Graphical abstract

Impact of treatment type on the total phenolic content of sour cherry.

Keywords: Antioxidant capacity, Basil seed gum, Guar gum, Sodium alginate, Total phenolics

Research highlights

-

•

Effect of sonication and edible coatings with guar, sodium alginate, and basil gums on total phenolic and antioxidant capacity of sour cherry was studied.

-

•

Gum coating increased the total phenolic, antioxidant properties, and rehydration ratio.

-

•

Coatings decreased the water diffusivity, color changes, and surface shrinkage.

-

•

The Midilli model satisfactorily described the drying behavior of sour cherries.

Abstract

Application of pretreatment methods such as ultrasound and edible coatings is used to reduce processing time and/or preserve food product quality in drying technology. The aim of this research was to measure the impacts of gum-based coatings (guar, sodium alginate, and basil seed gums) in combination with sonication before drying on total phenolic content (TPC), antioxidant capacity (AC), effective water diffusivity (Deff), total color difference (ΔE), surface shrinkage (SS), and rehydration ratio (RR) of sour cherries. Ultrasonic pretreatment (40 kHz, 150 W, at 25 °C, for 12 min) increased the TPC, AC, Deff, and RR, and decreased the drying time, ΔE, and SS values of sour cherries. Edible coating increased the TPC, AC, drying time, and RR, and decreased the Deff, ΔE, and SS values of sonicated sour cherries. The TPC for untreated, uncoated-sonicated, guar gum-coated, sodium alginate-coated, and basil seed gum-coated sour cherries were 2965.9, 3398.1, 3480.8, 3511.0, and 3898.3 µg gallic acid equivalent/g dry, respectively. The highest value of AC (71.2±3.7 %) was observed on coated sour cherries by basil seed gum. The experimental data for drying curves were fitted to several widely used models, and the Midilli model using the experimental constants that best represent the drying rate of sour cherries. The edible coatings significantly reduced the color changes and shrinkage of dried sour cherries, with the lowest ΔE and SS values in the basil seed gum-coated samples (p < 0.05).

1. Introduction

According to statistics from the Food and Agriculture Organization (FAO), about 1.2 million tons of cherries are produced annually in the world, and Iran is the fifth largest producer of cherries in the world [1]. Sour cherry (Prunus cerasus L) is one of the most popular fruits in almost every part of the world due to its anthocyanin content, TPC, AC, fibers, taste, sourness, nutritional value, and health-promoting properties [2], [3], [4]. According to various reports, sour cherries are native to northern Iran, south of Caucasus Mountains, and the region between the Caspian sea and the Black sea. The countries that produce the most sour cherries are Iran, Russia, Poland, Turkey, and USA [5], [6]. Drying is the oldest technique for processing and preservation of sour cherries [3], [4], [7], [8], [9]. Wojdyło, et al. [9] used convection and vacuum-microwave methods to dry sour cherry. Their results confirmed that dried sour cherries can be an excellent substitute for fresh fruit all year round due to their long shelf life.

Perishable foods such as fruits and vegetables have a short shelf-life, leading to significant post-harvest losses, posing a major challenge to the food supply chain [10]. Recently, edible coatings comprising of biodegradable and biocompatible polymer have been shown to be an effective means of reducing post-harvest infections and maintaining good fruit and vegetable products quality through physical barriers and hindering gas and water exchange between the products and the environment [11], [12]. Edible coatings help keep fruits and vegetables fresher, extend shelf life, and maintain nutritional value by enhancing the maintenance of color and flavor components [13]. Gum-based edible coatings serve as a pre-treatment for dehydration as they prevent nutrient oxidation and improve the quality of the dehydrated fruits [14], [15]. Mazidi and Hosseini Ghaboos [16] used basil and balangu seeds gums to improve the sensorial properties, quality and shelf-life of peaches. Their results showed that the use of these gums had a significant effect in reducing the respiration rate of peaches, and the use of 0.1 % of balangu and basil seeds gums was recommended as an edible coating to preserve quality and extend the shelf-life of samples.

Ultrasound is used as an alternative to heat treatment of agricultural products, which is one of the recent developments in the food industry. In addition, the ultrasound processing can create unfavorable conditions for microbes, but this depends on the type of microbes, the composition of the food products and the duration of the treatment [17]. In terms of cost, ultrasonic pre-treatment is less expensive than other technologies, and the main cost of operating a sonication system is electrical energy, making it more cost-effective and environmentally friendly than other methods [18], [19], [20], [21]. Adavi, et al. [7] recommend using ultrasound to reduce the temperature, time, and energy of the convective drying process of sour cherries. Liu et al. [22] examined the influence of chitosan coating combined with ultrasonic pre-treatment in sodium bicarbonate medium before freeze-drying on the quality characteristics of blueberries. Their results confirmed that ultrasonic pre-treatment and sodium bicarbonate soaking have a positive influence on improving the freeze-dried properties of blueberries. An et al. [23] examined the influence of carboxymethylcellulose (CMC)/pectin coatings combined with ultrasonic pre-treatment before drying on the quality characteristics of turmeric. The CMC-coating combined with ultrasonic pre-treatment enhanced the quality parameters of turmeric. Furthermore, their results showed that the CMC-coating preserved the bioactive compounds better than the pectin-coating.

