and Shen, R. Coal pore size distributions controlled by the coalification process: An experimental study of coals from the Junggar, Ordos, and Qinshui basins in China. Fuel2017, v. 206, pp 352–363. Copyright [2017] [Elsevier].

The Shizhuang block is situated in the southeastern part of the Qinshui Basin, covering a total area of approximately 400 km2, including two sub-blocks: Shizhuangnan block and Shizhuangbei block. The region boasts abundant coal resources with relatively favorable coal seam properties and a high CBM content. The study area represents a typical carboniferous-Permian coal-bearing stratum. The lowermost stratum is the Ordovician Fengfeng Formation, and the overlying strata, arranged from oldest to youngest, consist of the Benxi Formation, Taiyuan Formation, Shanxi Formation, Lower Shihezi Formation, Upper Shihezi Formation, Shiqianfeng Formation, and Liujiagou Formation.5,10,28 The Upper Carboniferous Taiyuan Formation and the Lower Permian Shanxi Formation are the primary coal-bearing strata in the study area (Figure 1c). During this stage, a total of 18 coal seams have been identified, with the nos. 3 and 15 coal seams being the primary targets for CBM development.29

After the formation of the coal-bearing strata in the Carboniferous and Permian periods, the Qinshui Basin has undergone multiple tectonic movements, including the Hercynian-Indosinian, Yanshan, and Himalayan movements.30 The Indosinian movement had a minimal impact on the overall tectonic structure of the basin. The coal seams primarily experienced strong compressional stress during the Yanshan period with a NW–SE orientation, leading to the formation of NE-oriented folds. During the early stage of the Himalayan orogeny, there were no significant structural features resulting from the NW–SE extension. However, in the late stage of the Himalayan orogeny until the present, a weak compressional stress field in the NE–SW direction has further intensified regional tectonic differentiation. The current maximum horizontal stress orientation of the basin is in NE direction.31

3. Methodology

The injection falloff test is a commonly used method in reservoir engineering to evaluate the properties and performance of a reservoir.18 During an injection falloff test, a known volume of fluid (typically water) is injected into a well at a constant rate, and then the injection is shut off. The pressure response is then monitored over time as the injected fluid spreads and interacts with the surrounding formation. The interpretation of an injection falloff test involves analyzing pressure transients and applying mathematical models such as pressure buildup analysis or pressure falloff analysis. By analyzing the pressure response during the falloff phase, reservoir properties such as permeability (k), skin factor, and reservoir pressure (Po) near the wellbore can be estimated.

The in situ stress measurement with multiple-cycle hydraulic fracturing method was conducted after the injection falloff test.19 This method involves the repeated injection of fluid at increasing pressure levels to induce fractures in the rock formation. During each hydraulic fracturing cycle, fluid is injected into the wellbore at increasing pressures until fractures propagate through the rock. The pressure required to initiate and propagate these fractures depends on the pre-existing stress conditions in the formation. Once the fractures are generated, the pressure will decrease sharply as fluid filtration occurs, and the recorded pressure presents the breakdown pressure (Pf). Typically, two or three cycles that exhibit favorable fracture initiation and closure effects are chosen for shut-in pressure (Pc) analysis. The square root of time method is employed, supplemented by verification using the double logarithmic method. A detailed description in the methodology can be found in a study by Chen et al. (2017).7

4. Results

4.1. Test Parameters

In the Shizhuang block, 45 wells with 56 seams conducted the injection falloff test and the in situ stress measurement at depths of 775–1454 m (averaging 1022 m). Here, the breakdown pressure ranges from 12.09 to 31.38 MPa (averaging 22 MPa), with a breakdown pressure gradient of 1.39–2.99 MPa/100 m (averaging 2.16 MPa/100 m). The shut-in pressure range from 12.92 to 29.09 MPa (averaging 21 MPa), with a pressure gradient of 1.35–2.68 MPa/100 m (averaging 2.03 MPa/100 m). With increasing depth, both the breakdown and shut-in pressures increase gradually but tend to decrease at depths >1200 m (Figure 2a). The phenomenon can be verified by the pressure gradient, which shows an increase-decrease trend in the vertical region (Figure 2b). There is also a linear increase in the reservoir pressure magnitude (3.01–12.06 MPa, averaging 7.61 MPa) with an increasing trend in the reservoir pressure gradient (0.3–1.17 MPa/100 m) (Figure 2c). Most seams are characterized by an under pressure reservoir (84% of the total) with a reservoir pressure gradient of less than 0.9 MPa/100 m, while there are several seams with normal pressure (0.9–1.1 MPa/100 m, 14% of the total) at depths of 800–1200 m (Figure 2d).

