Abstract

Organic waste generation has increased massively around the world during the last decades, especially the waste produced by the olive-growing industry. In order to manage the waste accumulation, composting process is an appropriate biotechnological solution which allows the waste organic matter biotransformation into a useful product the “compost”, used as an amendment for agricultural soils. The classical composting process presents several disadvantages; the major difficulty is to find the best feedstocks proportion to be used, leading to a final C/N ratio ranged between 12 and 15, a neutral pH, a humidity between 40% and 60% and organic matter (OM) content of 20–60%, at ambient temperature. Consequently, an accurate optimization of the composting process is needed for predicting the process parameters progress. To optimize these parameters and the waste rates initially mixed, the multiple regression method was used to determine the compost final parameters values, referring to the initial mixture of the different waste types. The best model filling the required standardized values included 49% of olive mill wastewater, 19.5% of exhausted olive mill cake, 15.5% of poultry manure, and 16% of green waste. This combination provides a pH of 7.5, a C/N ratio of 12.5 and an OM content of 44%. Such modelization would enshorten the composting required time.

Keywords: Composting process, Optimization, Multiple regression, Olive mill wastewater, Green waste, C/N ratio

1. Introduction

In the Maghreb, the latest statistical studies carried out predicted that by 2030, the waste amount will reach 39 million tons (MT), including 9.4 MT of household and similar waste (MSW) in Morocco [1], while according to ANGED (2018) [2], Tunisia produced 2.8 MT of MSW per year with a growth rate of 2.5% annually. The management of this huge volume as not to affect the environment and human life seems difficult. Consequently, it is necessary to consider alternatives to manage waste, with high organic matter (OM) content, such as olive oil extraction industries’ waste, which currently represent a real environmental threat in countries producing olive oil such as Tunisia and Morocco [3]. Thereby, composting is an interesting strategy that should be carried out for the treatment of this type of organic waste, which has long been a common method for organic waste management (2023).

The composting is a controlled process of biodegradable OM decomposition, and transformation, producing a practical product be beneficial for agriculture as soil amendment Fig. 1 [[4], [5], [6]]. It leads to two main goals: the waste valorization, and consequently pollution reduction, fitting in the circular economy framework.

Fig. 1.

Parameters affecting composting process.

Process optimization is performed using mathematical models to give the compost best quality value-added and the most cost-effective process. Modelling allows prediction of dependent variable as accurately as possible, especially when independent variable values are not available. As for multiple regression, optimization is a statistical technique used to model the relationship between a dependent variable and several independent variables. Other methodologies could be applied such as machine learning, giving more accurate results, but requiring a huge experimental data.

In composting processes, previous optimization and modelling approaches were investigated to accurately predict the temperature profile throughout the process based mainly on the microbial activity [[7], [8], [9]], predict CO2 output from the feedstock composting [10], optimize the processing parameters for improving compost quality [[11], [12], [13]], monitor moisture content in industrial-scale composting systems [14], estimate the enzymatic activity in the compost [15], forecast compost maturity [16,17] and classify its maturity [18]. These researches applied models rely on theoretical, analytical and statistical methodologies [19].

The application of multiple regression method in the context of composting can be used to predict or optimize some of the process parameters as a function of different variables. These could be decomposition time, compost windrow temperature, moisture content, nutrient content of the final compost, C/N ratio, pH, etc., as dependant variables and composition of the OM mixture, particle size, aeration, ambient temperature, etc., as independent variables. Generally, the waste initial proportions determination to be used producing a stable compost that complying with standards, requires the achievement of many experiences. This makes the process extremely time-consuming, especially when the OM content and the C/N ratio are relatively too high. In the litterature, no previous study dealing with modeling initial rate of co-composted materials issued from olive oil processing is available.

Therefore, the aim of this work was to optimize the substrates initial proportions to be co composted referring to a database collected from previous composting works promoting the recycling of olive-growing waste, by adjusting the output parameters. These were pH, OM content and C/N ratio set according to the standard values. For this purpose, an optimization based on multiple regression method incorporating the mixture design was applied on the collected database, and the resulting optimal model was evaluated. The findings contribute to composting promotion by providing the right feedstock ratio to be composted.

2. Materials and methods

2.1. Characterization of classical composts elaborated in Morocco and Tunisia

Three main types of waste were used to establish an optimized composting model; these are olive oil extraction wastes: olive mill wastewater (OMW), olive mill solid waste (OMSW), and exhausted olive mill cake (EOC), green waste (GW) and poultry manure (PM).

The present study was investigated to help olive-oil producing countries, especially Morocco and Tunisia, in managing the wastes related to olive oil sector. This initiative was justified by the disturbing environmental problem in relation with this type of waste dumped into rivers and lakes, or used for irrigation without any previous treatment, generating ecological disturbances in groundwater and surface water [7,9,20]. However, considering previous works, this effluent was integrated as humidifier during the composting process, and its composition was proved to boost the composting process [[21], [22], [23], [24], [25], [26]].

The green waste (GW) is most usually composed of refuse from gardens and domestic or industrial kitchen wastes, characterized by relatively high nitrogen concentrations used to increase composting processes efficiency [24,26].

The PM includes multiple nutritive elements, providing nitrogen (N), phosphorous (P) and mineral elements, these became assimilable by plant through once composted.

The compost quality is determined according to several physico-chemical parameters interfering during the bioprocess, notably the pH, the temperature, the OM concentration and the C/N ratio.

