Abstract

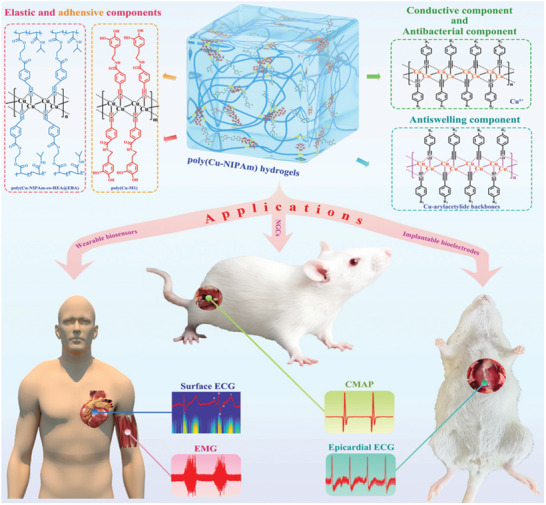

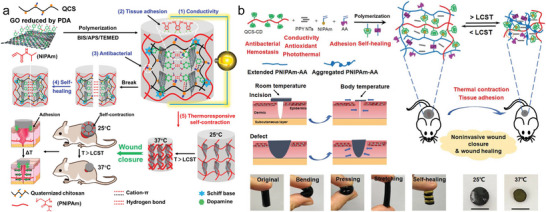

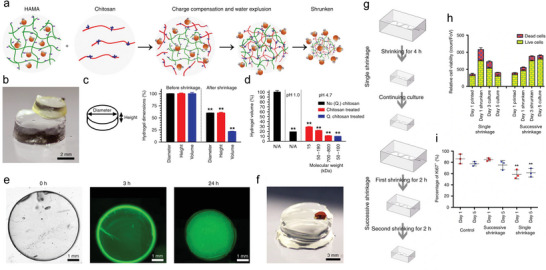

Hydrogels with tailor‐made swelling‐shrinkable properties have aroused considerable interest in numerous biomedical domains. For example, as swelling is a key issue for blood and wound extrudates absorption, the transference of nutrients and metabolites, as well as drug diffusion and release, hydrogels with high swelling capacity have been widely applicated in full‐thickness skin wound healing and tissue regeneration, and drug delivery. Nevertheless, in the fields of tissue adhesives and internal soft‐tissue wound healing, and bioelectronics, non‐swelling hydrogels play very important functions owing to their stable macroscopic dimension and physical performance in physiological environment. Moreover, the negative swelling behavior (i.e., shrinkage) of hydrogels can be exploited to drive noninvasive wound closure, and achieve resolution enhancement of hydrogel scaffolds. In addition, it can help push out the entrapped drugs, thus promote drug release. However, there still has not been a general review of the constructions and biomedical applications of hydrogels from the viewpoint of swelling‐shrinkable properties. Therefore, this review summarizes the tactics employed so far in tailoring the swelling‐shrinkable properties of hydrogels and their biomedical applications. And a relatively comprehensive understanding of the current progress and future challenge of the hydrogels with different swelling‐shrinkable features is provided for potential clinical translations.

Keywords: biomedical applications, high‐swelling hydrogels, hydrogels, non‐swelling hydrogels, shrinkable hydrogels

The current progress of high‐swelling hydrogels, non‐swelling hydrogels, and shrinkable hydrogels are summarized. These hydrogels are systematically introduced on the basis of the tactics employed so far in tailoring the swelling behavior of hydrogels and their practicable biomedical areas. Future challenges for clinical uses of these hydrogels are discussed as well.

1. Introduction

Hydrogels have been the subject of extensive research in a multifaceted range of biomedical fields. They are 3D cross‐linked materials that are capable of retaining a significant fraction of water.[ 1 ] The large water content and porous structure endow the hydrogels a degree of softness resemble natural living tissues,[ 2 ] and permeability to various chemical and biological molecules.[ 3 ] What's more, they are highly biocompatible,[ 4 ] which will not impair the function of biomolecules and cells being encapsulated within or in direct contact with the hydrogel.[ 5 ]

But beyond that, an important characteristic of hydrogels, is their swelling properties in aqueous environments. Basically, the swelling behaviors of hydrogels are determined by the pore size on the hydrogel surface, the intermolecular spaces inside hydrogel network structures, and the hydrophilic and hydrophobic performance of the hydrogel.[ 6 ] Under the comprehensive effect of these factors, hydrogels may exhibit different swelling behaviors in water. For example, hydrogels with large pores and a great deal of hydrophilic functional groups will swell to a great extent and imbibe water many times their own weights.[ 7 ] In contrast, hydrogels with high crosslinking density and/or hydrophobicity will barely swell in liquid, that is, own non‐swelling nature.[ 8 ] Besides, some stimuli‐responsive hydrogels can reversibly shrink with changes in external conditions, for example, temperature,[ 9 ] and pH.[ 10 ] The three types hydrogels can be respectively defined as high‐swelling hydrogels, non‐swelling hydrogels, and shrinkable hydrogels.

Of course, hydrogels with different swelling behaviors will have distinct physical properties, and therefore they are applicable to different biomedical scenarios. For example, high‐swelling hydrogels have mainly gained popularity in full‐thickness skin wound healing and tissue regeneration, and drug delivery over years due to that swelling ability is beneficial for absorbing blood and body fluid, transferring nutrients and metabolites, as well as diffusing and releasing drugs. Nevertheless, swelling in physiological conditions will inevitably cause obvious macroscopic deformation, and dramatically deteriorate the physical performance of the hydrogels, such as mechanical strength, tissue adhesion, and conductivity. Thus, non‐swelling hydrogels have served their functions extremely well in filling and repairing the vacant spaces of some internal vulnerable organs or tissues, use as bioadhesive sealants in surgical operations, bioelectronic devices, and so forth. Moreover, the volume shrinkage of hydrogels can actively drive noninvasive wound closure through exerting a centripetal force and enhance wound healing, and help achieve resolution enhancement of hydrogel‐based scaffolds for tissue regeneration. Besides, the shrinkage behavior can also be employed to accelerate drug release by squeezing out the entrapped biomolecules.

Nevertheless, to our knowledge, there still has been no literatures comprehensively summarizing the hydrogels from the perspective of swelling properties and their biomedical applications. Thus, it prompts us to give an overview on the hydrogels with different swelling features. The degree of swelling/deswelling of the as‐prepared hydrogels is often quantitatively indicated by swelling ratio (SR), which includes the weight swelling ratio and the volume swelling ratio.[ 11 ] Due to that the SRs of high‐swelling, non‐swelling and shrinkable hydrogels are not well‐defined in previous literatures, this review provides practical guides for high‐swelling hydrogels with an equilibrium SR of more than 150%, non‐swelling hydrogels in the range of 0–150% and shrinkable hydrogels < 0% based on the relevant publications in the past five years (Table 1 ). Current limitations and challenges of these hydrogels for clinical use are discussed as well. Therefore, we are fully confident that this review will gain readers greater insight into customizing the swelling properties of hydrogels for biomedical applications, and provide a clue to drive further development.

Table 1.

Brief summary of hydrogels with various swelling features

| Hydrogel types | Swelling ratios | Merits | Demerits | Fabrications | Biomedical applications | Refs. |

|---|---|---|---|---|---|---|

| High‐swelling hydrogels | >150% |

High wound exudates absorption capacity, high cell recruitment and migration, high drug entrapment, diffusion and release |

Macroscopic volume expansion, poor mechanical stability, weakened bioadhesion and conductivity, risk of tissue compression damage |

Chemical modification, hydrophilic polymer self‐crosslinking, adding small molecule cross‐linkers |

Tissue engineering, drug delivery |

[12] |

| Non‐swelling hydrogels | 0–150% |

Excellent dimensional stability, long‐term wet‐adhesion performance, persistent mechanical strength and conductivity |

Low drug loading and release efficiency, cannot exchange nutrients and bioactive molecules, low cell attachment, complex cross‐linked network design process |

Functional polymer self‐crosslinking, synthesizing amphiphilic copolymer, polymer self‐assembling, adding small molecule cross‐linkers, solvent exchange, surface hydrophobic grafting |

Tissue engineering, bioelectronics |

[13] |

| Shrinkable hydrogels | <0% |

Stimuli‐responsive, mechanically active, dynamic stiffening and contraction, promoted cell attachment and condensation, remotely controlled drug release |

Risk of tissue tension damage, complicated molecular structure regulation process |

Synthesizing stimuli‐responsive copolymer, introducing a second polymer, adding small molecule cross‐linkers |

Tissue engineering, drug delivery |

[14] |

2. High‐Swelling Hydrogels

High‐swelling hydrogels (HSHs) will swell rapidly when in contact with aqueous solutions. It can absorb and hold massive aqueous fluids within their 3D porous structure without dissolution.[ 15 ] This is primarily stemming from the low hydrogel network crosslink density and great quantities of hydrophilic groups (e.g., amino, hydroxyl, and carboxyl) on the macromolecular skeletons.[ 1 , 2 , 16 ] The swelling capacity is a very significant property for advanced biomedical settings such as tissue engineering, drug delivery and controlled release. Judging from the scientific achievements so far, HSHs can be constructed based on natural polymers, synthetic polymers or mixtures of both. Their properties and biomedical applications will be introduced in this part (Table 2 ).

Table 2.

Brief summary of the constructions, properties, and biomedical applications of HSHs

| Constructions | Hydrogel systems | Maximum SRs | Properties | Biomedical applications | Ref. |

|---|---|---|---|---|---|

| Based on natural polymers | CMCS, BTA, di‐amino Jeffamine | 7560% |

pH‐sensitive swelling, self‐healing, antibacterial |

Not specific | [30] |

| Gentamicin‐conjugated alginate | 4962% | Adhesive, antibacterial | Not involved | [40] | |

| Oxidized HPC, CS | 3570% | Self‐healing, injectable | Not specific | [12a] | |

| HA, chondroitin sulfate | 1200% | Self‐healing, injectable, noncytotoxic | Bioprinting | [59] | |

| HA‐DA, rGO@PDA | 300% | Injectable, self‐healing, photothermal, adhesive, conductive, hemostatic, antioxidant, antibacterial, sustained drug release | Wound healing | [12d] | |

| Gelatin, HP‐β‐CD, BMSC | 198% | Injectable, biocompatible, biodegradable, osteogenic, angiogenic | Bone regeneration | [12e] | |

| l‐glutamic acid‐g‐CS, DOX | 426% | pH‐responsive swelling, biocompatible, biodegradable, sustained drug release | Anti‐cancer drug delivery | [125] | |

| SA, gum tragacanth, phenolic compounds | 300% | pH‐responsive swelling, biodegradable, sustained release | Intestine‐targeted drug delivery | [131] | |

| Based on synthetic polymers | PAM, MPTAC, MBA | 25 000% | Transparent, robust, elastic | Not involved | [12b] |

| Carbopol934‐g‐PAA, EGDMA, diclofenac sodium | 800% |

pH‐responsive swelling, pH‐dependent drug release |

pH‐dependent drug delivery | [133] | |

| Blending natural and synthetic polymers | PAM, CS, SA | 1258% | Long‐term mechanical stability and gastric retention, biocompatibility, biodegradable | Long‐term drug delivery | [12c] |

| QCS, Matrigel, PAM | 1200% | Stretchable, adhesive, biocompatible, antibacterial, hemostatic | Wound healing | [86] | |

| Alginate‐Nb, PEG‐Tz, DOX | 2600% | Injectability, reduction‐responsive, biocompatible, remarkable drug loading efficiency, antitumor | Reduction‐responsive drug release | [138] |

2.1. Based on Natural Polymers

HSHs made from hydrophilic natural biopolymers (e.g., polysaccharides and proteins) have many advantages, such as high water absorption capacity, biocompatibility, biodegradability, biological activity, and low cost.[ 17 ] Besides, the presence of abundant reactive functional groups on the backbones of biopolymers can provide multifarious highly selective coupling points,[ 18 ] facilitating the formation of HSHs. These fantastic features endow them immense superiority in biological areas. Amid a magnitude of biopolymers, chitosan, alginate, cellulose, starch, hyaluronic acid, etc., have been frequently utilized.

