Abstract

This review highlights the critical concern foreign material contamination poses across the food processing industry and provides information on methods and implementations to minimize the hazards caused by foreign materials. A foreign material is defined as any non-food, foreign bodies that may cause illness or injury to the consumer and are not typically part of the food. Foreign materials can enter the food processing plant as part of the raw materials such as fruit pits, bones, or contaminants like stones, insects, soil, grit, or pieces of harvesting equipment. Over the past 20 years, foreign materials have been responsible for about one out of ten recalls of foods, with plastic fragments being the most common complaint. The goal of this paper is to further the understanding of the risks foreign materials are to consumers and the tools that could be used to minimize the risk of foreign objects in foods.

Keywords: Foreign materials, Food, Recalls

1. Introduction

Food safety needs to be viewed as a comprehensive control system designed to minimize the risks of foodborne illness through preventive means, responding to foodborne disease outbreaks, improving traceability to track food products or ingredients released into the marketplace, and providing safe products throughout the continuum from farm to fork [1]. Foreign materials are those unintentional physical, biological, and/or chemical hazards that enter the food production stream that must be minimized. Biological hazards include bacteria, viruses, or other naturally occurring aspects that can increase food safety risks. Chemical hazards include all-natural or synthetic chemicals that could harm someone consuming the food. Physical hazards, the focus of this paper, include all types of foreign matter that when unintentionally introduced into foods could be hazardous or cause quality concerns [2].

Physical foreign material (FM) contamination is a persistent problem that affects all types of food processing industries. Foreign material is defined as non-food, foreign bodies that may cause illness or injury to the consumer, and materials that are not typically part of the food product [3]. Based on a review of injuries from certain foods, the U.S. Food and Drug Administration (FDA) has established guidelines for “hard and sharp objects,” defining what they deem to be a hazard and what objects are not potentially hazardous [4]. Hazardous foreign materials are defined as “small materials that could be potentially put in the mouth with an upper size limit of 25 mm (1 inch)”, which means a stainless-steel nut 25 mm (1 inch) in diameter that may have fallen from a piece of processing equipment into the food production line is not considered a hazard because a consumer will likely recognize this object and not try to swallow an object this size; however, if a smaller, FM is concealed from view it can become a hazard. This regulatory guidance document also indicates that “hard and sharp objects smaller than 7 mm (0.28”) rarely cause injury except in special risk groups (infants, surgery patients, the elderly) [4]. Foreign materials can be classified as intrinsic (unintended foreign material typically found in the raw food such as bones, stems, or seed pits) or extrinsic (materials not typically expected to be found in food such as stones, insects, or fragments of plastic, metal, or glass). Food could be contaminated at different steps from production through processing to the consumers’ table.

Foreign material contamination in foods and beverages causes numerous recalls every year (Table 1). Recalls are classified by their relative risk; Class I or a High Risk is a situation where there is a reasonable probability that the use of the food will cause serious, adverse health consequences or possibly death. Class II or Low Risk is a situation where there is a remote probability of adverse health consequences from the use of the product. Class III, also Low Risk is a situation where the use of the product will not cause adverse health consequences [5].

Table 1.

2022 recalls of food and beverage for foreign material contamination.

| Total recalls | FM recalls | |

|---|---|---|

| USDA | 45 | 9 |

| FDA | 242 | 17 |

2. Main materials of concern as physical hazards and common sources

Table 2 lists the most common foreign materials of concern, their hazards, and common sources. Glass is a particularly difficult foreign material to detect as it is transparent and difficult to see when present in foods. At the same time, glass fragments are the most likely hazard to result in injury and litigation [6]. The most likely sources of glass in the processing plant are light fixtures, gauge covers, or glass food containers like bottles or jars. Fragments of plastic from manufacturing utensils or plastic from food contact and non-food contact surfaces are a major source of hard-to-separate foreign materials. Plastic foreign materials can contaminate food from many sources like equipment, hand tools, freezer belts, conveyors, and some packaging materials.

Table 2.

Materials of concern for physical hazards and common sources.

| Material | Injury Potential | Sources |

|---|---|---|

| Glass | Cuts, bleeding; may require surgery to find or remove | Bottles, jars, light fixtures, utensils, gauge covers |

| Wood | Cuts, infection, choking; may require surgery to remove | Fields, pallets, boxes, buildings |

| Stones | Choking, broken teeth | Fields, buildings |

| Bullet/BB Shot/Needles | Cuts, infection; may require surgery to remove | Animals shot in field, hypodermic needles used for treating food animal infections. |

| Jewelry | Cuts, infection; may require surgery to remove | Pens/pencils, buttons, careless employee practices. |

| Metal | Cuts, infection; may require surgery to remove | Machinery, fields, wire, employees |

| Insects and other filth | Illness, trauma, choking | Fields, plant post-process entry |

| Insulation | Choking; long-term harm if asbestos | Building materials |

| Bone | Choking, trauma | Fields, improper plant processing |

| Plastic | Choking, cuts, infection; may require surgery to remove | Fields, plant packaging materials, pallets, employees |

| Personal effects | Choking, cuts, broken teeth; may require surgery to remove | Employee |

Metals comprise the majority of food manufacturing equipment, manufacturing utensils, tools, and plant structures. Metallic foreign bodies can contaminate foods entering the food processing stream along with the raw ingredients, employees’ negligence, or disrepair of harvesting machines and equipment. Many foreign bodies occur in raw materials and intermediates because of improper processing, screening, cleaning, and sorting. Additionally, metal pieces can get to the food because of improper employee personnel practices, such as not wearing protective clothing, wearing jewelry, or careless handling of metallic elements. Metal fragments may enter the food from the processing area from damaged sieves, with broken pieces of the sieve entering the food product, or pieces of metallic particles from baking trays, scraped from the surface by mechanical friction [7].

Traditionally, wood was the most common material found in the traditional food industry facilities and used to be found as part of the interior of buildings, packaging, shelves, and tools. The use of wood in processing plants has practically been eliminated and other materials like concrete, plastic, aluminum, and stainless steel have taken over due to the variety of food safety risks associated with wood. Wood is not recommended to be used in food processing facilities during food production. However, wooden pallets are still occasionally used for shipping raw materials into the plant.

Hazardous foreign objects can be part of the food such as fruit seed pits, or bones, or come into the plant with the harvested raw materials like stones or insects are to be anticipated. Soil, grit, stones, pieces of harvesting equipment, and insects may be collected when harvesting field crops [8].

3. Risks and consequences of foreign objects in food

In 2001 the Food Safety and Inspection Service (FSIS) of the United States Department of Agriculture (USDA) established the Consumer Complaint Monitoring System (CCMS) as a centralized system for managing consumer complaints associated with FSIS-regulated meat, poultry, and processed egg products. It should be noted that this is a passive reporting system; it relies on consumers reporting their complaints and therefore does not capture the actual incidence of incidents of harm from FM in foods. In 2017, the most recent year for which data is available, foreign objects complaints were the primary complaint reported (45%) [9] There were 387 foreign object complaints reported in 2017, of which insects or animal parts (119) were the foreign objects most frequently reported. Injury from a foreign object was reported in 44 cases. Among injuries reported broken or loose teeth and toothaches (21) were the most common, followed by cuts (15), and choking (11). Most reported injuries involved bones (15) and metal (9). Thirteen people reported having to make a doctor or hospital visit, five of whom reported choking.

4. Overview of regulations about reducing risks from foreign matter

The U. S. Food and Drug Administration (FDA) defines a significant food hazard as:

-

a.

The product contains a hard or sharp foreign object that measures 7 mm–25 mm, in length and,

-

b.

The product is ready-to-eat (RTE), or according to instructions or other guidance or requirements, it requires only minimal preparation steps, e.g., heating, that would not eliminate, invalidate, or neutralize the hazard before consumption.

Samples found to contain foreign objects that meet criteria a. and b will be considered adulterated within the meaning of 21 U S C. 342(a) (1). Canada uses the same standards for foreign objects [10]. The European Union (EU) has no specific legal limits for foreign bodies in food [[11], [12], [13]].

Physical hazards are addressed in the Hazard Analysis and Critical Control Points (HACCP) plan to lower risk status. Food processors should evaluate each of their processes and regulatory requirements, and proactively identify potential causes of an injury or illness while conducting a hazard analysis for potential physical hazards [14].