2.2. Dataset

In the present investigation, the data used were based on Tunisian and Moroccan previously published studies dealing with composts mainly produced from olive oil extraction wastes, carried out between 2007 and 2018, where the OMW was valorized by composting. Table 1 presents the composition of the different composted substrates based on a mix of organic wastes at various rates, according to the authors and the country. Twelve types of composts were selected to establish the bioprocess modelling. These were characterized by their initial composition including olive oil extraction wastes (OMW, OMSW, EOC), PM, GW and composted for months to give a range of products. These obtained composts were the outcomes of returned windrows of sizes ranged from 1 to 20 tons. These composts were issued from fermentations at average and relatively high temperatures. While the OMW was used as humidifier, PM provided principally nitrogen and the SB was the balking agent improving the porosity. In the present study, 3 physicochemical parameters were considered for forcasting the bioprocess: these were the pH, OM and C/N rate (Table 1).

Table 1.

Synthesis of the organic industrial wastes and effluents composting: windrow composition and initial physicochemical characterization [[14], [15], [16], [17], [18], [19], [20], [21]].

|

Compost/Country |

Windrow composition (%) |

Compost characterization |

Reference | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OMW | OMSW | EOC | PM | GW | GM | SB | pH | MO (%) | C/N | |||

| C1/M | 31.7 | 0 | 0 | 21.5 | 46.8 | 0 | 0 | 8.83 | 44.59 | 12.00 | [14] | |

| C2/M | 34 | 22 | 0 | 0 | 22 | 22 | 0 | 7.02 | 32.00 | 12.00 | [15] | |

| C3/M | 48 | 0 | 0 | 0 | 26 | 26 | 0 | 8.83 | 58.00 | 12.24 | [15] | |

| C4/M | 17.4 | 0 | 0 | 17.4 | 65.2 | 0 | 0 | 8.13 | 49.85 | 13.02 | [16] | |

| C5/T | 54 | 0 | 34 | 0 | 0 | 0 | 12 | 8.50 | 48.80 | 9.63 | [17] | |

| C6/T | 58 | 31 | 0 | 0 | 0 | 0 | 11 | 8.40 | 40.70 | 11.59 | [17] | |

| C7/T | 60 | 30 | 0 | 10 | 0 | 0 | 0 | 8.90 | 30.10 | 11.90 | [18] | |

| C8/T | 41 | 0 | 44 | 15 | 0 | 0 | 0 | 8.25 | 44.68 | 16.50 | [19] | |

| C9/T | 41 | 0 | 29.5 | 29.5 | 0 | 0 | 0 | 7.98 | 72.96 | 15.60 | [19] | |

| C10/T | 41 | 0 | 15 | 44 | 0 | 0 | 0 | 8.34 | 32.43 | 13.60 | [19] | |

| C11/T | 68 | 19 | 0 | 0 | 0 | 0 | 13 | 8.71 | 36.68 | 18.75 | [20] | |

| C12/T | 68 | 19 | 0 | 13 | 0 | 0 | 0 | 8.32 | 26.21 | 16.21 | [21] | |

OMW: Olive Mill Wastewater, OMSW: Olive Mill Solid Waste, EOC: Exhausted Olive Cake, PM: Poultry Manure, GW: Green Waste, GM: Grape Marcs, SB: Sesame bark, M: Morocco, T: Tunisia.

2.3. Mixture design

According to the previously dataset listed, the mixture used in this study is composed of OMW, OMSW, EOC, GW, PM, SB and GM as inputs then the pH, the OM percentage, as well as the C/N ratio as outputs of the process. The mixture design inputs are the ingredients’ proportions involved in the mixture as shown in Equation (1) [27,28].

| (1) |

where:

xi: the proportion of each input variable;

n: the number of input variables (n = 7 in the present case).

The experimental design is the result of MinitabR software (version 19) application.

In the main mixture design modeling approach, the principal goal was the input variables effect prediction when one, two or more compounds proportion of the investigated mixture varied. The main difference between the mixture design and the other experiment designs would be the absence of the constant term included in the mixture design models.

To compare the available data, Scheffé canonical polynomial models were used as displayed in Equations (2), (3), (4), (5) [29,30]. These mathematical models established correlations between the desired responses represented by compost’ controlled parameters i.e., pH, OM percentage and C/N ratio, and the ingredient wastes’ rates involved in the blend. These investigated polynomial models are as follows:

Linear:

| (2) |

Quadratic:

| (3) |

Full cubic:

| (4) |

Special quartic:

| (5) |

where:

: the response predicted value;

: the input variables;

: the polynomial coefficients.

2.4. Stepwise multiple regression method

Stepwise multiple regression method was used to analyze the mixture design, a technique based on the simultaneously removal of the variables that did not affect heavily the process.

This method is a statistical technique using several variables (inputs) to predict the output of the responses of a variable, and the multiple regression is an extension of the simple linear regression, that uses just one variable as input.

Stepwise regression essentially does successively multiple regressions many times; the goal is to remove the weakest correlated variables. At the process end, the variables elucidating the best distribution are obtained for the data normally distributed (or rather, that the residuals are), without any correlation between the independent variables, known as collinearity.

Actually, there are 3 types of stepwise regressions: backward elimination, forward selection and two-way elimination. In the present work, the backward elimination was used. It is an iterative process whereby starting with all the input variables, and gradually eliminating those that do not meet a defined significance criterion.

First, a significance level (typically a = 0.05) was set. Second, a multiple linear regression was run with the features and the obtained coefficients for each variable. Third, the function with the highest p-value was established. Fourth, the p-value exceeding the a-value was checked: if this step was confirmed, the variable was removed and step 2 was reconducted; if not, the end of backward elimination was reached.

When the response-variables (i.e. pH, OM content and C/N ratio) fitted linear, quadratic, and full cubic models, to check the goodness of the adjusted models, the various model features were generated. These are the standard deviation (S), the correlation coefficient R-squared (R2), the predicted R2, the adjusted R2 and the predicted sum of squares. According to the literature, the best fitting model must have, on the one hand, a small standard deviation (S) and a low predicted squares sum, as well as a high value of the following parameters: predicted R2, the R2 correlation coefficient and adjusted R2 on the other side [31].