2.1.1. Chitosan

Chitosan (CS), isolated from shells of marine crustaceans, etc.,[ 19 ] is considered as one of the most important and abundant natural polymers on Earth. It is also the only linear alkalescent polysaccharide, which is constituted by irregularly arranged β‐(1,4)‐linked 2‐amino‐2‐deoxy‐d‐glucopyranose and β‐(1,4)‐linked 2‐acetamido‐2‐deoxy‐d‐glucopyranose units.[ 20 ] The protonation of lateral amino groups under acid environment empowers CS to adhere to the negatively charged cytoderm of bacteria, causing membrane permeabilization and intracellular fluids release.[ 21 ] Hence, CS have good antimicrobial activities against a board spectrum of microorganisms such as bacteria, fungi, and even some viruses.[ 22 ] Beyond that, CS also exhibits good anti‐inflammatory,[ 23 ] and hemostatic properties by promoting erythrocyte aggregation and platelet adhesion for blood clots formation.[ 24 ] Nonetheless, the poor solubility and mechanical property of CS bring inconvenience to its practical applications.[ 25 ] Many scientists have overcome the defects through chemical modification, or introducing nanoparticles.[ 26 ] After amendment, the CS can be crosslinked via covalent bonds, supramolecular interactions, or a combination of both to build a hydrogel network structure with more hydrophilicity, higher swelling capacity, and mechanical stability.[ 27 ] Therefore, CS has attracted much attention in developing HSHs with multiple biological properties.

In recent years, an indispensable strategy for preparing CS‐based HSHs is covalent crosslinking of CS or its derivatives with other biopolymers by virtue of Schiff base reaction. Schiff base is a dynamic imine linkage formed between amine and carbonyl groups, which can reversibly break and recombine.[ 28 ] Hence, Schiff base based‐hydrogels own excellent viscoelasticity,[ 29 ] and self‐healing ability.[ 30 ] On these grounds, Maroufi et al. developed antibacterial CS‐based HSHs via the formation of Schiff base between modified dialdehyde guar gum and CS.[ 31 ] Yu et al. reported a green strategy exploiting imine linkages for developing dynamic HSHs likewise. Differently, a water‐soluble CS derivative, carboxymethyl CS (CMCS), was crosslinked with benzene‐1, 3, 5‐tricarbaldehyde, whose hydrophilicity was improved by reacting with di‐amino Jeffamine. The amino and carboxyl groups along CMCS chains endowed the hydrogels strongly pH‐sensitive swelling behaviors. As a result, maximal SR was observed at pH 8, reaching 7560%. And the combination of positive‐charged amino groups and active Schiff bases containing aromatic ring was proved to impart the hydrogels brilliant antibacterial activity against E. coli.[ 30 ] At an advantage, these preparation methods avoided potentially toxic small‐molecule crosslinkers.

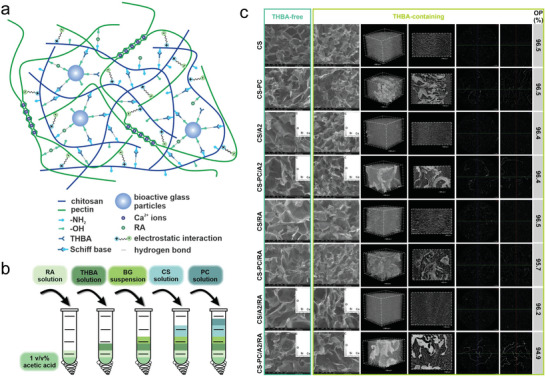

In addition, the electrostatic interaction between the positively charged CS and anionic compound, has been used to construct CS‐based HSHs as well. For instance, the electrostatic contacts between CS and poly(γ‐glutamic acid)(γ‐PGA) yielded a porous hydrogel with a high swelling capacity of 1398%.[ 6b ] Situ's group developed different ionically crosslinked CS hydrogels by using different anionic crosslinkers, that is, sodium hexametaphosphate and sodium tripolyphosphate. In comparison, hydrogels crosslinked by sodium tripolyphosphate had better swellability and biocompatibility.[ 32 ] Particularly interesting is that CS‐based hydrogels were first crosslinked with 2, 3, 4‐trihydroxybenzaldehyde (THBA), and modified with pectin (PC), bioactive glass (BG), and rosmarinic acid (RA) (Figure 1a), leading to enhanced mechanical strength, high swelling ability and delayed degradation. Benefiting from the adding order (Figure 1b), the CS‐PC/BG/RA hydrogels were relieved of BG agglomeration observed in PC/BG hydrogels (Figure 1c). And the synergetic advantages of the incorporated bioactive substances imparted the prepared hydrogels high antioxidant activity, anticancer activities, and ability to mineralize in simulated body fluid.[ 33 ]

Figure 1.

Synthesis and characterization of HSHs based on natural polymer. a) Illustration of the CS‐PC/BG/RA hydrogel network. b) Scheme of the adding order of the ingredients. c) SEM images and EDX spectra of the THBA‐free and THBA‐containing hydrogels. Representative µCT analyses of 3D reconstructions, cross sections, and open porosity (OP) of the THBA‐containing hydrogels. Adapted with permission.[ 33 ] Copyright 2022, The Authors. Published by Elsevier.

2.1.2. Alginate

Alginate is a linear anionic polysaccharide primarily extracted from brown algae.[ 34 ] It is a copolymer of α−1,4‐l‐guluronic acid (G) and β−1,4‐d‐mannuronic acid (M) units in either repeating or alternating sequence, linked by β−1,4‐glycosidic bonds.[ 35 ] In various studies, alginates have been demonstrated to lower proinflammatory cytokines concentration and inhibit free radical formation,[ 36 ] activate macrophages,[ 37 ] increase collagen I deposition, and promote re‐epithelization.[ 38 ] Therefore, this biocompatible biopolymer is highly attractive for clinical applications. And alginate hydrogel formation usually occurs through the ionic association between G units and divalent cations, such as Ca2+.[ 39 ]

Alginate hydrogels have long driven the research and development of HSHs based on natural polymers. For example, microbicidal alginate hydrogels achieved through reacting with antibiotic gentamicin sulfate mediated by carbodiimide chemistry, disclosed excellent SR (4962%) and antibacterial effect against S. aureus. and E. coli.[ 40 ] In another study, sodium alginate (SA) hydrogel matrix was imparted with anticancer and tissue regeneration activities through functionalized with graphene oxide (GO). The resulted multifunctional hydrogels could swell and release silver sulfadiazine under different pH media.[ 41 ] Anitua et al. reported three kinds of hydrogel bioinks with high swellability through combining alginate and gelatin (GA), enriching either hydroxyapatite (GAHA) or hydroxyapatite and Plasma Rich in Growth Factor (GAHAP). The hydroxyapatite‐contained GAHA and GAHAP hydrogels showed higher mechanical strength, proliferative rate, and osteogenic differentiation, while Plasma Rich in Growth Factor significantly enhanced cell adhesion and chemotaxis.[ 42 ]

2.1.3. Cellulose

Another natural polymer extensively explored for developing HSHs is cellulose. Predominantly constituted by β‐d‐glucose units linked through 1,4‐β‐glycosidic bonds, cellulose is ranked as the most profuse and nearly inexhaustible polysaccharide in natural sources.[ 43 ] Thus, it has many merits including but not limited to low price, biocompatibility and biodegradability.[ 44 ] The abundant hydrophilic hydroxyl groups on cellulose chains create many opportunities for designing cellulose‐based hydrogels by chemical bonds and electrostatic adsorption.[ 45 ] Nevertheless, in virtue of the strong intra‐ and inter‐molecular hydrogen bonds deriving from the absence of side chains, cellulose chains feature many ordered structures (i.e., crystalline regions).[ 46 ] This characteristic make cellulose hydrogels can hardly swell in water.[ 47 ] Chemical treatment by grafting or functionalization of the cellulose surface is an attractive measure to damage the hierarchical structure,[ 48 ] and increase the number of hydrophilic groups exposed to water molecules,[ 49 ] thereby overcome the limitation and develop new desired characteristics. As a result, cellulose derivatives, mainly including carboxymethyl cellulose (CMC) and hydroxypropyl cellulose (HPC), have more attractive in HSHs scenes compared to cellulose.

To this end, Edgar's group designed and prepared a family of oxidized HPC/CS hydrogels,[ 12a ] oxidized HPC/Jeffamine hydrogels,[ 50 ] which were crosslinked by Schiff base. Both type hydrogels exhibited high SRs, tunable mechanical modulus, and rapid self‐healing ability. Thanks to the Jeffamine crosslinker, the oxidized HPC/Jeffamine hydrogels further displayed thermal responsivity. Peighambardoust's team and Huang's team grafted hydrophilic copolymers onto CMC and acquired hydrogels with enhanced equilibrium swelling. Concretely, the former type CMC hydrogels were synthesized by grafting copolymerization of acrylic acid (AA) and itaconic acid along the CMC backbone,[ 51 ] while the latter were grafted with copolymers of AA and acrylamide (AM).[ 52 ] Interestingly, the presence of carbon black nanoparticles could further enhance the swelling performance of the hydrogels, while GO could enhance the thermal stability.

2.1.4. Starch

Amongst various types of biopolymers, starch is the main carbohydrate in maintaining human nutrition and health. It has the advantages of wide source, renewability, good biosecurity, and biodegradability.[ 53 ] Starch is comprised of two glucose polymers: lightly branched amylose and highly branched amylopectin, which are linked by α−1, 4 and α−1, 6‐glycoside bonds.[ 54 ] Similar to cellulose, the strong hydrogen bonding between the thousands of hydroxyl groups on starch chains leads to a rigid semi‐crystalline network, causing poor solubility and mechanical property.[ 55 ] By introducing new groups on its chains, starch can be a very prospective biopolymer used in developing HSHs.

