Abstract

Fire risks pose a substantial threat to the apparel manufacturing industry since they can lead to immense property damage, potential loss of life, disruption of business operations, and reputational damage. In an emerging economy like Bangladesh, fire-related hazards are crucial due to the numerous deadly industrial fire incidents in recent years. This research, thereby, proposes an integrated multi-criteria decision-making (MCDM) framework to identify and mitigate fire risk hazards in the apparel manufacturing industry. Initially, the study identified 30 significant fire risk factors from the literature review. Then, after expert validation, an integrated Best Worst Method (BWM) and Weighted Sum Model (WSM) framework was utilized to prioritize the fire risk factors. Twenty-three mitigation actions were proposed afterward for the top-ranked risk factors based on National Fire Protection Association (NFPA) codes. An Interpretive Structural Modeling (ISM) with a Cross-Impact Matrix Multiplication Applied to Classification (MICMAC) analysis was later used to explore the interrelationships and dependencies among the mitigation actions. The ranking obtained from the BWM-WSM assessment revealed ‘combustible storage unseparated by fire-rated construction,’ ‘non-standard inspection, testing, and maintenance’, and ‘inadequate means of egress for the occupant load’ as the three most critical fire risk factors. The ISM-MICMAC analysis revealed ‘fire-rated construction’ and ‘standardized detection and protection’ as the most-driving mitigation actions. The study outcomes are expected to aid the managers and policymakers in emerging economies in formulating sustainable fire risk management strategies for the apparel industry and thus improve the operational safety and resilience of the sector.

Keywords: Fire risk mitigation, Apparel manufacturing industry, Best worst method, Weighted sum model, Interpretive structural modeling

1. Introduction

The apparel manufacturing industry is a dynamic and competitive industrial sector that employs diverse processing operations that can have the propensity to start various fire hazards and may threaten the safety of the workers and the facilities. Fire incidents may be driven by factors like flammable materials, fabrics, dyes, machinery, chemicals, and so on [1]. For instance, cotton, wool, and other natural fiber-based fabrics may easily burst into flames and are quite flammable [2]. Electrical faults in electrical circuits can easily ignite cotton fluff, leading to a potentially severe fire [3]. Moreover, synthetic ones like nylon, polyester, and rayon are highly hazardous in the case of fire since they may ignite quickly and circulate rapidly [4]. A fire outbreak can severely impact the industry, causing injury, fatality, property damage, and operational disruptions [5]. In addition, the workplace environment, including overcrowding, inadequate fire safety precautions, poor ventilation, etc., may elevate the likelihood of fire hazards and make it challenging for the employees to evacuate if a fire outbreak occurs.

Policymakers, researchers, and practitioners in the industry are working to establish a safe and sustainable working environment in the apparel manufacturing industry of Bangladesh, which consists of over 4600 factories, employs over 4 million workers, and is the country's largest export earner, with a value of over $35 billion in the 2020–2021 financial year [[6], [7], [8]]. Fire incidents have been a major concern in this sector over the last three decades. Between 1990 and 2020, at least 40 major fire incidents occurred in the apparel industry, resulting in over 500 deaths [9]. The worst industrial fire in the nation's history was in 2012 at Tazreen Fashions Ltd., which killed over 100 people [10,11]. After that horrible accident, Accord, an independent monitoring and inspection organization based on the legally binding agreement between apparel buyers and trade unions, was constructed in 2013 to ensure a safe and healthy work environment in the apparel manufacturing sector [12]. Since then, due to the organization's continuous inspection and remediation activities, fire incidents in the Bangladeshi apparel sector have reduced to a great extent compared to the past [10,12]. The May 2021 Quarterly Aggregate Report of Accord states that over 1600 factories are within its inspection scope, and almost 90% of these factories have achieved initial remediation progress for fire safety [13]. However, many factories are still outside the Accord's scope and cannot comply with all the fire safety standards.

Apparel manufacturers may put fire safety standards into practice to reduce the possibility of incidents and assure the well-being of employees, which is a crucial aspect of sustainability. The relationship between safety and sustainability is closely intertwined, and safety can influence sustainability in practice since both have similar pillars, including the economy, environment, and society [14,15]. Implementing fire safety and risk mitigation practices can support economic sustainability by avoiding property damage and reducing potential financial losses. Businesses may lower their insurance expenses by implementing fire safety procedures, and they can avoid expensive operational disruptions [16]. Besides, industries may contribute to conserving the environment and striving toward environmental sustainability by implementing fire prevention and control strategies that decrease waste, habitat damage, and pollution caused by fires. Fire safety measures also support societal sustainability by securing people's well-being and safety [17]. It may reduce the risk of fire-related harm, fatalities, and eviction by setting up appropriate fire precautions that safeguard the lives of individuals who occupy the premises and work areas. Hence, sustainable fire safety measures are crucial and can significantly promote sustainability's triple bottom line (economic, social, and environmental) [18].

Due to several reasons, literature on the fire safety analysis of the apparel sector is gradually developing. First, apparel manufacturers can achieve long-term benefits by investing in permanent infrastructural changes to meet local and international fire safety standards [19]. Second is national and international pressure to maintain a safe and sustainable working environment [20]. Third is an ongoing cultural change to reach global standards as one of the leading apparel supplier nations of the world [21]. In recent years, fire safety regulations have been greatly influenced and encouraged by relevant government agencies, international clothing brands, and other apparel-related regulatory agencies [22]. This necessitates analyzing fire safety issues in the apparel sector using a more analytical and systematic approach.

In recent years, practitioners' interest in fire hazard research has significantly risen in various sectors due to stricter building code requirements, fire safety rules, and environmental protection mandated by buyer countries and local government bodies. For instance, qualitative studies have shown the importance of fire safety in apparel factories [19,20]. Khan et al. [23] analyzed the effects of non-standard fire safety practices on worker safety in apparel factories using computational fluid dynamics (CFD) modeling. Fuzzy analytic hierarchy process (AHP) has been used to identify weights of fire risk factors for commercial buildings [24,25]. Likewise, Alkış et al. [26] used AHP to rank risky, vulnerable facilities due to industrial fires. The failure mode and effects analysis (FMEA) and best-worst method (BWM) have been used to propose a fire risk-based ranking of hospital facilities [27]. An event tree method has been used to analyze the frequency and cause-effect of fire risk in industrial buildings with a probabilistic approach [28]. The fire risk index has been used to evaluate factories based on different fire risk parameter weights obtained through the fire and explosion index method [5]. Moreover, the spatial layout of apparel factory buildings has been examined through simulation and fire drills to determine occupant movement during fire incidents and evacuation [29].

Despite a positive attitude towards fire safety practices in the apparel manufacturing sector, decision-makers often struggle to implement proper strategies due to a lack of a systematic analytical framework. To address this issue, it is crucial to understand and identify the significant fire risks in this sector. Previous research has analyzed cause-effect or risk indexes, but none has focused on ranking fire risk factors and modeling mitigation strategies. This is a significant gap in existing studies. This study, thereby, focuses on the following research questions (RQs).

-

RQ1

What are the most critical fire risk factors in the apparel manufacturing industry?

-

RQ2

How these risk factors can be prioritized and addressed hierarchically?

-

RQ3

What are the risk mitigation actions for the top-ranked fire risk factors?

-

RQ4

How do the mitigation actions drive and depend on each other during implementation?

-

RQ5

What are the implications for managers and policymakers to ensure workplace safety and sustainability?

This study, thereby, intends to enhance the literature by accomplishing the following specific research objectives (ROs):

-

RO1

To identify the most significant fire risk factors in the apparel manufacturing industry.

-

RO2

To evaluate and rank the risk factors to determine their priority sequence.

-

RO3

To propose mitigation actions for the top-ranked fire risk factors.

-

RO4

To explore the interrelationships among those mitigation strategies based on their driving and dependence power over each other.

-

RO5

To suggest valuable theoretical and managerial insights to industrial managers and policymakers to utilize the study outcomes to facilitate workplace safety and sustainability.

An integrated Best Worst Method (BWM)-Weighted Sum Model (WSM) and Interpretive Structural Modeling (ISM) with a Cross-Impact Matrix Multiplication Applied to Classification (MICMAC) framework have been employed in this study to achieve the research objectives. This study utilized the integrated BWM-WSM to determine the criterion weights with BWM and the final ranking of fire risk factors using WSM. BWM can evaluate criteria weights based on expert feedback [30]. This method is less time-consuming and complex than other multi-criteria decision-making (MCDM) approaches, such as AHP or DEMATEL [[31], [32], [33]]. WSM is a simple MCDM technique that can be used effectively to determine the final ranking of alternatives when the criteria weights are calculated using another MCDM method in a hybridized framework [34]. After determining the final order of risk factors and proposing mitigation actions for the top-ranked factors, this study used the ISM-MICMAC approach to determine the relationships among the mitigation actions. ISM can show relationships among alternatives based on driving and dependency power over each other [35]. This method is significant when ranking the alternatives is not enough for implementation, and presenting relationships among alternatives can provide better insight to decision-makers [36]. MICMAC analysis visually depicts the relationships obtained from ISM and includes four divisions for alternatives: dependent, linked, independent, and autonomous [37].