2.5. Desirability function

To ensure the model satisfaction, the desirability function was used. This deviates between 0 and 1 reflecting the decision-making satisfaction degree. The overall desirability required (Dg) for the desired optimum responses is a function of the elementary desirability d(pH), d(OM) and d(C/N) defined by relation (6) as follows:

| (6) |

The desirability is equal to zero for an unsuitable response and is maximum when the given response is very satisfactory; it takes intermediate values for more or less satisfactory responses.

The environmental conditions such as temperature, humidity, aeration and biological conditions for instance microbial activity have a direct effect on the OM degradation, and subsequently on the time required to complete the process. In this study, these conditions were not taken into account, because the composts selected in the database were prepared under similar conditions in the conventional way (aerated windrows), humidified with olive oil wastewater, aerated in the same way (turning).

3. Results

3.1. The best fitting model

The mixing plan used in this study was personalized according to the matrix data of the previous Tunisian and Moroccan experiments held since 2007.

According to the mentioned guidelines, the most appropriate model for the different responses investigated: pH, OM content, and C/N ratio, was the full cubic model presenting low S value and the predicted square sum, as well as a high value for the predicted R2, the R2 correlation coefficient, and the adjusted R2.

The Minitab data analysis stepwise regression of the studied composting parameters is presented in Table 2.

Table 2.

Model features of pH, organic matter content (OM) percentage and C/N ratio.

| Response parameter | Regression | Standard deviation S | R2(%) | Adjusted R2 (%) |

Predicted R2 (%) |

Predicted squares sum |

|---|---|---|---|---|---|---|

| pH | Linear | 0.4852 | 59.18 | 10.19 | 0 | 10.2330 |

| Quadratic | 0.3659 | 81.42 | 48.91 | – | – | |

| Full Cubic | 0.0011 | 100 | 100 | 99.99 | 0.0004 | |

| Special Quartic | 0.3659 | 81.42 | 48.91 | – | – | |

| OM | Linear | 14.7044 | 44.12 | 0 | 0 | 8564.280 |

| Quadratic | 8.1604 | 89.67 | 62.14 | – | – | |

| Full Cubic | 0.1542 | 100 | 99.99 | - | 29.060 | |

| Special Quartic | 0.3593 | 99.93 | 99.93 | – | 153.691 | |

| C/N | Linear | 3.4564 | 21.13 | 0 | 0 | 327.132 |

| Quadratic | 1.5782 | 86.85 | 63.83 | 0 | 124.045 | |

| Full Cubic | 0.3344 | 99.56 | 98.38 | 94.09 | 4.477 | |

| Special Quartic | 1.5782 | 86.85 | 63.83 | 0 | 124.045 |

3.2. Mathematical models

The previous data matrix results studies mentioned above were used for the polynomial coefficients calculation.

The regression estimated coefficients for pH, OM content and C/N ratio allowed defining the mathematical equations (7), (8), (9), presenting the best fitting models, which may predict the variable responses with a low error margin, depending on the model features quality (Table 3).

Table 3.

Estimated regression coefficients for pH, organic matter content (OM%) and C/N ratio.

| Parameters | pH |

OM (%) |

C/N |

|||

|---|---|---|---|---|---|---|

| Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | |

| OMSW | 4.976 | – | 9.7 | – | −10.43 | – |

| EOC | 2.151 | – | −705 | – | 47.67 | – |

| SB | −22.199 | – | −182.57 | – | 54.61 | – |

| OMW | 19.319 | – | 167.3 | – | −24.27 | – |

| PM | −2.098 | – | −255.99 | – | 37.67 | – |

| GW | 7.379 | – | 99.934 | – | 6.06 | – |

| GM | −8.457 | – | −186.1 | – | 57.22 | – |

| EOC *PM | 10.376 | 0.003 | – | – | −474.1 | 0 |

| OMSW * OMW | 39.279 | 0.002 | 884.4 | 0.023 | – | – |

| OMW * PM | −61.782 | 0.001 | – | – | 59.22 | 0.005 |

| OMW * GW | −5.945 | 0.015 | – | – | – | – |

| EOC * OMW | – | – | 1198.6 | 0.016 | – | – |

| EOC * OMW * PM | – | – | 4006.9 | 0.008 | – | – |

| OMSW * SB | – | – | 539 | 0.143 | – | – |

OMSW: Olive Mill Solid Waste, EOC: Exhausted Olive Cake, SB: Sesame bark, OMW: Olive Mill Wastewater, PM: Poultry Manure, GW: Green Waste, GM: Grape Marcs.

The mathematical models correlating the different wastes rates used and the initial compost characteristics (pH, C/N ratio and organic matter content) are as follows:

| (7) |

| (8) |

| (9) |

The different figures affected to the variables refer to the regression coefficients represented in Table 3.

According to the regression coefficients comparative analysis of the a-value (0.05), all the second and the third degree terms of the pH, OM content and C/N ratio were significant, with a p-value <0.05, except the interaction olive mill solid waste (OMSW)/sesame barks (SB) which expressed a lack of correlation between these variables. Consequently, according to all the studied modeled results (pH, OM content and C/N ratio), sesame bark (SB) could be neglected and would not have a heavy impact on the process. Indeed, for enhancing the process, the SB was used as a balking agent, at relatively low rate (11–13%) compared to OMSW (19–31%), while the olive solid waste are mainly constituted of humidified lignocellulosic polymers, easy to be degraded.