By means of acid‐base synergistic pretreatments, Chen and coworkers synthesized hydroxybutyl starch with the highest degree of substitution (DS). After copolymerization with N‐isopropylacrylamide (NIPAm), the hydroxybutyl starch yielded a series of temperature‐sensitive hydrogels with increased water absorption rate and equilibrium SR.[ 56 ] Based on oxidized starch, Namazi's team prepared smart hydrogels with pH‐responsive swelling behaviors. The highest swelling was observed at pH 7 owing to the electrostatic repulsive forces between the carboxylate anions of oxidized starch. And the SR would decrease with the increase of salt concentration and valence of the cations. Furthermore, through introducing Zinc oxide nanoparticles (ZnO NPs), the hydrogels showed excellent antibacterial activities against S. aureus and E. coli.[ 57 ] Another study developed a superabsorbent starch‐graft‐polyacrylic acid (PAA) hydrogel using cellulose nanofibers (CNF) as reinforcing material. After adding 5 wt% CNF, the SRs in NaCl, CaCl2, and AlCl3 solutions respectively showed an increment from 109 to 193, 62 to 110, and 56 to 99 (g water/g hydrogel), which was due to the reduced entanglement of polymer chains and interactions between the hydrophilic groups. Compressive strength and Young's modulus achieved 63.3 and 31.6 kPa, respectively corresponded to 1.69 and 2.40 times of unreinforced samples. Also, the surface of CNF reinforced hydrogel could better facilitate the proliferation of live cells.[ 58 ]

2.1.5. Other Biopolymers

Also, there are some studies of HSHs based on other natural polymer materials, such as hyaluronic acid (HA) and gelatin. In the work of Mihajlovic et al., the combination of highly charged and hydrophilic chondroitin sulfate and HA yielded a viscoelastic double network (DN) hydrogel with significant swelling capacity (maximum SR ranging from 6 to 12). Integrating the short lifetime of dynamic hydrazone cross‐links and long‐lasting Diels‐Alder cross‐links, the formulated DN hydrogels simultaneously possessed easy processability and self‐healing features, and long‐term structural integrity. Moreover, they were noncytotoxic to mesenchymal stromal cells, and its degradation products would not affect the macrophages.[ 59 ] Another previous research has synthesized gelatin‐based hydrogels which exhibited mechanical properties similar to soft human tissue (G’ = 1–100 kPa) and high swelling capabilities (1000–3000 vol%), via thiol‐ene Michael‐addition between methacrylated gelatin and oligo(ethylene glycol) dithiols.[ 60 ]

2.2. Based on Synthetic Polymers

Synthetic polymer hydrogels outperform natural polymer hydrogels in many aspects, especially for their better mechanical properties because most of them were crosslinked by strong covalent bonds.[ 61 ] Their physicochemical properties can be much easier customized by adjusting chemical compositions, molecular weights, and block structures, in order to meet numerous specific requirements.[ 35 , 62 ] Typically, synthetic HSHs are polyelectrolyte hydrogels which have high osmotic pressure originated from plentiful dissociated counterions, and strong electrostatic repulsion between the ionized groups of polymer chains. And they are synthesized via free radical polymerization approach under an inert atmosphere.

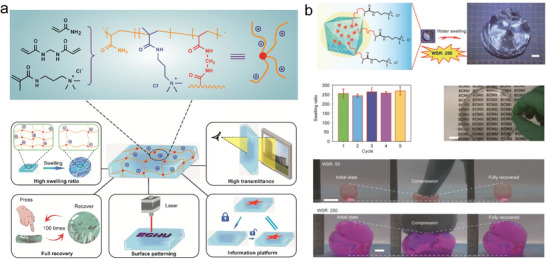

On this basis, Sorkhabi et al. constructed macroporous SiO2/PAA hydrogel with high SR (ranging from 500 to 4000) by in situ solution polymerization.[ 63 ] Thakur et al. synthesized a itaconic acid grafted poly(acrylic acid‐co‐aniline) hydrogel with a high swelling percentage of 1755.3%.[ 64 ] Cėpla et al. developed tens of nanometer‐thick hydrogel coatings containing methyl methacrylic acid, 2‐hydroxyethyl methacrylate (HEMA), and polyethylene glycol methacrylate (PEG10MA) monomers. Together with the SRs up to 3.2, the good stability and inhibition to nonspecific protein binding imparted the hydrogel great potential in mimicking extracellular matrix (ECM).[ 65 ] Ayres's group prepared polyurethane‐based hydrogels with high SRs (300–2500%) owing to the hydrophilicity of lactose units. And the swelling degree and mechanical properties of the resulting hydrogels could be controlled by the chain length of polyethylene glycol (PEG).[ 66 ] In another research, decomposable superabsorbent hydrogels were synthesized by modifying poly(allylamine hydrochloride) with a recombinant protein owning a specific thrombin recognition site. Although the recombinant protein was not a superabsorbent material like poly(allylamine hydrochloride), the hydrogel with 15% protein still maintained a high SR to 900%. And the degradability of the polyelectrolyte hydrogel was realized by adding specific enzyme thrombin at indicated time point.[ 67 ] Particularly interesting was the work of Xu et al., in which a cationic monomer was copolymerized into polyacrylamide (PAM) networks (Figure 2a). Advantageously, the hydrogel exhibited high SR and transmittance, as well as robust and elastic mechanical property, which enabled the camouflage of complex information on hydrogel surface by swelling, and decryption under white light (Figure 2a,b).[ 12b ]

Figure 2.

Synthesis and characterization of HSHs based on synthetic polymer. a,b) Representation of the synthetic polymer‐based cationic hydrogel with high water swelling ratio (WSR) and light transmittance after swollen, excellent mechanical property, surface patterning, and information camouflage and decryption. Scale bar: 1 cm. Adapted with permission.[ 12b ] Copyright 2022, American Chemical Society.

Nevertheless, chemically cross‐linked synthetic polyelectrolyte hydrogels are often subjected to high brittleness,[ 68 ] thus restricting their widespread applications. To acquire considerable toughness, designing physically cross‐linked synthetic polyelectrolyte hydrogels or introducing a second physical network have been identified as preferable choices. On this ground, a series of hydrophobic associated poly(acrylic acid‐acrylamide‐lauryl methacrylate) [poly(AA‐AM‐LMA)] hydrogels were developed. On one hand, the macroporous network brought the hydrogels high water absorption capacity, which could imbibe water up to 1000 g g−1 without dissolution. On the other hand, the multiple physical interactions inside the hydrogel endowed it high stretchability of 1500–3000%, tensile strength of 50–150 kPa, and toughness up to 2.4 MJ m−3.[ 69 ] In contrast, Dixit and Bag introduced a reversibly crosslinked polyvinyl alcohol (PVA)‐Borax network into permanently crosslinked poly(NIPAm‐co‐AM) network with temperature‐sensitivity and high swellability. Finally, the DN hydrogels indicated excellent maximum compressive stress of 5.75 MPa and fracture energy of 36.72 MJ m−3, and high stretchability up to 944% and tensile strength up to 0.473 MPa. And they also displayed desirable resilience, which could maintain their original shapes after many mechanical cycles.[ 70 ]

2.3. Based on Natural and Synthetic Polymers

The blend of biopolymers and synthetic polymers can result in a hybrid network integrating the intrinsic features of both kind polymers. Thus, the hybrid hydrogels will overcome the drawbacks of the individual components (e.g., poor mechanical stability of biopolymers, low biodegradability, and lack of biological activities of synthetic polymers). The superb comprehensive properties are beneficial for applying the hydrogels in biomedical sciences. Meanwhile, the synergistic cumulative effects of hydrophilicity can ease the realization of high swelling capacity. Therefore, there is a trend of developing HSHs through blending natural and synthetic polymers.

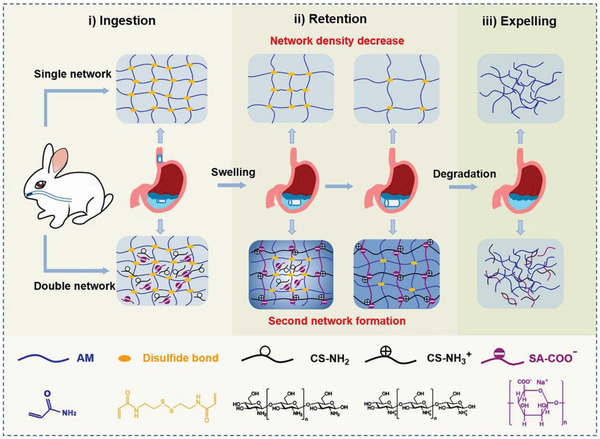

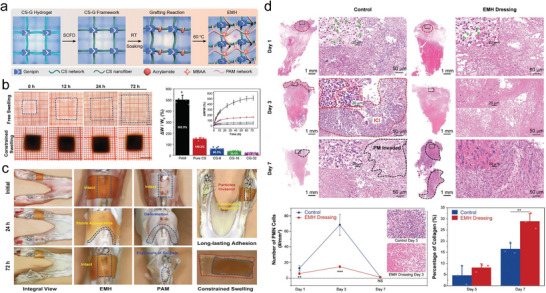

The first related work comes from Popescu et al., which produced degradable alginate/poloxamer hydrogels via thiol‐acrylate photopolymerization between alginate equipped with thiol groups and acrylate‐modified poloxamer. The as‐prepared hydrogels had high swelling capacity (SR ranging between 6 and 13) in simulated physiological conditions. In vitro biological assays have confirmed that the hybrid hydrogels could facilitate human keratinocyte proliferation, and had an anti‐inflammatory effect on lipopolysaccharides‐activated keratinocytes.[ 71 ] Particularly noteworthy is the approach for manufacturing dually cross‐linked (DC) and DN hybrid hydrogels integrating covalent and physical cross‐linking, which is superior in acquiring comprehensive mechanical properties.[ 72 ] According to this, a series of chemically physically DC CS/PVA hydrogels were obtained. The hydrogels displayed high SRs in water (up to 92) and phosphate‐buffered saline (PBS) (up to 74). Although the elastic modulus was not particularly distinguished (3–30 kPa), the hydrogels were very flexible and elastic. Notably, in situ formation of silver nanoparticles (Ag NPs) enabled the CS/PVA hydrogels remarkably inhibit the growth of S. aureus and K. pneumonia. And the cell vitality tests proved the non‐cytotoxicity of these natural and synthetic polymer‐based hydrogel systems.[ 73 ] Zhang's team prepared DN hybrid hydrogel with SR reaching 1258.1%. Interestingly, the formulated DN hydrogel could reside in stomach by the dramatic swelling of the first PAM network, and keep mechanical strength through gradually forming the second CS/SA network under the action of gastric fluid. After retention, the hydrogel can be biologically degraded and expelled from the body (Figure 3 ).[ 12c ]

Figure 3.

Synthesis of HSHs based on natural and synthetic polymer. The double network hybrid hydrogel can be ingested orally. Adapted with permission.[ 12c ] Copyright 2022, Elsevier Ltd.

2.4. Biomedical Applications

2.4.1. Tissue Engineering and Regenerative Medicine

Wound Healing

Wound healing involves four integrated and overlapping phases: hemostasis, inflammation, proliferation, and remodeling/maturation.[ 74 ] To deter impaired healing of the wound, these phases must progress in order with sufficient time.[ 75 ] HSHs have many superiorities in speeding up the four phases. First, benefiting from their high swelling rate and water absorption ability, HSHs can quickly absorb the blood and extrudates of the wounds.[ 76 ] Second, it can serve as physical barrier against external microorganisms, thereby reducing inflammation.[ 77 ] Besides, the interconnected porous network of HSHs provides benefits in transmitting oxygen, exchanging nutrients, and bioactive molecules, and recruiting stem cells for fast wound repair and regeneration.[ 78 ] And they can also maintain a comparable moist microenvironment on the wound bed,[ 71 ] which promotes epidermal migration and tissue regeneration with less scarring.[ 78 ] So, HSHs have a broad prospect in wound healing.

