Abstract

Background

This study aimed to evaluate enamel surface roughness and microhardness following the use of different bracket materials (metal or ceramic), etchants (total- and self-etchants), and adhesive systems (precoated or flash-free).

Method

A total of 99 extracted human premolars were selected for the analysis. The surface roughness was first assessed (roughness control). One specimen from each subgroup was examined using a scanning electron microscope to illustrate the surface topography. Eighty-eight teeth were prepared using total- or self-etchants and bonded to precoated or flash-free adhesive metal or ceramic brackets. The remaining 11 specimens were not bonded to brackets (microhardness controls). The brackets were debonded after immersion in distilled water for 24 h. The specimens were again scanned for surface roughness and topography imaging. Finally, the microhardness was assessed using a micro-Vickers hardness test at a force of 200 g for 10 s.

Result

An overall statistically significant increase in surface roughness and reduced surface microhardness were observed in all experimental groups when compared with those in the control groups. The etchant type was the only variable found to contribute to the measured surface properties, with increased roughness and reduced microhardness introduced by total-etching compared to those by self-etching.

Conclusion

Orthodontic brackets introduced a significant increase in enamel surface roughness and reduce microhardness compared with untreated enamel, regardless of the bracket material, etchant type, and adhesive system. The etchant type was the only variable contributing to these changes, with total etching having a more pronounced effect.

Keywords: Orthodontic Appliances, Fixed; Acid Etching, Dental; Microscopy, Electron; Dental Cements; Physical Phenomena

1. Introduction

The enamel surface serves as a protective layer on dental substrates against external factors (Molaasadolah et al., 2017). Surface roughness is defined as the overall level of exterior irregularities and referred to as the arithmetic mean (Ra) (Mullan et al., 2017). Surface hardness represents the mechanical resilience of a surface to penetration and deformation (Buzalaf et al., 2010, Molaasadolah et al., 2017). Alterations in surface properties contribute to surface degradation, mineral loss, and the development of carious lesions (Lacruz et al., 2017, Mathias et al., 2009).

Various bracket materials have distinct properties that can alter the oral flora, create different bonding interactions, and cause different debonding sequelae (Bora et al., 2021). The impact of fixed orthodontic appliances on the enamel begins with the bonding process, as it requires enamel surface preparation prior to bonding, which ensures appropriate bracket-to-enamel bond throughout the treatment duration (Iijima et al., 2010). Conventional total-etch (TE) surface treatment includes a separate enamel-etching step using phosphoric acid, subsequent rinsing and drying, and applying primers.

The trend of self-etch (SE) surface treatment requires less chair time owing to fewer clinical application steps (Horiuchi et al., 2009). SE combines the etching and priming stages using an acidic monomer, eliminating the need for separate etching, rinsing, and drying steps (Horiuchi et al., 2009, Nicolas-Silvente et al., 2020).

The available orthodontic adhesive brackets include precoated (PC) and flash-free (FF) systems. PC is precoated, which requires excess adhesive resin removal after bracket placement, whereas FF is precoated with the advantage of not requiring the removal of excess resin. Additionally, FF systems provide faster bonding, fewer adhesive resin remnants, and less plaque accumulation (Almosa et al., 2019a, Çokakoğlu and Tan, 2020).

This study aimed to assess the enamel surface roughness and microhardness following the use of different bracket materials (metal [M] or ceramic [C]), etchants (TE or SE), and adhesive systems (PC or FF). The null hypotheses evaluated were as follows: (1) there is no difference in enamel surface roughness following the use of M and C orthodontic brackets with different etchants (TE or SE) and adhesive systems (PC or FF) and (2) there is no difference in the enamel surface microhardness following the use of M and C orthodontic brackets with different etchants (TE or SE) and adhesive systems (PC or FF).

2. Materials and methods

This study was approved by the Institutional Review Board of Health Sciences (Reg. No. E-21–5917) and the Research Center (Reg. No. PR 0117). This study was conducted at the College of Dentistry and College of Applied Science facilities at King Saud University.

Using the G*Power calculator (version 3.1.9.6; Franz Faul, Universität Kiel, Germany), 59 samples were deemed sufficient at a significance level of 0.05, an effect size of 0.19, and 95% power for 9 subdivisions (8 experimental and 1 control) (Cohen, 1988). However, for an equal distribution among the different groups and similar sample size for future correlational assessment with another study, a total of 99 samples was selected.

Specimens of anonymous human premolar teeth extracted for orthodontic purposes were collected using the following inclusion criteria: intact teeth that were free from cracks, caries, and demineralization with no root canal treatments. These criteria were determined by visual inspection and digital microscope (KH-7700 Digital Microscope System; Hirox, Tokyo, Japan).

The teeth were disinfected by immersion in 10% formalin at room temperature for 7 days (Kumar et al., 2005). Any visible remnants were cleaned using an ultrasonic scaler in contact with the tooth surface in an occlusogingival direction under light pressure (George et al., 2017). This was followed by polishing for 15 s in a circular motion using a rubber cup and non-fluoridated polishing paste (Zircate Prophylaxis Paste; Dentsply, Milford, Delaware, USA) attached to a low-speed contra-angle handpiece (FX23 Contra Angle; NSK, Kanuma, Tochigi, Japan) at 3,000 rpm with a very small amount of water to irrigate the area (Camboni and Donnet, 2016, Chowdhary and Mohan, 2018).

Simple randomization was performed using Excel (version 16.0.12624; Microsoft, Redmond, WA, USA) and Kutools (version 22.00; ExtendOffice, Haikou, Hainan, China). The 99 specimens were distributed as follows: 88 teeth were divided according to the orthodontic bracket material (M or C); 11 teeth were included in the control group to compare the microhardness with other experimental groups; and the specimens under each bracket material were divided into 2 groups according to the etchant type (TE or SE) and subsequently subdivided based on the adhesive system (PC or FF).

The specimens were then embedded in polyvinyl chloride tubes with clear resin, leaving the buccal surface exposed. All specimens were stored in normal saline.