5. Prevention of foreign matter contamination

Numerous methods exist to prevent foreign objects from contaminating foods or to detect them once they enter the food processing line. Most detection methods are tailored to individual applications and are only suitable to be used in certain food products and will be ineffective with others [11]. A rigorous risk assessment must be made for each food product as to the type of foreign material contamination that is likely to occur as well as where in the processing stream this contamination is likely to happen. The methods used for the prevention of foreign materials contamination can be the same methods that are used in detecting them later in the process [11].

5.1. Screening

Foreign material in liquid may be screened out or solid foreign materials contaminating dry ingredients can be separated based on size. Sieves are routinely used for separating materials that are not part of the food or products including foreign materials and depending on the size required per product. Sieves are mostly used in dry ingredient processing facilities for breaking clumps, foreign matter prevention, and separation by size. The screens are made of stainless-steel mesh, net, or metal materials. Routine visual inspections of these screens are necessary to ensure the screens have not become damaged and have the potential to become foreign material contaminants of the food [11]. Sifters and screens are important, especially on dry ingredients, and if screens are damaged or not in use, foreign matter could be introduced and contaminate the finished food. Screens should have the proper mesh size to ensure the food product could flow through the screens without any kind of buildup issues due to using too small a mesh size, but it must still be capable of removing unwanted foreign materials. Some separation systems require shaking of the screen to allow the product to flow more freely, but the basic method is creating a physical barrier that removes as much of the foreign matter as possible (Fig. 1) [2]. Separation systems must be designed to capture the known hazards in the material. Other factors must be considered to minimize risks of foreign materials, including the speed of production lines. The advantages of these physical separation systems are they are relatively low in cost, have high throughput, and are highly effective, but sieves and filters must be adequately maintained as part of an overall food safety system to ensure they do not become a source of foreign material contamination [2].

Fig. 1.

Typical screens used in processing plants. On the left, a rotary drum screen, on the right, flat aluminum screen.

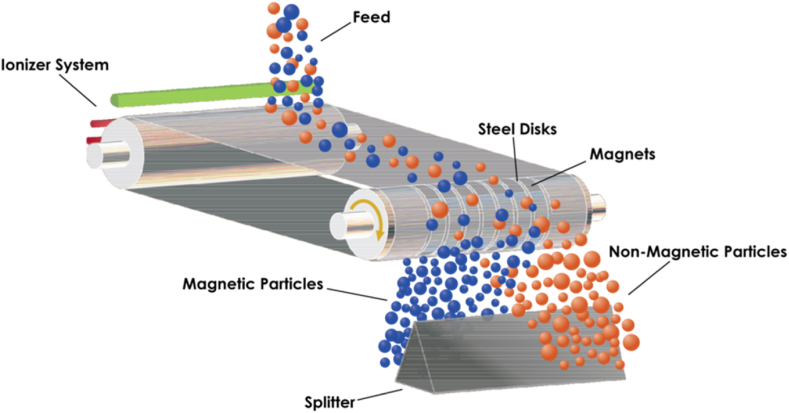

5.2. Magnets

Magnets can be used to remove ferrous metal contaminating food products (Fig. 2) [14]. Ceramic magnets are the least expensive for general uses, while Alnico (aluminum, nickel, and cobalt) magnets can be used for high-temperature processes [15]. Rare earth magnets are the strongest and most effective since they can also remove stainless metals that have been made magnetic as well as weakly magnetic materials; however, these magnets are not suitable for use with high-temperature processes [15]. The advantage of using magnets as a metal removal option is that they can remove a wide range of particle sizes, including metal dust and pieces too small to be easily identified by other methods, typical magnetic have very little maintenance, cost, or cause product loss [15]. Of course, the major disadvantage of magnets is that they can only remove magnetic materials, meaning aluminum, various stainless steels, and any other non-magnetic metal will not be removed from the product flow.

Fig. 2.

Magnetic separator.

5.3. Optical sorters

Optical sorters and laser sorters are another process control that is commonly used to remove foreign materials or items that do not meet quality parameters from the food product stream. These optical sorting cameras or lasers can detect many surface-level characteristics including color, shape, or variations in moisture. Once these differences are identified an air jet or other mechanical device can remove the nonconforming material from the food product flow [2]. Some studies have shown the ability to use these sorters as an effective measure for the removal of foreign materials as part of a HACCP program while also improving product quality through the removal of discolored, damaged, and misshaped products. This can be even more advantageous for areas with limited resources where additional control measures would not be as affordable [16].

6. Detection of foreign materials in food products

Some foreign materials will inevitably evade the various removal methods and will make their way into the finished product. It is important to detect these contaminants before they leave the processing plant and reach the consumer. High-density materials such as metal or stone are more easily detected than materials such as hard plastic or insect bodies as contaminants [17,18]. Additionally, some FM in foods will be easier to detect; for example, a fruit pit in juice will be easier to detect than a stone in cereal. These methods are summarized in Table 3.

Table 3.

Foreign material removal/detection systems in food processing.

| System | Removes/detects | Advantages | Disadvantages |

|---|---|---|---|

| Screens/sieves | Any material smaller than Screen/sieve | Simple, inexpensive | May suffer damage and contaminate product, difficult to clean and dry, difficult to filter suspensions, fat globules may plug the mesh |

| Magnets | Ferrous metal objects | Remove particles as small as dust | Only ferrous metals removed, must be consistently maintained |

| Optical/laser sorters | According to parameters set | Automated, High efficiency, Nondestructive |

Expensive, needs additional equipment (compressed air, etc) |

| Metal detectors | Ferrous metals | Sense and remove ferrous, nonferrous, and stainless metals | Only detect electrically conductive or magnetic objects. Some foods create false positives. |

| X-ray | Metal, glass, rubber, stone, and some plastics | Nondestructive | High cost, uses high voltage, trouble detecting paper, wood chips, plastic, cartilage, and insects |

| Thermal imaging | Nondestructive, no radiation | Sensitive to temperature interference | |

| NMR/MRI | Can determine other parameters than FM | Expensive, not very sensitive, low speed | |

| Ultrasound | Wood splinters, glass, metal, and plastic | Nondestructive, cost effective | Only useful in homogeneous matrices |

| NIR | Coins, glass, rubber | Nonionizing, can penetrate air gaps | Must be calibrated |

| Hyperspatial imaging | Polymer, wood, metal | Uses complete spectrum of light | High cost, low speed, data storage and interpretation |

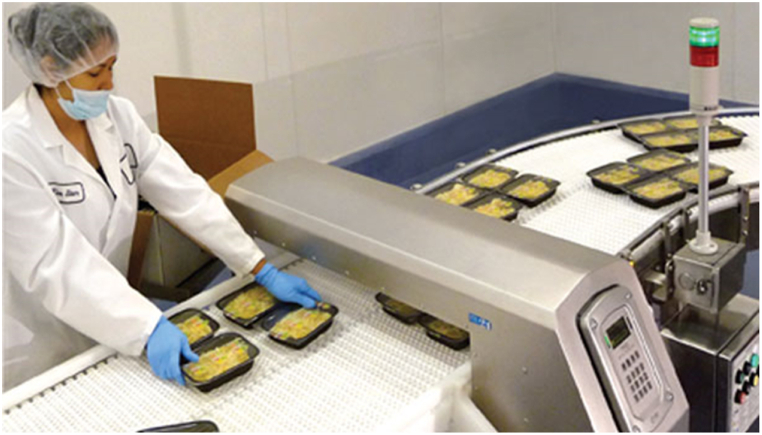

6.1. Metal detectors

Metal detectors are very common in food processing facilities and are usually the last line of defense against foreign materials before packaging (Fig. 3). Metal detectors can be utilized in raw material processing, and production, just before final packaging, and after final packaging. Typical metal detection systems have been developed to detect and isolate metal foreign material through automatic systems. It is important to understand that this system cannot be viewed as a total elimination device for foreign objects, there are possibilities of contamination to get past this system. It should be viewed as a notification device of potential hazards and through conducting a root cause analysis, corrective actions and preventive measures must be undertaken to prevent additional potential risks from occurring.

Fig. 3.

Typical metal detector in food processing.

Balanced coil metal detectors are the most common type. These balanced coil systems have one transmitting coil and two receiving coils. When a food item containing metal passes between the transmitting coil and the receiving coils, the metal interferes with the magnetic field from the transmitting coil, and the detectors identify changes in the amplitude and phase of the current caused by the metal [19]. This causes the metal detector to trip and remove the food with the metal from the product flow. With these types of detectors food materials that have higher conductivity levels, usually due to salt or moisture, can interfere and cause difficulties in identifying metal contamination. Magnetic field detectors use a strong magnetic field to identify magnetic metal inside aluminum cans and are used only for identifying metal inside already sealed cans [20]. These processes expand the abilities of magnets to detect additional types of metals and the ability to test post-canning.