From the viewpoint of clinical practice, injectability is a crucial property as it facilitates administration with minimal invasion and adaptability to the complex contour of target sites.[ 79 ] Hence, based on a dynamic sliding physical crosslinking mechanism, Zhu et al. prepared injectable self‐healing γ‐PGA‐Lysine hydrogels with a SR of 2750% in PBS and of nearly 10 000% in distilled water, which exhibited good capacity to accelerate wound closure and reconstruction. Through using 10% diethylene glycol as interstitial phases, the as‐prepared hydrogels demonstrated high stretchability with the maximum elongation of 2705%.[ 80 ] In order to assist the healing of chronic wounds, Dong et al. prepared an injectable γ‐PGA hydrogel loaded with superoxide dismutase, a kind of antioxidant that can minimize reactive oxygen species production. The injectability of the hydrogel was attributed to the introduction of poly(N‐isopropylacrylamide) (PNIPAm). With the phase transformation temperature of 28.2 °C, the hydrogel could be injected in vivo and in situ form a rigid hydrogel. Together with high SR (980%) and good water retention property, the superoxide dismutase‐loaded hydrogel dressings exhibited best wound closure rate in diabetic rat skin defect model.[ 81 ]

Nowadays, bacterial infection containing multi‐resistant bacterial strains infection, is one of the most critical clinical concerns after tissue trauma.[ 82 ] To earn a broad spectrum of strong antibacterial effects, scientists have explored many ingenious strategies, including chemically modifying the polymers, introducing metallic nanoparticles, carrying antibiotics, or in combination of them. Through taking full advantage of these methods, numerous outstanding antibacterial HSHs have been made for the recent years, which is highly desirable for producing a superior healing effect.

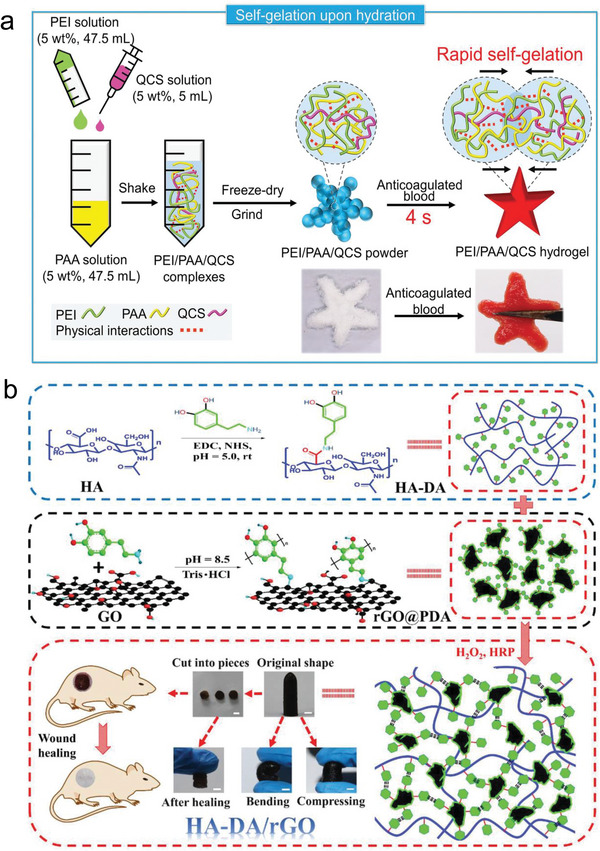

In the respects of chemical modification, introducing quaternary ammonium group into CS have been most extensively employed. It can not only enhance the inherent antimicrobial effects of CS by increasing the positive charges, but also greatly improve its water solubility.[ 83 ] In addition, quaternized chitosan (QCS) can form multi‐interactions (electrostatic interactions, hydrogen bonding, etc.) with biological tissues, which guarantees certain adhesion behavior of hydrogel.[ 84 ] The integration of antibacterial function and bioadhesiveness can ensure the injury site keep closed and combat bacterial infection.[ 85 ] So several research groups have invented antibacterial HSHs based on QCS. Xue et al. designed a high‐swelling multi‐functional QCS‐Matrigel‐PAM hydrogel with a physical‐chemical DN structure. The equilibrium SR of the hydrogel reached about 1200%. In addition, the hydrogel showed antibacterial, hemostatic, excellent stretchable, suitably adhesive, and biocompatible properties. As a result, in a full‐thickness skin defect model, it significantly enhanced wound closure, collagen deposition, and promote regeneration of skin appendages.[ 86 ] Being lyophilized or dried in advance, some hydrogel dressings with outstanding swelling ability still capable of in situ forming a hydrogel through absorbing the body fluid on the wound area. Therefore, these hydrogel dressings can be applicated in the shapes of a dry sponge, powder, and so on. The desiccation of these types wound dressings render it the capacity to swell more quickly and be preserved for a longer period of time. Specifically, in comparison with sponge, the powder can be more appliable to various wound surfaces.[ 87 ] With this background, an antibacterial polyethyleneimine (PEI)/PAA/QCS powder, was designed and prepared by Bian and coworkers (Figure 4a). After deposited on bleeding wounds, the powder could fastly transform into an adhesive hydrogel and aggregate blood cells and platelets. Thus, the PEI/PAA/QCS powder demonstrated rapid and effective hemostasis even against massive hemorrhage in non‐compressible porcine spleen and liver. Besides, it could expedite full‐thickness skin wound healing as well.[ 88 ] Overall, both the above elucidated hydrogels with synergistic effect of antibacterial, hemostatic, and adhesive properties provide inspirations for clinical use as bioactive wound dressings. But for noncompressible visceral, and high‐pressure arterial bleeding wounds, there are still many challenges remain to be addressed for simultaneously achieving rapid and effective hemostasis and subsequent wound healing process. Especially in the peculiar pathophysiological abnormalities of diabetic wound environment, the wound treatments place higher demands on the antibacterial, antioxidant, angiogenesis, bioadhesiveness, swelling rate, as well as moisture retention property of the hydrogel dressings.[ 89 ]

Figure 4.

Exploiting the high‐swelling properties for hemostasis and full‐thickness skin wound healing. a) Fabrication diagram of PEI/PAA/QCS powder and the formation of PEI/PAA/QCS hydrogel after adding anticoagulated blood. Adapted with permission.[ 88 ] Copyright 2021, Wiley‐VCH GmbH. b) Synthesis scheme and macroscopic performance of HA‐DA/rGO hydrogel applicated in wound healing. Scale bar: 5 mm. Adapted with permission.[ 12d ] Copyright 2019, Wiely‐VCH Verlag GmbH & Co. KGaA.

Adding metallic nanoparticles, especially silver,[ 90 ] or carrying antibiotics,[ 91 ] is also a superb idea for eradicating local bacterial infection and keeping a sterile wound healing environment.[ 26a ] For example, through adding sodium borohydride to generate silver nanocomposite from silver nitrate and crosslink guar gum‐grafted‐polyacrylamidoglycolic acid polymer, a variety of injectable self‐healing HSHs were prepared and exhibited enhanced bacterial inactivation properties against wound pathogens.[ 92 ] Notably, as famous antibacterial agents, the safety of Ag NPs and ZnO NPs are certificated by the Food and Drug Administration.[ 14 , 93 ] Furthermore, several research groups attempt to prepare antibacterial HSHs by delivering antibiotics. In one study, berberine was loaded into microbial transglutaminase and Ca2+ DC gelatin/SA hydrogels, which presented high SR over 9.99. The berberine‐carried hydrogels showed sustained drug release for 168 h and great antibacterial activity against S. aureus. Intriguingly, stemmed from the ethylene diamine tetraacetic acid‐induced detachment performances, the hydrogels could be painlessly detached from the wound.[ 94 ] In another, a class of micelle‐crosslinked hydrogels with high swelling capacity (4688–10 753%) and good water vapor transmission rate, were synthesized for releasing ciprofloxacin and silver sulfadiazine. Significantly, the drug‐loaded hydrogels exhibited inhibitory effect against Gram‐negative E. coli and P. aeruginosa and Gram‐positive S. aureus.[ 95 ] Notably, after encapsulating amoxicillin, a series of injectable hydrogel formed via Schiff base reaction between oxidized HA‐graft‐aniline tetramer (AT) and N‐carboxyethyl CS, revealed effective antibacterial property. The hydrogels themselves demonstrated high equilibrated SR from 23 to 36, as well as good in vitro biocompatibility and biodegradability. The existence of AT also imparted the amoxicillin‐loaded hydrogels conductivity and desirable antioxidant ability, which synergistically speeded up full‐thickness skin wound healing with thicker granulation tissue, higher collagen disposition, and more angiogenesis. The present approach provided a clue for designing promising electroactive injectable hydrogel wound dressings.[ 96 ] But should not be ignored is that the antibiotic abuse may build up bacterial resistance.[ 97 ]

Over the years, photothermal therapy has attracted particular attention in fighting against common pathogens or antibiotic‐resistant ones.[ 98 ] Therefore, it is meaningful for adding materials with photothermal activity into HSHs for wound healing. In one contribution, a suit of injectable photothermal antibacterial HSHs were developed based on hyaluronic acid‐dopamine (HA‐DA) and polydopamine‐coated‐reduced GO (rGO@PDA) (Figure 4b). The HA‐DA endowed the hydrogels with antioxidant, bioadhesive, and hemostatic capacities, while the incorporation of rGO@PDA promoted electrical conductivity and in vivo near‐infrared light (NIR) irradiation antibacterial behavior. Moreover, after loaded with doxycycline, the HA‐DA/rGO hydrogel also showed sustained drug release capacity more than 10 days, thus displayed best vascularization, granulation tissue thickness and collagen deposition in full‐thickness wound repair model.[ 12d ] The results above demonstrated that using a combined approach to promote antibacterial activity can contribute to a better therapeutic effect. But it is more suggested to utilize the methods which will not bring bacterial resistance.

All in all, the ongoing findings have clearly revealed lots of evidences on therapeutic efficacy of HSHs in speeding up full‐thickness skin wound healing. Nonetheless, the current investigations have not carried out comprehensive potential organ toxicity tests in mammals, and are limited to exploit single wound model.[ 16 ] Moreover, the latent factors (e.g., stress around the wound edges) influencing wound healing are yet to be explored.

Other Tissue Regeneration

It is widely known that hydrogels possess a close similarity to natural ECM.[ 99 ] And porous internal structure and high swelling behavior can powerfully support cell migration, the entrapment, diffusion, and release of nutrients and metabolites, thereby accelerating tissue regeneration.[ 100 ] Therefore, HSHs have been diffusely applied as tissue engineering scaffolds.[ 101 ]

However, the mechanical stability of classic HSHs is poor, which seriously impeded their actual utilization.[ 102 ] To address current bottlenecks, several groups have respectively prepared click, interpenetrating polymer network (IPN), and DN HSHs. The click hydrogel scaffold was obtained via the thiol‐acrylate photopolymerization of silk fibroin and thiol‐terminated PEG. This production approach acquired high DS of acrylate groups on HA backbone by employing dimethyl sulfoxide (DMSO) as solvent, and avoided oxygen inhibition effect. As a result, the hydrogel demonstrated improved stiff.[ 103 ] Combing sonication and photocrosslinking approaches, IPN hydrogels with equilibrium SRs of above 6 were formed between gelatin methacrylate (GelMA) and silk fibroin (SF). Exhibiting excellent mechanical properties and resistance to enzymatic degradation, the SF‐GelMA IPN hydrogels are extremely favorable for load‐bearing tissue engineering. And it was affirmed that MC3T3‐E1 pre‐osteoblasts could growth on both surface and inside of the hydrogels.[ 104 ] With maximum SR of 5312%, a DN hydrogel of gellan gum and poloxamer‐heparin demonstrated the potential as a cell vehicle for stem cell applied to tissue engineering by supporting the survival and retaining the morphology and phenotype of bone marrow‐derived stem cells (BMSCs) in vitro and in vivo.[ 105 ]

Equally significative is the publication dealing with the fabrication of injectable HSHs scaffolds. Utilizing hydroxypropyl‐β‐cyclodextrin (HP‐β‐CD) to crosslink gelatin via hydrogen bonds, Yuan et al. yielded hydrogels with good injectability, faster biodegradation and high swellability. After encapsulated into the hydrogels, BMSCs showed high cell viability (>90%) and more efficient osteogenic differentiation within 2 weeks than in the osteogenic medium. According to in vivo analysis, the injectable HP‐β‐CD‐gelatin/BMSC hydrogels effectively enhanced angiogenesis and osteogenesis of the necrosis site of the femoral head. In conclusion, the advanced injectable hydrogels offered a prospective way to improve femoral head necrosis bone repair.[ 12e ]

Based on the facts that appropriate biological functionality is an important factor for promoting tissue regeneration, Malik et al. achieved CS/CMC/hydroxyapatite hydrogels with high SRs (2181.9–2856.6%) and enhanced angiogenesis through holding one of the vital hormones within human body, thyroxin.[ 106 ] This further reflects another fantastic properties of HSHs, that is, top‐notch drug‐loading and releasing behavior, relying on which HSHs not only have superiorities in tissue engineering and regenerative medicine, but also drug delivery.

