Abstract

Additive Manufacturing (AM) demonstrates significant potential with rapid growth and widespread industrial adoption. To support the integration and innovation of AM technologies, the development of guidance tools and support methods are crucial, and a technological roadmap can assist in this effort. Despite its widespread use in production processes, the need for further research on the potential impact of AM remains significant. The full impact of AM is still uncertain and lacks consensus, highlighting the need for increased knowledge and investment from the scientific community and organizations. While the benefits of AM are recognized, the challenges of its adoption are not entirely known. AM will bring changes in the way organizations create, distribute, and derive value. Thus, in this article, a roadmap for AM is proposed and presented as a tool to map technological knowledge on the implementation and evolution of AM and serve as a strategic guide for organizations. The methodology for its elaboration involves three phases: planning and preparation, roadmap development, and review and update. Through a literature review, database and project consultation, and questionnaires to Portuguese companies that use AM in their production process it was possible to characterize the AM technology and through the visual format, based on a time horizon, summarize in a common framework all the information about the current and future state of AM in Portugal. The results of this study show that research and development initiatives are essential to promote the evolution of knowledge of the AM technology. Throughout this study and with the development of the roadmap it is anticipated that in the near future the AM will be widely used for prototyping and manufacturing of components and may be used for direct production in the short to medium term. It was also found that the main obstacles to the implementation of AM are the economic/productivity factors and the shortage of professionals with knowledge and skills in the area.

Keywords: Additive manufacturing, 3D printing, Knowledge management, Business models, Roadmap, Technology roadmap

Highlights

-

•

AM will cause changes in the way organizations create, distribute and capture value.

-

•

A roadmap for AM serving as a strategic guide for companies for Portugal was developed.

-

•

A roadmap model is developed through a survey supported by questionnaires.

-

•

The protection of intellectual property and the need for more regulations is required.

-

•

The production of the final product and 3D services will greatly impact business models.

1. Introduction

As societal challenges and ambitious goals such as the Sustainable Development Goals (SDG) become more prominent, roadmaps and roadmapping techniques are receiving increasing attention in the Science, Technology and Innovation (STI) policy community [1]. Public policies for long-term, ambitious sustainability goals are formulated, documented, planned and implemented using STI policy roadmaps. Roadmapping appears appropriate as a strategy for fostering sustainability transitions, since it is a sophisticated approach to strategic planning. Over the past thirty years, the practice and study of roadmapping has progressed in tandem, adapting to the shifting landscape brought about by the advent of new technologies and the swift evolution of society [2].

The use of roadmaps in industry is a means to chart the progression of a product, connecting the underlying business strategy to the development of its features, costs, and necessary technologies. Adopting this approach across a critical sector leads to multiple benefits [3]. For each product line, roadmaps serve as a bridge linking market strategy to product strategy and technology strategy. The product-level roadmaps provide the foundation for industry-wide technology planning, enabling a common understanding of needs, gaps, strengths, and weaknesses across the company. The roadmaps also concentrate attention on longer-range planning, improve communication and accountability, and focus the team's thinking on the most pressing priorities at each stage of the planning process [4]. The Roadmapping methodology has been widely implemented and spread among organizations of varying scale, from small businesses to large-scale government initiatives. Its purpose is to bring about a harmonious alignment of an organization's goals with the technology related to its products, and to ensure the critical success factors for numerous enterprises [5].

As a member of the United Nations, Portugal has committed itself to the 17 global goals of SDGs of the United Nations [6]. The Thematic Agenda of Research and Innovation for Industry and Manufacturing 2030 was generated by considering Goal 9 - build resilient infrastructure, promote inclusive and sustainable industrialization, and foster innovation and Goal 12 - ensure sustainable consumption and production patterns. This agenda aims to establish strategies that allow Portugal to follow the European dynamics of industry and manufacturing, increasing the efficiency of manufacturing processes and innovation of products and processes. One of the future challenges identified was the incorporation of industry knowledge and technological development, including AM technology [7].

Despite Portugal is considered a "technology follower" [8], there are several factors, such as government support, initiatives from institutions and companies, the business fabric, and education and training, that make this case study relevant for the establishment of a roadmap for additive manufacturing. In this context, it is worth mentioning the initiatives that have been implemented by the Portuguese government, such as funding programs aimed at research and encouraging the efficient use of all opportunities brought by new technologies, such as 3D printing [9,10]. Additionally, numerous educational institutions, private entities involved in research and innovation, and companies have been involved in European-funded programs for the promotion and development of additive manufacturing, such as MULTI-FUN [11], FUNGLASS [12], EVA [13], PRINT-AID [14], and 3D-NANOFOOD [15]. Furthermore, there are sectors in which Portugal is internationally competitive, such as the mold industry [8], in which 3D printing can contribute significantly to sector productivity. As the shortage of professionals with knowledge and skills is one of the obstacles to the adoption of AM technology, some educational institutions have invested in higher-level courses to train professionals with solid knowledge in the area of AM.

AM encompasses a set of manufacturing techniques that changes the way product designs, manufacturing processes, and distribution are conducted [16]. Various industries have benefited greatly from this technology in recent years [17]. It is expected that AM will become a commonly adopted manufacturing method as new processes and materials are developed. The use of AM can lead to changes in the economy and other dimensions of society in production processes, value chains, environment, safety, and intellectual property [18]. However, there is still a significant knowledge gap regarding AM technologies, before companies can adopt them in order to foster innovation will improve its performance, and in turn strengthen its competitiveness [19].

Companies must develop a technology strategy to help them interact with future technological developments given the unpredictable nature of the future of technology [20]. As a means of gaining and retaining a competitive advantage, alternative methods and tools for generating and exploiting knowledge must be developed through research [21].

Using roadmaps to integrate technologies and plan strategic initiatives has emerged as a helpful method [19]. For Industry 4.0 to become a reality, it is essential to establish roadmaps [20]. The adoption of AM can have a significant impact on of manufacturing process and consequently on all value chains and companies’ business models [22]. The roadmap tool has the potential to help its integration and innovation contributing to the acceleration of the digital transformation by allowing a single common "framework" to summarize all the important aspects and elements to help the adoption and use of a certain technology.

This work seeks to meet the challenge proposed by the Thematic Agenda of Research and Innovation for Industry and Manufacturing 2030, incorporating knowledge, and contributing to technological and logical development, particularly for the development of the AM industry.

The aim of this study is to propose a roadmap for AM that acts as a tool to map the technological knowledge and serve as a strategic guide for AM companies in Portugal. Thus, through a literature review, database and project consultation, and questionnaires to Portuguese companies that use AM in their production process, it is intended with this study to characterize the AM technology and through the visual format, based on a time horizon, summarize in a common framework all the information about the current and future state of AM in Portugal.

The main contributions of this document are the following.

-

(i)

Characterization of the use of AM and the possible evolutions of the Portuguese AM industry through the roadmap tool. This tool can serve as a strategic guide for companies that operate or intend to join the AM industry in Portugal.

-

(ii)

As this topic is an emerging area of research and its knowledge is of utmost importance for the digital transformation required for Industry 4.0, this study can be adopted by other researchers and stakeholders for developing a strategic vision in a particular industry, allowing them to shape their business strategy to industry conditions.

-

(iii)

Contribution to the extension of the literature in the sense that it contributes to the strategic analysis of companies from a different perspective, using a visual tool, a roadmap for the AM industry at the country level. This study is also a contribution to the literature, since the use of this tool for strategic technology mapping in the case of AM is still not thoroughly explored, as verified in the literature review conducted.