The use of metal detectors is quite common in the food industry, and research continues to improve the level of detection (size detected), accuracy (percent detected), and speed while remaining cost-effective [21] Metal detectors have also been developed that can be used in heat, where vibration is in effect, where moisture is high, and some can reduce the cross-signal effect from machinery or communication equipment [22].

Unfortunately, metal is far from the only risk for FM contamination. A multitude of other risks exist, including rubber, glass, hard plastic, seeds, insect bodies, and other nonmagnetic FM, which require additional or alternative methods to be implemented to ensure product safety and quality.

6.2. X-ray detection equipment

Not all FM objects in food products can be detected by well-maintained metal detection systems. Some of the sources of FM in food products are manufacturing equipment such as conveyor belts, freezer belts, blades, glass or hard brittle plastic, rubbers, gaskets, filters, wires, or employees dropping items into the food product stream. Some FM might come from the product or ingredient and could include rocks, wood pieces, seeds or pits, or other items. Therefore, X-ray detection systems are used to supplement metal detectors in the food production industry for quality control inspection (Fig. 4) [[23], [24], [25], [26]]. They provide non-destructive methods to detect foreign objects. However, conventional X-rays have difficulties in detecting FM such as paper, wood chips, plastic, cartilage, and insects [27]. Many modifications of conventional X-rays have been developed and tested. Phase contrast and dark field contrast show a better distinction between FM and food than conventional X-rays [[28], [29], [30]]. Einarsdóttir et al. [31] improved on this approach with grating-based multi-modal technology and determined that the method gave superior results in detecting some of the hardest-to-detect FMs. However, X-Rays sometimes cannot keep up with the manufacturing speed, and there is a limit to the allowable energy of the X-ray source which precludes using X-ray detectors on thicker products [31].

Fig. 4.

X-ray equipment for foreign object detection.

6.3. Thermal imaging

Thermal imaging can be used in two different ways. For one method, if the product and FM give off heat in different ranges, then infrared energy can be applied to the material and the difference between the FM and the food can be used to create a digital image. In another method, heat is applied in a short burst and a measure of how far into the material the heat penetrates. These methods create a contrast in thermal conductivity that allows detectors to identify the FM [[32], [33], [34]]. Thermal imaging systems typically consist of a camera, an optical system (focusing lens, collimating lenses, and filters), a detector array, signal processing, and an image-processing system [35]. The advantages of thermal imaging include that it is a noncontact detector, it does not emit harmful radiation and can operate in real-time [35], but temperature interference from other surfaces limits its applications in the food industry [36].

6.4. Nuclear magnetic resonance (NMR) and magnetic resonance imaging (MRI)

These two methods use strong magnetic energy fields applied to the food that is being tested, exciting protons within the material; when the protons return to their former state, they release energy that can be measured and converted into an image [20]. These techniques can be used for far more than identifying FM as they can also determine fat and moisture content, the concentration of any hazardous elements, and identify internal browning within produce. However, these techniques are costly, may lack the sensitivity required in FM detection, and testing speed is typically slow [37].

6.5. Ultrasound

Ultrasound detectors use sound waves above the frequencies of audible sound, nominally greater than 20 kHz [38]. Ultrasonic imaging uses the application of 20 kHz or larger sound waves to impinge on a food product and then detecting the resonating frequencies of materials [20] or the measurement of the time of sound transfer through the material to identify FM [39]. These methods have the advantages of being nondestructive and do not negatively affect the food being tested, can be used on many types of food products, and are cost-effective [39]. Ultrasound is most effective in fruit and vegetable products transported through water in flumes [20], but other studies have shown that ultrasound can detect differences between food and FM without contacting the food or the need for a conductive medium [39]. Ultrasound has also been used in the canning industry and has been able to identify FM as small as 1 mm in length in canned foods, but detection can be negatively affected by container shape and irregularities [40]. In-process methods using ultrasound may be effective in identifying FM in homogeneous foods but as end-of-line critical control points, they do not seem viable.

6.6. Near Infrared (NIR)

Near Infrared spectroscopy (NIR) is a spectroscopic method that uses the near-infrared region of the electromagnetic spectrum; NIR is based on “overtones and combinations of bond vibrations in molecules” [41]. The bond vibrations between the atoms of organic molecules cause a change of energy when exposed to NIR light [42]. The resulting patterns of absorption/reflection across the wavelength can be used to obtain the characteristics and features of the material tested. The quality and texture of foods have been successfully analyzed by NIR spectral imaging in several food types such as fish [43], milk [44], rice [45], and lamb [46]. The basic NIR setup features a camera for capturing the image, a spectrograph to separate light into a frequency spectrum, a lens for adjusting the receiving light, an illumination unit for determining the spectral range of the system, a translation stage for samples of food and a motor for moving the food [46]. There are two categories of light sources for spectrometric measurements: thermal and nonthermal [47]. Thermal sources such as tungsten halogen lamps produce radiation spanning a continuous spectral region, but it also affects the temperature of the sample [48]. Non-thermal sources, such as light emitting diodes (LED) and lasers produce radiation within a narrow spectral band, are low cost, portable, and emission wavelengths can be varied [49].

NIR has several advantages such as it is a nonionizing technique and its ability to penetrate air gaps within the food materials [50]. NIR is also capable of finding a small element in the food's internal structure as it can capture an image as small as a nanometer range [51]. NIR computes a mean spectrum of a sample and provides a single spectrum, but the data may be too little and too complex to analyze. NIR has some limitations as it depends on reference methods for calibration purposes [36,52].

A NIR imaging system was developed by Pallav et al. [50] to detect foreign bodies in several types of foods and was successfully tested in dough, cheese, meat, and chocolate bars artificially contaminated with coins, glass, and rubber. NIR spectral imaging was applied by Sugiyama et al. [53] to observe leaves and stems in blueberry products. The blueberry surface, the leaf, and the stem are clearly distinguished from each other in binary images. Foreign bodies contained in ham slices and chocolate were successfully distinguished by a NIR imaging system developed by Tashima et al. [54]. The ham slices and chocolates were contaminated by inserting hairs (0.1 mm in diameter) and insects (3 mm in width) at a depth of 2.6 mm from the surfaces. The foreign substances were clearly distinguished from the foods in the images.

Tunny et al. [55] sought to establish the crucial wavebands on NIR to identify FMs from different types of fresh-cut vegetables. They used cabbage, carrot, radish, green onion, onion, potato, and zucchini in their experiments and selected six wavebands that gave promising results [55]. They were subsequently able to identify FMs with 92.5% accuracy but said that more research should be conducted to increase resolution of the NIR camera and find a suitable background for differentiation of FMs [55]. Most hyperspectral imaging systems (HSI) employ fluorescence imaging (400–1000 nm), visible near-infrared imaging (VNIR; 400–1000 nm), and short-wave infrared imaging (SWIR; 1000–2500 nm) [56]. Experiments were conducted with vegetables to test each of these, and accuracy was found to be best for FMs with SWIR (198 out of 200), followed by the VNIR (178 out of 200) and fluorescence (128 out of 200) [56].

6.7. Hyperspectral imaging

Hyperspectral imaging is not limited to red, green, and blue spectra but can analyze images using the complete spectra of light [57]. Hyperspectral imaging was originally developed for remote sensing of the earth from satellites [58]. Hyperspectral imaging has been used in numerous fields including agriculture [59,60], medicine [61], and pharmaceuticals [62]. Applications for food quality and safety include the detection of contaminants, identification of defects, quantification of constituents, and sensory analysis [63]. Zhao et al. [64] successfully identified peanut and walnut powders contaminating whole wheat flour using hyperspectral imaging, an important development for persons who are allergic to nuts. Chung and Yoon [65] used hyperspectral imaging of artificially contaminated broiler breast meat to detect FM typically found in poultry processing plants. They prepared samples in two different sizes (5 × 5 mm2 and 2 × 2 mm2). Accuracies determined for detecting 2 × 2 mm2 pieces of polymer, wood, and metal were 95%, 95%, and 81%, respectively, while the detection accuracies for detecting 5 × 5 mm2 pieces of polymer, wood, and metal were all 100%. The advantages of hyperspectral imaging are clear, but disadvantages include high cost, slow imaging speed, the sheer amount of data generated which can present problems for storage and the data can be hard to interpret by processing plant employees.