2.1. Surface roughness assessment (Pre-bonding)

Using an optical microscope (Contour GT-K 3D; Bruker, Tucson, AZ, USA) with non-contact surface metrology and imaging, the pre-bonding enamel surface roughness of all specimens were assessed and considered as a control for surface roughness. This was indicated by the Ra in µm at the highest point of the mid-buccal surface of the tooth.

One specimen from each subgroup was randomly selected to evaluate the enamel surface topography as an illustrative representation of the enamel condition at the pre-bonding stage. The selected specimens were coated with gold (1100 Fine Coat Ion Sputter; JFC, Tokyo, Japan) to enhance surface conductivity and improve the image captured (Leslie and Mitchell, 2007), and scanned using a Scanning Electron Microscope (SEM) (JSM-6360 LV Scanning Electron Microscope; JEOL, Tokyo, Japan) with an accelerating voltage of 15 kV and magnification of × 300 and × 600.

2.2. Bracket bonding

2.2.1. Metal bracket with total-etch

Metal bracket specimens assigned to the TE group (M−TE) were etched on the mid-buccal surface using 37% phosphoric acid (CharmEtch; DentKist, Gyeonggi-do, Korea) for 20 s, rinsed for 10 s, and dried, following the manufacturer’s instructions. This procedure was followed by the placement of a thin primer layer (Transbond XT; 3 M, Monrovia, CA, USA) on the mid-buccal surface using a disposable micro-brush with a gentle airburst for 2 s, according to the manufacturer’s instructions.

Half of the specimens were bonded using a PC bracket system (M−TE [PC]) (APC Adhesive Coated Appliance System; 3 M, St. Paul, MN, USA); the bracket was placed and pressed on the mid-buccal surface parallel to the long axis of the tooth. The excess resin was removed using a dental explorer (Double-ended explorer 560/1; Medesy, Maniago, Italy), followed by a light emitting diode (LED) curing with an average light intensity of 1,470 mW/cm2 (Elipar DeepCure-S; 3 M, St. Paul, MN, USA) for 20 s to the mesial and distal sides (Bishara et al., 1997, Uşümez et al., 2004).

The remaining specimens were bonded using an FF bracket system (M−TE [FF]) (APC Flash-Free Adhesive Coated Appliance System; 3 M, St. Paul, MN, USA). The bracket was placed and pressed on the mid-buccal surface parallel to the long axis of the tooth without removing the excess resin. This was followed by LED curing (Elipar DeepCure-S; 3 M) for 20 s on the mesial and distal sides (Bishara et al., 1997, Uşümez et al., 2004).

2.2.2. Metal bracket with self-etch

Metal bracket specimens assigned to the SE group (M−SE) were prepared using an SE primer of methacrylate phosphoric acid esters (Transbond Plus Self Etching Primer; 3 M, St. Paul, MN, USA) on the mid-buccal surface with gentle rubbing for 5 s and an airburst for 2 s, following the manufacturer’s instructions. Half of the specimens were bonded using the PC bracket system (M−SE [PC]) (APC Adhesive Coated Appliance System; 3 M), and the other half were bonded using the FF bracket system (M−SE [FF]) (APC Flash-Free Adhesive Coated Appliance System; 3 M). LED curing was performed (Elipar DeepCure-S; 3 M) for 20 s on the mesial and distal sides (Bishara et al., 1997, Uşümez et al., 2004).

2.2.3. Ceramic bracket with total-etch

Ceramic bracket specimens assigned to the TE group (C-TE) were prepared in a similar manner to the previously mentioned M−TE protocol. Half of the specimens were bonded using a PC bracket system (C-TE [PC]) (Clarity APC Adhesive Coated Appliance System; 3 M, St. Paul, MN, USA). The bracket was placed and pressed on the mid-buccal surface parallel to the long axis of the tooth. Excess resin was removed using a dental explorer (Double-ended Explorer 560/1; Medesy, Maniago, Italy), followed by LED curing (Elipar DeepCure-S; 3 M) for 20 s through the bracket. The other half were bonded using an FF bracket system (C-TE [FF]) (Clarity APC Flash-Free Adhesive Coated Appliance System; 3 M, St. Paul, MN, USA). The bracket was placed and pressed on the mid-buccal surface parallel to the long axis of the tooth without removing the excess resin. Light curing was performed (Elipar DeepCure-S; 3 M) for 20 s through the bracket (Bishara et al., 1997, Chalipa et al., 2016).

2.2.4. Ceramic bracket with self-etch

Ceramic bracket specimens assigned to the SE group (C-SE) were prepared in a similar manner to that previously mentioned M−SE protocol. Half were bonded using the PC bracket system (C-SE [PC]) (Clarity APC Adhesive Coated Appliance System; 3 M), and the other half were bonded using the FF bracket system (C-SE [FF]) (Clarity APC Flash-Free Adhesive Coated Appliance System; 3 M). Light curing was performed (Elipar DeepCure-S; 3 M) for 20 s through the bracket (Bishara et al., 1997, Chalipa et al., 2016).

For standardization of the light-cure intensity, a radiometer (Elipar DeepCure-S; 3 M) was used to ensure consistent quality and effectiveness of the light-curing device. All specimens were stored in distilled water at room temperature for 24 before debonding (Soares Tenório et al., 2020).

2.3. Bracket De-bonding

A bracket-removing plier (Unitek Debonding Instrument 804–175; 3 M, St. Paul, MN, USA) was placed against the occlusogingival sides and gently squeezed until the metal brackets separated. The adhesive flashes around the ceramic bracket base were cleaned using a hand scaler. A debonding plier (Unitek Debonding Instrument 804–175; 3 M) was placed against the mesiodistal sides. squeezed until the ceramic brackets collapsed and gently rocked in the mesial/distal direction to completely separate the bracket from the enamel surface. This was followed by resin removal using a non-cutting, large, round carbide bur on a slow-speed handpiece (FX23 Contra Angle; NSK, Kanuma, Tochigi, Japan). For standardization purposes, a single operator (RZ) performed the bonding and debonding processes for both ceramic and metal brackets.

2.4. Surface roughness assessment (Post-debonding)

All debonded specimens were assessed for post-debonding enamel surface roughness using an optical microscope (Contour GT-K 3D; Bruker, Tucson, AZ, USA) following the previously mentioned protocol.