-

iv)

Contribution to knowledge management in AM, since this is a relatively recent manufacturing process, and it is important to generate useful information, encourage growth and preserve knowledge about this technology, especially for companies or organizations that use or intend to use AM.

This study is organized as follows: Section 2 presents a literature review about additive manufacturing, with a subsection dedicated to AM in Portugal, roadmapping and previous roadmapping studies. Section 3 describes the methodology used for the roadmap development, as well as the data collection procedure, and the sample characteristics. The characterization of the use of additive manufacturing that resulted from the survey results is performed in Section 4. The proposal of a roadmap for AM in Portugal is presented in Section 5, followed by the discussion in Section 6. Finally, Section 7 presents the main conclusions and points out the limitations of the study, as well as future research opportunities.

2. Literature review

This section presents the theoretical framework that serves as a basis not only for the identification of research gaps, but also for the development of a new roadmap for additive manufacturing. Thus, in the first section additive manufacturing is described, and the stages of the production process, advantages, and main limitations are explained. A framework about the state of development of additive manufacturing in Portugal is also presented. In the next section, a literature review about the characteristics and activities of roadmaps is presented, and finally in the last section a review about the application of roadmaps in several industries, especially in additive manufacturing, is presented and the research gaps that this study intends to fill are identified.

2.1. Additive manufacturing

Additive Manufacturing (AM) transforms the way products are designed and manufactured [[23], [24], [25]]. This technology was created by Charles Hull in 1986 and this method became recognized as stereolithography (SLA). Since the introduction of the first commercial machine, SLA-1, by 3D Systems™ in 1987, AM has been in rapid development with high growth rate. Its emergence has attracted the attention of the scientific community and industry. In 2016, a report detailed an impressive annual growth rate of 26.2% over the last 27 years [26]. The standardized definition of AM is defined by SO/ASTM 52900 (2015) as a “process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies” [27].

The stages of the production process differ from traditional manufacturing methods and can be summarized in three steps: the conception of the model, printing, and finishing processes [28]. While there are many different technologies, almost all work by forming solid objects from layers using liquid, powder, or solid materials. Thus, the basis of all AM technologies is the same and they all follow the same basic process for fabrication [25]. The process consists of creating the 3D model in CAD software that is later segmented into layers. The data from the layers are put into a specific format (usually a STL format) which is then fed into the machine. Finally, the material on the material is added layer by layer to create the 3D objects based on the STL information [29].

AM has enabled the creation of products that were complex or even impossible to create using traditional methods. In addition, AM makes it possible to create highly complex parts as a single object, allows reducing material waste through recycling and reuse, easily builds small internal corners and features, and allows predicting the mechanical and physical properties of the object. Simultaneity and fidelity are two features that differentiate AM processes from other process fabrications [30].

Funding and research has led to new AM procedures and these are used in different areas ranging from biomedical, automotive, aerospace, and other fields, to less common areas such as architectural design and digital art [31]. However, the aerospace, automotive, electronics, and medical industries are the ones that have demonstrated an increased rate of adoption of this technology [26].

Printing with AM allows designers to create parts with complex shapes, as well as customize products with a reduced use or even without needing traditional tools [16,32,33]. Reducing and even eliminating these tools, such as molds, allows for an increase in the rate at which a company can bring products to market and reduce its development time [24].

A major advantage of this technology lies in the fact that it allows manufacturing to be carried out directly from CAD files, thus removing the need for product inventories and its related costs [19]. AM allows researchers and engineers to manufacture products by combining different materials, which also becomes an advantage of this manufacturing technique over others. By combining the mechanical, physical, electrical, and other engineering properties in the manufactured products, many post-processing steps are no longer necessary [29]. In Ref. [33] other advantages are considered such as the consolidation of parts by manufacturing a single part, the machines working autonomously, the pre-processing being automated, and the achievement of greater cost savings that is greater the more complex the part.

However, there are important limitations that need to be overcome if AM is to be widely used in normal serial manufacturing. Possibly the most distinguished is the lack of knowledge. Codifying knowledge regarding design rules, principles, best practices, and standards has been identified as a major limiting factor in the acceptance of this technology [23]. Its adoption still involves significant capital expenditure and requires considerable investment by organizations. In addition, the produced parts have limitations on that surface finish that are associated with thermal aspects and influence the mechanical properties. The quality of the surface also depends on the part’ and deposition of the material orientation and the thickness of the layer [33].

In addition to technological impacts, AM has a great influence on the business process due to the rapid development of communication and the continuing trend of digitization [34]. AM technologies can be seen as disruptive in the way we manufacture. Disruptive technologies bring about extreme modifications in business models and systems. Digital technologies, in particular, made the more significant changes in the businesses that have adopted them [35].

2.1.1. Additive manufacturing in Portugal

Portugal invested in AM technology quickly. While polymer AM has been widely adopted, the adoption of metal AM has been more modest, even though it has enormous potential to improve long-term performance and competitiveness. The diffusion of these 2 a.m. technologies, polymer- and metal-based, has been assessed for the Portuguese mold industry and a theory of how different technological characteristics and industrial contexts interact with institutional instability, in particular the risks at the technological and industrial level, has been developed [36].

The mold industry is one of the most competitive industries in the country worldwide and is one of the main users of AM in Portugal [36]. In the automotive industry, AM, by making it possible to build tools for small production runs, allows molds in this industry to be produced using these technologies, making simple prototype molds to produce component samples [37].

In the aerospace industry, Cardeal et al. [38] applied and validated a new business model for the aircraft maintenance and repair business. The case study transitions from traditional maintenance and repair activities to the adoption of AM as an activity that enables the manufacture of optimized spare parts with customer benefits. AM can push for more sustainable business models in the aircraft maintenance sector.

In healthcare, Silva et al. [39] developed a study about the production of a multi-material dental implants that allowed the manufacturing of a customized implant for a specific patient with edentulism by applying a combination of AM processes, SLA and Selective laser melting (SLM). This combination makes possible the manufacturing flexibility and processability of different material combinations (metals and polymers), achieved through hybrid AM systems.

The footwear industry companies are using 3D scanning and customization of shoes, taking advantage of 3D foot scanning systems to produce customized molds to manufacture the shoe. This process allows the development of footwear adapted to the individual shape of each foot, ensuring perfect fit and comfort. These systems also integrate customization software for the choice of design and colors, and the conception and manufacture of ergonomic and repeatable footwear [40].

The assessment of the social impacts and challenges of AM has raised interest in the Portuguese scientific community. AM presented a positive impact in most of the evaluated social domains, such as safety and health, however, it also presented some negative impacts in these areas, namely due to concerns about some types of hazardous substances used and several mixed and no impacts [41].

2.2. Roadmapping

The term "roadmapping" refers to the process of creating roadmaps and has its origins deeply entrenched in the field of industrial engineering [42]. A roadmap serves as a very helpful tool for technology management and industrial policymaking in planning for the technological future [43]. Originating at Motorola™ in the 1970s, the roadmap has seen an extensive use as an approach for technology management [44]. The development of the roadmap normally includes social aspects and it is a learning and a communication approach [45]. Roadmapping is therefore strategic planning and seeks to strengthen innovation by facilitating in the recognition of the technology and other resources required to progress products, services, and systems following business goals and in responsive to market drivers [19].