7. Tactile image sensors

Some FMs are difficult to detect and often the final inspection is performed by human eyes or by touch [66]. For example, a bone in a soft fish filet may only be found with touch and thus requires human resources and time [66]. Tactile image sensors have been used mostly for grasping and manipulating by robot hands and manipulation tasks [[67], [68], [69]]. For use in food processing, Shimonomura et al. [66] developed a cylindrical tactile image sensor that would be rolled over the inspection object. The sensor was able to detect hard objects in raw shrimp, raw fish filets and ground chicken [66]. In testing the ability to detect shrimp shell fragments left on shrimp, the device was able to detect shells on the front side of the shrimp, but not the back, which would necessitate flipping the shrimp over [66]. Other practical considerations for the use of this technology include how to remove the FMs, and the necessity for keeping up with line speeds in processing plants.

A recent development is the so called “food radar” based on microwave technology which can detect these low density FMs [70]. It is designed for pumpable foods of low or high viscosity [70]. Another system is SAMMI®, a prototype developed at the Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR [71]. In preliminary studies researchers used SAMMI® to inspect sandwich cookies with a glass splinter in the chocolate filling; the glass splinter was easily detected by this system. Baby food manufacturers have taken the lead in employing this technology [72].

8. The special of low-density contaminants

Plastic is the most problematic of foreign materials for detection in foods. Consequently, many recalls involve the presence of these plastic fragments. In August of 2021, Fratelli Beretta recalled chicken salads and dips contaminated with hard white plastic. In September 2021, Ajinomoto Foods recalled several thousand pounds of potstickers due to the presence of a foreign material composed of hard plastic [5]. Some choices can be made to mitigate the problem of plastic as a contaminant.

One method would be to choose high-density plastics or plastics infused with metal. Most food manufacturers use low-density plastics due to cost; however, these plastics are less dense than water which makes them virtually invisible to detection systems. Spending extra money on high-density plastics could lower the risk of recalls due to contamination with plastic.

Secondly, thorough audits of plastic tools and materials must be conducted throughout the manufacturing process, with special attention to what could be replaced with products that are more easily detected. For example, replacing low-density plastic with high-density or with plastic that contains a detectable additive like metal makes it easier to find through inline metal detection systems. Coloring could be added to the plastic to aid in optical detection by operators on the line or using a camera. Color-coding detectable plastic can provide an extra layer of traceability and accountability by restricting the use of certain colors to specific areas, so you'll know exactly where to trace fragments that may have contaminated your product.

In a possible breakthrough in plastics detection, Mazzolini et al. [73] have had some success in detecting plastic using Fourier Transform Infrared Spectroscopy (μFT-IR) coupled with a microscope. Food leftovers, also called former food products (FFPs) due to logistical or production errors, surplus problems, or problems with packaging, are no longer suitable for sale and human consumption, but are valuable as components in food animal nutrition as ingredients [74,75]. These FFPs are unpacked mechanically, and the packaging removed, although small bits of the packaging usually remain [76,77]. Mazzolini et al. [73] were able to detect cellulose, aluminum, and plastic particles in the FFPs using the μFT-IR. This technique should be further investigated for its utilization in food processing environments.

Low-density FMs including paper, wood, plastic, hair, and insects are prominent causes of FM incidents reported by consumers [31,[78], [79], [80]]. As noted in section 6.2 a grating-based dark field x-ray imaging system was developed to detect low-density FMs in food products [31,80]. Even though the findings were promising the use of this method is difficult and expensive. A variation of this method has been developed called single-shot grid-based dark-field X-ray imaging which uses readily available X-ray grids which makes this method less complex [[81], [82], [83]]. Lim et al. [84] (2022) tested this system in food samples containing wood, Styrofoam, pencil lead, and soft plastic. They determined that all the FMs were clearly visible in dark-field images, while they were just observable in absorption images, and the dark field images were significantly larger than absorption images [84].

Sub-terahertz waves (millimeter-waves, 30–300 GHz) and terahertz waves (0.1–10 THz) are non-ionizing making them more suitable for use in food processing environments [78]. Additionally, these frequencies can detect low density GMs in foods [[85], [86], [87]]. Ok et al. [88] were able to identify low density materials, including plastic and insects concealed in dried milk using this method. This method has also been used successfully to detect insects [89] and tea stalks [90] in teas.

9. Best practices for avoiding foreign material contamination

Foreign materials can affect the quality and safety of products; utilizing advanced foreign material devices rejection technology throughout the process is critical for eliminating foreign material; however, the food industry should not rely entirely on equipment detection methods to control, prevent, reduce, and eliminate foreign materials from food products. The food industry should strive for continuous improvements by benchmarking, auditing their process, monitoring performance, setting KPIs, foreign object verifications, conducting FMEA (Failure Mode and Effects Analysis), an in-depth 5-step risk assessment investigation, including corrective actions, should be completed following each foreign object finding, and enhancing the food safety culture by conducting training, building an inclusive culture, open communication, and empowering team members. Let's further discuss a few examples of foreign materials tools that would aid food processing facilities to reduce their risks.

9.1. Benchmarking

Benchmarking is a tool for evaluating and comparing processes to attain continuous improvement. The food industry should utilize experienced consultants to assess their facilities against the industry metrics and practices to understand how and where they need to improve. Food companies should review each potential benchmarking to find an adequate assessment to find the deficiencies that potentially cause foreign material to be introduced into the process. Many companies have benefited from the aid of an external team to find the gaps in their processes by following several steps: building a cross-functional team, defining a goal, evaluating the processes, gathering helpful information, analyzing the study result against current practices, and finally closing the gaps and developing a plan to implement needed changes (https://asq.org/quality-resources/benchmarking).

9.2. Monitoring processes/Detection methods

Processing facilities should have methods for each process step to eliminate foreign materials from being introduced into the food processing line. The detection methods should include device technology, visual inspections, and one-point lessons that list the proper way of conducting specific tasks to minimize foreign material introduced into the process.

Here is a list of equipment inspections and process detections to keep in mind during daily production: Incoming inspections of all raw materials, QA inspections testing of materials at the receipt, during production and finished product, Retention samples inspections, sifter/screens daily tailings inspections, magnets, metal detector, X-Rays, vision/scanning systems, other technologies, and daily inspections of areas and equipment that could potentially create a foreign material issue such as belts, gaskets/seals integrity, residue, transfer points, metal to metal connections, fraying materials, HVAC units, and any material near or above open production areas. Foreign material goals and KPIs should be determined and reviewed during food safety team meetings and town halls to drive foreign material reduction.

9.2.1. Foreign object verifications

Foreign object verifications should include all potential foreign material sources, including raw materials, equipment, and the environment. The processing plant should implement frequent risk-based inspections and initiatives to monitor the processes. These inspections should include evaluating equipment with potential metal-to-metal contact, conveyor belting, any potential material that could fray, gauges, gaskets, seals, bolts, and any items directly or adjacent to food contact production surfaces areas, proper function of critical foreign material devices.

-

•

In-Process Best Practices should include GMPs, Foreign Material Verification during Sanitation and pre-operational of the equipment, Plant One Point Lessons on specific job tasks, Foreign Material Awareness, Pest Control, CCPs, Preventive Controls, Glass and Brittle audits, and others.

-

•

Wood-Usage of wood pallets should be kept at a minimum and inspected daily for integrity as wood chips broken from a pallet could potentially contaminate products. The facility should keep broken wooden pallets segregated and return them to the supplier or dispose of them. Plastic pallets are an excellent solution to wooden pallets; however, they should be kept clean, sanitary, and monitored for cracks.

-

•

This paper discussed magnets, screens, filters, and sifter tailings earlier. All these are control points for foreign materials that should be inspected daily, and any findings adequately documented in detail must be monitored and verified. Screens and filter integrity checks must be documented and verified at a specific frequency to ensure that foreign materials are identified at this process stage. Any problems with the integrity of the filters, screens, and sieves should be reported to ensure all potentially affected material is captured. The devices above should be inspected for loose bolts, frayed or detaching mesh, chipping coating materials, frayed edges, rips, tears, and holes. Sizing the screens and transition-fitting materials is critical for capturing foreign objects.