We found no report on the influence of gum coatings and ultrasonic on the convective drying rate of sour cherries in the literature. This research aimed to measure the effects of coating and ultrasonic pretreatment on the TPC, AC, Deff, ΔE, SS, and RR of sour cherries coated with guar gum, sodium alginate, and basil seeds gum.

2. Materials and methods

2.1. Preparation of sour cherries and gums

For use in the present study, sour cherries were obtained from a store in Bahar, Hamedan, Iran. The sour cherries were cut into half with a sharp knife and their seeds were removed. The moisture content of fresh and processed sour cherries was determined using a convective dryer at 105 °C for five hours (Shimaz, Iran). Guar gum, sodium alginate, and basil seed gum solutions were employed for coating fresh halved sour cherries. Food-grade guar gum and sodium alginate powders were obtained from Abdullabhai Abdul Kader Co. (India) and Qingdao Bright Moon Seaweed Group Co., Ltd. (China), respectively. Basil seed gum powder was prepared by the technique explained by Salehi et al. [24].

2.2. Pretreatment procedure

The halved sour cherry without pre-treatment was the control group. The guar gum, sodium alginate, and basil seed gum powders were dissolved in distilled water at 25 °C, by constantly stirring for 15 min to obtain transparent solutions (0.2 %, w/v). For the pretreatment procedure, the beakers containing six halved sour cherries and gum solution (dipped into 200 mL solution, guar gum or sodium alginate, or basil seed gum) were placed into an ultrasound bath (Backer vCLEAN1-L6, Iran). Then, the ultrasonic-coating pretreatment was performed in the ultrasonic bath at 150 W power, 40 kHz frequency, and at room temperature (25 °C) for 12 min. Finally, the halved sour cherries were removed from the gum solution and placed on a paper towel to remove excess solution.

2.3. Convective drying

Convection drying with hot-air is still commonly utilized in the production of dried foods due to its low cost. In this study, the convective drying experiments were performed during the period of June to July 2023 in Bahar, Hamedan Province, Iran. Convection drying of pretreated sour cherries was performed in a hot-air dryer at 70±2 °C (Shimaz, Iran).

2.4. Total phenolic content (TPC)

The extraction of phenolic compounds from sour cherries was performed pursuant to the technique described by Salehi et al. [25]. Also, the TPC of sour cherries was estimated pursuant to the technique described by Salehi, et al. [25]. Spectrophotometric analysis (using a UV–VIS spectrophotometer, at 765 nm, XD-7500, Lovibond, Germany) of TPC in the sour cherry extract was conducted using the Folin-Ciocalteu's phenol reagent (Sigma-Aldrich, USA) technique. The TPC of sour cherries was reported as microgram gallic acid equivalent/g dry matter (μg GAE/g).

2.5. Antioxidant capacity

For the AC analysis of sour cherries, the DPPH (2,2-Diphenyl-1-picrylhydrazyl, Sigma-Aldrich, USA) free radical-scavenging activity (FRSA) technique was used according to Salehi, et al. [25].

2.6. Mathematical modelling

The obtained drying curves were processed to find the best fit between 6 different expressions (Table 1) determining the drying rate. However, the moisture ratio was simplified to Mt/M0 as a substitute for the (Mt − Me)/(M0 − Me) because the relative humidity of the drying air fluctuated continuously during the dehydration procedure. Where Mt is the moisture content of the sour cherry halves (g water/g dry matter) at time t; Me and M0 are the equilibrium and initial moisture content of the sour cherry halves (g water/g dry matter), respectively [26], [27], [28]. Non-linear regression analysis and modelling were carried out using Matlab software (version R2012a).

Table 1.

The predicted values, constants and statistical analysis of the models fitted to the drying data for thin-layer guar gum-coated sour cherry.

| Model name | Model equation | Model constants | SSE | r | RMSE | Predicted moisture ratio | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Midilli | MR = aexp(-ktn) + bt | a = 0.9999 k = 0.0944 n = 0.5083 b = -0.0023 |

0.0002 | 0.9998 | 0.0082 | 1.000 | 0.653 | 0.518 | 0.417 | 0.331 | 0.256 | 0.188 |

| Page | MR = exp(-ktn) | k = 0.0504 n = 0.761 |

0.0015 | 0.9983 | 0.0177 | 1.000 | 0.673 | 0.511 | 0.401 | 0.321 | 0.260 | 0.213 |

| Wang and Singh | MR = 1 + at + bt2 | a = -0.0184 b = 0.0001 |

0.0141 | 0.9846 | 0.0531 | 1.000 | 0.747 | 0.538 | 0.375 | 0.256 | 0.183 | 0.154 |

| Newton | MR = exp(-kt) | k = 0.0198 | 0.0114 | 0.9876 | 0.0435 | 1.000 | 0.743 | 0.552 | 0.410 | 0.305 | 0.227 | 0.168 |

| Henderson and Pabis | MR = aexp(-kt) | a = 0.9533 k = 0.0187 |

0.0085 | 0.9908 | 0.0412 | 0.953 | 0.720 | 0.544 | 0.411 | 0.310 | 0.234 | 0.177 |

| Logarithmic | MR = aexp(-kt) + c | a = 0.8362 k = 0.0269 c = 0.1435 |

0.0048 | 0.9948 | 0.0346 | 0.980 | 0.702 | 0.517 | 0.393 | 0.310 | 0.255 | 0.218 |

| Experimental moisture ratio | 1.000 | 0.646 | 0.525 | 0.408 | 0.329 | 0.258 | 0.192 | |||||

* where, SSE is sum of squared errors; r is correlation coefficient; RMSE is root mean squared error; MR is moisture ratio (dimensionless); t is time (min); a, k, n, b, and c are coefficients of the models (dimensionless).