Through the years, the roadmap has become a tool used quite often for technology management in organizations [17]. Known for providing useful information, processes, and tools to produce comprehensive business and product plans, roadmaps are one of the most influential tools for technology management [46]. According to a survey, approximately 10% of 2000 UK manufacturing companies had used the roadmap, and eighty percent of these companies had used it repeatedly or continuously [47]. It is essential to consider the time dimension when harmonizing the various elements in a roadmap. Besides, the roadmap can be used within an organization, by an industry, and at the national level. The use of different layers in a roadmap allows a more detailed understanding beyond clarifying the present and predicting the future [17].

Essentially, a roadmap presents the current state (i.e., where we are currently) and a desired future state (i.e., where we want to go), as well as a path that should be travelled between them. By using this tool, managers of any organization can develop a common understanding of a complex situation in which there is a high degree of uncertainty. In addition to illustrating a company's short- and long-term visions [44], it can provide a visual format to help communicate and collaborate by linking its technology resources to those visions [42]. The roadmap provides graphical representations of market, product, and technology relationships, enabling companies to gain a better understanding of these relationships over time and support governments and organizations to make decisions and endure competitiveness by providing knowledge [46]. Recently, it is expanding its areas of application to the new product development process [48], knowledge management [49], and even innovation [50].

Several roadmap models have been used and elaborated, and the literature tries to classify them into various categories [51]. Although there are several classifications proposed and used in research, the most well-known one divides and classifies road-maps into four groups: science-technology roadmap, product-technology roadmap, industry roadmap, and product roadmap [46].

The process of developing a roadmap is as significant as its outputs. The various guidelines for roadmap development by countries and organizations can be summarized into three distinct phases: roadmap development, roadmap implementation, and roadmap use over time and can be combined with other management instruments, being very meaningful and useable for strategic planning [43]. The authors in Ref. [43] follow the three-phase iteration corresponding to the key roadmap phases defined by OECD (2014) adapting the phases to the context in which the roadmap is being carried out. There are many forms in which development of a roadmap can take place, and the development process needs to be flexible, allowing for customizing it for each context and topic [44]. Its use as a communication tool allows mutual compression by all involved, focus and prioritization of activities, and integration of different sources of information in a common framework are some of the advantages mentioned [49]. The very elaboration of a roadmap can be considered a learning experience and a communication tool for the participants in its elaboration [45].

However, its application presents many considerable challenges even though its structure and concept are simple. Commitment from top management and specific individuals is necessary for this approach to succeed. A roadmap can also be adopted to a particular case, but research papers rarely provide a direct answer in terms of adapting the approach in the absence of concrete principles [51]. There are a number of reasons why this tool cannot be properly applied, including interference from short-term responsibilities, excess of initiatives, and lack of data, knowledge, and information [45,47,49]. Additionally, roadmapping has a particular limitation of not being able to fit all companies and industries, so each company's roadmap is idiosyncratic, and it must be designed according to the organization's core drives, competencies, intent, abilities, priorities, goals, and resources [20].

The roadmap can also be changed by drastic and unpredicted future developments that are unknown, which is another limitation. It is therefore important to improve, maintain and update the roadmap [52]. Usually, it is advisable to update the roadmap every 2 years [43]. Roadmap management and maintenance are ultimately critical to success and the challenge is to keep a roadmap "alive" and up-to-date [49]. In a recent study, 65% of respondents detailed that roadmapping software might help overcome the issue produced by the lack of mapping techniques, tools, and methods. This software could support and assist in the development, storage, dissemination, and maintenance of roadmapping, allowing its continuous use and constant maintenance.

Finally, the presentation of the information in the roadmap can be a challenge since it can become complex very quickly, and some way of filtering and hierarchizing information is needed to reduce this complexity. In addition, the way people assimilate information varies a lot, that is, different people may prefer different ways of presentation [49].

A roadmap can present different forms and frameworks [53], which leads to some differences in the elaboration methods since each roadmap elaboration process is adapted to the reality in which it is being developed [54]. There are several roadmap processes, such as the one defined by the European Industrial Research Management Association (EIRMA), the Sandia National Laboratories roadmapping for strategic business development, the guide to roadmapping for the U.S. DoE Environmental Management, and the International Energy Agency roadmapping process [55]. However, one of the most widely used is the one proposed by the European Industrial Research Management Association (EIRMA) [17,56]. According to EIRMA, the roadmap is considered as a "living document and is constantly evolving as circumstances change" [57], the result of a team activity supported by top management [57]. In accordance with EIRMA, the roadmap presents a temporal perspective, time being an essential parameter for the different elements considered to be in consonance [17,42]. This time chart is composed of several levels and allows interconnecting different dimensions such as products, markets and technologies [17,42,56].

Fig. 1 illustrates the overall structure of a Roadmap defined by EIRMA, presenting a chart with several interconnected layers, allowing to understand the existing relationships between the layers throughout the projected period [58]. The top layer of the chart, associated with the market, customers, and business, concerns the objective ("why"). The middle layer concerns the "what", i.e., products, services, processes, among others, required to satisfy market and customer needs. The lower layers are related to the "how", i.e., the resources needed to achieve the objectives, whether those of tangible nature, such as technologies, infrastructure, and facilities, or those of intangible nature, such as skills and knowledge [17].

Fig. 1.

EIRMA model of a Roadmap.

2.3. Previous studies on roadmaps

Roadmaps can be used as a strategic tool [59], consisting of a set of technological and scientific plans in the form of maps [60], which enable organizations to deal with uncertain and complex innovation and organizational challenges [61]. Although numerous studies have pointed to Motorola, Philips, BP, Semiconductor Industry Association, and EIRMA as strong drivers of roadmap use; a recent study points to its origin as predating these organizations [42]. In this study it is pointed out its origin in the industrial engineering management of the 1960/70's, and it is highlighted the significant contribution of organizations such as NASA, Boeing, USAF, Rockwell International and the U.S. Department of Energy for the development of this tool [42].

In recent years there has been an increasing number of academic publications related to roadmaps, which shows the interest not only of the scientific community, but also of companies, since most publications have used the case study approach as methodology [62,63]. This tool has been widely applied at business, sectorial and national levels [59,62] in many different areas. The construction industry is one such example. Gottlieb et al. [64] developed a roadmap, based on the transition analysis perspective of strategic niche management, for the transition to a use of biogenic materials in the construction industry. To this end, they identified the barriers to its use, and structure the changes needed for this transition, both in the technology and in the institutional context. Also, Petrescu et al. [65] developed a roadmap, which resulted from the application of the adapted T-Plan Fast Start Process, for the development and diffusion of the use of biocomposite products in the construction industry. In this work, in addition to the roadmap, the concept of technology readiness level (TRL) was used, and both were used in a case study on "liquid wood".

Also in the construction sector, but with a different objective, Huo et al. [66] proposed a timetable and roadmap in view of the "dual carbon" strategy of China's construction sector. By establishing a dynamic scenario simulation model to explore evolutionary trajectories, the authors explored potential carbon peaks, and developed the calendar and roadmap. Another area where roadmaps can be useful, is in systems engineering. Motta et al. [67] developed an evidence-based roadmap to support systems engineering of Internet of Things (IoT) software.