-

•

Metal Detectors should be monitored and challenged daily to ensure the device works as intended. If the metal detector is a preventive control, it should be included in your Food Safety/HACCP Plan. Preventive Controls for physical hazards should be monitored, verified, and validated. The metal detector should be challenged, and the line stopped if not working per procedures. Any affected material should be segregated, retained, and investigations completed to find the potential root cause of contamination before releasing any food into commerce. All metal detector rejects must be investigated and documented.

-

•

One Point Lessons are critical to ensure team members correctly perform their tasks to minimize the introduction of foreign objects into the process. Ingredient packaging can become a source of foreign material if not opened correctly. Due to improper opening packaging procedures, one of the food industry's top foreign materials issues is paper, plastic, cardboard, strings, etc. This step in the process could appear to be an easy task; however, multiple issues due to contamination by packaging materials entering the product line continue to occur. Adequate procedures must be placed to minimize foreign objects due to packaging materials. Processing facilities should develop a detailed procedure demonstrating how to properly open a box, cut an ingredient bag, and transfer the ingredients into the process. Tools used to open the packaging materials must be appropriately sharpened. Dull blades and jagged cuts can result in small pieces of paper, tape, liners, or plastic getting into the product. Tools used to cut these materials should be evaluated to ensure the most effective cutting tool is used to reduce the risk of tears and debris in the product. Blades should be sharpened and changed frequently; team members should only use tools provided by the company, and all tools should be accounted for to ensure no tools end in the product. Finally, all team members should be adequately trained to open bags and boxes properly to minimize the risk of contamination. Best training should include a video clip or pictures demonstrating each step of cutting a bag/box. The best practice while opening a bag is to remove the outer layer, then complete a single clean cut with a sharp knife from one end of the bag to the other. When opening a box, the same steps should be followed. One-point lessons could be developed for tool accountability for all small tools that could potentially be introduced into the process, gasket/seal integrity verification, clearance of the line, belt inspections, and any line inspections.

-

•

Glass and Hard Brittle Plastic Audits inventory should be conducted based on risk level. While conducting the glass and hard brittle plastic inspections, all material at the facility that contains glass, hard and brittle plastic must be considered as part of the audit. If breakage occurs, the affected areas must be isolated, and employees around the area should look for glass or plastic pieces. Any material should be collected and properly discarded.

-

•

Pest Control - Pests and insects are also a source of foreign material contamination; pests are not part of food products. Pest inspections should be part of the Pest Control, GMP, and sanitation audits. Facilities should investigate any areas for signs of the pest, including any gaps; if you can see the light between or under doors, pests can get in, cracked or open dock doors, gaps in the ceilings, holes in the wall, and dirty drains. A mouse can fit through a hole the size of a dime. Good sanitation and plant structure is the best way to prevent pests from entering the building.

9.2.2. Risk assessment investigation

What to include in a robust risk assessment investigation? Multiple controls are vital for controlling, preventing, and eliminating foreign material; however, inspectors cannot forget documentation and investigation. Designated inspectors must document and investigate each incident; Foreign Material logs are not enough: document all the details of each incident to minimize the likelihood of a repeat incident. A Cross-functional team should be part of the investigation including Operations, Food Safety, Quality team, Maintenance, Sanitation, and line workers. The investigation should include:

-

•

A detailed description of the incident, including the date (Who, What, Why, When, Where)

-

•

FM size, shape, color, pictures, sample

-

•

Where and who found the foreign object? Isolated or several findings?

-

•

Was it embedded or on the surface of the product?

-

•

What product was affected (quantity, lbs.)?

-

•

Was the foreign material from a sanitary source? List all the potential steps on your equipment/processes from which the foreign object could have been initiated.

-

•

Build a foreign material library to compare findings; use a magnifying glass or microscope.

-

•

Inspect the foreign object for potential modifications due to heat, grinding, or milling equipment. Collect the safety data sheet of the source of the foreign object, including melting point if applicable, FDA approval for food processing, and chemical composition. Send a sample to a toxicology lab.

During the investigation to find the root cause of the foreign material incident, the facility should consider any potential failures or gaps in the process. The following are equipment/processes or records that should be part of the investigation.

-

•

Line inspection/process flow for a potential source, including downtime records.

-

•

Maintenance repairs

-

•

Tools, parts reconciliation

-

•

Equipment transfer-points

-

•

Incoming inspections

-

•

Sanitation

-

•

Pre-op inspections

-

•

Constructions (new line, roof repairs, wall, floor, etc.)

-

•

Inadequate procedures/OPLs

-

•

Supplier as a potential source

-

•

Packaging of raw materials

-

•

Finished product packaging.

-

•

Verify retention samples of raw materials and finished product.

-

•Monitoring of

-

oMagnets, screens, sieves, filters, sifters, metal detectors, x-rays, optical devices, records

-

oLast acceptable records

-

oCustomer complaints related to foreign material.

-

oAll Internal and external findings, including from foreign material devices, were adequately documented and investigated.

-

oFindings from foreign material audits/assessments

-

oAre Maintenance PMs and frequency adequate?

-

o

-

⁃People

-

oTeam member Interviews

-

oEmployee training

-

oPoor GMPs

-

oPPE Inspections

-

o

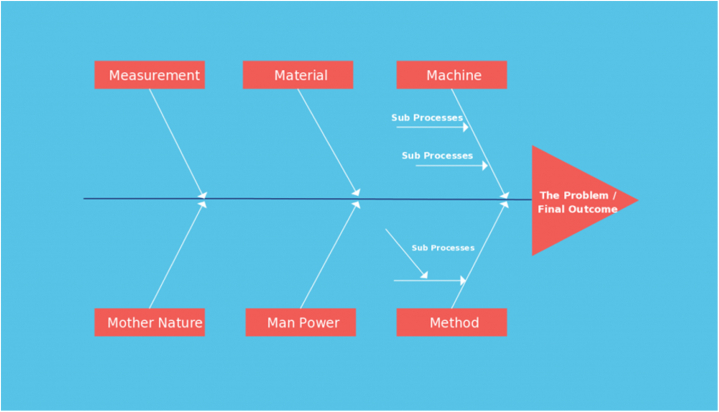

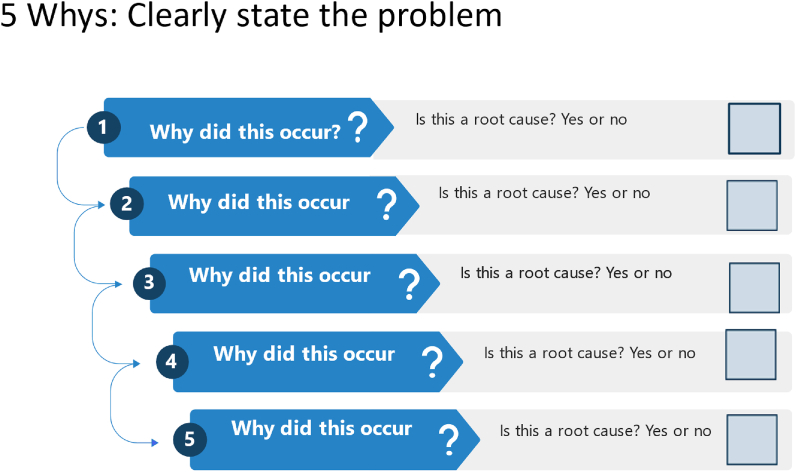

Some simple tools could be useful during an investigation. To begin the investigation flow, we could use a fishbone diagram [64] (Fig. 5), and then a 5 Why Analysis [65] (Fig. 6) could be completed on each item of the fishbone for a deeper investigation to find the root cause. The fishbone diagram helps identify the possible causes of a problem where the actual issue occurred, and the 5 Why's Analysis helps find the root cause. This analysis works great during brainstorming steps. Begin the process by writing down the problem in the fish's mouth and selecting the causes' categories. The benefit of the fishbone diagram is diving deeper to understand the cause of the problem better so it can be fixed. Continue with the 5 Why's Analysis. The 5 Why's is an analysis developed by Sakichi Toyoda [93] to determine the root cause of a problem. Begin with identifying the problem and asking “why”. Keep asking why to find deeper causes until you cannot respond. It might take fewer questions to determine the root cause.

Fig. 5.

Fishbone Diagram (also known as Cause-and-Effect Diagram or Ishikawa Diagram) [91].

Fig. 6.

5 whys analysis: Template & overview [92].