To the best of the author's knowledge, this is the first study to analyze fire risk in the apparel sector using these methods to find a sustainable solution for fire safety in an emerging economy. A stratified model for risk factors and their mitigations can help the apparel industry in Bangladesh overcome its challenges in fire safety management with limited resources and provide a strategic and structural outline for industrial decision-makers to formulate more efficient policies.

The prevalence of fire incidents and their devastating impact on human lives and industries in Bangladesh, as evident from the alarming figures provided in the Fire Service records, underscores the urgency of our research. The statistics compiled by the Bangladesh Fire Service and Civil Defence (FSCD) headquarters indicate that over 1700 individuals lost their lives in different fire incidents in the previous 15 years [38]. The stark reality of over 24,000 fire incidents causing 98 deaths in 2022, with a significant portion stemming from the readymade garments industry [38], is deeply distressing. These tragic events underscore the vulnerability of apparel industries and emphasize the pressing need for effective fire risk mitigation strategies to mitigate the loss of life, safeguard industries, and contribute to sustainable development. The motivation behind our research is driven by a sincere commitment to addressing this pressing challenge.

Despite the evident need for comprehensive fire risk mitigation frameworks, the current research landscape lacks a dedicated study that provides a robust framework specifically tailored for the apparel manufacturing industry. This void in the literature has inspired our research, as we seek to provide decision-makers, policymakers, and industry stakeholders with an innovative hierarchical framework that not only can address the unique safety-related challenges in the apparel manufacturing sector but also can assist in reforming fire risk mitigation strategies across various other industries.

The research aims to contribute to existing literature concerning fire safety, particularly within specific industrial sectors like the apparel manufacturing industry in developing economies. Moreover, this study will provide valuable insights for industry leaders and policymakers to develop well-informed strategies guided by analyzed risk factors and corresponding mitigating strategies. These strategies can potentially enhance the industry's capacity to establish a robust and efficient system for managing fire hazards and thus improving the overall safety and resilience of the production system.

The rest of the paper is arranged as follows: Section 2 reviews the studies on fire risk, the research gap, and study contributions; Section 3 describes the detailed research methodology; Section 4 shows the calculations and results; Section 5 discusses the results and the study's implications. Finally, Section 6 concludes the study and suggests some further research scopes.

2. Literature review

This literature review is organized into three subsections: relevant studies in the apparel manufacturing sector, relevant studies in other sectors, and research gaps and study contributions.

2.1. Fire risk-related studies in the apparel manufacturing industry

Regarding fire risk assessment of the RMG industry, some papers utilized classical fire risk index (FRI) methods; some presented qualitative observations, some utilized simulation-based computer modeling, and some dealt with statistical analysis of the existing scenario.

For instance, Wadud and Huda [39] and Islam and Roman [5] used weights of selected structural and managerial parameters to assess risk in RMG factories using FRI. However, these weights were not evaluated using multiple criteria, and there was no structured method for aggregating expert assessment scores. These studies also did not provide structured mitigation strategies. Hasan et al. [11] presented a statistical overview of deadly incidents in the apparel industry, including a qualitative cause-effect analysis of fire incidents. However, they did not focus on depicting a hierarchical ranking of the risk factors for mitigation. Haque and Chowdhury [40] analyzed the causes of electrical fires in apparel manufacturing factories to predict the probability of burn injuries but they only focused on electrical fires. Similarly, Barua et al. [41] focused on evacuation safety during fire hazards and compared standard and non-standard practices statistically but did not cover other aspects of fire incidents. These studies also had the limitation of using the same weight for all risk factors, resulting in no ranking or stratification of mitigation strategies.

Wiersma [10] and Habib et al. [42] presented a statistical overview of the fire incidents in the apparel industry after initiating a safety inspection by the Accord in 2013. With linear regression analysis, those papers showed that fire incidents had decreased in those factories under continuous monitoring and assessment by different regulatory authorities. Again, Haque et al. [43] used computer simulation to model fire and smoke propagation and evacuation scenarios. Khandoker et al. [44] used numerical simulation to model fire in multistoried apparel factory buildings with CFD tools. Nilufar & Choiti [29] determined a numerical correlation between emergency escape routes and occupant movements during evacuation using data from fire drills. These studies provided insights into fire incidents, evacuation routes, and occupant behavior but did not aim to help apparel managers by proposing hierarchical mitigation strategies.

Moreover, Rathnayake et al. [45] used the relative importance index (RII) to rank fire risk factors for the apparel industry in Sri Lanka. However, RII is a simple decision-making technique that does not consider criteria weights for ranking alternatives, which can overlook different aspects of risk factors [36]. While the study ranked risk factors and provided descriptive suggestions for risk remediation, subjective recommendations do not offer impactful insights for managers needing a stratified mitigation strategy for practical implementation. A summary of the recent literature on fire risk in the apparel manufacturing industry is presented in Table 1.

Table 1.

Summary of literature review on fire risk in the apparel industry.

| Author & Year | Applied Method | Study objective | Presented Risk Factors Ranking? | Proposed Stratified Mitigation Plan? |

|---|---|---|---|---|

| Asaduzzaman [46] | Descriptive statistics | Determining the relationship between fire safety management cost and profit increasing | No | No |

| Habib et al. [42] | Descriptive Statistics | Depicting the declining trend in the number of fire incidents after initiating fire safety inspection | No | No |

| Rathnayake et al. [45] | RII | Presenting a ranking of the fire risk factors and providing subjective suggestions for risk mitigation | Yes | No |

| Khan et al. [23] | CFD | Determining the effect of non-standard practices on evacuation during a fire incident | No | No |

| Nilufar and Choiti [29] | Computer Simulation | Determining the correlation between emergency escape routes and occupant movement behavior | No | No |

| Islam and Roman [5] | FRI | Determining weights of the fire risk parameters to evaluate the risk index of factories | Indirect | No |

| Barua et al. [41] | Descriptive Statistics | Depicting a comparison of the impact between standard and non-standard practices during an evacuation | No | No |

| Haque et al. [43] | Computer Simulation | Analyzing the fire and smoke propagation pattern and the evacuation scenario of the occupants | No | No |

| Haque and Chowdhury [40] | Empirical Probability | Establishing a probabilistic method to predict burn injury due to an electric fire | No | No |

| Hasan et al. [11] | Descriptive Statistics | Presenting historical data of deadly incidents statistically and forming a cause-effect relationship | No | No |

2.2. Fire risk-related studies on other sectors

Recent studies on fire risk assessment exist in industrial and commercial buildings, hospitals, and residential buildings. For example, Cvetković et al. [47] used statistical analyses to study occupant behavior during a fire in a residential building, and De la Hoz et al. [48] used descriptive statistics to examine the relationship between following fire safety regulations and the level of risk in an industry. However, neither provided a ranking or stratification framework. Medved [49] descriptively recommended fire risk mitigation measures such as fire-rated building materials and fire safety systems for sustainable fire safety but did not provide a hierarchical implementation strategy.

Wang et al. [24] and Yilmaz et al. [25] introduced the fuzzy AHP method for MCDM to determine the weights of selected fire risk factors. Alkış et al. [26] used classic AHP to rank the most endangered facilities near a fire incident. However, BWM, used in this study, is easier to apply and more consistent than AHP or fuzzy AHP [31]. Additionally, collecting expert feedback through questionnaires is complex for AHP, as ensuring consistency in the pairwise comparison matrix through continuous iteration can distract decision-makers [27].

Omidvari et al. [27] used a hybrid MCDM approach combining FMEA, BWM, and CODAS to determine the Risk Priority Number (RPN) of fire risk factors with weighted values, ranking different wards of a hospital based on their weighted RPN. However, this method has a significant limitation in that it overlooks essential aspects of risk factors, such as the effects of the ‘fire alarm system’ on the probability and severity of a fire incident in the proposed framework. Brzezińska and Bryant [18] proposed a performance-based FSRI for fire safety factors to determine an optimal risk index for building sustainability. However, risk indexing often presents similar values for multiple factors, making it challenging to provide a definitive ranking. Rahardjo and Prihanton [50] proposed a ranking method for high-risk buildings with fire risk indicators but did not focus on ranking the risk factors or mitigation methods.

A summary of the recent literature on fire risk in sectors other than the apparel manufacturing industry can be found in Table 2.

Table 2.