2.4.2. Drug Delivery

HSHs with highly porous structures have the merits of efficiently encapsulating and releasing both hydrophilic and hydrophobic drugs, proteins, and peptides.[ 107 ] This is due to the reason that the high swelling ability will strongly facilitate the solvent uptake and drug diffusion.[ 108 ] In addition, they are highly biocompatible and biodegradable.[ 76a ] Therefore, HSHs are remarkable candidates for drug delivery and swelling‐controlled releasing. And the drug release profile is governed by the coupling of diffusion and macromolecular relaxation.[ 109 ]

In this context, Grimaudo et al. developed high swelling inserts of sodium hyaluronate and HP‐β‐CD using poly(ethylene glycol) diglycidyl ether (PEGDGE) as cross‐linker, to deliver cyclosporine to ocular surface.[ 110 ] In order to mimic the composition of bone, Chung and co‐workers synthesized an oxidized HA/type I collagen hydrogel containing β‐tricalcium phosphate. With a high SR of 420%, the hydrogel manifested 93% of tetracycline release after 5 days, which qualified this guided bone regeneration material as an antibacterial drug delivery system for treating chronic periodontitis.[ 111 ] To achieve therapeutic effects, several researchers have made remarkable progress in injectable hydrogel delivery systems. For delivering bovine serum albumin (BSA), Ma et al. developed injectable HSHs via in situ formation of Schiff base bonds between aldehyde HA and hydrazide‐modified γ‐PGA. The highest SR of the hydrogels could reach 70.[ 112 ] In turn, Torchio et al. fabricated a series of injectable HSHs with marked self‐healing properties based on host‐guest interactions. High concentration (80 µg mL−1) of curcumin could be entrapped into the hydrogels and release progressively up to 4 days.[ 113 ] Another injectable and high swelling multicomponent biomimetic gel (MBG) was developed by intercross‐linking polyamidoamine dendrimer G3, mesoporous silica NPs (MSNPs), and dendrimer‐templated Ag NPs with PEGDGE via the amine‐epoxy click reaction. PEG network delivered hydrophilic antibiotic isoniazid, whereas MSNs carried the hydrophobic antibiotic rifampicin. It was found that isoniazid could be quicky released while rifampicin could be released in a more sustained profile. Taken all the above facts, the MBGs with structural features for cartilage defect grafts could also offer antibiotic treatment benefits.[ 114 ]

To acquire controlled and targeted delivery of therapeutic molecules, there is a growing need to attain hydrogels whose swelling behaviors will change in reaction to different endogenous stimulus, for instance, pH,[ 115 ] temperature,[ 116 ] enzyme,[ 117 ] redox conditions,[ 118 ] or hypoxia.[ 119 ] By far, the most widely used stimuli‐responsive hydrogels are pH‐sensitive hydrogels.[ 120 ] These types hydrogels usually include at least one kind of polyelectrolyte within the network. With the variation in pH significantly influencing the molecular interactions like hydrogen bonding and electrostatic forces in the hydrogels,[ 121 ] these “smart” or “intelligent” hydrogels will swell and deswell at specific pH, whereby prolong the protection of drugs in stomach or intestine, and dictate the release process.

As the only cationic natural polymers existing in nature,[ 122 ] CS can provide a pH‐responsive controlled release profile of drugs and other bioactive molecules, resulting from the pH‐sensitive ionization of ‐NH2 groups in CS backbone.[ 123 ] At acidic pH, the ‐NH2 groups will convert into ammonium groups (NH3 +), which gives rise to an increase in the intermolecular electrostatic repulsion.[ 124 ] While at basic pH, the NH3 + groups are significantly deprotonated, diminishing the charge imbalance.[ 125 ] As such, CS‐based hydrogels will exhibit distinctive swelling behaviors in gastrointestinal tract, which is reliant on the tradeoff between the repulsive forces of polymer chains and the constraints imposed by cross‐linked network structure. And this feature may make them appropriate for being selected as targeted drug delivery systems (DDS).

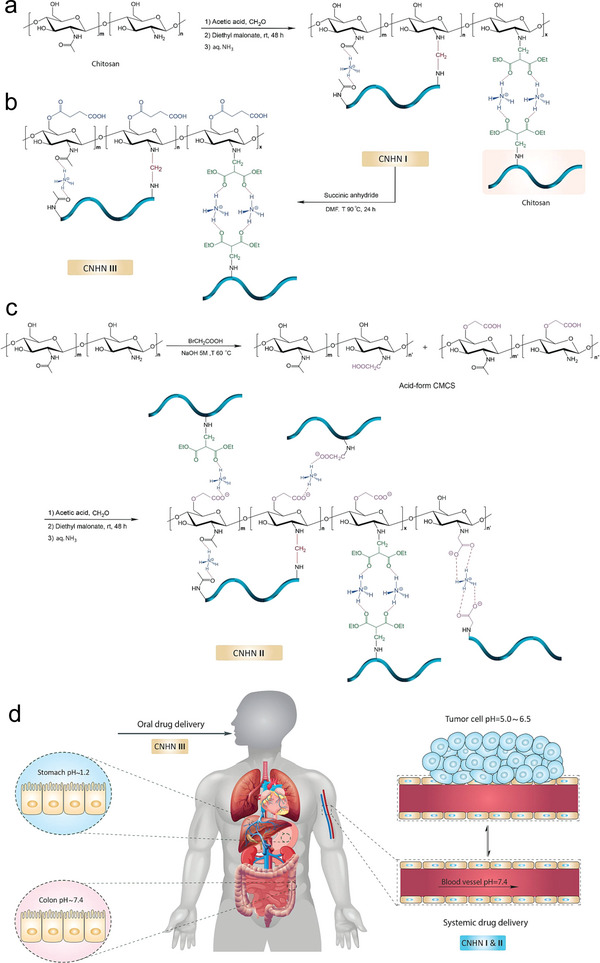

For this purpose, Rasool et al. attained pH‐sensitive hydrogels with antibacterial activity and biodegradability, by mixing CS with poly(N‐vinyl‐2‐pyrrolidone) (PVP) and using neutralized PAA as cross‐linker. The hydrogel samples manifested low swelling at acidic pH and high swelling at neutral pH. Their release profile of Ag‐sulfadiazine (antibiotic for burnt wounds) was in a controlled manner, which exhibited 91.2% of drug release within 1 h in PBS.[ 123 ] Cesco et al. obtained physically crosslinked CS/PC blend hydrogel (CPB) and CS/DNA blend hydrogels (CDB) for releasing antineoplastic agent methylene blue (MB). It was determined that both hydrogels exhibited higher SRs in simulated gastric fluid (SGF). As such, in SGF (pH 1.2) at 25 °C, the cumulative release of MB respectively reached values of 55% and 96% for CPB and CDB after 6 h, whereas in simulated intestinal fluid (SIF) (pH 6.8), these values respectively decreased by 20% and 50%. This was due to the lower electrostatic interaction between the polymer and MB in CDB.[ 126 ] Interestingly, a library of self‐healing hydrogels was fabricated based on Diels–Alder reaction between furan‐modified PC and maleimide‐modified CS. The click reaction substantially increased the cross‐linking density of PC/CS hydrogels, and did not cause any cytotoxicity. What's more, it brought significant transformation in the SR in response to temperature. Finally, the hybrid hydrogel indicated high encapsulation efficiency (53.67–65.27%) of 5‐fluorouracil, and sustained release performance under different simulated media, with the accumulative release retarded at pH 1.2 but increased at 7.4.[ 127 ] Furthermore, Hafeez et al. developed injectable pH‐sensitive hydrogels by utilizing low molecular weight γ‐irradiated CS with higher hydrophilia, and varying concentrations of glycerol crosslinkers. Being able to inflow into the bacteria cell and rupture its metabolism more efficiently, γ‐irradiated CS‐based hydrogels displayed improved antibacterial activity. And the response against pH trigger made the hydrogel loaded with Montelukast sodium released all the drugs in 0.5 h in SGF. While in SIF, the drug was released in a more sustained manner (99.62% in 3 h). This evaluation results suggested the hydrogel as an injectable drug administration.[ 128 ] Another group exploited γ‐irradiation to initiate the graft copolymerization between CS and l‐glutamic acid monomers. Ultimately, they attained highly porous, pH‐responsive, biocompatible, and biodegradable hydrogel beads. The highest SR (426%) and drug release (81.33% in 144 h) of a model anti‐tumor drug doxorubicin (DOX) was observed at pH 5.8, close to the pH of tumor (pH 5.5–6.0). And a significant cancer cell toxicity (78.18%) further qualified the CS‐based hydrogel beads as controlled carrier and deliverer of antitumor drugs for local cancer therapies.[ 125 ] Interestingly, Omrani et al. reported three different CS nanohydrogel networks (CNHN I‐III) (Figure 5a–c). The CNHN I and II had high SR in acidic environments, which were able to achieve an extraordinary loading efficiency of DOX (up to 95%). Dissimilarly, the CNHN III had substantial resistance in pH 1.2 but high swelling in pH 7.4, thus exhibited a high drug loading capacity of 5‐fluorouracil (up to 92%). Therefore, the CNHN I and II had been advocated for systemic drug delivery, while the CNHN III was nominated for oral drug delivery (Figure 5d).[ 129 ]

Figure 5.

pH‐responsive HSHs for systemic and oral drug delivery. Synthesis pathways of CS nanohydrogel networks: a) CNHN I, b) CNHN III, c) CNHN II. d) Classification of hydrogels for oral and systemic drug delivery. Adapted with permission.[ 129 ] Copyright 2022, Elsevier Ltd.