FMEA (Failure Mode and Effects Analysis) [94,95] is a proactive method for assessing a process to identify where and how it may fail. It could also evaluate the risk or impact of the failures, which is vital to prioritize which areas are critical. FMEA is used to control, reduce, and eliminate failures, starting with the highest-priority failures (where the process could fail). FMEA review should cover steps in the process, what could go wrong, the causes of the failure, and the consequences of each failure. FMEA can improve the process and reduce foreign material causes that are considered failures. Processing facilities should use FMEA when redesigning the process, when the process is out of control, when having several foreign material issues without root causes, when setting goals, etc. [94,95].

After inspecting the equipment and reviewing documents, it is crucial to assess the information collected to determine the actions to be taken and if the product was affected. It is essential to summarize the information to understand whether the finding was isolated or multiple. Additionally, if the incident caused any microbiological or chemical hazards on top of the physical hazard. The process should be evaluated to determine if it is adequate to produce safe food products or if changes need to be made before resuming operations.

After completion of the investigation, the facility should utilize the information collected to bring the process back in control. The root cause should be used to implement short (immediate actions) and long-term corrective actions. Preventive measures should be defined to prevent future incidents, and an action plan should list programs, procedures, systems, and processes. After implementing corrective actions, the facility should ensure to close out the investigations and assess the food safety/HACCP and SSOP plan if applicable. All foreign material findings should be trended to bring the issues to light.

10. Conclusions

With the globalization of the food supply chain, robust FM detection processes will need to continue to grow in both magnitude and geographic distance. Foreign material contaminations can come from any point in the food production system from the field through manufacturing to transport to retail. Inadequate removal of FM can lead to potential consumer safety concerns, quality concerns, or product recalls, which are costly and detrimental to the image of a company. Therefore, proactive, and effective means are needed to remove these potential risks and reduce their potential to reach a consumer as much as possible.

To meet these demands, risk-based food safety systems are being implemented to evaluate the risks for the industry. Once risks are determined and critical limits are set, the overall level and food safety and quality should improve if these systems are followed. To meet these limits, process controls can be implemented to help remove and reduce the potential risks from FM. These controls must be used along with effective maintenance.

Funding

Not applicable.

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article.

Data availability statement

No data was used for the research described in the article.

Additional information

No additional information is available for this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Stewart K., Gostin L.O. Food and Drug Administration regulation of food safety. JAMA. 2011;306(1):88–89. doi: 10.1001/jama.2011.885. [DOI] [PubMed] [Google Scholar]

- 2.Motarjemi Y., Lelieveld H., editors. Food Safety Management: a Practical Guide for the Food Industry. Academic Press; 2013. pp. 213–217. [Google Scholar]

- 3.Driscoll B. Uncovering foreign materials. 2013. https://www.foodqualityandsafety.com/article/getting-a-handle-on-foreign-materials/ Available at:

- 4.FDA CPG sec 555.425 foods, adulteration involving hard or sharp foreign objects. 2005. https://www.fda.gov/regulatory-information/search-fda-guidance-documents/cpg-sec-555425-foods-adulteration-involving-hard-or-sharp-foreign-objects Available at: [PubMed]

- 5.USDA Recalls and public health alerts. 2021. https://www.fsis.usda.gov/recalls Available at:

- 6.Safefood 360 Glass and hard plastic control. 2013. https://safefood360.com/resources/Glass-Plastic-Control.pdf Available at:

- 7.Edwards M.C., Stringer M.F. The breakdowns in food safety group observations on patterns in foreign material investigations. Food Control. 2007;18:773–782. [Google Scholar]

- 8.Edwards M. In: Hygiene in Food Processing (441-464) Lelieveld H.L.M., Holah J.T., Napper D., editors. Woodhead Publishing; Cambridge: 2014. Food hygiene and foreign bodies. [Google Scholar]

- 9.FSIS . 2017. FSIS Consumer Complaint Monitoring System (CCMS) Complaints Annual Report – Calendar Year (CY) 2017.https://www.fsis.usda.gov/sites/default/files/media_file/2020-07/CCMS-annual-report-cy17.pdf Available at: [Google Scholar]

- 10.Wilm K.H. Foreign object detection: integration in food production. 2012. https://www.food-safety.com/articles/3722-testing-foreign-object-detection-integration-in-food-production#Reference Available at:

- 11.Appels K., Koojimans R. The key to successful foreign object prevention. 2019. https://www.foodsafety-experts.com/food-safety/fo-prevention/ Available at:

- 12.Anon Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 laying down the general principles and requirements of food law, establishing the European Food Safety Authority and laying down procedures in matters of food safety. 2002 https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32002R0178 Document 32002R0178. [Google Scholar]

- 13.International Food Safety and Quality Network EU regulation for foreign bodies in food? 2022. https://www.ifsqn.com/forum/index.php/topic/45238-eu-regulation-for-the-size-of-foreign-bodies-in-food/ Available at:

- 14.Stier R.F. Managing and controlling foreign materials. Cereal Foods World. 2017;62(1):30–34. [Google Scholar]

- 15.Wilks M. Magnetic separators: removing unwanted debris. Filtrat. Separ. 2006;5(43):40–41. [Google Scholar]

- 16.Bayram M., Öner M.D. Determination of applicability and effects of colour sorting system in bulgur production line. J. Food Eng. 2006;74(2):232–239. [Google Scholar]

- 17.Mohammadi V., Ghasemi-Varnamkhasti M., Ebrahimi R., Abbasvali M. Ultrasonic techniques for the milk production industry. Measurement. 2014;58:93–102. [Google Scholar]

- 18.Li F., Liu Z., Sun T., Ma Y., Ding X. Confocal three-dimensional micro X-ray scatter imaging for non-destructive detecting foreign bodies with low density and low-Z materials in food products. Food Control. 2015;54:120–125. [Google Scholar]

- 19.Yamazaki S., Nakane H., Tanaka A. Basic analysis of a metal detector. IEEE Trans. Instrum. Meas. 2002;51(4):810–814. [Google Scholar]

- 20.Graves M., Smith A., Batchelor B. Approaches to foreign body detection in foods. Trends Food Sci. Technol. 1998;9(1):21–27. [Google Scholar]

- 21.Choi K.N. Two-channel metal detector using two perpendicular antennas. J. Sens. 2014 doi: 10.1155/2014/412621. 2014. Article ID 412621 |. [DOI] [Google Scholar]

- 22.Ries B. How multiscan technology will revolutionize metal detection and food safety. Food Manuf. 2017 https://www.manufacturing.net/safety/article/13165914/how-multiscan-technology-will-revolutionize-metal-detection-and-food-safety Available at: [Google Scholar]

- 23.Haff R.P., Toyofuku N. X-ray detection of defects and contaminants in the food industry. Sensing and Instrumentation for Food Quality and Safety. 2008;2(4):262–273. [Google Scholar]

- 24.Kwon J.S., Lee J.M., Kim W.Y. Consumer Electronics, 2008. IEEE international symposium; 2008. Real-time detection of foreign objects using X-ray imaging for dry food manufacturing line; pp. 1–4. ISCE 2008. [Google Scholar]

- 25.Mery D., Lillo I., Loebel H., Riffo V., Soto A., Cipriano A., et al. Automated fish bone detection using X-ray imaging. J. Food Eng. 2011;105(3):485–492. [Google Scholar]

- 26.Zwiggelaar R., Bull C.R., Mooney M.J., Czarnes S. The detection of “soft” materials by selective energy Xray transmission imaging and computer tomography. J. Agric. Eng. Res. 1997;66(3):203–212. [Google Scholar]

- 27.Takashi A. Proceedings 55th International Congress of Meat Science and Technology. 2009. Detection for foreign bodies and bones in meat and meat products. Copenhagen, Denmark. [Google Scholar]

- 28.Bech M., Bunk O., Donath T., Feidenhans’l R., David C., Pfeiffer F. Quantitative x-ray dark-field computed tomography. Phys. Med. Biol. 2010;55(18):5529. doi: 10.1088/0031-9155/55/18/017. [DOI] [PubMed] [Google Scholar]

- 29.Pfeiffer F., Weitkamp T., Bunk O., David C. Phase retrieval and differential phase-contrast imaging with low-brilliance X-ray sources. Nat. Phys. 2006;2:258–261. [Google Scholar]

- 30.Pfeiffer F., Bech M., Bunk O., Kraft P., Eikenberry E.F., Bronnimann C., et al. Hard X-ray dark field-imaging using a grating interferometer. Nat. Mater. 2008;7(23):134–137. doi: 10.1038/nmat2096. [DOI] [PubMed] [Google Scholar]