Figure 2.

Vertical variations in break down pressure (a), shut-in pressure (b), reservoir pressure magnitudes (c), and gradients (d).

Stress regime descriptions typically involve three stress components including σv (vertical stress), σH (maximum horizontal stresses), and σh (minimum horizontal stresses). The σh is equivalent to the shut-in pressure (eq 1,32), while the estimation of the σH follows eq 2(33)

| 1 |

| 2 |

Following eqs 1 and 2, the maximum horizontal stress ranges from 17.40 to 45.33 MPa (averaging 32.56 MPa) and tends to increase with depth, with a maximum horizontal stress gradient of 2.17–4.4 MPa/100 m (averaging 3.2 MPa/100 m) (Figure 3). The magnitude and gradient of the maximum horizontal stress exhibit a similar trend of increasing initially and then decreasing with depth. Horizontal stress difference refers to the disparity between the horizontal stresses acting on a geological formation or rock mass and is a key parameters for hydraulic fracturing. A high horizontal stress difference promotes the development of fractures along the orientation of maximum stress, while fractures propagating under low horizontal stress difference condition will be influenced by the presence of pre-existing fractures or weak planes. In the Shizhuang block, the horizontal stress differences are 4.06–18.54 MPa (averaging 11.83 MPa). Most seams (71%) have a higher horizontal stress difference (>10 MPa), which may contribute to the generation of simple and lengthy fractures during hydraulic fracturing.

Figure 3.

Vertical variations in maximum horizontal stress magnitude (a), maximum horizontal stress gradient (b), and horizontal stress difference (a).

For these data sets, coal permeability ranges from 0.008 to 2.15 mD, and 71% of the total are lower than 0.1 mD. Only five testing seams (9% of the total, at depths <1000 m) have a permeability greater than 1 mD (Figure 4a). With increasing depth, permeability decreases gradually and tends to converge toward 0.01 mD (Figure 4b). Such low permeability seams are challenging to extract CBM, and hydraulic fracturing is required to create pathways for gas and water flow.

Figure 4.

Vertical variations in coal permeability measured by injection fall (a) /off test (b).

4.2. Stress Regimes and Stress Ratios

According to the relative magnitudes of the three stress components, the stress regime can be classified into normal (σv > σH > σh), strike-slip (σH > σv > σh), and reverse (σH > σh > σv) faulting stress regimes, representing weak, moderate, and strong stress intensity.8 The vertical stress is primarily influenced by the weight of the overlying strata, which can be estimated using an empirical formula with a vertical stress gradient of 0.025 MPa/100 m in Chinese coal-bearing basins.25Figure 5a indicates that strike-slip fault stress regimes (76% of the total) are predominantly observed at depths ranging from 800 to 1400 m, with occasional occurrences of normal fault stress regimes (18% of the total). Reverse faulting stress regimes account for the lowest proportion (6%). To be more detailed, horizontal stress magnitudes tend to increase from 800 to 1200 m, and stress regimes transform from a normal fault stress regime to a strike-slip fault stress regimes at the critical depth of ∼850 m; for coals at deeper seams (>1200 m), stress magnitudes decrease gradually, and stress regimes convert into a normal fault stress regimes at ∼1400 m depth.

Figure 5.

(a) Changes in stress regimes with increasing depth and (b) changes in the stress ratios (lateral pressure coefficient, σH/σv, σh/σv) with increasing depth;.