Summary of literature review on fire risk in sectors other than the apparel industry.

| Author & Year | Applied Method | Application Case Area | Study objective | Presented Risk Factors Ranking? | Proposed Stratified Mitigation Plan? |

|---|---|---|---|---|---|

| Cvetković et al. [47] | Descriptive Statistics | Residential buildings | Determining occupant behavior during a fire emergency | No | No |

| De la Hoz et al. [48] | Descriptive Statistics | Industrial buildings | Finding a relationship between regulations and fire risk impact | No | No |

| Medved [49] | Descriptive | Buildings | Suggesting fire safety measures | No | No |

| Wang et al. [24] | FAHP | Commercial Buildings | Determining the weights of fire risk factors | Indirect | No |

| Alkış et al. [26] | AHP | Industrial Fire | Presenting a ranking of the endangered infrastructures near an industrial fire | No | No |

| Yilmaz et al. [25] | FAHP | Commercial Buildings | Determining the weights of fire risk factors | Indirect | No |

| Omidvari et al. [27] | FMEA, BWM, CODAS | Hospital | Presenting a ranking of the endangered wards of a hospital during a fire | Indirect | No |

| Rathnayake et al. [51] | Descriptive | Buildings | Reviewing critical fire risk factors | No | No |

| Brzezińska and Bryant [18] | FSRI | Buildings | Presenting a sustainable way of fire safety strategy | No | No |

| Rahardjo and Prihanton [50] | AHP, Objective matrix, Traffic light system | Residential buildings | Presenting a ranking of the buildings based on the presence of risk indicators | Indirect | No |

2.3. Research protocol, research gap, and contributions

This research aimed to identify the fire risk factors in the apparel manufacturing industry to improve workplace safety and sustainability. A systematic literature review of studies published in the relevant field between 2017 and 2023 revealed a significant research gap. A research protocol was developed during the literature review process, including databases, research timeline, key phrases, and inclusion and exclusion criteria, as provided in Table 3. In addition, the snowballing technique was used to explore further related studies on fire risks in the apparel industry through cross-reference analysis [52,53]. Over 80 articles were retrieved in the systematic literature search that utilized specific keywords. After a comprehensive full-text screening and strict research protocol application, 32 relevant research articles and reports were selected to address the research questions.

Table 3.

Research protocol implemented for systematic literature review.

| Research protocol | Brief description |

|---|---|

| Databases | Scopus and Google Scholar |

| Language | English |

| Timeline | 2017 to 2023 |

| Search Keywords | “risks” OR “hazards” AND ““fire” AND “Apparel industry” OR “RMG industry” OR “fire risk factors in apparel industry” OR “apparel industry fire hazards” OR “fire risk factors in RMG” OR “factors posing fire risk to the apparel manufacturing industry in emerging economies" |

| Inclusion criteria | (i) Articles related to RQs; (ii) Scientific reports or articles highlighting the risks, threats, and hazards of fire incidents in the apparel industry. |

| Exclusion criteria | (i) Articles published in languages other than English; (ii) studies that do not provide sufficient information on the methodology, data collection, or statistical analysis; (iii) studies that lack relevance to the specific RQs or study design and (iii) articles that are not indexed in Scopus or Google Scholar. |

| Data extraction | The selected fire risks were a significant threat to safe and sustainable operations in the apparel manufacturing sector |

Fire hazards in urban and industrial areas have become more severe and diverse due to the growth of the global economy [54]. Researchers are seeking sustainable fire risk management approaches for modern industrial infrastructure, leading to an increase in fire risk studies in various industries and urban sectors [55]. To mitigate fire risks, it is crucial to prioritize risk factors based on their significance [56]. Numerically analyzed decisions are more effective than subjective decisions in ensuring sustainable fire safety management in critical decision-making environments [57]. As discussed, a few numerical decision-making studies have been performed for various sectors and urban areas focusing on fire risks. However, none have been explicitly performed to aid the decision-makers of the apparel manufacturing sector in emerging economies in prioritizing fire risk factors and finding a stratified implementation strategy to promote workplace safety and sustainability. Thus, this research contributes to the body of literature in the following ways.

-

a)

Identifying the most relevant fire risk factors that impact the safety and sustainability of Bangladesh's apparel industry.

-

b)

Employing an integrated BWM-WSM approach to develop a hierarchical ranking of the identified risk factors according to the respective criteria.

-

c)

Determining mitigation strategies for the top-ranked risk factors.

-

d)

Exploring the mitigation strategies and establishing the relationship among each other.

-

e)

Enabling the decision-makers to make well-informed decisions to ensure workplace safety and achieve sustainability.

3. Research methodology

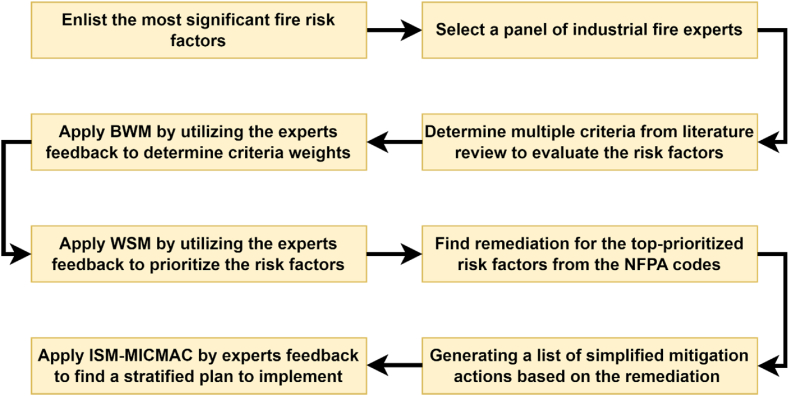

The research methodology of this study consists of the following phases: data collection for determining the most frequently observed fire risk factors, selection of industrial fire experts, and a brief description of the BWM, WSM, ISM, and MICMAC approaches. The methodological approach is illustrated in Fig. 1.

Fig. 1.

Methodological framework of the study.

Multi-Criteria Decision Making (MCDM) technique is a widely accepted method among researchers in scenarios where decision-making becomes intricate due to the presence of multiple criteria of different importance levels and the lack of required empirical data for decision analysis. This study focused on fire risk management in the apparel manufacturing industry and found an absence of databases providing pertinent data. Information about specific causes of devastating fires, their frequency, and their potential for prioritization for mitigation actions was lacking. Consequently, we resorted to analyzing expert opinions to investigate this issue, a common practice in such scenarios [32,58].

Among various MCDM techniques, we chose the Best Worst Method (BWM) to determine criteria weights, due to its inherent advantages over other weight-determining methods like the Analytical Hierarchy Process (AHP). These advantages include its accuracy, its simplicity for the decision-makers when responding to questionnaires, and its numeric simplicity compared to other methods [12].

To make the overall study framework accessible to industrial decision-makers and to avoid calculation complexity, we adopted the Weighted Sum Model (WSM) [59]. It's widely recognized for solving MCDM problems and is relevant for risk management studies [60]. Our proposed BWM-WSM hybrid framework will enable industrial managers to adapt and respond to any new circumstances that arise in the context of fire risk factors.

We employed ISM to visualize and stratify our mitigation strategies. Unlike ranking tools, ISM provides a stratified framework, offering a more comprehensive view of implementation hierarchies, an aspect often overlooked when simply ranking. Very often, the Matrice d'Impacts Croisés Multiplication Appliquée à un Classement (MICMAC) analysis served as a complementary tool to ISM. Researchers have combined MICMAC with ISM for enhanced data visualization in numerous past decision-making studies. This combination effectively illustrates the interrelationships among the variables being analyzed, thereby aiding decision-makers in understanding the patterns and connections [36].

3.1. Most significant fire risk factors in the apparel industry

By conducting a comprehensive analysis of relevant articles using Google Scholar and Scopus databases from 2017 to 2023, we have developed an initial list of 28 significant fire risk factors affecting the apparel manufacturing industry. Moreover, the reports generated by Accord on fire safety inspection in apparel manufacturing industries in Bangladesh were also taken into account for primarily identifying the risk factors. The Accord conducted fire safety inspections with highly trained fire safety engineers in more than 1600 apparel manufacturing factories in Bangladesh from 2013 to 2020 [61]. The reports generated from the findings of those fire safety inspections can be found on their openly accessible website (https://bangladeshaccord.org/).

Later, the experts were contacted by email and requested to submit their feedback via Google Forms to validate and finalize the initially identified risk factors. The experts did not exclude any initially identified factor. However, they added two more factors (’‘Utility machinery unseparated by fire-rated construction’’ and ‘‘Unseparated exit discharge path from the building interior’‘) considering the context examined. The questionnaire used to verify the risk factors is provided in Appendix A of the supplementary materials. Then, the finalized list was established with the help of experts' feedback, as shown in Table 4.

Table 4.