As mentioned earlier, organizations such as NASA, contributed significantly to the development of roadmapping in the 1960/70s [42], and this tool is still used in this organization today. Siegel et al. [68] developed a NASA roadmap for planetary protection for future human missions to Mars. In order to identify the steps needed in order to bridge the knowledge gaps, the authors identified similarities between planetary protection needs and other Mars readiness roadmaps. Thus, the roadmap was developed in an integrated manner with other related roadmaps, which, according to the authors, will need to be updated as new technologies develop or as some of the roadmaps are filled.

However, the application of roadmaps is not limited to these examples, there are a myriad of different companies and sectors that use this tool to support innovation and development and improve strategic planning. Tourism [69], banking sector [70], mobile services sector [71], science-intensive organizations (drug discovery and development program for neglected diseases) [72], green hydrogen development [73], hypersonic transportation systems [74], fusion start-ups [55], virtual coupling deployment in different segments of the railway market [75], are some of these examples.

The establishment of roadmaps for new materials and/or new processes can play a very significant role for efficient strategic development and contribute considerably to the growth of the role that additive manufacturing can play in industry. In addition, the role of roadmaps has also been studied and proposed as effective in dealing with the uncertainty and complexity that technology-based start-ups face [17]. Thus, many papers have been published that propose a roadmap for additive manufacturing, with a very diverse scope, ranging from those directed at teaching AM [76], AM value chain [77], impact of AM on supply chains [78], materials [[79], [80], [81], [82], [83]], devices [[84], [85], [86]], industry/sector [[87], [88], [89], [90], [91]] to more general ones [19,52].

Roadmaps for the adoption or future research of using new materials for 3D printing, such as meta-biomaterials [79], cell-free biologically active architectural structures [92], geopolymers [80], natural-derived biopolymers [82], non-castable alloy [81], are some of the examples found in the literature that reflect the importance of studying new materials for additive manufacturing. Also, the roadmaps for new devices obtained by 3D printing have raised the interest of the scientific community. The piezoelectric nanogenerator, a mechanical energy harvesting device used in portable power supplies and self-powered sensor systems [84], 3D-printed nanogenerators for energy harvesting [86], and 3D printed devices for energy transition [85] are some of these examples. In terms of industry/sectors, there are also several where roadmaps for AM have been established, such as construction [[87], [88], [89]], textile industry [90], aerospace industry [91], and healthcare [17].

In addition to these roadmaps with a narrower scope, studies have also been published that propose roadmaps for additive manufacturing in a broader sense. One of the examples, was the study developed by Despeisse et al. [19], in which the authors proposed a structured approach to take sustainability into account in the strategic planning and innovation process for the adoption of AM. Arcos-Novillo and Güemes-Castorena [52] developed a technology landscape for identifying AM opportunities in Mexico and established milestones in the evolution of technology at the product, capability, and market levels.

Apart from these studies, there are others that propose roadmaps in the context of additive manufacturing or 3D printing, but the approach taken is not as broad, nor does it have a graphical representation, nor the typical roadmap structure [[93], [94]]. There are also studies whose application of the proposed model was performed in the additive manufacturing or 3D printing context, however the scope is directed to other objectives, such as circular economy, using Industry 4.0 and lean management [95].

The methodologies used in the studies are mostly literature review [79,80,84,88,89]. In addition, questionnaires [76,87], and experimental methods [81,83,92] were also used.

Within the scope of roadmaps for additive manufacturing, a considerable number of articles have been published in recent years [96], as illustrated above, however there is still a research gap concerning more comprehensive roadmaps, i.e., directed towards additive manufacturing itself and not only towards one technology, or industry. Although some already exist [19,52], these either concern a geographical location [52], or base their study only on a literature review [19,52]. Thus, this study aims to fill some research gaps by being more comprehensive not only in methodology by basing the study on a literature review, but also on questionnaires, previously validated by experts, to companies that use AM in their production process; but also in scope, by summarizing in a common framework all the information about the current and future state of AM in Portugal.

3. Materials and methods

The roadmap proposal developed in this work will be performed for a national context and will be oriented to a single technology, AM. This tool will describe the aspects necessary for greater knowledge and development of this technology.

The methodology of literature-based discovery provides a foundation for determining a substantial number of the central technical and managerial disciplines that are required for the potential development of disruptive technologies and discontinuous innovations. When coupled with a practical workshop or roadmap process, it significantly increases the prospects for success [97]. In this study, the authors adopt the Beijing school's method of employing a blend of qualitative techniques, such as literature reviews, expert interviews, and expert workshops, alongside bibliometric analysis [98].

3.1. Roadmap elaboration

Roadmap elaboration followed a three-step process adapted from the roadmap elaboration process developed by Mohebalizadeh and Ghazinoori [43] that followed the three-phase iteration corresponding to the key roadmap phases defined by OECD [99]. This methodology was the one considered to be the easiest to adapt to the context in which the study is being conducted. Table 1 summarizes the process adopted for its elaboration.

Table 1.

- Roadmap development process (adapted from Mohebalizadeh and Ghazinoori [43]).

| Phase 1 Planning and Preparation |

Phase 2 Roadmap development |

Phase 3 Review and update |

|

|---|---|---|---|

| Objectives |

|

|

|

| Sources |

|

|

|

| Activities |

|

|

|

| Duration | 2 months | 4 months | |

The first phase is dedicated to the planning and preparation of the work that was important for the familiarization with the concept and the process of development and execution of the roadmap. This study resulted in the literature review presented previously. The process for conducting this research work and the intended structure of the roadmap was defined. In the second phase, data and information collection and analysis were essential through questionnaires, and the consultation of some databases and projects to characterize the current and future state. In addition to these, the literature was also used to collect information. The information collected was studied and was used to build the roadmap, identifying important elements of the AM and assigning them to each layer stipulated in phase 1 for the roadmap. Finally, in the third phase, the proposed roadmap was reviewed and some changes were implemented. In addition, an expert on AM technologies was also consulted for the validation of the model. The validation of the developed roadmap was conducted to identify possible inaccuracies and subsequently modify the roadmap. This validation aimed to analyze, provide suggestions and correct the roadmap content, especially the information that was removed from the questionnaire, thus making it more robust. The version presented in this paper is already the final proposal with the recommendations and changes suggested and implemented.

3.2. Data collection

For the development of the roadmap, it is necessary to collect data [100]. Besides the information taken from theoretical sources including articles, books, or dissertations focused on the topic of AM implementation in Portugal, a questionnaire was also sent to Portuguese companies that use AM in their production process. The questionnaire was the most efficient and quickest way found to obtain the necessary information, and by being standardized, they allow comparisons and generalizations and can lead to more solid assumptions [101].

To validate the questionnaire developed, two experts with extensive experience in the field of additive manufacturing were consulted beforehand. This exercise proved useful in identifying the necessary corrections to be made to the questionnaire, ensuring that it did not contain irrelevant information and was as realistic as possible. The questionnaire was available online between May 23 and June 10, 2022. In addition to questions that allowed for the characterization of the companies surveyed, the questions created took into consideration two distinct parts: the current state of technology and the main challenges and needs, and a future outlook of the company.

The population of this study is the organizations in Portugal that use AM technology in their production process, for which it is intended to generalize the findings of this research. The study was developed based on a sample of organizations drawn from the population. Organizations that use AM technologies in Portugal were considered, using them in their production process, either as a production method or as a tool to support it, or even as research and development companies. Initially the sampling was carried out through the selection of a part of the most accessible population and through database consultation of business directories and industry associations and online information of the companies. After contact with this first sampling, it was possible to extend the number of instances through snowball sampling [102]. The companies were contacted via e-mail, through which a brief description of the research carried out was presented. The second contact was made by conference call, where the invitation to participate in the questionnaire was reinforced.