The lateral pressure coefficient, which represents the ratio between the average horizontal stress [(σH > σh)/2] and the vertical stress (σv), is a parameter used in geotechnical engineering to describe the stress state.3,4 Here, the lateral pressure coefficient ranges from 0.74 to 1.39, σH/σv values are 0.87–1.76, and σh/σv values are 0.54–1.07. All of these stress ratios increase at depths <1200 m and then gradually decrease with further increases in depth (Figure 5b). This phenomenon is in line with the changes in the stress magnitude, stress gradient, and horizontal stress difference. Based on this trend, the deeper seams (>1400 m) are characterized by a normal fault stress regime with a lateral pressure coefficient< 1.

5. Discussion

5.1. Influence of Stress on Permeability and CBM Extraction

Permeability is an important factor to consider when extracting the CBM from deep seams. The permeability of a seam depends on several factors, including its composition and structure, the presence of fractures, and the degree of compaction.6,34,35 Generally, the permeability of coal can exhibit obvious stress dependency as it changes with cleat closure or compaction of the coal matrix under varying stress conditions.7,16,36–38Figure 6 indicates that an increase in horizontal stress magnitudes and horizontal stress difference can lead to a reduction in permeability. Permeability tends to stabilize when the maximum horizontal stress> 40 MPa, minimum horizontal stress >25 MPa, and horizontal stress difference >15 MPa. In other words, the cleat and matrix compressibility will reach the lowest value in deep seams and become insensitive to further increase in stress magnitudes. For most deep seams, permeability may remain around 0.01 mD. Also, a strike slip fault stress regime with a lateral pressure coefficient >1.1 and a reserve fault stress regime are unfavorable for the formation of relatively high permeability zones (Figure 6d).

Figure 6.

Correlations between permeability and maximum horizontal stress (a), minimum horizontal stress (b), horizontal stress difference (c), and lateral pressure coefficient (d).

Considering the extremely low permeability of deep coal reservoirs in the study area, hydraulic fracturing has been widely applied to improve the recovery efficiency of CBM. In situ stress plays a significant role in determining the breakdown pressure required for hydraulic fracturing. As depth increases, both the breakdown pressure and shut-in pressure recorded during the hydraulic fracturing process of production wells increase sharply at 900–1100 m, which is agreed with changes in horizontal stress magnitudes, indicating that coals are hard to be fractured under such high stress levels (Figure 7). When the depth is greater than 1100 m, both the breakdown pressure and shut-in pressure tend to decrease. All of this information verifies the accuracy of the in situ stress measurement results to some degree. Different hydraulic fracturing schemes must be adopted for different depths, considering the variations in the stress regimes. However, an almost identical fracturing scale is currently being used, with an injection fluid of 300–450 m3, sand-adding volume of 40–50 m3, injection rate of 6–8 m3/min, and sand concentration of 11–15% (Figure 8). Obviously, it does not effectively address the challenges posed by low permeability in deep seams, which will lead to reduced productivity in the vertical.

Figure 7.

Changes in recorded breakdown and shut-in pressures of production wells with increasing depth.

Figure 8.

Vertical variations in injection fluid volume (a), sand-adding volume (a), injection rate (b), and sand concentration for hydraulic fracturing (b).

As shown in Figure 9, there are 82 vertical wells (with depths ranging from 892 to 1290 m) with a production duration for more than 2 years, and the maximum gas rate is less than 1000 m3/d per well. With an increase depth from 900 to 1100 m, the gas rate decreases from ∼800 to ∼200 m3/d, representing a strong depth sensitivity in gas productivity. The most important reason for this phenomenon is that the existing fracturing scale does not adequately account for these depth-related factors (including stress magnitudes and in situ permeability). It might be necessary to refine the fracturing scale or develop alternative strategies that better address the challenges associated with stress and permeable conditions at different depths.

Figure 9.

Changes in the average gas rate with increasing depth.