Most frequently observed fire risk factors in the apparel industry.

| Code | Risk factors | Source |

|---|---|---|

| F1 | Narrow egress aisles/exit discharge | Anner [62]; Accord [61] |

| F2 | Length exceeding common path of egress travel and dead-end aisles | Nilufar & Choiti [29]; Mahmood et al. [63] |

| F3 | In-swing doors at the exit discharge | Yilmaz et al. [25] |

| F4 | Non-standard (collapsible/sliding/rolling shutter) doors at exits | Rathnayake et al. [64] |

| F5 | Egress doors/gates with non-standard locking features | Islam & Roman [5]; Accord [61] |

| F6 | No handrails for exit stairs | Barua et al. [41] |

| F7 | Closely located exits (a single fire event can compromise both exits) | Nilufar & Choiti [29] |

| F8 | Lack of fire training and drills | Omidvari et al. [27] |

| F9 | Material storage in the egress path/exit stair | Khan et al. [23] |

| F10 | Absence of stair designation signs/occupant load signs | Nilufar & Choiti [29] |

| F11 | Utility machinery unseparated by fire-rated construction | Expert feedback |

| F12 | Exit stairs unseparated by fire-rated construction | Khan et al. [23] |

| F13 | Improper separation of exterior exit stairs from the building | Haque et al. [43] |

| F14 | Unsealed penetrations in the floor/ceiling assemblies/stair enclosures | Wei et al. [65]; Accord [61] |

| F15 | Inadequate fire separation for fire pump room | Wiersma [10] |

| F16 | Combustible storage unseparated by fire-rated construction | Dârmon [28]; Accord [61] |

| F17 | Unseparated exit discharge path from the building interior | Expert feedback |

| F18 | Absence of ‘No Smoking’ sign | Omidvari et al. [27] |

| F19 | Smoke/fire detection alarms inaudible throughout the building | Yilmaz et al. [25]; Wang et al. [24] |

| F20 | Floor area exceeding standard size without automatic sprinkler | Khandoker et al. [44] |

| F21 | Floor exceeding standard height without a standpipe | Wei et al. [65]; Accord [61] |

| F22 | Non-standard Inspection, Testing, and Maintenance (ITM) | Dârmon [28] |

| F23 | Inadequate lighting along egress routes | Wang et al. [24]; Accord [61] |

| F24 | Misplaced/non-functional exit signs | Barua et al. [41] |

| F25 | Manual on-off switches for emergency lighting/exit signage units | Islam and Roman [5] |

| F26 | LNG/CNG cylinder storage within the factory building | Wang et al. [24] |

| F27 | Non-standard fire detection and protection system | Dârmon [28] |

| F28 | Inadequate means of egress for the occupant load | Khan et al. [23]; Accord [61] |

| F29 | Uncertified fire-rated doors | Rathnayake et al. [64]; Accord [61] |

| F30 | Faulty electrical panels at a non-standard location | Rathnayake et al. [64] |

3.2. Industrial fire experts selection

A panel of 19 industrial fire experts was selected purposively for this study. Purposive or judgemental selection of decision-makers is necessary where specialized opinion can only serve the study objectives, which a random sample of decision-makers cannot do [36,66]. Unlike other casual sampling methods, purposive sampling depends on an expert evaluation of the sample's appropriateness and a compelling justification that a specified sample of participants gives a credible base for survey-experimental results [67]. The purpose of the study would eventually be accomplished by using this strategy, which enables researchers to obtain subjective expert opinions [68,69]. The inclusion criteria for the experts in this study were having at least 10 years of working experience as an industrial fire safety personnel, having at least a bachelor's degree, understanding the survey questionnaire, and being willing to respond to the survey. Those selected experts participated in the online response (through Google form) in all the subsequent experts' opinion-based steps of this research. A brief overview of the expert panel is shown in Table 5.

Table 5.

Profile of the participating experts in this study.

| Total number of experts (N) | Designations | n | Experience | Percentage |

|---|---|---|---|---|

| N = 19 | Fire safety engineer | 4 | From 10 up to 15 years | 79% |

| Safety manager | 4 | |||

| Utility manager | 2 | |||

| Health and safety engineer | 3 | |||

| Operations Manager | 2 | |||

| Managing Director | 1 | More than 15 years | 21% | |

| Chief safety officer | 1 | |||

| Head of operations | 2 |

3.3. Best-worst Method (BWM) & Weighted Sum Model (WSM)

BWM, initially proposed by Professor Jafar Razaei in 2015, is a widely used novel pairwise comparison-based approach for multi-criteria decision-making [70,71]. The best-to-others and others-to-worst pairwise comparison vectors are used as input for an optimization model in this structured pairwise comparison technique to determine the optimum weights for the criterion (or alternatives) [72]. The number of necessary pairwise comparisons can be reduced, and the consistency of the results can be improved with BWM [73,74]. The detailed procedural steps of BWM [30] to determine criteria weights are provided in Appendix C of the supplementary materials. Some recent studies using the BWM method is provided in Table 6.

Table 6.

Recent studies using the BWM approach.

| Objectives | Tools | Sources |

|---|---|---|

| Selection of sustainable and resilient IoT supplier | Spherical fuzzy BWM and TRUST | Bonab et al. [75] |

| Evaluating man-made risks to urban areas and crucial resources | Grey BWM-Grey MARCOS | Bitarafan et al. [76] |

| Evaluating barriers to implementing circular economy in the electronics industry | BWM-ISM-MICMAC | Debnath et al. [74] |

| Exploring the Industry 5.0 challenges for post-pandemic supply chain sustainability | BWM-ISM-MICMAC | Karmaker et al. [53] |

| Analyzing Warehouse Accident Risks during Picking and Material Handling | BWM-Grey Relational Analysis | Hsu et al. [77] |

| Examining sustainable entrepreneurship determinants in SMEs. | Cognitive mapping-BWM | Mendes et al. [78] |

| Quantifying the Level of Digitalization in Municipalities | Cognitive mapping-BWM | Vieira et al. [79] |

The BWM method has numerous salient advantages compared to other MCDM methods. With the advent of MCDM methods like the Ordinal Priority Approach (OPA) [80,81] and Level Based Weight Assignment (LBWA) [82], the challenge lies in assessing the accuracy of decision-makers responses, as they are now compelled to maintain consistency throughout the process [83]. Again, despite being less data-intensive, the Simple Multi-Attribute Rating Technique (SMART) and Swing methods encounter the drawback of being incapable of computing the consistency ratio (CR). In comparison, BWM-based methods present a distinct advantage - the ability to identify careless questionnaire responses by scrutinizing the CR. While the Full Consistency Method (FUCOM) [84] performs better than the BWM method in consistency and pairwise comparisons, it requires an initial priority assignment based on the decision-maker's experience, causing potential confusion. In contrast, the BWM method only needs simple pairwise comparisons, making it easier for decision-makers to respond [85]. This ensures that the decision-maker's inadvertent errors are appropriately taken into account. Again, BWM performs better when we need to determine the subjective weights of the criteria, compared to methods like FUCOM, which perform better while determining the semi-objective or objective weights of the criteria [53,86]. Furthermore, although methods like Depth-Image-Based Rendering (DIBR) [[87], [88], [89]] and LBWA require fewer pairwise comparisons while defining interrelationships between ranked criteria, they require complete criteria ranking in advance. In complex emergency decision-making, accurately ranking the criteria is often difficult due to limited reference information. In such situations, these methods are unsuitable for deriving criteria weights. In contrast, BWM is more accessible and reliable, as it only requires the identification of the best and worst criteria to handle emergency decision-making problems [90].

The WSM approach is a distinctive method for evaluating and ranking alternatives. It strives to ascertain the combined weighted sum of performance ratings for a given set of alternatives based on certain decision criteria [91]. This approach offers a particular advantage in terms of its ease of use and ability to transform raw data into proportionate and linear measurements [92]. Detailed steps of WSM [34] are described in Appendix E of the supplementary materials.

3.4. Interpretive Structural Modeling (ISM)

ISM is a recognized and effective methodology for identifying the interrelationships between qualitative items that define a problem or issue [93]. The method uses graph theories and matrix algebra to express the visual representation [53]. The simple idea and easy-to-develop computational structure have made it popular, with extensive use across various domains. The key steps of ISM methodology [36] are as follows-

Step 1

Develop a structural self-interaction matrix (SSIM) of the mitigations for the top-most prioritized 25 risk factors.

Step 2

Develop an initial reachability matrix (IRM) from the SSIM.

Step 3

Develop the IRM's final reachability matrix (FRM), fulfilling the transitivity rule.

Step 4

Calculate the driving and dependence power for each of the mitigation actions.

The ISM methodology's detailed procedures are explained in Appendix G of the supplementary materials.

3.5. Cross-Impact Matrix Multiplication Applied to classification (MICMAC)

MICMAC analysis involves categorizing factors into four clusters based on their level of influence and dependence [52]. The four clusters identified in MICMAC analysis include as follows: Cluster I, which comprises Autonomous Factors that have little to no reliance on other factors; Cluster II, consisting of Dependent Factors that heavily rely on other factors; Cluster III, made up of Linkage Factors that are highly influential in connecting other factors but are themselves unstable; and Cluster IV, which includes Independent Factors that have weak influence from other factors and require close attention due to their strong impact on key factors. Due to its ability to hierarchically sort complicated linkages between factors, ISM-MICMAC has gained the interest of diverse fields [32,35,37].

4. Calculations and results

4.1. Risk prioritization criteria selection

Most existing studies described fire risk factors with four clustered divisions-causative, detection, protection, and egress [27,39,94]. Therefore, this study has also considered these four criteria by analyzing the existing literature on fire risk. The details of the evaluation criteria are presented in Table 7.

Table 7.