The participation of the companies in this study was voluntary and all the information collected was handled by the first and last authors, always guaranteeing the confidentiality of the participating companies. To this end, letters were assigned to designate each company, allowing their identification and characterization without compromising their identity. The questionnaire was answered by AM specialists, engineers, and maintenance technicians from the Portuguese industry who have direct contact with the use of AM in the company.

For the development of this research, and in order to achieve more accurate information, other sources were used related to Portugal and AM. These sources allowed to fill the gaps, reinforce, and validate the information collected by the questionnaires and are shown in Table 2.

Table 2.

– Other sources used to complete the roadmap.

| Source | Description | Reference |

|---|---|---|

| PORDATA | Portuguese database that presents statistics from various areas, for Portugal, municipalities, and European countries. | [103] |

| ePortugal | This online tool aims to facilitate interactions between citizens, companies, and the state. | [104] |

| AMable | Group of people from different organizations that provide specialized AM knowledge. | [105] |

| National Strategy for Economy Digitization - Industry 4.0 | Initial measures plan for valorisation, promotion, and investment in the digitization of the Portuguese economy. | [106] |

| Skills Strategy in Additive Manufacturing (SAM) ERASMUS+ | The Skills Strategy in Additive Manufacturing (SAM) sector project is a strategic approach to AM skills by identifying failures to encourage AM growth. | [107] |

3.2.1. Sample characteristics

To collect real information about the use of AM, in Portugal, 35 companies were contacted, which constituted the theoretical sample and were included in the sampling list. Of these 35 companies, 23 answered the questionnaire, which corresponds to a response rate of 65.71%. Thus, the sample considered in this work is composed of 23 companies working in Portugal and using AM technology in their production process. There is no company from the primary sector in the sample of companies surveyed, 16 companies are part of the secondary sector of the economy and are mostly manufacturing companies. The remaining seven companies belong to the tertiary sector of services, such as consulting, research, and education.

In terms of business areas, of the 16 companies belonging to the secondary sector that responded to the survey, seven (43.75%) are engaged in mold manufacturing and plastic injection. Automotive component manufacturing and machine and tool manufacturing (metalmechanics) were the second most frequent business areas in the sample, with two companies each. In addition to these, companies belonging to the manufacture of sanitary components, manufacture of paper and pulp, manufacture of unmanned aerial vehicles, production of 3D printers and construction and carpentry also responded to the survey, with one company in each area. In the tertiary sector, the business areas with the most responses, with two each, were those related to product development, and 3D printing services. In addition to these, responses were also obtained, one each from the following business areas: research and education, consulting services, and consulting and auditing services and calibrations.

Regarding the number of employees, of the surveyed firms, seven (30.43%) have "More than 250″ employees, six (26.09%) have "Less than 10″ and the same number of firms (six) have "More than 50 and less than 250". The remaining four companies claim to have "More than 10 and less than 50″ employees which corresponds to 17.39%. The annual turnover of most of the firms involved is less than "2 000 000€" which corresponds to 43.48% of the correspondents, i.e., ten firms. Six (26.09%) companies claim to have an annual turnover of "More than 50 000 000€" and four (17.39%) "More than 10 000 000€ and less than 50 000 000€". With an annual turnover of "More than 2 000 000€ and less than 10 000 000€" are the remaining three companies (13.04%).

The mold manufacturing was the sector where more answers were obtained. This fact coincides with the importance that this sector has in the national economy, being globally competitive, given the volume of exports [108]. Although the AM technology is already used in this sector [8], the proposed roadmap can serve as a strategic guideline and allow the sector to remain competitive, facing other markets that already use this technology more frequently. Also, companies engaged in the production of a wide variety of products and production in small batches and with complex geometries [109,110], like some of the respondents, can benefit from AM. Thus, the roadmap can help in anticipating possible scenarios and in this way maintain or improve their competitive position.

Furthermore, the number of employees and annual turnover revealed that the surveyed companies are mostly micro and small enterprises, which is representative of Portuguese industry. Often being family businesses, they have limited resources to invest in technology and are more risk averse [8]. The proposed roadmap can be an aid in this regard, since by enabling the mapping of technological knowledge about the implementation and evolution of AM technology not only in its current state, but also in its future, it has the potential to serve as a strategic guide and to direct innovation, development, and commercialization activities.

4. Characterization of the use of AM: survey results

The analysis of the questionnaire responses allows to detail the characteristics of the sample. Thus, to know which AM technologies are most used by Portuguese companies, it was questioned what type of additive technology is used. In Fig. 2 it is possible to identify that the Fused Deposition Modeling (FDM) is the most used process, being used by 65.22%, which corresponds to fifteen companies. Selective Laser Sintering (SLS) and stereolithography (SLA) processes follow, being used respectively by eleven and ten of the surveyed companies.

Fig. 2.

a.m. technologies used by companies (maximum 23 companies).

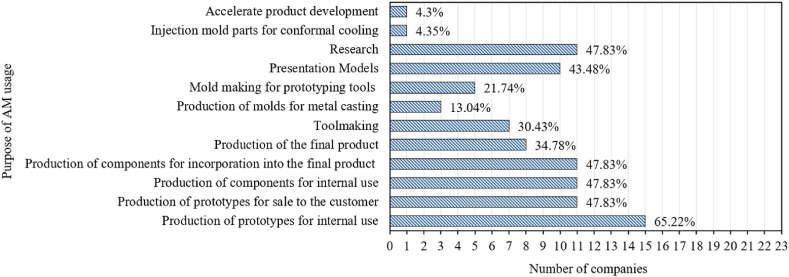

In addition to the type of technology employed, this research needs to know for what purpose AM is used by Portuguese companies. Thus, each company was asked in which part of its production process they used this technology and the results are detailed in Fig. 3. Analyzing the chart, it can be stated that 65.22% of the companies that answered the questionnaire, fifteen companies, use AM for the production of internal prototypes. Eleven companies, 47.83%, use AM for research, in the production of prototypes for sale to the customer, on the production of components for internal use, and for the production of components for incorporation into the final product.

Fig. 3.

Purpose of AM use by companies (maximum 23 companies).

The material most used by the surveyed companies in the AM process, with 86.96%, is polymers followed by metal and composites with ten and five companies respectively. These results are shown in Fig. 4.

Fig. 4.

Type of material used by companies (maximum 23 companies).

Autonomous learning was the way most indicated by the companies for the acquisition of knowledge on AM technology, with 78.26% of the companies mentioning this as one of the ways used. Besides this, collaboration with academia and training with third parties are the other two most mentioned ways to acquire knowledge. The results are shown in Fig. 5.

Fig. 5.

Ways of acquiring knowledge by companies (maximum 23 companies).

Fig. 6 shows the various ways in which companies protect the knowledge they have acquired. Ten of them state that there is no protection whatsoever. When it does exist, ten of the companies mention that it is through trade secrets in conjunction with confidentiality agreements.

Fig. 6.

Ways to protect acquired knowledge by companies (maximum 23 companies).