5.2. Influence of Stress on Hydraulic Fractures

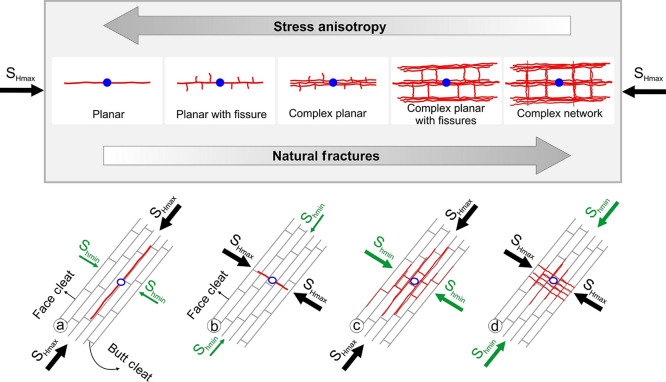

Hydraulic fracturing of unconventional reservoirs generally generates different types of fractures under different stress regimes. For normal and strike-slip faulting stress regimes, hydraulic fracturing generally produces vertical fractures perpendicular to the σh orientation and parallel to the σH orientation. In contrast, a reverse faulting stress regime most likely contributes to horizontally oriented hydraulic fractures.31 In the study area, a strike-slip faulting stress regime is dominant at depths of 800–1400 m and a normal faulting stress regime is dominant at depths >1400 m. These stress regimes may contribute to vertical hydraulic fractures paralleling to the maximum horizontal stress direction. Moreover, understanding stress anisotropy in fracture-developed reservoirs is crucial for optimizing hydraulic fracturing operations. Specifically, the presence of pre-existing fractures (e.g., coal cleats in coal) can significantly affect the propagation of hydraulic fractures (Figure 10). The interaction between hydraulic fractures and natural fractures (or coal cleats) usually falls into three types: hydraulic fractures penetrating natural fractures, hydraulic cracks stopping expansion, and hydraulic fractures diverting and following the path of the natural fracture surface. A high stress difference between the horizontal stresses allows hydraulic fractures to penetrate natural fractures, contributing to the formation of simple and long hydraulic fractures that preferentially propagate along the direction of the maximum horizontal stress. Conversely, when the stress difference is low, hydraulic fractures are more likely to branch and create a network of interconnected fractures.20,23,24 This occurs because the stress field is more isotropic, allowing for the development of multiple fracture paths. Figure 11 illustrates the changes in hydraulic fracture length (obtained from microseismic monitoring) with increasing depth. The hydraulic fracture length at deep seams (>800 m) ranges from 107 to 366 m and tends to increase with depth, which is consistent with the changing trend in horizontal stress difference.

Figure 10.

Fracture geometry changes with horizontal stress anisotropy (after20). Reprinted (adapted or reprinted in part) with permission from [20. Rajabi, M., Tingay, R. King, and O. Heidbach. Present-day stress orientation in the Clarence-Moreton Basin of New South Wales, Australia: a new high density data set reveals local stress rotations: Basin Res2017, v. 29, pp 622–640.]. Copyright [2017] [John Wiley and Sons].

Figure 11.

Changes in the measured hydraulic fracture length and horizontal stress difference with increasing depth.

However, the longer fractures in deeper seams did not contribute to a high gas rate (Figure 9). One of the most important reasons is that coal exhibits strong stress sensitivity, and there is poor proppant filling effect in deep coal seams. This phenomenon was also evidenced by deep CBM development in the Ordos Basin of China.6,37 More specifically, although there are longer hydraulic fractures in deep seams due to the higher horizontal stress difference, the fracture height is limited. During fracturing construction, the pressure curve fluctuates significantly, and a sand plug frequently occurs under the current fracturing scale (Figure 12). A sand plug typically refers to the formation of sand that obstructs the fluid flow. Once the sand plug occurs, the pressure suddenly surges, and construction must be stopped to prevent potential damage or safety hazards. For several wells, sand was not added due to excessive pressure (Figure 12d).

Figure 12.

Typical fracturing construction curve in deep seams.

The above analysis has indicated that the deep seams have higher horizontal stress magnitudes and differences, which are favorable for generating longer and simple hydraulic fractures. However, the greater effective stress and limited fracture height are not conducive to sand filling, as evidenced by the common sand plug phenomenon. Fractures with poor-support and limited sand migration distance provide suboptimal seepage channels with strong stress sensitivity for both gas and water drainage. Meanwhile, the current hydraulic fracturing never considers the variable stress regime and permeability at various depths but rather employs the same fracturing schemes. All of these factors thereby lead to a reduction in gas productivity in the vertical.