3.3. Response plot diagram

To survey the effect of each substrate on the different variable responses pH, OM content, and C/N ratio, the component effects diagram, also called the Cox response diagram, was used. These plot curves showed the effect of changing the corresponding component along an imaginary line connecting the reference mixture to a vertex. The pH, OM percentage and C/N ratio responses results’ are illustrated in Fig. 2 (a), (b) and (c).

Fig. 2.

Cox response of fitted pH (a), fitted OM% (b) and fitted C/N ratio (c).

Based on these findings, it could be deduced that as the OMW, GW and EOC proportions increased, the pH increased rapidly unlike PM and OMSW where the pH was almost stable; the other remaining substrates (i.e. SB and G) did not present any effect on the pH progress. Then, when the EOC and GW proportions increased, the OM percentage reached rapidly its maximum value, but when the OMSW increased, the OM decreased rapidly and similarly to the pH evolution, the effects of SB and GM were negligible. Finally, as the PM and EOC proportions increased, the C/N ratio increased in parallel, exhibiting a decrease of compost stability.

Finally, it could be noticed that to achieve the desired pH value (around 7), OM percentage (between 20% and 60%) and C/N rate (between 10 and 15), the olive wastes (OMW and EOC), and GW proportions should be increased. However, the OMSW and PM proportions should be decreased and the other substrates (SB and GM) have to be neglected or eliminated.

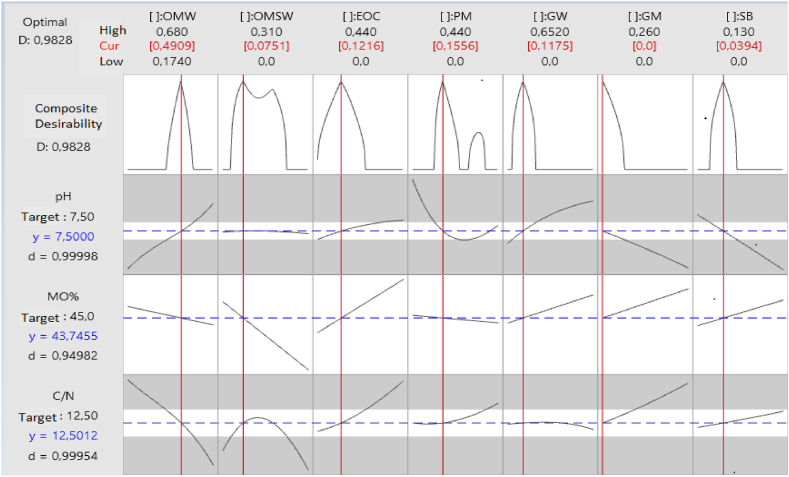

3.4. Optimal solution

The response optimization tool of the Minitab software was used to determine the optimal solution. The targets set for all the responses of the pH, the OM content and the C/N ratio were 7.5, 45% and 12.5 respectively; their specific constraints are presented in Table 4.

Table 4.

The cible constraints’ of pH, OM and C/N ratio to be respected by the mature compost.

| Parameter | Lower | Target | Upper |

|---|---|---|---|

| pH | 7.0 | 7.5 | 8.0 |

| OM (%) | 20 | 45 | 60 |

| C/N | 10 | 12.5 | 15 |

At the process starting, while considering the cible constrainsts, the feedstock optimization combination fitting the imposed constraints was the combinaison of 49% of OMW, 7.5% of OMSW, 12% of EOC, 15.5% of PM, 12% of GW and 4% of SB, as shown in Fig. 2. The data arrangement provides a pH of 7.5, a C/N ratio of 12.5 and an OM content of 44%.

While considering the answers diagrams’ analysis (Fig. 3), the SB should be eliminated and replaced by the GW. Similarly, since the OMSW percentage was not very important, it could be replaced by the EOC. As a result, the final model will be made up of 49% of OMW, 19.5% of EOC, 15.5% of PM, 16% of GW.

Fig. 3.

Optimization combination plot.

The desirability values predicting the responses were respectively of 0.9999, 0.9995 and 0.9498 for the pH, the OM content and the C/N ratio. The overall desirability was 0.9828 indicating that the optimal initial pH, the OM content and the C/N ratio were satisfying and within acceptable limits (Fig. 3) [32].