For enamel surface topography evaluation, the same selected specimens from each subgroup at the pre-bonding stage were gold-coated (1100 Fine Coat Ion Sputter; JFC, Tokyo, Japan) and scanned using an SEM (JSM-6360 LV Scanning Electron Microscope; JEOL, Tokyo, Japan) with an accelerating voltage of 15 kV and magnification of × 300 and × 600.

2.5. Surface microhardness assessment

All 99 specimens (including the control group) were assessed for microhardness using the quasistatic indentation test and micro-Vickers hardness number (VHN) measurement (Hysitron TI 750; Innovatest, Nihonbashi, Horidomecho Chuoku, Tokyo, Japan) with a 200 g force for 10 s on the mid-buccal surface of the tooth (Rajendran et al., 2021).

2.6. Statistical analyses

Statistical analyses were performed using the SPSS (version 26; IBM, Armonk, NY, USA) at a significance level of p < 0.05. Each output is described by the mean, standard deviation, and maximum and minimum values. Distribution normality was assessed using the Kolmogorov–Smirnov test. Three-way analysis of variance (ANOVA) was used to evaluate the interaction between the variables (type of bracket material, etchant, and adhesive), followed by Tukey’s test to assess the significance between the different variables. A paired t-test was used to assess the significance within each variable for the paired measurements (surface roughness). The mean differences and means within each variable were analyzed using Student’s independent t-test.

3. Results

Overall normality was satisfied for both the surface roughness and microhardness outcomes. The detected outliers for surface roughness or microhardness data did not influence the statistical decisions, with mean consideration for data analysis.

3.1. Surface roughness

Descriptive statistics of the surface roughness, using pre- and post-mean differences, showed the greatest changes in roughness for M−TE (PC), followed by C-TE (PC), with mean differences of 1.077 and 0.916, respectively (Table 1). The smallest roughness changes were observed for M−SE (PC) and (FF), with mean differences of 0.468 and 0.444, respectively (Table 1).

Table 1.

Surface roughness and micro-hardness descriptive statistics (with comparsion to control), and Three-way analysis of variance (within-subject effect) (SD: Standard Deviation, M: Metal, C: Ceramic, TE: Total-Etch, SE: Self-Etch, PC: Pre-Coated, FF: Flash-Free, **: Statistically Significant with p < 0.01).

|

Surface Roughness Descriptive Statistics and Pre- and Post-bonding Comparison | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bracket Material | Etchant Type | Adhesive System | Pre-bonding |

Post-debonding |

Mean Difference (Post & Pre) | p-value (vs Control) | ||

| Mean | SD | Mean | SD | |||||

| M | TE | PC | 2.120 | 0.636 | 3.197 | 0.796 | 1.077 | < 0.0001** |

| FF | 2.401 | 0.635 | 3.101 | 0.723 | 0.7 | < 0.0001** | ||

| SE | PC | 2.311 | 0.513 | 2.779 | 0.624 | 0.468 | 0.001** | |

| FF | 2.923 | 0.826 | 3.367 | 0.976 | 0.444 | < 0.0001** | ||

| C | TE | PC | 2.493 | 0.775 | 3.409 | 0.810 | 0.916 | < 0.0001** |

| FF | 2.850 | 1.196 | 3.558 | 0.919 | 0.708 | < 0.0001** | ||

| SE | PC | 2.837 | 0.990 | 3.307 | 0.835 | 0.47 | < 0.0001** | |

| FF | 2.721 | 0.852 | 3.243 | 0.801 | 0.522 | < 0.0001** | ||

| Surface Micro-hardness Descriptive Statistics | ||||||||

| Bracket Material | Etchant Type | Adhesive System | Mean | SD | p-value (vs Control) | |||

| M | TE | PC | 384.436 | 18.2218 | < 0.0001** | |||

| FF | 384.345 | 17.7418 | < 0.0001** | |||||

| SE | PC | 404.418 | 14.1233 | < 0.0001** | ||||

| FF | 402.655 | 21.4508 | < 0.0001** | |||||

| C | TE | PC | 386.564 | 17.9471 | < 0.0001** | |||

| FF | 382.545 | 14.1796 | < 0.0001** | |||||

| SE | PC | 390.827 | 19.8703 | < 0.0001** | ||||

| FF | 397.191 | 17.0393 | < 0.0001** | |||||

| Control | – | – | 448.555 | 19.081 | 1 | |||

| Three-way Analysis of Variance (within-subject effect) | ||||||||

| Source | Sum of Squares | df | Mean Square | F | p-value | |||

| Roughness | 19.351 | 1 | 19.351 | 281.384 | < 0.0001** | |||

| Roughness * Bracket Material | 0.004 | 1 | 0.004 | 0.055 | 0.815 | |||

| Roughness*Etchant | 1.537 | 1 | 1.537 | 22.354 | < 0.0001** | |||

| Roughness*Adhesive | 0.213 | 1 | 0.213 | 3.091 | 0.083 | |||

| Roughness * Bracket Material * Etching | 0.038 | 1 | 0.038 | 0.549 | 0.461 | |||

| Roughness * Bracket Material * Adhesive | 0.041 | 1 | 0.041 | 0.599 | 0.441 | |||

| Roughness * Etching * Adhesive | 0.259 | 1 | 0.259 | 3.765 | 0.056 | |||

| Roughness * Bracket Material * Etching * Adhesive | 0.006 | 1 | 0.006 | 0.086 | 0.769 | |||

The data showed a statistically significant increase in surface roughness from pre-bonding to post-debonding values (p < 0.0001 and p = 0.001), regardless of the bracket material, etchant type, and adhesive system (Table 1). The three-way ANOVA suggested an interaction between the surface roughness and etchant (F = 22.354, p < 0.0001), with no significant interaction attributed to the bracket material or adhesive system (p > 0.05) (Table 1).