5.3. Optimization for Deep CBM Development

There are several measures to overcome CBM extraction challenges in deep seams, following the successful development of deep CBM (1500–2500 m in depth) in the eastern margin of Ordos Basin.39,40 First, using the high viscosity fracturing fluid to improve its sand-carrying capacity; second, increasing the sand volume from 40 to 50 to >300 m3 and using low-density proppants to improve the migration distance of proppant; third, increasing the injection rate from 6 to 8 m3/min to >12 m3/min to avoid sand plugging and elevate the net pressure inside the fracture; and fourth, decreasing the sand concentration from 11 to 15% to below 10%. The core of these measures is to expand the proppant distribution by increasing both the fracturing volume and the sand-adding volume. A better positive correlation between fracturing scale and gas productivity exists, which indicates that the current fracturing scale cannot meet the requirements (Figure 13). Meanwhile, the other methods such as microwave irradiation can also be used as an auxiliary technology for hydraulic fracturing.41

Figure 13.

Correlations among fluid injection volume, sand-adding volume, and gas rate.

A single-branch horizontal well could be another effective way for developing deep CBM. Starting from 2021, several horizontal wells with staged fracturing have been drilled and put into production (Figure 14). These horizontal wells have a horizontal length of 500–850 m, with 6–9 stages of fracturing, an injection fluid volume of 200–300 m3 per section, and a sand-adding volume of 17–26 m3 per section. Currently, these horizontal wells are still in the period of increasing yields, and the gas rates reached 5000 m3/day per well. In contrast to the large-scale fracturing (>400 m3/section of sand-adding volume and >15 m3/min of injection rate) used for horizontal wells in deep seams in the Yanchuannan and Daning-jixian blocks in the Ordos Basin, which have achieved a breakthrough in gas rates of >100,000 m3/day per well, the fracturing scale for horizontal wells can also be significantly improved to maximize the production potential.42

Figure 14.

Gas and water production curves of single-branch horizontal well with staged fracturing (a–c).

6. Conclusions

-

(1)

For deep seams in the Shizhuang block, the horizontal stress magnitude and gradient exhibit an increase-decrease change trend with increasing depth. A strike-slip fault stress regime (76% of the total) is predominantly at depths of 800–1400 m, while seams at depths >1400 m are subjected to a normal fault stress regime with a lateral pressure coefficient< 1.

-

(2)

Deep seams have extremely low permeability ranging from 0.008 to 2.15 mD, with 71% of which being lower than 0.1 mD. As depth increases, permeability decrease gradually, but the decrease is accompanied by a reduction in the cleat and matrix compressibility. When the maximum horizontal stress> 40 MPa, minimum horizontal stress >25 MPa, and horizontal stress difference >15 MPa, permeability tends to converge and remain around 0.01 mD.

-

(3)

The hydraulic fracture length increases with depth in accordance with the rise in horizontal stress difference. However, there is no obvious relationship between fracture length and gas productivity. Poorly supported fractures limit gas productivity in deep seams, and the uniform fracturing schemes without considering the depth effect lead to a reduction in the gas rate with depth.

-

(4)

Using high viscosity fracturing fluid, increasing the sand volume and injection rate, while decreasing sand concentration, were recommended for hydraulic fracturing to enhance proppant distribution and maximum gas production potential. Single-branch horizontal wells with staged fracturing also demonstrate better applicability for deep CBM extraction.

Acknowledgments

This work was supported by China United CBM Co., Ltd., Seven-Year Action Plan Technology Project: Research on CBM Storage and Transportation Technology (CNOOC-KJ135ZDXM 40 ZL01), and the Research on CBM Exploration and Development Technology, Topic 3 of the “New Bedding System and New Field Strategy and Evaluation Technology for New CBM Regions” (2021DJ2303). The authors are grateful to editor and anonymous reviewers for their careful reviews and detailed comments, which helped substantially improve the manuscript. The authors would like to thank CNOOC for providing data of observation and production wells.

The authors declare no competing financial interest.

References

- Kang H.; Zhang X.; Si L.. Study on in-situ stress distribution law in deep underground coal mining areas. ISRM International Symposium on Rock Mechanics—SINOROCK; The University of Hong Kong: China, 2009. 19–22 May.