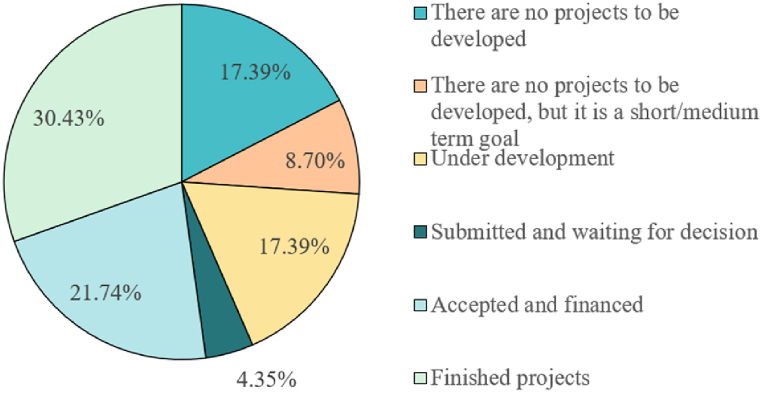

Portuguese companies have shown that they are involved in Research and development (R&D) projects, as can be seen in the pie chart in Fig. 7. Thus, 30.43% state that they already have completed projects and 21.74% have projects accepted and funded. Only 4 companies are not and have not been involved in R&D projects.

Fig. 7.

R&D Projects (maximum 23 companies).

In Fig. 8 is possible to find the information regarding partnerships with companies and/or universities, and it is possible to observe that 65.22% state that they have partnerships with both organizations and only one states that it does not have partnerships and that it is not a possibility.

Fig. 8.

Partnerships (maximum 23 companies).

In the second part of the questionnaire, as already mentioned, a set of questions was carried out to try to predict the future situation for AM in Portugal. Companies were asked about their intentions to extend AM technology to more processes in their company and 73.91% stated that it was an objective, with 60.87%, 14 companies foreseeing this growth between 2023 and 2025. Fig. 9 summarizes the responses obtained to this question.

Fig. 9.

Intention to increase the use of AM in the company's production process (maximum 23 companies).

Subsequently, the seventeen companies that answered yes and that had the goal of expanding the use of AM in their production process were asked for what purpose this technology would be used. The majority, 76.47%, stated that the goal is to produce the final product using AM. This is followed by the production of components to be incorporated into the final product with 64.71% and the production of prototypes for internal use with 58.82%. The answers obtained are summarized in the graph in Fig. 10.

Fig. 10.

The purpose for which the AM may be used by companies (maximum 17 companies).

Fig. 11 shows the graph with information on the limiting resources that it would be important to strengthen so that there can be greater adoption of this technology. Respondents, in their opinion, pointed out that it was essential to reduce the costs of both equipment and materials, with 69.57% and 65.22% respectively, and the need for financial support, with 52.17%. Thus, economic reasons are a major stumbling block in the adoption of AM by organizations. The lack of qualified professionals and the need for training and knowledge sharing are also mentioned by the majority with 56.52% and 47.83% respectively.

Fig. 11.

Limiting resources in the adoption of AM in Portugal (maximum 23 companies).

Finally, regarding the areas in which AM is expected to have a more significant growth in the next 10 years in Portugal, the molds industry was the most mentioned with 69.57%. This was followed by the automotive and aerospace industries, with 56.52%, and lastly the health area, with 39.13%. The results obtained are shown in Fig. 12.

Fig. 12.

Areas where AM will have significant growth (maximum 23 companies).

As for the maturity of the enterprises that comprise the sample, the Technology Readiness Level (TRL) score was used. TRL is perhaps one of the best-known and of most widely used metrics in assessing technological progress [111]. After enquiring all companies directly through the questionnaire what their TRL level was, the analysis of the data, for the situation in Portugal, allowed us to conclude that approximately 60% of the companies claim to have a TRL higher than 7, having already reached a high level of maturity for AM technology. Even though, about 35% say they are still between levels 1 and 3 on the TRL scale, which means that they are still at an early stage of implementation. These results are presented graphically in Fig. 13.

Fig. 13.

TRL results for the case of Portugal.

5. Proposal of a roadmap for AM in Portugal

The development of this tool allows the mapping of technological knowledge, on the implementation and evolution of AM and serves as strategic guidance for Portuguese companies. The result emerged from the identification of the different components that characterize the AM technology and through the visual format, based on a time horizon, all the information about the current and future state of AM in Portugal was summarized in a common framework. The roadmap was developed following the guidelines defined in the methodology section and can be seen in Fig. 14.

Fig. 14.

Roadmap for AM in Portugal.

The format adopted for its elaboration followed the format defined by the EIRMA [58]. The several interconnected layers will allow a simple and clear understanding of the relationships among them over time. The detailed description is made according to the different layers related to the market, products, technology, and other resources. The references to the different elements present in the roadmap are in the supplementary material, Figure A1. The arrows make the logical connection between the layers and the different elements that compose each one of them, and the time horizon considered was from 2023 to 2030, establishing a three-year interval to define the short and medium term. The beds, the time horizon used to create the roadmap, and its structure were adapted from the literature [52].

5.1. Market

AM is present mainly in two of the three economic sectors in Portugal. In the secondary sector, AM is mainly present in the manufacturing industry, but also construction, for example. In the tertiary sector, it is used in 3D consulting and services, education, and research and development. The mold industry is one of the industries in the country with strong adoption of AM technology [36], and is expected to continue to be one of the areas with significant growth in the future.

When analyzing the four scenarios predicted for AM by Jiang et al. [112], the emergence of business models was the one more recognized. After the limitations related to costs, processing times, and others are overcome, the goal is to utilize the customization advantage, to produce fully functional end products and achieve mass customization. The direct manufacturing of end products will influence the organization's business models [113].

Service-oriented 3D printing is recognized as a trend [113] and is also predicted to contribute to the creation of new business models. With its emergence and the rise of digital marketplaces, the development of intelligent virtual 3D printing cloud networks brings the possibility of new 3D printing service business models that may allow mass personalization to be achieved [114]. Although AM enables the transition from mass manufacturing to mass customization, this change will be slower and more gradual than it appears [37].

It is home manufacturing that has the most disruptive characteristics in which the consumer also plays an active role in value creation, as a prosumer [115]. Home manufacturing has increased innovation and user entrepreneurship and it is believed that its growth is yet to come [116]. For the growth of AM in Portugal and a greater adoption of this technology in the long term, it is essential that in the short/medium term there is a reduction in the material costs and equipment and also some financial support. Then, knowledge and knowledge sharing are also recognized by the industry as essential.

According to the respondent's opinion, the areas in which AM would have greater growth, besides the molds industry, which is currently already a significant industry in Portugal in the use of this technology, include the automotive, aerospace, and medical industries. Also in the Sector Skills Strategy in Additive Manufacturing [107], are indicated the main industries that will have a large adoption of AM in the coming years. In aerospace, fuel nozzles and systems, guide vanes, and turbine blades are predicted to be the most likely parts to be manufactured. In the automotive sector, spare parts, low-volume interior parts, and engine components will be produced using this technology. Finally, in the medical sector, implants, prosthetics, and surgical components could also be manufactured using AM. In the literature, the automotive, aerospace, and medical industries also show an increasing rate of adoption of this technology [26,30].

5.2. Product

Portuguese industry currently uses AM technologies, most prominently, for the production of prototypes for internal use as well as for sale to the customer, and the production of components for internal use and incorporation into the final product. Presentation models are also manufactured by companies through the use of AM. In the secondary sector, all the product types listed are manufactured. However, in 3D printing services, besides the fact that these can themselves be a "delivery", the prototypes and components for incorporation into the final product are the products that are delivered to the end customer.