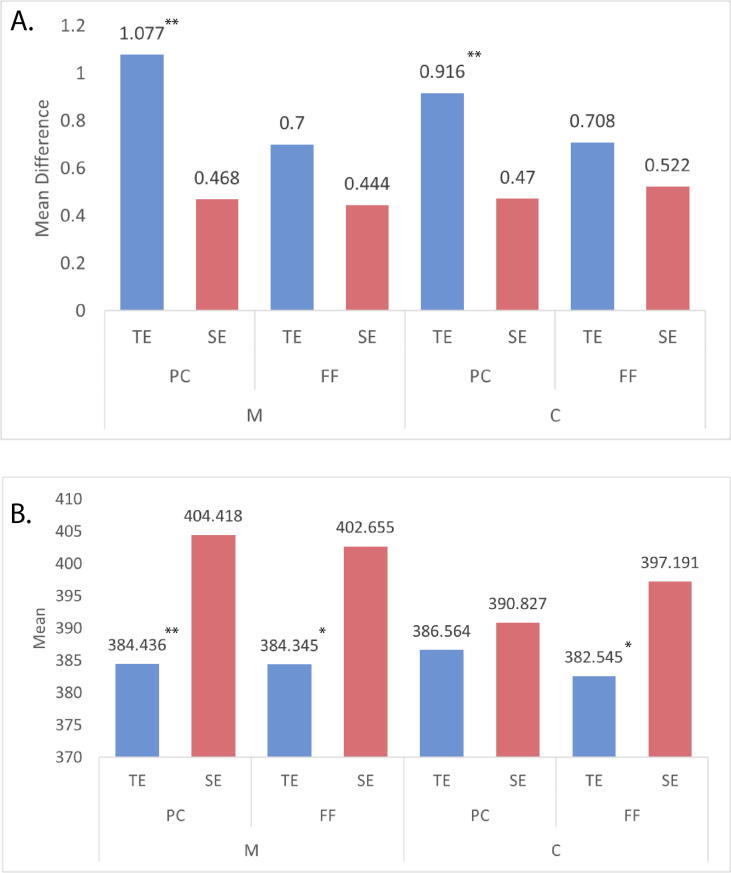

The data for each variable were pooled separately to assess the effects of bracket material, etchant type, and adhesive system on surface roughness. The bracket material and adhesive system produced no statistically significant differences in the surface roughness (p > 0.05) (Tables 2). The surface roughness changes were attributed to the etchant type; a rougher surface was introduced with TE than with SE. TE combined with PC adhesive correlated with a statistically significant rougher surface for both metal and ceramic brackets (p = 0.003 and p = 0.011, respectively) than SE (Fig. 1-A). However, no significant difference was introduced by the etchant type (TE or SE) for specimens combined with FF for either the metal or ceramic brackets (p = 0.059 and p = 0.271, respectively) (Table 2).

Table 2.

Surface roughness comparison according to bracket material, adhesive system, and etchant-type (SD: Standard Deviation, M: Metal, C: Ceramic, TE: Total-Etch, SE: Self-Etch, PC: Pre-Coated, FF: Flash-Free, **: Statistically Significant with p < 0.01, t-test).

|

Surface Roughness Comparison According to Bracket Material | |||||

|---|---|---|---|---|---|

| Adhesive type | Etchant Type | Bracket Material | Mean Difference (Post & Pre) | SD | p-value |

| PC | TE | M | 1.077 | 0.488 | 0.420 |

| C | 0.916 | 0.430 | |||

| SE | M | 0.468 | 0.332 | 0.988 | |

| C | 0.470 | 0.304 | |||

| FF | TE | M | 0.700 | 0.378 | 0.967 |

| C | 0.708 | 0.439 | |||

| SE | M | 0.444 | 0.191 | 0.494 | |

| C | 0.522 | 0.318 | |||

| Surface Roughness Comparison According to Adhesive System | |||||

| Bracket Material | Etchant Type | Adhesive System | Mean Difference (Post & Pre) | SD | p-value |

| M | TE | PC | 1.077 | 0.488 | 0.057 |

| FF | 0.7 | 0.378 | |||

| SE | PC | 0.468 | 0.332 | 0. 841 | |

| FF | 0.444 | 0.191 | |||

| C | TE | PC | 0.916 | 0.430 | 0.275 |

| FF | 0.708 | 0.439 | |||

| SE | PC | 0.47 | 0.304 | 0.698 | |

| FF | 0.522 | 0.318 | |||

| Surface Roughness Comparison According to Etchant Type | |||||

| Bracket Material | Adhesive System | Etchant Type | Mean Difference (Post & Pre) | SD | p-value |

| M | PC | TE | 1.077 | 0.488 | 0.003** |

| SE | 0.468 | 0.332 | |||

| FF | TE | 0.70 | 0.378 | 0. 059 | |

| SE | 0.444 | 0.191 | |||

| C | PC | TE | 0.916 | 0.430 | 0.011** |

| SE | 0.470 | 0.304 | |||

| FF | TE | 0.708 | 0.439 | 0.271 | |

| SE | 0.522 | 0.318 | |||

Fig. 1.

A. Surface roughness mean differences comparison according to etchant type. B. Surface micro-hardness mean comparison according to etchant type (M: Metal, C: Ceramic, TE: Total-Etch, SE: Self-Etch, PC: Pre-Coated, FF: Flash-Free, **: Statistically Significant with p < 0.01, t-test, *: Statistically Significant with p < 0.05, t-test).

The images obtained from the optical microscope were supplemented with SEM images for qualitative evaluation of the enamel surface topography. Enamel irregularities were more pronounced in specimens treated with TE than in those treated with SE (Fig. 2-A and 2-B). These irregularities in the TE specimens had more surface area extension than those of irregularities in the SE specimens, which showed a more localized etching pattern.

Fig. 2.

Surface roughness and topography images: A. M−TE (PC) group (on the left: images retrieved from the optical microscope, on the right: images captured by Scanning Electron Microscope). B. M−SE (PC) (on the left: images retrieved from the optical microscope, on the right: images captured by Scanning Electron Microscope).

3.2. Surface microhardness

Descriptive statistics of the surface microhardness showed the highest mean value for the control group, followed by the M−SE and C-SE groups, whereas the M−TE and C-TE groups had the lowest mean values (Table 1). An overall representation based on the mean average of each variable showed a remarkably reduced surface microhardness of the experimental groups compared to that of the control group; the disparate changes in the surface microhardness were attributed to the etchant types (Table 1).