- Kang H.; Zhang X.; Si L.; Wu Y.; Gao F. In-situ stress measurements and stress distribution characteristics in underground coal mines in China. Eng. Geol. 2010, 116, 333–345. 10.1016/j.enggeo.2010.09.015. [DOI] [Google Scholar]

- Brown E. T.; Hoek E. Trends in relationships between measured in situ stresses and depth. Int. J. Rock Mech. Geomech. Abstr. 1978, 15, 211–215. 10.1016/0148-9062(78)91227-5. [DOI] [Google Scholar]

- Hoek E.; Brown E. T.. Underground Excavations in Rock. The Institution of Mining and Metallurgy; CRC Press: London, 1980. [Google Scholar]

- Tao S.; Wang Y. B.; Tang D. Z.; Xu H.; Lv Y. M.; He W.; Li Y. Dynamic variation effects of coal permeability during the coalbed methane development process in the Qinshui Basin, China. Int. J. Coal Geol. 2012, 93, 16–22. 10.1016/j.coal.2012.01.006. [DOI] [Google Scholar]

- Tao S.; Pan Z. J.; Chen S. D.; Tang S. L. Coal seam porosity and fracture heterogeneity of marcolithotypes in the Fanzhuang Block, southern Qinshui Basin, China. J. Nat. Gas Sci. Eng. 2019, 66, 148–158. 10.1016/j.jngse.2019.03.030. [DOI] [Google Scholar]

- Chen S.; Tang D.; Tao S.; Xu H.; Li S.; Zhao J.; Ren P.; Fu H. In-situ stress measurements and stress distribution characteristics of coal reservoirs in major coalfields in China: Implication for coalbed methane (CBM) development. Int. J. Coal Geol. 2017, 182, 66–84. 10.1016/j.coal.2017.09.009. [DOI] [Google Scholar]

- Anderson E. M.The Dynamics of Faulting and Dyke Formation with Application to Britain, 2nd ed.; Oliver & Boyd.: Edinburgh, 1951. [Google Scholar]

- Bell J. S.; Bachu S. In situ stress magnitude and orientation estimates for Cretaceous coal-bearing strata beneath the plains area of central and southern Alberta. Bull. Can. Petrol. Geol. 2003, 51, 1. 10.2113/gscpgbull.51.1.1. [DOI] [Google Scholar]

- Tao S.; Tang D. Z.; Xu H.; Gao L. J.; Fang Y. Factors controlling high-yield coalbed methane vertical wells in the Fanzhuang Block, southern Qinshui Basin. Int. J. Coal Geol. 2014, 134–135, 38–45. 10.1016/j.coal.2014.10.002. [DOI] [Google Scholar]

- Rajabi M.; Tingay M.; Heidbach O. The present-day stress field of New South Wales, Australia. Aust. J. Earth Sci. 2016, 63, 1–21. 10.1080/08120099.2016.1135821. [DOI] [Google Scholar]

- Tao S.; Pan Z. J.; Tang S. L.; Chen S. D. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019b, 202, 95–108. 10.1016/j.coal.2018.11.020. [DOI] [Google Scholar]

- Han J.; Zhang H.; Liang B.; Rong H.; Lan T.; Liu Y.; Ren T. Influence of Large Syncline on In Situ Stress Field: A Case Study of the Kaiping Coalfield, China. Rock Mech. Rock Eng. 2016, 49, 4423–4440. 10.1007/s00603-016-1039-4. [DOI] [Google Scholar]

- Nasehi M. J.; Mortazavi A. Effects of in-situ stress regime and intact rock strength parameters on the hydraulic fracturing. J. Pet. Sci. Eng. 2013, 108, 211–221. 10.1016/j.petrol.2013.04.001. [DOI] [Google Scholar]

- Zhang P.; Meng Z.; Jiang S.; Chen X. Characteristics of in-situ stress distribution in Zhengzhuang Region, Southern Qinshui Basin, China and its stress path during depletion. Eng. Geol. 2020, 264, 105413. 10.1016/j.enggeo.2019.105413. [DOI] [Google Scholar]