Evaluation criteria for prioritizing the fire risk factors.

| Criteria | Description of the Criteria | Source |

|---|---|---|

| Causative | To evaluate how much a risk factor is responsible for initiating a fire | Uğurlu [95]; Wang et al. [94] |

| Detection | To evaluate how much a risk factor is responsible for the failure to detect a fire | Omidvari et al. [27] |

| Protection | To evaluate how much a risk factor is responsible for failure to protect from a fire | Wadud and Huda 39; Dârmon [28] |

| Egress | To evaluate how much a risk factor is responsible for the obstruction of safe evacuation | Wadud and Huda 39; Nilufar and Choiti [29] |

4.2. Fire risk factors prioritization by combined BWM-WSM approach

For BWM, a questionnaire-based online survey has been conducted to get the expert's evaluation of the selection criteria. A sample of the questionnaire and response from an expert is provided in Appendix B of the supplementary materials. A sample weight calculation of criteria by an individual expert's response is shown in Table C1 of Appendix C in the supplementary materials. Finally, obtained weights of the criteria from each expert were aggregated with the geometric mean and then normalized consequently. Thereby, the calculated aggregated and normalized criteria weights are provided in Table 8.

Table 8.

Weights of criteria by BWM.

| Criteria | Aggregated Weights | Normalized Weights |

|---|---|---|

| Causative | 0.30052 | 0.325 |

| Detection | 0.18015 | 0.199 |

| Protection | 0.15439 | 0.171 |

| Egress | 0.27598 | 0.305 |

After obtaining the criteria weights, WSM has been applied to achieve the final ranking of the risk factors. The weights of the criteria from BWM have been utilized as input in this approach. Experts have evaluated the risk factors on a scale of 1–9 based on previously mentioned criteria, where ‘1′ represents ‘extremely low,’ and ‘9′ means ‘extremely high.’ A sample of the questionnaire and response from an expert can be found in Appendix D, Table D1 of the supplementary materials. The final ranking of the fire risk factors can be found in Table 9.

Table 9.

Ranking of the risk factors.

| Risk factors | Summation of the weighted scores | Rank |

|---|---|---|

| F16 | 0.53714 | 1 |

| F22 | 0.52929 | 2 |

| F28 | 0.52001 | 3 |

| F27 | 0.50065 | 4 |

| F30 | 0.49551 | 5 |

| F19 | 0.46055 | 6 |

| F26 | 0.44456 | 7 |

| F9 | 0.43207 | 8 |

| F29 | 0.41023 | 9 |

| F1 | 0.39772 | 10 |

| F11 | 0.39676 | 11 |

| F5 | 0.38714 | 12 |

| F12 | 0.38504 | 13 |

| F14 | 0.38274 | 14 |

| F4 | 0.36542 | 15 |

| F8 | 0.36115 | 16 |

| F23 | 0.35986 | 17 |

| F3 | 0.35612 | 18 |

| F24 | 0.34776 | 19 |

| F20 | 0.34393 | 20 |

| F25 | 0.33353 | 21 |

| F7 | 0.32787 | 22 |

| F21 | 0.32756 | 23 |

| F17 | 0.32436 | 24 |

| F2 | 0.31795 | 25 |

| F6 | 0.30248 | 26 |

| F10 | 0.29010 | 27 |

| F13 | 0.27775 | 28 |

| F18 | 0.27509 | 29 |

| F15 | 0.24516 | 30 |

In BWM, the maximum possible weight for any criterion is 1 (100%). The obtained weights in this study represent the proportionate importance of each criterion in the overall fire risk assessment. The assessment is determined by 32.5% for the Causative criterion, which has a maximum weight of 0.325. The second-highest weight, 0.305, is assigned to the Egress criterion, contributing 30.5% to the risk evaluation. With a weight of 0.199, the detection criterion contributes 19.9% to the risk prioritization. The final criterion, Protection, has a weight of 0.171 and contributes 17.1% to the overall fire risk evaluation. These calculated weights offer a data-driven foundation for understanding the relative significance of each criterion, aiding stakeholders in effectively prioritizing fire risk mitigation efforts in the apparel industry.

The emphasis on the Causative criterion is well-justified, as effective fire risk mitigation critically hinges on a comprehensive understanding of the underlying causes that may initiate a fire incident. By identifying these causative factors, proactive measures can be implemented, thereby reducing the probability of fire incidents occurring in the first place. Negligence or oversight in recognizing and addressing the root causes of fire accidents has historically led to catastrophic consequences, including the tragic loss of life and substantial property damage. Therefore, prioritizing the Causative criterion in evaluating fire risk factors is essential to foster a safer environment in the apparel industry and prevent potential disasters.

The emphasis on the Egress criterion is highly relevant due to the critical role of efficient evacuation procedures in ensuring human safety during fire incidents. Well-designed escape routes, functional emergency exits, and regular evacuation drills significantly reduce the likelihood of fire-related fatalities. Past tragic fire incidents in the apparel manufacturing sector underscored the importance of unobstructed egress as a leading factor influencing the loss of lives [12]. Prioritizing the Egress criterion in assessing fire risk factors is vital for creating a safer environment and preventing potential tragedies in the apparel industry.

In the final evaluation of fire risk factors, we utilized criteria weights obtained from the BWM and numerically calculated the experts' responses by applying the WSM. The resulting scores for each risk factor reveal their significance relative to one another. For instance, risk factors F16 (0.53714), F22 (0.52929), and F28 (0.52001) received almost similar scores, making them the top three in the final prioritization ranking. However, there is no significant difference in the severity of the risks they represent, suggesting that these factors should be treated with almost equal importance when considering mitigation approaches. In contrast, risk factor F15 (0.24516) obtained a significantly lower score, placing it in the last (30th) among all the risk factors in the final ranking. As a result, this particular risk factor is not as significant as the top-most prioritized risks identified in our study.

Industrial managers and policymakers should carefully consider the numerical explanation of the study results to derive the best possible insights from it. Understanding the relative significance of each risk factor can aid in making informed decisions and effectively addressing fire risk in the industry.

4.3. Determination of stratified mitigation strategies by ISM-MICMAC

After obtaining the ranking of the fire risk factors, remediation for the top-ranked 25 factors has been proposed based on the National Fire Protection Association (NFPA) standards and further reviewed by fire safety experts. These remediation actions for respective factors are presented in Table 10.

Table 10.

Remediation of the top-ranked 25 fire risk factors.

| Ranked Order | Risk Factors | Corresponding mitigation actions | Simplified generalized mitigation actions | NFPA Standard |

|---|---|---|---|---|

| 1 | F16 | Combustible storage separation with a minimum 1-h fire-rated construction | Fire-rated construction | NFPA 101 [96] |

| 2 | F22 | Regular standardized ITM for fire detection, sprinkler, fire extinguisher, fire pump, and standpipe | Inspection, testing, and maintenance | NFPA 72 [97]; NFPA 25 [98]; NFPA 10 [99]; NFPA 20 [100]; NFPA 14 [101] |

| 3 | F28 | Occupant load reduction as per regulation or providing additional exits to increase exit capacity | Adequate exit capacity | NFPA 101 [96] |

| 4 | F27 | Fire detection and protection system standardization according to occupant load and area coverage | Standardized detection and protection | NFPA 101 [96]; NFPA 1 [102] |

| 5 | F30 | Electrical connections standardization in panel and distribution board at an approved location | Standardized electrical safety | NFPA 70 [103]; NFPA 70E [104] |

| 6 | F19 | Provide automatic smoke detection with audible alarms throughout the building | Audible alarm | NFPA 72 [97] |

| 7 | F26 | Separate the gas cylinder room with a 2-h fire-rated construction and seal all penetrations/openings with 1.5-h fire-rated materials Or, Relocate and maintain a minimum 3 m (10 ft) spatial separation distance from the building. |

Relocate unsafe equipment | NFPA 101 [96] |

| 8 | F9 | Keep egress paths and stairs clear of storage or any obstruction | Unobstructed egress | NFPA 101 [96] |

| 9 | F29 | Ensure self-closing, positive latching certified fire doors | Certified fire doors | NFPA 80 [105] |

| 10 | F1 | Maintain minimum unobstructed clear width of 0.9 m (36 in.) | Widened egress | NFPA 101 [96] |

| 11 | F11 | Separate heat-producing equipment by a minimum 2-hr fire-rated construction, and seal all penetrations and openings with 1.5-hr fire-rated materials to maintain the fire separation. All exhaust systems shall discharge to the exterior of the building in a safe location. In case of relocation, maintain a minimum 3 m (10 ft) spatial separation distance from the building. |

Sealed penetrations | NFPA 101 [96] |

| Outside exhaust discharge | ||||

| 12 | F5 | Unlock egress doors, or remove all non-standard locking features from egress doors | Unlocked egress doors | NFPA 101 [96] |

| 13 | F12 | Enclose stairs with a minimum 1-h fire-rated construction | Fire-rated construction | NFPA 101 [96] |

| 14 | F14 | Seal all penetrations and openings with fire-rated materials for at least 1-hr fire separation | Sealed penetrations | NFPA 101 [96] |

| 15 | F4 | Use side‐hinged swinging-type doors | Side‐hinged swinging doors | NFPA 80 [105]; NFPA 101 [96] |

| 16 | F8 | Arrange regular fire training and drills | Training and drills | NFPA 101 [96] |

| 17 | F23 | Provide adequate illumination (10.8 lux at the floor level) | Adequate illumination | NFPA 101 [96] |

| 18 | F3 | Make the exit doors swing in the direction of egress travel | Outward directed doors | NFPA 101 [96] |

| 19 | F24 | Provide illuminated directional/exit signs (with uninterruptable power supply) along the path of travel | Illuminated exit signs | NFPA 101 [96] |

| 20 | F20 | Provide automatic sprinkler protection throughout the building for floor areas greater than 2000 sq m | Sprinkler protection | NFPA 13 [106] |

| 21 | F25 | Remove the manual on/off switch for emergency lighting/exit signage units | Automated emergency lighting | NFPA 101 [96] |

| 22 | F7 | Provide remoteness of the exists at least one-half of the maximum diagonal length of the area to be served | The remoteness of the exists | NFPA 101 [96] |

| 23 | F21 | Provide standpipe protection for floor lengths greater than 10 m | Standpipe protection | NFPA 14 (2019) |

| 24 | F17 | Separate the exit corridor by a minimum 1-hr fire-rated construction | Fire-rated construction | NFPA 101 [96] |

| 25 | F2 | Reduce the maximum distance to at most 45 m, if there are no automated fire safety systems and additional exits | Shortened dead-end aisles | NFPA 101 [96] |

Table 10 indicates that a total of 23 simplified generalized mitigation actions can address the top 25 risk factors, which is presented in Table 11.