Regarding investing in extending the use of AM to other production processes, most of the companies surveyed state that this is a possibility in the short/medium term. Besides continuing to use AM technology to manufacture prototypes and components both for internal use and also for sale, the interest for direct production, i.e., manufacturing the final product using only AM, was noticeable. This purpose was the most mentioned by Portuguese companies when the goal is to expand the use of this technology in the production process.

AM may allow companies, when it makes sense in terms of economics, costs, or delivery time, to produce fully functional final components that will have to be qualified and follow existing (and future) standards and that will have an impact on business models.

5.3. Technology

5.3.1. AM technology

The three technologies most currently used by Portuguese companies are FDM, SLS, and SLA. Polymer-based AM in Portugal is significantly more employed than metal-based AM [36] which may justify that the technologies most used by companies are the ones presented above. FDM is an AM technique aimed for polymer processing and SLS and SLA, although they can process both types of material, metal and polymer, are primarily used for polymer processing. Other technologies such as SLM, Digital Light Processing (DLP), and inkjet printing (IJP) are also used.

Regarding the adoption of different types of AM technologies, in addition to those that are already currently in use, as opposed to extending AM to more of the company's production processes, the data analysis is inconclusive. What may explain why a large number of companies do not choose to adopt another type of AM technology in the future are the costs associated with this extension, since AM machines require a high investment and also all the other associated costs such as hiring skilled labor make another AM technology a significant burden for an organization's accounts. However, when the adoption of more technologies is an option for the future, the most suitable are technologies that are already employed today such as SLA, FDM, SLM, DLP, and beyond these Wire Arc Additive Manufacturing (WAMM), another technology that companies have shown interest in. New AM processes have been developed [31,33], so it is predictable that in the short term future distinct processes will emerge that are still unknown to date.

5.3.2. Materials

The most commonly used printing material are polymers, but more materials such as metal alloys, ceramics, glass, or even paper are also used [35]. Polymers are a very common type of material and are considered the basic material for AM due to their accessibility, low costs, good mechanical properties, and ease of use in different processes [117]. In Portugal, polymers are the go-to material for AM. It is followed by metals and ceramics. The results obtained through the questionnaire are in line with those obtained by the [107], in which metal and plastic are the materials most used by AM, followed by composites.

In the future, new materials can be expected to emerge [33]. AM allows for the creation and development of new materials, capable of improving the mechanical and physical properties of manufactured products [29]. The reduction in the price of the materials used for AM is important and will facilitate the adoption of this technology by companies and users.

5.3.3. Hardware e software

Since AM is one of the key elements for digital transformation, there must be technical support. However, the AM support software is still far from being enough to support engineers in understanding the requirements and necessary limitations of the parts manufactured using AM to optimize production [118]. This support software is distinct and independent from the software used for printing since it is not possible to make any changes because they only depend on the equipment manufacturer.

Information Technologies (IT) can play a key role in dealing with the technical challenges and can contribute to AM development by serving as a foundation that can facilitate the complete characterization of the materials used creating greater confidence in the products manufactured and improved monitoring leading to an optimization of the AM process [119].

Regarding the physical equipment used for AM (the hardware), 3D printers are already produced in Portugal. However, the cost of the equipment is still high and is a limiting factor for the adoption of this technology, and the acquisition of equipment is often responsible for large investments, becoming a clear disadvantage of AM.

5.4. Other resources

5.4.1. Knowledge and skills

Securing the information and knowledge needed for business and process development is essential for any situation. For the successful adoption of AM, countries must be willing to bet on developing the necessary national know-how [36]. It is therefore essential to secure the information and knowledge necessary for the development or adoption of this technology. R&D projects are a way to generate new knowledge. It is an activity carried out by companies to emerge new products, and procedures, or to improve existing ones. In Portugal, according to the data collected, R&D projects are a concern for the companies and most of them say they are, have been involved, or if not, it is a short/medium term goal. The AM in Portugal has suffered from critical problems of institutional instability where the end of some research institutions and the unexpected decrease in the availability of capital for R&D projects [36].

In addition, although technical and higher education courses are starting to emerge, the lack of qualified professionals in the area is one of the problems of AM in Portugal. As such, Portuguese companies state that knowledge is acquired autonomously. One justification may be that companies do not want to share the acquired knowledge, using it as a competitive advantage, or even because the existence of a huge variety of machines, materials, processes, and human resources means that each organization has its own way of working with AM. Collaboration with academia and training with third parties are the other two ways most used by companies.

The training of qualified professionals in the area and the knowledge sharing are acknowledged as important towards a greater adoption and development of this technology. The lack of technological knowledge and skills and the availability of qualified personnel were identified by the SAM (Sector Skills Strategy in Additive Manufacturing) project as the challenges and skills needed [107]. Also in the literature review, the lack of knowledge is recognized as a limitation of this technology [19,23].

It is important that in Portugal, R&D activities continue to be supported and carried out so that development and innovation are not forgotten and there is constant evolution and innovation, particularly in AM technology. Also, knowledge sharing between organizations or even within the organization itself is essential and the evolution of information and communication technologies (ICT) can help in this sharing and the common understanding of knowledge since they allow the reuse of domain knowledge between people. Knowledge sharing can also be done through visits to other companies, open days, workshops, and participation in projects that allow and encourage the exchange of knowledge and know-how to know the technologies and processes used in AM by other companies and share experiences.

5.4.2. Partnerships

Partnerships are important for two or more parties where everyone benefits from that relationship. Portuguese companies have partnerships with both other companies and also with universities and state that they have applied or are applying for research/community funds through partnerships with other companies and universities. The Portuguese government provides some incentives for business development, innovation, and competitiveness [104]. Some of the known governmental supports, both national and European, to help companies and organizations in adopting and using AM in Portugal are Product R&D Mobilizer Projects, Horizon Europe (H2020), Portugal 2020, Erasmus +, and co-promoted projects.

In the short/medium term, it is expected that the financial support will be increased, especially financial support more directed to AM to encourage the growth of this technology in Portugal. According to Roca et al. [37], governments might focus on sectors in which their industries are already competitive and fund the progress of AM capabilities targeting those sectors. However, this opinion generates some controversy since, although this measure allows supporting the innovation of technologies in already competitive sectors [36], it ends up closing doors to companies that intend to employ this technology.

5.4.3. Legislation and ethics

With the advance in technology, with 3D printers becoming increasingly more accessible to anyone, and with an increasing number of companies engaging in 3D printing services, the protection of acquired knowledge has become a challenge. Intellectual property is one of the big factors in the digital age, and in particular in AM. Without the existence of any regulatory system, it becomes difficult to ensure its protection [18,28]. Therefore, AM technology requires new methods of protection and respect for legal rights [41]. By reading the roadmap and based on the sample, some companies stated that there is no form of knowledge protection. However, when it exists, the most used form is industrial secrets together with confidentiality agreements, also conveyed by Fig. 6.

The existence of standardization allows for standardizing and guiding the implementation of AM technology. The lack of international and national AM standardization is recognized as a barrier to this technology. The variety of machines, materials, and processes makes the development of a standard challenging [18,29,120] and means that there is still much uncertainty and unknown regarding AM.