2.7. Determination of water diffusivity (Deff)

The Deff value (m2/s) of sour cherries during convective dehydration was determined pursuant to the technique explained by Salehi et al. [29].

2.8. Color and surface measurement

An iPhone 12 megapixels camera (iPhone 12 Pro, Apple Co., USA) was used to photograph the sour cherry halves. The surface color of sour cherries was analyzed using Image J software (V.1.42e, USA). The L* (lightness), a* (greenness/redness), and b* (blueness/yellowness) values for each sample were recorded in triplicates. The ΔE and SS were determined with the help of Eq. (1) and Eq. (2), respectively [30], [31].

| (1) |

| (2) |

where, ΔE is the total color difference; L1, a1, and b1 denote the value of dried sour cherry color; L0, a0, and b0 denote the values of fresh sour cherry color; SS is the surface shrinkage (%); Si (cm2) and Sf (cm2) are the surface areas of fresh and dried sour cherry, respectively.

2.9. Rehydration

The rehydration tests were conducted with a water bath (R.J42, Pars Azma Co., Iran). The RR (%) of dried sour cherries was determined as the ratio of the final weight of rehydrated sour cherry (in distilled water, at 50 °C, for 30 min) over the dried sour cherry weight ×100 [31].

2.10. Statistical analysis

SPSS 21 (IBM, USA) was employed for the data analysis. One-way analysis of variance (ANOVA) and multiple comparisons (post-hoc Duncan) were employed to calculate significant differences in the processing data at p-value < 0.05. The data were reported as means ± standard deviation (n = 3).

3. Results and discussion

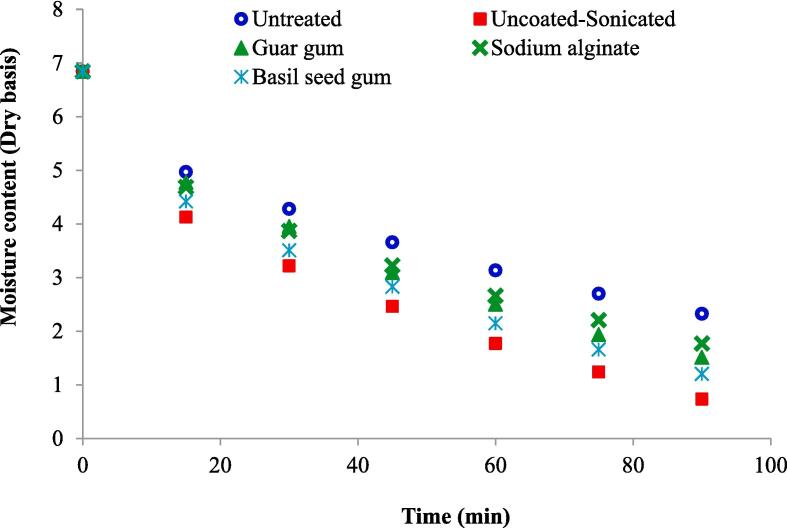

3.1. Total phenolic content

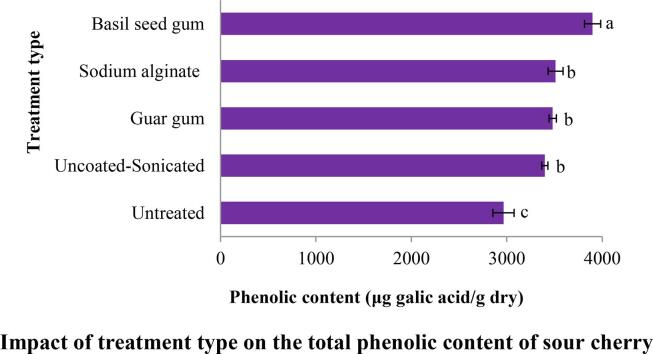

The impacts of coating on the TPC of sour cherries are presented in Fig. 1. The TPC of sonicated and coated sour cherries was higher than the untreated sample (p < 0.05). The mean TPC for untreated, uncoated-sonicated, guar gum-coated, sodium alginate gum-coated, and basil seed gum-coated sour cherries were 2965.9, 3398.1, 3480.8, 3511.0, and 3898.3 μg GAE/g dry, respectively. The main reason for this is the reduced exposure (short drying time) to air for polyphenol oxidation after ultrasonic treatment [32]. Also, edible gum coating creates a modified atmosphere around the samples by providing a semi-permeable barrier to CO2 and O2, thereby reducing the rate of oxidative reactions. An, et al. [23] results confirmed that the CMC-coating combined with ultrasonic pre-treatment showed significantly lower ΔE, higher curcumin content, TPC, and AA in all dried turmeric slices. Drying kinetics, TPC, AC, and physicochemical characteristics of litchi fruit using ultrasound-assisted hot-air drying were studied by Cao, et al. [32]. Their results demonstrated that shear-stress plus increasing heat decreased drying time by approximately 50 %, and preserved 70 % of vitamin C and 60 % of TPC. Additionally, the ultrasonic treatment achieves approximately 75 % vitamin C and 70 % TPC through inhibition of ultrasonic heat.