Table 11.

List of mitigation actions for the top-ranked 25 risk factors.

| Mitigation Denotations | Simplified generalized mitigation actions |

|---|---|

| M1 | Fire-rated construction |

| M2 | Inspection, testing, and maintenance |

| M3 | Training and drills |

| M4 | Standardized detection and protection |

| M5 | Standardized electrical safety |

| M6 | Audible alarm |

| M7 | Relocate unsafe equipment |

| M8 | Unobstructed egress |

| M9 | Certified fire doors |

| M10 | Widened egress |

| M11 | Sealed penetrations |

| M12 | Outside exhaust discharge |

| M13 | Unlocked egress doors |

| M14 | Side‐hinged swinging doors |

| M15 | Adequate exit capacity |

| M16 | Adequate illumination |

| M17 | Outward directed doors |

| M18 | Illuminated exit signs |

| M19 | Sprinkler protection |

| M20 | Automated emergency lighting |

| M21 | The remoteness of the exists |

| M22 | Standpipe protection |

| M23 | Shortened dead-end aisles |

Afterward, a simple questionnaire-based survey was conducted to determine the dependence or influence of one mitigation action over another. Detailed steps of the ISM [36] approach are described in Appendix G of the supplementary materials. The four symbols (V, A, X, and O) chosen to represent the interdependence among the mitigation strategies were applied to develop the structural self-interaction matrix (SSIM) based on the expert's feedback. Table 12 represents the SSIM for the fire risk mitigation strategies.

Table 12.

Development of SSIM for the fire risk mitigation strategies.

| M23 | M22 | M21 | M20 | M19 | M18 | M17 | M16 | M15 | M14 | M13 | M12 | M11 | M10 | M9 | M8 | M7 | M6 | M5 | M4 | M3 | M2 | M1 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | O | O | O | O | V | O | O | O | O | O | O | O | V | O | V | O | V | O | V | X | O | O | X |

| M2 | V | A | V | V | A | V | V | V | V | V | V | O | O | V | O | V | O | V | A | A | V | X | |

| M3 | V | A | V | A | A | A | V | A | V | V | V | O | O | V | O | X | O | X | A | O | X | ||

| M4 | O | V | O | O | V | O | O | V | O | O | O | O | O | O | V | O | O | V | V | X | |||

| M5 | O | V | O | O | X | O | O | O | O | O | O | O | A | O | O | O | V | V | X | ||||

| M6 | O | O | O | A | O | A | O | A | V | O | V | O | O | O | O | A | O | X | |||||

| M7 | O | O | O | A | A | A | O | O | O | O | O | X | A | A | O | O | X | ||||||

| M8 | V | A | V | A | O | A | V | A | V | V | V | O | O | V | O | X | |||||||

| M9 | O | O | O | O | O | O | X | O | O | X | X | O | A | O | X | ||||||||

| M10 | X | O | X | A | O | A | A | A | X | A | O | O | O | X | |||||||||

| M11 | O | V | O | O | V | O | O | O | O | O | O | V | X | ||||||||||

| M12 | O | O | O | O | O | O | O | O | O | O | O | X | |||||||||||

| M13 | V | O | O | A | O | A | X | A | V | X | X | ||||||||||||

| M14 | O | O | O | A | O | O | X | O | V | X | |||||||||||||

| M15 | X | V | X | A | O | A | A | A | X | ||||||||||||||

| M16 | O | A | O | V | O | V | V | X | |||||||||||||||

| M17 | O | O | O | A | O | A | X | ||||||||||||||||

| M18 | V | O | O | V | O | X | |||||||||||||||||

| M19 | O | X | O | O | X | ||||||||||||||||||

| M20 | O | A | V | X | |||||||||||||||||||

| M21 | A | O | X | ||||||||||||||||||||

| M22 | O | X | |||||||||||||||||||||

| M23 | X |

After that, by transforming the symbols into binary values (0 and 1) utilizing Table 12, we produced the initial reachability matrix (IRM), shown in Table G2 of Appendix G in the supplementary materials. Then, we determined the transitivity and developed the final reachability matrix (FRM) presented in Table 13. Here, the values marked with a (*) act as an indication of the transitivity.

Table 13.

Formation of FRM.

| M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M11 | M12 | M13 | M14 | M15 | M16 | M17 | M18 | M19 | M20 | M21 | M22 | M23 | Driving Power | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 1 | 1* | 1* | 1 | 1 | 1* | 1 | 1* | 1 | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1* | 1* | 23 |

| M2 | 0 | 1 | 1 | 0 | 0 | 1 | 1* | 1 | 1* | 1 | 0 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 17 |

| M3 | 0 | 0 | 1 | 0 | 0 | 1 | 1* | 1 | 1* | 1 | 0 | 1* | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 13 |

| M4 | 1 | 1 | 1* | 1 | 1 | 1 | 1* | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1 | 1* | 1* | 1 | 1* | 23 |

| M5 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1 | 1 | 1 | 1* | 1* | 1* | 21 |

| M6 | 0 | 0 | 1 | 0 | 0 | 1 | 1* | 1* | 1* | 1* | 0 | 1* | 1 | 1* | 1 | 0 | 1* | 0 | 0 | 0 | 1* | 0 | 1* | 13 |

| M7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| M8 | 0 | 0 | 1 | 0 | 0 | 1 | 1* | 1 | 1* | 1 | 0 | 1* | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 13 |

| M9 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 1 | 1* | 0 | 1* | 1 | 1 | 1* | 0 | 1 | 0 | 0 | 0 | 1* | 0 | 1* | 10 |

| M10 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1* | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 6 |

| M11 | 0 | 1* | 1* | 0 | 1 | 1* | 1 | 1* | 1 | 1* | 1 | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1 | 1* | 21 |

| M12 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| M13 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 1 | 1* | 0 | 1* | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1* | 0 | 1 | 10 |

| M14 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 1 | 1 | 0 | 1* | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1* | 0 | 1* | 10 |

| M15 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 0 | 1 | 0 | 1* | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 6 |

| M16 | 0 | 0 | 1 | 0 | 0 | 1 | 1* | 1 | 1* | 1 | 0 | 1* | 1 | 1* | 1 | 1 | 1 | 1 | 0 | 1 | 1* | 0 | 1* | 16 |

| M17 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 1 | 1 | 0 | 1* | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1* | 0 | 1* | 10 |

| M18 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1* | 1 | 0 | 1* | 1 | 1* | 1 | 1 | 1 | 1 | 0 | 1 | 1* | 0 | 1 | 16 |

| M19 | 0 | 1 | 1 | 0 | 1 | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1 | 1* | 21 |

| M20 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1* | 1 | 0 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1* | 0 | 1 | 16 |

| M21 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 0 | 1 | 0 | 1* | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1* | 6 |

| M22 | 0 | 1 | 1 | 0 | 1* | 1* | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1 | 1 | 1* | 1 | 1* | 21 |

| M23 | 0 | 0 | 0 | 0 | 0 | 0 | 1* | 0 | 0 | 1 | 0 | 1* | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 6 |

|

Dependence Power |

2 | 7 | 13 | 2 | 6 | 13 | 23 | 13 | 17 | 21 | 6 | 23 | 17 | 17 | 21 | 10 | 17 | 10 | 6 | 10 | 21 | 6 | 21 |