Analogously, the protonation and deprotonation at specific pH of ‐COOH groups of anionic natural and synthetic polymers,[ 130 ] for example, SA, CMC, or PAA, have been exploited to construct pH‐responsive hydrogel DDS as well. Apoorva et al. prepared a SA‐Gum tragacanth composite hydrogels, which revealed higher swelling behavior, loading efficiency, and more sustained release of naturally derived antioxidant phenolic compounds in SIF.[ 131 ] Based on AA/xanthan gum biopolymer, Hajikhani et al. synthesized semi‐IPNs showing the highest and lowest SRs in basic and acidic environments, respectively.[ 132 ] Suhail et al. and Nath et al. exploited the anionic property of AA as well. The former team synthesized Carbopol934‐g‐PAA hydrogels by free‐radical polymerization,[ 133 ] while the latter one utilized CMC‐g‐PAA and layered double hydroxide.[ 134 ] With pH‐responsive swelling behaviors same as the abovementioned semi‐IPNs, both the hydrogels demonstrated a greater drug release at basic (pH 7.4) mediums. Notably, a pH‐responsive biocompatible hydrogel was prepared by grafting HEMA onto soy protein isolate. The hydrogel exhibited faster swelling rate and higher cumulative drug release (70%) at pH 7.4, which was decreased to 30% at pH 1.2.[ 135 ] Therefore, these hydrogels are ideal candidates for intestinal targeted drug delivery. In another study, a combination of PAM, NaCMC and MgO NPs yielded smart hydrogels with appropriate drug release conditions being at 37.5 °C and pH 4.1.[ 136 ]

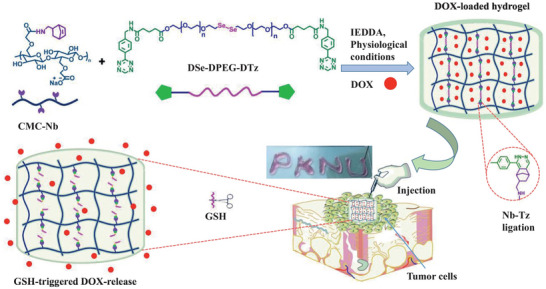

HSHs sensitive to other stimuli have also emerged for targeted drug delivery. For example, redox‐responsive hydrogels can release the payload of therapeutic agents when met diseased tissues (e.g., tumor) with over expressed levels of reducing agent glutathione (GSH).[ 137 ] An example for the use of reduction‐responsive HSHs was developed by Lim's team via inverse electron demand Diels‐Alder reaction (IEDDA). The hydrogels were formulated from alginate‐norbornene (Nb) and PEG‐tetrazine (Tz) based disulfide cross‐linker. It possessed high SRs, injectability, cytocompatibility, and remarkable DOX loading efficiency (92%). Moreover, after 11 days, the DOX release rate of the hydrogels in 10 mm GSH solution (93%) was much higher than in PBS (36%).[ 138 ] In the next year, the same team replaced the alginate in the previous click hydrogels by CMC, and used another diselenide‐based cross‐linker bearing two terminal Tz groups (DSe‐DPEG‐DTz) (Figure 6 ). The resulting hydrogels also exhibited excellent DOX loading efficiencies (>85%), and faster DOX release rate (99%, after 12 h) in 10 mm GSH solution.[ 12f ] Therefore, this preparation strategy offered a general paradigm for the progress of redox‐responsive drug release applications.

Figure 6.

Redox‐responsive HSHs loaded with DOX for cancer therapy. Schematic representation for the construction and drug release mechanism of the redox‐responsive hydrogels. Adapted with permission.[ 12f ] Copyright 2022, Elsevier B.V.

Despite of the high drug loading efficiency and sustained release behavior of above HSHs, the biological studies carried out have been confined to only in vitro assays. Undoubtedly, it is insufficient to confirm that these hydrogels are suitable for treating specific human diseases. Therefore, in the future, there is an urgent need to roundly study the in vivo safety and therapeutic effect of swelling‐controlled DDS for practical implementation.

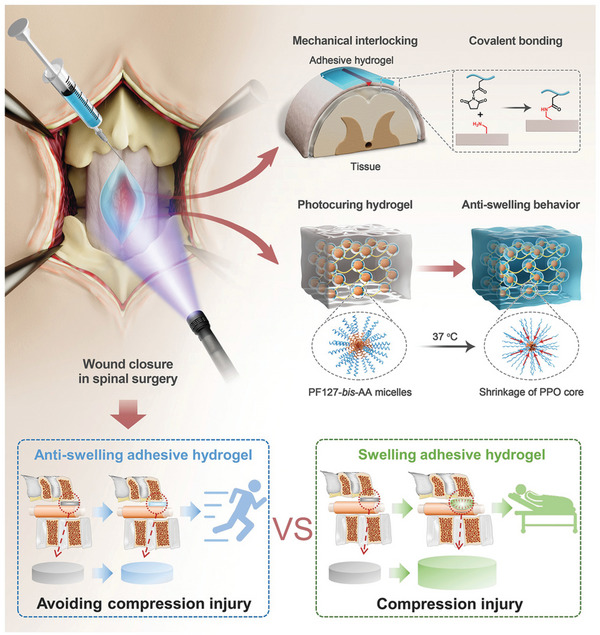

3. Non‐Swelling Hydrogels

Although hydrogels will not disintegrate in water due to its physically and/or chemically crosslinked 3D network structure,[ 1 , 139 ] the swelling of HSHs may cause suboptimal performance and unpredicted outcomes after applied in vivo. For example, the mechanical performance and dimensional stability of HSHs will be drastically weakened.[ 140 ] And in particular, swelling will induce compression on local neighboring organs or tissues, reduce the adhesion and cause detachment from the installation site.[ 141 ] Hence, HSHs are unaccommodated for biomedical areas which need excellent integrated properties to withstand long‐period load, keep original sizes, and shapes, avoid irritations to adjacent fragile tissues, or maintain durable and strong bioadhesion, such as bioelectronics, human organ implants, scaffolds in nerve, blood vessels, and cartilage tissue engineering, bioadhesive sealants in internal surgical operations, etc.[ 139 , 142 ] In this case, non‐swelling hydrogels with high‐strength and versatile functionalities rise in response to the actual requirements in these areas.

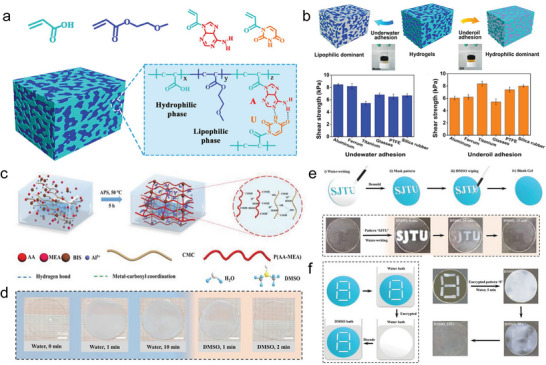

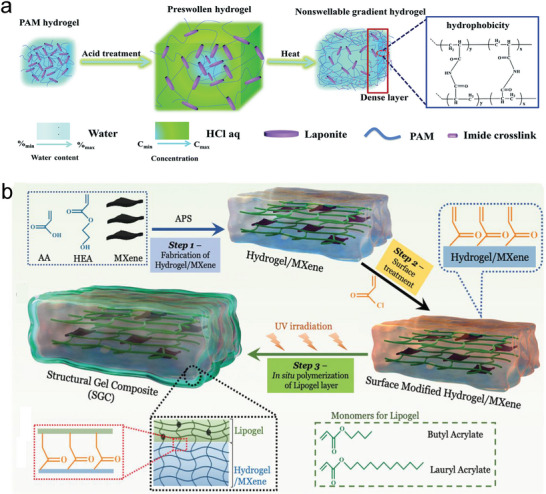

Non‐swelling hydrogels (NSHs), also known as anti‐swelling, non‐swellable, or swelling‐resistant hydrogels, refer to a type of hydrogel whose swelling behavior is very nearly an equilibrium state.[ 141 , 143 ] In other words, these NSHs can retain their initial shapes and intrinsic properties underwater,[ 139 ] Common strategies on developing NSHs can be categorized as increasing the crosslinking density,[ 13a–d ] controlling the polymer/water interaction parmater,[ 13 , 144 ] introducing thermosensitive polymers,[ 145 ] and so on.[ 143 , 146 ] Obviously by virtue of different methods and therein distinct chemical designs to deliver non‐swelling features can bring up different functions to the hydrogels. Based on these reasons, we have summarized and classified the recent five years advanced researches on NSHs as follows (Table 3 ).

Table 3.

Brief summary of the constructions, crosslinking mechanisms, properties, and biomedical applications of NSHs

| Constructions | Hydrogel systems | Crosslinking mechanisms | Properties | Biomedical applications | Ref. |

|---|---|---|---|---|---|

| By increasing crosslinking density | HA‐norbornene, HA‐ methylphenyltetrazine | IEDDA reaction | Non‐swelling, transparent, cytocompatible biodegradable | Not‐involved | [13b] |

| HB‐PEGDA, HA‐SH, colloidal photonic crystal | Michael addition reaction | Non‐swelling, robust, photonic, biocompatible | Bio‐optical application | [157] | |

| CS, PAM, antibiotics | Double covalent network | Anti‐swelling, robust, adhesive, antibacterial | Intraoral wound healing | [219] | |

| PVA, TA | Multiple H‐ bonding | Hierarchically anisotropic, super‐strong, nonswellable, cytocompatible | Not specific | [13d] | |

| PVA, DMSO | H‐bonding | Anti‐swelling, strong, wet adhesive | Not specific | [13c] | |

| PEGDA, TA | H‐bonding | Non‐swelling, tough, notch insensitive, self‐healing, tailorable topography, wet adhesion, on‐demand detachment, biocompatible | Underwater wound sealant | [227] | |

| P(AA‐co‐LMA), CTAB | Hydrophobic association, electrostatic interaction, H‐bonding | Tough, self‐recovery, anti‐swelling, conductive, wet adhesive, strain‐sensitive | Underwater sensor | [180] | |

| SA, P(AM‐co‐AA), Fe3+ | Dual ionic crosslinking | Robust, tough, fatigue‐resistant, self‐recovery, pH‐triggered healing, shape memory, anti‐swelling, 3D‐printable | Not specific | [183] | |

| P(AA‐co‐DMAA), Al(OH)3 | Metal nanoparticle coordination | Nonswellable, ultra‐strong, superoleophobic | Not involved | [13a] | |

| PSBVI, graphene | Cation‐π interaction | Conductive, bioadhesive, non‐swelling, high conformability, biocompatible | Bioelectronics | [243a] | |

| GelMA, acryloyl‐β‐CD, β‐CD‐rGO | Covalent bonding, host‐guest complexation | Conductive, non‐swelling, biocompatible, photothermal antibacterial, osteogenic | Bone defect repair | [231] | |

| ‐CHO‐capped tetra‐arm PEG, ‐ONH2‐capped PEG‐UPy‐PEG |

Chemical and micelle physical dual crosslinking |

Injectable, strong, tough, stable, non‐swelling, an‐fatigue, tissue‐adhesive, cytocompatible | Not specific | [195b] | |

| pHEMA, alginate, Fe3+ | Interpenetrating covalently and ionically crosslinked networks | Non‐swelling, stiff, tough, cytocompatible | Not involved | [203] | |

| Cellulose, PAM, aniline | H‐bonding, covalent bonding | Conductive, tough, stretchable, elastic, non‐swelling, biocompatible, underwater strain‐sensitive | Strain sensor | [47] | |

| By regulating polymer‐water interaction | P(AA‐co‐MEA), nucleobase pairs, DMSO‐water binary solvent | H‐bonding | Non‐swelling, anti‐freezing, wet adhesive, tough, mechanically stable | Sweaty skin sensor | [144] |

| P(AA‐co‐MEA), CMC, Al3+, DMSO‐water binary solvent | Covalent bonding, ionic crosslinking, H‐bonding | Anti‐swelling, anti‐freezing, moisturizing retention, underwater/oil strain‐sensitive, optically adjustable, flexible | Multipurpose biosensor | [13f] | |

| Hydrogel components: P(HEA‐co‐DMA), clay nanosheets, Organogel components: PBA | Covalent bonding | Stretchable, tough, enduring anti‐swelling, low dehydration | Not specific | [206b] | |

| Hydrogel layer: P(AA‐co‐HEA)/MXene, Lipogel layer: hydrophobic lipid gel | Covalent bonding | Anti‐swelling, anti‐hydration, long‐term ultra‐stable, underwater mechanosensitive |