All groups displayed a statistically significant reduction in the hardness compared with the control group (p < 0.0001) (Table 1). The data for each variable were pooled separately to assess the effects of bracket material, etchant type, and adhesive system on the surface microhardness. The mean of each variable was then compared, and no significant differences were found in either the bracket material or adhesive type (p > 0.05) (Tables 3).

Table 3.

Surface micro-hardnesscomparisonaccording to bracket material, adhesive system, and etchant-type (SD: Standard Deviation, M: Metal, C: Ceramic, TE: Total-Etch, SE: Self-Etch, PC: Pre-Coated, FF: Flash-Free; **: Statistically Significant with p < 0.01, t-test, *: Statistically Significant with p < 0.05, t-test).

|

Surface Micro-hardness Comparison According to Bracket Material | |||||

|---|---|---|---|---|---|

| Etchant Type | Adhesive System | Bracket Material | Mean | SD | p-value |

| TE | PC | M | 384.436 | 18.2218 | 0.7855 |

| C | 386.564 | 17.9471 | |||

| FF | M | 384.345 | 17.7418 | 0.7954 | |

| C | 382.545 | 14.1796 | |||

| SE | PC | M | 404.418 | 14.1233 | 0.0793 |

| C | 390.827 | 19.8703 | |||

| FF | M | 402.655 | 21.4508 | 0.5159 | |

| C | 397.191 | 17.0393 | |||

| Surface Micro-hardness Comparison According to AdhesiveSystem | |||||

| Bracket Material | Etchant Type | Adhesive System | Mean | SD | p-value |

| M | TE | PC | 384.436 | 18.2218 | 0.991 |

| FF | 384.345 | 17.7418 | |||

| SE | PC | 404.418 | 14.1233 | 0.822 | |

| PC | 402.655 | 21.4508 | |||

| C | TE | PC | 386.564 | 17.9471 | 0.567 |

| FF | 382.545 | 14.1796 | |||

| SE | PC | 390.827 | 19.8703 | 0.430 | |

| PC | 397.191 | 17.0393 | |||

| Surface Micro-hardness Comparison According to Etchant Type | |||||

| Bracket Material | Adhesive System | Etchant type | Mean | SD | p-value |

| M | PC | TE | 384.436 | 18.2218 | 0.009** |

| SE | 404.418 | 14.1233 | |||

| FF | TE | 384.345 | 17.7418 | 0.041* | |

| SE | 402.655 | 21.4508 | |||

| C | PC | TE | 386.564 | 17.9471 | 0.603 |

| SE | 390.827 | 19.8703 | |||

| FF | TE | 382.545 | 14.1796 | 0.040* | |

| SE | 397.191 | 17.0393 | |||

The reduced surface microhardness was attributed to the etchant type, which had a higher impact when the surface was treated with TE (Fig. 1-B). The M−TE (PC), M−TE (FF), and C-TE (FF) groups showed a statistically significant reduction in microhardness (p = 0.009, p = 0.041, and p = 0.040, respectively) compared with the SE groups (Fig. 1-B, Table 3). Although the C-TE (PC) group showed no statistically significant effect on hardness compared with the C-SE (PC) group, it followed the general pattern of hardness reduction (p = 0.603) (Table 3).

4. Discussion

This study aimed to evaluate the effects of different orthodontic bracket materials, etchant types, and adhesive systems on the enamel surface roughness and microhardness. Although previous studies have assessed the enamel surface roughness using fixed orthodontic appliances, a multifactorial assessment of the influence of different orthodontic and dental materials has not yet been reported. Moreover, the impact of these factors on the enamel surface hardness has not been thoroughly assessed.

The mechanical properties of the enamel can affect the resistance of dental substrates to environmental conditions (Iijima et al., 2010). Furthermore, the enamel surface roughness contributes to plaque retention and the risk of caries at a threshold of Ra = 0.2 µm (Alizae Marny et al., 2018, Bollen et al., 1997, Mathias et al., 2009, Mullan et al., 2017, Nogueira et al., 2017). Although normal enamel has surface irregularities, the risk of caries increases with higher surface roughness (Bollen et al., 1997, Nogueira et al., 2017). Surface hardness is related to enamel demineralization, which affects the resistance to surface invasion through its mineral content and micro-integrity (Alkattan et al., 2018, Althagafi, 2022, Gutiérrez-Salazar and Reyes-Gasga, 2001).

The first null hypothesis was rejected only for the etchant and accepted for the bracket material and adhesive system. In this study, the surface roughness was measured using the Ra at the pre-bonding and post-debonding stages for each specimen. The bonding and debonding of fixed orthodontic appliances (regardless of the bracket material, etchant type, or adhesive system) increased the enamel surface roughness to values higher than the general roughness threshold found to trigger plaque retention (Bollen et al., 1997). This agrees with previous findings pertaining to surface roughness alteration after debonding (Degrazia et al., 2018, Özer et al., 2010).

This study concluded that neither the bracket material nor adhesive system affected the surface roughness. Previous studies have found that enamel roughness increases after the removal of ceramic and metal brackets (Albuquerque et al., 2010, Karan et al., 2010). However, other studies found no statistically significant increase in surface roughness following the removal of metal and ceramic brackets compared to that of the baseline control group (Caixeta et al., 2021, Moosavi et al., 2013). These studies did not directly compare the effects of metal and ceramic brackets on the enamel surface roughness.

This study revealed a significant relationship between the etchant type and roughness changes when used with a PC adhesive system. In other words, TE combined with PC produced a rougher surface after debonding than SE. Although the combination of TE with FF system did not result in statistically significant values, it followed the same pattern of higher roughness. Goel et al. (2017) found that SE produced lower Ra values than TE alone when combined with Sof-Lex for adhesive removal (Goel et al., 2017). Additionally, Zope et al. (2016) revealed that SE produced a smoother surface than TE, although they employed non-precoated brackets (Zope et al., 2016).