Fig. 1.

Impact of treatment type on the total phenolic content of sour cherry.Various letters near the bars denote for statistically significant differences at p < 0.05.

3.2. Antioxidant capacity (AC)

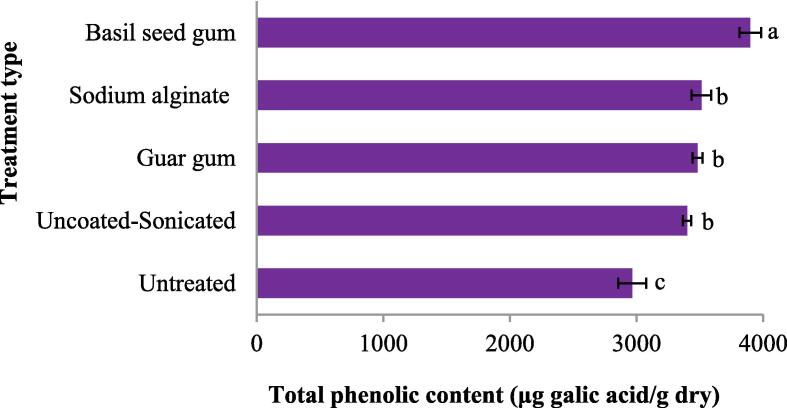

The influence of gum coatings on the AC of sour cherries is presented in Fig. 2. The AC of the dried sour cherries was preserved by the coating. The AC of coated sour cherries was higher than the uncoated sour cherry halves. The maximum AC (71.2±3.7 %) was observed on coated sour cherry samples by basil seed gum. The average AA for untreated, uncoated-sonicated, guar gum-coated, sodium alginate-coated, and basil seed gum-coated sour cherries were 57.1, 59.0, 63.3, 63.8, and 71.2 %, respectively. The study results showed that gum coating was associated with improved TPC, as well as AA of dried sour cherries. This improvement in TPC offers significant health benefits as phenolic compounds are known for their powerful AA that can help prevent disease [33]. do Nascimento et al. [34] studied the effects of high-intensity ultrasound on the drying kinetics and AC of passion fruit peel. Increasing the temperature and applying ultrasonic waves significantly reduces drying time. Furthermore, the application of ultrasound also reduces the loss of TPC and maintains the AC of dried passion fruit peel. The impacts of edible coating and sonication on the TPC and AC of sweet cherries were examined by Salehi, et al. [25]. The authors reported that the AC of uncoated and coated sweet cherries ranged from 39.75 % to 61.04 %.

Fig. 2.

Impact of treatment type on the antioxidant capacity of sour cherry. Various letters near the bars denote for statistically significant differences at p < 0.05.

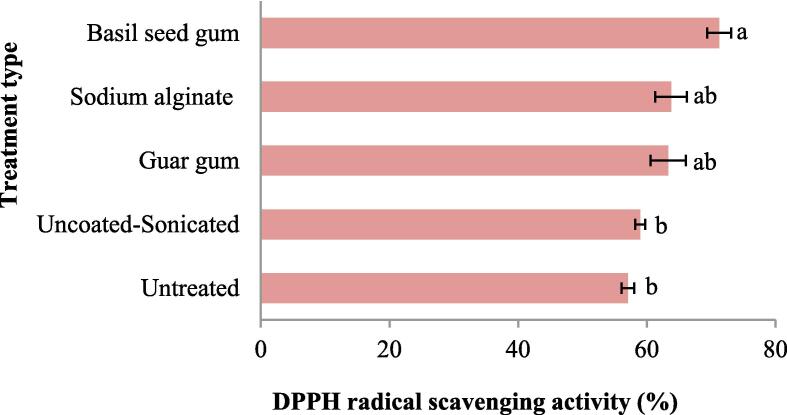

3.3. Water loss during drying

High-frequency ultrasonic waves induce mechanical stress within solid products and create micro-vibrations at solid-gas interfaces that can affect internal and external moisture transport [34]. In the present study, the moisture content of fresh sour cherries was 87.25 %. The changes in the moisture content of untreated and treated sour cherries with time are presented in Fig. 3. This figure clearly indicates that the drying rate (water loss) of sonicated sour cherry was higher than the untreated sample; So, the drying duration of sonicated sour cherry was lower than the untreated sample. Adavi, et al. [7] reported that sonication reduced the drying time from 7 h to 3 h.

Fig. 3.

Moisture content of untreated, uncoated, and coated sour cherries during drying in the convective dryer.