Underwater mechanosensing |

[210b] | |

| By including thermo‐responsive polymer | 2‐arm thiol‐ terminated Pluronic l‐64 PEG, 3‐arm alkyne terminated PEG | Thiol‐yne click reaction | Non‐swelling, cytocompatible | Soft tissue scaffold | [145a] |

| Di‐acrylated Pluronic F127 | Covalent bonding | Non‐swelling, autoclavable, degradation‐resistant | Not specific | [145b] | |

| HA‐MA, Pluronic F127‐bis‐acryloyloxy acetate | Covalent bonding | Anti‐swelling, injectable, wet adhesion, biocompatible | Hemostasis and wound sealing | [13h] |

3.1. Achieved by Increasing Crosslinking Density

Densifying crosslinking density is the most crucial method to construct hydrogels with anti‐swelling ability. This is because the increased structural tightness not only limits intake of water molecules whereby restricts swelling, but also brings better mechanical performance.[ 147 ] To this end, recent attempts have been made to select various types crosslinking methods to yield NSHs. From the perspective of chemistry, these methods can be categorized into utilizing chemical cross‐linking or physical cross‐linking or a combination of both. The huge differences in the binding energy and reversibility between the two cross‐linking support the tailoring of distinct desired properties, such as robustness, ductility, injectability, or self‐healing ability. Hence, in this section, various NSHs was presented on account of crosslinking patterns.

3.1.1. Covalent Crosslinking

Chemical cross‐linking techniques can produce hydrogels with high crosslinking density,[ 148 ] and more controlled physicochemical properties,[ 149 ] thus have been adopted in the preparation of NSHs. In general, by virtue of externally initiated free radical polymerization and chemical crosslinking reagents, which involves formation of strong and permanent covalent bonds that interconnect polymers, can achieve hydrogels with good stability under physiological conditions.[ 150 ] However, these hydrogels tend to be brittle and not injectable, because the energy dissipation of covalent bonds under stress will cause unrecoverable rupture.[ 151 ] Besides, the addition of initiators and other reactive chemicals may increase the cytotoxicity of the hydrogels, which impedes their biomedical application in future.[ 152 ] Therefore, stable covalent bonds are often combined with dynamic noncovalent interactions for the design of practical non‐swelling hydrogel systems (Section 3.1.3). And the biocompatibility of the hydrogels is mainly improved by introducing biopolymers therein.

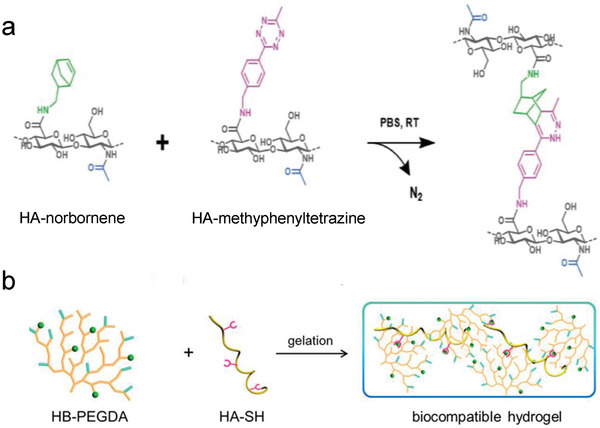

Recently, dynamic covalent bonds have emerged for addressing the issues in fabricating NSHs solely by chemical cross‐linking. It can reversibly convert polymer precursors into a gel, which is beneficial for conferring NSHs with multiple function. In this area, the most employed are click reactions, including thiol‐yne/ene addition,[ 145 , 153 ] Michael addition,[ 154 ] IEDDA,[ 13b ] or a combination thereof.[ 155 ] In click chemistry, high yields of hydrogel products can be achieved by mixing two components equipped with functional groups at mild condition.[ 156 ] For example, Delplace et al.[ 13b ] first developed two modified HA precursors, that is, HA‐norbornene and HA‐methylphenyltetrazine (Figure 7a). After mixing, gelation was caused through IEDDA reaction between the two components within tunable times. By optimizing HA molar mass, transparency and non‐swelling property were achieved with very low polymer content (0.5% (w/v)). The IEDDA hydrogels exhibited biodegradability and cytocompatibility as well, which enabled them pertinent for cell culture and retinal explant imaging. More advantageously, the hydrogels doubled the multiphoton imaging time (>38 h) of embedded retinal explants of the existing standard agarose thermo‐gels (<20 h). In the works of Macdougall et al.,[ 145a ] two straightforward routes were put forward to render the thiol‐yne PEG hydrogel non‐swellable. One route increased the cross‐linking density by using multi‐arm PEG precursors instead of previously reported 2‐arm PEG.[ 153 ] The other introduced a thermo‐sensitive segment into the PEG network, which would be elaborately descripted in Section 3.3. The multi‐arm click‐hydrogels showed shorter gelation time than the thermo‐responsive hydrogel. And both pathways resulted in preserved robust mechanical properties under physiological conditions over time. Ulteriorly, as shown in Figure 7b, hyperbranched PEG diacrylate (HB‐PEGDA) polymers with high amount of pendant vinyl groups were synthesized to quickly form numerous junctions with thiolated HA (HA‐SH) via Michael addition reaction. Rooting in its relatively compacted network structure, this hydrogel showed non‐swelling characteristics, thus could maintain robust structural integrity under diverse complex physiological conditions.[ 157 ]

Figure 7.

Synthesis of NSHs via dynamic covalent crosslinking. a) Schematic illustration of HA‐based NSHs formed via IEDDA reaction between HA‐norbornene and HA‐methylphenyltetrazine. Adapted with permission.[ 13b ] Copyright 2020, Wiley‐VCH Verlag GmbH & Co. KGaA. b) Preparation of NSHs via thiol‐ene Michael addition between HB‐PEGDA and HA‐SH. Adapted with permission.[ 157 ] Copyright 2018, American Chemical Society.

In addition to click reactions, addition‐fragmentation chain transfer (AFCT) reaction has regeneration nature as well.[ 158 ] Therefore, Wu et al. synthesized HA‐SH and allyl sulfide‐functionalized ε‐poly‐l‐lysine to create a non‐swellable and biocompatible hydrogel system, based on reversible AFCT reaction between thiol and allyl sulfide functional groups under UV irradiation. The modulus of the hydrogel was reversed and could be tuned by controlling UV irradiation dosage, and the patterning of fluorescent markers was dynamic as well, which facilitated the imitation of natural ECM. Thus, this dynamically controllable hydrogel displayed better advantages for tissue engineering applications.[ 159 ]

In summary, the above two dynamic chemical cross‐linking strategies both occupy an important position in preparing NSHs constituted by a single covalent network structure. But differently, in click chemistry, the mechanics and biochemistry of hydrogels can be regulated through varying the concentration or architecture of the polymers, while in AFCT reaction, the turning can be dynamically and reversibly realized through controlling the dose of required external stimulus, for example, light irradiation.

3.1.2. Noncovalent Crosslinking

Physical crosslinking approach have drawn much attention in manufacturing NSHs due to the merits of noncovalent bonds in reversibility and configurability. Physical hydrogels can be formed via varied noncovalent interactions (e.g., hydrogen bonding, ionic complexing/electrostatic interaction, hydrophobic association, or metal coordination).[ 13 , 160 ] Compared to covalent bonds, intra‐ and intermolecular noncovalent interactions are quite weak, and may demonstrate sensitivity to certain external stimuli such as pH, temperature or ionic strength.[ 161 ] Therefore, noncovalent interactions have frequently come in combination (i.e., multiple noncovalent interactions). Meanwhile, by the presence of multiple hydrogen bonds or hydrophobic association, the molecular chain may self‐assembly into ordered microdomains or nanodomains, which further intensify the physical crosslinking.[ 162 ] Therefore, the multiple and dense physical crosslinking sites can endow hydrogels with excellent anti‐swelling ability. What's more, the “weaker” crosslinks that are readily reversible can effectively dissipate energy under external stress, while the “stronger” one can provide a strong mechanical support. Thus, the physical crosslinked NSHs unite appealing functionalities like injectability, rapid self‐repairing, shape memory, recyclability, and extraordinary mechanical properties, which is advantageous for practical applications.

H‐bonding

Among a variety of noncovalent interactions, H‐bonding is most widely existent in physically crosslinked hydrogel systems. H‐bonding is the electrostatic attraction between two vicinal polar groups, each of which contains a H‐bonded electronegative atom and one termed as donor while the other as acceptor.[ 161 , 162 ] Single H‐bond has low binding energy and strong competition with water, thus plays a minor role in stabilizing the hydrogel network in water.[ 163 ] But multiple H‐bonds can be as strong as covalent bonds,[ 79 , 164 ] and in a macromolecule, the self‐assembling structures of multiple H‐bonds such as crystallite can provide an additional stabilization.[ 165 ] Therefore, multiple H‐bonds make a major contribution to prepare H‐bonding crosslinked NSHs with high strength and stability. And the dynamic nature of H‐bonding can endow the hydrogels with admirable rheological properties and injectability as well.