The SEM images indicated more surface irregularities with TE than with SE, which supports the findings in the literature on shallower irregularities and less enamel dissolution with SE (Hashimoto et al., 2013, Horiuchi et al., 2009). The surface roughness findings and reduced invasiveness of the FF adhesive and SE could be related to the less resin removal with the FF system, whereas the weaker etching composition of SE might have resulted in a less distinct surface, reduced resin penetration, and less removal need of the remnants (Baysal et al., 2015, Visel et al., 2014).

The second null hypothesis was only rejected for the etchant and accepted for the bracket material and adhesive system. The microhardness of the enamel surface was evaluated using the Vickers hardness test, which involved pressing a diamond indenter into the sample using a known loading force and dwell time. The results for the control specimens in this study (mean = 448.555 ± 19.08 VHN) were close to those reported in the literature (348–440 VHN) (Craig and Peyton, 1958, Gutiérrez-Salazar and Reyes-Gasga, 2003, Ryge et al., 1961).

This study found that fixed appliances could significantly reduce enamel surface microhardness, regardless of the bracket material, etchant type, or adhesive system. The bracket materials and adhesive systems used did not alter the microhardness. No previous studies have evaluated the impact of bracket materials (M or C) and adhesive systems (PC or FF) on enamel hardness. A study evaluating the nanocomposite adhesive and regular composite of a non-precoated ceramic bracket found that enamel hardness was reduced compared with that of non-bonded areas (Karimzadeh et al., 2015). Another study concluded that the enamel surface bonded with metal brackets had a lower microhardness than that of the non-bonded enamel surface (Rajendran et al., 2021).

Hardness reduction was attributed to the type of etchant, with TE resulting in a significant reduction compared to SE. However, for ceramic brackets with PC adhesives, neither TE nor SE had a significant impact on hardness, although the same pattern of hardness reduction was observed. Studies found that TE produced further hardness reduction than SE (Machoy et al., 2021, Salehi et al., 2022). Iijima et al. (2010) arrived at a similar conclusion of a higher surface hardness reduction with TE than that with SE; this reduction was not significant for the non-bonded surface (Iijima et al., 2010). Kohda et al. (2012) used a nanoindentation assessment of different etchants with unified fixed appliances and supported the current finding of less reduction in surface hardness with SE (Kohda et al., 2012).

Essentially, the etching procedure removes part of the enamel structure, rendering it vulnerable to increased surface roughness and reduced surface microhardness. This is particularly the case with the higher etching aggressiveness potential of TE and its significant effect on the mechanical properties of the enamel (Machoy et al., 2021, Pashley and Tay, 2001).

This study conducted in vitro, hence, it does not represent clinical conditions. Future studies, such as that with additional surface treatment modalities, are needed to confirm and add to the presented findings. Nevertheless, the findings of this study reflected the impact of dental materials on dental structures (altered enamel surface roughness and microhardness). With the concluded effect of dental materials on dental substrates and the high risk of enamel surface integrity loss, further studies, including those in vivo setting, are required.

5. Conclusions

-

•

The overall use of fixed orthodontic appliances could significantly increase enamel surface roughness and reduce surface microhardness compared with the control, regardless of the bracket material, etchant type, or adhesive system.

-

•

Neither the type of bracket material nor the adhesive system contributed to surface roughness or microhardness alterations.

-

•

The etchant type significantly influenced the measured surface properties, with an overall pattern of rougher surface production and higher microhardness reduction accompanying TE than SE surface treatment.

-

•

TE caused a significantly higher surface roughness than SE, except when combined with FF adhesive system.

-

•

TE contributed to a statistically significant lower surface microhardness than SE, except when combined with a ceramic bracket and PC adhesive system.

-

•

Scanning electron microscopy images confirmed the surface roughness findings. TE introduced pronounced surface irregularities on the enamel compared to SE.

6. Ethical approval and IRB

All methods were carried out in accordance with relevant guidelines and regulations.

Institutional Review Board for Health Sciences This study was approved by the Institutional Review Board for Health Sciences Colleges Research on Human Subjects, College of Medicine, King Saud University, Riyadh, Saudi Arabia (Reg. No. E-21–5917) and the College of Dentistry Research Center, Riyadh, Saudi Arabia (Reg. No. PR 0117).

7. Place of research

This study was conducted at the College of Dentistry and College of Applied Science facilities at King Saud University, Riyadh, Saudi Arabia.

CRediT authorship contribution statement

RAHAF N. ZAWAWI: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Resources, Data curation, Visualization, Project administration, Writing - original draft, Writing - review & editing. NAIF A. ALMOSA: Conceptualization, Methodology, Validation, Visualization, Supervision, Writing - review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Peer review under responsibility of King Saud University. Production and hosting by Elsevier.

Supplementary data to this article can be found online at https://doi.org/10.1016/j.sdentj.2023.05.015.

Contributor Information

RAHAF N. ZAWAWI, Email: Rahaf-z@live.com.

NAIF A. ALMOSA, Email: nalmosa@ksu.edu.sa.

Appendix A. Supplementary material

The following are the Supplementary data to this article:

Data Availability

All data used to support the findings of this study will be included in the submitted documents, any additional data are available from the corresponding author upon request.

References

- Albuquerque G.d.S., Filho M.V., Lucato A.S., Boeck E.M., Degan V., Kuramae M. Evaluation of enamel roughness after ceramic bracket debonding and clean-up with different methods. Brazilian J. Oral Sci. 2010;9:81–84. [Google Scholar]

- Alizae Marny M., Kiong Hung W., Wan Jen L., Murshida M.N., Haizal M.H., Tanti Irawati R. In vitro study of white spot lesion: maxilla and mandibular teeth. Saudi Dent. J. 2018;30:142–150. doi: 10.1016/j.sdentj.2017.12.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alkattan R., Lippert F., Tang Q., Eckert G.J., Ando M. The influence of hardness and chemical composition on enamel demineralization and subsequent remineralization. J. Dent. 2018;75:34–40. doi: 10.1016/j.jdent.2018.05.002. [DOI] [PubMed] [Google Scholar]