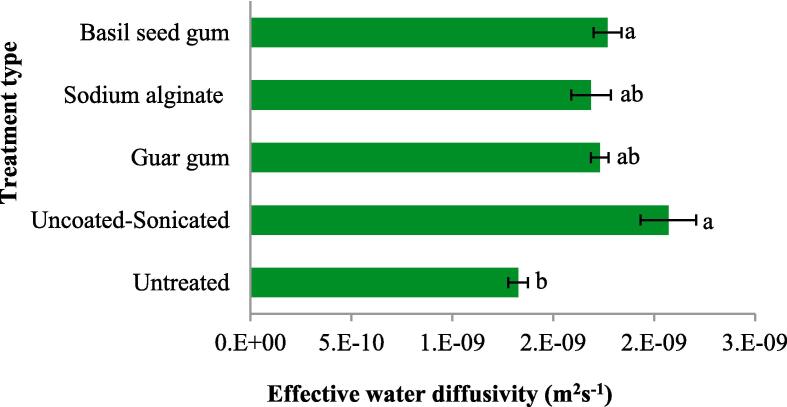

3.4. Water diffusivity

Applying high-intensity ultrasound before and during the drying process can intensify the operation, thereby reducing drying time and/or reducing processing temperature [34]. The influence of gum coating on the Deff of sour cherries is presented in Fig. 4. Deff value of the sonicated sour cherry was higher than the untreated sample. Also, the Deff of coated-sonicated sour cherries was lesser than the uncoated-sonicated sample. The average Deff for untreated, uncoated-sonicated, guar gum-coated, sodium alginate-coated, and basil seed gum-coated sour cherries was 1.33×10−9, 2.07×10−9, 1.73×10−9, 1.69×10−9, and 1.77×10−9m2/s, respectively. do Nascimento, et al. [34] reported that the use of ultrasound waves increased both the Deff and the mass transfer coefficient during drying of passion fruit peels. In another study, Bozkir et al. [35] confirmed that ultrasound (35 kHz for 10, 20, and 30 min) assisted osmotic dehydration of persimmon fruit demonstrated a significant reduction in drying time, increased drying rate, and Deff increased about 21 % in 30 min.

Fig. 4.

Impact of treatment type on the effective water diffusivity coefficient of coated sour cherry. Various letters near the bars denote for statistically significant differences at p < 0.05.

3.5. Kinetics modeling

Table 1 presents the predicted values and statistical parameters obtained to verify the fitting of each empirical equation with calculated moisture ratio throughout drying of sour cherries coated with guar gum. All the six models achieved the r values greater than 0.98, which is within the acceptable range. Between the six drying equations, the Midilli equation achieved the highest r value and the lowest SSE (sum of squared errors), and RMSE (root mean squared error) values, followed by the Page equation. The statistical parameters reported in Table 1 show that the Midilli equation is suitable for describing the drying rate of sour cherries. The Midilli model was considered to be the appropriate model for characterizing the drying rate of many fruits and vegetables such as sour cherry [4], tomato slices [36], peach slices [37], and mint leaves [38].

The results of the regression procedure and the statistical analysis and constants (a, k, n, and b) of the Midilli equation in agreement with the sour cherry drying data are presented in Table 2. The SSE, RMSE, and r for all samples ranged from 0.0000 to 0.0004, 0.0026–0.0113, and 0.9995–0.9999, respectively. Wojdyło, et al. [9] identified the Page model as the appropriate model to explain the drying rate of sour cherry in convection and vacuum–microwave dryers.

Table 2.

The constants of the Midilli model.

| Coating type | a | k | n | b | SSE | r | RMSE |

|---|---|---|---|---|---|---|---|

| Untreated | 0.9999 | 0.0825 | 0.4449 | −0.0027 | 0.0001 | 0.9998 | 0.0053 |

| Uncoated-Sonicated | 0.9999 | 0.1254 | 0.4245 | −0.0030 | 0.0002 | 0.9998 | 0.0073 |

| Guar gum-coated | 0.9998 | 0.0862 | 0.4933 | −0.0028 | 0.0002 | 0.9997 | 0.0089 |

| Sodium alginate-coated | 1.0000 | 0.1159 | 0.4058 | −0.0031 | 0.0001 | 0.9999 | 0.0054 |

| Basil seed gum-coated | 0.9999 | 0.0972 | 0.4820 | −0.0025 | 0.0001 | 0.9999 | 0.0057 |

* where, a, k, n, and b are the constants of the Midilli model (dimensionless); SSE is sum of squared errors; r is correlation coefficient; RMSE is root mean squared error.

3.6. Color changes and surface shrinkage

The average L*, a*, and b* indexes for fresh sour cherry halves were 33.79, 12.66, and −0.23, respectively. After the drying procedure, the lightness and redness values of the sour cherries decreased. The average L*, a*, and b* values for dried sour cherry halves were 32.12, 0.53, and −0.61, respectively. The influence of sonication and gum coatings on the ΔE of dried sour cherries is shown in Fig. 5. The edible coatings had a significant influence on the color change of sour cherries (p < 0.05). The edible coating reduced the color changes of dried samples, with the lowest ΔE values in the basil seed gum-coated sour cherries. In this study, the average ΔE index for untreated, uncoated-sonicated, guar gum-coated, sodium alginate gum-coated, and basil seed gum-coated sour cherries were 19.36, 16.56, 11.87, 10.36, and 8.44 %, respectively. Sakooei-Vayghan et al. [39] demonstrated that the edible coating preserves the quality of ultrasonic pretreated dried apricot cubes. Wojdyło, et al. [9] reported the L*, a*, and b* indexes values of 28.4, 16.5, and 2.4 for fresh sour cherry, respectively. Their results also showed that the ΔE values of all dehydrated sour cherry halves were higher than those of the freeze-dried samples (ΔE = 7.5), indicating that these samples were darker than the fresh sour cherries (lower L* values).