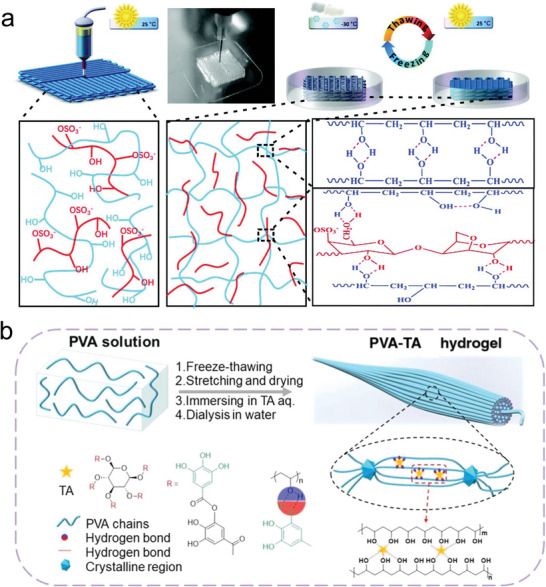

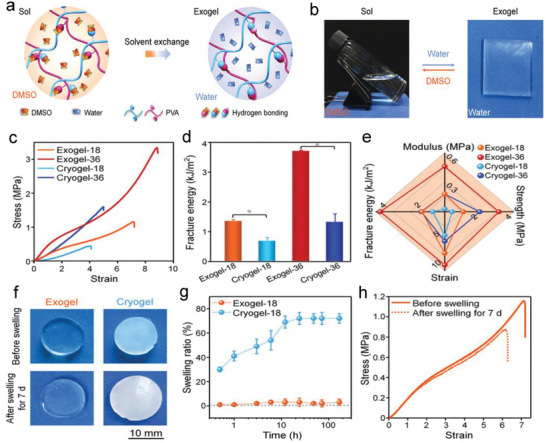

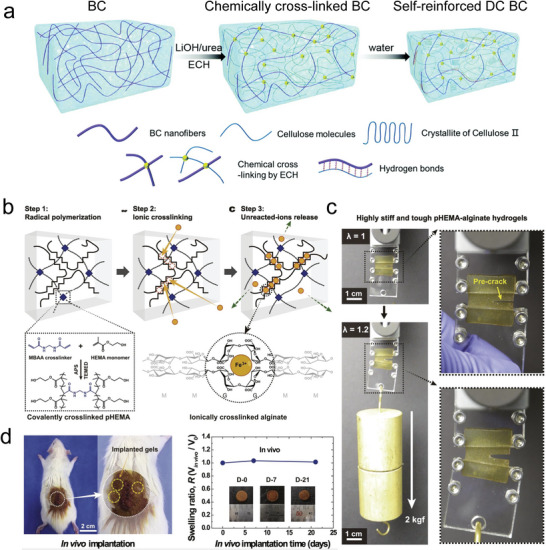

The most classic non‐swelling hydrogel relying on H‐bonding is PVA hydrogels. PVA chains can be crosslinked by the crystallization in PVA during repeated freeze‐thawing (FT) process (cryogel), which was induced by the H‐bonding between the pendant ‐OH groups.[ 166 ] In addition, the abundant ─OH groups offer many opportunities for PVA forming H‐bonding with other reactive substances.[ 167 ] It has been reported that traditional frozen‐thawed PVA hydrogels are compliant and brittle.[ 168 ] In order to prepare PVA‐based NSHs possessing higher stiffness and toughness, attention have been paid to synchronously take advantage of the two H‐bonding crosslinking methods of PVA. For instance, Jiang et al. first prepared 3D printed hydrogel inks with outstanding rheological properties based on wide‐ranging H‐bonding and van der Waals interactions between PVA with κ‐carrageenan (Figure 8a). With the aid of followed FT processes, the mechanical and anti‐swelling properties of the printed structures were strengthened.[ 169 ] Notably, soaking in sodium silicate solution after FT could convert PVA into layered hydrogels with a compact outside and a porous center. Crosslinked by ordered polarized H‐bonds, the cover layer endowed the hydrogels superior robustness against swelling. And the hydrogels could retain exceptional mechanical stability in harsh liquid conditions like strong acidic/alkaline, concentrated electrolytes, and salting‐in and H‐bond‐breaking reagents even at elevated temperatures.[ 170 ] Luo's team have also achieved the goal of toughening PVA‐based NSHs through employing different post‐treatments after FT. As the first example, the subsequent step of immerging PVA/agarose precursor in (NH4)2SO4 aqueous solution induced phase separation micro‐regions thereby increased crystallinity of PVA. The obtained PVA/agarose hydrogels exhibited high tensile strength of 1.1 MPa, tensile strain of 324% and compressive stress of 12.5 MPa.[ 171 ] Later, exploiting a pre‐stretching strategy and an energy dissipation mechanism offered by H‐bonding between PVA and tannic acid (TA), they fabricated a super‐strong PVA/TA hydrogel (Figure 8b). Compared to previously reported swelling‐resistant PVA/TA hydrogel,[ 172 ] this strategy induced hierarchically anisotropic structures similar to tendon. Consequently, the acquired hydrogel showed a huge breakthrough in tensile stress (19.3 MPa) and toughness (32.1 MJ m−3).[ 13d ] Both the two PVA‐based hydrogels barely expanded in deionized water and PBS, thus could maintain their initial strength after water immersion for a week. And the bio‐inspired PVA/TA hydrogel have further been investigated to be non‐swelling in simulated body fluid solutions. Benefiting from the biocompatibility of starting materials and dialysis in water to remove residues, the two hydrogels displayed splendid cell compatibility, promoting its potential as load‐bearing devices. Particularly meaningful is that Xu et al. proposed a facile but highly effective solvent exchange approach to substitute the complicate cyclic FT process and further strengthen the PVA hydrogels (Figure 9a,b). Key to this strategy was first choosing a good solvent (i.e., DMSO) to dissolve PVA, which favored a fully stretched polymer conformation of PVA without any nano‐aggregated states. Subsequently, the switch of DMSO into a poor solvent (i.e., water) intensified the intermolecular H‐bonding of PVA and resulted the formation of cross‐linked hydrogel networks (named as exogels). Due to the different polymer conformation and aggregation state in the two preparation routes, the exogels exhibited better stiffness, toughness, transparency, and anti‐swelling performances than cryogels though the chemical compositions were exactly the same (Figure 9c–h).[ 13c ]

Figure 8.

Synthesis of NSHs via H‐bonding crosslinking. a) Illustrations for the preparation and post‐processing of the 3D printed hydrogels composed by PVA and κ‐carrageenan; Adapted with permission.[ 169 ] Copyright 2019, The Royal Society of Chemistry. b) Fabrication illustration of the tendon‐inspired PVA‐TA hydrogel. Adapted with permission.[ 13d ] Copyright 2022, American Chemical Society.

Figure 9.

Synthesis and characterization of NSHs based on solvent exchange‐intensified H‐bonding crosslinking. a) Fabrication of stiff and non‐swelling PVA exogel. b) Reversible sol‐gel transitions of PVA exogel achieved by altering solvent. c) Tensile stress‐strain curves, d) fracture energy, and e) comprehensive mechanical properties of PVA exogel and cryogel with varied PVA content. f) Optical images and g) SRs of PVA exogel and cryogel in water at determined time point. h) Tensile stress‐strain curves of PVA exogel before and after swelling for 7 days. Adapted with permission.[ 13c ] Copyright 2020, Wiley‐VCH GmbH.

Some natural polymers like agarose,[ 173 ] and cellulose,[ 174 ] have also been utilized to prepare NSHs. Thanks to existed numerous intermolecular and intramolecular hydrogen bonds, its molecular chains are prone to aggregate to form Table 3D hydrogel network which hardly swell in water.[ 175 ] Taking advantage of the stiff helical chains of agarose, which was driven by cooling hot agarose solution below the critical gelation temperature, Topuz et al. successfully synthesized a kind of nanocomposite non‐swelling agarose hydrogels. The incorporation of bioactive nanosilicates (Laponite) enhanced the biological activity of bioinert agarose matrices without affecting its non‐swelling nature.[ 176 ] Interestingly, by means of surface modification of cationic CS onto supramolecular fiber structure of oxidized dialdehyde bacterial cellulose (DABC), Pedige et al. invented hydrogel composites integrating pH‐responsive stiffness and pH‐insensitive swelling resistance. In order to prevent CS from diffusing out of the composites, the first formed imine bonds between CS and DABC which was unstable in acid conditions, were then reduced into secondary amines.[ 177 ]

Hydrophobic Association

Increasing research attention has also been dedicated in deformable self‐assembly structures like micelles of amphiphilic macromolecules based on hydrophobic association. In comparison to assembling structures induced by multiple hydrogen bonds, that caused by hydrophobic aggregation are more flexible. Accordingly, the structures have been employed as reversible physical crosslinkers to efficiently dissipate energy under repetitive loading and provide substantial toughness or other specific properties to NSHs.[ 178 ]

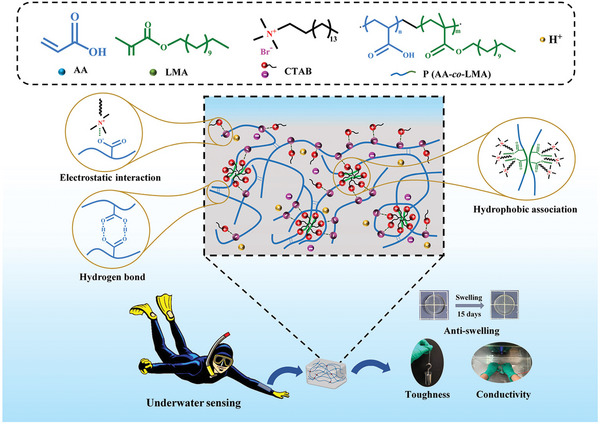

For instance, based on the rigid self‐assembled tri‐helix structure of gelatin and reversible aggregation of free and gelatin‐grafted hydrophobic moieties, Feng et al. prepared non‐swelling and thermoplastic supramolecular gelatin hydrogels, which become highly malleable upon heating but extremely stretchable and tough after cooling to room temperature.[ 179 ] By copolymerizing hydrophilic AA and hydrophobic LMA in the presence of cationic surfactant cetyltrimethylammonium bromide (CTAB), another supramolecular hydrogel was facilely synthesized via the formation of hydrophobic association zones (Figure 10 ). By forming electrostatic interaction with COO− on AA segments, CTAB could further promote the toughness and hydrophobicity of the hydrogel network. The resulting hydrogel showed prominent swelling resistance, superior tensile strength and stretchability, rapid room‐temperature self‐recovery, and stable conductivity in wet environments. Notably, anhydrous ethanol treatment would partially destruct the hydrophobic association zones and improve the motion of polymer chains, which facilitated the diffusion of polymer chains for forming strong adhesion with substrates via diverse interactions.[ 180 ] Moreover, through decreasing the hydrophobic domains’ size and interacting with charged solid surfaces of many materials, the introduction of electrostatic interactions can also promote the adhesion of hydrophobic hydrogels.[ 181 ]

Figure 10.

Synthesis of NSHs via hydrophobic association. Preparation scheme of the tough, anti‐swelling, and conductive P(AA‐co‐LMA)CTAB hydrogel. Adapted with permission.[ 180 ] Copyright 2022, American Chemical Society.

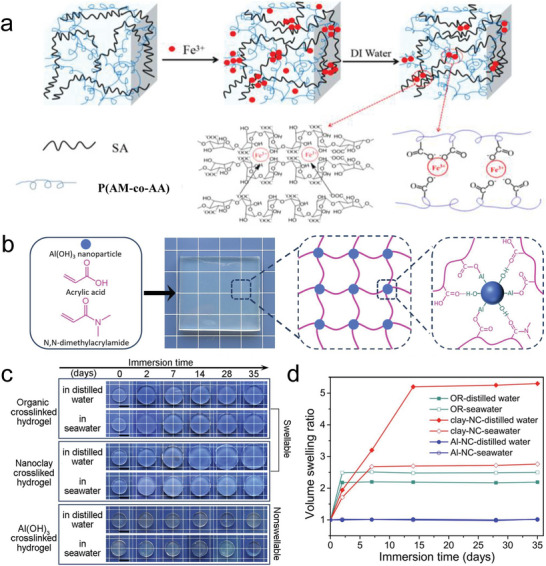

Ionic Complexing/Electrostatic Interaction

Leveraging ionic complexing/electrostatic interaction as physical crosslinks is a facile and alternative path to construct NSHs with good electrical properties. Ionic cross‐linking junctions formed by strong coordination bonds between anionic groups of polymers and multivalent metal cations (Fe3+, Al3+, Ca2+, Mg2+, La3+),[ 182 ] can be easily achieved by incubating as‐prepared hydrogel precursors in metal ions aqueous solution. The addition of metal cations can not only impart hydrogel anti‐swelling properties, but also sensitive conductivity, providing the hydrogel a promising application as wearable sensors. And the effortless tuning of ions concentration eases the modulation of cross‐linking density.