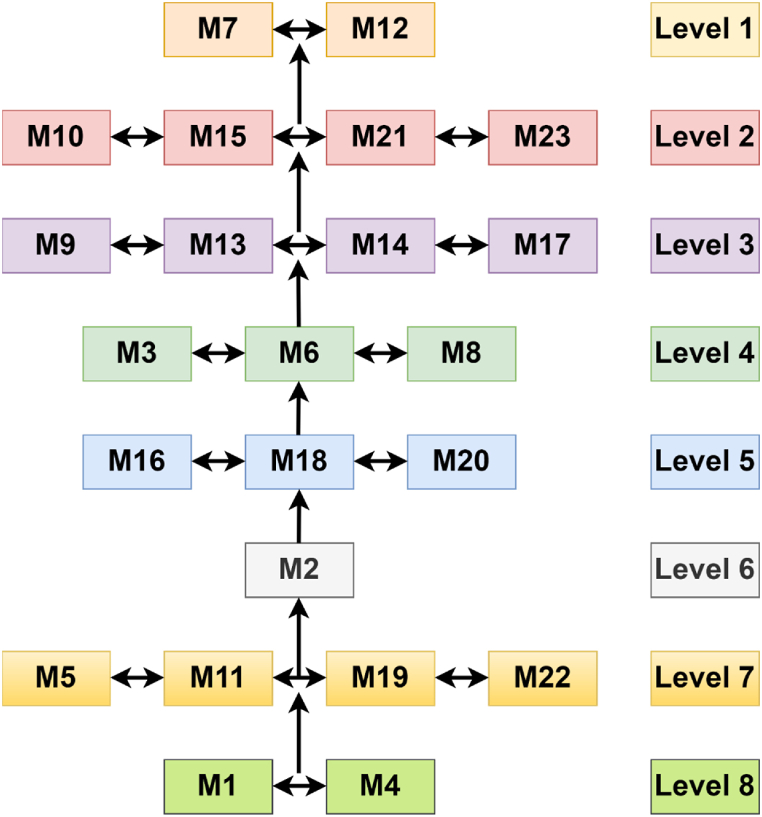

Table 13 demonstrates the dependence and driving power of each mitigation strategy. Subsequently, as explained in subsection 3.5, we used these outcomes to classify the mitigation strategies using MICMAC analysis. A total of 7 iterations have been required to get the final interpretive structural model of mitigation actions consisting of 8 interconnected levels. The level partitioning from the FRM was then used to identify the various levels of the strategies. The final level partitioning (FLP), represented in Table G4, Appendix G of the supplementary materials, is created following seven level partitioning iterations. The levels obtained from FLP were used to build the ISM visual structure depicted in Fig. 2. The diagram illustrates the hierarchical links between the strategies and their correlation with one another.

Fig. 2.

Hierarchical action plans for mitigation.

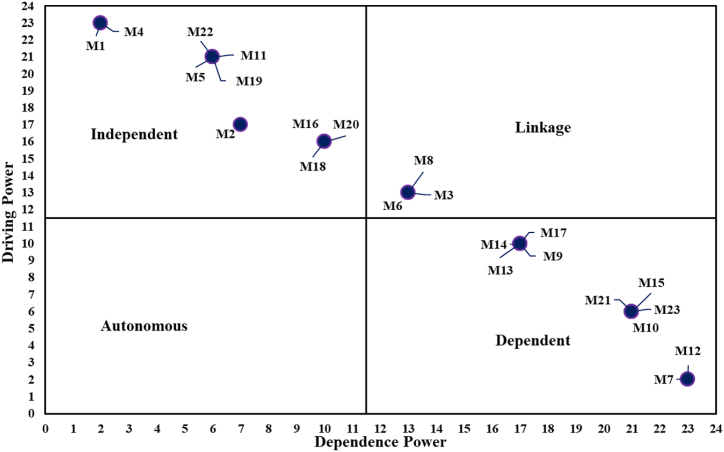

4.4. Categorizing the mitigation strategies utilizing the MICMAC technique

Each strategy's driving and dependence power, as provided in Tables 13 and is applied to develop the MICMAC diagram shown in Fig. 3.

Fig. 3.

MICMAC analysis.

MICMAC analysis indicated the independent strategies based on their high driving and less dependence power as follows: Fire-rated construction (M1), Standardized detection and protection (M4), Standardized electrical safety (M5), Sealed penetrations (M11), Sprinkler protection (M19), Standpipe protection (M22), Inspection, testing, and maintenance (M2), Adequate illumination (M16), Illuminated exit signs (M18), Automated emergency lighting (M20). These are the most crucial strategies to mitigate fire risks in the apparel manufacturing industry. Moreover, Certified fire doors (M9), Unlocked egress doors (M13), Side‐hinged swinging doors (M14), Outward directed doors (M17), Widened egress (M10), Adequate exit capacity (M15), The remoteness of the exists (M21), and Shortened dead-end aisles (M23) are the dependent drivers due to their high dependence power and less driving power. Training and drills (M3), Audible alarm (M6), and Unobstructed egress (M8) are the linkage mitigation strategies that have significant driving and dependence power. However, there is no strategy in the autonomous cluster.

5. Discussion

In this research work, the criteria weights are determined as Causative (0.325) > Egress (0.305) > Detection (0.199) > Protection (0.171) (see Table 8). Most experts emphasize the criterion of Causative and the criterion of egress for evaluating the fire risk factors, which seems reasonable from the perspective of previously occurring deadly fire incidents in the apparel industry. Negligence to determine the causal factors of initiating fire and obstructed egress has taken many lives [9,10].

Using these criteria weights obtained from BWM, the ascertained ranking of the fire risk factors determined by the BWM-WSM framework is F16> F22> F28> F27> F30> … …. F18> F15 (see Table 9). ‘Combustible storage unseparated by fire-rated construction’ ranked at the top as a risk factor in the experts' evaluation. Different raw materials, finished products, and combustible chemicals used in apparel manufacturing are always the prime concerns for fire safety [45]. Storage of such products is often done without fire-rated separation in Bangladeshi apparel factories, which may cause severe fire incidents. ‘Non-standard Inspection, Testing, and Maintenance (ITM)' was found to be the second highest-ranking risk factor. This risk factor is critical for the existing working environment and practice culture. Fire incidents cannot be dealt with effectively except for adequate inspection, testing, and maintenance for the fire causes, detection, and protection accessories, resulting in significant harm to people and property [25]. ‘Inadequate means of egress for the occupant load’ was determined as the third-ranked critical risk factor. Due to inadequate means of egress, even properly trained people may be unaware of the safety regulations, thus creating panic and consuming more evacuation time [107]. Panic and chaos during actual incidents are significant obstacles to fire extinguishing and evacuation.

Besides these three top-ranked risk factors, ‘Non-standard fire detection and protection system,’ ‘Faulty electrical panels at a non-standard location,’ ‘Smoke/fire detection alarms that are inaudible throughout the building,’ ‘LNG/CNG cylinder storage within the factory building,’ are some of the other critically ranked fire risk factors in this study. These are also top prioritized fire risk factors in some existing literature [5,24,45]. Experts evaluated these risk factors based on their experiences with existing practices in the apparel sector of Bangladesh.

Utilizing ISM, we found ‘Fire-rated construction (M1)' and ‘Standardized detection and protection (M4)' as the most driving mitigation action over others. Therefore, these have been placed in the highest level of the stratified structure, Level 8. Fire-rated construction can be illustrated as fire separators, such as fire-rated walls, which can obstruct the spreading of fire and are an essential feature for the Sustainability of the infrastructure [50]. On the other hand, a standardized fire detection and protection system can minimize resource damage during a fire and unnecessary water consumption for fire extinguishing. Experts have decided that fire separation and standardized detection and protection systems are the most effective mitigation action plans against critical fire risk factors in the apparel industry.

In the ISM approach, the variables with relatively stronger influences or driving power and lower dependency occur at a higher level. On the other hand, the variables with relatively higher dependency and lower driving power take place in the lower level. Besides these, variables at a similar level carry similar driving or dependent power. Following these rules, this study organized the mitigation actions from Level 1 to Level 8 with their relative influence over each other (see Fig. 2). In this study, ‘Relocate unsafe equipment (M7)' and ‘Outside exhaust discharge (M12)' are the two mitigation actions with the lowest driving and highest dependency, thus placing them in the lowest level, Level 1.

In the MICMAC analysis, among the 23 mitigation actions analyzed in this research (see Table 13 and Fig. 3), ten mitigation actions are placed in the independent category, which can drive all the other actions. Three mitigation actions were determined to be in the linkage category since they are moderately driven and dependent simultaneously. On the other hand, ten mitigation actions were placed in the dependence category. No mitigation action has been found to be autonomous, which means all the mitigation actions are interrelated in the implementation context.

In contrast to recent, closely related studies on fire risks in the RMG-related sectors, this study presents unique findings. For instance, Asaduzzaman [46] asserted that the inadequacy of fire detection and protection systems is the primary cause of fire risks in RMG factories. Rathnayake et al. [45] identified faulty electrical wiring, sparks from welding jobs, and accumulation of solid waste as the top three prioritized causal factors for fire risks in RMG factories. In contrast, our study utilized a multi-criteria approach to assess the overall significance of risk factors and found that the top three factors requiring immediate attention to save lives and property were related to fire separation, fire safety equipment, and safe evacuation. For instance, in this study, ‘Combustible storage unseparated by fire-rated construction’ is the top risk factor that indicates the separation of combustible materials can prevent fires. While fire detection and protection systems are essential, they are only necessary after the occurrence of a fire.

Again, Habib et al. [42] have emphasized the importance of continuing regulatory inspections of RMG factories to ensure fire safety measures, including fire drills and fire detection and protection equipment quality. In contrast, this study has determined that it is more critical to establish ‘fire-rated construction’ and ‘standardized detection and protection’ systems to achieve sustainable, long-lasting fire risk mitigation. These measures can be the foundation for all other mitigation strategies and cannot be achieved solely through visual inspections.