- Almosa, Alqasir, A.M., Aldekhayyil, M.A., Aljelayel, A., Aldosari, M.A., 2019a. Enamel demineralization around two different orthodontic bracket adhesive systems: An in vivo study. Saudi Dent. J. vol. 31, pp. 99–104. https://doi.org/10.1016/J.SDENTJ.2018.11.005. [DOI] [PMC free article] [PubMed]

- Althagafi N. Impact of fluoride-releasing orthodontic adhesives on the shear bond strength of orthodontic brackets to eroded enamel following different surface treatment protocols. J. Orthod. Sci. 2022;11:3. doi: 10.4103/jos.jos_139_21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baysal A., Yasa B., Sogut O., Ozturk M.A., Uysal T. Effects of different orthodontic primers on enamel demineralization around orthodontic brackets. J. Orofac. Orthop. 2015;76:421–430. doi: 10.1007/s00056-015-0304-6. [DOI] [PubMed] [Google Scholar]

- Bishara S.E., Olsen M., Von Wald L. Comparisons of shear bond strength of precoated and uncoated brackets. Am. J. Orthod. Dentofac. Orthop. 1997;112:617–621. doi: 10.1016/s0889-5406(97)70226-9. [DOI] [PubMed] [Google Scholar]

- Bollen C.M., Lambrechts P., Quirynen M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: a review of the literature. Dent. Mater. 1997;13:258–269. doi: 10.1016/s0109-5641(97)80038-3. [DOI] [PubMed] [Google Scholar]

- Bora, N., Mahanta, P., Kalita, D., Deka, S., Konwar, R., Phukan, C., 2021. Enamel surface damage following debonding of ceramic brackets: A hospital-based study. Sci. World J. 2021. [DOI] [PMC free article] [PubMed]

- Buzalaf M.A.R., Hannas A.R., Magalhães A.C., Rios D., Honório H.M., Delbem A.C. pH-cycling models for in vitro evaluation of the efficacy of fluoridated dentifrices for caries control: strengths and limitations. J. Appl. Oral Sci. 2010;18:316–334. doi: 10.1590/S1678-77572010000400002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Caixeta R.V., Berger S.B., Lopes M.B., Paloco E.A.C., Faria É.M., Contreras E.F.R., Gonini A., Guiraldo R.D. Evaluation of enamel roughness after the removal of brackets bonded with different materials: in vivo study. Braz. Dent. J. 2021;32:34–40. doi: 10.1590/0103-6440202104399. [DOI] [PubMed] [Google Scholar]

- Camboni S., Donnet M. Tooth surface comparison after air polishing and rubber cup: a scanning electron microscopy study. J. Clin. Dent. 2016;27:13–18. [PubMed] [Google Scholar]

- Chalipa J., Jalali Y.F., Gorjizadeh F., Baghaeian P., Hoseini M.H., Mortezai O., Mortezai O. Comparison of bond strength of metal and ceramic brackets bonded with conventional and high-power LED light curing units. J. Dent. (Tehran) 2016;13:423–430. [PMC free article] [PubMed] [Google Scholar]

- Chowdhary Z., Mohan R. Efficiency of three different polishing methods on enamel and cementum: a scanning electron microscope study. J. Indian Soc. Periodontol. 2018;22:18–24. doi: 10.4103/jisp.jisp_40_17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cohen J. 2nd ed. Lawrence Erlbaum Associates; 1988. Statistical power analysis for the behavioral sciences. [Google Scholar]

- Çokakoğlu S., Tan A. Effects of adhesive flash-free brackets on debonding pain and time: a randomized split-mouth clinical trial. Angle Orthod. 2020;90:758–765. doi: 10.2319/030820-162.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Craig R.G., Peyton F.A. The microhardness of enamel and dentin. J. Dent. Res. 1958;37:661–668. doi: 10.1177/00220345580370041301. [DOI] [PubMed] [Google Scholar]

- Degrazia F.W., Genari B., Ferrazzo V.A., dos Santos-Pinto A., Grehs R.A. Enamel roughness changes after removal of orthodontic adhesive. Dent. J. 2018;6 doi: 10.3390/dj6030039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- George M.D., Preshaw P., Donley T.G. 1st ed. Wiley-Blackwell; 2017. Ultrasonic periodontal debridement : theory and technique. [Google Scholar]

- Goel A., Singh A., Gupta T., Gambhir R.-S. Evaluation of surface roughness of enamel after various bonding and clean-up procedures on enamel bonded with three different bonding agents: an in-vitro study. J. Clin. Exp. Dent. 2017;9:608–624. doi: 10.4317/jced.53237. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gutiérrez-Salazar M.P., Reyes-Gasga J. Enamel hardness and caries susceptibility in human teeth. Rev. Latinoam. Metal. y Mater. 2001;21:36–40. [Google Scholar]

- Gutiérrez-Salazar M.d.P., Reyes-Gasga J. Microhardness and chemical composition of human tooth. Mater. Res. 2003;6:367–373. [Google Scholar]

- Hashimoto Y., Hashimoto Y., Nishiura A., Matsumoto N. Atomic force microscopy observation of enamel surfaces treated with self-etching primer. Dent. Mater. J. 2013;32:181–188. doi: 10.4012/dmj.2012-227. [DOI] [PubMed] [Google Scholar]

- Horiuchi S., Kaneko K., Mori H., Kawakami E., Tsukahara T., Yamamoto K., Hamada K., Asaoka K., Tanaka E. Enamel bonding of self-etching and phosphoric acid-etching orthodontic adhesives in simulated clinical conditions: debonding force and enamel surface. Dent. Mater. J. 2009;28:419–425. doi: 10.4012/dmj.28.419. [DOI] [PubMed] [Google Scholar]

- Iijima M., Muguruma T., Brantley W.A., Ito S., Yuasa T., Saito T., Mizoguchi I. Effect of bracket bonding on nanomechanical properties of enamel. Am. J. Orthod. Dentofac. Orthop. 2010;138:735–740. doi: 10.1016/j.ajodo.2009.01.028. [DOI] [PubMed] [Google Scholar]