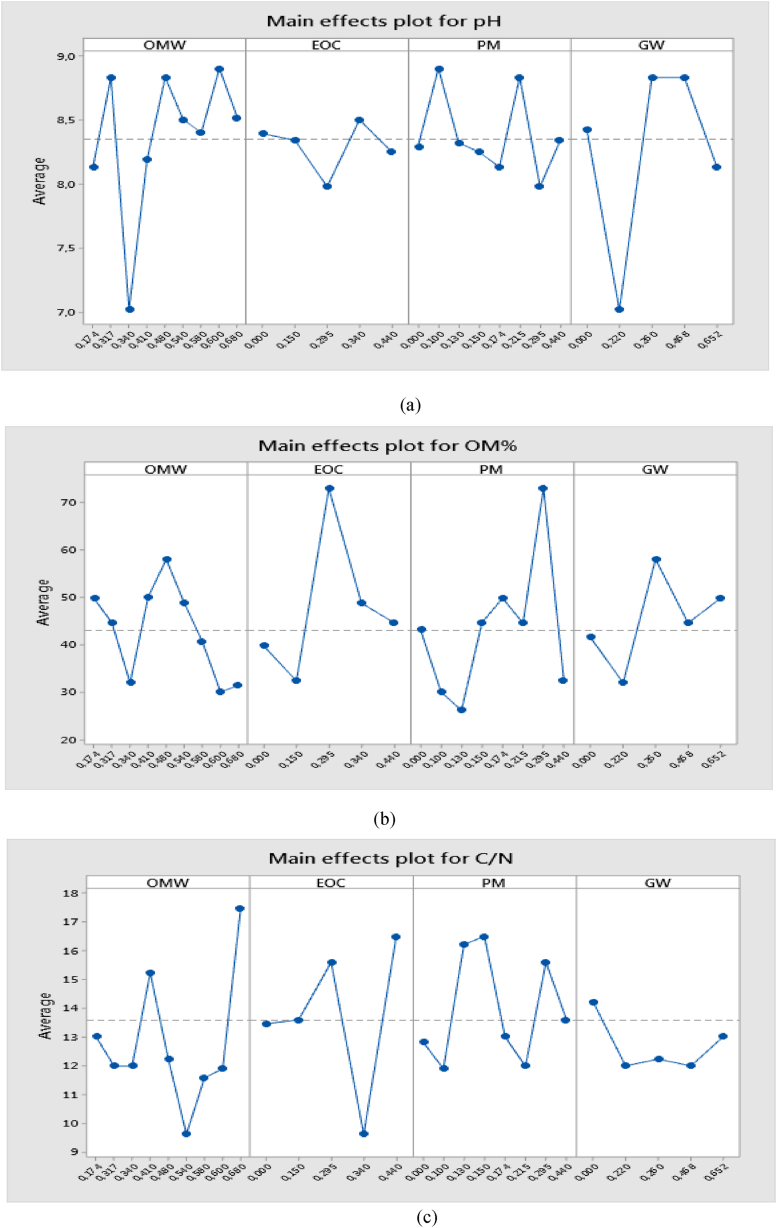

The waste initial composition (GW, PM, EOC, and OMW) main effects' on the physicochemical characteristic responses (pH, OM%, and C/N) is illustrated in Fig. 4 (a), (b), and (c). This effect occurs when different substrate levels affect differently the outputs characteristic (responses). For a two-level factor, it could be noticed that one level impacted the mean heavly than the other. This difference represents the main waste rates’ effect.

Fig. 4.

Main effects plot for pH (a), fitted OM% (b), and fitted C/N ratio (c).

These results indicated that for the pH, the main effects plot exhibited that OMW and GW have the prevalent effects on this parameter response, this would be in relation with the acidity variation between both of the substrates: GW is generally basic while OMW is an acidic effluent, the interaction between both of these keept the neutrality of the pH around 7. On the other hand, the EOC had a weak effect on this parameter compared to the average. Considering OM content effect, EOC and PM exhibited the highest outcomes; indeed these substrates included lignocellulosic material, proteins and ammonia, rich in organic carbon and nitrogen respectively.

Moreover, the olive waste are well known for its richness in carbon and nitrogen, influencing the compost levels in these elements; this is presented in Fig. 4 (c).

3.5. Olive wastes concentration effects on pH, OM content and C/N ratio: contour diagram

In addition to the optimization, the objective of this work was the olive industries waste valorization considering olive mill wastewater, exhausted olive cake, and olive mill solid waste. The present study is concerned on the first two types. Consequently, it is very interesting to know each waste-type effect on the output parameters evolution i.e. pH, OM content, and C/N ratio. Fig. 5 (a), (b), and (c) illustrates specifically the OMW and the EOC concentration effects on the output parameters.

Fig. 5.

Contour plot of pH (a), OM% (b), C/N ratio (c) as functions of OMW and EOC.

To ensure the desired pH (between 7 and 8), both interesting OMW and EOC combinations could be selected; these are in percentages as follows: OMW between 35% and 40% and EOC varying from 0 to 5%, or OMW between 40% and 45% with 30% of EOC. For a C/N ratio ranged between 10 and 15, the following proportions should be avoided: >40% of EOC, 37% < OMW <45%, and >67% of OMW. Finally, the desirable OM content value could be higly appreciable for the following combinations: 25% < EOC <35% and 32% < OMW <48%, or 0 < EOC <35% and 45% < OMW <52%. Consequently, according to the experimental substrates rates used, to achieve the desired pH values, the best OMW and EOC proportions in OM content and C/N ratio would be:

35% < OMW < 40% and 0 < EOC <5%.

4. Discussion

In previous work, Echarrafi et al. [9] were able to determine an optimal model of composting wastes composed of 7.07% of GW, 36.67% of OMSW, 21.22% of OMW and 35,03% PM, with an overall desirability equal to 0.9995 [32].

This result was obtained by an experimental mixing plan defined by using the Simplex-centroid design with axial points called “pure blends” and 3 replicates of center point called “centroid blend” [32].

The objectives of the present study and that of Echarrafi et al. [9] were to setup an optimized model where the OMW is recycled at the highest rate. Consequently, we can deduce that the use of 3 output variables (pH, OM content, and C/N ratio) instead of 2 (OM content and C/N ratio), and the data exploitation already validated by research laboratories [[21], [22], [23], [24],[33], [34], [35]], give an improved and satisfactory result. Indeed, Table 5 summurized the determined initial composting materials composition rates according to both of the studies. It showed that the model found in the present work valorized all the products of olive oil extraction (Milinkovi'c et al., 2019),which are OMW, and solid waste OMSW, as well as EOC with very high percentages (68.5%), compared to the previous study of Echarrafi et al. [9] which treated only 2 types of olive wastes (OMSW and OMW) with 10% less valorized substrates.

Table 5.