- Meng Z. P.; Zhang J. C.; Wang R. In-situ stress, pore pressure, and stress-dependent permeability in the southern Qinshui Basin. Int. J. Rock Mech. Min. Sci. 2011, 48, 122–131. 10.1016/j.ijrmms.2010.10.003. [DOI] [Google Scholar]

- Mukherjee S.; Rajabi M.; Esterle J.; Copley J. Subsurface fractures, in-situ stress and permeability variations in the Walloon Coal Measures, eastern Surat Basin, Queensland, Australia. Int. J. Coal Geol. 2020, 222, 103449. 10.1016/j.coal.2020.103449. [DOI] [Google Scholar]

- Li Y.; Tang D. Z.; Xu H.; Yu T. X. In-situ stress distribution and its implication on coalbed methane development in Liulin area, eastern Ordos basin, China. J. Pet. Sci. Eng. 2014, 122, 488–496. 10.1016/j.petrol.2014.08.010. [DOI] [Google Scholar]

- Zhao J.; Tang D.; Xu H.; Li Y.; Li S.; Tao S.; Lin W. J.; Liu Z. X. Characteristic of in situ stress and its control on the coalbed methane reservoir permeability in the eastern margin of the Ordos basin, China. Rock Mech. Rock Eng. 2016, 49, 3307–3322. 10.1007/s00603-016-0969-1. [DOI] [Google Scholar]

- Rajabi M.; Tingay M.; King R.; Heidbach O. Present-day stress orientation in the Clarence-Moreton Basin of New South Wales, Australia: a new high density dataset reveals local stress rotations:. Basin Res. 2017, 29, 622–640. 10.1111/bre.12175. [DOI] [Google Scholar]

- Chen S.; Tang D.; Tao S.; Liu P.; Mathews J. P. Implications of the in situ stress distribution for coalbed methane zonation and hydraulic fracturing in multiple seams, western Guizhou, China. J. Pet. Sci. Eng. 2021, 204, 108755. 10.1016/j.petrol.2021.108755. [DOI] [Google Scholar]

- Ju W.; Jiang B.; Miao Q.; Wang J.; Qu Z.; Li M. Variation of in situ stress regime in coal reservoirs, eastern Yunnan region, South China: Implications for coalbed methane production:. AAPG Bull. 2018, 102, 2283–2303. 10.1306/04241817376. [DOI] [Google Scholar]

- Fisher K.; Warpinski N. R. Hydraulic-Fracture-Height Growth: Real Data:. SPE Prod. Oper. 2012, 27, 8–19. 10.2118/145949-PA. [DOI] [Google Scholar]

- Leem J.; Day R.; Latimer C.; Lakani R.; Reyna J.. Geomechanics in Optimal Multi-Stage Hydraulic Fracturing Design for Resource Shale and Tight Reservoirs. EAGE Workshop on Geomechanics in the Oil and Gas Industry; European Association of Geoscientists & Engineers, 2014.

- Kang H.; Zhang X.; Si L.; Wu Y.; Gao F. In-situ stress measurements and stress distribution characteristics in underground coal mines in China. Eng. Geol. 2010, 116, 333–345. 10.1016/j.enggeo.2010.09.015. [DOI] [Google Scholar]

- Heidbach O.; Rajabi M.; Reiter K.; Ziegler M. WSM-Team World Stress Map Database Release 2016. GFZ. Data Serv. 2016, 10, 1. 10.5880/WSM.2016.001. [DOI] [Google Scholar]

- Su X.; Lin X.; Zhao M.; Song Y.; Liu S. The upper Paleozoic coalbed methane system in the Qinshui basin, China. AAPG Bull. 2005, 89, 81–100. 10.1306/07300403125. [DOI] [Google Scholar]

- Lv Y.; Tang D.; Xu H.; Luo H. Production characteristics and the key factors in high-rank coalbed methane fields: A case study on the Fanzhuang Block, Southern Qinshui Basin, China. Int. J. Coal Geol. 2012, 96–97, 93–108. 10.1016/j.coal.2012.03.009. [DOI] [Google Scholar]