The contrast presented in this study can assist industrial managers by providing a new perspective on the most critical risk factors and mitigation strategies for fire safety in the RMG industry. This underscores the novelty and significance of the study. Following the study's findings, the factory management should focus on implementing appropriate measures to prevent and mitigate fire hazards, ultimately improving the safety and well-being of workers and establishing a sustainable, healthy, and resilient production system.

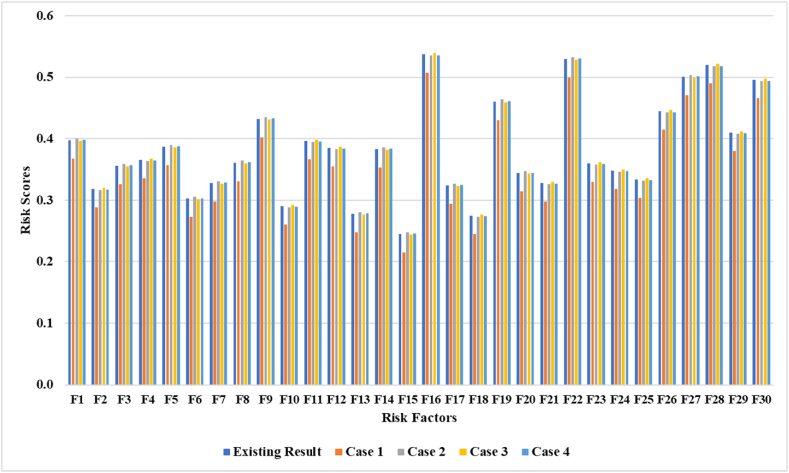

The robustness of our study's outcomes was demonstrated by performing a sensitivity analysis with different weightage scenarios. For this analysis, we divided the 19 experts into four groups for the sensitivity analysis: Group 1 (Expert 1 to Expert 5), Group 2 (Expert 6 to Expert 10), Group 3 (Expert 11 to Expert 15), and Group 4 (Expert 16 to Expert 19). Then we prepared 4 cases or scenarios. In Case 1, Group 1 was assigned 40% weightage, and the rest of the groups received the remaining 20% weightage, totaling 100%. In Case 2, Group 2 received 40%, and the remaining groups received 20%, totaling 100%. Similar weightage allocation was performed for Group 3 in Case 3 and Group 4 in Case 4.

The risk scores were changed for each case, but the ranking remained the same as the primary result, as shown in Fig. 4. It indicates that the obtained result is quite robust and assures the reliability of our findings. It also highlights that the conclusions drawn from our research are dependable and not heavily influenced by the specific weightage given to each expert group during the analysis.

Fig. 4.

Sensitivity analysis with different expert weightage.

Criteria weights have been calculated again with the Bayesian BWM approach to check the reliability of the evaluation process. In this study, the obtained criteria weights by applying Bayesian BWM were almost similar to the primary weights obtained using BWM. The weight values differed in BWM and Bayesian BWM approaches since they used different calculation procedures. However, the ranking of the criteria weights remains the same under both approaches. This indicates that the BWM ranking performed in this study was reliable. A comparison of aggregated weight providing the ranking of criteria using the BWM and Bayesian BWM is provided in Table 14.

Table 14.

Comparison of criteria ranking using BWM and Bayesian BWM approach.

| Criteria | BWM | Bayesian BWM |

|---|---|---|

| Causative | 0.30052 | 0.320 |

| Detection | 0.18015 | 0.197 |

| Protection | 0.15439 | 0.170 |

| Egress | 0.27598 | 0.309 |

Again, another MCDM framework was applied for the methodological comparison by combining Bayesian BWM and TOPSIS methods. Note that the same expert group participated in the BWM-WSM and Bayesian BWM-TOPSIS analysis. The final ranking obtained from this framework is close (but not exactly similar) to the ranking obtained from the BWM-WSM framework, as presented in Table 15. For instance, under both frameworks, the rankings show that F16 is the top-most prioritized risk factor. However, upon closer examination, it is evident that the positions of some risk factors have changed slightly. These changes occurred due to the slight variations in the weights of criteria by the BWM and the Bayesian BWM, as well as the differences in calculation techniques between the WSM and the TOPSIS. Despite these slight variations, the change in the position of risk factors is not very significant. The risk factors that were closely positioned in the BWM-WSM also obtained close positions in the Bayesian BWM-TOPSIS framework. This consistency indicates the reliability and credibility of our study and provides a more robust understanding of the prioritization of fire risk factors in the apparel industry.

Table 15.

Comparison between the fire risk factors ranking in two MCDM frameworks.

| Rank | Bayesian BWM-TOPSIS | BWM-WSM | Rank | Bayesian BWM-TOPSIS | BWM-WSM |

|---|---|---|---|---|---|

| 1 | F16 | F16 | 16 | F8 | F8 |

| 2 | F30 | F22 | 17 | F21 | F23 |

| 3 | F22 | F28 | 18 | F12 | F3 |

| 4 | F27 | F27 | 19 | F4 | F24 |

| 5 | F26 | F30 | 20 | F23 | F20 |

| 6 | F28 | F19 | 21 | F3 | F25 |

| 7 | F11 | F26 | 22 | F25 | F7 |

| 8 | F19 | F9 | 23 | F24 | F21 |

| 9 | F14 | F29 | 24 | F7 | F17 |

| 10 | F9 | F1 | 25 | F17 | F2 |

| 11 | F29 | F11 | 26 | F2 | F6 |

| 12 | F1 | F5 | 27 | F6 | F10 |

| 13 | F20 | F12 | 28 | F10 | F13 |

| 14 | F5 | F14 | 29 | F13 | F18 |

| 15 | F18 | F4 | 30 | F15 | F15 |

5.1. Theoretical implications

This study's findings provide significant implications for researchers from a theoretical perspective. Compared to other studies, this one strengthens the fundamentals of fire hazard incidents and offers a more comprehensive and systematic framework for analyzing and evaluating the development and adaptation of stratified mitigation strategies. The study used an integrated BWM-WSM approach to identify and prioritize key fire risk factors based on some criteria for safe operation in the apparel industry. Stratified mitigation strategies for corresponding risk factors are assessed using the ISM-MICMAC approach. To the best of our knowledge, this research is the first study that uses an integrated BWM-WSM and ISM-MICMAC technique to examine fire risk hazards and associated mitigation strategies in emerging economies' apparel manufacturing sector. Future researchers may use this study as a benchmark to analyze the fire hazards in other industrial sectors. With the help of this integrated model, other industries of a similar type may also prioritize risks and determine the most effective plan of action to promote safety and minimize the probability and effects of fire incidents in their respective sectors.

5.2. Managerial and policy implications

This study offers several important managerial and policy implications for professionals, practitioners, and decision-makers in the relevant field. In industrial management, the risk of combustible storage in RMG factories is a significant concern as it poses a severe threat to the safety of the workers and the overall facility. One of the most effective ways to mitigate this risk is by implementing the guidelines provided by the NFPA, which recommend separating combustible storage areas with a minimum of 1-h fire-rated construction. It implies that the storage areas should be enclosed with fire-rated walls, floors, and ceilings that can withstand the fire for at least 1 h, giving enough time for the workers to evacuate the building and for the fire department to control the fire.

Again, non-standard ITM of fire safety systems in RMG factories can lead to catastrophic consequences during fire incidents. By complying with the NFPA codes, management can implement checking the fire detection system for any faults, testing the sprinkler system to ensure proper water distribution, inspecting and refilling fire extinguishers, testing and maintaining the fire pump, and ensuring the proper functioning of the standpipe system. It provides the reliability of the fire protection systems while minimizing the risk of failure during a fire emergency, which is critical for the reputation and sustainability of the RMG factories.

Moreover, inadequate means of egress for the occupant load can compromise the workers' safety during a fire emergency. Overcrowding workers in the factory can lead to congestion and blockage of the means of egress, making it challenging for the workers to evacuate the building during a fire emergency. Therefore, to mitigate this risk, the NFPA codes recommend implementing measures to reduce the occupant load per the regulations or providing additional exits to increase the exit capacity. Additional exits can include installing emergency exit doors, widening the existing exits, and adding new exit routes. However, similar to these top prioritized risk factors mentioned, managers can follow the mitigation hierarchy according to the obtained result of this study to optimize their resources in case of existing limitations.

The findings suggest the formation of specific beneficial management and policy reforms, and it is possible to facilitate sustainable development in terms of worker safety in this sector. This will offer a unique perspective to managers and policymakers in deciding appropriate preventative actions to apply the law and develop fire safety standards for the apparel sector. Moreover, the government needs to uphold strict standards for the infrastructure development of factory facilities.

5.3. Implications for sustainability

By mitigating critical fire risk factors, the industry can improve the safety of its workers, protect resources and achieve environmental sustainability while maximizing profits. Ensuring fire safety in the apparel industry of Bangladesh can help the country to achieve several important SDGs, promoting a sustainable future.