Quality control of products manufactured using AM technologies is also a key challenge. A component may perform well in tests designed by the manufacturer, yet, for a variety of reasons, perform poorly when in service. ASTM International and the International Organization for Standardization are trying to address these issues and are collaborating to develop standards for AM [37]. In Ref. [105] the author has created a guide with all the standards that are currently in place to guide and rule the use of AM technologies.

The lack of regulation coupled with the problems related to intellectual property protection leads to ethical problems associated with the use of AM. Digitization can lead individuals to invade conventional forms of intellectual protection due to the transformation of physical objects into digital files and to create copies. In addition to this ethical problem caused by the digitization of products, the printing of objects, such as weapons, and the use of living tissue as printing material are other examples that can raise questions and reinforce the need for regulations [17,18]. Ensuring the maintenance of current standards and regulations is indispensable. This also is valid for the creation of future standards, to be able to keep up with the technological evolution.

6. Discussion

6.1. Synopsis and roadmap implications

The proposed roadmap allows the mapping of technological knowledge, on the implementation and evolution of AM and serves as strategic guidance for Portuguese companies. Fig. 15 illustrates the main aspects of the proposed roadmap in each of the intervals considered in the time horizon from 2023 to 2030.

Fig. 15.

Main aspects of the roadmap for AM.

Additive manufacturing has a high potential for the production of small and complex parts with low production volumes [121]. However, its use is not limited to these characteristics, and it has been applied in many different situations [122]. However, there are still several challenges and limitations [16] that may limit its more expressive use. The proposed roadmap, by providing all the information about the current and future state of the AM, allows organizations to access technological knowledge about the implementation and evolution of the AM, which can help in anticipating possible scenarios and thus maintain or improve their competitive position.

In addition, micro and small businesses face additional challenges. The limited resources to invest in technology and being more risk-averse [8], which are characteristics of this group of companies, bring additional challenges. The proposed roadmap can be an aid in this regard, since by enabling the mapping of technological knowledge, about the implementation and evolution of technology AM not only its current state but also its future, it has the potential to serve as a strategic guide and to direct innovation, development, and commercialization activities.

As a new form of production and having the ability to be disruptive, additive manufacturing will have an impact in the manufacturing and business models of organizations, as in their entire value chain. The roadmap developed can serve as a strategic guide for organizations that use AM in Portugal and even for those that intend to start using it. The developed model can also be used for countries other than Portugal, although it was developed for a specific case.

6.2. Critical analysis

After the development of the roadmap, some inferences can be made regarding the use of AM in Portugal and its evolution. From it, it is possible to deduce that the protection of intellectual property and ensuring the existence of more international and national regulations and norms are two fundamental factors to able to overcome some problems of legislation and ethics that are frequent in the use of AM since it is a technology that can adopt a disruptive character in the industry.

Also, the roadmap indicates that R&D is essential and will be so in the future. It aims to promote the development and evolution of AM, generating more knowledge and contributing to the innovation and competitiveness of organizations. Informatics can be an impulse for this technology and can help overcome technical challenges encountered in development work. It is expected that in the short/medium term there will be a growth and development of AM support software to improve and even optimize production.

Currently, manufacturing industries, construction, and 3D services are part of the AM market in Portugal. The most used material is plastic followed by metal and composites. The most used technologies are FDM, SLS, and SLA which are often used for the production of prototypes for internal use and sale to the customer, for the production of components for internal use and incorporation in the final product, and the production of presentation models. Portuguese companies have partnerships with other companies and universities, use autonomous learning, training with third parties and collaboration with academia for the acquisition of knowledge, and resort essentially to industrial secrets together with confidentiality agreements for the protection of knowledge. Government incentives exist; however, they should be more directed towards AM since when they exist, they are directed more broadly for example for Industry 4.0.

In a future situation, new materials and new technologies are expected to emerge in the short/medium term. The AM technologies that are expected to be the most used in Portugal continue to be FDM, SLA, and SLS. AM will continue to be used for prototyping and component manufacturing and can be used for direct production in the short to medium term. The intention to expand AM to more of the company's productive processes is demonstrated by the companies and it is recognized that it could enable the production of fully functional final parts. The economic factors, the cost of materials and equipment, and the lack of financial support for AM were the reasons most pointed out for AM not having a greater implementation. The lack of knowledge and qualified professionals in the area are also two reasons that limit this technology, and they must be overcome in the short/medium term.

Also from the roadmap it is possible to infer that AM will bring new business models and the changing role of the consumer. End-product production and AM services will have a big impact on business models and the growth of home printing will be more and more a reality. Consumers will play an active role in the production process, especially in domestic printing, but also in AM services where the customer himself is the designer of his product. Aerospace, automotive, and healthcare will be the areas that will have significant growth in the coming years.

7. Conclusions

AM holds tremendous potential with rapid growth and widespread industrial adoption. A technological roadmap can assist organizations in integrating and innovating AM. Though AM is poised to become the norm in production processes, further research into its impact and potential is crucial. AM may encounter bottlenecks in industrialization and intellectualization, hindering its industrial applications. While there are many advantages to using AM, difficulties in adoption are present and must be overcome. AM will change the way organizations create, distribute, and capture value. As such, in this paper a roadmap for AM was developed as a tool to map technological knowledge and serve as a strategic guide for companies. This allowed for the characterization of the current state and future state of AM in a visual way, generating knowledge about how this technology operates, changes, and needs. Portugal was selected as an example. The methodology involved 3 phases: planning, development, and revision. The roadmap model was developed through surveys and literature, highlighting factors that influence AM adoption, especially in Portugal. It was found that the production of final products and 3D services will impact business models and home printing will become increasingly common.

Through the roadmap it was assessed that, in the near future, it is expected for new materials and technologies to emerge. AM is projected to be widely adopted by companies, with FDM, SLA, and SLS being the most commonly used technologies. AM will be used for prototyping and component manufacturing and may be used for direct production in the short to medium term. Companies seek to expand AM to more of their processes, which would enable the production of fully functional final parts. The main reasons hindering wider implementation of AM include economic factors such as cost of materials and equipment and lack of financial support. The shortage of knowledgeable and skilled professionals is another obstacle that needs to be overcome. AM will bring about new business models and the role of consumers will change. Home printing will increase, and consumers will have an active role in the production process, especially in domestic printing and 3D services. The aerospace, automotive, and healthcare industries are expected to experience significant growth in the coming years.

The main contribution of this research is the characterization of the use of AM and possible evolutions of this technology through the roadmap tool. This tool can serve as a strategic guide for companies that already use or intend to integrate AM. As this topic is an emerging area of research and its knowledge is of utmost importance for the digital transformation required for Industry 4.0, this study can be adopted and adapted by researchers and other stakeholders for the development of a strategic vision in a given industry, allowing them to shape their business strategy to industry conditions. On the other hand, this study also contributes to the extension of the literature in the sense that it provides a strategic technology mapping using a visual tool, the roadmap for the AM industry at a country level. It also contributes to knowledge management in AM, being a relatively recent manufacturing process, it is important to generate useful information, encourage growth and preserve knowledge regarding this technology especially for companies or organizations that make or intend to make use of AM in Portugal.

Although one of the concepts of this study is knowledge management, this study does not evaluate knowledge management practices or how knowledge is shared and managed within the organization. This point is important because companies using AM operate in disruptive and emerging industries whose business dynamics are not yet fully known and knowledge plays a key role in an organization's innovation process.