- Li Y.; Zhang C.; Tang D.; Gan Q.; Niu X.; Wang K.; Shen R. Coal pore size distributions controlled by the coalification process: An experimental study of coals from the Junggar, Ordos and Qinshui basins in China. Fuel 2017, 206, 352–363. 10.1016/j.fuel.2017.06.028. [DOI] [Google Scholar]

- Wang Y.; Liu D.; Cai Y.; Yao Y.; Pan Z. Constraining coalbed methane reservoir petrophysical and mechanical properties through a new coal structure index in the southern Qinshui Basin, northern China: Implications for hydraulic fracturing. AAPG Bull. 2020, 104, 1817–1842. 10.1306/02282018110. [DOI] [Google Scholar]

- Meng Z. P.; Wang Y. H.; Zhang K.; Lu Y. X.; Chen J.; Yao M. Analysis of hydraulic fracturing cracks for coal reservoirs and in - situ stress direction in Southern Qinshui Basin (in Chinese with English abstract). Coal Sci. Technol. 2019, 47, 216–222. [Google Scholar]

- Haimson B. C.; Cornet F. H. ISRM suggested methods for rock stress estimation-part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int. J. Rock Mech. Min. Sci. 2003, 40, 1011–1020. 10.1016/j.ijrmms.2003.08.002. [DOI] [Google Scholar]

- Bredehoeft J.; Wolff R.; Keys W.; Shuter E. Hydraulic fracturing to determine the regional in situ stress field, Piceance Basin, Colorado. Geol. Soc. Am. Bull. 1976, 87, 250–258. . [DOI] [Google Scholar]

- Pan Z.; Connell L. D. Modelling permeability for coal reservoirs: a review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. 10.1016/j.coal.2011.12.009. [DOI] [Google Scholar]

- Gao Q.; Liu J.; Huang Y.; Li W.; Shi R.; Leong Y. K.; Elsworth D. A critical review of coal permeability models. Fuel 2022, 326, 125124. 10.1016/j.fuel.2022.125124. [DOI] [Google Scholar]

- Lin Y.; Qin Y.; Duan Z.; Ma D.; Chen L. In-situ stress and permeability causality model of a low-rank coalbed methane reservoir in southwestern Ordos Basin, China. Pet. Sci. Technol. 2021, 39, 196–215. 10.1080/10916466.2021.1898422. [DOI] [Google Scholar]

- Xue Y.; Ranjith P. G.; Gao F.; Zhang Z.; Wang S. Experimental investigations on effects of gas pressure on mechanical behaviors and failure characteristic of coals. J. Rock Mech. Geotech. Eng. 2023, 15, 412–428. 10.1016/j.jrmge.2022.05.013. [DOI] [Google Scholar]

- Li Y.; Yang J.; Pan Z.; Tong W. Nanoscale pore structure and mechanical property analysis of coal: An insight combining AFM and SEM images. Fuel 2020, 260, 116352. 10.1016/j.fuel.2019.116352. [DOI] [Google Scholar]

- Yao H.; Chen Z.; He X.; Wang Y.; Jiang Y. ″Effective support″ concept and innovative practice of deep CBM in South Yanchuan Gas Field of the Ordos Basin. Nat. Gas. Ind. 2022, 42, 97–106. [Google Scholar]; (In Chinese with English abstract)

- Yan X.; Xu F.; Nie Z.; Kang Y. Microstructure characteristics of Daji area in east Ordos Basin and its control over the high yield dessert of CBM. J. China Coal Soc. 2021, 46, 2426–2439. [Google Scholar]; (In Chinese with English abstract)

- Liu J.; Xue Y.; Fu Y.; Yao K.; Liu J. Numerical investigation on microwave-thermal recovery of shale gas based on a fully coupled electromagnetic, heat transfer, and multiphase flow model. Energy 2023, 263, 126090. 10.1016/j.energy.2022.126090. [DOI] [Google Scholar]

- Xu F.; Yan X.; Li S.; Xiong X.; Wang Y.; Zhang L.; Liu C.; Han J.; Feng Y.; Zhen H.; Yang Y.; Wang C.; Li Y. Difficulties and countermeasures in theory and technology of deep CBM exploration and development in the eastern edge of Ordos Basin. Coal Geol. Explor. 2023, 51, 115–130. [Google Scholar]; (In Chinese with English abstract)