Dear Editor,

The anaesthesia workstation consists of various electronic parts and requires routine check-ups before its use. This decreases the chances of intraoperative workstation malfunction.[1] An in-built electronic self-check algorithm is often incorporated in most advanced anaesthesia workstations.

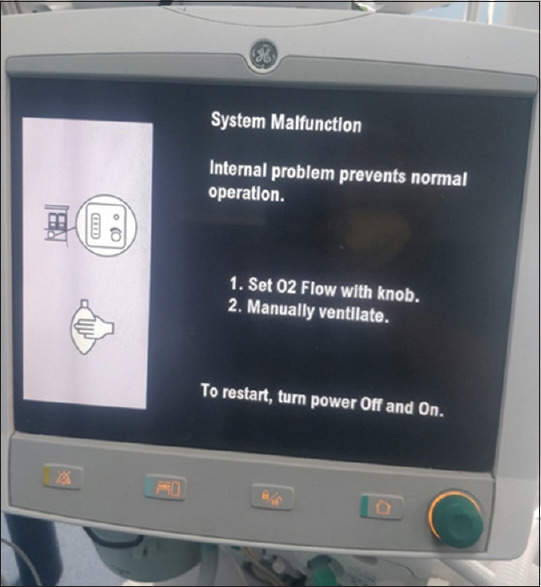

We report a technical glitch that occurred in a GE Avance CS2 anaesthesia workstation (Datex-Ohmeda Inc., Madison, USA) when a middle-aged male patient was undergoing laparoscopic cholecystectomy under general anaesthesia. The workstation passed the built-in electronic self-test without any leak in the breathing circuit. General anaesthesia was administered as per the standard protocol of the institution. As the surgery began, the ambient temperature and humidity started increasing due to the failure of the air conditioning system. The workstation then suddenly stopped working, with its monitor displaying ‘system malfunction-internal problem prevents normal operation-set oxygen flow with knob-manually ventilate’ [Figure 1].

Figure 1.

The anaesthesia workstation monitor displaying the system malfunction

A Bain circuit was attached to ventilate the lungs until an alternate workstation was arranged. Meanwhile, the workstation was switched off and restarted as per the advice displayed on the monitor. The operating theatre (OT) power supply was checked. The technical support team of the workstation manufacturer was intimated. They discovered the following findings:

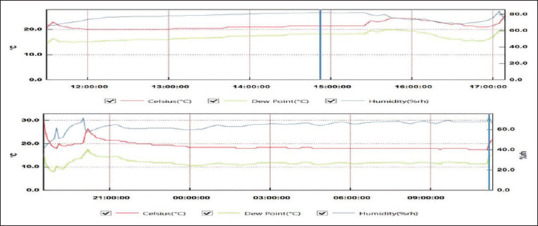

Temperature and humidity: Under normal condition, the OT temperature should be 20°C–22°C and humidity should be between 40% and 60%. However, it was found that OT humidity remained above 60% and went up to 90% with varying temperatures. An internal audit was planned. The temperature and humidity data were collected from two OTs every two hourly for 12 hours. It was observed that the humidity remained above 60% and reached a maximum of 82% in OT 1. Similarly, it remained above 60% and reached 72.5% in OT 2, and temperature also varied between 17.5°C and 30°C [Figure 2].

Power supply: Power above 240 V may damage the parts of the equipment. We found some raw power points on the walls of the OT, with voltage measuring up to 246 V.

Figure 2.

Data logger reading operating rooms

The internal audit revealed that the OT air circulation was interrupted during evening and night hours, if no cases were posted.This led to condensation during night time due to variations in temperature, especially in the summer during which the current situation occurred. We noticed water droplets inside the workstation and varying degrees of rusting. This could also have contributed to the failure of equipment [Figure 3].

Figure 3.

Water spots inside the GE Avance CS2 anaesthesia workstation

All electronic devices function best at a particular range of temperature and humidity, and this applies to anaesthesia workstations as well. General Electric company recommends avoiding fluctuations of more than 5°C and maintaining humidity between 40% and 60%. These recommendations must be strictly adhered to under all circumstances because workstation malfunction can compromise patient safety. Kumar et al.[2] reported a similar failure of the Dräger Primus anaesthesia workstation due to inconsistent humidification. Ushijima et al.[3] also reported a system failure of a workstation due to dew condensation.

It is essential to routinely check humidification, temperature, flow change rate, differential pressure, and high-efficiency particulate air (HEPA) filter status of the operation theatre. The National Accreditation Board for Hospitals and Healthcare Providers also recommends periodic check-ups, maintenance, and cleaning of filters every 15–30 days.[4] Anaesthesia workstations, like any other mechanical equipment, require regular maintenance and ideal conditions to function at its maximum potential, which will mitigate any untoward incidents and increase the life of the machine. The manufacturers can also add built-in warning indicators for maintaining humidity and temperature within the optimal range.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Subrahmanyam M, Mohan S. Safety features in anaesthesia machine. Indian J Anaesth. 2013;57:472–80. doi: 10.4103/0019-5049.120143. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Kumar N, Mishra N, Kumar A, Kumar S. Internal system failure of Drager Primus anaesthesia workstation because of inefficient humidification inside the operating room. Indian J Anaesth. 2022;66:680–1. doi: 10.4103/ija.ija_506_22. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Ushijima K, Yamada Y, Ikuta Y, Sakamoto M. An anesthesia machine malfunction due to dew condensation produced by abnormally high humidity in the electronically-controlled panel. Masui. 1997;46:406–8. [PubMed] [Google Scholar]

- 4.National Accreditation Board for Hospitals &Healthcare Providers (NABH) [[Last accessed on 2023 Mar 02]]. Available from: https://www.nabh.co/images/pdf/RevisedGuidelines_AirConditioning_OT.docx .