Fig. 5.

Impact of treatment type on the total color difference of dried-coated sour cherry.Various letters near the bars denote for statistically significant differences at p < 0.05.

The average surface area values for fresh and dried sour cherries were 3.10 cm2 and 1.64 cm2, respectively. The influence of sonication and gum coatings on the SS of dried sour cherries is shown in Fig. 6. The gum coatings had a significant influence on the SS of sour cherries. The edible coating reduced the shrinkage rate of sour cherries during drying, with the lowest SS values in the basil seed gum-coated samples. In this study, the average SS values for untreated, uncoated-sonicated, guar gum-coated, sodium alginate gum-coated, and basil seed gum-coated sour cherries were 53.06, 50.16, 46.50, 45.06, and 40.36 %, respectively. Nadery Dehsheikh and Taghian Dinani [40] found lower changes in TPC and lower ΔE and SS values of banana slices with CMC-coating and ultrasonic pre-treatment prior to convective drying.

Fig. 6.

Impact of treatment type on the surface shrinkage of dried-coated sour cherry. Various letters near the bars denote for statistically significant differences at p < 0.05.

3.7. Rehydration

The impact of sonication and gum coatings on the RR of dried sour cherries is shown in Fig. 7. The RR of sonicated and coated samples by guar and sodium alginate gums was significantly higher than the untreated sample (p < 0.05). The mean RR for untreated, uncoated-sonicated, guar gum-coated, sodium alginate gum-coated, and basil seed gum-coated sour cherries were 177.05, 190.05, 199.36, 198.85, and 191.10 %, respectively. Similar results were found by Salehi, et al. [25] for edible coatings and ultrasonic pretreatment of sweet cherries. They observed that the rehydration ratios of uncoated, xanthan gum-coated, guar gum-coated, and wild sage seed gum-coated sweet cherries were 141.81, 167.26, 176.21, and 156.87 %, respectively. In another study, Bozkir, et al. [35] reported that the RR of persimmons treated with ultrasound (35 kHz for 20 min) before hot-air drying was higher than that of the untreated group.

Fig. 7.

Impact of treatment type on the rehydration rate of dried sour cherry. Various letters near the bars denote for statistically significant differences at p < 0.05.

4. Conclusion

The influence of ultrasonic treatment (12 min, 40 kHz, and 150 W) and gum coatings (guar, sodium alginate, and basil seed gums) on the TPC, AC, and convective drying characteristics of sour cherry halves were studied. The TPC of sonicated and coated sour cherry halves was higher than the untreated sample. Furthermore, the AC of the treated halves was preserved by the coating. The drying duration of sonicated halves was lower than the untreated sample. In this study, the sour cherry Deff as calculated by the second Fick law varied from 1.33 × 10−9 m2/s to 2.07 × 10−9 m2/s. The Deff value of sonicated halves was higher than the untreated sample. The drying kinetics of sour cherries were modeled using Midilli’s mathematical model. The estimated results demonstrated good agreement with the test values. The ΔE and SS values of sonicated and coated sour cherries were lower than the untreated halves. The RR of coated sour cherries by guar and sodium alginate gums was significantly higher than the untreated sample (p < 0.05). Based on the results, the application of ultrasound and edible coating shortened the drying time and caused the least changes in the quality characteristics of sour cherries.

CRediT authorship contribution statement

Fakhreddin Salehi: Conceptualization, Methodology, Data curation, Formal analysis, Investigation, Software, Validation, Writing – original draft, Writing – review & editing. Moein Inanloodoghouz: Data curation, Formal analysis, Investigation, Software.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Farhadi S., Javanmard M. Mechanical and physical properties of polyethylene/sour cherry shell powder bio-composite as potential food packaging. Food Sci. Nutr. 2021;9:3071–3077. doi: 10.1002/fsn3.2264. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Salehi F. Physicochemical characteristics and rheological behaviour of some fruit juices and their concentrates. J. Food Meas. Charact. 2020;14:2472–2488. [Google Scholar]

- 3.Šumić Z., Tepić A., Vidović S., Jokić S., Malbaša R. Optimization of frozen sour cherries vacuum drying process. Food Chem. 2013;136:55–63. doi: 10.1016/j.foodchem.2012.07.102. [DOI] [PubMed] [Google Scholar]

- 4.Doymaz İ. Influence of pretreatment solution on the drying of sour cherry. J. Food Eng. 2007;78:591–596. [Google Scholar]

- 5.Tomar O., Akarca G., Gök V., İstek Ö. Chemical composition and antifungal potential of apricot, sour cherry, and cherry tree bio-products (resins) against food-borne molds. Food Biosci. 2022;47 [Google Scholar]

- 6.Khadivi-Khub A., Jafari H.-R., Zamani Z. Phenotypic and genotypic variation in Iranian sour and duke cherries. Trees. 2013;27:1455–1466. [Google Scholar]

- 7.Adavi P., Askari S., Asadi G. Textural properties changes during facile drying of sour cherry using ultrasound waves: investigation of sonication parameters using response surface methodology. J. Food Biosci. Technol. 2022;12:47–61. [Google Scholar]