Synthesis of the results expressed in percentages, obtained in the present and the previous studies..

| Waste types | Olive oil extraction by-products | Agro food | ||||

|---|---|---|---|---|---|---|

| Waste | Solid waste (OMSW) | Wastewater (OMW) | Exhausted cake (EOC) | Total | Poultry manure (PM) | Green waste (GW) |

| Previous work 2019 [6] |

36.67 | 21.22 | 0 | 57.89 | 35.03 | 7.07 |

| Present study | 0 | 49 | 19.5 | 68.5 | 15.5 | 16 |

Other previous studies are dealing with the insurance of a successful composting process through different methods, but they all used linear regression. The latter was considered among the principal techniques used to model composting process parameters based on independent predictors. However, two ways are available to model the process based on one variable (single linear regression) or multiples variables (multiple linear regression) used in the present study. Among these previously published works, during composting process, the nutrients elements efficiency and feasibility of poultry manure based on physico-chemical parameters such as pH, electrical conductivity, and dry matter as input variables and loss of total nitrogen, phosphorus and potassium as target variables were studied. The results showed that the dry matter is a better predictor as a single linear regression of nutrients, while dry matter and pH are more efficient for multiple linear regression [36,37].

On the other hand, the predicted quality parameters provided by the combination of the optimal pH value of 7.5, an OM content of 44%, and a C/N ratio of 12.5 were in line with the literature.

4.1. pH

The pH is considered as one of the most important and sensitive parameters in composting process. It can drop below 4.5 and limit microbial activity, thus slowing down the process. Experiments indicated that at the beginning of the composting, the environment becomes acidic, with pH values ranged at less than 5. This is due to the OM decomposition and the organic acids as well as the CO2 production. Thereafter, the pH gradually increases as the composting progressed, reaching eventually values between 7.0 and 8.9, the optimal pH range for most microorganisms’ activities. This alkalization is the result of the abundant thermophilic flora activity. Thereafter, at the ammonia production end, through proteins and organic nitrogen bacterial hydrolysis, the pH was stabilized. At the end of the process the engineered compost according to the different mixtures has a stable pH, ranged between 7 and 8 [6,9,[21], [22], [23],28,33,35].

4.2. Organic matter

During the composting, the OM mixture content evolution is considered as an important biodegradation and transformation parameter characterizing the process progress. The OM gradually decreases with the process evolution and the compost stabilization, reaching finally values between 20% and 60%, exhibiting the experimentally optimal OM percentage range loss of 35–50% in the mature product [23,35]. According to the initial waste rates co-composted, the remaining OM rates varied from 32 to 73%.

4.3. C/N ratio

Referring to the set of experiments held [[21], [22], [23], [24], [25],27,33,34], the carbon/nitrogen ratio ranged between 9 and 19 for the different produced composts, in agreement with the standard recommended value. The difference noticed is related to the raw materials variety used, and characterized by different physico-chemical parameters. The composting reduced the C/N ratio for materials with high nitrogen content such as PM, and the C/N ratio varied around 12. However, some composts are characterized by relatively high C/N ratio due to dry matter loss in terms of carbon dioxide and water evaporation during the OM mineralization [22,23].

5. Conclusions

Based on the results of previous research on composts conceived from olive oil extraction waste in Morocco and Tunisia, by applying multiple regression method, and incorporating the mixture design, we have succeed in establishing an optimum model predicting compost quality parameters (pH, OM content and C/N ratio). This elaborated model presented a great satisfaction with a significant desirability value of 0.9828 close to 1, and integrating a relatively important olive mill wastewater rate issued from olive oil extraction (68.5%).

It will be important to ensure the validity of the model considering the experimental plan. This validation will be will be carried out according to 3 different operating modes: classical mode which will be under windrow, in in-vessel heater, and with a composting unit which will be designed where the most important physico-chemical parameters will be monitored as required. Also, the same data investigated in the present study will be adopted to other prediction methods, making comparison of the effectiveness of the different modeling methods.

Funding statement

The authors declare that no funding was provided to support this study.

Author contribution statement

Soukaina Fouguira: Conceived and designed the experiments, Performed the experiments; Contributed reagents, materials, analysis tools or data; Analyzed and interpreted the data and Wrote the paper.

Mounia El Haji: Contributed reagents, materials, analysis tools or data; Analyzed and interpreted the data and Wrote the paper.

Jamal Benhra: Conceived and designed the experiments; Contributed reagents, materials, analysis tools and Wrote the paper.

Emna Ammar: Conceived and designed the experiments; Analyzed and interpreted the data, Contributed reagents, materials, analysis data and Wrote the paper.

Data availability statement

Data will be made available on request.

Additional information

No additional information is available for this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work is held in the framework of the Mixed Tuniso-Moroccan Laboratory “Laboratoire Mixte Tuniso-Marrocain: Environnement et développement Durable (E2D)”. It was supported by Ministry of National Education, Vocational Training, Higher Education and Scientific Research, Department of Higher Education and Scientific Research, in Morocco, and by Ministry of High Education and Scientific Research in Tunisia.

References

- 1.Ingénierie Etudes. March 2019. Formation et Assistance, and Enviro Consulting International (EIFAEC): La stratégie nationale de réduction et de valorisation des déchets Rapport de synthèse; p. 20. Rapport_de_synthese_SNRVD_FR.pdf (logipro.ma) [Google Scholar]

- 2.Agence Nationale de Gestion des Déchets (ANGED) 2018. Evaluation nationale des indicateurs H2020/PAN Tunisie.http://www.anged.nat.tn/ [Google Scholar]

- 3.Baldantoni D., Bellino A., Cicatelli A., Castiglione S. Influence of the choice of cultivar and soil fertilization PTE concentration in Lactua sativa L. in the framework of the regenerative agriculture revolution. Land. 2021;10:1053. doi: 10.3390/Land10101053. [DOI] [Google Scholar]