- 31.Einarsdóttir H., Emerson M.J., Clemmensen L.H., Scherer K., Willer K., Bech M., Larsen R., Ersbøll B.K., Pfeiffer F. Novelty detection of foreign objects in food using multi-modal X-ray imaging. Food Control. 2016;67:39–47. [Google Scholar]

- 32.Ginesu G., Giusto D.D., Margner V., Meinlschmidt P. Detection of foreign bodies in food by thermal image processing. IEEE Trans. Ind. Electron. 2004;51(2):480–490. [Google Scholar]

- 33.Orina I., Manley M., Williams P.J. Non-destructive techniques for the detection of fungal infection in cereal grains. Food Res. Int. 2017;100:74–86. doi: 10.1016/j.foodres.2017.07.069. [DOI] [PubMed] [Google Scholar]

- 34.Vadivambal R., Jayas D.S. Applications of thermal imaging in agriculture and food industry - a review. Food Bioprocess Technol. 2011;4(2):186–199. [Google Scholar]

- 35.Gowen A.A., Tiwari B.K., Cullen P.J., McDonnell K., O'Donnell C.P. Applications of thermal imaging in food quality and safety assessment. Trends Food Sci. Technol. 2010;21(4):190–200. [Google Scholar]

- 36.Jha S.N., Narsaiah K., Basediya A.L., Sharma R., Jaiswal P., Kumar R., Bhardwaj R. Measurement techniques and application of electrical properties for nondestructive quality evaluation of foods - a review. J. Food Sci. Technol. 2011;48(4):387–411. doi: 10.1007/s13197-011-0263-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Marcone M.F., Wang S., Albabish W., Nie S., Somnarain D., Hill A. 2013. Diverse Food-Based Applications of Nuclear Magnetic Resonance (NMR) Technology. [Google Scholar]

- 38.Awad T.S., Moharram H.A., Shaltout O.E., Asker D., Youssef M.M. Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res. Int. 2012;48(2):410–427. [Google Scholar]

- 39.Cho B.-K., Irudayaraj J.M.K. Foreign object and internal disorder detection in food materials using noncontact ultrasound imaging. Food Engineering and Physical Properties. 2003;68(3):967–974. [Google Scholar]

- 40.Meftah H., Azimin E.M. Detection of foreign bodies in canned foods using ultrasonic testing. Int. Food Res. J. 2012;19(No. 2):543–546. [Google Scholar]

- 41.Wang W., Paliwal J. Near-infrared spectroscopy and imaging in food quality and safety. Sensing and Instrumentation for Food Quality and Safety. 2007;1(4):193–207. [Google Scholar]

- 42.Li J.L., Sun D.W., Cheng J.H. Recent advances in nondestructive analytical techniques for determining the total soluble solids in fruits: a review. Compr. Rev. Food Sci. Food Saf. 2016;15(5):897–911. doi: 10.1111/1541-4337.12217. [DOI] [PubMed] [Google Scholar]

- 43.Mathiassen J.R., Misimi E., Bondø M., Veliyulin E., Østvik S.O. Trends in application of imaging technologies to inspection of fish and fish products. Trends in Food Science and Technology. Food Res. Int. 2011;51(2):729–747. 22(6), 257–275. [Google Scholar]

- 44.Huang M., Kim M.S., Chao K., Qin J., Mo C., Esquerre C., Zhu Q. Penetration depth measurement of near-infrared hyperspectral imaging light for milk powder. Sensors. 2016;16(4) doi: 10.3390/s16040441. 441–411. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Kong W., Zhang C., Liu F., Nie P., He Y. Rice seed cultivar identification using near-infrared hyperspectral imaging and multivariate data analysis. Sensors. 2013;13(7):8916–8927. doi: 10.3390/s130708916. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Kamruzzaman M., Elmasry G., Sun D.W., Allen P. Application of NIR hyperspectral imaging for discrimination of lamb muscles. J. Food Eng. 2011;104(3):332–340. [Google Scholar]

- 47.Osborne B., Fearn T., Hindle P. second ed. Longman Scientific & Technical; London, England: 1993. Practical NIR Spectroscopy with Applications in Food and Beverage Analysis. [Google Scholar]

- 48.Butz P., Hofmann C., Tauscher B. Recent developments in noninvasive techniques for fresh fruit and vegetable internal quality analysis. J. Food Sci. 2005;70:R131–R141. doi: 10.1111/j.1365-2621.2005.tb08328.x. [DOI] [Google Scholar]

- 49.McClure W.F., Moody D., Stanfield D.L., Kinoshita O. Hand-held NIR Spectrometry. Part II: an economical no-moving parts spectrometer for measuring chlorophyll and moisture. Appl. Spectrosc. 2002;56(6):720–724. [Google Scholar]

- 50.Pallav P., Diamond G.G., Hutchins D.A., Green R.J., Gan T.H. A near-infrared (NIR) technique for imaging food materials. J. Food Sci. 2009;74(1):E23–E33. doi: 10.1111/j.1750-3841.2008.01011.x. [DOI] [PubMed] [Google Scholar]

- 51.Tsuta M., Takao T., Sugiyama J., Wada Y., Sagara Y. Foreign substance detection in blueberry fruits by spectral imaging. Food Sci. Technol. Res. 2006;12(2):96–100. [Google Scholar]

- 52.Manley M. Near-infrared spectroscopy and hyperspectral imaging: non-destructive analysis of biological materials. Chem. Soc. Rev. 2014;43(24):8200–8214. doi: 10.1039/c4cs00062e. [DOI] [PubMed] [Google Scholar]

- 53.Sugiyama T., Sugiyama J., Tsuta M., Fujita K., Shibata M., Kokawa M.…Sagara Y. NIR spectral imaging with discriminant analysis for detecting foreign materials among blueberries. J. Food Eng. 2010;101(3):244–252. [Google Scholar]

- 54.Tashima H., Genta T., Ishii Y., Ishiyama T., Arai S., Fukuda M. Near-infrared imaging system for detecting small organic foreign substances in foods. Current Developments in Lens Design and Optical Engineering. 2013;XIV:1–8. Paper presented at the Proceedings of SPIE 8841. California, CA. [Google Scholar]

- 55.Tunny S.S., Amanah H.Z., Faqeerzada M.A., Wakholi C., Kim M.S., Baek I., Cho B.-K. Multispectral wavebands selection for the detection of potential foreign materials in fresh-cut vegetables. Sensors. 2022;22:1775. doi: 10.3390/s22051775. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Tunny S., Kurniawan H., Amanah H., Baek I., Kim M.S., Chan D.E., Farqeerzada M., Wakholi C., Cho B. Hyperspectral imaging techniques for detection of foreign materials from fresh-Cut vegetables. Postharvest Biol. Technol. 2023;201 doi: 10.1016/j.postharvbio.2023.112373. [DOI] [Google Scholar]

- 57.Huang H., Liu L., Ngad N.O. Recent developments in hyperspectral imaging for assessment of food quality and safety. Sensors. 2014;14:7248–7276. doi: 10.3390/s140407248. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 58.Goetz A.F.H., Vane G., Solomon J.E., Rock B.N. Imaging spectrometry for earth remote-sensing. Science. 1985;228:1147–1153. doi: 10.1126/science.228.4704.1147. [DOI] [PubMed] [Google Scholar]

- 59.Jay S.C., Lawrence R.L., Repasky K.S., Rew L.J. Detection of leafy spurge using hyper-spectral-spatial-temporal imagery. IEEE International Geoscience and Remote Sensing Symposium. 2010:4374–4376. doi: 10.1109/IGARSS.2010.5652580. 2010. 2010. [DOI] [Google Scholar]

- 60.Yang Z., Tian J., Feng K., Gong X., Liu J. Application of a hyperspectral imaging system to quantify leaf-scale chlorophyll, nitrogen and chlorophyll fluorescence parameters in grapevine. Plant Physiol. Biochem. 2021;166:723–737. doi: 10.1016/j.plaphy.2021.06.015. [DOI] [PubMed] [Google Scholar]