- 8.K. Siucińska, M. Mieszczakowska-Frąc, A. Połubok, D. Konopacka, Effects of ultrasound assistance on dehydration processes and bioactive component retention of osmo-dried sour cherries, J. Food Sci., 81 (2016) C1654-C1661. [DOI] [PubMed]

- 9.Wojdyło A., Figiel A., Lech K., Nowicka P., Oszmiański J. Effect of convective and vacuum–microwave drying on the bioactive compounds, color, and antioxidant capacity of sour cherries. Food Bioprocess Tech. 2014;7:829–841. [Google Scholar]

- 10.Kumar S., Reddy A.R.L., Basumatary I.B., Nayak A., Dutta D., Konwar J., Purkayastha M.D., Mukherjee A. Recent progress in pectin extraction and their applications in developing films and coatings for sustainable food packaging: A review. Int. J. Biol. Macromol. 2023;239 doi: 10.1016/j.ijbiomac.2023.124281. [DOI] [PubMed] [Google Scholar]

- 11.Yan T., Hu C., Que Y., Song Y., Lu D., Gu J., Ren Y., He J. Chitosan coating enriched with biosynthetic CuO NPs: Effects on postharvest decay and quality of mango fruit. Int. J. Biol. Macromol. 2023;253 doi: 10.1016/j.ijbiomac.2023.126668. [DOI] [PubMed] [Google Scholar]

- 12.Das S., Chaudhari A.K., Singh V.K., Dwivedy A.K., Dubey N.K. Chitosan based encapsulation of Valeriana officinalis essential oil as edible coating for inhibition of fungi and aflatoxin B1 contamination, nutritional quality improvement, and shelf life extension of Citrus sinensis fruits. Int. J. Biol. Macromol. 2023;233 doi: 10.1016/j.ijbiomac.2023.123565. [DOI] [PubMed] [Google Scholar]

- 13.Feng Z., Wu G., Liu C., Li D., Jiang B., Zhang X. Edible coating based on whey protein isolate nanofibrils for antioxidation and inhibition of product browning. Food Hydrocolloid. 2018;79:179–188. [Google Scholar]

- 14.F. Salehi, Edible coating of fruits and vegetables using natural gums: A review, Int. J. Fruit Sci., 20 (2020) S570-S589.

- 15.Gholipour Shahraki P., Fazel M. Effect of edible coating and time and temperature of drying on properties of dried fig. Iranian Food Science and Technology Research Journal. 2019;15:77–89. [Google Scholar]

- 16.Mazidi D., Hosseini Ghaboos S.H. Effect of Basil and Balangu seeds gum on sensorial properties, quality and shelf life of peaches, Journal of. Food Research. 2020;30:137–149. [Google Scholar]

- 17.Mukhtar K., Nabi B.G., Arshad R.N., Roobab U., Yaseen B., Ranjha M.M.A.N., Aadil R.M., Ibrahim S.A. Potential impact of ultrasound, pulsed electric field, high-pressure processing and microfludization against thermal treatments preservation regarding sugarcane juice (Saccharum officinarum) Ultrason. Sonochem. 2022;90 doi: 10.1016/j.ultsonch.2022.106194. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Jalilzadeh A., Hesari J., Peighambardoust S.H., Javidipour I. The effect of ultrasound treatment on microbial and physicochemical properties of Iranian ultrafiltered feta-type cheese. J. Dairy Sci. 2018;101:5809–5820. doi: 10.3168/jds.2017-14352. [DOI] [PubMed] [Google Scholar]

- 19.Ali M., Cheng J.-H., Tazeddinova D., Aadil R.M., Zeng X.-A., Goksen G., Lorenzo J.M., Esua O.J., Manzoor M.F. Effect of plasma-activated water and buffer solution combined with ultrasound on fungicide degradation and quality of cherry tomato during storage. Ultrason. Sonochem. 2023;97 doi: 10.1016/j.ultsonch.2023.106461. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Aadil R.M., Zeng X.-A., Sun D.-W., Wang M.-S., Liu Z.-W., Zhang Z.-H. Combined effects of sonication and pulsed electric field on selected quality parameters of grapefruit juice, LWT- Food Sci. Technol. 2015;62:890–893. [Google Scholar]

- 21.Manzoor M.F., Xu B., Khan S., Shukat R., Ahmad N., Imran M., Rehman A., Karrar E., Aadil R.M., Korma S.A. Impact of high-intensity thermosonication treatment on spinach juice: Bioactive compounds, rheological, microbial, and enzymatic activities. Ultrason. Sonochem. 2021;78 doi: 10.1016/j.ultsonch.2021.105740. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Liu W., Zhang M., Mujumdar A.S., Chitrakar B., Yu D. Effects of chitosan coating on freeze-drying of blueberry enhanced by ultrasound pre-treatment in sodium bicarbonate medium. Int. J. Biol. Macromol. 2021;181:631–643. doi: 10.1016/j.ijbiomac.2021.03.172. [DOI] [PubMed] [Google Scholar]

- 23.An N.-N., Shang N., Lv W.-Q., Li D., Wang L.-J., Wang Y. Effects of carboxymethyl cellulose/pectin coating combined with ultrasound pretreatment before drying on quality of turmeric (Curcuma longa L.) Int. J. Biol. Macromol. 2022;202:354–365. doi: 10.1016/j.ijbiomac.2022.01.021. [DOI] [PubMed] [Google Scholar]