- Karan S., Kircelli B.H., Tasdelen B. Enamel surface roughness after debonding. Angle Orthod. 2010;80:1081–1088. doi: 10.2319/012610-55.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Karimzadeh A., Ayatollahi M.R., Hosseinzadeh-Nik T. Effects of a nano-composite adhesive on mechanical properties of tooth enamel after removing orthodontics bracket – an experimental study using nano-indentation test. Exp. Mech. 2015;55:1769–1777. [Google Scholar]

- Kohda N., Iijima M., Brantley W.A., Muguruma T., Yuasa T., Nakagaki S., Mizoguchi I. Effects of bonding materials on the mechanical properties of enamel around orthodontic brackets. Angle Orthod. 2012;82:187–195. doi: 10.2319/020411-78.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar M., Sequeira P.S., Peter S., Bhat G.K. Sterilisation of extracted human teeth for educational use. Indian J. Med. Microbiol. 2005;23:256–258. [PubMed] [Google Scholar]

- Lacruz R.S., Habelitz S., Wright J.T., Paine M.L. Dental enamel formation and implications for oral health and disease. Physiol. Rev. 2017;97:939–993. doi: 10.1152/physrev.00030.2016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leslie S.A., Mitchell J.C. Removing gold coating from SEM sample. Palaeontology. 2007;50:1459–1461. [Google Scholar]

- Machoy M., Wilczyński S., Szyszka-Sommerfeld L., Woźniak K., Deda A., Kulesza S. Mapping of nanomechanical properties of enamel surfaces due to orthodontic treatment by AFM method. Appl. Sci. 2021;11:3918–3928. [Google Scholar]

- Mathias J., Kavitha S., Mahalaxmi S. A comparison of surface roughness after micro abrasion of enamel with and without using CPP-ACP: an in vitro study. J. Conserv. Dent. 2009;12:22. doi: 10.4103/0972-0707.53337. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Molaasadolah F., Eskandarion S., Ehsani A., Sanginan M. In vitro evaluation of enamel microhardness after application of two types of fluoride varnish. J. Clin. Diagn. Res. 2017;11:64–66. doi: 10.7860/JCDR/2017/30121.10412. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Moosavi H., Ahrari F., Mohamadipour H. The effect of different surface treatments of demineralised enamel on microleakage under metal orthodontic brackets. Prog. Orthod. 2013;14:1–6. doi: 10.1186/2196-1042-14-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mullan F., Austin R.S., Parkinson C.R., Hasan A., Bartlett D.W. Measurement of surface roughness changes of unpolished and polished enamel following erosion. PLoS One. 2017;12 doi: 10.1371/journal.pone.0182406. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nicolas-Silvente A.I., Chiva-Garcia F., Sanchez-Perez A. The effect of dental enamel pre-etching for self-etching adhesives according to their primer pH: an in vitro bond strength, etching pattern and adhesive failure evaluation. J. Dent. 2020;2:1–7. [Google Scholar]

- Nogueira R.D., Silva C.B., Lepri C.P., Guenka R., Dibb P., Geraldo-Martins V.R., Rangel V., Martins G., Sabino A.N. Evaluation of surface roughness and bacterial adhesion on tooth enamel irradiated with high intensity lasers. Braz. Dent. J. 2017;28:24–29. doi: 10.1590/0103-6440201701190. [DOI] [PubMed] [Google Scholar]

- Özer T., Başaran G., Kama J.D. Surface roughness of the restored enamel after orthodontic treatment. Am. J. Orthod. Dentofac. Orthop. 2010;137:368–374. doi: 10.1016/j.ajodo.2008.02.025. [DOI] [PubMed] [Google Scholar]

- Pashley D.H., Tay F.R. Aggressiveness of contemporary self-etching adhesives: part II: etching effects on unground enamel. Dent. Mater. 2001;17:430–444. doi: 10.1016/s0109-5641(00)00104-4. [DOI] [PubMed] [Google Scholar]

- Rajendran R., Sudhakar V., Rangarajan R., Chinnasamy A., Vasupradha G., Jeeva J. Evaluation of change in surface enamel microhardness in patients undergoing fixed orthodontic appliance therapy – a randomized control trial. J. Pharm. Bioallied Sci. 2021;13:S1106–S1110. doi: 10.4103/jpbs.jpbs_259_21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ryge G., Foley D.E., Fairhurst C.W. Micro-indentation hardness. J. Dent. Res. 1961;40:1116–1126. [Google Scholar]

- Salehi P., Shavakhi M., Nazari S., Ajami S. The effect of multiple enamel conditioning on enamel micro-hardness. Dent. Res. J. (Isfahan) 2022;19:62. [PMC free article] [PubMed] [Google Scholar]

- Soares Tenório K.C., Neupmann Feres M.F., Tanaka C.J., Augusto M.K.M., Rodrigues J.A., Pereira da Silva H.D., Arana-Chavez V.E., Roscoe M.G. In vitro evaluation of enamel surface roughness and morphology after orthodontic debonding: traditional cleanup systems versus polymer bur. Int. Orthod. 2020;18:546–554. doi: 10.1016/j.ortho.2020.04.006. [DOI] [PubMed] [Google Scholar]

- Uşümez S., Büyükyilmaz T., Karaman A.I. Effect of light-emitting diode on bond strength of orthodontic brackets. Angle Orthod. 2004;74:259–263. doi: 10.1043/0003-3219(2004)074<0259:EOLDOB>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- Visel D., Jäcker T., Jost-Brinkmann P.G., Präger T.M. Demineralization adjacent to orthodontic brackets after application of conventional and self-etching primer systems. J. Orofac. Orthop. 2014;75:358–373. doi: 10.1007/s00056-014-0233-9. [DOI] [PubMed] [Google Scholar]

- Zope A., Zope-Khalekar Y., Chitko S.S., Kerudi V.V., Patil H.A., Bonde P.V., Jaltare P., Dolas S.G. Comparison of self-etch primers with conventional acid etching system on orthodontic brackets. J. Clin. Diagnostic Res. 2016;10:19–22. doi: 10.7860/JCDR/2016/18842.9031. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data used to support the findings of this study will be included in the submitted documents, any additional data are available from the corresponding author upon request.