- 4.Abid W., Ben Mahmoud I., Masmoudi S., Triki M.A., Mounier S., Ammar E. Physico-chemical and spectroscopic quality assessment of compost from date palm (Phoenix dactylifera L.) waste valorization. J. Environ. Manag. 2020;264 doi: 10.1016/j.jenvman.2020.110492. [DOI] [PubMed] [Google Scholar]

- 5.Rojas J.A., Dhar A., Naeth M.A. Urban naturalization for green spaces using soil tillage, herbicide application, compost amendment and native vegetation. Land. 2021;10:854. doi: 10.3390/land10080854-15.Aug.2021. [DOI] [Google Scholar]

- 6.Delgado A., Chammem N., Issaoui M., Ammar E. In: Bioactive Phytochemicals from Vegetable Oil and Oilseed Processing By-Products. Fawzy Hassanien M., editor. Springer Nature Swizerland; 2022. Bioactive phytochemicals from olive oil and table olives processing by-products; p. 44. (Reference Series in Phytochemistry). [DOI] [Google Scholar]

- 7.Seki H. Stochastic modeling of composting processes with batch operation by the Fokker-Planck equation. American Society of Agricultural Engineers. 2000;43:169–179. doi: 10.13031/2013.2682. [DOI] [Google Scholar]

- 8.Ajmal M., Aiping S., Awais M., Saif Ullah M., Saeed R., Uddin Saad, Ahmad I., Zhou M., Zihao B. Optimization of pilot-scale in-vessel composting process for various agricultural wastes on elevated temperature by using Taguchi technique and compost quality assessment. Process Saf. Environ. Protect. 2020;140:34–45. doi: 10.1016/j.psep.2022.05.001. [DOI] [Google Scholar]

- 9.Echarrafi K., Ben Abbou M., Taleb M., Rais Z., El Hassani I., El Haji M. In: Artificial Intelligence and Industrial Applications, Advances in Intelligent Systems and Computing 1193. Masrour T., et al., editors. Springer Nature Switzerland; 2021. A comparative study between mixture and stepwise regression to model the parameters of the composting process. [DOI] [Google Scholar]

- 10.Li Y., Li S., Sun X., Hao D. Prediction of carbon dioxide production from green waste composting and identification of critical factors using machine learning algorithms. Bioresour. Technol. 2022;360 doi: 10.1016/j.biortech.2022.127587. [DOI] [PubMed] [Google Scholar]

- 11.Aycan Dûmenci N., Cagcag Yolcu O., Aydin Temel F., Turan N.G. Identifying the maturity of co-compost of olive mill waste and natural mineral materials: modelling via ANN and multi-objective optimization. Bioresour. Technol. 2021 doi: 10.1016/j.biortech.2021.125516. [DOI] [PubMed] [Google Scholar]

- 12.Ding S., Huang W., Xu W., Wu Y., Zhao Y., Fang P., Hu B., Lou L. Improving kitchen waste composting maturity by optimizing the processing parameters based on machine learning model. Bioresour. Technol. 2022;360 doi: 10.1016/j.biortech.2022.127606. [DOI] [PubMed] [Google Scholar]

- 13.Yilmaz E.C., Aydin Temel F., Cagcag Yolcu O., Turan N.G. Modeling and optimization of process parameters in co-composting of tea waste and food waste : radial basis function neural networks and genetic algorithm. Bioresour. Technol. 2022 doi: 10.1016/j.biortech.2022.127910. [DOI] [PubMed] [Google Scholar]

- 14.Moncks P.C.S., Corrêa E.K., Guidoni L.L.C., Moncks R.B., Corrêa L.B., Lucia T., JR, Araujo 2R. M., Yamin A.C., Marques M.S. Bioresource Technology; 2022. Moisture Content Monitoring in Industrial-Scale Composting Systems Using Low-Cost Sensor-Based Machine Learning Techniques. [DOI] [PubMed] [Google Scholar]

- 15.Charkraborty S., Das B.S., Ali Md N., Li B., Sarathjith M.C., Majumdar K., Ray D.P. Waste Management; 2014. Rapid Estimation of Compost Enzymatic Activity by Spectral Analysis Method Combined with Machine Learning. [DOI] [PubMed] [Google Scholar]

- 16.Xue W., Hu X., Wei Z., Mei X., Chen X., Xu Y. Bioresource Technology; 2019. A Fast and Easy Method for Predicting Agricultural Waste Compost Maturity by Image-Based Deep Learning. [DOI] [PubMed] [Google Scholar]

- 17.Wan X., Lie J., Xie L., Wei Z., Wu J., Tong Y.W., Wang X., He Y., Zhang J. Bioresource Technology; 2022. Machine Learning Framework for Intelligent Prediction of Compost Maturity towards Automation of Food Waste Composting Waste. [DOI] [PubMed] [Google Scholar]

- 18.Kujawa S., Mazurkiewicz J., Czekala W. Using conventional neural networks to classify the maturity of compost based on sewage sludge and rapeseed straw. J. Clean. Prod. 2020 doi: 10.1016/j.jclepro.2020.120814. [DOI] [Google Scholar]

- 19.Andrade Cruz I., Chuenchart W., Long F., Surendra K.C., Andrade L.R.S., Bilal M., Liu H., Figueiredo R.T., Khanal S.K., Ferreira L.F.R. Bioresource Technology; 2021. Application of Machine Learning in Anaerobic Digestion : Perspectives and Challenges. [DOI] [PubMed] [Google Scholar]

- 20.Magdich S., Abid W., Boukhris M., Ben Rouina B., Ammar E. Effects of long-term olive mill wastewater spreading on the physiological and biochemical responses of adult Chemlali olive trees (Olea europaea L.) Ecol. Eng. 2016;97:122–129. doi: 10.1016/j.ecoleng.2016.09.004. [DOI] [Google Scholar]