- 24.Salehi F., Haseli A., Roustaei A. Coating of zucchini slices with Balangu, Basil, and Wild sage seeds gums to improve the frying properties. Eur. J. Lipid Sci. Technol. 2022;124:2100120. [Google Scholar]

- 25.Salehi F., Ghazvineh S., Inanloodoghouz M. Effects of edible coatings and ultrasonic pretreatment on the phenolic content, antioxidant potential, drying rate, and rehydration ratio of sweet cherry. Ultrason. Sonochem. 2023;99 doi: 10.1016/j.ultsonch.2023.106565. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Amini G., Salehi F., Rasouli M. Drying kinetics of basil seed mucilage in an infrared dryer: Application of GA-ANN and ANFIS for the prediction of drying time and moisture ratio. J. Food Process. Preserv. 2021;45:e15258. [Google Scholar]

- 27.Salehi F., Satorabi M. Influence of infrared drying on drying kinetics of apple slices coated with basil seed and xanthan gums. Int. J. Fruit Sci. 2021;21:519–527. [Google Scholar]

- 28.Manikantan M., Mridula D., Sharma M., Kochhar A., Prasath V.A., Patra A., Pandiselvam R. Investigation on thin-layer drying kinetics of sprouted wheat in a tray dryer. Qual. Assur. Saf. Crop. Foods. 2022;14:12–24. [Google Scholar]

- 29.F. Salehi, M. Inanloodoghouz, S. Ghazvineh. Influence of microwave pretreatment on the total phenolics, antioxidant activity, moisture diffusivity, and rehydration rate of dried sweet cherry. Food Sci. Nutr. (2023). [DOI] [PMC free article] [PubMed]

- 30.Salehi F. Color changes kinetics during deep fat frying of kohlrabi (Brassica oleracea var. gongylodes) slice. Int. J. Food Prop. 2019;22:511–519. [Google Scholar]

- 31.Salehi F., Razavi Kamran H., Goharpour K. Effects of ultrasound time, xanthan gum, and sucrose levels on the osmosis dehydration and appearance characteristics of grapefruit slices: process optimization using response surface methodology. Ultrason. Sonochem. 2023;98 doi: 10.1016/j.ultsonch.2023.106505. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Cao X., Islam M.N., Zhong S., Pan X., Song M., Shang F., Nie H., Xu W., Duan Z. Drying kinetics, antioxidants, and physicochemical properties of litchi fruits by ultrasound-assisted hot air-drying. J. Food Biochem. 2020;44:e13073. doi: 10.1111/jfbc.13073. [DOI] [PubMed] [Google Scholar]

- 33.Khalil A.A., Khan A.A., Khalid A., Abid Z., Proestos C., Bhat Z.F., Shahbaz M.U., Aadil R.M. Comparing the antioxidant properties and volatile compounds of carrot-orange juice blend processed through varied chemical, pasteurization and ultrasound conditions. Ultrason. Sonochem. 2023;98 doi: 10.1016/j.ultsonch.2023.106534. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.E.M.G.C. do Nascimento, A. Mulet, J.L.R. Ascheri, C.W.P. de Carvalho, J.A. Cárcel, Effects of high-intensity ultrasound on drying kinetics and antioxidant properties of passion fruit peel, J. Food Eng., 170 (2016) 108-118.

- 35.Bozkir H., Rayman Ergün A., Serdar E., Metin G., Baysal T. Influence of ultrasound and osmotic dehydration pretreatments on drying and quality properties of persimmon fruit. Ultrason. Sonochem. 2019;54:135–141. doi: 10.1016/j.ultsonch.2019.02.006. [DOI] [PubMed] [Google Scholar]

- 36.Alvi T., Khan M.K.I., Maan A.A., Rizwan M., Aamir M., Saeed F., Ateeq H., Raza M.Q., Afzaal M., Shah M.A. Microwave–vacuum extraction cum drying of tomato slices: Optimization and functional characterization. Food Sci. Nutr. 2023;11:4263–4274. doi: 10.1002/fsn3.3352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Akhoundzadeh Yamchi A., Yeganeh R., Kouchakzadeh A. Effect of ultrasonic pretreatment on drying kinetics and physio-mechanical characteristics of peach slices. J. Food Process Eng. 2022:e14053. [Google Scholar]

- 38.Özbek B., Dadali G. Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J. Food Eng. 2007;83:541–549. [Google Scholar]

- 39.Sakooei-Vayghan R., Peighambardoust S.H., Hesari J., Peressini D. Effects of osmotic dehydration (with and without sonication) and pectin-based coating pretreatments on functional properties and color of hot-air dried apricot cubes. Food Chem. 2020;311 doi: 10.1016/j.foodchem.2019.125978. [DOI] [PubMed] [Google Scholar]

- 40.Nadery Dehsheikh F., Taghian Dinani S. Coating pretreatment of banana slices using carboxymethyl cellulose in an ultrasonic system before convective drying. Ultrason. Sonochem. 2019;52:401–413. doi: 10.1016/j.ultsonch.2018.12.018. [DOI] [PubMed] [Google Scholar]