- 61.Lu G., Fei B. Medical hyperspectral imaging: a review. J. Biomed. Opt. 2014 Jan;19(1) doi: 10.1117/1.JBO.19.1.010901. PMID: 24441941; PMCID: PMC3895860. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Al Ktash M., Stefanakis M., Boldrini B., Ostertag E., Brecht M. Characterization of pharmaceutical tablets using UV hyperspectral imaging as a rapid in-line analysis tool. Sensors. 2021;21(13):4436. doi: 10.3390/s21134436. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Kang Z., Zhao Y., Chen L., Guo Y., Mu Q., Wang S. Advances in machine learning and hyperspectral imaging in the food supply chain. Food Eng. Rev. 2022 doi: 10.1007/s12393-022-09322-2. [DOI] [Google Scholar]

- 64.Zhao X., Wang W., Ni X.Z., Chu X., Li Y.F., Sun C.P. Evaluation of near-infrared hyperspectral imaging for detection of peanut and walnut powders in whole wheat flour. Applied Sciences-Basel. 2018;8:1079. doi: 10.3390/app8071076. [DOI] [Google Scholar]

- 65.Chung S., Yoon S.-C. Detection of foreign materials on broiler breast meat using a fusion of visible near-infrared and short-wave infrared hyperspectral imaging. Appl. Sci. 2021;11 doi: 10.3390/app112411987. [DOI] [Google Scholar]

- 66.Shimonomura K., Chang T., Murata T. Detection of foreign bodies in soft foods employing tactile image sensor. Front Robot AI. 2021;3(8) doi: 10.3389/frobt.2021.774080. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Shimonomura K., Nakashima H. SENSORS. IEEE; 2013. A combined tactile and proximity sensing employing a compound-eye camera; pp. 1–2. 2013 IEEE. [Google Scholar]

- 68.Shimonomura K., Nakashima H., Nozu K. 2016 IEEE International Conference on Robotics and Automation (ICRA) IEEE; 2016. Robotic grasp control with high-resolution combined tactile and proximity sensing; pp. 138–143. [Google Scholar]

- 69.Nozu K., Shimonomura K. 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM) IEEE; 2018, July. Robotic bolt insertion and tightening based on in-hand object localization and force sensing; pp. 310–315. [Google Scholar]

- 70.Radar Food. Making the invisible visible. 2022. https://www.foodradar.com/ Available at:

- 71.Fraunhofer H.F.R. Using radar to detect foreign objects in foods. 2020. https://www.fhr.fraunhofer.de/en/press-media/press-releases/2020/using-radar-to-detect-foreign-objects-in-foods.html Available at:

- 72.Food Safety Magazine A new unique detection technology for “invisible” foreign bodies. 2014. https://www.food-safety.com/articles/2448-a-new-unique-detection-technology-for-e2809cinvisiblee2809d-foreign-bodies Available at:

- 73.Mazzoleni S., Magni S., Tretola M., Luciano A., Ferrari L., Bernardi C.E.M., Lin P., Ottoboni M., Binelli A., Pinotti L. Packaging contaminants in former food products: using Fourier Transform Infrared Spectroscopy to identify the remnants and the associated risks. J. Hazard Mater. 2023;448 doi: 10.1016/j.jhazmat.2023.130888. ISSN 0304-3894. [DOI] [PubMed] [Google Scholar]

- 74.European Commission . Off J. Eur Union; 2013. Commission Regulation (EU) No 68/2013 of 16 January 2013 on the Catalogue of Feed Materials. L 29. Available from: [Google Scholar]

- 75.Lecrenier M.C., Fumiere O., Baeten V. Book of Abstracts of the 72nd Annual Meeting of the European Federation of Animal Science. Eaap Davos; 2021. Giving a second life to food waste: what to expect from the use of former foodstuff in animal feed? [Google Scholar]

- 76.Tretola M., Ottoboni M., Di Rosa A.R., Giromini C., Fusi E., Rebucci R., Pinotti L. Former food products safety evaluation: computer vision as an innovative approach for the packaging remnants detection. J. Food Qual. 2017;2017:6. doi: 10.1155/2017/1064580. Article ID 1064580. [DOI] [Google Scholar]

- 77.Calvini R., Luciano A., Ottoboni M., Ulrici A., Tretola M., Pinotti L. Multivariate image analysis for the rapid detection of residues from packaging remnants in former foodstuff products (FFPs)–a feasibility study. Food Addit. Contam. 2020;37(8):1399–1411. doi: 10.1080/19440049.2020.1769195. [DOI] [PubMed] [Google Scholar]

- 78.Ok G., Park K., Kim H.J., Chun H.S., Choi S.W. High-speed terahertz imaging toward food quality inspection. Appl. Opt. 2014;53(7):1406–1412. doi: 10.1364/AO.53.001406. [DOI] [PubMed] [Google Scholar]

- 79.Li F., Liu Z., Sun T., Ma Y., Ding X. Confocal three-dimensional micro X-ray scatter imaging for non-destructive detecting foreign bodies with low density and low-Z materials in food products. Food Control. 2015;54:120–125. [Google Scholar]

- 80.Nielsen M.S., Lauridsen T., Christensen L.B., Feidenhans R. X-ray dark-field imaging for detection of foreign bodies in food. Food Control. 2013;30(2):531–535. [Google Scholar]

- 81.Wen H., Bennett E.E., Hegedus M.M., Carroll S.C. Spatial harmonic imaging of x-ray scattering—initial results. IEEE Trans. Med. Imag. 2008;27(8):997–1002. doi: 10.1109/TMI.2007.912393. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 82.Wen H., Bennett E.E., Hegedus M.M., Rapacchi S. Fourier X-ray scattering radiography yields bone structural information. Radiology. 2009;251(3):910–918. doi: 10.1148/radiol.2521081903. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 83.Stein A.F., Ilavsky J., Kopace R., Bennett E.E., Wen H. Selective imaging of nano-particle contrast agents by a single-shot x-ray diffraction technique. Opt Express. 2010;18(12):13271–13278. doi: 10.1364/OE.18.013271. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 84.Lim H., Lee J., Lee S., Cho H., Lee H., Jeon D. Low-density foreign body detection in food products using single-shot grid-based dark-field X-ray imaging. J. Food Eng. 2022;335 doi: 10.1016/j.jfoodeng.2022.111189. [DOI] [Google Scholar]

- 85.Jördens C., Koch M. Detection of foreign bodies in chocolate with pulsed terahertz spectroscopy. Opt. Eng. 2008;47(3) 037003-037003. [Google Scholar]

- 86.Lee Y.K., Choi S.W., Han S.T., Woo D.H., Chun H.S. Detection of foreign bodies in foods using continuous wave terahertz imaging. J. Food Protect. 2012;75(1):179–183. doi: 10.4315/0362-028X.JFP-11-181. [DOI] [PubMed] [Google Scholar]

- 87.Ok G., Choi S.W., Park K.H., Chun H.S. Foreign object detection by sub-terahertz quasi-Bessel beam imaging. Sensors. 2012;13(1):71–85. doi: 10.3390/s130100071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 88.Ok Gyeongsik, Kim Hyun Jung, Chun Hyang, Choi Sung-Wook. Foreign-body detection in dry food using continuous sub-terahertz wave imaging. Food Control. 2014;42:284–289. doi: 10.1016/j.foodcont.2014.02.021. [DOI] [Google Scholar]

- 89.Sun X., Li J., Shen Y., Li W. Non-destructive detection of insect foreign bodies in finishing tea product based on terahertz spectrum and image. Front. Nutr. 2021;8 doi: 10.3389/fnut.2021.757491. 2021 Oct 18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 90.Sun X., Cui D., Shen Y., Li W., Wang J. Non-destructive detection for foreign bodies of tea stalks in finished tea products using terahertz spectroscopy and imaging. Infrared Phys. Technol. 2022;121 doi: 10.1016/j.infrared.2021.104018. [DOI] [Google Scholar]

- 91.Creatley Fishbone diagram templates (cause and effect/Ishikawa templates) 2022. https://creately.com/blog/examples/fishbone-diagram-templates/#Manufacturing Available at:

- 92.Study.com 5 Whys Analysis: Template & Overview. 2022 https://study.com/academy/lesson/5-whys-analysis-template-overview.html Available at: [Google Scholar]

- 93.Toyota Industries The story of Sakichi Toyoda. 2022. https://www.toyota-industries.com/company/history/toyoda_sakichi/ Available at:

- 94.Institute for Healthcare Improvement . 2022. Failure Modes and Effects Analysis. [Google Scholar]

- 95.American Society for Quality Failure Mode and effects analysis (FMEA) 2022. https://asq.org/quality-resources/fmea Available at:

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.