- 21.Hachicha S., Sellami F., Medhioub K., Hachicha R., Ammar E. Quality assessment of composts prepared with OMW and agricultural wastes. Waste Manage. (Tucson, Ariz.) 2009;28:2593–2603. doi: 10.1016/j.wasman.2007.12.007. [DOI] [PubMed] [Google Scholar]

- 22.Hachicha S., Cegarra J., Sellami F., Hachicha R., Drira N., Medhioub K., Ammar E. Elimination of polyphenols toxicity from olive mill wastewater sludge by its co-composting with sesame barks. J. Hazard Mater. 2009;161:1131–1139. doi: 10.1016/j.jhazmat.2008.04.066. [DOI] [PubMed] [Google Scholar]

- 23.Hachicha S., Cegarra J., Sellami F., Hachicha R., Drira N., Medhioub K., Ammar E. Biological activity during co-composting of sludge issued from the OMW evaporation pounds within poultry manure – physico-chemical characterization of the processed organic matter. J. Hazard Mater. 2009;162:402–409. doi: 10.1016/j.jhazmat.2008.05.053. [DOI] [PubMed] [Google Scholar]

- 24.Ben Abbou M., El Haji M., Fadil F. Impact of wastes on the quality of water resources of the Oued Inaouen watershed and their valorization by composting. Bibliothéque FST de Fès | Impact des rejets sur la qualité des ressources hydriques du bassin versant de l’Oued Inaouen et leur valorisation par compostage (fst-usmba.ac.ma) 2014:183. [Google Scholar]

- 25.Majbar Z., Lahlou K., Ben Abbou M., Ammar E., Triki A., Abid W., Nawdali M., Bouka H., Taleb M., El Haji M., Rais Z. Co-composting of olive mill wastewater and wine-processing waste: an application of compost and soil amendment. Hindawi J. Chem. 2018;7918583:9. [Google Scholar]

- 26.Dutournié P., Jeguirim M., Khiari B., Goddard M.L., Jellali M.S. Olive mill wastewater: from a pollutant to green fuels, agricultural water source, and bio-fertilizer, Part 2: water recovery. Water. 2019;11:768. doi: 10.3390/w11040768. [DOI] [PubMed] [Google Scholar]

- 27.Hao H., Zhu X., Zhang X., Zhang C. R-optimal design of the second-order Scheffé mixture-model. Stat. Probab. Lett. 2021;173 doi: 10.1016/j.spl.2021.109069. [DOI] [Google Scholar]

- 28.Masmoudi S., Magdich S., Rigane H., Medhioub K., Rebai A., Ammar E. Effects of compost and manure application rate on the soil physico-chemical layers properties and plant productivity. Waste Biomass Valor. 2020;11:1883–1894. doi: 10.1007/s12649-018-0543-z. [DOI] [Google Scholar]

- 29.Pinto E.R., Pereira L.A. Estimation and variable selection in joint mean and dispersion models applied to mixture experiments. Chemometr. Intell. Lab. Syst. 2022;227 doi: 10.1016/j.chemolab.2022.104590. [DOI] [Google Scholar]

- 30.Dan-asabe B., Yaro S.A., Yawas D.S., Aku S.Y. Statistical modeling and optimization of the flexural strength, water absorption and density of a doum palm-Kankara clay filler hybrid composite. Journal of King Saud University – Engineering Sciences. 2019;31:385–394. doi: 10.1016/j.jksues.2017.11.003. [DOI] [Google Scholar]

- 31.Lubke G.H., Campbell L. Inference based on the best-fitting model can contribute to the replication crisis: assessing model selection uncertainty using a bootstrap approach. Struct. Equ. Model.: A Multidiscip. J. 2016;23(4):479–490. doi: 10.1080/10705511.2016.1141355. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Waqas W., Nizami A.S., Aburiazaiza A.S., Barakat M.A., Rashid M.I., Ismail I.M.I. Optimizing the process of food waste compost and valorizing its applications: a case study of Saudi Arabia. J. Clean. Prod. 2018;176:426–438. doi: 10.1016/j.jclepro.2017.12.165. [DOI] [Google Scholar]

- 33.Sellami F., Hachicha S., Chtourou M., Medhioub K., Ammar E. Bioconversion of wastes from the olive oil and confectionary industries: spectroscopic study of humic acids. Environ. Technol. 2007;28:1285–1298. doi: 10.1080/09593332808618890. [DOI] [PubMed] [Google Scholar]

- 34.Lahlou K., El Haji M., El Kinnani S. Recovery of sludge from the sewage treatment plant in the city of Fez (STEP) through the composting process. J. Mat. Environ. Sci. 2017;8:4582–4590. doi: 10.26872/jmes.2017.8.12.884. [DOI] [Google Scholar]

- 35.Hachicha R., Hachicha S., Trabelsi I., Woodward S., Mechichi T. Evolution of the fatty fraction during co-composting of olive oil industry wastes with animal manure. Chemosphere. 2009;75:1382–1386. doi: 10.1016/j.chemosphere.2009.02.064. [DOI] [PubMed] [Google Scholar]

- 36.Milinković M., Lalević B., Jovicić-Petrović J., Golubović-Curguz V., Kljujev I., Raicević V. Biopotential of compost and compost ′ products derived from horticultural waste effect on plant growth and plant pathogens' suppression. Process Saf. Environ. Protect. 2019;121:299–306. doi: 10.1016/j.psep.2018.09.024. [DOI] [Google Scholar]

- 37.Abdullah N., Chin N.L. Simplex-centroid mixture formulation for optimized composting of kitchen waste. Bioresour. Technol. 2010;101:8205–8210. doi: 10.1016/j.biortech.2010.05.068. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.